Page 1

FILE NO. 2B0-200007

SERVICE MANUAL

CORDLESS TELEPHONE

FT-8800

PUBLISHED IN JAPAN, Sep., 2000

Page 2

CONTENTS

SAFETY PRECAUTIONS ............................................................................................................ 1

OPERATING CONTROLS........................................................................................................... 2

ALIGNMENT PROCEDURE ........................................................................................................ 3

BLOCK DIAGRAMS..................................................................................................................... 7

SCHEMATIC DIAGRAMS............................................................................................................9

TROUBLESHOOTING HINTS ................................................................................................... 13

IC AND TRANSISTOR VOLTAGE CHART ............................................................................... 20

SEMICONDUCTOR LEAD IDENTIFICATION........................................................................... 25

ELECTRICAL PARTS LOCATION............................................................................................. 27

WIRING DIAGRAMS .................................................................................................................29

EXPLODED VIEW AND MECHANICAL PARTS LIST............................................................... 31

PARTS LIST............................................................................................................................... 35

ASSEMBLY PARTS LIST .......................................................................................................... 47

SPECIFICATIONS ..................................................................................................................... 48

SAFETY PRECAUTIONS

Before returning any models to the customer, a safety check of the entire instrument should be made.

The service technician must be sure that no protective device built into the instrument by the manufacture

has become defective or inadvertently degraded during servicing.

1.WARNING:

Alterations of the design or circuitry of these models should not be made.

Any design changes or additions such as, but not limited to, circuit modifications, auxiliary speaker

jacks, switches, grounding, active or passive circuitry, etc. may alter the safety characteristics of these

models and potentially create a hazardous situation for the user.

Any design alterations or additions will void the manufacturer's warranty and will further relieve the

manufacturer of responsibility for personal injury or property damage resulting therefrom.

2.PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in this chassis have special characteristics. These characteristics

often pass unnoticed and the protection afforded by them cannot necessarily be obtained by using

replacement components rated for higher voltage, wattage, etc. Replacement parts that have these

special safety characteristics are identified in this manual and its supplements; electrical components

having such features are indentified by a in the schematic diagram and the parts list. Before

replacing any of these components, read the parts list in this manual carefully. The use of substitute

replacement parts that do not have the same safety characteristics as specified in the parts list may

create shock, fire or other hazards.

1

Page 3

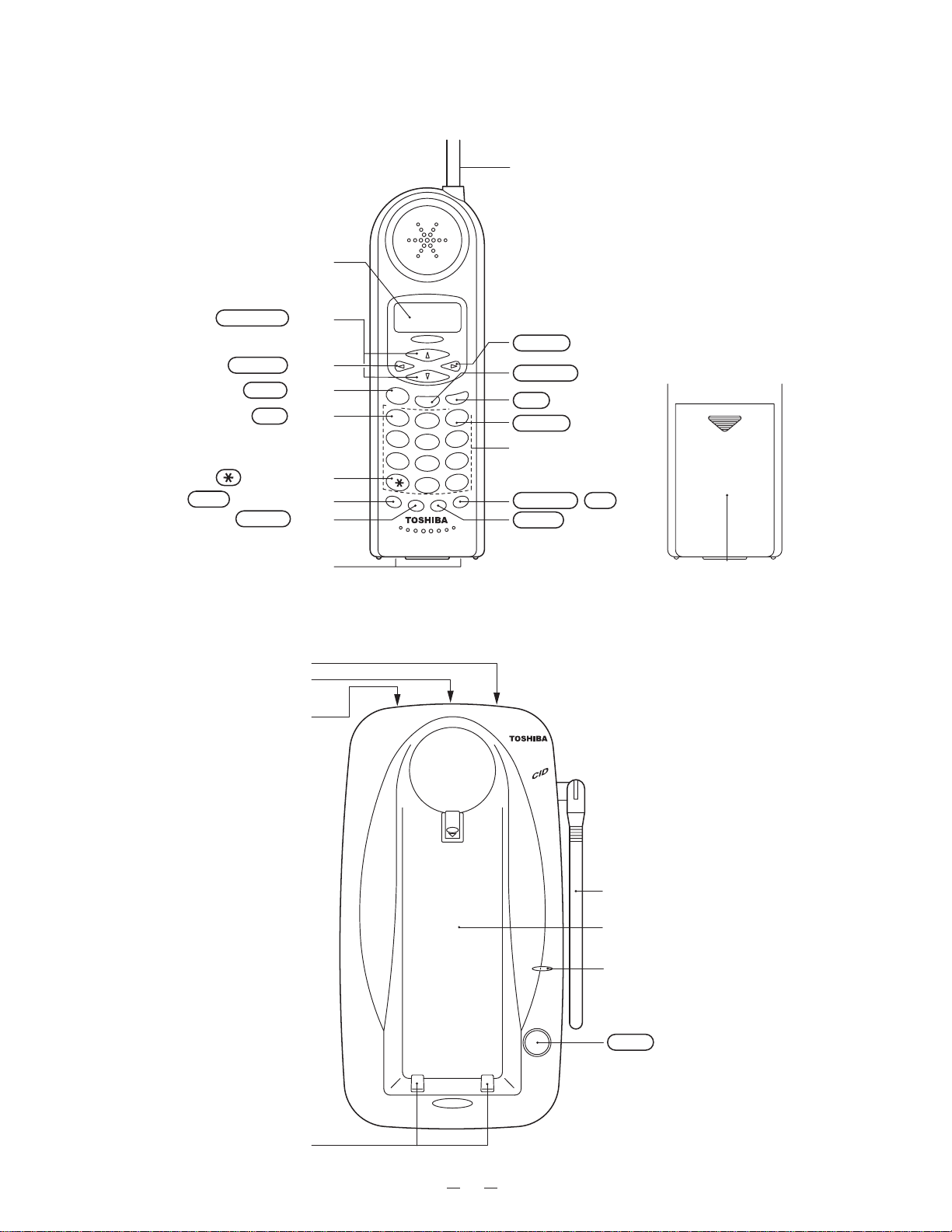

OPERATING CONTROLS

HANDSET CONTROLS AND FUNCTIONS

Antenna

LCD Display

VOL/RING Button

900

MHz

COMPANDOR NOISE REDUCTION

REDIAL FLASH

VOL/

TALK

GHI

PQ

RS

TONE

MEM

RING

CID

SELECT

LOCALL.D.

DEF

ABC

TUV

OPER

3

2

MNO

6

JKL

5

WX

9

YZ

8

#

0

DELETE

FUNC

CH

1

4

7

PAUSE

REDIAL Button

TALK Button

L.D. Button

(TONE) Button

MEM (Memory) Button

PAUSE Button

FLASH Button

SELECT Button

CID Button

LOCAL Button

Dialpad

DELETE CH Button

FUNC Button

Charging contact

BASE UNIT CONTROLS AND FUNCTIONS

PULSE/TONE Switch

DC IN 9V Jack

TEL LINE Jack

CALLER-ID

CORDLESS

TELEPHONE

FT-8800

DIGITAL

IN USE

CHARGE

Rechargeable

Battery Pack(back)

Antenna

Cradle

IN USE/CHARGE LED

Charging Contact

900

COMPANDOR NOISE REDUCTION

MHz

2

PAGE

PAGE Button

Page 4

Base Unit

ALIGNMENT PROCEDURE

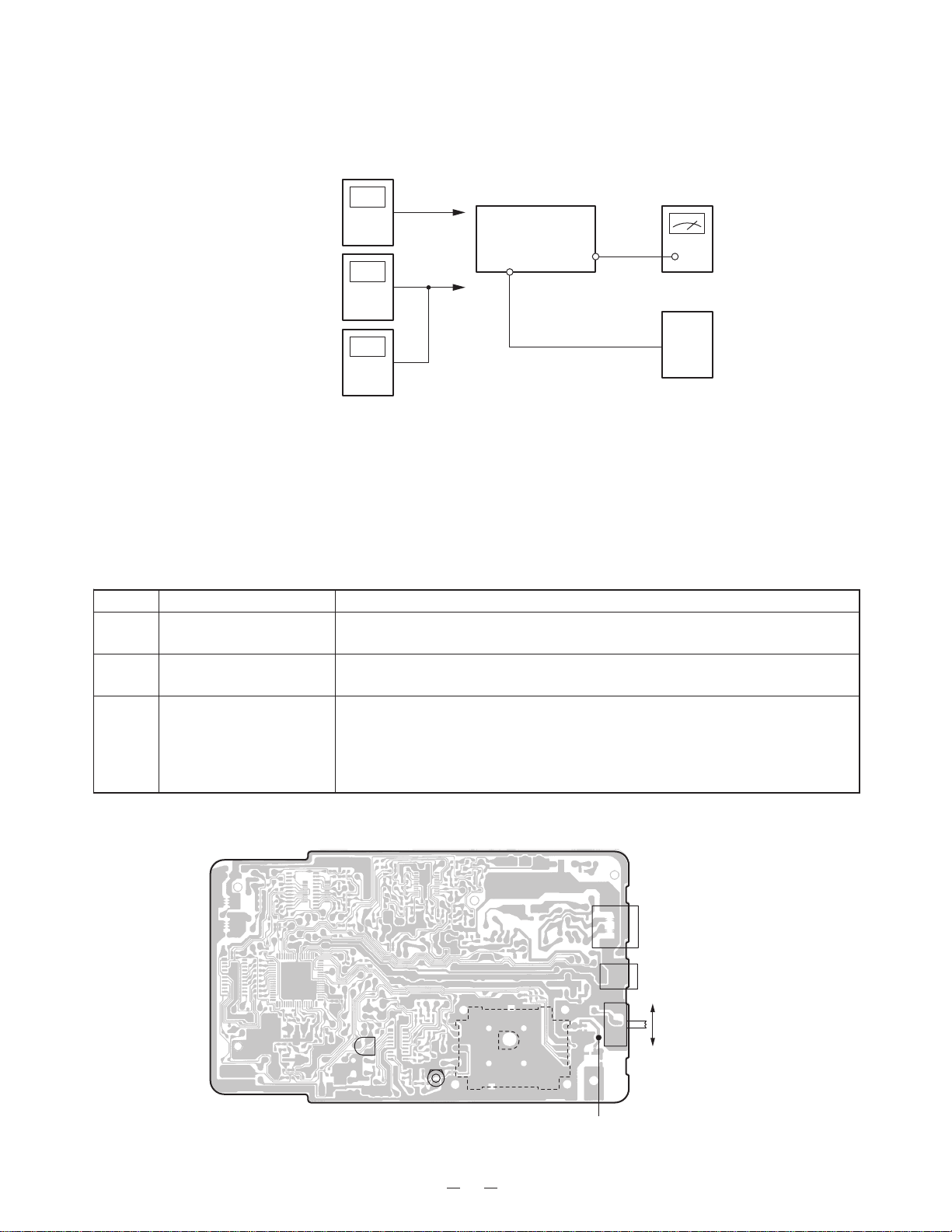

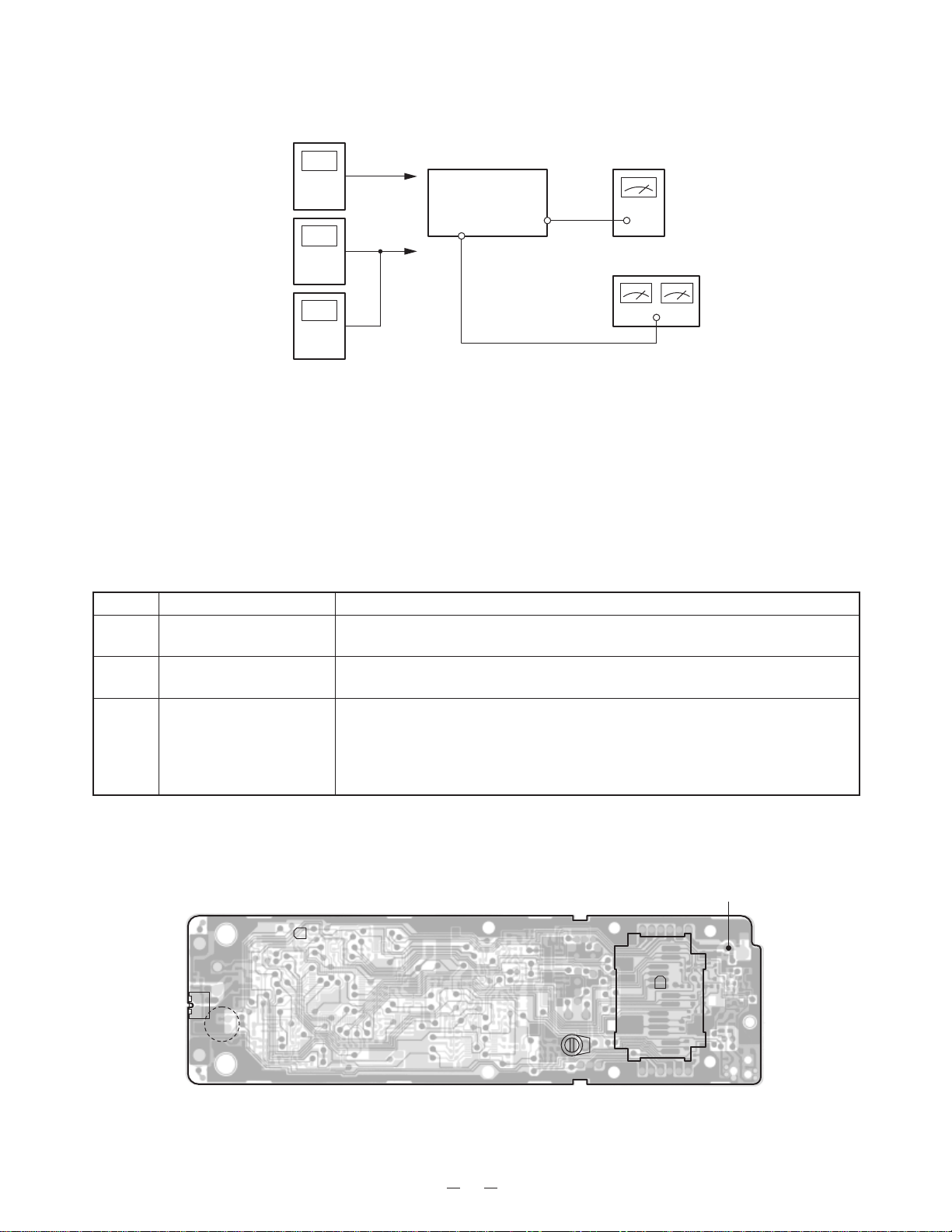

Transmitter Section

Connections

Power

Meter

Frequency

Counter

Deviation

Mater

RF

Test Point

RF

Test Point

BASE Unit

J2

DC IN

9V Jack

TEL Line

Jack

J1

1kHz -15dBm

AF GEN.

AC

Adapter

AC 120V

60Hz

Preset

a) Connect the base RF unit to the base main unit.

b) Set the “TONE / PULSE” switch to PULSE.

c) Connect the AC adapter to the base unit while pressing the “PAGE” key, and keep pressing it continuously for

approximate 2 sectonds.

d) Release the “PAGE” key when entering TEST mode 1 with IN USE LED lighting.

Alignment Procedure

step

1

2

3

Adjustment

RT301

(TX P ower)

CT1

(TX Frequency)

RT3

(TX Modulation)

Remarks

Connect the Po w er Meter to the RF test point on the Base MAIN PCB.

Adjust RT301 for a -7dBm reading on the Power Meter.

Connect the Frequency Counter to the RF test point on the Base MAIN

PCB. Adjust CT1 to make sure that the frequency is 926.897468 MHz.

Press the “PAGE” k e y to enter the TEST Mode 2. Connect the AF Generator

to the TEL Line J a ck on the Base Main PCB. Make sure that the output is 1

kHz -15dBm from the AF Generator .

Connect the Deviation Meter to the RF test point on the Base MAIN PCB.

Adjust RT3 to indicate ±8 kHz De v.

