Page 1

BSI(Service Note) TOSHIBA

TOSHIBA TEC CORPORATION

2-4-1, Shibakoen, Minato-ku, TOKYO, 105-8524 JAPAN

BSI No

F98B201

SUBJECT

Adhesive for the Screws Locking

Date

98/03/09

MODEL

CATEGORY

Other

Refer to the text

CONTENT

[Adhesive for the Screw Locking]

<Carriage mirror 1,2>

* Replacement of mirror 1, 2

* Adjustment of distorted image of mirror 1,2

When the adjustment screw is turned for the above reason:

After adjustment of the image distortion, apply the adhesive (BOND-1324) for the screw locking as

shown below.

Part Name

Adhesive

2060, 2860, 2870, 3560, 3570, 4560, 4570, DP2460

FIELD APPLICATION

To be applied when necessary

FACTORY APPLICATION

Added Part Appearance

4408687380

BOND-1324

UNIT

Optical

To improve the productivity, the adjustment screw has been changed with applying the adhesive

(BOND-1324) as shown below.

Page

P.18

P.19

[Application Method of the Adhesive for the Screw Locking]

The application method of the adhesive varies, therefore pay attention to the following points.

Model

DP2460 ~ Jan. 1998 at the

Current New Model Factory

Application

4401962790

SCREW-MIR-M3-10

Factory Application Method

factory

Feb. 1998 at the

factory ~

4402458930

SCREW-M3-10-213

Method (2)

Method (1)

3560,3570

4560,4570

Except for

above

models

Factory application

from the first lot ~

From Nov. 1998 at

the factory ~

Page 2

BSI No. F98B201 Page 2

Except for above

models

Method (1)

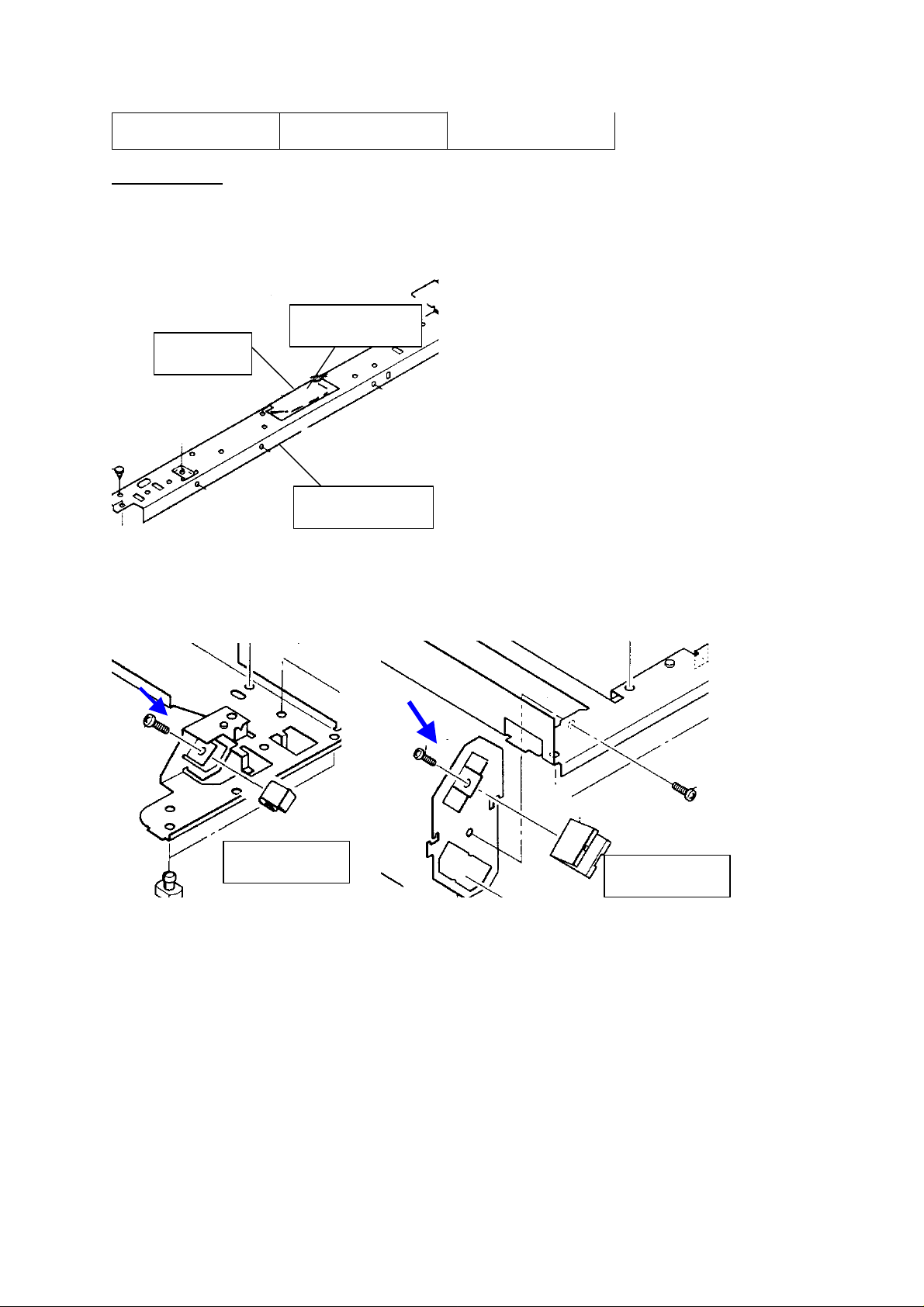

1) Adjust the image distortion.

2) Remove the original glass.

3) Move the carriage 1 in order to match the position of the notch portion of the STAY-GLASS (front

side).

Factory application

from the first lot ~

Notch portion

Mylar

STAY-GLASS

4) Apply the adhesive (BOND-1324) to the adjustment screw of carriage 1,2.

Note) Adjustment screw in carriage 1

* Be careful not to peel off the mylar.

Carriage 1

Note) Application Method

* Apply well in sufficient quantity to the "Application area".

* Application needs 12 hours to harden completely.

Carriage 2

Page 3

BSI No. F98B201 Page 3

Application

area

6) Install the original glass.

Method (2)

2) Adjust the image distortion.

3) Remove the original glass.

Indicator unit

Carriage

frame

Mirror

5) Apply the adhesive (BOND-1324) to the adjustment screw of carriage 1/2.

Note) Consult "Application Method" for how to apply the adhesive.

6) Remove the indicator unit.

7) Confirm that there is no dust on mirror 1/2/3 or the SHD board.

8) Install the original glass.

9) Install the left top cover.

[Procedure Improvement]]

Method (1) is better than Method (2), so the following changes have been made.

Part Name Page-Item Part No./Name Remarks Application

Stay 8-16

Mylar 8-41

4408676010

STAY-GLASS-F

4401960460

MYLAR-GLASS-F

* Notch portion

addition

* Part No. no

change

* Addition Factory application:

Model: DP2460

From Feb. 1998

Page 4

BSI No. F98B201 Page 4

Loading...

Loading...