Toshiba FT 8000 Service Manual

FILE NO. 2B0-200006

SERVICE MANUAL

CORDLESS TELEPHONE

FT-8000

PUBLISHED IN JAPAN, Aug., 2000

CONTENTS

SAFETY PRECAUTIONS ............................................................................................................ 1

OPERATING CONTROLS........................................................................................................... 2

ALIGNMENT PROCEDURE ........................................................................................................ 3

BLOCK DIAGRAMS..................................................................................................................... 7

SCHEMATIC DIAGRAMS............................................................................................................9

TROUBLESHOOTING HINTS ...................................................................................................13

IC AND TRANSISTOR VOLTAGE CHART ............................................................................... 20

SEMICONDUCTOR LEAD IDENTIFICATION........................................................................... 24

ELECTRICAL PARTS LOCATION............................................................................................. 26

WIRING DIAGRAMS .................................................................................................................28

EXPLODED VIEW AND MECHANICAL PARTS LIST............................................................... 30

PARTS LIST ............................................................................................................................... 34

ASSEMBLY PARTS LIST .......................................................................................................... 44

SPECIFICATIONS ..................................................................................................................... 45

SAFETY PRECAUTIONS

Before returning any models to the customer, a safety check of the entire instrument should be made.

The service technician must be sure that no protective device b uilt into the instrument by the manu facture

has become defective or inadvertently degraded during servicing.

1.WARNING:

Alterations of the design or circuitry of these models should not be made.

Any design changes or additions such as, but not limited to, circuit modifications, auxiliary speaker

jacks, switches, grounding, active or passive circuitry, etc. may alter the safety characteristics of these

models and potentially create a hazardous situation for the user.

Any design alterations or additions will void the manufacturer's warranty and will further relieve the

manufacturer of responsibility for personal injury or property damage resulting therefrom.

2.PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in this chassis have special characteristics. These characteristics

often pass unnoticed and the protection afforded by them cannot necessarily be obtained by using

replacement components rated for higher voltage, wattage, etc. Replacement parts that have these

special safety characteristics are identified in this manual and its supplements; electrical components

having such features are indentified by a in the schematic diagram and the parts list. Before

replacing any of these components, read the parts list in this manual carefully. The use of substitute

replacement parts that do not have the same safety characteristics as specified in the parts list may

create shock, fire or other hazards.

1

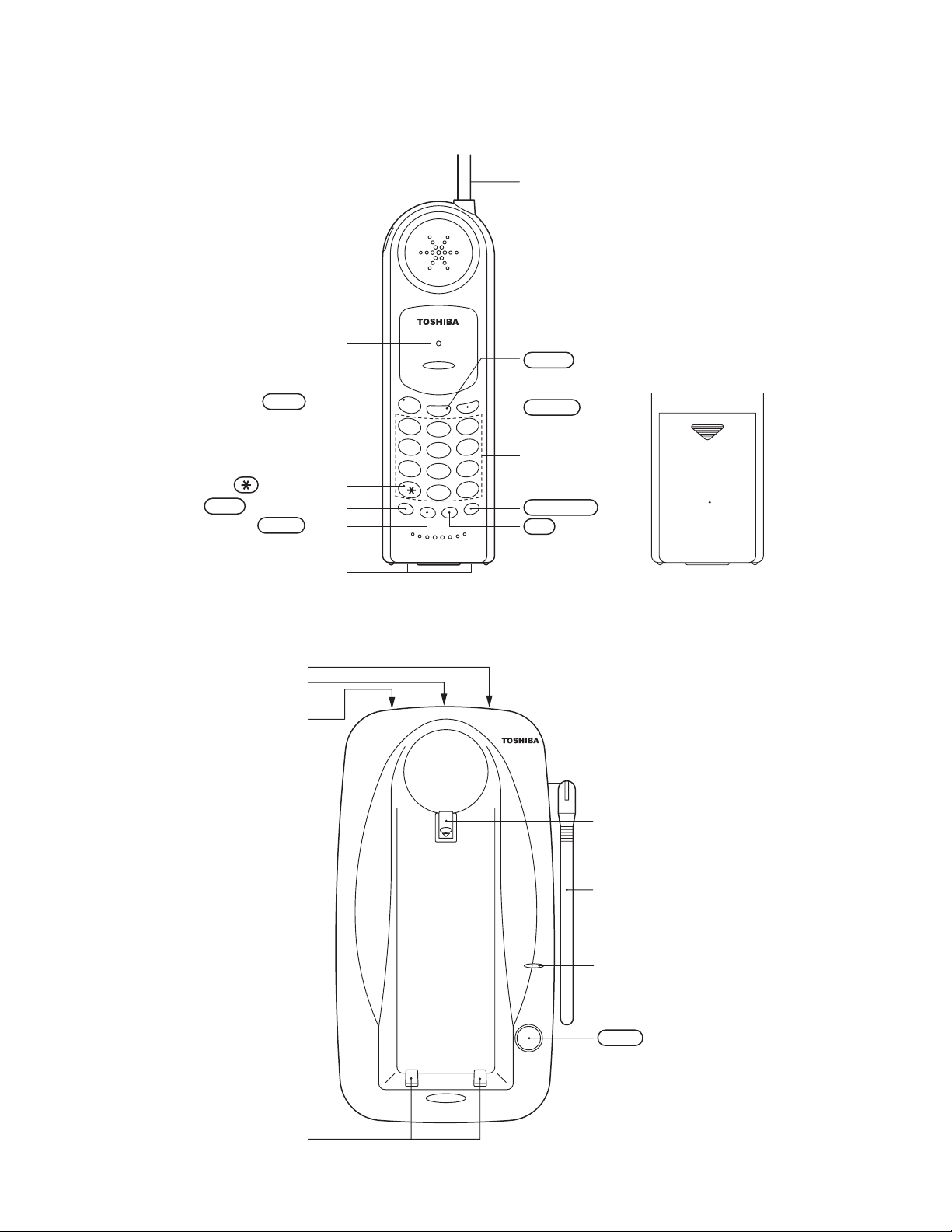

OPERATING CONTROLS

HANDSET CONTROLS AND FUNCTIONS

Antenna

TALK/BATT LOW LED

TALK Button

(TONE) Button

MEM (Memory) Button

TALK

BATT LOW

900

COMPANDOR NOISE REDUCTION

RLD/P

TALK

1

ABC

GHI

4

JKL

PQ

RS

TUV

7

TONE

OPER

MEM

MUTE

MHz

FLASH

DEF

3

2

MNO

6

5

WX

9

YZ

8

#

0

VOL/RING

CH

MUTE Button

Charging contact

BASE UNIT CONTROLS AND FUNCTIONS

PULSE/TONE Switch

DC IN 9V Jack

TEL LINE Jack

CORDLESS

TELEPHONE

FT-8000

RDL/P (Redial/Pause)Button

FLASH Button

Dialpad

VOL/RING Button

CH (channel)Button

Rechargeable

Battery Pack(back)

