Page 1

BSI No.: G00F058

Publish

2000/06/21

Date:

Subject: New Model FC15 (Service Manual)

Model: FC15

Category Field Application UNIT

New Model Description Others General

FactoryApplication: -

CONTENT

BSINo. G00F058 Page 1

No Service Manual has been specially prepared for the FC15 and this BSI, in which the differences

from the FC22 are shown, is to serve as a substitute. Refer to the attaching file for the details.

Attached File

G00F058.pdf

Related Documents:

LinkTo: Link From:

Page 2

In this manual, colors are sometimes shown in abbreviations as below:

Yellow : Y ; Magenta : M ; Cyan : C ; Black : K

1. SPECIFICATIONS · ACCESSORIES · OPTIONS · SUPPLIES

1.1 Specifications

• Copy process Indirect electrophotographic process (dry)

• T ype Console type

• Original table Fixed table (the left rear corner used for Standard original placement)

• Acceptable originals T ype: Sheets , books and 3-dimensional objects. Ho wev er , the automatic document feeder only accepts sheets of paper (64~90 g/m2, or 17~24 lb.), excluding carbon paper, pasted sheets and stapled sheets.

Size : A3/LD max.

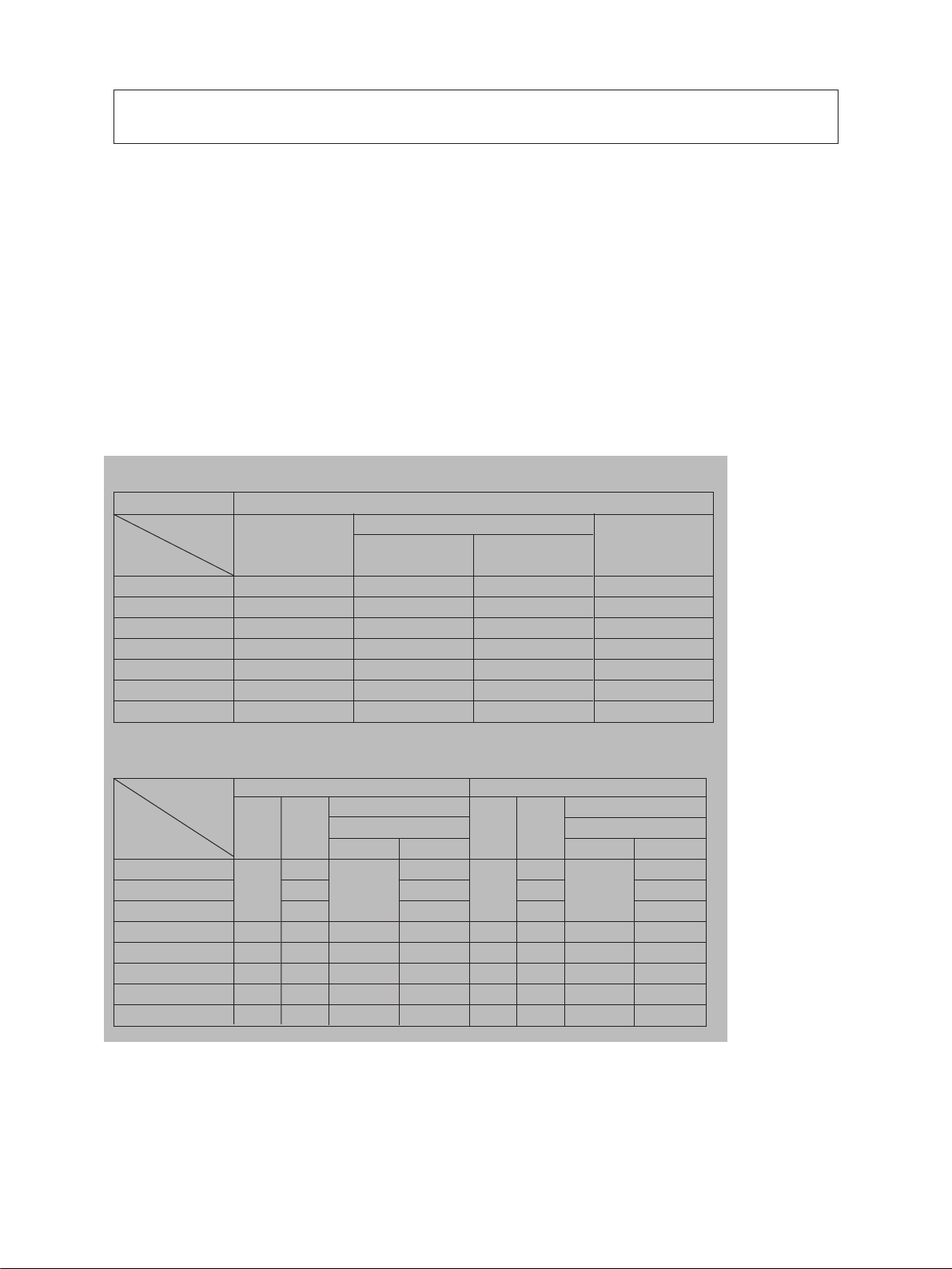

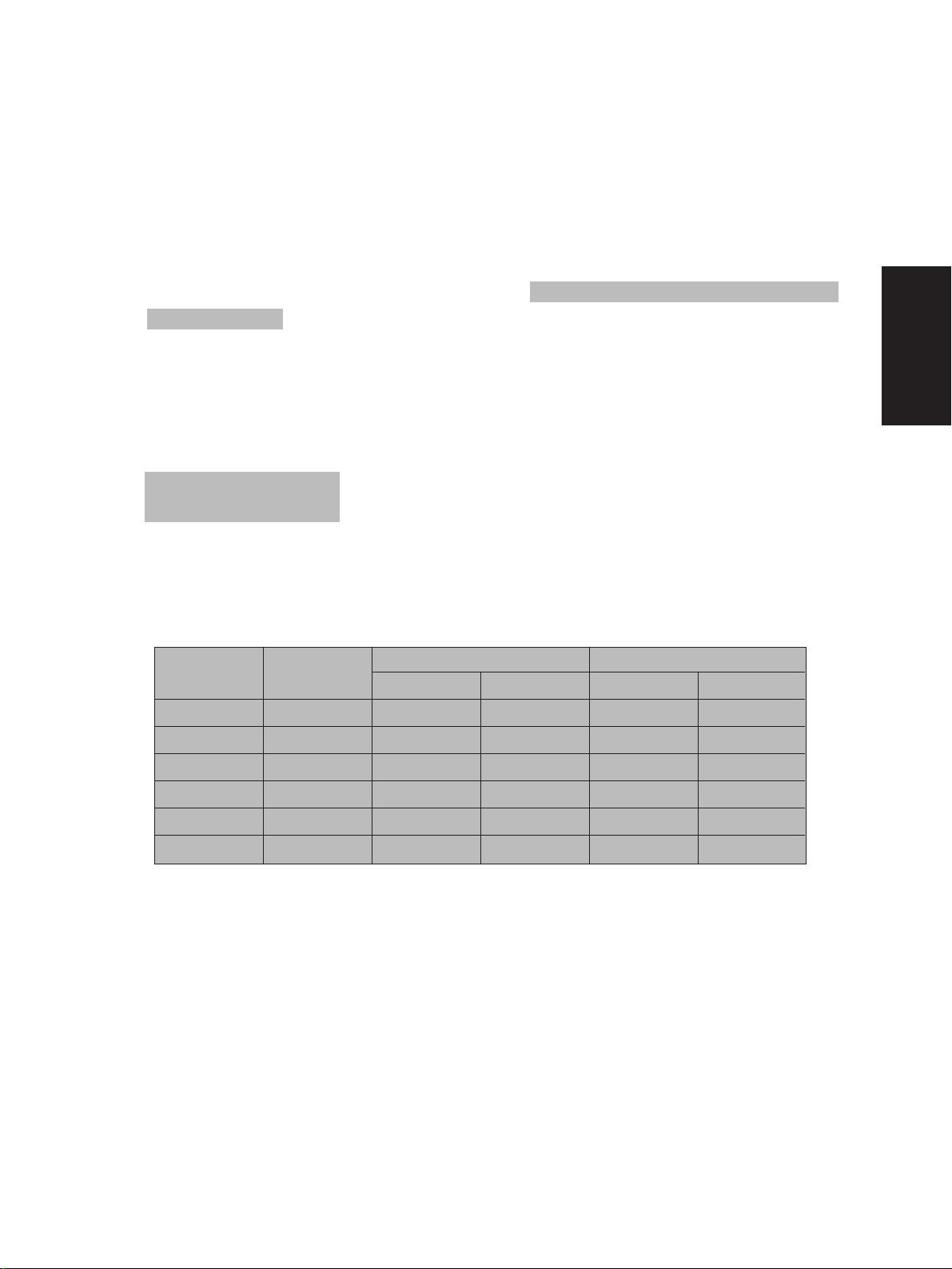

• Copy speed (For FC-22) (Copies/min.)

The same speed in both color and monochrome modes

Paper supply

Paper size

A4, LT

B5, A5-R, ST-R

A4-R, B5-R, LTR

B4, LG

A3, LD

OHP sheets (A4, LT)

Full bleed (12" x 18")

Cassette

22

22

17

14

12

4

–

Size specification

Bypass feeding

YES

18

18

15

14

12

4

12

Size specification

NO

12

12

12

12

12

–

12

LCF

22

–

–

–

–

–

–

• Copy speed (For FC-15) (Copies/min.)

Paper supply

Cassette

Paper size

A4

B5

A5-R

A4-R, B5-R

B4

A3

OHP sheets (A4)

A3 WIDE

January 2000 © TOSHIBA TEC 1 - 1 FC-22 SPECIFICATIONS

15

12

10

8

4

–

Color modes

LCF

15

–

–

–

–

–

–

–

SFB

Size specification

YES

15

12

10

8

4

8

NO

8

10

15

12

10

8

–

8

Cassette

Monochrome modes

LCF

22

22

17

14

12

–

–

–

–

–

4

–

–

–

SFB

Size specification

YES

18

15

14

12

4

12

NO

12

14

18

15

14

12

–

12

Page 3

The copy speed is the same in both color and black modes.

