Page 1

FM TRANSCEIVER

FT-2800M

Technical Supplement

©2003 VERTEX STANDARD CO., LTD. EH014N90A

VERTEX STANDARD CO., LTD.

4-8-8 Nakameguro, Meguro-Ku, Tokyo 153-8644, Japan

VERTEX STANDARD

US Headquarters

10900 Walker Street, Cypress, CA 90630, U.S.A.

International Division

8350 N.W. 52nd Terrace, Suite 201, Miami, FL 33166, U.S.A.

YAESU EUROPE B.V.

P.O. Box 75525, 1118 ZN Schiphol, The Netherlands

YAESU UK LTD.

Unit 12, Sun Valley Business Park, Winnall Close

Winchester, Hampshire, SO23 0LB, U.K.

VERTEX STANDARD HK LTD.

Unit 5, 20/F., Seaview Centre, 139-141 Hoi Bun Road,

Kwun Tong, Kowloon, Hong Kong

PWR MHz REV LOW D/MR

Introduction

This manual provides technical information necessary for servicing the FT-2800M FM Transceiver.

Servicing this equipment requires expertise in handling surface-mount chip components. Attempts by non-qualified per-

sons to service this equipment may result in permanent damage not covered by the warranty, and may be illegal in some

countries.

Two PCB layout diagrams are provided for each double-sided circuit board in the Transceiver. Each side of is referred to

by the type of the majority of components installed on that side (“leaded” or “chip-only”). In most cases one side has only

chip components, and the other has either a mixture of both chip and leaded components (trimmers, coils, electrolytic

capacitors, ICs, etc.), or leaded components only.

While we believe the technical information in this manual to be correct, VERTEX STANDARD assumes no liability for

damage that may occur as a result of typographical or other errors that may be present. Your cooperation in pointing out

any inconsistencies in the technical information would be appreciated.

Contents

Specifications..................................................... 2

Exploded View & Miscellaneous Parts........... 3

Block Diagram .................................................. 5

Circuit Description .......................................... 7

Alignment .......................................................... 9

Board Unit (

µCOM Unit /RF Unit Circuit Diagram ..........................13

µCOM Unit Parts Layout .............................................. 15

µCOM Unit Parts List ................................................... 17

RF Unit Parts Layout .....................................................21

RF Unit Parts List ..........................................................23

Schematics, Layouts & Parts

)

1

Page 2

Specifications

General

Frequency Range: Tx 144 - 146 MHz or 144 - 148 MHz

Rx 144 - 146 MHz or 137 - 174 MHz

Channel Step: 5/10/12.5/15/20/25/50/100 kHz

Standard Repeater Shift: ±600 kHz

Frequency Stability: Better than ±10 ppm [–4 °F to +140 °F (–20 °C to +60 °C)]

Modes of Emission: F2/F3

Antenna Impedance: 50 Ohms, unbalanced

Supply voltage: 13.8 V DC ±15%, negative ground

Current Consumption (typical): Rx: less than 0.7 A, less than 0.3 A (squelched)

Tx: 10 A (65 W)/7 A (25 W)/5 A (10 W)/4 A (5 W)

Operating Temperature Range: –4° F to +140° F (–20° C to +60° C)

Case Size (WxHxD): 6.3” x 2.0” x 7.3” (160 x 50 x 185 mm) (w/o knobs)

Weight (Approx.): 4.0 lb (1.8 kg)

Transmitter

Output Power: 65 W/25 W/10 W/5 W

Modulation Type: Variable Reactance

Maximum Deviation: ±5 kHz/±2.5 kHz

Spurious Radiation: Better than –60 dB

Microphone Impedance: 2000 Ohms

Receiver

Circuit Type: Double Conversion Superheterodyne

Ifs: 21.7 MHz & 450 kHz

Sensitivity (for 12dB SINAD): Better than 0.2 µV

Selectivity (–6/–60dB): 12 kHz/28 kHz

IF Rejection: Better than 70 dB

Image Rejection: Better than 70 dB

Maximum AF Output: 3 W into 4 Ohms @10 % THD

Specifications subject to change without notice or obligation. Specifications guaranteed only within Amateur band

2

Page 3

Ä

Å

S8101427

CONNECTOR

(with BLADE FUSE)

S8002057

S8002059

CASE-FRONT

S8002062

BUTTON

S8002056

REFLECTOR

S8002060

FILTER-LCD

S8002061

CONNECT-LCD

S8101434

LCD

S8002055

PLATE-EARTH

µCOM Unit

Â

CASE-MAIN

Â

Â

Exploded View & Miscellaneous Parts

S8101435

CABLE

Â

S8002064

SPACER

S8002052

KNOB-VOL

Á

S8002052

KNOB-VOL

Á

S8002053

Á

KNOB-DIAL

Screw List

REF. VXSTD P/N Description Qty.

U30308007 FLAT HEAD SCREW M3x8B 6

À

S8002065 BOLT CAP M3x20 BZC 3

Á

S8002066 TAPTITE SCREW 3x8ZC 4

Â

U44306001 TAPTITE SCREW M3x6 9

Ã

S8002067 TAPTITE SCREW 3x10ZC 8

Ä

S8002068 WASHER-PLAIN 2

Å

RF ASSY

À

À

S8002058

COVER-BOTTOM ASSY

Accessories

Description VXSTD P/N

FOOT S8002050

BRACKET S8002051

BLADE FUSE ATC 15A Q0000075

CABLE ND-A35-2500CB S8101436

MIC MH48A6J AAA43X001

À

À

À

À

S8002063

CAP-SP

Ä

Ã

Å

Ã

Ã

Ã

Ä

Ã

Ä

Ä

Ã

Ä

S8101433

SPEAKER

Ã

Ã

Ã

Ä

Ä

3

Page 4

Exploded View & Miscellaneous Parts

Note

4

Page 5

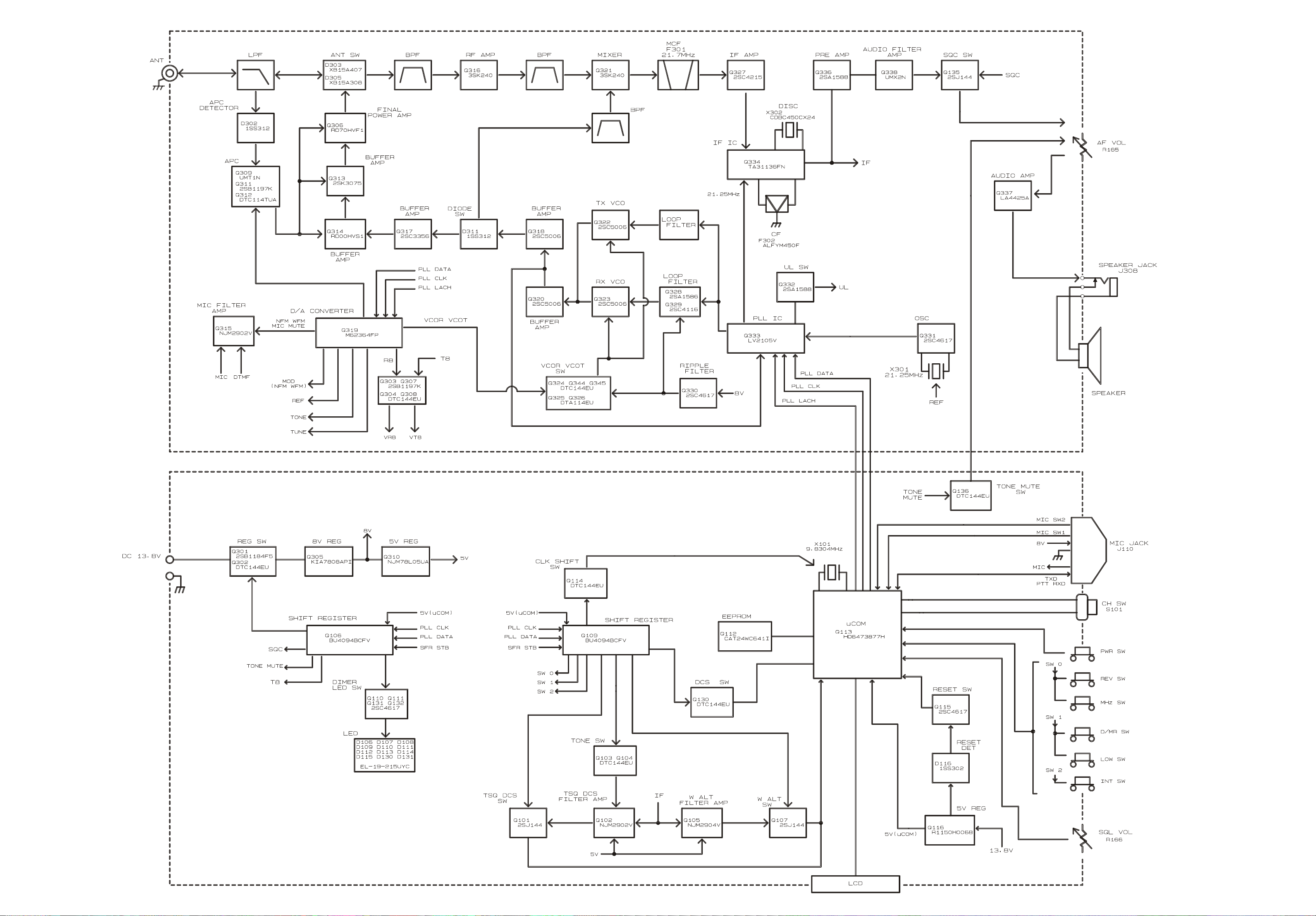

Block Diagram

5

Page 6

Block Diagram

Note

6

Page 7

Circuit Description

Reception and transmission are switched by “RX” and

“TX” lines from the microprocessor unit (MPU). The receiver uses double-conversion superheterodyne circuitry,

with a 21.7 MHz 1st IF and 450 kHz 2nd IF. The 1st local, produced by a PLL synthesizer, yields the 21.7 MHz

1st IF.

The 2nd local uses a 21.250 MHz (21.7 MHz - 450 kHz)

signal generated by a crystal oscillator. The 2nd mixer

and other circuits use a custom IC to convert and amplify

the 2nd IF, and detect FM to obtain demodulated signals.

During transmit, the PLL synthesizer oscillates at the desired frequency directly, for amplification to obtain RF

power output. During transmit, voice modulation and

CTCSS (or DCS) modulation are applied to this synthesizer. Transceiver functions, such as TX/RX control, PLL

synthesizer settings, and channel programming, are controlled using the MPU.

Receiver

Incoming RF signals from the antenna connector are delivered to the RF Unit, and pass through a lowpass filter

(LPF) consisting of coils L303, L305, and L307, capacitors C303, C309, C310, and C316, and antenna switching

diodes D305 and D306 (Both MA111) for delivery to the

receiver front end.

Signals within the frequency range of the transceiver are

then passed through a varactor-tuned bandpass filter consisting of diodes D308, D322, D310 and D323 (all

HVC3508), and coils L334, L335, L320 and L322 and

associated circuitry before RF amplification by Q316

(3SK240).

The amplified RF signal is then bandpass filtered again

by varactor-tuned resonators consisting of diodes D312,

D324, D313 and D325 (all HVC3508), and coils L336,

L337, L325 and L327 and associated circuitry, to ensure

pure in-band input to 1st mixer Q321 (3SK240).

The 2nd local in the IF-IC is produced from crystal X302

(21.250 MHz), and the 1st IF is converted to 450 kHz by

the 2nd mixer and stripped of unwanted components by

ceramic filter F302. After passing through a limiter amplifier, the signal is demodulated by the FM detector.

Demodulated receive audio from the IF-IC is amplified

by Q336 (2SA1588Y) and Q338 (UMX2M). After volume adjustment by the AF power amplifier Q337

(LA4425A), the audio signal is passed to the optional

headphone or 8-ohm loudspeaker.

