Page 1

BSI No.: G00B931

Publish

2000/02/09

Date:

Subject: ROM Version Improvement

Model: FC22

Category Field Application UNIT

Change of Parts To be applied when necessary Software

FactoryApplication: From Jan. 2000

BSINo. G00B931 Page 1

CONTENT

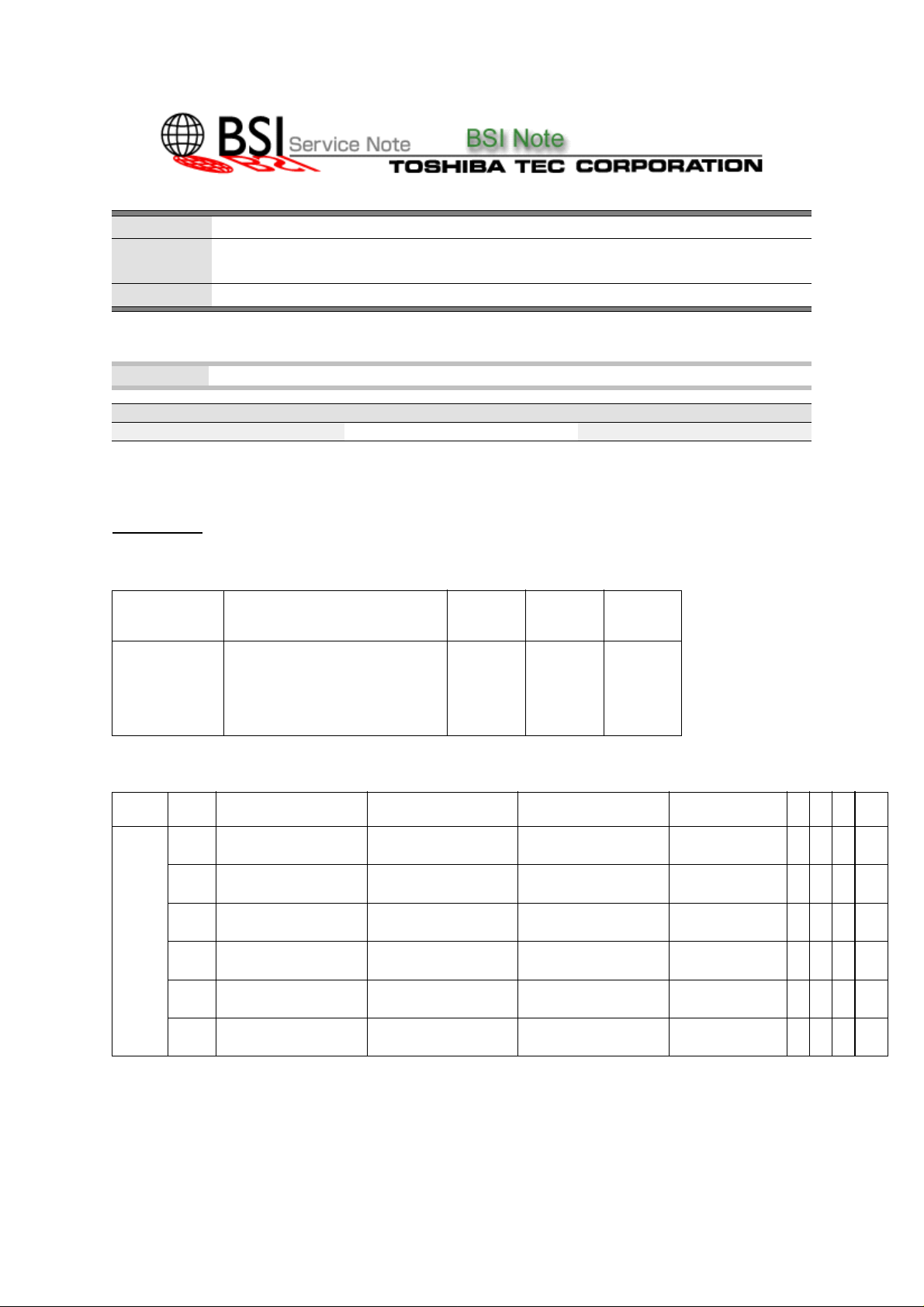

The ROMs version have been improved as follows.

