Page 1

Global Stock System

GSS STORE OWNER’S MANUAL

TEC America, Inc.

Page 2

______________________________________________________

Page 3

______________________________________________________

TEC AMERICA, INC.

90-DAY LIMITED WARRANTY

FS-3600 GSS-STORE SOFTWARE

BEFORE USING THIS PRODUCT, YOU SHOULD CAREFULLY READ THE FOLLOWING TERMS AND

CONDITIONS. YOUR USE OF THIS PRODUCT INDICATES YOUR ACCEPTANCE OF THESE TERMS.

IF YOU DO NOT AGREE WITH THEM, YOU SHOULD NOT USE THIS PRODUCT AND SHOULD

PROMPTLY RETURN THE PRODUCT TO THE SELLER.

TEC AMERICA, INC. warrants this product to be free from defects in materials and workmanship for

a period of 90 days from the date of purchase from an authorized TEC AMERICA, INC. dealer. This

warranty is limited to the original purchaser, and to TEC AMERICA, INC. products that are sold and

used within the continental United States and Hawaii. A copy of a valid dated sales receipt must be

submitted with the product for warranty service. Third Party Operating System and Third Party

Application Software are specifically excluded from this warranty.

This limited warranty applies only to TEC AMERICA, INC. products that do not function properly

under normal use, within the manufacturer’s specifications. It does not apply to products that, in the

sole opinion of TEC AMERICA, INC., have been damaged as a result of accident, misuse, neglect, or

improper packing or shipping. This warranty is void if the TEC AMERICA, INC. label or logo, or the

rating label or serial number have been removed or defaced, or the product has been modified or

serviced by other than TEC AMERICA, INC. or an authorized TEC AMERICA, INC. Service Center.

During the 90-day warranty period, TEC AMERICA, INC. will repair or replace, at its option, any

defective product with no charge for parts or labor.

TEC AMERICA, INC.’S LIABILITY HEREUNDER SHALL BE LIMITED TO REPAIR OR REPLACEMENT

OF THE DEFECTIVE PART OR PARTS AND SUCH CORRECTION SHALL CONSTITUTE A

FULFILLMENT OF ITS WARRANTY HEREUNDER.

TEC AMERICA, INC. MAKES NO WARRANTIES, EXPRESS OR IMPLIED, INCLUDING

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, EXCEPT AS EXPRESSLY

STATED HEREIN.

UNDER NO CIRCUMSTANCES SHALL TEC AMERICA, INC. BE LIABLE TO THE PURCHASER OR

ANY USER FOR ANY DAMAGES, INCLUDING INCIDENTAL OR CONSEQUENTIAL DAMAGES,

EXPENSES, LOST PROFITS, LOST SAVINGS, OR OTHER DAMAGES ARISING OUT OF THE USE OF

OR THE INABILITY TO USE THIS PRODUCT.

To obtain warranty service, contact your TEC AMERICA, INC. dealer. You may also write or phone:

TEC AMERICA, INC., 4401-A BANKERS CIRCLE

ATLANTA, GA 30360

PHONE NO.: (770) 449-3040 FAX: (770) 453-0909

If the problem cannot be remedied by telephone, TEC AMERICA, INC. will determine how service will

be provided. Do not ship the equipment to TEC AMERICA, INC. without a return authorization

number. The purchaser must prepay any shipping costs and insurance, and assume the risk of loss

during shipping.

i

Page 4

______________________________________________________

TEC America, Inc. provides this publication as is without Warranty of any kind,

either expressed or implied. This publication could include technical inaccuracies

or typographical errors. Changes are periodically made to the information herein;

these changes will be incorporated in new editions of the publication. TEC

America, Inc. may make improvements and/or changes in the product(s) and/or

program(s) described in this publication at any time.

Copyright 2002 by TEC America, Inc.

4401-A Bankers Circle, Atlanta, GA 30360

All rights reserved.

ii

Page 5

______________________________________________________

CONTENTS

INTRODUCTION..............................................................................................................1

NAVIGATION KEYS .........................................................................................................2

MAINTENANCE ...............................................................................................................3

LOCATION.......................................................................................................................5

Location Details ............................................................................................................ 5

Cash Regis er Details .................................................................................................... 6 t

Subnet De ails .............................................................................................................. 7

NETWORK CONFIGURATION..........................................................................................8

FS-3600 SCREENS ........................................................................................................10

FS-3600 CATEGORIES ..................................................................................................12

FS-3600 DISCOUNTS....................................................................................................13

t

FINANCIAL ...................................................................................................................14

Cash Classifications..................................................................................................... 14

Cash Table ................................................................................................................. 15

Hourly Table............................................................................................................... 16

EMPLOYEE ....................................................................................................................17

Employee To al Names Maintenance............................................................................. 19

SUPPLIER .....................................................................................................................20

GROUP CLASSIFICATIONS ...........................................................................................21

PRODUCT GROUP .........................................................................................................22

STOCK UNITS................................................................................................................23

SALES UNIT ..................................................................................................................24

PRODUCT MAINTENANCE.............................................................................................25

Product G oup ............................................................................................................ 27

Pricing ....................................................................................................................... 28

Stock ......................................................................................................................... 30

Product Options.......................................................................................................... 32

Status Options............................................................................................................ 33

User Fields ................................................................................................................. 34

t

r

RECIPES........................................................................................................................35

RECIPE ...................................................................................................................... 36

iii

Page 6

______________________________________________________

STOCK...........................................................................................................................38

STOCK MANAGEMENT...................................................................................................39

Method 1 - Using Recommended Order......................................................................... 39

Method 2 - Using manual Ordering ............................................................................... 39

Method 3- Using Deliveries and Purchase Invoicing........................................................ 40

Method 4- Using simplistic purchasing .......................................................................... 40

STOCK MANAGEMENT...................................................................................................41

ORDERS ........................................................................................................................43

ORDER DETAILS......................................................................................................... 43

Information Entry ....................................................................................................... 43

DELIVERIES..................................................................................................................45

DELIVERY .................................................................................................................. 45

SUPPLIER DETAILS ..................................................................................................... 45

DELIVERY DETAILS..................................................................................................... 45

Information Entry ....................................................................................................... 46

PURCHASES ..................................................................................................................47

PURCHASE ................................................................................................................. 47

SUPPLIER DETAILS ..................................................................................................... 47

PURCHASE DETAILS.................................................................................................... 47

SPECIAL INSTRUCTIONS............................................................................................. 48

Information Entry ....................................................................................................... 48

TRANSFERS ..................................................................................................................50

Special ins ructions ..................................................................................................... 50 t

INFORMATION ENTRY................................................................................................. 50

WRITE OFFS .................................................................................................................52

STOCK MANAGEMENT...................................................................................................53

Update Current Stock Movements ................................................................................ 53

Take Stock Snapshot................................................................................................... 53

Physically Count Stock Items........................................................................................ 53

Enter Stock Take ........................................................................................................ 53

Analyze resul s of stock count ...................................................................................... 53

t

Update Current Stock .................................................................................................. 53

Set Opening Stock ...................................................................................................... 54

SET OPENING STOCK....................................................................................................55

STOCK TAKING SNAPSHOT ..........................................................................................57

ENTERING STOCK TAKE ...............................................................................................58

Produc s .................................................................................................................... 58

UPDATE CURRENT STOCK ............................................................................................60

UPDATE.........................................................................................................................61

t

iv

Page 7

______________________________________________________

Update Recipe cos s.................................................................................................... 61 t

Clear Sales WARNING ............................................................................................. 61

Clear Stock WARNING !............................................................................................. 61

GLOBAL PRICE CHANGE ...............................................................................................62

REPORTS ......................................................................................................................63

!!!

!!

Produc s .................................................................................................................... 63

Employee................................................................................................................... 63

Financial .................................................................................................................... 64

Hour.......................................................................................................................... 64

REPORT SELECTION .....................................................................................................65

Customizing Reports ................................................................................................... 66

View Report / Print and Save Features.......................................................................... 66

VIEW LOG FILES...........................................................................................................68

GSS STORE OPTIONS....................................................................................................69

Product File ................................................................................................................ 70

Product File 2 ............................................................................................................. 72

Shelf edge.................................................................................................................. 73

Orders /Transfers........................................................................................................ 74

Miscellaneous ............................................................................................................. 75

VIEW - GSS JOURNAL...................................................................................................76

WINDOW ......................................................................................................................78

USER .............................................................................................................................79

Log off User ............................................................................................................... 79

Set-up User................................................................................................................ 79

Users......................................................................................................................... 79

t

GSSEVENT – EVENT MANAGER.....................................................................................81

Event Time Table........................................................................................................ 82

Location..................................................................................................................... 83

Logs .......................................................................................................................... 84

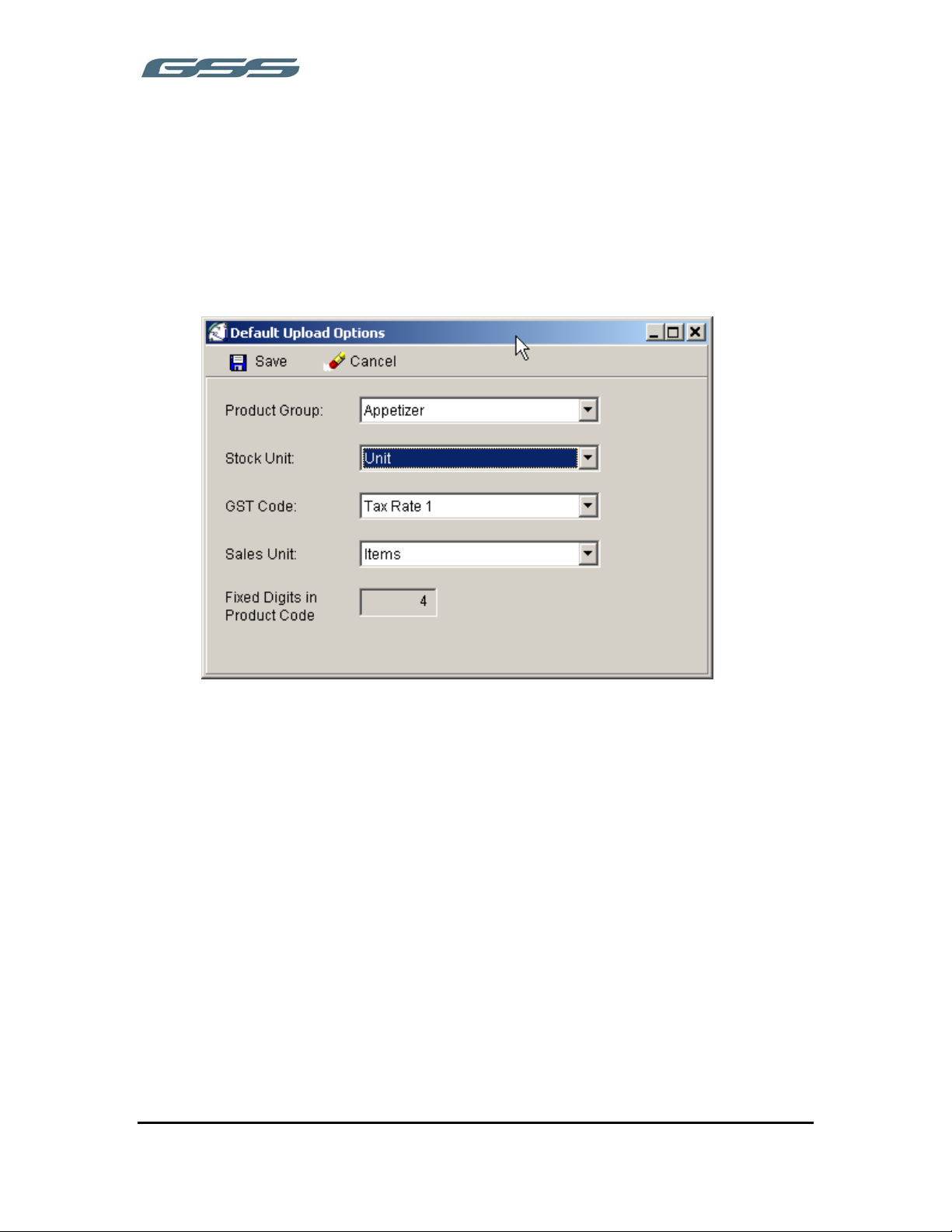

Default Upload Options ............................................................................................... 85

GSSEVENT – Script ..................................................................................................... 86

BACKUPS ......................................................................................................................87

TROUBLESHOOTING.....................................................................................................88

v

Page 8

Page 9

______________________________________________________

INTRODUCTION

This package has been designed to provide a simple and effective solution to the FS3600 stock taking requirements for numerous establishment types.

The simplistic windows based functionality allows for ease of use, with such features as

navigation keys provided through out the package, to assist the user.

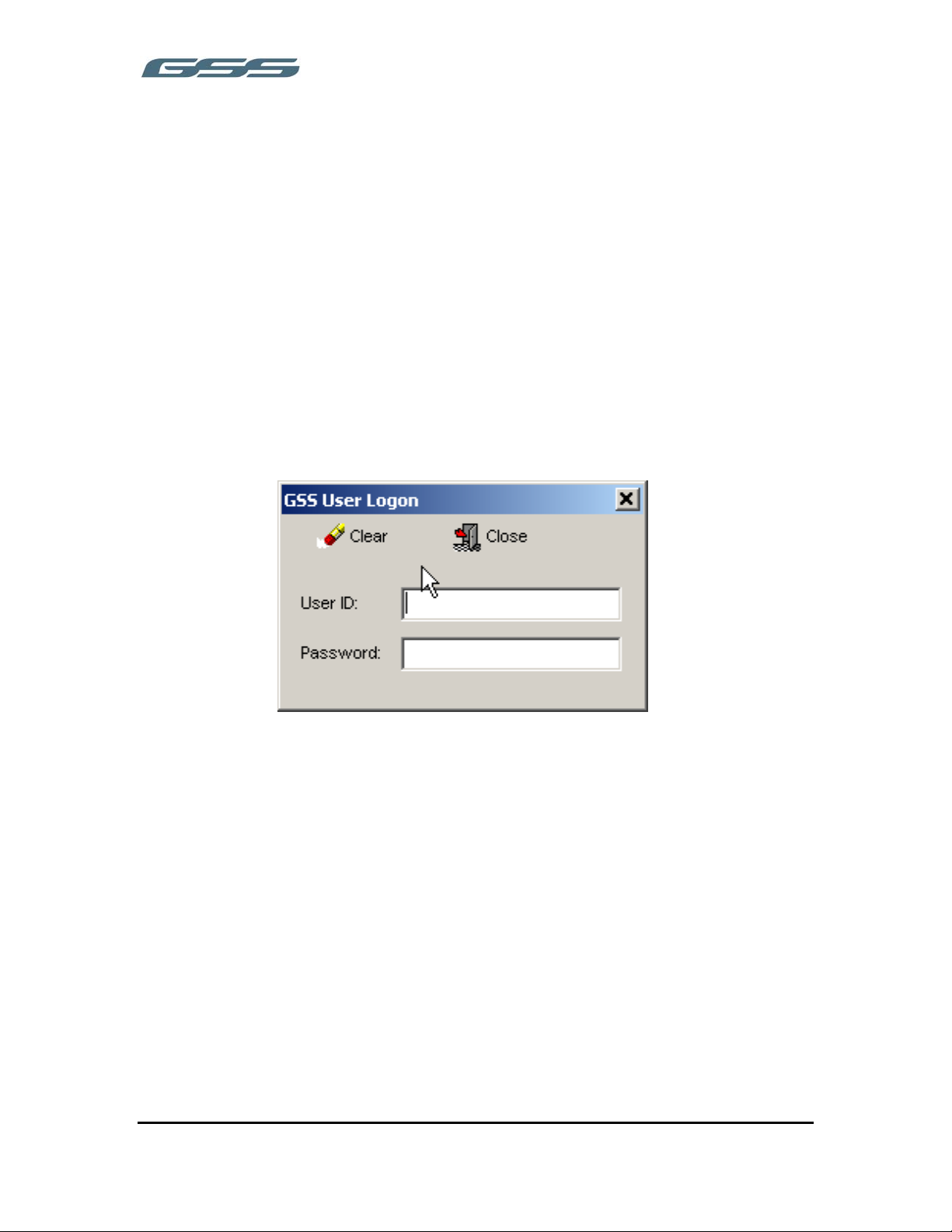

The GSS Store package also has built-in security, with the ability to restrict actions to

individual users. This means it is necessary to select USER and LOG ON after loading to

allow access the main menu options.

