Page 1

GENERAL PRECAUTIONS REGARDING THE INSTALLATION

AND SER VICE FOR THE COPIER FC-210/310

The installation and service should be done by a qualified service technician.

1. Transportation/Installation

• When transporting/installing the copier, move it by the casters while lifting the stoppers.

The copier is quite heavy and weighs approximately 187 kg (413 lb), therefore pay full attention

when handling it.

• Be sure to use a dedicated outlet with AC 115V or 120V/20A (220V, 230V, 240V/10A) or more

for its power source.

• The copier must be grounded for safety.

Never ground it to a gas pipe or a water pipe.

• Select a suitable place for installation.

Avoid excessive heat, high humidity, dust, vibration and direct sunlight.

• Also provide proper ventilation as the copier emits a slight amount of ozone.

• To insure adequate working space for the copying operation, keep a minimum clearance of

80 cm (32”) on the left, 80 cm (32”) on the right and 10 cm (4”) in the rear.

• The socket-outlet shall be installed near the copier and shall be easily accessible.

2. Service of Machines

• Basically, be sure to turn the main switch off and unplug the power cord during service.

• Be sure not to touch high-temperature sections such as the exposure lamp, the fuser unit, the

damp heater and their periphery.

• Be sure not to touch high-voltage sections such as the chargers, high-voltage transformer,

exposure lamp control inverter, inverter for the LCD backlight and power supply unit. Especially,

the board of these components should not be touched since the electirc charge may remain in

the condensers, etc. on them even after the power is turned OFF.

• Be sure not to touch rotating/operating sections such as gears, belts, pulleys, fan, etc.

• Be careful when removing the covers since there might be the parts with very sharp edges underneath.

• When servicing the machines with the main switch turned on, be sure not to touch live sections

and rotating/operating sections. Avoid exposure to laser radiation.

• Use suitable measuring instruments and tools.

• Avoid exposure to laser radiation during servicing.

− Avoid direct exposure to the beam.

− Do not insert tools, parts, etc. that are reflective into the path of the laser beam.

− Remove all watches, rings, bracelets, etc. that are reflective.

Page 2

3. Main Service Parts for Safety

• The breaker, door switch, fuse, thermostat, thermofuse, thermistor, etc. are particularly important

for safety. Be sure to handle/install them properly.

If these parts are shorted circuit and/or made their functions out, they may burn down, for instance,

and may result in fatal accidents.

Do not allow a short circuit to occur.

Do not use the parts not recommended by Toshiba TEC Corporation.

4. Cautionary Labels

• During servicing, be sure to check the rating plate and the cautionary labels such as “Unplug the

power cord during service”, “Hot area”, “Laser warning label” etc. to see if there is any dirt on their

surface and whether they are properly stuck to the copier.

5. Disposition of Consumable Parts/Packing Materials

• Regarding the recovery and disposal of the copier, supplies, consumable parts and packing materials, it is recommended to follow the relevant local regulations or rules.

6. When parts are disassembled, reassembly is basically the reverse of disassembly unless

otherwise noted in this manual or other related documents. Be careful not to reassemble

small parts such as screws, washers, pins, E-rings, star washers in the wrong places.

7. Basically , the machine should not be operated with any parts removed or disassembled.

8. Precautions Against Static Electricity

• The PC board must be stored in an anti-electrostatic bag and handled carefully using a wristband,

because the ICs on it may become damaged due to static electricity.

Caution: Before using the wristband, pull out the power cord plug of the copier and make

sure that there are no uninsulated charged objects in the vicinity .

Caution : Dispose of used batteries and RAM-ICs including lithium batteries

according to the manufacturer’s instructions.

Attention : Se débarrasser de batteries et RAM-ICs usés y compris les batteries en

lithium selon les instructions du fabricant.

V orsic ht : Entsorgung des gebrauchten Batterien und RAM-ICs (inklusive

der Lithium-Batterie) nach Angaben des Herstellers.

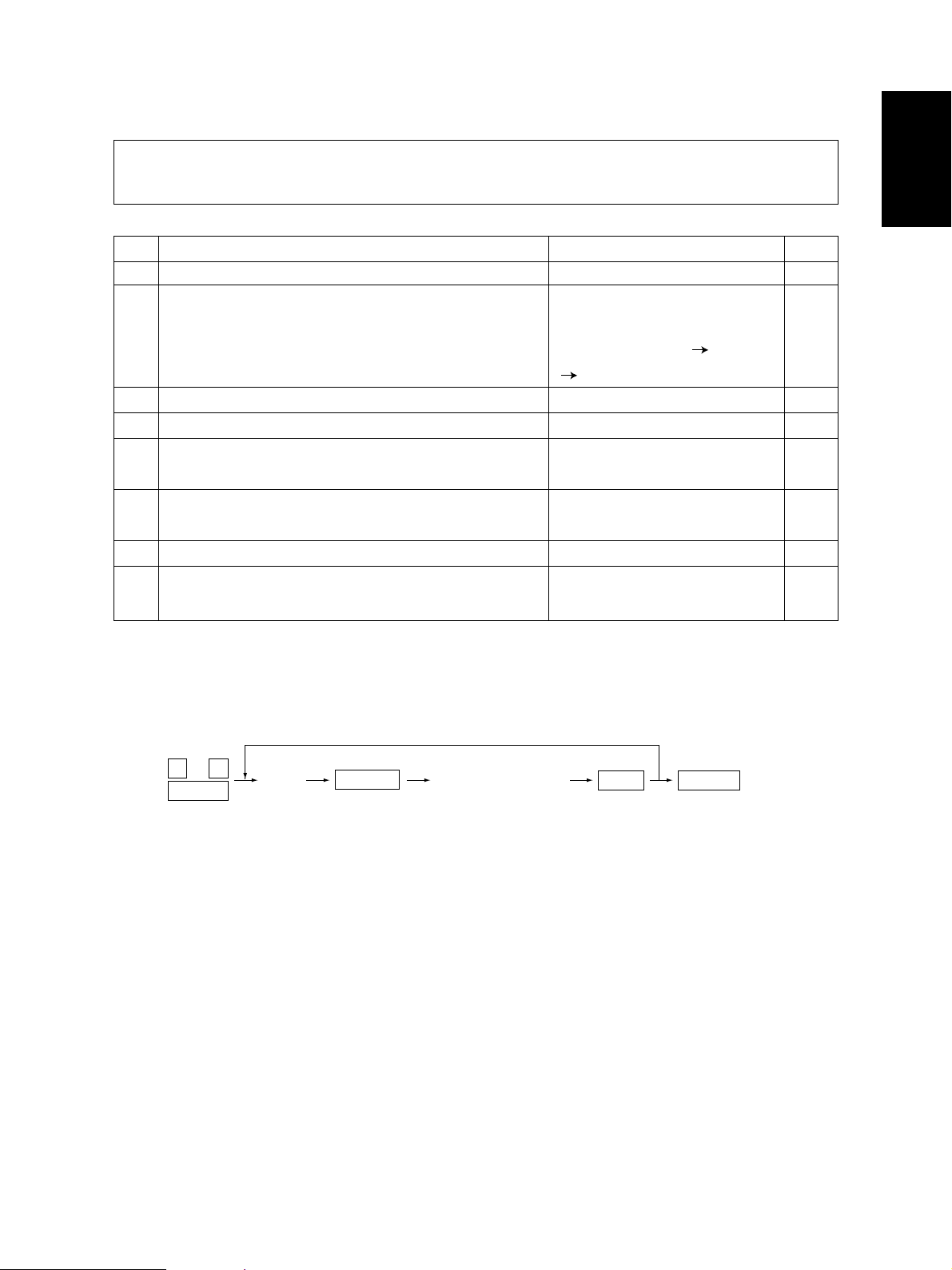

Page 3

1. ERROR CODE AND SELFDIAGNOSIS

2. ADJUSTMENT

3. PREVENTIVE MAINTENANCE

(PM)

4. TROUBLESHOO TING

5. UPDA TING THE FIRMWARE

6. POWER SUPPLY UNIT

7. WIRE HARNESS

CONNECTION DIAGRAMS

Page 4

CONTENTS

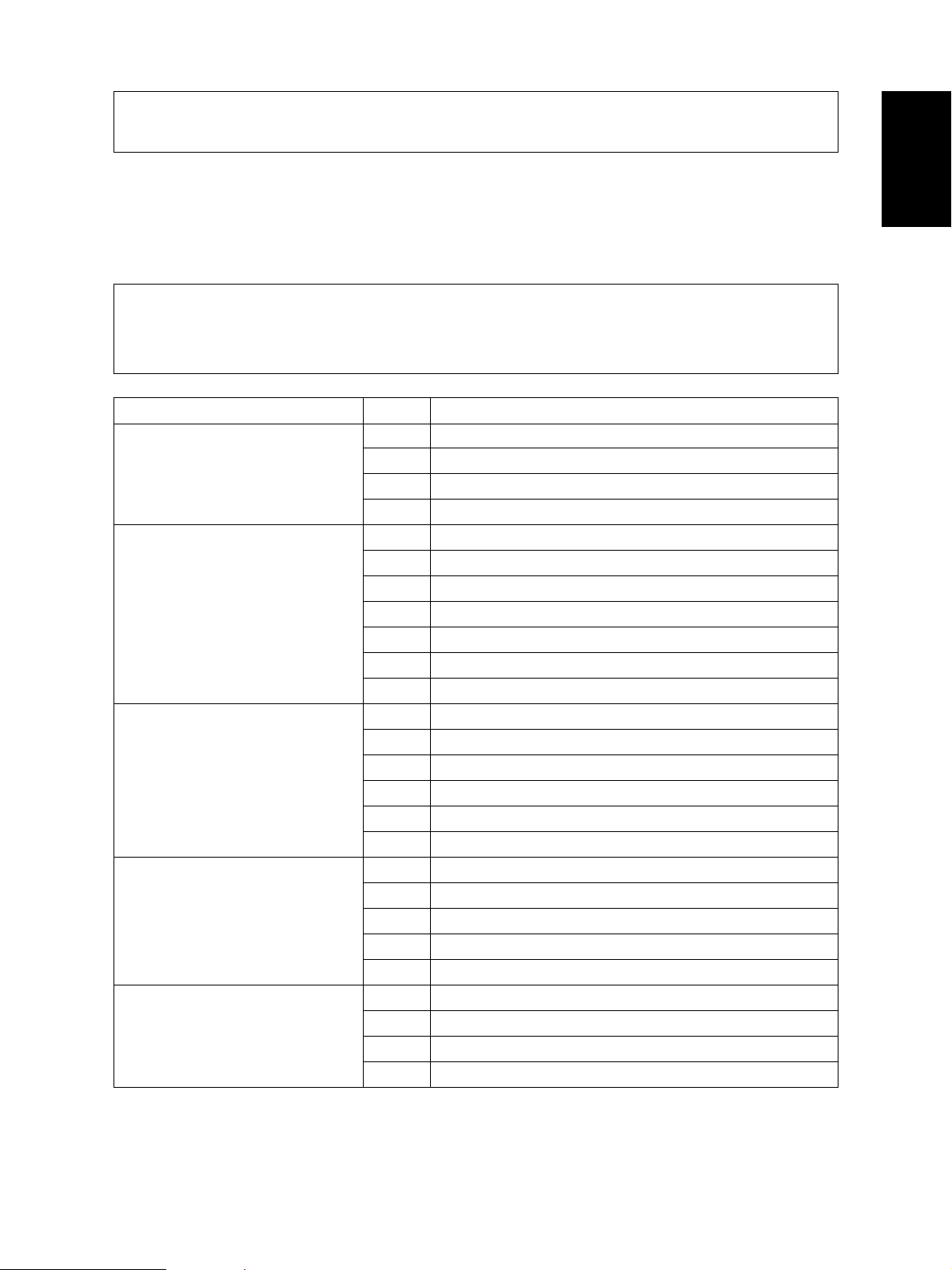

1. ERROR CODE AND SELF-DIAGNOSIS................................................................................... 1-1

1.1 Error Code List...................................................................................................................... 1-1

1.2 Self-Diagnosis Mode ............................................................................................................. 1-6

1.2.1 Input check (Test mode 03) ..................................................................................... 1-8

1.2.2 Output check (Test mode 03) .................................................................................. 1-15

1.2.3 Test print mode (04) ................................................................................................. 1-19

1.2.4 Adjustment mode (05) ............................................................................................. 1-20

1.2.5 Setting mode (08) .................................................................................................... 1-33

2. ADJUSTMENT ........................................................................................................................... 2-1

2.1 Adjustment Order (Image Related Adjustment) ...................................................................... 2-1

2.2 Adjustment of the Auto-Toner Sensor ..................................................................................... 2-2

2.2.1 Automatic removing of developer material ............................................................... 2-2

2.2.2 Initialization of auto-toner sensor ............................................................................ 2-3

2.3 Adjustment of Image Quality Control ..................................................................................... 2-7

2.4 Adjustment of Color Registration Control................................................................................ 2-8

2.5 Image Dimensional Adjustment.............................................................................................. 2-9

2.5.1 Paper alignment (paper buckle) at the registration roller ............................................ 2-11

2.5.2 Registration motor speed adjustment ........................................................................ 2-12

2.5.3 Printer section related adjustment............................................................................. 2-13

2.5.4 Scanner related adjustment ...................................................................................... 2-16

2.6 Image Quality Adjustment...................................................................................................... 2-24

2.6.1 Automatic gamma adjustment .................................................................................. 2-24

2.6.2 Density adjustment ................................................................................................... 2-25

2.6.3 Color balance adjustment ......................................................................................... 2-26

2.6.4 Offset adjustment for background processing ........................................................... 2-27

2.6.5 Judgment threshold for ACS ..................................................................................... 2-27

2.6.6 AI mode setting ........................................................................................................ 2-28

2.6.7 Sharpness adjustment .............................................................................................. 2-39

2.7 High-Voltage Transformer Settings .......................................................................................... 2-30

2.7.1 Overview .................................................................................................................. 2-30

2.7.2 Settings after replacing main high-voltage transformers ............................................ 2-30

2.7.3 Settings after replacing transfer transformer ............................................................. 2-31

2.8 Adjustment of the Developer Unit........................................................................................... 2-32

2.8.1 Doctor-to-Sleeve Gap ............................................................................................... 2-32

2.9 Adjustment of the Scanner Section........................................................................................ 2-33

2.9.1 Carriages .................................................................................................................. 2-33

2.9.2 Lens unit ................................................................................................................... 2-37

2.10 Adjustment of the Paper Feeding System .............................................................................. 2-39

2.10.1 Cassette sidewise deviation ..................................................................................... 2-39

2.11 Key Copy Counter (MU-8, MU-10) .......................................................................................... 2-40

I February 2002 © TOSHIBA TECFC-210/310 CONTENTS

Page 5

3. PREVENTIVE MAINTENANCE (PM) ........................................................................................ 3-1

3.1 Types of Preventive Maintenance ......................................................................................... 3-1

3.2 Outline of the Maintenance Order ......................................................................................... 3-2

3.3 Preventive Maintenance Checklist........................................................................................ 3-2

3.4 PM Kit ................................................................................................................................... 3-11

3.5 List of Adjustment Tools ........................................................................................................ 3-12

3.6 Precautions for Storing/Handling Supplies and Parts ........................................................... 3-13

3.6.1 Precautions for storing TOSHIBA supplies .............................................................. 3-13

3.6.2 Checking and cleaning of the photoconductive drum .............................................. 3-13

3.6.3 Checking and cleaning of the drum cleaning blade and transfer belt cleaning blade .... 3-15

3.6.4 Checking and replacing the transfer belt ................................................................. 3-15

3.6.5 Checking and replacing the transfer roller and fuser roller ......................................... 3-15

3.6.6 Checking and cleaning of the fuser belt and lower heat roller .................................... 3-15

3.6.7 Checking and replacing the oil roller and cleaning roller ............................................ 3-16

4. TROUBLESHOOTING ............................................................................................................... 4-1

4.1 Diagnosis and Prescription for Each Error Code .................................................................. 4-1

4.1.1 Paper transport jam inside the copier ........................................................................ 4-1

4.1.2 Paper feeding jam ..................................................................................................... 4-4

4.1.3 Paper transport jam (Paper not reaching the registration sensor after feeding) .......... 4-6

4.1.4 Cover open jam ........................................................................................................ 4-7

4.1.5 Paper jam in ADU and reversing area........................................................................ 4-9

4.1.6 Original jam in the RADF .......................................................................................... 4-10

4.1.7 Paper jam in the finisher ........................................................................................... 4-12

4.1.8 Special sheet jam ..................................................................................................... 4-20

4.1.9 Drive system related service call .............................................................................. 4-21

4.1.10 Paper feeding system related service call ................................................................. 4-23

4.1.11 Scanner related service call ...................................................................................... 4-25

4.1.12 Copy process related service call ............................................................................. 4-26

4.1.13 Fuser unit related service call ................................................................................... 4-29

4.1.14 Communications related service call ......................................................................... 4-31

4.1.15 ADF related service call ............................................................................................ 4-32

4.1.16 Other service call (1) ................................................................................................ 4-33

4.1.17 Laser optical unit related service call ........................................................................ 4-34

4.1.18 Finisher related service call ...................................................................................... 4-36

4.1.19 Image quality related service call .............................................................................. 4-54

4.1.20 Other service call (2) ................................................................................................ 4-62

4.1.21 Image processing related service call ....................................................................... 4-63

4.2 Troubleshooting of Image ....................................................................................................... 4-64

IIFebruary 2002 © TOSHIBA TEC FC-210/310 CONTENTS

Page 6

5. UPDATING THE FIRMWARE ...................................................................................................... 5-1

5.1 Installing Software for Firmware Update ................................................................................. 5-2

5.1.1 Outline ...................................................................................................................... 5-2

5.1.2 Requirements ........................................................................................................... 5-2

5.1.3 Dial-up networking function ....................................................................................... 5-4

5.1.4 Installing dial-up networking ...................................................................................... 5-8

5.1.5 Setting dial-up networking ......................................................................................... 5-10

5.1.6 Installing software for FTP server ............................................................................. 5-14

5.2 Operation Procedure in [3][9] Mode ........................................................................................ 5-18

5.2.1 Outline ...................................................................................................................... 5-18

5.2.2 Preparation ............................................................................................................... 5-18

5.2.3 Updating firmware ..................................................................................................... 5-20

5.2.4 Display ..................................................................................................................... 5-28

5.3 Updating the Firmware Using the Downloading Jig ................................................................. 5-32

5.3.1 System firmware ....................................................................................................... 5-33

5.3.2 Engine firmware ........................................................................................................ 5-39

6. POWER SUPPLY UNIT ........................................................................................................6-1

6.1 Output Channel ...................................................................................................................... 6-1

7. WIRE HARNESS CONNECTION DIAGRAMS ........................................................................7-1

7.1 AC Wire Harness ................................................................................................................... 7-2

7.2 DC Wire Harness .......................................................................................................... Appendix

<Appendix> SPECIFICATIONS · A CCESSORIES · OPTIONS · SUPPLIES ................................ A- 1

1. Specifications ........................................................................................................................ A-1

2. Accessories ........................................................................................................................... A-5

3. Options .................................................................................................................................. A-6

4. Replacement Units/Supplies .................................................................................................. A-6

5. System List ........................................................................................................................... A-7

