Page 1

G7 Adjustable Speed Drive

Operation Manual

Document Number: 51546-009

Date: March, 2005

Page 2

Introduction

Congratulations on the purchase of the new G7 True To rque Control2 Adjustable Speed Drive (ASD).

The G7 True Torque Control

T orque Contr ol

provide compensation for motor slip, which results in smooth, quick starts and highly efficient operation.

The G7 use s digitally-cont rolled pulse width modula tion. The programmable functions may be accessed

via the easy-to-use menu or via the Direct Access Numbers (see page 59). This feature, combined with

Tos hiba’ s high-performance software, delivers unparalleled motor control and relia bility.

The G7 is a very powerful tool, yet s urprisingl y simple to operat e. The user -fri endly El ectron ic O perator

Interface (EOI) of the G7 has an easy-to-read 240 x 64 pixel graphical LCD screen. The EOI provides

easy access to the many monitoring and programming features of the G7.

The motor control software is menu-driven, which allows for easy access to the motor control parameters

and quick changes when required.

To m aximize the abilities of your new G7, a working familiarity wit h this manual will be required. This

manual has been prepared for the G7 ASD installer, user, and maintenance personnel. This manual may

also be used as a reference guide or for training. With this in mind, use this ma nual to develop a system

familiarity before attempting to install or operate the device.

2

. TIC’s Ve ctor Cont rol Algorit hm enable s the motor t o devel op hig h star ting tor que a nd

2

Adjustable Speed Drive is a solid - sta te AC driv e th at featu r es True

Important Notice

The instructions contained in this manual are not intended to cover all details or variations in equipment

types, nor may it provide for every possible contingency concerning the installation, operation, or

maintenance of this equipment. Should additional information be required contact your Toshiba

representative.

The contents of this ma nual shall not become a part of or modify a ny p rior or existing agreement,

commitment, or relationship. The sales contract contains the entire obligation of Toshiba International

Corporation. The warranty contained in the cont ract between the parties is th e so le warranty of Toshiba

International Corpora tion and an y statement s containe d herein do not creat e new warranties or modify the

existing warranty.

Any electrical or mechanical modifications to this equipment without prior written consent of

Toshiba International Corporation will void all warranties and may void the UL/CUL lis ting or

other safety certifications. Unauthorized modifications may also result in a safety hazard or

equipment damage.

Misuse of this equipment could result in injury and equipment damage. In no event will To shiba

Corporation be responsible or liable for direct, indirect, special, or consequential damage or injury

that may result from the misuse of this equipment.

Page 3

Contacting Toshiba’s Customer Support

Center

Toshiba’s Customer Support Center can be contacted to obtain help in resolving any Adjustable Speed

Drive system problem that you may experience or to provide application information.

The center is open from 8 a.m. to 5 p.m. (CST ), Monday through Friday. The Support Center’s toll free

number is US (800) 231-1412/Fax (713) 466-8773 — Canada (800) 527-1204.

You may also contact Toshiba by writing to:

Toshiba Inter n ational Corporation

13131 West Little York Road

Houston, Texas 77041-9990

Attn: ASD Product Manager.

For further information on Tos hiba’s products and services, please vis it our website at

www.tic.toshiba.com (right click and select Open Weblink in Browser).

TOSHIBA INTERNATIONAL CORPORATION

G7 Adjustable Speed Drive

Please complete the Warranty Card supplied with the ASD and return it to Toshiba by prepaid mail. This will

activate the 12 month warranty from the date of installation; but, shall not exceed 18 months from the shipping

date.

Complete the following information and retain for your records.

Model Number: ______________________________________________________________________

Serial Number:_____ _________________________________________________________________

Project Number (i f applicable):__________________________________________________________

Date of Installation:

Inspected By:______________________________________________________________________

Name of Application:_________________________________________________________________

__________________________________________________________________

Page 4

About This Manual

This manual was written by the To s h iba Technical Public ations Group. This group is tasked with

providing te chnical documentation for the G7 Adjustable Speed Drive. Every effo rt has been made to

provide accurate and concise information to you, our customer .

At Toshiba we’re continuo usly searching for better ways to meet the constantly changing needs of our

customers. Email your comments, questions, or concerns about this publication to

Technical-Publications-Dept@TIC.TOSHIBA.COM.

Manual’s Purpose and Scope

This manual provides information on how to safely install, operate , m aintain, and dispose of your

True Torque Control2 Adjustable Speed Drive. The information provided in this ma nual is

G7

2

applicable to the G7 True Torque Control

This operation manual provides information on the various fea tures and functions of th is powerful costsaving device, including

• Installation,

• System operation,

Adjustable Speed Drive only.

• Configuration and menu options, and

• Mechani cal and electrical specifications.

Included is a section on general safety instruc tions that des cribe the warning labels and symbols t hat are

used throughout the manual. Read the manual completely before installing, operatin g, performing

maintenance , or dis posing of this equip men t.

This manual and the accompanying drawings should be considered a permanent part of the equipment

and should be readily available for reference a nd review. Dimensions shown in the manual are in metric

and/or the English equivalent.

Because of ou r commit ment to c ontinu ous im prov ement, Toshiba International Cor pora tio n reserve s the

right, without prior notice, to update information, make product changes, or to discontinue any product

or service identified in this publication.

Toshiba International Corporation (TIC) shall not be liable for direct, indirect, special, or

consequential damages resulting from the use of the information contained within this manual.

TOSHIBA is a registered trademark of the Toshiba Corporation. All other product or trade re fere nces

appearing in thi s manual are registered trad emarks of their respective owners .

This manual is copy righted. No part of this manual may be photocopied or reproduced in any form

without the prior wr itten consent of Toshiba International Corporation.

© Copyright 2005 Toshiba International Corporation.

All rights reserved.

Printed in the U.S .A.

Page 5

Table of Contents

CE Compliance Requirements ............................................................................................. 10

EMC Installation Guidelines ............................................................................................ 10

Motor C h a ra ct e ri s tics ................. .. ... ....... .. ... .............. ... .. ........ .. .. ............... .. ... ....... ... .. .......... 13

Motor Autotuning ............................................................................................................. 13

Pulse Width Modulation Operat ion ......................... ............................... .................... ......13

Low Speed O p er at i on . ....... .. ... ....... ... .. ............... .. .. ............... .. ... ....... ... .. ............... .. ... ....... 1 3

Overload Protection Adjustment ...................................................................................... 13

Operation Above 60 Hz .................................................................................................... 14

Power F ac to r Co rr ection ..... ... .. ........ .. .. ............... .. ... ....... ... .. ............... .. .. ........ .. ... ............ 14

Light Load Condi tions ............................................ ................... ...................................... 14

Motor/Load Combinations ............................................................................................... 14

Load-p ro d uc e d Neg ative Torque ........ .. ... .............. ... .. ............... .. ... ....... .. ... ............... .. .. ... 15

Motor Braking ..................................................................................................................15

ASD Characteristics .............................................................................................................. 16

Over-current Protection .................................................................................................... 16

ASD Capacity ...................................................................................................................16

Using Vector Contr ol .. ....... .. ... .............. ... .. ........ .. .. ............... .. ... ....... ... .. ............... .. ... ....... 16

Local/Remote Operation .................................................................................................. 16

Instal la t io n a n d Con nectio n s ...... .. ... .............. ... .. ....... ... .. ........ .. .. ............... .. ... ....... ... .. ....... ... 17

Install at i on N ot e s ... .. ............... .. ... ....... .. ... .............. ... .. ........ .. .. ... ....... ... .. ....... ... .. ............... 17

Mounting the ASD ........................................................................................................... 18

Conne ct in g th e A SD ........ .. .. ............... .. ... ....... ... .. ............... .. .. ........ .. ... .............. ... .. ....... ... 19

I/O and Co n tr o l . ............... .. .. ........ .. ... .............. ... .. ....... ... .. ............... .. ... ....... .. ... .............. ... 22

G7 ASD Control ............................................................................................................... 26

Typical Connection Diagram ..................... .......... .................... ........................................30

Comma n d M o d e a nd Freq uency Mo d e C o nt rol ...... ... .. ............... .. ... .............. ... .. ........ .. .. ... 31

Command Control (F003) ................................................................................................31

Frequency Control (F004) ................................................................................................ 32

Override Operation ........................................................................................................... 34

Electronic Operator Interface .............................................................................................. 36

EOI Featu r es ... .. .. ........ .. ... .............. ... .. ....... ... .. ............... .. ... ....... .. ... .............. ... .. ........ .. ..... 36

EOI Oper at io n ......... ... ....... .. ... .............. ... .. ........ .. .. ............... .. ... ....... ... .. ............... .. ... .......37

System Operation .................................................................................................................. 38

Initia l Set u p . ... .. ....... ... .. ....... ... .. ........ .. .. ............... .. ... ....... ... .. ............... .. .. ........ .. ... ............ 38

Opera ti on ( L o ca l) .... ........ .. .. ........ .. ... .............. ... .. ....... ... .. ............... .. ... ....... .. ... .............. ... 38

Default Setting Changes ................................................................................................... 39

Startup Wizar d R equ i rem ents ..... ... .. ............... .. ... .............. ... .. ....... ... .. ............... .. ... ....... .. ... 40

System Configuration and Menu Options ........................................................................... 43

Root Menus ...................................................................................................................... 43

Direct Ac ce ss Pa r am eter Info rmatio n ... ....... ... .. ............... .. ... .............. ... .. ....... ... .. ............... 5 9

Direct Access Parameters/Numbers ................................................................................. 59

G7 ASD Operation Manual i

Page 6

Alarms, Trips, and Troubleshooting .................................................................................. 173

Alarms an d Trips ..... ... ....... .. ... .............. ... .. ........ .. .. ............... .. ... ....... ... .. ............... .. ... ..... 173

Alarms ............................................................................................................................174

User No ti f ic at io n Co d es .. .. .. ........ .. ... ....... .. ... ....... .. ... .............. ... .. ........ .. .. ........ .. ... ....... .. . 176

Trips/Fau lts ..... .. ..... ..... ..... .. ..... ..... ..... .. ..... ..... ..... .. ..... ..... ..... .. ..... ..... .. ..... ..... ..... .. ..... ..... ... 176

Enclosure Dimensions and Conduit Plate Information ................................................... 182

Enclosu r e D imensio n s /Weight ......... .. .. ... ....... ... .. ....... ... .. ............... .. ... ....... .. ... .. ........ .. .. . 182

Conduit Plate Information .......... ........................................................................... .........187

Conduit Extender Box (option) ........... .......... .......... .......... ........... .......... .......... .......... .... 189

EOI Rem o t e M o u nt in g .... .. ....... ... .. ........ .. .. ........ .. ... .............. ... .. ....... ... .. ....... ... .. ............... .. . 190

Current/Voltage Specifications ........................................................................................... 193

Cable/Termin a l Sp ec if i ca t i o ns .... ....... ... .. ....... ... .. ............... .. ... ....... .. ... .............. ... .. ........ .. .. . 195

Dynamic Braking Resistor Wire/Cable Specifications .................................................. 198

Link Rea c t or I nf or mation ..... .. ... ....... ... .. ....... ... .. ............... .. ... ....... .. ... .............. ... .. ........ .. .. . 199

G7 Optional Devices ............................................................................................................ 200

G7 ASD Spare Parts Listing ............................................................................................... 201

ii G7 ASD Operation Manual

Page 7

General Safety Information

DO NOT attempt to install, operate, maintain or dispose of this equipment until you have read and

understood all of the product safety inf ormation and directions tha t are contained in this manua l.

