Page 1

BSINo. G00C981 Page 1

BSI No.: G00C981

Publish

2000/03/27

Date:

Subject: Change of Stacker ROM

Model: MJ1006, MJ1007

Category Field Application UNIT

Other, Other countermeasures Others Finisher

FactoryApplication: From Feb. 2000 at the factory

CONTENT

The part change has been made for the following reasons.

[Changed/Added Part No.]

P-I Before Change After Change Note P I R

27-2

P-I: Page-Item P: Content of Change I: Interchangeability R: Reason for Change

[Label]

[Changed Contents]

1.

Setting Method

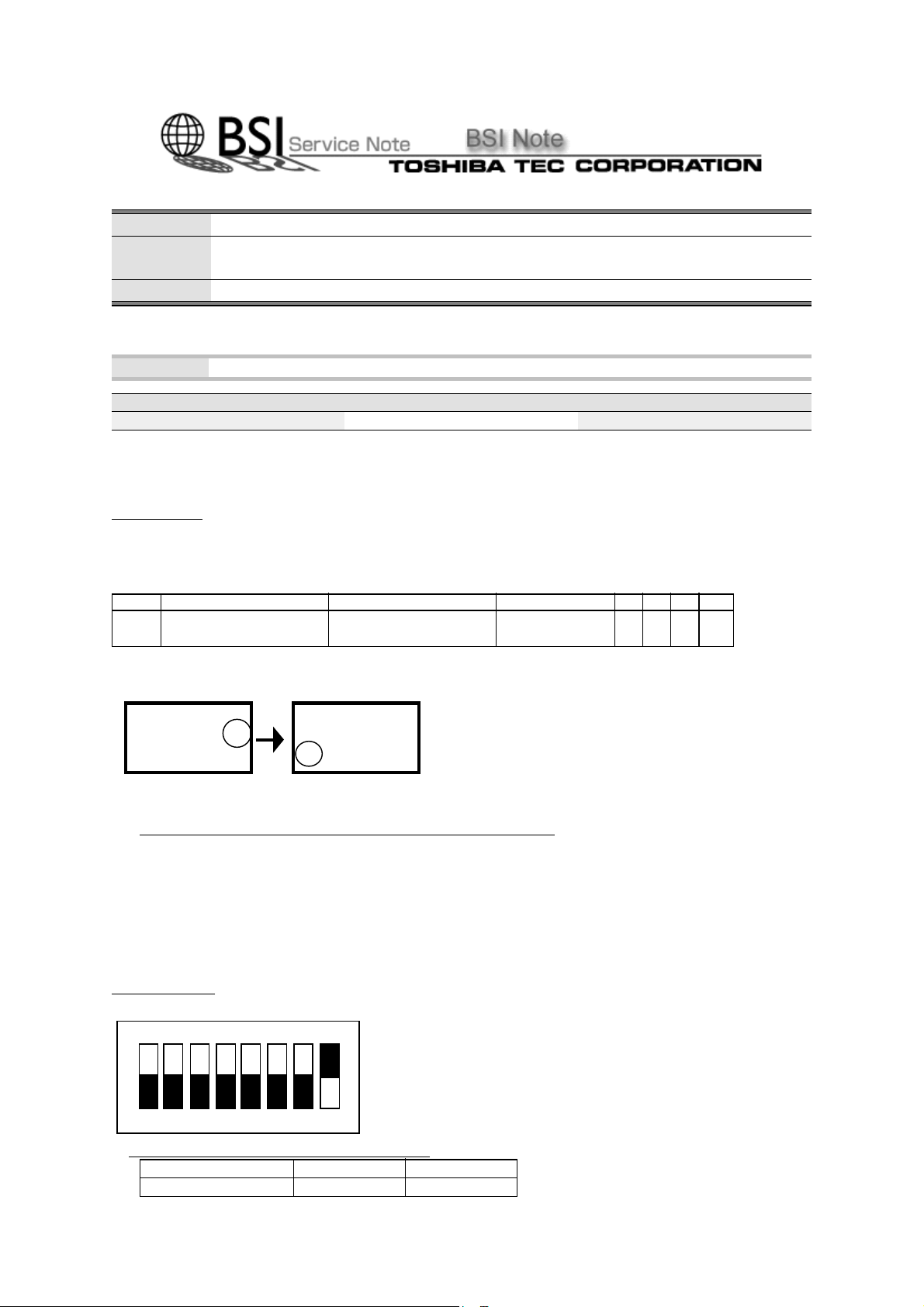

IP_SW No.8 of the finisher controller board is turned ON.

