TOSHIBA ft8509 Service Manual

),/(#121#5%30<<36

6(59,&(#0$18$/

&25'/(66#7(/(3+21(

)70;83<

38%/,6+('#,1#-$3$1/#$XJ1/#4<<<

CONTENTS

SAFETY PRECAUTIONS ...........................................................................................................1

OPERATING C O NTROLS ..........................................................................................................2

ALIGNMENT PROCEDURE .......................................................................................................3

BLOCK DIAGRAMS....................................................................................................................9

SCHEMATIC DIAGRAM .........................................................................................................11

TROUBLESHOOTING HINTS ..................................................................................................16

IC AND TRANSISTOR VOLTAGE CHART................................................................................ 23

SEMICONDUCTOR LEAD IDENTIFICATION ...........................................................................28

ELECTRICAL PARTS LOCATION.............................................................................................30

WIRING DIAGRAM .................................................................................................................33

EXPLODED VIEW AND MECHANICAL PARTS LIST...............................................................35

PARTS LIST..............................................................................................................................39

ASSEMBLY PARTS LIST..........................................................................................................49

SPECIFICAT IONS ....................................................................................................................50

SAFETY PRECAUTIONS

Before returning any models to the customer, a safety check of the entire instrument should be made.

The service technician must be sure that no protective device built into the instrument by the

manufacture has become defective or inadvertently degraded during servicing.

1.WARNING:

Alterations of the design or circuitry of these models should not be made.

Any design changes or additions such as, but not limited to, circuit modifications, auxiliary speaker

jacks, switches, grounding, active or passive circuitry, etc. may alter the safety characteristics of these

models and potentially create a hazardous situation for the user.

Any design alterations or additions will void the manufacturer's warranty and will further relieve the

manufacturer of responsibility for personal injury or property damage resulting therefrom.

2.PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in this chassis have special characteristics. These

characteristics often pass unnoticed and the protection afforded by them cannot necessarily be

obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts

that have these special safety characteristics are identified in this manual and its supplements;

electrical components having such features ar identified by a

parts list. Before replacing any of these components, read the parts list in this manual carefully. Th

use of substitute replacement parts that do not have the same safety characteristics as specified in

the parts list may create shock, fire or other hazards.

in the schematic diagram and th

1

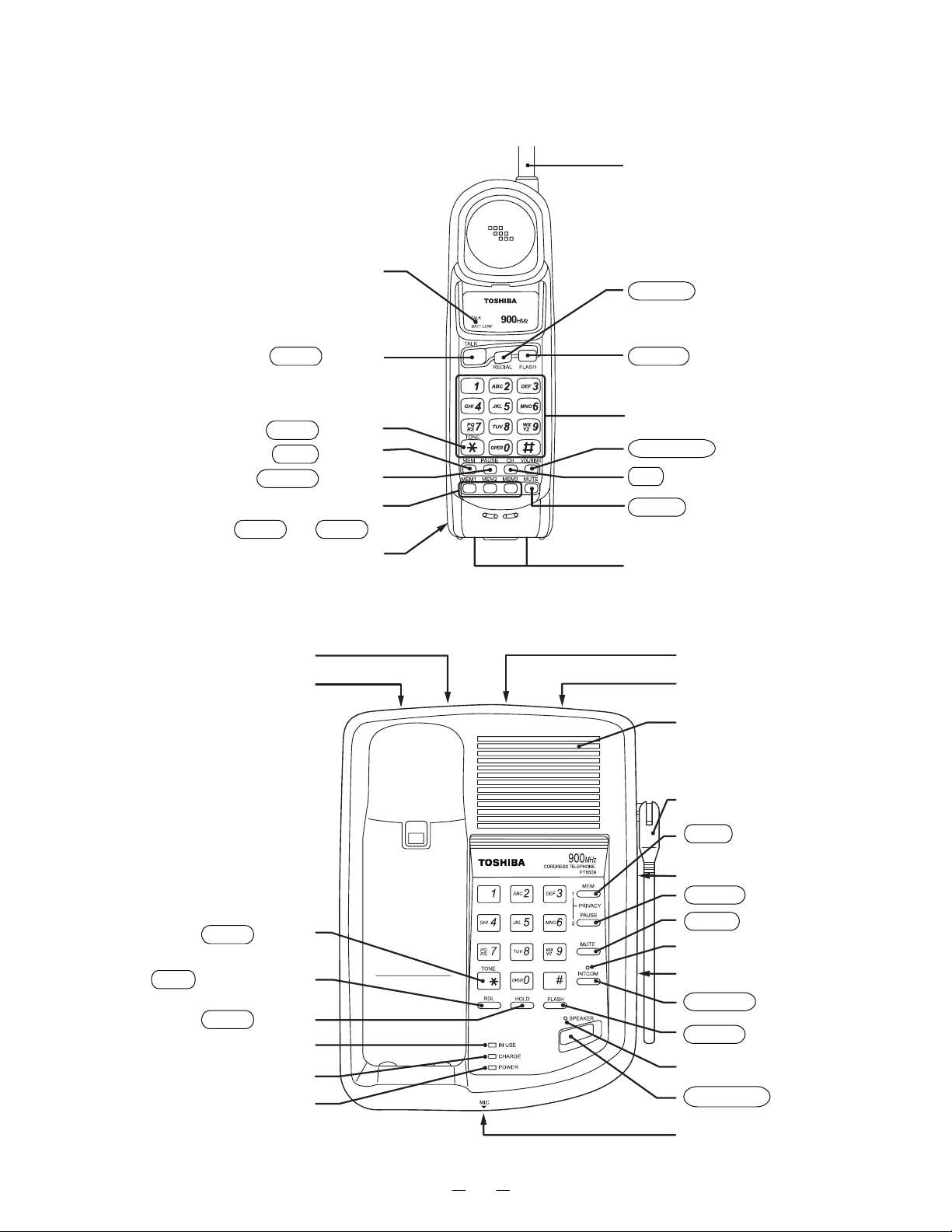

OPERATING CONTROLS

HANDSET CONTROLS AND FUNCTIONS

TALK/BATT.LO W LED

Antenna

REDIAL Button

TALK Button

TONE Button

MEM Button

PAUSE Button

One-touch dialing Button

( MEM1 - MEM3 )

Rechargeable Battery Pac

(back)

BASE UNIT CONTROLS AND FUNCTIONS

DC 9V IN Jack

TEL Line Jac

FLASH Button

Dialpad

VOL/RING Button

CH Button

MUTE Button

Charging Contact

TONE/PULSE Switch

Line Ringer Volume Switch

Speaker

Antenna

TONE Button

RDL (Redial) Button

HOLD Button

IN USE LED

CHARGE LED

POWER LED

MEM (Memory) Button

Speed Dial Index (1 to 10)

PAUSE Button

MUTE Button

INTCOM LED (Green)

Speaker Volume Control

INTCOM Button

FLASH Button

Speaker LED (Green)

