Page 1

BSI(Service Note) TOSHIBA

TOSHIBA TEC CORPORATION

2-4-1, Shibakoen, Minato-ku, TOKYO, 105-8524 JAPAN

BSI No

F98L458

SUBJECT

FC-70 Packing Instruction for Transport

MODEL

CATEGORY

Treatment in the field

----------

CONTENT

These instructions are to prevents the following problems occurring caused by vibration during transit.

FC70

FIELD APPLICATION

Others

FACTORY APPLICATION

* Pitch line problems include impulse line problems.

* Leakage of fusing oil

UNIT

Other

Date

98/12/15

----

These instructions will be of use in the following situations.

* When the copier is transported after it is unpacked and set up.

* When the copier is transported to another place or returned by the user.

*NOTE

Save all packing materials because they are used for transport.

The following packing materials are needed for transport.

Page 2

BSI No. F98L458 Page 2

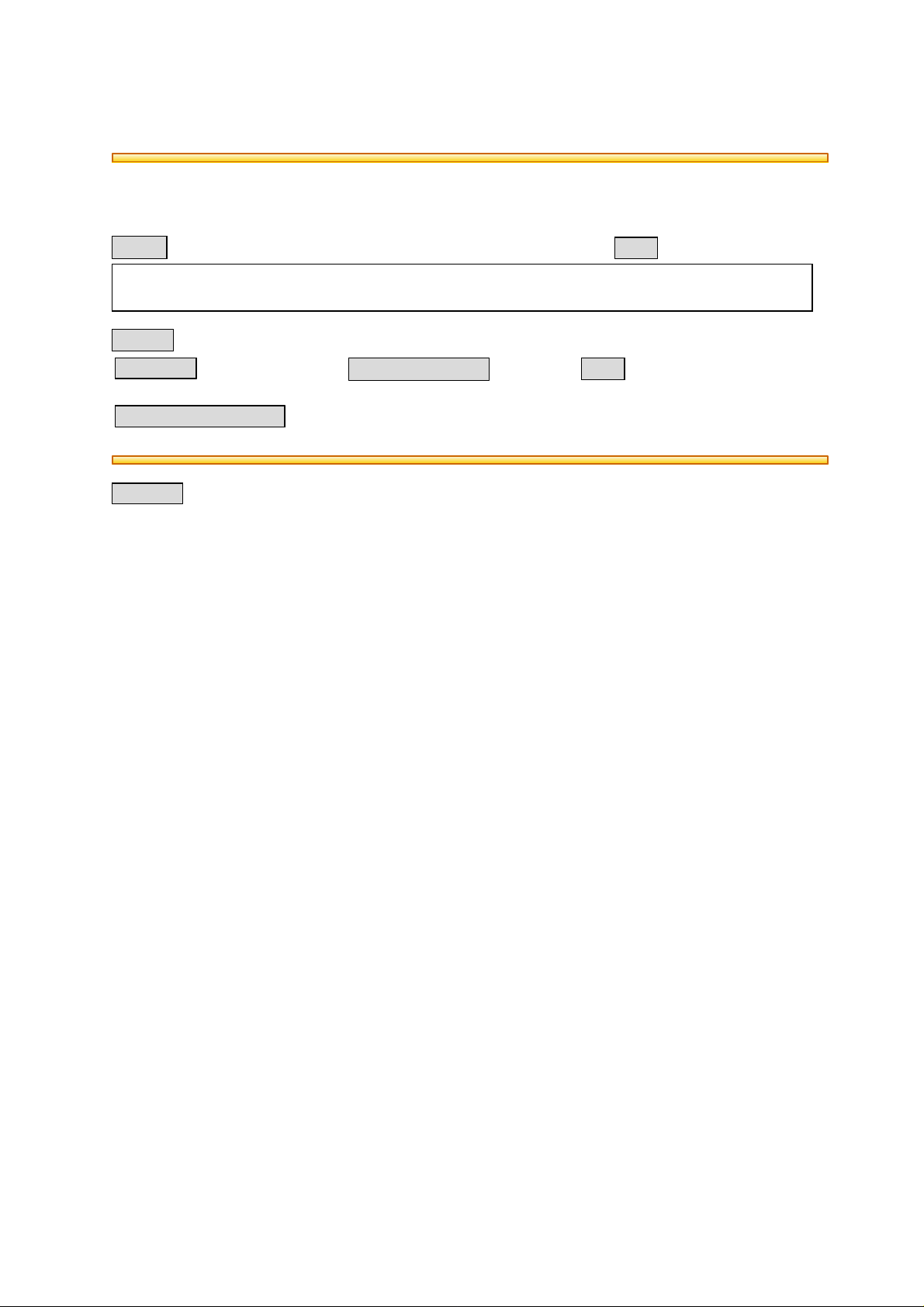

1.1st scanner locking pin 2.Pin locking the transfer drum shaft (iincluding the washer)

3. Cushioned holding plate of the static charge unit 4. Sponge 5. Stops in the

transfer drum unit rails(X2) 6. Holding plate in the charge neutralizing corona

assembly

7.Cushion packed above the transfer drum lock release handle 8.Basic plate

Packing procedure

Before conducting the procedure, make sure that you thoroughly understand the following points.

* NOTE

* Inject the fusing oil into the fuser oil bottle in the user's place of work in order to prevent oil

leakage during transit.

* Drain the fusing oil out of the bottle when the copier is transported.

* Fill the syringe with 10ml of oil three times and inject it into the bottle. 30ml of oil can make 20

copies of A3 size. As a guide for this, add the oil to the bottle.

