Page 1

BSI(Service Note) TOSHIBA

.20.

.20.

TOSHIBA TEC CORPORATION

2-4-1, Shibakoen, Minato-ku, TOKYO, 105-8524 JAPAN

BSI No

F99K846

SUBJECT

Change of Saddle ROM

MODEL

CATEGORY

Other

From Jan. 2000

CONTENT

The part change has been made for the following reasons. The Service Manual content has

been altered in accordance with this change.

[Changed/Added Part No.]

P-I Before Change After Change Note P I R

28-3

P-I: Page-Item P: Content of Change I: Interchangeability R: Reason for Change

MJ1007

FACTORY APPLICATION

4402964090

PRA-502FIN-04

FIELD APPLICATION

Others

4402964100

PRA-502FIN-05

---- C B J Y

Date

99/12/02

UNIT

Software, Finisher

DTM-F9X10

FAA

[Label]

4F1-1150O

1.2.3.4.5.6.

7.8.9.10

4F1-1150O

1.2.3.4.5.6.

7.8.9.10

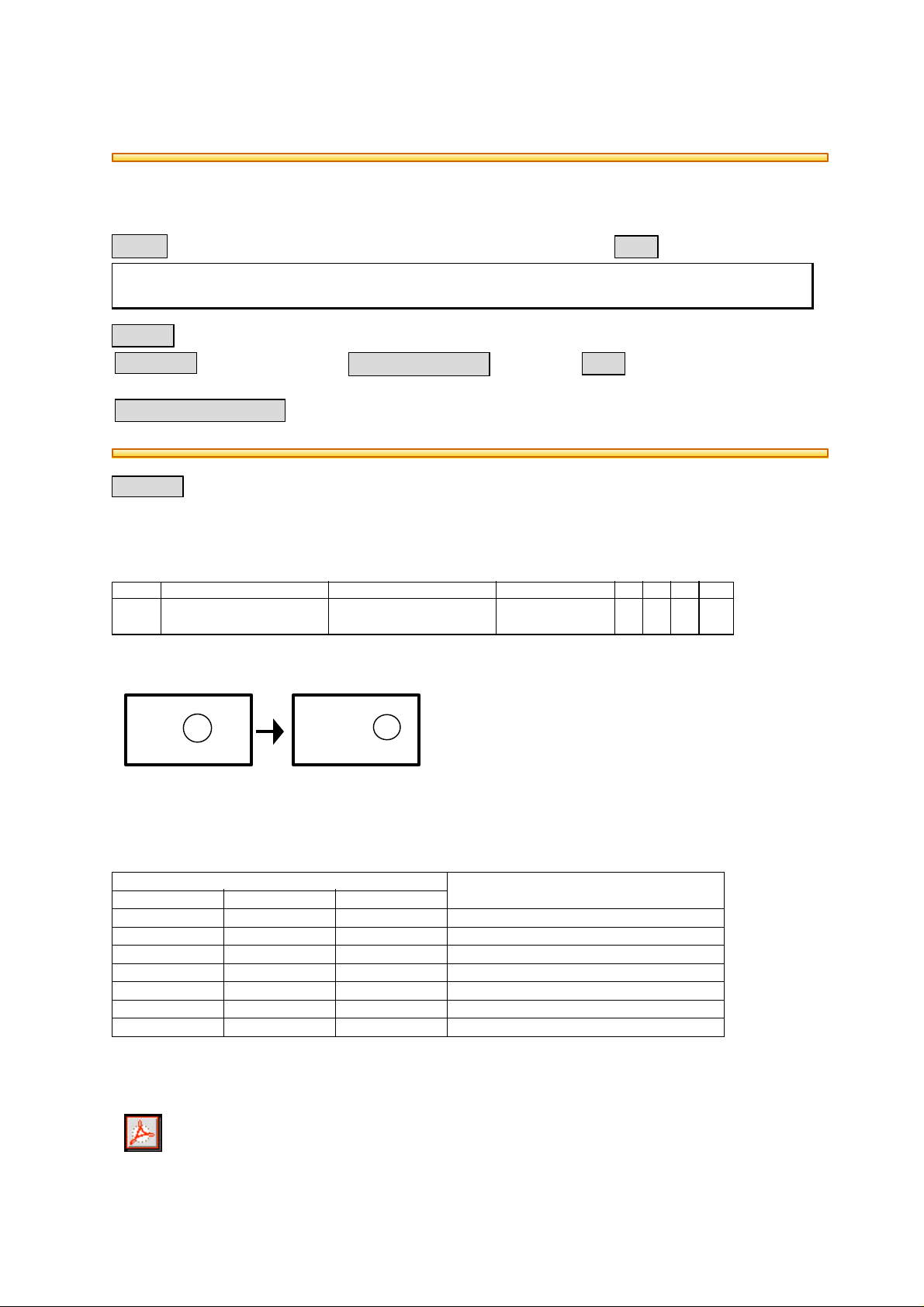

[Changed Contents]

The folding position adjustment values (staple position) of the saddle stitcher have been

changed from "per 1 step,

0.25 mm shift" to "per 1 step, 0.5 mm".

Bit setting of DIP_SW1

Bit 6 Bit 7 Bit 8

OFF ON ON +3 (+1.5 mm)

OFF ON OFF +2 (+1.0 mm)

OFF OFF ON +1 (+0.5 mm)

OFF OFF OFF 0

ON OFF ON -1 (-0.5 mm)

ON ON OFF -2 (-1.0 mm)

ON ON ON -3 (-1.5 mm)

Setting value

(Units of 0.5 mm)

[Changed Contents of Service Manual]

Some errors have been corrected as shown on the attached PDF type file. The corrected

points are shown shaded.

SM-E.pdf

Page 2

BSI No. F99K846 Page 2

Page 3

CHAPTER 6 TROUBLESHOOTING

• If for “negative width adjustment,”

set DIPSW1 so that the sum resulting from

addition of the interval to the appropriate

setting is provided.

For instance, if DIPSW1 is currently set to

-1 and the interval is -1 mm, set DIPSW1

to reflect +1.

Figure 6-116

9) By referring to Table 6-101 below, change

the settings of bits 6 through 8 on DIPSW1.

• If the width adjustment is ‘0’,

the stitching position and the folding position match, requiring no change.

• If for “positive width adjustment,”

Set DIPSW1 so that the difference resulting from subtraction of the interval from

the appropriate setting in Table 6-101 is

provided.

For instance, if the DIPSW1 is currently

set to +2 and the interval is +1 mm, set

DIPSW1 to reflect 0.

Table 6-101

10) Shift bits 1 through 4 on DIPSW1 to OFF .

2. Stitching Position (adjusting center stitching)

This adjustment should be carried out in

the copier’s user mode.

Refer to the copier’ s service manual for the

adjustment method.

3. Feed motor operation check

This mode is for driving the feed motor.

Figure 6-117

1) To start feed motor operation, press SW2.

Operation is controlled cyclically at the fol-

lowing speeds at each press of SW2.

(1) 170 mm/sec → (2) 420 mm/sec →

(3) stop → (1) and so forth

6-6

Loading...

Loading...