Toshiba GRD150, GRD150-10 Series, GRD150-20 Series, GRD150-30 Series, GRD150-40 Series User Manual

GRD150

2

FEATURES

Protection functions

Non-directional and directional overcurrent and

earth-fault protection and sensitive earth fault

protection (option)

Overvoltage and undervoltage protection

Thermal overload protection

Underfrequency or overfrequency protection

Negative phase sequence overcurrent

protection

Undercurrent protection

Circuit breaker failure protection

Autoreclose function (option)

Control functions

Indication of the status of switching devices, i.e.

circuit breakers and disconnectors

Open and close commands for switching

devices

Synchronism check function (option)

MIMIC configuration display

Monitoring and Metering

Circuit breaker condition monitoring

Trip circuit supervision

Metering: three-phase currents and voltages,

residual current and voltage, frequency, active

and reactive power, power factor, and max.

demand values.

Recording

Event record: 480 most recent events

Alarm record: 32 most recent alarms

Fault record: 8 most recent faults

Disturbance record: 9 analog and 32 binary

signals

User Interface

Menu-based HMI system

Graphical LCD display

PLC function

Configurable binary inputs and outputs

Configurable LED indications

Communication Interface: RS485, Fibre optic

or Ethernet LAN (option)

APPLICATION

GRD150 feeder manager is designed for protection,

control, metering and supervision of medium voltage

networks.

GRD150 includes multiple, high accuracy, overcurrent

protection elements (for phase and/or earth fault) with

inverse time (IDMTL) and definite time delay (DTL)

functions. All phase, earth and sensitive earth fault

overcurrent elements can be independently subject to

directional control. The directional elements provide

user-settable characteristic angles.

Other protection functions are also available, including

thermal protection to IEC60255-8, negative sequence

overcurrent protection, under/overvoltage and under/

over frequency protections.

GRD150 provides continuous monitoring of internal

circuits and of software. External circuits are also

monitored, by trip circuit supervision, CT and VT

supervision, and CB condition monitoring features.

A user-friendly HMI is provided through a backlit LCD,

programmable LEDs, keypad and menu-based

operating system. PC access is also provided, either

for local connection via a front-mounted RS232 port,

or for remote connection via a rear-mounted RS485

or fibre optic port. The communication system allows

the user to read and modify the relay settings, and to

access data gathered by the relay’s metering and

recording functions.

Data available either via the relay HMI or communications

ports includes the following functions.

Metering

Fault recording

Event recording

Alarm recording

Disturbance recording (available via

communications ports)