III February 2002 © TOSHIBA TECFC-210/310 CONTENTS

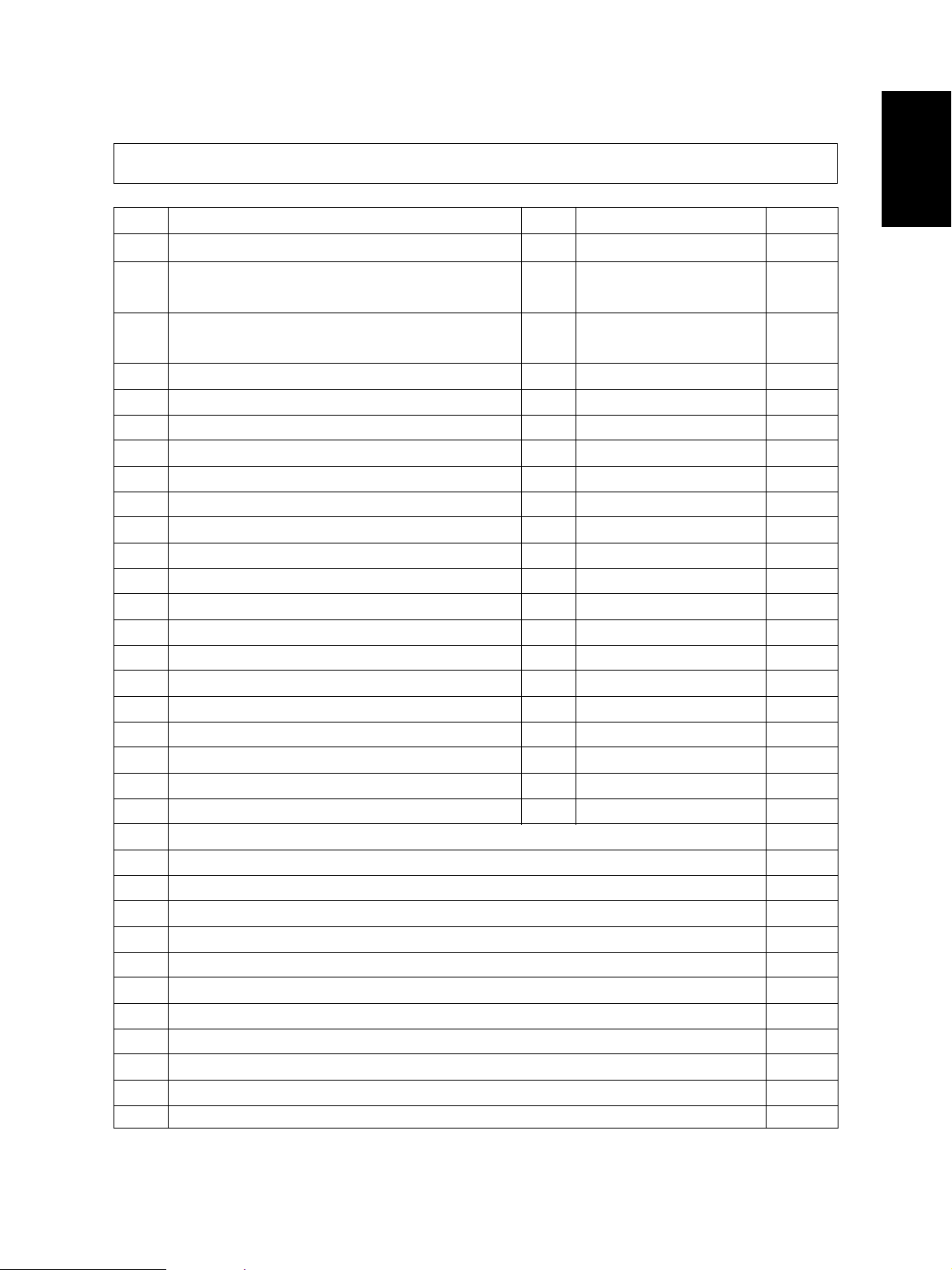

Page 7

In this manual, colors are sometimes described using abbreviations as listed below:

Yellow : Y Magenta : M Cyan : C Black : K

1. ERROR CODES AND SELF-DIA GNOSIS

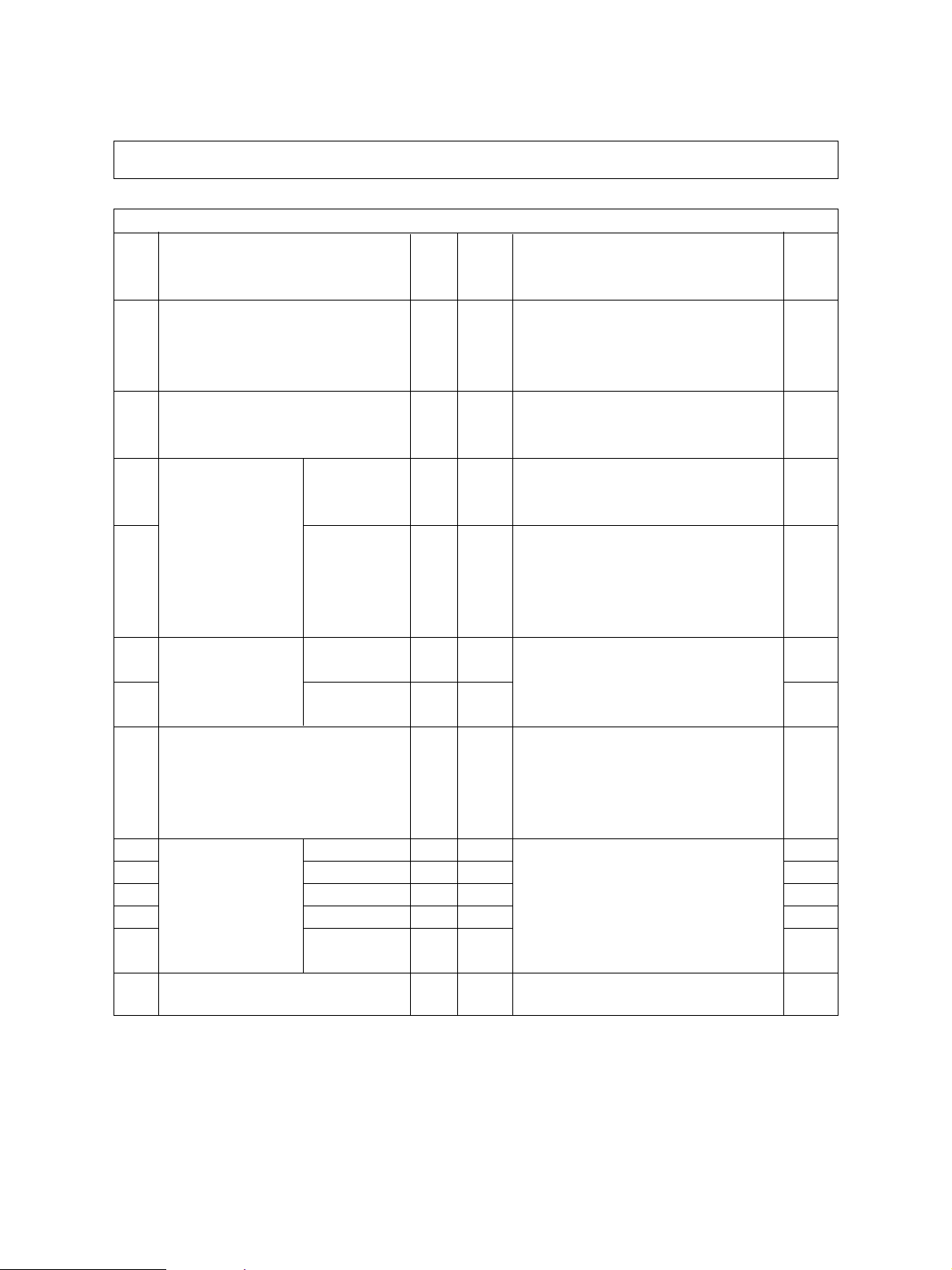

1.1 Error Code List

While the “CLEAR PAPER” or “CALL SERVICE” symbol is flashing, pressing the [CLEAR] key and the

digital key [8] at the same time shows one of the following error codes on the copy-quantity indicator as

long as those keys are pressed.

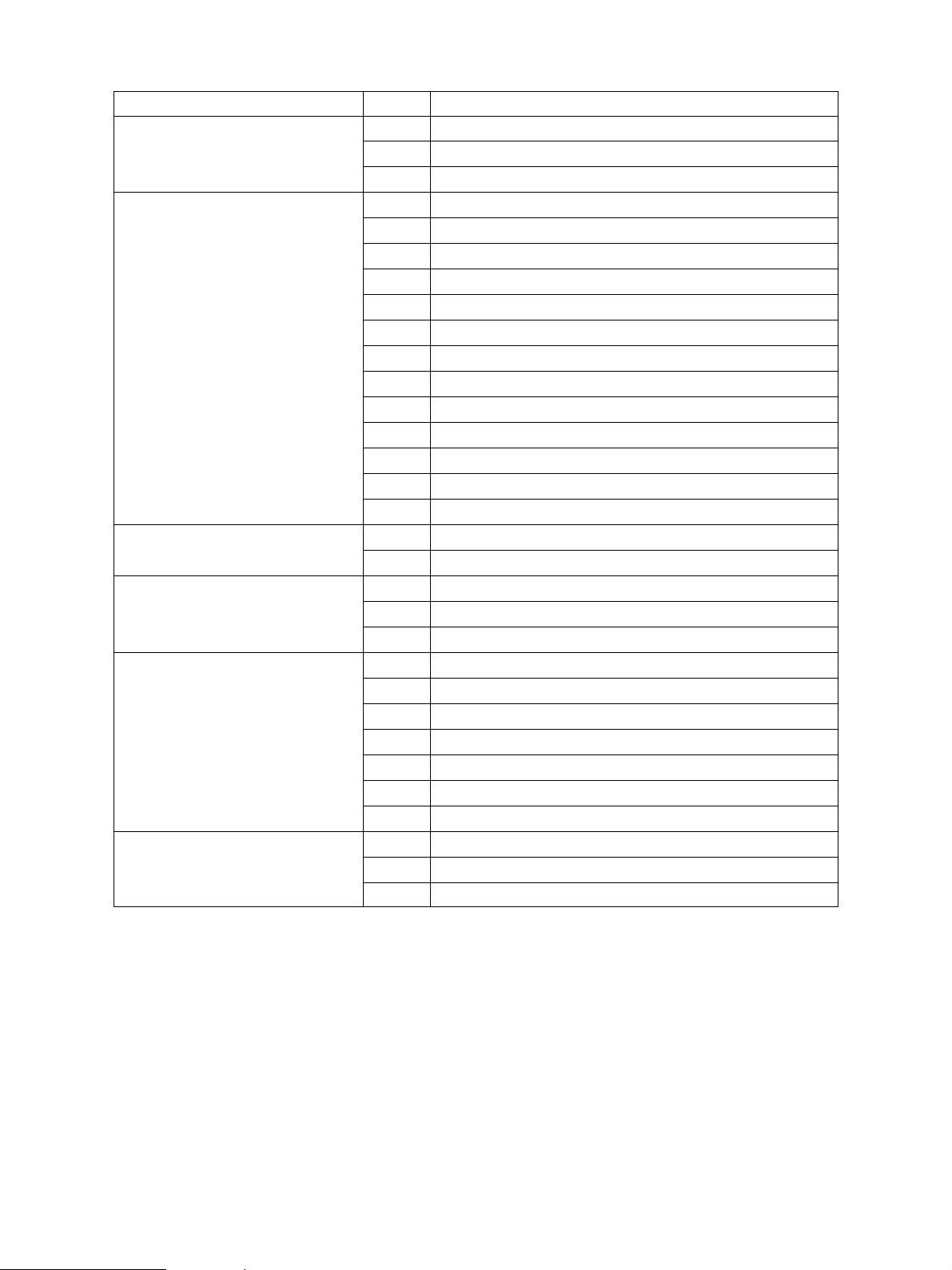

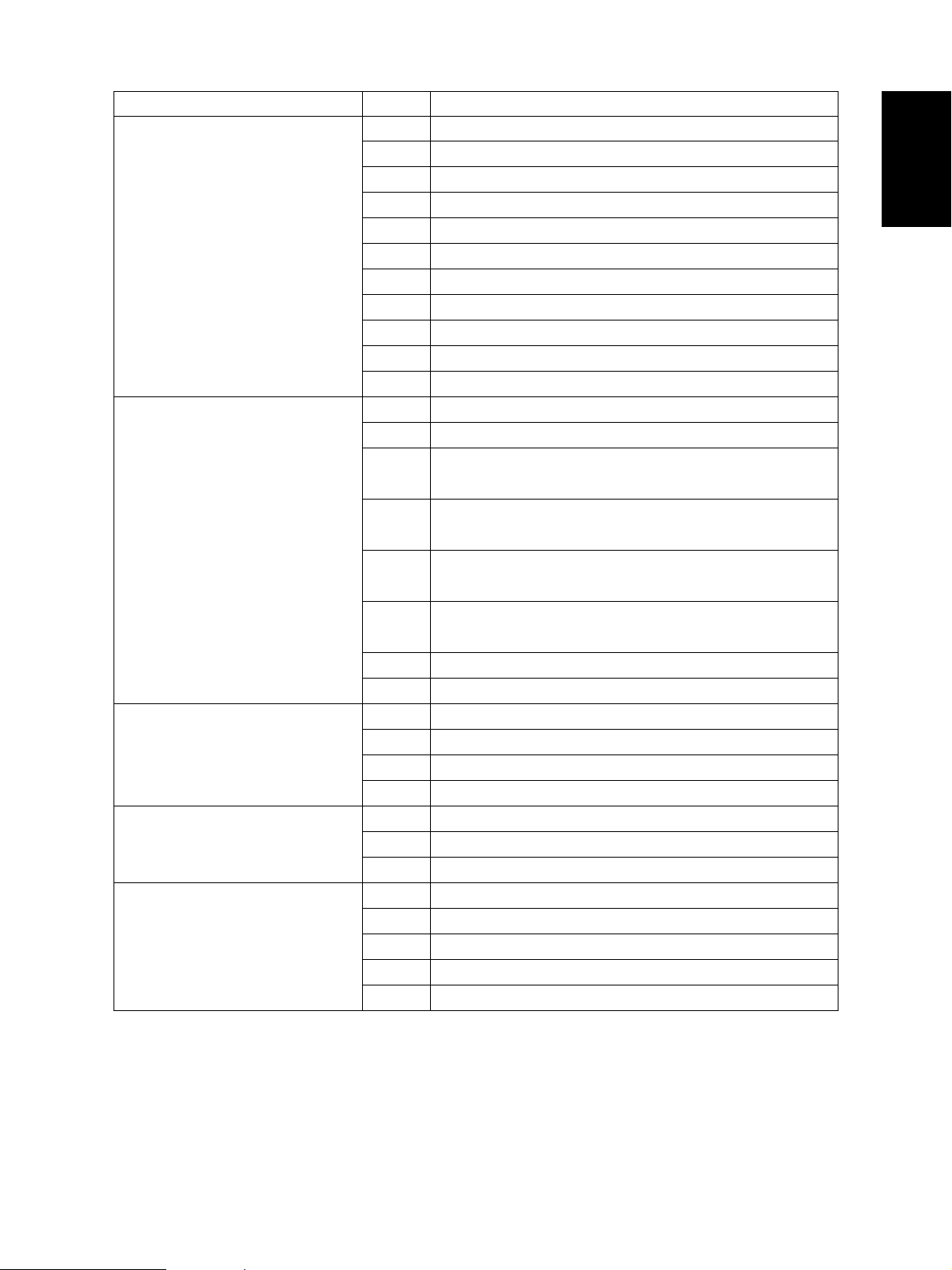

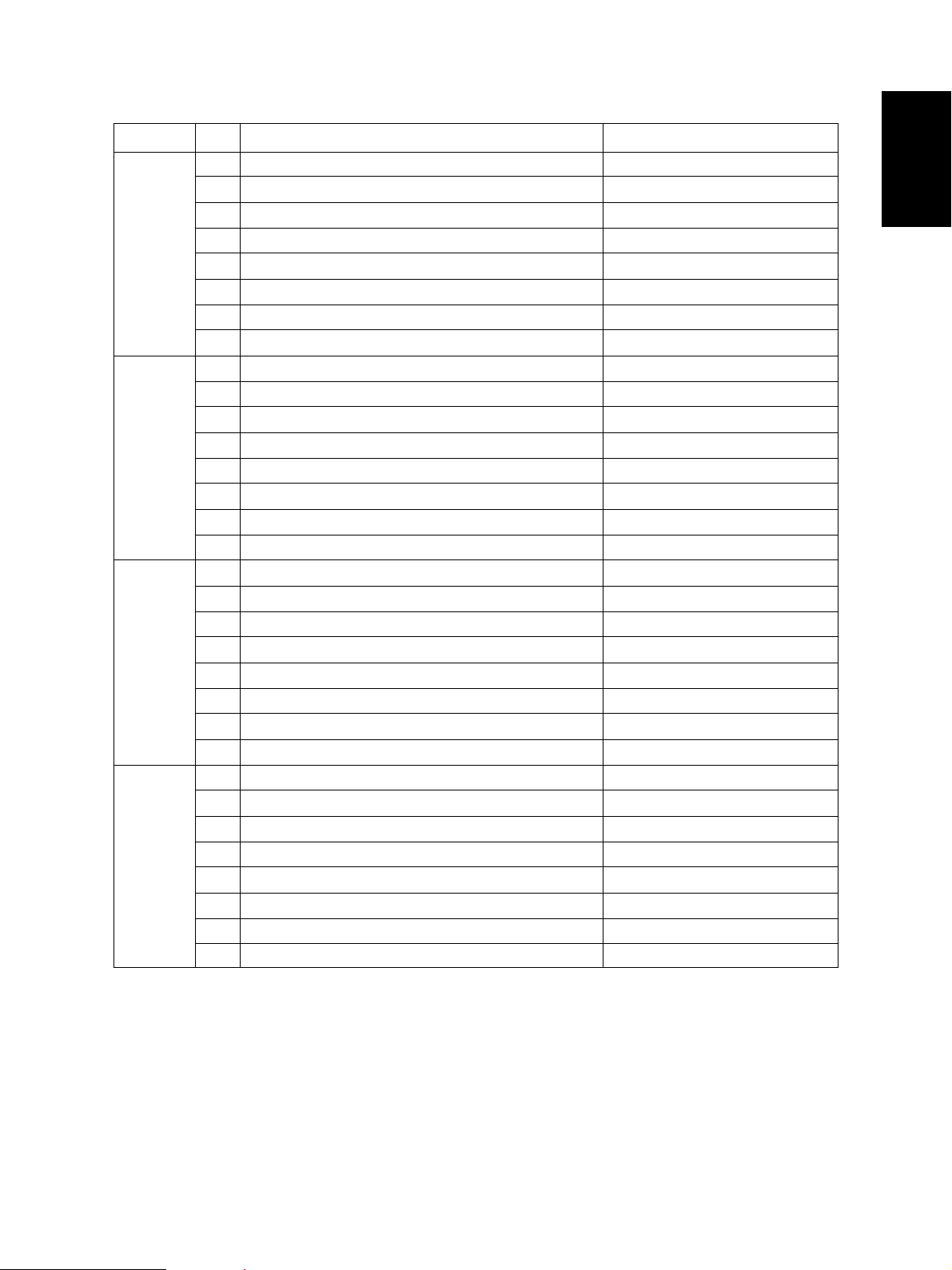

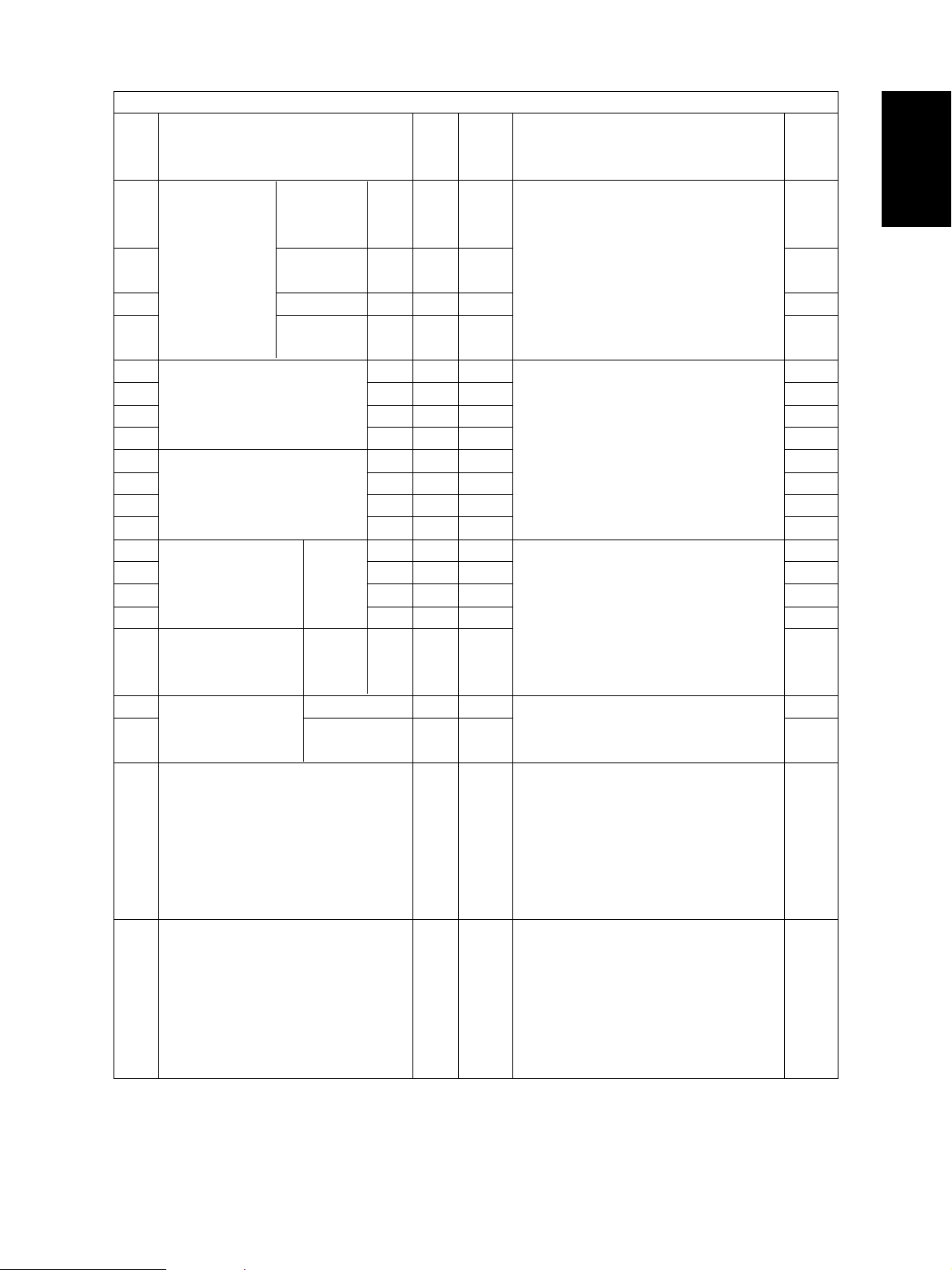

Classification Error code Contents

Paper transport jam E01 Paper leading edge not reaching the exit sensor

inside the copier E02 Paper trailing edge not passing the exit sensor

E03 Paper remaining inside the copier at power ON

EB7 Restart time-out error

Paper feeding jam E11 Paper misfeed from the ADU

E12 Paper misfeed from the bypass tray

E13 Paper misfeed from the 1st cassette

E14 Paper misfeed from the 2nd cassette

E15 Paper misfeed from the 3rd cassette

E16 Paper misfeed from the 4th cassette

E19 Paper misfeed from the LCF

Paper transport jam E21 Paper transport jam from the LCF

(Paper not reaching the registration E22 Paper transport jam from the 1st cassette

