Page 1

BSINo. G00G081 Page 1

BSI No.: G00G081

Publish

2000/08/09

Date:

Subject: Correction of FC15 Service Manual

Model: FC15

Category Field Application UNIT

Correction of Service Manual Others Documents

FactoryApplication: -

CONTENT

With the life specification change of parts connected with the transfer in FC15, the contents of the

Service Manual have been changed.

Contents:

The life of the transfer belt unit and transfer belt related consumable has been changed from

80K to 120K.

(The corrected points are shown type enclosed by "yellow" lines in the following file form

attached.) Parts enclosed by bold lines

The life of the transfer belt unit and transfer belt related consumable is listed below.

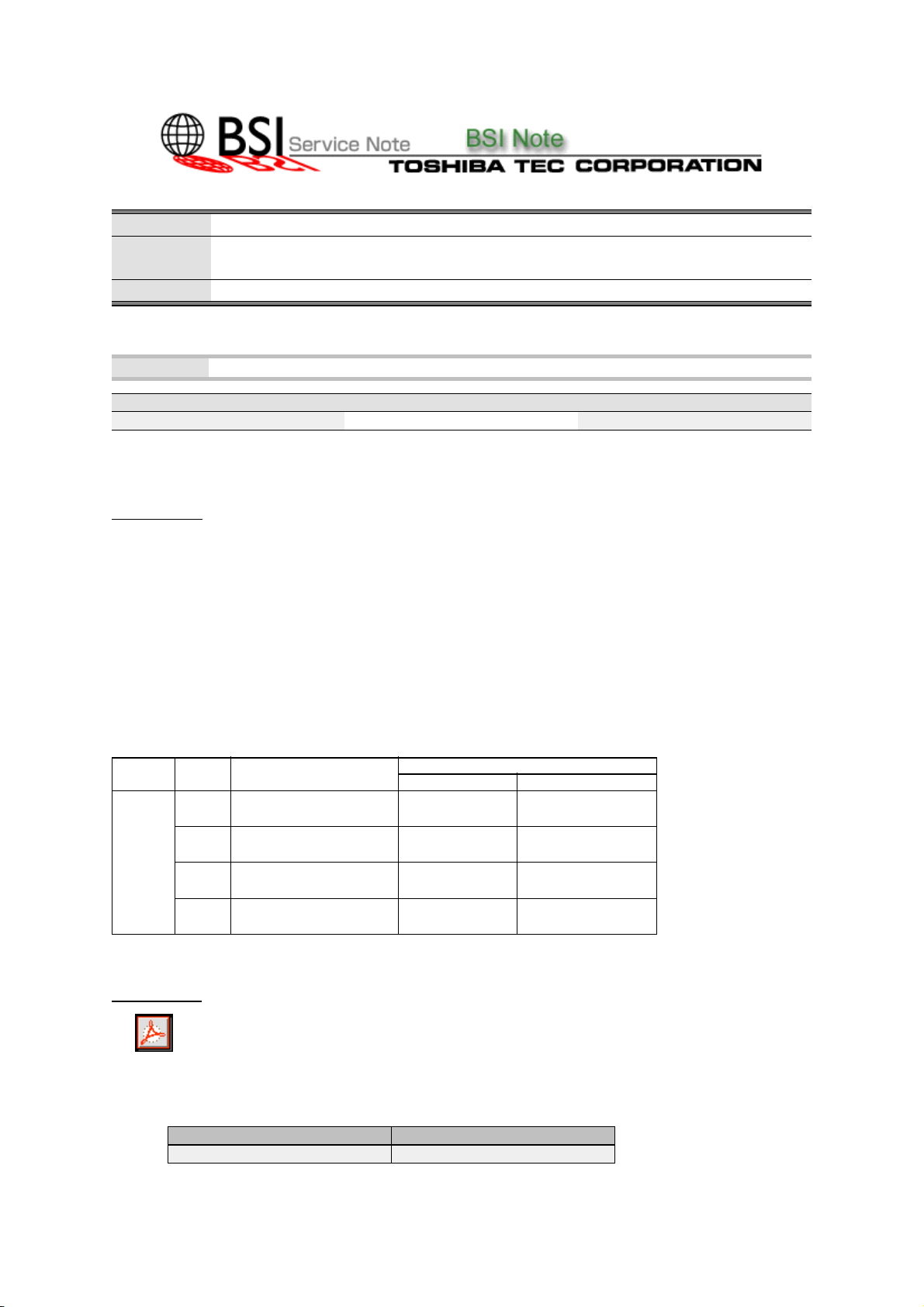

[Changed/Added Part No.]