Figure 1 - Front View

GRD150

3

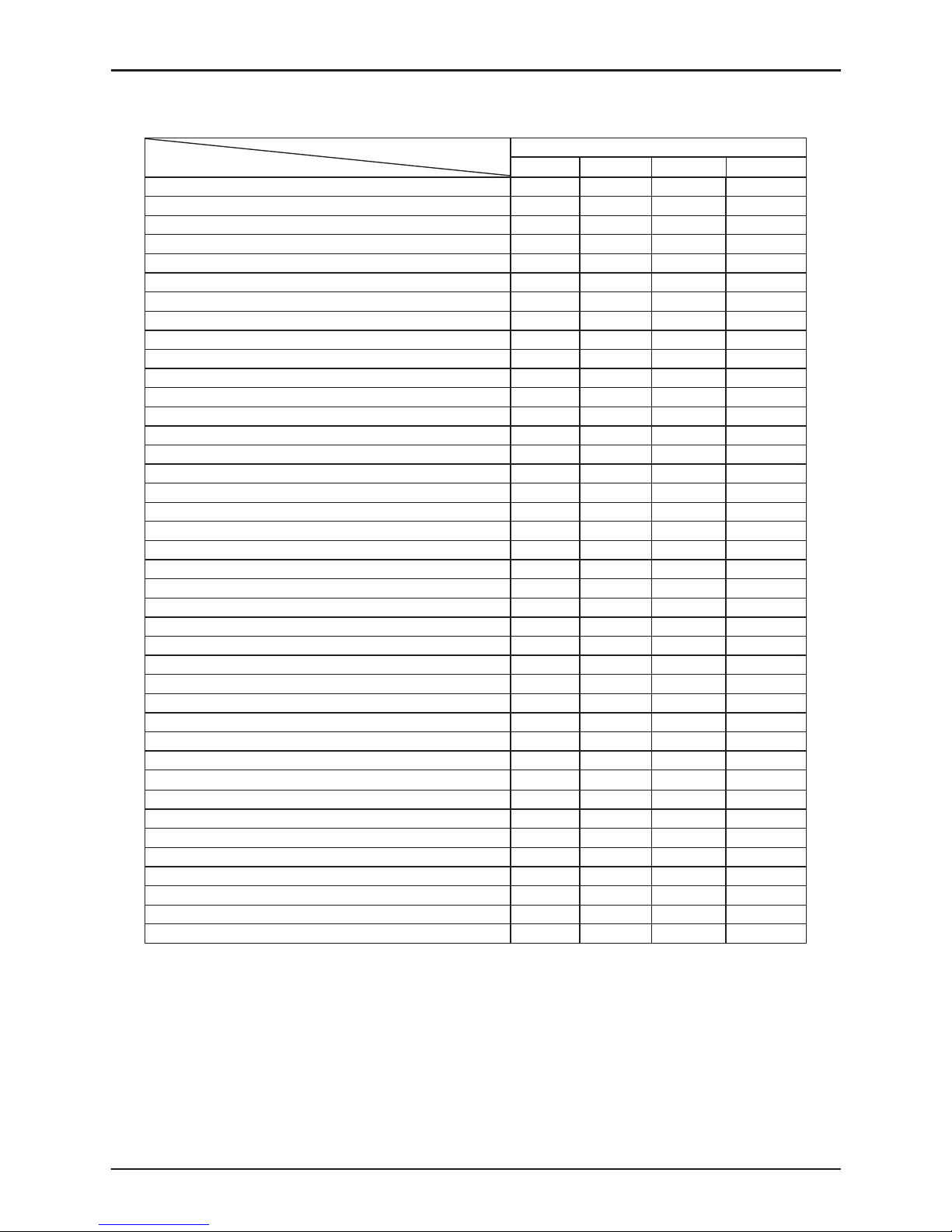

Table 1 GRD150 models and Functions

GRD150- Models

Function

10∗ series 20∗ series 30∗ series 40∗ series

Non-directional overcurrent OC (IDMTL, DTL, INST)

Non-directional earth fault EF (IDMTL, DTL, INST)

Non-directional sensitive earth fault SEF (IDMTL, DTL, INST)

Directional overcurrent DOC (IDMTL, DTL, INST)

Directional earth fault DEF (IDMTL, DTL, INST)

Directional sensitive earth fault DSEF (IDMTL, DTL, INST)

Undercurrent UC

Thermal over load THM

Non-directional negative phase overcurrent NOC (IDMTL, DTL, INST)

Directional negative phase overcurrent DNOC (IDMTL, DTL, INST)

Broken conductor detection BCD

Circuit breaker failure protection CBF

Cold load pick-up feature

Overvoltage OV (IDMTL, DTL, INST)

Undervoltage UV (IDMTL, DTL, INST)

Zero phase sequence overvoltage ZOV (IDMTL, DTL, INST)

Negative phase sequence overvoltage NOV (IDMTL, DTL, INST)

Under/over frequency FRQ

Autoreclose function

Fault locator

Indication of the status of switching devices

Open and close commands for switching devices

Synchronism check function

MIMIC configuration picture (*)

PLC function (*)

CT supervision

VT supervision

Trip circuit supervision

Self supervision

CB state monitoring

Trip counter alarm

∑Iy alarm

CB operate time alarm

Multiple settings groups

Metering

Fault records

Alarm records

Event records

Disturbance records

Communication

IDMTL: inverse definite minimum time

DTL: definite time

INST: instantaneous

(*): PC tools (MIMIC editor and PLC editor) are option.

GRD150

4

FUNCTIONS

Protection

- 4-stage non-directional and directional overcurrent

and earth-fault protection and sensitive earth fault

protection (option)

1

st

and 2nd stage: Instantaneous, IDMTL or DTL

3

rd

and 4th stage: Instantaneous or DTL

- 2-stage non-directional and directional negative

phase sequence overcurrent protection

1

st

stage: Instantaneous, IDMTL or DTL

2

nd

stage: Instantaneous or DTL

- 2-stage overvoltage and undervoltage protection

1

st

stage: Instantaneous, IDMTL or DTL

2

nd

stage: Instantaneous or DTL

- 6-stage underfrequency or overfrequency protection

- Thermal overload protection

- Cold load protection function or Inrush current (2

nd

harmonic) detector provided for energising the

system

- Undercurrent protection

- Broken conductor detection

- Circuit breaker failure protection

- Autoreclose function: 5-shots, 3-phase autoreclose

(option)

Control

Two-stepped operation (select-control) is used for the

control procedure of circuit breakers, disconnectors,

earthing disconnector switches and transformers to

ensure highly reliable operation.

