Page 1

BSI No.: G00B944

Publish

2000/02/22

Date:

Subject: Countermeasure to E54 Jam (ADU feed non-arrival)

Model: DP4580, DP5570, DP6570

Category Field Application UNIT

Countermeasure to field trouble,

To improve the reliability

FactoryApplication: ---

To be applied when necessary ADD/ADU

BSINo. G00B944 Page 1

CONTENT

If

high incidence of

poor

.

E54

jam --- A jam when the stacked sheet is fed from the ADU.

Poor turning

all.

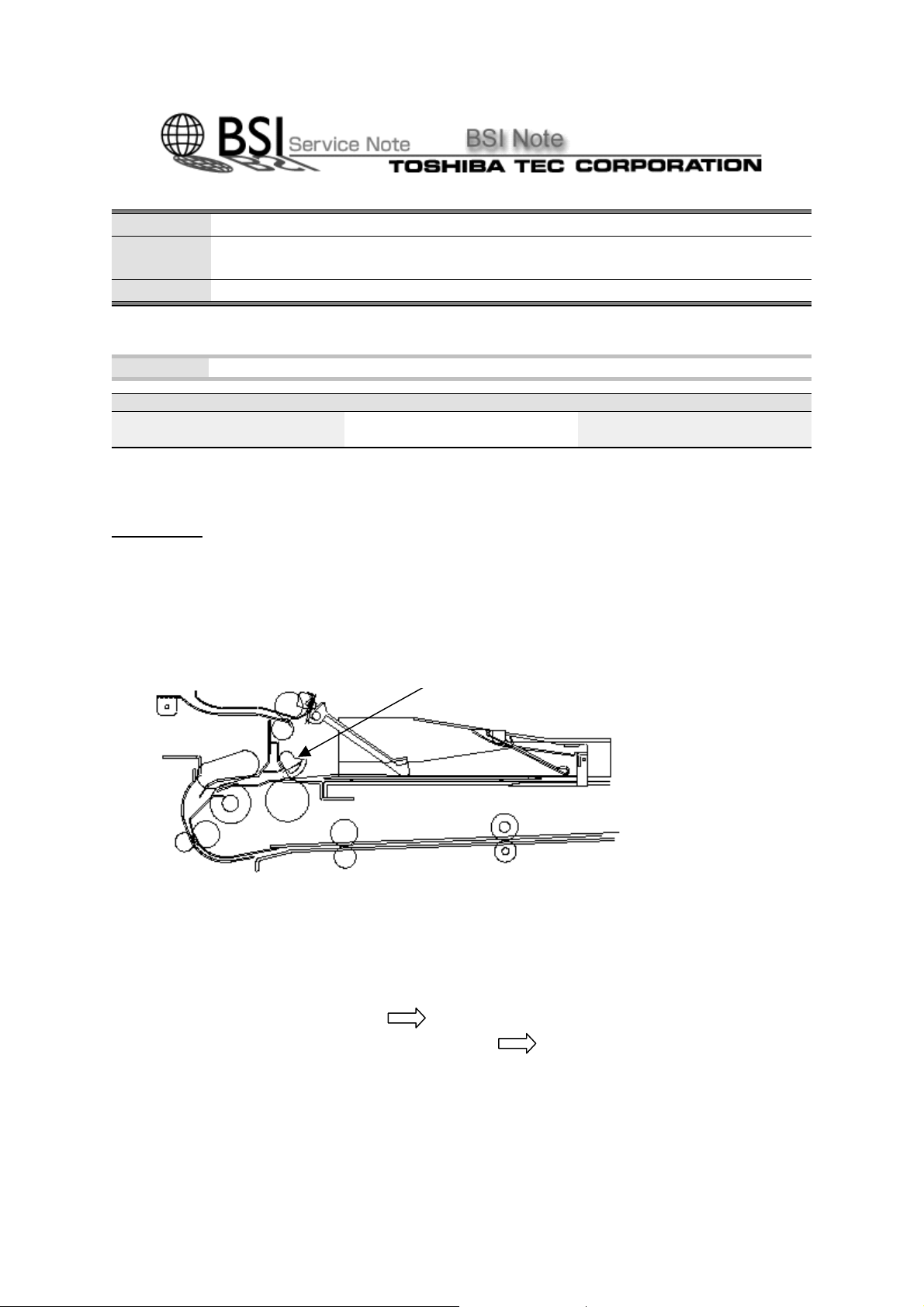

Pushing gate

Figure 1: cross-sectional view of ADU

[Operation Check of Pushing Gate]

Pull out the ADU, after removing the gray cover which is covering the field unit (two screws). 1.

Replace it inside the copier.

Start Duplex copying with the left front cover of the copier opened by using the door switch jig.2.

Check the turning of the shaft S shown on the left side (figure 2) of the ADU.3.

z

When shaft S turns two times

z

When shaft S does not turn at all or only once

PS)

To connect with the shaft S and the pushing gate, it is possible to check the movement of the pushing

gate by looking at the rotation of shaft S.

