Page 1

BSI(Service Note) TOSHIBA

TOSHIBA TEC CORPORATION

2-4-1, Shibakoen, Minato-ku, TOKYO, 105-8524 JAPAN

BSI No

F97I037

SUBJECT

New Model 1560

MODEL

CATEGORY

New Model Description

CONTENT

The new model 1560 is based on the existing model 1550 with some small changes.

Therefore, this BSI will explain the changes, so a service manual and Service Parts List will be not

be provided.

1560

FIELD APPLICATION

Others

FACTORY APPLICATION

Date

UNIT

General

97/11/04

------

1. Contents

The bypass paper feeding capacity for the 1560 has been changed from single to stack feeding of 60

sheets. Moreover, for energy saving, when there has been no input for a fixed time, the main switch

will now automatically be turned "OFF". For bypass feeding area the 1560 uses the same bypass

paper feeding device as the 2060 (2860) and drive is provided through the main motor to the

aligning roller unit. As new electrical parts, there is an ON/OFF electromagnetic clutch in the feeding

roller and a bypass switch for paper-empty detection.

(The time until it goes off can be adjusted.)

The consumable parts and options are all common to the 1550 ones. However, when using the key

counter mounting kit KN-1550K, a hole has been added to the copier cover for easy installation.

2. Specification changes

2. 1) Bypass

Copying speed : 8 copies/minute ( all sizes)