- Control of circuit breakers, disconnectors and

earthing disconnector switches

- Interlock check

- Synchronism check for circuit breaker closing

(option)

- MIMIC configuration picture displayed on LCD

- Double command blocking

- Switchgear operation counter

- Control blocking

Password protection is provided to operate above

functions.

Monitoring and Metering

- Status monitoring of switchgear devices and failure

monitoring of power apparatus, control equipment,

protection relays and ancillary equipment

- Metering: current, voltage, frequency, active power,

reactive power and max. demand values

An energy calculation (Watt-hour, var-hour) is also

available.

- Limit value checking of metering

- Opening and closing time monitoring

These data are available on the HMI and at a local or

remote PC.

Recording

- Event records: The most recent 480 time-tagged

events with 1ms resolution are stored.

- Alarm records: The most recent 32 time-tagged

alarms with 1ms resolution are stored.

- Fault records: The most recent 8 time-tagged faults

with 1ms resolution are stored.

- Disturbance records: GRD150 can record 9 analog

and 32 binary signals, initiated by relay tripping. Pretrigger and post-trigger recording times can be set,

and the maximum number of records which can be

stored is dependent on the recording times chosen.

These records are available on the HMI and at a local

or remote PC.

GRD150

5

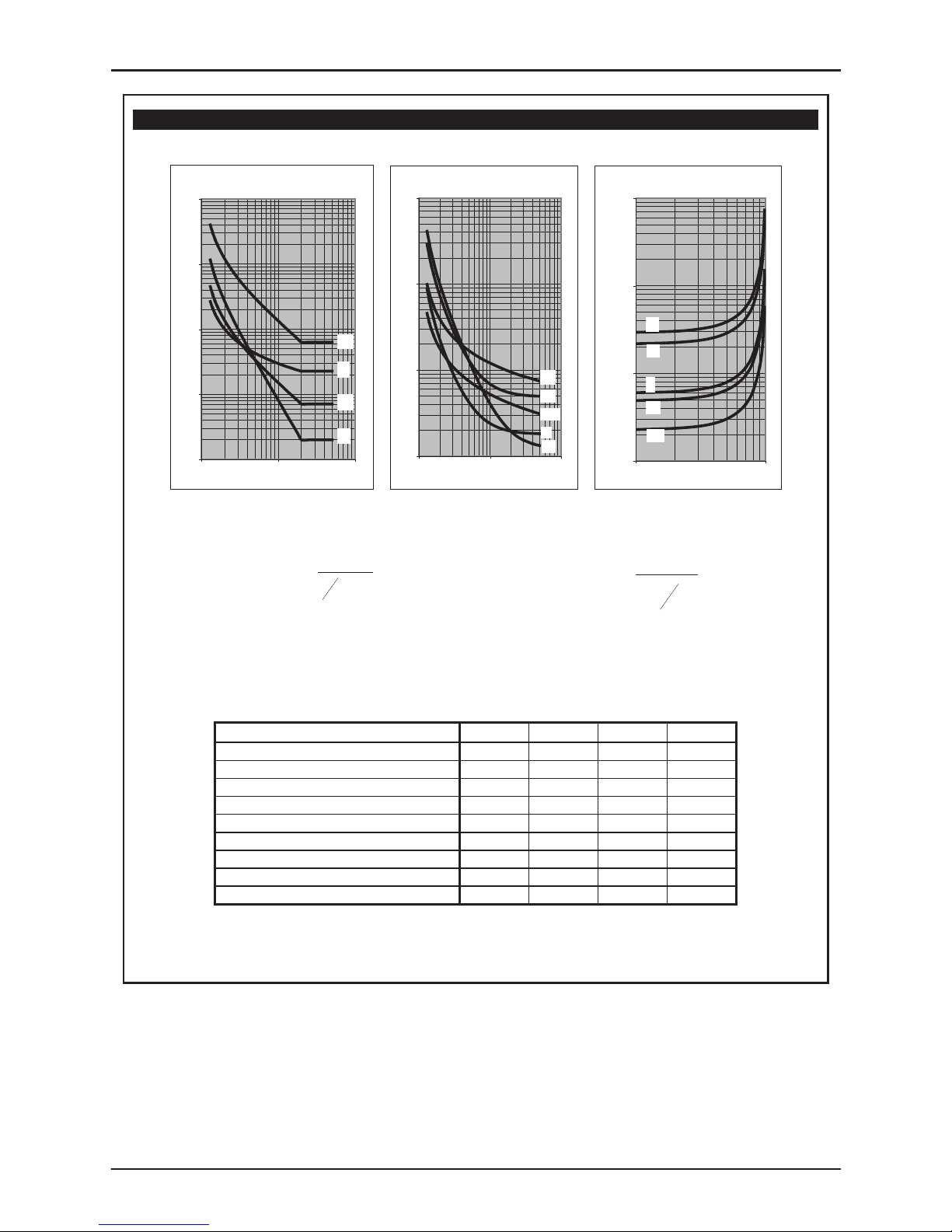

Figure 2 - Operate and Reset Characteristics of IDMTL

Inverse Time Operate and Reset Curves

IEC/UK Inverse Curves

(Time Muliplier TMS = 1)

0.1

1

10

100

1000

1 10 100

Current (Multiple of Setting)