sensor after feeding) E23 Paper transport jam from the 2nd cassette

E24 Paper transport jam from the 3rd cassette

E25 Paper transport jam from the 4th cassette

E26 Paper transport jam from the bypass tray

Cover open jam E41 Front cover opened during printing

E42 Side door opened during printing

E43 ADU pulled out during printing

E45 LCF jam access cover opened during printing

E46 Bypass unit opened during printing

Paper transport jam in the ADU and E50 Paper not reaching the ADU

reversing area E51 Paper not reaching the ADU stack

E52 Paper not reaching the ADU path sensor

E54 ADU paper transport jam

February 2002 © TOSHIBA TEC 1 - 1 FC-210/310

ERROR CODES AND SELF-DIAGNOSIS

Page 8

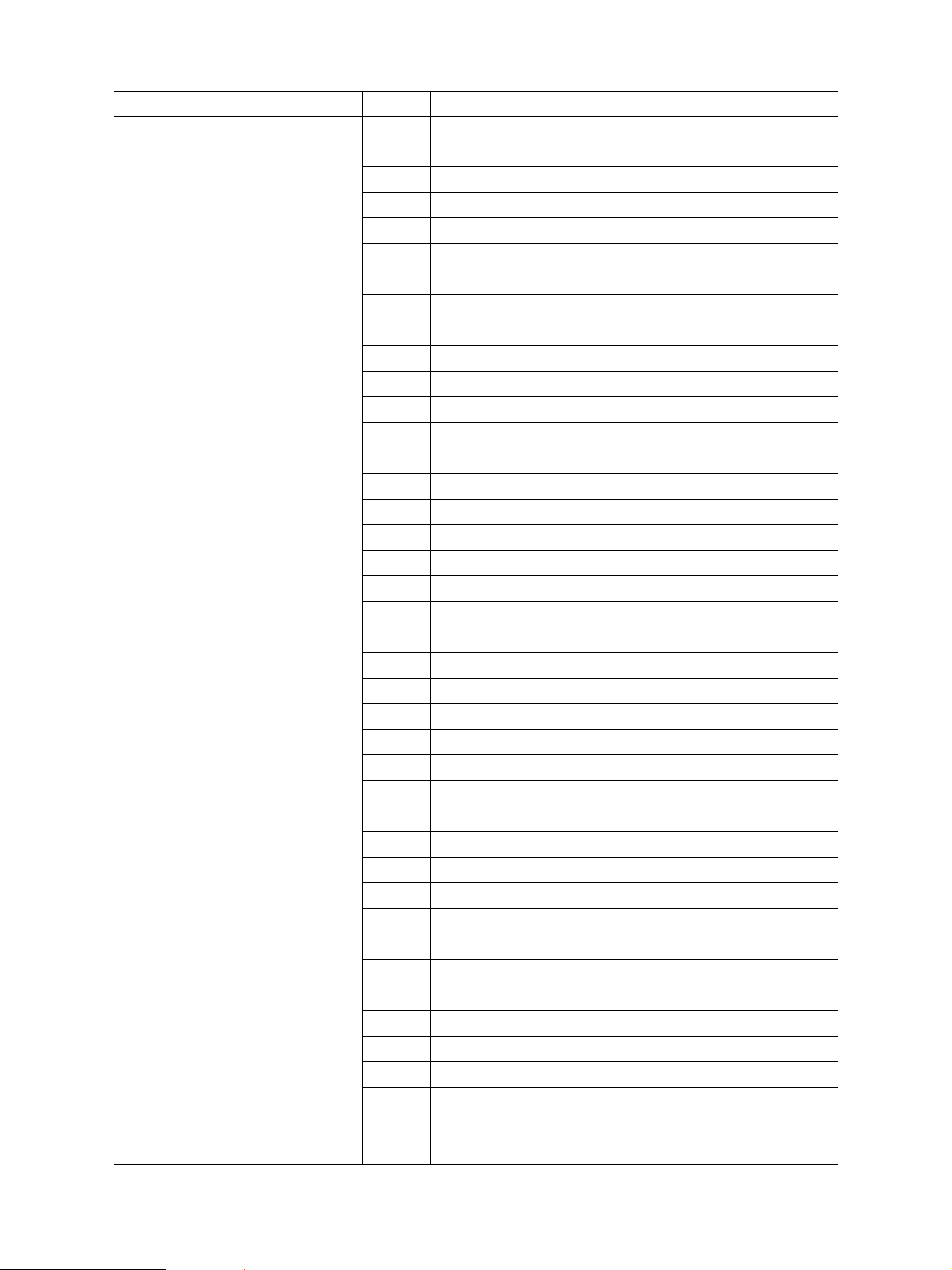

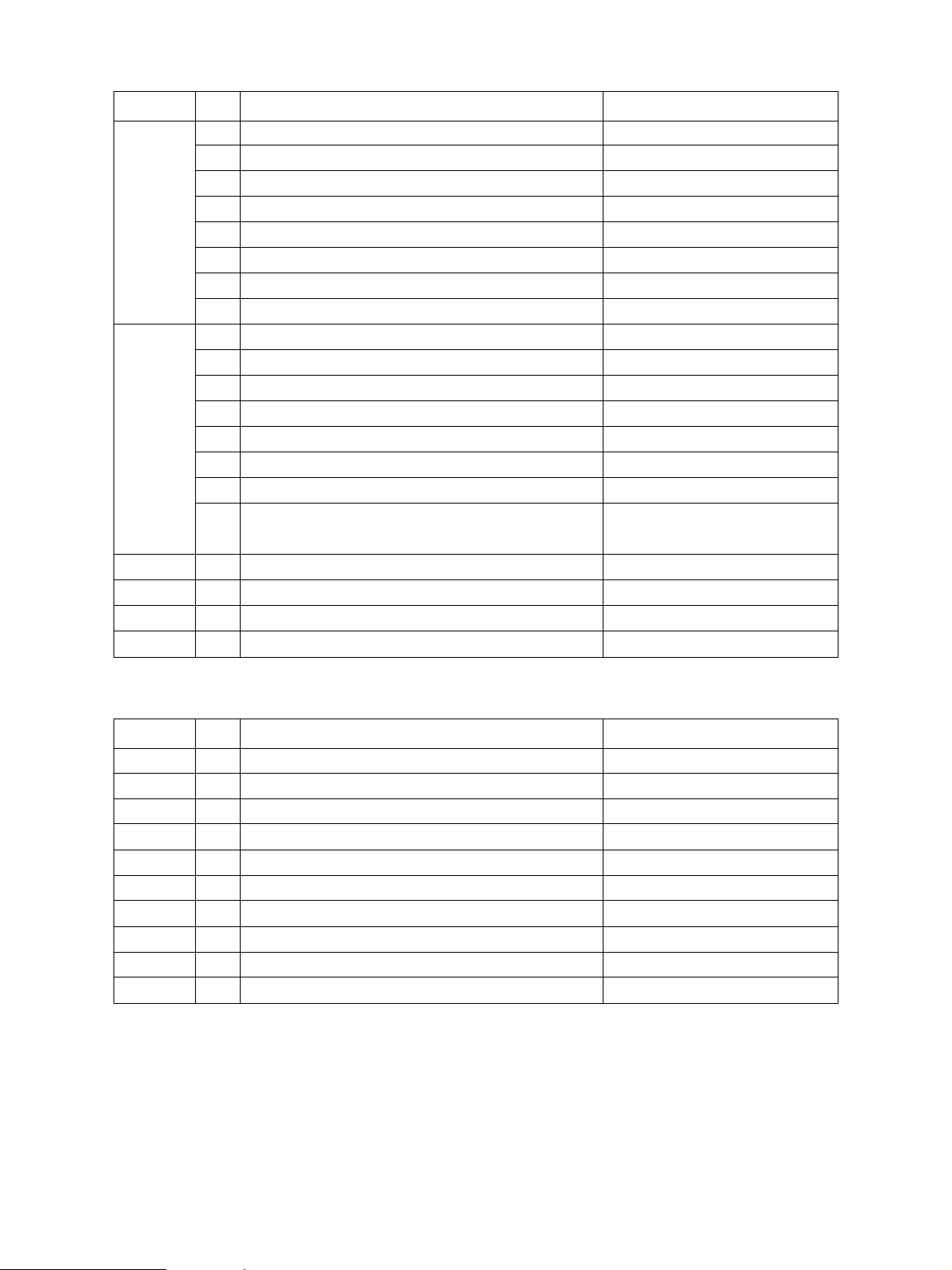

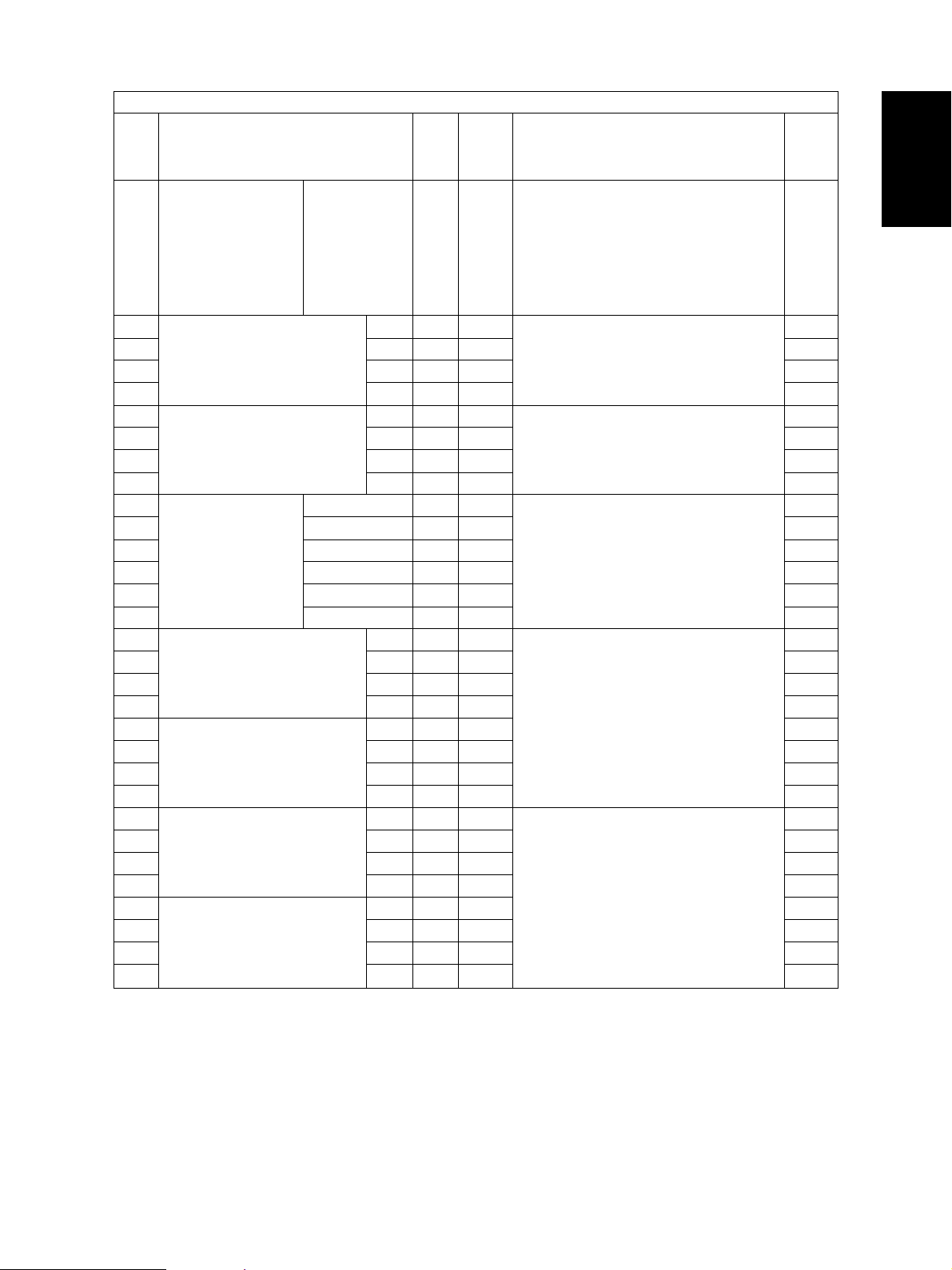

Classification Error code Contents

Original jam in the ADF E71 Original not reaching the aligning sensor

E72 Original not reaching the exit sensor

E73 Original not passing the exit sensor

Paper jam in the finisher E9F Punching jam

EA1 Paper transport delay jam

EA2 Paper transport stop jam

EA3 Paper remaining inside the finisher at power ON

EA4 Finisher front door opened during printing

EA5 Finisher stapling jam

EA6 Finisher early arrival jam

EA8 Saddle stitcher stapling jam

EA9 Saddle stitcher front door opened during printing

EAA Paper remaining in the saddle stitcher at power ON

EAB Saddle stitcher transport stop jam

EAC Saddle stitcher transport delay jam

EAE Finisher receive time-out jam

Special sheet jam EC2 OHP film jams when not fed from bypass tray or 2nd cassette

EC3 OHP film used in non-OHP mode

Drive system related service call C05 ADU motor rotation abnormal

C06 Feed motor rotation abnormal

C0A Developer motor rotation abnormal

Paper feeding system related C11 ADU paper side guide operation abnormal

service call C12 ADU paper end guide operation abnormal

C13 1st cassette tray operation abnormal

C14 2nd cassette tray operation abnormal

C15 3rd cassette tray operation abnormal

C16 4th cassette tray operation abnormal

C18 LCF tray operation abnormal

Scanner related service call C27 Carriage home position sensor not turning OFF within a fixed time

C28 Carriage home position sensor not turning ON within a fixed time

C29 Exposure lamp disconnection detected

FC-210/310

ERROR CODES AND SELF-DIAGNOSIS

1 - 2 February 2002 © TOSHIBA TEC

Page 9

Classification Error code Contents

Copy process related service call C31 Used toner transport motor rotation abnormal

C33 Developer removal shutter abnormal

C35 Transfer belt unit contact/release operation abnormal

C38 Auto-toner error (K)

C39 Auto-toner error (C)

C3A Auto-toner error (M)

C3B Auto-toner error (Y)

C3C Main charger wire cleaning abnormal (K)

C3D Main charger wire cleaning abnormal (C)

C3E Main charger wire cleaning abnormal (M)

C3F Main charger wire cleaning abnormal (Y)

Fuser unit related service call C41 Thermistor or heater abnormal when warming-up is started

C42 Thermistor abnormal after the copier has become ready

C43 Thermistor abnormal during warming-up after abnormality

judgment

C44 Heater abnormal during warming-up after abnormality

judgment

C46 Heater abnormal (low temperature) after the copier has

become ready

C47 Rear thermistor abnormal after the copier has become

ready

C48 Heater abnormal (high temperature)

C7 Error C7

Communications related service call C57 Communications error between LGC-CPU and IPC board

C5A Communications error between LGC-CPU and printer controller

C5B LGC-CPU signal transmission error to IMC-CPU

C5C LGC-CPU signal reception error from IMC-CPU

ADF related service call C72 Aligning sensor automatic adjustment error

C73 EEPROM initializing error

C74 Paper exit sensor automatic adjustment error

Other service call (1) C94 LGC-CPU abnormal

C9A Main memory abnormal

C9B LGC-CPU protocol abnormal

C9D IMC-CPU protocol abnormal

C9E IMC board connection abnormal

February 2002 © TOSHIBA TEC 1 - 3 FC-210/310

ERROR CODES AND SELF-DIAGNOSIS

Page 10

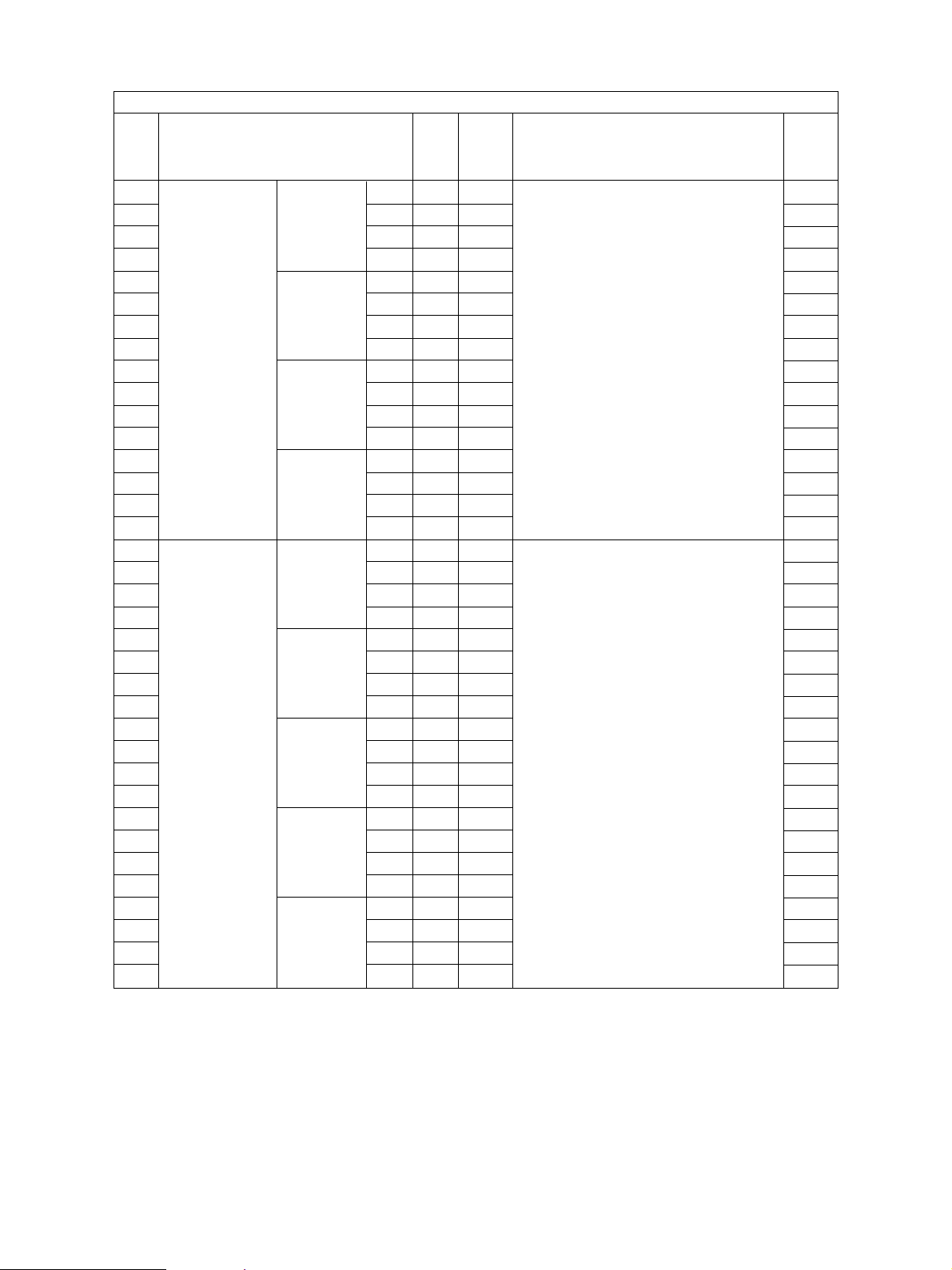

Classification Error code Contents

Laser optical unit related service call CA1 Polygonal motor rotation abnormal

CA2 H-SYNC abnormal

CD1 Laser calibration error (K)