ROM Name Before

Change

SYS-ROM

M-ROM

IMC-ROM

SCM-ROM

AI-ROM

PMA-T310Sxx-ZZZ

PRA-T310M-ZZ

PRA-T310IMC-ZZ

PRA-T310SCM-ZZ

PRA-T511MAC-ZZ

130

10

10

10

06

[Changed/Added Part No.]

MODELP-I Before Change From Jan. at the

factory

FC22 8-10

8-12 A

8-12 B

8-12

C

9-17

10-41

P-I: Page-Item P: Contents of Change I: Interchangeability R: Reasons for Change

4406573850

PRA-T310IMC-10

4406573980

PMA-T310SUC-130

4406573990

PMA-T310SEU-130

4406574000

PMA-T310SX-130

4406573900

PRA-T310M-10

4406573950

PRA-T310SCM-10

4406574030

PRA-T310IMC-11

4406574050

PMA-T310SUC-140

4406574060

PMA-T310SEU-140

4406574070

PMA-T310SX-140

4406574020

PRA-T310M-11

4406574010

PRA-T310SCM-11

From Jan.

at the

factory

From Feb.

at the

factory

140

11

11

11

07

From Feb. at the

factory

4406574210

PRA-T310IMC-12

4406574170

PMA-T310SUC-150

4406574180

PMA-T310SEU-150

4406574190

PMA-T310SX-150

4406574200

PRA-T310M-12

<-----

150

12

12

11

07

NAD

MJD

AUD ASD, SAD

Note P I R

C - J Y

C - J

C - J

C - J

C - J Y

C - J Y

FAA

Y

Y

Y

[Notes]

Be sure to carry out simultaneous exchange for SIC-ROM, M-ROM and IMC-ROM.1.

Although simultaneous exchange is recommended for the other ROMs there is no problem even 2.

if this does not take place.

Page 2

BSINo. G00B931 Page 2

When Ver.130 of SYS-ROM/Ver.10 of M-ROM/IMC-ROM is changed, be sure to perform [Work 3.

after ROMs change].

[Work after ROMs change]

Carry out the following procedure after changing ROMs.

1. Initialization of image parameters *Note1

(1) [1] +[3]+[POWER] : While pressing keys [1] and [3] simultaneously, turn on the main

switch.

(2) Wait about 20 seconds. The main switch is turned off when the following messages

appear on the LCD.

"Initialized image parameters.

Please turn off and on the copier. Thank you."

2. Initialization of image quality control

Please refer to "3. Image Quality Control Adjustment" on the "26 ADJUSTMENT" page of

the unpacking instructions for the FC22.

(1) [0] +[5]+[POWER]

(2) Key in code "879" and press the START key. Wait about 3 minutes.

3. Automatic Calibration of Gradation

Please refer to "4. Automatic Calibration of Gradation" on the "26 ADJUSTMENT" page of

the Unpacking Instructions for the FC22.

(1) Select the cassette of A3 (or LD) sized paper.

(2) [For TEXT and MAP modes]

a. Key in code "4", then press the SETTING key. The test chart is output.

b. Set the test chart on the original glass.

c. Key in code "643" and press the START key. Wait a few seconds.

d. Press the "2" key, the START key and INTERRUPT key in that order.

e. After the message "SCAN COMPLETED" appears, press the START key.

f. After the message "COMPLETED" appears, press the STOP key.

(3) [For PHOTO made]

a. Key in code "5", then press the SETTING key. The test chart is output.

b. Set the test chart on the original glass.

c. Key in code "643" and press the START key. Wait a few seconds.

d. Press "3" key, the START key and INTERRUPT key in that order.

e. After the message "SCAN COMPLETED" appears, press the START key.

f. After the message "COMPLETED" appears, press the STOP key.

4. Turn off the main switch.

*Note1 Initialization of image parameters

When initialization of the image parameters is performed, the following adjustment value will

be changed to the initial value. Please readjust if needed.