Operating Time (s)

LTI

NI

VI

EI

IEEE/US Inverse Curves

(Time Multiplier TMS = 1)

0.1

1

10

100

1 10 100

Current (Multiple of S etting)

Operating Time (s)

MI

VI

STI

I

EI

IEEE/US Reset Curves

(Time Multiplier T MS = 1)

1.00

10.00

100.00

1000.00

0.1 1

Current (Multiple of S etting)

Time (s)

MI

VI

EI

STI

I

()

⎪

⎭

⎪

⎬

⎫

⎪

⎩

⎪

⎨

⎧

+

⎥

⎥

⎥

⎦

⎤

⎢

⎢

⎢

⎣

⎡

−

×= c

Is

I

k

TMSt

1

α

⎥

⎥

⎥

⎥

⎦

⎤

⎢

⎢

⎢

⎢

⎣

⎡

⎟

⎠

⎞

⎜

⎝

⎛

−

×=

2

1

S

r

I

I

t

RTMSt

Inverse time operate function Dependent time reset function

Constants for dependent time curves

Curve Description k

α

C t

r

IEC Normal Inverse (NI)

0.14 0.02 0 -

IEC Very Inverse (VI)

13.5 1 0 -

IEC Extremely Inverse (EI)

80 2 0 -

UK Long Time Inverse (LTI)

120 1 0 -

IEEE Moderately Inverse (MI)

0.0515 0.02 0.114 4.85

IEEE Very Inverse (VI)

19.61 2 0.491 21.6

IEEE Extremely Inverse (EI)

28.2 2 0.1217 29.1

US CO8 Inverse (I)

5.95 2 0.18 5.95

US CO2 Short Time Inverse (STI)

0.02394 0.02 0.01694 2.261

GRD150

6

USER INTERFACE

Relay Front Panel

A user friendly interface is provided on the relay front

panel. A menu-based system provides for easy

programming of relay functions and access to realtime and stored data. The front panel includes the

following features.

Graphical LCD

display with backlight.

12 LEDs including 8

user programmable

LEDs.

Keypad.

RS232C serial port for connection of local PC.

Local PC Connection

The user can communicate with the GRD150 from a

local PC via the RS232C port on the front panel. Using

RSM100 software, the user can view and modify

settings, monitor real-time metering and analyse

recorded data.