If additional security is required on the system this is covered in section “Set-up Users”.

If the password for the Master User is forgotten, access to all options of the system

previously available to that user becomes restricted.

1

Page 10

______________________________________________________

NAVIGATION KEYS

These keys are used through out the package to assist with record management.

SAVE

This is used to save a record, which is being edited. In the case of stock management,

it allows the information to be saved, recalled later for amendments and additions then

committed, to move onto the next stage.

CANCEL

This option cancels the products input and refreshes the users current screen

LABELS

This option allows the user to print product pricing labels for all goods ordered where

the Label Req. box is ticked and the product has barcode label required selected. The

labels are printed to a self adhesive thermal label printer. This option only applies during

Stock Orders/Deliveries/Purchases.

This will display to screen the relevant report, then allow a hard copy to be printed. The

prints can be produced for both saved and committed information. This information can

also be sent to file at this stage in varying formats such as CSV, HTML, XLS, RTF, WMF

etc.

COMMIT

This moves the information onto the next stage; i.e. Orders are accepted and moved to

Delivery stage. Deliveries are accepted and moved to the Purchase stage ready for

invoices to be entered.

DELETE

This will delete a saved Order, Delivery or Purchase, removing the relevant totalizer

from the product file, alternatively this will delete the current record on-screen.

EXIT

This leaves the current screen

F2

This provides a quick access key for finding products

2

Page 11

______________________________________________________

MAINTENANCE

The software package is designed to help you manage your business profitably, the key

to this is understanding your business and translating this into a product file. The first

consideration is the number of establishments you will be controlling using the system.

Each establishment is given a Location. The Location file controls the most basic of

information, such as the name of the site, the type of Point of Sale terminal connected

etc, this information is unique for each Location.

Other details such as the product file can be either Location unique for such details as

the retail price or details can be maintained simultaneously for all sites. It may be

necessary for example to control different price, suppliers etc. for each Location due to

regional differences.

There is a Location box displayed on the Product screen, allowing you to select which

Location, the record is saved to. i.e. by selecting Location 2 while editing a products

retail price you can determine that this information relates solely to Location 2.

The View Options tab, allows on multi-Location packages, to determine which fields are

unique and which fields are have changes updated across the Locations.

Once the software has been installed, the first thought must be how to organize the

data, the main components of any stock control system are the products you sell. These

saleable products consist of two parts; the retail information that is required to appear

on the Point of Sale terminal, i.e. price, description etc. The other consideration is how

the item is to be Purchased. What size box/bottle/barrel etc does the product arrive in

and how many saleable units are in that Stock Unit. This information can then be

organized into two levels of grouping for more comprehensive reporting.

It is recommended the information is created in the following order:

Basic Point of Sale and site Location details

• View Options

• Locations

• Hourly Table

• Cash Classifications

• Cash Table

• Staff Detail

3

Page 12

______________________________________________________

Product and Product related Details

• Supplier Name

• Group Classification Code

• Product Group

• Stock Units

• Sales Units

• Products

4

Page 13

______________________________________________________

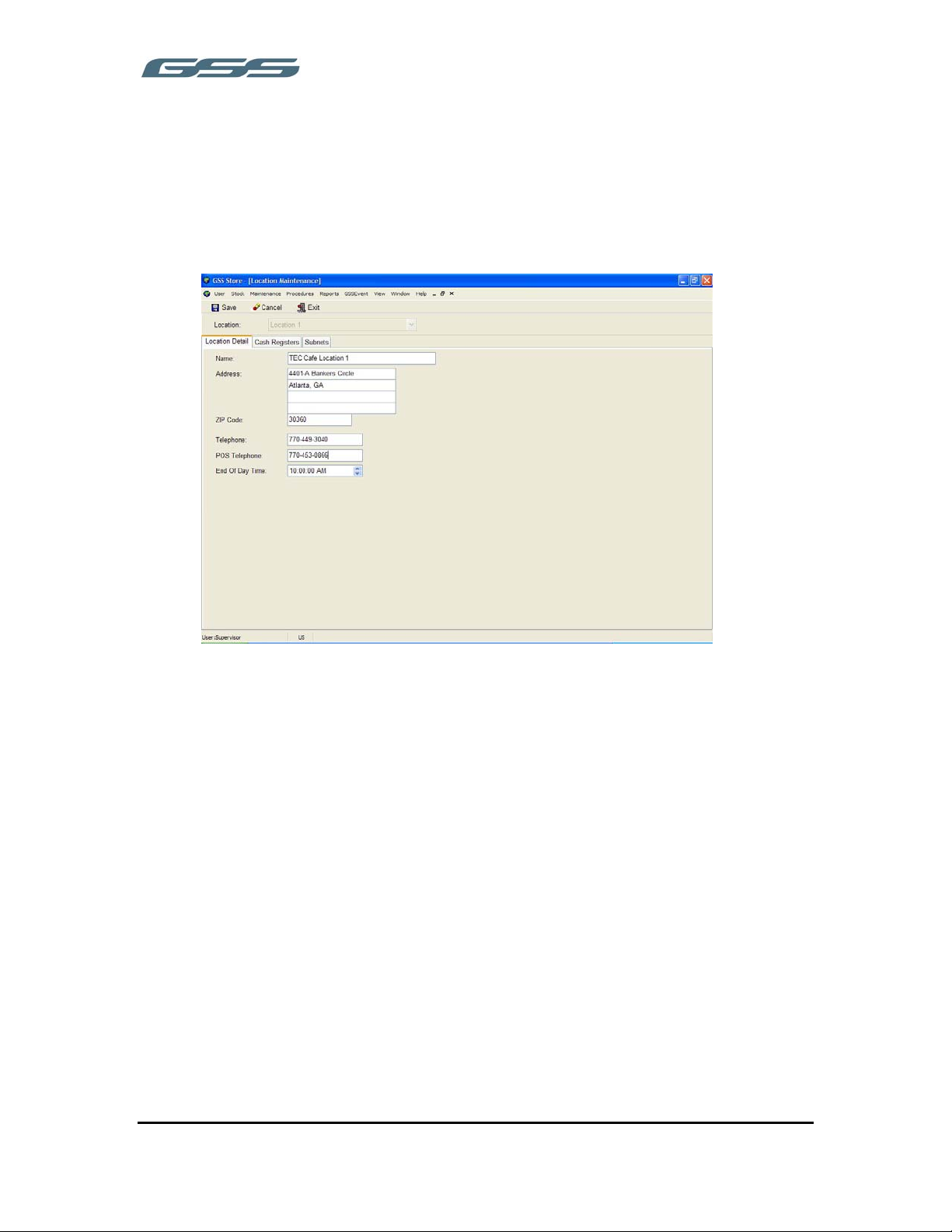

LOCATION

This controls the address and Point of Sale model for each site of the establishment.

GSS Store can either be a single Location or multi Location

LOCATION DETAILS

Name

This is the name of the Location, which will appear on the reports, and is displayed

when changing between Locations.

Address

This is available for storing the Location’s address for reference purposes and printed on

Orders etc.

ZIP Code

This is part of the address for the Location.

POS (POINT OF SALE) Telephone Number (GSS Host Option)

If you are communicating with the Point of Sale terminal via modem, this is the

telephone number the modem needs to call to connect with the remote Location. Please

note if the telephone normally requires 9 for an outside line, the POS telephone number

must be preceded with 9 followed by a comma. I.e. 9,01234567890 (no spaces to be

entered)

End of Day Time

The end of day time denotes that latest time that communications could take place with

a Location and the figures should be filed into the previous day’s date. For example,

5

Page 14

______________________________________________________

with the end of day time shown as above at 10:00am, any sales figures collected from

the Point of Sale terminals up to 10:00am will be filed into the previous day’s date. This

is used where establishments are open past midnight and the sales figures should be

filed for the previous day.

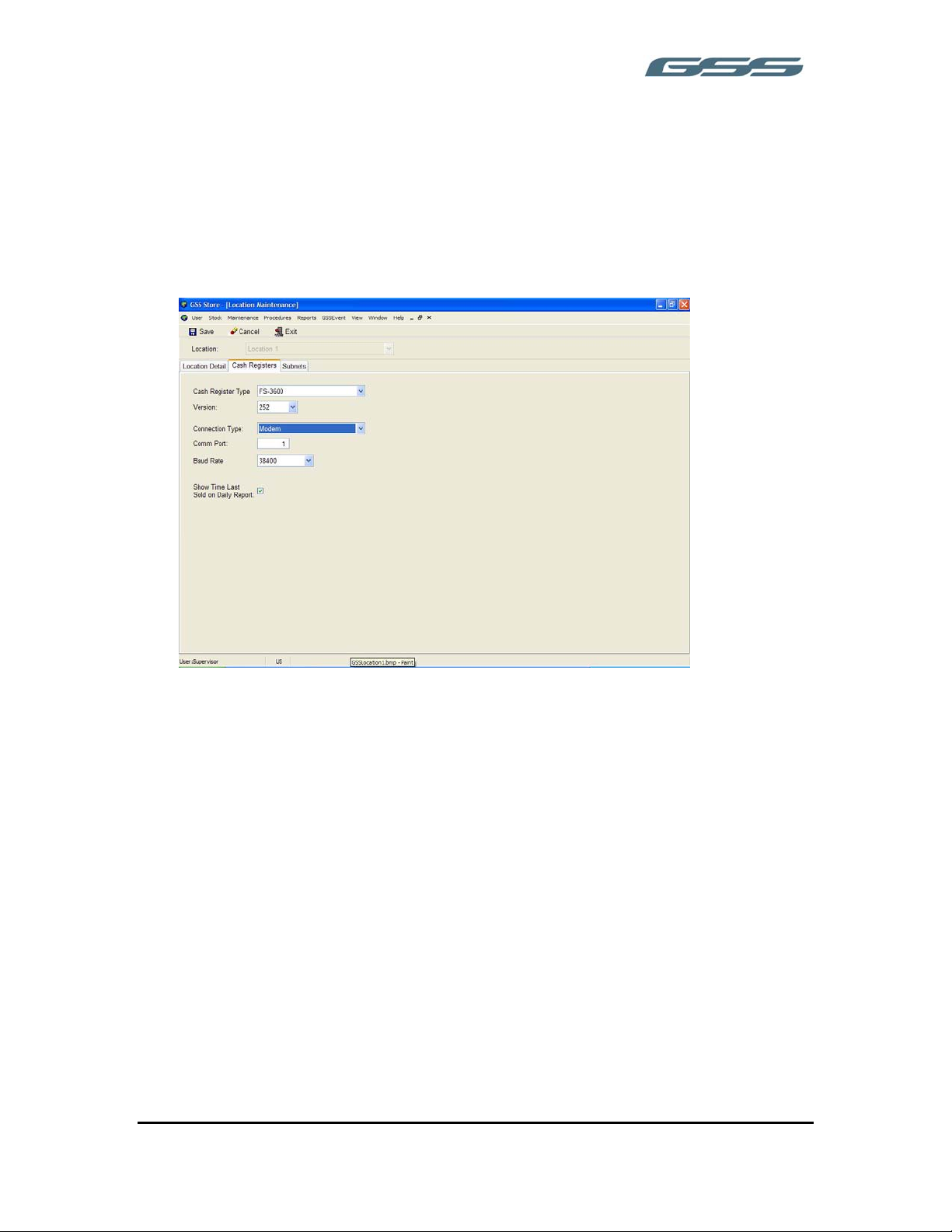

CASH REGISTER DETAILS

Cash Register Type

Currently GSS Store supports the TEC FS-3600 terminal.

Version Number

Must be set to 252.

Connection Type

Available communication modes:

• Direct Serial

• Modem: refer to Terminal Configuration-Help for recommended modem settings

• Network

Comm Port

Used for Direct Serial and Modem only.

Set to the host PC serial port number to which the modem or direct serial cable will be

connected. This is NOT the port on the FS-3600 terminal.

Baud Rate

Used for Direct Serial and Modem only.

6

Page 15

______________________________________________________

This speed must be equivalent to the speed set at the FS-3600 terminal with which it is

communicating. This can be set differently for each location.

Show time last sold on Daily Report

The TEC FS-3600 terminal records the time last sold for each product and if this box is

checked it will be displayed on the Individual Daily Product Sales report.