Charging Contact

900

MHz

COMPANDOR NOISE REDUCTION

Hook

Antenna

IN USE

CHARGE

PAGE

IN USE/CHARGE LED

PAGE Button

2

ALIGNMENT PROCEDURE

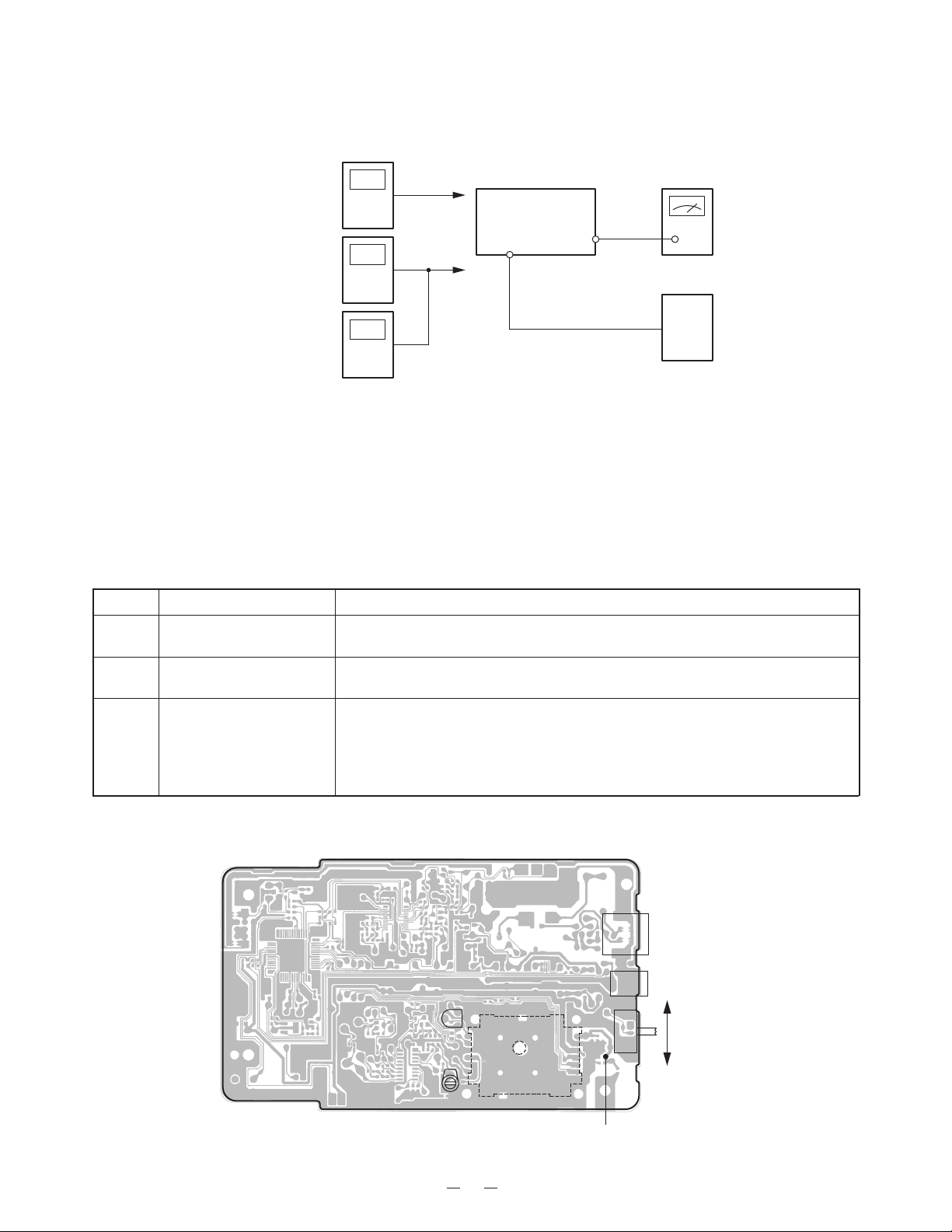

Base Unit

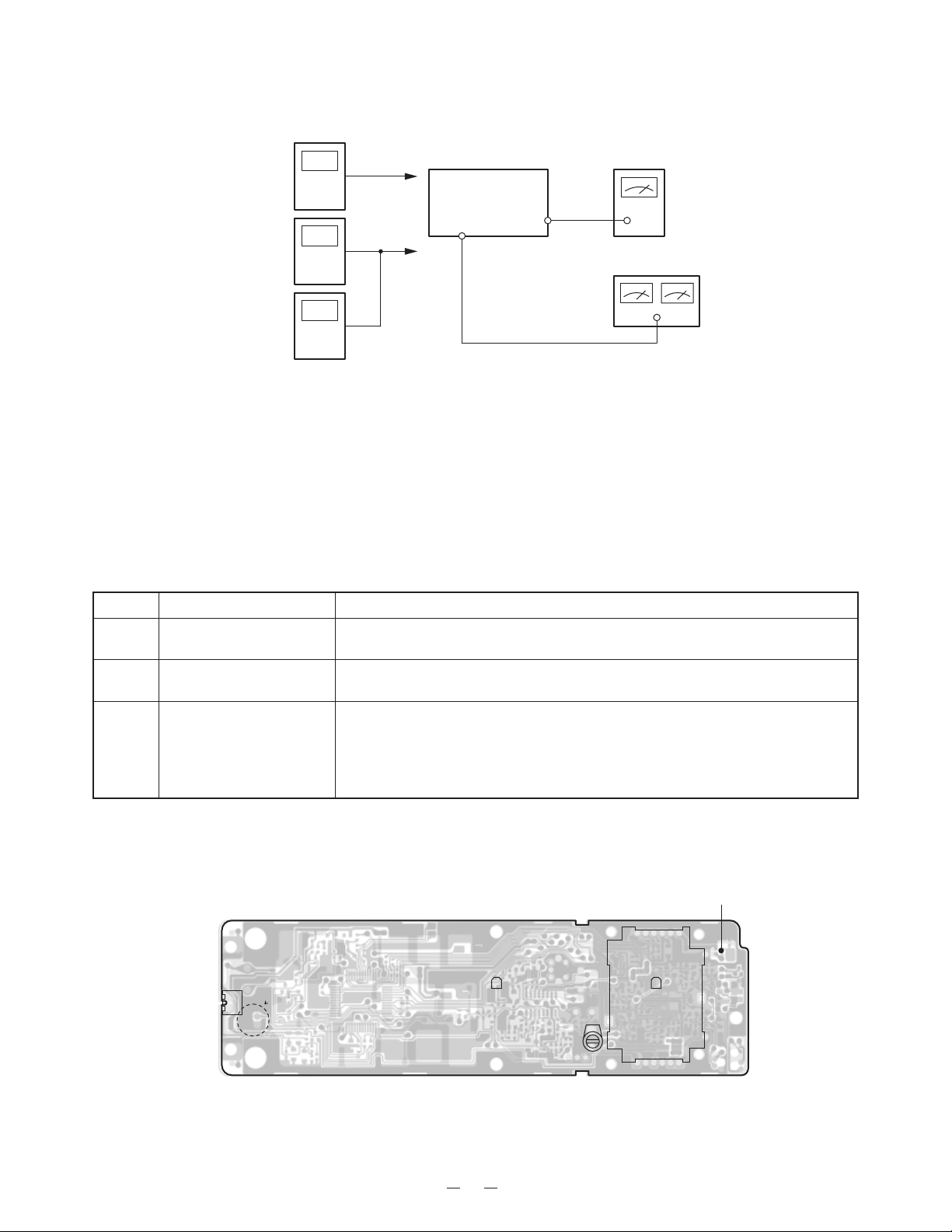

Transmitter Section

Connections

Power

Meter

Frequency

Counter

Deviation

Mater

RF

Test Point

RF

Test Point

Preset

a) Connect the base RF unit to the base main unit.

b) Set the “TONE / PULSE” switch to PULSE.

c) Connect the AC adapter to the base unit while pressing the “PAGE” key, and keep pressing it continuously for

approximate 2 sectonds.

d) Release the “PAGE” key when entering TEST mode 1 with IN USE LED lighting.

BASE Unit

J2

DC IN

9V Jack

TEL Line

Jack

J1

1kHz 138mV

AF GEN.

AC

Adapter

AC 120V

60Hz

Alignment Procedure

step

1

2

3

Adjustment

RT301

(TX Po wer)

CT1

(TX Frequency)

RT3

(TX Modulation)

Remarks

Connect the Po w er Meter to the RF test point on the Base MAIN PCB.

Adjust RT301 for a -6.5dBm reading on the Power Meter.

Connect the Frequency Counter to the RF test point on the Base MAIN

PCB. Adjust CT1 to make sure that the frequency is 926.897468 MHz.

Press the “PAGE” ke y to enter the TEST Mode 2. Connect the AF Generator

to the TEL Line J a ck on the Base Main PCB. Mak e sure that the output is 1

kHz 138 mV from the AF Generator .