Safety Alert Symbol

The Safety Alert Symbol indicates that a potential personal injury hazard exists. The symbol is

comprised of an equilateral triangle enclosing an exclamation mark.

Signal Words

Listed below are the signal words that are used throughout this manual followed by their descriptions

and associated symbols. When the words DANGER, WARNING and CAUTION are used in th is

manual they will be followed by important safety information that must be carefully adhered to.

The word DANGER pre ce d ed by th e safety al er t symbol in di ca t es th a t an immine nt l y h az ar d o us

situatio n exis ts that, if not avoided, will result in death or seri ous injury to personnel.

DANGER

The word WARNING preceded by the safety alert symbol indicates that a potentially hazardous

situatio n exis ts that, if not avoided, could result in death or serious injury to personnel.

WARNING

The word CAUTION preceded by the safety alert symbol indicates that a potentially hazardous

situation exists which, if not avoided, may result in minor or moderate injury.

CAUTION

The word CAUTION without the safety ale rt symbol indicates a pote ntially hazardous si tuation exists

which, if not avoided, may result in equipment and property damage.

CAUTION

G7 ASD Operation Manual 1

Page 8

Special Symb ols

To identify special hazards, other symbols may appear in conjunction with the DANGER, WARNING

and CAUTION signal words. Thes e symbols indicate areas that require special and/ or strict adherence

to the procedures to prevent serious injury to personnel or death.

Electrical Hazard Symbol

A symbol which indicates a hazard of injury from electrical

shock or burn. It is comprised of an equilateral triangle

enclosing a lightning bolt.

Explosion Hazard Symbol

A symbol which indicates a hazard of injury from exploding

parts. It is comprised of an equilateral triangle enclosing an

explosion image.

Equipment Warning Labels

DO NOT attempt to insta ll, operate, perform main tenance, or dispose of this equipment until you have

read and understood all of the product labels and us er directions that are contained in this manual.

Shown below are examples of safety labels that may be found attached to the equipment. DO NOT

remove or cover any of the labe ls. If the labels are damaged or if additional labels are required, contact

your Toshiba sales representative for additional labels.

Labels atta ched to the equipment are there to provide useful info rma tion or to indicate an imminently

hazardous s ituation that may result in serious injury, severe property a nd equipment damage, or death if

the inst r uctions are not followed.

Figure 1. Examples of labels that may be found on the equipment.

DANGER

DANGER

!

DO NOT REMOVE, DESTROY, OR COVER THIS LABEL.

READ THE INSTRUCTION MANUAL CAREFULLY BEFORE

ENTERING THIS COMPARTMENT.

HAZARDOUS VOLTAGE Behind These Panels.

Contact With Energized Main Bus Will Cause

Severe Injury, Death, Fire, Explosion, Or

Property Damage.

Turn Off And Lockout Primary And

Control Circuit Power Before Opening

These Panels.

Qualified Operators Only.

CAUTION

!

Excessive Loading of Operating Shaft

Can Prevent Contactor From Closing

Properly Resulting In Major Damage.

Do Not Use Contactor Shaft To Drive

Accessories Such As Mechanical Interlocks

Which Require More Than 5 Kgf-cm Of

Torque To Operate.

DO NOT OPEN THIS DOOR WHILE THE UNIT IS RUNNING.

THIS DOOR IS INTERLOCKED WITH ASD OPERATION.

!

DO NOT REMOVE, DESTROY, OR COVER THIS LABEL.

READ THE INS TRUCTION MANUAL CA RE FULLY BEFORE

INSTALLING, OPERATING, OR SERVICING THIS EQUIPMENT.

HAZARDOUS VOLTAGE

Can Cause Severe Injury, Death, Explosion,

Fire, Or Property Damage.

Only Qualified Personnel Should Be Permitted

To Operarate or Service This Equipment.

Disconnect And Lockout Primary And Control

Circuit Power Before Servicing.

Keep All Panels And Covers Securely In Place.

Never Defeat, Modify, Or Bypass Safety

Interlocks.

Foreign Voltage May Be Present At Interface

Terminals. Isolate Before Performing Service

Or Repairs.

Unauthorized Modifications To This Equipment

Will Void The Warranty.

!

DANGER

HAZARDOUS VOLTAGE MAY BE PRESENT.

Capacitors Are Charged. Wait

At Least 5 Minutes Before Entry.

Check For Charged Voltage

To Dissipate To A Safe Level

Before Opening T he Equipment.

2 G7 ASD Operation Manual

Page 9

Qualified Personnel

Installatio n, ope ratio n, and maint enanc e shal l be perfor med by Qualified Personnel Only. A Qualified

Person is one that has the skills and knowledge relating to the construction, installation, operat ion, and

maintenance of the elec trical equipment and has rece ived safety training on the hazards involved (Refer

to the latest edition of NFPA 70E for additional safety requirements).

Qualified Personnel shall:

• Have carefully rea d the enti re ope ration manual.

• Be familia r with the construction and func tion of the ASD, the equipment being dr iven, and the

hazards involved.

• Able to recognize and properly address hazards associated with the application of motor-driven

equipment.

• Be traine d and au thorized to safely energize, de-energize, ground, lockout/tagout circuits and

equipment, and clear faults in accordance with established safety prac tices.

• Be trained in the proper care and use of protective eq uipment such as safety shoes , rubber gloves,

hard hats, safety glasses, face shields, fl ash clothing, etc., in accord ance with established safety

practices.

• Be trained in rend ering first aid.

For further information on workplace safety visit www.osha.gov.

Equipment Inspection

• Upon receipt of the equipment inspect the packaging and equip me nt for shipping damage.

• Carefully unpack the equipment and check for parts that were damaged during shipping, missing

parts, or conce aled damage. If any discrepa ncies are discovered, it should be noted with t he carrier

prior to accepting the shipment, if possible. File a claim with th e carrier if necessary and

immediately notify your T oshiba sales representative.

• DO NOT install or energize equipment that has been damaged. Damaged equipment may fail

during operation resulting in equipment damage or personal injury.

• Check to see that the rated capacity and the model number specified on the nameplate conform to

the order specifi cations.

• Modification of this equipment is dangerous and must not be performed except by factory trained

representat ives. When modifications are re quired contact your Toshiba sales representative .

• Inspections may be required before and after moving installed equipment.

• Keep the equ ipm ent in an upright position.

• Contact your Toshiba sales representative to report discrepancies or for assistance if required.

G7 ASD Operation Manual 3

Page 10

Handling and Storage

• Use prope r lifting techniques when movi ng the ASD; including properly sizing up the l oad, getting

assistance, an d usi ng a forklift if required.

• Sto re in a well-ventilated covere d lo cation an d p r eferably in the original ca r ton if the equip me n t

will not be used upon receipt.

• Store in a cool, clean, and dry location. Avoid storage locations with extreme temperatures, rapid

temperature ch anges, high humidity, moisture, dust, corrosive gases, or metal particle s.

• The storage temperature range of the G7 ASD is 14° to 104° F (-10 to 40° C) .

• Do not store the unit in pl aces tha t are e xposed to outside we ather c onditi ons (i. e., wi nd, rain , snow,

etc.).

• Store in an upright position.

Disposal

Never dispose of electrical components via incineration. Contact your state environmental agency for

details on disposal of electrical components and packaging in your area.

Installation Precautions

Location and Ambient Requirements

• The Toshiba ASD is intended for permanent installations only .

• Installation should conform to the 2002 National Electrical Cod e — Articl e 110 (NEC)

(Requirements For Electrical In stallati ons), al l regulations of the Occupational Safety and

Health Administration, and any other applicable na tional, regional , or industry codes and

standards.

• Select a mounting location that is easily accessible, has adequate personnel working space, and

adequate il lum ination for adjustment, inspection, and maintenance of the equipm ent (refer to 2002

NEC Article 110-13).

• A noncombustible insulati ng floor or mat should be provided in the area immediately surrou nding

the electrical system.

• Do Not mount the ASD in a location that would produce catastrophic results if it were to fall from

its mounting loca tion (equipment damage or injury).

• Do Not mount the ASD in a locati on that would allow it to be exposed to flammable chemicals or

gases, water, solvents, or other fluids.

• Avoid installation in areas where vibration, heat, humidity, dust, fibers, steel particles, explosive/

corrosive mists or gases, or sources of electrical noise are present.

• The installation location shall not be exposed to direct sunlight.

• Allow proper cl earance spaces for installation. Do not obstruct the ventilation openings. Refe r to

the section titled

requirements.

Installation and Connections on pg. 17 for further information on ventilation

• The ambient operating temperature range of the G7 ASD is 14° to 104° F (-10 to 40° C).

• See th e sec ti on titl ed I nst alla tion an d Conne ctio ns on pg. 17 for a dditio nal informati on on i nsta lling

the drive.

4 G7 ASD Operation Manual

Page 11

Mounting Requirements

• Only Qualified Personnel should install this equipment.

• Install the unit in a secure and upright position in a well-ventilated area.

• A noncombustible insulati ng floor or mat should be provided in the area immediately surrou nding

the electrical system at th e place where maintenance operations are to be perfo r med.

• As a minimum, the installation of the equipment should conform to the NEC Article 110

Requirements F or Ele ctric al Ins tal latio ns , OSHA, as we ll as any o the r appli cable nati ona l, reg ional,

or industry codes and standards.

• Installation practices should conform to the late s t revision of NFPA 70E Electrical Safety

Requirements for Employee Workplaces.

• It is the responsibility of the pers on ins talling the ASD or the electrical maintenance personnel to

ensure that the unit is installed in to an e nclosure that will protect personnel against electric shock.

Conductor Routing and Grounding

WARNING

• Use sepa rate me tal c ondui ts fo r rout ing the i nput power, output power, and c ont rol cir cui ts and e ach

shall have its own ground cable.

• A separate ground cable should be run inside the conduit with the input power, outpu t power, and

and control circuit s.

• DO NOT connect control terminal strip return marked CC to earth ground.

• Always ground the unit to prevent elec trical shock and to help reduce electrical nois e.

• It is the responsibility of the pers on ins talling the ASD or the electrical maintenance personnel to

provide proper grounding and branch circuit protection in accordance with the 2002 NEC and any

applicable local codes.

The Metal Of Conduit Is Not An Acceptable Ground.

Power Connections

DANGER

Contact With Energized Wiring Will Cause Severe Injury Or Death.

• Turn off, lockout , an d tagout all power sources before proceeding to connect th e power wiring to

the equ ip ment.

• After ensuring that all power sources are turned off and isolated in accordance with established

lockout/ta gout procedures, connect thre e-phase power source wiring of the corre ct voltage to the

correct input terminals and connect the output terminals to a motor of the corr ec t voltage and type

for the application (refer to NEC Article 300 – Wiring Methods and Article 310 – Conductors For

General Wiring). Size the branch circuit conductors in accordance with NEC Table 310.16.

• If multip le condu ctors that are small er than t he recommende d siz es are used in par allel for th e in put

or output powe r, each branch of the parallel set shall have its own conduit and not share its c onduit

with other parallel sets (i.e., place U1, V1, and W1 in one conduit and U2, V2, and W2 in anoth er)

(refer to NEC Article 300. 20 and Article 310.4). National and local electrical codes should be

G7 ASD Operation Manual 5

Page 12

referenced if three or more power conduc tors are run in the same conduit (refer to 2002 NEC

Article 310 adjustment factors on page 70-142).

