Page 1

BSI(Service Note) TOSHIBA

E_CH-6.pdf

TOSHIBA TEC CORPORATION

2-4-1, Shibakoen, Minato-ku, TOKYO, 105-8524 JAPAN

BSI No

F99I776

SUBJECT

Countermeasure to No Stapling

MODEL

CATEGORY

Treatment in the field

--------

CONTENT

[Phenomenon]

Paper may exit without being stapled though in the staple mode.

[Cause]

After the sheet is stapled on the stapling tray in the staple mode (the front and back of the stacked

sheets are aligned at the alignment plate on the rear side of the staple tray), stapling is performed and

the stacked sheets exit. If the alignment plate is over-aligned, the sheet becomes warped (the rising of

the center area), and the paper detection sensor on the staple tray goes OFF. It is then judged that t

here is no paper, and so stapling is not operated.

MJ1006, MJ1007

FIELD APPLICATION

To be applied when necessary

FACTORY APPLICATION

Date

UNIT

Finisher

99/09/22

----

[Countermeasure]

If the above occurs, carry out A-2 "Adjusting the Alignment Position" listed the following file, to adjust

the aligning quantity of the alignment plate suitably.

The sending file is the same as the file for BSI "F99E618". The shaded points were shown for the

changed contents of "F99E618" and are not related to this BSI.

[Sending file]

Page 2

I. ADJUSTMENTS

A. Electrical System (finisher

unit)

CHAPTER 6 TROUBLESHOOTING

1. Adjusting the Height Sensor (PS1)

Perform the following adjustments whenever you have replaced the finisher controller

PCB or the height sensor (PS1).

1) Set SW3 on the finisher controller as indi-

cated.

Figure 6-101

2) Put blank plain paper (A4 or LT) on all

trays.

3) Press SW2 on the finisher controller PCB.

A press causes the finisher to execute au-

tomatic adjustment, in which the tray unit

will shift tray 1 and then tray 2 in sequence.

• At the end of adjustment, trays will return

to home position.

• During adjustment, LED 1 flashes. At the

end of adjustment, LED1 turns and remains on.

• If automatic adjustment fails, the mechanism stops while the tray in question is

being adjusted. (At the same time, LED1

turns off.)

4) Shift all bits on SW3 to OFF*, and turn

off the copier once.