PLL Synthesizer

The 1st local maintains stability from the PLL synthesizer by using a 21.250 MHz reference signal from crystal

X301. PLL synthesizer IC Q333 (LV2105V) consists of

a prescaler, reference counter, swallow counter, programmable counter, a serial data input port to set these counters

based on external data, a phase comparator, and a charge

pump.

The PLL-IC divides the 21.250 MHz reference signal by

4,250 using the reference counter (5.0 kHz comparison

frequency). The VCO output is divided by the prescaler,

swallow counter and programmable counter. These two

signals are compared by the phase comparator and applied to the charge pump. A voltage proportional to their

phase difference is delivered to the low-pass filter circuit,

then fed back to the VCO as a voltage with phase error,

controlling and stabilizing the oscillating frequency. This

synthesizer also operates as a modulator during transmit.

The RX VCO is comprised of Q323 (2SC5006) and

D314/D326 (Both 1SV282), and oscillates at 21.7 MHz

during receive.

The TX VCO is comprised of Q322 (2SC5006) and

D316/D327 (Both 1SV282) and oscillates at the funda-

mental frequency during transmit, with direct frequencymodulation using varactor diode D315 (1SV214).

Buffered output from the VCO Unit is amplified by Q318

(2SC5006) and lowpass-filtered by L339, C414, and

C413, to provide a pure 1st local signal between 112.3

and 152.3 MHz, which is delivered to the 1st mixer.

The 21.7 MHz 1st mixer product then passes through dual

monolithic crystal filter F301 (7.5 kHz BW), and is amplified by Q327 (2SC4215Y) and delivered to the input

of the FM IF subsystem IC Q334 (TA31136FN).

This IC contains the 2nd mixer, 2nd local oscillator, limiter amplifier, FM detector, noise amplifier, S-meter amplifier and squelch gates.

The VCO output passes through buffer amplifier Q320

(2SC5005), and a portion is fed to the PLL IC, and at the

same time is amplified by Q318 (2SC5006) to obtain

stable output. Synthesizer output is fed to the 1st mixer

by diode switch D311 (1SS321) during receive, and to

pri-drive amplifier Q317 (2SC3356) for transmit.

The reference oscillator feeds the PLL synthesizer, and is

composed of crystal X301 (21.250 MHz) and transmit

(DCS) modulation circuit D317 (HVC350B).

The VCO DC supply is regulated by Q330 (2SC4617).

7

Page 8

Circuit Description

Transmitter

The speech signal from the microphone is delivered via

the MIC Jack to the RF Unit; after passing through Q315

(NJM2902V) which consists of amplifier, pre-emphasis,

limiter (IDC instantaneous deviation control) and lowpass

filter, to Q319 (M6364FP) which is adjusted for optimum deviation level and delivered to the TX VCO Q322.

The speech signal from the microphone and CTCSS are

FM modulated by the TX VCO of the synthesizer, while

DCS audio is modulated by the reference frequency oscillator of the synthesizer.

Synthesizer output, after passing through diode switch

D311 (1SS321), is amplified by pri- drivers Q317

(2SC3356) and Q314 (RD00HVS1), driver Q313

(2SK3075), and power amplifier Q305 (RD70HVS1)

to obtain full RF output. The RF energy then passes

through antenna switch D303 (XB15A407) and a lowpass filter circuit and finally to the antenna connector.

RF output power from the final amplifier is sampled by

C318 and C324 and is rectified by D302 (1SS321).

The resulting DC is fed through Automatic Power Con-

troller Q309 (UMT1N), Q312 (DTC114), and Q311

(2SB1197) to transmitter RF amplifier Q305 and is used

to provide control of the power output.

Generation of spurious products by the transmitter is minimized by the fundamental carrier frequency being equal

to the final transmitting frequency, modulated directly in

the transmit VCO.

Additionally harmonic suppression is provided by a lowpass filter consisting of L303, L305, C303, C309, C310,

and C316, resulting in more than 60 dB of harmonic suppression prior to delivery of the RF

8

Page 9

Alignment

Introduction and Precautions

The FT-2800M has been carefully aligned at the factory

for the specified performance at the 144 MHz amateur

band. Realignment should therefore not be necessary except in the event of a component failure. All component

replacement and service should be performed only by an

authorized Vertex Standard representative, or the warranty

policy may be voided.

The following procedures cover the sometimes critical and

tedious adjustments that are not normally required once

the transceiver has left the factory. However, if damage

occurs and some parts are replaced, realignment may be

required. If a sudden problem occurs during normal operation, it is likely due to component failure; realignment

should not be done until after the faulty component has

been replaced.

We recommend that servicing be performed only by authorized Vertex Standard service technicians who are experienced with the circuitry and fully equipped for repair

and alignment. Therefore, if a fault is suspected, contact

the dealer from whom the transceiver was purchased for

instructions regarding repair. Authorized Vertex Standard

service technicians realign all circuits and make complete

performance checks to ensure compliance with factory

specifications after replacing any faulty components.

Those who do undertake any of the following alignments

are cautioned to proceed at their own risk. Problems caused

by unauthorized attempts at realignment are not covered

by the warranty policy. Also, Vertex Standard must reserve the right to change circuits and alignment procedures in the interest of improved performance, without

notifying owners.

Under no circumstances should any alignment be attempted unless the normal function and operation of the transceiver are clearly understood, the cause of the malfunction has been clearly pinpointed and any faulty components replaced, and the need for realignment determined

to be absolutely necessary.

Required Test Equipment

The following test equipment (and thorough familiarity

with its correct use) is necessary for complete realignment. Correction of problems caused by misalignment

resulting from use of improper test equipment is not covered under the warranty policy. While most steps do not

require all of the equipment listed, the interactions of some

adjustments may require that more complex adjustments

be performed afterwards. Do not attempt to perform only

a single step unless it is clearly isolated electrically from

all other steps. Have all test equipment ready before beginning, and follow all of the steps in a section in the

order presented.

r Regulated DC Power Supply: adjustable from 10 to

17 VDC, 15 A

r RF Signal Generator with calibrated output level at

200 MHz

r Frequency Counter: ±0.1 ppm accuracy at 200 MHz

r AF Signal Generator

r SINAD Meter

r Deviation Meter (linear detector)

r AF Milivoltmeter

r AF Dummy Load: 8-Ohm, 5 W

r DC Voltmeter: high impedance

r Inline Wattmeter with 5% accuracy at 200 MHz

r 50-Ohm non-reactive Dummy Load:

r 100 watts at 200 MHz

r VHF Sampling Coupler

Set up the test equipment as shown for the transceiver

alignment, and apply 13.8 VDC power to the transceiver.

Alignment Preparation & Precautions

A dummy load and inline wattmeter must be connected to

the antenna jack in all procedures that call for transmission, except where specified otherwise. Correct alignment

is not possible with an antenna. After completing one step,

read the following step to determine whether the same

test equipment will be required. If not, remove the test

equipment (except dummy load and wattmeter, if connected) before proceeding.

Correct alignment requires that the ambient temperature

in the repair shop be the same as that of the transceiver

and test equipment, and that this temperature be held constant between 68 oC and 86 oF (20 oC ~ 30 oC). When

the transceiver is brought into the shop from hot or cold

air it should be allowed some time for thermal equalization with the environment before alignment. If possible,

alignments should be made with oscillator shields and circuit boards firmly affixed in place. Also, the test equipment must be thoroughly warmed up before beginning.

Notes: Signal levels in dB referred to in alignment are

based on 0 dBµ = 0.5 µV.

9

Page 10

Alignment

Entering the Alignment mode

Alignment of the FT-2800M is performed using a frontpanel software-based procedure. To perform alignment

of the transceiver, it must first be placed in the “Alignment Mode,” in which the adjustments will be made and

then stored into memory.

To enter the Alignment mode:

1. Press and hold in the [LOW] key and [D/MR] key

while turning the radio on. Once the radio is on, release these two keys.

2. Press and hold the [MHz] key for one second to activate the “Set” (Menu) mode.

3. Rotate the DIAL knob to select “35 D/ASMT,” then

press the [MHz] key.

4. You will now note the appearance of “REF” on the

display, this signifies that the transceiver is now in

the “Alignment mode.”

PLL Reference Frequency (REF)

1. Tune the transceiver to 146.000 MHz.

2. Set the transceiver to Alignment mode, then rotate the

DIAL knob to set the Alignment parameter to “REF.”

3. Press the PTT switch to activate the transmitter, and

press the [REV] or [D/MR] key, as needed, so that

the counter frequency reading is 146.000 MHz.

4. Press and hold the [LOW] key for one second to save

the new setting.

5. Press and hold the [MHz] key for one second to exit

to the normal operation.

PLL VCO

1. Connect the DC voltmeter to TP-RVC on the RF Unit.

2. Tune the frequency to 146.000 MHz.

3. Adjust L330 on the RF Unit for 1.5 V on the DC volt-

meter.

4. Connect the DC voltmeter to TP-TVC on the RF Unit.

5. Press the PTT switch to activate the transmitter, and

adjust L329 on the RF Unit for 1.3 V on the DC voltmeter.

RF Front-end Tuning

(TUN137/TUN146/TUN160/TUN173)

1. Connect the DC voltmeter to the Test Point (RSSI:

Pin 6 of J307) on the RF Unit.

2. Tune the transceiver to 137.050 MHz.

3. Set the transceiver to Alignment mode, then rotate the

DIAL knob to set the Alignment parameter to

“TUN137.”

4. Inject a 137.050 MHz signal at a level of –5 dBµ (with

1 kHz modulation @ ±3.5 kHz deviation) from the

RF Signal Generator.

5. Press the [REV] or [D/MR] key for maximum deflection of the DC voltmeter.

6. Press and hold the [LOW] key for one second to save

the new setting, then press and hold the [MHz] key

for one second to exit to the normal operation.

7. Tune the transceiver to 146.050 MHz.

8. Set the transceiver to Alignment mode, then rotate the

DIAL knob to set the Alignment parameter to

“TUN146.”

10

TP-RVC

L329

RSSI

TP-TVC

L330

RF UNIT ALIGNMNT POINTS

Page 11

Alignment

9. Inject a 146.050 MHz signal at a level of –5 dBµ (with

1 kHz modulation @ ±3.5 kHz deviation) from the

RF Signal Generator.

10. Press the [REV] or [D/MR] key for maximum

def4lection of the DC voltmeter and maximum deflection of the SINAD meter.

11. Press and hold the [LOW] key for one second to save

the new setting, then press and hold the [MHz] key

for one second to exit to the normal operation.

12. Tune the transceiver to 160.050 MHz.

13. Set the transceiver to Alignment mode, then rotate the

DIAL knob to set the Alignment parameter to

“TUN160.”

14. Inject a 160.050 MHz signal at a level of –5 dBµ (with

1 kHz modulation @ ±3.5 kHz deviation) from the

RF Signal Generator.

15. Press the [REV] or [D/MR] key for maximum deflection of the DC voltmeter voltmeter at the higher side

of the bandpass filter peaks.

16. Press and hold the [LOW] key for one second to save

the new setting, then press and hold the [MHz] key

for one second to exit to the normal operation.

17. Tune the transceiver to 173.050 MHz.

18. Set the transceiver to Alignment mode, then rotate the

DIAL knob to set the Alignment parameter to

“TUN173.”

19. Inject a 173.050 MHz signal at a level of –5 dBµ (with

1 kHz modulation @ ±3.5 kHz deviation) from the

RF Signal Generator.

20. Press the [REV] or [D/MR] key for maximum deflection of the DC voltmeter at the higher side of the

bandpass filter peaks.

21. Press and hold the [LOW] key for one second to save

the new setting, then press and hold the [MHz] key

for one second to exit to the normal operation.

S-Meter Sensitivity (SMTL 10/SMTL 2)

1. Set the transceiver to Alignment mode, then rotate the

DIAL knob to set the Alignment parameter to “SMTL

10.”

2. Inject a 146.050 MHz signal at a level of +25 dBµ

(with 1 kHz modulation @ ±3.5 kHz deviation) from

the RF Signal Generator.

3. Press and hold the [LOW] key for one second to save

the new setting.

4. Rotate the DIAL knob one click to clockwise to set

the Alignment parameter to “SMTL 2.”

