Page 1

BSI(Service Note) TOSHIBA

TOSHIBA TEC CORPORATION

2-4-1, Shibakoen, Minato-ku, TOKYO, 105-8524 JAPAN

BSI No

F99D591

SUBJECT

Correction to Service Handbook

MODEL

CATEGORY

Correction of Service Manual

-

CONTENT

Errors and omissions in the explanation have been found in the Service Handbook. This BSI is to

provide the necessary correction.

DP5570, DP6570

FIELD APPLICATION

Others

FACTORY APPLICATION

1. Adjustment

1.1 Error Codes

[Changes]

Main Points

* Elimination (EAD) and Addition (C46,E12) of error code

* Addition of reference items

* Alteration of Group

* Supplement and correction of content

The changed error codes list is attached as follows.

UNIT

Other

Date

99/04/27

-

error code.pdf

1.10.1 Adjustment

(1) Preparation for Measurement

1. Charging

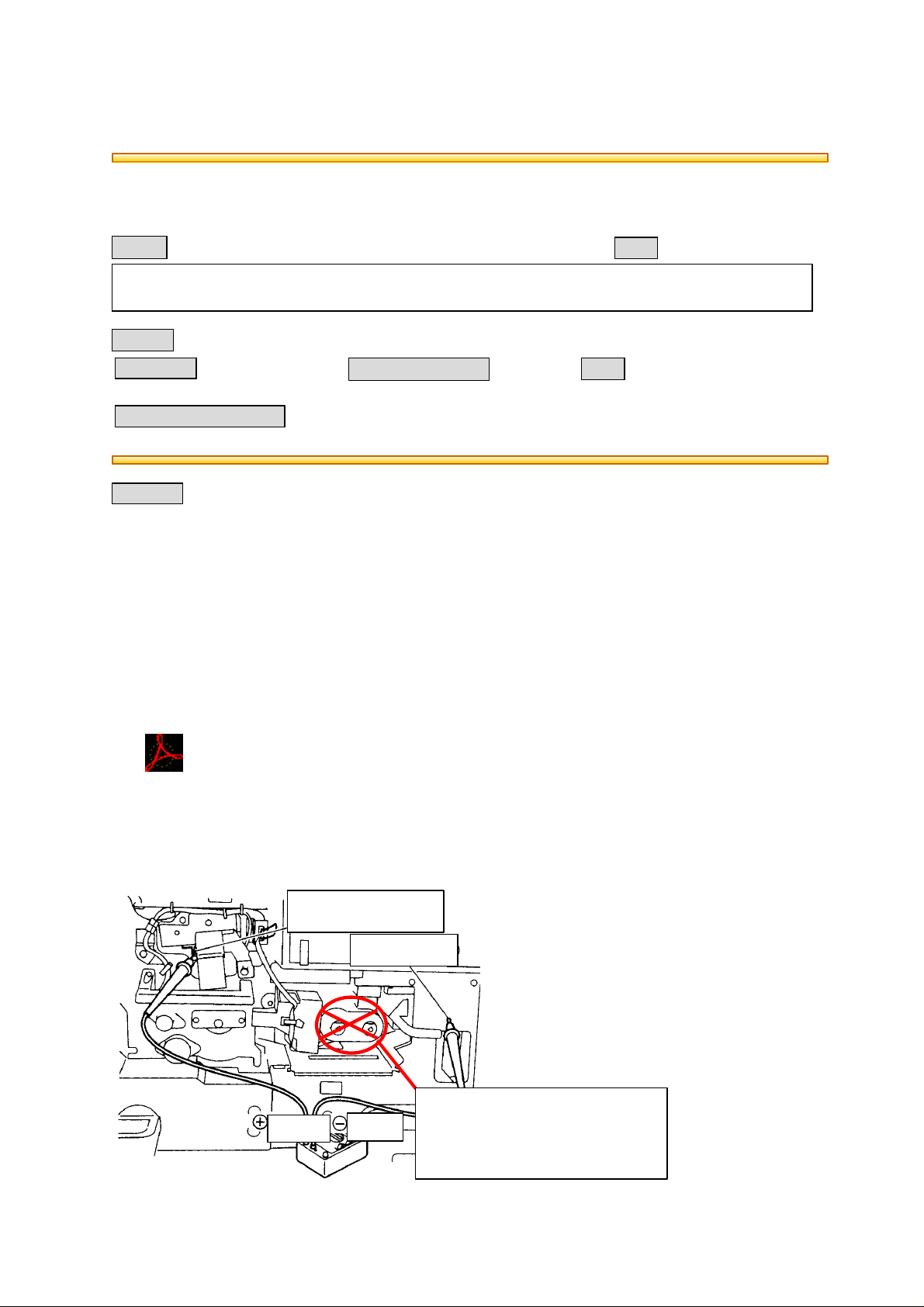

[Error]

Main charger rail

Terminal

Frame (ground

Remove the developer unit as

Terminal

described in the explanation.