CD2 Laser calibration error (C)

CD3 Laser calibration error (M)

CD4 Laser calibration error (Y)

Finisher related service call CB1 Feed motor abnormal

CB2 Delivery motor abnormal

CB3 Tray lift motor abnormal

CB4 Alignment motor abnormal

CB5 Staple motor abnormal

CB6 Stapler shift motor abnormal

CB7 Height sensor abnormal

CB8 Backup RAM data abnormal

CB9 Saddle stitcher/paper pushing plate motor abnormal

CBA Saddle stitcher/stitcher motor (front) abnormal

CBB Saddle stitcher/stitcher motor (rear) abnormal

CBC Saddle stitcher/alignment motor abnormal

CBD Saddle stitcher/guide motor abnormal

CBE Saddle stitcher/paper folding motor abnormal

CBF Saddle stitcher/paper positioning plate motor abnormal

CD5 Saddle stitcher/sensor connector connection error

CD6 Saddle stitcher/microswitch abnormal

CD7 Communication error between finisher and saddle stitcher

CD9 Swing motor abnormal

CDA Horizontal registration motor abnormal

CDB Punch motor abnormal

Image quality related service call CE1 Image quality sensor abnormal (OFF level)

CE2 Image quality sensor abnormal (no pattern level)

CE4 Image quality control test pattern abnormal

CE5 Temperature/humidity sensor upper-limit abnormal

CE6 Drum thermistor abnormal (Y)

CE9 Drum thermistor abnormal (K)

CF1 Color registration control abnormal

Other service call (2) F07 Communications error between system-CPU and LGC-CPU

F09 Communications error between system-CPU and scanner-CPU

F10 HDD formatting error

F11 Communications error between system-CPU and scanner-CPU

F12 Communications error between system-CPU and scanner-CPU

Image processing related service F51 Communications error between system-CPU and AI board

call during pre-scanning

FC-210/310

ERROR CODES AND SELF-DIAGNOSIS

1 - 4 February 2002 © TOSHIBA TEC

Page 11

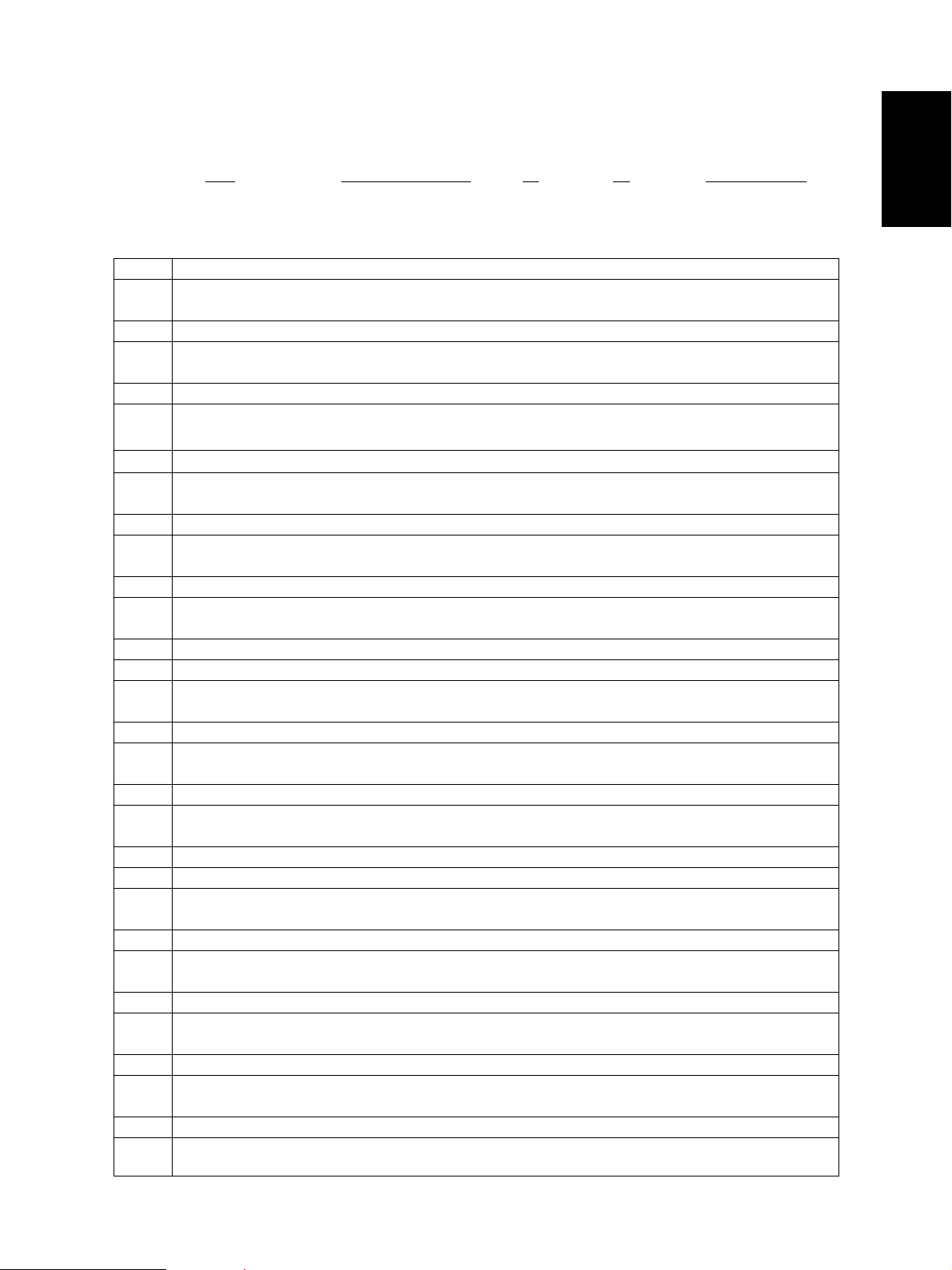

<<Error history>>

In the setting mode (08-253), the latest twenty groups of error data will be displayed.

Display example

EA1 01 08 26 17 57 32 64 64 236210000000

Error code

YY MM DD HH MM SS

MMM NNN

3 digits 12 digits (Year is indicated 3 digits 3 digits 12 digits

with its last two digits.)

A Paper source

0: Not selected 1: Bypass feed 2: LCF 3: 1st 4: 2nd 5: 3rd 6: 4th 7: ADU feed

B Paper size code

0: A5/ST 1: A5-R 2: ST-R 3: LT 4: A4 5: B5-R 6: LT-R 7: A4-R 8: OTHER/UNIV

9: B5 A: FOLIO/COMP B: LG C: B4 D: LD E: A3 F: 13"LG H: A6-R I: Card Z: Not selected

C Sort mode / staple mode

0: Non-sort/Non-staple 1: Group 2: Sort 7: Front staple

8: Double staple 9: Rear staple A: Saddle stitch

D ADF mode

0: Unused 1: AUTO FEED (SADF) 2: STACK FEED

E APS / AMS mode

0: Not selected 1: APS 2: AMS

ABCDEFHIJLOP

F Duplex mode

0: Not selected 1: Book 2: Two-sided / Single-sided 4: Two-sided / Duplexed

8: Single-sided / Duplexed

G Unused

H Image shift

0: Unused 1: Book 2: Left 4: Right

I Editing

0: Unused 1: Masking 2: Trimming 3: Mirror image 4: Negative / Positive

J Edge erase / Dual-page

0: Unused 1: Edge erase 2: Dual-page 3: Edge erase & Dual-page

K Unused

L Function

0: Copying 1: Unused 2: Unused 3: Unused 4: Printing 5: Unused

MMM Primary scanning reproduction ratio (Display in hexadecimal)

(Mx256)+(Mx16)+M

NNN Secondary scanning reproduction ratio (Display in hexadecimal)

(Nx256)+(Nx16)+N

O Color mode

0: Auto color 1: Full color 2: Black 3: Monocolor

P AI board

0: Unused 1: Used

February 2002 © TOSHIBA TEC 1 - 5 FC-210/310

ERROR CODES AND SELF-DIAGNOSIS

Page 12

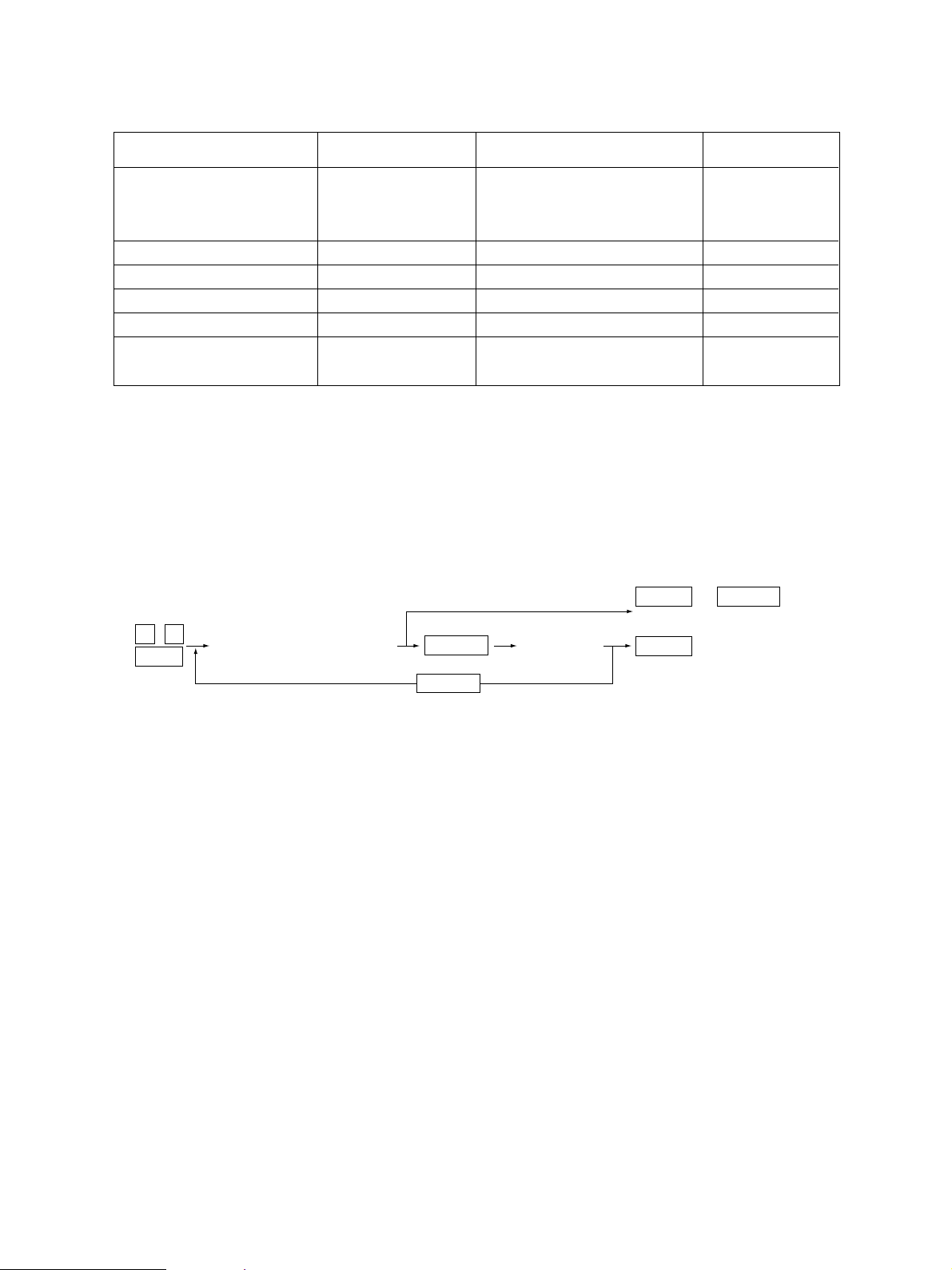

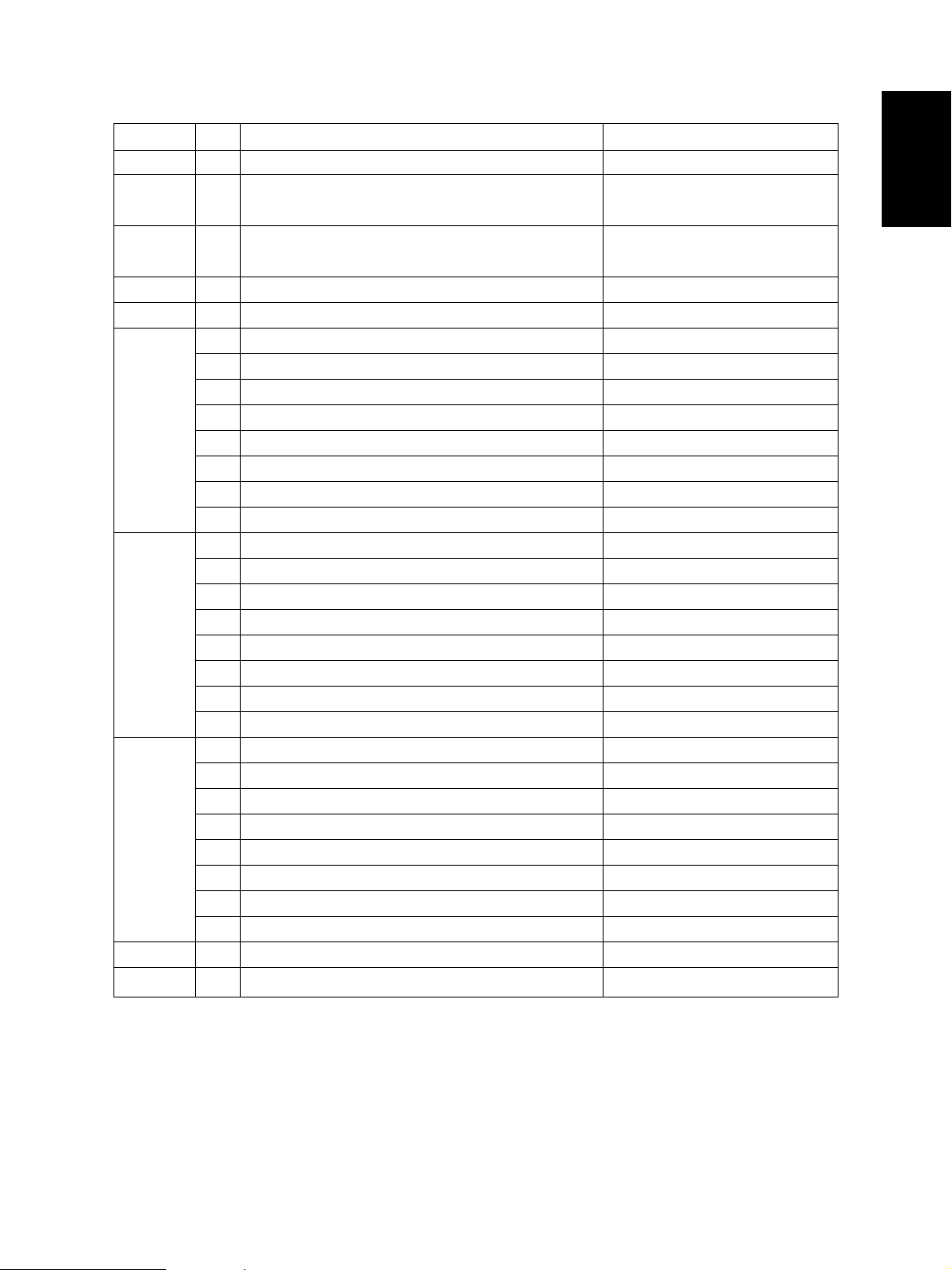

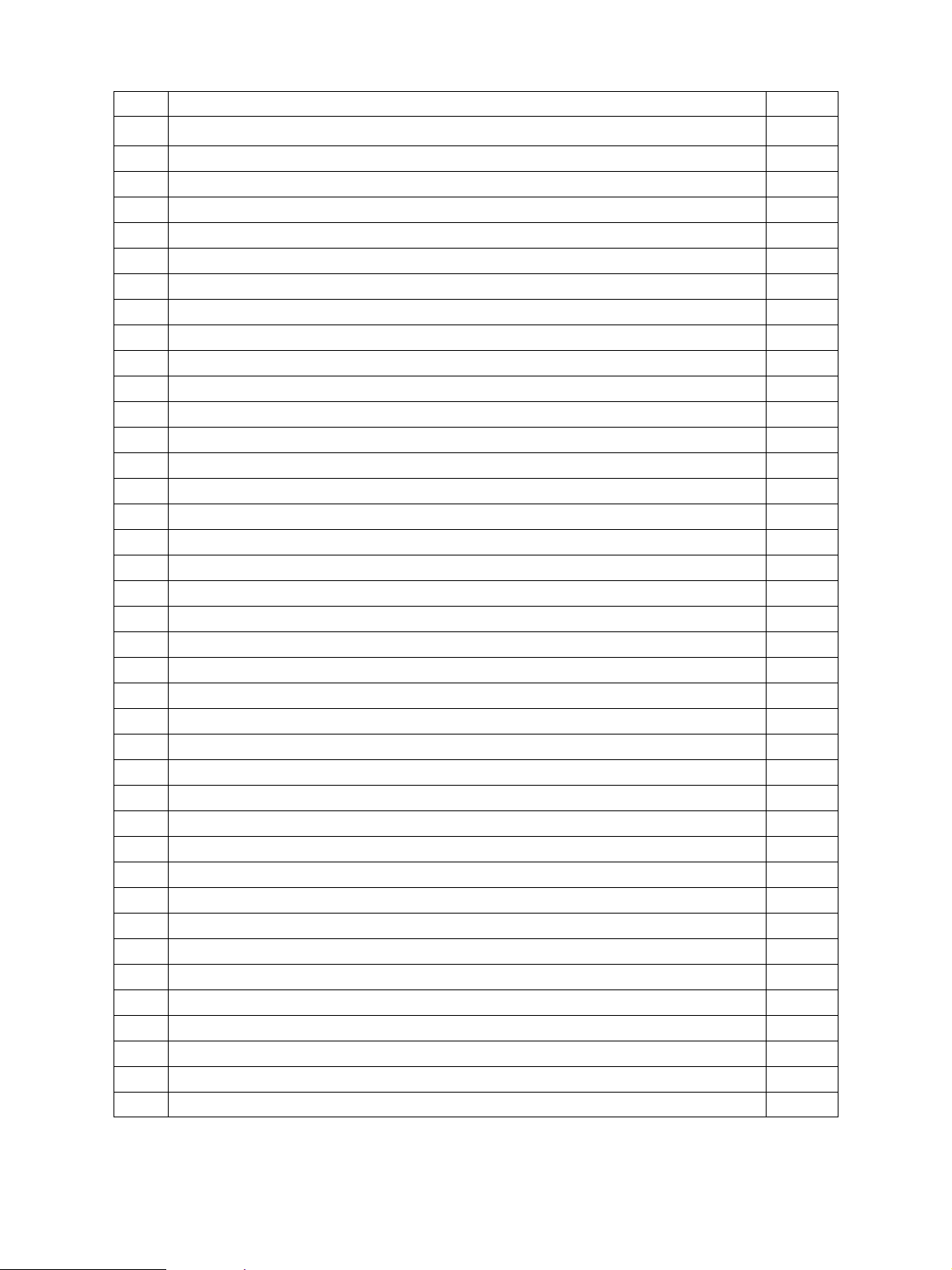

1. 2 Self-Diagnosis Mode

Mode Starting Contents Exit

Control panel check [0]+[1]+[POWER] All control panel LEDs are lit, [CLEAR] or

mode and all LCD pixels are turned [POWER]OFF/ON

ON/OFF repeatedly.