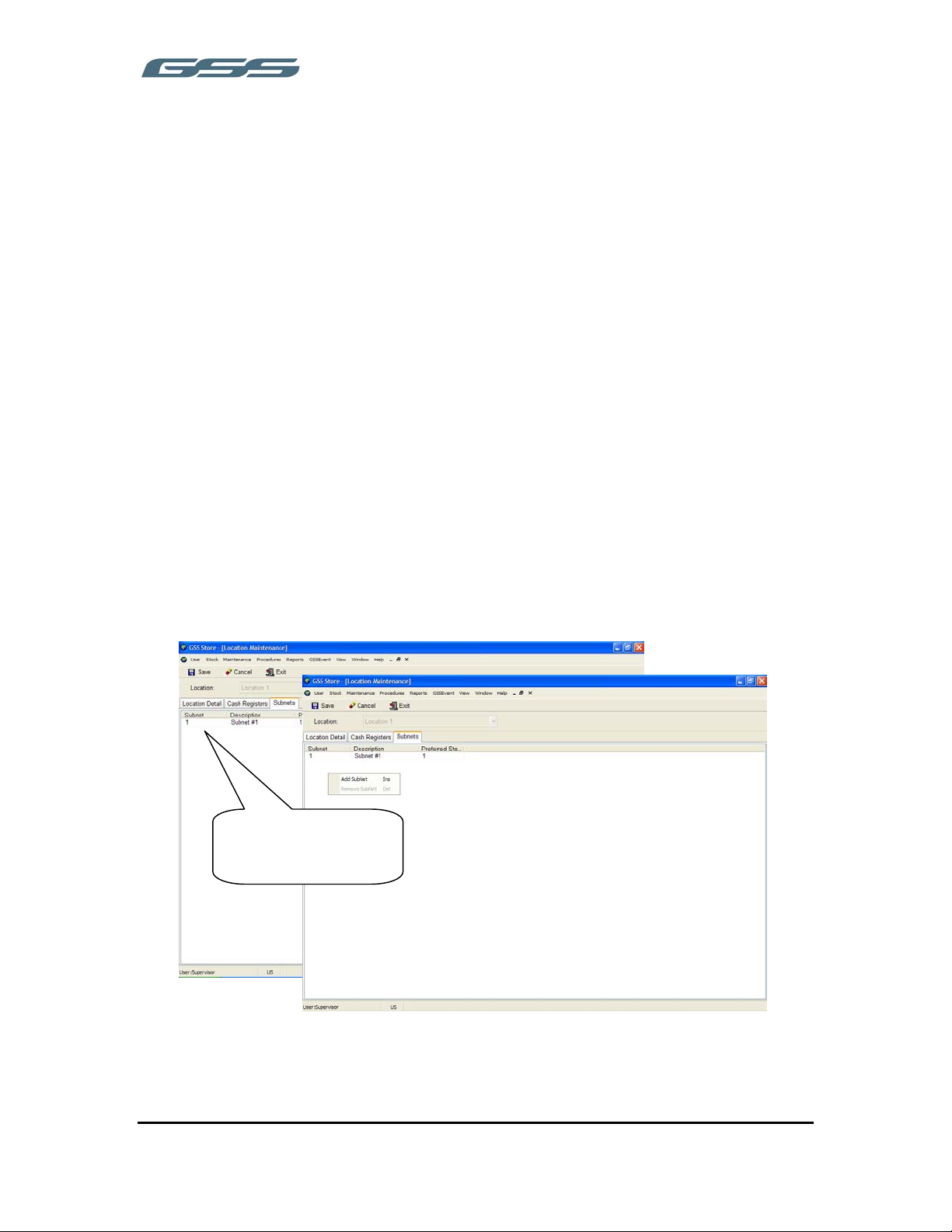

SUBNET DETAILS

Subnet

This is the subnet number for the particular FS-3600 system to be polled.

Description

Enter a unique name for each of the subnets.

Preferred Station

Valid setting is 1-6.

For Network Connection:

This is the station number for the terminal which will generate the export files. The

location of these files are dependent on the Reset options of the FS-3600 terminal.

For Direct Serial and Modem Connection:

This is the station number that the modem or direct connect cable is connected to.

Right-Click here to

add or remove a

7

Page 16

______________________________________________________

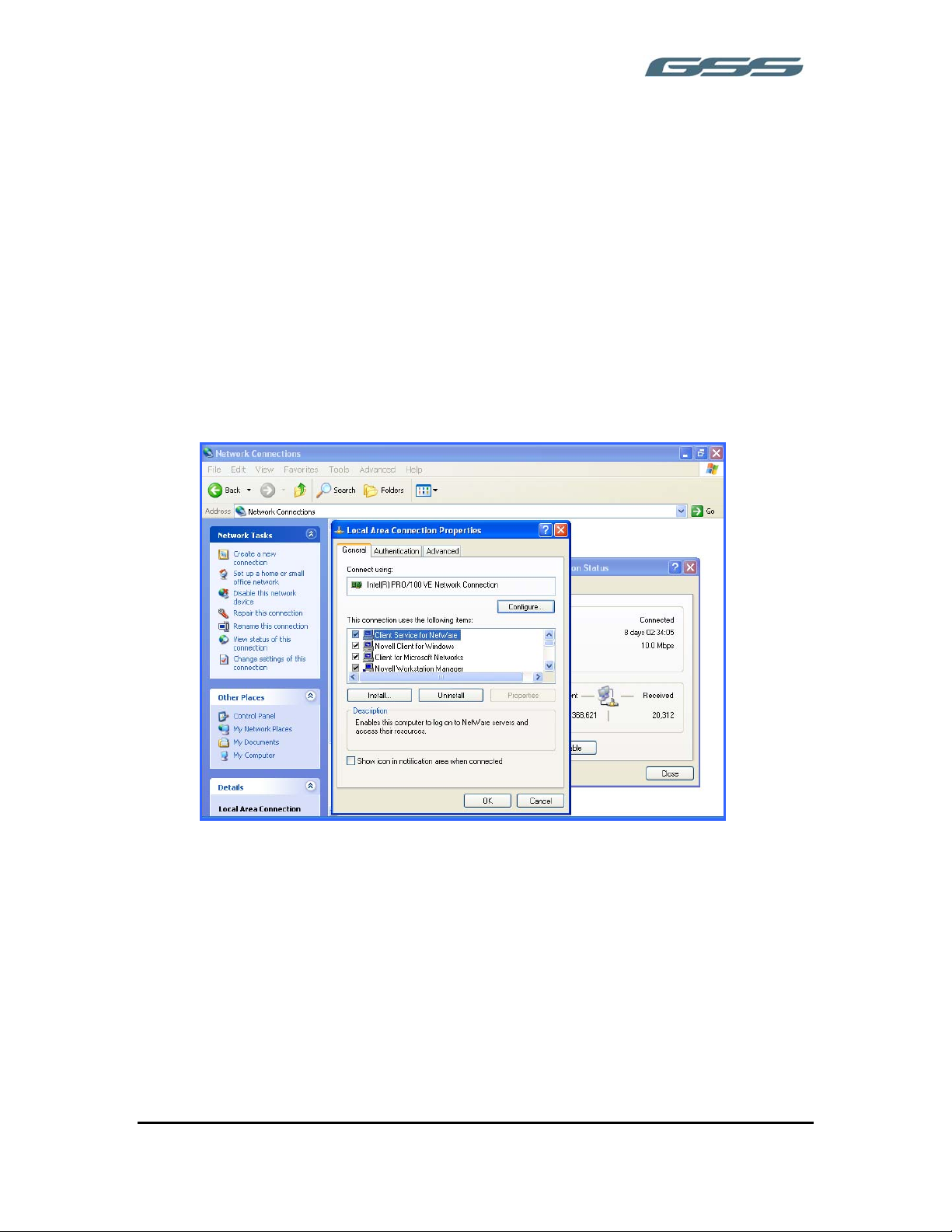

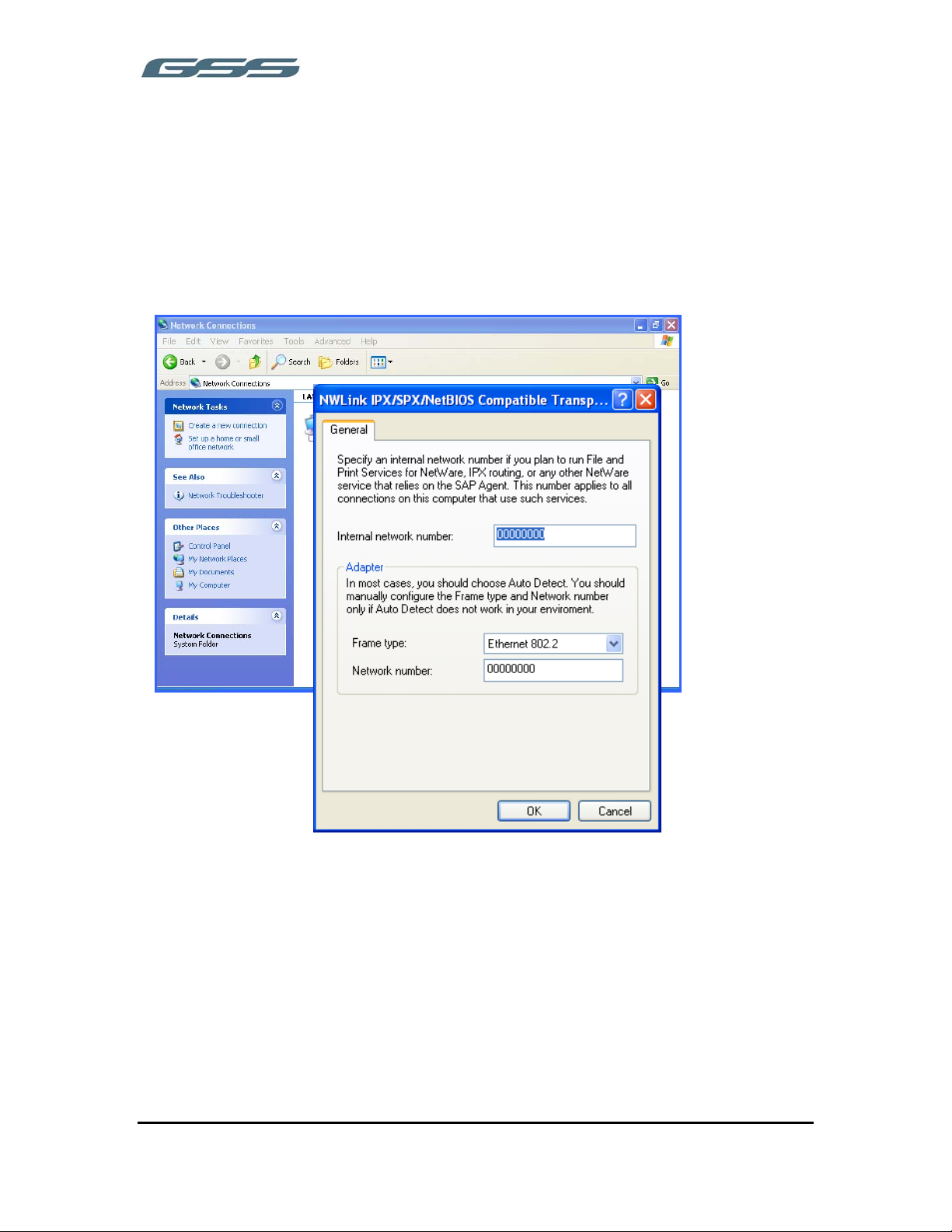

NETWORK CONFIGURATION

Following are some notes to assist with the network configuration for communication to

the FS-3600. However please beware these may not be the exact requirements for the

PC on which GSS is running, especially if there is currently a network environment in

place. Please consult your supplier if there are any concerns over which options relate to

your system. Under no circumstances attempt the following procedure if all the facts

and relevant experience are not at your disposal. Uninformed entry to any following field

may result in existing network failure.

• Select the Start Programs - Settings - Control Panel - Network Settings

• Then within Configuration ensure there is a Client for NetWare networks option. If

this is not available then use the INSTALL option to create the selection.

8

Page 17

______________________________________________________

• The Primary Network Logon can then be default to Client for NetWare Networks,

providing there are no other client operations available. Uninformed entry to this

field may result in loss of existing network.

• When Client for NetWare networks is available, this provides the relevant IPX –

options that are used by the FS-3600 network communications.

9

Page 18

______________________________________________________

FS-3600 SCREENS

It is possible to manage certain aspects of the ECR from the PC. This is designed to

assist with product creation and restaurant management. New products can be added to

the ECR Screens, and new restaurant table layouts can be designed. However it should

be noted, this option is not designed to manage the ECR programming in it’s entirety

just to assist with the product management aspects of the stock control system.

It is possible to add new buttons to the screen, for selected functions, management of

the buttons is carried out using the following key presses.

Adding a New Button

While holding down the left button of the mouse, drag to create the button size. The

shape of the button can then be control by right clicking. It is then necessary then to

select the button type, and enter the Item ID. If the button is a menu item then the

beacon icon can be used to select from the product list. It should be noted that all types

of functions are shown within the function box. This is to ensure that all keys are

displayed. However, if an unavailable function type is chosen for addition then the item

ID box will be gray, in this instance do not attempt to amend.

10

Page 19

______________________________________________________

Button Re-Sizing

The button can be re-sized using the Width and Height boxes displayed on the left hand

screen. Alternatively, the SHIFT key and CURSOR keys can be used.

Button Movement

The button can be moved by setting the X, Y co-ordinates on the left hand screen

alternatively the ALT key and the CURSOR keys can be used.

Button Copy

Buttons can be copied en-mass across screens. The buttons to be copied are selected by

depressing SHIFT and right clicking then highlighting all required keys. This can then be

copied by selecting EDIT COPY then PASTE.

Deleting Button

The button can be deleted by highlighting the button and pressing the ‘Delete’ key on

the keyboard.