*

“–” shows “Not usable”.

*

The copy speeds listed are available when originals are manually placed for single-side, multiple

*

copying.

When the document feeder is used,

*

(1) FC-22

the copy speed of 22 sheets per minute is only avilable under the following conditions:

• Or iginal/Mode: Single-side originals of A4/LT size, not select auto color, APS,

automatic density and advance image enhancement mode

• Number of sheets set: 22 or over.

• Paper feeding: LCF

• Reproduction ratio: Actual ratio

(2) FC-15

the copy speed of 15 sheets per minute is only avilable under the following conditions:

• Or iginal/Mode: Single-side originals of A4/LT size, not select auto color, APS,

automatic density and advance image enhancement mode

• Number of sheets set: 15 or over.

• Paper feeding: LCF

• Reproduction ratio: Actual ratio

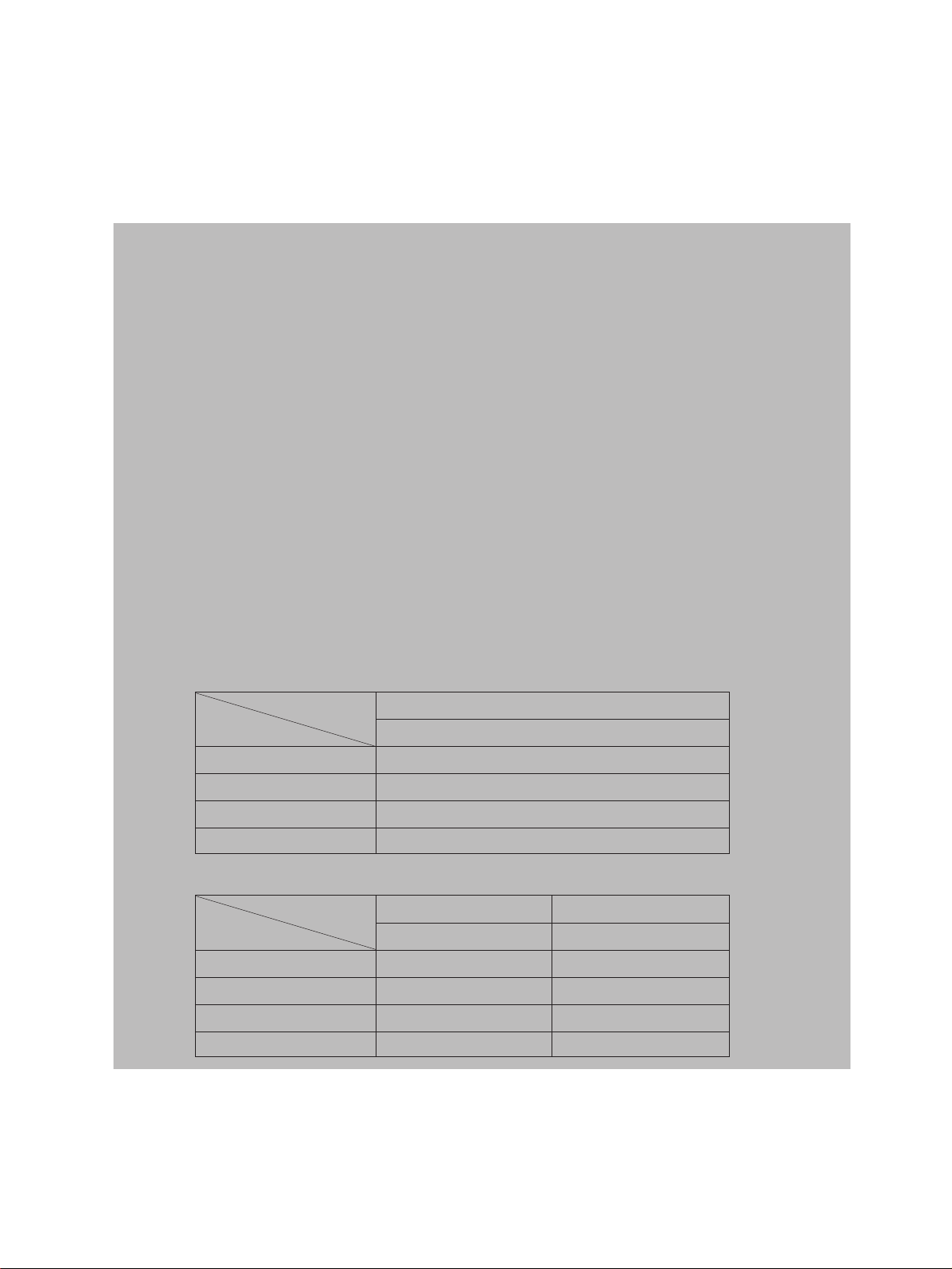

Reverse side copying speed of the automatic duplexing unit

*

(When specific paper size is selected)

For FC-22

Copy mode

Paper size

A4, B5, A5-R 22

A4-R, B5-R 17

B4 14

A3 12

For FC-15

Copy mode

Paper size

A4, B5, A5-R 15 22

A4-R, B5-R 12 17

B4 10 14

A3 8 12

The same speed in both color and monochrome modes

Color modes Monochrome modes

Copies/min. Copies/min.

