Page 1

BSI(Service Note) TOSHIBA

TOSHIBA TEC CORPORATION

2-4-1, Shibakoen, Minato-ku, TOKYO, 105-8524 JAPAN

BSI No

F98I394

SUBJECT

Backup Memory RAM to Become a Service Part

MODEL

CATEGORY

Available as a service part

---

CONTENT

The backup memory (RAM) will be established as a Service Part. Then, the replacement of the RAM

with a new one should be performed as in the following procedure.

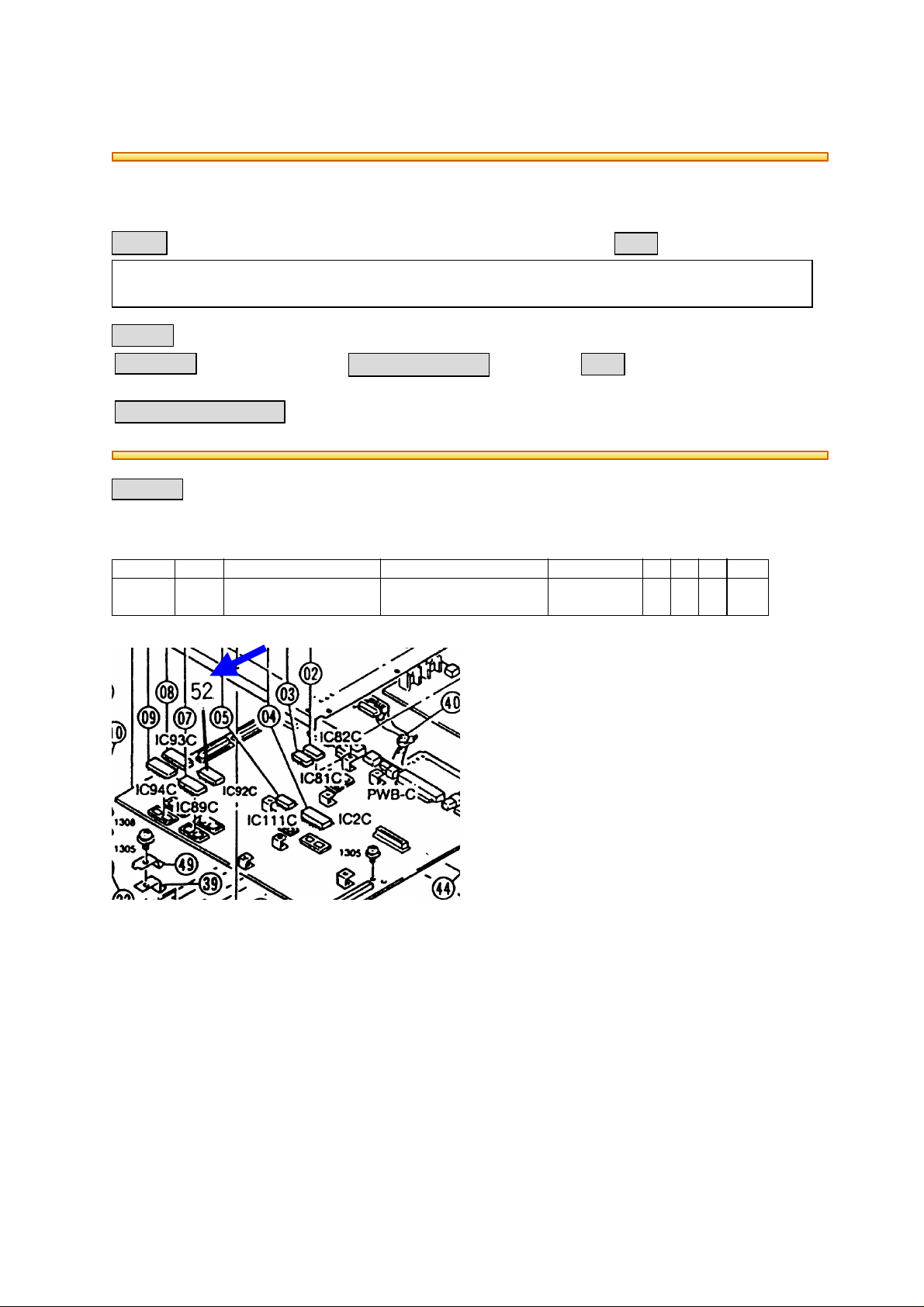

[Changed/Added Part No.]