(Illustration error)

)

Page 2

1.2.4 Adjustment Mode ("05")

[Error]

Code Name Mode Default Value Allowance

Value

335-0 Acceleration curve setting

(50~59%)

452-0 PFP middle cassette aligning

amount

(upper unit RGT section)

330mm~

456-0 PFP lower cassette aligning

amount (upper unit RGT

section) 330mm~

580 Automatic gamma

adjustment for error diffusion

[Error]

Error Item Corrected Content Available Code

Mode (Standard)

(Text/Photo)

Adjustment HPF strength setting

HPF strength setting in same reproduction

scale

ALL

ALL

ALL

PPC -

1

2

5

2

5

2

503,505,508,514,593,620,

620

0~2

0~31

0~31

BSI No. F99D591 Page 2

Operation

Procedure

Group

6

7

5

1.2.5 Setting Mode ("08")

[Error] [Error list]

Error Item Corrected Content Available

Code

Image Mode Photo/Text

Text/Photo

Remarks Standard

Text/Photo

503 Errors have been found in the list after

"1.6 item"

Photo/Text (error) ->

Text/Photo (correct)

550

1.5.2 Adjusting the printer section

(e) Image distortion adjustment

(3) Coat with screw locking agent after the image skew adjustment.

[Addition]

Screw locking agent

* 4406361350 BOND-1401E

* At the time purchase each can contains 1kg which is

quite a lot to carry around with you, so you should divide

up the amount into smaller containers.

Note

1.24 Fine Adjustment of Binding Position/Folding Position

[Addition]

By moving the paper positioning plate up or down, fine adjustment of the binding position/folding

position can be made.

Page 3

BSI No. F99D591 Page 3

Adjustment Code "05" - Code "468-0~2"

* Increasing the adjustment value shifts the binding position/folding position towards the right-hand

page by 0.25mm for each/step.

* Decreasing the adjustment value shifts the binding position/folding position towards the left-hand

page by 0.25mm for each/step.

Adjustment value=0 Adjustment value (+) Adjustment value (-)

Right-hand

page

Left-hand

page

Note

* When fine adjustment of the binding position/folding position is performed, the following result

should be obtained.

* When a book is made, to have it opening from the right: page 1 (see figure A below).

A A

Adjustment value (+) Adjustment value (-)

1.25 Adjustment of RADF Height

[Addition]

The adjustment screws attached to the hinge are to adjust the height of the gap between the glass

and the RADF.

(1) Adjustment screws:

If they are turned counterclockwise, the gap becomes narrower.

The adjustment screws are on the right hinge and the left hinge (2 places).

(2) The gap (arrow A) of the adjustment value is 0 ~ 0.5mm.

Page 4

BSI No. F99D591 Page 4

Adjustment screw

A A

DF spacer DF spacer

1.26 Flapper Solenoid Adjustment

[Addition]

(1) Push the flapper solenoid plunger by hand.

(This makes the solenoid able to be pulled in electrically.)

(2) Install BRKT-SOL-RVS so that it contacts with the flapper rubber and the flapper lever.

(3) Fix BRKT-SOL-RVS with the screw.

(4) With the solenoid pulled out, confirm that there is no gap between the flapper rubber and the

flapper lever.

Flapper lever

Plunger

Flapper rubber

Original glass

Screw

2. Periodical Maintenance

2.3 Periodic Inspection Check List

[Addition]

BRKT-SOL-RVS

Page 5

BSI No. F99D591 Page 5

Category Item to check Cleaning at

400,000

copies

(340,000

copies)

Scanner 21-1 Shading glass O <P.44-I.7>

Lubrication at

400,000

copies

(340,000

copies)

Replace

X 1,000

Check

while

on

Remarks

<Page-Item>

21-1

4. Troubleshooting

4.2 Process Line Service Calls

[Addition]

[C42] Drum thermistor disconnection

(1) Check the Drum thermistor connector (the relay connector is attached to the front frame of

Cleaner Unit)

* Thermistor broken?

* Is the connector disconnected?

* Is the Pin disconnected?

(2) Check the relay connector J728: the connector for the Cleaner Unit)

* Is the connector disconnected or about to become so?

* Is the pin disconnected out?