SPEAKER Button

Microphone

2

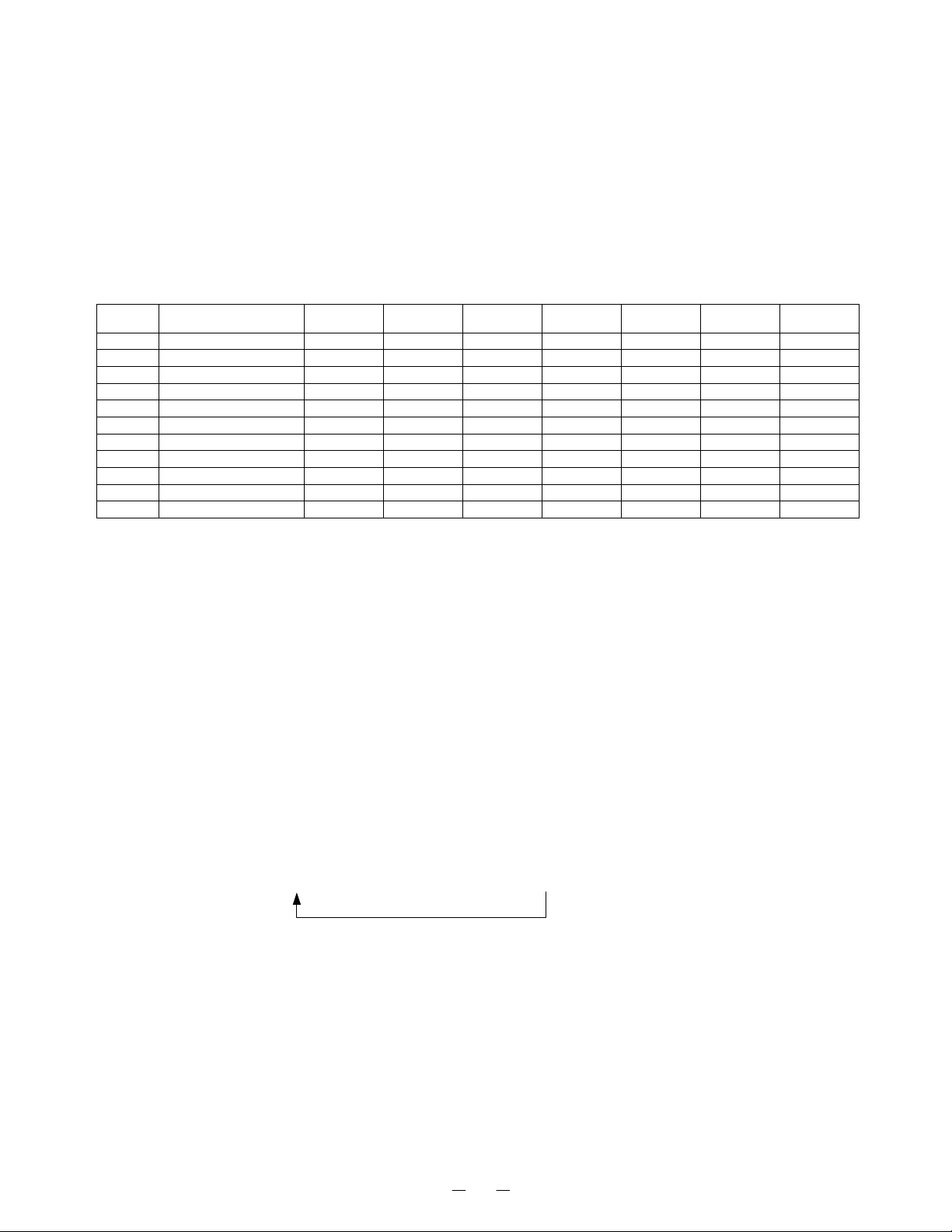

ALIGNMENT PROCEDURE

Test Mode For Base Unit

Press the “*” and “#” keys at the same tim e about 1.5 seconds while turning the powe r on, the confirmation

beep will sound to indicate that the unit is in the test mode.

1. To change the TEST mode: Press the number key for the corresponding TEST mode.

(Refer to the following table)

2. To change channel: Press the “RDL” key, but if ch anging the step, the channel returns to the start

channel.

3. To cancel Test mode: Bell rings, charge the Handset or Power off.

STEP FUNCTION KE START CH TX CONT TX MUTE RX MUTE RL CONT REMARKS

1 VO/TX FRQ. ADJ 1 19 L L L L

2 TX MODE CHECK 2 19 L H L H

3TX DATA 3 19 L L L L *1

4 RX SENS. 4 19 H L H H

5 SQ SENS. 5 19 L L H/L H *2

6 RING CHECK 6 19 H L L L

7 DUAL TONE CHECK 7 19 H L L H *3

8 DATA IN CHECK 8 19 L L L H *4

CHANNEL DATA CHECK

9

10 DUPLE 0 19 L H H H

1 1 INT COM MEM 19 L H H L

919H L L L*5

*1 : “0000...” (250Hz) will be fed out continuously as transmitting data.

*2 : Bell rings when sensing SQ.

*3 : Every pushing of FLASH key makes tone change. (In the case of Dual Tone, changes as

1Ö2Ö3Ö4Ö5Ö6Ö7Ö8Ö9Ö0Ö∗Ö#Ö1.)

DTMF Frequency

ROW1 : 697 ROW2 : 770

ROW3 : 852 ROW4 : 941

COL1 : 1209 COL2 : 1336

COL3 : 1477

*4 : Bell rings when the received data are “0000...” (250Hz).

*5 : Charge LED lights when detecting Charge ON.

Channel rotation

19 Ö20Ö21Ö40Ö1Ö2Ö3Ö4Ö5............37Ö38Ö39Ö40

3

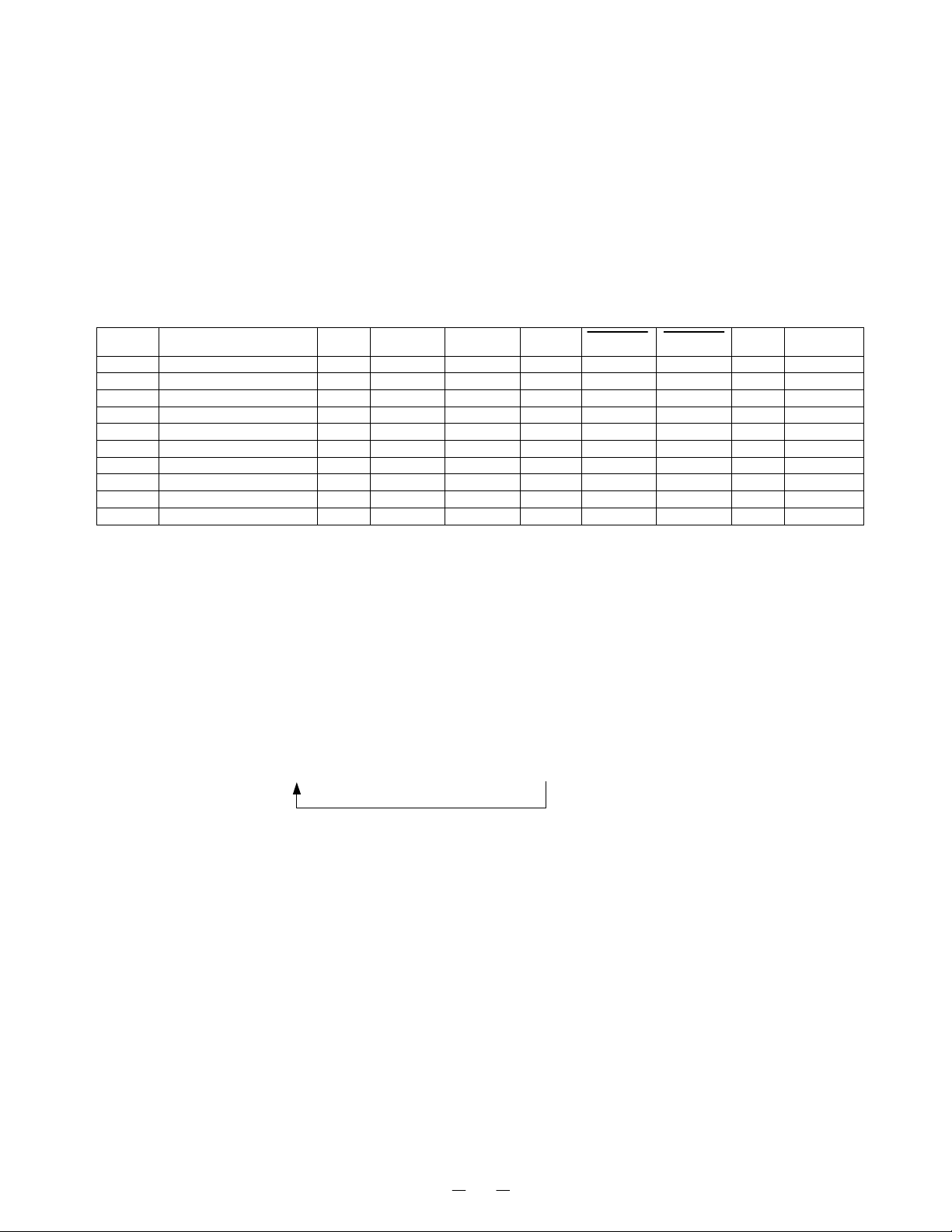

Test Mode For Handset Unit

To perform the TEST mode, turn the power ON by pressing the “*” and “#” buttons at the same time.

When entered the TEST mode, the bell rings and the unit enters TEST mode 1. (Refer to the following table.)

1. To change the TEST mode: Press the number key for the corresponding TEST mode.

(Refer to the following table)

2. To change channel: Press “CH” key.

(Note: If the step is changed, the channel returns to the start channel.)

