Page 1

BSI(Service Note) TOSHIBA

TOSHIBA TEC CORPORATION

2-4-1, Shibakoen, Minato-ku, TOKYO, 105-8524 JAPAN

BSI No

F98A149

SUBJECT

Addition to the Service Manual

MODEL

CATEGORY

Correction of Service Manual

---------

CONTENT

If an obstacle is put in the lower bin unit, it must still be made to stop moving without any phase

sideslip. So a

added to 1st production machines. Since this

Service Manual, it's details are given in this BSI. In order to facilitate the removal of the transport

roller, a new step order has been applied to present production machines.

MG2012

FACTORY APPLICATION

object detection switch accompanied by current detection circuit has been

Correct Page

2-5

FIELD APPLICATION

Others

object detection switch was not mentioned in the

Change Point

Date

UNIT

Documents

98/02/10

----

2-31

3-8

5-13

5-14

A-1

Sorter controller input (2/2) Fig.2-105

3. Bin shift motor control Fig. 2-506

C. Removal transport roller

Motor/switch/solenoid/PCB etc. Fig.5-302

Motor/switch/solenoid/PCB etc. Table 5-302

A. Circuit Diagram

a-1.pdf

3-8.pdf

2-5.pdf

2-31.pdf

5-13.pdf

5-14.pdf

Page 2

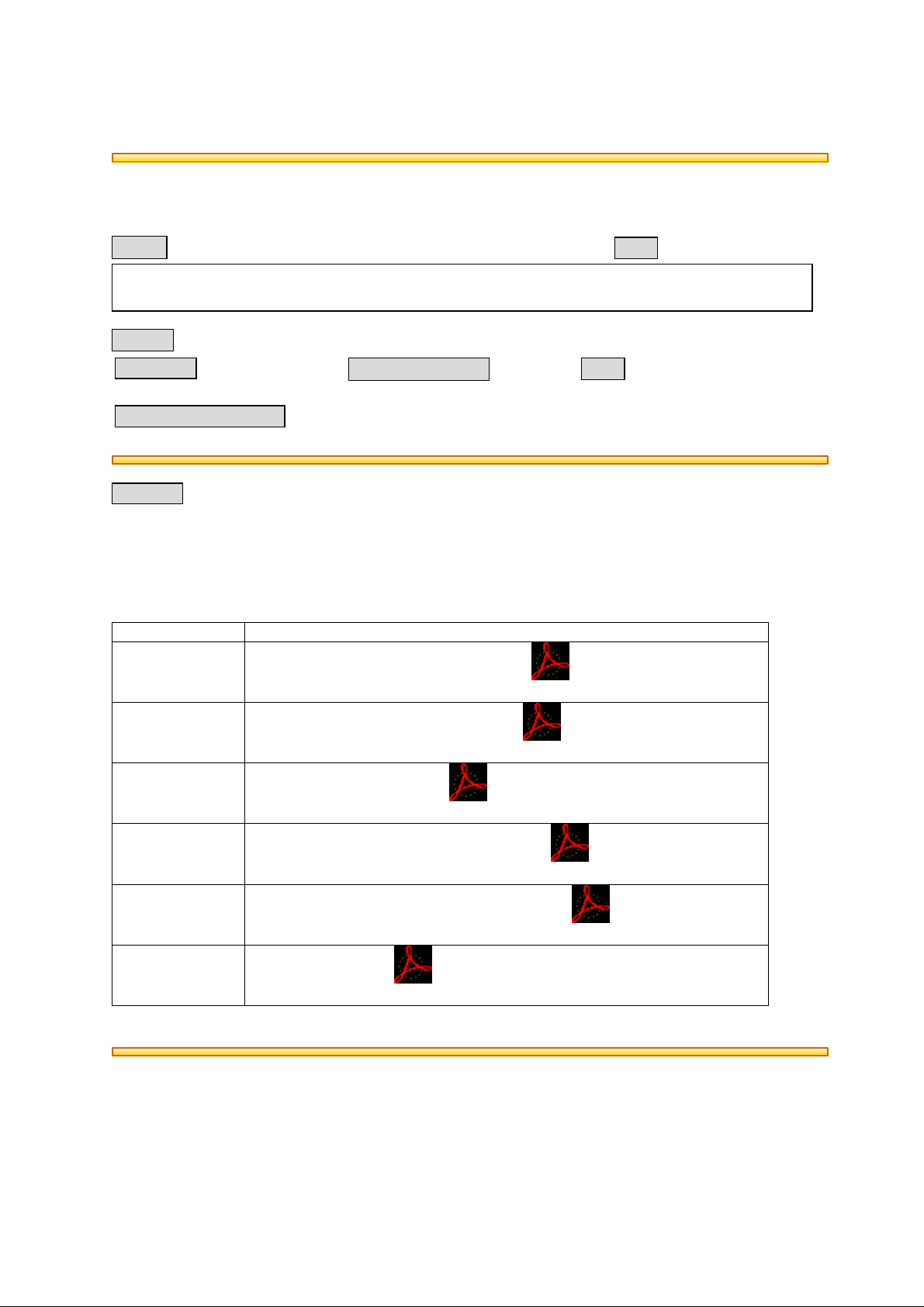

Inputs to the Sorter Controller (2/2)