11

Page 20

______________________________________________________

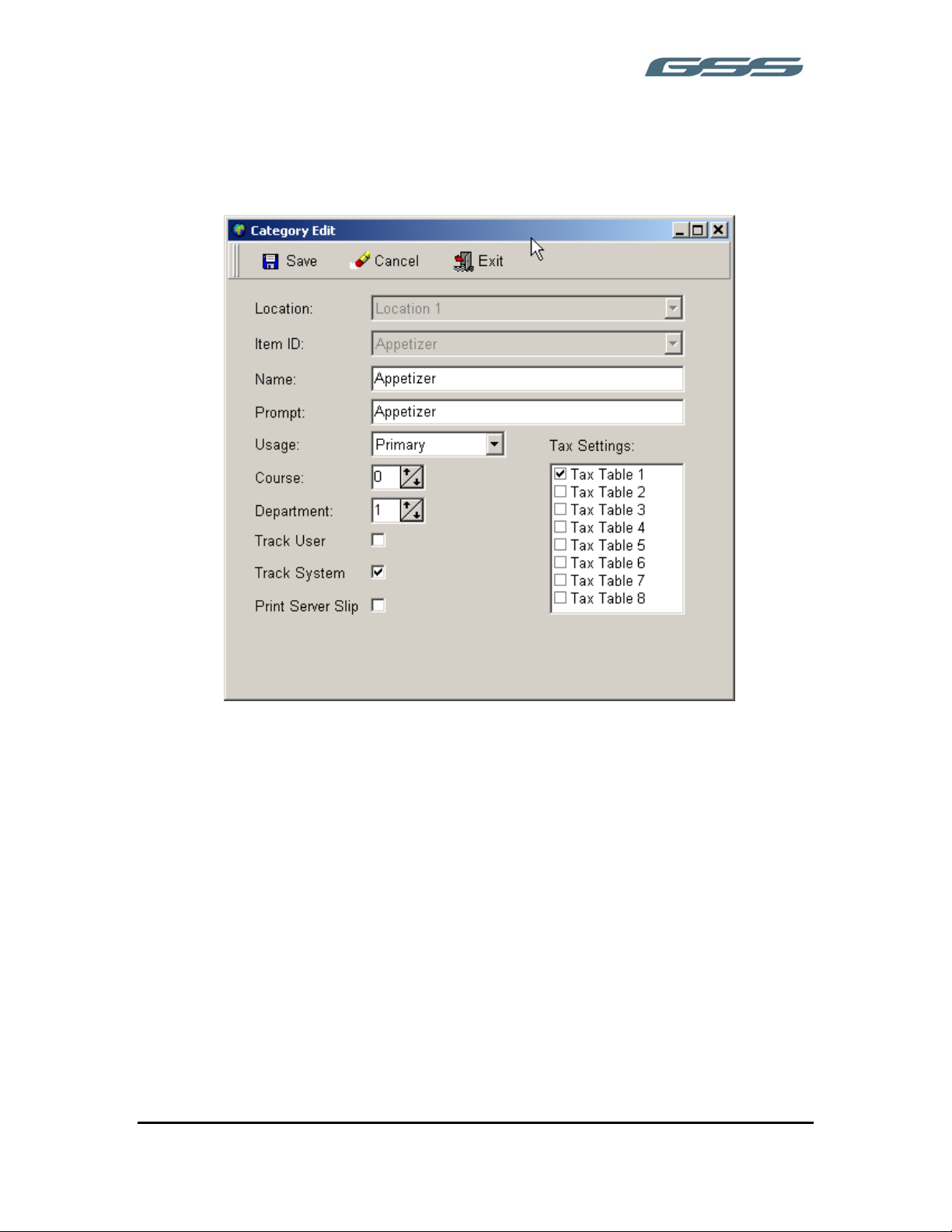

FS-3600 CATEGORIES

This is used, to program category specification for the FS-3600. The following settings

will be detailed by the ECR provider.

12

Page 21

______________________________________________________

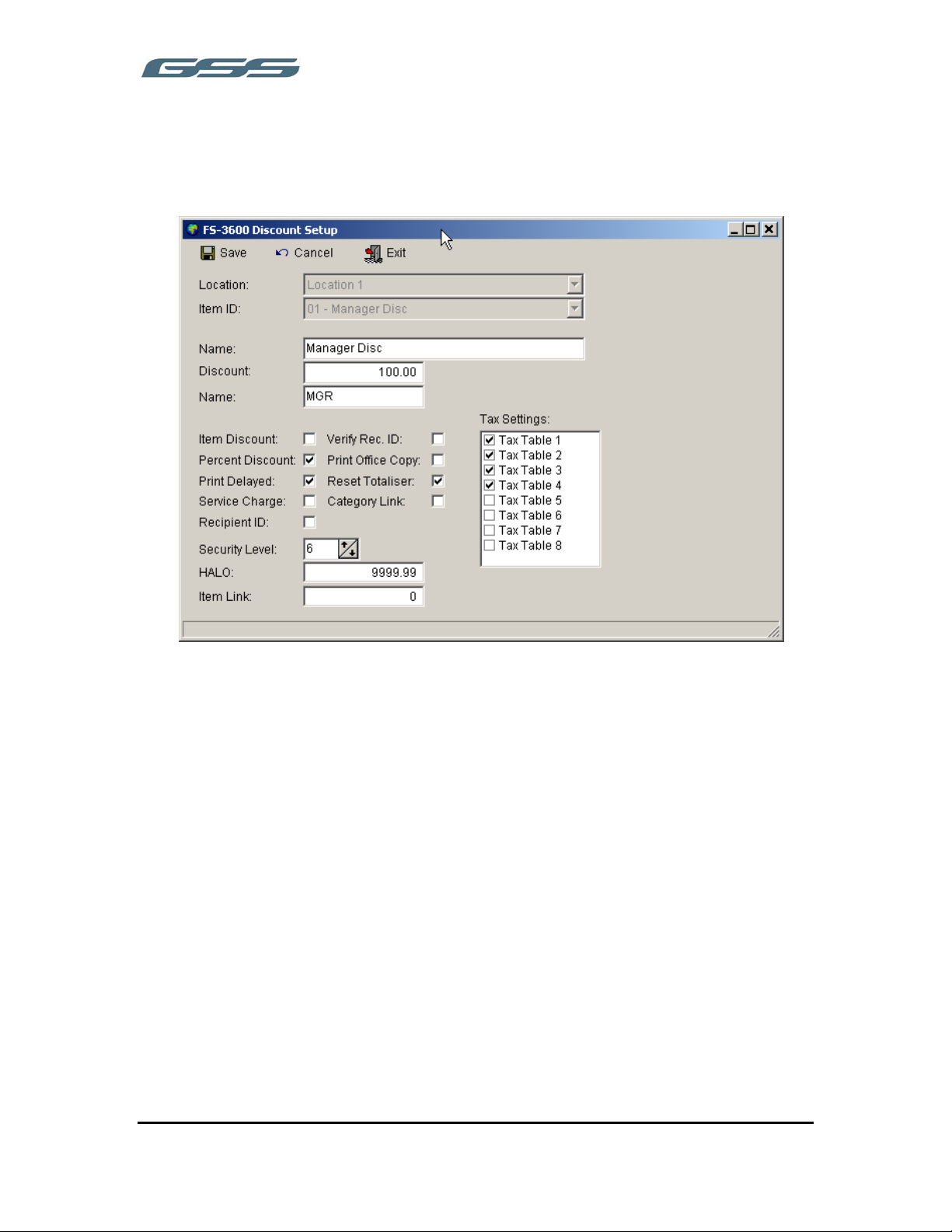

FS-3600 DISCOUNTS

The discounts used within the FS-3600 can be maintained from the Discounts screen.

The settings for this screen would be detailed by the ECR provider.

13

Page 22

______________________________________________________

FINANCIAL

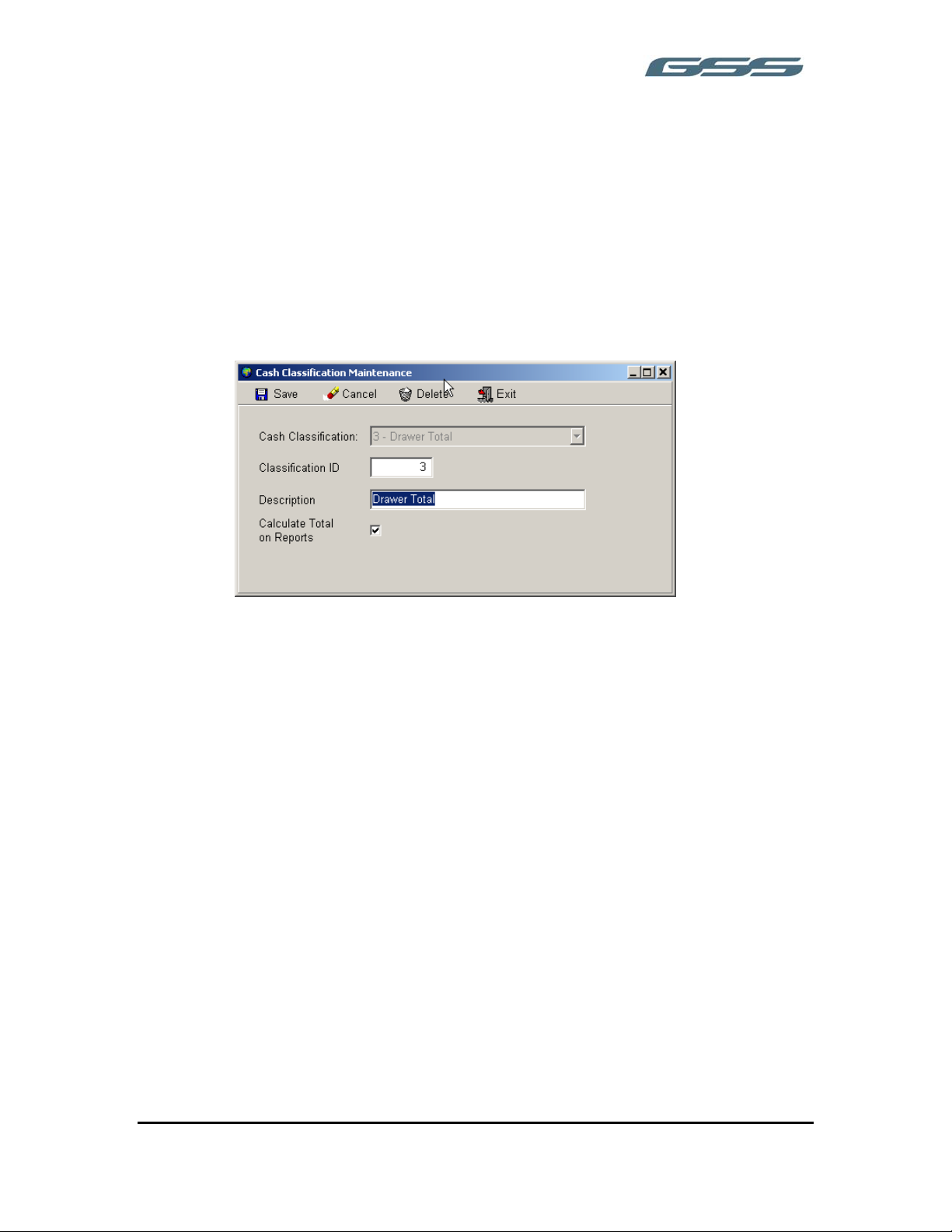

CASH CLASSIFICATIONS

The POS terminal will file the financial sales data to the computer, such as the Cash,

Check and Credit Cards, Voids, Refunds etc. into Media Totals. It is then possible to

group these media totals so that a total will be available, for example, of all Voids and

adjustments etc. They are as standard pre-defined groups, these can be amended if

required.

Classification ID

This is a consecutive record Number

Description

This is the description of the Classification Group

Calculate on totals

This determines if the group will require a subtotal of all values printed on the financial

reports.

14

Page 23

______________________________________________________

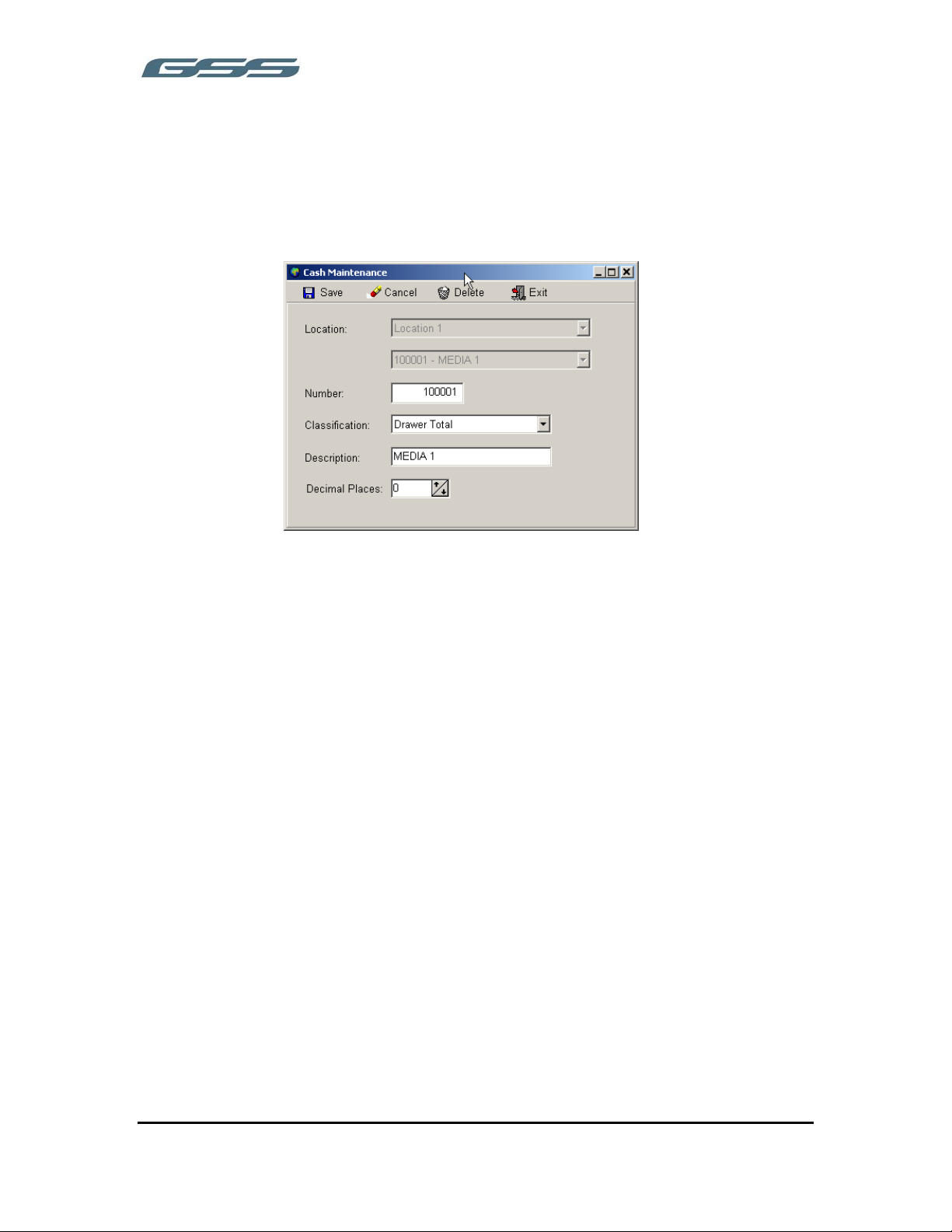

CASH TABLE

This is where the POS terminal cash fields are defined, this relates directly to the Point

of Sale programming and is set-up as part of the initial installation, determining for

example which field is CASH IN DRAWER etc.

Number

This is the financial total record number.

Classification

This will link this financial total such as Cash, Credit Card etc. to the Classification Group.

This will then provide the option to produce reports of specific types i.e. Finalization

keys, Voids.

Description

This is the description of the financial totalizer

Decimal Places

It is necessary for certain fields of financial reporting to set the number of decimal

places. This will be set by your dealer, however if a field is displayed as 600 not 6 on a

financial report, setting this field to 2 decimal places will resolve the issue.