3. To cancel the Test mode: Turn the power OFF, charge the Handset, or press the “TALK” key.

STEP FUNCTION KE START CH TX CONT SC TX MUTE RX MUTE CONV REMARKS

1 VO/TX FRQ. ADJ 1 21 L H L L H

2 TX MOD. CHECK 2 21 L H H L L

3 TX DATA 3 21 L H L L L *1

4 RX SENS. 4 21 H H L H L

5 SQ SENS. 5 21 L H L *A L

6 RECEIVE DATA CHECK 6 21 L H L L H *2

7 BELL 7 21 H L L L H *3

8 BATTERY LOW CHECK 8 21 H L L L H *4

9 CHARGE CHECK 9 21 H L L L H *5

10 DUPLE 0 21 L H H H L

*A : Squelch ON is H, or Squelch OFF is L.

*1 : In the TEST mode 3, “0000...” will be fed out continuously as transmitting data.

*2 : In the TEST mode 6, bell (1kHz) rings when the data received is “0000...”.

*3 : In the TEST mode 7, bell rings with initial 2 tone (2kHz, 2.2kHz).

*4 : In the TEST mode 8, bell (1kHz) rings when P_BATLOW is “L”.

*5 : In the TEST mode 9, bell rings when P_CHRGIN is “L”.

Channel rotation

21 Ö20Ö19Ö40Ö1Ö2Ö3Ö4Ö5............37Ö38Ö39Ö40

4

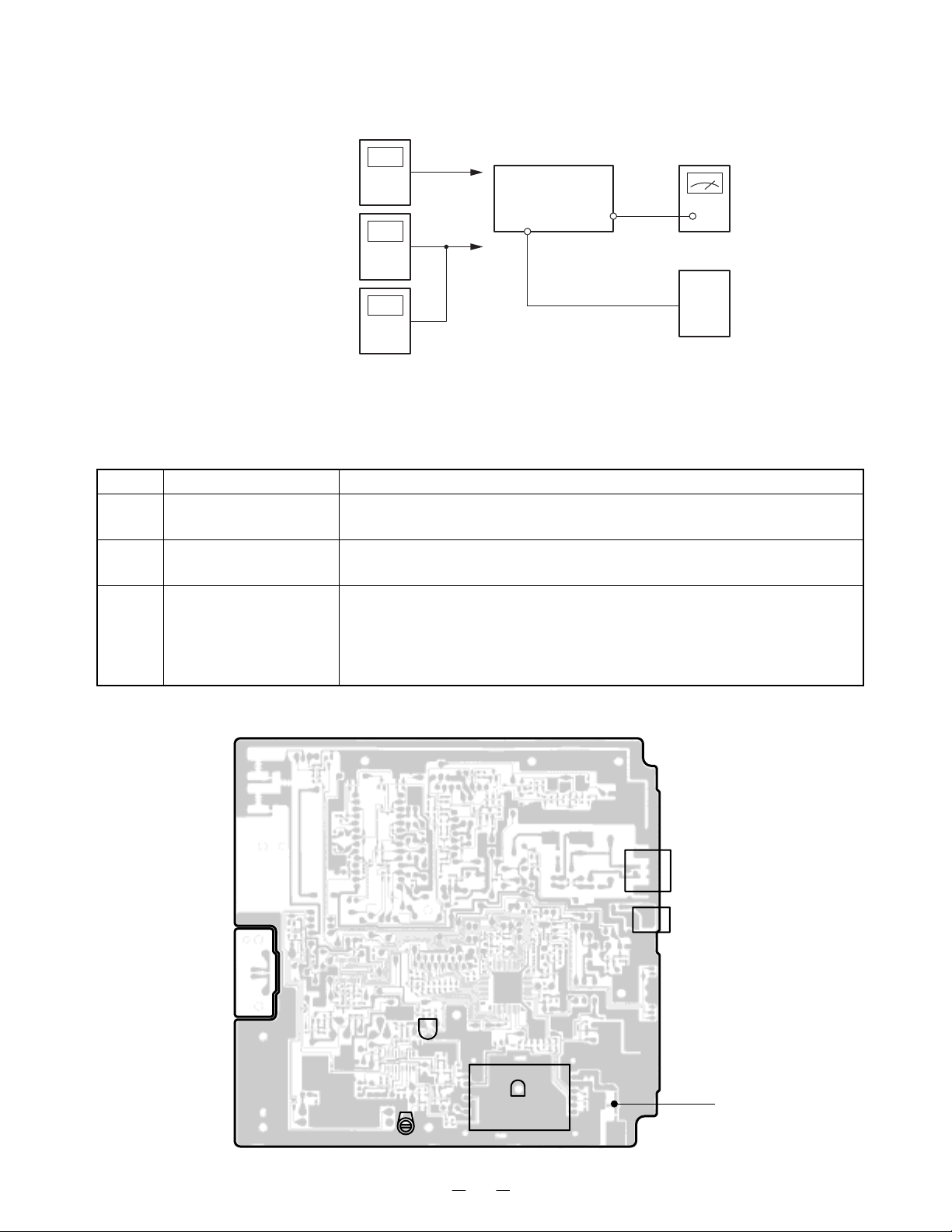

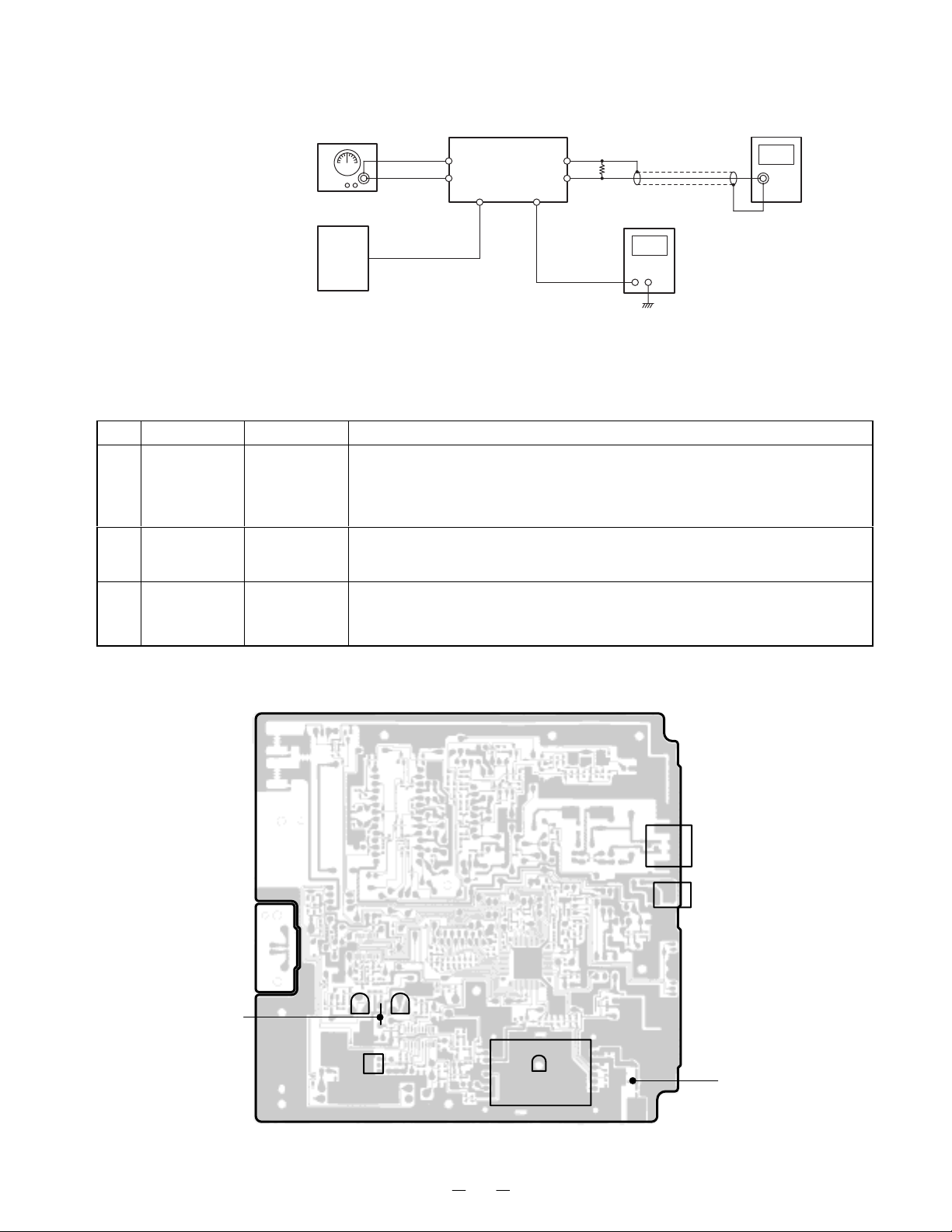

Base Unit

Transmitter Section

Connections

Preset

Place the Base unit in VCO/TX FREQ. ADJ mo de in ac co rdance with the procedure on page 3.