Alignment Point Location on Base Main PCB and Base RF PCB

Base Main PCB

Base RF PCB

RT3

CT1

RT301

RF Test Point

3

J1

TEL LINE Jack

J2

DC IN 9V Jack

T

S2

TONE/PULSE Switch

P

Page 5

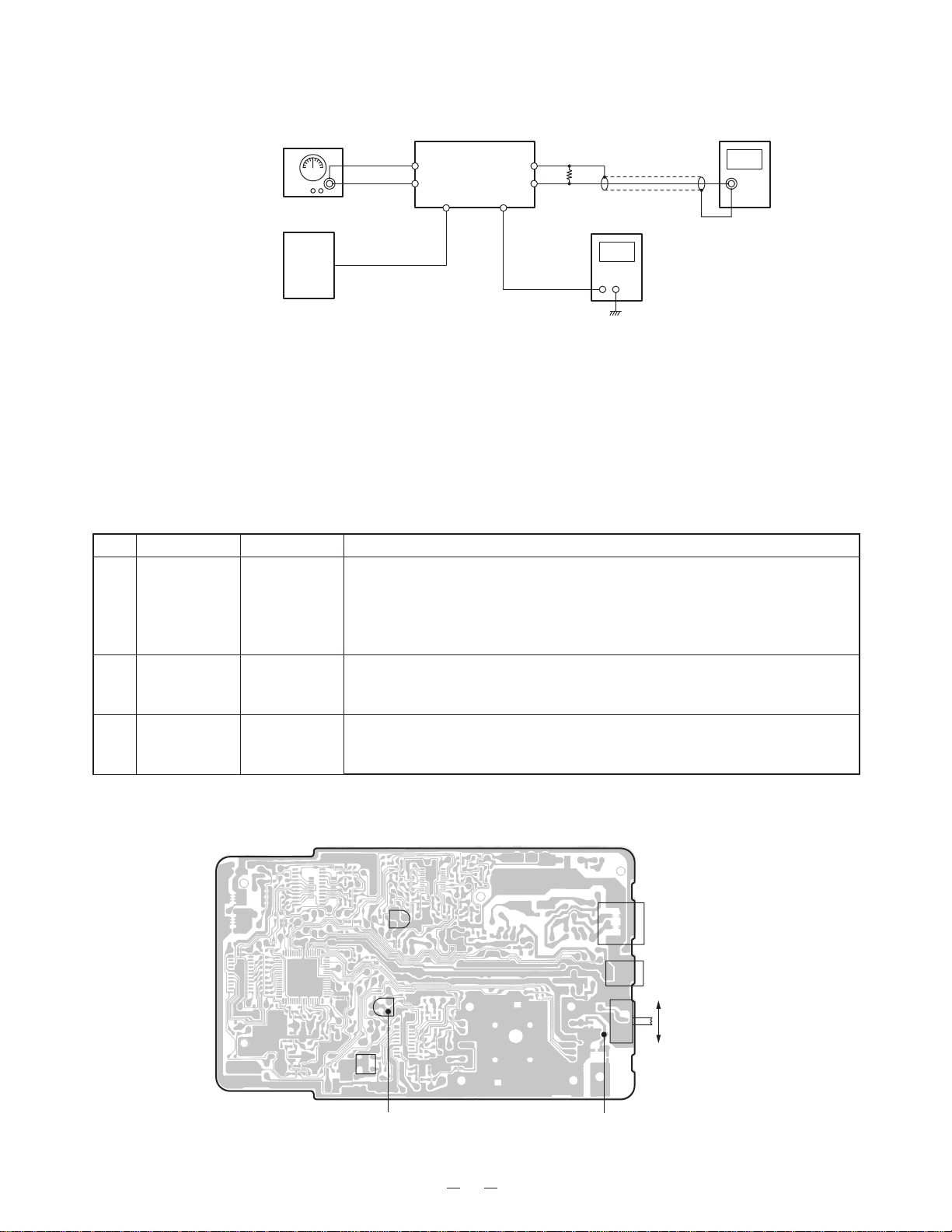

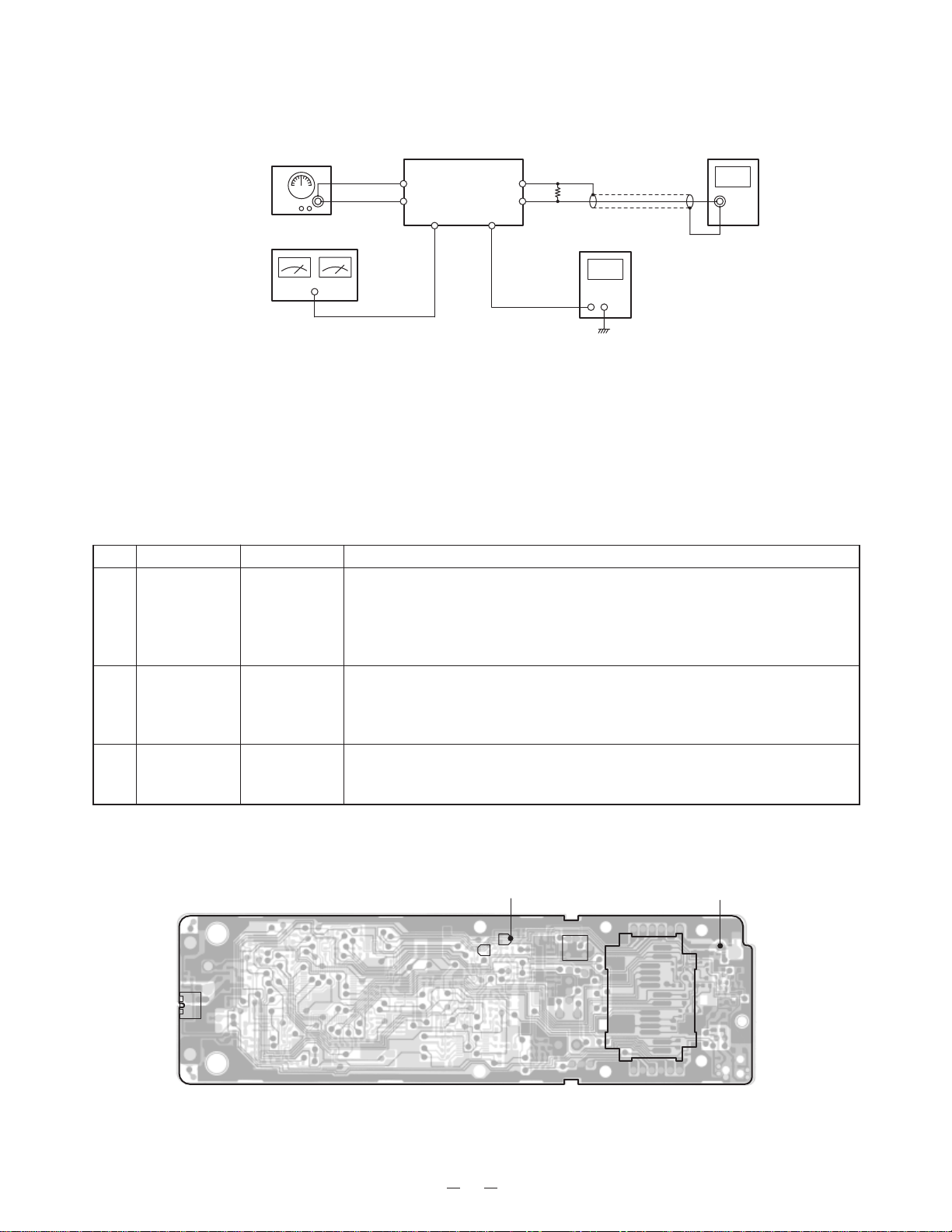

Receiver Section

Connections

RF SG

+

RF

Test Point

TEL Line

Jack

J1

Dummy Load

(600-ohm)

+

AC V oltmeterBASE Unit

AC 120V

60Hz

AC

Adapter

DC IN 9V Jack

J2

AF

Terminal

DC V oltmeter

Preset

a) Connect the base RF unit to the base main unit.

b) Set the “TONE/PULSE” switch to PULSE.

c) Connect the AC adapter to the base unit while pressing the “PAGE” key, and keep pressing it continuously for

approximate 2 seconds.

d) Release the “PAGE” key when entering TEST mode 1 with IN USE LED lighting.

Alignment Procedure

step

Preset to

1

SG: 1mV

No modulation

SG: 1mV

1 kHz ±8kHz

2

deviation

SG: -6.0 dB

1kHz ±8kHz

3

Deviation

Adjustment

(Discriminator

Voltage)

(RX AF

Voltage)

µµ

µV

µµ

(SQ Point)

L3

RT2

RT1

Remarks

Press the “PAGE” key for 3 times to enter the TEST Mode 4. Connect the

RF Signal Generator to the RF test point on the Base MAIN PCB. Make

sure that the frequency is 902.952467 MHz.

Connect the DC Voltmeter to the Discr iminator test point. Adjust L3 to

indicate DC 0.95 V.

Connect the AC Voltmeter across a 600-ohm dummy to the Telephone Line

Jack. Adjust RT2 for a -11dBm reading on the AC voltmeter.

Press the “PAGE” key to enter the TEST Mode 5. Make sure that the

frequency of RF SG output is 902.952467 MHz. Adjust RT1 to turn to the

point where the CHG LED just turns on.

Alignment Point Location on Base Main PCB and Base RF PCB

Base Main PCB

RT2

RT1

L3

RF Test PointDiscriminator Test Point

4

J1

TEL LINE Jack

J2

DC IN 9V Jack

T

S2

TONE/PULSE Switch

P

Page 6

Handset Unit

Transmitter Section

Connection

Power

Meter

Frequency

Counter

Deviation

Mater

RF

Test Point

RF

Test Point

HANDSET Unit

J603

Battery

Connector

MIC+Pin

AF GEN.

1kHz 9mV

DC Power Supply

DC 3.8V

Preset

a) Connect the handseet RF unit to the handset main unit.

b) Connect DC power supply to battery connector on the handset unit.

c) Turn the DC power supply On while pressing " *" and " # " keys, and keep pressing the keys continuously for

approximate 2 seconds.

d) Release keys when entering TEST mode 1 with beep.

Alignment Procedure

step

1

2

Adjustment

RT501

(TX Po wer)

CT601

(TX Frequency)

Remarks

Connect the RF power Meter to the RF test point on the handset MAIN PCB.

Adjust RT501 for a -5dBm reading on the Power Meter.

Connect the Frequency Counter to the RF test point on the handset MAIN

PCB. Adjust CT601 to make sure that the frequency is 903.052467 MHz.

Press the “2” key to enter the TEST Mode 2. Connect the AF Generator to

3

RT603

(TX Modulation)

the MIC Connector make sure that the output is 1kHz 9mV from the AF

Generator.

Connect the Deviation Meter to the RF test point on the handset MAIN PCB .

Adjust RT603 to indicate ±8 kHz De v.

Alignment Point Location on Handset Main PCB and Handset RF PCB

Handset PCB

RT603

J603

CT601

MC601

RF PCB

RT501

RF Test Point

5

Page 7

Receiver Section

Connections

RF SG

DC Power Supply

+

J603

Battery

Connector

DC 3.8V

RF

Test Point

Connector

SP

AF

Terminal

Dummy Load

(150-ohm)

+

Preset

a) Connect the handset RF unit to the handset main unit.

b) Connect DC power supply to battery connector on the handset unit.

c) Turn the DC power supply ON while pressing “

” and “ # ” keys, and keep pressing the keys continuously for

*

approximate 2 seconds.

d) Release keys when entering TEST mode 1 with beep.

Alignment Procedure

step

Preset to

1

SG: 1mV

No modulation

SG: 1mV

1 kHz ±8kHz

2

deviation

SG: -6.0 dB

1kHz ±8kHz

3

Deviation

Adjustment

L603

(Discriminator

Voltage)

RT602

(RX AF

Voltage)

µµ

µV

µµ

RT601

(SQ Point)

Press the “4” key to enter the TEST Mode 4. Connect the RF Singal

Generator to the RF test point on the handset MAIN PCB. Make sure that

the frequency is 926.997467 MHz.

Connect the DC Voltmeter to the Discriminator test point. Adjust L603 to

indicate DC 0.85 V.

Connect the RF Signal Generator to the RF test point on the handset MAIN

PCB. Make sure that the frequency is 926.997467 MHz.

Connect the AC Voltmeter across a 150-ohm dummy to the MIC Connector.

Adjust RT602 for a 100 mV reading on the AC Voltmeter.

Press the “5” k e y to enter the TEST Mode 5. Mak e sure that the frequency

of RF SG output is 926.997467 MHz. Adjust RT601 to turn to the point

where the Ringer just beeps.