Bin inside paper

sensor

S1

(light-emitting unit)

Bin inside paper

sensor

S2

(light-receiving unit)

Guide bar home

position sensor

1

2

3

PI3

J203

1

2

1

4

2

3

1

2

J108

J204

2

1

2

2

1

1

3

4

2.OPERATIONS AND TIMING

Sorter controller PCB

+5V

J4

1

2

BIN LED

When "1", the LED is turned on

(flashes).

3

4

PA CHE

When there is paper inside the bin,

"1"

+5V

6

7

8

STYGHP

When the guide bar is at

the home position, "1"

Joint switch

MS1

NO

Bin shift motor

clock sensor

Lead cam home

position sensor

Stapler unit cover

switch

PI1

PI2

COM

3

2

1

3

2

1

MS2

NO

Stapler unit home

position switch

COM

MS4

PI7

COM

3

2

1

NO

Stapler unit cover

sensor

S3

Objection detection switch

MS7

NO COM

J115

1

2

3

4

5

6

7

1

2

3

4

5

6

7

J301

J202 J104

1

2

4

1

4

2

4

1

3

2

1

4

+24V

J10

1

2

JOI SW

When the sorter is connected

to the copier, "1"

+5V

J5

1

3

2

SHIFT CLK

Pulse corresponding to

the rpm of the shift motor

+5V

4

6

5

CUMH

When the lead cam is at

the home position, "1"

+24V

J6

1

2

SPLOPN

When the stapler unit cover

is closed, "1"

+24V

3

4

3

2

1

J14

SPUHP

+5V

SPL COV

When the stapler unit

is at the home position

for swing operation, "1"

When the stapler unit cover

is closed, "1"

J3

1

4

3

1

2

4

SPL ED

HARI LED

When stapling is possible, "1"

When there are no staples, "1"