15

Page 24

______________________________________________________

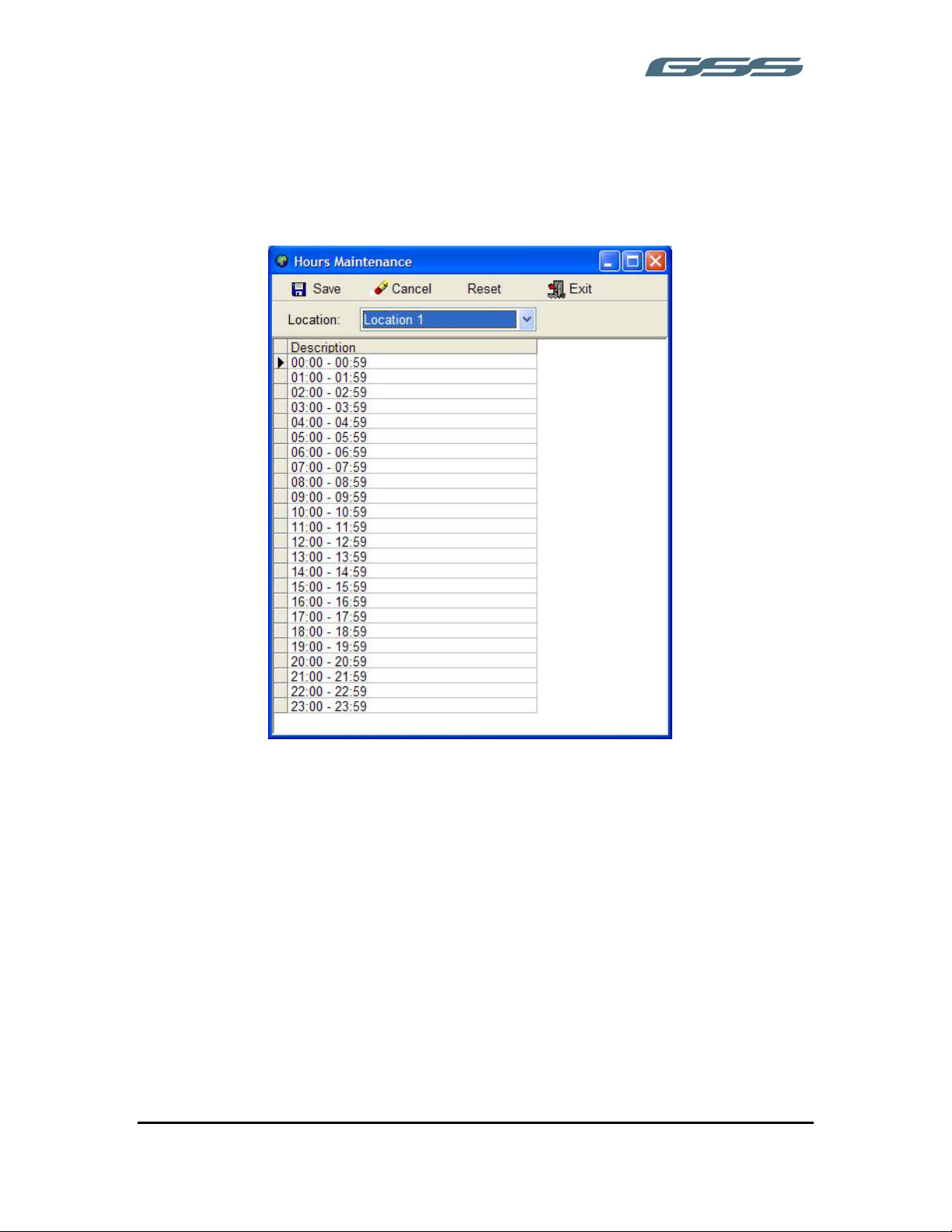

HOURLY TABLE

This controls how the time periods sales analysis collected back from the POS terminal is

reported

Location

Each Location connects with a POS terminal which is capable of storing the sales

transactions value in specific time periods usually 24hour time periods, the descriptions

can be changed or new time periods added depending on the model of POS terminal

which is connected.

Description

The order the report prints can be change by highlighting the row and dragging this to a

new position with the mouse this means that the report can start at 8.00am rather than

midnight.

Reset

This will re-sort the order of the time period descriptions into the original order i.e. time

period 1 midnight as the first option

16

Page 25

______________________________________________________

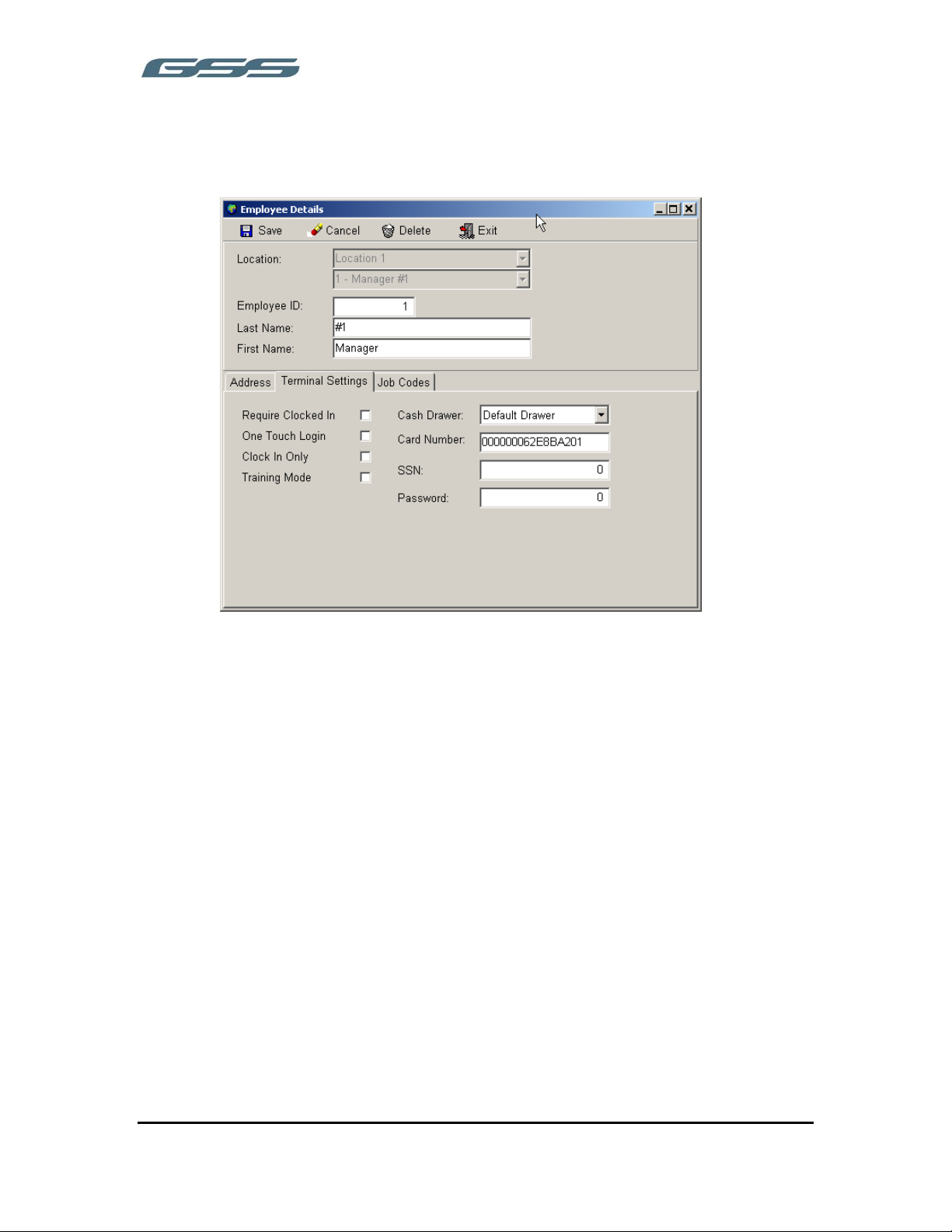

EMPLOYEE

This stores the Employee’s personal details for that Location. The POS terminal will

transmit the value of Employee’s sales back to the computer for reporting purposes.

Employee ID

This corresponds to the User Sign-On number used at the POS terminal

Last Name / First Name

These are the names to be printed on the Employee Sales Reports and used on the

terminal.

Address Tab

Employee address and contact information can be stored on this tab.

Terminal Settings

The settings on this tab determine how the Employee ID will function on the terminal.

Please consult the ECR manual for an explanation of these functions.

Job Codes

This tab determines which Job Code(s) the Employee is allowed to clock in under and

the rate of pay for each Job Code.

17

Page 26

______________________________________________________

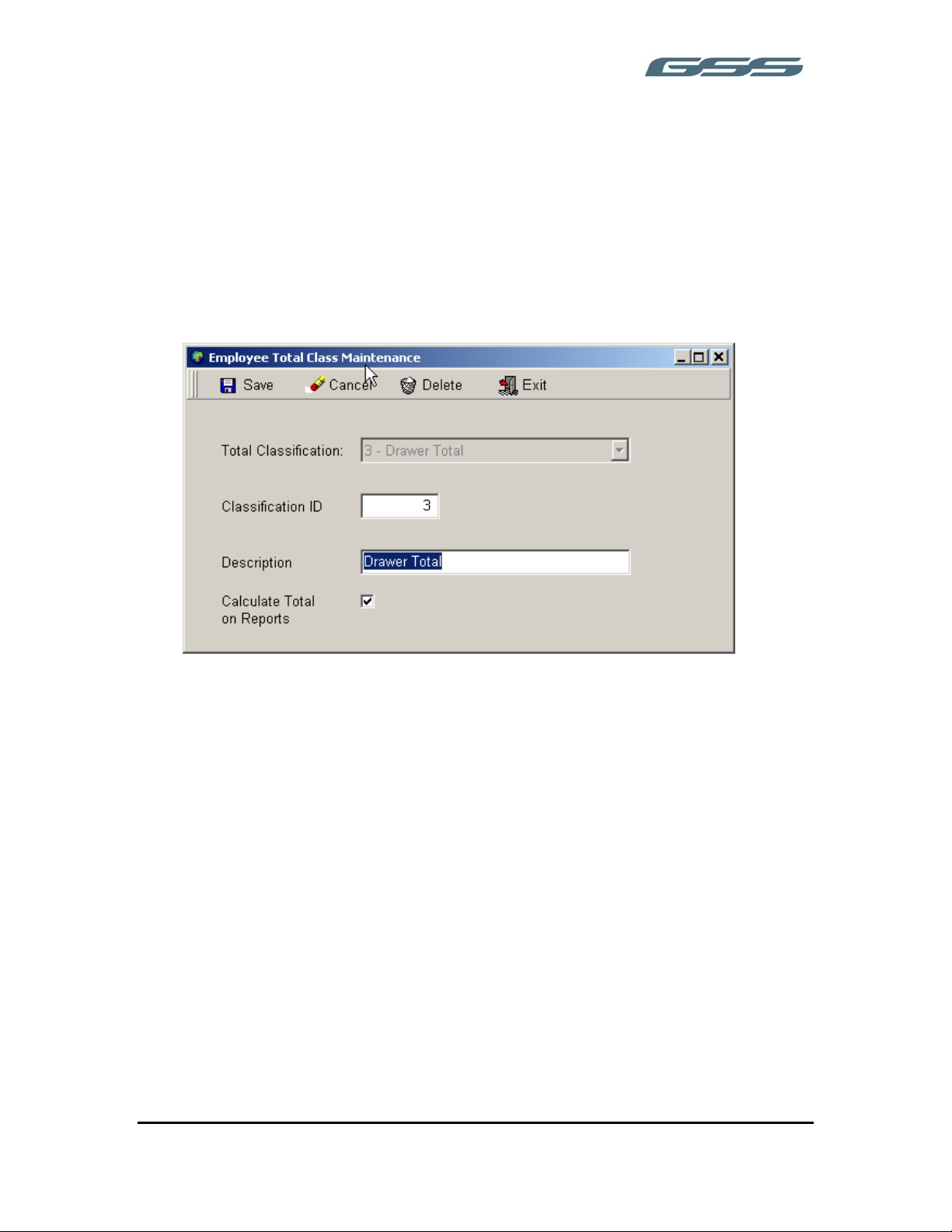

Employee Total Class Maintenance

This section records the information relating to the Point of Sale terminal Employee

reporting. This information is normally set-up by your system provider.

Employee Total Classification Names

The POS terminal will file the Employee Financial Sales data to the computer, such as

the Cash, Check and Credit Card, Voids, Refunds etc. into Media Totals. It is then

possible to group these Media Totals so that a total will be available, for example, of All

Void and adjustments. There are pre-defined groups but these can be amended if

required.

Classification ID

This is a consecutive record Number

Description

This is the description of the Classification Group

Calculate on totals

This determines if the group will require a subtotal of all values included printed on

reports.

18

Page 27

______________________________________________________

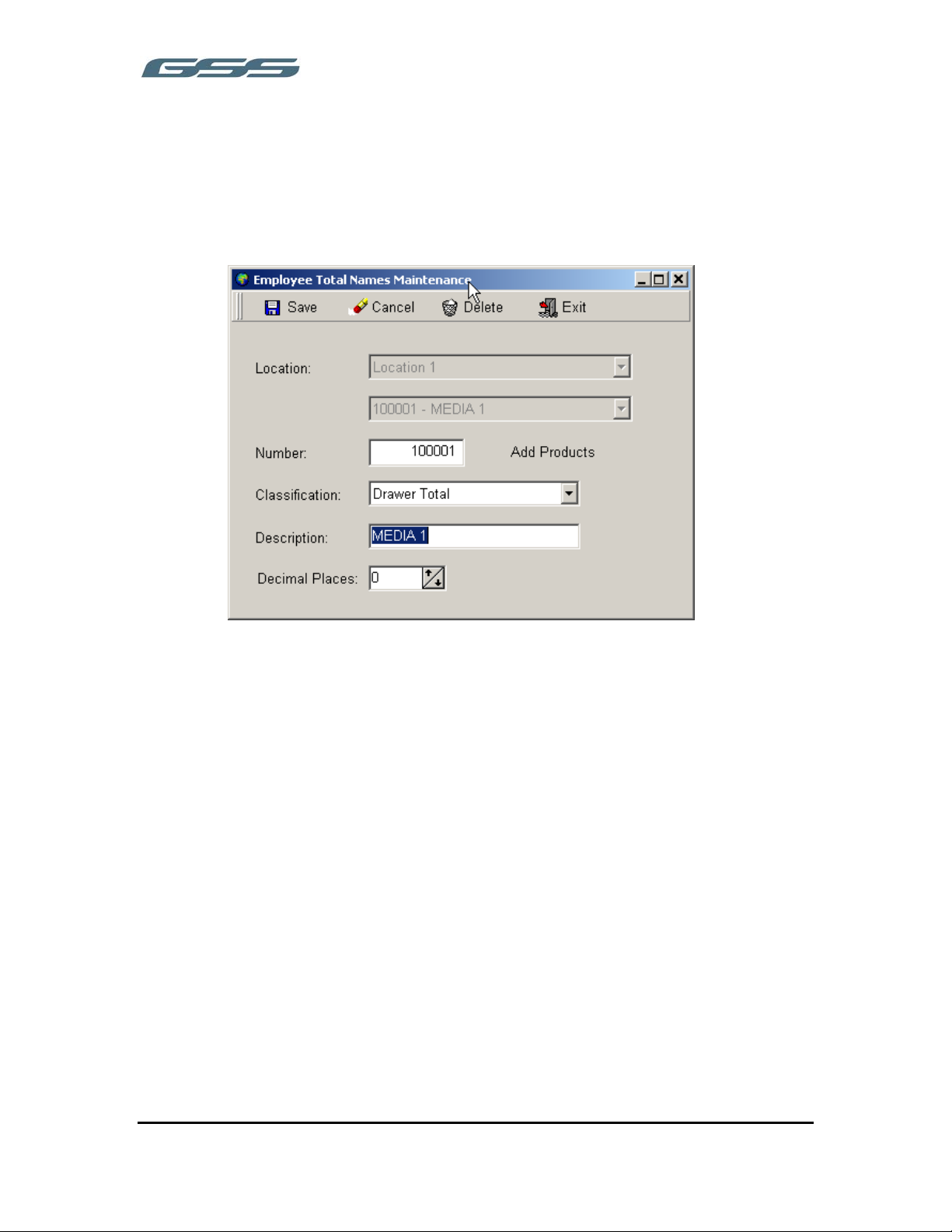

EMPLOYEE TOTAL NAMES MAINTENANCE

Employee Total Names

This is where the POS terminal cash fields are defined, this relates directly to the Point

of Sale programming and is set-up as part of the initial installation, determining for

example which field is CASH IN DRAWER etc.