MODEL P-I Note

FC-22 FC-15

FC-15 100-11

4406554000

30K KIT 20K KIT

DEV-KIT-FC22

100-12

4406554020

60K KIT 40K KIT

EPU-KIT-FC22

100-13

4406554040

90K KIT 60K KIT

FU-KIT-FC22

100-14

4406554060

TBU-KIT-FC22

P-I: Page-Item P: Contents of Change I: Interchangeability R: Reasons for Change

120K KIT

Change:

80K KIT -> 120K KIT

Attached File

G00G081.pdf

Related Documents:

LinkTo: Link From:

Page 2

2. 2 Maintenance to be Performed

FC-22: Every 30,000, 60,000, 90,000 and 120,000 Copies

FC-15: Every 20,000, 40,000, 60,000 and 120,000 Copies

(1) Preparation

1 Discuss current machine conditions with the key operator and note them down.

2 Before starting maintenance, make a few sample copies by TCC-1 chart and save them for

later reference purposes.

3 Turn OFF the power switch, and be sure to unplug the copier.

(2) Perf orm pre v entiv e maintenance following the checklist shown below. During maintenance, refer to

the illustrations attached and the Service Manual as required.

(3) After having finished the maintenance, plug in the copier , turn ON the power switch, and mak e a few

copies to confirm that the copier is working normally.

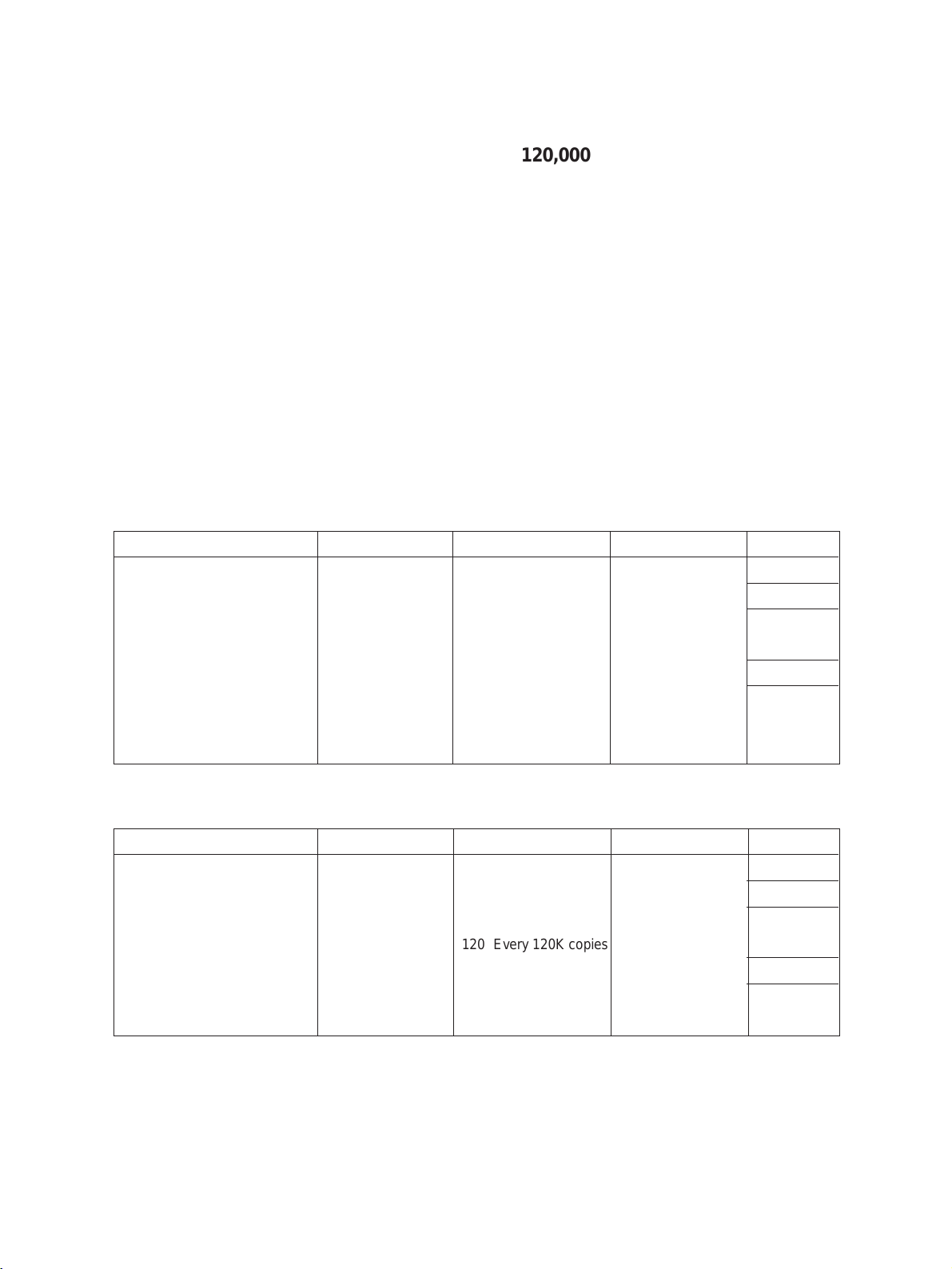

2. 3 Preventive Maintenance Checklist

Symbols used in the checklist (For FC-22)

Cleaning Coating Replacing Operation check Date

A Cleaning with alcohol

Z Cleaning with soft pad,

cloth or vacuum cleaner

W White grease

(Molycoat)

AV Alvania No.2

30 Every 30K copies

60 Every 60K copies

90 Every 90K copies

120 Every 120K

copies

> Replace if

deformed or

damaged

Z After cleaning

or replacing,

check for no

abnormality.