Alignment Procedure

step Adjustment Remarks

1

RT301

(TX Power)

Power

Meter

Frequency

Counter

Deviation

Meter

Connect the Power Meter to the RF test point on the Base MAIN PCB.

Adjust RT301 for a -5.0dBm reading on the Power Meter.

RF

Test Point

RF

Test Point

BASE Unit

J1

DC IN

9V Jack

TEL Line

Jack

J3

1kHz 77.6mV

AF GEN.

AC

Adapter

AC 120V

60Hz

2

CT1

(TX Frequency)

Connect the Freq uency Counter to th e RF test point on the Base MAIN

PCB. Adjust CT1 to make sure that the frequency is 926.897468 MHz.

Press the “2” key to enter the TEST Mode 2. Connect the AF Generator

3

RT3

(TX Modulation)

to the TEL Line Jack on the B ase M ain PCB. Make sure that the o utput

is 1 kHz 77.6 mV from the AF Generator.

Connect the Deviation Meter to the RF test point on the Base MAIN PCB.

Adjust RT3 to indicate ±8 kHz Dev.

Alignment Point Location on Base Main PCB and Base RF PCB

Base Main PCB

J3

TEL LINE Jack

J1

DC IN 9V Jack

CT1

RT3

BASE RF PCB

RT301

5

RF TEST POINT

Receiver Section

Connections

RF SG

+

BASE Unit

RF

Test Point

TEL Line

Jack

J3

Dummy Load

(600-ohm)

-

+

AC Voltmeter

AF

Terminal

DC Voltmeter

AC 120V

60Hz

DC IN 9V Jack

J1

AC

Adapter

Preset

Place the Base unit in RX SENS mode (step 4) in accordance with the procedure on page 3.

Alignment Procedure

step Preset to Adjustment Remarks

Connect the RF Signal Generator to the RF t est point on the Base MAIN

PCB. Make sure that the frequency is 902.952467 MHz.

Connect the DC Voltmeter to the AF test p oint (JV21). Adjust L3 to

indicate DC 1.9V.

Connect the AC Voltmeter across a 600-ohm dummy to the Telephone

Line Jack. Adjust RT2 for a 218 mV reading on the AC voltmeter.

Press the “5” key to enter the TEST Mode 5. Make sure that the

frequency of RF SG output is 902.952467 MHz. Adjust RT1 to turn to

the point where the bell rings.

1

SG: 1mV

No modulation

SG: 1mV

2

1kHz ±8kHz

deviation

SG: -7dBµV

3

No modulation

L3

(Discriminator

Voltage)

RT2

(RX AF

Voltage)

RT1

(SQ Point)

Alignment Point Location on Base Main PCB and Base RF PCB

Base Main PCB

RT1

RT2

AF TEST POINT

JV21

L3

BASE RF PCB

RT301

J3

TEL LINE Jack

J1

DC IN 9V Jack

RF TEST POINT

6

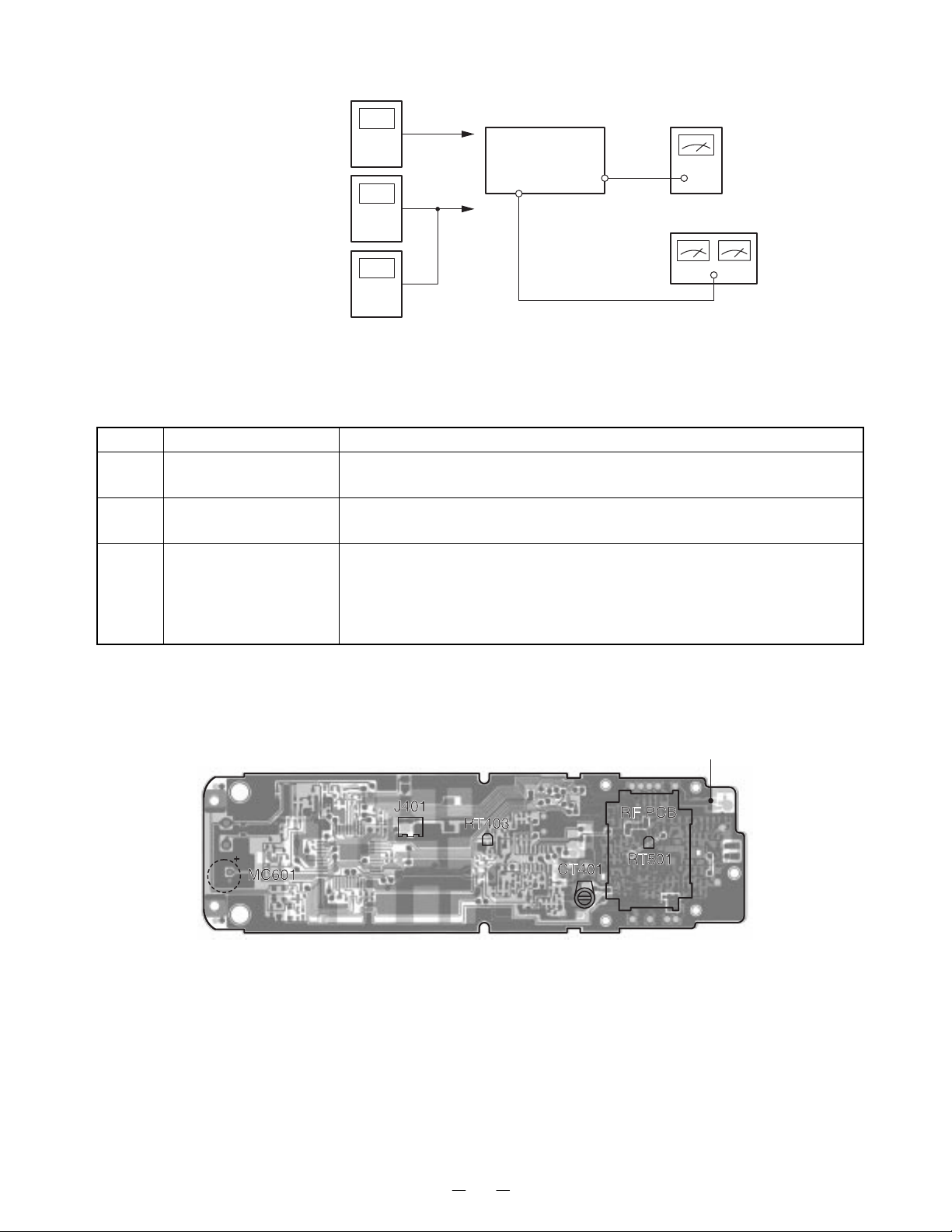

Handset Unit

Transmitter Section

Connection

Preset

Place the Handset in VCO/TX FREQ. ADJ mode in accordance with the procedure on page 4.

Alignment Procedure

step Adjustment Remarks

1

RT501

(TX Power)

Power

Meter

Frequency

Counter

Deviation

Meter

Connect the RF Power Met er to the RF test point on the Handset MAI

PCB. Adjust RT501 for a -7.5dBm reading on the Power Meter.

RF

Test Point

RF

Test Point

HANDSET Unit

J401

Batter

Terminals

MIC+Pin

DC 3.8V

AF GEN.

1kHz 9mV

DC Power Supply

2

CT401

(TX Frequency)

Connect the Fre quenc y Counter to th e RF t est p oint on the handset M AIN

PCB. Adjust CT401 to make sure that the frequency is 903.052467 MHz.

Press the “2” key to enter the TEST Mode 2. Connect the AF Generator

3

RT403

(TX Modulation)

to the MIC Connector make sure that the output is 1kHz 9mV from the AF

Generator.

Connect the De viation Meter to the RF test poi nt on the handset MAIN

PCB. Adjust RT403 to indicate ±8 kHz Dev.