S4

Figure 2-105

2-5

Page 3

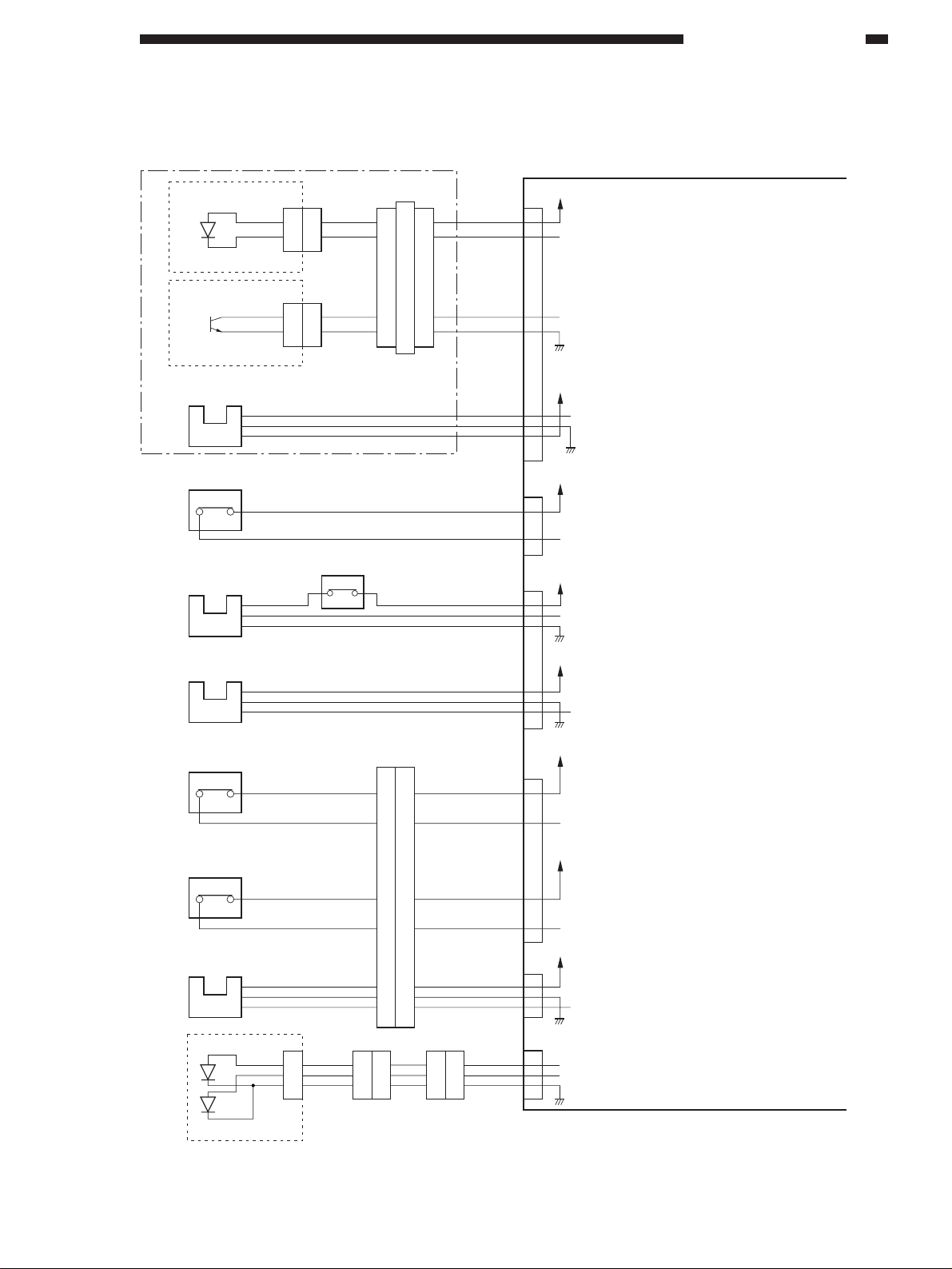

2.OPERATIONS AND TIMING

3. Controlling the Bin Shift Motor

Figure 2-506 shows the control circuit for the

bin shift motor.

The bin shift motor (M1) is a DC motor. This

motor is controlled by the drive circuit to raise and

lower the bin unit.

The bin unit raise/lower speed is detected and

controlled by the shift motor clock sensor.

The stop position of the bin unit is detected by

the lead cam home position sensor.

When the stapler unit is not at the home position, the 24 V po wer supply is cut off b y the stapler

home position switch to prevent the rotation of the

bin shift motor in order to avoid a collision of the bin

unit and the stapler unit.

Overrun is prevented b y the bin unit upper and

lower limit sensors.

A current detection circuit is also provided to

detect overcurrent when the bin unit contacts a f oreign object to stop the bin unit.

When an obstacle is found under the bin unit

raising the lead cam, the objection detection switch

opens and the shift motor stops transmitting clock

signals to the CPU. Therefore the CPU terminates

the shift motor.

Sorter controller PCB

Q1

CPU

Stapler home

position switch

ON

+24V

BMUP

BMDWN

PWM

MS4

Current

detection

circuit

Bin unit upper

limit sensor

PI4 PI5

Drive circuit

Bin unit lower

limit sensor

LCHP

Bin shift motor

M1

PI2

Lead cam home

position sensor

MS7

Shift motor clock

sensor

PI1

Figure 2-506

COMNO

Objection

detection switch

2-31

Page 4

3.MECHANICAL SYSTEM

III. FEEDING GUIDE UNIT

A. Removing the Feeding

Guide Unit

1) Remove the front co ver.

2) Remove the screw to take out the latch

lever holder .

2

Figure 3-301

3) Remove the latch lever , the latch and the

latch stay .

4) Remove the screw to take out the feeding

guide unit .

1

B. Removing the Feeder

Motor (M2)

1) Remove the rear cover.

2) Disconnect the connector and remove two

screws to take out the feeder motor .

3

2

1

Figure 3-303

7

3

6

5

C. Removing the Feed Roller

1) Remove the right cover, front cover, feeding

guide unit, rear cover and f eeder motor.

2) Remove feed roller block and gears .

3) Remove screw , and then, remove the feed

roller holder .