AC V oltmeterHANDSET Unit

DC V oltmeter

Remarks

Alignment Point Location on Handset Main PCB and Handset RF PCB

Handset PCB

J603

Discriminator Test Point

RT601

RT602

L603

6

RF PCB

RF Test Point

Page 8

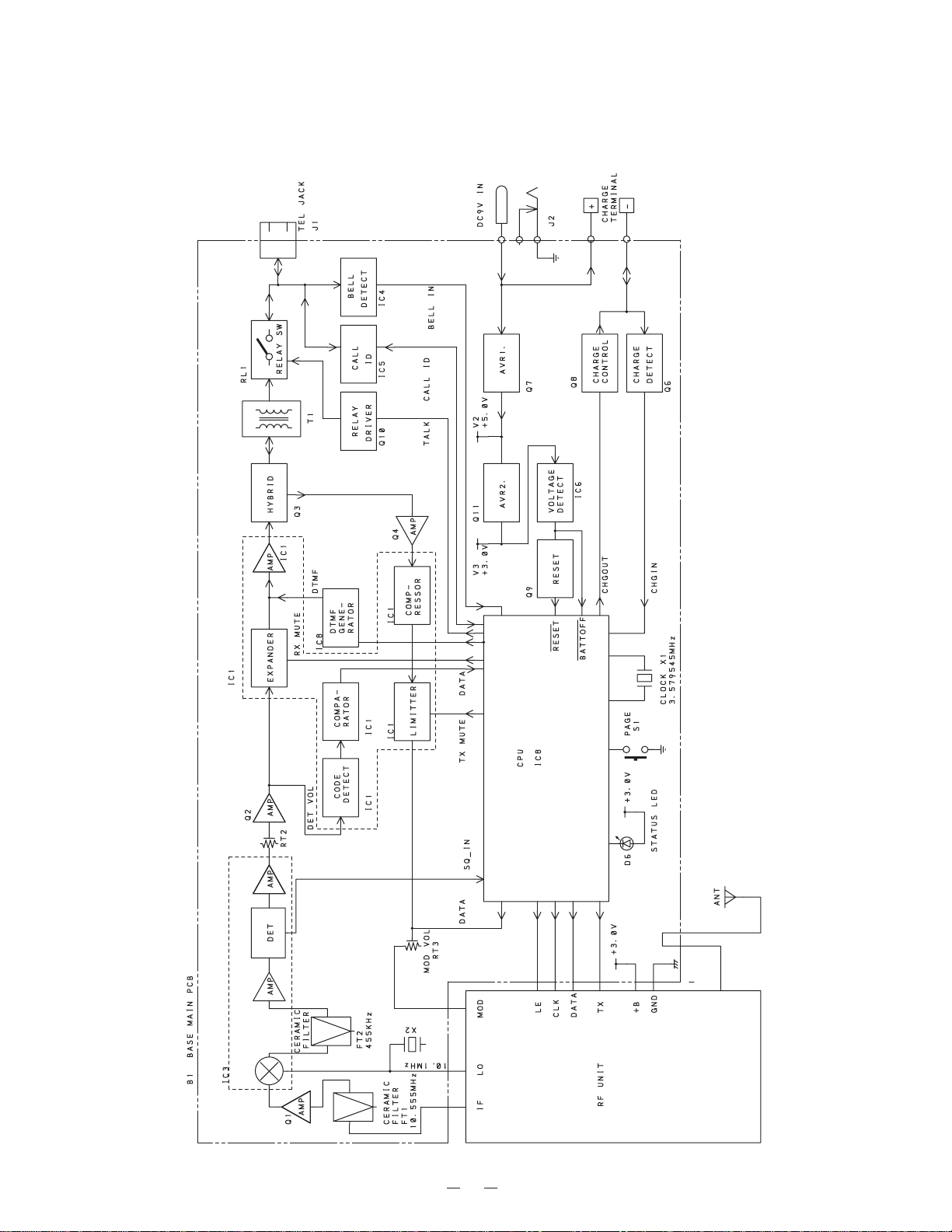

Base Unit

BLOCK DIAGRAMS

B301

7

Page 9

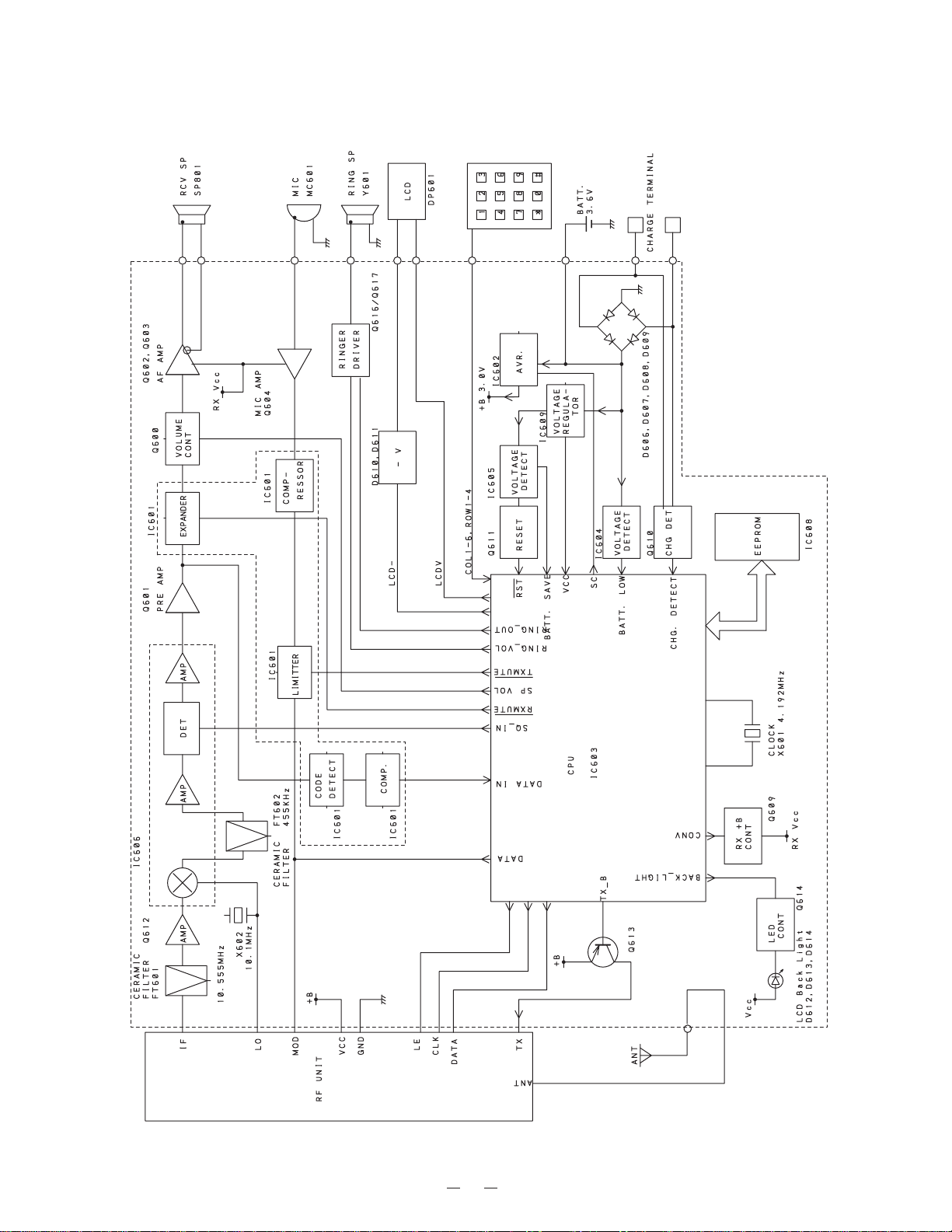

Handset

B501

8

Page 10

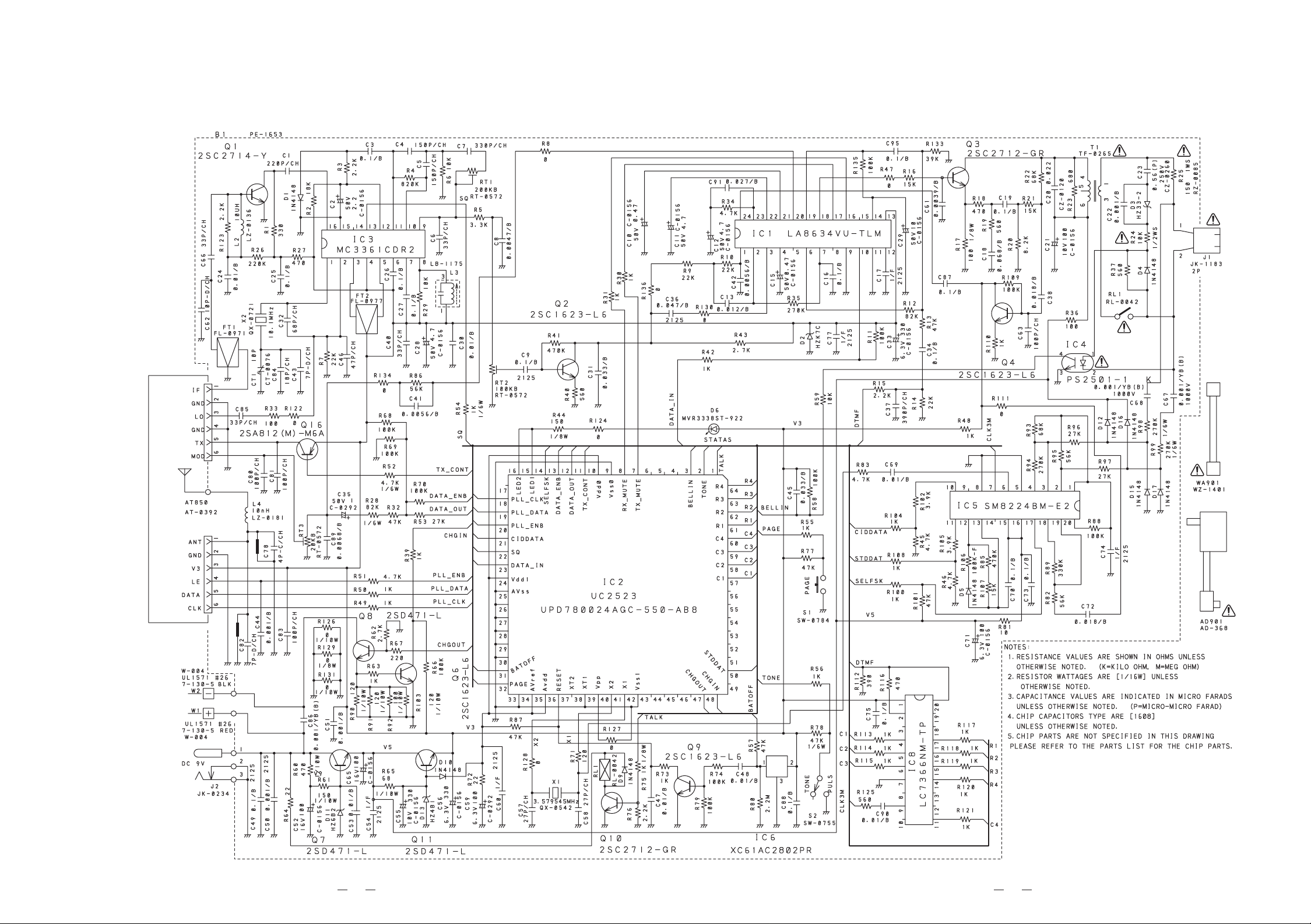

Base Unit

SCHEMATIC DIAGRAMS

B301

RF MODULE

9

10

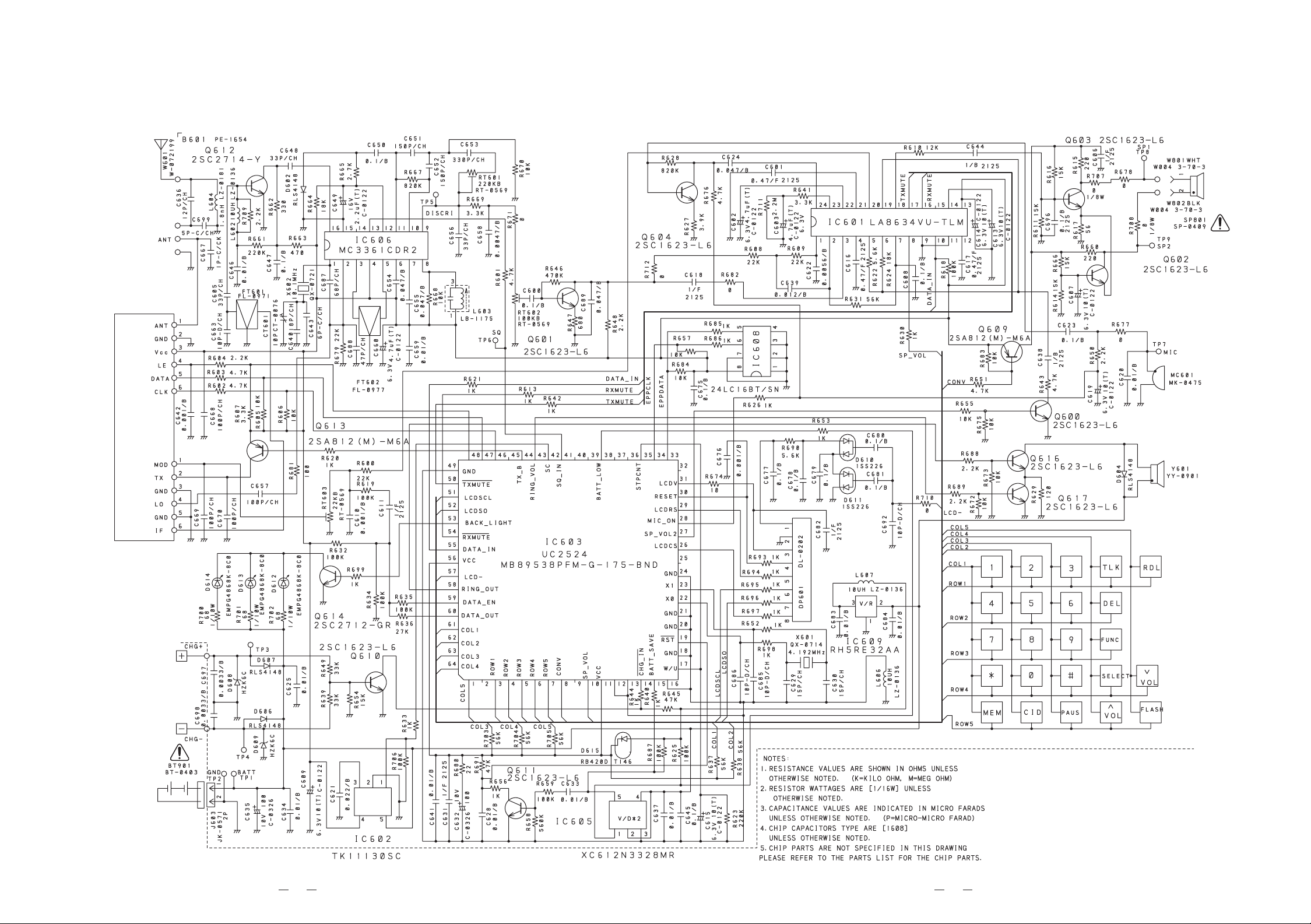

Page 11

Handset

B501

RF MODULE

11

12

Page 12

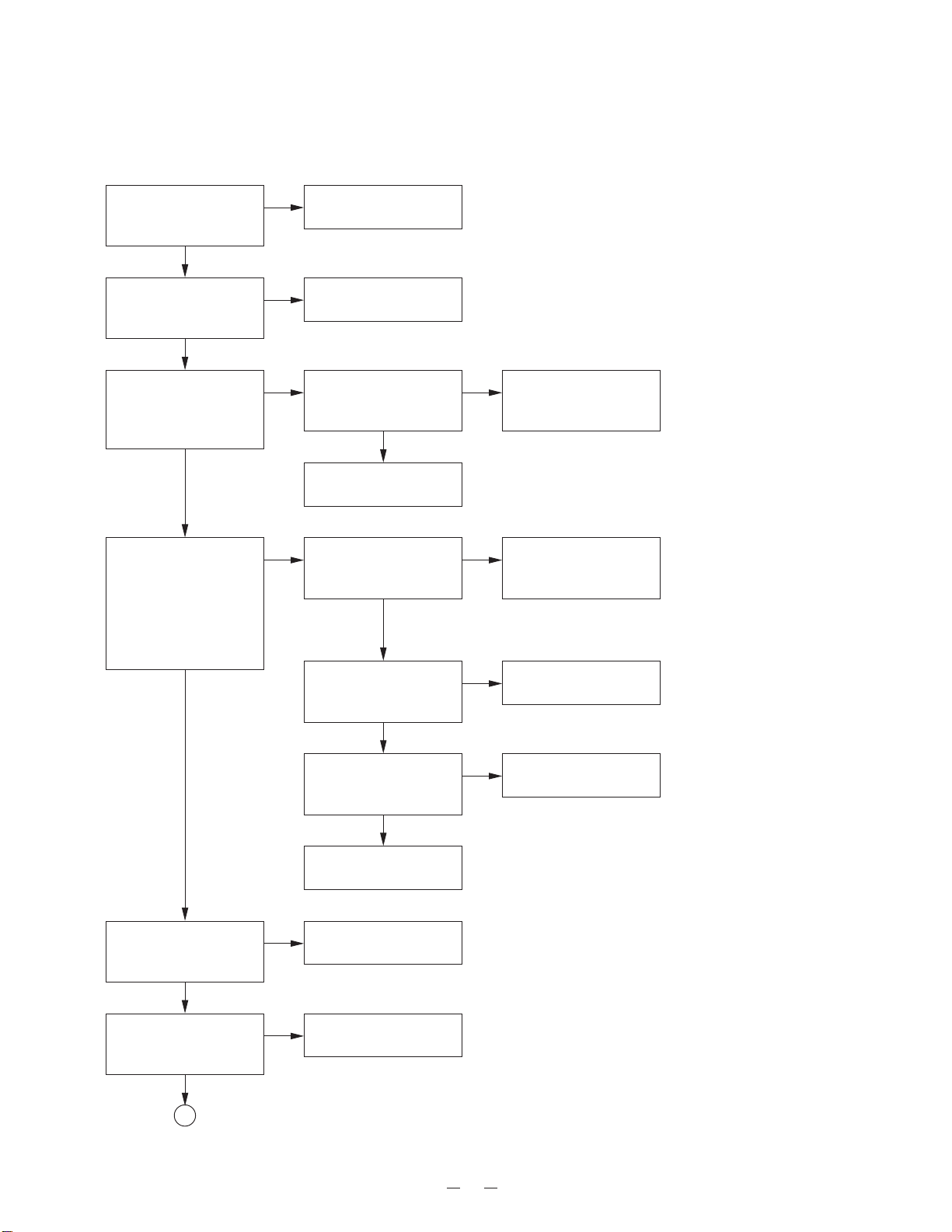

TROUBLESHOOTING HINTS

1. The bell does not ring.

When the PAGE SW of the

base is pressed, does the

ringer on the handset ring?

OK

When the TEL SG is joined

with the base to make bell

signal, is there pulse wave at

pin 4 of IC4?

OK

Is there pulse wave at

pin 3 of IC2?

OK

Check IC2 and its

peripheral circuit.

NG

NG

NG

See 2. The bell does not ring

& page does not ring.

Check IC4 and TEL network

circuit.

Check R58 and R59.

Deletion of the Caller ID memory

To delete the Caller ID memory in the EEPROM, proceed with the f ollo wing process:

1) Connect the battery with pressing and # buttons, and keep pressing the buttons continuously for

approximate 2 seconds.

2) Release buttons when entering TEST mode with beep.

3) Press CID button.

4) A confirmation beep will sound after about 8 seconds, then the data for caller ID is deleted.

(Note: Do not disconnect the battery until you hear the confirmation beep, otherwise the data may not be

completely deleted.)

13

Page 13

2. The bell does not ring & page does not ring.

Can the base and handset be

connected?

OK

Press handset DIAL key

while in TALK MODE.

Can key touch sound be

heard from the ringer?

OK

When the PAGE SW of the

base is pressed, does pin32

of IC2 change from high to

low?

NG

NG

NG

See 3. The base and handset

cannot be connected.

When the key of the handset is

pressed, can the pulse output

at pin 58 of IC603 be seen?

OK

At the Q616 collector, can the

pulse wave be seen?

OK

Check RINGER Y601.

Check R55, R77 and S1.

NG

NG

Check IC603.

Check R688, R673, R689,

R672, R629, Q616 and Q617.

OK

Check IC4 and its peripheral

circuit.

14

Page 14

3. The base and handset cannot be connected.

Check whether the base

is able to set in the test

mode 1.

OK

Check the TX POWER

and the TX FREQ UENCY

on the base unit.

OK

Press “PAGE” key twice,

check whether deviation

of the TX data is app. 8

kHz Dev.

OK

Press “PAGE” key 7

times, 902.952467 MHz

(250 Hz ±8 kHz Dev.)

1mV output signal from

RF jack is applied.

Can the IN USE LED be

lighted?

OK

NGACheck IC4 and its

peripheral circuit.

NG

Check base RF unit.

NG Check whether there is a

250 Hz data wavef orm at

C80.

OK

Check base RF unit.

NG Check whether there is a

250 Hz data wavef orm at

pin 9 of IC3.

OK

Check whether there is a

250 Hz data wavef orm at

the Q2 collector.

OK

Check RT3, R53, R70,

NG

R68, R69, R28, C35,

C80 and C89.

Check base RF unit and

NG

the peripheral circuit of

IC3.

Check RT2, Q2 and their

NG

peripheral circuit.

Check whether the

handset is able to set in

the test mode 1.

OK

Check the TX POWER

and the TX FREQ UENCY

on the handset unit.

OK

Check whether there is a

250 Hz data wavef orm at

pin 23 of IC2.

Check IC2 and its

peripheral circuit.

Check IC603 and its

NG

peripheral circuit.

NG

Check handset RF unit.

OK

Check IC1 and their

NG

peripheral circuit.