Test mode [0]+[3]+[POWER] Input/output signals are checked.

Test print mode [0]+[4]+[POWER] A test pattern print is made.

Adjustment mode [0]+[5]+[POWER] Adjustment of various items

Setting mode [0]+[8]+[POWER] Setting of various items

List printing mode [9]+[START]+[POWER] Printing of list of 05 and 08 code

data

Note: Starting for various modes:

While pressing simultaneously the two digital keys corresponding to the mode you want to set

(for example, [0] and [5]), turn ON the main switch [POWER].

<Operation procedure>

[POWER]OFF/ON

[POWER]OFF/ON

[POWER]OFF/ON

[POWER]OFF/ON

[POWER]OFF/ON

• Control panel check mode (01) :

0 1

Power

(LEDs light/LCD flashes)

START

START

(Check Keys)

CLEAR

(Exit)

CLEAR

(Exit)

POWER OFF/ON

or

Notes: 1. During the “Check keys” state, [CLEAR] alone can exit.

During the “LEDs light/LCD flashes” state, [CLEAR] can clear the mode.

2. Check keys :

Any key with LED (when it is pressed, the LED goes out.)

Any key without LED (when it is pressed, an indication is displayed in the message area.)

• Test mode (03) : Refer to "1.2.1 Input check (Test mode 03)" and "1.2.2 Output check

(Test mode 03)".

• Test print mode (04) : Refer to "1.2.3 Test print mode (04)".

• Adjustment mode (05) : Refer to "1.2.4 Adjustment mode (05)".

• Setting mode (08) : Refer to "1.2.5 Setting mode (08)".

FC-210/310

ERROR CODES AND SELF-DIAGNOSIS

1 - 6 February 2002 © TOSHIBA TEC

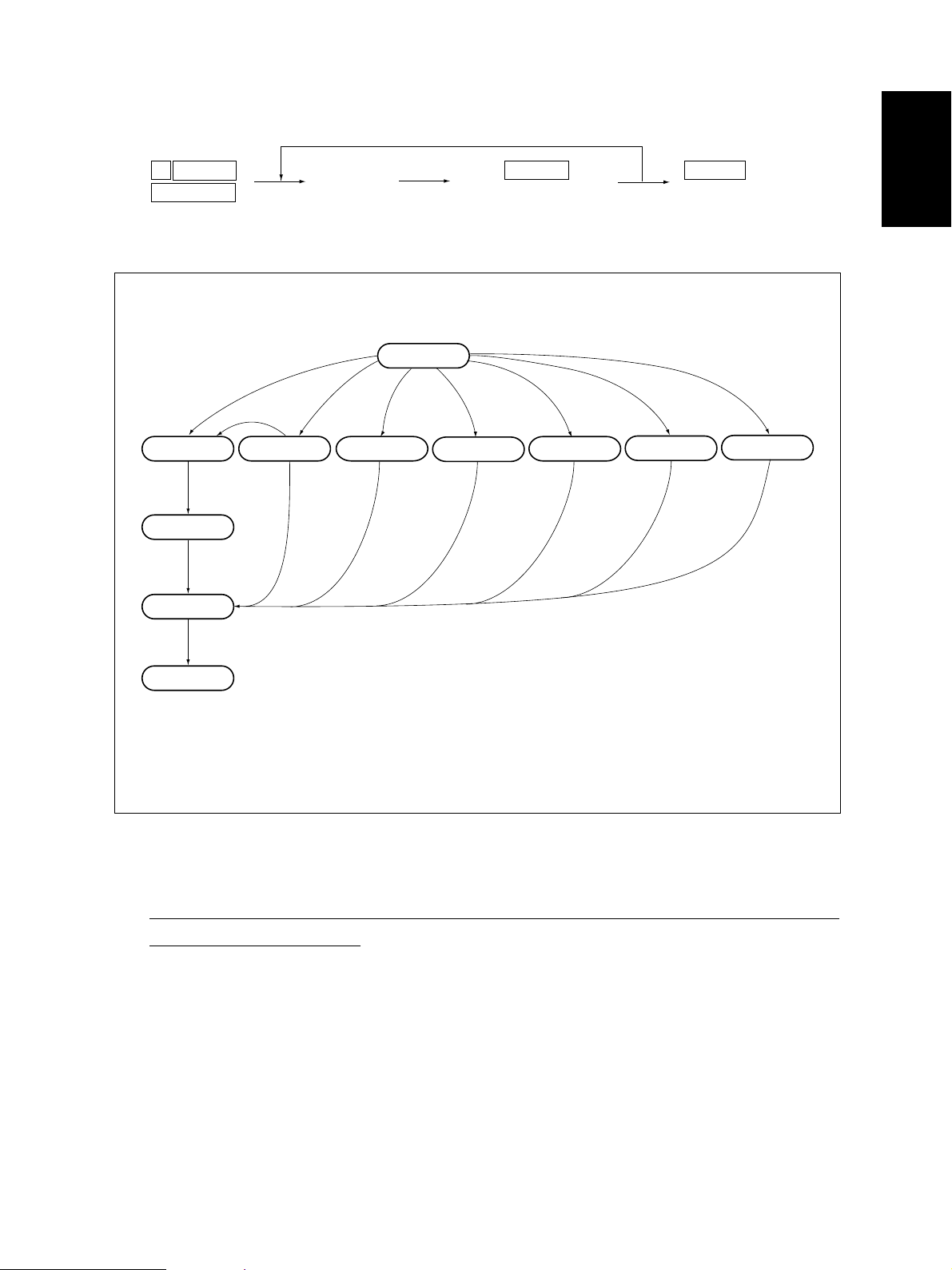

Page 13

• List printing mode

9

START

POWER

Warming up

Standby

[POWER]OFF/ON

(Code)

101: Adjustment mode (05)

102: Setting mode (08)

Normal

[0][1]

[CLEAR]

Control panel

check mode

*1

START

(Operation is started)

[POWER] ON

[0][3] [0][5] [0][8]

[0][4]

Test print mode

Adjustment mode

POWER OFF/ON

(Exit)

[9][START]

Setting modeTest mode

List printing mode

*2

Hand over to user

T ransition diagram of self-diagnosis mode conditions

*1 : During the activation of the “Control panel check mode”, copying is not possible. But after pressing

[CLEAR] to make the copier ready, you can make copies.

*2 : After having used the self-diagnosis mode, be sure to turn OFF and then ON the power before return-

ing the copier to the customer.

February 2002 © TOSHIBA TEC 1 - 7 FC-210/310

ERROR CODES AND SELF-DIAGNOSIS

Page 14

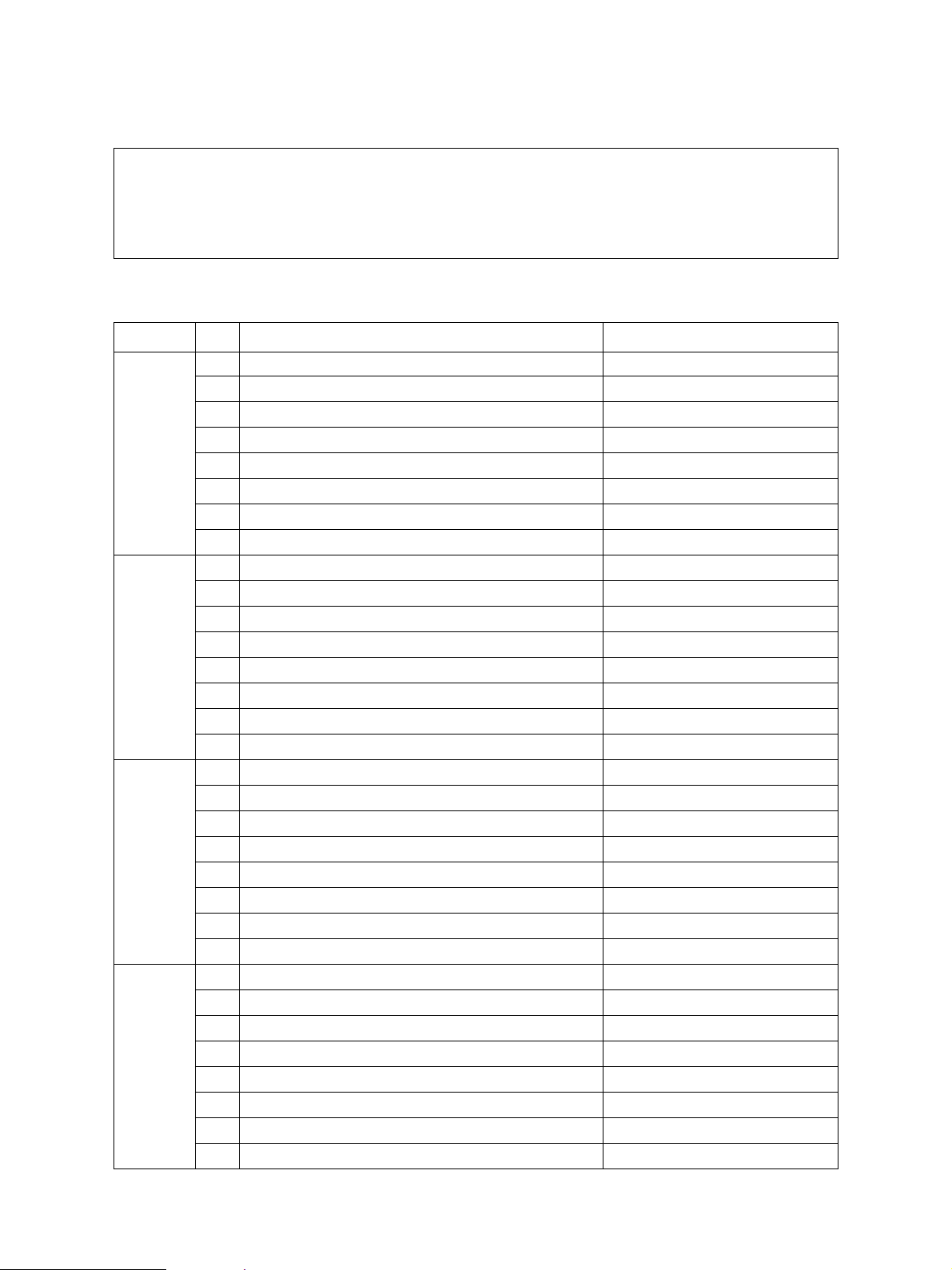

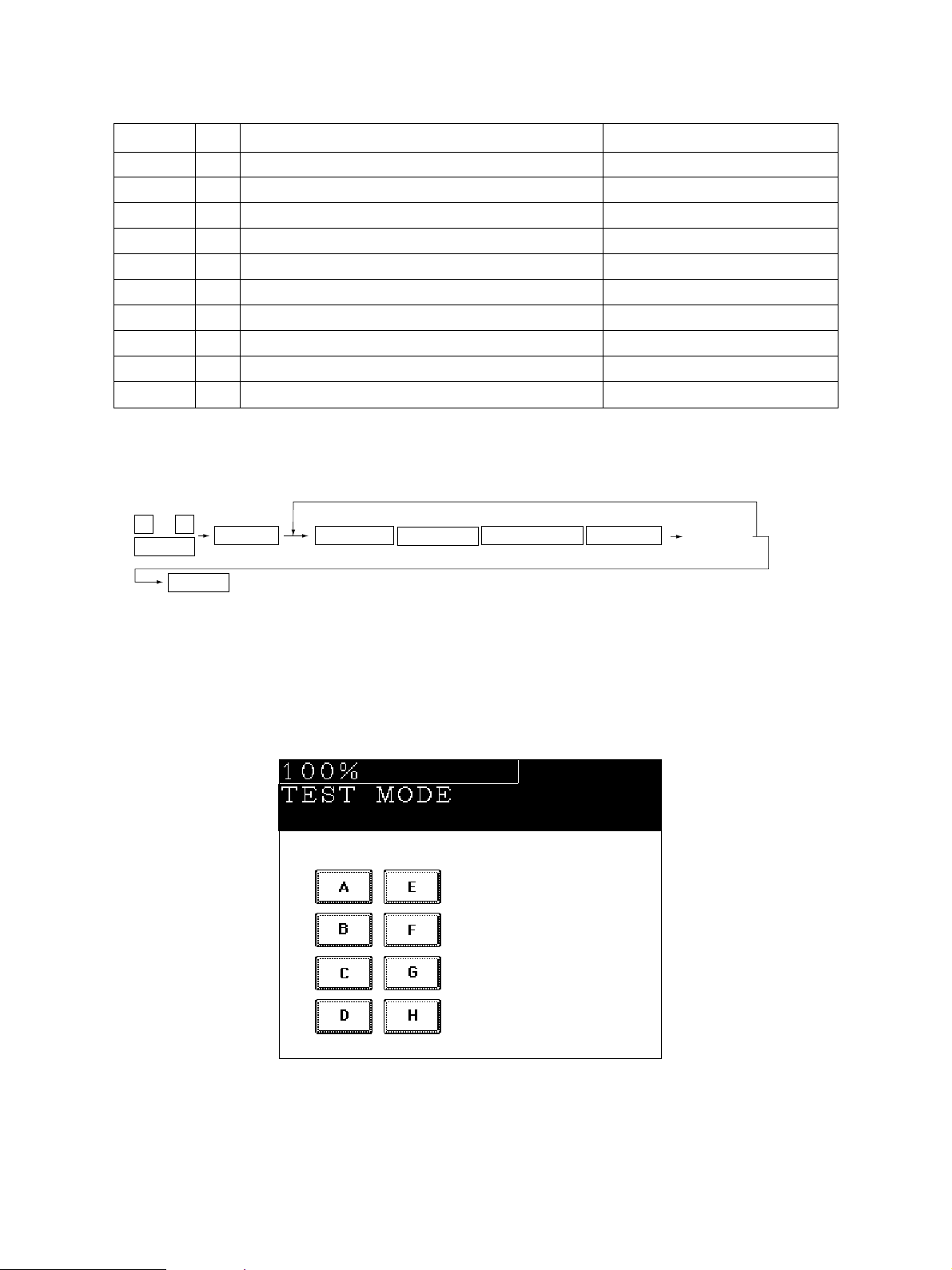

1. 2. 1 Input check (Test mode 03)

The status of each item can be checked by setting ON/OFF of each [FULL COLOR], [AUTO COLOR],

[ENERGY SAVER], and then pressing each of the corresponding digital key in this test mode 03.

Note: When icon is displayed with black letter on white background, it indicates the value is 0, while in

reverse black and white, it indicates the value is 1.

[FULL COLOR]key: OFF, [AUTO COLOR]key: OFF, [ENERGY SAVER]key: OFF

Digital key Icon Item Condition

A —

B —

C —

[1]

[2]

[3]

[4]

D —

E 1st cassette paper-empty sensor 1: No paper

F 1st cassette tray-up limit sensor 1: Tray is upper limit.

G 1st cassette feed-jam sensor 1: Paper present

H 1st cassette detection switch 1: No cassette

A —

B —

C —

D —

E 2nd cassette paper-empty sensor 1: No paper

F 2nd cassette tray-up limit sensor 1: Tray is upper limit.

G 2nd cassette feed-jam sensor 1: Paper present

H 2nd cassette detection switch 1: No cassette

A —

B —

C —

D —

E 3rd cassette paper-empty sensor 1: No paper

F 3rd cassette tray-up limit sensor 1: Tray is upper limit.

G 3rd cassette feed-jam sensor 1: Paper present

H 3rd cassette detection switch 1: No cassette

A —

B —

C —

D —

E 4th cassette paper-empty sensor 1: No paper

F 4th cassette tray-up limit sensor 1: Tray is upper limit.

G 4th cassette feed-jam sensor 1: Paper present

H 4th cassette detection switch 1: No cassette

FC-210/310

ERROR CODES AND SELF-DIAGNOSIS

1 - 8 February 2002 © TOSHIBA TEC

Page 15

Digital key Icon Item Condition

A Bypass paper-width sensor 0 Refer to Table 1.

B Bypass paper-width sensor 1 Refer to Table 1.

C Bypass paper-width sensor 2 Refer to Table 1.

[5]

[6]

[7]

[8]

D —

E Bypass paper sensor 1: No paper

F Bypass unit open/close switch 1: Unit is opened.

G Side door open/close switch 1: Side door is opened.

H Bypass unit is installed or not 0: Unit is installed.

A LCF paper-empty sensor 1: No paper

B LCF lower-limit sensor 1: Tray limit (lower)

C LCF tray-up sensor 1: Tray limit (upper)

D LCF tray-down switch 0: Switch is ON.

E LCF paper supply door sensor 1: Door is opened.

F LCF is installed or not 0: LCF is installed.

G ADU motor rotation status 0: Normal rotation

(Motor is rotating by output check 03)

H ADU is installed or not 0: ADU is installed.

A ADU paper-jam sensor 1: Paper present

B ADU paper-empty sensor 0: No paper

C ADU end switch 1: End guide is at home position.

D ADU side switch 1: Side guide is at home position.

E —

F —

G Key copy counter is installed or not 0: Key copy counter is installed.

H —

A Developer removal shutter home position sensor 0: Shutter is at closed position.

B —

C Transfer belt unit is installed or not 0: Unit is installed.

D —

E —

F Developer motor rotation status 0: Normal rotation

(Motor is rotating by output check 03)

G Transfer belt limit switch 0: Transfer belt is in black mode position.

H Transfer belt home position switch 0: Transfer belt is in color mode position.

February 2002 © TOSHIBA TEC 1 - 9 FC-210/310

ERROR CODES AND SELF-DIAGNOSIS

Page 16

Digital key Icon Item Condition

A External printer controller power ON/OFF 0: Controller power ON

B —

C —

[9]

[0]

D Front cover switch 1: Front cover is opened.

E OHP sensor 0: Opaque paper is installed.

F —

G Registration sensor 1 : Paper present

H IPC board (Finisher installation kit) is installed or not 0: Board is installed.

A ADU path sensor 1: Paper present

B —

C Exit sensor 1: Paper present

D Paper-exit unit open/close switch 1: Paper-exit unit is opened.

E Toner bag limit sensor 1: Used toner full

F —

G —

H —

Table 1. Relation between bypass paper-width sensor status and paper-width size.