Number

This is the financial total record number taken from the POS programming book

Classification

This will link this financial total such as Cash, Credit Card etc. to the Classification Group.

This will then provide the option to produce reports of specific types of fields i.e.

Finalization keys,

Description

This is the description of the financial totalizer

Decimal Places

It is necessary for certain fields of financial reporting to set the number of decimal

places. This will be set by your dealer, however if a filed is displayed as 600 not 6 on a

staff report, setting this field to 2 decimal places will resolve the issue.

Add Products

It is possible using the POS terminal to have reporting by each Employee for all

products. Selecting a new classification field then, clicking on Add Products will

automatically set up the file with all the products from the product file start at code

200001 for PLU 1.

19

Page 28

______________________________________________________

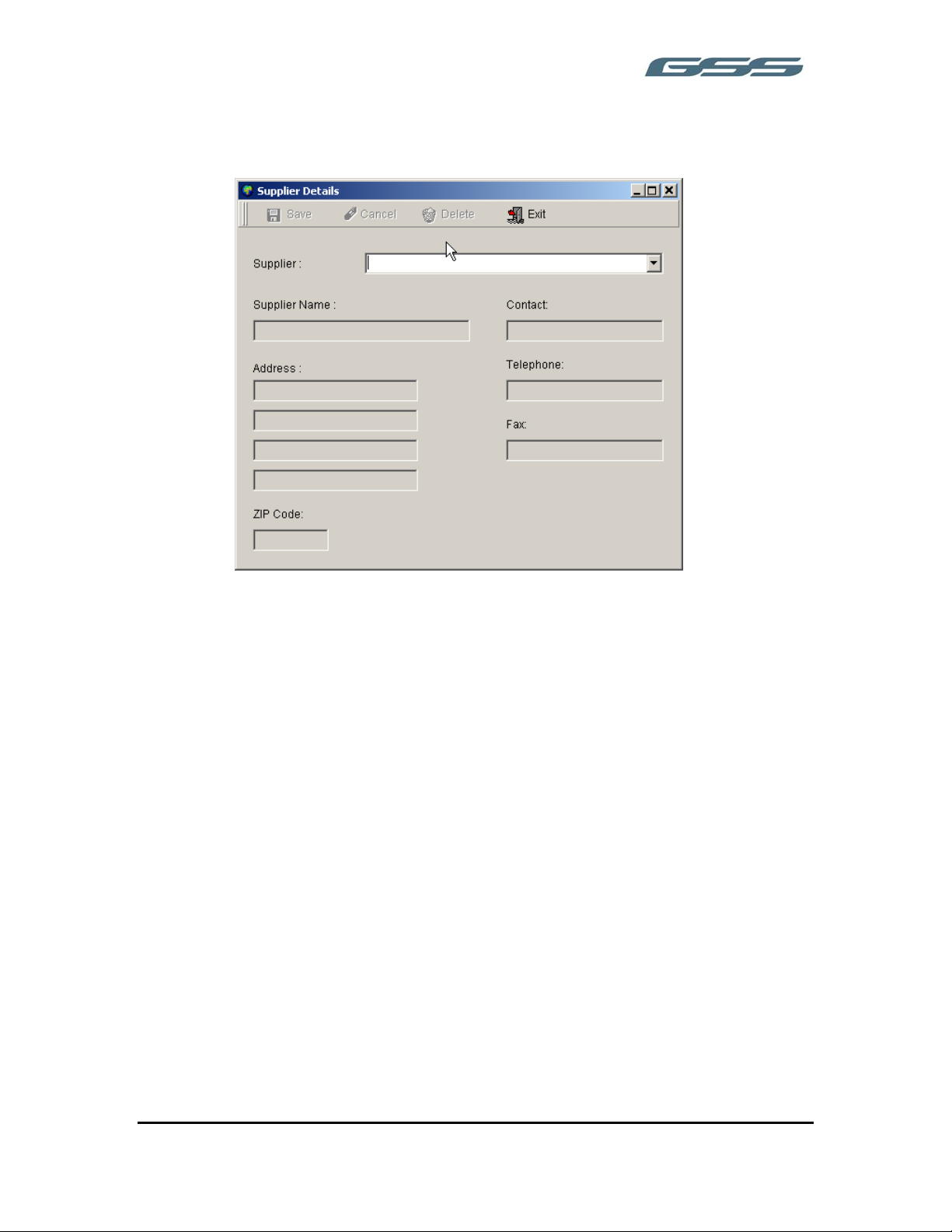

SUPPLIER

This stores all the details for the suppliers from which products are purchased

Supplier Name

This is the name of the supplier which can then be stored against individual products

and used to recall suppliers for ordering and Delivery purposes.

Address, ZIP Code

This is the address of the supplier, this will be printed on the Order, Delivery etc.

Contact, Telephone, Fax number

This stores the relevant contact details for this supplier.

20

Page 29

______________________________________________________

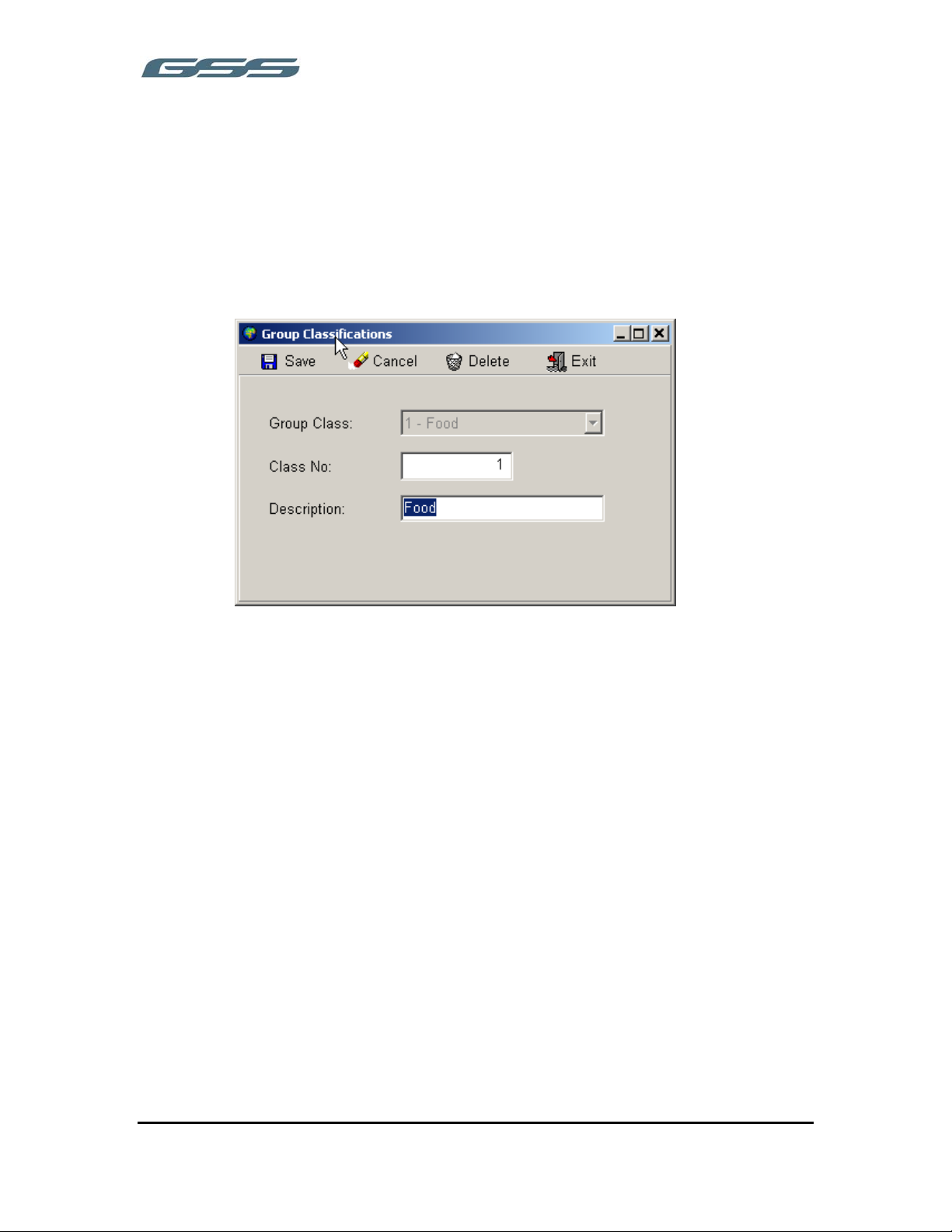

GROUP CLASSIFICATIONS

Group Classification is similar to the Department Names on the FS-3600. It is possible to

link Products into Product Groups such as Domestic Beers, Appetizers etc. These Product

Groups can then be linked to Group Classifications, which are the first level of grouping.

For example total Beers, total Food goods. Therefore entered below should be the

highest level of grouping to which the Product Group categories are to be linked.

Class Number

This is the sequential record number for the Classification Group

Description

This is the description of the highest level of group I.e. Food, Beer, Wine, Liquor, etc. to

which Product Groups such as Domestic Beers, Appetizers etc. are to be linked.

21

Page 30

______________________________________________________

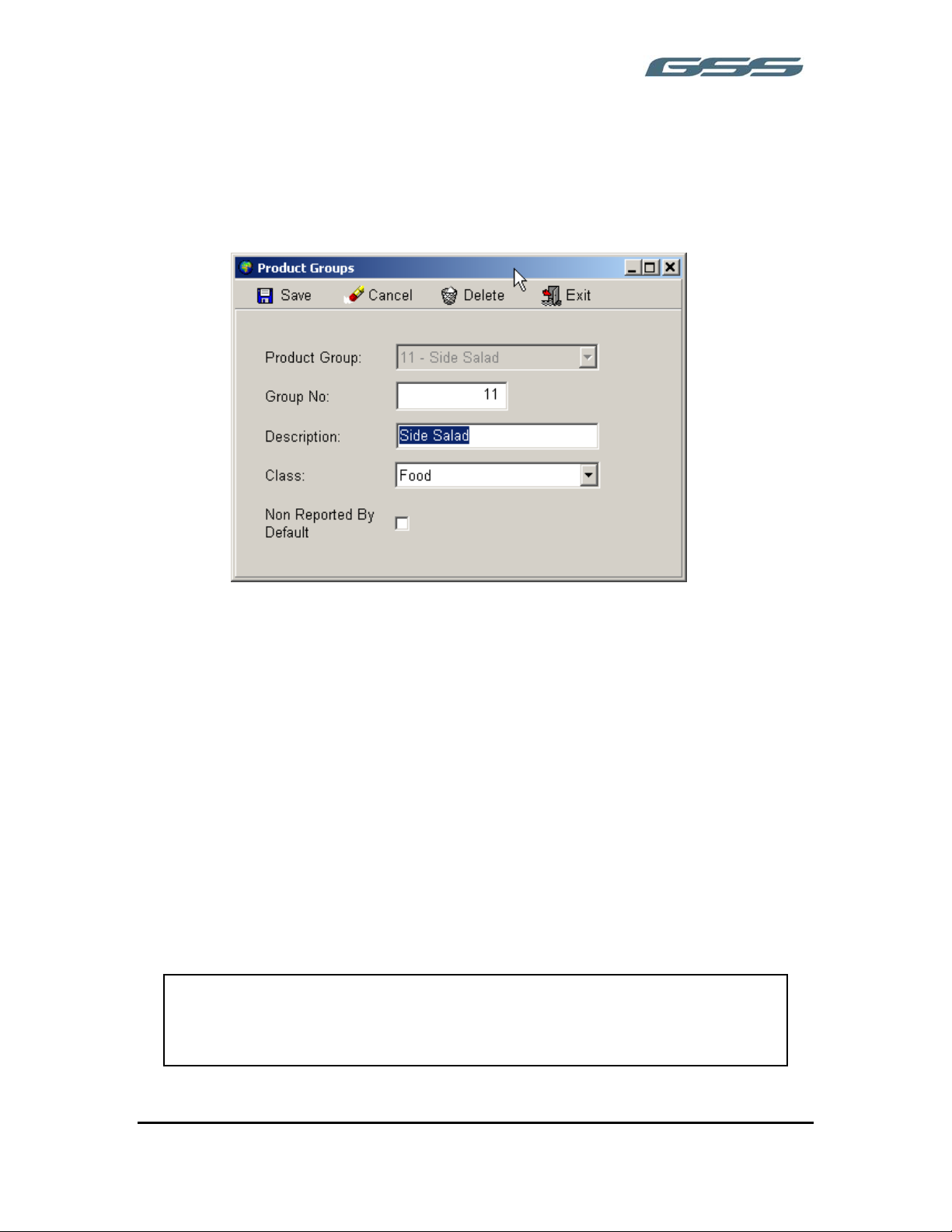

PRODUCT GROUP

Product Group is similar to the Category Names on the FS-3600. This allows products to

be linked to group categories such as Domestic Beers, Appetizers etc, these Product

Groups in turn can be linked, to Group Classification for totaling of a number of Product

Groups. Therefore entered below should be the minor category names.