• Ensure that the 3-phase input power is Not connect ed to the output of the ASD. This will dama ge

the ASD and may cause injury to personnel.

• Do not insta ll the ASD if it is damaged or if it is missing any component(s).

• Do Not connect resistors ac ross terminals PA – PC or PO – PC. This may cause a fire.

• Ensure the correct phase sequence and the desi red direction of motor rotation in the Bypass mode

(if applicable).

• Turn the power on only after attaching and/or securing the front cover.

Protection

• Ensure that primary protect ion exis ts for the input wiring to the equipm ent. This protect ion must be

able to interru pt the available fault current from the power line. The equipme nt may or ma y not be

equipped with an in put disconnect (opti on).

• All cable entry openings must be sealed to reduce the risk of entry by vermin and to allow for

maximum cooling efficiency.

• Follow all warnings and precautions and do not exceed equipment ratings.

• If using multiple motors provide separate overload protection for each motor and use V/f control.

• External dynamic braking resistors must be thermally prot ec ted.

• It is the responsibility of the pers on ins talling the ASD or the electrical maintenance personnel to

setup the Emergency Off brak ing syste m of the ASD. The function of the Emergency Off braking

function is to remove output power from the drive in the eve nt of an emergency. A supplemental

braking system may also be engaged in the event of an emergency. For further information on

braking systems, see

Enable on pg. 112.

Note: A supplemental emergency stopping system should be used with the ASD. Emergency

stopping shou ld not be a task of the ASD alone.

• Follow all warnings and precautions and do not exceed equipment ratings.

DC Injection Brak ing Start Frequency on pg. 105 and Dynamic Braking

6 G7 ASD Operation Manual

Page 13

Syste m In teg r at ion Precau tions

The following preca utions are provided as general guidelines for the setup of the ASD withi n the

system.

• The Toshiba ASD is a general-purpose product. It is a system component only and the syste m

design should take this into consideration. Please contact your Toshiba sales representat ive for

application-specific information or for training support.

• The Toshiba ASD is part of a larger system and the safe operation of the ASD will depend on

observing certain precautions and performing proper system integr ation.

• A detailed system analysis and job safety ana lysis should be performed by the s ys tems designer

and/or syste ms inte grator be fore the i nstal lati on of t he ASD com ponent. Con tact your Toshiba sales

representat ive for options availability and for application-spe cific system integration information if

required.

Personnel Protection

• Instal lation, operation, and maintenance shall be performed by Qualified Personnel Only.

• A thorough understanding of the ASD will be required before the installation, operation, or

maintenance of the ASD.

WARNING

• Rotating machinery and live con ductors can be hazardous and shall not come into contact with

humans. Personnel should be protected from all rotating machinery and electrical hazards at all

times.

• Insulat ors , machine guards, and electrical safeguards may fail or be defeated by the purposeful or

inadvertent actions of workers. Insulators, machine guards, and electrical safeguards are to be

inspected (and tested where possible ) at installation and pe riodically after installation for potential

hazardous conditions.

• Do not allow personnel near rotating machinery. Warning signs to this effect shall be posted at or

near the machinery.

• Do not all ow pe rsonne l near e lectr ical conduc tors. Human cont act wi th e lect rical conduct ors c an be

fatal. Warning signs to this effec t shall be posted at or near the hazard.

• Personal protection equip ment shall be provided and used to pr otect employees from any hazards

inherent to system operation.

• Follow all warnings and precautions and do not exceed equipment ratings.

System Setup Requirements

• When using the ASD as an integral part of a larger system, it is the responsibility of the ASD

installer or maintenance per sonnel t o en sure that th ere is a fail-safe in place, i.e., an arrangement

designed to switch the system to a safe condition if there is a fault or failure.

• System safety features should be employed and designed into the int egrated system in a manner

such that s ys te m op e r at io n , ev en in th e ev e nt of sy s te m fa i lu r e, wi ll no t cau s e h arm o r res ul t in

personnel injury or system damage (i.e., E-Off, Auto-Restart settings, System Interloc ks, etc.).

• The programming s etup and system configuration of the ASD may allow it to start the motor

unexpectedly. A familiarity with the Auto-r estart settings are a requi rem ent to use this product.

G7 ASD Operation Manual 7

Page 14

• Improperl y desig ned or impr operly inst al led syst em interl ocks may ren der the m otor unabl e to sta rt

or stop on command.

• The failure of external or ancillary components may cause intermittent system operation, i.e., the

system may sta rt the motor without warning.

• There may be thermal or physical properties, or ancillary dev ices integrated into the overall system

that may allow for the ASD to start the motor without warning. Signs at the equipment installation

must be posted to this effect.

• If a secondary magnetic contactor (MC) is used between the ASD and the load, it should be

interlocke d to halt the ASD before the secondary cont act opens. If the output contactor is used for

bypass operati on, it must be interlocked such that commercial power is never applie d to the ASD

output terminals (U, V, W).

• Power factor improvement capacitors or surge absorbers must not be installed on the output of the

ASD.

• Use of the built-in system protective features is highly recommended (i.e ., E-Off, Overload

Protection, etc.).

• The operating controls and system status indicators should be clearly readable and positioned

where the operator can se e the m wit hout obstruction.

• Additi onal warnings and notifications shall be poste d at the equipment installation locatio n as

deemed required by Qualified Personnel.

• Follow all warnings and precautions and do not exceed equipment ratings.

Operati ona l an d M ain te na nc e Prec au tio ns

WARNING

• Turn off, lockout , and tagout the main power, the control power, and instrumentation connections

before inspecti ng or servicing the drive, or ope ning the door of the enclosure.

• Turn off, lockout , and tagout the main power, the control power, and instrumentation connections

before proceeding to disconnect or connect the power wiring to the equipment.

• The capac itors of t he ASD mai ntain a resi dual c harge for a pe riod of time after turn ing the ASD off .

The required time for each ASD typeform is indicated with a cabinet la bel and a Charge LED.

Wait for at least the minimum time indicated on the enclosure-m ounted label and ensure that the

Charge LED has gone out before opening the door of the ASD once the ASD power has been

turned of f.

• Turn the power on only after attaching (or closing) the front cover and Do Not remove the front

cover of the ASD when the power is on.

• Do Not attempt to disassemble, modify, or repair the ASD. Call your Toshiba sales representative

for repair information.

• Do not place any objects inside of the ASD.

• If the ASD should emit smoke or an unusual odor or sound, turn the power of f im me diately.

• The heat si nk and other components may become ext remel y hot to the t ouch. All ow the unit to cool

before coming in contact with these items.

• Remove power from the ASD during extended periods of non-use.

• The system should be inspected periodically for damaged or improperly functioning parts,

cleanliness, and to ensure that the connectors are tightened securely.

8 G7 ASD Operation Manual

Page 15

• Ensure that the Run functions (F, R, Preset Speed, etc.) of the ASD are off before performing a

Reset. The post-rese t settings may allow th e ASD to sta rt unexpectedly.

• Retry or Reset settings may allow the motor to start unex pectedly. Warnings to this ef fect should

be clearly poste d near the ASD and motor.

• In the event of a power failure, the motor may restart after power is restored.

• Follow all warnings and precautions and do not exceed equipment ratings.

DO NOT install, operate, perform maintenance, or dispose of this equipm ent until you have read and

understood all of the product warnings and user direc tions. Failure to do so may result in equipment

damage, operator injury, or loss of life.

Service Life Information

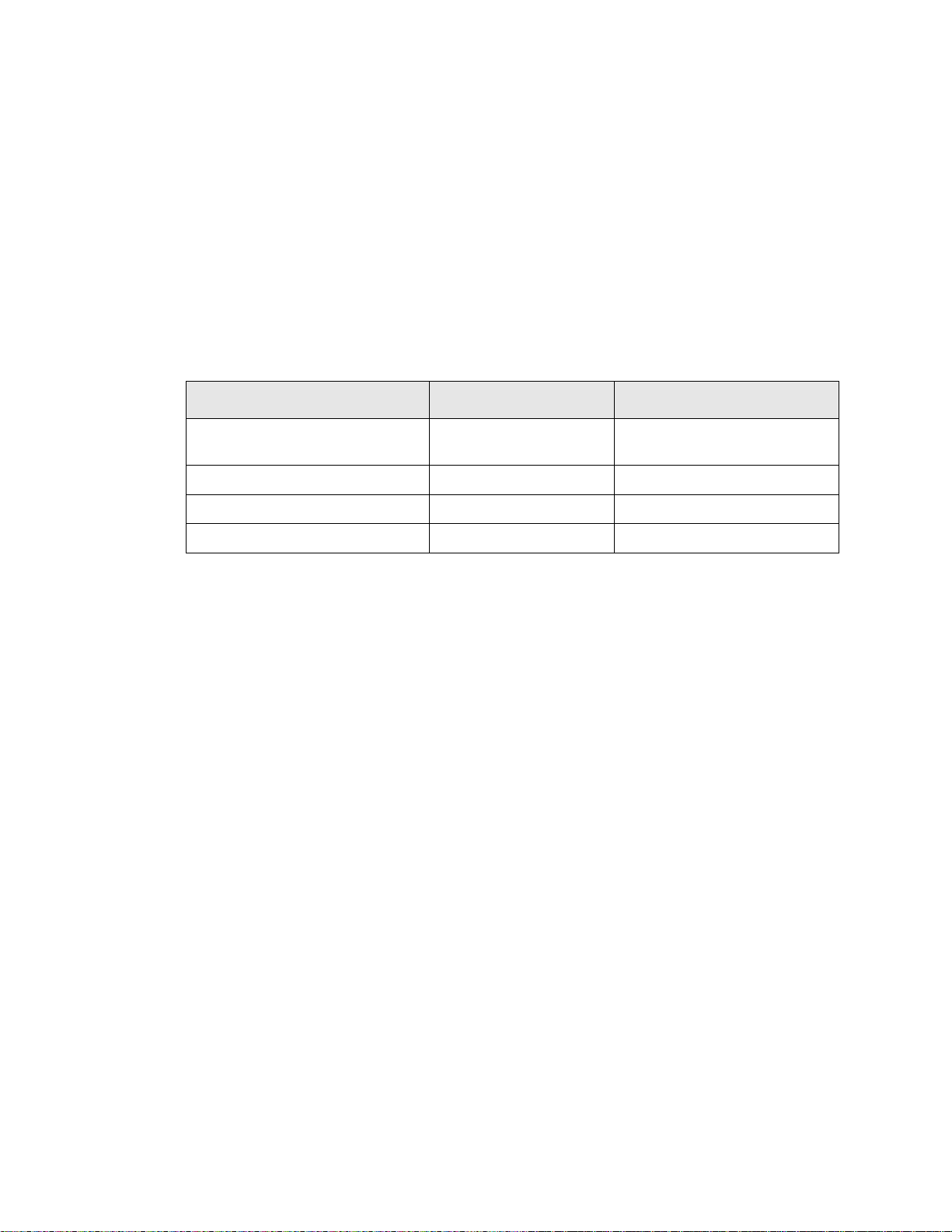

Part Name Service Life Remarks

Large Capacity Electrolytic

Capacitor

Cooling Fan 26,00 0 H o urs

CN Connectors 100 Connec ts/Disconnects

On-board Relays 500,000 Actuations

5 Years

When not used for long periods,

charge semi-annually.