15

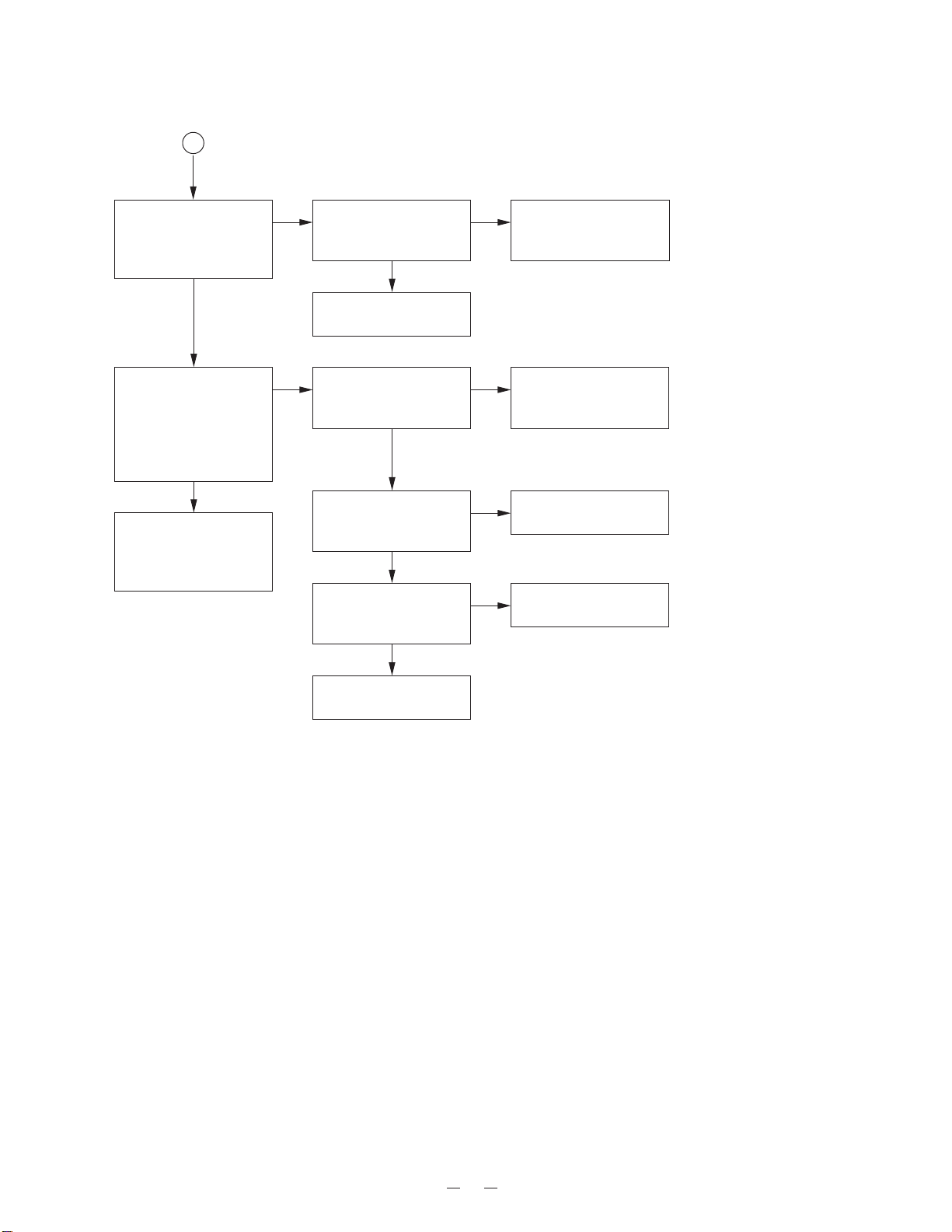

Page 15

A

Press “3” key, check

whether deviation of the

TX data is app. 8 kHz

Dev.

OK

Press “6” key,

926.997467 MHz (250

Hz ±8 kHz Dev.) 1mV

output signal from RF

jack is applied. Check

whether the bell ring.

OK

Place the handset on the

base to charge about 5

seconds, then connect

again.

NG Check whether there is a

250 Hz data wavef orm at

C669.

OK

Check handset RF unit.

Check whether the 250

NG

Hz data waveform from

pin 9 of IC606 is fed.

OK

Check whether there is a

250 Hz data wav eform at

the Q601 collector.

OK

Check whether there is a

250 Hz data wav eform at

pin 55 of IC603.

OK

Check R635, R636,

NG

R634, R632, R619,

C610, C669 and RT603.

Check handset RF unit

NG

and the peripheral circuit

of IC606.

Check RT602, Q601 and

NG

their peripheral circuit.

Check IC601 and their

NG

peripheral circuit.

Check IC603 and its

peripheral circuit.

16

Page 16

4. Cannot make a phone call (pulse).

Can the base and handset

be connected?

OK

While in TALK MODE, press

dial key of the handset.

Check whether square

waveform from pin 1 of IC2

is fed.

OK

Check Q10, RL1 and their

peripheral circuits.

NG

NG

See 3. The base and handset

cannot be connected.

Check IC2.

5. Cannot make a phone call (tone).

Can the base and handset be

connected?

OK

NG

See 3. The base and handset

be cannot be connected.

While in TALK MODE, press

dial key of the handset.

Can tone waveform from Pin

20 of IC8 is fed?

OK

Can tone signal be heard

from the handset speaker?

OK

Check the base TEL-line

circuit and RELAY control

circuit.

NG

NG

Check IC8.

Check IC1, Q3 and their

peripheral circuits.

17

Page 17

6. Voice cannot be transmitted to other party (outgoing call).

Can the base and handset be

connected?

OK

The 1 kHz, 9.0mV sine

waveform is applied to

+

MC601

sine waveform from pin 24 of

IC601 be fed?

Check whether there is the

1 kHz sine waveform at

pin 20 of IC601.

Check whether there is the

1 kHz sine waveform at

C669.

TX output signal from the

handset is detected by the

liner detector, can the 1 kHz

sine waveform be fed?

side, can the 1 kHz

OK

OK

OK

OK

NG

NG

NG

NG

NG

See 3. The base and handset

cannot be connected.

Check Q604 and its

peripheral circuit.

Check IC601 and its

peripheral circuit.

Check RT603 and its

peripheral circuit.

Check handset RF unit.

Check whether there is the

1 kHz sine wave form at pin 9

of IC3 on the base unit.

OK

Check whether there is the

1 kHz sine wave form at pin 3

of IC1.

OK

Check whether there is the

1 kHz sine waveform at

pin 18 of IC1.

OK

Check whether there is the

1 kHz sine waveform at the

Q3 collector.

OK

Check whether the 1 kHz sine

waveform from TEL-line

output is fed.

OK

Check MC601 of handset.

NG

NG

NG

NG

NG

Check base RF unit and the

peripheral circuit of IC3.

Check RT2, Q2 and their

peripheral circuits.

Check IC1 and its

peripheral circuit.

Check Q3 and its peripheral

circuit.

Check T1, RL1 and their

peripheral circuits.

18

Page 18

7. The voice of the caller cannot be heard (incoming call).

Can the base and handset be

connected?

OK

The 1 kHz, 77.5mV sine

waveform is applied to TELline of the base, can the 1 kHz

sine waveform from the Q3

collector be fed?

OK

Check whether there is the

1 kHz sine waveform at

pin 24 of IC1.

OK

Check whether there is the

1 kHz sine waveform at

pin 20 of IC1.

OK

Check whether there is the

1 kHz sine waveform at C80.

OK

TX output signal from the

base is detected by the liner

detector, can the 1 kHz sine

waveform be fed?

OK

NG

NG

NG

NG

NG

NG

See 3. The base and handset

cannot be connected.

Check the base TEL-line

circuit and REPLAY control

circuit.

Check Q4 and its peripheral

circuit.

Check C1 and its peripheral

circuit.

Check RT3 and its

peripheral circuit.

Check base RF unit.

Check whether there is the

1 kHz sine wave f o rm at pin 9

of IC606 on the handset unit.

OK

Check whether there is the

1 kHz sine wave f o rm at pin 3

of IC601.

OK

Check whether there is the

1 kHz sine waveform at the

pin 18 of IC601.

OK

Check whether there is the

1 kHz sine wavef orm at R678

or R708.

OK

Check SP801 and WA801,

WA802.

NG

NG

NG

NG

Check handset RF unit and

the peripheral circuit of IC606.

Check RT602, Q601 and

their peripheral circuits.

Check IC601 and its

peripheral circuit.

Check Q602, Q603 and its

peripheral circuit.

19

Page 19

IC AND TRANSISTOR VOLTAGE CHART

Base Unit Unit[V] Unit[V]

Ref. No. PIN STBY TALK NOTE Ref. No. PIN STBY TALK NOTE

1 1.7V DC 1.7V DC

2 1.7V DC 1.7V DC

3 1.7V DC 1.7V DC

4 0.7V DC 1.7V DC

5 1.7 VDC 1.7V DC

6 1.7V DC 1.7V DC

7 1.7V DC 1.7V DC

8 3.2V 3.2V

9 0V 0V GND

10 0-3.2V 0-3.2V PULSE

11 0V 0V GND

IC1 12 1.7V DC 1.7V DC

13 3.2V DC 3.2V DC Vcc

14 1.7V DC 1.7V DC

15 1.7V DC 1.7V DC

16 0‚u DC 3.2V DC RXMUTE

17 0V DC 3.2V DC TXMUTE

18 1.7V DC 1.7V DC

19 1.7V DC 1.7V DC

20 1.7V DC 1.7V DC

21 0.6V DC 0.6V DC

22 1.7V DC 1.7V DC

23 1.7V DC 1.7V DC

24 1.7V DC 1.7V DC

1 0V 3.2V DC T ALK

2 0V 3.2V DC TONE

3 0V 3.2V DC

40V 0V

50V 0V

60V 0V

7 0V 3.2V DC TXMUTE

8 0V 3.2V DC RXMUTE

90V 0V

IC2 10 3.2V DC 3.2V DC VDD

11 2.7V DC 0.1V DC

12 1.0V DC 1.0V DC

13 0V 0V

14 0V 0V

15 3.2V DC 0.1V DC LED1

16 3.2V DC 0.1V DC LED2

17 0V 0V

18 0V 0V

19 0V 3.1V DC

20 3.2V DC 3.2V DC

IC2 42 0V 0V GND

21 2.6V DC 2.6V DC

22 0-3.2V DC 0V SQ

23 3.2V DC 3.2V DC

24 3.2V DC 3.2V DC VDD

25 0V 0V

26 0V 0V

27 0V 0V

28 0V 0V

29 0V 0V

30 0V 0V

31 3.2V DC 3.2V DC

32 3.2V DC 3.2V DC

33 0V 0V GND

34 3.2V DC 3.2V DC

35 3.2V DC 3.2V DC

36 3.2V DC 3.2V DC

37 3.2V DC 3.2V DC

38 0V 0V GND

39 0V 0V GND

40 0.3-3.0V 0.3-3.0V SINE WAVE

41 0.4-2.4V 0.4-2.4V SINE WAVE

43 0V 0V

44 0V 0V

45 0V 0V

46 0V 0V

47 2.4V DC 2.4V DC

48 3.1-3.2V 3.1-3.2V PULSE

49 0V 0V

50 2.7V DC 2.7V DC

51 0V 0V

52 0V 0V

53 0V 0V

54 0V 0V

55 0V 0V

56 0V 0V

57 0V 0V

58 0V 0V

59 0V 0V

60 0V 0V

61 0V 0V

62 0V 0V

63 0V 0V

64 0V 0V

20

Page 20

Unit[V] Unit[V]

Ref. No. PIN STBY TALK NOTE Ref. No. PIN STBY TALK NOTE

1 2.6-3.8V 2.6-3.8V SINE WA VE

2 3.4-4.2V 3.4-4.2V SINE WA VE

3 2.6V DC 2.4-3.0V PULSE

4 3.2V DC 3.2V DC Vcc

5 2.8V DC 2.5-3.0V SINE W AVE

6 2.8V DC 2.8V DC

7 2.8V DC 2.8V DC

IC3 8 3.2‚u DC 3.2‚u DC

90V 0V

10 0.6V DC 0.6V DC

11 0.7V DC

12 0.6V DC 0.8V DC

13 3.2V DC 0V DC

14 0‚u DC 0V DC

15 0V DC 0V DC

16 3.2V DC 300mVp-p SINE WAVE

10V 0V

IC4

IC5 10 5.0V DC 5.0V DC

IC6 2 3.2V DC 3.2V DC

20V 0V

30V 0V

4 3.2V DC 3.2V DC

1 2.5V DC 2.5V DC

2 2.5V DC 2.5V DC

3 2.5V DC 2.5V DC

4 2.5V DC 2.5V DC

5 0V 0V GND

6 1.8-2.5V 1.8-2.5V SINE WA VE

7 0.5-4.5V 0.5-4.5V SINE WA VE

8 0V 0V GND

9 5.0V DC 5.0V DC

11 5.0V DC 5.0V DC

12 0V 0V

13 0V 0V

14 5.0V DC 5.0V DC

15 5.0V DC 5.0V DC

16 5.0V DC 5.0V DC

17 0V 0V

18 2.5V DC 2.5V DC

19 2.5V DC 2.5V DC

20 2.5V DC 2.5V DC

1 3.2V DC 3.2V DC

30V 0V

IC8 10 0-3.2V 0-3.2V

Q1 C 2.1V DC 580mVp-p SINE WAVE

Q2 C 1.7V DC 1.7V DC

Q3 C 4.3V DC 4.3V DC

Q4 C 2.1V DC 2.1V DC

Q6 C 3.2V DC 3.2V DC

Q7 C 9V DC 9V DC

Q8 C 0V 0V

Q9 C 3.2V DC 3.2V DC

1 3.2V DC 3.2V DC

2 1.2V DC 1.2V DC

30V 0V

4 2.8V DC 2.8V DC

5 2.8V DC 2.8V DC

60V 0V

7 0V 0V GND

80V 0V

9 3.0Vpp 3.0Vpp SINE WAVE

11 0V 0V

12 3.2V DC 3.2V DC

13 0V 0V

14 0V 0V

15 0V 0V

16 0V 0V

17 2.8V DC 2.8V DC

18 0V 0V

19 0V 0V

20 1.2V DC 1.2V DC

E 0V 0V GND

B 0.8V DC 0.8V DC

E 0.3 VDC 0.3 VDC

B 0.9V DC 0.9V DC

E 0.7V DC 0.7V DC

B 1.3V DC 1.3V DC

E 1.1V DC 1.1V DC

B 1.7V DC 1.7V DC

E 0V 0V GND

B0V 0V

E 5.2V DC 5.2V DC

B 6V DC 6V DC

E0V 0V

B 0.9V DC 0.9V DC

E 0V 0V GND

B0V 0V

21

Page 21

Unit[V]

Ref. No. PIN STBY TALK NOTE

E 0V 0V GND

Q10 C 9V DC 0V

B 0V 0.8V

E 3.2V DC 3.2V DC

Q11 C 5.2V DC 5.2V DC

B 3.8V DC 3.8V DC

E 2.6V DC 2.6V DC

Q16 C 0V 2.6V DC

B 2.5V DC 2.2V DC

22

Page 22

Handset Unit[V] Unit[V]

Ref. No. PIN STBY TALK NOTE Ref. No. PIN STBY TALK NOTE

1 0-2.8V 1.9V DC

2 0-2.8V 1.9V DC

3 -0.2-2.6V 1.6V DC

4 0.4-0.8V 0.6V DC

5 0.4-1.5V 1.5V DC

6 0.4-1.5V 1.5V DC

7 0-2.0V 1.9V DC

8 0-3.0V 0V DC

9 0V DC 0V DC GND

10 0-3.0V 0-3.0V PULSE

11 0V DC 0V DC GND

IC601 12 0-1.5V 1.5V DC

13 0-3.0V 3.0V DC

14 0-1.5V 1.5V DC

15 0-1.5V 1.5V DC

16 0V DC 3.0V DC RXMUTE

17 0V DC 3.0V DC TXMUTE

18 0-1.5V 1.5V DC

19 0-15.V 1.5V DC

20 0-1.5V 1.5V DC

21 1.0-4.0V 0.7V DC

22 1.6V DC 1.5V DC

23 1.6V DC 1.5V DC

24 1.6V DC 1.5V DC

1 0-2.9V 2.9V DC

2 0V DC 0V DC GND

IC602 3 0-1.2V 1.2V DC

4 0-3.0V 3.0V DC

5 3.8V DC 3.8V DC

1 3.0V DC 3.0V DC

2 0V DC 0V DC

3 0V DC 0V DC

4 0V DC 0V DC

5 0V DC 0V DC

6 0V DC 0V DC

7 0V DC 0V DC

IC603 8 3.0V DC 0V DC CONV

9 0V DC 0V DC

10 0-3.0V 0/3V SP-V OL

11 3.0V DC 3.0V DC VCC

12 0V DC 0V DC

13 0V DC 0V DC GND

14 3.2V DC 3.2V DC BATSAVE

15 3.2V DC 3.2V DC

IC603 38 3.2V DC 3.2V DC BATLOW

16 0V DC 0V DC

17 1.4-3.0V 3.0V DC W/U

18 0V DC 0V DC GND

19 3.0V DC 3.0V DC RST

20 0V DC 0V DC GND

21 0V DC 0V DC GND

22 0.3-1.9V 0.3-1.9V SINE WAVE

23 0-3.0V 0-3.0V SINE WA VE

24 0V DC 0V DC GND

25 0V DC 0V DC

26 0V DC 2.9V DC LCD27 0V DC 2.9/0V SP-VOL2

28 0V DC 2.9V DC MIC-ON

29 0V DC 2.9V DC LCDRS

30 0V DC 2.9V DC RESET

31 0V DC 2.9V DC LCDV

32 0V DC 0V DC

33 2.9V DC 2.9V DC

34 0V DC 0V DC

35 2.9V DC 2.9V DC

36 0V DC 0V DC

37 0V DC 0V DC

39 0V DC 0V DC

40 0V DC 0V DC

41 0-2.9V 0V DC SQ-IN

42 0-2.9V 2.9V DC SC

43 0V DC 0/2.9V RINGVOL

44 0-2.5V 0V DC TXB

45 0V DC 0V DC

46 0-2.9V 0V DC

47 0-2.9V 0V DC

48 0-2.9V 2.9V DC

49 0V DC 0V DC GND

50 0V DC 2.9V DC TXMUTE

51 2.9V DC 2.9V DC LCDSCL

52 0V DC 0-2.9V PULSE

53 0V DC 0V DC

54 0V DC 2.9V DC

55 0-2.9V 0-2.9V PULSE

56 3.0V DC 3.0V DC

57 0V DC 0-2.9V PULSE

58 0V DC 0V DC

59 0V DC 0V DC

23

Page 23

Unit[V] Unit[V]