Alignment Point Location on Handset Main PCB and Handset RF PCB

Handset PCB

RF TEST POINT

7

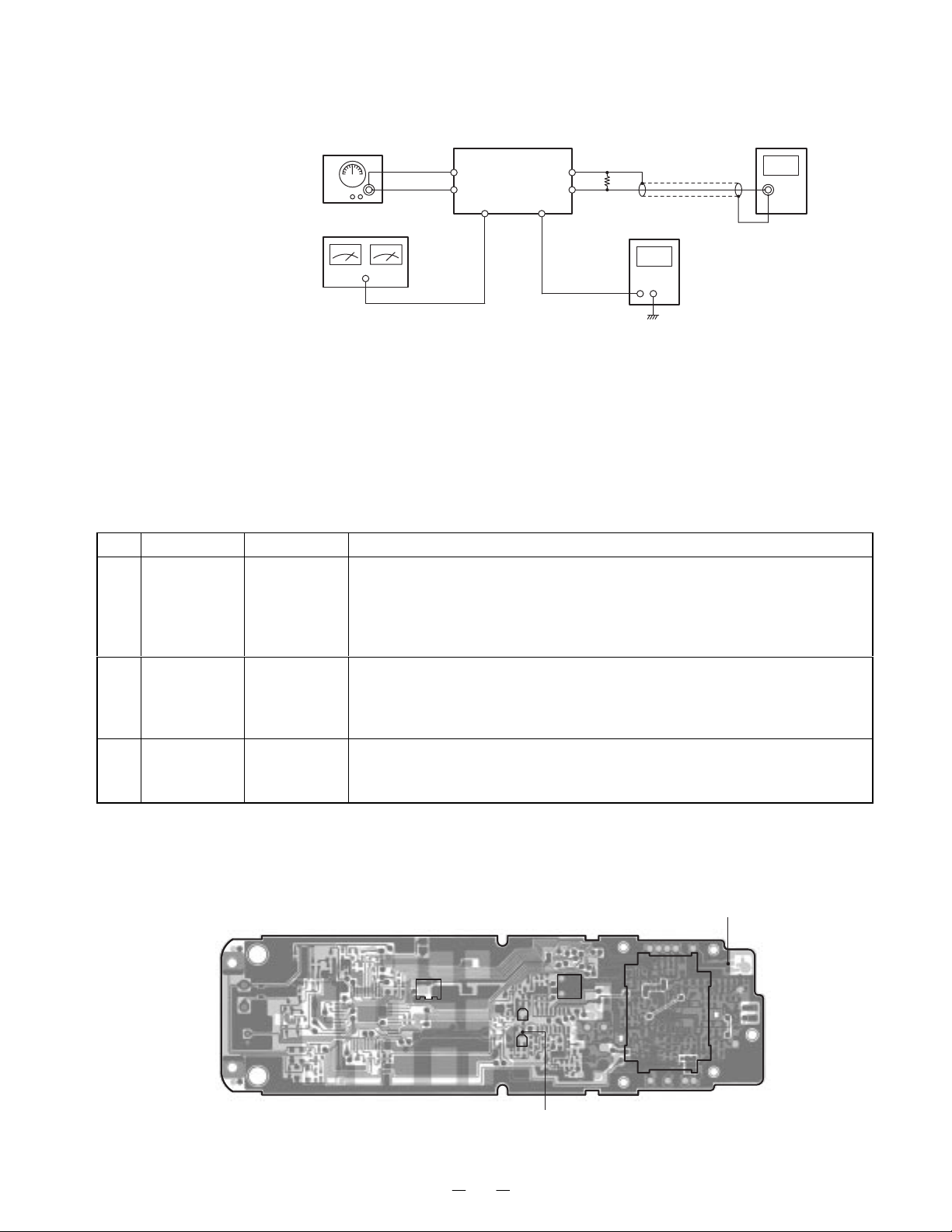

Receiver Section

Connections

RF SG

+

RF

Test Point

HANDSET Unit

Connector

SP

Dummy Load

(150-ohm)

-

+

AC Voltmeter

DC Power Supply

J401

Batter

Terminal

DC 3.8V

AF

Terminal

DC Voltmeter

Preset

a) Connect the handset RF unit to the handset main unit.

b) Connect DC power supply to battery connector on the handset unit.

c) Turn the DC power supply O N while pressing “ *” and “#” k eys, and keep pressin g the key cont inuously for

approximate 2 seconds.

d) Release keys when entering TEST mode 1 with TALK LED lighting and beep.

Alignment Procedure

step Preset to Adjustment Remarks

Press the “4” key to enter the TEST Mode 4. Connect the RF Signal

1

SG: 1mV

No modulation

SG: 1mV

2

1kHz ±8kHz

Deviation

L402

(Discriminator

Voltage)

RT402

(RX AF

Voltage)

Generator to the RF test point on the handset MAIN PCB. Make sure

that the frequency is 926. 997 467 MHz.

Connect the DC Vo ltmeter to the AF test point. Adjust L402 t o indicate

DC 1.00 V.

Connect the RF Signal Generator to the RF test point on the handset

MAIN PCB. Make sure that the frequency is 926.997467 MHz.

Connect the AC Voltmeter across a 150-ohm dummy to the MIC

Connector. Adjust RT402 for a 128 mV reading on the AC Voltmeter.

Press the “5” key to enter the TEST Mode 5. Make sure that the frequency

of RF SG output is 926.997467 MHz. Adjust RT401 to turn to the point

where the bell rings.

3

SG: -7dBµV

1kHz ±8kHz

Deviation

RT401

(SQ Point)