Size : A3~A5-R

LD~ST-R

Paper stacking capacity : 60 copies

Copy paper size : 64~80g/m2 : 60 copies stacking

16~22lbs : 60 copies stacking

80~130g/m2 : single-sheet feeding

22~34lbs : single-sheet feeding

1. 2 Weight of machine: 38kg

1. 3 Size of a machine: W571 x D541 x H340mm

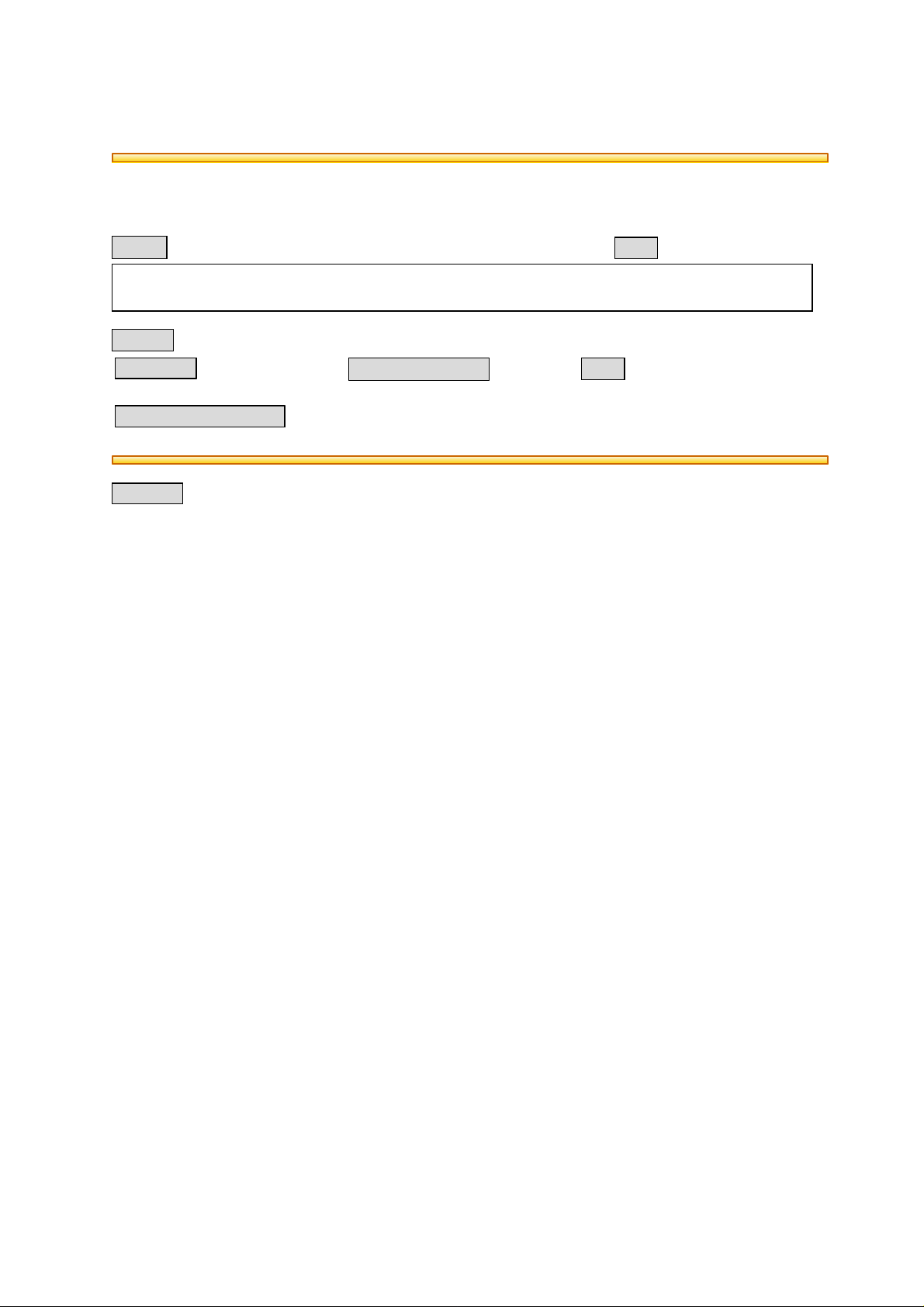

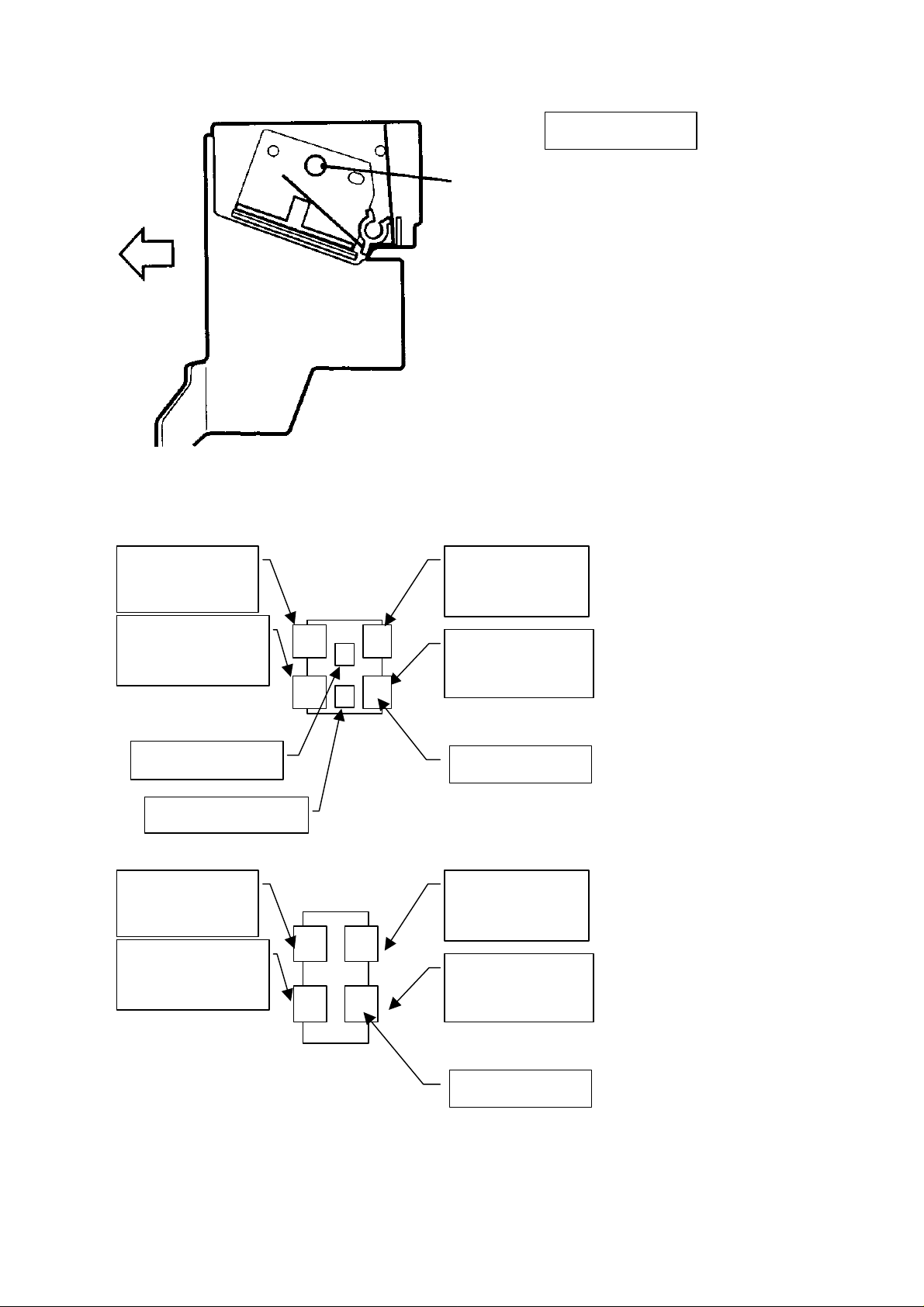

3. Bypass area/sectional view

Page 2

BSI No. F97I037 Page 2

Bypass paper guide

Bypass paper-feed roller

Bypass pick-up roller

Bypass separation pad

4. Operation Explanation "Bypass paper-feed copying"

(1) Insert the paper in the bypass paper-feed slot.

Switch ON the bypass

The bypass LED of the control panel lights up.

(2) Press the PRINT key

The main chager/transfer chager/separation charger/transfer bias/discharger lamp/LED eraser lamp

are turned ON/and the optical system fan motor rotates at a high speed.

The main motor comes ON~the drum/developert/heat roller/and paper-exit roller rotate.

(3) Bypass paper-feed operation

The manual feed clutch comes ON~the bypass pick-up roller/paper feed roller rotate.

Aligning operation (the paper reaches the aligning roller)~switch is turned on paper stop.

After a fixed time, the manual feed clutch goes OFF~ paper-feeding is finished.

(4) Thereafter, the paper-feeding operation is the same as with the cassette.

5. Disassembly and exchange

5. 1. Removal of door switch and main switch

(1) Remove the rear cover.

(2) Open the front cover and raise the upper unit.

(3) Remove the bypass paper-feed cover (2 screws).

(4) Remove the front support bracket (1 screw) of the bypass and take out the bypass tray. (See

Illustration A.)

(5) Remove the rear support bracket (1 screw). (See Illustration A.)

(6) Remove the bypass paper guides (upper/2 pieces) (1 screw each). (See Illustration A.)

(7) Remove the 2 screws of the bypass separation pad bracket. (See Illustration B.)

(8) Push down the pick-up roller and take out the separation pad bracket by pushing down the paper

stop lever and the arm of the paper sensor.

For the removal of the bypass paper feed roller, the separation pad and the clutch, details are given

later.

Page 3

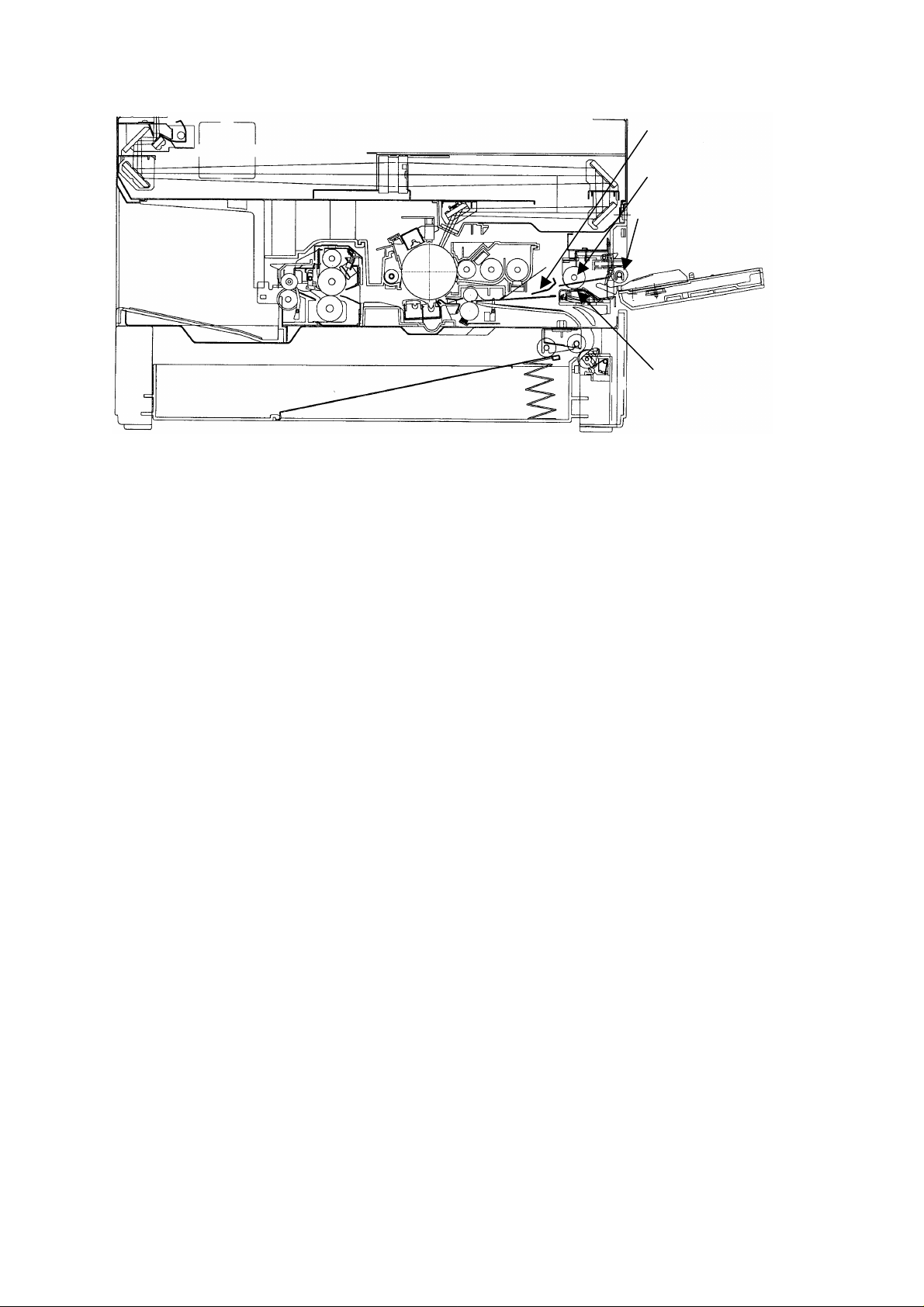

5. 1 (4)

<Illustration B>

BSI No. F97I037 Page 3

5. 1 (6)

<Illustration A>

Bypass tray

5. 1 (7)

Bypass paper guide

Paper stop lever

Separation pad

5. 1 (5)

Pick-up roller

(9) Remove the process unit, inner cover (upper) and the control panel.

(10) Remove the paper-feed side gas spring (E-ring, 1 piece). Then, open the original cover to

prevent the upper unit from falling down.