Connect the Deviation Meter to the RF test point on the Base MAIN PCB .

Adjust RT3 to indicate ±8 kHz Dev.

Alignment Point Location on Base Main PCB and Base RF PCB

Base Main PCB

Base RF PCB

RT3

CT1

RT301

J1

TEL LINE Jack

J2

DC IN 9V Jack

T

S2

T/P Switch

P

RF Test Point

3

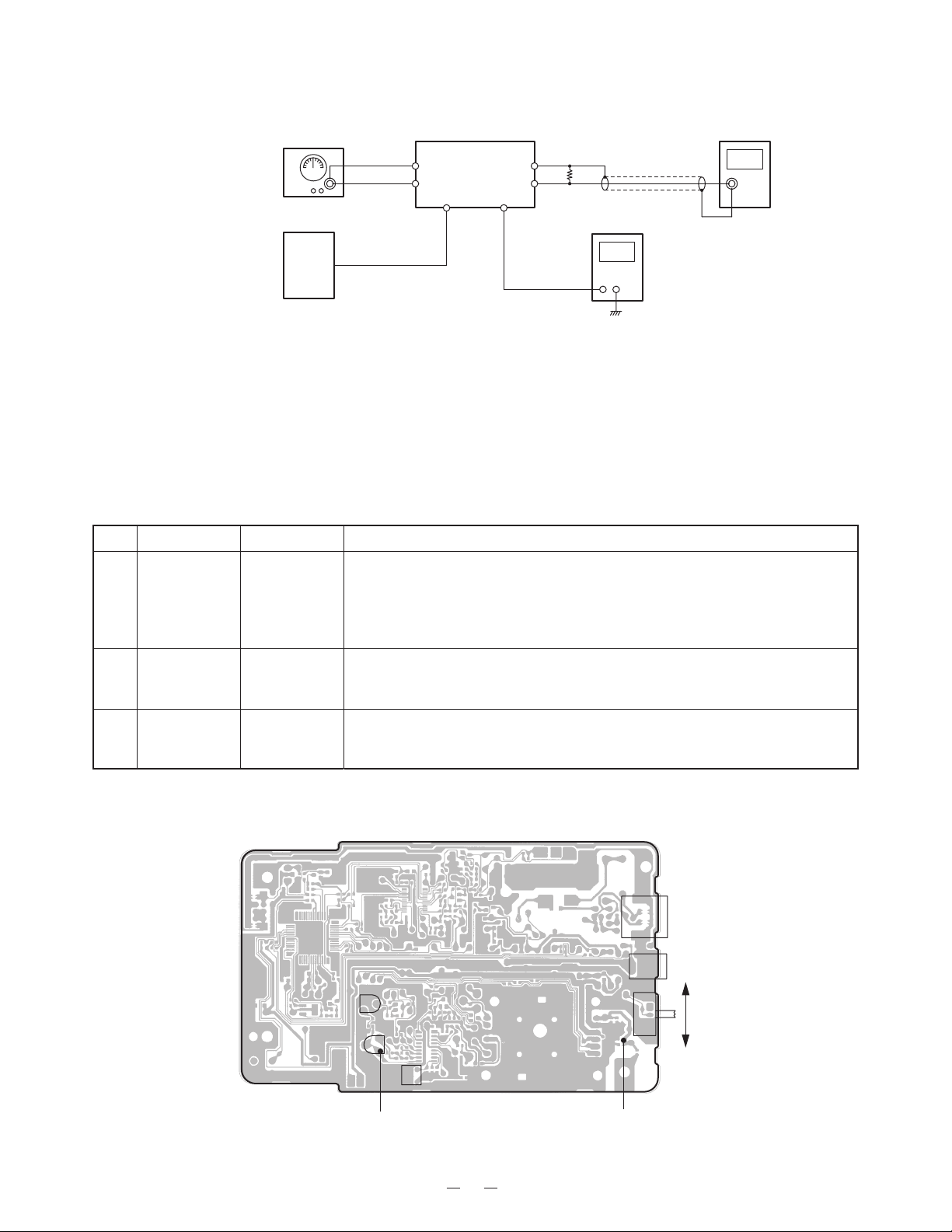

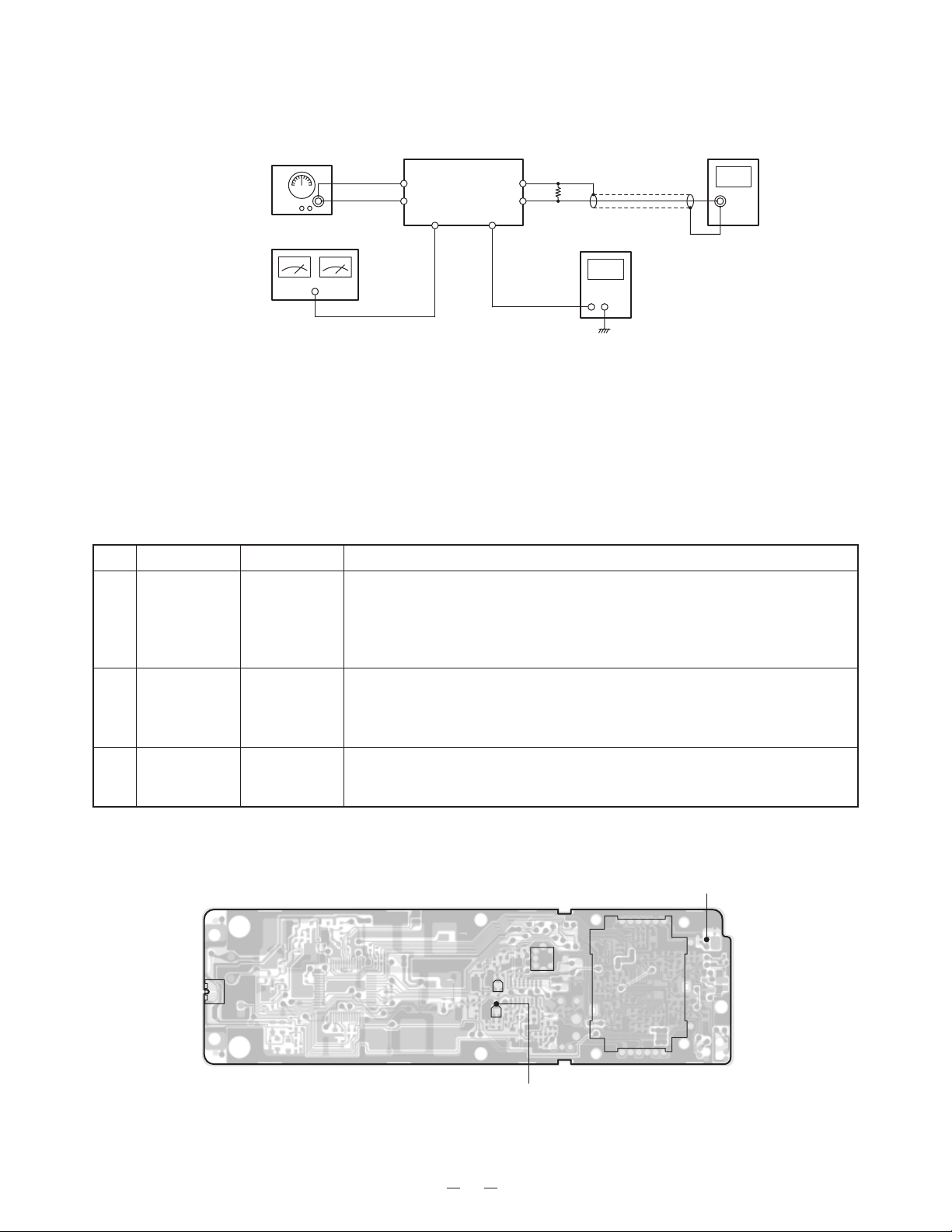

Receiver Section

Connections

RF SG

+

RF

Test Point

TEL Line

Jack

J1

Dummy Load

(600-ohm)

+

AC V oltmeterBASE Unit

AC 120V

60Hz

AC

Adapter

DC IN 9V Jack

J2

AF

Terminal

DC V oltmeter

Preset

a) Connect the base RF unit to the base main unit.

b) Set the “T ONE/PULSE” switch to PULSE.

c) Connect the AC adapter to the base unit while pressing the “PAGE” key, and keep pressing it continuously for

approximate 2 seconds.

d) Release the “PAGE” key when entering TEST mode 1 with IN USE LED lighting.