G7 ASD Operation Manual 9

Page 16

CE Compliance Requirements

In addition to the local and regional safety re quirements, this section describes additional criteria that

must be met to qualify for European Confor mity (CE) certification. All relevant apparatus placed on

the European market is required to comply to the European Community directive on electromagnetic

compatibility (EMC). The following instructions provide a means of compliance for the 7-series of

ASDs. A Technical Const ruct ion File (TFC ) indica tes the rationa le used to de clare compl iance an d is on

file at Toshiba Inter national Corporation, Houston, Texas U.S.A.

EMC Installation Guidelines

All systems placed on the Europ ean market ar e required to comply wi th th e Europea n Co mm u n ity

directive regarding electromagnet compatibility (EMC). Toshiba ensures that all systems deployed in

the European market ha ve be en s cre ened and are in 100% compliance with the following standards:

• Radiated Interference: EN 55011 Group 1 Class A

• Mains Interference: EN 55011 Group 1 Cla ss A

• Radiate d S usceptibility: IEC 801-3 1984

• Conducted RFI Susceptibility: prEN55101-4 (prIEC801-6) Doc 90/30270

• Electrostatic Dischar ge: IEC801-2 1991

• Electrical Fast Transient: IEC 801-4 1988

• Surge : IEC1000-4-5 1995 2 KV line-to-line, 4 KV line-to-earth

• Voltage Interruption: IEC 1000-4-11

General EMC Guidelines for Consideration

• Input filters of the appropriate rating shall be used.

• Proper grounding is a requirement.

• Grounds shall be kept to the minimum length to accomplish the connection.

• Grounds shall have low RF impedance.

• A central ground shall employed in a complex system.

• Paint or corrosion can hamper good grounding; remove as required.

• Keep control and power cabling separated. Minimize exposed (unsc reened) cable.

• Use 3600 screened connections where possible.

CE Compliant Installation Guidelines

ASDs should be instal led in accordance with the following guidelines.

1. Filtering — An input f ilter sh al l be us ed with the ASD. A S chaf f ner F N258 seri es in put f ilt er of th e

appropriate rating shall be mounted next to the ASD.

2. Mechanical — The ASD and the associated equipment shall be mounted on a flat metallic

backplane. A minimum space of 5 cm (2 inches) shall be between the ASD and the filter to allow

for ventilation. The filter output cable is to be connected from the bottom of the filter to the ASD

power input and is to be the minimum lengt h required for a connection. See

filter selection assistance.

Table 1 on page 11 for

10 G7 ASD Operation Manual

Page 17

Units received as an Open Chassis shall not be placed into operation until being placed into an

approved enclosure that will protect personnel against electrical shock.

Opening and closing of enclosures or barriers should be possible only with th e us e of a key or a

tool.

3. Cabling — The power, filter, and motor cables shall be of the appropriate current rating. The

cables shall be connected in accor dance with the guidelines of the manufacturer and the applicable

local and national agencies. A 4-core screened cable (such as RS 379-384) is to be used for the

power and earth connections to minimize RF emissions. Control cabling must be screened using

P/N RS 367-347 or a similar component.

4. Grounding — The mains (input) ground shall be conne cted at the grou nd ter minal provide d on the

filter. The filter and motor shall be grounded at the ground terminals provided in the ASD.

5. Screening — The mains (input) screen is to be conne cted to the metallic back-plane at the filter;

remove any finish coating as required. The screen over the filter output cables, the motor cable

screen, and the control wire screens must be connected to the ASD case using glands or conduit

connectors. The motor ca ble screen shall be connect ed to the motor case. When using a braking

resistor, the cabling between the resistor and ASD shall also be screened. This screen shall connect

to both the ASD enclo sure and the resistor enclosure.

6. Where residual-current-operated pr otective device (R CD) is used for protection in case of direct or

indirect contact, only RCD of type B is allowed on the supply side of this Ele ctronic Equipment

(EE). Otherwise, a noth er protecti ve meas ure shall be appli ed, such as s eparati on of the EE from the

environment by double or feinforced insulat ion, or isolation of the EE and the supply system by a

transformer.

See the G7 Filter Selection below for the recommended input filters for a given typeform.

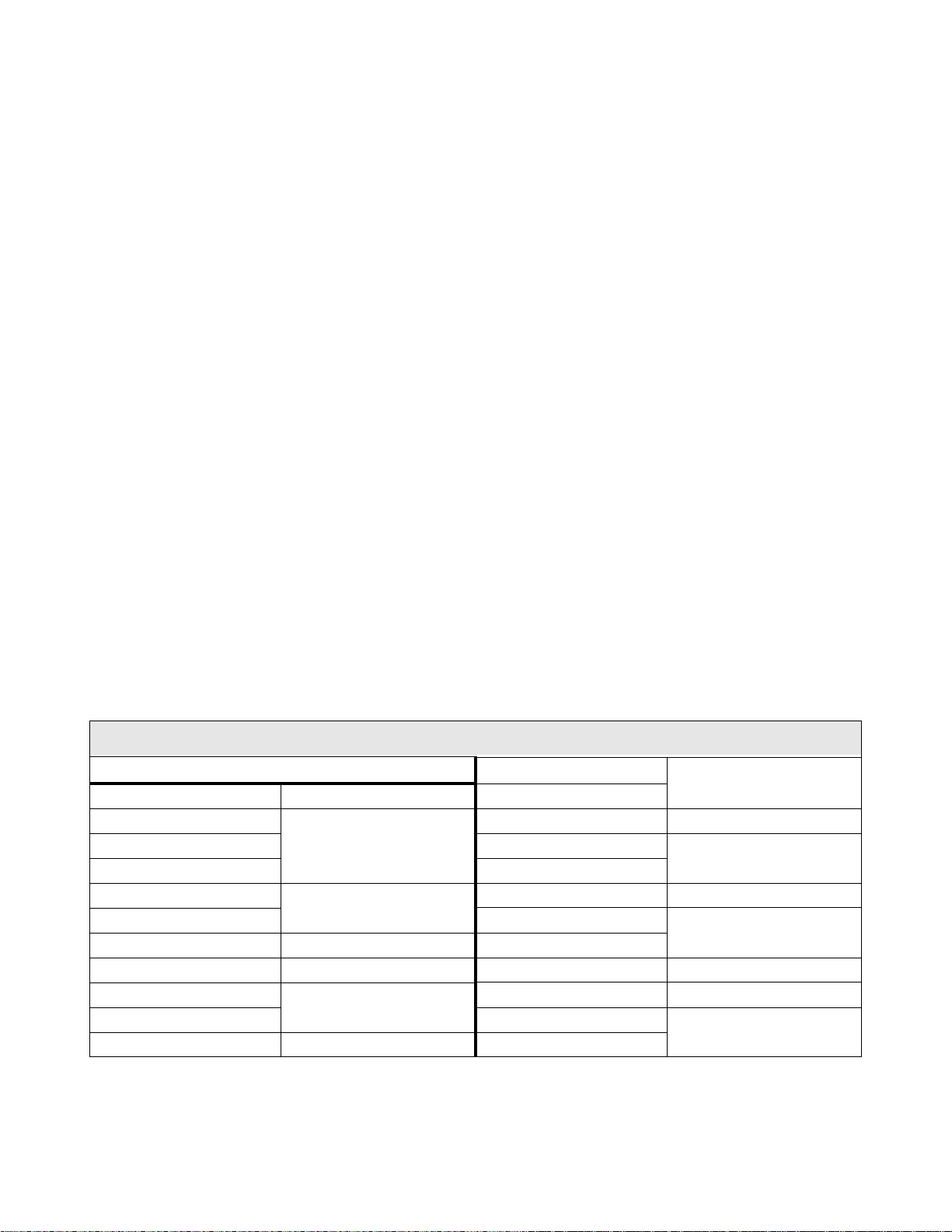

Table 1.