Copies/min.

January 2000 © TOSHIBA TEC 1 - 1 - 1 FC-22 SPECIFICATIONS

Page 4

System copy speed

*

FC-15 FC-22

Copy mode

Number of

sheets set

Color modes

Monochrome

modes

The same speed in both color

and monochrome modes

Copies/min.Copies/min. Copies/min.

Single-sided originals 1 set 12 16 16

훹 3 sets 14 19 19

Single-sided copies 5 sets 14 20 20

Single-sided originals 1 set 4 4 4

훹 3 sets 8 9 9

Two-sided copies 5 sets 10 12 12

Two-sided originals 1 set 4 4 4

훹 3 sets 8 9 9

Two-sided copies 5 sets 10 12 12

Two-sided originals 1 set 11 12 12

훹 3 sets 13 17 17

Single-sided copies 5 sets 14 19 19

Any of the left copy speeds includes the first cop y time and is available when the corresponding copy

*

mode is used and 10 A4-sized originals are set in the automatic document feeder.

These values are attained in full color mode copying.

*

• Copy paper

Cassette Duplex copy LCF Bypass copy Remarks

Size A3~A5R A4, LT A3~A5-R Irregular or

LD~ST-R LD~ST-R arbitrary sizes can be set.

Weight 64~90g/m

Special paper – – – Recommended

2

, 17~24 lb. 64~209g/m

17~110 lb. index

OHP film

2

• First copy time .................. Approx. 10 seconds or under (A4/LT, the first cassette, 100%)

• Warming-up time...............Approx. 9 minutes

• Multiple copying ................ Up to 999 copies;entry by digital keys

• Reproduction ratio............. Actual ratio: 100±0.5%

Zooming: 25~400% in increments of 1%

• Resolution/Gradation Read: 600 dpi/256 gradation

Write: Corresponding to 9600 dpi x 600 dpi

(primary scanning only : 16 division smoothing)

• Excluded image width Leading edge: 5.0±2.0 mm, Trailing edge: 2.5±2.0 mm

Side edge: 2.0±2.0 mm

• Paper feeding .................... Automatic feeding: Copier’s cassettes–2 pieces standard (expandable up

to 4 pieces by installing optional cassettes)

LCF–Optional (Stack height 165 mm : Equivalent to 1500

sheets of 80 g/m2, 20 lb.)

Bypass feeding:

(Stack height 8 mm : Equivalent to 50 sheets of 80 g/m

• Capacity for originals .......................................A4, A4-R, B5, B5-R, A5-R, LT, LT-R, ST-R:

2

, 20 lb.)

50 sheets

(Optional automatic document feeder) B4, Folio, LG, Comp: 35 sheets

A3, LD: 25 sheets

FC-22 SPECIFICATIONS 1 - 2 January 2000 © TOSHIBA TEC

Page 5

2. PREVENTIVE MAINTENANCE (PM)

2. 1 Types of Preventive Maintenance

The following two types of preventive maintenance should be performed:

(1) General maintenance

General maintenance should be performed based on the value of the PM counter (08-857).

This maintenance, which covers the black developer unit as well as the entire machine, should be

conducted in conjunction with the replacement cycle (For FC-22: every 30K Copies, For FC-15:

every 20K Copies) of the black developer material.

(2) Color maintenance

Color maintenance should be performed based on the value of the color PM counter (08-897).

This maintenance, which is performed with a focus on the color developer units, should be conducted in conjunction with the replacement cycle of the color developer materials.

FC-22: every 30K copies

FC-15: every 20K copies

The replacement cycle (counter value) of color maintenance is determined by the ratio of color cop y

to black copy, as shown by the following table, "Variation in PM cycles due to color/black output

ratios".