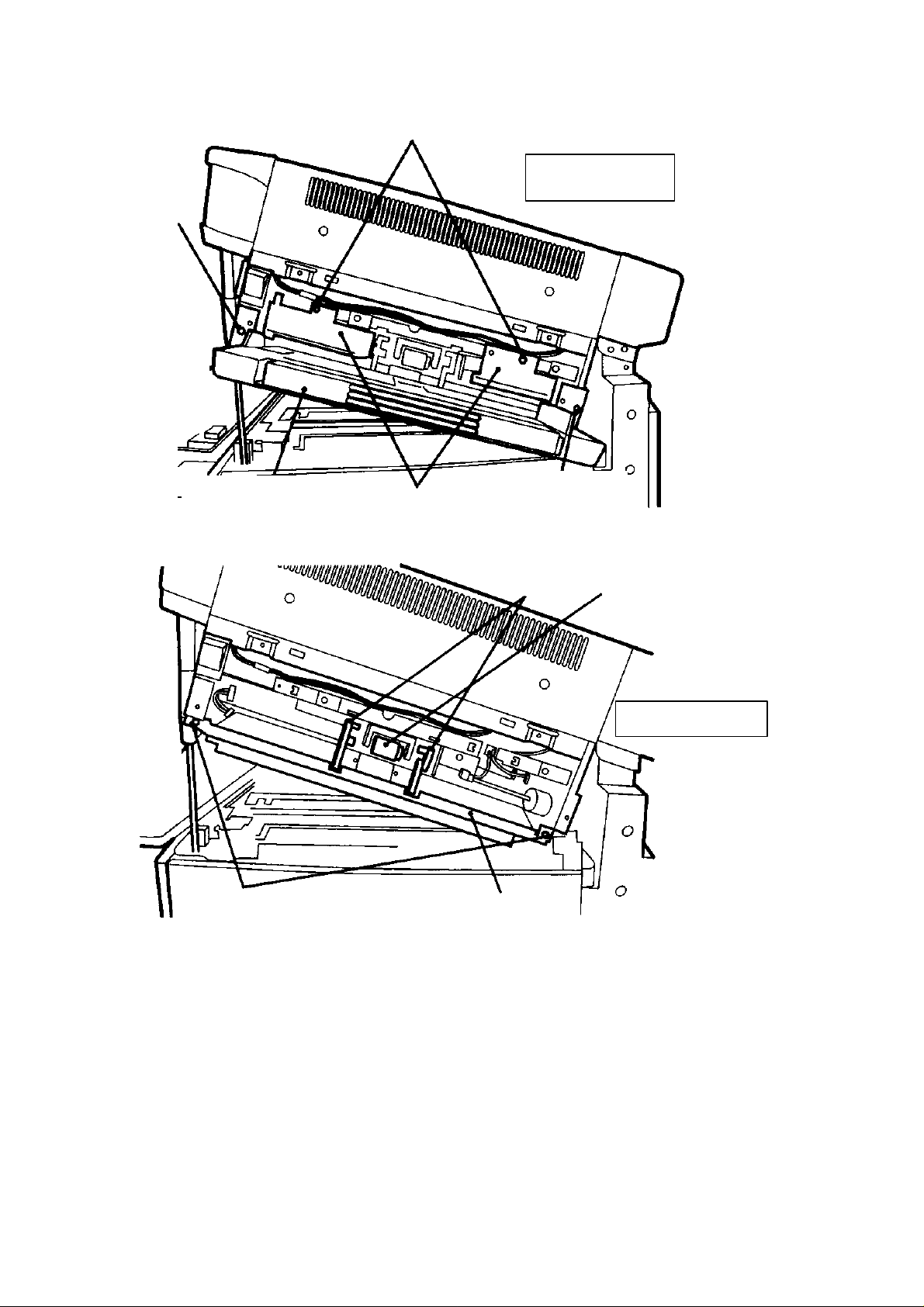

(11) Remove 1 screw of the paper guide and pull it out toward the front. (two paper guides can

removed at the same time.)(See Illustration C.)

(12) Remove the right cover.

(13) Remove the connector cover of the switch.

(14) Remove the 3 screws of the bracket fixing the switch. (See Illustration D.)

(15) Pull the bracket out with the harness connected.

< For removing the lens motor, details are given later. >

Page 4

<Illustration C>

5. 1 (11)

Paper guide

BSI No. F97I037 Page 4

5. 1 (14)

5. 1 (14)

5. 1 (13)

<Illustration D>

Connector cover

5. 1 (14)

(16) Take out the main switch connector and remove the switch while pushing the switch pawl.

(17) Take out the door switch bracket (1 screw) and remove the bracket in the direction of the arrow.

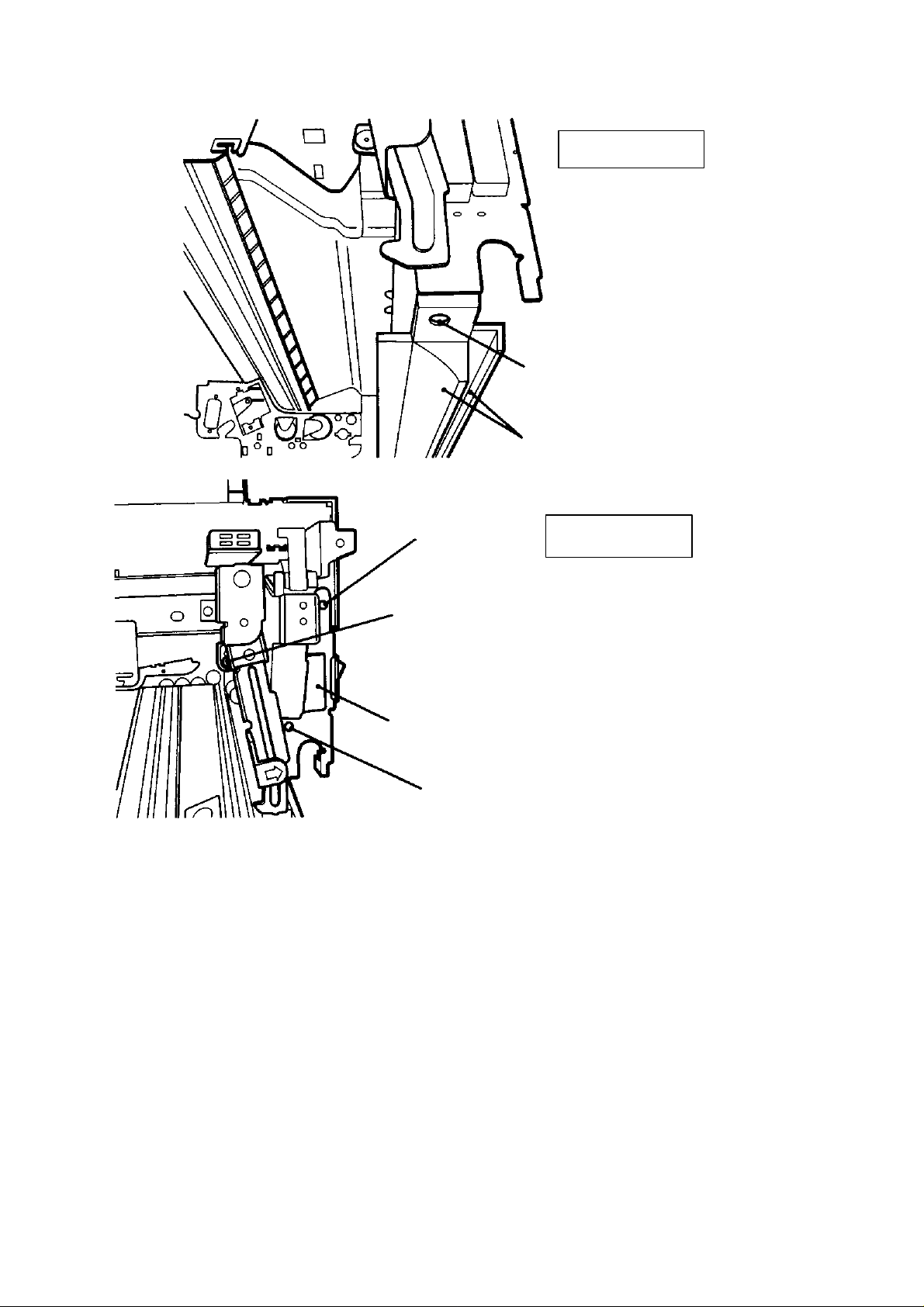

(See Illustration E.)

(18) Take out the switch connector and remove the switch while pushing the switch pawl. When

reassembling, take care with the contacting of the connector.

Page 5

5. 1 (17)

BSI No. F97I037 Page 5

<Illustration E>

Main switch connector connecting diagram.

Harness: white

Connector: blue

Harness: white

Connector: yellow

1

3

5

42

6

Harness: red

Harness: gray

Door switch connector connecting diagram.

