Page 1

BSI(Service Note) TOSHIBA

TOSHIBA TEC CORPORATION

2-4-1, Shibakoen, Minato-ku, TOKYO, 105-8524 JAPAN

BSI No

F99E610

SUBJECT

Addition of Attaching Position (Automatic Original Feeder: ADF)

MODEL

CATEGORY

Correction of Service Manual

-

CONTENT

The attaching position connected with the following parts has been added.

Gasket (transfer belt unit) P.84-I.26 Countermeasure to electromagnetic waves

Discharge brush (paper feed area) P.81-I.59 Prevention of static electricity occurring during

Shield mylar (DF cover) P.85-I.40 Preventing connect with PC board and cover

Pad cushion P.81-I.60 Keeping the original-separation performance

Reverse area entrance mylar P.83-I.37 & 38 Preventing inserting into the gap between the

Reverse area side mylar P.83-I.39 & 40 Preventing the corners folding in Letter size

DP5570, DP6570

FIELD APPLICATION

Others

FACTORY APPLICATION

Part Name Parts List (P-1) Content

paper feeding

belt and the reverse guide

reverse operation

UNIT

ADF

Date

99/05/17

-

Service Manual

16. Automatic Document Feeder (ADF)

16. 12 Disassembly and Replacement

[V] Mylar sheet, etc.

[Addition]

Page 2

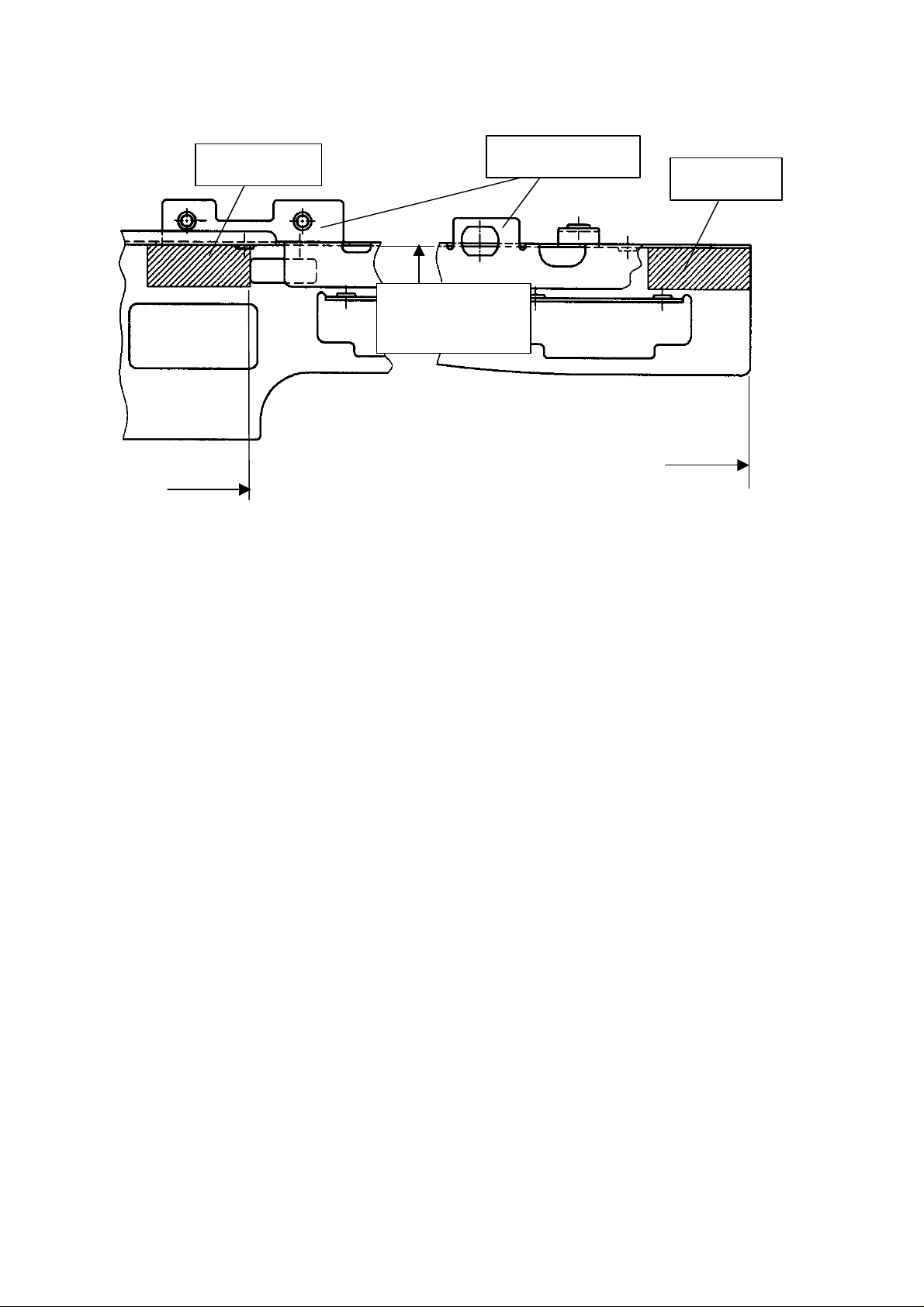

17. Gasket (transfer belt unit)

BSI No. F99E610 Page 2

Gasket

Window

FRAME-BELT-F

Aligning

Gap: 0 ~ 1mm

-0 ~ 1mm

Must not protrude

beyond the window

Must not protrude beyond

the edge of the frame

18. Discharge (Paper feeder area)

[Attaching Position]

Attach it to the two edge positions in GUIDE-ALGN-IN (A and B below).