5. Reduce the RF Signal Generator output level to –5

dBµ.

6. Press and hold the [LOW] key for one second to save

the new setting.

7. Press and hold the [MHz] key for one second to exit

to the normal operation.

TX Power Output

(TXPW H/TXPW M/TXPW L2/TXPW L1)

1. Tune the transceiver to 146.000 MHz, and set the

Transmitter Power Level to “HIGH.”

2. Set the transceiver to Alignment mode, then rotate the

DIAL knob to set the Alignment parameter to “TXPW

H.”

3. Press the PTT switch to activate the transmitter, and

press the [REV] or [D/MR] key for 65 Watts on the

wattmeter, and confirm that supply current remains

below 12.5 A.

4. Press and hold the [LOW] key for one second to save

the new setting, then rotate the DIAL knob one click

to clockwise to set the Alignment parameter to

“TXPW M.”

5. Press the PTT switch to activate the transmitter, and

press the [REV] or [D/MR] key for 25 Watts on the

wattmeter, and confirm that supply current remains

below 7.5 A.

6. Press and hold the [LOW] key for one second to save

the new setting, then rotate the DIAL knob one click

to clockwise to set the Alignment parameter to

“TXPWL2.”

7. Press the PTT switch to activate the transmitter, and

press the [REV] or [D/MR] key for 10 Watts on the

wattmeter, and confirm that supply current remains

below 5 A.

8. Press and hold the [LOW] key for one second to save

the new setting, then rotate the DIAL knob one click

to clockwise to set the Alignment parameter to

“TXPWL1.”

9. Press the PTT switch to activate the transmitter, and

press the [REV] or [D/MR] key for 5 Watts on the

wattmeter, and confirm that supply current remains

below 4 A.

10. Press and hold the [LOW] key for one second to save

11

Page 12

Alignment

the new setting, then press and hold the [MHz] key

for one second to exit to the normal operation.

TX Deviation (MODWFM/MODNFM)

1. Tune the transceiver to 146.000 MHz.

2. Inject a 1 kHz audio tone at a level of 60 mV from the

Audio Generator.

3. Set the transceiver to Alignment mode, then rotate the

DIAL knob to set the Alignment parameter to

“MODWFM.”

4. Press the PTT switch to activate the transmitter, and

press the [REV] or [D/MR] key so that the deviation

meter reading is 4.2 kHz.

5. Press and hold the [LOW] key for one second to save

the new setting, then rotate the DIAL knob one click

to clockwise to set the Alignment parameter to

“MODNFM.”

6. Press the PTT switch to activate the transmitter, and

press the [REV] or [D/MR] key so that the deviation

meter reading is 2.1 kHz.

7. Press and hold the [LOW] key for one second to save

the new setting, then press and hold the [MHz] key

for one second to exit to the normal operation.

CTCSS TX Deviation (TONE W/TONE N)

1. Tune the transceiver to 146.000 MHz.

2. Set the CTCSS tone to 100 Hz.

r Press and hold the [MHz] key for one second to

activate the “Set” (Menu) mode.

r Rotate the DIAL knob to select “27 SQ TNF.”

r Press the [MHz] key momentarily, then rotate the

DIAL knob to select to 100.0 (Hz).

r Press and hold the [MHz] key for one second to

exit to the normal operation

3. Set the transceiver to Alignment mode, then rotate the

DIAL knob to set the Alignment parameter to “TONE

W.”

4. Press the PTT switch to activate the transmitter, and

press the [REV] or [D/MR] key so that the deviation

meter reading is 0.6 kHz.

5. Press and hold the [LOW] key for one second to save

the new setting, then rotate the DIAL knob one click

to counter clockwise to set the Alignment parameter

to “TONE N.”

6. Press the PTT switch to activate the transmitter, and

press the [REV] or [D/MR] key so that the deviation

meter reading is 0.3 kHz.

7. Press and hold the [LOW] key for one second to save

the new setting, then press and hold the [MHz] key

for one second to exit to the normal operation.

12

Page 13

3.88V

(0V)

7.58V

(0V)

7.33V

(0V)

µCOM Unit /RF Unit Circuit Diagram

HI(65W):13.79V(13.31V)

M(25W):13.79V(13.52V)

L2(10W):13.79V(14.16V)

L1(5W):13.79V(13.79V)

13.75V

(13.62V)

HI(65W):0V(7.89V)

M(25W):0V(7.9V)

L2(10W):0V(7.9V)

L1(5W):0V(7.9V)

HI(65W):0V(2.43V)

M(25W):0V(2.04V)

L2(10W):0V(1.11V)

L1(5W):0V(0.76V)

0V

(0V)

0V

(2.5V)

13.07V

(12.94V)

4.18V(4.18V)

0V

(0V)

13.66V

(13.48V)

HI(65W):0V(2.99V)

M(25W):0V(2.44V)

L2(10W):0V(1.6V)

L1(5W):0V(1.25V)

7.98V

(7.24V)

HI(65W):13.79V(13.31V)

M(25W):13.79V(13.56V)

L2(10W):13.79V(13.74V)

L1(5W):13.79V(13.66V)

HI(65W):0V(2.65V)

M(25W):0V(0.37V)

L2(10W):0V(0.35V)

L1(5W):0V(0.35V)

7.98V

(7.98V)

7.95V

(0V)

HI(65W):13.79V(13.23V)

M(25W):13.79V(13.49V)

L2(10W):13.79V(13.58V)

L1(5W):13.79V(13.55V)

HI(65W):0V(1.26V)

M(25W):0V(7.39V)

L2(10W):0V(7.40V)

L1(5W):0V(7.42V)

4.95V

(4.95V)

HI(65W):0V(7.89V)

M(25W):0V(4.21V)

L2(10W):0V(3.23V)

L1(5W):0V(2.82V)

HI(65W):0V(7.24V)

M(25W):0V(7.47V)

L2(10W):0V(7.56V)

L1(5W):0V(7.81V)

0V

(1.96V)

3.29V

(3.29V)

1.82V

(1.82V)

1.93V

(1.93V)

1.95V(1.95V)

1.86V

(1.87V)

0V

(0V)

1.93V

(2.53V)

1.94V

(2.47V)

1.95V

(2.51V)

4.95V

(4.95V)

0V

(3.2V)

0.36V

(0V)

7.15V

(0V)

5.3V

(0V)

0.71V

(0V)

5.42V

(0V)

4.52V

(5V)

1.82V

(1.82V)

5.37V

(5.28V)

0V

(6.98V)

0V

(1.29V)

1.82V

(1.82V)

6.65V

(6.65V)

0.74V

(0.29V)

0V

(1.79V)

6.92V

(0V)

1.86V

(0V)

0V

(0V)

0V

(2.24V)

1.47V

(0V)

7.21V

(0V)

1.51V

(0V)

7.41V

(0V)

0V

(1.41V)

0V

(7.26V)

1.51V

(0V)

0.71V

(0V)

0V

(7.22V)

4.97V

(4.97V)

1.5V

(0.2V)

1.85V

(1.85V)

5.1V

(0V)

7.25V

(0V)

0V

(4.11V)

5.1V

(0V)

4.38V

(0V)

7.2V

(0V)

3.76V

(3.76V)

7.26V

(7.26V)

7.94V

(7.94V)

0V

(0V)

7.2V

(0.4V)

4.79V

(4.79V)

3.24V

(3.24V)

7.98V

(7.98V)

4.4V

(4.4V)

2.47V

(2.48V)

2.55V

(2.55V)

5.6V

(0V)

4.94V

(4.94V)

1.33V

(0.77V)

0V

(0V)

0.96V

(0V)

0V

(0V)

4.84V

(4.84V)

5.57V

(0V)

0V

(0V)

4.94V

(4.94V)

0.65V

(0V)

5.07V

(0.2V)

0V(0V)

2.09V

(0V)

4.39V

(0V)

5.23V

(0V)

7.15V

(2V)

0V

(1.49V)

4.74V(0V)

5.23V(0V)

0.72V(0V)

4.18V

(4.38V)

4.89V

(4.89V)

5.6V

(0V)

1.24V

(0V)

0.65V

(0V)

1.3V

(0V)

1.95V

(0V)

1.98V

(0V)

1.07V

(1.06V)

4.42V

(0V)

4.75V

(0V)

7.93V

(0V)

2.94V

(0V)

6.55V

(6.52V)

2.45V

(0V)

13.65V

(13.47V)

13.8V

pin1:0V(0V)

pin2:0V(0V)

pin3:0V(0V)

pin5:5.01V(5.01V)

pin6:1.3V(0V)

pin8:0V(0V)

pin9:5V(5V)

pin10:0V(0V)

pin11:5.03V(5.03V)

pin12:0V(0V)

0V

(0V)

0V

(0V)

7.97V

(0V)

0V

(4.97V)

0.14V

(0.14V)

2.1V

(2.1V)

0V

(7.96V)

7.29V

(7.27V)

1.98V

(1.98V)

4.4V

(0V)

Q319

pin1:0V(3.98V)

pin2:4.38V(4.34V)

pin3:1.95V(1.96V)

pin4:0V(0V)

pin5:4.94V(4.94V)

DCS/Tone freq.<150Hz:0V(0V)

DCS/Tone freq.>150Hz:0.1V(0.1V)

2.03V

(2.03V)

1.84V

(1.84V)

pin6:0V(0.39V)

pin7:0.56V(0V)

pin8:4.94V(3.32V)

pin9:0V(0V)

pin10:4.38V(4.38V)

2.03V

(2.03V)

Q319 pin 14

HI(65W):0.64V(3.77V)

M(25W):0.64V(1.75V)

L2(10W):0.64V(1.1V)

L1(5W):0.64V(0.96V)

pin11:4.38V(0.28V)

pin12:0V(0V)

pin13:0V(0V)

pin15:0V(0.18V)

pin16:0V(0V)

1.83V

(1.83V)

4.95V

(4.95V)

pin17:4.94V(4.72V)

pin18:4.38V(4.38V)

pin19:4.91V(4.91V)

pin20:0V(0V)

pin21:0V(0V)

2.02V

(2.02V)

pin22:1.98V(1.98V)

pin23:4.38V(4.23V)

pin24:4.36V(4.36V)

WALT

ON:0V(0v)

OFF:4.99V(4.99V)

5.03V

(5.03V)

0V

(0.7V)

0V

(0V)

5.03V

(5.03V)

4.93V

(4.93V)

4.93V

(4.93V)

CLK SHT

ON:0V(0V)

0FF:4.99V(4.99V)

pin1:0V(4.96V)

pin2:4.93V(4.93V)

pin3:0V(0V)

pin4:13.78V(13.78V)

pin5:4.95V(4395V)

pin6:1.99V(2V)

pin7:0.1V(0.1V)

pin8:7.97V(7.97V)

pin9:0V(0V)

pin10:0V(0V)

pin11:0V(0V)

pin12:0V(2.46V)

RX(TX)

RX Frequency:146.1MHz

TX Frequency:146MHz

(Power Output 5W)

DCS/TSQ

ON:0V(0V)

OFF:4.99V(4.99V)

Q106

pin 12 pin 13 pin 14

DIMR

OFF 0V(0V) 0V(0V) 0V(0V)

1 0V(0V) 0V(0V) 4.98V(4.98V)

2 0V(0V) 4.97V(4.97V) 0V(0V)

3 4.97V(4.97V) 0V(0V) 0V(0V)

2.07V

(2.07V)

2.03V

(2.03V)

0V

(0V)

2.03V

(2.03V)

2.02V

(2.02V)

1.87V

(1.87V)

DCS/Tone freq.<150Hz:0V(0V)

DCS/Tone freq.>150Hz:0.3V(0.3V)

4.95V

(4.95V)

SQL

ON:5.03V(5.03V)

OFF:0V(0V)

0V

(0V)

5.03V

(5.03V)

2.03V

(2.03V)

5V

(5V)

4.99V

(4.99V)

2.03V

(2.03V)

2.02V

(2.02V)

0V

(4.97V)

5.03V

(5.03V)

0V

(0V)

