Page 1

BSI(Service Note) TOSHIBA

TOSHIBA TEC CORPORATION

2-4-1, Shibakoen, Minato-ku, TOKYO, 105-8524 JAPAN

BSI No

F97J050

SUBJECT

C3500 Error Troubleshooting

MODEL

CATEGORY

Treatment in the field

--------

CONTENT

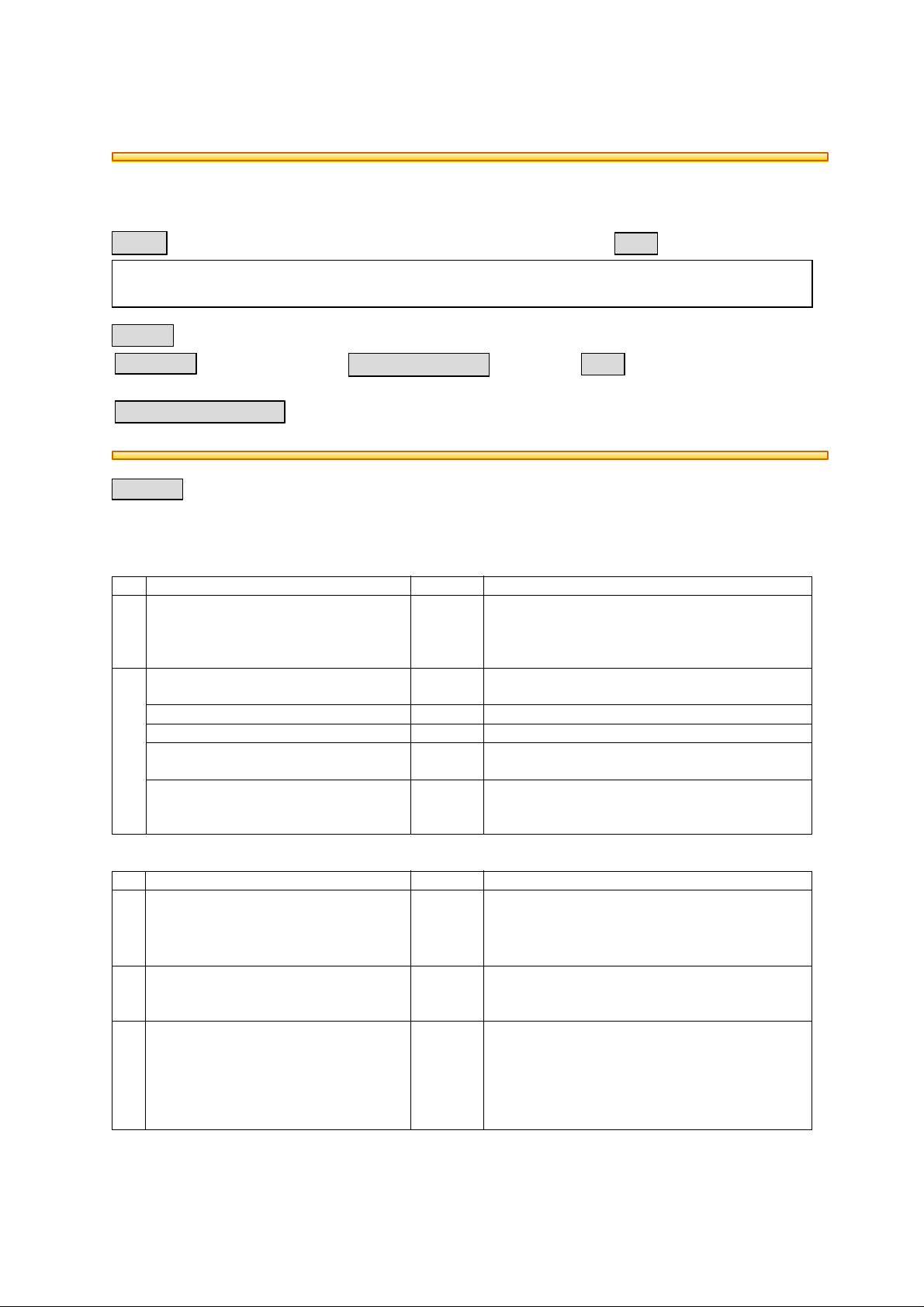

Troubleshooting for C3500 is listed below. When an error occurs in the C3500, perform the following

checks and treatment.