Group Number

This is the sequential record number for the Product Group

Description

This is the description of the second level of group i.e. Domestic Beers etc

Classification Group

This is a selection box, allowing the Product Group to be linked to a Classification Group,

i.e. Domestic and Bottled Beers groups can be linked to a Classification Group total

beers.

Non Reported By Default

When a product report is selected and this box is checked, this Product Group will be

excluded from the report. It can be added manually, by clicking the add button on the

report screen. This is useful for Product Groups used for kitchen messages, etc. which

are not required to be included in sales reports.

Note:

Initially, the FS-3600 Categories are imported into the GSS Product

Group table. From that point forward they can be managed

separately, providing more reporting flexibility.

22

Page 31

______________________________________________________

STOCK UNITS

This is the section where the Purchases and stock keeping sizes for each Product Group

are created, for example beer may be purchased by the case and wine by the case or

individual bottles.

Product Group

The sizes created are associated with the Product Group for that item, i.e. all purchases

sizes for wine will be associated with the wine Product Group. It is therefore necessary

to create records for each Product Group listing all possible purchase sizes, I.e. Draft

Beers, would require units such as barrel etc.

Description

This is the name of the Purchased/Stock Keeping unit, i.e. box, case, barrel etc

Units for Sale

This is the number of sales units which are purchased in one outer. For example an 11

Gallon Barrel for draft beer would equal 88 pints/units for sales. This is used for

ordering/deliveries purposes to calculate how many saleable units are purchased within

each Stock Unit.

23

Page 32

______________________________________________________

SALES UNIT

Sales units are simply labels to help clarify product sales on product reports.

Description

This is the name of the, sales unit which is to be printed on the report. i.e. Wine is sold

by the Glass, Beer by the Pint.

24

Page 33

______________________________________________________

PRODUCT MAINTENANCE

This screen allows input of all relevant stock keeping and retail information for a

saleable/stock Product Code.

Product Code

This is the in-house code number for the item, it may be an internal reference number,

or it may directly relate to the ECR number.

If the Product Code is to be the same as the ECR number, then the system may benefit

from having the options screen set so the ECR code is automatically updated with the

Product Code. This means only one code number needs to be maintained. (See Options)

It should be noted, due to the fact the Product Code is an alphanumeric field, it is

possible to have Product Codes such as ABC0001, ABC0002etc. It also means in order to

provide numeric sorting the system works on a fixed number of digits i.e. code 1

becomes 000001, 000002, etc.

Description

This is the long description for the product, which appears on the reports.

25

Page 34

______________________________________________________

ECR Description

This is the description, which appears on the Point of Sale terminal, which is 18

characters long, a counter is provided to indicate when 18 characters have been input.

It is recommended upper case be used for the ECR description used for the sales

receipt.

Note :

Do not use a Comma or Quotation marks in the descriptor field as these are a special

field separator characters.

26

Page 35

______________________________________________________

PRODUCT GROUP

Product Group

This is a selection box, allowing this product to be linked to one of the existing groups,

i.e. bottled beers, etc. for reporting and stock keeping purposes, also to assist with

product searching and reporting totalizers.

Default Stock Unit

This is a selection box, which allows you to select the purchase size for this product,

only the sizes allocated to that Product Group, are available for selection

Sales Unit

This is the description of the actual sales unit for reporting and stock keeping purposes,

i.e. if the default Stock Unit is barrel this description may be Pint as that is the unit the

item is sold in

Location

This is the site this product information relates to i.e. at which shop, bar etc.

ECR Code

This is the code number the items sells at on the POS terminal, this is usually the same

as the Product Code but must be in the range 1-9999. If the ECR code is to be the same

as the Product Code number, the system can be set so the ECR code is automatically

updated from the Product Code in the options section. If no ECR code is entered or 0 is

entered for the ECR code, this product is not available for sale at the POS terminal,

27

Page 36

______________________________________________________

PRICING

This selection tab stores all information relating to product cost and retail pricing.

Average Cost Price

This is calculated from the Purchase screen, taking all purchased prices for the products

and varying sizes, producing an average cost price per product

Last Cost

This is the last cost price of this product based on the last price entered on the purchase

GST Rate

This is a selection box, allowing the correct GST rate (where applicable) to be allocated

to this product.

RRP

This is the recommended retail price of the product based on the cost, Vat and the

desired target margin.

Apply Price Change to all Locations

The retail price of this item, may only apply to this particular Location and when

changed it will not affect the retail prices of any other Locations. This flag ticked ensures

that changes made to this product within this Location, will automatically be copied

across Locations. View options determine what information is to be copied across.

28

Page 37

______________________________________________________

Price Level 1 - 4

This is the retail price the product is sold for at the Point of Sale terminal.

The onscreen descriptor for the price levels and the number of price levels available can

be changed within the options section.

Profit

This is the dollar value profit, which is being made, when it is sold at this particular price

level.

Margin

This is the percentage profit, which is being made on this item, when it is sold at this

price

29

Page 38

______________________________________________________

STOCK

This selection tab stores all information relating to the stock holding for this Product

Code.

Current Stock

This is the number of items held in stock, the number of units is determined by the

Default Stock Unit i.e. 176 Pints in a Barrel would show as 1, if the Stock Unit was set to

Barrel. Alternatively if the Stock Unit was changed to Pints, the figure on-screen would

be recalculated as 176 Pints.

Max Stock

This is the maximum holding. When an Item falls below the Re-Order Level or product

supply is insufficient for the number of Days Stock, it is suggested an Order is generated

to this level.

Re-Order Level

This is the number of Stock Units that are required, to be ordered at any one time,

Suppliers may have a minimum re-ordering level, or alternative pricing policies

quantities purchased

Days stock to order

This is the number of day’s stock for this item that you wish to keep, comparisons and

analysis reports can be printed on such reports as the Product Supply report.

Shelf Facings

This is used for printing of the shelf edge label report, the number here indicates how

many Shelf Edge Labels are required for this product, when the report is printed.

30

Page 39

______________________________________________________

Supplier

This is a selection box, allowing a supplier to be associated with this product. More than

one supplier can be used to purchase a product, also more than one Stock Unit can be

purchased from a supplier. This information is stored in the supplier matrix, shown on

the screen. When the appropriate Reference for a purchase size is entered on the

Order/Delivery/Purchase screen, the correct purchase size is automatically brought onscreen using this table information.

Stock Unit

This is a selection box allowing entry of the stock taking size purchased from this

supplier, i.e. Barrel, Case etc.

Reference

This is the supplier reference for this product relating directly to a particular Stock Unit

purchased from a particular supplier.

Barcode label req.

The package has a link to a barcode printer, this can be used to print barcode pricing

labels, for products as they arrive into stock. The availability of this option is set using

this tick box

31

Page 40

______________________________________________________

PRODUCT OPTIONS

This selection tab stores information relating to activities at the Point of Sale terminal.

All necessary explanations can be found within the FS-3600 manuals.

32

Page 41

______________________________________________________

STATUS OPTIONS

This section controls the Point of Sale terminal programming, determining such features

as whether the item is to print on different printers and which price levels are available.

Note:

Item Enabled = Valid (FS-3600)

Addit. Price Item = Add-on (FS-3600)

33

Page 42

______________________________________________________

USER FIELDS

This section allows classification of products by using up to four fields for any

information relating to this product that you require. These are selected via a drop list

and the list of these fields are maintained via the User Fields screen. For example, you

may wish to record the Size, Color or Style of products. It is possible to change the onscreen names of these fields within the View Option section.

34

Page 43

______________________________________________________

RECIPES

There are two main types of recipes :-

Saleable items

Firstly where both the items are saleable products and they are linked together for stock

taking purposes

i.g. Pint and Half of Beer

Both are sold through the POS terminal. The half however is a recipe using the pint as

an ingredient with a quantity of 0.5.

Example 1

Recipe Item Half Pint of Beer

Ingredients Pint of Beer Quantity 0.5

Stock Recipes

The second type of receipt is where a number of ingredients are linked to one recipe to

ensure the stock of the items making up that product is correct.

i.e. a Ham Sandwich is a saleable recipe with the ingredients being 2 slices of bread and

3oz of Ham.

Both the bread and the ham, will be a Product Code which exists with a zero ECR code.

This will prevent the bread or ham from being sold individually at the terminal, only the

Ham sandwich recipe item can be sold.

Example 2

Recipe Item Ham Sandwich

Ingredients Sliced Bread Bought as a Loaf with 32 Slices Qty 2.00 (2 Slices)

Roast Ham Bought as a 2 lbs or 32 ounces Qty 3 (3oz)

When the Product Codes are created for the sliced bread and the ham, the Stock Unit

will be how the product is purchased i.e. a loaf of bread or a pound of ham. The sales

units will then be set as the lowest usable unit within a recipe i.e. 32 ounces in a 2

pounds of ham or 32 slices in a loaf of bread. Then as the recipe is created the quantity

for the ingredients reflects the number of sales units that item uses i.e. 2 slices of bread

or 3oz of ham.

35

Page 44

______________________________________________________

RECIPE

A new recipe can be selected from the box, you are then presented with a list of

products so that you may select which is the recipe item, i.e. the Pint of Beer or the

Ham Sandwich.

Use Prices From The Location in which this item is to be sold and purchased should be entered here for a multi-Location package. The recipe file is for all Locations, this field is to ensure the correct costing are utilized for the on-screen recipe calculations.

Retail Price

This is the retail price of the item from the chosen Location.

Current Cost Price

This is the current cost of the recipe, which does not include the current amendments

until the item is updated.

Current Profit/Margin

This is current stored dollar value and percentage profit of the item, this does not

include the current amendments until the item is updated.

Recipe Cost This is the on-screen calculation of the cost of the recipe.

36

Page 45

______________________________________________________

Recipe Profit/Margin

This is the calculation of the dollar value and percentage profit using the on-screen

quantities.

Product Code

This allows you to use this table to enter the ingredients, if the Product Code is not

known the search icon in the right hand side of the Product Code box can be used.

Description

Once the ingredient is found, such as the Pint of Beer or the Bread then the description

is automatically brought on Screen.

Quantity

This is the quantity of the stock item to be used when this RECEIPE item is sold,

i.e. 0.5 of a pint is used every time a half pint of beer is sold, or 2 slices of bread for

every ham sandwich

When the Recipe screen is exited a prompt appears asking whether recipe costs should

be updated. For example the half pint beer costs nothing until the recipe was created

stating it uses 0.5 of a pint. The half pint will now be updated in the average/cost field

for the product. These costs are also maintained at purchases, as the cost of the

ingredients increases.

Render

If the item is a sub recipe such as roll & butter used in a main recipe such as soup &

roll. It is necessary if a change has been made to the costing of the sub recipe to render

to ensure the true cost of the main recipe is shown. For example, if the number of

butter portions within the bread and butter has increased the cost would also increase.

When the Soup & Roll recipe was called up on screen immediately after this change the

cost would not be correct unless Regenerate is carried out. When a recipe is saved, the

price is automatically rendered.

37

Page 46

______________________________________________________

STOCK

The main Stock menu tab, provides access to all relevant stock movement options such

as :

ORDER SECTION

The system can if required produce a report showing which items should be re-ordered.

This information can be based on either average days usage or re-ordering based on

minimum and maximum stock reporting. This report information can then be entered

manually onto the Order screen. Alternatively the Order can be generated automatically

by using the suggested re-order icon. This will generate a complete Order based on the

users decisions at this stage. Once the Order has been entered it is possible to print the

Order out to be sent to the supplier. The outer on Order field for each of the products is

updated, when an Order is placed, allowing reporting of items on ordered.

DELIVERY SECTION

If the information is entered as an Order this information can then be recalled at the

Delivery stage, and the quantity received can then be entered as necessary.

Alternatively if the goods have arrived with a Delivery Note, and there was no Order

previously entered the information can be entered directly at the Delivery stage

bypassing the Order stage. A Delivery Note can be printed at this stage. When the

Delivery is committed the current stock levels are increased. The costing however are

not updated until the purchase is entered.

PURCHASE SECTION

Deliveries entered can be recalled when the Purchase invoice arrives, allowing any

changes in the cost prices to be entered, a Purchase invoice can be printed out if

required. This option is also ideally used if stock arrives into the building without

previously being ordered and the cost prices are known. This would ensure both the

stock of the item and the costing are updated simultaneously.

TRANSFER SECTION

This section is used to move stock holding between Locations. The stock quantities will

be deducted from one Location and added to another.

WRITE OFF SECTION

This is used for removing items from stock that are used but not sold. I.e. damaged

goods. These can be shown in the Write Off report.

REVIEW INVOICES

This is used for reviewing historically, paid invoices. Once an invoice is completed, it is

stored and available for view within this option.

38

Page 47

______________________________________________________

STOCK MANAGEMENT

The system can provide a very simplistic or sophisticated order system depending on the

nature of the business. Stock’s arrival into the established can be covered in three ways

METHOD 1 - USING RECOMMENDED ORDER

Order The suggested order information is generated based on the following

rules.

Current Stock is less than the Re-Order Level entered for each product

Or Current Stock is less than the Re-Order Level and recommended to max

stock levels.

Or Current Stock based on usage per day is insufficient to meet the days

stock need, recommend the required amount to maintain stock levels.

Or Current Stock based on usage per day is insufficient to meet the days

stock need, recommended the required amount to max stock levels.

Deliver The stock arrives and the previously entered Order is accepted. This

updates the current stock for each product and removes the item from

the on Order list. NOTE: Backorders are not possible, the item(s) needed

to be on backorder will have to be re-ordered or entered at the time of

the Stock Purchase.

Invoice When the invoice arrives the cost prices are entered against the Delivery.

This updates the costing of the products.

METHOD 2 - USING MANUAL ORDERING

Order Enter the details of the products to be ordered. This updates the items on

Order for each product

Deliver The stock arrives and the previously entered Order is accepted. This

updates the current stock for each product and removes the item from

the on Order list. NOTE: Backorders are not possible, the item(s) needed

to be on backorder will have to be re-ordered or entered at the time of

the Stock Purchase.

Invoice When the invoice arrives the cost prices are entered against the Delivery.

This updates the costing of the products.

39

Page 48

______________________________________________________

METHOD 3- USING DELIVERIES AND PURCHASE INVOICING

Deliver The stock arrives is entered into the system. This updates the current

stock field for each product. NOTE: Backorders are not possible, the

item(s) needed to be on backorder will have to be re-ordered or entered

at the time of the Stock Purchase.

Invoice When the invoice arrives the cost prices are entered against the Delivery.

This updates the costing of the products.

METHOD 4- USING SIMPLISTIC PURCHASING

Invoice When the stock arrives the details are entered. This will update both the

current stock and the products costing simultaneously.