CLK SHT

ON:0V(0V)

5.03V

OFF:4.99V(4.99V)

(5.03V)

DCS/Tone freq.<150Hz:4.96V(4.96V)

DCS/Tone freq.>150Hz:0V(0V)

0V

(0V)

5.03V

(5.03V)

DCS/TSQ

ON:0V(0V)

OFF:5.03V(5.03V)

4.76V

(4.76V)

4.76V

(4.76V)

4.87V

(4.87V)

5.03V

(5.03V)

0V

(0.2V)

4.76V

(4.76V)

4.76V

(4.76V)

5.03V

(5.03V)

DIMR

OFF:3.88V(3.88V)

1:2.54V(2.54V)

2:2.17V(2.17V)

3:1.91V(1.91V)

DIMR

OFF:0V(0V)

1:0.02V(0.02V)

2:0.22V(0.22V)

3:0.5V(0.5V)

DIMR

OFF:0V(0V)

1:0.67V(0.67V)

2:0.89V(0.89V)

3:1.2V(1.2V)

DIMR

OFF:0V(0V)

1:0.67V(0.67V)

2:0.89V(0.89V)

3:1.2V(1.2V)

DIMR

OFF:4.01V(4.01V)

1:2.52V(2.52V)

2:2.2V(2.2V)

3:1.96V(1.96V)

DIMR

OFF:0V(0V)

1:0.02V(0.02V)

2:0.21V(0.21V)

3:0.5V(0.5V)

4.99V

(4.99V)

0V

(0V)

1.64V

(1.64V)

0V

(0V)

(DCS ON 2.3V)

3.26V

(3.26V)

4.89V

(4.89V)

0V

(0V)

5.03V

(5.03V)

5.03V

(5.03V)

4.99V

(4.99V)

0V

(0V)

5.03V

(5.03V)

2.38V

(2.38V)

5.03V

(5.03V)

2.34V

(2.34V)

0V

(0V)

(DTMF ON 2.46V)

0V

(0V)

4.99V

(4.99V)

5.03V

(5.03V)

5.03V

(5.03V)

0V

(0V)

0.1V

(0.1V)

5.03V

(5.03V)

0V

(0V)

0.89V

(0.89V)

0V

(0V)

2.74V

(2.74V)

13V

(13V)

6.9V

(6.9V)

5.04V

(5.04V)

7.97V

(7.97V)

5.03V

(5.03V)

4.99V

(1.2V)

J110

pin1:4.99V(4.99V)

pin2:4.99V(4.99V)

pin3:7.96V(7.96V)

pin4:0V(0V)

pin5:0V(0V)

pin6:4.99V(1V)

13

Page 14

µCOM Unit /RF Unit Circuit Diagram

Note

14

Page 15

A B C D E F G

µCOM Unit Parts Layout

2SJ144Y (VY)

(Q101, 107, 135)

R1150H006B

(Q116)

1

NJM2902V

(Q102)

1SS302 (C3)

(D101, 102, 116, 118)

2

DTC144EU (26)

(Q103, 104, 130, 136, 137)

Side A

NJM2904V

(Q105)

DAP202U (P)

(D104, 105)

a b c d e f

g

BU4094BCFV

(Q106, 109)

1

2SC4617R (BR)

(Q110, 111, 115, 130, 132)

2

CAT24WC64JI

(Q112)

Side B

HD6473877H

(Q113)

15

Page 16

µCOM Unit Parts Layout

Note

16

Page 17

µCOM Unit Parts List

REF DESCRIPTION VALUE V/W TOL. MFR'S DESIG VXSTD P/N VERS.

PCB with Components S8101442 A2 (USA)

C101 CHIP CAP. 1uF 10V B GRM188B11A105KA61D S8101390 1C102 CHIP CAP. 0.1uF 16V B GRM39B104K16PT K22124805 1C103 CHIP CAP. 0.015uF 50V B GRM188B11H221KD01D S8101391 1C104 CHIP CAP. 1uF 6.3V B GRM39B105K6.3PT K22084801 1C105 CHIP CAP. 0.0027uF 50V B GRM39B272K50PT K22174829 1C106 CHIP CAP. 390pF 50V B GRM39B391K50PT K22174804 1C107 CHIP CAP. 0.0068uF 50V B GRM39B682K50PT K22174834 1C108 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C109 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C110 CHIP CAP. 680pF 50V B GRM39B681K50PT K22174807 1C111 CHIP CAP. 0.015uF 50V B GRM188B11H221KD01D S8101391 1C112 AL.ELECTRO.CAP. 100uF 6.3V MV6.3VC100MH63 S8101399 1C113 CHIP CAP. 0.0068uF 50V B GRM39B682K50PT K22174834 1C114 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C115 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C116 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C117 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C118 CHIP CAP. 0.027uF 16V R GRM39R273K16PT K22124802 1C119 AL.ELECTRO.CAP. 10uF 16V MV16VC10MD55 S8101398 1C120 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C121 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C125 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C126 CHIP CAP. 18pF 50V CH GRM39CH180J50PT K22174217 1C128 CHIP CAP. 6pF 50V CH GRM39CH060D50PT K22174207 1C129 CHIP CAP. 0.01uF 25V B GRM39B103K25PT K22144803 1C130 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C131 CHIP CAP. 1uF 6.3V B GRM39B105K6.3PT K22084801 1C132 CHIP CAP. 1uF 6.3V B GRM39B105K6.3PT K22084801 1C133 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C134 AL.ELECTRO.CAP. 100uF 6.3V MV6.3VC100MH63 S8101399 1C135 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C136 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C137 AL.ELECTRO.CAP. 100uF 16V UWX1C101MCR1GB S8101395 1C138 CHIP CAP. 0.01uF 50V B GRM39B103K50PT K22174823 1C150 CHIP TA.CAP. 10uF 6.3V TEMSVA0J106M-8R K78080027 1C152 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C155 CHIP CAP. 0.1uF 16V B GRM39B104K16PT K22124805 1C158 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C159 CHIP CAP. 0.0047uF 50V B GRM39B472K50PT K22174833 1C160 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C161 CHIP CAP. 0.01uF 50V B GRM39B103K50PT K22174823 1C162 CHIP CAP. 0.01uF 50V B GRM39B103K50PT K22174823 1C163 CHIP CAP. 56pF 50V CH GRM39CH560J50PT K22174229 1C164 CHIP CAP. 1uF 10V B GRM188B11A105KA61D S8101390 1C165 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C167 CHIP CAP. 0.01uF 50V B GRM39B103K50PT K22174823 1D101 DIODE 1SS302 TE85R G2070088 1- B e1

D102 DIODE 1SS302 TE85R G2070088 1- B f1

D103 DIODE MA111-(TX) G2070338 1- B b1

D104 DIODE DAP202U T106 G2070160 1- B a1

D105 DIODE DAP202U T106 G2070160 1- B a1

D106 LED 19-215UYC/S530A2/TR8 S8101421 1- A F2

D107 LED 19-215UYC/S530A2/TR8 S8101421 1- A D2

D108 LED 19-215UYC/S530A2/TR8 S8101421 1- A C2

D109 LED 19-215UYC/S530A2/TR8 S8101421 1- A F2

D110 LED 19-215UYC/S530A2/TR8 S8101421 1- A D1

D111 LED 19-215UYC/S530A2/TR8 S8101421 1- A C1

D112 LED 19-215UYC/S530A2/TR8 S8101421 1- A C1

D113 LED 19-215UYC/S530A2/TR8 S8101421 1- A E1

D114 LED 19-215UYC/S530A2/TR8 S8101421 1- A E1

D115 LED 19-215UYC/S530A2/TR8 S8101421 1- A D1

D116 DIODE 1SS302 TE85R G2070088 1- B d2

D117 DIODE MA111-(TX) G2070338 1- B c2

D118 DIODE 1SS302 TE85R G2070088 1- B d1

D130 LED 19-215UYC/S530A2/TR8 S8101421 1- A E2

D131 LED 19-215UYC/S530A2/TR8 S8101421 1- A D2

D135 DIODE 1SS400 TE61 G2070634 1- B b1

J101 CONNECTOR TKC-M12P-B1 S8101428 1J109 CONNECTOR TKC-M12P-B1 S8101428 1J110 CONNECTOR (MIC) MJD0606KX06 S8101431 1L101 M.RFC 4.7uH LK1608 4R7K-T L1690688 1L102 M.RFC 4.7uH LK1608 4R7K-T L1690688 1L103 M.RFC 4.7uH LK1608 4R7K-T L1690688 1L105 M.RFC 4.7uH LK1608 4R7K-T L1690688 1L106 M.RFC 4.7uH LK1608 4R7K-T L1690688 1-

LOT

SIDE

LAY ADR

17

Page 18

µCOM Unit Parts List

REF DESCRIPTION VALUE V/W TOL. MFR'S DESIG VXSTD P/N VERS.