Bypass paper-width sensor

210

1 0 0 A3/LD

0 1 0 A4-R/LT-R

1 0 1 A5-R/ST-R

0 1 1 Card size

0 0 0 B4/LG

1 1 0 B5-R

Paper-width size

FC-210/310

ERROR CODES AND SELF-DIAGNOSIS

1 - 10 February 2002 © TOSHIBA TEC

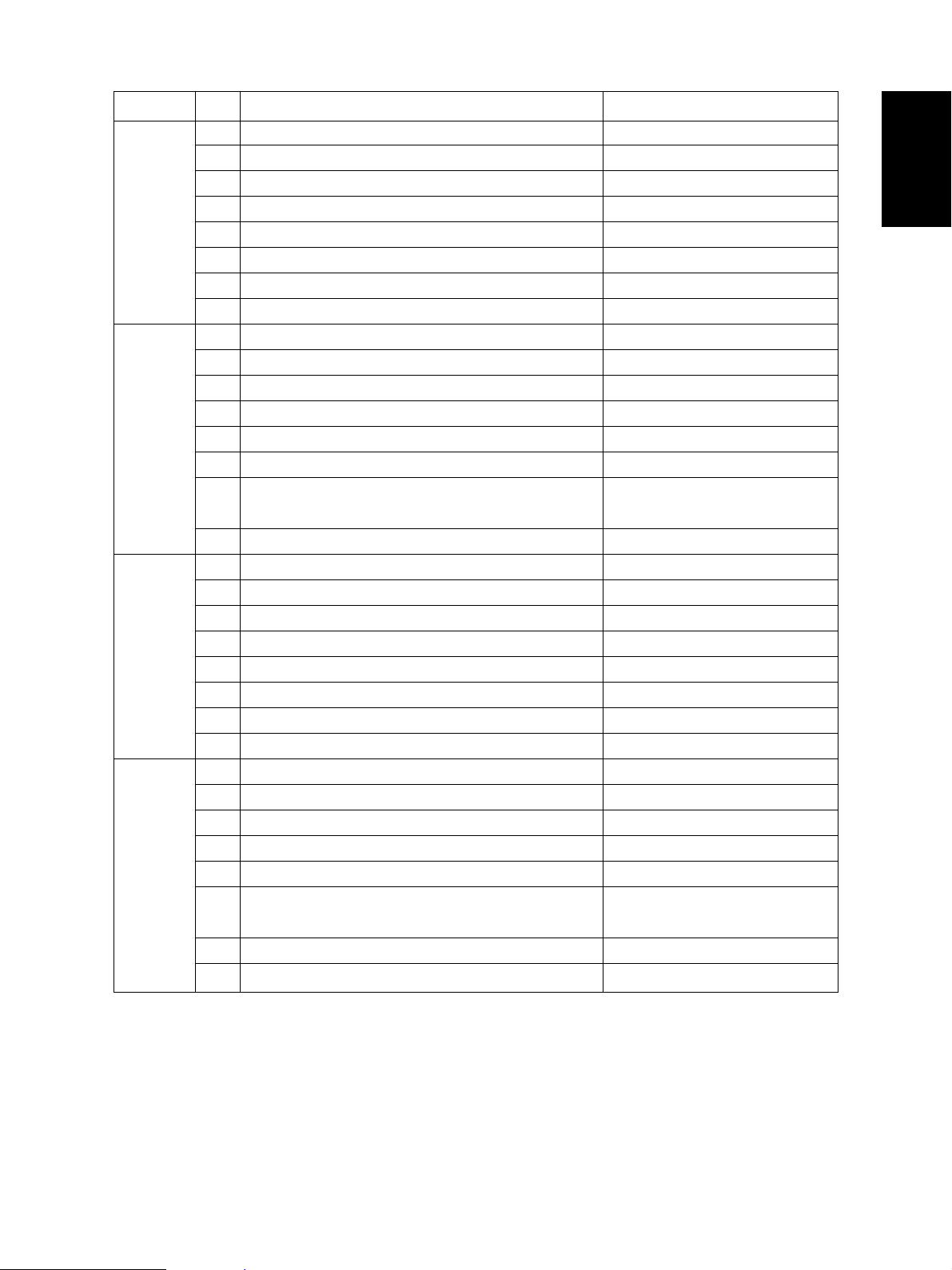

Page 17

[FULL COLOR]key: OFF, [AUTO COLOR]key: OFF, [ENERGY SAVER]key: ON

Digital key Icon Item Condition

A —

B —

C —

[1]

[2]

[3]

[4]

D —

E —

F —

G —

H —

A Developer cartridge Y is installed or not 0: Cartirdge is installed.

B Developer cartridge M is installed or not 0: Cartirdge is installed.

C Developer cartridge C is installed or not 0: Cartirdge is installed.

D Developer cartridge K is installed or not 0: Cartirdge is installed.

E Processing unit is installed or not 0: Unit is installed.

F Fuser unit is installed or not 0: Unit is installed.

G —

H —

A Wire cleaner home position switch Y 0: Cleaning pad is at home position.

B Wire cleaner home position switch M 0: Cleaning pad is at home position.

C Wire cleaner home position switch C 0: Cleaning pad is at home position.

D Wire cleaner home position switch K 0: Cleaning pad is at home position.

E Wire cleaner limit switch Y 0: Cleaning pad is at limit position.

F Wire cleaner limit switch M 0: Cleaning pad is at limit position.

G Wire cleaner limit switch C 0: Cleaning pad is at limit position.

H Wire cleaner limit switch K 0: Cleaning pad is at limit position.

A —

B —

C —

D —

E —

F —

G —

H —

February 2002 © TOSHIBA TEC 1 - 11 FC-210/310

ERROR CODES AND SELF-DIAGNOSIS

Page 18

Digital key Icon Item Condition

A —

B —

C —

[5]

[6]

[7] ——

[8] — Upper heat roller thermistor (center) check

[9] — Upper heat roller thermistor (rear) check

[0] — Lower heat roller thermistor (center) check

D —

E —

F —

G —

H —

A —

B —

C —

D —

E —

F —

G Front cover, paper-exit unit open/close check 1: Cover/unit is opened.

H Polygonal motor rotation status 0: Normal rotation

(Motor is rotating by output check 03)

Thermistor output value is displayed with 8 bits.

Thermistor output value is displayed with 8 bits.

Thermistor output value is displayed with 8 bits.

[FULL COLOR]key: OFF, [AUTO COLOR]key: ON, [ENERGY SAVER]key: OFF

Digital key Icon Item Condition

[1] — Lower heat roller thermistor (rear) check

[2] — Temperature sensor check

[3] — Humidity sensor check

[4] — Drum thermistor Y check

[5] ——

[6] ——

[7] — Drum thermistor K check

[8] ——

[9] ——

[0] ——

Thermistor output value is displayed with 8 bits.

Sensor output value is displayed with 8 bits.

Sensor output value is displayed with 8 bits.

Thermistor output value is displayed with 8 bits.

Thermistor output value is displayed with 8 bits.

FC-210/310

ERROR CODES AND SELF-DIAGNOSIS

1 - 12 February 2002 © TOSHIBA TEC

Page 19

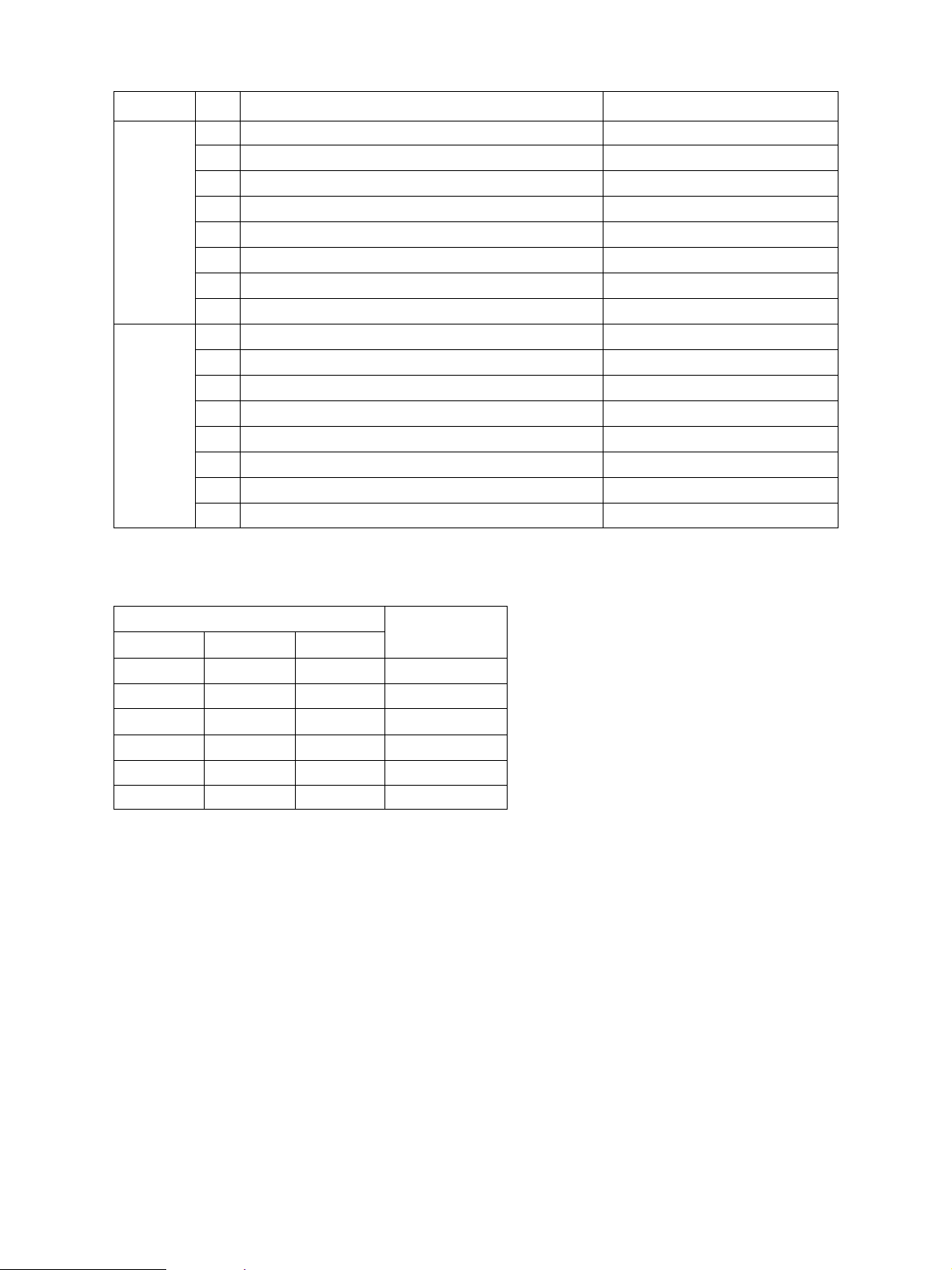

[FULL COLOR]key: OFF, [AUTO COLOR]key: ON, [ENERGY SAVER]key: ON

Digital key Icon Item Condition

[1] ——

[2] — Color registration sensor (front) "0" is displayed with reflection at

(Sensor LED is turned ON by output check 03.) transfer belt.

[3] — Color registration sensor (rear) "0" is displayed with reflection at

(Sensor LED is turned ON by output check 03.) transfer belt.

[4] — Image quality sensor

[5] ——

A ADF aligning sensor 1: Original present

B ADF exit sensor 1: Original present

C ADF open/close sensor 1: ADF is opened.

[6]

[7]

[8]

[9] — SCM board input 24V check Output value is displayed with 8 bits.

[0] ——

D ADF empty sensor 1: Original present

E ADF size sensor 1

F —

G ADF size sensor 2

H ADF unit is installed or not 1: ADF unit is installed.

A —

B —

C —

D —

E —

F Carriage home position sensor 1: Carriages are at home position.

G —

H Platen sensor 1: Platen cover is closed.

A —

B —

C —

D APS sensor (APS-R) 1: Original present

E APS sensor (APS-C) 1: Original present

F APS sensor (APS-3) 1: Original present

G APS sensor (APS-2) (for A4 series) 1: Original present

H APS sensor (APS-1) 1: Original present

Sensor output value is displayed with 10 bits.

February 2002 © TOSHIBA TEC 1 - 13 FC-210/310

ERROR CODES AND SELF-DIAGNOSIS

Page 20

[FULL COLOR]key: ON, [AUTO COLOR]key: OFF, [ENERGY SAVER]key: OFF

Digital key Icon Item Condition

[1] — Auto-toner sensor Y

[2] — Auto-toner sensor M

[3] — Auto-toner sensor C

[4] — Auto-toner sensor K

[5] ——

[6] ——

[7] ——

[8] ——

[9] ——

[0] ——

Sensor output value is displayed with 8 bits.

Sensor output value is displayed with 8 bits.

Sensor output value is displayed with 8 bits.

Sensor output value is displayed with 8 bits.

<Operation procedure>

0 3

POWER

POWER OFF/ON

Note: After initialization, the copier goes into the test mode.

START

(Exit)

(

FULL COLOR

AUTO COLOR

ENERGY SAVER Digital keys

)

(LCD ON)

FC-210/310

Note: When icon is displayed with white letter on black background on the control

panel, it indicates the value is 1.

ERROR CODES AND SELF-DIAGNOSIS

1 - 14 February 2002 © TOSHIBA TEC

Page 21

1. 2. 2 Output check (Test mode 03)

Output signal status can be checked by entering the following code in the test mode 03.

Code Function Code Function Procedure

150 All output OFF 1

101 Drum motor and transfer belt motor rotation 151 Code No. 101 function OFF 1

with normal printing speed ON

102 Drum motor and transfer belt motor rotation 152 Code No. 102 function OFF 1

with OHP printing speed (low) ON

103 Paper feed motor ON 153 Code No. 103 function OFF 1

104 Fuser motor ON 154 Code No. 104 function OFF 1

105 Developer motor (color mode) ON 155 Code No. 105 function OFF 1

106 Developer motor (black mode) ON 156 Code No. 106 function OFF 1

107 Registration motor ON 157 Code No. 107 function OFF 1

108 Used toner transport motor ON 158 Code No. 108 function OFF 1

109 ADU motor ON 159 Code No. 109 function OFF 1

110 Toner motor Y ON 160 Code No. 110 function OFF 1

111 Toner motor M ON 161 Code No. 111 function OFF 1

112 Toner motor C ON 162 Code No. 112 function OFF 1

113 Toner motor K ON 163 Code No. 113 function OFF 1

114 Image quality sensor shutter solenoid ON 164 Code No. 114 function OFF 1

130 Polygonal motor standby speed ON 180 Code No. 130 function OFF 1

131 Polygonal motor normal speed ON 181 Code No. 131 function OFF 1

132 Image quality sensor LED ON 182 Code No. 132 function OFF 1

133 Color registration sensor LED (front) ON 183 Code No. 133 function OFF 1

134 Color registration sensor LED (rear) ON 184 Code No. 134 function OFF 1

135

Image quality sensor mode switching ON (Black mode)

201 1st cassette feed clutch ON/OFF 3

202 2nd cassette feed clutch ON/OFF 3

203 3rd cassette feed clutch ON/OFF 3

204 4th cassette feed clutch ON/OFF 3

205 Feed path clutch ON/OFF 2

206 Bypass feed clutch ON/OFF 3

207 1st cassette tray-up motor ON (tray goes up) 2

208 2nd cassette tray-up motor ON (tray goes up) 2

209 3rd cassette tray-up motor ON (tray goes up) 2

210 4th cassette tray-up motor ON (tray goes up) 2

211 Paper-exit gate solenoid ON/OFF 3

213 Ozone exhaust fan motor ON/OFF 3

185

Code No. 135 function OFF (Color mode)

1

February 2002 © TOSHIBA TEC 1 - 15 FC-210/310

ERROR CODES AND SELF-DIAGNOSIS

Page 22

Code Function Procedure

214 Fuser exhaust fan motor Low/High speed 3

215 PC board cooling fan motor ON/OFF 3

216 Wire cleaner drive motor Y CW/CCW (continuous reciprocating) 2

217 Wire cleaner drive motor M CW/CCW (continuous reciprocating) 2

218 Wire cleaner drive motor C CW/CCW (continuous reciprocating) 2

219 Wire cleaner drive motor K CW/CCW (continuous reciprocating) 2

220 Transfer belt contact/release motor CW/CCW (continuous reciprocating) 2

223 LCF paper feed motor ON/OFF 3

224 LCF tray motor ON/OFF 2

225 ADU feed clutch ON/OFF 3

226 ADU gate solenoid ON/OFF 3

227 ADU side motor ON/OFF 3

228 ADU end motor ON/OFF 3

229 Pre-feed clutch (front) ON/OFF 3

230 Pre-feed clutch (rear) ON/OFF 3

235 Main charger Y ON/OFF 3

236 Main charger M ON/OFF 3

237 Main charger C ON/OFF 3

238 Main charger K ON/OFF 3

243 Developer bias (Y) DC(-) ON/OFF 3

244 Developer bias (M) DC(-) ON/OFF 3

245 Developer bias (C) DC(-) ON/OFF 3

246 Developer bias (K) DC(-) ON/OFF 3

247 Developer bias (Y) AC ON/OFF 3

248 Developer bias (M) AC ON/OFF 3

249 Developer bias (C) AC ON/OFF 3

250 Developer bias (K) AC ON/OFF 3

251 Cleaning blade bias (Y) DC ON/OFF 3

252 Cleaning blade bias (M) DC ON/OFF 3

253 Cleaning blade bias (C) DC ON/OFF 3

254 Cleaning blade bias (K) DC ON/OFF 3

255 Transfer roller bias (Y) ON/OFF 3

256 Transfer roller bias (M) ON/OFF 3

257 Transfer roller bias (C) ON/OFF 3

258 Transfer roller bias (K) ON/OFF 3

259 Suction charger ON/OFF 3

260 Discharge lamp Y ON/OFF 3

261 Discharge lamp M ON/OFF 3

262 Discharge lamp C ON/OFF 3

FC-210/310

ERROR CODES AND SELF-DIAGNOSIS

1 - 16 February 2002 © TOSHIBA TEC

Page 23

Code Function Procedure

263 Discharge lamp K ON/OFF 3

280 Laser (Y) ON/OFF 3

281 Laser (M) ON/OFF 3

282 Laser (C) ON/OFF 3

283 Laser (K) ON/OFF 3

300 Carriage fan motor rotation at standby speed (high speed) ON/OFF 3

301 Carriage fan motor rotation at normal speed (low speed) ON/OFF 3

302 SCM fan motor Low/High speed 3

304 Scanner exposure lamp ON/OFF 4

331 ADF pick-up roller rotation ON/OFF 3

332 ADF aligning roller rotation ON/OFF 3

333 ADF transport belt CW rotation ON/OFF 3

334 ADF transport belt CCW rotation ON/OFF 3

351 Scan motor (carriages reciprocating once) 2

352 Document motor (indicator reciprocating once) 2

February 2002 © TOSHIBA TEC 1 - 17 FC-210/310

ERROR CODES AND SELF-DIAGNOSIS

Page 24

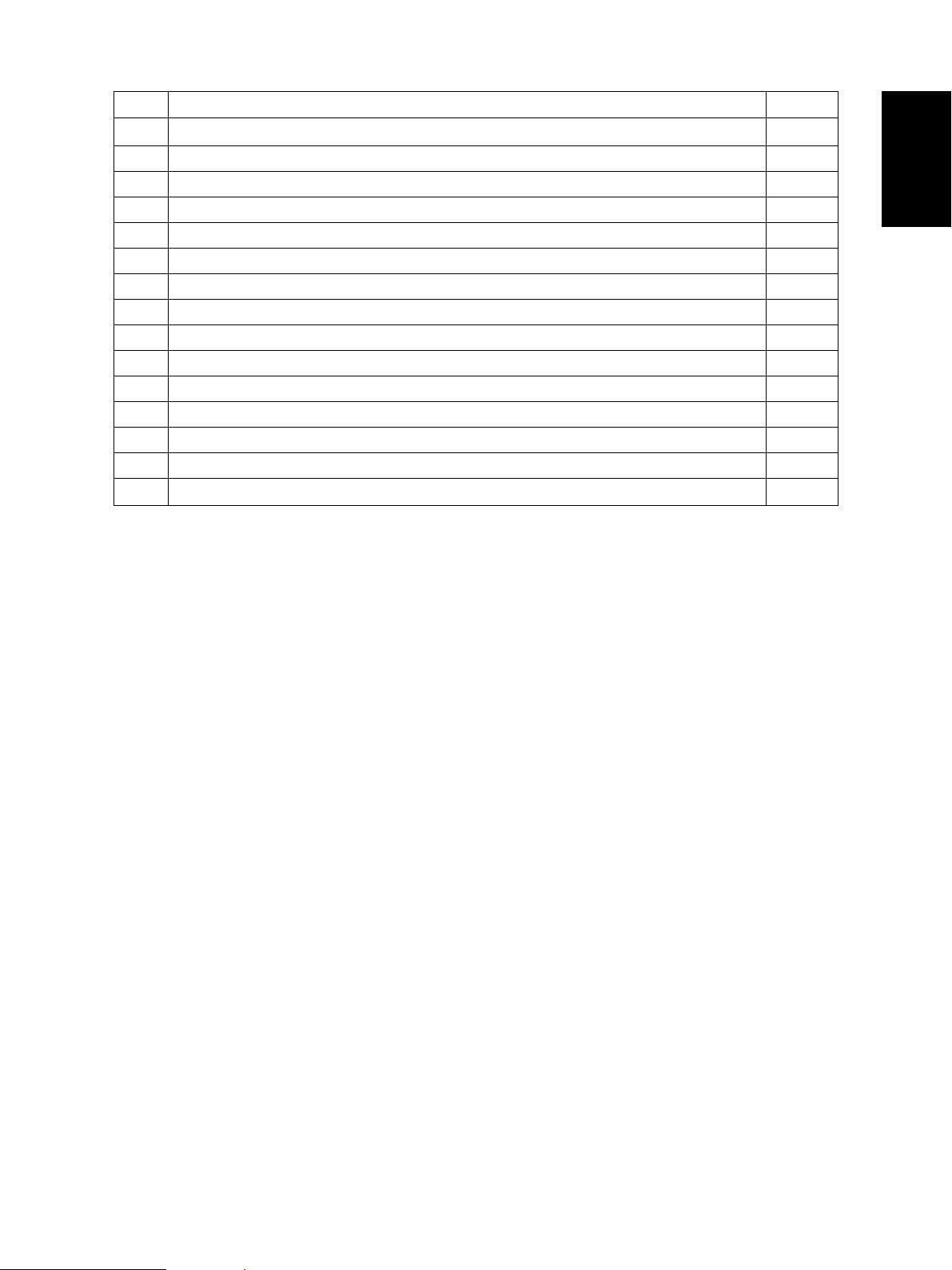

<Operation procedure>

Procedure 1

0 3

POWER

Procedure 2

0 3

POWER

Procedure 3

0 3

POWER

(Code)

(Code)

(Code)

START START

START

START START

(One-direction operation)

(Operation ON) (Operation OFF)

(Code)(Operation ON)

(Operation OFF)

POWER OFF/ONCLEAR

(Exit)

POWER OFF/ON

(Exit)

POWER OFF/ONCLEAR

(Exit)

Procedure 4

0 3

POWER

FC-210/310

(Code)

START

(Operation ON) (Operation OFF)

ERROR CODES AND SELF-DIAGNOSIS

START

CLEAR

or

6 sec. later

POWER OFF/ON

(Exit)

1 - 18 February 2002 © TOSHIBA TEC

Page 25

1. 2. 3 Test print mode (04)

In the test print mode (04), you can print each test pattern by entering its corresponding code as

follows.