G7 Filter Selection Table

230V VT130G7U4110B

VT130G7U2010B FN258-7 VT130G7U4160B

VT130G7U2015B

VT130G7U2025B VT130G7U4270B

VT130G7U2035B VT130G7U4330B

VT130G7U2055B

VT130G7U2080B VT130G7U4500B

VT130G7U2110B FN258-42 VT130G7U4600B

VT130G7U2160B FN258-75 VT130G7U4750B FN258-130

VT130G7U2220B

VT130G7U2270B VT130G7U412KB

VT130G7U2330B FN258-130 VT130G7U415KB

FN258-16

FN258-30

FN258-100

VT130G7U4220B FN258-42

VT130G7U4400B FN258-75

VT130G7U410KB FN258-180

FN258-30

FN258-55

FN258-100

FS5236-300

G7 ASD Operation Manual 11

Page 18

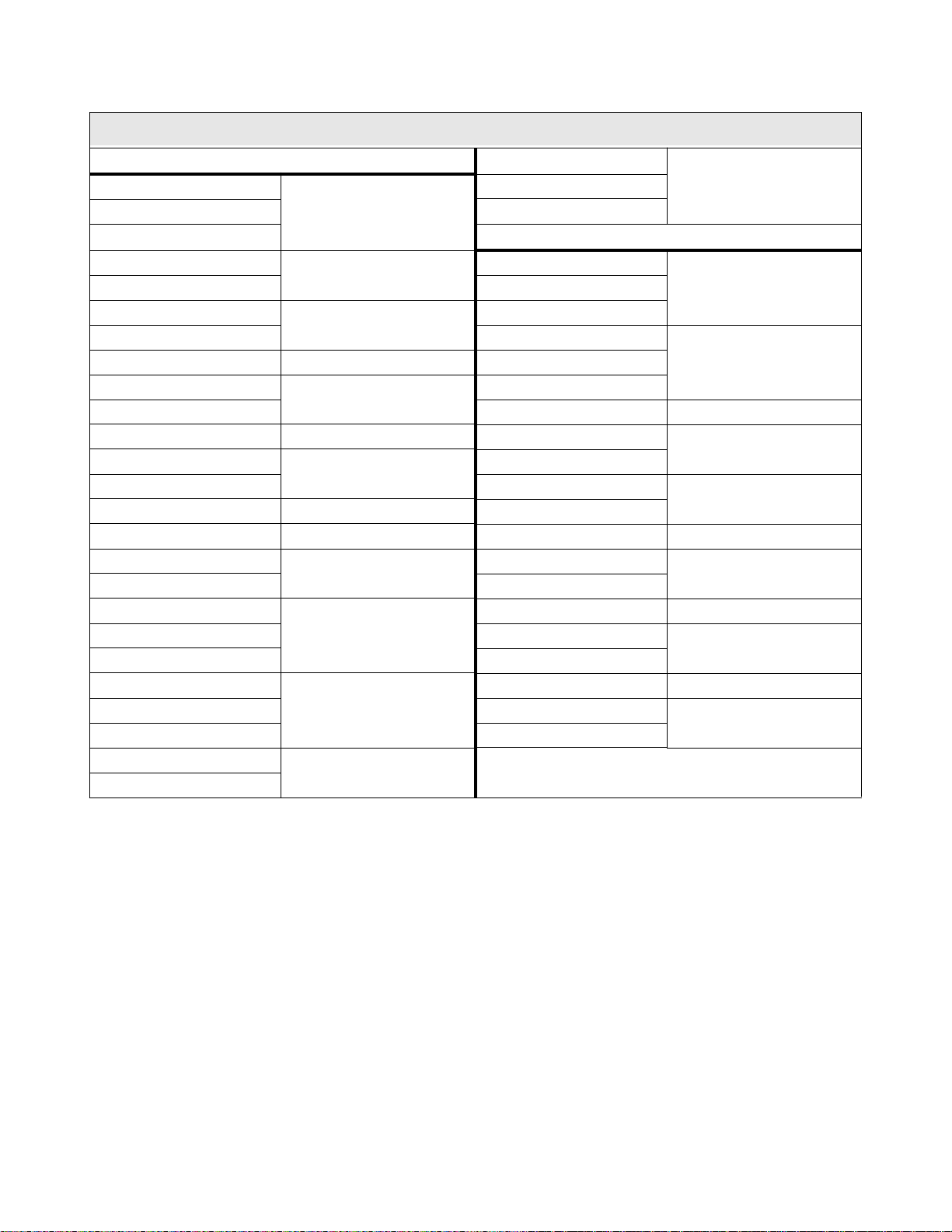

G7 Filter Selection Table

460V

VT130G7U4015B

VT130G7U4025B VT130G7U430KB

VT130G7U4035B 600V

VT130G7U4055B

VT130G7U4110B

VT130G7U4160B VT130G7U6055B

VT130G7U4270B

VT130G7U4330B VT130G7U6160B FN258-30

VT130G7U4400B FN258-75 VT130G7U6220B

VT130G7U4500B

VT130G7U4600B VT130G7U6330B

VT130G7U4750B FN258-130 VT130G7U6400B

VT130G7U410KB FN258-180 VT130G7U6500B FN258-75

VT130G7U412KB

VT130G7U415KB VT130G7U6750B

VT130G7U420KB

VT130G7U425KB VT130G7U612KB

VT130G7U430KB VT130G7U615KB

VT130G7U4015B

VT130G7U4025B VT130G7U625KB

VT130G7U4035B VT130G7U630KB

VT130G7U4055B

VT130G7U4080B

FN258-7

FN258-16

FN258-30

FN258-55

FN258-100

FS5236-300

FS5236-500

FN258-7

FN258-16

VT130G7U420KB

VT130G7U425KB

VT130G7U6015B

VT130G7U6035B

VT130G7U6110B

VT130G7U6270B

VT130G7U6600B

VT130G7U610KB FN258-130

VT130G7U620KB FS5236-300

FS5236-500

FN258-7VT130G7U4080B VT130G7U6025B

FN258-16VT130G7U4220B FN258-42 VT130G7U6080B

FN258-42

FN258-55

FN258-100

FS5236-180

FS5236-500

12 G7 ASD Operation Manual

Page 19

Motor Characteristics

Listed below are some variable speed AC motor control concepts with which the user of the

G7 Adjustable Speed Drive should become familiar.

Motor Autotuning

Motor production methods may cause minor differences in the motor operation. The negative effects of

these diffe r ences may be minimized by using the Autotune feature of the G7 ASD. Autotuning is a

function of the G7 that measures several para meters of the c onnected motor and places these readings in a

stored table. The software uses the informatio n in the table to help optimize the response of the ASD to

application-specific load and operational requirements. The Autotuning function may be enabled for

automatic tuning , co nfigured manually at

The measured parameters include the rotor resistance, the stator resistance, the required excitation

inductance, rotational inertia values, and leakage inductance values.

The G7 ASD is also equipped with a factory-loaded table of motor parameters that fit several different

types of motors. To use this function, disable Autotune and sel ect a motor type at

Pulse Width Modula tio n Op e ration

F400, or disabled.

F413.

The G7 ASD uses a sinusoi d al Pulse Width Modulation (PWM) control system. The output current

waveform generated by the ASD approaches that of a perfect sine wave; however, the output wavefo rm is

slightly distorted. For this reason, the motor may produce more heat, noise, and vibration when operated

by an ASD, rather than directly from commercial power.

Low Sp eed Operatio n

Operating a general-purpose motor at lower speeds may cause a decrease in the cooling ability of the

motor. Reducing the torque requ irement of the motor at lower speeds will decrease the generated heat at

lower speeds.

When the motor is to be operated at low spee d (less than 50% of full speed) and at the rated torque

continuously, a Tos hiba VF motor (designed for use in conjunction with an ASD) is recommended. When

the ASD is used with a VF motor, the VF Motor overload protection set ting must be enabled (see

Program ⇒ Protection Parameters ⇒ Overload ⇒

V/f Motor Enable/Disable).

Overload Protection Adjustment

The G7 ASD software monitors the output current of the sys tem and determines when an overload

condition occurs. The overload current level is a percentage of the rating of the motor. This function

protects the motor from overload.

The default setting for the overload detection circuit is set to the maximum rated current of the ASD at the

factory. This set ting will have to be adjusted to match the rating of the motor with which the ASD is to be

used. To change the overload reference level, see

G7 ASD Operation Manual 13

Electro ni c Thermal Protection #1 on pg. 154.

Page 20

Operation Above 60 Hz

A motor produces more noise and vibration when it is operate d at frequencies above 60 Hz. Also, when

operating a motor a bove 60 Hz, th e rated lim it of the motor or its bear ings m ay be ex ceeded; t his may void

the motor warranty.

Contact the motor manufacturer for additional information before operating the motor above 60 Hz.

Power Factor Correction

DO NOT connect a power factor correction capacitor or surge absorber to the output of the ASD.

If the ASD is used with a motor that is equipped with a capacitor for power factor correction, remove the

capacitor from the motor.

Connecting eit her of these devices to the output of the ASD may cause the ASD to malfunction and trip,

or the output device may cause an over-current condition resulting in damage to the device or the ASD.

Light Load Conditions

When a motor is operated under a co ntinuous light load (i. e., at a load of less than 50% of its rated

capacity) or it drives a load which produces a very small amount of inertia, it may become unstable and

produce abnormal vibration or trips because of an over-current condition. In such a case, the carrier

frequency may be lowered to compensate for this undesirabl e condition (see Program ⇒ Special Control

Parameters ⇒

Carrier Frequency).

Note: For proper operation, the carrier freq uency must be 2.2 kHz or above except when

operating in the Constant Torque, Variable Torque , or the 5-Point Setting modes.

Motor/Load Combinations

When the ASD is used in comb ination with one of the following motors or loads, it may result in unstable

operation.

• A motor with a rated capacity that exceeds the motor capacity recommended for the ASD.

• An explosion-proof motor.

When using the ASD with an explosion-proof motor or other special motor types, lower the carrier

frequency to s tabilize the o per ation. DO NOT set the carrier frequency below 2.2 kHz if operati ng the

system in the vector control mode.

Note: For proper operation, the carrier freq uency must be 2.2 kHz or above except when

operating in the Constant Torque, Variable Torque , or the 5-Point Setting modes.

• If the motor that is coupled to a load that has a large backlash or a reciprocating load, use one of the

following procedures to stabilize its operation.

• Adjust the S-pattern acceleration/deceleration setting,

• If in the Vector control mode, adjust th e response time, or

• Switch to the Constant Torque control m ode.

14 G7 ASD Operation Manual

Page 21

Load-pro du ce d Nega tiv e Torque

When the ASD is used with a load that produces negative torque (an ove rhauling load), the over-voltage

or over-current protective functions of the ASD may cause nuisance trippin g.

To m inimize the undesirable effects of negative torque the dynamic braking system may be used. The

dynamic braking syste m converts the regenerate d ene rgy into heat that is dissipated using a braking

resistor. The braking resistor must be suitably matched to the load. Dynamic braking is also effective in

reducing the DC bus voltage during a momentary over-voltage conditi on.

CAUTION

If under extreme conditions the dynamic braking syste m or a compo nent of this system were to fail, the

dynamic braking resistor may experience an extended over-current condition. The DBR circuit was

designed to dissipate excessive amounts of heat and if the extended over-current condition were allowed

to exceed the circuit param eters, this condition could result in a fire hazard.

To c ombat this c onditi on, the 3-pha se in put may be connect ed usi ng conta ctors that a re confi gure d to open

in the event of an extende d DBR over-current condit ion or an internal circuit failure. Using a thermal

sensor and/or overload protection as the 3-phase input contactor drive signal, the contactors will open and

remove the 3-phase input power in the event of an extended DBR over-c urrent or system over-voltage

condition.

Motor Braking

The motor may continue to rotat e and c oast t o a sto p after being shu t off due to t he inert ia of the load. If an

immediate stop is required, a braking system should be used. The two most common types of motor

braking systems used with the G7 ASD are DC Injection Braking and Dynamic Braking.

For further information on braking systems, see DC Injection Braking on pg. 105 and Dynamic

Braking Enable on pg. 112.

G7 ASD Operation Manual 15

Page 22

ASD Characteristics

Over- current Protection

Each G7 ASD model was designed for a specified operating power range. The ASD will incur a trip if the

design specifications are exceeded.

However, the ASD may be operated at 110% of the specified output-curre nt range continuously or at

150% for a limited amount of time as indicated in the sect ion titled

193. Also, the Overcurrent Stall Level may be ad justed to help with nuisan ce over-current trips (se e

F601).

When using the ASD fo r an application th at controls a motor which is rated signi f icantly less th an the

maximum current rating of the ASD, the over-current limit (Thermal Overload Protection) setting will

have to be changed to match th e application. For furth er information on this parame ter, see

Thermal Protection #1 on pg. 154.

ASD Capacity

The G7 ASD must not be us ed wi t h a mo to r th at ha s a sig n if i cantly la rger capacit y, even if th e mo tor is

operated under a small load. An ASD being used in this way will be susceptible to a high-output peak

current which may result in nuisance tripping.

Current/Voltage Specifications on pg.

Electronic

Do not apply a level of input voltage to an ASD that is beyond that which the ASD is rated. The input

voltage may be stepped down when requ ired with the use of a step-down transform er or some other type

of voltage-reduction system.

Using Vector Control

Using Vector Control enables the system to produce very high torque over the entire ope rating range

even at ex t r emely low sp ee ds. Vector Control may be used with or without feedback. However, using

feedba ck increases the speed accuracy for applications requiring precise speed control. En ab ling the

Automatic Energy Savings fur ther increases the efficiency o f the G7 ASD while maintaining its robust

performance.

Vector Control is not capable of operating multiple motors connec ted in parallel.

See F015 on pg. 64 for further information on using Vector Co ntr ol.

Local/Remote Operation

While running in th e Local mode at a non-zer o speed, if the RJ45 conne ctor is remove d from the EOI and

then reinserted, the ASD remains in the Local mode even though the Local LED is of f (press Run to

illuminate the Local LED). The ASD output remains at the frequency of the F requency Command field

at the time of the disconnect so long as the connect or is disconnected.

Once reinserted, the reference fre quency that was loaded into the EEPROM (not RAM) before the

disconnect will be the fre quency to which the ASD output will return.

To prevent this condition, before disconnecting the RJ45 connector ensure that the ASD is off.

16 G7 ASD Operation Manual

Page 23

Installation and Connections

The G7 Tr ue Torque Control2 Adjustable Speed Drive may be set up initially by performing a few

simple config uration sett ings. To operate properly , the ASD mus t be secu rely mo unted an d connec ted to

a power source (3-phase AC input at the L1/R, L2/S, and L3/T terminals). The control terminals of the

ASD may be used by connecting the terminals of the Control Terminal Strip to the proper sensors or

signal input sources (see the section titled

Note: The optional ASD-Multicom boards may be used to e xpand the I/O functionality of

the ASD. See the section titled

information on the available options.