Ref. No. PIN STBY TALK NOTE Ref. No. PIN STBY TALK NOTE

60 0V DC 0V DC

61 3.0V DC 3.0V DC

IC603 62 3.0V DC 3.0V DC

63 3.0V DC 3.0V DC

64 3.0V DC 3.0V DC

1 3.2V DC 3.2V DC

IC604 2 3.8V DC 3.8V DC

3 0V DC 0V DC

1 3.2V DC 3.2V DC

2 3.8V DC 3.8V DC

IC605 3 0V DC 0V DC

4 3.8V DC 3.8V DC

5 3.2V DC 3.2V DC

1 0-3.7V 2.3-3.7V SINE W A VE

2 0-2.9V 2.2-2.9V SINE W A VE

3 0-2.5V 2.2-2.8V

4 3.0V DC 3.0V DC

5 0-2.5V 2.3-2.8V

6 0-2.5V 2.5V DC

7 0-2.5V 2.5V DC

IC606 8 0-3.0V 2.8V DC

9 0-1.5V 0.5-1.0V SINE W A VE

10 0-0.7V 0.6V DC

11 0-0.7V 0.6V DC

12 0-0.7V 0.8V DC

13 0V DC 0V DC

14 0V DC 0V DC

15 0V DC 0V DC

16 0-3.0V 2.6-3.2V SINE WA VE

1 0V DC 0V DC

2 0V DC 0V DC

3 0V DC 0V DC

IC608 4 0V DC 0V DC

5 0-3.0V 3.0V DC

6 0V DC 0V DC

7 0V DC 0V DC

8 0-3.0V 3.0V DC

1 0V DC 0V DC

IC609 2 3.8V DC 3.8V DC

3 3.2V DC 3.2V DC

E 0V DC 0V DC

Q600 C 0V DC 0V DC

B 0V DC 0.7V DC

Q601 C 0-2.0V 1.9V DC

Q602 C 0-0.2V 1.5V DC

Q603 C 0V DC 1.6V DC

Q604 C 0V DC 1.7V DC

Q609 C 0V DC 3V DC

Q610 C 3.2V DC 0V DC

Q611 C 3.2V DC 2.9V DC

Q612 C 0-2.2V 1.5-2.5V SINE WA VE

Q613 C 0.3V 3.0V DC

Q614 C 2.4V DC 2.4V DC

Q616 C 3.8V DC 3.8V DC

Q617 C 0V DC 0V DC

E 0-0.4V 1.0V DC

B 0-1.0V 0.3V DC

E 0V DC 0.7V DC

B 0V DC 1.3V DC

E 0V DC 0.6V DC

B 0V DC 1.3V DC

E 0V DC 0.7V DC

B 0V DC 1.2V DC

E 0-0.3V 0V DC

B 0-3.0V 2.3V DC

E 0V DC 3.2V DC

B 0V DC 0V DC

E 0V DC 0V DC

B 0V DC 0V DC

E 0V DC 0V DC

B 0-0.7V 0.7 DC

E 0-3.0V 3.0V DC

B 0-2.5V 2.2V DC

E 0V DC 0V DC

B 0V DC 0V DC

E 0V DC 0V DC

B 0V DC 0V DC

E 0V DC 0V DC

B 0V DC 0V DC

24

Page 24

Base Unit

SEMICONDUCTOR LEAD IDENTIFICATION

D1/D4/D5/D9/D10

/D12/D15/D16/D17 : 1N4148

D3 : HZ33-2

D11 : HZ6B2

D13 : HZ4B1

Anode

Cathode

Q7 / Q8 / Q11 : 2SD471

E

C

B

IC1

LA8634VU

PRE. IN24

PRE. NF23

CMP. NF22

CMP. VREC21

CMP. OUT20

LPF2 IN19

LPF2 OUT18

CMP. MUTE CONT17

EXP. MUTE CONT16

TX. DATA IN15

VREF14

D2 : HZK7C

Cathode

IC2

µPD780024AGC

VCC13

P50/A8

P51/A9

P52/A10

P53/A11

P54/A12

P55/A13

P56/A14

P57/A15

SS0

V

DD0

V

P30

P31

P32

P33

P34/SI31

P35/SO31

D6 : MVR3338ST-922

Anode

Anode

P47/AD764

P46/AD663

P45/AD562

P44/AD461

P43/AD360

1

2

3

4

5

6

7

8

9

10

11

12

17P36/SCK31

18P20/SI30

19P21/SO30

20P22/SCK30

21P23RxD0

P42/AD259

P41/AD158

P40/AD057

22P24/TxD0

23P25/ASCK0

24V

Cathode

P67/ASTB56

P66/WAIT55

25AVSS26P17/ANI7

Q1 : 2SC2714

Q2/Q4/Q6/Q9 : 2SC1623

Q3/Q10 : 2SC2712

Q16 : 2SA812(M)

B

E

B : Base

E : Emitter

C : Collector

P75/BUZ5229P14/ANI4

P74/PCL5130P13/ANI3

P73/TI51/TO515031P12/ANI2

P65/WR54

P64/RD53

27P16/ANI6

28P15/ANI5

P72/TI50/TO504932P11/ANI1

42

3514

3415

C

P71/TI0148

P70/TI00/TO047

P03/INTP3/ADTRG46

P02/INTP245

P01/INTP144

P00/INTP043

SS1

V

X141

X240

IC39

XT138

XT237

RESET3613

DD

AV

REF

AV

P10/ANI03316

1LPF1 IN

2LPF1 OUT

3EXP. IN

4EXT. VREC

IC3

MC3361CDR2

Mixer Input16Ground15Audio Mute14Scan Control

1

2

3

Crystal Osc

Mixer Output

5INT. OUT

6TEL. OUT

Squelch Input

13

12

4

5

Vcc

Limiter Input

7V. HOLD

8INTC. CONT

9CHARGE CONT

10FSK OUT

11GND

12ST. BY

Filter Output

Filter Input10Demodulator Output

9

11

6

7

8

Ouad Coil

Decoupling

IC4

PS2501

1

23

4

IC6

XC61CC2802PR

/XC61AC2802PR

IC5

SM8224BM-E2

DT120

DT219

18

DTQ

S017

S116

VDD15

TO14

13

CR

DTDET12

STR11

RING

MODE 8

1AGND

2TIP

3

4TRQ

5GND

6OSCIN

7OSCOUT

9TEST

10DOUT

Vout

Vin

DD1

Vss

IC8

LC7366NM

DD

1V

2XMIT

3

4C1

5C2

6C3

SS

7V

8

9OSCI

10OSCO

TONE OUT20

CD19

18

R117

R216

R315

R414

13

MUTE12

C411

25

Page 25

Handset

D602/D604

/D606/D607 : RLS4148

D608/D609 : HZK6C

D610/D611 : 1SS226

Cathode / Anode

D612/D613/D614 :

EMPG4868K-8C0

D615 : RB420D

Cathode

Cathode

Anode

Q600/Q601/Q602/Q603/Q604

/Q610/Q611/Q616/Q617 : 2SC1623

Q609/Q613 : 2SA812(M)

Q612 : 2SC2714

Q614 : 2SC2712

B

E

B : Base

E : Emitter

C : Collector

C

IC603

MB89538PFM

64 P45/INT25

63 P44/INT24

62 P43/INT23

61 P42/INT22

60 P41/INT21

19RST

20MOD0

21MOD1

59 P40/EC/INT20

22X0

1P46/INT26

2P47/INT27

3P50

4P51

5P52

6P53

7P54

8P55

9P56

10P57

11Vcc

12Vcc

17P63/INT13

18P64

Vcc55P3454

58 P37/PTO1

57 P36/WTO

56

23X1

24Vss

25P27

P35/PWC

P33/SI1(UI1)53

26P26

27P25

28P24

Cathode Anode

Anode

IC601

LA8634VU

PRE. IN24

PRE. NF23

CMP. NF22

1LPF1 IN

2LPF1 OUT

3EXP. IN

P32/SO1(UO1)5229P23

P31/SCK1(UCK1)5130P22

P30/PPG03/MCO5031P21

NC4932P20/PWCK

P0048

P0147

P0246

P0345

P0444

P0543

P0642

P0741

P1040

P1139

P1238

P1337

P143613Vss

P153514P60/INT10

P163415P61/INT11

P173316P62/INT12

Cathode

CMP. VREC21

CMP. OUT20

LPF2 IN19

4EXT. VREC

5INT. OUT

6TEL. OUT

LPF2 OUT18

CMP. MUTE CONT17

EXP. MUTE CONT16

TX. DATA IN15

7V. HOLD

8INTC. CONT

9CHARGE CONT

10FSK OUT

IC606

MC3361CDR2

1

IC602

TK11130SCL

VREF14

VCC13

11GND

12ST. BY

Mixer Input16Ground15Audio Mute14Scan Control

13

2

3

4

Vcc

Crystal Osc

Mixer Output

(open)Anode

Vin5

1on/off Control

Squelch Input

Filter Output

Filter Input10Demodulator Output

11

6

7

Decoupling

9

8

12

5

Limiter Input

2GND

Ouad Coil

Vout4

3Np(Vref)

IC605

XC612N3328MR

25

DET

V

1V

1

DET

IC608

IC609 : RH5RE32AA

24LC16BT/SN

24

IN

V

2V

3V

1

SS

IN

1A0

2A1

4Vss

Vcc8

WP7

6

SCLA2 3

SDA5

3

2

1

26

Page 26

Base Unit

Main PCB

ELECTRICAL PARTS LOCATION

27

Page 27

Handset

Main PCB

28

Page 28

Base Unit

WIRING DIAGRAMS

29

Page 29

Handset

30

Page 30

EXPLODED VIEWS AND MECHANICAL PARTS LIST

Base Unit

8

6

3

10

15

4

12

MAIN PCB ASSY

9

12

12

1

11

14

RF MODULE

(BASE)

2

13

7

13

5

31

ANTENNA

Page 31

Base Unit

LOC.

NO. NO.

PART NO.

1 RC009453 GNBZ447684A BUTTON, PUSH ABS 1

2 RC009447 GCAS347682Z CASE, BOTTOM ABS 1

3 RC009525 GCAS347692Z CASE, TOP ABS 1

4 RC009325 HTML446079Z CHARGE TERMINAL C5191(PBP) 2

5 RC009327 LFUT441122Z FOO T 2

6 RC009450 GCAS447683Z HOOK ABS 1

7 RC009531 PLBB448213A LABEL, BARCODE 1

8 RC009534 PLBZ448214Z LABEL, INDICATION 1

9 RC009535 PLBZ448215Z LABEL, TA POLYESTER 1

10 RC009313 GCAS446076Z LED LENS PMMA 1

11 RC008289 SSCW192005N SCREW, BIND HD + M2×5 NI 4

12 RC000941 SSCW802608N SCREW, P TIGHT BIND HD + D2.6×8 NI 7

13 RC004028 SSCW802616N SCREW, P TIGHT BIND HD + D2.6×16 NI 4

14 RC001752 SSCW283012N SCREW, TAPPING BIND+& SP WASHER D3×12 NI 1

15 RC009338 RUTC442550Z WOOL CO ATED PAPER, WOOL TACK 1

REF.

DESCRIPTION QTY

32

Page 32

Handset

9

11

23

MAIN PCB ASSY

24

6

1

RF MODULE

22

(HANDSET)

23

12

23

23

17

7

21

2

20

16

15

19

18

4

13

3

10

8

5

14

33

Page 33

Handset

LOC.

NO. NO.

PART NO.

1 RC008346 RBLD442400Z BLIND PC 1

2 RC009366 RBLD447533Z BLIND PC 1

3 RC009530 GNBZ447699Z BUTTON, FUNCTION ABS 1

4 RC009528 GNBZ447696Z BUTTON, FUNCTION (COMP) ABS 1

5 RC009526 GCAS347694Z CASE, FRONT ABS 1

6 RC009449 GCAS347686A CASE, REAR ABS 1

7 RC009326 HTML446093Z CHARGE TERMINAL C2680(BSP) 2

8 RC008703 GCAS457897Z COVER ELASTOMER 1

9 RC009451 GCAS447687A COVER, BATTER Y ABS 1

10 RC008348 RCUN442433Z CUSHION NEOPRENE 1

11 RC009337 RCUN447997Z CUSHION MOLTOPREN 1

12 RC005609 RCUN451805Z CUSHION NEOPRENE 1

13 RC008466 RCUN459780Z CUSHION NEOPRENE 1

14 RC009527 GCAS447695Z DISPLA Y WINDOW PMMA 1

15 RC009328 LHDZ446090Z DUAL HOLDER EPDM 1

16 RC009356 GHDZ444918A HOLDER, DISPLAY PC 1

17 RC009316 GHDZ346084Z HOLDER, SPEAKER ABS 1

18 RC009329 LNBZ346091Z KEY RUBBER SI 1

19 RC009533 PLBS448216Z LABEL, ID 1

20 RC008457 RETC459777Z REFLECTION SHEET 1

21 RC008289 SSCW192005N SCREW, BIND HD + M2×5 NI 2

22 RC009367 SSCW802008N SCREW, P TIGHT BIND HD + D2×8 NI 2

23 RC000941 SSCW802608N SCREW, P TIGHT BIND HD + D2.6×8 NI 8

24 RC003327 SSCW802610N SCREW, P TIGHT BIND HD + D2.6×10 NI 2

REF.

DESCRIPTION QTY

34

Page 34

PARTS LIST

PRODUCT SAFETY NOTE : Products marked with a have special characteristics important to safety.

Before replacing any of these components, read carefully the product safety notice of this service manual.

Don't degrade the safety of the product through important servicing.

Symbol F G J K M N Z P

% ±1 ±2 ±5 ± 10 ±20 ± 30 -20+80 0+100

LOC.

NO. NO.

CAPACITORS

The following codes indicate v ariation of capacitors against temper atures,:

YA=±5%, YB=±10%, YD=+20-30%, YE=+20-50%(-25~+85°C), ZF=+30-80%,(-10~+79°C),

CH=0±60ppm/°C, TH=-470ppm/°C , ±60ppm/°C , B=±10%, F=+30-80%,

SL=+350ppm/°C~-1000ppm/°C, UJ=-750ppm/°C ±120ppm/°C , CJ=0±120ppm/°C , CK=0±250ppm/°C

C1 RC005214 BCMM812214Z CERAMIC M/L (1608) 220PF 50V J CH

C2 RC001807 BCAZ812296Z ELECTROLYTIC 2.2UF 50V M C-156

C3 RC005202 BCML311045Z CERAMIC M/L (1608) 0.1UF 16V K B

C4 RC005420 BCMM811514Z CERAMIC M/L (1608) 150PF 50V J CH

C5 RC005420 BCMM811514Z CERAMIC M/L (1608) 150PF 50V J CH

C6 RC005216 BCMM813304Z CERAMIC M/L (1608) 33PF 50V J CH

C7 RC005217 BCMM813314Z CERAMIC M/L (1608) 330PF 50V J CH

C8 RC005208 BCML814725Z CERAMIC M/L (1608) 0.0047UF 50V K B

C9 RC002229 BCXT511045Z CERAMIC M/L (2125) 0.1UF 25V K B

C10 RC001809 BCAZ814786Z ELECTROLYTIC 0.47UF 50V M C-156

C11 RC001810 BCAZ814796Z ELECTROLYTIC 4.7UF 50V M C-156

C12 RC001810 BCAZ814796Z ELECTROLYTIC 4.7UF 50V M C-156

C13 RC008270 BCML811235Z CERAMIC M/L (1608) 0.012UF 50V K B

C15 RC001809 BCAZ814786Z ELECTROLYTIC 0.47UF 50V M C-156

C16 RC005202 BCML311045Z CERAMIC M/L (1608) 0.1UF 16V K B

C17 RC008731 BCXK311050Z CERAMIC M/L (2125) 1UF 16V Z F

C18 RC008269 BCML316835Z CERAMIC M/L (1608) 0.068UF 16V K B

C19 RC005202 BCML311045Z CERAMIC M/L (1608) 0.1UF 16V K B

C20 RC000777 BCZY0120001 SEMI-CONDUCTOR CZ-120 0.022UF 18V

C21 RC001794 BCAZ111016Z ELECTROLYTIC 100UF 10V M C-156

C22 RC005204 BCML811025Z CERAMIC M/L (1608) 0.001UF 50V K B

C23 RC008020 BCZY0260001 MYLAR METALLIZED CZ-260 0.56UF 250V K

C24 RC005205 BCML811035Z CERAMIC M/L (1608) 0.01UF 50V K B

C25 RC005202 BCML311045Z CERAMIC M/L (1608) 0.1UF 16V K B

C26 RC005202 BCML311045Z CERAMIC M/L (1608) 0.1UF 16V K B

C27 RC005202 BCML311045Z CERAMIC M/L (1608) 0.1UF 16V K B

C28 RC001810 BCAZ814796Z ELECTROLYTIC 4.7UF 50V M C-156

C29 RC004138 BCAZ811006Z ELECTROLYTIC 10UF 50V M C-156

C30 RC005205 BCML811035Z CERAMIC M/L (1608) 0.01UF 50V K B

C31 RC008843 BCML313335Z CERAMIC M/L (1608) 0.033UF 16V K B

C32 RC005220 BCMM816804Z CERAMIC M/L (1608) 68PF 50V J CH

C33 RC004445 BCAZ903316Z ELECTROLYTIC 330UF 6.3V M C-156

PART NO.

REF.

DESCRIPTION

Symbol C D

pF ±0.25 ±0.5

35

Page 35

LOC.

NO. NO.