Code Types of test pattern Remarks

14 Gamma table check pattern To check gradation A3/LD

204 Grid pattern (Printer reproduction ratio/Registration Pattern width: 1 dot, Pitch: 5mm A3/LD

adjustment pattern) (same as the grid pattern printed

by adjustment mode

[PRINTER/NETWORK])

219 6% test pattern A4/LT

220 8% test pattern A4/LT

230 Gradation check pattern (2 pixels standard) Pattern width: 10mm, A3/LD

32 gradation steps

231 Gradation check pattern (3 pixels standard) Pattern width: 10mm, A3/LD

32 gradation steps

234 Halftone A3/LD

270 Image quality control test patten To check image quality control A3/LD

Note: Full color (YMCK) mode is not available in 230, 231 and 234.

[1]

Paper size

<Operation procedure>

0 4

POWER

Notes:1. When an error has occurred, it is indicated, but the recovery operation is not performed. So, turn the

power OFF and then back ON to clear the error.

2. During test printing, when "Wait adding toner" is displayed, the [STOP] key is disabled.

February 2002 © TOSHIBA TEC 1 - 19 FC-210/310

(Code)

START

(Continuous test

print operation)

POWER OFF/ONSTOP

(Exit)

ERROR CODES AND SELF-DIAGNOSIS

Page 26

1. 2. 4 Adjustment mode (05)

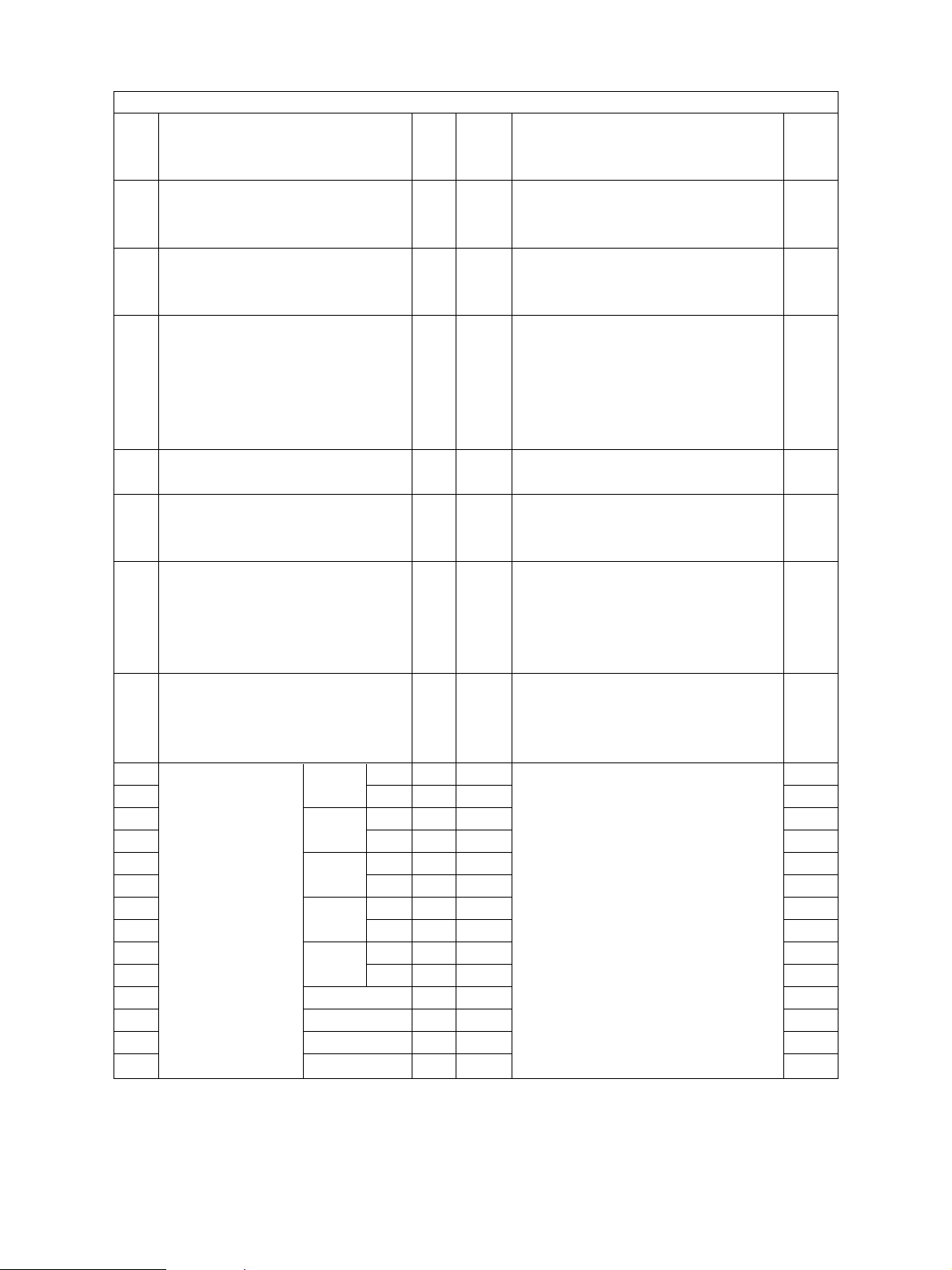

In the adjustment mode (05), the following adjustment items can be corrected, changed or checked.

*The numbers after hyphens under the code columns stand for sub-codes.

Adjustment mode (05)

Accep-

Code Description/Mode

104 Reproduction ratio adjustment of 128 1~255 When the value increases by 1, the re- 1

secondary-scanning direction production ratio in the secondary-scan-

(scanner section) ning direction (vertical paper feeding di-

105 Image location adjustment of 128 85~171 When the value increases by 1, the 1

secondary-scanning direction image shifts by approx. 0.1213mm to(scanner section) ward the trailing edge of the paper.

106 Image location For regular 180 5~251 When the value increases by 1, the 1

adjustment of prima- copy mode image shifts by approx. 0.042mm toward

ry-scanning direction the front side of the paper (machine).

108 (scanner section) For full image 133 5~251 When you enter a value,which is 47 1

copy mode steps (equivalent to 2mm) smaller than

135 RADF single-sided 8 0~15 Changes the position where the original 1

original stop position stops. When the value increases by 1,

136 two-sided 8 0~15 the original stop position shifts by 1mm 1

137 RADF sensor automatic adjustment – – By pressing the START key, WAIT is dis- 6

and EEPROM initialization played while the automatic adjustment

200 Automatic filling of All (Y, M, C, K) – 0~255 Fills the developer from the developer 5

201 developer material Y – 0~255 cartridge (about 3 min.) and then adjusts 5

202 and automatic ad- M – 0~255 the auto-toner sensor output to set in the 5

203 justment of the auto- C – 0~255 range of 3.50~4.50V (about 2 min.). 5

204 toner sensor K – 0~255 (As the value increases, the sensor out- 5

213 Display of auto-toner sensor output 0 0~1023 D isplays the auto-toner sensor output 10

Default

table Contents

Value

rection) increases by approx. 0.1522%.

the set value of [106], the rear original

edge and the front copy edge match

(0.042mm/step).

away from the original scale.

is performed. This adjustment should be

carried out when EEPROM, RADF PC

board or sensors are replaced.

put increases correspondingly.)

value.

Proce-

dure

FC-210/310

ERROR CODES AND SELF-DIAGNOSIS

1 - 20 February 2002 © TOSHIBA TEC

Page 27

Adjustment mode (05)

Accep-

Code Description/Mode

221 Automatic filling of Color (Y, M, C) – 0~255 Fills the developer from the developer 5

developer material cartridge (about 3 min.) and then adjusts

and automatic ad- the auto-toner sensor output to set in the

justment of the auto- range of 3.50~4.50V (about 2 min.).

toner sensor (As the value increases, the sensor out-

223 Developer bias DC (–) Y 136 0~255 As the value increases, the transformer 1

224 output adjustment M 136 0~255 output increases. The adjustment value 1

225 C 136 0~255 becomes effective only when the setting 1

226 K 136 0~255 mode (08-400,401,409) is 0 (disabled). 1

241 Main charger grid bias Y 120 0~255 As the value increases, the transformer 1

242 output adjustment M 120 0~255 output increases. The adjustment value 1

243 C 120 0~255 becomes effective only when the setting 1

244 K 120 0~255 mode (08-400,401,409) is 0 (disabled). 1

245 Automatic adjust- All (Y,M,C,K) – 0~255 Auto-toner sensor output is adjusted 5

246 ment of the auto- Y – 0~255 to set the output range within 3.50~ 5

247 toner sensor M – 0~255 4.50V automatically (about 2 min.). As 5

248 C – 0~255 the value increases, the sensor ouptut 5

249 K – 0~255 increases correspondingly.) (No deve- 5

250 Color (Y,M,C) – 0~255 loper filling is carried out.) 5

252-0 Main charger bias Y 250 0~999 Actual output voltage of main charger 4

252-1 output voltage 1 (lower) M 250 0~999 grid bias. After replacing the main high- 4

252-2 C 250 0~999 voltage transformer, enter the value ac- 4

252-3 K 250 0~999 cording to the supplementary data sheet. 4

253-0 Main charger bias Y 900 0~999 4

253-1 output voltage 2 (upper) M 900 0~999 4

253-2 C 900 0~999 4

253-3 K 900 0~999 4

257-0 Developer bias DC(-) Y 100 0~999 Actual output voltage of the developer 4

257-1 output voltage 1 (lower) M 100 0~999 bias. After replacing the main high- 4

257-2 C 100 0~999 voltage transformer, enter the value ac- 4

257-3 K 100 0~999 cording to the supplementary data sheet. 4

258-0 Developer bias DC(-) Y 700 0~999 4

258-1 output voltage 2 (upper) M 700 0~999 4

258-2 C 700 0~999 4

258-3 K 700 0~999 4

Default

table Contents

Value

put increases correspondingly.)

Proce-

dure

February 2002 © TOSHIBA TEC 1 - 21 FC-210/310

ERROR CODES AND SELF-DIAGNOSIS

Page 28

Adjustment mode (05)

Accep-

Code Description/Mode

318 Transfer bias

319 output adjust- mode / Thin M 59 0~255 set. The higher the value, the larger the 1

320 ment paper mode C 5 9 0~255 transformer output becomes. The adjust- 1

321 (Full color) K 59 0~255 ment value becomes effective only when 1

326

327 mode M 59 0~255 (disabled). 1

328 C 59 0~255 1

329 K 59 0~255 1

330 OHP mode Y 59 0~255 1

331 M 99 0~255 1

332 C 109 0~255 1

333 K 139 0~255 1

334 Thick paper 2 Y 69 0~255 1

335 mode M 69 0~255 1

336 C 69 0~255 1

337 K 69 0~255 1

356-0 Transfer bias

356-1 offset adjust- mode / Thin M 4 0~8 set. 4

356-2 ment paper mode C 4 0~8 0: -400V 1: -300V 2: -200V 4

356-3 K 4 0~8 3: -100V 4: 0V 5: +100V 4

357-0

357-1 mode M 4 0~8 4

357-2 C 4 0~8 4

357-3 K 4 0~8 4

358-0 Thick paper 2 Y 4 0~8 4

358-1 mode M 4 0~8 4

358-2 C 4 0~8 4

358-3 K 4 0~8 4

359-0 Thick paper 3 Y 4 0~8 4

359-1 mode M 4 0~8 4

359-2 C 4 0~8 4

359-3 K 4 0~8 4

360-0 OHP mode Y 4 0~8 4

360-1 M 4 0~8 4

360-2 C 4 0~8 4

360-3 K 4 0~8 4

Normal paper

Thick paper

Normal paper

Thick paper

1 Y 59 0~255 the setting mode (08-400,401,409)is 0 1

1 Y 4 0~8 6: +200V 7: +300V 8: +400V 4

Default

Y 59 0~255 The bias value of the transfer roller is 1

Y 4 0~8 The offset value of the transfer bias is 4

table Contents

Value

Proce-

dure

FC-210/310

ERROR CODES AND SELF-DIAGNOSIS

1 - 22 February 2002 © TOSHIBA TEC

Page 29

Adjustment mode (05)

Accep-

Code Description/Mode

361 Transfer bias Normal paper K 4 9 0~255 The bias value of the transfer roller is 1

output adjust- mode / Thin set. The higher the value, the larger the

ment (Black) paper mode transformer output becomes. This ad-

363 Thick paper 1 K 4 9 0~255 justment value becomes effective only 1

mode when the setting mode (08-400, 401,

364 OHP mode K 69 0~255 409) is 0 (disabled). 1

365 Thick paper 2 K 5 9 0~255 1

mode

367-0 Transfer bias output Y 589 0~5000 Actual output voltage of the transfer 4

367-1 voltage 1 (lower) M 589 0~5000 roller bias. After replacing the transfer 4

367-2 C 589 0~5000 transformer, enter the value according to 4

367-3 K 589 0~5000 the supplementary data sheet. 4

368-0 Transfer bias output Y 3929 0~5000 4

368-1 voltage 2 (upper) M 3929 0~5000 4

368-2 C 3929 0~5000 4

368-3 K 4715 0~5000 4

381 Transfer bias output Thick Y 89 0~255 The bias value of the transfer roller is 1

382 adjustment paper 3 M 89 0~255 set. The higher the value, the larger the 1

383 (Full color) mode C 89 0~255 transformer output becomes. The ad- 1

384 K 89 0~255 justment value becomes effective only 1

385 Transfer bias output Thick K 79 0~255 when the setting mode(08-400, 401, 1

adjustment paper 3 409) is 0 (disabled).

(Black) mode

391 Automatic removing Color (Y, M, C) – – The developer material in the developer 6

392 of developer mate- K – – unit is removed into the toner bag. 6

rial

400 Reproduction ratio adjustment of 1222 1209~ When the value increases by 1, the re- 1

primary-scanning direction 1235 production ratio in the primary-scanning

(Fine adjustment of polygonal motor direction (horizontal paper feeding di-

rotation speed) rection) decreases by approx. 0.082%.

401 Reproduction ratio adjustment of 1787 1608~ When the value increases by 1, the re- 1

secondary-scanning direction 1965 production ratio in the secondary-scan-

(Fine adjustment of drum motor/ ning direction (vertical paper feeding di-

transfer belt motor rotation speed) rection) decreases by approx. 0.074%.

Default

table Contents

Value

(If the values of this code 400 is changed, the values of code 05-401,402,403,

404,410 and 474 are optimized.)

(If the values of this code 401 is changed, the values of code 05-402,403,404,

410 and 474 are optimized.)

Proce-

dure

February 2002 © TOSHIBA TEC 1 - 23 FC-210/310

ERROR CODES AND SELF-DIAGNOSIS

Page 30

Adjustment mode (05)

Accep-

Code Description/Mode

402 Fine adjustment of 3767 0~ When the value increases by 1, the rota- 1

fuser motor rotation speed 65535 tion speed of fuser motor decreases

404 Fine adjustment of 9832 0~ When the value increases by 1, the rota- 1

feed motor rotation speed 65535 tion speed of the paper feed motor de-

406 Registration motor speed adjustment – – The paper transport speed of registra- 15

407 Forced performing of – – Performs the color registration control. 6

color registration control

408 Correction of fuser motor speed 0 0~20 In the thick paper 3 mode, when the 1

(For the Thick paper 3 mode ) value increases by 1, the fuser motor

410 Fine adjustment of 2853 2567~ When the value increases by 1, the re- 1

registration motor rotation speed 3138 gistration motor rotation speed decreases

428 Adjustment of image trailing edge 160 0~255 When the value increases by 1, the mar- 1

margin gin at the trailing edge along the paper

439 Paper aligning 1st Long 20 0~40 When the value increases by 1, the ali- 1

440 amount adjustment cassette Short 25 0~40 gning amount increases by about 1

441 2nd Long 20 0~40 0.8mm. 1

442 cassette Short 25 0~40 1

443 3rd Long 20 0~40 Notes: 1

444 cassette Short 25 0~40 Long (= Long size paper) : 1

445 4th Long 20 0~40 Paper length 330mm or longer 1

446 cassette Short 25 0~40 (A3/LD/A3 wide/FULL BLEED) 1

447 ADU Long 20 0~40 Short (= Short size paper) : 1

448 Short 25 0~40 Paper length 220mm ~ 329mm 1

449 LCF 25 0~40 1

450 Bypass feed 35 0~40 1

451 Thick paper 2 40 0~50 1

452 Thick paper 3 40 0~50 1

Default

table Contents

Value

by 0.026%.

creases by 0.023%.

tion roller in relation to the image printing speed is set at the optimum value.

(If the value of this code 406 is performed, the values of the code 05-404 and

410 are optimized.)

rotation speed decreases by 0.026%.

by 0.035%. (If the value of this code 410

is performed, the value of the code 05-404

is optimized.

feeding direction becomes narrower by

approx. 0.042mm.

Proce-

dure

FC-210/310

ERROR CODES AND SELF-DIAGNOSIS

1 - 24 February 2002 © TOSHIBA TEC

Page 31

Adjustment mode (05)

Accep-

Code Description/Mode

461 Color registration status display 0 0~255 The value of Y(0) shows the error status 10

470 Adjustment of primary-scan- K 100 0~255 When the value increases by 1, the im- 1

ning laser writing start position age shifts by approx. 0.042mm toward

474 Adjustment of secondary-scan- 8 1~15 When the value increases by 1, the im- 1

ning laser writing start position age shifts by approx. 0.6mm toward the

482 Reproduction ratio adjustment of 127 112~ When the value increases by 1, the re- 1

the primary-scanning direction 142 production ratio of the primary-scanning

(scanner section) direction (paper feeding in horizontal

491 Adjustment of the Thick paper 3 9 0~14 When the value increases by 1, the time 1

pushing amount bypass feeding period the bypass feed roller is driven

from behind when the paper has started to be trans-

492 Paper aligning amout adjustment 40 0~50 When the value increases by 1, the ali- 1

(OHP bypass feeding) gning amount increases by about

493 Adjustment of the OHP 9 0~14 When the value increases by 1, the time 1

pushing amount bypass feeding period the bypass feed roller is driven

from behind when the paper has started to be trans-

494 LCF 0 0~12 When the value increases by 1, the time 1

495 Thin paper 0 0~14 When the value increases by 1, the time 1

bypass feeding period the bypass feed roller is driven

496 Normal paper 9 0~14 when the paper has started to be trans- 1

bypass feeding ported from the registration section in-

497 Thick paper 1 9 0~14 creases by 7ms. 1

bypass feeding

498 Thick paper 2 9 0~14 1

bypass feeding

Default

table Contents

Value

of the color registration sensor.