The output terminals of the ASD (T1/U, T2/V, and T3/W) must be connected to the motor that is to be

controlled (see

As a minimum, the installation of the ASD shall conform to Article 110 of the 2002 NEC, the

Occupational Safety and Health Administration requirements, and to any other loca l and regional

industry code s a nd st andards.

Upon initial syst em powerup, the Startup Wizard starts automatically. The Startup Wizard assists the

user with the initial configuration of the G7 True Torque Control

section titled

Figure 18 on pg. 30).

Initial Setup on pg. 38 for additional information on the Startup Wizard.

Installation Notes

I/O and Control on pg. 22).

G7 Optional Devices on pg. 200 for further

2

Adjustable Speed Drive. See the

When a brake-equip p ed motor is con n ected to the A SD, it is possib le that the brake may not release at

startup be cause of i nsuf f icie nt vo ltage . To avoid this, Do Not co nnec t t he b rake or t he bra ke cont ac to r to

the output of the ASD.

If an output cont actor i s used for byp ass opera tion, it mus t be int erlock ed such tha t commer cial po wer is

never applied to the output terminals of the ASD (T1/U, T2/V, or T3/W).

If a secondary magnetic contact or (MC ) is used between the output of the ASD and the motor, it s hould

be interlocked such that the ST – CC connecti on is disconnected befor e the output contactor is ope ned.

Do Not open and then close a seco ndary magnetic contactor between the ASD and the moto r unless the

ASD is off and the motor is not rotating.

Note: Re-applicat ion of power via a secondary co ntact while the ASD is on or while the

motor is s t il l turni n g m a y ca u s e ASD dam a g e .

On some devices the ST-to-CC connection is further enhanced by the operation of the MS1 AUX relay

circuit. The MS1 AUX relay circuit is normal ly open and closes the ST-to-CC connection (via ST1)

only after norma l system power is available. The MS1 AUX relay circuit prohibits the ST-to-CC

connection in the event that the MS1 contactor fail s to close during start up or if MS1 open s while the

ASD is running. For the 230 volt ASD this feature is available on the 30 HP system, on the 460 volt

ASD this feature is available on the 75 HP and above systems, and on the 600 volt ASD it is availabl e

on the 60 HP and above systems.

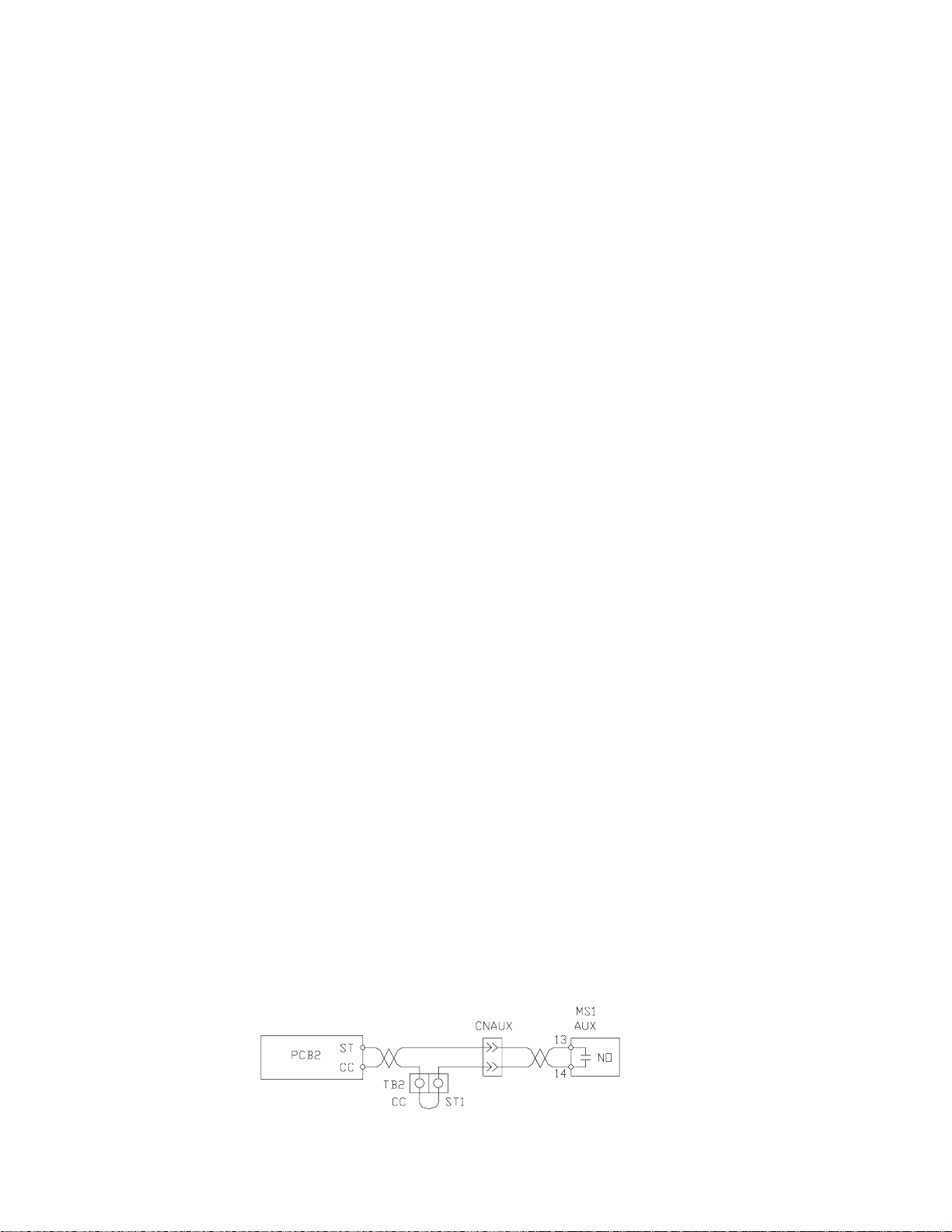

Figure 2. ST activation using the MS1 AUX circuit configuration.

G7 ASD Operation Manual 17

Page 24

The ASD input voltage should remain within 10% of the specified input voltage ra nge. Input voltages

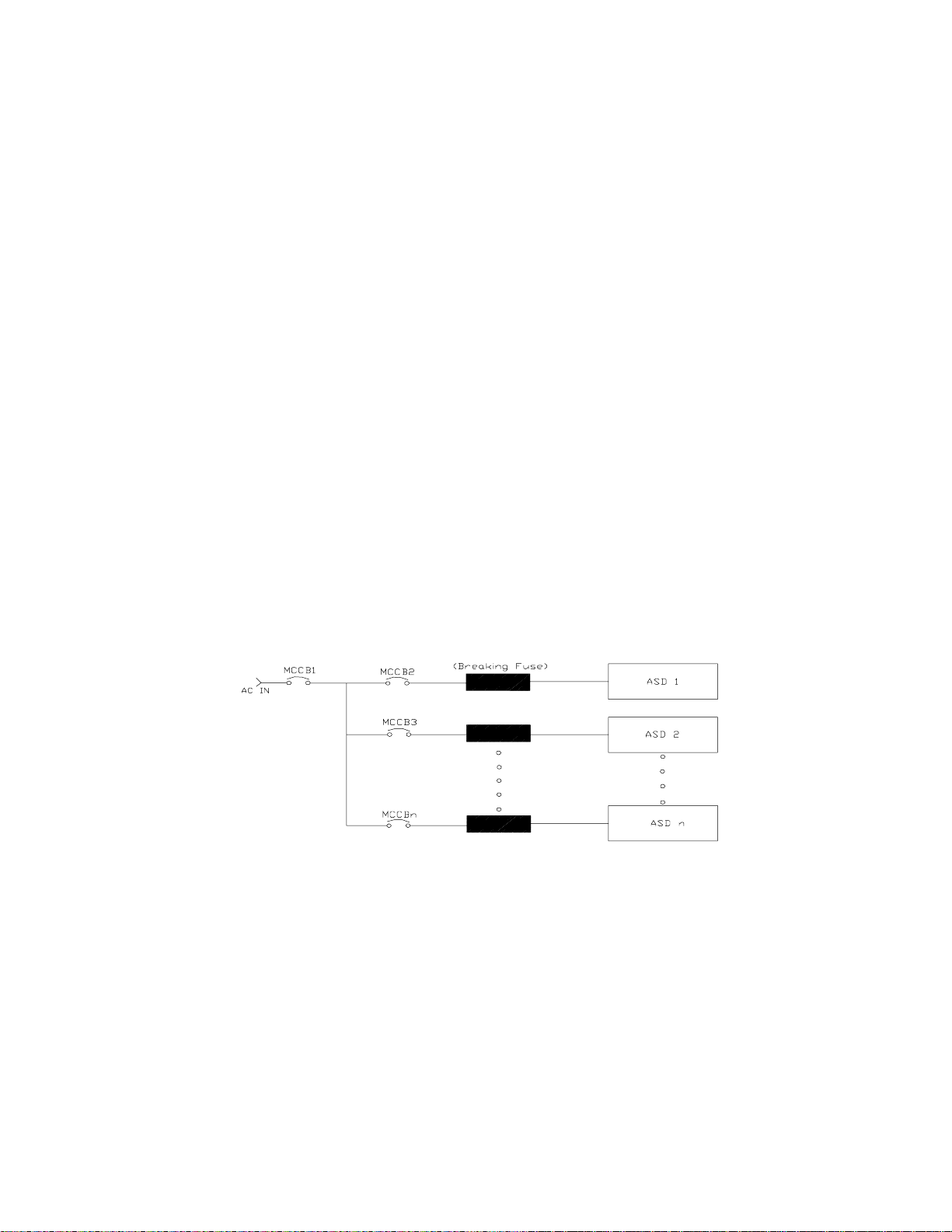

Figure 3. Circuit breaker configuration.

approaching the upper or lower limit setti ngs may require that the overvoltage and undervoltage stall

protection level parameters,

should be avoided.

The frequency of the inp ut power should be ±2 Hz of the specifi ed input frequency.

Do not use an ASD with a motor t hat has a power rating that is higher than the rated output of the ASD.

The ASD is designed to operate NEMA B motors. Consult with your sales repr esentative before using

the ASD for special applica tions such as with an explosion-proof motor or applications with a piston

load.

Do Not apply commercial power to the output terminals T1/U, T2/V, or T3/W.

Disconnect the ASD from the motor before megging or applying a bypas s vol tage to the motor.

Interface problems may occur when an ASD is used in conjunction with some types of process

controllers. Signal isolation may be req uired to prevent controller and/or ASD malfunction (contact

your Toshiba sales repres entative or the process control ler manufacturer for additiona l information

about compatibility and signal isolation).

Use caution when setting the output frequency. Over speeding a motor decrea se s its ability to deliver

torque and may result in da ma ge to the motor and/or the driven equipment.

All G7 AS Ds are equipped with internal DC bus fuses. However, not all G7 ASDs are equipped with

internal primary power input fuses (HP dependent). When connecting two or more drives that have no

internal fuse to the same power line as shown in

breaking configuration that will ensure that if a short circuit occurs in ASD 1, only MCCB2 trips, not

MCCB1. If it is not feasible to use this configuration, insert a fuse between MCCB2 and ASD 1.