Harness: white

Connector: blue

1 3

Harness: white

Connector: white

2 4

Harness: black

Connector: blue

Harness: black

Connector: yellow

Terminal No.

Harness: black

Connector: blue

Harness: black

Connector: white

Terminal No.

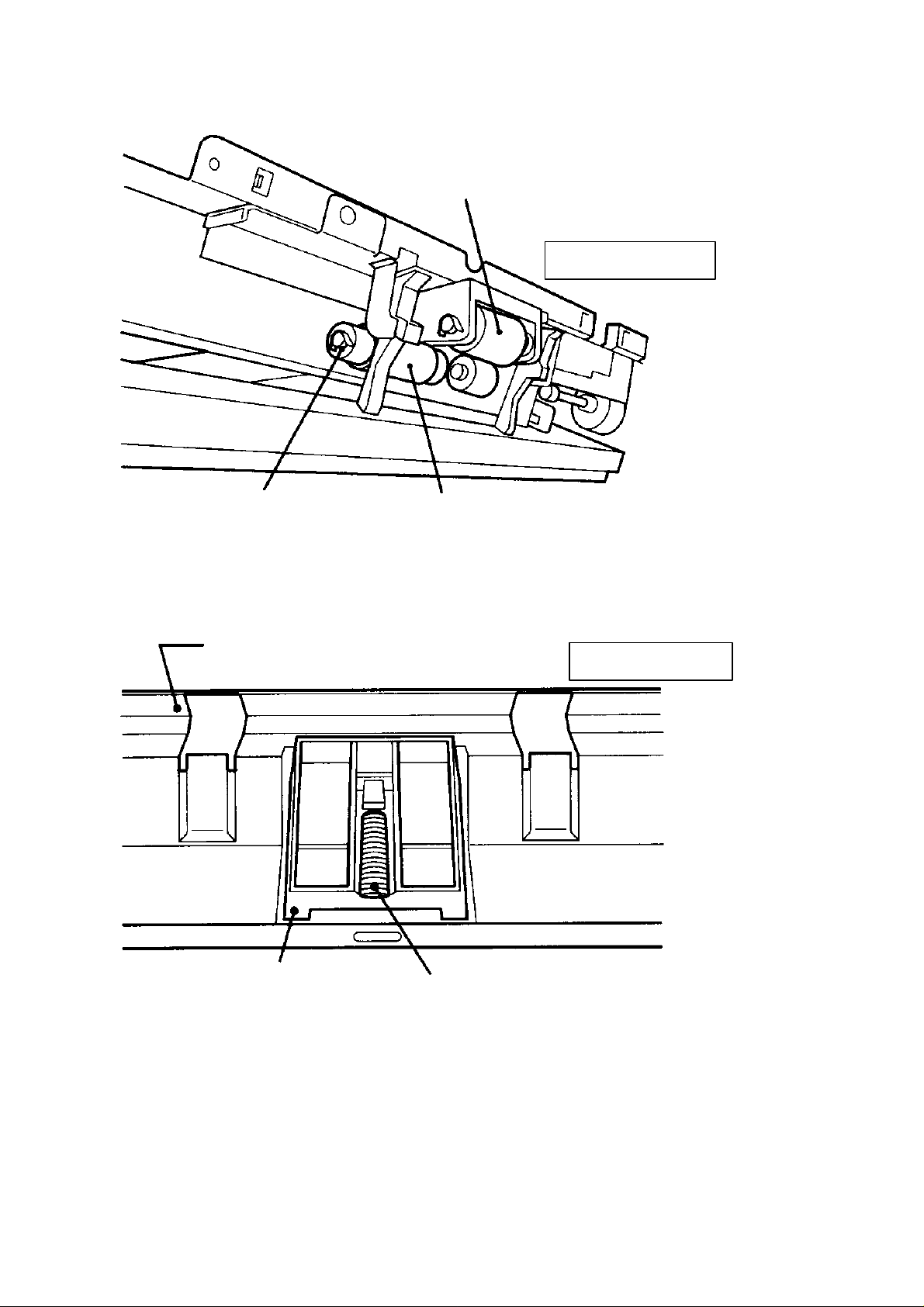

5. 2 Removal of the bypass feed roller

(1)~(8) is the same as in "5.1. Removal of the main switch/door switch".

(9) Remove the feed roller stop-ring. (See Illustration F)

Page 6

(10) Take out the feed roller.

BSI No. F97I037 Page 6

Pick-up roller

<Illustration F>

5. 2 (9) Stop-ring

5. 3 Removal of the separation pad

(1)~(8) is the same as in "5. 1. Removal of the main switch/door switch".

(9) Take off the rear-side spring of the separation pad and remove the separation pad. (See

Illustration G)

Separation pad holder

Paper-feed roller

<Illustration G>

Separation pad holder

5. 4 Removal of the clutch

(1)~(8) is the same as in "5. 1. Removal of the main switch/door switch".

(9) Removal the clutch and the paper sensor.

(10) Close the upper unit.

(11) Remove 2 screws from the upper unit, slide the unit to the front and take it out in the direction of

paper feeding. (See Illustration H.)

(12) Remove the hexagonal screw and the stop-ring of the clutch and take out the clutch.

5. 3 (9) Spring

Page 7

5.4 (11)

BSI No. F97I037 Page 7

<Illustration H>

<Notes>

1. When installing the clutch, align the end face of the clutch to the shaft groove and align the

hexagonal screw to the milling cutting surface. Insert the projection of the clutch and the gear arm in

the hole of the bracket. (See Illustration I.)

2. Confirm that there is no oil, etc. on the surface of the paper feed roller or the separation pad.

3. When reassembling the timing belt (removed when taking cut the pick-up roller) pass it through the

upper side of the belt tensioner.

4. When installing the separation pad bracket to the copier, first free the paper stop lever by pushing

down the pick-up roller downwards.

Note 1:

Put the projection

into the bracket hole.

Note 1:

Put the projection into the

bracket hole

Align with the groove

5.5 Removal of the lens motor

(1)~(15) is same the as in "5.1. Removal of the main switch/door switch".

(16) Remove the lens motor connector.

(17) Remove the lens motor screw. (See Illustration J)

<Illustration I>

Page 8

BSI No. F97I037 Page 8

Lens motor

<Illustration J>

5.5 (17

)

6. Periodic Maintenance

The bypass roller, separation pad and pick-up roller should be replaced every 60,000 copies.

7. Installation of Key Copy Counter

KN-1550K should be installed in the copier using 2 screws, but there is only one hole in the cover of

the 1560. With regard to this kit installation, make a hole for a screw with a cutter or a this thin driver

(a minus driver is better) in the bypass paper feed cover. (Only this part of the cover is thin.) (See

Illustration K.)

Paper feed cover

Cutter

<Illustration K>

8. PC board repair manual

The following table is added to "2.1.3 Terminal connection for the main CPU".

Page 9

BSI No. F97I037 Page 9

Port Name

P26/A6/A22

P25/A5/A21

The following table is added to "2.2.3 Terminal connection for the gate array".

Terminal

Name

O30

O31

O32

O33 ~ O37

Type Signal Name Meaning

Input

SFB-PSW

Input

SFB-SET

Input/output Signal Name

Output SFB paper feed clutch

Output ------Output Main switch forced off

Output -------

SFB paper present/absent

SFB unit present/absent

9. Adjustment Code, Test Code Added (for service)

9-1 The following table is added to "Input check (1.2.1)"

EXP1 EXP2 EXP3

Stack bypass

------------

1

9-2 The following table is added to "Output (1.2.2)"

Code

Stack bypass clutch ON

65

Main SW OFF

69

paper

(No paper)

Function Code Function

Stack bypass mounting

(No mounted)

Stack bypass clutch OFF

75

9-3 The following table is added to "Adjustment mode (1.2.3)"

Code

88

9-4 The following table is added to "Setting mode (1.2.4)"

Code

88

64

Description Allowable

Aligning amount (stack

bypass)

Description Allowable

Auto shut OFF time

Bypass half scanning

operation

input

value

0 - 15 8

input

value

0 - 20

0 - 1 0

Initial

value

Initial

value

6

Content

Each increase by "1" causes the paper to

incline more.