0 / 16 or above: Normal

1~14: Data abnormal (sensor normal)

15: Color registration pattern reading

error

the right side of paper feed direction.

leading edge of paper feed direction.

direction) decreases by 0.082%.

ported from the registration section increases by 7ms.

0.8mm.

ported from the registration section increases by 7ms.

period the LCF feed roller is driven

when the paper has started to be transported from the pre-feed roller section increases by 50ms.

Proce-

dure

February 2002 © TOSHIBA TEC 1 - 25 FC-210/310

ERROR CODES AND SELF-DIAGNOSIS

Page 32

Adjustment mode (05)

Accep-

Code Description/Mode

550 Density

551 adjustment Text 128 0~255 made at center density become darker. 1

552 "Manual density"

553 fine adjustment Photo 128 0~255 1

554 (center setting) Map 128 0~255 1

555

556 Text 128 0~255 1

557

558 Photo 128 0~255 1

559 Map 128 0~255 1

560 Density

561 adjustment Text 20 0~255 made at the “dark” side become darker. 1

562 "Manual density"

563 fine adjustment Photo 20 0~255 1

564 (darker setting) Map 20 0~255 1

565

566 Text 20 0~255 1

567

568 Photo 20 0~255 1

569 Map 20 0~255 1

570 Density

571 adjustment Text 20 0~255 made at the “light” side become lighter. 1

572 "Manual density"

573 fine adjustment Photo 20 0~255 1

574 (lighter setting) Map 20 0~255 1

575

576 Text 20 0~255 1

577

578 Photo 20 0~255 1

579 Map 20 0~255 1

580 Density

581 adjustment Text 128 0~255 come darker. 1

582 "Automatic

583 density" fine Photo 128 0~255 1

584 adjustment Map 128 0~255 1

585

586 Text 128 0~255 1

587

588

589

Full color Text/Photo

Printed image

Black Text/Photo

Printed image

Full color Text/Photo

Printed image

Black Text/Photo

Printed image

Full color Text/Photo

Printed image

Black Text/Photo

Printed image

Full color Text/Photo

Printed image

Black Text/Photo

Printed image

Photo 128 0~255 1

Map 128 0~255 1

Default

table Contents

Value

128 0~255 When the value increases, images 1

128 0~255 1

128 0~255 1

128 0~255 1

20 0~255 When the value increases, images 1

20 0~255 1

20 0~255 1

20 0~255 1

20 0~255 When the value increases, images 1

20 0~255 1

20 0~255 1

20 0~255 1

128 0~255 When the value increases, images be- 1

128 0~255 1

128 0~255 1

128 0~255 1

Proce-

dure

FC-210/310

ERROR CODES AND SELF-DIAGNOSIS

1 - 26 February 2002 © TOSHIBA TEC

Page 33

Adjustment mode (05)

Accep-

Code Description/Mode

612 Adjustment of Normal paper 255 0~255 When the value decreases, images 1

613 maximum toner Thick paper 1 249 0~255 become lighter. 1

614 amount Thick paper 2 237 0~255 Note: When the value increases, image 1

615 Thick paper 3 237 0~255 offset may occur. 1

616 OHP 230 0~255 1

617 Thin paper 255 0~255 1

643 Automatic gamma adjustment – – Adjusts the gradation reproduction for 13

675 Judgment threshold for ACS 104 0~255 When the value increases, originals 1

678 AI mode setting Discrimination 0 0~4 Sets the operation mode of discrimina- 1

setting tion processing in AI mode.

682 Time-out 63 11~99 Sets the maximum amount of processing 1

setting time for image discrimination.

698 Offset

699 adjustment Text 128 0~255 ground becomes darker. 1

700 for background

701 processing Photo 128 0~255 1

702 (Adjustment of Map 128 0~255 1

703 background

704 density) Text 128 0~255 1

705

706 Photo 128 0~255 1

707 Map 128 0~255 1

Full color Text/Photo

Printed image

Black Text/Photo

Printed image

Default

table Contents

Value

each color Y, M, C, K.

tend to be judged as monochrome, and

when the value decreases, they tend to

be judged as color in Auto color mode.

0: Standard (for regular)

1: Photograph priority

2: Only judgment of original type

3: Only judgment of original type with

photograph priority

4: Discrimination is not performed in

AI mode.

Two digits are designated: the 1st digit is

A3/LD

for setting

git is for setting

128 0~255 When the value increases, the back- 1

128 0~255 1

128 0~255 1

128 0~255 1

original and the 2nd di-

A4/LT

original.

(unit: second)

Proce-

dure

February 2002 © TOSHIBA TEC 1 - 27 FC-210/310

ERROR CODES AND SELF-DIAGNOSIS

Page 34

Adjustment mode (05)

Accep-

Code Description/Mode

708 Offset adjust709 ment Text 128 0~255 comes darker. 1

710 for background

711 processing Photo 128 0~255 1

712 (Adjustment of Map 128 0~255 1

713 text density)

714 Text 128 0~255 1

715

716 Photo 128 0~255 1

717 Map 128 0~255 1

737 Sharpness

738 adjustment Text 0 0~31 becomes sharper. When the value 1

739

740 Photo 0 0~31 The smaller the value, the fewer the 1

741 Map 0 0~31 moire becomes. 1

742

743 Text 0 0~31 (center value). 1

744

745 Photo 0 0~31 1

746 Map 0 0~31 1

779-0 Color balance Text/ L 128 0~255 When the value increases, the target 4

779-1 adjustment Photo M 128 0~255 color, the original mode and the density 4

779-2 (Y) H 128 0~255 area become darker. 4

780-0 Text L 128 0~255 4

780-1 M 128 0~255 Notes: 4

780-2 H 128 0~255 L: Low density area 4

781-0 Printed L 128 0~255 M: Medium density area 4

781-1 image M 128 0~255 H: High density area 4

781-2 H 128 0~255 4

782-0 Photo L 128 0~255 4

782-1 M 128 0~255 4

782-2 H 128 0~255 4

783-0 Map L 128 0~255 4

783-1 M 128 0~255 4

783-2 H 128 0~255 4

Full color Text/Photo

Printed image

Black Text/Photo

Printed image

Full color Text/Photo

Printed image

Black Text/Photo

Printed image

Default

table Contents

Value

128 0~255 When the value increases, the text be- 1

128 0~255 1

128 0~255 1

128 0~255 1

0 0~31 When the value increases, the image 1

0 0~31 decreases, the image becomes softer. 1

0 0~31 *The default value 0 is equivalent to 16 1

0 0~31 1

Proce-

dure

FC-210/310

ERROR CODES AND SELF-DIAGNOSIS

1 - 28 February 2002 © TOSHIBA TEC

Page 35

Adjustment mode (05)

Accep-

Code Description/Mode

784-0 Color balance Text/ L 128 0~255 When the value increases, the target 4

784-1 adjustment Photo M 128 0~255 color, the original mode and the density 4

784-2 (M) H 128 0~255 area become darker. 4

785-0 Text L 128 0~255 4

785-1 M 128 0~255 Notes: 4

785-2 H 128 0~255 L: Low density area 4

786-0 Printed L 128 0~255 M: Medium density area 4

786-1 image M 128 0~255 H: High density area 4

786-2 H 128 0~255 4

787-0 Photo L 128 0~255 4

787-1 M 128 0~255 4

787-2 H 128 0~255 4

788-0 Map L 128 0~255 4

788-1 M 128 0~255 4

788-2 H 128 0~255 4

789-0 Color balance Text/ L 128 0~255 When the value increases, the target 4

789-1 adjustment Photo M 128 0~255 color, the original mode and the density 4

789-2 (C) H 128 0~255 area become darker. 4

790-0 Text L 128 0~255 4

790-1 M 128 0~255 Notes: 4

790-2 H 128 0~255 L: Low density area 4

791-0 Printed L 128 0~255 M: Medium density area 4

791-1 image M 128 0~255 H: High density area 4

791-2 H 128 0~255 4

792-0 Photo L 128 0~255 4

792-1 M 128 0~255 4

792-2 H 128 0~255 4

793-0 Map L 128 0~255 4

793-1 M 128 0~255 4

793-2 H 128 0~255 4

Default

table Contents

Value

Proce-

dure

February 2002 © TOSHIBA TEC 1 - 29 FC-210/310

ERROR CODES AND SELF-DIAGNOSIS

Page 36

Adjustment mode (05)

Accep-

Code Description/Mode

794-0 Color balance Text/ L 128 0~255 When the value increases, the target 4

794-1 adjustment Photo M 128 0~255 color, the original mode and the density 4

794-2 (K) H 128 0~255 area become darker. 4

795-0 Text L 128 0~255 4

795-1 M 128 0~255 Notes: 4

795-2 H 128 0~255 L: Low density area 4

796-0 Printed L 128 0~255 M: Medium density area 4

796-1 image M 128 0~255 H: High density area 4

796-2 H 128 0~255 4

797-0 Photo L 128 0~255 4

797-1 M 128 0~255 4

797-2 H 128 0~255 4

798-0 Map L 128 0~255 4

798-1 M 128 0~255 4

798-2 H 128 0~255 4

817 Output value display When the light – 0~1023 Displays the output value of image qua- 2

of image quality source is OFF lity sensor when the sensor light source

sensor is OFF.

818 Transfer belt – 0~1023 Displays the output value of image qua- 2

surface lity sensor (when there is no test pattern)

819 Low-density – 0~1023 Displays the output value of image qua- 10

pattern lity sensor when a low-density test pat-

820 High-density – 0~1023 Displays the output value of image qua- 10

pattern lity sensor when a high-density test pat-

821 Light amount adjustment results of – 0~255 This sensor's LED light amount adjust- 2

image quality sensor ment value is the reference value for

822 Output value Medium-density – 0~1023 Displays the output value of image qua- 10

display of image pattern lity sensor when a medium-density test

quality sensor pattern is written.

878 Forced performing of – – Performs the image quality control. 6

image quality control

879 Automatic initialization of – – Performs the image quality control and 6

image quality control restore the initial value.

912-0 Magazine sort/ A4-R/LT-R 0 -14~14 When the value increases by 1, the 4

912-1 fine adjustment of B4 0 -14~14 folding and stapling position shift by 4

912-2 folding and stapling A3/LD 0 -14~14 approx. 0.25mm toward the right page. 4

position

Default

table Contents

Value

on the transfer belt.

tern is written.

tern is written.

setting the reflected light amount from

the belt surface.

Proce-

dure

FC-210/310

ERROR CODES AND SELF-DIAGNOSIS

1 - 30 February 2002 © TOSHIBA TEC

Page 37

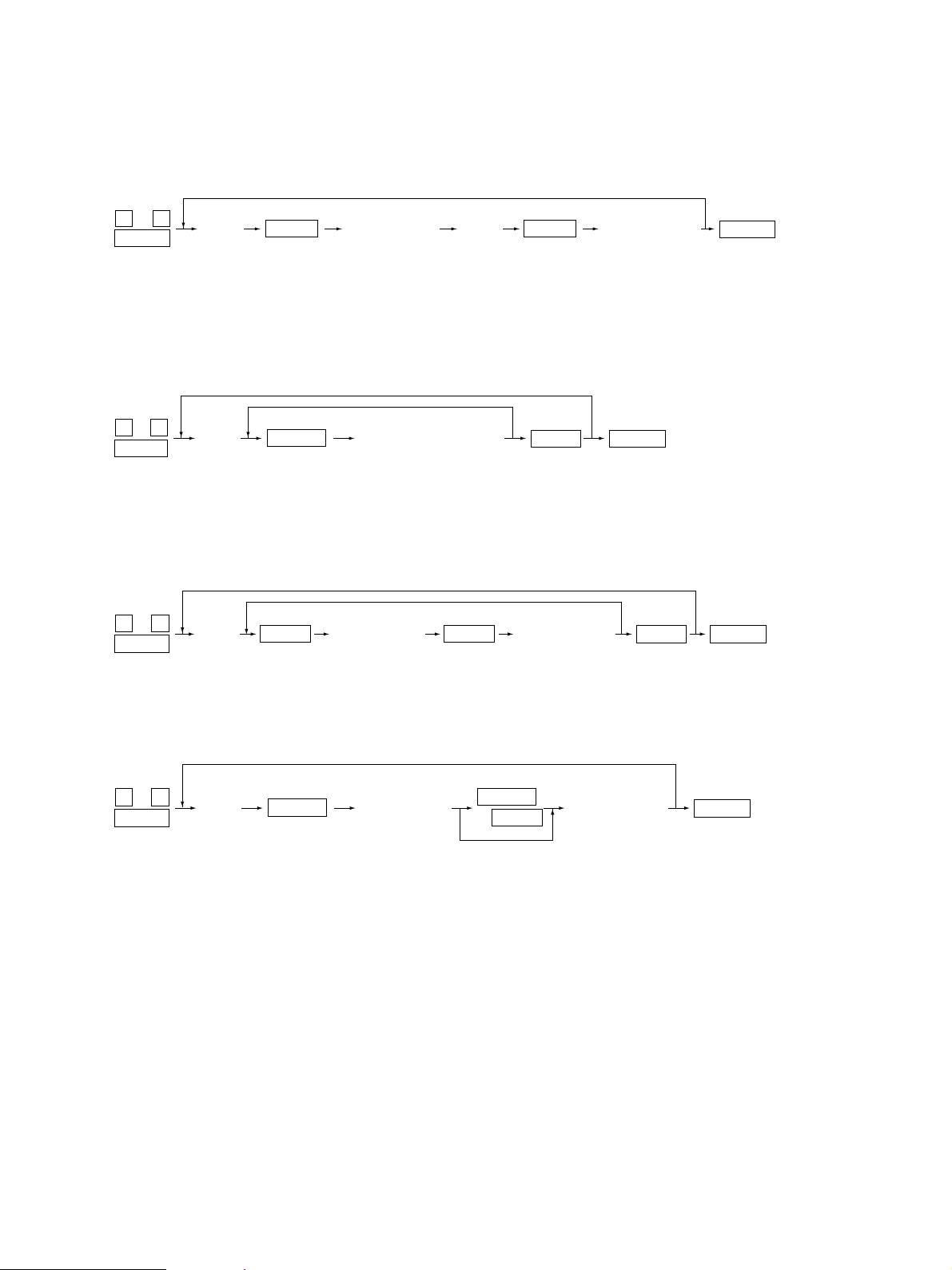

<Operation procedure>

Procedure 1

0 5

POWER

Procedure 2

0 5

POWER

(Code)

Procedure 4

0 5

POWER

(Code)

(Code)

CANCEL or

(For correction)

START

CANCEL

(For correction)

START

START START

CLEAR

or

CLEAR

(Set a value)

(A value

displayed)

(Sub-code) (Set a value)

SET INTERRUPTor

(Stored in memory)

SET INTERRUPTor

(Value changing

not allowed)

START

( ENERGY SAVER START )

( ENERGY SAVER START )

(Test copy)

( ENERGY SAVER START )

(Test copy)

SET INTERRUPTor

(Stored in memory)

(Test copy)

POWER OFF/ON

POWER OFF/ON

(Exit)

POWER OFF/ON

(Exit)

(Exit)

Procedure 5

0 5

POWER

(Code)

START

(Automatic

adjustment)

INTERRUPT

(Stored in memory)

February 2002 © TOSHIBA TEC 1 - 31 FC-210/310

( ENERGY SAVER START )

(Test copy)

POWER OFF/ON

(Exit)

ERROR CODES AND SELF-DIAGNOSIS

Page 38

Procedure 6

0 5

POWER

Procedure 10

0 5

POWER

Procedure 13

(Code)

(Code) (Sub-code)

START

START START

(Automatic

adjustment)

START

( ENERGY SAVER START )

(Test copy)

SET INTERRUPTor

(Value changing not allowed)

( ENERGY SAVER START )

(Test copy)

POWER OFF/ON

(Exit)

POWER OFF/ON

(Exit)

0 5

POWER

Procedure 15

0

5

POWER

(Code)

(Set 5 adjustment

charts for bypass)

START

(Image processing calculation)

STOP

(Code)

(Automatic

adjustment)

START

START

*Not acceptable

when error occurs.

( ENERGY SAVER START )

(Test copy)

(Automatic

adjustment)

(Jam or Error)

INTERRUPT

CLEAR

POWER OFF/ON

(Exit)

POWER OFF/ON

(Exit)(Stored in memory)

FC-210/310

ERROR CODES AND SELF-DIAGNOSIS

1 - 32 February 2002 © TOSHIBA TEC

Page 39

1. 2. 5 Setting mode (08)

The following items can be set or changed in this mode (08).

Setting mode (08)

Accep-

Code Name Default table Contents

value

200 Date and time setting – 13 digits Year/month/date/day/hour/minute/second 1

Example: 99:08:07:5:11:30:48

201 Destination selection EUR:0 0 ~ 2 0: Europe (A4/A3/Folio) 1

UC:1 1: USA/Canada (Letter/Ledger)

JPN:2 2: Japan (A4/B4)

202 Externally installed copy 0 0 ~ 3 0: No external copy counter/controller device 1

counter/controller device 1: Coin controller 2: Copy key card

3: Key copy counter

204 Auto-clear timer setting 3 0 ~ 10 When the [START] key is not pressed, the 1

time lag before automatic clearing works

clear settings to defaults.

0: Disabled 1 to 10: Set number x 15 seconds

205 Energy saver timer setting 0 0 ~ 15 Timer for switching to Energy Saver mode se- 1

lected in 08-618 when the copier is not used.

0: Disabled 1: 30sec. 2: 60sec.

3: 90sec. 4: 120sec. 5: 150sec.

6: 3min 7: 4min 8: 5min 9: 7min

10: 10min 11: 15min 12: 20min

13: 30min 14: 45min 15: 60min

206 Automatic shutoff timer setting 20 0 ~ 20 Timer for switching to automatic shutoff state 1

when the copier is not used. US Energy Star

Compliance

0: 3min 1: 5min 2: 10min 3: 15min

4: 20min 5: 25min 6: 30min

7: 40min 8: 50min 9: 60min

10: 70min 11: 80min 12: 90min

13: 100min 14: 110min 15: 120min

16: 150min 17: 180min 18: 210min

19: 240min 20: Disabled

209 Timer for print job start-up time 1 1 ~ 10 Sets the period the control panel is not ope- 1

from copy mode when auto- rated when the data of the printer function is

clear is disabled sent before the print job starts. This function

is enabled when the auto-clear timer setting

(08-204) is set as "0" (disabled).

(Set number x 15 seconds)

to

Proce-

dure

February 2002 © TOSHIBA TEC 1 - 33 FC-210/310

ERROR CODES AND SELF-DIAGNOSIS

Page 40

Setting mode (08)

Accep-

Code Name Default table Contents

value

217 Information of cassettes 15 0 ~ 15 0: 4 cassettes 1: 2 cassettes 2: 3 cassettes 1

installation 3: 4 cassettes 4: 1 cassette(Forcibly

installing OFF) 15: Automatic

220 Selection of language (UI) EUR:0 0 ~6 0: Language 1 1: Language 2 1

on the display panel UC:6 2: Language 3 3: Language 4

JPN:5 4: Language 5 5: Language 6

6: Language 7

Note: On the control panel,

EUR, JPN: language 1 to 6 are selectable.

UC: language 2 to 7 are selectable.

229 Paper size setting/ – 0~255 Paper size is selected with the icons on

bypass feed LCD.

230 Paper size setting/ EUR:A4 0~255 Paper size is selected with the icons on the 1

1st cassette UC:LT LCD.

JPN:A4

231 Paper size setting/ EUR:A3 0~255 Paper size is selected with the icons on the 1

2nd cassette UC:LD LCD.

JPN:A3

232 Paper size setting/

3rd cassette UC:LT-R LCD.

233 Paper size setting/ EUR:A4 0~255 Paper size is selected with the icons on the 1