Page 1

BSI(Service Note) TOSHIBA

TOSHIBA TEC CORPORATION

2-4-1, Shibakoen, Minato-ku, TOKYO, 105-8524 JAPAN

BSI No

F99I769

SUBJECT

Service Parts for Countermeasure to Prevent Pitch Line Problems

MODEL

CATEGORY

Other countermeasures

----------

CONTENT

In a machine used for a long time, there is a possibility that pitch line problems may occur. To prevent

this, parts with improved rigidity and coupling have been newly appointed as service parts for market

installation. Be sure to install them according to the "Instructions for setup".

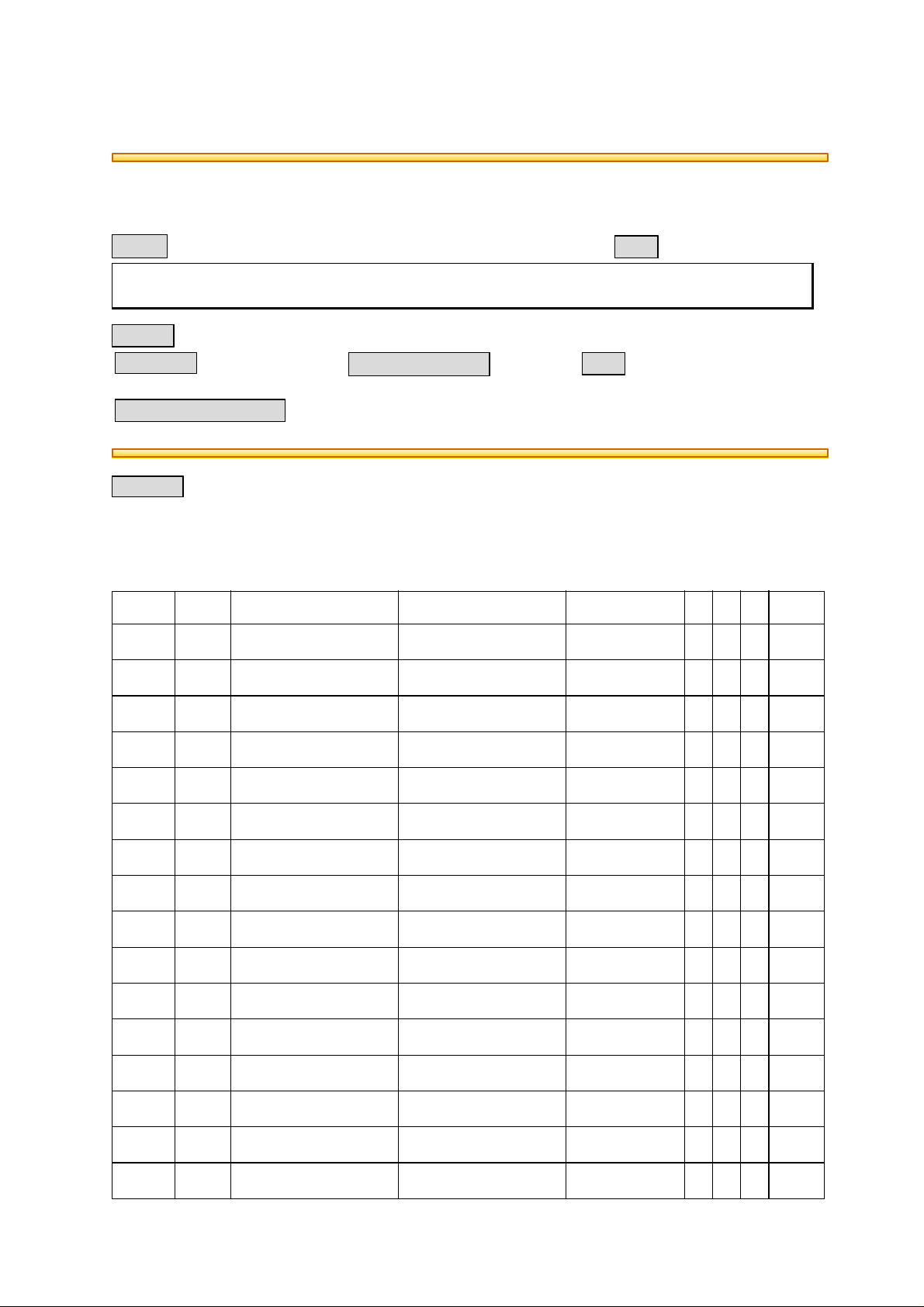

[Changed/Added Part No.]