User’s name

Serial No.

Inspector’s

name

Remarks

Symbols used in the checklist (For FC-15)

Cleaning Coating Replacing Operation check Date

A Cleaning with alcohol

Z Cleaning with soft pad,

cloth or vacuum cleaner

FC-22 PREVENTIVE MAINTENANCE 2 - 2 January 2000 © TOSHIBA TEC

W White grease

(Molycoat)

AV Alvania No.2

20 Every 20K copies

40 Every 40K copies

60 Every 60K copies

120 Every 120K copies

> Replace if

deformed or

damaged

Z After cleaning

or replacing,

check for no

abnormality.

User’s name

Serial No.

Inspector’s

name

Remarks

Page 3

FC-15

W

Replace every

1K copies

Section Item to inspect

Image quality 35. Image quality sensor’s area Z(40)

control

Color 36. Color registration sensor Z(40)

registration

Laser unit 37. Slit glass Z(40)

38. Pick-up roller 90

39. Feed roller >

40. Separation roller >

41. Bypass pick-up roller 90

Paper feeding

system 43. Bypass separation pad A 90>

Scanner 54. Reflector Z(40)

Transfer/ 63. Drive roller cleaning felt 120

transport unit 64. Transfer belt cleaning blade 120

(TBU) 65. Transfer belt recovery blade Z(120) >

42. Bypass feed roller

44. Registration roller A >

45. Paper guide Z(40) >

46. Paper dust brush Z(20) >

47.

Paper feeding system drive gears (tooth face)

48. Registration unit support bushings W

49. Original glass

50. Platen cover

51. Mirror 1 Z(40)

52. Mirror 2 Z(40)

53. Mirror 3 Z(40)

55. Lens Z(40)

56. Exposure lamp > Z

57. Original-width indicator Z

58. Automatic original detection unit Z

59. Slide sheet >

60. Air filter Z(40) >

61. Transfer belt 120

62. Transfer roller (Y, M, C, K) 120

66. Transfer belt drive roller Z(60) >

67. Transfer belt driven roller Z(60) >

Cleaning

Z(40)or A

Z(40)or A

Coating

Operation

check <P-1>

Remarks

<P14-I13>

<P17-I32>

<P17-I10>

<P30-I2>

<P30-I22>

<P30-I27>

<P30-I46>

Notes: 1.<P-I> in the “Remarks” column indicates a page item in the Parts List.

2. The replacement cycle of each supply item of a particular paper feeding system corresponds with the

maximum number of sheets specified for the paper feed source.

January 2000 © TOSHIBA TEC 2 - 5 - 2 FC-22 PREVENTIVE MAINTENANCE

Page 4

PM Kit

Kit name Classification of kits Part name Q'ty

1. Developer material (Y) PS-ZDFC22Y 1

1. Developer material (M) PS-ZDFC22M 1

DEV-KIT-FC22

(20K kit)

EPU-KIT-FC22

(40K kit)

FU-KIT-FC22 25. Separation finger SCRAPER-PR 9

(60K kit) 28. Lower oil roller SR-FC22L 1

TBU-KIT-FC22 62. Transfer roller CR-FC22TR 4

(120K kit) 63. Drive roller cleaning felt FP-FC22TR 1

1. Developer material (C) PS-ZDFC22C 1

1. Developer material (K) PS-ZDFC22K 1 20K

26. Upper oil roller (fuser unit) SR-FC22H 1

27. Upper cleaning roller (fuser unit) B-FC22H 1

– Doctor blade cleaning jig

6. Cleaning blade BL-FC22D 4

12. Charger wire cleaning pad WIRE-CH-310 4

13. Main charger wire K-PAD-WIRE 4 40K

14. Main charger grid GRID-CH-310 4

21. Ozone filter K-FILTER-OZN 1

23. Upper fuser roller HR-FC22-U 1

24. Lower fuser roller HR-FC22-L 1

29. Lower cleaning roller B-FC22L 1

39. Pick-up roller (cassette feed section)

61. Transfer belt BT-FC22TR 1

64. Transfer belt cleaning blade BL-FC22TR 1

JIG-CLEAN-DOC

K-ROL-PICK-310

FC-15

No. of copies for

replacement cycle

1

60K

1

120K

* The numbers in the “Classification of kits” column above correspond with the numbers in the

Preventive Maintenance Checklist.

FC-22 PREVENTIVE MAINTENANCE 2 - 12 -1 January 2000 © TOSHIBA TEC

Loading...

Loading...