F626 and F629, be adjusted. Voltages outside of the permissible tolerance

Figure 3, it will be necessary to select a ci rcuit-

Mounting the ASD

Install the unit securely in a well venti lated area that is out of direct sunlight using the mounting holes

18 G7 ASD Operation Manual

on the rear of the ASD.

The ambient temperature rating for the G7 ASD is from 14 to 104° F (-10 to 40° C). The process of

converting AC to DC, and then back to AC produces heat. During normal ASD operation, up to 5% of

the inp u t energy to the ASD may be dissipated as heat. If in stalling the ASD in a cabinet, ensure that

there is adequate ventilation.

Do Not operate the ASD with the enclosure door open.

CAUTION

Page 25

When ins t alling mu ltiple ASDs, ensure th at there is a clearance space of at l east 8 inches (20 cm) from

the top and the bottom of adjacent units. There should be at least 2 inches (5 cm) on either side of

adjacent un its. For the models below 50 HP the top and bot tom clea rance spe cific ations may be reduc ed

to 4 inch es (10 cm ) . Thi s sp ace ensur es th a t ad eq u ate ventilati on is p rov i ded (see th e sectio n ti tl ed

Enclosure Dimensions and Conduit Plate Informati on on pg. 182 for additional information on

mounting space requirements).

Note: Ensure that the ventilation openings are not obstructed.

ASDs produce high-frequency noise — steps must be taken during installation to avoid the negative

effects of noise. Listed below are some examples of measures that will help to combat noise problems.

• Separate the input and output power conduc tors of the main circuit . Do not ins tall the input and

output wires in th e sam e duct or in parallel with each other, and do not bind them together.

• Do not insta ll the input or output power conduc tors of the main circuit and the wires of the control

circuit in the sa me duct or in parallel with each other, and do not bind them together.

• Use shielded wires or twis te d wires for the control circuits.

• Ensure that the grounding terminals (G/E) of the ASD are securely connected to ground.

• Connect a surge suppressor to every e lec tromagnetic contactor and every relay installed near the

ASD.

• Install noise filters as req u ir ed.

Connecting the ASD

DANGER

Refer to the section titled Installation Precautions on pg. 4 and the section tit led Lead Length

Specifications on pg. 21 before attempting to connect the ASD and the motor to electrical power.

System Grounding

Proper grounding helps to prevent electrical shock and to reduce electrical noise. The ASD is designed

to be grounded in accordance with Article 250 of the 2002 NEC or Section 10/Part One of the

Canadian Electrical Code (CEC).

The grounding condu ctor shall be sized in accordance with Article 250-122 of the NEC or Part One-

Table

6 of the CEC.

Note: The metal of conduit is not an acceptable ground.

The input, output, and control lines of the system shall be run in separate me tal conduits and each shall

have its own ground conductor.

Power Connections

DANGER

L1/R, L2/S, and L3/T are the 3-phase input supply terminals for the ASD. The ASD may be operated

from a single-phase supply. When operating using a single-phase supply, use the L1 and L3 term in als.

T1/U, T2/V, and T3/W are the output terminals of the ASD that connect to the motor.

G7 ASD Operation Manual 19

Page 26

An inductor may be connecte d ac ross terminals PA and PO to provide additional filtering. When not

used, a jumper is connected across these terminals (see

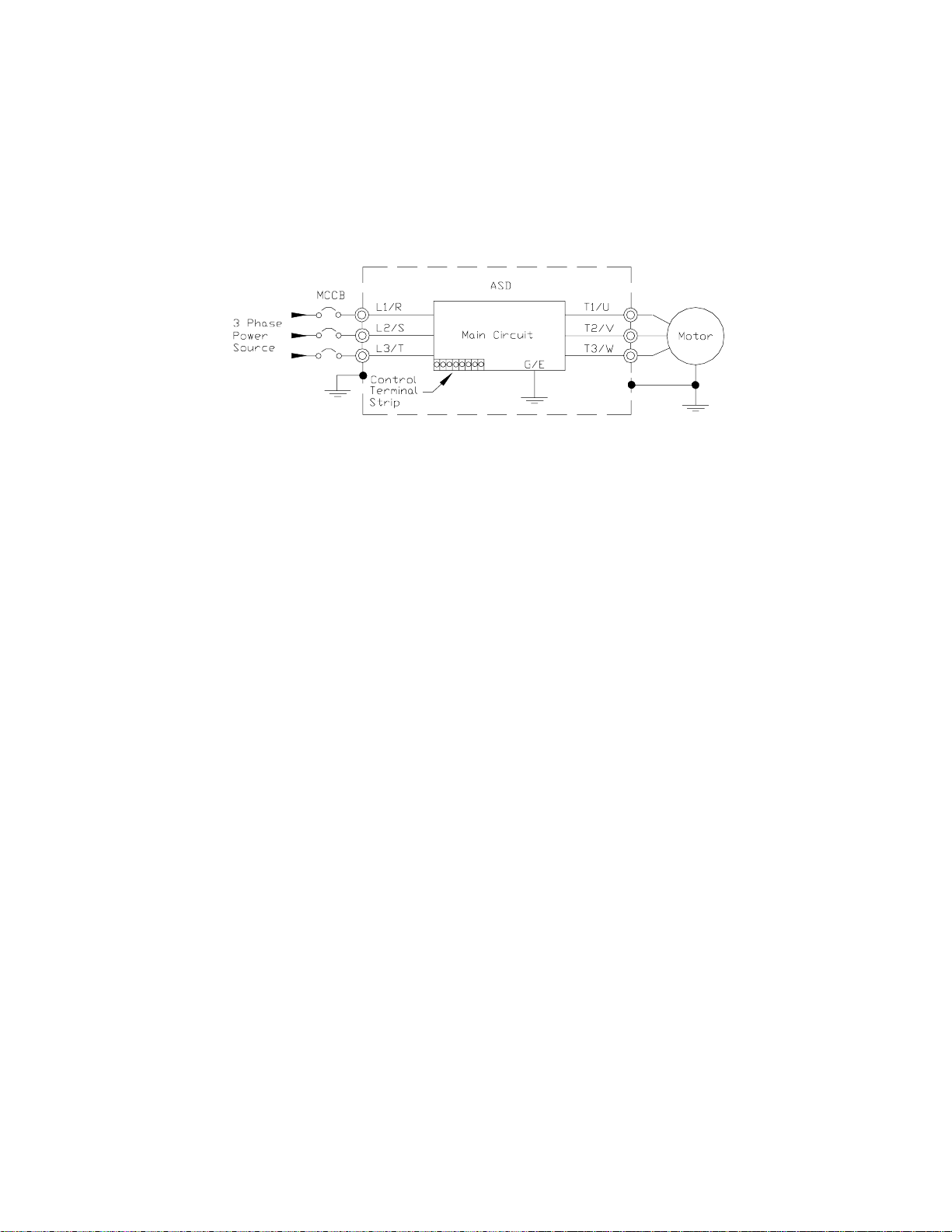

Connect the inpu t and output power lines of the ASD as shown in Figure 4.

Note: In the event that the motor rotates in the wrong direction when powered up, reverse

any two of the three A SD output power leads connec ted to the motor.

Figure 4. ASD/Motor connection diagram.

Connect the 3-phase input power to the input terminals of the ASD at L1/R, L2/S, and L3/T. Connect

the output of the ASD to the motor from terminals T1/U, T2/V, and T3/W. The input and output

conductors and terminal lugs used shall be in accordance with the requirements listed in the section

titled

Cable/Terminal Specificat ions on pg. 195.

If multiple conductors are used in parallel for the input or output power and it is necessary to use

separate conduits, each parallel set shall have its own conduit and not share its conduit with other

parallel set s (i.e., place U1, V1, and W1 in one conduit and U2, V2, and W2 in another) (refer to NEC

Article 300.20 and Article 310.4). National and local electrical codes should be referenced if three or

more power conducto rs are run in the same conduit (refer to 2002 NEC Article 310 adjus tm ent factors).

Figure 18 on pg. 30).

Note: National and local codes should be referenced when running more than three

conductors in the same conduit.

Install a molded c ase ci rcuit bre aker (MCC B) or fuse bet ween the 3-ph ase power sourc e and th e ASD in

accordance with the fault current setting of the ASD and 2002 NEC Article 430.

CAUTION

For 600 volt ASDs, the 15 HP or less ASDs (P/N VT130G7U6015B – 6160B) require a class-J fuse

rated at 600 Volts/30 A.

A phase-shifting transformer (or other means) must be supplied by the user when configured for 12pulse operation.

External fuses are r equired on the ASDs listed below when configured for 12-pulse operation .

VT130G7U2600B(DR)

VT130G7U2750B(DR)

VT130G7U412KB(DR)

VT130G7U415KB(DR)

VT130G7U610KB(DR)

VT130G7U612KB(DR)

VT130G7U615KB(DR)

Use either the Ferraz Shawmut Semic onductor fuse (P/N A70QS200) and fuse bloc k P234C, or the

Toshiba ASD-FUSEKIT-12P. The Toshiba kit includes the required fuses and the mounting hardware

for the fuses.

20 G7 ASD Operation Manual

Page 27

Lead Length Specifications

Adhere to the NEC and any local codes during the installat ion of ASD/Motor systems. Exces si ve lead

lengths may adversely effect the performance of the motor. Special cables are not required. Lead lengths

from the ASD to the motor in excess of those listed in

of the ASD. Table 2 lists the suggested maximum lead lengths for the listed motor voltages.

Table 2.

Table 2 may require filters to be added to the output

Model

230 Volt All 1000 feet

460 Volt

600 Volt

Note: Contact Toshiba for application as si stance when using lead le ngths in excess of those

listed.

PWM Carrier

Frequency

< 5 kHz 600 feet

≥ 5 kHz 300 feet

< 5 kHz 200 feet

≥ 5 kHz 100 feet

NEMA MG-1-1998 Section IV Part 31

Compliant Motors

2

Exceeding the peak voltage rating or the allowable thermal rise time of the motor

insulation will reduce the life expectancy of the motor.

For proper operation, the carrier frequency must be 2.2 kHz or above except when

operating in the Constant Torque, Variable Torque , or the 5-Point Setting modes.

Startup and Test

Perform the following checks before turning on the unit:

• L1/R, L2/S, and L3/T are connected to the 3-phase input power.

• T1/U, T2/V, and T3/W are connected to the motor.

• The 3-phase input voltage is within th e s pecified tolerance.

• There are no shorts and all grounds are secured.

G7 ASD Operation Manual 21

Page 28

I/O and Control

The ASD can be controlled by s everal input type s and combinations thereof, as well as operate within a

wide range of output frequency and voltage levels. This section disc usses the ASD c ontrol methods and

supported I/O func tions.

The Control Terminal Str ip PCB (P/N 4857 0) support s discrete and ana log I/O func tio ns and is shown

in

Figure 6 on pg. 25. Table 3 lists the names, the default settings, and the descriptions of the input and

output termin als of the Control Terminal Strip PCB.

Note: To use the input control lines of the Control Te rmi nal Strip the Comman d M ode

setting must be set to Use Control Terminal Strip (Program ⇒ Fundamental

Parameters ⇒ Standard Mode Selection ⇒ Command Mode ⇒ Use Control

Terminal Strip).

Figure 18 on pg. 30 shows the basi c connection diagram for the G7 system.