E54

happens, then the turning of the "pushing gate" in the ADU may be become

--- Though the pushing gate normally turns two times, it can turn only one time or not at

Normal

Poor turning

Page 2

Field Unit Shaft S

Caution:

If it is not possible to make a visual

evaluation, one can judge by the noise of the

rotation of the pushing gate. And if such

checking cannot be carried out, if an E54

jam occurs, it is recommended to put into

effect the

rotation of the pushing gate.

countermeasure to poor

Figure 2

[Countermeasure to Poor Rotation of the Pushing Gate]

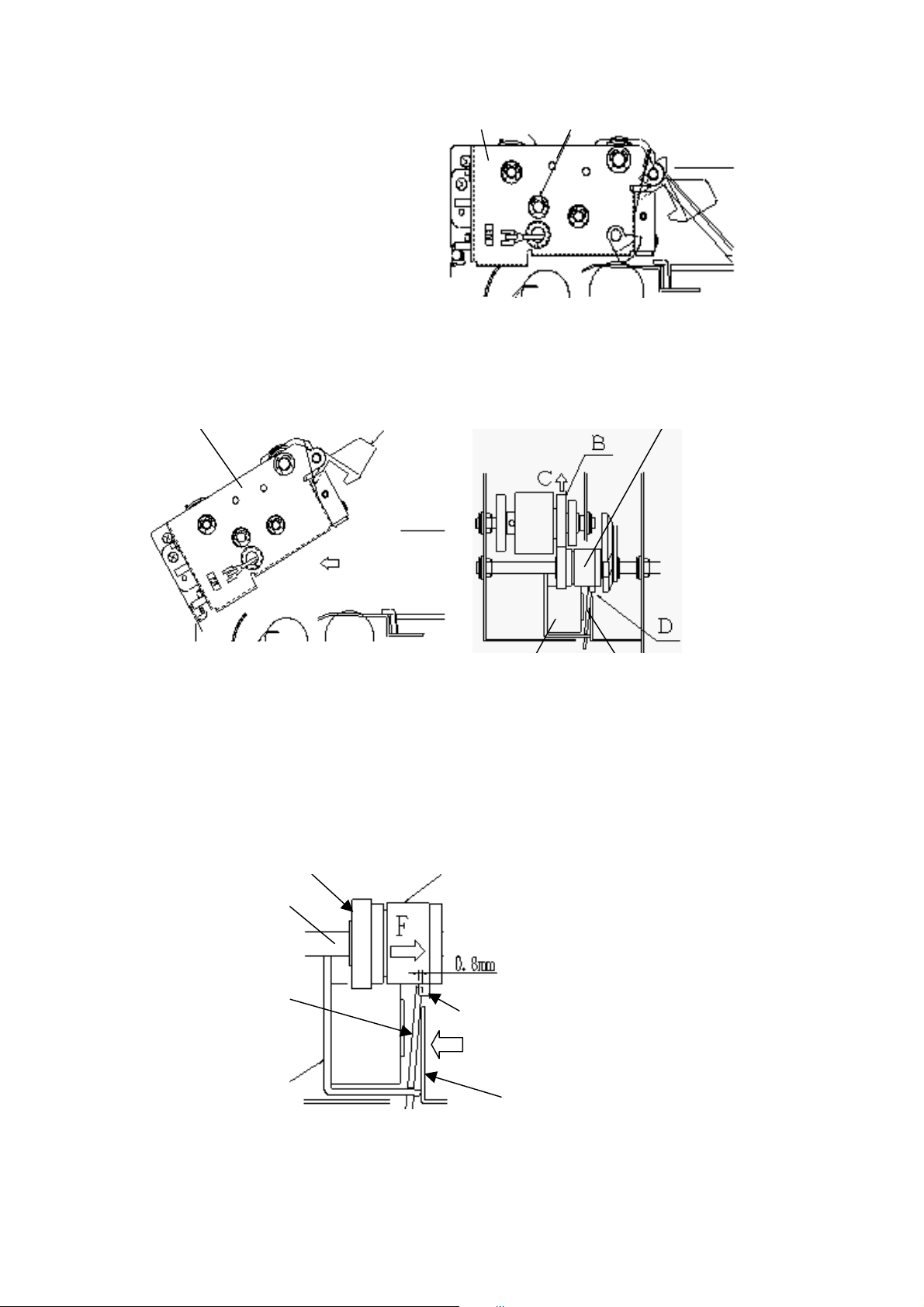

Open the feed unit with lever H. (See Figure 3) 1.

Field unit H lever

sleeve

BSINo. G00B944 Page 2

A

Figure 3

Turn the gear

sleeve contacts with the armature edge of the solenoid. (See Figure 4)

Most of the time, poor rotation of the pushing gate occurs when the solenoid is on but not pulled to 3.

the armature. The engagement of the armature and the sleeve become wrong and they

immediately do not become out of position. In this case, use the method in 4. below to recreate

smooth movement of the armature.

Pushing the gear

sleeve unit in the direction F too.

Shaft S

Armature

(B)

in an upward direction

in the direction

(E)

Gear E Sleeve

F,

Solenoid Armature

Figure 4. Field unit viewed from the direction A.

(C)

until the projecting portion

shift the entire shaft towards the rear. Then shift the 1.

(D)

of the spring clutch 2.

D

G

Solenoid

Bending portion for armature control

Figure 5

With the situation as in 4, make the thickness of the armature place to about half (0.8 mm) when 2.

the armature and the sleeve projection

armature control bending portion a little in the direction G.

(D)

are meshed. Then adjust by bending the bracket

Page 3

BSINo. G00B944 Page 3

Check that the rotation of the pushing gate is normal. (See

3.

pushing gate

Attached File

.)

Related Documents:

LinkTo: Link From:

checking the movement of the

Loading...

Loading...