Content

0: 3 min., 1: 5 min., 2: 10 min.,

3: 15 min., 4: 20 min., 5: 25 min.,

6: 30 min., 7: 40 min., 8: 50 min.,

9: 60 min., 10: 70 min., 11: 80 min.,

12: 90 min., 13: 100 min., 14: 110 min.,

15: 115 min., 16: 150 min., 17: 180 min.,

18: 210 min., 19: 240 min., 20: None

0: Allowed 1: Forbidden

* A above code 64: Supplementary Explanation

In the 1560, when the above code 64 is set to "0", the copy speed from the bypass has been made

faster by using the key operation below. (As before, from approx. 8 cpm to approx. 14 cpm.)

In the usual bypass method, the optical system scan (total scanning), but in this mode offers A4/LT

scanning (half scanning).

<Key operation>

1. Set paper in the bypass guide. (Bypass paper feeding is selected.)

2. Press the "CASSETTE" key while pushing the "%" key. (The bypass symbol start flashing.)

3. Start copying by pushing the PRINT key.

When this mode is used, there are the following limits.

Page 10

BSI No. F97I037 Page 10

1. If the paper width in the feeding direction is 216 mm or over, the paper becomes jammed.

2. If thick sheets of paper is used, toner fusing may become insufficient. (especially for postcards).

3. When the bypass mode is changed to the cassette mode or when the bypass guide runs out of

paper, this mode is cleared.

When this mode is not used, set AD (08) mode/code 64 to 1". (At the time of shipment, it is set to

"0".)

10. Circuit diagram & DC harness Connection Diagram

This copier has different LGC circuit board and DC harness connection diagram than the 1550. The

LGC circuit and DC harness connection diagram have the icons given below added to it. The file

form is "Adobe Acrobat".

1560scm.pdf 1560DC.pdf

Page 11

12

VDD

C37

1/10W4700

21

R38

R106

R17

R37

R18

R80

R41

R20

R87

R86

R81

R66

R65

R64

R45

R46

1

C

2

CC1000P/50

A

[ZC]

ACKB-S

SRXD

STXD

ACKB-DF

DFRXD

DFTXD

5VCHK

REQ-DF

ZC

S-REQ

DFACK

SACK

MOT-FG

DF-REQ

MRR-D

MRR-C

MRR-B

MRR-A

LNS-D

LNS-C

LNS-B

LNS-A

SCN-D

SCN-C

SCN-B

SCN-A

AES-VIN

ATSVIN

DRM-THM

TH-

VDD

R125

RTP

[ACKB-S]

[SRXD]

[STXD]

[ACKB-DF]

[DFRXD]

[DFTXD]

B

C

[5VCHK]

[REQ-DF]

[S-REQ]

[DFACK]

[SACK]

[MOT-FG]

[DF-REQ]

[MRR-D]

[MRR-C]

[MRR-B]

[MRR-A]

[LNS-D]

[LNS-C]

[LNS-B]

[LNS-A]

[SCN-D]

[SCN-C]

[SCN-B]

[SCN-A]

[AES-VIN]

[ATSVIN]

[DRM-THM]

[TH-]

D

E

1/10W4700

12

RTP

1/10W4700

21

RTP

1/10W4700

12

RTP

1/10W4700

21

RTP

1/10W4700

12

RTP

1/10W4700

12

RTP

1/10W4700

12

RTP

1/10W4700

21

RTP

1/10W22K

12

RTP

1/10W22K

21

RTP

CC1000P/50

1/10W22K

12

RTP

1/10W22K

21

RTP

1/10W22K

12

RTP

1/10W22K

21

RTP

1/10W22K

21

RTP

1/10W22K

12

RTP

R43

R127

R47

R30

C26

GND

1/10W22K

21

RTP

1/10W22K

12

RTP

1/10W22K

12

RTP

1/10W22K

21

RTP

GND

TP1

C27

1

1

C

2

GND

CC1000P/50

C2

CC2200P/50

1

2

C

C19

GND

C25

1

CC1000P/50

1/10W33K

CC2200P/50

1

RTP

C2

12

C54

D12

R126

C2

IC19

GND

02CZ5.1Y

32

7407M

43

IC14

7407M

89

GND

C17

1

1/10W22K

21

CC2200P/50

1

RTP

2

C

R44

C14

R95

X2

12M

7407M

IC14

7407M

65

IC14

IC14

7407M

10 11

MC74

HC14F

IC14

21

CC1000P/50

C

2

CC0.1/25

02CZ5.1Y

1

2

C

23

D4

C34

12

RTP

1/10W1M

31

2

12

34

P95/SCK1

33 71

P94/RXD1

32

P93/TXD1

31

P92/SCLK0

30

P91/RXD0

29

P90/TXD0

20

P87/INT0

19

P86/TO6

18

P85/INT7

17

P84/INT6

16

P83/TO5

15

P82/TO4

14

P81/INT5

13

P80/INT4

GND

12

P73/TO3

11

P72/TO2

10

P71/TO1

9

P70/T10

8

P67/PG13

7

P66/PG12

6

P65/PG11

5

P64/PG10

4

P63/PG03

3

P62/PG02

2

P61/PG01

1

P60/PG00

VDD

76

P53/AN3

75

P52/AN2

74

P51/AN1

73

P50/AN0

78

VREF

79

AGND

27

X2

26

X1

21

NMI

28

EA

23

RESET

IC10

TMP96C141AFZ

R84

543 678

VDD

1/10W4700

12

RTP

1/10W4700

21

RTP

1/10W4700

12

RTP

1/10W4700

12

RTP

1/10W4700

21

RTP

1/10W4700

12

RTP

1/10W1000

12

RTP

1/10W4700

21

RTP

1/10W4700

21

RTP

1/10W4700

12

RTP

1/10W22K

RTP

1/10W100

RTP

1/10W100

21

RTP

1/10W100

RTP

1/10W22K

RTP

1/10W22K

21

RTP

1/10W22K

RTP

1/10W22K

21

RTP

1/10W22K

RTP

1/10W4700

1/10W4700

21

RTP

RTP

12

R99

R102

D15

D14

1/10W4700

1/10W4700

1/10W4700

21

RTP

RTP

12

12

R98

R96

R97

D13

D12

D11

1/10W4700

1/10W4700

21

RTP

RTP

R90

D10D9D8D7D6D5D4D3D2

1/10W4700

1/10W4700

21

21

RTP

RTP

RTP

12

R88

R74

R89

1/10W4700

1/10W4700

1/10W4700

21

RTP

RTP

RTP

12

12

R72

R73

R71

VDD

1/10W4700

1/10W4700

1/10W4700

1/10W4700

21

RTP

RTP

RTP

12

12

R55

R57

R58

R56

D1

A

CS2

[CS2]

CS1

[CS1]

CTR-CNT

HTR-RDY

SFB-PSW

SFB-SET

+24VCHK

R182

R183

1/10W4700

1/10W4700

HTR-ON

5VSWON

STORE

DR-SW2

DEV-SW

PLL-OK

RTP

RTP

EXP

A16

[HTR-ON]

[CTR-CNT]

[HTR-RDY]

[EXP]

[5VSWON]

[STORE]

WR

[WR]

RD

[RD]

[SFB-PSW]

[SFB-SET]

[+24VCHK]

[DR-SW2]

[DEV-SW]

[PLL-OK]

[A16]

VDD

21

21

*2

B

C

D

21

RTP

D0

D[0:15]

WDT

ALE

[D[0:15]]

[WDT]

[ALE]

/CTS0

/TI7

/TI6

/TI5

/TI4

RTP

P42/CS2

P41/CS1

P40/CS0

P37/RAS

P36/R/W

P35/BSAK

P34/BSRQ

P33/WAIT

P32/HWR

P17/AD15

P16/AD14

P15/AD13

P14/AD12

P13/AD11

P12/AD10

P11/AD9

P10/AD8

P07/AD7

P06/AD6

P05/AD5

P04/AD4

P03/AD3

P02/AD2

P01/AD1

P00/AD0

1/10W100

21

/CAS2

/CAS1

/CAS0

P31/WR

P30/RD

P27/A7

/A23

P26/A6

/A22

P25/A5

/A21

P24/A4

/A20

P23/A3

/A19

P22/A2

/A18

P21/A1

/A17

P20/A0

/A16

/A15

/A14

/A13

/A12

/A11

/A10

WDTOUT

/A9

/A8

ALE

CLK

R105

R148

R179

R50

R52

R34

R49

R36

R48

R32

72

70

69

R33

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

52

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

22

35

24

R53

R51

R54

R180

R181

R68

R70

R69

D15

D14

D13

D12

D11

D10

D9

D8

D7

D6

D5

D4

D3

D2

D1

D0

12

12

12

12

12

12

E

GND

F

4402906020

4402906120

[RST]