(3) Replace the LGC board

4.3 Fuser

[Addition]

[C46] Lower thermistor trouble (e.g. to do with the pressure roller) after having become ready

(1) Check the thermistor

* Are the connectors disconnected?

* Is the thermistor firmly contacting the pressure roller?

* Is the thermistor harness broken?

(2) Checking of the LGC board is the same as with [C41].

(3) Reset the status counter

* When [C46] occurs, reset the status counter 3 to 0 by the same procedure as for error [41].

4.4 Communication System Service Calls

[Addition]

[F07] SYS board-LGC board communication trouble

[F11] SYS board-SLG board communication trouble

(1) Check the connectors J102 and J108 on the SYS board for disconnection.

(2) Check the connector J330 on the LGC for disconnection.

(3) Check the connector J2 on the SLG board for disconnection.

(4) Check the harness between the SYS and the SLG for breaks and disconnected pins.

(5) Check the harness between the SYS and the LGC for breaks and disconnected pins.

(6) Check the FROM version on the SYS board.

Page 6

BSI No. F99D591 Page 6

(7) Check the MROM (IC36) version on the LGC board.

(8) Check the SROM version on the SLG board.

(9) Replace the SYS board.

(10) Replace the SLG board.

(11) Replace the LGC board.

4.5 ADF System Service Calls

[Addition]

[C76] Transmission time-out error

[C77] Transmission buffer full

[C78] ADF power ON I/F error

[C79] Reception time-out error

(1) Check the harness between the ADF control PC board and the scanner control PC board for

disconnections or breaks.

(2) Check mainly the IC2,IC3,IC14,CN1 on the ADF control PC board for breaks and short-circuits.

(3) Check mainly the IC1,IC7,J8 on the scanner control PC board for disconnections and

short-circuits.

(4) Replace the ADF control PC board.

(5) Replace the scanner control PC board (SLG board).

[C93] ADF original stop signal not received

(1) Check the harness between the ADF control PC board and the scanner control PC board for

disconnections and breaks.

(2) Check mainly the IC2,IC3,IC14,CN1 on the ADF control PC board for disconnections and

short-circuits.

(3) Check mainly the IC1,IC7, J8 on the scanner control PC board for disconnections and

short-circuits.

(4) Check whether the ADF aligning sensor and the ADF timing sensor are detecting normally or not.

(5) Replace the ADF control PC board.

(6) Replace the scanner control PC board.

4.7 Others Trouble Service Calls

[Addition]

[CD1] Brush motor lock error

(1) Check whether the fur brush has become locked mechanically.

* Are there any foreign objects?

* Are there any toner clumps in the transport section?

(2) Check whether connectors on the LGC board have become removed or the pins disconnected,

etc..

(3) Replace the brush motor.

(4) Replace the LGC board.

[CD2] Auger motor lock error

(1) Check whether the auger has become locked mechanically.

* Are there any foreign objects?

* Are there any toner clumps in the transport section?

(2) Check whether connectors on the LGC board have become removed or the pins disconnected,

etc..

(3) Replace the auger motor.

(4) Replace the LGC board.

[F10] HDD formatting malfunction

(1) Perform the "HDD formatting" (Setting Mode: 08 -> 690 -> 2).

(2) Make sure that the HDD is mounted.

(3) Make sure that a dedicated HDD is mounted.

(4) Make sure that the HDD connector pins are not bent.

Page 7

BSI No. F99D591 Page 7

(5) Check HDD connector J106 on the SYS board for disconnection.

(6) Replace the harness.

(7) Replace the HDD.

(8) Replace the SYS board.

4.9 Finisher System Service Calls

[Addition]

[CCO] Sensor connector connection error: [Procedure 1]

Is the guide home position sensor (P13S) or saddle stitcher controller board connector connected?

YES

Is there a disconnection between the sensor and the saddle stitcher?

YES

Is DC5V being supplied from J9-7 on the saddle stitcher control board?

YES

Is J9-8 of the saddle stitcher controller board correctly connected to the ground?

YES

END

[CCO] Sensor connector connection error: CCO [Procedure 2]

Is the connector of the paper pressing plate home position sensor (P14S) or the connector of the

saddle stitch controller board connected?

YES

Is the connector between the sensor and the stitcher disconnected?

YES

Is DC5V from J9-10 of the saddle stitcher controller board supplied?

NO

Connect the connector.

NO

Correct this.

NO

Replace the saddle stitcher controller board.

NO

Replace the saddle stitcher controller board.

NO

Connect the connector.

NO

Correct.

YES

Is J9-11 of the saddle stitcher controller board correctly connected to the ground?