Figure 6-102

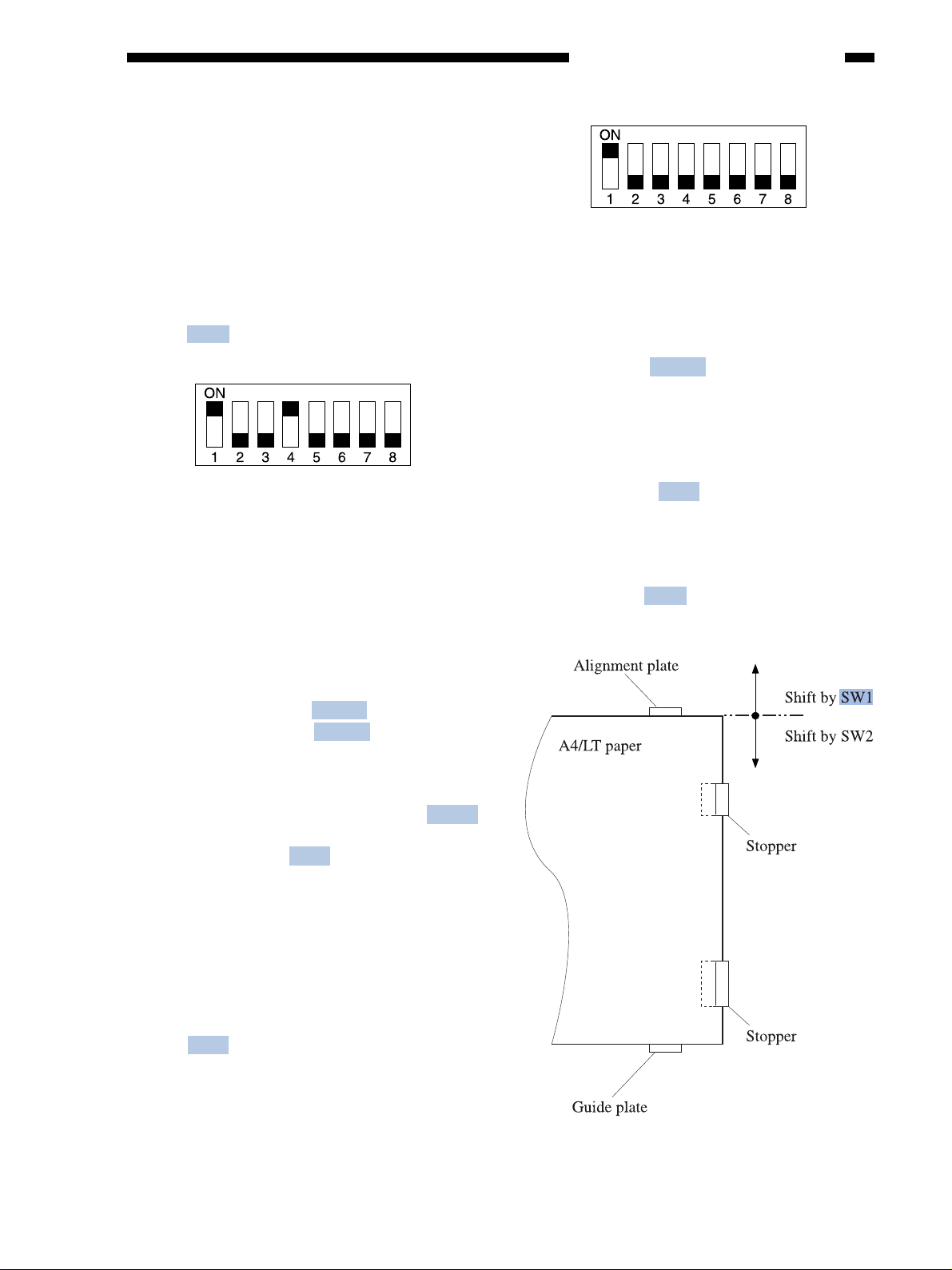

3) If you are using A4 paper, press SW2 on

the finisher controller PCB. If you are using L T paper , on the other hand, press SW1

on the finisher controller PCB.

• A press on SW2/1 will open the swing

guide and cause the alignment plate to

move to A4/LT position.

4) Place 10 sheets of A4/LT paper between

the alignment plate and the guide plate,

butting them against the stoppers.

5) Press SW2 or SW1 on the finisher controller PCB, and butt the alignment plate

against the sheets.

• A press on SW2 will shift the alignment

plate to the front in increments of 0.35 mm.

• A press on SW1 will shift the alignment

plate to the rear in increments of 0.35 mm.

2. Adjusting the Alignment Position

If you have replaced the finisher controller PCB or if an alignment fault occurs, make

the adjustments that follow. Performing the

steps will affect all paper sizes.

1) Remove the rear cov er of the finisher unit.

2) Set SW3 of the finisher controller PCB as

indicated.

Figure 6-103

6-1

Page 3

CHAPTER 6 TROUBLESHOO TING

6) Press SW2 and SW1 simultaneously to

store the adjustment value. (This will lo wer

the swinging guide.)

7) Shift all bits of SW3 to OFF*, and install

the rear cover of the finisher unit.

3. Adjusting the Stapling Position

(stapler movement range)

Make the adjustments that follow if you

have replaced the f inisher controller. Performing the steps will affect all paper sizes and all

stapling positions.

1) Remove the rear cover from the finisher

unit.

2) Set SW3 on the finisher controller PCB as

indicated.

Figure 6-104

3) If you are using A4 paper, press SW2 on

the finisher controller PCB. If you are using LT paper, press SW1 on the finisher

controller PCB.

• A press on SW2/1 will open the swing

guide and cause the feed belt to rotate.

4) Within 5 sec after pressing the switch, place

two sheets of A4/LT paper between the

alignment plate and the guide plate, butting it against the stoppers.

• When the finisher detects the paper , it will

lower the swing guide and execute stapling

(rear, 1-point). Take out the stapled paper

manually, however; deli very operation will

not be executed.

Figure 6-105

5) If the stapling position is correct, shift all

bits on SW3 to OFF* to end the adjustments. If you need to change the stapling

position, on the other hand, go to the next

step.

6) To suit the position of the staple on the

paper, press SW2 or SW1 on the finisher

controller PCB as many times as necessary .

• A press on SW2 will shift the stapling position to the front in increments of 0.3 mm.

• A press on SW1 will shift the stapling position to the rear in increments of 0.3 mm.

6-2

Page 4

Figure 6-106

7) Press SW2 and SW1 simultaneously.

• The press will open the swing guide, and

cause the feed belt to rotate. Placement of

two sheets of A4/LT paper will cause the

finisher to start stapling operation.