PWA-F-LGC-141

PWB-F-LGC-141

RST

R85

1/10W4700

12

RTP

GND

CC2200P/50

C33

GND

1

C

2

F

1

781 65423

8

Page 12

12

A

[RST-SW]

[SFB-ON1]

RST-SW

SFB-ON1

[OPTON]

[OPT-H/L]

OPTON

EXT-H/L

OPT-H/L

[EXT-H/L]

EXTON

B

[HVT-M]

[EXTON]

HVT-M

[HVT-GB]

[HVT-TR]

HVT-TR

HVT-GB

[HVT-SP]

HVT-SP

7407M

[SCN0]

SCN0

7407M

21

[SCN1]

SCN1

43

IC17

7407M

[SCN2]

SCN2

IC17

7407M

65

[SCN3]

SCN3

89

IC17

7407M

[SCN4]

SCN4

IC17

7407M

1011

[SCN5]

SCN5

13 12

IC17

7407M

[REQ-S]

REQ-S

IC11

IC17

13 12

[PKUPCLT]

[TNRMOT]

TNRMOT

PKUPCLT

[RGTCLT]

[FEDCLT]

RGTCLT

FEDCLT

[MOTON2]

[PKUPCLT2]

MOTON2

PKUPCLT2

[RGTCLT2]

[FEDCLT2]

FEDCLT2

RGTCLT2

*8

RTP

12

R173

1/10W4700

1/10W4700

1/10W4700

1/10W4700

1/10W4700

1/10W4700

1/10W4700

1/10W4700

VDD

21

RTP

RTP

12

R174

R176

R175

21

21

RTP

RTP

RTP

12

R178

R177

RTP

12

R164

R172

543 678

[TR-VREF]

[G-VREF]

G-VREF

4

3

AO3

[SP-VREF]

TR-VREF

SP-VREF

5

AO5

AO4

VDD

[THM-VREF]

THM-VREF

7

6

10

AO7

AO6

AO8

1

[VCC]

8

9

C41

CC0.1/25

C2

[VDD/U]

[GND]

16

21

DUMMY

E6

[VSS/L]

1

VDD

DG

GND

[MRR-CHG]

[CSSRAM]

CSSRAM

MRR-CHG

[WRRAM]

[EXP-PWM]

WRRAM

EXP-PWM

1/10W4700

RTP

12

R16

1213

IC14

7407M

A

B

SIZ10

21

RTP

12

R142

[SIZ12]

[SIZ11]

[SIZ10]

SIZ11

SIZ12

21

RTP

RTP

RTP

12

R141

R137

[SIZ13]

[FED-SW2]

[EMP-SW2]

SIZ13

FED-SW2

EMP-SW2

21

RTP

RTP

RTP

12

12

R140

R139

R136

R135

[CST2]

[RGT-SW]

CST2

RGT-SW

21

RTP

RTP

12

R132

[MOTON]

[MOTDIR]

MOTON

MOTDIR

*8

1/10W1000

1/10W1000

1/10W1000

1/10W1000

1/10W1000

1/10W1000

1/10W1000

1/10W1000

[MOTBRK]

[SCN-H]

SCN-H

MOTBRK

[SCN-L]

SCN-L

CTR-ON

[CTR-ON]

[CN-ON]

ERSON

CN-ON

[LED-DAT]

[LED-LTH]

[ERSON]

LED-DAT

LED-LTH

7407M

56

IC11

7407M

7407M

34

[DSP-ON0]

[DSP-LTH]

[DSP-DAT]

[LED-SCK]

[DSP-SCK]

DSP-SCK

LED-SCK

DSP-LTH

DSP-DAT

IC11

IC11

7407M

11 10

1011

IC11

7407M

98

DSP-ON1

DSP-ON0

IC11

7407M

7407M

12

12

IC18

IC18

7407M

98

[DSP-ON1]

IC18

D/A8

ATSVREF

1114

15

DO

IC2

DICKLD

[AA62353S]

13

[ATSVREF]

[M-VREF]

M-VREF

2

AO2

AO1

12

C

363738

39

43

O00

O01

O02

O03

IN00

IN01

IN02

IN03

68756974707371

VDD

RTP

*16

12

D

R169

R171

1/10W4700

1/10W4700

1/10W4700

1/10W4700

1/10W4700

1/10W4700

1/10W4700

1/10W4700

1/10W4700

1/10W4700

1/10W4700

1/10W4700

1/10W4700

1/10W4700

1/10W4700

1/10W4700

21

21

RTP

RTP

12

R40

R149

RTP

21

RTP

R19

RTP

12

R63

R143

21

RTP

RTP

12

12

R124

R123

RTP

21

RTP

R144

RTP

12

R146

R145

21

21

RTP

R147

21

RTP

RTP

RTP

12

R159

R160

21

*8

RTP

RTP

12

R128

R161

1/10W22K

1/10W22K

1/10W22K

1/10W22K

1/10W22K

1/10W22K

1/10W22K

1/10W22K

R151

72

21

RTP

RTP

RTP

12

12

12

R130

R152

R129

E

O04

IN04

RTP

44

O05

IN05

21

RTP

R153

46

45

O07

O06

IN07

IN06

21

*8

RTP

RTP

12

R154

R131

R134

1/10W22K

1/10W22K

1/10W22K

1/10W22K

1/10W22K

1/10W22K

1/10W22K

1/10W22K

50

49

48

O11

O10

IN11

IN10

78

77

76

21

21

RTP

RTP

12

R155

R156

52

51

O14

O13

O12

IN14

IN13

IN12

85

86

RTP

RTP

RTP

12

12

R122

R121

54

53

O16

O15

IN16

IN15

88

87

21

RTP

RTP

12

R138

R158

R133

55

O17

IN17

89

21

RTP

119

O20

IN20

115

21

*4

RTP

R118

R119

1/10W22K

1/10W22K

1/10W22K

1/10W22K

123

124

125

126

O21

O22

O23

IN21

IN23

IN22

116

118

117

21

RTP

RTP

RTP

12

12

R107

R108

127

128

129

151

152

153

154

155

156

157

158

O24

O25

O26

O27

O30

O31

O32

O33

O34

O35

O36

O37

DT0

DT1

DT2

DT3

DT4

DT5

DT6

DT7

DT8

DT9

DT10

DT11

DT12

111213143032171822232425262728

D0D1D2D3D4D5D6D7D8D9D10

VDD

1/10W4700

1/10W4700

1/10W4700

1/10W4700

*4

RTP

RTP

12

12

R167

R165

R166

21

RTP

RTP

12

R168

D11

D12

91929394959697

IO00

IO01

IO02

IO03

IO04

IO05

DT13

DT14

DT15

ADR0

ADR1

29

141

133

A1A2A3A4A5A6A7A8A9

D14

D[0:15]

D15

A0

A[0:15]

D13

IO06

ADR2

134

98

IO07

ADR3

142

ADR4

136

102

IO10

ADR5

137

103

148

IO11

ADR6

104

IO12

ADR7

149

105

131

IO13

ADR8

106

IO14

ADR9

132

108

107

IO16

IO15

ADR11

ADR10

144

143

A10

A11

R157

12

1/10W1M

109

61625960666563

IO17

LELTH

LEDAT

ADR15

ADR14

ADR13

ADR12

139

147

146

138

A12

A13

A14

A15

X1

8M

31

RTP

2

DADAT

82

GND

SCK

X2

DSPDAT

X1

83

VDD

64

DSON0

DSON1

DSPLTH

TE01

TEST2

8

57

1/10W4700

1/10W4700

21

RTP

RTP

12

R150

R116

58

DALTH

ALE

7

ALE

112

RD

RD

CSIPC2

WR

111

WR

4

6

CS1

2

CSRAM1

CSRAM2

CSIPC1

RST

EN0

CSI1

9

113

1/10W4700

1/10W4700

RTP

RTP

12

12

R120

R117

GARST

3453

TO1

31

33

PWM

WRRAM

C

1

2

C49

CC2200P/50

IC12

65641GD160

VDD_PIN=130,150

VDD_PIN=100,110,120

VDD_PIN=47,67,81,90

GND_PIN=15,16,21,35,41

VDD_PIN=1,10,20,40

GND

GND_PIN=84,101,114,121

GND_PIN=42,56,79,80

GND_PIN=122,135,140

GND_PIN=145,159,160

C

D

E

[RD]