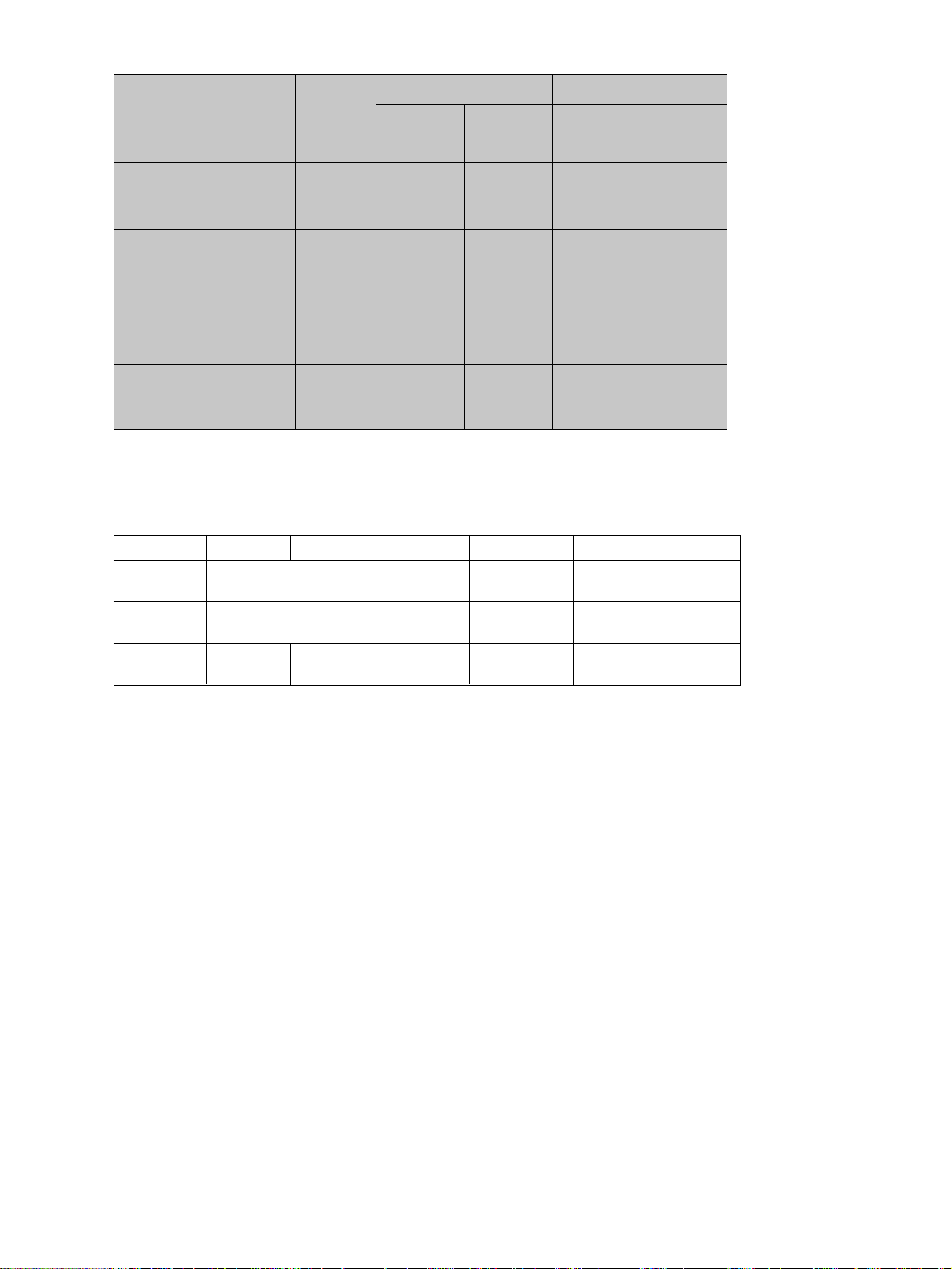

Variation in PM cycles due to color/black output ratios

Color modes

100% 0% 20.0K 20.0K 30.0K 30.0K

90% 10% 20.0K 22.2K 30.0K 33.3K

80% 20% 20.0K 25.0K 30.0K 37.5K

70% 30% 20.0K 28.5K 30.0K 42.9K

60% 40% 20.0K 33.3K 30.0K 50.0K

50% 50% 20.0K 40.0K 30.0K 60.0K

*Therefore, replacing parts, cleaning and coating oil for the paper feeding unit, scanner unit, trans-

fer/transport unit, fuser unit, all should be checked and maintained in conjunction with the replacement cycle of the black developer material.

e.g. )Replacing fuser rollers : At the 3rd cycle of replacing black developer material

Replacing the transfer belt : At the 4th cycle of replacing black developer material

Monochrome FC-15 FC-22

modes PM (copies)

(30K × 3 = 90K copies)

Color PM (copies)

PM (copies)

Color PM (copies)

(30K × 4 = 120K copies)

*For the details of maintenance items, refer to the checklist described later.

*Yields are based on factory defaults.

January 2000 © TOSHIBA TEC 2 - 1 FC-22 PREVENTIVE MAINTENANCE

Page 6

2. 2 Maintenance to be Performed

FC-22: Every 30,000, 60,000, 90,000 and 120,000 Copies

FC-15: Every 20,000, 40,000, 60,000 and 80,000 Copies

(1) Preparation

1 Discuss current machine conditions with the key operator and note them down.

2 Before star ting maintenance, make a few sample copies by TCC-1 chart and save them for

later reference purposes.

3 Turn OFF the power switch, and be sure to unplug the copier.

(2) Perf orm pre v entiv e maintenance following the checklist shown below. During maintenance, refer to

the illustrations attached and the Service Manual as required.

(3) After having finished the maintenance, plug in the copier , turn ON the power switch, and mak e a few

copies to confirm that the copier is working normally.

2. 3 Preventive Maintenance Checklist

Symbols used in the checklist (For FC-22)

Cleaning Coating Replacing Operation check Date

A Cleaning with alcohol

Z Cleaning with soft pad,

cloth or vacuum cleaner

W White grease

(Molycoat)

AV Alvania No.2

30 Every 30K copies

60 Every 60K copies

90 Every 90K copies

120 Every 120K

copies

> Replace if

deformed or

damaged

Z After cleaning

or replacing,

check for no

abnormality.

User’s name

Serial No.