Alignment Procedure

step

Preset to

1

SG: 1mV

No modulation

SG: 1mV

2

1 kHz ±8kHz

deviation

SG: -6.0 dB

3

1kHz ±8kHz

Deviation

Adjustment

(Discriminator

Voltage)

(RX AF

Voltage)

µµ

µV

µµ

(SQ Point)

L3

RT2

RT1

Remarks

Press the “PAGE” k ey for 3 times to enter the TEST Mode 4. Connect the

RF Signal Generator to the RF test point on the Base MAIN PCB. Make

sure that the frequency is 902.952467 MHz.

Connect the DC Voltmeter to the AF Terminal of R T1. Adjust L3 to indicate

DC 1.00 V.

Connect the AC Voltmeter across a 600-ohm dummy to the Telephone Line

Jack. Adjust R T2 for a 195 mV reading on the AC voltmeter.

Press the “PAGE” key to enter the TEST Mode 5. Make sure that the

frequency of RF SG output is 902.952467 MHz. Adjust RT1 to turn to the

point where the CHG LED just turns on.

Alignment Point Location on Base Main PCB and Base RF PCB

Base Main PCB

RT2

RT1

L3

AF Terminal RF Test Point

4

J1

TEL LINE Jack

J2

DC IN 9V Jack

T

S2

T/P Switch

P

Handset Unit

Transmitter Section

Connection

Power

Meter

Frequency

Counter

Deviation

Mater

RF

Test Point

RF

Test Point

HANDSET Unit

J601

Battery

Connector

MIC+Pin

DC 3.8V

AF GEN.

1kHz 9mV

DC Power Supply

Preset

a) Connect the handseet RF unit to the handset main unit.

b) Connect DC power supply to battery connector on the handset unit.

c) Turn the DC power supply On while pressing " ∗ " and " # " keys, and keep pressing the keys continuously for

approximate 2 seconds.

d) Release keys when entering TEST mode 1 with T ALK LED lighting and beep.

Alignment Procedure

step

1

2

Adjustment

RT501

(TX Po wer)

CT601

(TX Frequency)

Remarks

Connect the RF power Meter to the RF test point on the handset MAIN PCB.

Adjust RT501 for a -7.0dBm reading on the Power Meter.

Connect the Frequency Counter to the RF test point on the handset MAIN

PCB. Adjust CT601 to make sure that the frequency is 903.052467 MHz.

Press the “2” key to enter the TEST Mode 2. Connect the AF Generator to

RT603

3

(TX Modulation)

the MIC Connector. Make sure that the output is 1kHz 9mV from the AF

Generator.

Connect the Deviation Meter to the RF test point on the handset MAIN PCB.

Adjust RT603 to indicate ±8 kHz De v.

Alignment Point Location on Handset Main PCB and Handset RF PCB

Handset PCB

RF PCB

RT501

J601

RT603

MC601

CT601

RF Test Point

5

Receiver Section

Connections

RF SG

DC Power Supply

+

Battery

Connector

DC 3.8V

RF

Test Point

J601

SP

Connector

AF T erminal

of RT601

Dummy Load

(150-ohm)

+

DC V oltmeter

AC V oltmeterHANDSET Unit

Preset

a) Connect the handset RF unit to the handset main unit.

b) Connect DC power supply to battery connector on the handset unit.

c) Turn the DC power supply ON while pressing “ ∗ ” and “ # ” keys, and keep pressing the keys continuously for

approximate 2 seconds.

d) Release keys when entering TEST mode 1 with T ALK LED lighting and beep.

Alignment Procedure

step

Preset to

1

SG: 1mV

No modulation

SG: 1mV

1 kHz ±8kHz

2

deviation

SG: -6.0 dB

1kHz ±8kHz

3

Deviation

Adjustment

(Discriminator

Voltage)

RT602

(RX AF

Voltage)

µµ

µV

µµ

RT601

(SQ Point)

L602

Remarks

Press the “4” key to enter the TEST Mode 4. Connect the RF Singal

Generator to the RF test point on the handset MAIN PCB. Make sure that

the frequency is 926.997467 MHz.

Connect the DC Voltmeter to the AF Terminal of RT601. Adjust L602 to

indicate DC 0.85 V.

Connect the RF Signal Generator to the RF test point on the handset MAIN

PCB. Make sure that the frequency is 926.997467 MHz.

Connect the AC Voltmeter across a 150-ohm dummy to the SP Connector .

Adjust RT602 for a 247 mV reading on the AC Voltmeter.

Press the “5” k e y to enter the TEST Mode 5. Mak e sure that the frequency

of RF SG output is 926.997467 MHz. Adjust RT601 to turn to the point

where the indication is just vibrated.