40

Page 49

______________________________________________________

STOCK MANAGEMENT

The screen displays a number of icons which are explained below.

SAVE

This allows a screen to be saved while the information is being entered, allowing recall

at a later date for further items to be entered. This does not update any of the

totalizers.

CANCEL

This allows any information entered prior to the last save to be cancelled.

LABELS

It is possible to print labels for product which are Order, Delivered or Purchased.

This will print the current information entered, saving the details prior to printing.

COMMIT

This saves all details, and updates the relevant stock and Order totals.

DELETE

This will delete the current on-screen Order.

41

Page 50

______________________________________________________

SUGGEST

This is used to suggest a recommended re-order. This can be based on :

Current Stock is less than the Re-Order Level entered for each product,

Or

Current Stock is less than the Re-Order Level and recommended to max stock

levels,

Or

Current Stock based on usage per day is insufficient to meet the days stock

need, recommend the required amount,

Or

Current Stock based on usage per day is insufficient to meet the days stock

need, recommended the required amount to max stock levels.

42

Page 51

______________________________________________________

ORDERS

This is used to generate an Order for your Supplier, this has no direct effect on the stock

levels and is designed only to indicate stock has been requested for Delivery.

ORDER REFERENCE

This selection box can be used to begin a new Order or recall a saved Order. Clicking on

the icon, will automatically generate the number, using the View-Options settings would

allow a prefix or suffix to be added to the Order reference when it was generated.

LOCATION

This is the Location to which the stock is to be delivered. Clicking on the Location tab

will allow entry of the delivery address.

SUPPLIER DETAILS

This is the Supplier from whom the goods are to be purchased, the address details are

recalled for the Supplier file, which contains a list of all your Suppliers which were

created previously.

ORDER DETAILS

Reference

This allows an Order reference to be entered, which will print on the Order.

Order Date

This is the date the Order is placed, Orders can be created with dates in advance of the

current date, saved and then committed ready for Delivery at the appropriate time, A

calendar is available by clicking on the small gray selection box.

SPECIAL INSTRUCTIONS

Any relevant information can be entered here for printing on the Order.

INFORMATION ENTRY

Product Code

This is used to recall the product to be ordered, the code can be input at this stage or

recalled from a list of Products by clicking on the small gray selection box.

Description

This is automatically recalled on selecting the Product Code.

Stock Unit

This is the unit the item is purchased in. Stock units are created in maintenance and

attached to a Product Group. These are explained in the section entitled Stock.

Label Req

There is an option to print product pricing labels, as the goods are ordered, This will

print only if barcode required is selected on the Product Maintenance screen for this

item.

43

Page 52

______________________________________________________

Order Qty

This is the number of Stock Units to be ordered i.e. The number of cases or barrels

Last Cost

This is calculated from the Last cost price held on the Product Maintenance screen

multiplied by the number of sales units within the selected Stock Unit. i.e. If 2 Cases of

24 are selected and the cost is 1.00 per unit then 24.00 will be displayed in the Last

Cost column

Line Total

This is the total of goods ordered for this product it is calculated from the last cost

column Which is the last cost per Stock Unit multiplied by the number of Stock Units

purchases. i.e. if 2 Cases of 24 are selected and the cost is 1.00 per unit then 24.00 will

be displayed in the Last Cost column and 48.00 in the line total column.

Current Order Total

This is a running total of the total value of goods purchased on this Order.

Discounts

By clicking on this icon it is possible to allow dollar value or percentage amendments of

the current Order total either discount or premium.

44

Page 53

______________________________________________________

DELIVERIES

This is used to confirm that the Stock has arrived at the premises committing a Delivery

adds the Stock Delivery into the current Stock Holding for the product but this does not

affect the costs of the product.

DELIVERY

DELIVERY REFERENCE

This box is used to recall a saved Delivery, which requires further information to be

entered before being committed as a Purchase. Alternatively, a new Delivery can be

selected.

LOCATION

This is the Location to which the stock is to be delivered. Clicking on the Location tab

will allow entry of the Location delivery address for the supplier.

SUPPLIER DETAILS

This is the supplier from whom the goods are being purchased, the address details are

recalled from the Supplier file, which contains a list of all your Suppliers.

DELIVERY DETAILS

Reference

This allows an Order reference to be entered, which will print on the Order.

Delivery Date

This allows entry of the delivery date. A calendar is available by clicking on the small

grey selection box.

45

Page 54

______________________________________________________

Special Instructions

Any relevant information can be entered here for printing on the delivery, information

previously entered to an Order is automatically recalled.

INFORMATION ENTRY

Product Code

This is used to recall the Product to be ordered, the code can be input at this stage or

the recalled from a list of products by clicking on the small grey selection box.

Description

This is automatically recalled on selecting the Product Code.

Stock Unit

This is the unit the item is purchased in. Stock units are created in Maintenance and

attached to a Product Group.

Label Required

There is an option to print Product Pricing labels, as the goods are ordered. This will

print only if barcode required is selected on the Product Maintenance screen for this

item.

Order Qty

This is the number of Stock Units to be purchased. I.e. The number of cases or barrels.

Delivery Qty

This is the number of Stock Units, which actually arrived and may vary from the order

qty depending if the Order was completely fulfilled.

Last Cost

This is calculated from the Last Cost Price held on the Product Maintenance screen

multiplied by the number of Sales Units within the selected Stock Unit. i.e. If 2 Cases of

24 are selected and the cost is 1.00 per unit then 24.00 will be displayed in the Last

Cost column.

Line Total

This is the total value of goods purchased for this product. It is calculated from the LAST

COST column, which is the last cost per Stock Unit multiplied by the number of Stock

Units delivered. I.e. if 2 Cases of 24 are selected and the cost is 1.00 per unit then

24.00 will be displayed in the Last Cost column and 48.00 in the line total column.

Current Order Total

This is a running total of the total value of goods purchased on this Order.

Example, Delivery Note.

Discounts

By clicking on this icon it is possible to allow dollar value or percentage amendments of

the current Order total either discount or premium.

46

Page 55

______________________________________________________

PURCHASES

This is used to enter the costing for the Products, i.e. when the invoice arrives. The

Delivery can be recalled, the costs adjusted if required and the new costing information

can then be committed to a Product.

PURCHASE

PURCHASE REFERENCE

This box is used to recall a saved Purchase, which requires further information to be

entered before being committed. Alternatively a new Purchase can be selected.

LOCATION

This is the Location to which costing data is to be calculated. Clicking on the Location

tab will allow entry of the Location delivery address for the Supplier.

SUPPLIER DETAILS

This is the Supplier from whom the goods are to be purchased, the address details are

recalled from the Supplier file, which contains a list of all your Suppliers which were

created previously

PURCHASE DETAILS

Reference

This allows an Order reference to be entered, which will print on the Order.

47

Page 56

______________________________________________________

Delivery Date

This allows entry of the delivery date. A calendar is available by clicking on the small

icon to the right.

SPECIAL INSTRUCTIONS

Any relevant information can be entered here for printing on the Purchase, information

previously entered to an Order is automatically recalled.

INFORMATION ENTRY

Product Code

This is used to recall the Product to be ordered. The code can be input at this stage or

the recalled from a list of Products by clicking on the small grey selection box.

Description

This is automatically recalled on selecting the Product Code.

Stock Unit

This is the unit the item is purchased in. Stock units are created in maintenance and

attached to a Product Group. These are explained in the section entitled Stock.

Label Required

There is an option to print Product Pricing Labels, as the goods are ordered. This will

print only if barcode required is selected on the Product Maintenance screen for this

item.

Order Qty

This is the number of Stock Units to be purchased. I.e. The number of Cases or Barrels.

Purchased Qty

This is the number of Stock Units, which actually arrived and may vary from the

delivered qty.

Last Cost

This is calculated from the Last cost price held on the Product Maintenance screen

multiplied by the number of sales units within the selected Stock Unit. i.e. If 2 Cases of

24 are selected and the cost is 1.00 per unit then 24.00 will be displayed in the Last

Cost column.

Line Total

This is the total value of goods purchased for this product it is calculated from the LAST

COST column which is the last cost per Stock Unit multiplied by the number of Stock

Units purchased. I.e. If 2 Cases of 24 are selected and the cost is 1.00 per unit then

24.00 will be displayed in the Last Cost column and 48.00 in the line total column.

48

Page 57

______________________________________________________

Current Purchase Total

This is a running total of the total value of goods purchased on this Order.

Discounts

By clicking on this icon it is possible to allow dollar value or percentage amendments of

the current Order total either discount or premium.

On leaving the Purchases screen the prompt update Recipe Costs appears. If for

example you have purchases a pint of beer and the cost has changed, this will have a

direct effect on the cost of a half pint. Answering Yes ensures the costing and profit

margins of the half-pint are also maintained.

49

Page 58

______________________________________________________

TRANSFERS

This controls the movement of stock from one Location to another.

Stock Transfer

This allows the creation of a new Transfer note or the option to recall a saved Transfer

Reference

This allows entry of a reference number for the Transfer

Date

This is the date of the Transfer

From Location

This is the Location the stock is to be moved / deducted from

To Location

This is the Location the stock is to be moved / added to

SPECIAL INSTRUCTIONS

This allows entry of any special instructions, which can then be printed on the Transfer

Note

INFORMATION ENTRY

Product code

This is used to recall the product to be Ordered. The code can be input at this stage or

recalled from a list of products by clicking on the small gray selection box.

50

Page 59

______________________________________________________

Description

This is automatically recalled on selecting the Product Code.

Stock unit

This is the unit the item is purchased in. Stock units are created in maintenance and

attached to a Product Group.

Label Required

There is an option to print product pricing labels, as the goods are Ordered. This will

print only if barcode required is selected on the Product Maintenance screen for this

item.

Transfer Quantity

This is the number of units to be move to another Location.

Last cost

This is calculated from the Last cost price held on the Product Maintenance screen,

multiplied by the number of sales units within the selected Stock Unit. i.e. If 2 Cases of

24 are selected and the cost is 1.00 per unit then 24.00 will be displayed in the Last

Cost column

Value at Cost

This is the number of units to be transferred multiplied by the last cost price.

Value at Retail

This is the number of units to be transferred multiplied by the retail price

51

Page 60

______________________________________________________

WRITE OFFS

This screen allows for items to be Written Off from stock held on the computer.

Location

This is the Location that this stock item is to be Written Off for.

Product Code

This is the code number for the Product, the item can be searched for using the search

icon.

Date

This is the date, the stock quantity is Written Off.

Quantity

This is the quantity to be Written Off and the number is related to the Stock Unit size.

Reason

This is why the stock is Written Off. i.e. Damaged etc. As reasons are entered they, are

stored in the list for use in the future.

52

Page 61

______________________________________________________

STOCK MANAGEMENT

GSS Store provides a comprehensive Stock Management System, including Period Stock

Discrepancy Reporting, through to complete Month End Analysis.

Stock taking for a given Location in GSS Store can be viewed as a staged procedure.

The purpose of which is to ensure that for a large stock take, such as at a year-end,

there is sufficient time for the count to be entered and analyzed. There is no

requirement for all the steps within stock taking to be completed within one day.

UPDATE CURRENT STOCK MOVEMENTS

Before you begin the stock check you need to make sure that all Sales, Deliveries and

Write Offs have been entered into GSS Store.

TAKE STOCK SNAPSHOT

A Stock Snapshot is a picture of the current stock holding at a known point in time.

When GSS Store takes a Stock Snapshot for a Location, it makes a copy of the current

stock value held for every item at that Location and stores it separately from the current

'live' stock.

PHYSICALLY COUNT STOCK ITEMS

GSS Store has a report specifically for the production of Stock Count Sheets. Using the

Stock Count Sheets, the stock should be counted and entered on the Stock Count

Sheets.

ENTER STOCK TAKE

After counting the stock items, the quantities of each item needs to be entered into GSS

Store

ANALYZE RESULTS OF STOCK COUNT

Once the Stock Count has been entered, you should print out the Stock Variance report

from the list of Product Reports. This report shows the difference and value of that

difference, in terms of both retail and cost values, between the Stock Snapshot and the

Stock Count. Any discrepancies can be investigated and if necessary, the Stock Count

entry re-entered.

UPDATE CURRENT STOCK

The final stage of stocktaking is to update the current stock. This procedure posts the

discrepancies found between the stock Snapshot and the stock count to the current 'live'

stock. Optionally, any items for which no count has been entered can have their stock

set to zero. Following this procedure the current 'live' stock will be correct as of the last

Stock Take.

53

Page 62

______________________________________________________

SET OPENING STOCK

It is optional as to whether at the end of the month the set Opening Stock procedure is

carried out. This will copy the actual month end stock to the Opening Stock value for the

next period. It is possible to use the Opening Stock option more than once during a

given stock period if an Opening Stock per week and movements analysis is required

along with a month option also.

54

Page 63

______________________________________________________

SET OPENING STOCK

In order to produce more, comprehensive reports such as the example given. The Set

Opening Stock sequence would be incorporated into the month end procedure. This can

be carried manually by selecting Set Opening Stock or automatically via the GSSEvent

communications timetable. The sequence will copy the current stock quantity to the

Opening Stock quantity and commencing calculating movements from the period start

date which was set. It is possible to have numerous Opening Stocks running

The concept of storing different Opening Stock names is to allow reports for different

period start dates, once that period date, alternatively to allow a number of period

reports to run within the same time scale.

For example, a 4 Weekly Period reports running within one month, each Opening Stock

name, storing a different start stock value and totaling all the report data such as

transfers etc from a different start point, i.e. the 1

Week3, Week4, which is in actual fact 5 Opening Stock names for a one month period.

st

of the month the Week1, Week2,

55

Page 64

______________________________________________________

The Maintain Opening Stock section, allows the numerous Opening Stock files stored for

various period start dates to deleted or for the descriptor to be edited.

Note:

The Opening Stock reporting is a very sophisticated and date orientated for this reason it is

absolutely necessary that the Opening Stock is set at the beginning of a day, before Deliveries

and stock movement begins. This can be automated using GSSEvent.

56

Page 65

______________________________________________________

STOCK TAKING SNAPSHOT

When the take Snapshot is selected the current stock is then copied to a separate figure

for stock taking calculations. This allows the current stock figure to be updated normally

by sales, deliveries etc without it affecting the stock taking results. If the stock taking

day is Monday, a snap shot of the stock will be taken on Monday.

For example :-

100 pints of beer were the Snapshot on Monday, during the course of the stock taking

week the 100 pints of beer will be decreased by sales and increased by deliveries

leaving at Friday 80 pints of beer. On the Monday of the stock take, 110 pints of beer

were actual counted and finally entered on the Friday as the stock take figure.

It is not the 110 pints that is to be copied back to the current stock figure but the

discrepancy. We had 100 on the computer when we started the stock take, 110 when

we actually counted that means, we were over by 10 pints. The figure in the current