Inspector’s

name

Remarks

Symbols used in the checklist (For FC-15)

Cleaning Coating Replacing Operation check Date

A Cleaning with alcohol

Z Cleaning with soft pad,

cloth or vacuum cleaner

FC-22 PREVENTIVE MAINTENANCE 2 - 2 January 2000 © TOSHIBA TEC

W White grease

(Molycoat)

AV Alvania No.2

20 Every 20K copies

40 Every 40K copies

60 Every 60K copies

80 Every 80K copies

> Replace if

deformed or

damaged

Z After cleaning

or replacing,

check for no

abnormality.

User’s name

Serial No.

Inspector’s

name

Remarks

Page 7

General Maintenance Checklist FC-22

Section Item to inspect

1. Developer material 30 ∗9

2. Doctor blade Z(30/60) > ∗1

3. Developer unit drum seal Z(60) > ∗10

4. Front/rear sides of developer unit Z(60) ∗2

5. Oil seal portion AV

6. Cleaning blade 60 ∗3

7. Recovery blade Z(60) > ∗4

8.

Felt seals on both ends of the cleaning blade

Processing

unit (EPU)

(Only Black

related parts)

Around-EPU

area 22. Toner bag 30

Fuser unit

9. Entire developer/cleaner unit Z(60) ∗8

10. Main charger case Z(60) ∗7

11. Dischiarge LED Z(60)

12. Wire cleaning pad 60 Z

13. Main charger wire 60 ∗7

14. Main charger grid 60

15. Main charger contact Z(60)

16. Drum 60 ∗5

17. Drum shaft Z(60)

18. Drum thermister Z(60)

19. Toner recovery auger drive Z(60) W

20. Toner cartridge drive gear W

21. Ozone filter 60 ∗6

23. Upper fuser roller 90 ∗11

24. Lower fuser roller 90 ∗12

25. Separation fingers 90 ∗14

26. Upper oil roller 30 ∗13

27. Upper cleaning roller 30 ∗13

28. Lower oil roller 90 ∗13

29. Lower cleaning roller 90 ∗13

30. Upper thermistors A(30) >

31. Lower thermistors A(30) >

32. Fuser roller inlet guide A(90)

33. Fuser roller exit guide A(90)

34. Paper exit roller A

Cleaning Coating

Z(60) >

Replace every

1K copies

Operation Remarks

check <P-1>

<P23-I13>

<P22-I21>

<P22-I15>

<P22-I24>

<P22-I38>

<P6-I37>

Key-operator’s

item

<P33-I33>

<P27-I17>

<P27-I4>

<P28-I31>

<P28-I56>

<P28-I57>

<P28-I11>

<P28-I12>

January 2000 © TOSHIBA TEC 2 - 3 FC-22 PREVENTIVE MAINTENANCE

Page 8

W

Replace every

1K copies

Section Item to inspect

Image quality 35. Image quality sensor’s area Z(60)

control

Color 36. Color registration sensor Z(60)

registration

Laser unit 37. Slit glass Z(60)

38. Pick-up roller 90

39. Feed roller >

40. Separation roller >

41. Bypass pick-up roller 90

Paper feeding

system 43. Bypass separation pad A 90>

Scanner 54. Reflector Z(60)

Transfer/ 63. Drive roller cleaning felt 120

transport unit 64. Transfer belt cleaning blade 120

(TBU) 65. Transfer belt recovery blade Z(120)

42. Bypass feed roller

44. Registration roller A >

45. Paper guide Z(60) >

46. Paper dust brush Z(60) >

47.

Paper feeding system drive gears (tooth face)

48. Registration unit support bushings W

49. Original glass

50. Platen cover

51. Mirror 1 Z(60)

52. Mirror 2 Z(60)

53. Mirror 3 Z(60)

55. Lens Z(60)

56. Exposure lamp > Z

57. Original-width indicator Z

58. Automatic original detection unit Z

59. Slide sheet >

60. Air filter Z(60) >

61. Transfer belt 120

62. Transfer roller (Y, M, C, K) 120

66. Transfer belt drive roller Z(60) >

67. Transfer belt driven roller Z(60) >

Cleaning

Z(60)or A

Z(60)or A

Coating

Operation

check <P-1>

Remarks

<P14-I13>

<P17-I32>

<P17-I10>

<P30-I2>

<P30-I22>

<P30-I27>

<P30-I46>

FC-22

Notes: 1.<P-I> in the “Remarks” column indicates a page item in the Parts List.

2. The replacement cycle of each supply item of a particular paper feeding system corresponds with the

maximum number of sheets specified for the paper feed source.

FC-22 PREVENTIVE MAINTENANCE 2 - 4 January 2000 © TOSHIBA TEC

Page 9

Color Maintenance Checklist FC-22

Section Item to inspect

1. Developer material (Y, M, C) 30 ∗9

2. Doctor blade Z(30/60) > ∗1

3. Developer unit drum seal Z(60) > ∗10

4. Front/rear sides of developer unit Z(60) ∗2

5. Oil seal portion AV

6. Cleaning blade 60 ∗3

7. Recovery blade Z(60) > ∗4

8.