Alignment Point Location on Handset Main PCB and Handset RF PCB

Handset PCB

L602

RF PCB

RT602

J601

RT601

AF Terminal

6

RF Test Point

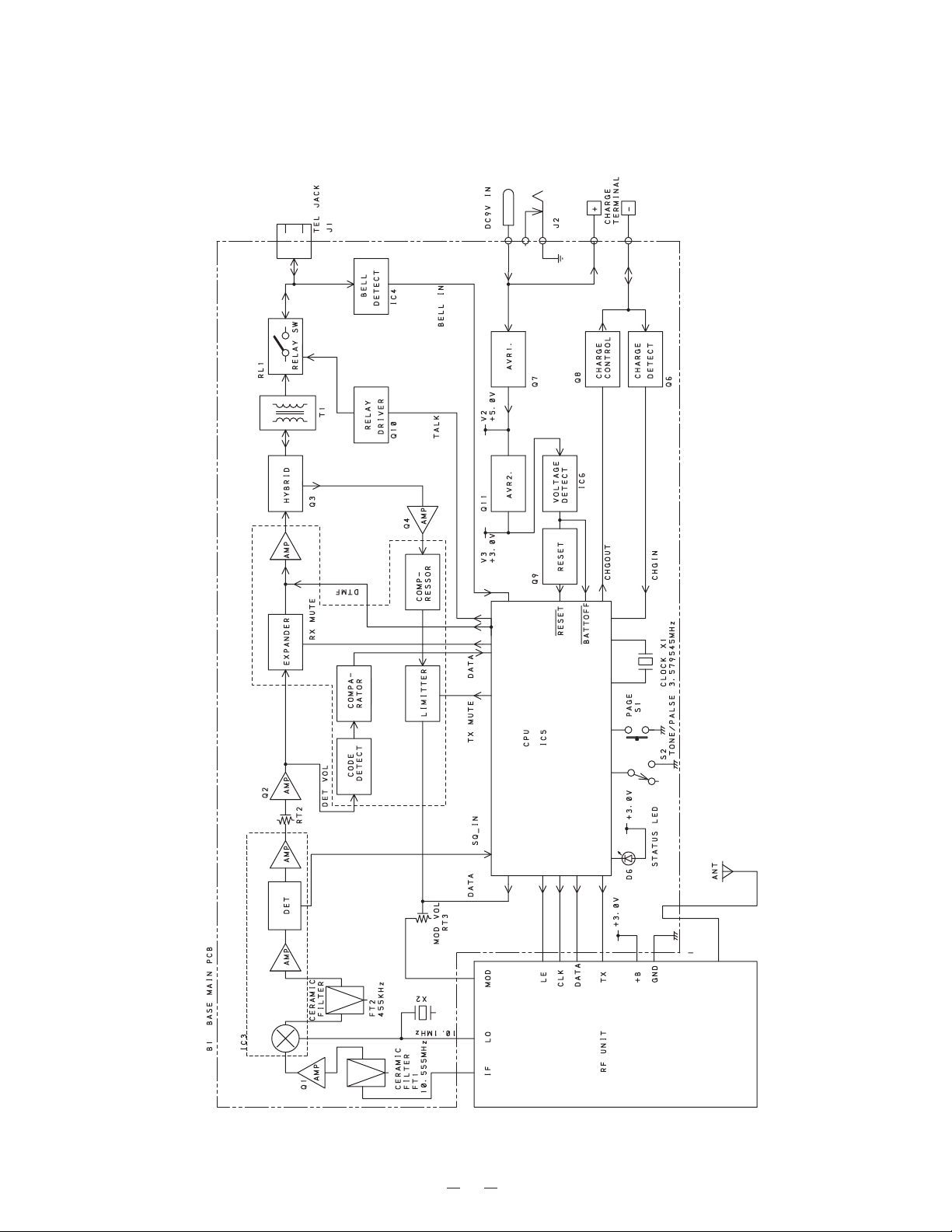

Base Unit

BLOCK DIAGRAMS

PS2501

RL-0042

2SC2712

IC1 LA8634V

2SC1623

TF-265

2SC1623

2SC1623

2SD471

2SD471

2SC1623

MB89176

2SD471

XC61CC2802PR

2SC1623

MC3361

2SC2714

FL-977

FL-971

QX-721

B301

7

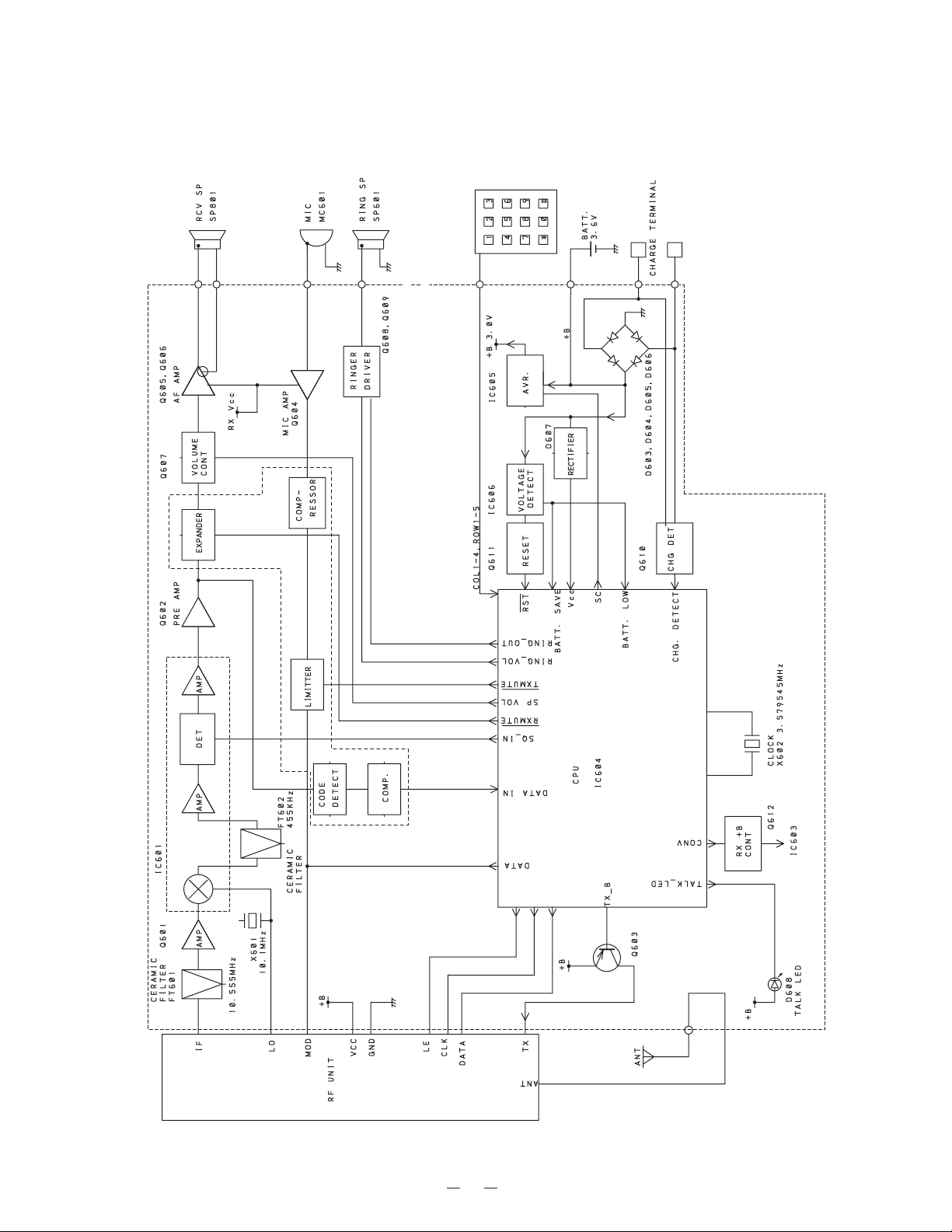

Handset

2SC1623

2SC1623

2SC1623

