Page 1

BSINo. G00B945 Page 1

BSI No.: G00B945

Publish

2000/02/29

Date:

Subject: Change of Part and Developer Agent Automatic Discharge Structure

Model: FC22

Category Field Application UNIT

Change of Parts To be applied when necessary Developer

FactoryApplication: From Mar. 2000

CONTENT

In the case of automatic discharge of the developer material, sometimes the discharge shutter

cannot be opened or closed.

C33 error (abnormality in the operation of the developer material discharge shutter)

The alignment of the gears driving the developer material discharge shutter is shallow and

occasionally the gears will jump. This countermeasure is to make the alignment normal.

This change corresponds to machines assembled from Number BA010311; those before are

not included. For machines which have not had this countermeasure applied, when a C33

error happen, using [the assembly instructions] below, carry out adjustment. However, if the

part change below is made, this adjustment is unnecessary.

[Assembly instruction]

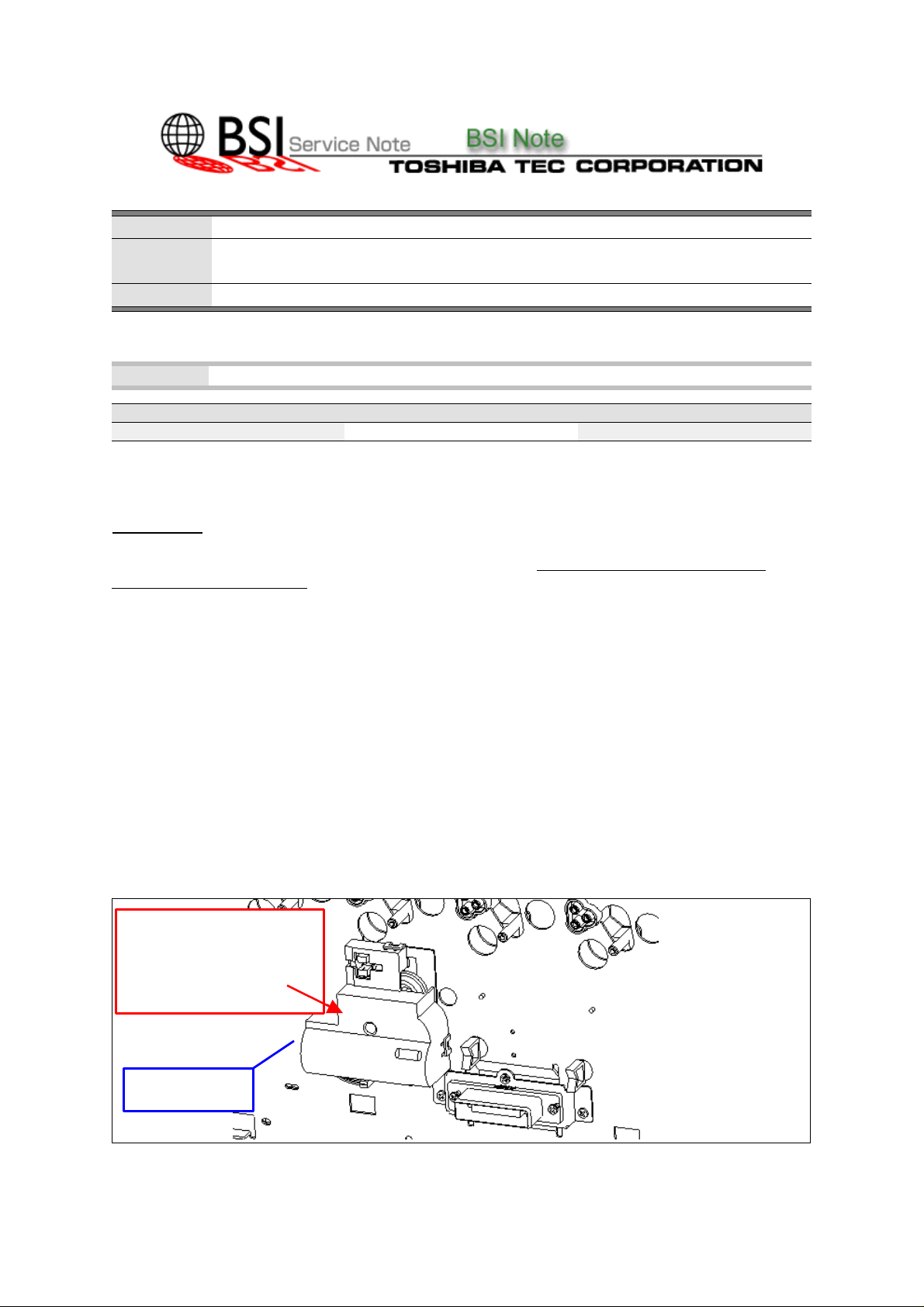

1. Machine

If you open the front cover and remove the EPU unit, then as shown in the figure below, you will be

able to check whether the developer material discharge shutter opening and closing unit is attached

to the rear frame or not.

This unit is fixed to the upper part of the rear frame by one 3mm screw and 3 dowel diameter in one

place.