[WR]

[CS1]

[A[0:15]]

[D[0:15]]

[ALE]

[GARST]

SIZ01

SIZ03

K-RTN4

K-RTN5

K-RTN6

K-RTN7

CRG-HOM

LNS-HOM

K-RTN1

K-RTN2

K-RTN3

K-RTN0

[K-RTN7]

[K-RTN6]

[K-RTN5]

[K-RTN4]

[K-RTN3]

[K-RTN2]

[K-RTN1]

[K-RTN0]

F

MRR-HOM

[MRR-HOM]

[LNS-HOM]

[CRG-HOM]

S-CNT

DF-CNT

[S-CNT]

EXT-SW

TNR-FULL

[DF-CNT]

[TNR-FULL]

EMP-SW

[EMP-SW]

[EXT-SW]

SIZ02

[SIZ02]

[SIZ01]

SIZ05

[SIZ05]

[SIZ03]

F

2

781 65423

8

Page 13

12

543 678

1

2

GND

VDD

A

14

7407M

1

2

IC15

7

14

7407M

3

4

IC15

7

14

7407M

5

6

IC15

7

14

7407M

9

8

IC15

7

14

7407M

11

13

C

7

6

5

4

3

2

1

9

8

7

14

7

I6

I5

I4

I3

I2

I1

I0

VCC

GND

IC3

62305F

IC15

7407M

IC15

10

12

O6

O5

O4

O3

O2

O1

O0

PKUP-CLT2

FED-CLT2

RGT-CLT2

[PKUP-CLT2]

[FED-CLT2]

[RGT-CLT2]

B

MOT-ON2MOTON2

MOT-DIR

MOT-BRK

[MOT-ON2]

[MOT-DIR]

[MOT-BRK]

C

10

11

12

13

14

15

16

MOT-ON

ERS-ON

LED-CN-ON

HVT-M-ON

HVT-TR-ON

HVT-GB-ON

HVT-SP-ON

[MOT-ON]

[ERS-ON]

[LED-CN-ON]

[HVT-M-ON]

[HVT-TR-ON]

[HVT-GB-ON]

[HVT-SP-ON]

D

E

A

[D[0:15]]

[A[0:15]]

B

[CS2]

C

D

[STORE]

[WRRAM]

[CSSRAM]

E

[A16]

[RD]

D[0:15]

A16

A[0:15]

CS2

RD

STORE

WRRAM

CSSRAM

VDD

CC0.1/25

C55

A15

A14

A13

A12

A11

A10

A9

A8

A7

A6

A5

A4

A3

A2

A1

A12

A11

A10

+5VSW +24V

[LNS-D]

[LNS-C]

[SKT]

DQ7

DQ6

DQ5

DQ4

DQ3

DQ2

DQ1

DQ0

Q15

Q14

Q13

Q12

Q11

Q10

NC

3

D15

4

D14

5

D13

6

D12

7

D11

D10

8

D9

9

Q9

Q8

Q7

Q6

Q5

Q4

Q3

Q2

Q1

Q0

NC

D8

10

D7

12

D6

13

D5

14

D4

15

D3

16

D2

17

D1

18

D0

19

38

D7

19

D6

18

D5

17

D4

16

D3

15

D2

13

D1

12

D0

11

26

37

A15

36

A14

35

A13

34

A12

33

A11

32

A10

31

A9

29

A8

28

A7

27

A6

26

A5

25

A4

24

A3

23

A2

22

A1

21

39

2

20

1

C40

CC0.1/25

2

23

21

24

25

3

4

5

6

7

8

9

10

1

27

20

22

28

14

A0

PGM

CE

OE

VPP

IC13

27C1024120F1

[SKT]

A12

A11

A10

A9

A8

A7

A6

A5

A4

A3

A2

A1

A0

NE

W

E

G

VDD

GND

IC9

10C68-P45V

VDD

1

C2

GND

A9

A8

A7

A6

A5

A4

A3

A2

A1

A0

1

C2

[LNS-B]

[LNS-A]

[MRR-D]

[MRR-C]

[MRR-B]

[MRR-A]

[CTR-ON]

[PKUPCLT]

[FEDCLT]

[RGTCLT]

LNS-D

LNS-C

LNS-B

LNS-A

C24

CC0.1/25

MRR-C

MRR-B

MRR-A

C32

CC0.1/25

CTR-ON

PKUPCLT

FEDCLT FED-CLT

RGTCLT

C58

CC0.1/25

14

I3

11

I2

67

3

I0

8

VDD1

1

+5VSW

1

2

+5VSW +24V

1

1

VDD0

13

C2

C

C2

GND3

12

GND2

5

GND1

4

GND0

18

GND1FIN

17

GND0FIN

IC5

62308F

DG

14

I3

11

I2

3

I0

8

VDD1

1

VDD0

13

GND3

12

GND2

5

GND1

4

GND0

18

GND1FIN

17

GND0FIN

IC4

62308F

DG

14

I3

11

I2

67

3

I0

8

VDD1

1

VDD0

13

GND3

12

GND2

5

GND1

4

GND0

18

GND1FIN

17

GND0FIN

IC8

62308F

COM1

COM0

COM1

COM0

COM1

COM0

15

O3

10

O2

O1I1

2

O0

16

9

+24V

15

O3

10

O2

76

O1I1

2

O0

16

9

15

O3

10

O2

O1I1

2

O0

16

9

LNS-MOT-D

LNS-MOT-C

LNS-MOT-B

LNS-MOT-A

MRR-MOT-D

MRR-MOT-C

MRR-MOT-B

MRR-MOT-A

DUMMY

12

E4

K-CTR

T-CTR

PKUP-CLT

RGT-CLT

[LNS-MOT-D]

[LNS-MOT-C]

[LNS-MOT-B]

[LNS-MOT-A]

[MRR-MOT-D]

[MRR-MOT-C]

[MRR-MOT-B]

[MRR-MOT-A]

[K-CTR]

[T-CTR]

[PKUP-CLT]

[FED-CLT]

[RGT-CLT]

[PKUPCLT2]

[FEDCLT2]

[RGTCLT2]

[MOTON2]

[MOTDIR]

[MOTBRK]

[MOTON]

[ERSON]

[CN-ON]

[HVT-M]

[HVT-TR]

[HVT-GB]

[HVT-SP]

PKUPCLT2

FEDCLT2

RGTCLT2

MOTDIR

MOTBRKMRR-D

MOTON

ERSON

CN-ON

HVT-M

HVT-TR

HVT-GB

HVT-SP

CC0.1/25

CC0.1/25

C39

C67

+5VSW

GND

1

2

C

GND

DG

F

F

3

781 65423

8

Page 14

12

543 678

1

2

3

+24V

2

Q6

2SA1313Y

3

+24V

Q19

2SC2873Y

D6

1SS193

23

DG

32

D13

1SS193

MRR24V

TNR-MOT

A

[MRR24V]

B

[TNR-MOT]

+24V

A

R111

1/10W4700

RN1401

[EXT-H/L]

B

[EXTON]

EXT-H/L

EXTON

1

4700

4700

1

4700

4700

RN2401

3

Q15

2

2

Q18

3

GND

+5VSW

R110

RTP

1/10W10K

R109

12

RTP

1/10W1000

21

1/10W4700

1SS193

R112

21

RTP

1

D10

2

Q17

2SA1313Y

3

32

DG

2

Q16

1

2SC2873Y

3

RTP

12

+24V

R2

F-1W150

12

+24V

32

D11

1SS193

DG

DUMMY

E5

4700

EXT-FAN1

21

EXT-FAN2

EXT-F-ON

[EXT-FAN1]