2SC1623

IC603 LA8634V

2SC1623

TK11130

XC612N3328MR

2SC1623

2SC1623

QX-709

MB89177

MC3361

2SC2714

FL-971

QX-721

FL-977

2SC1623

2SA812

B501

8

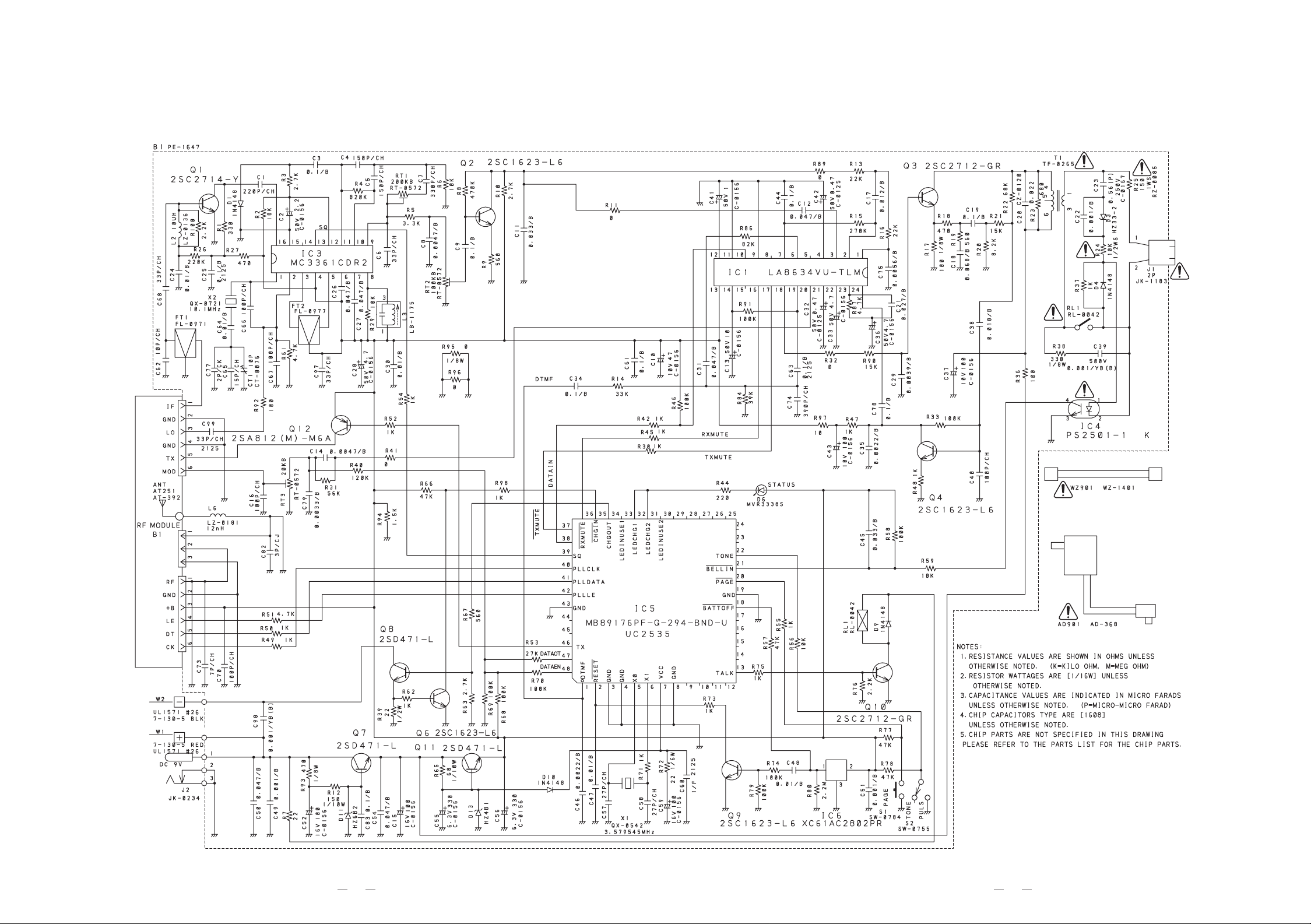

Base Unit

SCHEMATIC DIAGRAMS

9

10

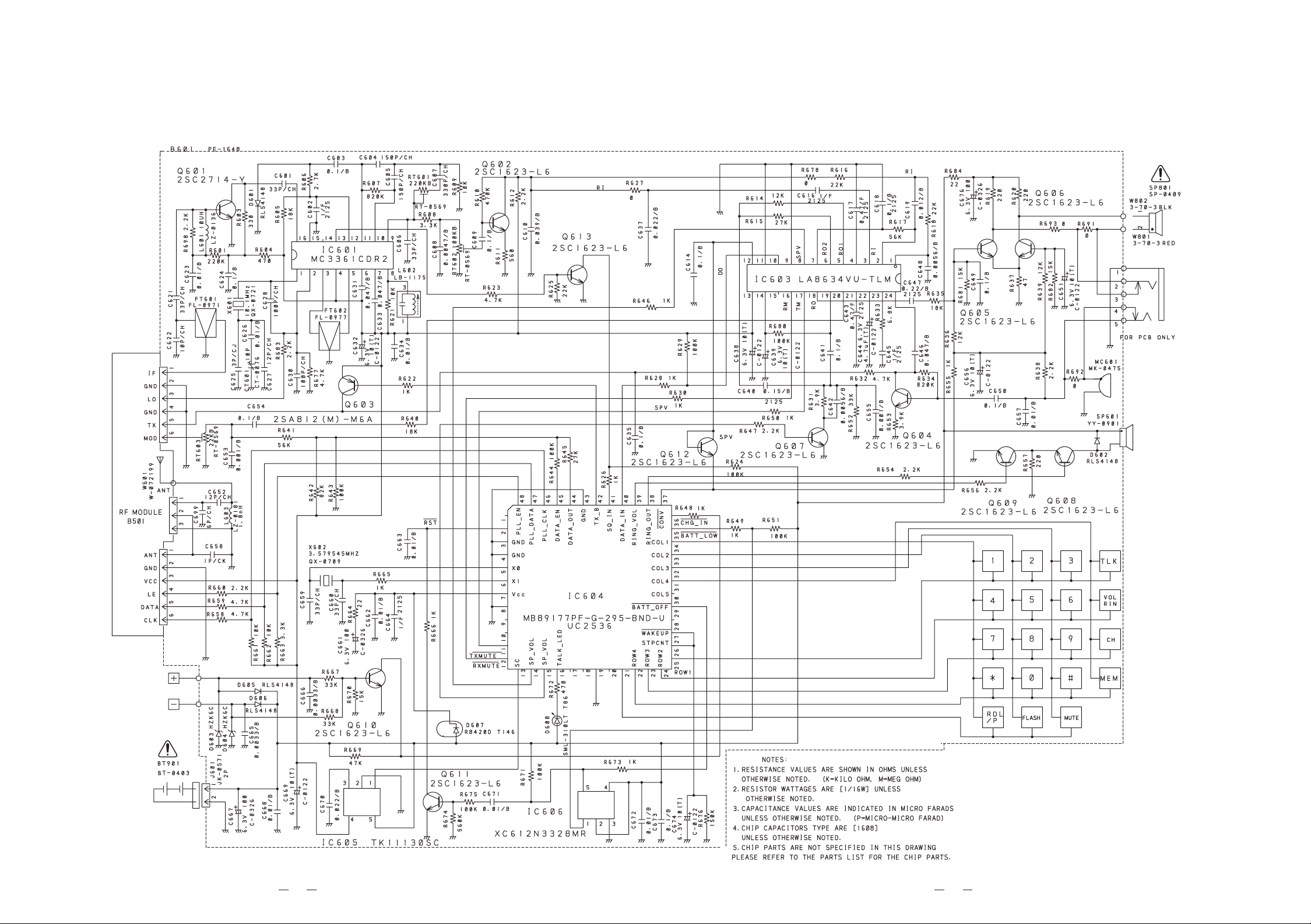

Handset

11

12

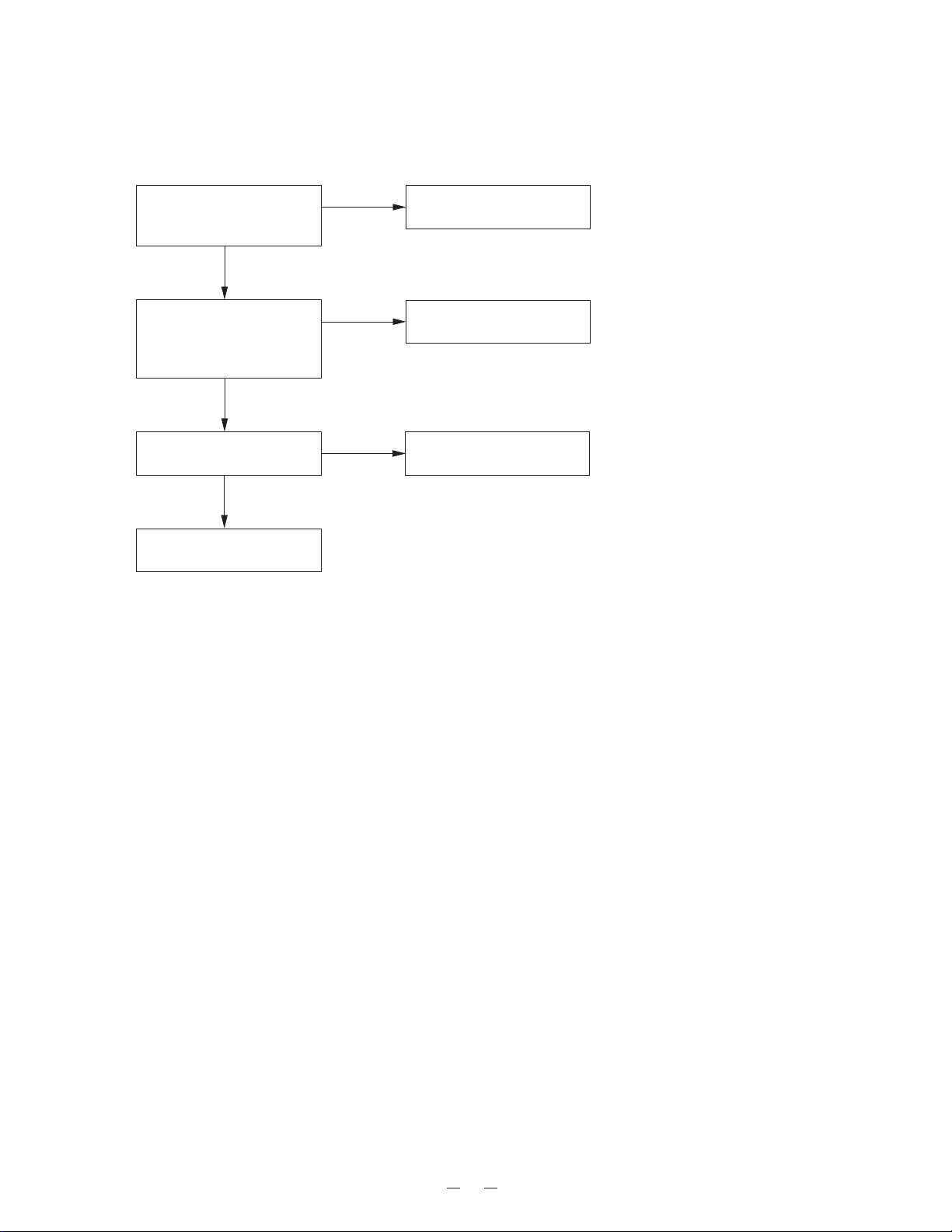

TROUBLESHOOTING HINTS

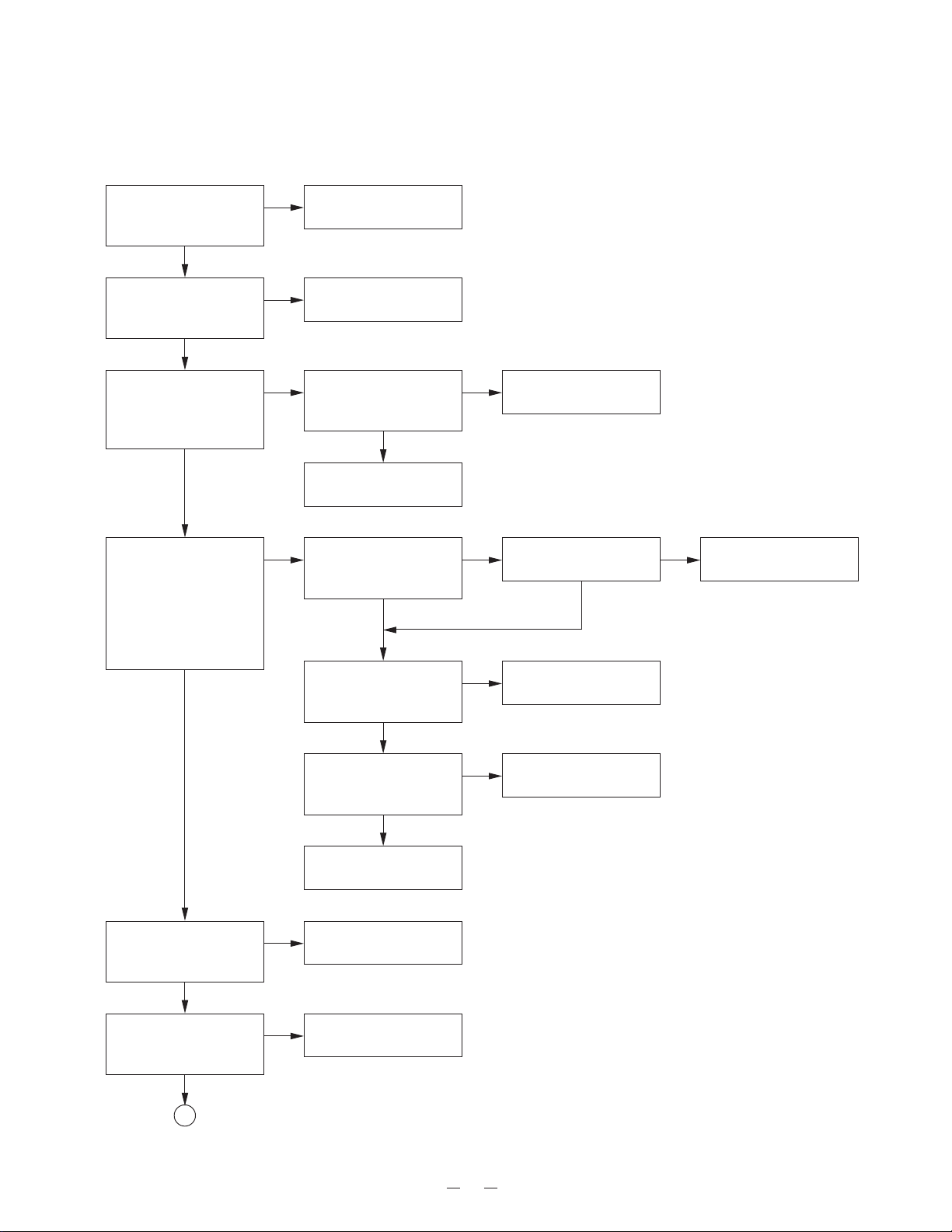

1. The bell does not ring.

When the PAGE SW of the

base is pressed, does the