Refer to

No.

FC70

FIELD APPLICATION

To be applied when necessary

FACTORY APPLICATION

P-I Before Change After Change Note P I R FAA

01 101-1 ---------- 4401922370

SHAFT

02 101-2 ---------- 4401922380

PLATE

03 101-3 ---------- 4401922390

GEAR100T

04 101-4 ---------- 4401922400

BUSHING

05 101-5 ---------- 4402417600

C-RING

06 101-6 ---------- 4401922410

BUSHING

07 101-7 ---------- 4401922420

COLLAR

08 101-8 ---------- 4401922430

PRESSURE SPRING

09 101-9 ---------- 4401922440

PLATE

10 101-10 ---------- 4401922450

HOLDER

11 101-11 ---------- 4401922460

FLYWHEEL ASSY

12 101-12 ---------- 4401922470

PRESSURE SPRING

13 101-13 ---------- 4402405810

HOLDER

14 101-14 ---------- 4402423670

SCREW

15 101-15 ---------- 4401922480

SCREW

16 101-16 ---------- 4402424030

SPRING WASHER

---- A - D -

---- A - D -

---- A - D -

---- A - D -

---- A - D -

---- A - D -

---- A - D -

---- A - D -

---- A - D -

---- A - D -

---- A - D -

---- A - D -

---- A - D -

---- A - D -

---- A - D -

---- A - D -

UNIT

Other

Date

99/10/04

1144-016-089

Page 2

BSI No. F99I769 Page 2

P-I: Page-Item P: Contents of Change I: Interchangeability R: Reasons for Change

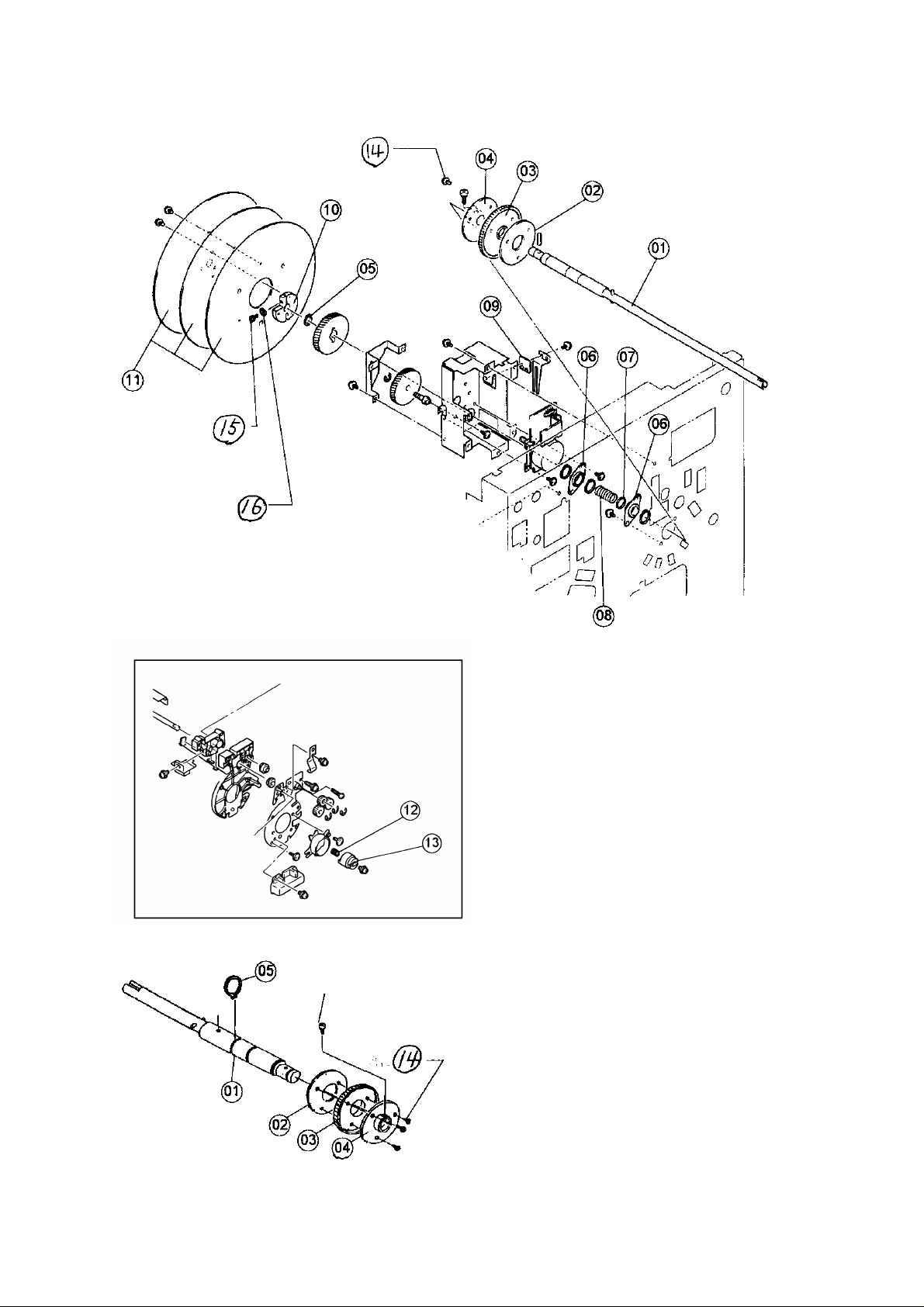

[Instructions for setup]

Stepped screw

Page 3

BSI No. F99I769 Page 3

After setting the plate (02), the gear (03) and the bushing (04) to the PC shaft (01), and screwing 1.

them with 3 screws (14), fix the step screw (Service Parts List Page 8 Item No.36 "4402406000").

Install the C-ring (05) to the PC shaft (01).2.

PC front frame

Installation screw

After inserting the PC shaft (01) to the bushing of the copier, temporarily fix the PC front frame.3.

Install the bushing (06), collar (07), the pressure spring (08) and C-ring (05).4.