4) Remove the feed roller

1 4 5

2

3

4

Figure 3-302

Figure 3-304

3-8

Page 5

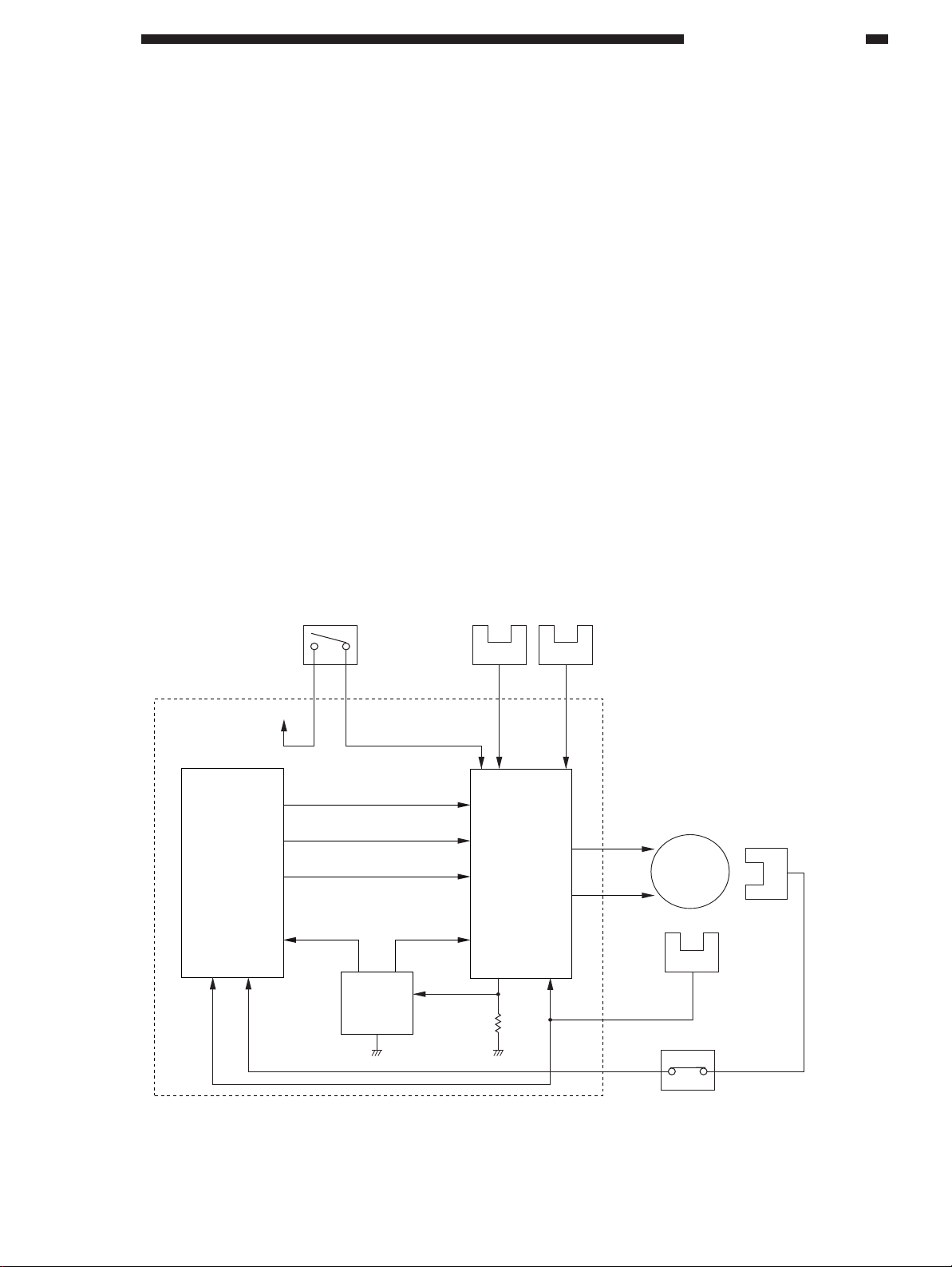

B. Motors, Switches, Solenoids and PCBs

5.TROUBLESHOOTING MALFUNCTIONS

1

M5

M4

M3

M1

M2

Figure 5-302

MS5

MS6

MS7

SW

MS1

MS3

MS4

MS2

2

5-13

Page 6

5.TROUBLESHOOTING MALFUNCTIONS

Motors, switches, solenoids and PCBs

Symbol Description Notation

M

Bin shift motor

Feeder motor

Guide bar swing motor

Stapler unit swing motor

Stapler motor

Joint switch

Stapler cover switch

Stapler safety switch

Stapler unit home position switch

No staple detection switch

No cartridge detection switch

Objection detection switch

Manual staple switch

Control panel PCB

Sorter controller PCB

M 1

M 2

M 3

M 4

M 5

MS 1

MS 2

MS 3

MS 4

MS 5

MS 6

MS 7

SW

1

2

T able 5-302

5-14

Page 7

A. GENERAL CIRCUIT DIAGRAM

A-1

Loading...

Loading...