Felt seals on both ends of the cleaning blade

Processing

unit (EPU)

(Color (Y, M,

C) related

parts)

Image quality 35. Image quality sensor’s area Z(60)

control

Color 36. Color registration sensor Z(60)

registration

Laser unit 37. Slit glass Z(60)

9. Entire developer/cleaner unit Z(60) ∗8

10. Main charger case Z(60) ∗7

11. Dischiarge LED Z(60)

12. Wire cleaning pad 60 Z

13. Main charger wire 60 ∗7

14. Main charger grid 60

15. Main charger contact Z(60)

16. Drum 60 ∗5

17. Drum shaft Z(60)

18. Drum thermister Z(60)

19. Toner recovery auger drive Z(60) W

Cleaning Coating

Z(60) >

Replace every

1K copies

Operation Remarks

check <P-1>

<P23-I13>

<P22-I21>

<P22-I15>

<P22-I24>

<P22-I38>

Note: 1.<P-I> in the “Remarks” column indicates a page item in the Parts List.

January 2000 © TOSHIBA TEC 2 - 5 FC-22 PREVENTIVE MAINTENANCE

Page 10

General Maintenance Checklist FC-15

Section Item to inspect

1. Developer material (Y, M, C) 20 ∗9

2. Doctor blade Z(20/40) > ∗1

3. Developer unit drum seal Z(40) > ∗10

4. Front/rear sides of developer unit Z(40) ∗2

5. Oil seal portion AV

6. Cleaning blade 40 ∗3

7. Recovery blade Z(40) > ∗4

8.

Felt seals on both ends of the cleaning blade

Processing

unit (EPU)

(Only Black)

related

parts)

Processing

unit Around

EPU area

Fuser unit

9. Entire developer/cleaner unit Z(40) ∗8

10. Main charger case Z(40) ∗7

11. Dischiarge LED Z(40)

12. Wire cleaning pad 40 Z

13. Main charger wire 40 ∗7

14. Main charger grid 40

15. Main charger contact Z(40)

16. Drum 40 ∗5

17. Drum shaft Z(40)

18. Drum thermister Z(40)

19. Toner recovery auger drive Z(40) W

20. Toner cartridge drive gear W

21. Ozone filter 40 ∗6

22.

Toner bag 30

23. Upper fuser roller 60 ∗11

24. Lower fuser roller 60 ∗12

25. Separation fingers 60 ∗14

26. Upper oil roller 20 ∗13

27. Upper cleaning roller 20 ∗13

28. Lower oil roller 60 ∗13

29. Lower cleaning roller 60 ∗13

30. Upper thermistors A(20) >

31. Lower thermistors A(20) >

32. Fuser roller inlet guide A(60)

33. Fuser roller exit guide A(60)

34. Paper exit roller A

Cleaning Coating

Z(40) >

Replace every

1K copies

Operation Remarks

check <P-1>

<P23-I13>

<P22-I21>

<P22-I15>

<P22-I24>

<P22-I38>

<P6-I37>

Key-operator’s

item

<P33-I33>

<P27-I17>

<P27-I4>

<P28-I31>

<P28-I56>

<P28-I57>

<P28-I11>

<P28-I12>

January 2000 © TOSHIBA TEC 2 - 5 - 1 FC-22 PREVENTIVE MAINTENANCE

Page 11

FC-15

W

Replace every

1K copies

Section Item to inspect

Image quality 35. Image quality sensor’s area Z(40)

control

Color 36. Color registration sensor Z(40)

registration

Laser unit 37. Slit glass Z(40)

38. Pick-up roller 90

39. Feed roller >

40. Separation roller >

41. Bypass pick-up roller 90

Paper feeding

system 43. Bypass separation pad A 90>

Scanner 54. Reflector Z(40)

Transfer/ 63. Drive roller cleaning felt 80

transport unit 64. Transfer belt cleaning blade 80

(TBU) 65. Transfer belt recovery blade Z(80) >

42. Bypass feed roller

44. Registration roller A >

45. Paper guide Z(40) >

46. Paper dust brush Z(20) >

47.

Paper feeding system drive gears (tooth face)

48. Registration unit support bushings W

49. Original glass

50. Platen cover

51. Mirror 1 Z(40)

52. Mirror 2 Z(40)

53. Mirror 3 Z(40)

55. Lens Z(40)

56. Exposure lamp > Z

57. Original-width indicator Z

58. Automatic original detection unit Z

59. Slide sheet >

60. Air filter Z(40) >

61. Transfer belt 80

62. Transfer roller (Y, M, C, K) 80

66. Transfer belt drive roller Z(40) >

67. Transfer belt driven roller Z(40) >

Cleaning

Z(40)or A

Z(40)or A

Coating

Operation

check <P-1>

Remarks

<P14-I13>

<P17-I32>

<P17-I10>

<P30-I2>

<P30-I22>

<P30-I27>

<P30-I46>

Notes: 1.<P-I> in the “Remarks” column indicates a page item in the Parts List.

2. The replacement cycle of each supply item of a particular paper feeding system corresponds with the

maximum number of sheets specified for the paper feed source.