Developer material discharge

shutter opening and closing

unit

Rear frame

Page 2

Rear frame

BSINo. G00B945 Page 2

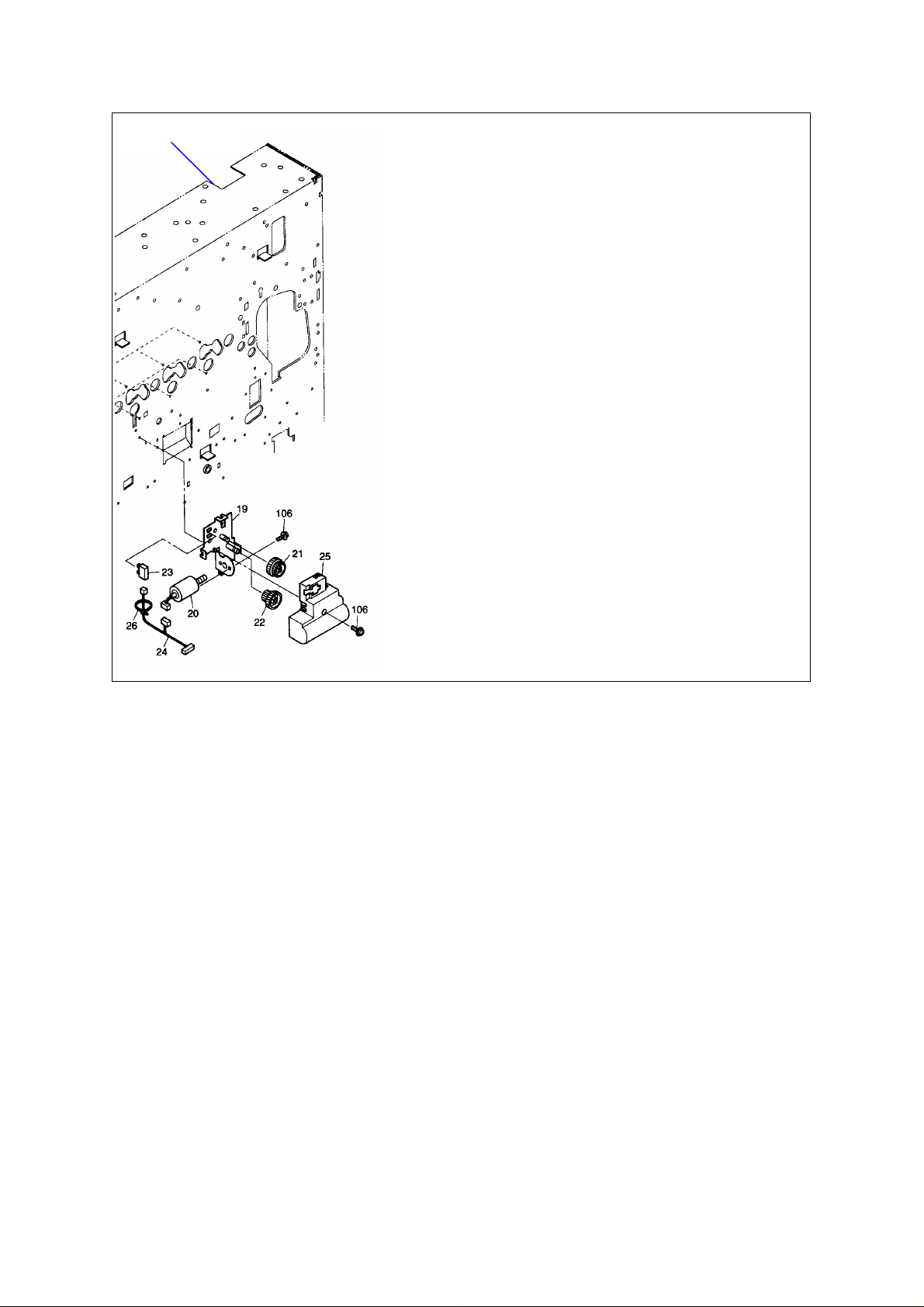

Carry out adjustment as follows.

Page 3

BSINo. G00B945 Page 3

direction.

Procedure

1. Temporarily fix a screw is not the center of the 3mm screw hole. Turn dowel playing clockwise

until it is projected.

2. Fix the drive unit with 3mm screws.

3. Check that the dowel has not come out from the hole in the figure on the right.

Note: Check that the

frame dowel has not

removed itself from the

Rotate the center of the M3

screw hole in a clockwise

hole and that it has not

come upon to drive unit.

M3 screw hole

(Rotation center)

2. EPU side

Adjust the opening/closing spring in the figure below.

Opening/closing spring

Page 4

BSINo. G00B945 Page 4

From the U-turn hook, adjust the upper

side so that there are at least 27 winding.

(1)

by pulling the spring in the direction of the arrow.

Pull the lower side of the opening/closing spring which is hanging in a U shape in the direction of the

arrow (1). Adjust the upper side so that there are at least 27 winding.

(2)

U-turn

hook

Make sure that there is a gap for the spring of the upper side

The following parts have been applied from March at the factory. If this change is applied, no

assembly change is necessary.

[Changed/Added Parts No.]

MODEL P-I Before Change After Change Note P I R

FC-22 7-19

7-21

4406531550

K-BRKT-DRV-DEV

4406531620

GG10S024/08S035

4406531560

K-BRKT-DRV-DEV

4406531650

GG10S024/08S035

3mm hole

diameter added

Change of teeth

thickness:

5mm -> 6.5mm

C B E Y

C B E Y

FAA

Attached File

Related Documents:

LinkTo: Link From:

Loading...

Loading...