Please refer to page 1-73 from page 1-69 in the Service Handbook.

1-8. Density Adjustment (08/550-589)

1-9. Color Balance Adjustment (08/779-798)

1-10. Offset Amount for Processing Background (08/698/717)

1-11. Judgment Threshold for ACS (08/675)

1-12. AI Mode Setting (08/678, 682)

1-13. Sharpness Adjustment (08/730-745)

SYS-ROM

[130 --> 140]

1. The setting code (08/217) of the cassette loading status has been added as follows.

Setting Mode (08)

Page 3

BSINo. G00B931 Page 3

Code Setting Item Default Acceptable

value

217 Cassette loading

15 0 ~ 15 1 : 1st and 2nd cassette

status

2 : 1st, 2nd, 3rd cassette

Contents Operation

procedure

group

3 : 1st, 2nd, 3rd, 4th cassette

4 : 1st cassette ( Auto cassette

detection is not available )

15 : Auto cassette detection

0,5-14: Change value to "3" forcibly.

(1st, 2nd, 3rd, 4th cassette)

2. Mistaken detection in the automatic paper selection (APS) mode when the original is placed on the

glass has been corrected as follows.

In order to correct this right after turning on the power switch, the Software has been changed to

display the initial screen and reject the APS function during the warming up.

3. The message "Wait Fuser Stabilizing" has been added during the temperature adjustment of the

fuser.

4. The "YMCK" icon was detected from the test pattern selection screen.

This is because 04/230, 04/231, and 04/234 test patterns are prohibit when using the four color

mode (YMCK).

04/230 (gradation check pattern of 2 pixels standard)

04/231 (gradation check pattern of 3 pixels standard)

04/234 (halftone)

1

5. The adjustment code (05/213) has been added to indicate the auto toner output value.

Setting Mode (05)

Code Description/Mode Default Acceptable Contents Operation

213 Auto toner output

value

0 0 ~ 1023 Auto toner output value is

displayed.

6. The copy image quality in the photo mode and the AI mode (optional) and the accuracy of

the automatic gamma adjustment have been improved.

7. The Fiery scan mode with Z4 has been changed from one to two scanning operations.

8. The following code has been added on the setting mode (08).

Setting Mode (08)

Code Name Default Allowable

input

value

956

Auto Clear on paper

0 0 ~ 1 0: Disabled

empty for printer

1: Enabled

Contents Operation

This code is for making printing continue from the printer, when the copy operation is interrupted,

due to running out of paper.

9. The software related to the Z4 controller has been improved.

procedure

group

10

procedure

group

1

[140 --> 150]

1. The icon of "2 ->1 (single-sided copies with two-sided originals)" and "2 -> 2 (duplexing copies with

two-sided originals)" in the duplexing setting mode has been corrected.

2. A density check pattern (04/256) in the test print mode (04 mode) has been added.

Setting Mode (04)

Code Type of test pattern Remarks Paper size

256

Density check pattern None A3/LD

Page 4

BSINo. G00B931 Page 4

3. The following has been changed. When the AI board is not installed, the "AI" icon is not indicated

in the 05 test copy selection.

4. In a automatic calibration of gradation, please refer to the unpacking instructions, "Press 2 key, the

START key and INTERRUPT key in that order" is mentioned.

However when the front cover is opened and closed before pressing the INTERRUPT key, entry

with the digital keys will be permitted. This software bug has been corrected.

5. Though F13 error occurs rarely, the software bug has been corrected.

F13 means a communications error between the System-CPU and the Main-CPU; however this is

not listed in the Service Handbook.

6. The software related to the Z4 controller has been improved.

M-ROM

[10 --> 11]

1. In order to improve the halftone image at the leading edge, the value of the transfer high voltage

has been changed as follows.

Current New

Paper

0 3mm 0 3 11mm

on(100%) on(100%)

off (0%) off (0%)off (0%) on (80%) off (0%)

2. When the door switch is closed forcibly while opening the front cover, the fuser unit is removed

and reinstalled, sometimes the machine control is locked up. This firmware bug has been

corrected.