Alignment Point Location on Handset Main PCB and Handset RF PCB

Handset PCB

J401

RT402

RT401

AF TEST POINT

8

L402

RF PCB

RF TEST POINT

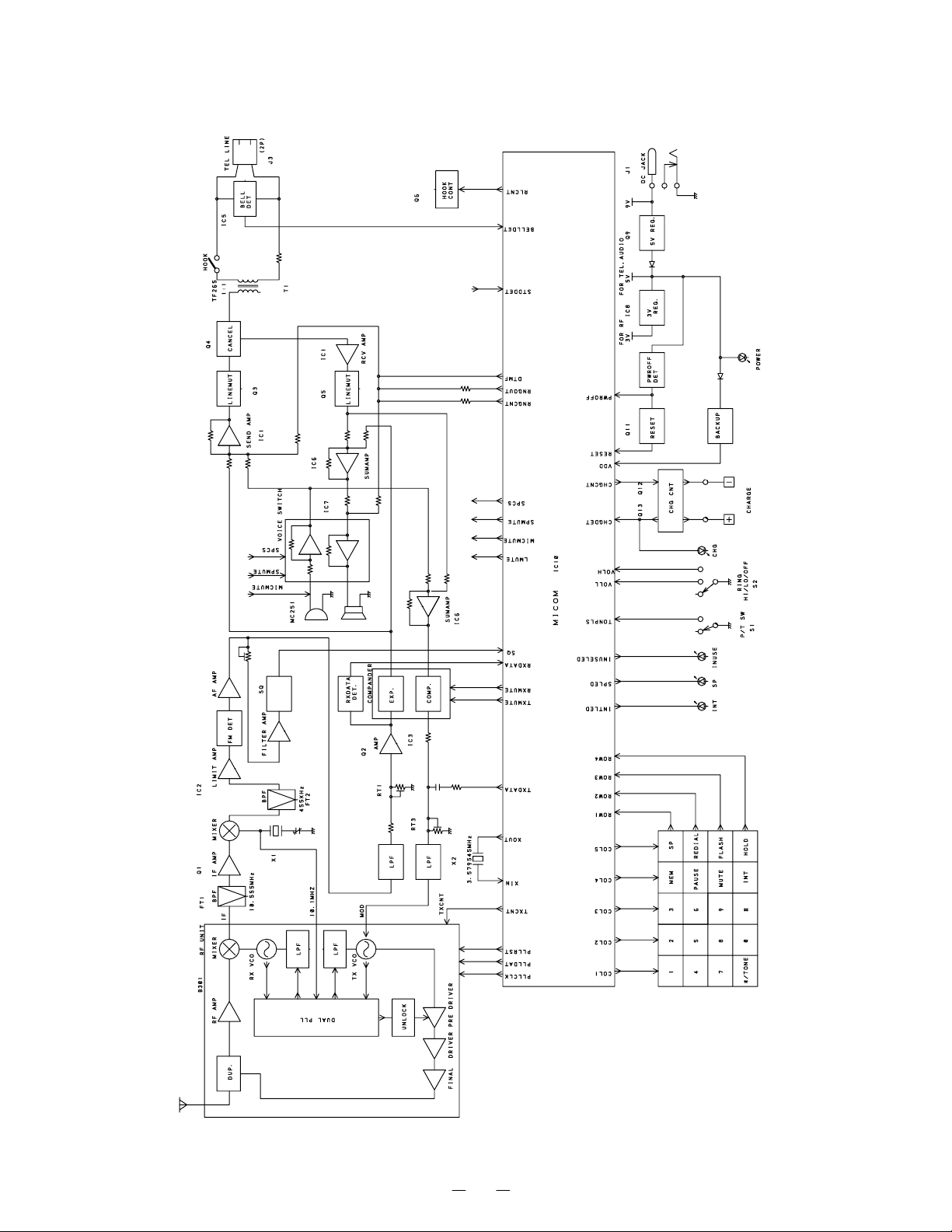

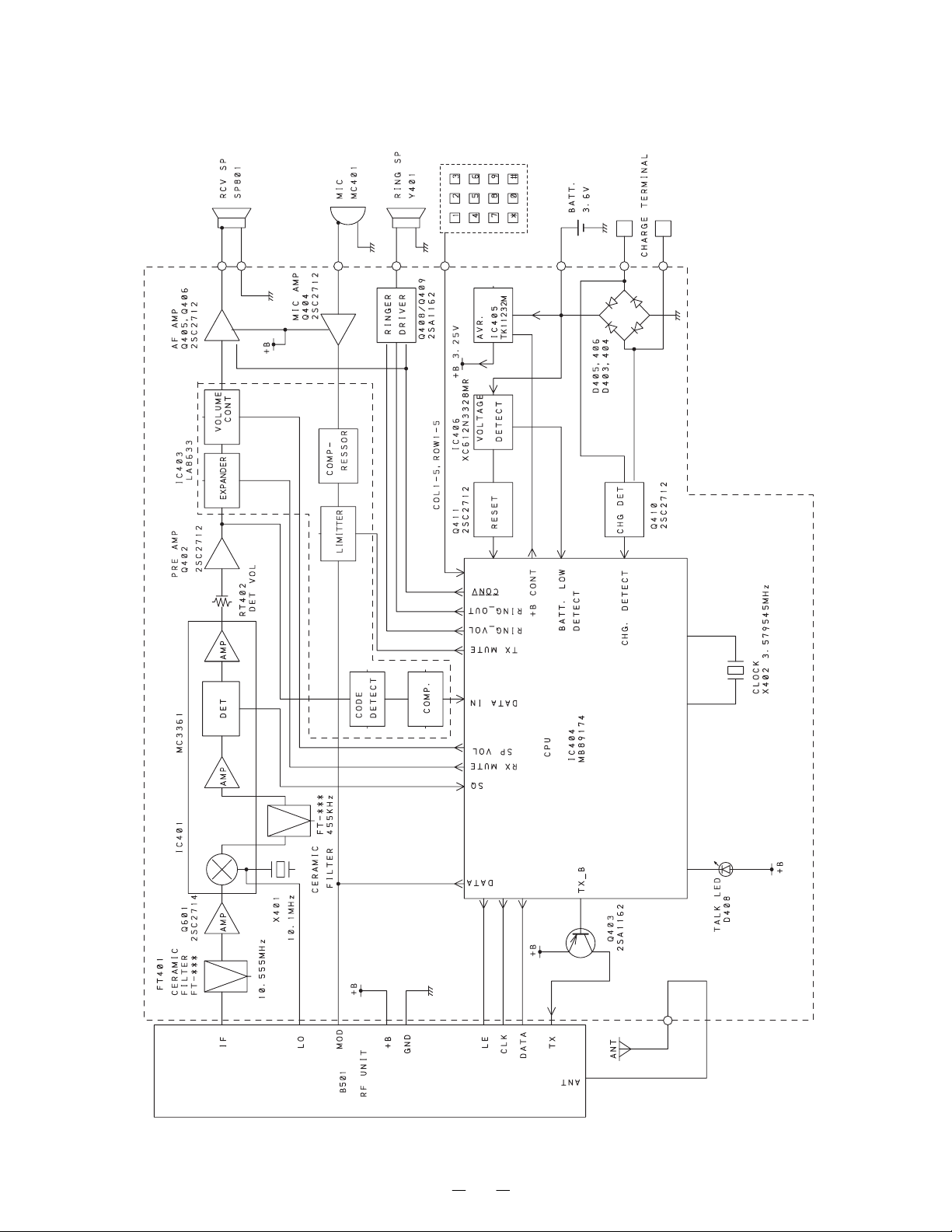

Base Unit

BLOCK DIAGRAMS

9