YES

END

[CC0] Sensor connector connection error: [Procedure 3]

Is the connector of the paper pressing edge position (P15S) or the saddle stitcher controller board

connected?

YES

Is the connection between the sensor and the saddle stitcher disconnected?

YES

Is DC5V from J9-13 of the saddle stitcher controller board supplied?

YES

Is J9-4 on the saddle stitcher controller board correctly connected to the ground?

NO

Replace the saddle stitcher controller board.

NO

Replace the saddle stitcher controller board.

NO

Connect the connector.

NO

Correct.

NO

Replace the saddle stitcher controller board.

Page 8

BSI No. F99D591 Page 8

YES

END

[CC1] Microswitch malfunction: [Procedure 1]

Check the switch actuator in the entrance door. Are the switch and the sensor being moved correctly

?

YES

Check the entrance door switch. Is the switch normal?

YES

Measure the J1-8 voltage on the saddle stitcher controller board when the entrance door is open.

Is there 5V being supplied?

YES

Measure the voltage across J19-2 (+) and J19-2 (-) on the saddle stitcher controller board. Is 24 V?

YES

Check and correct the wiring between J19 and J1 of the saddle stitcher controller board and replace

the saddle stitcher controller board if the wiring is normal.

NO

Replace the saddle stitcher controller board.

NO

Correct the mechanism.

NO

Replace the switch.

NO

The sensor is broken, so replace it.

NO

Replace the saddle stitcher controller board.

[CC1] Microswitch malfunction: [Procedure 2]

Check the switch actuator of the front door. Are the switch and the sensor being moved correctly?

YES

Check the front door switch. Is the switch normal?

YES

Measure J11-12 voltage access of the saddle switcher controller with the front door open. Is 5V being

supplied?

YES

Replace the saddle stitcher controller board.

[CC1] Microswitch malfunction: [Procedure 3]

Check the switch actuator of the exit door. Are the switch and the sensor being moved correctly?

YES

Check the exit door switch. Is the switch normal?

YES

Measure J11-9 voltage access of the saddle stitcher when the exit door is open. Is it 5V ?

YES

Replace the saddle stitcher controller board.

NO

Correct the mechanism.

NO

Replace the switch.

NO

The sensor is broken, so replace it.

NO

Correct the mechanism.

NO

Replace the switch.

NO

The sensor is broken, so replace it.

[CC2] Communication error between finisher saddle

Does turning the power switch on the main unit OFF and then ON again rectify the trouble?

YES

NO

END

Page 9

BSI No. F99D591 Page 9

Is the wiring between the finisher controller board and the saddle stitcher board normal?

YES

Measure the voltage access between J3-2 (+) on the finisher controller board and J3-1 (-). Is it DC

24V?

YES

Replace the saddle stitcher controller board.

[Elimination of following two items]

4.10 Optional Attachment System Service Calls

4.11 SM Communication Trouble Service Calls

NO

Correct.

NO

Replace the finisher controller board.

Page 10

Group Error code Machine status

Transporting jam inside the

copier 1

Paper feeding jam

Transport jam from feed for

RGT

opened during copying

ADU reversal section transport

line jam

Original tr an sporting ja m at the

ADF

Paper jam at the fin ish er

E01 Fuser exit switch non-arrival jam

E02 Fuser exit switch accumulation jam

E03

E09

Paper remaining inside the copier at power ON

Jam caused by HDD error

E0A Image transport ready timeout

(Image data transport error between SYS board and PLG

board)

E12 Bypass feeding jam

E15 PFP 1st cassette feeding jam

E16 PFP 2nd cassette feeding jam

E17 PFP 3rd cassette feeding jam

E19 LCF feeding jam

PFP transport jam (non-arrival at RGT)

E31

E32

E33

E31:During upper cassette feed

E32:During middle cassette feed

E33:During lower cassette feed

PFP transport jam PFP

E34

E35

E36

E31:During upper cassette feed

E32:During middle cassette feed

E33:During lower cassette feed

E41 Copier front cover is opened during copyingPaper jam if some cov er is

E47 Exit jam processing cover is opened during copying

E51 ADU RGT non-arrival

E51 ADU transport TR1 non-arrival

E52 ADU transport TR2 non-arrival

E53 PFP upper cassette RGT non-arrival (from ADU feed)