Gasket

-0 ~ 1mm

Note 1. Insert the discharge brush between the FRM-FEED-794 and the GUIDE-ALGN-IN (rear side

only).

Note 2. To perform correctly Note 1, be sure to make the discharge brush rise up from the

GUIDE-ALGN-IN.

(Refer below.)

Page 3

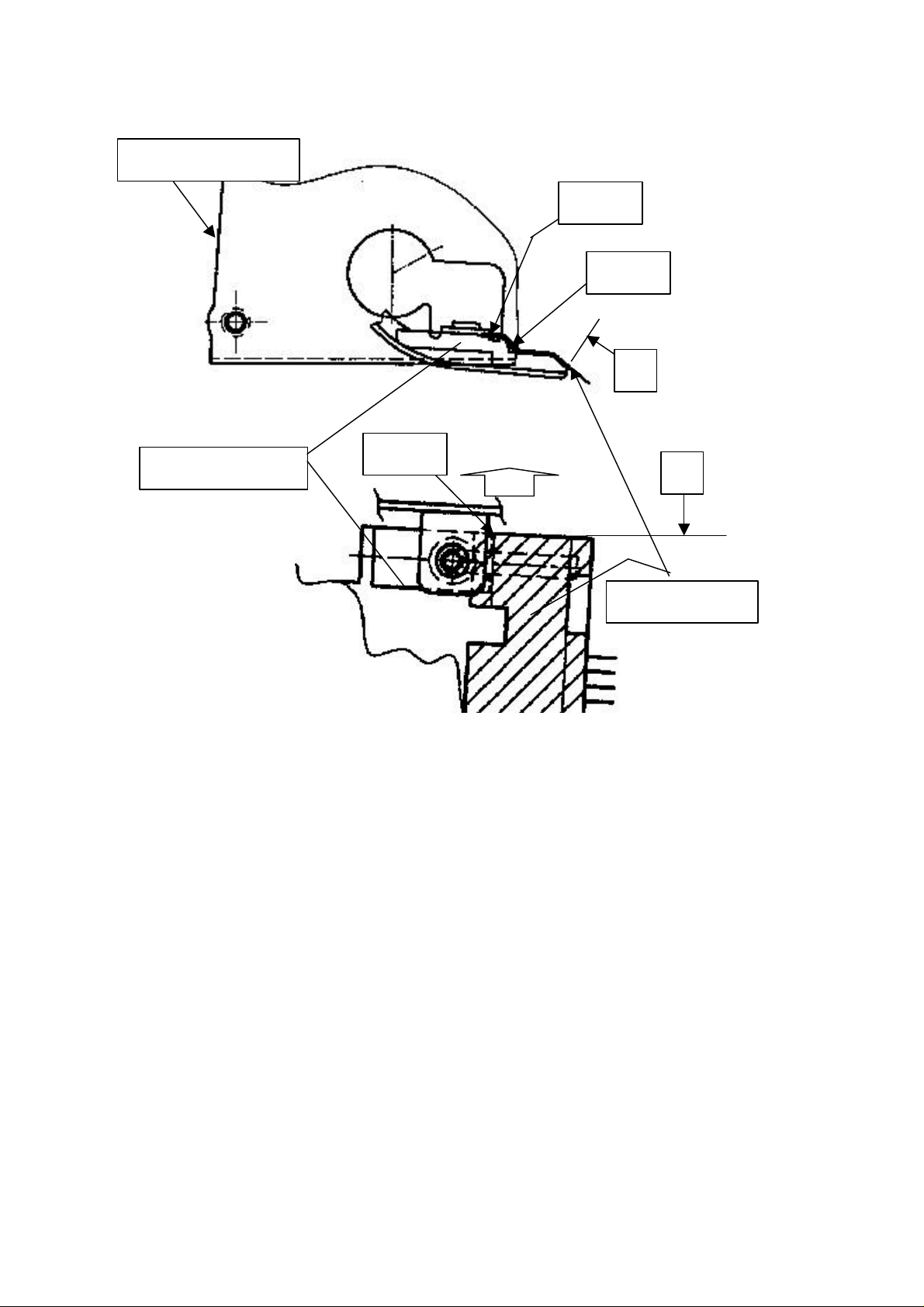

FRM-FEED-794-R

BSI No. F99E610 Page 3

Note 1

Note 2

A

GUIDE-ALGN-IN

Note 2

Rear side

B

Discharge brush

Page 4

19. Shield mylar (DF cover)

BSI No. F99E610 Page 4

0 ~ 1mm

20. Pad cushion

Aligning with rib

0 ~ 1mm

Aligning with rib

Shield mylar

COV-DF-794

(2.4 ~ 2.5)