Handset Unit

10

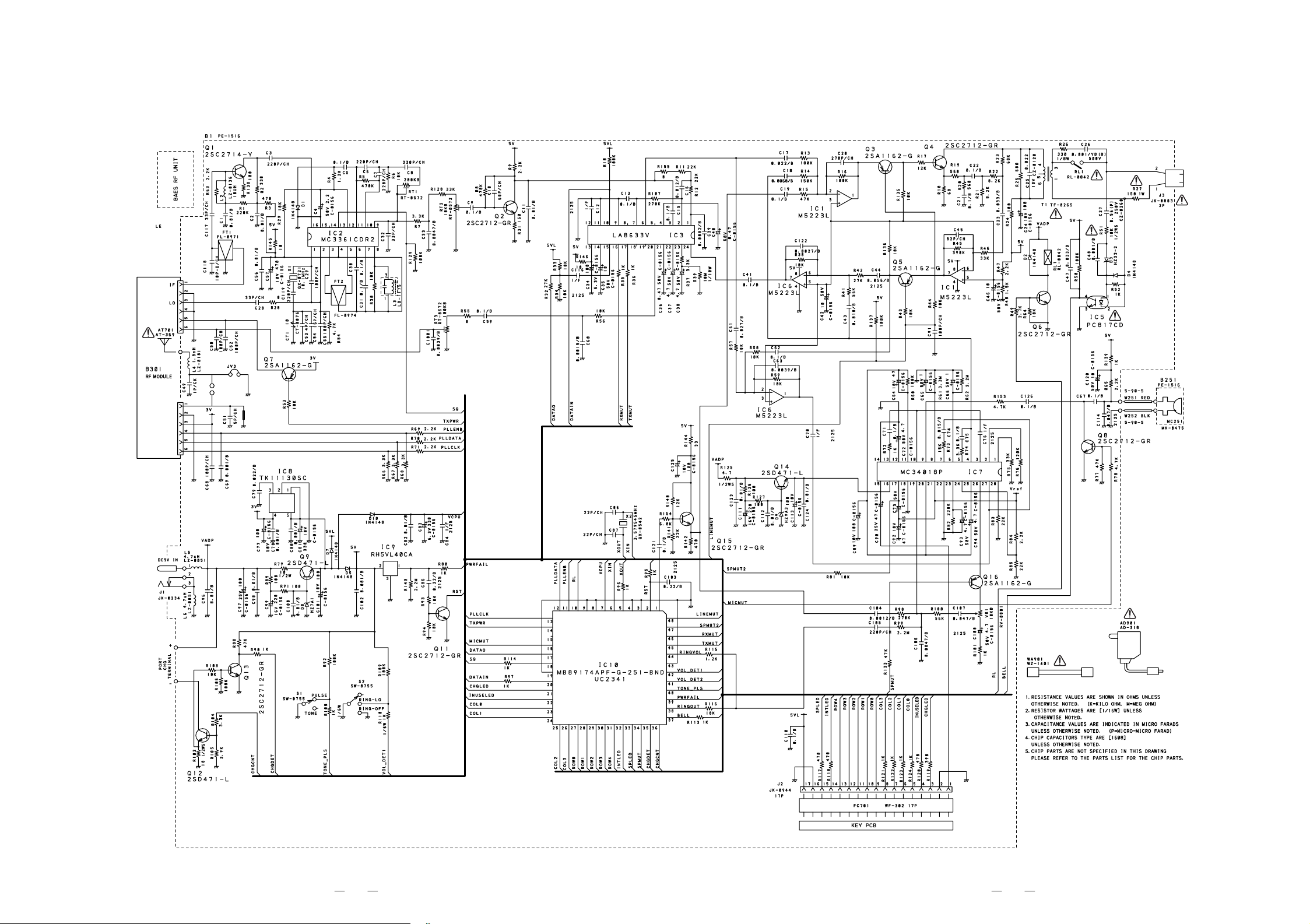

%DVH#8QLW/#0DLQ

6&+(0$7,&#',$*5$06

4544

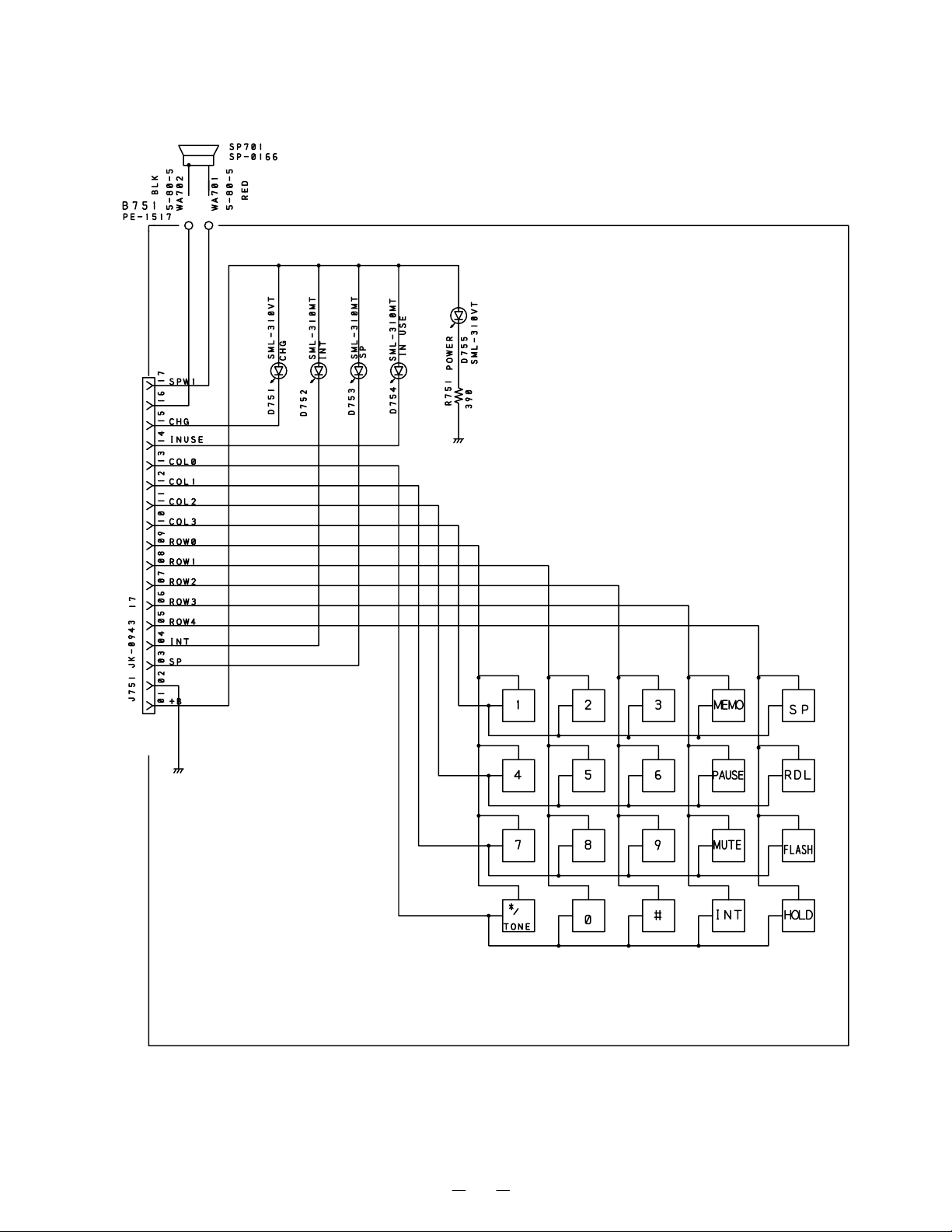

Base Unit, ke

NOTES:

1. RESISTANCE VALUES ARE SHOWN IN OHMS UNLESS

OTHERWISE NOTED. (K=KILO OHM, M=MEG OHM)