C34 RC005202 BCML311045Z CERAMIC M/L (1608) 0.1UF 16V K B

C35 RC004369 BCDR811096Z ELECTROLYTIC 1UF 50V M C-292

C36 RC002234 BCXT814735Z CERAMIC M/L (2125) 0.047UF 50V K B

C37 RC008485 BCMM813914Z CERAMIC M/L (1608) 390PF 50V J CH

C38 RC009372 BCML511835Z CERAMIC M/L (1608) 0.018UF 25V K B

C40 RC005216 BCMM813304Z CERAMIC M/L (1608) 33PF 50V J CH

C41 RC008318 BCML815625Z CERAMIC M/L (1608) 0.0056UF 50V K B

C42 RC008318 BCML815625Z CERAMIC M/L (1608) 0.0056UF 50V K B

C43 RC008062 BCMM817092Z CERAMIC M/L (1608) 7PF 50V D CH

C44 RC005204 BCML811025Z CERAMIC M/L (1608) 0.001UF 50V K B

C45 RC008843 BCML313335Z CERAMIC M/L (1608) 0.033UF 16V K B

C46 RC005219 BCMM814704Z CERAMIC M/L (1608) 47PF 50V J CH

C47 RC005205 BCML811035Z CERAMIC M/L (1608) 0.01UF 50V K B

C48 RC005205 BCML811035Z CERAMIC M/L (1608) 0.01UF 50V K B

C49 RC002229 BCXT511045Z CERAMIC M/L (2125) 0.1UF 25V K B

C50 RC001068 BCXT811025Z CERAMIC M/L (2125) 0.001UF 50V K B

C51 RC005204 BCML811025Z CERAMIC M/L (1608) 0.001UF 50V K B

C52 RC001800 BCAZ311016Z ELECTROLYTIC 100UF 16V M C-156

C53 RC005205 BCML811035Z CERAMIC M/L (1608) 0.01UF 50V K B

C54 RC008731 BCXK311050Z CERAMIC M/L (2125) 1UF 16V Z F

C55 RC001796 BCAZ113316Z ELECTROLYTIC 330UF 10V M C-156

C56 RC004445 BCAZ903316Z ELECTROLYTIC 330UF 6.3V M C-156

C57 RC005215 BCMM812704Z CERAMIC M/L (1608) 27PF 50V J CH

C58 RC005215 BCMM812704Z CERAMIC M/L (1608) 27PF 50V J CH

C59 RC004197 BCDR901016Z ELECTROLYTIC 100UF 6.3V M C-292

C60 RC008731 BCXK311050Z CERAMIC M/L (2125) 1UF 16V Z F

C61 RC005275 BCML813925Z CERAMIC M/L (1608) 0.0039UF 50V K B

C62 RC005209 BCMM811002Z CERAMIC M/L (1608) 10PF 50V D CH

C63 RC005210 BCMM811014Z CERAMIC M/L (1608) 100PF 50V J CH

C65 RC001800 BCAZ311016Z ELECTROLYTIC 100UF 16V M C-156

C66 RC005216 BCMM813304Z CERAMIC M/L (1608) 33PF 50V J CH

C67 RC005512 BCKB131025Z CERAMIC 0.001UF 1000V K YB(B)

C68 RC005512 BCKB131025Z CERAMIC 0.001UF 1000V K YB(B)

C69 RC005205 BCML811035Z CERAMIC M/L (1608) 0.01UF 50V K B

C70 RC005202 BCML311045Z CERAMIC M/L (1608) 0.1UF 16V K B

C71 RC001811 BCAZ901016Z ELECTROLYTIC 100UF 6.3V M C-156

C72 RC008392 BCML811835Z CERAMIC M/L (1608) 0.018UF 50V K B

C73 RC005202 BCML311045Z CERAMIC M/L (1608) 0.1UF 16V K B

C74 RC008731 BCXK311050Z CERAMIC M/L (2125) 1UF 16V Z F

C75 RC005202 BCML311045Z CERAMIC M/L (1608) 0.1UF 16V K B

C77 RC008731 BCXK311050Z CERAMIC M/L (2125) 1UF 16V Z F

C78 RC005218 BCMM814091Z CERAMIC M/L (1608) 4PF 50V C CH

C80 RC005210 BCMM811014Z CERAMIC M/L (1608) 100PF 50V J CH

C81 RC005210 BCMM811014Z CERAMIC M/L (1608) 100PF 50V J CH

C82 RC008062 BCMM817092Z CERAMIC M/L (1608) 7PF 50V D CH

C83 RC005210 BCMM811014Z CERAMIC M/L (1608) 100PF 50V J CH

C84 RC005213 BCMM811804Z CERAMIC M/L (1608) 18PF 50V J CH

PART NO.

REF.

DESCRIPTION

36

Page 36

LOC.

NO. NO.

C85 RC005216 BCMM813304Z CERAMIC M/L (1608) 33PF 50V J CH

C86 RC000744 BCKB811025Z CERAMIC 0.001UF 50V K YB(B)

C87 RC005202 BCML311045Z CERAMIC M/L (1608) 0.1UF 16V K B

C88 RC005202 BCML311045Z CERAMIC M/L (1608) 0.1UF 16V K B

C89 RC008146 BCML816825Z CERAMIC M/L (1608) 0.0068UF 50V K B

C90 RC005205 BCML811035Z CERAMIC M/L (1608) 0.01UF 50V K B

C91 RC008752 BCML512735Z CERAMIC M/L (1608) 0.027UF 25V K B

C95 RC005202 BCML311045Z CERAMIC M/L (1608) 0.1UF 16V K B

C600 RC005202 BCML311045Z CERAMIC M/L (1608) 0.1UF 16V K B

C601 RC004347 BCXK514740Z CERAMIC M/L (2125) 0.47UF 25V Z F

C602 RC008319 BCSH904796Z TANTALUM CHIP 4.7UF 6.3V M C-122

C603 RC008319 BCSH904796Z TANTALUM CHIP 4.7UF 6.3V M C-122

C605 RC005216 BCMM813304Z CERAMIC M/L (1608) 33PF 50V J CH

C606 RC008731 BCXK311050Z CERAMIC M/L (2125) 1UF 16V Z F

C607 RC008296 BCSH901006Z TANTALUM CHIP 10UF 6.3V M C-122

C608 RC005202 BCML311045Z CERAMIC M/L (1608) 0.1UF 16V K B

C609 RC008296 BCSH901006Z TANTALUM CHIP 10UF 6.3V M C-122

C610 RC005204 BCML811025Z CERAMIC M/L (1608) 0.001UF 50V K B

C611 RC008731 BCXK311050Z CERAMIC M/L (2125) 1UF 16V Z F

C613 RC008296 BCSH901006Z TANTALUM CHIP 10UF 6.3V M C-122

C614 RC008296 BCSH901006Z TANTALUM CHIP 10UF 6.3V M C-122

C615 RC008296 BCSH901006Z TANTALUM CHIP 10UF 6.3V M C-122

C616 RC004347 BCXK514740Z CERAMIC M/L (2125) 0.47UF 25V Z F

C617 RC004347 BCXK514740Z CERAMIC M/L (2125) 0.47UF 25V Z F

C618 RC008731 BCXK311050Z CERAMIC M/L (2125) 1UF 16V Z F

C619 RC008296 BCSH901006Z TANTALUM CHIP 10UF 6.3V M C-122

C620 RC005205 BCML811035Z CERAMIC M/L (1608) 0.01UF 50V K B

C621 RC005203 BCML512235Z CERAMIC M/L (1608) 0.022UF 25V K B

C622 RC008318 BCML815625Z CERAMIC M/L (1608) 0.0056UF 50V K B

C623 RC005202 BCML311045Z CERAMIC M/L (1608) 0.1UF 16V K B

C624 RC008268 BCML314735Z CERAMIC M/L (1608) 0.047UF 16V K B

C625 RC005205 BCML811035Z CERAMIC M/L (1608) 0.01UF 50V K B

C628 RC005205 BCML811035Z CERAMIC M/L (1608) 0.01UF 50V K B

C629 RC005212 BCMM811504Z CERAMIC M/L (1608) 15PF 50V J CH

C630 RC005212 BCMM811504Z CERAMIC M/L (1608) 15PF 50V J CH

C631 RC008731 BCXK311050Z CERAMIC M/L (2125) 1UF 16V Z F

C632 RC009270 BCDB111016Z ELECTROLYTIC 100UF 10V M C-326

C633 RC005205 BCML811035Z CERAMIC M/L (1608) 0.01UF 50V K B

C634 RC005205 BCML811035Z CERAMIC M/L (1608) 0.01UF 50V K B

C635 RC009270 BCDB111016Z ELECTROLYTIC 100UF 10V M C-326

C636 RC005211 BCMM811204Z CERAMIC M/L (1608) 12PF 50V J CH

C637 RC005205 BCML811035Z CERAMIC M/L (1608) 0.01UF 50V K B

C638 RC005401 BCXT111055Z CERAMIC M/L (2125) 1UF 10V K B

C639 RC008270 BCML811235Z CERAMIC M/L (1608) 0.012UF 50V K B

C640 RC005213 BCMM811804Z CERAMIC M/L (1608) 18PF 50V J CH

C641 RC005205 BCML811035Z CERAMIC M/L (1608) 0.01UF 50V K B

C642 RC005204 BCML811025Z CERAMIC M/L (1608) 0.001UF 50V K B

PART NO.

REF.

DESCRIPTION

37

Page 37

LOC.

NO. NO.

C643 RC005223 BCMS812091Z CERAMIC M/L (1608) 2PF 50V C CK

C644 RC005401 BCXT111055Z CERAMIC M/L (2125) 1UF 10V K B

C645 RC005202 BCML311045Z CERAMIC M/L (1608) 0.1UF 16V K B

C646 RC005205 BCML811035Z CERAMIC M/L (1608) 0.01UF 50V K B

C647 RC005202 BCML311045Z CERAMIC M/L (1608) 0.1UF 16V K B

C648 RC005216 BCMM813304Z CERAMIC M/L (1608) 33PF 50V J CH

C649 RC008447 BCSH312296Z TANTALUM CHIP 2.2UF 16V M C-122

C650 RC005202 BCML311045Z CERAMIC M/L (1608) 0.1UF 16V K B

C651 RC005420 BCMM811514Z CERAMIC M/L (1608) 150PF 50V J CH

C652 RC005420 BCMM811514Z CERAMIC M/L (1608) 150PF 50V J CH

C653 RC005217 BCMM813314Z CERAMIC M/L (1608) 330PF 50V J CH

C654 RC008268 BCML314735Z CERAMIC M/L (1608) 0.047UF 16V K B

C655 RC008268 BCML314735Z CERAMIC M/L (1608) 0.047UF 16V K B

C656 RC005216 BCMM813304Z CERAMIC M/L (1608) 33PF 50V J CH

C657 RC005210 BCMM811014Z CERAMIC M/L (1608) 100PF 50V J CH

C658 RC005208 BCML814725Z CERAMIC M/L (1608) 0.0047UF 50V K B

C659 RC005205 BCML811035Z CERAMIC M/L (1608) 0.01UF 50V K B

C660 RC008319 BCSH904796Z TANTALUM CHIP 4.7UF 6.3V M C-122

C663 RC005209 BCMM811002Z CERAMIC M/L (1608) 10PF 50V D CH

C667 RC005222 BCMS811091Z CERAMIC M/L (1608) 1PF 50V C CK

C668 RC005210 BCMM811014Z CERAMIC M/L (1608) 100PF 50V J CH

C669 RC005210 BCMM811014Z CERAMIC M/L (1608) 100PF 50V J CH

C670 RC005210 BCMM811014Z CERAMIC M/L (1608) 100PF 50V J CH

C675 RC005202 BCML311045Z CERAMIC M/L (1608) 0.1UF 16V K B

C676 RC005204 BCML811025Z CERAMIC M/L (1608) 0.001UF 50V K B

C677 RC005202 BCML311045Z CERAMIC M/L (1608) 0.1UF 16V K B

C678 RC005202 BCML311045Z CERAMIC M/L (1608) 0.1UF 16V K B

C679 RC005202 BCML311045Z CERAMIC M/L (1608) 0.1UF 16V K B

C680 RC005202 BCML311045Z CERAMIC M/L (1608) 0.1UF 16V K B

C681 RC005202 BCML311045Z CERAMIC M/L (1608) 0.1UF 16V K B

C682 RC008731 BCXK311050Z CERAMIC M/L (2125) 1UF 16V Z F

C683 RC005205 BCML811035Z CERAMIC M/L (1608) 0.01UF 50V K B

C684 RC005205 BCML811035Z CERAMIC M/L (1608) 0.01UF 50V K B

C685 RC005209 BCMM811002Z CERAMIC M/L (1608) 10PF 50V D CH

C686 RC005209 BCMM811002Z CERAMIC M/L (1608) 10PF 50V D CH

C687 RC005220 BCMM816804Z CERAMIC M/L (1608) 68PF 50V J CH

C688 RC008515 BCMM815604Z CERAMIC M/L (1608) 56PF 50V J CH

C689 RC008268 BCML314735Z CERAMIC M/L (1608) 0.047UF 16V K B

C692 RC005209 BCMM811002Z CERAMIC M/L (1608) 10PF 50V D CH

C696 RC002229 BCXT511045Z CERAMIC M/L (2125) 0.1UF 25V K B

C697 RC005207 BCML813325Z CERAMIC M/L (1608) 0.0033UF 50V K B

C698 RC005207 BCML813325Z CERAMIC M/L (1608) 0.0033UF 50V K B

C699 RC005289 BCMM815091Z CERAMIC M/L (1608) 5PF 50V C CH

CT1 RC008272 BCTY0076100 TRIMMER CT -076 TZ3Z100FR 10PF

CT601

PART NO.

RC008272 BCTY0076100 TRIMMER CT-076 TZ3Z100FR 10PF

REF.

DESCRIPTION

38

Page 38

LOC.

NO. NO.

DIODES

D1 RC002236 BDAY0246003 1N4148 T-77

D2 RC004851 BDAY0432007 ZENER HZK7C TR

D3 RC002468 BDAY0492008 ZENER HZ33-2 TD

D4 RC002236 BDAY0246003 1N4148 T-77

D5 RC002236 BDAY0246003 1N4148 T-77

D6 RC008274 BDAY1084001 LED MVR3338ST-922

D9 RC002236 BDAY0246003 1N4148 T-77

D10 RC002236 BDAY0246003 1N4148 T-77

D11 RC008885 BDAY0492031 ZENER HZ6B2 TD

D12 RC002236 BDAY0246003 1N4148 T-77

D13 RC008273 BDAY0492036 ZENER HZ4B1 TD

D15 RC002236 BDAY0246003 1N4148 T-77

D16 RC002236 BDAY0246003 1N4148 T-77

D17 RC002236 BDAY0246003 1N4148 T-77

D602 RC001826 BDAY0433001 RLS4148 TE11

D604 RC001826 BDAY0433001 RLS4148 TE11

D606 RC001826 BDAY0433001 RLS4148 TE11

D607 RC001826 BDAY0433001 RLS4148 TE11

D608 RC003195 BDAY0432004 ZENER HZK6C TR

D609 RC003195 BDAY0432004 ZENER HZK6C TR

D610 RC001635 BDAY0274001 1SS226 TE85L

D611 RC001635 BDAY0274001 1SS226 TE85L

D612 RC009347 BDAY1109001 EMPG4868K-8C0

D613 RC009347 BDAY1109001 EMPG4868K-8C0

D614 RC009347 BDAY1109001 EMPG4868K-8C0

D615 RC008448 BDAY1065001 RB420D T146

FIL TERS

FT1 RC008279 BFLY0971001 CERAMIC FL-971 FFE1054NA11UXL

FT2 RC008280 BFLY0977001 CERAMIC FL-977 L TFS455B5

FT601

FT602

IC's

IC1 RC009438 BDEY3972003 LA8634VU-TLM

IC2 RC009520 BDDY1067001 UC2523 UPD780024AGC-550-AB8

IC3 RC004870 BDEY2768003 MC3361CDR2

IC4 RC008277 BDEY2268001 PS2501-1 K

IC5 RC009522 BDEY4007003 SM8224BM-E2

IC6 RC009439 BDEY3980003 XC61CC2802PR/XC61AC2802PR

IC8 RC005516 BDEY1058003 LC7366NM-TP-T2

IC601 RC009438 BDEY3972003 LA8634VU-TLM

IC602 RC008322 BDEY3882003 TK11130SCL

IC603 RC009521 BDD Y1068001 UC2524 MB89538PFM-G-175-BND

IC605 RC008323 BDEY3886003 XC612N3328MR

IC606 RC004870 BDEY2768003 MC3361CDR2

IC608 RC008799 BDEY3181003 24LC16BT/SN

IC609 RC008859 BDEY2927003 RH5RE32AA-T1

PART NO.

RC008279 BFLY0971001 CERAMIC FL-971 FFE1054NA11UXL

RC008280 BFLY0977001 CERAMIC FL-977 LTFS455B5

REF.

DESCRIPTION

39

Page 39

LOC.

NO. NO.