MODEL

FC70 6-52 ----- 4402429650

P-I: Page-ItemP: Content of Change I: Interchangeability R: Reason for Change

FC70

FIELD APPLICATION

Others

FACTORY APPLICATION

P-I Before Change After Change Note P I R FAA

IC92C A - J -

IC

Date

98/10/12

UNIT

Electrical Circuit

---

-- Procedure --

Operations before replacement

1. Select list output (service mode), output the image related/feed related (image/feed list) and

setting/adjustment, machine situation, counter (mode list).

Note): As administration mode, RD-mode, original, detect sensor, CH cleaning and editor screen of

setting cannot be outputted, please confirm in advance and make a memo. Also, because user mode

cannot be outputted, in response to need, please confirm in advance and make a memo.

Operations after replacement

1. Clean the optical parts like PH assembly, original glass, lens, mirror, lamp.

2. Pour in the fusing oil till the required position.

3. Replace the used toner bag or dispose of the used toner from the bag.

Page 2

BSI No. F98I394 Page 2

4. In order to prevent a pre-run, remove the rear cover.

Note): Because new BC-RAM has no old developer data, if a pre-run occurs, there may be a

possibility of detecting errors related to the developer.

5.Correct the position on the touch panel using the correction mode.

6.Select counter life 3 (other) of the service mode, press the "Yes" key of toner collection.

7.As the display on the touch panel is in English, in response one's need, select other languages

using the user selection function in the user mode.

8.Select the marketing area on the setting of the service mode; the same area before replacement

should be set.

9.Perform the following operation in order in the developer mode.

Items Setting Operation Order

Developer

Developer Discharge (1)

Developer Filling (2)

AIDC

AIDC Sensor Adjust VR to 4.0 + - 0.1V A (3)

AIDC Offset Level Automatic adjustment A (4)

ATDC Sensor C/M/Y: Adjust VR to 6.0 + - 0.2V A (5)

B: Automatic adjustment A (6)

A: Adjustment

10.Select BK on State Confirmation of the service mode, and confirm that "Machine Constant" is

between -0.1 ~ 1.0.

(If the values are other than these, there is a possibility of an adverse effect on the image.)