4402963960

PRA-793FIN-06

4F1-1051

1.2.3.4.5.6.

7.8.9.10.20.

Addition of setting to clear staple stacking count control

Though the finisher-full count control and the stacking height control continue as now, finisher-full

occurs. So, when the staple stacking count control is cleared, the following detriments occur. Be

sure to explain them user.

(1) If many sheets are stacked, there is a possibility that they may fall from the exit tray.

(2) The paper-exit positioning and orientation become bad.

4402963970

PRA-793FIN-07

4F1-1051

1.2.3.4.5.6.

7.8.9.10.20.

---- C B J Y

FAA

ON

1 2 3 4 5 6 7 8

2. Change of control for varying size height

Before Change After Change

Varying size 44mm or less 74mm or less

Page 2

BSINo. G00C981 Page 2

Varying staple 22 mm or less 74mm or less

Non varying staple 44mm or less 74mm or less

Reference; 80g/m2 sheets

44mm = about 300 sheets

74mm = about 500 sheets

[Change of Service Manual]

Together with this change, the Service Manual has been changed to attach an RDF type file (the

corrected points shown by shaded points).

ˀ˅ʪʮʫ˭ˡˣ ˀ˅ʪʳʫ˭ˡˣ

Attached File

Related Documents:

LinkTo: Link From:

Page 3

CHAPTER 1 GENERAL DESCRIPTION

II. SPECIFICATIONS

A. Specifications

1. Finisher Unit

Item

Stacking method

Stacking orientation

Stacking size

Paper weight

Bins

Modes

Stacking capacity

Size mixing

Description

Trays 1 through 2: by lifting tray

Face-up

AB: A3, A4, A4-R, A5-R, B4, B5, B5-R

Inch: LD, LG, LT, LT-R, ST-R

60 to 128 g/m

2

Trays 1 through 2

Non-sort: tray 1, 2

Sort: tray 1, 2

Staple: tray 1, 2

Non staple sort Small-size Tray 1: 147 mm high (1000 sheets)

(Note 1)

Tray 2: 147 mm high (1000 sheets)

(Note 2)

Large-size Tray 1: 74 mm high (500 sheets)

(Note 1)

Tray 2: 74 mm high (500 sheets)

Staple sort Small-size Tray 1: 110 mm high/30 sets (750 sheets)

(Note 1)

Tray 2: 110 mm high/30 sets (750 sheets)

Large-size Tray 1: 74 mm high/30 sets (500 sheets)

(Note 1)

Tray 2: 74 mm high/30 sets (500 sheets)

Size mixing: 74 mm or less

Stapling: 74 mm or less

Stacking mixing

Notes:

1. Approximate when computed with reference to 80 g/m

2. Alignment may not be correct if 750 or more small-size sheets are stacked on tray 2.

3. The accuracy of the stack height is ±7 mm.

Face-up

2

paper.

Table 1-201

1-2

Page 4

CHAPTER 6 TROUBLESHOO TING

6. Aging mode

This mode is for simulated running of the

MJ-1006/1007.

Figure 6-109

1) To start the aging, press SW2.

2) The bin is lowered to the lowermost position (home position).

3) From here on, the operation in each of the

operation modes is repeated. (To stop aging, press SW2.)

7. Feed motor 1 operation check

This mode is for operating feed motor 1.

10. Switching of stacking capacity in

staple sort limit

Change of the stacking capacity in staple

sorting from 30 to 50 copies.

1) The stacking capacity in staple sorting is

increased to 50 copies by changing the DIP

switch settings on the Finisher controller

board.

Figure 6-111

Figure 6-110

1) T o start the operation of feed motor 1, press

SW2.

2) T o stop the operation of feed motor 1, press

SW1.

The operation is controlled cyclically at the

following speeds at each press of push-switch

2.

(1) 100 mm/sec → (2) 350 mm/sec →

(3) 650 mm/sec → (1) and so forth

8. Tray shift up check

The tray is raised. (Set all DIP switch set-

tings to OFF.)

1) To raise the trays, press SW2.

2) Tray shifting is canceled when SW2 at the

tray 2 position.

9. Tray shift down check

The tray is lowered. (Set all DIP switch

settings to OFF.)

1) To lower the trays, press SW1.

2) Tray shifting is canceled when SW1 at the

tray 1 position.

Figure 6-112

2) The stacking capacity in staple sorting is

increased to limitless by changing the

DIP_SW settings on the Finisher controller board.

* However, it stops when stacking capacity

is full.

Figure 6-113

Note:

When the stacking capacity in staple sorting

exceeds 30 copies, stacking defects may

occur.

6-4

Loading...

Loading...