13

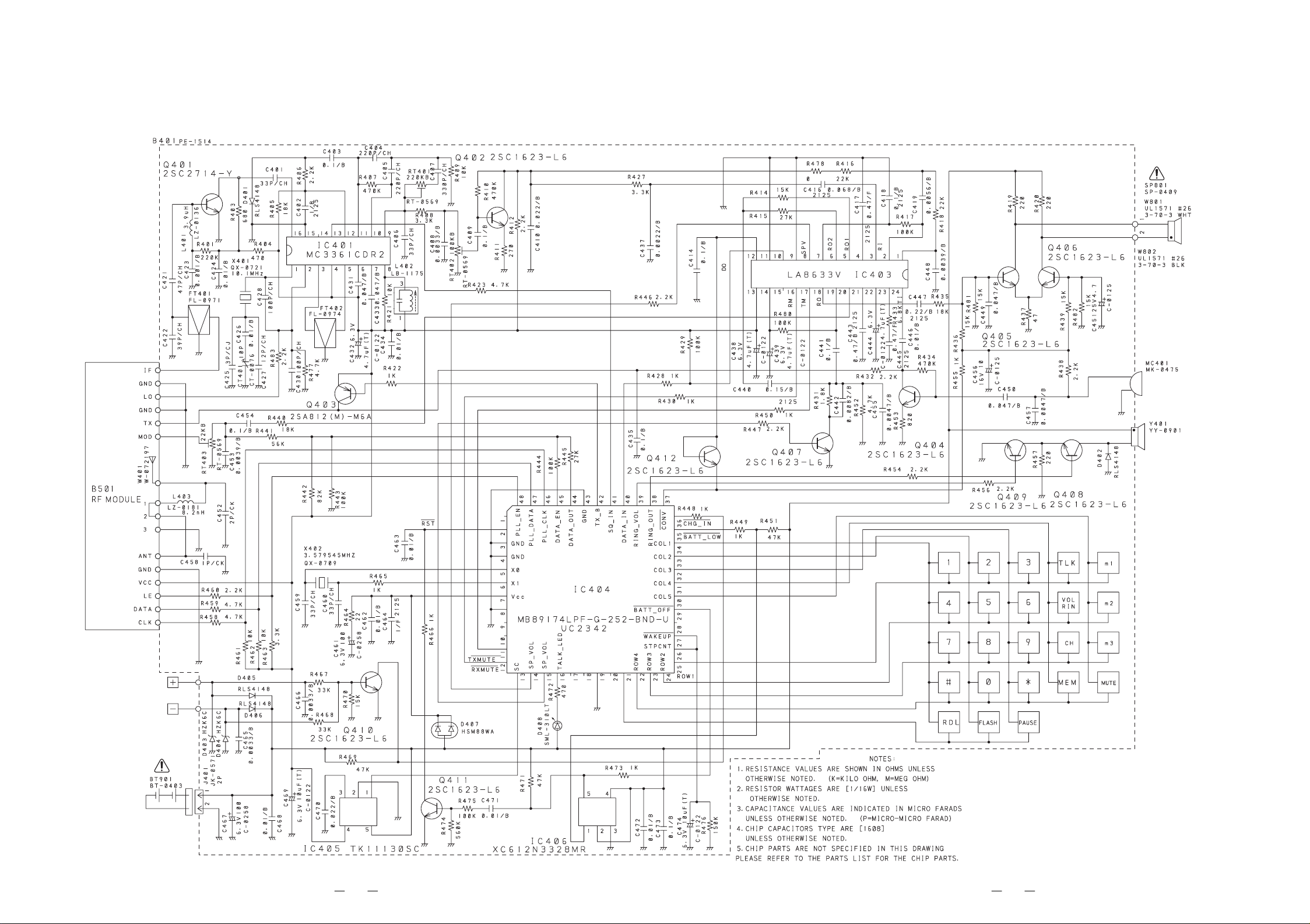

+DQGVHW/#0DLQ

##

4847

TROUBLESHOOTING HINTS

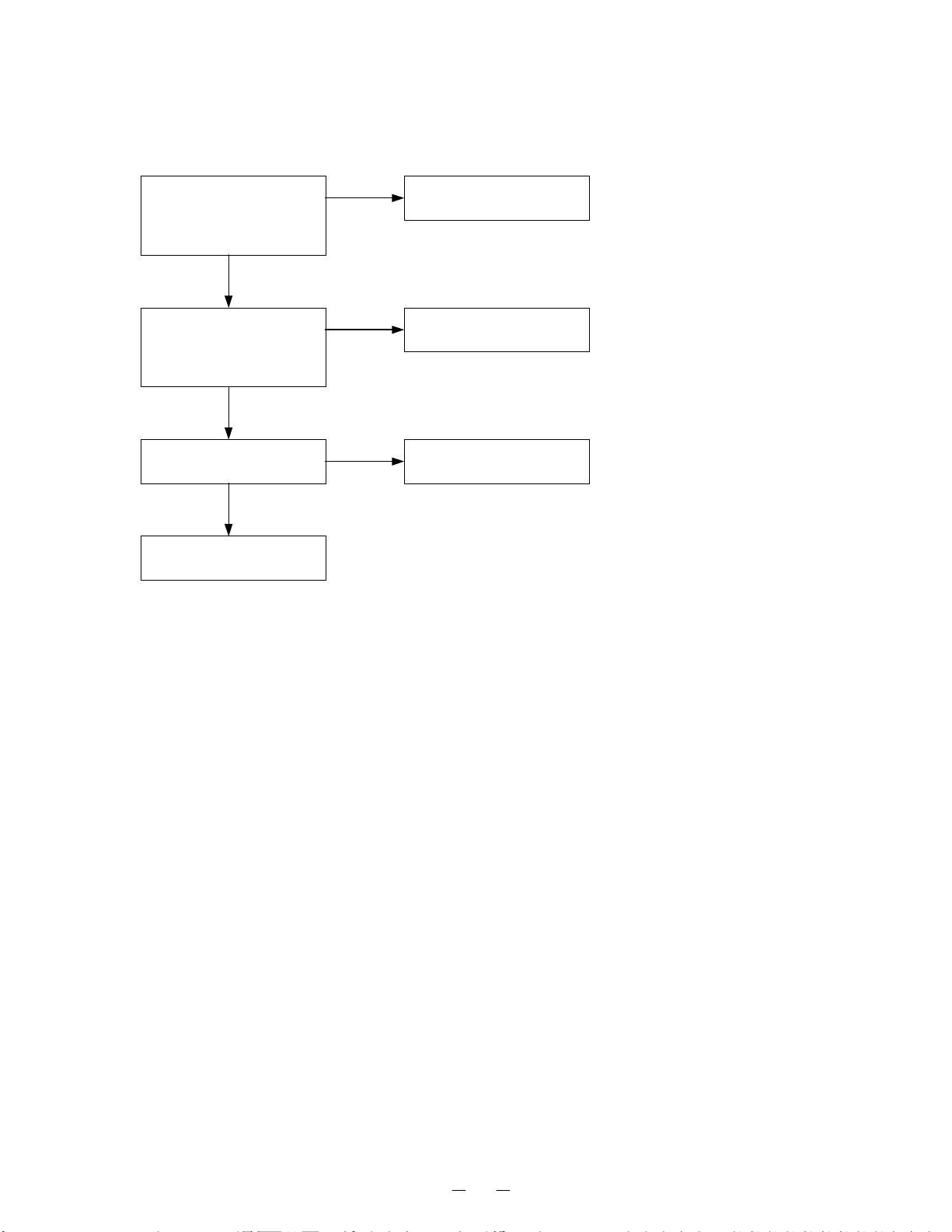

1. The bell does not ring.

When the INTCOM key of

the base is pressed, does

the ringer on the handset

ring?

OK

When the TEL SG is joined

with the base to make bell

signal, is there pulse wave

at pin 4 of IC5?

OK

Is there pulse wave at pin

37 of IC10?

OK

Check IC10 and its

periphe ral circuit.

NG

NG

NG

See 2. The bell does not

ring & page does not ring.

Check IC5 and TEL network

circuit.

Check R50, R113 and C47.

16

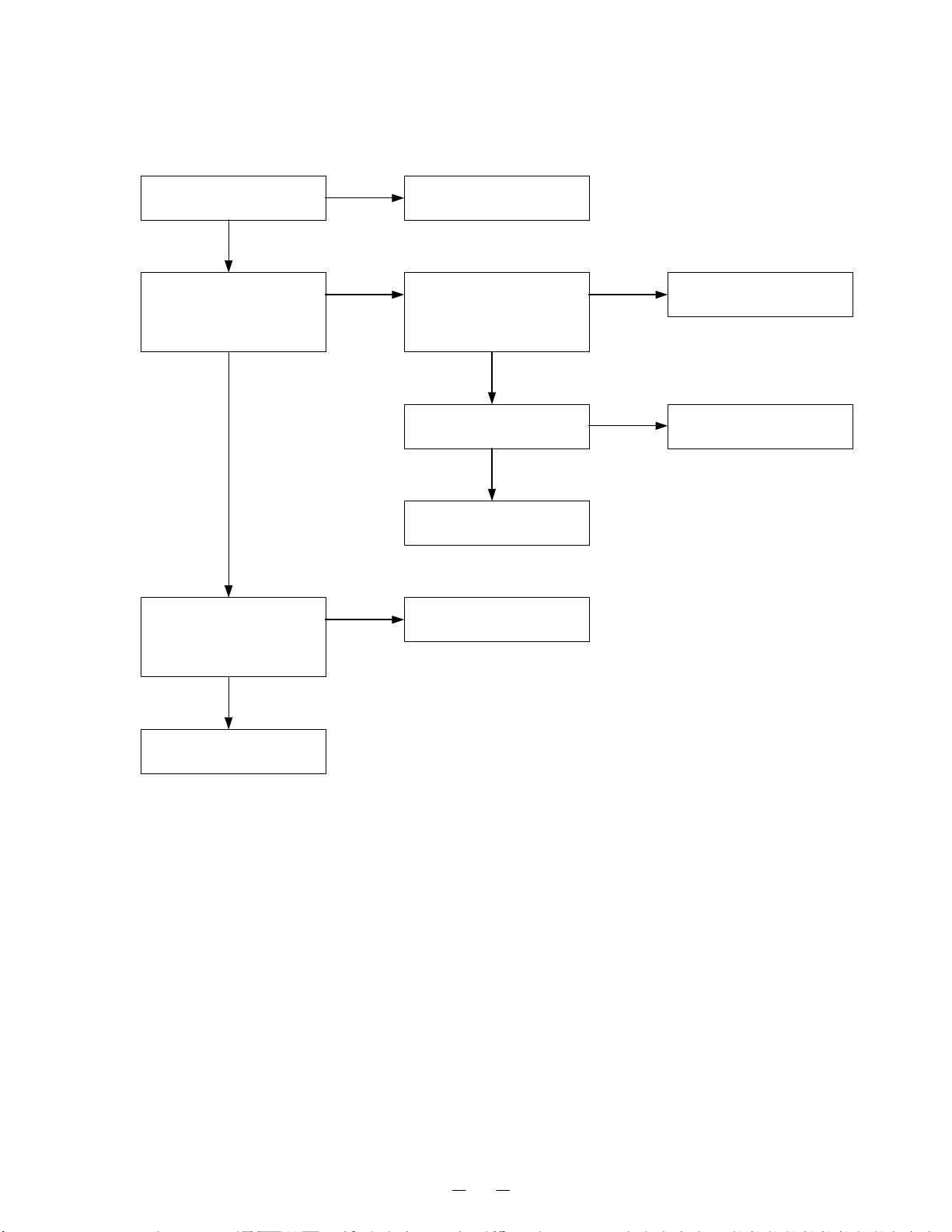

2. The bell does not ring & page does not ring.

Can the base and handset

be connected?

OK

Press handset DIAL key

while in TALK MODE.

Can key touch sound be

heard from the ringer?

OK

When the INTCOM key of

the base is pressed, does

pin 14 of IC10 change from

to low?

OK

NG

NG

NG

See 3. The base and handset

cannot be connected.

When the ke y of the handset

is pressed, can the pulse

output at pin 38 of IC404 be

seen?

OK

At the Q408 collector, can

the pulse wave be seen?

OK

Check RINGER Y401.

Check Keyboard Rub ber.

NG

NG

Check IC404.

Check R454, R457, R456,

Q408, Q409 and D402.

Check IC10 and its

periphe ral circuit.

17

Loading...

Loading...