Q101 TRANSISTOR 2SJ144Y TE85R G3701447Y 1- B e1

Q102 IC NJM2902V-TE1 G1091679 1- B e1

Q103 TRANSISTOR DTC144EU T106 G3070041 1- B e1

Q104 TRANSISTOR DTC144EU T106 G3070041 1- B e1

Q105 IC NJM2904V-TE1 G1091677 1- B f1

Q106 IC BU4094BCFV-E2 G1093527 1- B b1

Q107 TRANSISTOR 2SJ144Y TE85R G3701447Y 1- B f1

Q109 IC BU4094BCFV-E2 G1093527 1- B a1

Q110 TRANSISTOR 2SC4617 TL R G3346178R 1- B a1

Q111 TRANSISTOR 2SC4617 TL R G3346178R 1- B b1

Q112 IC CAT24WC64JI-TE13 S8101423 1- B d1

Q113 IC HD6473877H R0759 S8101437 A2 (USA) 1- B c1

Q115 TRANSISTOR 2SC4617 TL R G3346178R 1- B d2

Q116 IC R1150H006B-T1 S8101422 1- B d2

Q130 TRANSISTOR DTC144EU T106 G3070041 1- B d1

Q131 TRANSISTOR 2SC4617 TL R G3346178R 1- B b1

Q132 TRANSISTOR 2SC4617 TL R G3346178R 1- B b1

Q135 TRANSISTOR 2SJ144Y TE85R G3701447Y 1- B e1

Q136 TRANSISTOR DTC144EU T106 G3070041 1- B f1

Q137 TRANSISTOR DTC144EU T106 G3070041 1- B c2

R101 CHIP RES. 100k 1/16W 5% RMC1/16 104JATP J24185104 1R102 CHIP RES. 15k 1/16W 5% RMC1/16 153JATP J24185153 1R104 CHIP RES. 270k 1/16W 5% RMC1/16 274JATP J24185274 1R105 CHIP RES. 47K 1/16W 5% RMC1/16 473JATP J24185473 1R106 CHIP RES. 68k 1/16W 5% RMC1/16 683JATP J24185683 1R107 CHIP RES. 390k 1/16W 5% RMC1/16 394JATP J24185394 1R108 CHIP RES. 10k 1/16W 5% RMC1/16 103JATP J24185103 1R109 CHIP RES. 10k 1/16W 5% RMC1/16 103JATP J24185103 1R110 CHIP RES. 8.2k 1/16W 5% RMC1/16 822JATP J24185822 1R111 CHIP RES. 68k 1/16W 5% RMC1/16 683JATP J24185683 1R112 CHIP RES. 27k 1/16W 5% RMC1/16 273JATP J24185273 1R113 CHIP RES. 390k 1/16W 5% RMC1/16 394JATP J24185394 1R114 CHIP RES. 68k 1/16W 5% RMC1/16 683JATP J24185683 1R115 CHIP RES. 390k 1/16W 5% RMC1/16 394JATP J24185394 1R116 CHIP RES. 390k 1/16W 5% RMC1/16 394JATP J24185394 1R119 CHIP RES. 33k 1/16W 5% RMC1/16 333JATP J24185333 1R120 CHIP RES. 15k 1/16W 5% RMC1/16 153JATP J24185153 1R121 CHIP RES. 18k 1/16W 5% RMC1/16 183JATP J24185183 1R122 CHIP RES. 15k 1/16W 5% RMC1/16 153JATP J24185153 1R123 CHIP RES. 22K 1/16W 5% RMC1/16 223JATP J24185223 1R124 CHIP RES. 27k 1/16W 5% RMC1/16 273JATP J24185273 1R126 CHIP RES. 27k 1/16W 5% RMC1/16 273JATP J24185273 1R128 CHIP RES. 39k 1/16W 5% RMC1/16 393JATP J24185393 1R131 CHIP RES. 10 1/16W 5% RMC1/16 100JATP J24185100 1R132 CHIP RES. 47K 1/16W 5% RMC1/16 473JATP J24185473 1R133 CHIP RES. 10 1/16W 5% RMC1/16 100JATP J24185100 1R134 CHIP RES. 100k 1/16W 5% RMC1/16 104JATP J24185104 1R135 CHIP RES. 100k 1/16W 5% RMC1/16 104JATP J24185104 1R136 CHIP RES. 10k 1/16W 5% RMC1/16 103JATP J24185103 1R137 CHIP RES. 10k 1/16W 5% RMC1/16 103JATP J24185103 1R138 CHIP RES. 10k 1/16W 5% RMC1/16 103JATP J24185103 1R139 CHIP RES. 10k 1/16W 5% RMC1/16 103JATP J24185103 1R140 CHIP RES. 10k 1/16W 5% RMC1/16 103JATP J24185103 1R141 CHIP RES. 10k 1/16W 5% RMC1/16 103JATP J24185103 1R142 CHIP RES. 1M 1/16W 5% RMC1/16 105JATP J24185105 1R143 CHIP RES. 10k 1/16W 5% RMC1/16 103JATP J24185103 1R144 CHIP RES. 100k 1/16W 1% RMC1/16 104FTP J24183104 1R145 CHIP RES. 100k 1/16W 5% RMC1/16 104JATP J24185104 1R146 CHIP RES. 15k 1/16W 5% RMC1/16 153JATP J24185153 1R147 CHIP RES. 0 RMC1/16 000JATP J24185000 1R148 CHIP RES. 22K 1/16W 5% RMC1/16 223JATP J24185223 1R149 CHIP RES. 100k 1/16W 5% RMC1/16 104JATP J24185104 1R150 CHIP RES. 390k 1/16W 5% RMC1/16 394JATP J24185394 1R151 CHIP RES. 47K 1/16W 5% RMC1/16 473JATP J24185473 1R152 CHIP RES. 100k 1/16W 5% RMC1/16 104JATP J24185104 1R153 CHIP RES. 100k 1/16W 1% RMC1/16 104FTP J24183104 1R158 CHIP RES. 4.7K 1/16W 5% RMC1/16 472JATP J24185472 1R160 CHIP RES. 4.7K 1/16W 5% RMC1/16 472JATP J24185472 1R161 CHIP RES. 4.7K 1/16W 5% RMC1/16 472JATP J24185472 1R162 CHIP RES. 100k 1/16W 1% RMC1/16 104FTP J24183104 1R163 CHIP RES. 100k 1/16W 1% RMC1/16 104FTP J24183104 1R164 CHIP RES. 100k 1/16W 1% RMC1/16 104FTP J24183104 1R165 VR 20k XV09211NPV30F15A20K S8101386 1R166 VR 100k XV09211NPV30F1B100K S8101387 1R167 CHIP RES. 4.7K 1/16W 5% RMC1/16 472JATP J24185472 1R180 CHIP RES. 47K 1/16W 5% RMC1/16 473JATP J24185473 1-

LOT

SIDE

LAY ADR

18

Page 19

µCOM Unit Parts List

REF DESCRIPTION VALUE V/W TOL. MFR'S DESIG VXSTD P/N VERS.

R181 CHIP RES. 10k 1/16W 5% RMC1/16 103JATP J24185103 1R182 CHIP RES. 10k 1/16W 5% RMC1/16 103JATP J24185103 1R183 CHIP RES. 4.7K 1/16W 5% RMC1/16 472JATP J24185472 1R184 CHIP RES. 10k 1/16W 5% RMC1/16 103JATP J24185103 1R185 CHIP RES. 2.2K 1/16W 5% RMC1/16 222JATP J24185222 1R186 CHIP RES. 2.2K 1/16W 5% RMC1/16 222JATP J24185222 1R187 CHIP RES. 100k 1/16W 5% RMC1/16 104JATP J24185104 1R188 CHIP RES. 220 1/16W 5% RMC1/16 221JATP J24185221 1R189 CHIP RES. 10 1/16W 5% RMC1/16 100JATP J24185100 1R190 CHIP RES. 10 1/16W 5% RMC1/16 100JATP J24185100 1R191 CHIP RES. 10 1/16W 5% RMC1/16 100JATP J24185100 1R192 CHIP RES. 10 1/16W 5% RMC1/16 100JATP J24185100 1R193 CHIP RES. 10k 1/16W 5% RMC1/16 103JATP J24185103 1R200 CHIP RES. 47K 1/16W 5% RMC1/16 473JATP J24185473 1R201 CHIP RES. 220K 1/16W 5% RMC1/16 224JATP J24185224 1R202 CHIP RES. 47K 1/16W 5% RMC1/16 473JATP J24185473 1R203 CHIP RES. 100k 1/16W 5% RMC1/16 104JATP J24185104 1R204 CHIP RES. 82k 1/16W 5% RMC1/16 823JATP J24185823 1R205 CHIP RES. 4.7K 1/16W 5% RMC1/16 472JATP J24185472 1R206 CHIP RES. 4.7K 1/16W 5% RMC1/16 472JATP J24185472 1R207 CHIP RES. 470K 1/16W 5% RMC1/16 474JATP J24185474 1R208 CHIP RES. 470K 1/16W 5% RMC1/16 474JATP J24185474 1R209 CHIP RES. 470K 1/16W 5% RMC1/16 474JATP J24185474 1R211 CHIP RES. 10k 1/16W 5% RMC1/16 103JATP J24185103 1R212 CHIP RES. 0 RMC1/16 000JATP J24185000 1R220 CHIP RES. 100k 1/16W 5% RMC1/16 104JATP J24185104 1R221 CHIP RES. 390k 1/16W 5% RMC1/16 394JATP J24185394 1R223 CHIP RES. 47K 1/16W 5% RMC1/16 473JATP J24185473 1R226 CHIP RES. 10k 1/16W 5% RMC1/16 103JATP J24185103 1S101 ROTARY SWITCH

X101 XTAL TR-3.5 10.0MHz S8101425 1-

XRE0121PVB30FINB1-2-24PCE

S8101432 1-

LOT

SIDE

LAY ADR

19

Page 20

µCOM Unit Parts List

REF DESCRIPTION VALUE V/W TOL. MFR'S DESIG VXSTD P/N VERS.

Note

LOT

SIDE

LAY ADR

20

Page 21

RF Unit Parts Layout

A B C D E F G

2SB1197K (AH)

(Q303, 307)

DTC144EU (26)

(Q304, 324)

RD70HVF1

(Q306)

2SK3075

(Q313)

2SC5006 (24)

(Q320, 322, 323)

DTA114EU (14)

(Q325, 326)

1

2

3

KIA7808API

(Q305)

LA4425A

(Q337)

4

5

Side A

21

Page 22

RF Unit Parts Layout

a b c d e f

1

g

2SB1184

(Q301)

DTC144EU (26)

(Q302, 344, 345)

DTC114TUA (04)

(Q312)

RD00HVS1

(Q314)

2SA1586GR (SG)

(Q328)

2SA1588Y (ZY)

(Q332, 336)

LV2105V

(Q333)

2

UMT1N (T1)

(Q309)

NJM2902V

(Q315)

TA31136FN

(Q334)

3

NJM78L05UA (8C)

(Q310)

3SK240 (UN)

(Q316, 321)

UMX2N

(Q338)

4

2SB1197K (AH)

(Q311)

5

Side B

2SC3356 (R24)

(Q317)

2SC5006 (24)

(Q318)

2SC4215Y (QY)

(Q327)

2SC4116GR (LG)

(Q329)

2SC4617R (BR)

(Q330, Q331)

M62364FP

(Q319)

1SS312

(D302, 311)

22

Page 23

RFUnit Parts List

REF DESCRIPTION VALUE V/W TOL. MFR'S DESIG VXSTD P/N VERS.

PCB with Components S8101438 A2 (USA)

C301 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C302 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C303 CHIP CAP. 15pF 500V CH GRM42-6CH150J500PT K22271217 1C305 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C306 CERAMIC CAP. 0.001uF 500V B HM60SJYB102K500 S8101392 1C307 CHIP CAP. 15pF 500V CH GRM42-6CH150J500PT K22271217 1C308 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C309 CHIP CAP. 27pF 500V CH GRM42-6CH270J500PT K22271223 1C310 CHIP CAP. 3pF 50V CJ GRM40CJ030C50PT K22170204 1C311 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C312 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C313 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C315 FILM CAP. 47pF 500V UC232H0470J-T K33279034 1C316 CHIP CAP. 27pF 500V CH GRM42-6CH270J500PT K22271223 1C317 CHIP CAP. 0.1uF 16V B GRM39B104K16PT K22124805 1C318 CHIP CAP. 1pF 200V CK GRM40CK010C200PT K22230208 1C319 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C320 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C321 FILM CAP. 68pF 500V UC232H0680J-T K33279030 1C322 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C323 AL.ELECTRO.CAP. 3300uF 16V KMG16VB3300M S8101401 1C324 CHIP CAP. 1pF 200V CK GRM40CK010C200PT K22230208 1C327 AL.ELECTRO.CAP. 470uF 16V SMG16VB470M S8101402 1C328 CHIP CAP. 27pF 500V CH GRM42-6CH270J500PT K22271223 1C329 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C330 CHIP CAP. 27pF 500V CH GRM42-6CH270J500PT K22271223 1C331 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C332 CHIP CAP. 27pF 500V CH GRM42-6CH270J500PT K22271223 1C333 FILM CAP. 120pF 500V UC232H1200J-T K33279049 1C335 CERAMIC CAP. 0.001uF 500V B HM60SJYB102K500 S8101392 1C336 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C337 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C338 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C339 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C340 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C341 CHIP CAP. 0.1uF 16V B GRM39B104K16PT K22124805 1C342 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C343 CHIP CAP. 0.1uF 16V B GRM39B104K16PT K22124805 1C344 CHIP CAP. 220pF 50V B GRM39B221K50PT K22174801 1C345 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C346 AL.ELECTRO.CAP. 10uF 16V MV16VC10MD55 S8101398 1C347 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C348 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C350 AL.ELECTRO.CAP. 4.7uF 35V MVJ35VC4R7MD60 S8101396 1C351 CHIP CAP. 39pF 50V CH GRM39CH390J50PT K22174225 1C352 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C353 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C354 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C355 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C357 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C359 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C360 CHIP CAP. 0.1uF 16V B GRM39B104K16PT K22124805 1C363 AL.ELECTRO.CAP. 100uF 16V UWX1C101MCR1GB S8101395 1C364 CHIP CAP. 10pF 50V CH GRM39CH100D50PT K22174211 1C365 CHIP TA.CAP. 4.7uF 16V F931C475MAA S8101394 1C366 CHIP CAP. 100pF 50V CH GRM39CH101J50PT K22174235 1C367 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C368 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C370 CHIP CAP. 100pF 50V CH GRM39CH101J50PT K22174235 1C371 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C372 CHIP CAP. 2.5pF 50V CJ GRM39CJ2R5C50PT K22174259 1C374 CHIP CAP. 0.1uF 16V B GRM39B104K16PT K22124805 1C375 CHIP CAP. 100pF 50V CH GRM39CH101J50PT K22174235 1C376 CHIP CAP. 0.0047uF 50V B GRM39B472K50PT K22174833 1C377 CHIP CAP. 1uF 10V B GRM188B11A105KA61D S8101390 1C378 CHIP CAP. 2pF 50V CK GRM39CK020C50PT K22174203 1C379 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C380 CHIP CAP. 0.01uF 25V B GRM39B103K25PT K22144803 1C381 CHIP CAP. 0.1uF 16V B GRM39B104K16PT K22124805 1C382 CHIP CAP. 100pF 50V CH GRM39CH101J50PT K22174235 1C384 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C385 CHIP CAP. 2.5pF 50V CJ GRM39CJ2R5C50PT K22174259 1C386 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C387 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C388 CHIP CAP. 150pF 50V CH GRM39CH151J50PT K22174239 1-

LOT

SIDE

LAY ADR

23

Page 24

RF Unit Parts List

REF DESCRIPTION VALUE V/W TOL. MFR'S DESIG VXSTD P/N VERS.