JACKS

J1 RC008992 BJKY1183002 JACK JK-1183 MJ-62J-RD315

J2 RC001094 BJKY0234001 JACK JK-234 DJ13-1

J603 RC001653 BJKY0571001 JACK JK-571 M60-002-020-HKAD

COILS

L2 RC008397 BLZY0136100 INDUCTOR:MOLDED CHIP LZ-136 MLF1608K100KT 10UH

L3 RC008281 BLBY1175001 COIL LB-1175 7002BE-A0026HM

L4 RC008587 BLZY0181107 INDUCTOR:MOLDED CHIP LZ-181 10NH J

L602 RC008397 BLZY0136100 INDUCTOR:MOLDED CHIP LZ-136 MLF1608K100KT 10UH

L603 RC008281 BLBY1175001 COIL LB-1175 7002BE-A0026HM

L604 RC008398 BLZY0181186 INDUCTOR:MOLDED CHIP LZ-181 1.8NH

L606 RC008397 BLZY0136100 INDUCTOR:MOLDED CHIP LZ-136 MLF1608K100KT 10UH

L607 RC008397 BLZY0136100 INDUCTOR:MOLDED CHIP LZ-136 MLF1608K100KT 10UH

T1 RC003234 BTFY0265001 TRANSFORMER:HYBRID TF-265 AT-24E7-1B(295403)

TRANSISTORS

Q1 RC002245 BDBC2714124 DB-718 2SC2714-Y TE85L

Q2 RC003031 BDBC1623648 DB-380 2SC1623-L6 T1B

Q3 RC001637 BDBC2712303 DB-381 2SC2712-GR TE85L

Q4 RC003031 BDBC1623648 DB-380 2SC1623-L6 T1B

Q6 RC003031 BDBC1623648 DB-380 2SC1623-L6 T1B

Q7 RC003200 BDBD0471111 DB-411 2SD471-L

Q8 RC003200 BDBD0471111 DB-411 2SD471-L

Q9 RC003031 BDBC1623648 DB-380 2SC1623-L6 T1B

Q10 RC001637 BDBC2712303 DB-381 2SC2712-GR TE85L

Q11 RC003200 BDBD0471111 DB-411 2SD471-L

Q16 RC008275 BDBA0812695 DB-035 2SA812(M)-M6A T1B

Q600 RC003031 BDBC1623648 DB-380 2SC1623-L6 T1B

Q601 RC003031 BDBC1623648 DB-380 2SC1623-L6 T1B

Q602 RC003031 BDBC1623648 DB-380 2SC1623-L6 T1B

Q603 RC003031 BDBC1623648 DB-380 2SC1623-L6 T1B

Q604 RC003031 BDBC1623648 DB-380 2SC1623-L6 T1B

Q609 RC008275 BDBA0812695 DB-035 2SA812(M)-M6A T1B

Q610 RC003031 BDBC1623648 DB-380 2SC1623-L6 T1B

Q611 RC003031 BDBC1623648 DB-380 2SC1623-L6 T1B

Q612 RC002245 BDBC2714124 DB-718 2SC2714-Y TE85L

Q613 RC008275 BDBA0812695 DB-035 2SA812(M)-M6A T1B

Q614 RC001637 BDBC2712303 DB-381 2SC2712-GR TE85L

Q616 RC003031 BDBC1623648 DB-380 2SC1623-L6 T1B

Q617 RC003031 BDBC1623648 DB-380 2SC1623-L6 T1B

RESISTORS

R1 RC005252 BRFC163314Z CARBON FIXED CHIP 330 1/16W J

R2 RC005245 BRFC161834Z CARBON FIXED CHIP 18K 1/16W J

R3 RC005281 BRFC162224Z CARBON FIXED CHIP 2.2K 1/16W J

R4 RC005288 BRFC168244Z CARBON FIXED CHIP 820K 1/16W J

R5 RC005253 BRFC163324Z CARBON FIXED CHIP 3.3K 1/16W J

R6 RC005241 BRFC161034Z CARBON FIXED CHIP 10K 1/16W J

R7 RC005248 BRFC162234Z CARBON FIXED CHIP 22K 1/16W J

PART NO.

REF.

DESCRIPTION

40

Page 40

LOC.

NO. NO.

R8 RC005311 BRFC160004Z CARBON FIXED CHIP 0 1/16W J

R9 RC005248 BRFC162234Z CARBON FIXED CHIP 22K 1/16W J

R10 RC005248 BRFC162234Z CARBON FIXED CHIP 22K 1/16W J

R11 RC005242 BRFC161044Z CARBON FIXED CHIP 100K 1/16W J

R12 RC005262 BRFC168234Z CARBON FIXED CHIP 82K 1/16W J

R13 RC005257 BRFC164734Z CARBON FIXED CHIP 47K 1/16W J

R14 RC005248 BRFC162234Z CARBON FIXED CHIP 22K 1/16W J

R15 RC005281 BRFC162224Z CARBON FIXED CHIP 2.2K 1/16W J

R16 RC005280 BRFC161534Z CARBON FIXED CHIP 15K 1/16W J

R17 RC003225 BRFC181014Z CARBON FIXED CHIP 100 1/8W J

R18 RC005255 BRFC164714Z CARBON FIXED CHIP 470 1/16W J

R19 RC008091 BRFC165614Z CARBON FIXED CHIP 560 1/16W J

R20 RC005261 BRFC168224Z CARBON FIXED CHIP 8.2K 1/16W J

R21 RC005280 BRFC161534Z CARBON FIXED CHIP 15K 1/16W J

R22 RC005260 BRFC166834Z CARBON FIXED CHIP 68K 1/16W J

R23 RC005259 BRFC166814Z CARBON FIXED CHIP 680 1/16W J

R24 RC002349 BRSJ221034Z METAL OXIDE 10K 1/2WS J

R25 RC009305 BRZY0085001 METAL OXIDE (FORMED) RZ-085 150 1WS J (P=12.5)

R26 RC005249 BRFC162244Z CARBON FIXED CHIP 220K 1/16W J

R27 RC005255 BRFC164714Z CARBON FIXED CHIP 470 1/16W J

R28 RC005603 BRPA618234Z CARBON AXIAL LEAD (26) 82K 1/6W J

R29 RC005241 BRFC161034Z CARBON FIXED CHIP 10K 1/16W J

R30 RC005240 BRFC161024Z CARBON FIXED CHIP 1K 1/16W J

R31 RC005240 BRFC161024Z CARBON FIXED CHIP 1K 1/16W J

R32 RC005257 BRFC164734Z CARBON FIXED CHIP 47K 1/16W J

R33 RC005239 BRFC161014Z CARBON FIXED CHIP 100 1/16W J

R34 RC005256 BRFC164724Z CARBON FIXED CHIP 4.7K 1/16W J

R35 RC008286 BRFC162744Z CARBON FIXED CHIP 270K 1/16W J

R36 RC005239 BRFC161014Z CARBON FIXED CHIP 100 1/16W J

R37 RC005240 BRFC161024Z CARBON FIXED CHIP 1K 1/16W J

R39 RC005240 BRFC161024Z CARBON FIXED CHIP 1K 1/16W J

R40 RC008091 BRFC165614Z CARBON FIXED CHIP 560 1/16W J

R41 RC005258 BRFC164744Z CARBON FIXED CHIP 470K 1/16W J

R42 RC005240 BRFC161024Z CARBON FIXED CHIP 1K 1/16W J

R43 RC008028 BRFC162724Z CARBON FIXED CHIP 2.7K 1/16W J

R44 RC008481 BRFC181514Z CARBON FIXED CHIP 150 1/8W J

R45 RC005256 BRFC164724Z CARBON FIXED CHIP 4.7K 1/16W J

R46 RC005256 BRFC164724Z CARBON FIXED CHIP 4.7K 1/16W J

R47 RC005311 BRFC160004Z CARBON FIXED CHIP 0 1/16W J

R48 RC005240 BRFC161024Z CARBON FIXED CHIP 1K 1/16W J

R49 RC005240 BRFC161024Z CARBON FIXED CHIP 1K 1/16W J

R50 RC005240 BRFC161024Z CARBON FIXED CHIP 1K 1/16W J

R51 RC005256 BRFC164724Z CARBON FIXED CHIP 4.7K 1/16W J

R52 RC004972 BRPA614724Z CARBON AXIAL LEAD (26) 4.7K 1/6W J

R53 RC005283 BRFC162734Z CARBON FIXED CHIP 27K 1/16W J

R54 RC004174 BRPA611024Z CARBON AXIAL LEAD (26) 1K 1/6W J

R55 RC005240 BRFC161024Z CARBON FIXED CHIP 1K 1/16W J

PART NO.

REF.

DESCRIPTION

41

Page 41

LOC.

NO. NO.

R56 RC005240 BRFC161024Z CARBON FIXED CHIP 1K 1/16W J

R57 RC005257 BRFC164734Z CARBON FIXED CHIP 47K 1/16W J

R58 RC005242 BRFC161044Z CARBON FIXED CHIP 100K 1/16W J

R59 RC005241 BRFC161034Z CARBON FIXED CHIP 10K 1/16W J

R60 RC002320 BRFC014714Z CARBON FIXED CHIP 470 1/10W J

R61 RC002915 BRFC011514Z CARBON FIXED CHIP 150 1/10W J

R62 RC008028 BRFC162724Z CARBON FIXED CHIP 2.7K 1/16W J

R63 RC005240 BRFC161024Z CARBON FIXED CHIP 1K 1/16W J

R64 RC005246 BRFC162204Z CARBON FIXED CHIP 22 1/16W J

R65 RC002327 BRFC016804Z CARBON FIXED CHIP 68 1/10W J

R66 RC005242 BRFC161044Z CARBON FIXED CHIP 100K 1/16W J

R67 RC005247 BRFC162214Z CARBON FIXED CHIP 220 1/16W J

R68 RC005242 BRFC161044Z CARBON FIXED CHIP 100K 1/16W J

R69 RC005242 BRFC161044Z CARBON FIXED CHIP 100K 1/16W J

R70 RC005242 BRFC161044Z CARBON FIXED CHIP 100K 1/16W J

R71 RC008732 BRFC161214Z CARBON FIXED CHIP 120 1/16W J

R72 RC005246 BRFC162204Z CARBON FIXED CHIP 22 1/16W J

R73 RC005240 BRFC161024Z CARBON FIXED CHIP 1K 1/16W J

R74 RC005242 BRFC161044Z CARBON FIXED CHIP 100K 1/16W J

R75 RC002799 BRFC181024Z CARBON FIXED CHIP 1K 1/8W J

R76 RC005281 BRFC162224Z CARBON FIXED CHIP 2.2K 1/16W J

R77 RC005257 BRFC164734Z CARBON FIXED CHIP 47K 1/16W J

R78 RC004184 BRPA614734Z CARBON AXIAL LEAD (26) 47K 1/6W J

R79 RC005242 BRFC161044Z CARBON FIXED CHIP 100K 1/16W J

R80 RC008734 BRFC162254Z CARBON FIXED CHIP 2.2M 1/16W J

R81 RC008765 BRFC161004Z CARBON FIXED CHIP 10 1/16W J

R82 RC005285 BRFC165634Z CARBON FIXED CHIP 56K 1/16W J

R83 RC005256 BRFC164724Z CARBON FIXED CHIP 4.7K 1/16W J

R85 RC005258 BRFC164744Z CARBON FIXED CHIP 470K 1/16W J

R86 RC005285 BRFC165634Z CARBON FIXED CHIP 56K 1/16W J

R87 RC005257 BRFC164734Z CARBON FIXED CHIP 47K 1/16W J

R88 RC005242 BRFC161044Z CARBON FIXED CHIP 100K 1/16W J

R89 RC008767 BRFC163344Z CARBON FIXED CHIP 330K 1/16W J

R90 RC003446 BRFC011214Z CARBON FIXED CHIP 120 1/10W J

R91 RC003446 BRFC011214Z CARBON FIXED CHIP 120 1/10W J

R92 RC002295 BRFC011014Z CARBON FIXED CHIP 100 1/10W J

R93 RC005260 BRFC166834Z CARBON FIXED CHIP 68K 1/16W J

R94 RC008286 BRFC162744Z CARBON FIXED CHIP 270K 1/16W J

R95 RC005285 BRFC165634Z CARBON FIXED CHIP 56K 1/16W J

R96 RC005283 BRFC162734Z CARBON FIXED CHIP 27K 1/16W J

R97 RC005283 BRFC162734Z CARBON FIXED CHIP 27K 1/16W J

R98 RC008022 BRPA612744Z CARBON AXIAL LEAD (26) 270K 1/6W J

R99 RC008022 BRPA612744Z CARBON AXIAL LEAD (26) 270K 1/6W J

R100 RC005240 BRFC161024Z CARBON FIXED CHIP 1K 1/16W J

R101 RC005257 BRFC164734Z CARBON FIXED CHIP 47K 1/16W J

R102 RC008029 BRFC163924Z CARBON FIXED CHIP 3.9K 1/16W J

R103 RC003446 BRFC011214Z CARBON FIXED CHIP 120 1/10W J

PART NO.

REF.

DESCRIPTION

42

Page 42

LOC.

NO. NO.

R104 RC005240 BRFC161024Z CARBON FIXED CHIP 1K 1/16W J

R105 RC008029 BRFC163924Z CARBON FIXED CHIP 3.9K 1/16W J

R106 RC008553 BRFC161043Z CARBON FIXED CHIP 100K 1/16W F

R107 RC005280 BRFC161534Z CARBON FIXED CHIP 15K 1/16W J

R108 RC005240 BRFC161024Z CARBON FIXED CHIP 1K 1/16W J

R109 RC005242 BRFC161044Z CARBON FIXED CHIP 100K 1/16W J

R110 RC005240 BRFC161024Z CARBON FIXED CHIP 1K 1/16W J

R111 RC005311 BRFC160004Z CARBON FIXED CHIP 0 1/16W J

R112 RC005434 BRFC163914Z CARBON FIXED CHIP 390 1/16W J

R113 RC005240 BRFC161024Z CARBON FIXED CHIP 1K 1/16W J

R114 RC005240 BRFC161024Z CARBON FIXED CHIP 1K 1/16W J

R115 RC005240 BRFC161024Z CARBON FIXED CHIP 1K 1/16W J

R116 RC005255 BRFC164714Z CARBON FIXED CHIP 470 1/16W J

R117 RC005240 BRFC161024Z CARBON FIXED CHIP 1K 1/16W J

R118 RC005240 BRFC161024Z CARBON FIXED CHIP 1K 1/16W J

R119 RC005240 BRFC161024Z CARBON FIXED CHIP 1K 1/16W J

R120 RC005240 BRFC161024Z CARBON FIXED CHIP 1K 1/16W J

R121 RC005240 BRFC161024Z CARBON FIXED CHIP 1K 1/16W J

R122 RC005311 BRFC160004Z CARBON FIXED CHIP 0 1/16W J

R123 RC005281 BRFC162224Z CARBON FIXED CHIP 2.2K 1/16W J

R124 RC005311 BRFC160004Z CARBON FIXED CHIP 0 1/16W J

R125 RC008091 BRFC165614Z CARBON FIXED CHIP 560 1/16W J

R126 RC002898 BRFC010004Z CARBON FIXED CHIP 0 1/10W J

R127 RC005311 BRFC160004Z CARBON FIXED CHIP 0 1/16W J

R128 RC005311 BRFC160004Z CARBON FIXED CHIP 0 1/16W J

R129 RC002899 BRFC180004Z CARBON FIXED CHIP 0 1/8W J

R130 RC005311 BRFC160004Z CARBON FIXED CHIP 0 1/16W J

R131 RC002898 BRFC010004Z CARBON FIXED CHIP 0 1/10W J

R133 RC005673 BRFC163934Z CARBON FIXED CHIP 39K 1/16W J

R134 RC005311 BRFC160004Z CARBON FIXED CHIP 0 1/16W J

R135 RC005242 BRFC161044Z CARBON FIXED CHIP 100K 1/16W J

R136 RC005311 BRFC160004Z CARBON FIXED CHIP 0 1/16W J

R600 RC005248 BRFC162234Z CARBON FIXED CHIP 22K 1/16W J

R601 RC005256 BRFC164724Z CARBON FIXED CHIP 4.7K 1/16W J

R602 RC005256 BRFC164724Z CARBON FIXED CHIP 4.7K 1/16W J

R603 RC005256 BRFC164724Z CARBON FIXED CHIP 4.7K 1/16W J

R604 RC005281 BRFC162224Z CARBON FIXED CHIP 2.2K 1/16W J

R605 RC005241 BRFC161034Z CARBON FIXED CHIP 10K 1/16W J

R606 RC005241 BRFC161034Z CARBON FIXED CHIP 10K 1/16W J

R607 RC005253 BRFC163324Z CARBON FIXED CHIP 3.3K 1/16W J

R608 RC005248 BRFC162234Z CARBON FIXED CHIP 22K 1/16W J

R609 RC005248 BRFC162234Z CARBON FIXED CHIP 22K 1/16W J

R610 RC008027 BRFC161234Z CARBON FIXED CHIP 12K 1/16W J

R611 RC005280 BRFC161534Z CARBON FIXED CHIP 15K 1/16W J

R613 RC005240 BRFC161024Z CARBON FIXED CHIP 1K 1/16W J

R614 RC005280 BRFC161534Z CARBON FIXED CHIP 15K 1/16W J

R615 RC005247 BRFC162214Z CARBON FIXED CHIP 220 1/16W J

PART NO.

REF.

DESCRIPTION

43

Page 43

LOC.

NO. NO.