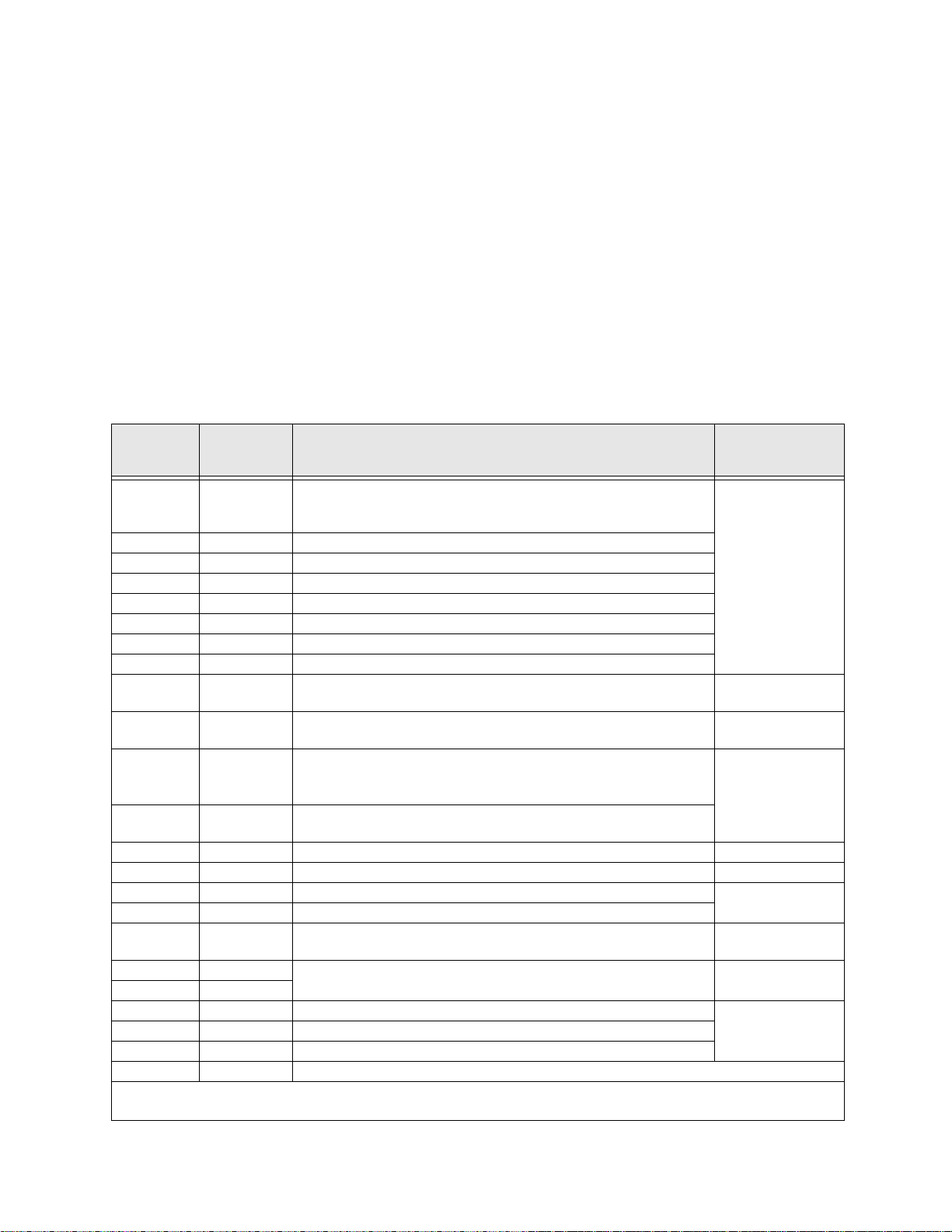

Table 3. Control Terminal Strip default assignment terminal names and functions.

Default

Term.

Setting

ST Discret e Input

RES Discret e Input Reset — Multifunct ional program m able discre te input.

F Discret e Input Forward — Multifunctional programmable discrete input.

R Discret e Input Reverse — Multifunctional programmable discrete input.

S1 Discret e Input Preset Speed 1 — Multifunctional programmabl e discrete input.

S2 Discret e Input Preset Speed 2 — Multifunctional programmabl e discrete input.

S3 Discret e Input Preset Speed 3 — Multifunctional programmabl e discrete input.

S4 Discret e Input Emergency Off — Multifunctional programmable discrete input.

RR Analog Input

RX Analog Input

II Analog Input

VI Analog Input

P24 DC Output 24 VDC @ 50 mA output. Figure 12 on pg. 29.

PP DC Output PP — 10.0 VDC volta ge source for the external potentiomet er. Figure 13 on pg. 29.

OUT1 Discrete Output Low Frequency — Multifunctional programmable discrete output.

OUT2 Discrete Output Reach Frequency — Multifunctional programmable discrete output.

FP Output

AM Output

FM Output

FLC Output F a ul t re la y (co m m o n) .

FLA Output F a ul t re la y (N. O .) .

CC — Control common (Do Not connect to Earth Gnd).

Discrete Input Terminals ⇒ Connect to CC to activate.

Analog Input Terminals reference CC.

Input/Output

(also see

Standby (jumper to CC to operate the unit) — Multifunctional

programmable discrete input (see

inform ation on this terminal).

RR — Multifunction programmable analog input

(0.0 to 10 volt input — 0 to 80 Hz output ). Reference CC.

RX — Multifunctional programmable analog input

(-10 to +10 VDC input — -80 to +80 Hz output). Refere n ce CC.

II — Multifuncti onal programmable analog input (4 [0] to 20 mADC

input — 0 to 80 Hz output) (see

the II terminal). Reference CC.

VI — Multifunctional programmable analog input

(0 to 10 VDC input — 0 to 80 Hz output). Refere nce CC.

Frequency Pulse — an output pulse train th at has a frequency which is

based on the output frequency of the ASD.

Produces an output current that is proportional to the magnitude o f the

function assigned to this terminal (see

Default Function

Terminal Descriptions on pg. 23)

Installation Notes on pg. 17 for further

Figure 6 on pg. 25 for the location of

Table 7 on pa ge 61).

Circuit Config.

Figure 8 on pg. 29.

Figure 9 on pg. 29.

Figure 10 on pg. 29.

Figure 11 on pg. 29.

Figure 14 on pg. 29.

Figure 15 on pg. 29.

Figure 16 on pg. 29

Figure 17 on pg. 29.FLB Output Faul t re la y (N. C .) .

22 G7 ASD Operation Manual

Page 29

Terminal Descriptions

Note: The programmable term inal assignments may be accessed and changed from their

default settings as mapped on

Direct Acce ss ⇒ applicable parameter number. See th e s ectio n tit le d Pr ogram Mode

on pg. 47 for the applicable Direct Access parameter numb e rs.

For further information on terminal assignments and default setting changes, see the

section tit led

on pg. 47.

ST — The default setting for this terminal is ST. The function of this input as ST is a Standby mode

controller (system is in Sta ndby when on). As the default setting, this terminal must be connected to

CC for normal operation. If not connected to CC, Off is displayed on the LCD screen. This input

terminal may be programm ed to any 1 of the 68 possible functions that are listed in

(see F113).

RES — The default setting for this terminal is RE S. The function of this input as RES is a system

Reset. A momentary connection to CC resets the ASD and any fault indications from the display. This

input terminal may be programmed to any 1 of the 68 possible functions that are listed in

page 76 (see F114). Reset is effective when faulted only.

F — The default setting for this termina l is F. The func tion of this input as F is Forward Run. A

connection to CC runs the motor in the Forward direction when it is on. This input terminal may be

programmed to any 1 of the 68 poss ible functions that are listed in

Output Terminal Functi ons on pg. 49 and CHANGED FROM DEFAULT

pg. 47 or via the Direct Access method: Program ⇒

Table 8 on page 76

Table 8 on

Table 8 on page 76 (see F111).

R — The default setting for this terminal is R. The functi on of this input as R is Reverse Run. A

connection to CC runs the motor in the Reverse direction when it is on. This input term inal may be

programmed to any 1 of the 68 poss ible functions that are listed in

S1 — The default setting for this terminal is S1. The function of this input as S1 is to run the motor at

Preset Speed #1 (see

to any 1 of the 68 possible functions that are list ed in Table 8 on page 76 (see F115).

S2 — The default setting for this terminal is S2. The function of this input as S2 is to run the motor at

Preset Speed #2 (see

to any 1 of the 68 possible functions that are list ed in Table 8 on page 76 (see F116).

S3 — The default setting for this terminal is S3. The function of this input as S3 is to run the motor at

Preset Speed #3 (see

to any 1 of the 68 possible functions that are list ed in Table 8 on page 76 (see F117).

S4 — The default setting for this terminal is Emergency Off (normally closed). The function of this

input as Emergency O ff is to remove power from the output of the ASD and may apply a supplemental

braking sys tem using the method se lected at

the 68 possible func tions that are listed in Table 8 on page 76 (see F118).

RR — The default function assigned to this terminal is to ca rry out the Frequency Mode #1 setting.

The RR terminal accepts a 0 – 10 VDC input signal that controls the function assigned to this ter mi nal.

This inpu t terminal may be programmed to control the speed or torque of the motor. It may also be used

to regulate (li mi t) the speed or torque of the motor. The gain and bias of this terminal may be adjust ed

for appli cation - sp ecific s u it ab i li ty ( see

Preset Spee d #1 on pg. 66) wh en it is on. This inp ut termi nal may be progra mmed

Preset Spee d #2 on pg. 66) wh en it is on. This inp ut termi nal may be progra mmed

Preset Spee d #3 on pg. 67) wh en it is on. This inp ut termi nal may be progra mmed

F603. This input terminal may be programmed to any 1 of

F210 – F213).

Table 8 on page 76 (see F112).

RX — The RX termina l accepts a ±10 VDC input signal tha t controls the function assigned to this

terminal. This inp ut term inal m ay b e progr ammed t o con trol the sp ee d, tor que, or dire ct ion of the mo tor.

It may also be used to regulat e (limit) the speed or torque of the moto r. The gain and bias of this

terminal m ay be adjusted for ap plication-sp ecific suitability (se e

G7 ASD Operation Manual 23

F216 – F219).

Page 30

II — The function of the II input is to receive a 4 – 20 mA input signal that controls a 0 – 80 Hz output.

This input termi nal may be programmed to control the speed or torque of the motor and may not be used

when us in g th e VI inp u t. Also, the gai n and bias of this ter minal may be adjus ted (see

F201 – F204).

VI — The function of the VI input terminal is to receive a 0 – 10 VDC input signal that controls a

0 – 80 Hz output. This input te rminal may be programmed to control the speed or torque of the motor and

may not be used when using the II input. Also, the gain and bias of this terminal may be adjusted (see

F201 – F204).

P24 — +24 VDC @ 50 mA power supply for customer use.

PP — The function of output PP is to pro vide a 10 VDC outp ut that m ay be divi ded usi ng a potent iome ter.

The tapped voltage is applied to the RR input to provide manual control of the RR programmed function.

OUT1 — The default setting for this output terminal is the Output Low Speed indicator. This output

terminal may be programm ed to provide an indication that 1 of 60 possible events has taken place. This

function may be used to signal external equipment or to activate the brake (see

F130). The OUT1 contact

is rated at 2A/250 VAC.

OUT2 — The default setting for this output terminal is the ACC/DEC Complete indicator. This output