Page 1

BSI(Service Note) TOSHIBA

TOSHIBA TEC CORPORATION

2-4-1, Shibakoen, Minato-ku, TOKYO, 105-8524 JAPAN

BSI No

F99B532

SUBJECT

Countermeasure to Pick-up Errors in Bypass Feeding

MODEL

CATEGORY

Other countermeasures

From Jan. 1998

CONTENT

[Countermeasure]

During bypass feeding, the lowering operation may stop before the pick-up roller reaches the sheets

stacked on bypass. The result is that the sheets cannot be fed. (bypass pick-up error)

[Cause]

The bypass pick-up roller has usually been attached to the upper position.

* The paper feed roller rotates at the same time as the start of feeding.

* The bypass pick-up roller is lowered by the rotation of the bypass paper feed roller.

* The lowering operation is stopped by releasing the spring clutch.

The lowering operation is performed as stated above.

1560, 2060, 2860, 2870, 3560, 3570

FIELD APPLICATION

To be applied when necessary

FACTORY APPLICATION

Date

UNIT

Feeder

99/03/15

DTM-F7Z06

At almost the same time as the bypass pick-up roller contacts the sheet, the lowering operation is

stopped. As a result, the pick-up roller cannot completely contact on the sheet.

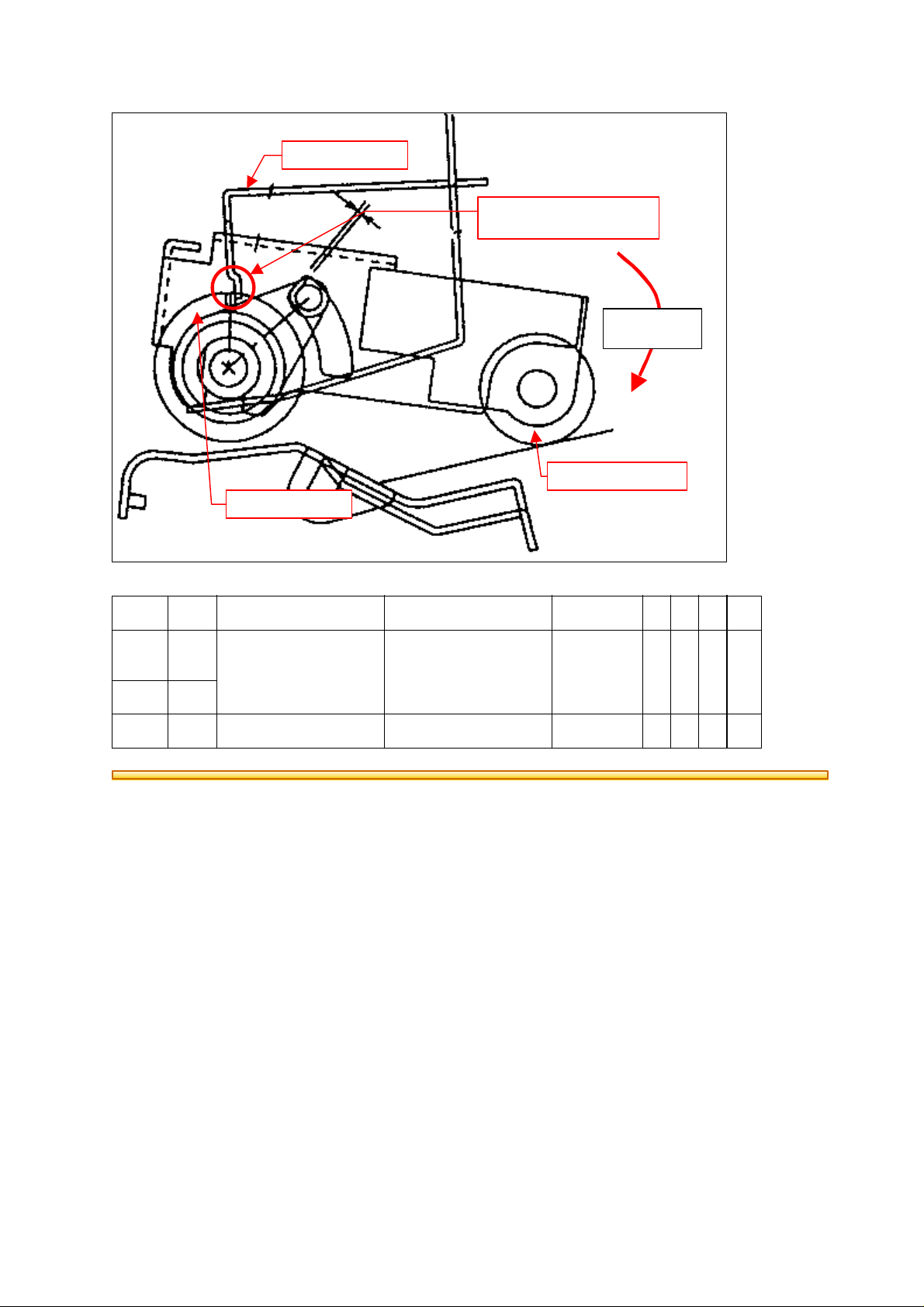

[Countermeasure]

To make the pick-up roller contact the sheet, the stopper (bypass frame part) is bent to enable a later

clearance timing of the spring clutch (contact timing with the spring clutch).

Page 2

Bypass frame

Spring clutch

BSI No. F99B532 Page 2

Bent portion of stopper

(bypass frame part)

Lowering

operation

Pick-up roller

[Changed/Added Part No.]

MODELP-I Before Change After Change Note P I R FAA

2060

2860

2870

3560

3570

1560 32-1 4402902020

P-I: Page-Item P: Contents of Change I: Interchangeability R: Reasons for Change

14-1 4401965160

K-BKT-BYPASS-L

15-1

K-BKT-SFB-L

4401966250

K-BKT-BYPASS-L2

4402902100

K-BKT-SFB-L2

C B D Y

C B D Y

Loading...

Loading...