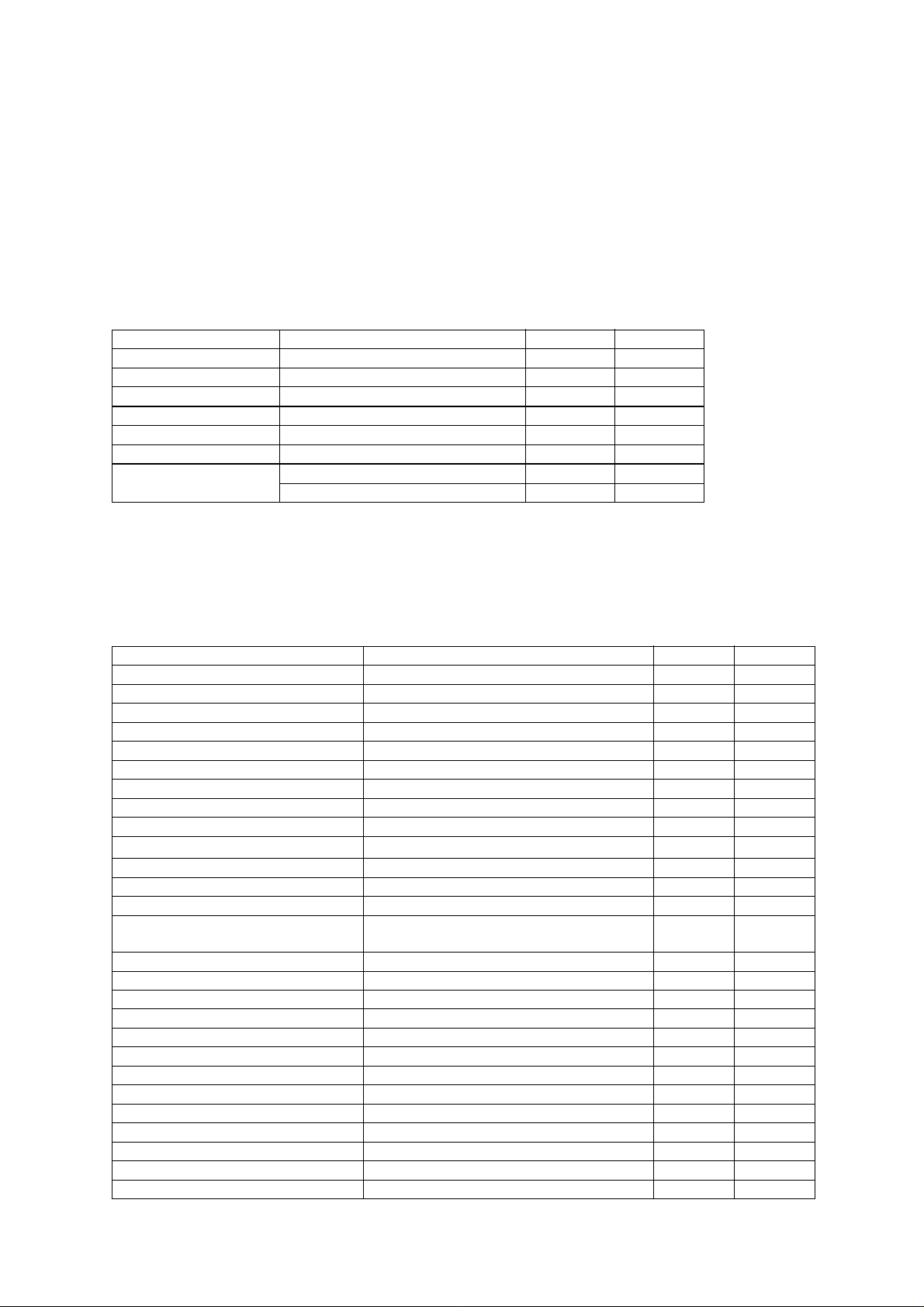

11. Perform the following operation in order in the service mode.

Note): As counter values cannot be reinputted, it is necessary to use the output counter list before

replacement.

Items Setting Operation Order

Image Adjust

PRT Max. Density Confirm "0". lf not, set to "0" C (1)

PRT HighIight Confirm "0". lf not, set to "0" C (2)

Background Voltage Confirm "0". lf not, set to "0" C (3)

ATDC Level Setting Confirm "6%". If not, set to "6%" C (4)

VB Shift Confirm "0". lf not, set to "0" C (5)

AE Adjustment Confirm "2". lf not, set to "2" C (6)

Machine Adjustment

Fuser Speed I (8)

Fuser Temperature

Transfer Output I (20)

Feed Motor Speed I (10)

PRT Area

Top Margin

Image Start Position I (12)

Leading Edge Position I (13)

Left Margin I (14)

Duplex Left Margin I (15)

IR Area

Left Image I (16)

Top Image I (17)

CD-Mag I (18)

FD-Mag I (19)

IR Lamp Confirm "0". If not, set to "0" C (11)

Setting

Paper Size I (7)

Count Up Selection I (26)

Administration Mode I (27)

Confirm "155 oC". lf not, set to "155 oC"

C (9)

Page 3

BSI No. F98I394 Page 3

RD Mode I (25)

Manual Paper Width Automatic Adjustment A (24)

Original Detection Sensor I (28)

Serial # Input I (23)

CH Cleaning I (29)

OHP Speed I (22)

Transfer Table Confirm "1". If not, set to "1" C (21)

Editor Screen I (30)

I : Input the memorized values before replacement

A : Adjustment C : Confirmation

12. Install the rear cover.

13. Turn the Power Switch OFF and ON again.

14. Select the g Auto Adjust of Service Mode, perform the g auto adjust.

Loading...

Loading...