1. Confirmation Items

No.

1 Are there more than one problem

2

FC70

FIELD APPLICATION

To be applied when necessary

FACTORY APPLICATION

Check Point Result Treatment

NO Solve the trouble by opening and closing the

items when screen "State Confirm"

-->Stabilizer Trouble is opened in the

service mode?

Confirm combination of problem

items in the Stability Trouble screen

BK developer only ---- Go to treatment item No. 1

BK developer + PC ---- Go to treatment item No. 8

BK developer + VO sensor ---- Service Manual T- 91 (7) Treat VO sensor

BK developer + C + M + Y developer ---- Service Manual T-91 (6) Perform OFF/ON

---- --------------------

front cover, and after reinitializing the C3500,

check the Stability Trouble screen.

(If a problem is found, go to No. 2)

failure

motion of Main SW after treating AIDC sensor

failure

Date

UNIT

General

97/10/30

----

2. Treatment Items

No.

1 The value of DEV. BK in element

data BK should be close to 3000 and

η value lower than 1000. Check if the

image is smooth.

2 Check if the AIDC sensor has

become dirty or the adjustment data

have shifted (4+0.1V, 4-0.1V)

3 Has C3500 or a problem appeared

after replacement of developer

material? (Has the life counter been

cleared, after performing

compensation of BK when

replacing?)

Check Point Result Treatment

YES Replace developer material

YES Clean or replace the AIDC sensor and readjust

the AIDC sensor.

YES If more than 10 copies are made, it is

necessary to replace the developer material

and perform compensation after clearing the

life counter.