Page 5

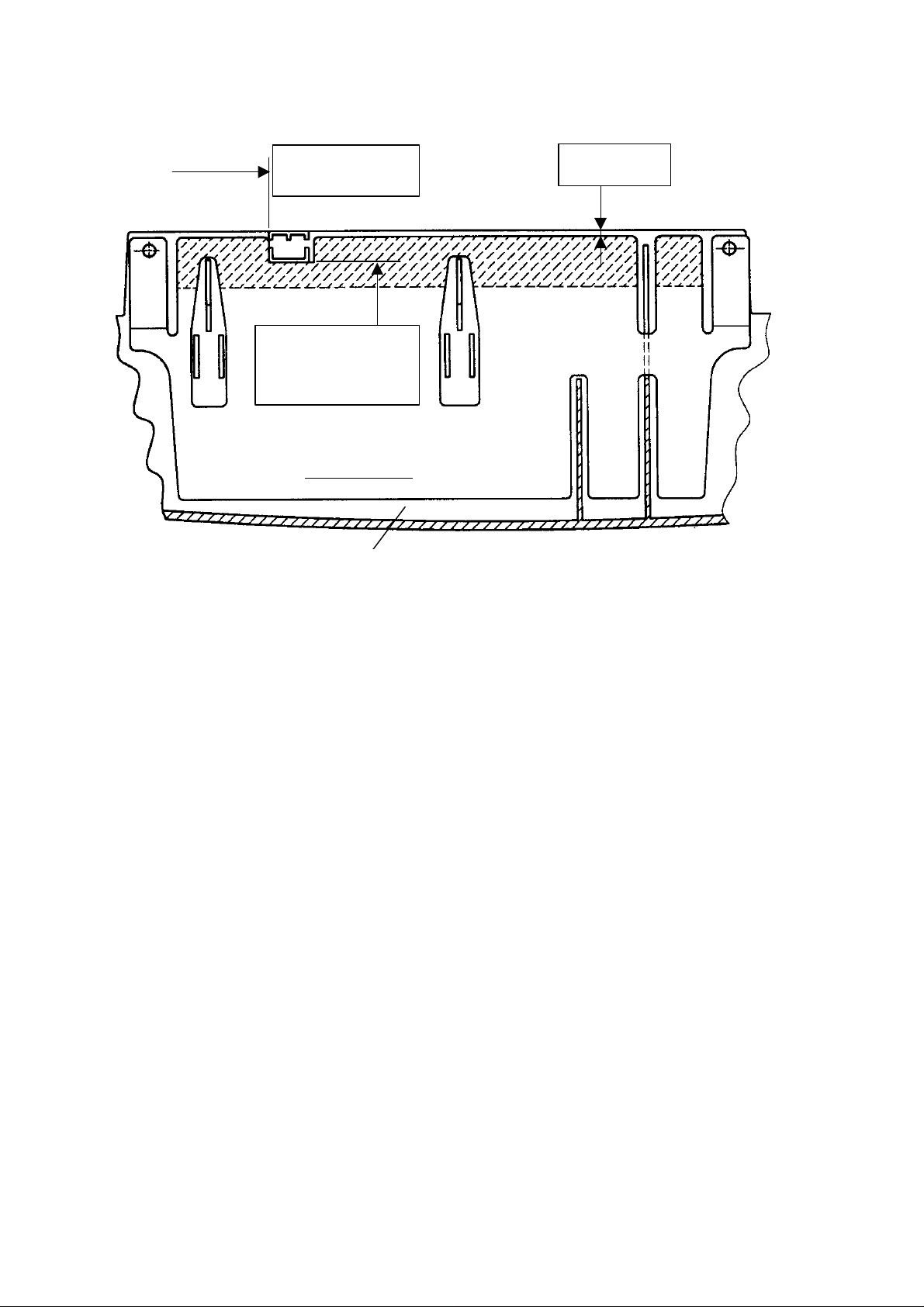

Pad cushion

BKT-PAD-SPT-794

Pad cushion

BSI No. F99E610 Page 5

0~1mm

Must not protrude beyond the bracket

21. Reverse section entrance mylar

0~1mm

Must not protrude beyond the bracket

Align and then attach

(Gap = 0~0.5mm)

Page 6

Unit: mm

BSI No. F99E610 Page 6

SHEET-RVS-M

BELT

22. Reverse section side mylar

1

0 ~ 1

+0.5

-0.5

0 ~ 1

0 ~ 0.5

MYLAR-RVS-M

SHEET-RVS-M

MYLAR-RVS-M

Not to protrude

Page 7

0~`0.5

Not to become stuck on the rib

MYLAR-RVS-U-R

MYLAR-RVS-U-F

0~`0.5

Not to become stuck on the rib

BSI No. F99E610 Page 7

Rounded corner end

+1

0

-1

View

Unit: mm

Loading...

Loading...