E54 ADU feed non-arrival

E55 Paper on transport path at copy end

E56 Paper on PFP transport path after door open/close

E57 Reversal switch non-arrival jam

E58 Reversal switch accumulation jam

E59 Exit switch accumulation jam

E5A Exit switch non-arrival jam

E5B ADU transport start timeout jam

E71 Original feeding jam at the feed section of the ADF

E72 Original transporting jam at the transport section of

the ADF

E73 Original exiting jam at the exit section of the ADF

EA1 Transporting delay jam

EA2 Transporting stationary jam

EA3 Jam at power ON

EA4 Door open jam

EA5 Staple jam

EA6 Early arrival jam

Reference

Page 11

Group Error code Machine status

Paper jam at the fin ish er

Service call from the optical

system

Service call from the process

Fuser related

Service call from

communication

Service call ADF

EA8 Finisher saddle staple jam

EA9 Finisher saddle door open jam

EAA Finisher saddle power ON jam

EAB Finisher saddle transport accumulation jam

EAC Finisher saddle transport delay jam

EAE Finisher receive time-out jam

Paper cannot be detected from the copier in a fixed-time

.

EB3 Finisher ready time-out error

(Finisher cannot prepare for receiving the paper after the

leading edge of the paper reaches to RGT in a fixed-time.)

EB5Copier transport jam 2

EB6

C26 Peak detection error

C27 Home switch does not turn OFF

C28 Home switch does not turn ON

C29

C36 Charger cleaning operation error

C37 Transfer belt operation error

C42 Drum thermistor disconnection

C41 Abnormal thermistor or heater disconnection at power

Double jam

(Residence jam occurs because of the double paper is separated

in paper feeding.)

Scanner disconnection detection

4.1

4.1

4.1

4.1

4.2

4.2

4.2

4.3

ON

C43 Warming up mode after disconnection judgment, or

4.3

abnormal thermistor after ready

C44

C45

C46

Warm-up time after detected disconnection or heater

disconnection after ready

Thermistor disconnection at HTR edge portion

Lower thermistor (press roller) error after ready (Low

temperature is detected because of disconnection or conn ect or

omission.)

C56 Communication error between PFC and MCPU

C57 Communication error between MCPU and IPC

C58 Communication error between IPC and the finisher

C59 Communications error between MCPU and LCPU

F07 Communications error between SYS and LGC boards.

4.3

4.3

4.3

4.4

4.4

4.4

4.4

4.4

F11 Communications error between SYS and SLG boards 4.4

C72 Defective adjustment by the aligning sensor detected

C73 EEPROM defect i v e ini tial iza tio n

C74 Defective adjustment by the exit/reversal sensor

4.5

4.5

4.5

detected

C76 Transmission time-out error

C77 Transmission buffer full

C78 ADF power ON I/F error

C79 Reception time-out error

C80 Defective adjustment of ADF timing sensor

4.5

C93 ADF original stop signal not received

Reference

Page 12

Group Error code Machine status

Service call from the laser optical

Service call from the finisher

Service call from the others

CA1 Polygonal motor is abnormal

CA2 HSYNC is abnormal

CA3 Secondary scanning rough adjustment error

CA4 Primary scanning counter load error

CA5 Laser power adjustment error

CA6 Laser PWM calibration error

CA9 Image data transfer malfunction from SYS board

CAA Secondary scanning fine adjustment error

CAB Secondary scanning inter-page compensation error

CAC Primary scanning dot adjustment error

CAD Primary scanning tap adjustment error

CAE Primary scanning tap amount measurement error

CAF Primary scanning inter-page compensation error

CD0 Laser initialize time-out error

CB1 Transport motor is abnormal

CB2 Exit motor is abnormal

CB3 Tray elevation motor is abnormal

CB4 Alignment motor is a bn or mal

CB5 Staple motor is abnorma l

CB6 Staple unit shift motor is abnormal

CB7 Stacking sensor is abnormal

CB8 Backup RAM data is abnormal

CB9 Saddle thrust motor is abnormal

CBA Saddle front staple motor is abnormal

CBB Saddle inner staple motor is abnormal

CBC Saddle align men t mo to r is abn or ma l

CBD Saddle guide motor is abnormal

CBE Saddle fold motor is abnormal

CBF Saddle positioning plate motor is abnormal

CC0 Sensor connector connection error

CC1 Microswitch error

CC2 Communications error between finisher saddle

C92 Power abnormality interrupt error

C94 MCPU is abnormal

C99 PFC microcomputer is abnormal

CD1 Brush motor lock error

CD2 Auger motor lock error

F10 HDD formatting error

Reference

4.8

4.8

4.8

4.8

4.8

4.8

4.8

4.8

4.8

4.8

4.8

4.8

4.8

4.8

4.9

4.9

4.9

4.9

4.9

4.9

4.9

4.9

4.9

4.9

4.9

4.9

4.9

4.9

4.9

4.7

4.7

4.7

4.7

4.7

4.7

Loading...

Loading...