Page 2

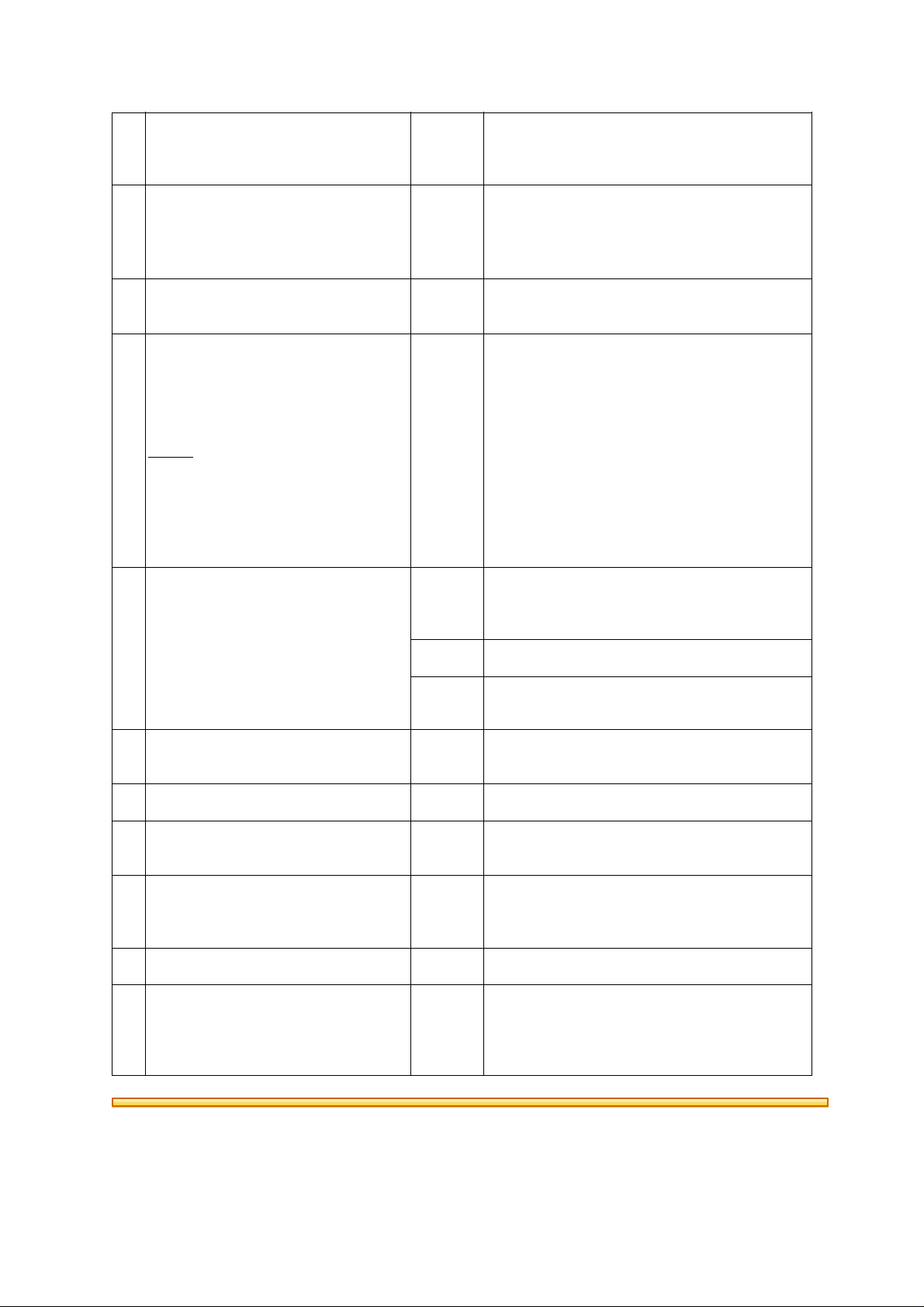

BSI No. F97J050 Page 2

4

The value of η and BK constant in

the element data BK cannot be

stabilized for each copy.

5 Did COF38 appear before C3500?

Is the value of η and Stick in element

data BK shown at a very low level? (

η is below than 1500, Stick is below

than 100)

6 Is there any toner caked in the toner

hopper?

7 When supplying black toner by

opening the toner supply screen in

the developer mode, check whether

or not the toner supply motor starts to

rotate.

Notes:

The toner supply motor does not

rotate if the value of BK Constant in

the element data is shifted to higher

than the specification value.

8 1) Turn ON the Main SW with the pre

run mode OFF.

2) Confirm condition of the test

copies which are taken using the

following procedures

[Press the START key selecting half

tone (Black), 64 LIMOS 1 by opening

the test print screen in the service

mode]

9 Is the mesh of the main charger

getting dirty or has cleaner stopped

at other than its home position?

10 Is the window of PH lower Assy.

getting dirty?

11 Is there any object interfering with

the LD optical path.

12 Check if no resolution can be

reproduced in low image density

areas or no thin lines in the FD

direction.

13 Check whether or not a different type

of toner is used

14 Measure the grid voltage of the main

charger using a tester with the Main

SW turned ON and confirm its output

voltage change to 500V -> 900V ->

700V

YES Make 10 copies after turning the Main SW

OFF and ON. Then perform gamma automatic

compensation after turning the Main SW OFF

and ON. Repeat this operation 10 times.

YES Go to No. 8

YES Stir the caked toner in the toner hopper with a

screw driver. Instruct users to shake the toner

bottle when installing a new one.

NO 1) Check rotating condition of each roller and

gear, and clean the toner hopper unit or

replace the whole unit if any abnormality is

found.

2) Clean the contact point of the drawer CN

for the toner hopper and machine.

3) Check the wiring condition from PWB-1 to

M9.

4) Check whether overload has been applied

on the motor drive unit; if there is no

abnormality, replace the M9.

5) If there is no problem in the above (1) to

(4), replace PWB-1.

White

Go to 9

band

with FD

direction

Low

Go to 12

density

Solid

Go to 14

black

YES Change the mesh or replace the main charger

unit.

YES Clean the window of PH lower Assy.

YES Check the fixing condition of the covers in the

optical path. Remove foreign material in the

optical path.

YES Replace PH Assy, PWB-JA or PU1.

Concerning PU1, the failure of + or - 12V for

PH may be considerable.

YES Replace BK toner in the toner hopper with the

proper one. Replace BK developer material.

NO Check the wiring condition through PWB-1 to

HV1 and check connectors on HV1. If any

abnormality is found, replace the HV1.

Loading...

Loading...