C389 CHIP CAP. 100pF 50V CH GRM39CH101J50PT K22174235 1C390 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C391 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C393 AL.ELECTRO.CAP. 10uF 16V MV16VC10MD55 S8101398 1C394 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C395 CHIP CAP. 10pF 50V CH GRM39CH100D50PT K22174211 1C396 CHIP CAP. 0.01uF 25V B GRM39B103K25PT K22144803 1C397 CHIP CAP. 1uF 6.3V B GRM39B105K6.3PT K22084801 1C398 CHIP CAP. 0.0047uF 50V B GRM39B472K50PT K22174833 1C399 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C400 CHIP CAP. 0.01uF 25V B GRM39B103K25PT K22144803 1C401 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C402 CHIP CAP. 0.0033uF 50V B GRM39B332K50PT K22174831 1C403 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C404 CHIP CAP. 1.5pF 50V CK GRM39CK1R5C50PT K22174258 1C405 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C407 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C408 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C409 AL.ELECTRO.CAP. 4.7uF 25V MV25VC4R7MB55 S8101397 1C410 CHIP CAP. 100pF 50V CH GRM39CH101J50PT K22174235 1C411 CHIP CAP. 2pF 50V CK GRM39CK020C50PT K22174203 1C413 CHIP CAP. 22pF 50V CH GRM39CH220J50PT K22174219 1C415 CHIP CAP. 2.5pF 50V CJ GRM39CJ2R5C50PT K22174259 1C416 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C417 CHIP CAP. 100pF 50V CH GRM39CH101J50PT K22174235 1C418 CHIP CAP. 22pF 50V CH GRM39CH220J50PT K22174219 1C419 CHIP CAP. 0.1uF 16V B GRM39B104K16PT K22124805 1C420 CHIP CAP. 1uF 6.3V B GRM39B105K6.3PT K22084801 1C421 CHIP CAP. 3pF 50V CJ GRM39CJ030C50PT K22174204 1C422 CHIP CAP. 0.0015uF 50V B GRM39B152K50PT K22174827 1C423 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C424 CHIP CAP. 1uF 6.3V B GRM39B105K6.3PT K22084801 1C425 CHIP CAP. 0.1uF 16V B GRM39B104K16PT K22124805 1C426 CHIP CAP. 1pF 50V CK GRM39CK010C50PT K22174202 1C427 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C428 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C429 CHIP CAP. 39pF 50V CH GRM39CH390J50PT K22174225 1C430 CHIP CAP. 47pF 50V CH GRM39CH470J50PT K22174227 1C431 CHIP CAP. 0.0047uF 50V B GRM39B472K50PT K22174833 1C432 CHIP CAP. 33pF 50V CH GRM39CH330J50PT K22174223 1C433 CHIP CAP. 0.01uF 25V B GRM39B103K25PT K22144803 1C434 CHIP CAP. 1uF 10V B GRM188B11A105KA61D S8101390 1C435 CHIP CAP. 39pF 50V CH GRM39CH390J50PT K22174225 1C436 CHIP CAP. 47pF 50V CH GRM39CH470J50PT K22174227 1C437 CHIP CAP. 1uF 10V B GRM188B11A105KA61D S8101390 1C438 CHIP CAP. 100pF 50V CH GRM39CH101J50PT K22174235 1C439 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C440 CHIP CAP. 33pF 50V CH GRM39CH330J50PT K22174223 1C441 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C442 CHIP CAP. 1pF 50V CK GRM39CK010C50PT K22174202 1C443 CHIP CAP. 1pF 50V CK GRM39CK010C50PT K22174202 1C446 CHIP CAP. 10pF 50V CH GRM39CH100D50PT K22174211 1C447 CHIP CAP. 0.01uF 25V B GRM39B103K25PT K22144803 1C449 CHIP TA.CAP. 0.1uF 35V TESVA1V104M1-8R K78160025 1C450 CHIP CAP. 47pF 50V CH GRM39CH470J50PT K22174227 1C451 CHIP TA.CAP. 4.7uF 10V TEMSVA1A475M-8R K78100022 1C452 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C453 CHIP CAP. 0.1uF 16V B GRM39B104K16PT K22124805 1C454 AL.ELECTRO.CAP. 1uF 50V UWT1H010MCR1GB K78170005 1C455 CHIP CAP. 12pF 50V CH GRM39CH120J50PT K22174213 1C456 CHIP CAP. 0.01uF 50V B GRM39B103K50PT K22174823 1C457 CHIP CAP. 0.01uF 25V B GRM39B103K25PT K22144803 1C458 CHIP CAP. 150pF 50V CH GRM39CH151J50PT K22174239 1C459 CHIP CAP. 150pF 50V CH GRM39CH151J50PT K22174239 1C460 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C461 AL.ELECTRO.CAP. 10uF 16V MV16VC10MD55 S8101398 1C462 CHIP CAP. 0.01uF 25V B GRM39B103K25PT K22144803 1C463 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C464 CHIP CAP. 10pF 50V CH GRM39CH100D50PT K22174211 1C465 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C466 AL.ELECTRO.CAP. 4.7uF 25V MV25VC4R7MB55 S8101397 1C467 CHIP CAP. 100pF 50V CH GRM39CH101J50PT K22174235 1C468 CHIP CAP. 100pF 50V CH GRM39CH101J50PT K22174235 1C470 CHIP CAP. 100pF 50V CH GRM39CH101J50PT K22174235 1C471 CHIP CAP. 10pF 50V CH GRM39CH100D50PT K22174211 1C474 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1-

LOT

SIDE

LAY ADR

24

Page 25

RF Unit Parts List

REF DESCRIPTION VALUE V/W TOL. MFR'S DESIG VXSTD P/N VERS.

C475 AL.ELECTRO.CAP. 47uF 16V MV16VC47MF55 S8101400 1C476 AL.ELECTRO.CAP. 10uF 16V MV16VC10MD55 S8101398 1C477 CHIP CAP. 10pF 50V CH GRM39CH100D50PT K22174211 1C478 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C480 CHIP CAP. 100pF 50V CH GRM39CH101J50PT K22174235 1C481 CHIP CAP. 10pF 50V CH GRM39CH100D50PT K22174211 1C482 CHIP CAP. 0.01uF 50V B GRM39B103K50PT K22174823 1C483 CHIP CAP. 0.01uF 50V B GRM39B103K50PT K22174823 1C485 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C486 CHIP CAP. 0.01uF 50V B GRM39B103K50PT K22174823 1C488 CHIP CAP. 100pF 50V CH GRM39CH101J50PT K22174235 1C489 CHIP CAP. 0.1uF 16V B GRM39B104K16PT K22124805 1C490 CHIP CAP. 150pF 50V CH GRM39CH151J50PT K22174239 1C491 CHIP CAP. 150pF 50V CH GRM39CH151J50PT K22174239 1C493 CHIP CAP. 0.01uF 50V B GRM39B103K50PT K22174823 1C494 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C495 CHIP CAP. 220pF 50V CH GRM39CH221J50PT K22174243 1C496 CHIP CAP. 0.1uF 16V B GRM39B104K16PT K22124805 1C497 CHIP CAP. 0.01uF 50V B GRM39B103K50PT K22174823 1C498 CHIP CAP. 0.068uF 16V B GRM39B683K16PT K22124808 1C499 CHIP CAP. 0.1uF 16V B GRM39B104K16PT K22124805 1C500 CHIP CAP. 0.1uF 16V B GRM39B104K16PT K22124805 1C501 CHIP CAP. 0.027uF 16V R GRM39R273K16PT K22124802 1C502 CHIP CAP. 0.0022uF 50V B GRM39B222K50PT K22174822 1C503 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C504 AL.ELECTRO.CAP. 470uF 16V SMG16VB470M S8101402 1C506 CHIP CAP. 0.01uF 50V B GRM39B103K50PT K22174823 1C507 CHIP CAP. 0.01uF 50V B GRM39B103K50PT K22174823 1C508 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C509 AL.ELECTRO.CAP. 47uF 16V MV16VC47MF55 S8101400 1C510 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C511 CHIP CAP. 0.1uF 16V B GRM39B104K16PT K22124805 1C513 CHIP CAP. 0.01uF 25V B GRM39B103K25PT K22144803 1C514 CHIP CAP. 0.1uF 16V B GRM39B104K16PT K22124805 1C515 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C516 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C517 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C519 CHIP CAP. 0.1uF 16V B GRM39B104K16PT K22124805 1C520 CHIP CAP. 82pF 50V CH GRM39CH820J50PT K22174233 1C521 CHIP CAP. 0.001uF 50V CH GRM39CH102J50PT S8101389 1C522 CHIP CAP. 0.1uF 16V B GRM39B104K16PT K22124805 1C523 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C524 CHIP CAP. 0.01uF 25V B GRM39B103K25PT K22144803 1C525 CHIP CAP. 0.01uF 25V B GRM39B103K25PT K22144803 1C526 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C532 AL.ELECTRO.CAP. 10uF 16V MV16VC10MD55 S8101398 1C533 CHIP CAP. 33pF 50V CH GRM39CH330J50PT K22174223 1C534 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C535 AL.ELECTRO.CAP. 10uF 16V MV16VC10MD55 S8101398 1C537 CHIP CAP. 1uF 10V B GRM188B11A105KA61D S8101390 1C538 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C541 CHIP CAP. 27pF 500V CH GRM42-6CH270J500PT K22271223 1C542 CHIP CAP. 56pF 50V CH GRM39CH560J50PT K22174229 1C543 CHIP CAP. 2.5pF 50V CJ GRM39CJ2R5C50PT K22174259 1C545 CHIP TA.CAP. 22uF 6.3V F930J226MAA S8101393 1C546 CHIP CAP. 0.033uF 50V B GRM40B333K50PT K22170857 1C547 CHIP CAP. 0.033uF 16V B GRM39B333K16PT K22124812 1C551 CHIP CAP. 0.001uF 50V B GRM39B102K50PT K22174821 1C553 CHIP CAP. 0.22uF 10V B GRM39B224K10PT K22104801 1D301 SURGE ABSORBER P6KE18A Q9000630 1- A B1

D302 DIODE 1SS312-TE85R S8101420 1- B a2

D303 DIODE XB15A407A2GB G2090741 1- A E2

D305 DIODE XB15A308A2GB G2090742 1- A F3

D306 DIODE MA111-(TX) G2070338 1- A F3

D307 DIODE MA111-(TX) G2070338 1- A F3

D308 DIODE HVC350B-TRF G2070596 1- A F3

D309 DIODE MA111-(TX) G2070338 1- B e4

D310 DIODE HVC350B-TRF G2070596 1- B a3

D311 DIODE 1SS312-TE85R S8101420 1- B d3

D312 DIODE HVC350B-TRF G2070596 1- B b3

D313 DIODE HVC350B-TRF G2070596 1D314 DIODE 1SV282(TPH3) G2070778 1- A C4

D315 DIODE 1SV214 TPH G2070356 1- A B4

D316 DIODE 1SV282(TPH3) G2070778 1- A C4

D317 DIODE HVC350B-TRF G2070596 1- B d4

D318 DIODE HVC350B-TRF G2070596 1- B d4

LOT

SIDE

LAY ADR

25

Page 26

RF Unit Parts List

REF DESCRIPTION VALUE V/W TOL. MFR'S DESIG VXSTD P/N VERS.