ringer on the handset ring?

OK

When the TEL SG is joined

with the base to make bell

signal, is there pulse wave at

pin 4 of IC4?

OK

Is there pulse wave at

pin 21 of IC5?

OK

Check IC5 and its

peripheral circuit.

NG

NG

NG

See 2. The bell does not ring

& page does not ring.

Check IC4 and TEL network

circuit.

Check R58, C45 and R59.

13

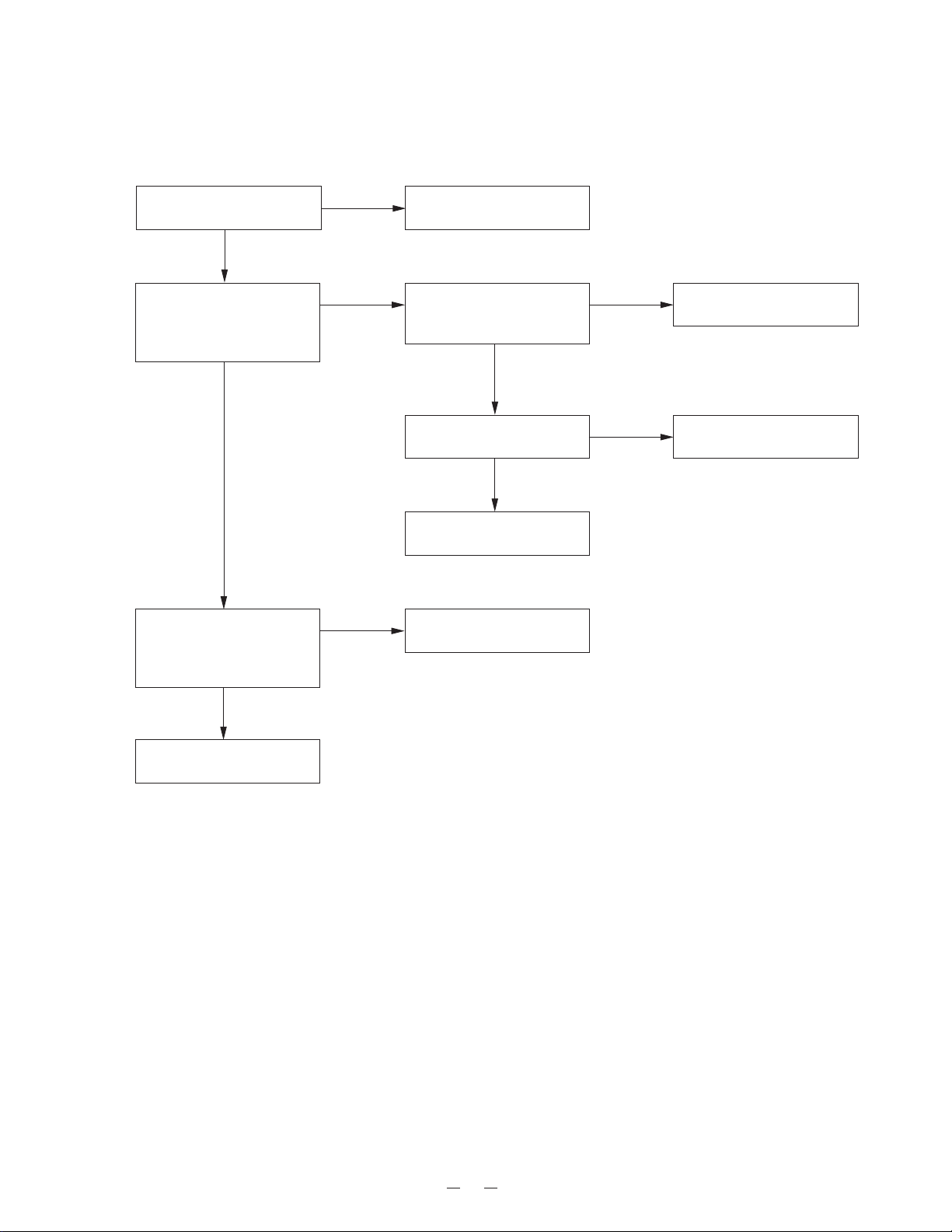

2. The bell does not ring & page does not ring.

Can the base and handset be

connected?