8) Check the stapling position. If good, shift

all bits of SW3 to OFF*. If readjustments

are necessary, go back to step 6).

CHAPTER 6 TROUBLESHOOTING

Tray shift time

Within a specific period of time:

LED 1 lights (normal).

When more than a specific period of

time:

LED 1 goes out (abnormal).

3) Likewise, when push-switch 1 is pressed,

the tray is lowered by one step. Note, however , that tray mo vement is canceled when

the current position is the lowest.

5. Delivery feeding speed check

Make sure that the deliv ery feeding speed

is 650 mm/sec or more with the delivery feeding motor fully ON.

Make sure that the deliver y feeding motor

can perform its required functions at all times.

1) Set the DIP switch settings on the Finisher

controller board as follows:

Note:

The settings held by the finisher controller

are changed as soon as SW2 or SW1 is

pressed. As such, to recover the previous

settings after the press, you must press the

other of the two switches as many times as

you pressed previously.

4. Tray shift time check

Make sure that the tray shift time is within

a specific period of time (under a load of 1500

sheets of A4 size paper of equivalent).

1) Set the DIP switch settings on the Finisher

controller board as follows:

Figure 6-107

Figure 6-108

2) When push-switch D is pressed, the delivery feeding motor operates, the number of

pulses from the encoder fed by the delivery feed motor is calculated, and LED 1

lights or goes out according to the following conditions:

Delivery feeding speed

When 650 mm/sec or less:

LED 1 lights (normal).

When less than 650 mm/sec:

LED 1 goes out (abnormal).

3) When push-switch 1 is pressed, checking

of the ability of the delivery feeding motor

to perform its functions is carried out.

2) When push-switch 2 is pressed, the time

required for tray shifting is calculated, and

LED 1 lights or goes out according to the

following conditions. Note, however, that

tray movement is canceled when the current position is the 2nd bin.

6-3

Page 5

CHAPTER 6 TROUBLESHOO TING

6. Aging mode

This mode is for simulated running of the

MJ-1006/1007.

Figure 6-109

1) To start the aging, press push-switch 2.

2) The bin is lowered to the lowermost position (home position).

3) From here on, the operation in each of the

operation modes is repeated. (To stop aging, press push-switch 2.)

7. Feed motor 1 operation check

This mode is for operating feed motor 1.

10. Switching of stacking capacity in

staple sort limit

Change of the stacking capacity in staple

sorting from 30 to 50 copies.

1) The stacking capacity in staple sorting is

increased to 50 copies by changing the DIP

switch settings on the Finisher controller

board.

Figure 6-111

Figure 6-110

1) T o start the operation of feed motor 1, press

push-switch 2.

2) T o stop the operation of feed motor 1, press

push-switch 1 again.

The operation is controlled cyclically at the

following speeds at each press of push-switch

2.

(1) 100 mm/sec → (2) 350 mm/sec →

(3) 650 mm/sec → (1) and so forth

8. Tray shift up check

The tray is raised. (Set all DIP switch set-

tings to OFF.)

1) To raise the trays, press push-switch 2.

2) Tray shifting is canceled when push-switch

2 at the tray 2 position.

9. Tray shift down check

The tray is lowered. (Set all DIP switch

settings to OFF.)

1) To lower the trays, press push-switch 1.

2) Tray shifting is canceled when push-switch

1 at the tray 1 position.

6-4

Figure 6-112

Note:

When the stacking capacity in staple sorting

exceeds 30 copies, stacking defects may

occur.

B. Electrical System (saddle

stitcher unit)

1. Adjusting the Folding Position

The folding position is adjusted by changing the settings of bits 6 through 8 of DIPSW1

on the saddle stitcher controller PCB so as to

match with the stitching position (i.e., adjusting the distance over which the paper positioning plate is moved to the folding position from

the stitching position).

If you have replaced the saddle stitcher

controller PCB, be sure to set the new DIPSW1

so the settings will be the same as those on the

old DIPSW1. If, for any reason, you must

change the folding position, perform the following steps:

Page 6

CHAPTER 6 TROUBLESHOOTING

C. Variable Resistors (VR), Light-Emitting Diodes (LED), and

Check Pins by PCB

Of the VRs, LEDs, and check pins used in the machine, those needed in the field are discussed

herein.

Note:

The VRs and check pins not discussed herein are for f actory use only . Making adjustments and checks

using these will require special tools and instruments and adjustments must be to high accuracy. Do

not touch them in the field.

1. Finisher Controller PCB

Figure 6-211

Table 6-211

6-21

Loading...

Loading...