R616 RC005280 BRFC161534Z CARBON FIXED CHIP 15K 1/16W J

R617 RC008454 BRFC165604Z CARBON FIXED CHIP 56 1/16W J

R618 RC005242 BRFC161044Z CARBON FIXED CHIP 100K 1/16W J

R619 RC005242 BRFC161044Z CARBON FIXED CHIP 100K 1/16W J

R620 RC005240 BRFC161024Z CARBON FIXED CHIP 1K 1/16W J

R621 RC005240 BRFC161024Z CARBON FIXED CHIP 1K 1/16W J

R622 RC008030 BRFC165624Z CARBON FIXED CHIP 5.6K 1/16W J

R623 RC005249 BRFC162244Z CARBON FIXED CHIP 220K 1/16W J

R624 RC005245 BRFC161834Z CARBON FIXED CHIP 18K 1/16W J

R625 RC005242 BRFC161044Z CARBON FIXED CHIP 100K 1/16W J

R626 RC005240 BRFC161024Z CARBON FIXED CHIP 1K 1/16W J

R627 RC008029 BRFC163924Z CARBON FIXED CHIP 3.9K 1/16W J

R628 RC005288 BRFC168244Z CARBON FIXED CHIP 820K 1/16W J

R629 RC008732 BRFC161214Z CARBON FIXED CHIP 120 1/16W J

R630 RC005240 BRFC161024Z CARBON FIXED CHIP 1K 1/16W J

R631 RC005285 BRFC165634Z CARBON FIXED CHIP 56K 1/16W J

R632 RC005242 BRFC161044Z CARBON FIXED CHIP 100K 1/16W J

R633 RC005240 BRFC161024Z CARBON FIXED CHIP 1K 1/16W J

R634 RC005242 BRFC161044Z CARBON FIXED CHIP 100K 1/16W J

R635 RC005242 BRFC161044Z CARBON FIXED CHIP 100K 1/16W J

R636 RC005283 BRFC162734Z CARBON FIXED CHIP 27K 1/16W J

R637 RC005285 BRFC165634Z CARBON FIXED CHIP 56K 1/16W J

R638 RC005285 BRFC165634Z CARBON FIXED CHIP 56K 1/16W J

R639 RC005284 BRFC163334Z CARBON FIXED CHIP 33K 1/16W J

R640 RC005240 BRFC161024Z CARBON FIXED CHIP 1K 1/16W J

R641 RC005253 BRFC163324Z CARBON FIXED CHIP 3.3K 1/16W J

R642 RC005240 BRFC161024Z CARBON FIXED CHIP 1K 1/16W J

R643 RC005256 BRFC164724Z CARBON FIXED CHIP 4.7K 1/16W J

R644 RC005240 BRFC161024Z CARBON FIXED CHIP 1K 1/16W J

R645 RC005257 BRFC164734Z CARBON FIXED CHIP 47K 1/16W J

R646 RC005258 BRFC164744Z CARBON FIXED CHIP 470K 1/16W J

R647 RC005259 BRFC166814Z CARBON FIXED CHIP 680 1/16W J

R648 RC005281 BRFC162224Z CARBON FIXED CHIP 2.2K 1/16W J

R649 RC005284 BRFC163334Z CARBON FIXED CHIP 33K 1/16W J

R650 RC005281 BRFC162224Z CARBON FIXED CHIP 2.2K 1/16W J

R651 RC005256 BRFC164724Z CARBON FIXED CHIP 4.7K 1/16W J

R652 RC005240 BRFC161024Z CARBON FIXED CHIP 1K 1/16W J

R653 RC005240 BRFC161024Z CARBON FIXED CHIP 1K 1/16W J

R654 RC005280 BRFC161534Z CARBON FIXED CHIP 15K 1/16W J

R655 RC005241 BRFC161034Z CARBON FIXED CHIP 10K 1/16W J

R656 RC005240 BRFC161024Z CARBON FIXED CHIP 1K 1/16W J

R657 RC005241 BRFC161034Z CARBON FIXED CHIP 10K 1/16W J

R658 RC005286 BRFC165644Z CARBON FIXED CHIP 560K 1/16W J

R659 RC005242 BRFC161044Z CARBON FIXED CHIP 100K 1/16W J

R660 RC005247 BRFC162214Z CARBON FIXED CHIP 220 1/16W J

R661 RC005249 BRFC162244Z CARBON FIXED CHIP 220K 1/16W J

R662 RC005252 BRFC163314Z CARBON FIXED CHIP 330 1/16W J

PART NO.

REF.

DESCRIPTION

44

Page 44

LOC.

NO. NO.

R663 RC005255 BRFC164714Z CARBON FIXED CHIP 470 1/16W J

R664 RC005245 BRFC161834Z CARBON FIXED CHIP 18K 1/16W J

R665 RC008028 BRFC162724Z CARBON FIXED CHIP 2.7K 1/16W J

R666 RC005280 BRFC161534Z CARBON FIXED CHIP 15K 1/16W J

R667 RC005288 BRFC168244Z CARBON FIXED CHIP 820K 1/16W J

R668 RC005241 BRFC161034Z CARBON FIXED CHIP 10K 1/16W J

R669 RC005253 BRFC163324Z CARBON FIXED CHIP 3.3K 1/16W J

R670 RC005241 BRFC161034Z CARBON FIXED CHIP 10K 1/16W J

R671 RC005311 BRFC160004Z CARBON FIXED CHIP 0 1/16W J

R672 RC005241 BRFC161034Z CARBON FIXED CHIP 10K 1/16W J

R673 RC005241 BRFC161034Z CARBON FIXED CHIP 10K 1/16W J

R674 RC008765 BRFC161004Z CARBON FIXED CHIP 10 1/16W J

R675 RC005241 BRFC161034Z CARBON FIXED CHIP 10K 1/16W J

R676 RC005256 BRFC164724Z CARBON FIXED CHIP 4.7K 1/16W J

R677 RC005311 BRFC160004Z CARBON FIXED CHIP 0 1/16W J

R678 RC005311 BRFC160004Z CARBON FIXED CHIP 0 1/16W J

R679 RC005248 BRFC162234Z CARBON FIXED CHIP 22K 1/16W J

R680 RC005246 BRFC162204Z CARBON FIXED CHIP 22 1/16W J

R681 RC005239 BRFC161014Z CARBON FIXED CHIP 100 1/16W J

R682 RC005311 BRFC160004Z CARBON FIXED CHIP 0 1/16W J

R683 RC005241 BRFC161034Z CARBON FIXED CHIP 10K 1/16W J

R684 RC005241 BRFC161034Z CARBON FIXED CHIP 10K 1/16W J

R685 RC005240 BRFC161024Z CARBON FIXED CHIP 1K 1/16W J

R686 RC005240 BRFC161024Z CARBON FIXED CHIP 1K 1/16W J

R687 RC005242 BRFC161044Z CARBON FIXED CHIP 100K 1/16W J

R688 RC005281 BRFC162224Z CARBON FIXED CHIP 2.2K 1/16W J

R689 RC005281 BRFC162224Z CARBON FIXED CHIP 2.2K 1/16W J

R690 RC008030 BRFC165624Z CARBON FIXED CHIP 5.6K 1/16W J

R691 RC005257 BRFC164734Z CARBON FIXED CHIP 47K 1/16W J

R693 RC005240 BRFC161024Z CARBON FIXED CHIP 1K 1/16W J

R694 RC005240 BRFC161024Z CARBON FIXED CHIP 1K 1/16W J

R695 RC005240 BRFC161024Z CARBON FIXED CHIP 1K 1/16W J

R696 RC005240 BRFC161024Z CARBON FIXED CHIP 1K 1/16W J

R697 RC005240 BRFC161024Z CARBON FIXED CHIP 1K 1/16W J

R698 RC005240 BRFC161024Z CARBON FIXED CHIP 1K 1/16W J

R699 RC005240 BRFC161024Z CARBON FIXED CHIP 1K 1/16W J

R700 RC002327 BRFC016804Z CARBON FIXED CHIP 68 1/10W J

R701 RC002327 BRFC016804Z CARBON FIXED CHIP 68 1/10W J

R702 RC002327 BRFC016804Z CARBON FIXED CHIP 68 1/10W J

R703 RC005285 BRFC165634Z CARBON FIXED CHIP 56K 1/16W J

R704 RC005285 BRFC165634Z CARBON FIXED CHIP 56K 1/16W J

R705 RC005285 BRFC165634Z CARBON FIXED CHIP 56K 1/16W J

R706 RC005242 BRFC161044Z CARBON FIXED CHIP 100K 1/16W J

R707 RC002899 BRFC180004Z CARBON FIXED CHIP 0 1/8W J

R708 RC002899 BRFC180004Z CARBON FIXED CHIP 0 1/8W J

R709 RC005281 BRFC162224Z CARBON FIXED CHIP 2.2K 1/16W J

R710 RC005311 BRFC160004Z CARBON FIXED CHIP 0 1/16W J

PART NO.

REF.

DESCRIPTION

45

Page 45

LOC.

NO. NO.

R711 RC008734 BRFC162254Z CARBON FIXED CHIP 2.2M 1/16W J

R712 RC005311 BRFC160004Z CARBON FIXED CHIP 0 1/16W J

RT1 RC008287 BRTY0572204 SEMI-FIXED RT-572 NVZ6TL1B204 200KB

RT2 RC004606 BRTY0572104 SEMI-FIXED RT-572 NVZ6TL1B104 100KB

RT3 RC005661 BRTY0572203 SEMI-FIXED RT-572 NVZ6TL1B203 20KB

RT601

RT602

RT603

CR YTSTALS

X1 RC003629 BQXY0542001 CRYSTAL QX-542 3.579545MHZ

X2 RC008285 BQXY0721001 CRYSTAL QX-721 10.1MHZ

X601 RC008453 BQXY0714001 CRYSTAL QX-714 4.192MHZ CSA-309

X602 RC008285 BQXY0721001 CRYSTAL QX-721 10.1MHZ

OTHER ELECTRICAL PARTS

AD901

AT850

B301 RC009431 AC267BHBB RF MODULE (B)

B501 RC009433 AC267BHPB RF MODULE (P)

BT901

DP601

MC601

RL001

S1 RC004253 BSWY0784001 SWITCH SW-784 KSM0611B

S2 RC003604 BSWY0755001 SWITCH:SLIDE SW -755 SBHA12B-06

SP801

W1 RC008998 CUPB013032Z WIRE W-004 UL 1571 #26 7-130- 5 RED

W2 RC008999 CUPK013032Z WIRE W-004 UL 1571 #26 7-130- 5 BLK

W601 RC008329 CZDZ072199Z WIRES ASSEMBLED W-072199

W801 RC009390 CUPJ007011Z WIRE W-004 UL 1571 #26 3- 70- 3 WHT

W802 RC001317 CUPK007011Z WIRE W-004 UL 1571 #26 3- 70- 3 BLK

WA901

Y601 RC004910 BYYY0901001 RINGER YY-901 CB-12AP-03

PACKING PARTS

PART NO.

RC008328 BRTY0569224 SEMI-FIXED RT-569 POZ3AN-1-224N-T00

RC008326 BRTY0569104 SEMI-FIXED RT-569 POZ3AN-1-104N-T00

RC008327 BRTY0569223 SEMI-FIXED RT-569 POZ3AN-1-223N-T00

RC004930 BADY0368001 AC ADAPTOR AD-368 HY-9322

RC009434 BATY0392001 ANTENNA AT-392 AT-40

RC004931 BBTY0403001 BATTERY BT-403 GP60AAK3BMX

RC009351 BDLY0202001 LIQUID CRYSTAL DISPLAY DL-202 NCOG089(NCOG100)

RC004062 BMKY0475001 MICROPHONE MK-475 WM-034BZ

RC000867 BRLY0042001 RELAY RL-042 OMR-108H

RC008336 BSPY0409001 SPEAKER SP-409 DTR169HP-005

RC008231 BWZY1401001 TEL CORD WZ-1401 UNL-020-2GY-214

RC009245 GBCT447691Z WALL MOUNT ABS

RC004688 PLBB454286Z LABEL:BARCODE PAPER

RC009532 PLBB462821Z LABEL:BARCODE PAPER

RC009249 UCZZ01268BZ OWNER'S MANUAL

RC009168 UCZZ69676BA QUICK REFERENCE GUIDE

RC005198 UDZZ73535ZZ CAUTION BELT

RC008351 VNYH1303500 VINYL BAG 300X350X0.05T HIPE

RC008783 VNYL2304060 VINYL BAG 300X400X600X0.07T

RC008353 VNYL3101000 VINYL BAG 100X100X0.1T

RC003649 VNYL3203000 VINYL BAG 200X300X0.1T

RC009236 WBXZ347721Z DISPLAY BOX

RC009536 WCTZ462746Z SHIPPING CARTON BOX

RC004291 WETC420086Z COVER:ANT. EPE

RC009341 WSLV344952Z SLEEVE

REF.

DESCRIPTION

46

Page 46

LOC.

NO. NO.

PART NO.

RC009342 WSLV344953Z SLEEVE

RC009343 WSLV428000Z PACKING BAG(PORT.) MIRA MAT

RC009344 WSLV444958Z SLEEVE

REF.

DESCRIPTION

ASSEMBLY PARTS LIST

NOTE: Following part numbers are not available as replacement parts.

Order parts necessary for repair or contact the Toshiba Factory Service Center.

LOC.

NO. NO.

PART NO.

RC009518 AC268BHBA BASE MAIN PCB ASSEMBLY

RC009519 AC268BHPA HANDSET MAIN PCB ASSEMBLY

REF.

DESCRIPTION

47

Page 47

SPECIFICATIONS

MEASUREMENT CONDITIONS

1. Standard Voltage :Portable Unit .... DC 3.8V ± 0.025V

:Base Unit .... AC 120V ± 3V 60Hz

2. Temperature :25°C ± 5°C

3. Channel FCC CH Portable(TX Frequency) Base(TX Frequency)

1 902.052464MHz 925.997470MHz

2 902.102465MHz 926.047470MHz

3 902.152465MHz 926.097470MHz

4 902.202465MHz 926.147470MHz

5 902.252465MHz 926.197470MHz

6 902.302465MHz 926.247469MHz

7 902.352465MHz 926.297469MHz

8 902.402465MHz 926.347469MHz

9 902.452465MHz 926.397469MHz

10 902.502466MHz 926.447469MHz

11 902.552466MHz 926.497469MHz

12 902.602466MHz 926.547469MHz

13 902.652466MHz 926.597469MHz

14 902.702466MHz 926.647468MHz

15 902.752466MHz 926.697468MHz

16 902.802466MHz 926.747468MHz

17 902.852467MHz 926.797468MHz

18 902.902467MHz 926.847468MHz

19 902.952467MHz 926.897468MHz

20 903.002467MHz 926.947468MHz

21 903.052467MHz 926.997467MHz

22 903.102467MHz 927.047467MHz

23 903.152467MHz 927.097467MHz

24 903.202468MHz 927.147467MHz

25 903.252468MHz 927.197467MHz

26 903.302468MHz 927.247467MHz

27 903.352468MHz 927.297467MHz

28 903.402468MHz 927.347466MHz

29 903.452468MHz 927.397466MHz

30 903.502468MHz 927.447466MHz

31 903.552468MHz 927.497466MHz

32 903.602469MHz 927.547466MHz

33 903.652469MHz 927.597466MHz

34 903.702469MHz 927.647466MHz

35 903.752469MHz 927.697466MHz

36 903.802469MHz 927.747465MHz

37 903.852469MHz 927.797465MHz

38 903.902469MHz 927.847465MHz

39 903.952470MHz 927.897465MHz

40 904.002470MHz 927.947465MHz

4. Tel. Line Voltage/Load : DC 48V ± 2V / 600 OHMS

5. Ring Frequency : 20 Hz

6. Ring Duration : 2 Sec ON, 4 Sec OFF

7. Standard Deviation : 1KHz ± 8KHz Dev.

8. Secure Code : 65536 Combinatin

9. Method of Measurement : According to EIA Standard RS-316A

10. Portable RX AF Load : 150 OHM

48

Page 48

BASE UNIT

RECEIVER

1. Sensitivity 12 dB SINAD with CCITT Filter

2. Frequency Response (Ref:1kHz) 0.3kHz

3.0kHz

3. Distortion at 1 mV RF Input

4. S/N r atio at 1 mV RF Input with CCITT Filter

5. Selectivity (NQ20dB) 6dB Bandwidth +

6dB Bandwidth

6. Image Rejection Ratio SINAD 12dB with CCITT Filter

1st Image

2nd Image

7. Tel Line Output Level (600Ω Load) (Dev: 8kHz)

TRANSMITTER

1. RF Power (50Ω Load)

2. Modulation Sensitivity (Dev: 8kHz)

3. Frequency Response (Ref:1kHz) 0.3kHz

3.0kHz

4. Frequency Tolerance (25°C)

5. Code Deviation

6. Distortion

7. Adjacent CH Power (+)

(-)

8. S/N Ratio with CCITT Filter

UNIT

dBm

dB

dB

%

dB

kHz

-

kHz

dB

dB

dBm

UNIT

dBm

dBm

dB

dB

Hz

kHz

%

dB

dB

dB

NOMINAL

-115

-4.5

-6.0

1.5

70

15

15

35

55

-11

NOMINAL

-7.0

-15.0

-3.5

3.5

0

8.0

1.5

55

55

35

LIMIT

< -107

-8.5~-0.5

-10.0~-2.0

< 5

60 <

10 <

10 <

30 <

30 <

-14~-8

LIMIT

-10.0~-4.0

-19~-11

-6.5~-0.5

+0.5~+6.5

-2500~+2500

< 11

< 5

50 <

50 <

30 <

TELEPHONE LINE