D319 DIODE UDZS TE-17 5.6B G2070910 1- B b4

D322 DIODE HVC350B-TRF G2070596 1- A F3

D323 DIODE HVC350B-TRF G2070596 1- B a3

D324 DIODE HVC350B-TRF G2070596 1- B b3

D325 DIODE HVC350B-TRF G2070596 1- B b3

D326 DIODE 1SV282(TPH3) G2070778 1- A C4

D327 DIODE 1SV282(TPH3) G2070778 1- A C4

D328 DIODE MA111-(TX) G2070338 1- B c4

D329 DIODE MA111-(TX) G2070338 1- B c4

D331 DIODE MA111-(TX) G2070338 1- B f4

D332 DIODE 1SS400 TE61 G2070634 1- A E4

F301 XTAL FILTER UM-5 21.7MHz S8101426 1F302 CERAMIC FILTER ALFYM450F=K H3900531 1J306 CONNECTOR TKC-M12P-A1 S8101429 1J307 CONNECTOR TKC-M12P-A1 S8101429 1J308 CONNECTOR (EXT SP) JY-3564 S8101430 1J309 CONNECTOR B8B-ZR P0090650 1L301 FERRITE BEADS SMB304729 L9190094 1L302 FERRITE BEADS SMB304729 L9190094 1L303 COIL 1.0PEW3.0D6.0T_E2 S8101405 1L304 COIL 1.0PEW3.0D5.0T_E2 S8101406 1L305 COIL 1.0PEW3.0D6.0T_E2 S8101405 1L306 COIL 1.0PEW2.5D1.5T S8101408 1L307 COIL 1.0PEW3.0D6.0T_E2 S8101405 1L308 COIL 4.7uH LAL03KH4R7K S8101413 1L310 COIL 1.0PEW3.0D6.0T_E2 S8101405 1L311 COIL 0.8PEW3.2D7.0T_E2 S8101407 1L312 COIL 0.8PEW3.2D7.0T_E2 S8101407 1L314 COIL 0.35UEW1.6D8.0T_E2 S8101404 1L315 COIL 0.35UEW1.6D8.0T_E2 S8101404 1L317 M.RFC 0.027uH HK1608 27NJ-T L1690521 1L318 COIL 0.35UEW1.6D6.0T_E-2 S8101403 1L319 M.RFC 0.047uH HK1608 47NJ-T L1690524 1L320 CHIP COIL 0.039uH LQN21A39NJ04 L1690616 1L322 CHIP COIL 0.082uH LQN21A82NJ04 L1690919 1L323 M.RFC 0.1uH HK1608 R10J-T L1690528 1L325 CHIP COIL 0.039uH LQN21A39NJ04 L1690616 1L327 CHIP COIL 0.082uH LQN21A82NJ04 L1690919 1L328 M.RFC 0.47uH ELJ-NCR47JF L1690655 1L329 COIL S-VCO-TX S8101410 1L330 COIL S-VCO-RX S8101409 1L331 M.RFC 0.082uH HK1608 82NJ-T L1690527 1L332 COIL ACB1608M-120-T S8101414 1L333 COIL ACB1608M-120-T S8101414 1L334 CHIP COIL 0.12uH LQN21AR12J04 L1690621 1L335 CHIP COIL 0.015uH LQN21A15NJ04 L1690611 1L336 CHIP COIL 0.068uH LQN21A68NJ04 L1690605 1L337 CHIP COIL 0.068uH LQN21A68NJ04 L1690605 1L338 COIL 0.56uH NL252018T-R56J S8101411 1L339 M.RFC 0.082uH HK1608 82NJ-T L1690527 1L340 M.RFC 4.7uH LK1608 4R7K-T L1690688 1L342 COIL 0.22uH MLF1608DR22KT S8101412 1Q301 TRANSISTOR 2SB1184F5-Q S8101415 1- B f2

Q302 TRANSISTOR DTC144EU T106 G3070041 1- B f2

Q303 TRANSISTOR 2SB1197K(Q) S8101416 1- A A4

Q304 TRANSISTOR DTC144EU T106 G3070041 1- A A4

Q305 IC KIA7808API G1093164 1- A A3

Q306 FET RD70HVF1 G3090140 1- A D1

Q307 TRANSISTOR 2SB1197K(Q) S8101416 1- A A4

Q308 TRANSISTOR DTC144EU T106 G3070041 1- A A3

Q309 TRANSISTOR UMT1N TR S8101418 1- B b3

Q310 IC NJM78L05UA TE1 G1091325 1- B f3

Q311 TRANSISTOR 2SB1197K(Q) S8101416 1- B b3

Q312 TRANSISTOR DTC114TUA T106 S8101417 1- b b3

Q313 FET 2SK3075(TE12L) G3830758 1- A C1

Q314 FET RD00HVS1 S8101419 1- B e2

Q315 IC NJM2902V-TE1 G1091679 1- B f4

Q316 FET 3SK240(TE85L) G4802407 1- B a3

Q317 TRANSISTOR 2SC3356-T2B R24 G3333567D 1- B e3

Q318 TRANSISTOR 2SC5006-T1 G3350068 1- B d3

Q319 IC M62364FP 600D G1093033 1- A B4

Q320 TRANSISTOR 2SC5006-T1 G3350068 1- A C3

Q321 FET 3SK240(TE85L) G4802407 1- B b3

Q322 TRANSISTOR 2SC5006-T1 G3350068 1- A B4

Q323 TRANSISTOR 2SC5006-T1 G3350068 1- A C4

Q324 TRANSISTOR DTC144EU T106 G3070041 1- A B4

LOT

SIDE

LAY ADR

26

Page 27

RF Unit Parts List

REF DESCRIPTION VALUE V/W TOL. MFR'S DESIG VXSTD P/N VERS.

Q325 TRANSISTOR DTA114EU T106 G3070083 1- A B3

Q326 TRANSISTOR DTA114EU T106 G3070083 1- A B3

Q327 TRANSISTOR 2SC4215Y TE85R G3342157Y 1- B c4

Q328 TRANSISTOR 2SA1586GR TE85R G3115867G 1- B c3

Q329 TRANSISTOR 2SC4116GR TE85R G3341167G 1- B c3

Q330 TRANSISTOR 2SC4617 TL R G3346178R 1- B d3

Q331 TRANSISTOR 2SC4617 TL R G3346178R 1- B d4

Q332 TRANSISTOR 2SA1588Y(TE85L) G3115888Y 1- B c4

Q333 IC LV2105V-TLM G1093191 1- B d4

Q334 IC TA31136FN(EL) G1091605 1- B b4

Q336 TRANSISTOR 2SA1588Y(TE85L) G3115888Y 1- B b4

Q337 IC LA4425A G1092241 1- A A3

Q338 TRANSISTOR UMX2N TR G3070254 1- B b5

Q344 TRANSISTOR DTC144EU T106 G3070041 1- B e3

Q345 TRANSISTOR DTC144EU T106 G3070041 1- B e4

R301 CHIP RES. 47k 1/10W 5% RMC1/10T 473J J24205473 1R302 CHIP RES. 10k 1/16W 5% RMC1/16 103JATP J24185103 1R303 CHIP RES. 10k 1/16W 5% RMC1/16 103JATP J24185103 1R304 THERMISTOR TBPS1R473J475H5Q S8101388 1R305 CHIP RES. 2.7k 1/16W 5% RMC1/16 272JATP J24185272 1R306 CHIP RES. 1k 1/16W 5% RMC1/16 102JATP J24185102 1R307 CHIP RES. 100 1/4W 5% RMC1/4 101JATP J24245101 1R308 CHIP RES. 10k 1/16W 5% RMC1/16 103JATP J24185103 1R309 CHIP RES. 15k 1/16W 5% RMC1/16 153JATP J24185153 1R310 THERMISTOR TBPS1R473J475H5Q S8101388 1R311 CHIP RES. 0 RMC1/16 000JATP J24185000 1R312 CHIP RES. 2.7k 1/16W 5% RMC1/16 272JATP J24185272 1R313 CHIP RES. 1k 1/16W 5% RMC1/16 102JATP J24185102 1R314 CHIP RES. 4.7K 1/16W 5% RMC1/16 472JATP J24185472 1R315 CHIP RES. 10k 1/16W 5% RMC1/16 103JATP J24185103 1R316 CHIP RES. 4.7K 1/16W 5% RMC1/16 472JATP J24185472 1R318 CHIP RES. 10k 1/16W 5% RMC1/16 103JATP J24185103 1R319 CHIP RES. 2.2K 1/16W 5% RMC1/16 222JATP J24185222 1R320 CHIP RES. 220 1/10W 5% RMC1/10T 221J J24205221 1R321 CHIP RES. 33k 1/10W 5% RMC1/10T 333J J24205333 1R322 CHIP RES. 22K 1/16W 5% RMC1/16 223JATP J24185223 1R323 CHIP RES. 22K 1/16W 5% RMC1/16 223JATP J24185223 1R324 CHIP RES. 4.7K 1/16W 5% RMC1/16 472JATP J24185472 1R325 CHIP RES. 1k 1/16W 5% RMC1/16 102JATP J24185102 1R326 CHIP RES. 33k 1/10W 5% RMC1/10T 333J J24205333 1R328 CHIP RES. 56 1/16W 5% RMC1/16 560JATP J24185560 1R329 CHIP RES. 27k 1/16W 5% RMC1/16 273JATP J24185273 1R330 CHIP RES. 33k 1/16W 5% RMC1/16 333JATP J24185333 1R331 CHIP RES. 4.7K 1/16W 5% RMC1/16 472JATP J24185472 1R332 CHIP RES. 47K 1/16W 5% RMC1/16 473JATP J24185473 1R333 CHIP RES. 1M 1/16W 5% RMC1/16 105JATP J24185105 1R334 CHIP RES. 470 1/16W 5% RMC1/16 471JATP J24185471 1R335 CHIP RES. 5.6k 1/16W 5% RMC1/16 562JATP J24185562 1R337 CHIP RES. 4.7K 1/16W 5% RMC1/16 472JATP J24185472 1R338 CHIP RES. 1M 1/16W 5% RMC1/16 105JATP J24185105 1R339 CHIP RES. 56 1/16W 5% RMC1/16 560JATP J24185560 1R340 CHIP RES. 10k 1/16W 5% RMC1/16 103JATP J24185103 1R341 CHIP RES. 100k 1/16W 5% RMC1/16 104JATP J24185104 1R342 CHIP RES. 33k 1/16W 5% RMC1/16 333JATP J24185333 1R343 CHIP RES. 470K 1/16W 5% RMC1/16 474JATP J24185474 1R344 CHIP RES. 330K 1/16W 5% RMC1/16 334JATP J24185334 1R345 CHIP RES. 47K 1/16W 5% RMC1/16 473JATP J24185473 1R346 CHIP RES. 47K 1/16W 5% RMC1/16 473JATP J24185473 1R347 CHIP RES. 390k 1/16W 5% RMC1/16 394JATP J24185394 1R348 CHIP RES. 2.7k 1/16W 5% RMC1/16 272JATP J24185272 1R349 CHIP RES. 47K 1/16W 5% RMC1/16 473JATP J24185473 1R350 CHIP RES. 100 1/16W 5% RMC1/16 101JATP J24185101 1R351 CHIP RES. 10k 1/16W 5% RMC1/16 103JATP J24185103 1R352 CHIP RES. 470 1/16W 5% RMC1/16 471JATP J24185471 1R353 CHIP RES. 5.6k 1/16W 5% RMC1/16 562JATP J24185562 1R354 CHIP RES. 30k 1/16W 5% RMC1/16 303JATP J24185303 1R355 CHIP RES. 22 1/16W 5% RMC1/16 220JATP J24185220 1R356 CHIP RES. 8.2k 1/16W 5% RMC1/16 822JATP J24185822 1R357 CHIP RES. 1k 1/16W 5% RMC1/16 102JATP J24185102 1R358 CHIP RES. 4.7K 1/16W 5% RMC1/16 472JATP J24185472 1R359 CHIP RES. 220 1/16W 5% RMC1/16 221JATP J24185221 1R361 CHIP RES. 22 1/16W 5% RMC1/16 220JATP J24185220 1R362 CHIP RES. 4.7K 1/16W 5% RMC1/16 472JATP J24185472 1R363 CHIP RES. 2.2K 1/16W 5% RMC1/16 222JATP J24185222 1R364 CHIP RES. 470K 1/16W 5% RMC1/16 474JATP J24185474 1R365 CHIP RES. 220 1/16W 5% RMC1/16 221JATP J24185221 1-

LOT

SIDE

LAY ADR

27

Page 28

RF Unit Parts List

REF DESCRIPTION VALUE V/W TOL. MFR'S DESIG VXSTD P/N VERS.