3. The output check function (03 mode) has been corrected as follows.

code 03/133; Color registration sensor LED (front) ON

code 03/183; Code No.133 function OFF

code 03/134; Color registration sensor LED (rear) ON

code 03/184; Code No.134 function OFF

code 03/114; Image quality sensor shutter solenoid ON

code 03/164; Code No.114 function OFF

4. After performing the 05/879 function (Automatic initialization of IQC), when opening and closing

the front cover, sometimes the machine control is locked up with the "warming up" indication.

5. When the fuser temperature becomes extremely high, the main switch is supposed to be turned

off forcibly. But the current software does not work correctly. This firmware bug has been

corrected.

6. When setting the duplex copy mode with two-sided originals (2 - 2) selected and the copy quantity

"3", if the third sheet is jammed in the exit area as an E02 error and this is removed from the

machine, sometimes the machine control is locked up.

Page 5

BSINo. G00B931 Page 5

7. An auto cassette detection function has been added in the cassette loading status. (08/217)

For example, when the third cassette is newly installed, the machine recognizes that the third

cassette is now installed when the power is turned on and then the value of 08/217 is changed as

the default.

[11 --> 12]

1. When making an OHP copy from a high image density original, the image is lacking at the leading

area 0~30mm on the OHP sheet. This firmware bug has been corrected.

2. The value "5" has been added into the cassette loading status as follows. (08/217)

Setting Mode (08)

Code Name Default Allowable

value

217 Cassette loading

15 0 ~ 15

status

1: 1st and 2nd cassette

2: 1st, 2nd, 3rd cassette

Contents Operation

procedure

group

3: 1st, 2nd, 3rd, 4th cassette

4: 1st cassette ( Auto cassette

detection is not available )

5 : 1st cassette ( Auto cassette

Addition ->

detection is available )

15: Auto cassette detection

6,5 ~ 14: Change value to "3" forcibly.

(1st, 2nd, 3rd, 4th cassette)

3. When making a test copy in the 04 mode, the drum life counter "08/840,841,842,843" and

developer-material counter "08/844,845,846,847" did not count up correctly.

Also these counters did not count up correctly in the mono-color copy.

These firmware bugs have been corrected.

1

4. The value of "Large size double counting" (08/802) was not read correctly, namely the code was

indicating the wrong value.

But the double counting operation in the copy mode is correct, and the writing value operation of the

code is working correctly. This firmware bug has been corrected.

5. When a feeding jam occurs to the last sheet and the jammed sheet is removed from the machine,

it tries to feed the paper from the cassette in spite of there being no more paper. The feeding jam

occurs again. This firmware bug has been corrected.

6. The indicated value of the image quality sensor in the 03" mode has been corrected.

7. The firmware related to the Z4 controller has been improved.

IMC-ROM

[10 --> 11]

1. The density of the grid pattern (04/204) in the test print mode has been slightly changed so as to

become light.

2. The test print pattern data (04/204) has been changed.

3. In order to improve the IQC, the ON/OFF timing of the transfer high voltage for the IQC test pattern

formed on the transfer belt has been changed.

[11 --> 12]

1. When the 03/280 function (Y-Laser ON/OFF) is executed, Y-Laser is turned on and off

periodically.

03/281(M),282(C),283(K) functions are the same as for Y-Laser. These firmware bugs have been

corrected.

Page 6

BSINo. G00B931 Page 6

2. In the "03" mode ( input check mode), the value of the image quality sensor is indicated wrongly.

(Please refer to page 1-13 in the Service Handbook for details.)

3. The firmware related to the Z4 controller has been improved.

SCM-ROM

[06 --> 07]

The leading void has been improved to be more accurate in the enlargement copying (X-Y zoom).

AI-ROM

[10 --> 11]

Advanced Image ROM (AI-ROM)

1. The image discrimination has been improved to render it more accurately.

2. The processing time for the image discrimination is reduced.

Attached File

Related Documents:

LinkTo: Link From:

Loading...

Loading...