January 2000 © TOSHIBA TEC 2 - 5 - 2 FC-22 PREVENTIVE MAINTENANCE

Page 12

Color Maintenance Checklist FC-15

Section Item to inspect

1. Developer material (Y, M, C) 20 ∗9

2. Doctor blade Z(20/40) > ∗1

3. Developer unit drum seal Z(40) > ∗10

4. Front/rear sides of developer unit Z(40) ∗2

5. Oil seal portion AV

6. Cleaning blade 40 ∗3

7. Recovery blade Z(40) > ∗4

8.

Felt seals on both ends of the cleaning blade

Processing

unit (EPU)

(Color (Y, M,

C) related

parts)

Image quality 35. Image quality sensor’s area Z(40)

control

Color 36. Color registration sensor Z(40)

registration

Laser unit 37. Slit glass Z(40)

9. Entire developer/cleaner unit Z(40) ∗8

10. Main charger case Z(40) ∗7

11. Dischiarge LED Z(40)

12. Wire cleaning pad 40 Z

13. Main charger wire 40 ∗7

14. Main charger grid 40

15. Main charger contact Z(40)

16. Drum 40 ∗5

17. Drum shaft Z(40)

18. Drum thermister Z(40)

19. Toner recovery auger drive Z(40) W

Cleaning Coating

Z(40) >

Replace every

1K copies

Operation Remarks

check <P-1>

<P23-I13>

<P22-I21>

<P22-I15>

<P22-I24>

<P22-I38>

Note: 1.<P-I> in the “Remarks” column indicates a page item in the Parts List.

January 2000 © TOSHIBA TEC 2 - 5 - 3 FC-22 PREVENTIVE MAINTENANCE

Page 13

2. 4 PM Kit

Kit name Classification of kits Part name Q'ty

DEV-KIT-FC22

(30K kit)

EPU-KIT-FC22

(60K kit)

FU-KIT-FC22 25. Separation finger SCRAPER-PR 9

(90K kit) 28. Lower oil roller SR-FC22L 1

TBU-KIT-FC22 62. Transfer roller CR-FC22TR 4

(120K kit) 63. Drive roller cleaning felt FP-FC22TR 1

No. of copies for

replacement cycle

1. Developer material (Y) PS-ZDFC22Y 1

1. Developer material (M) PS-ZDFC22M 1

1. Developer material (C) PS-ZDFC22C 1

1. Developer material (K) PS-ZDFC22K 1 30K

26. Upper oil roller (fuser unit) SR-FC22H 1

27. Upper cleaning roller (fuser unit) B-FC22H 1

– Doctor blade cleaning jig

6. Cleaning blade BL-FC22D 4

12. Charger wire cleaning pad WIRE-CH-310 4

13. Main charger wire K-PAD-WIRE 4 60K

14. Main charger grid GRID-CH-310 4

21. Ozone filter K-FILTER-OZN 1

23. Upper fuser roller HR-FC22-U 1

24. Lower fuser roller HR-FC22-L 1

29. Lower cleaning roller B-FC22L 1

38. Pick-up roller (cassette feed section)

61. Transfer belt BT-FC22TR 1

64. Transfer belt cleaning blade BL-FC22TR 1

JIG-CLEAN-DOC

K-ROL-PICK-310

1

90K

1

120K

FC-22

* The numbers in the “Classification of kits” column above correspond with the numbers in the

Preventive Maintenance Checklist.

FC-22 PREVENTIVE MAINTENANCE 2 - 12 January 2000 © TOSHIBA TEC

Page 14

PM Kit

Kit name Classification of kits Part name Q'ty

1. Developer material (Y) PS-ZDFC22Y 1

1. Developer material (M) PS-ZDFC22M 1

DEV-KIT-FC22

(20K kit)

EPU-KIT-FC22

(40K kit)

FU-KIT-FC22 25. Separation finger SCRAPER-PR 9

(60K kit) 28. Lower oil roller SR-FC22L 1

TBU-KIT-FC22 62. Transfer roller CR-FC22TR 4

(80K kit) 63. Drive roller cleaning felt FP-FC22TR 1

1. Developer material (C) PS-ZDFC22C 1

1. Developer material (K) PS-ZDFC22K 1 20K

26. Upper oil roller (fuser unit) SR-FC22H 1

27. Upper cleaning roller (fuser unit) B-FC22H 1

– Doctor blade cleaning jig

6. Cleaning blade BL-FC22D 4

12. Charger wire cleaning pad WIRE-CH-310 4

13. Main charger wire K-PAD-WIRE 4 40K

14. Main charger grid GRID-CH-310 4

21. Ozone filter K-FILTER-OZN 1

23. Upper fuser roller HR-FC22-U 1

24. Lower fuser roller HR-FC22-L 1

29. Lower cleaning roller B-FC22L 1

39. Pick-up roller (cassette feed section)

61. Transfer belt BT-FC22TR 1

64. Transfer belt cleaning blade BL-FC22TR 1

JIG-CLEAN-DOC

K-ROL-PICK-310

FC-15

No. of copies for

replacement cycle

1

60K

1

80K

* The numbers in the “Classification of kits” column above correspond with the numbers in the

Preventive Maintenance Checklist.

FC-22 PREVENTIVE MAINTENANCE 2 - 12 -1 January 2000 © TOSHIBA TEC

Loading...

Loading...