1. Pull out the transfer drum and remove the transfer unit cover.

2. Attach the sponge and the cushioned holding plate of the static charge unit as shown.

(Insert the sponge between the static charge unit and the joint of the transfer drum

in order to

prevent the transfer film being dented.)

3. Screw the pin locking the transfer drum shaft (including the washer) as shown.

Washer

Pin locking the transfer drum

shaft

Sponge

Cushioned holding plate of the static

Page 3

BSI No. F98L458 Page 3

4. Tape the transfer drum back flange as shown.

-> Do not tape the rubber part of the flange.

Tape up

Note: Tape up firmly

Note: Do not tape the rubber portion

Transfer drum

5. Attach the holding plate in the charge neutralizing unit corona assembly and tape the two stops

in the transfer drum unit rails as shown.

6. Tape the two stops in the transfer drum unit rails as if they are coiling on the rail.

Tape the two stops in the transfer drum

unit rails

Holding plate in the charge neutralizing

corona assmbly

6. Attach the transfer unit cover and install the transfer drum.

7. Attach the cushion packed above the transfer drum lock release handle and tape it up while the

transfer unit lock lever is released as shown.

-> Do not tape on the label.

Note: Do not tape on the label

Tape up

Cushion packed above the transfer drum lock release handle

8. Tape the toner hopper as shown.

-> Tape the rails of right and left.

Page 4

Tape the toner hopper up on the

right and left rails

9. Attach the 1st scanner locking pin and tape it up as shown.

BSI No. F98L458 Page 4

Tape the 1st scanner locking pin

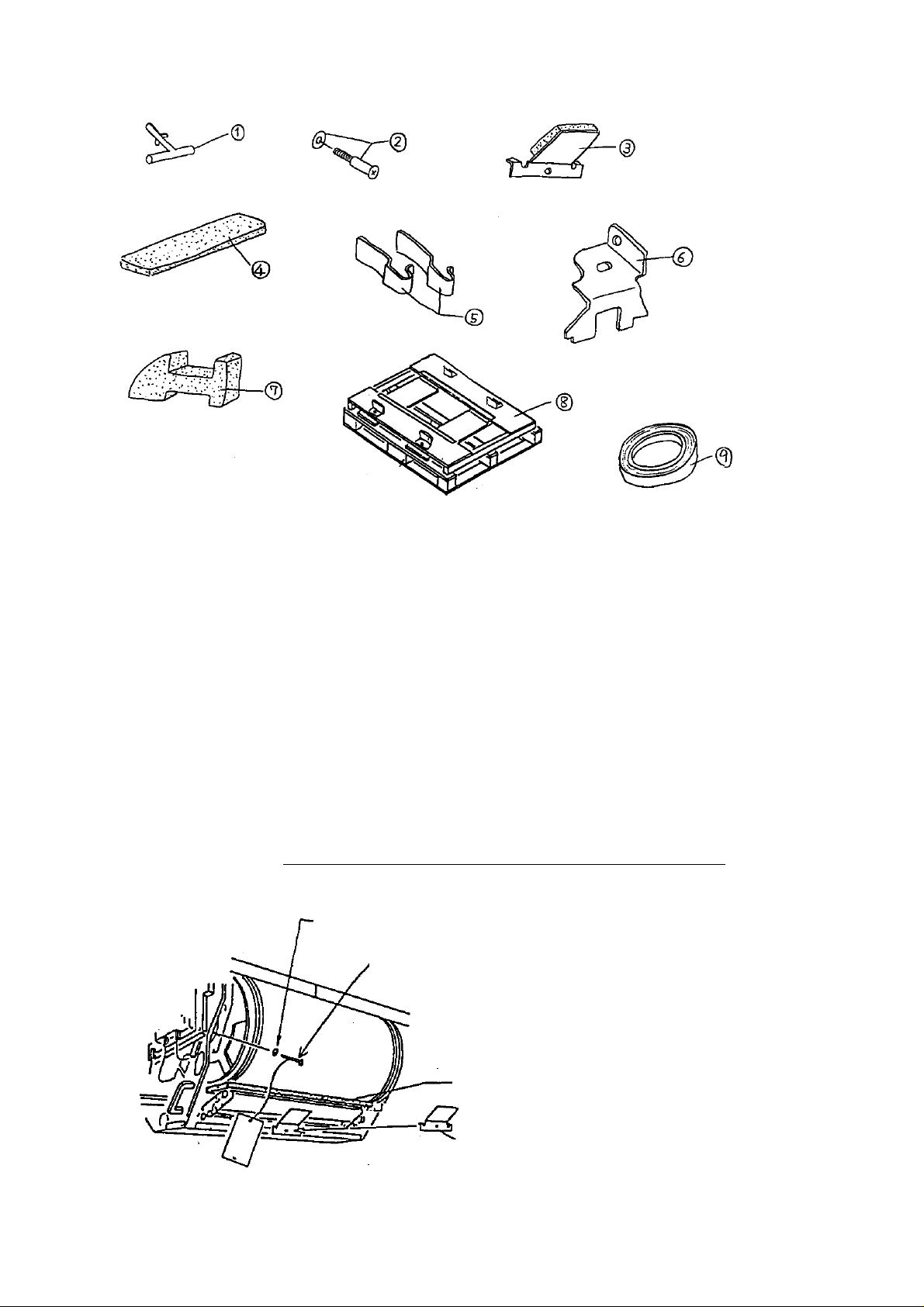

10. Tape the copier as shown.

Tapes

Tapes

Tapes

Tapes

11. Put the copier on the basic plate and fasten it.

If there is a box, cover the copier with it.

Tapes

Page 5

BSI No. F98L458 Page 5

Loading...

Loading...