R366 CHIP RES. 47K 1/16W 5% RMC1/16 473JATP J24185473 1R367 CHIP RES. 1M 1/16W 5% RMC1/16 105JATP J24185105 1R369 CHIP RES. 1M 1/16W 5% RMC1/16 105JATP J24185105 1R370 CHIP RES. 15 1/16W 5% RMC1/16 150JATP J24185150 1R371 CHIP RES. 47 1/16W 5% RMC1/16 470JATP J24185470 1R372 CHIP RES. 15 1/16W 5% RMC1/16 150JATP J24185150 1R373 CHIP RES. 100k 1/16W 5% RMC1/16 104JATP J24185104 1R374 CHIP RES. 100 1/16W 5% RMC1/16 101JATP J24185101 1R375 CHIP RES. 220 1/16W 5% RMC1/16 221JATP J24185221 1R376 CHIP RES. 82 1/16W 5% RMC1/16 820JATP J24185820 1R377 CHIP RES. 680 1/16W 5% RMC1/16 681JATP J24185681 1R378 CHIP RES. 22K 1/16W 5% RMC1/16 223JATP J24185223 1R379 CHIP RES. 4.7K 1/16W 5% RMC1/16 472JATP J24185472 1R381 CHIP RES. 10 1/16W 5% RMC1/16 100JATP J24185100 1R382 CHIP RES. 47 1/16W 5% RMC1/16 470JATP J24185470 1R383 CHIP RES. 270 1/16W 5% RMC1/16 271JATP J24185271 1R384 CHIP RES. 10 1/16W 5% RMC1/16 100JATP J24185100 1R385 CHIP RES. 56 1/16W 5% RMC1/16 560JATP J24185560 1R386 CHIP RES. 1k 1/16W 5% RMC1/16 102JATP J24185102 1R387 CHIP RES. 100 1/16W 5% RMC1/16 101JATP J24185101 1R388 CHIP RES. 47 1/16W 5% RMC1/16 470JATP J24185470 1R389 CHIP RES. 270 1/16W 5% RMC1/16 271JATP J24185271 1R390 CHIP RES. 22K 1/16W 5% RMC1/16 223JATP J24185223 1R391 CHIP RES. 10k 1/16W 5% RMC1/16 103JATP J24185103 1R392 CHIP RES. 100k 1/16W 5% RMC1/16 104JATP J24185104 1R393 CHIP RES. 22K 1/16W 5% RMC1/16 223JATP J24185223 1R394 CHIP RES. 10k 1/16W 5% RMC1/16 103JATP J24185103 1R395 CHIP RES. 1k 1/16W 5% RMC1/16 102JATP J24185102 1R396 CHIP RES. 47K 1/16W 5% RMC1/16 473JATP J24185473 1R397 CHIP RES. 470K 1/16W 5% RMC1/16 474JATP J24185474 1R398 CHIP RES. 220K 1/16W 5% RMC1/16 224JATP J24185224 1R399 CHIP RES. 47K 1/16W 5% RMC1/16 473JATP J24185473 1R401 CHIP RES. 2.2K 1/16W 5% RMC1/16 222JATP J24185222 1R402 CHIP RES. 1.5k 1/16W 5% RMC1/16 152JATP J24185152 1R403 CHIP RES. 220 1/16W 5% RMC1/16 221JATP J24185221 1R405 CHIP RES. 47K 1/16W 5% RMC1/16 473JATP J24185473 1R406 CHIP RES. 2.7k 1/16W 5% RMC1/16 272JATP J24185272 1R407 CHIP RES. 220K 1/16W 5% RMC1/16 224JATP J24185224 1R408 CHIP RES. 470K 1/16W 5% RMC1/16 474JATP J24185474 1R409 CHIP RES. 330 1/16W 5% RMC1/16 331JATP J24185331 1R411 CHIP RES. 100k 1/16W 5% RMC1/16 104JATP J24185104 1R412 CHIP RES. 1k 1/16W 5% RMC1/16 102JATP J24185102 1R413 CHIP RES. 1k 1/16W 5% RMC1/16 102JATP J24185102 1R414 CHIP RES. 1k 1/16W 5% RMC1/16 102JATP J24185102 1R415 CHIP RES. 100 1/16W 5% RMC1/16 101JATP J24185101 1R416 CHIP RES. 47K 1/16W 5% RMC1/16 473JATP J24185473 1R417 CHIP RES. 18k 1/16W 5% RMC1/16 183JATP J24185183 1R418 CHIP RES. 47K 1/16W 5% RMC1/16 473JATP J24185473 1R419 CHIP RES. 68k 1/16W 5% RMC1/16 683JATP J24185683 1R420 CHIP RES. 220K 1/16W 5% RMC1/16 224JATP J24185224 1R421 CHIP RES. 100 1/16W 5% RMC1/16 101JATP J24185101 1R422 CHIP RES. 2.2K 1/16W 5% RMC1/16 222JATP J24185222 1R423 CHIP RES. 1k 1/16W 5% RMC1/16 102JATP J24185102 1R424 CHIP RES. 100k 1/16W 5% RMC1/16 104JATP J24185104 1R425 CHIP RES. 470K 1/16W 5% RMC1/16 474JATP J24185474 1R426 CHIP RES. 470K 1/16W 5% RMC1/16 474JATP J24185474 1R427 CHIP RES. 1k 1/16W 5% RMC1/16 102JATP J24185102 1R428 CHIP RES. 1k 1/16W 5% RMC1/16 102JATP J24185102 1R429 CHIP RES. 270 1/16W 5% RMC1/16 271JATP J24185271 1R430 CHIP RES. 1k 1/16W 5% RMC1/16 102JATP J24185102 1R433 CHIP RES. 10 1/16W 5% RMC1/16 100JATP J24185100 1R436 CHIP RES. 220K 1/16W 5% RMC1/16 224JATP J24185224 1R437 CHIP RES. 0 RMC1/16 000JATP J24185000 1R440 CHIP RES. 1.2k 1/16W 5% RMC1/16 122JATP J24185122 1R441 CHIP RES. 10k 1/16W 5% RMC1/16 103JATP J24185103 1R442 CHIP RES. 150k 1/16W 5% RMC1/16 154JATP J24185154 1R445 CHIP RES. 150k 1/16W 5% RMC1/16 154JATP J24185154 1R447 CHIP RES. 0 RMC1/16 000JATP J24185000 1R448 CHIP RES. 3.3K 1/16W 5% RMC1/16 332JATP J24185332 1R450 CHIP RES. 100k 1/16W 5% RMC1/16 104JATP J24185104 1R451 CHIP RES. 47K 1/16W 5% RMC1/16 473JATP J24185473 1R452 CHIP RES. 4.7K 1/16W 5% RMC1/16 472JATP J24185472 1R453 CHIP RES. 10k 1/16W 5% RMC1/16 103JATP J24185103 1R454 CHIP RES. 100 1/16W 5% RMC1/16 101JATP J24185101 1R456 CHIP RES. 10k 1/16W 5% RMC1/16 103JATP J24185103 1R457 CHIP RES. 47K 1/16W 5% RMC1/16 473JATP J24185473 1-

LOT

SIDE

LAY ADR

28

Page 29

RF Unit Parts List

REF DESCRIPTION VALUE V/W TOL. MFR'S DESIG VXSTD P/N VERS.

R458 CHIP RES. 1M 1/16W 5% RMC1/16 105JATP J24185105 1R460 CHIP RES. 1M 1/16W 5% RMC1/16 105JATP J24185105 1R461 CHIP RES. 10k 1/16W 5% RMC1/16 103JATP J24185103 1R462 CHIP RES. 3.9k 1/16W 5% RMC1/16 392JATP J24185392 1R463 CHIP RES. 1M 1/16W 5% RMC1/16 105JATP J24185105 1R464 CHIP RES. 10k 1/16W 5% RMC1/16 103JATP J24185103 1R465 CHIP RES. 0 RMC1/16 000JATP J24185000 1R470 CHIP RES. 47K 1/16W 5% RMC1/16 473JATP J24185473 1R471 CHIP RES. 47K 1/16W 5% RMC1/16 473JATP J24185473 1R473 CHIP RES. 10k 1/16W 5% RMC1/16 103JATP J24185103 1R474 CHIP RES. 10 1/16W 5% RMC1/16 100JATP J24185100 1R475 CHIP RES. 10k 1/16W 5% RMC1/16 103JATP J24185103 1R476 CHIP RES. 10k 1/16W 5% RMC1/16 103JATP J24185103 1R477 CHIP RES. 10k 1/16W 5% RMC1/16 103JATP J24185103 1R479 CHIP RES. 4.7K 1/16W 5% RMC1/16 472JATP J24185472 1R480 CHIP RES. 4.7K 1/16W 5% RMC1/16 472JATP J24185472 1R481 CHIP RES. 100 1/16W 5% RMC1/16 101JATP J24185101 1R482 CHIP RES. 47K 1/16W 5% RMC1/16 473JATP J24185473 1R490 CHIP RES. 0 RMC1/16 000JATP J24185000 1R493 CHIP RES. 10k 1/16W 5% RMC1/16 103JATP J24185103 1R494 CHIP RES. 10k 1/16W 5% RMC1/16 103JATP J24185103 1R495 CHIP RES. 0.33 1/10W 1% SR731JTDR330F S8101385 1R496 CHIP RES. 10k 1/16W 5% RMC1/16 103JATP J24185103 1R498 CHIP RES. 1k 1/16W 5% RMC1/16 102JATP J24185102 1R500 CHIP RES. 0 RMC1/16 000JATP J24185000 1R501 CHIP RES. 270 1/16W 5% RMC1/16 271JATP J24185271 1R502 CHIP RES. 150 1/16W 5% RMC1/16 151JATP J24185151 1R503 CHIP RES. 4.7K 1/16W 5% RMC1/16 472JATP J24185472 1R504 CHIP RES. 2.2K 1/16W 5% RMC1/16 222JATP J24185222 1R507 CHIP RES. 100 1/16W 5% RMC1/16 101JATP J24185101 1R509 CHIP RES. 47K 1/16W 5% RMC1/16 473JATP J24185473 1R510 CHIP RES. 0 RMC1/16 000JATP J24185000 1R515 CHIP RES. 0 RMC1/16 000JATP J24185000 1R516 CHIP RES. 100 1/16W 5% RMC1/16 101JATP J24185101 1R517 CHIP RES. 2.2M 1/16W 5% RMC1/16 225JATP J24185225 1R518 THERMISTOR TBPS1R473J475H5Q S8101388 1X301 XTAL UM-5.2S 21.25MHz S8101424 1X302 CERAMIC DISC. CDBC450CX24-TC H7901340 1-

CASE-SHIELD S8002054 1-

SPRING-EARTH S8002069 1-

SPACER S8002064 1-

CABLE (with BLADE FUSE) S8101435 1-

LOT

SIDE

LAY ADR

29

Page 30

RF Unit Parts List

REF DESCRIPTION VALUE V/W TOL. MFR'S DESIG VXSTD P/N VERS.

Note

LOT

SIDE

LAY ADR

30

Page 31

13

Page 32

Copyright 2003

VERTEX STANDARD CO., LTD.

All rights reserved

No portion of this manual

may be reproduced without

the permission of

VERTEX STANDARD CO., LTD.

Printed in Japan.

14

Loading...

Loading...