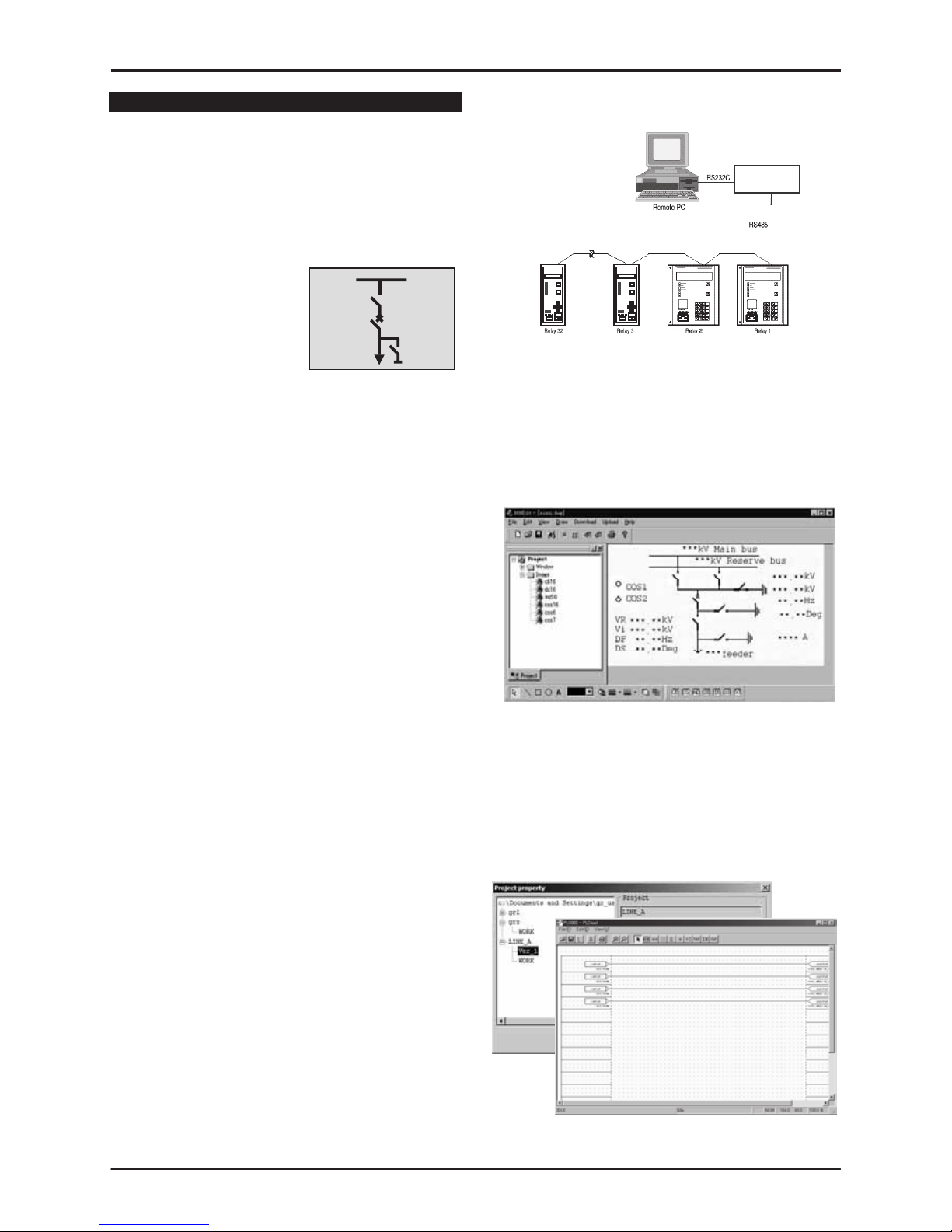

Relay Setting and Monitoring (RSM)

and Remote Control System

GRD150 can be connected to the RSM system via

the rear mounted serial communications port, using

RS485 or other connections such as fibre optic,

Ethernet LAN, etc., (specified at time of order). Using

RSM100 software, the user can view and modify

settings, monitor real-time metering and analyse

recorded data.

A maximum of 32 relays can be connected to the

remote PC in multi-drop mode, by connection via a

protocol converter, with data transmission rate of

64kbps using RSM-X protocol. Modbus®(RTU) protocol

can be also available.

The figures below show the configuration of the RSM

system and typical displays from the RSM100 software.

Using an additional port (option), GRD150 can be

connected to a Substation Control System. In this

case, GRD150 supports IEC60870-5-103 or DNP3.0

transmission protocols.

Figure 3 - Relay Setting and Monitoring System

Mimic Editor (MMEdit)

Yhe user can configure and customize the MIMIC

data displayed on the LCD of GRD150 using

MMEdit software. The MIMIC data produced by the

MMEdit software can be uploaded to GRD150 via the

PC communication port (RS232C).

Figure 4 - PC Display of MMEdit

PLC Editor (PLCEdit)

The user can customize logic functions on GRD150

such as trip and interlock sequence, etc., using

PLCEdit software. The PLC data produced by the

PLCEdit software can be uploaded to GRD150 via PC

communication port (RS232C).

Figure 5 - PC Display of PLCEdit

Converter

G1PR2

Loading...

Loading...