Page 1

BSI(Service Note) TOSHIBA

TOSHIBA TEC CORPORATION

2-4-1, Shibakoen, Minato-ku, TOKYO, 105-8524 JAPAN

BSI No

F98D277

SUBJECT

Change of Shape of Swing Unit Blind Cover

MODEL

CATEGORY

Other countermeasures

From Apr. 1998 at the factory

CONTENT

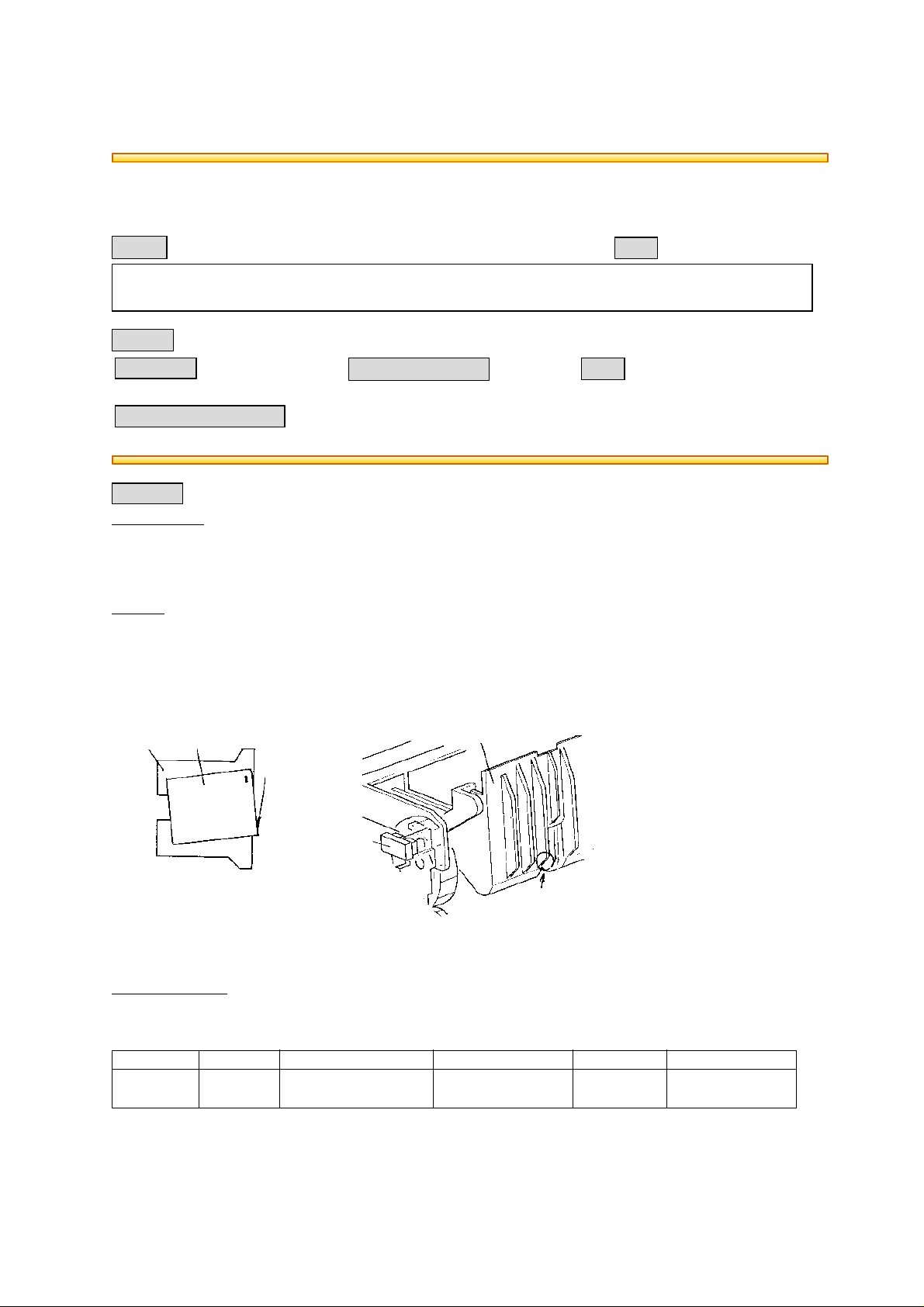

Phenomenon

A CB3 error can occur (elevation mortor of the finisher is abnormal) when the tray starts a cascade

movement while a small number of sheets, such as 2 to 4, are continuously being stapled and

stacked in one place.

MJ1003

FIELD APPLICATION

To be applied when necessary

FACTORY APPLICATION

Date

UNIT

Finisher

98/05/11

DTM-F8403

Reason

When a small number of stapled exiting sheets are being stacked and the stapled side becomes

higher, they have a tendency to slip and fall down on to the opposite side during the stacking,

meaning that on the tray being shifted upwards, they catch in the swing guide ribs causing this error

to be produced.

Tray

Paper

Rear

Front

Catching in

the swing

guide ribs

Swing guide

Paper catches on this rib.

Countermeasure

An idle roller has been added to the blind cover fixed into the swing guide, so that in the conditions

described above when the tray is shifted upwards, the paper trailing edge corner is sent forward to

the tray side by the roller and the paper no longer catches in the swing guide ribs.

Part Name Page-Item Before Change After Change Note Interchangeability

Cover 9-24

4402352520

COVER

4402353010

COVER-ROL

---- B

Page 2

Swing guide ribs

Addition of an idle roller (Front, Rear)

BSI No. F98D277 Page 2

Loading...

Loading...