OK

Press handset DIAL key

while in TALK MODE.

Can key touch sound be

heard from the ringer?

OK

When the PAGE SW of the

base is pressed, does pin20

of IC5 change from high to

low?

NG

NG

NG

See 3. The base and handset

cannot be connected.

When the key of the handset is

pressed, can the pulse output

at pin 38 of IC604 be seen?

OK

At the Q608 collector, can the

pulse wave be seen?

OK

Check RINGER SP601.

Check R55, R77 and S1.

NG

NG

Check IC604.

Check R654, R657 and D602.

OK

Check IC5 and its peripheral

circuit.

14

3. The base and handset cannot be connected.

Check whether the base

is able to set in the test

mode 1.

OK

Check the TX POWER

and the TX FREQUENCY

on the base unit.

OK

Set the base in the test

mode 3, check whether

deviation of the TX data

is app. 8 kHz Dev.

OK

Set the base in the test

mode 8, 902.952467

MHz (250 Hz ±8 kHz

Dev.) 1mV output signal

from RF jack is applied.

Can the status LED be

lighted?

OK

NGACheck IC5 and its

peripheral circuit.

NG

Check base RF unit.

NG Check whether there is a

250 Hz data wav eform at

“MOD” of RF unit.

OK

Check base RF unit.

NG Check whether there is a

250 Hz data wav eform at

pin 9 of IC3.

OK

Check whether there is a

250 Hz data wav eform at

the Q2 collector.

OK

Check RT3, R40, R68,

NG

R69, R53, R70 and C79.

Check IC3, Q1 and their

NG

peripheral circuit.

Check RT2, Q2 and their

NG

peripheral circuit.

OK

NG

Check base RF unit.

Check whether the

handset is able to set in

the test mode 1.

OK

Check the TX POWER

and the TX FREQUENCY

on the handset unit.

OK

Check whether there is a

250 Hz data wav eform at

pin 38 of IC5.

Check IC5 and its

peripheral circuit.

Check IC604 and its

NG

peripheral circuit.

NG

Check handset RF unit.

OK

Check R42, R46, IC1 and

NG

their peripheral circuit.

15

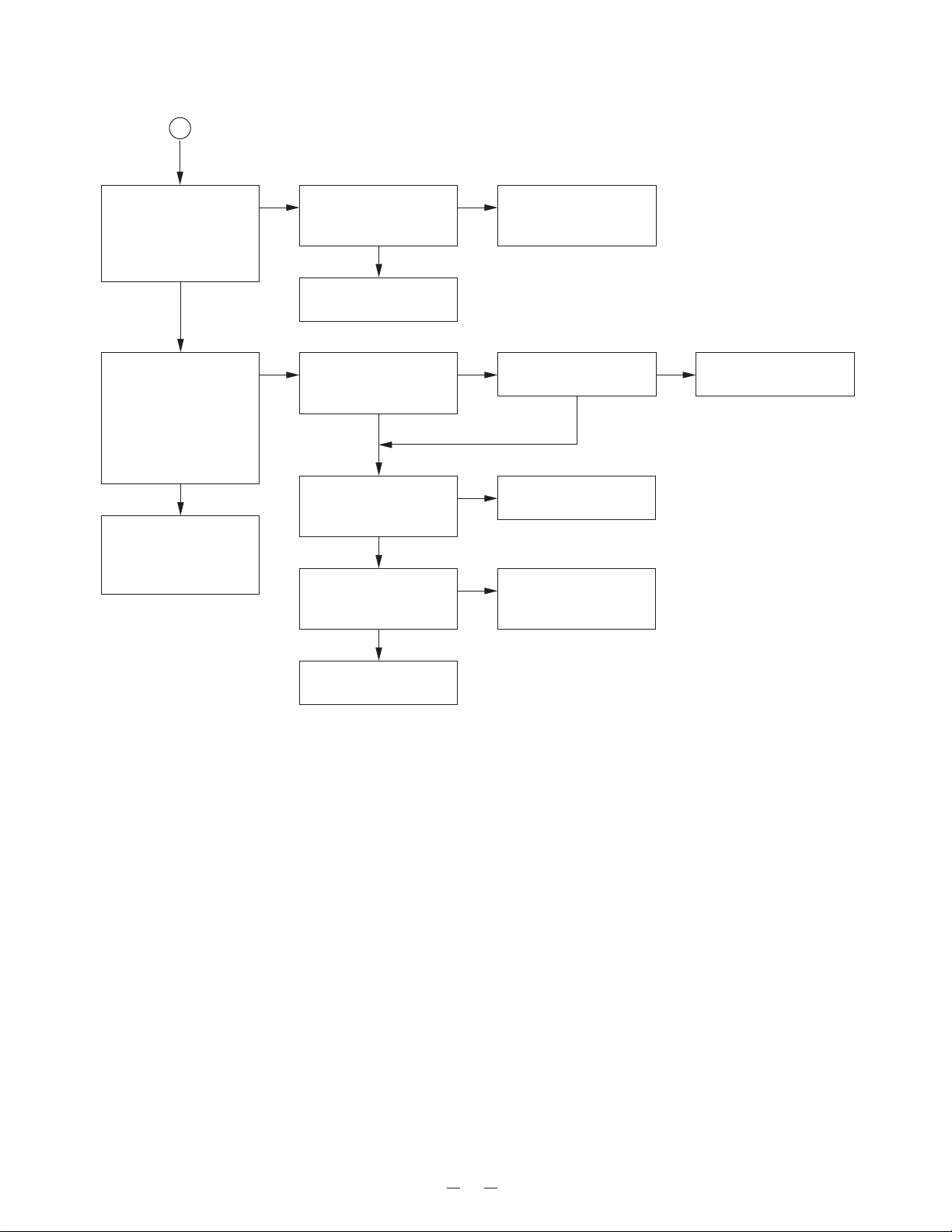

A

Set the handset in the

test mode 3, check

whether deviation of the

TX data is app. 8 kHz

Dev.

OK

test mode 6, 926.997467

MHz (250 Hz ±8 kHz

Dev.) 1mV output signal

from RF jack is applied.

Check whether the bell

ring.

OK

Place the handset on the

base to charge about 5

seconds, then connect

again.

NG Check whether there is a

250 Hz data wavef orm at

“MOD” of RF unit.

OK

Check handset RF unit.

NG Check whether the 250

Hz data waveform from

pin 9 of IC601 is fed.

OK

Check whether there is a

250 Hz data wavef orm at

the Q602 collector.

OK

Check whether there is a

250 Hz data wavef orm at

pin 40 of IC604.

OK

Check RT603, R641,

NG

R642, R643, R644,

R645 and C653.

Check IC601, Q601 and

NG

their peripheral circuit.

Check RT602, Q602 and

NG

their peripheral circuit.

Check R628, R629,

NG

IC603 and their

peripheral circuit.

OK

NGSet the handset in the

Check handset RF unit.

Check IC604 and its

peripheral circuit.

16

Loading...

Loading...