PC rear frame

Earth plate

Remove the earth plate from the PC rear frame.5.

Fix with the plate (09) and the earth plate.6.

(Note) When there is insufficient grease, apply some grease. ("Conductive grease" can be used if

it is available locally.)

Replace the bushing (06).7.

PC rear frame

Temporarily fix the PC rear frame.8.

Tighten completely while pushing the PC rear frame in a straight direction.9.

Install the C-ring (05).10.

Page 4

BSI No. F99I769 Page 4

The C-ring must be slightly lower than center.

NO GOOD

Remove the PC front frame and reinstall.11.

(Note) Then, check that the PC front can be installed smoothly without any contact against the PC

shaft.

<When the frame cannot be installed smoothly>

1. Remove the bushing and check the position of the PC shaft (01).

2. When the PC shaft (01) is not fix at its correct home position, remove the PC rear frame and

start again from "8".

Parallel pin

PC outside gear

C-ring

Setting the parallel pin of the copier, install the PC outside gear and fix it with the C-ring. 12.

The installation holder of the fly wheel (10) is attached while pressing, and is fixed to the PC shaft 13.

with a bolt (15) and a washer (16).

C-ring

Page 5

PC outside gear

After the PC outside gear and the PC driving gear have been cleaned, apply sufficient grease. 14.

BSI No. F99I769 Page 5

PC driving gear

Install the fly wheel assembly (11) by means of 3 screws (14).15.

(Note) Check whether there is any rattling. If there is any, reinstall then.

PC unit

PC front frame

Charger unit assembly

Remove the PC front frame and install the PC unit.16.

Install the pressure spring (12) and the holder (13).17.

Reinstall all the removed parts.18.

Loading...

Loading...