[EXT-FAN2

[EXT-F-ON]

[MRR-CHG]

[TNRMOT]

MRR-CHG

TNRMOT

1

4700

4700

1

4700

RN2401

RN2401

+5VSW

2

Q10

3

2

Q20

3

+5VSW

RN1401

4700

1

4700

1/10W1000

R163

RTP

R82

1/10W4700

3

Q7

2

GND

21

12

1/10W10K

R162

1/10W4700

R83

RTP

RTP

12

1

RTP

12

C

R104

1/10W4700

RN1401

4700

[OPT-H/L]

OPT-H/L

D

[OPTON]

OPTON

1

4700

4700

1

4700

RN2401

3

Q13

2

2

Q12

3

GND

+5VSW

R103

12

RTP

1/10W10K

R100

RTP

1/10W1000

21

1/10W4700

RTP

12

1

D9

1SS193

R101

2

Q14

2SA1313Y

3

23

DG

1

21

RTP

2

3

E

+5VSW

[SFB-ON1]

SFB-ON1

4700

1

4700

RN2401

2

Q24

3

R187

12

RTP

1/10W1000

R186

1/10W4700

2

1

3

21

RTP

+24V

Q11

2SC2873Y

+24V

Q23

2SC2873Y

21

R3

F-1W56

12

E3

D8

1SS193

23

DG

D15

1SS193

23

DUMMY

OPT-FAN-R

OPT-FAN-F

OPT-F-ON

SFB-CLT

[OPT-FAN-R]

[OPT-FAN-F]

[OPT-F-ON]

[SFB-CLT]

[ATS-VIN]

[ATSVREF]

ATS-VIN

ATSVREF

GND

R113

12

RTP

1/10W10K

R114

12

RTP

+24V

8

5

6

4

DG

R115

RTP

1/10W10K

1/10W15K

358M

IC1

+24V

21

7

8

3

2

4

358M

IC1

DG

1

1

C53

C

2

CC0.1/50G

ATSVIN

[ATSVIN]

C

D

DG

ATS-VREF

[ATS-VREF]

E

F

F

DG

4

781 65423

8

Page 15

12

543 678

D1

A

1/10W22K

1/10W4700

+24V

R4

R6

21

RTP

RTP

12

GND

R5

12

RTP

1/10W6800

CC0.1/25

1

C7

GND

B

[TH+]

[THM-VREF]

[TH-]

TH+

THM-VREF

TH-

R170

R28

C

1/10W4700

1/10W3900

[HTR-ON]

HTR-ON

1/10W4700

21

RTP

1/10W3900

12

RTP

R27

R29

RTP

12

1

21

C2

RTP

C13

1SS184

23

1

C2

VDD

R7

RTP

1/10W10K

12

1/10W1000

R8

RTP

1/10W3300

12

CC2200P/50

GNDGNDGND

VDD

21

RTP

RTP

12

GND

R25

12

RTP

CC0.1/25

4700

1

4700

RN2401

R21

1/10W22K

R24

1/10W22K

1

[AK75393S]

C12

+5VSW

2

Q8

3

R26

3

2

C2

[AK75393S]

12

RTP

VDD

IC6

8

+

VCC

VEE

-

4

GND

RN1401

4700

1

4700

IC6

5

+

6

-

1/10W1M

1

C11

CC0.1/25

R23

21

VDD

8

7

VCC

VEE

4

GND

1

C

2

3

Q9

2

RTP

1/10W560K

RN1401

4700

1

4700

Q1

VDD

A

21

R22

RTP

1/10W4700

[RST-SW]

+5VSW

+24VCHK

RST-SW

HTR-RDY

[+24VCHK]

4700

1

4700

[HTR-RDY]

RN2401

VDD

2

Q21

3

1/10W1000

R184

RTP

D14

1SS193

21

R185

12

RTP

1/10W4700

1

+24V

32

2

Q22

2SC2873Y

3

DG

MAINOFF

[MAINOFF]

B

C

4700

3

1

4700

2

GND

RN2401

2

Q3

3

SSR+

SSR-

[SSR+]

[SSR-]

VDD

D

[SCN-H]

[SCN-L]

[SCN-D]

[SCN-B]

[SCN-C]

[SCN-A]

SCN-H

SCN-L

SCN-D

SCN-B

SCN-C

SCN-A

R31

R35

RTP

RTP

1/10W4700

21

1/10W4700

21

1SS181

R10

RTP

12

21

RTP

1

23

D2

1/10W2700

R11

1/10W1500

+5VSW

GND

R15

R13

R14

R12

16

14

15

13

11

9

1/10W4700

12

RTP

1/10W4700

21

RTP

1/10W4700

21

RTP

1/10W4700

12

RTP

NB

B

NA

A

VREF1

VREF0

ONB

OB

ONA

OA

TB1

TB0

E

1

VCC

4

CC0.1/25

C10

GND

1

C2

1/10W180

R9

RTP

12

CC0.1/25

1

C8

2

C

GNDGND

5

PG

SG

IC7

6712MK3

VDD

D

7

6

3

2

10

8

+24V

1

C1

CE22/35

2

SCN-MOT-D

SCN-MOT-B

SCN-MOT-C

SCN-MOT-A

6712G

[SCN-MOT-D]

[SCN-MOT-B]

[SCN-MOT-C]

[SCN-MOT-A]

E

[6712G]

F

F

5

781 65423

8

Page 16

12

VDD

543 678

A

A

VDD

D3

C3

CE4.7/16

1

2

C

GND

1SS184

32

1

CC0.1/25

C31

R60

D5

RTP

12

RN1401

1

4700

32

4700

MC74

10

9

HC

00F

8

IC16

R61

3

Q5

2

GND

13

12

RTP

MC74

HC

00F

1/10W1000

21

11

IC16

4700

1

4700

RN2401

R42

1/10W4700

11

BB

5

BA

12

AB

4

AA

14

CX/RXB

2

CX/RXA

13

CLRB

3

CLRA

16

VDD

1

15

GND2

8

GND

1

GND1

GND0

IC20

14538F

MC74

5

HC

4

00F

C2

NQB

NQA

IC16

QB

QA

6

10

6

9

7

1SS193

+5VSW

2

Q4

3

1/10W4700

12

RTP

2

Q2

1

2SA1313Y

3

R59

12

RTP

VDD

R39

RTP

1/10W4700

12

GND

1/10W330

+5VSW

EXP-ON

[EXP-ON]

B

C

1/10W100K

1/10W820K

21

RTP

RTP

12

R78

R79

[EXP]

B

[5VSWON]

EXP

5VSWON

R62

R75

C

[WDT]

WDT

1/10W1000

12

RTP

1/10W1000

21

RTP

CC0.1/25

C23

1

1

C2

GND GND

1/10W4700

C2

R76

RTP

C21

CC0.1/25

CE22/16

21

C5

CC2200P/50

MC74

2

HC

1

00F

1

2

IC16

1

2

GNDGND

C22

3

1/10W22K

VDD

MC74

HC14F

IC19

MC74

HC14F

IC19

65

1/10W4700

R92

1/10W4700

21 RST

RTP

1

C28

CC2200P/50

C2

GND

R77

1213

RTP

1/10W4700

21

MC74

HC14F

IC19

43

R91

D7

1SS181

1

23

1

C2

CE4.7/16

2

GND

RTP

1/10W1800

21

R67

12

RTP

MC74

HC14F

IC19

89

7407M

1213

IC18

DSP-RST

GARST

5VCHK

[RST]

[DSP-RST]

[GARST]

[5VCHK

D

E

VDD

D

R94

RTP

1/10W4700

12

[ACOFF]

ACOFF

R93

12

RTP

E

F

F

6

781 65423

8

Page 17

12

VDD

VDD

VDD

+24V

C64

GND

E1

R1

1

CC0.1/50G

C

2

DG

DUMMY

12

E2

+5VE

GNDE

21

GND

SSR+1

RXE017

21

1

2

C

1

C2

GND

TNR-FULL

ATS-VREF

LED-CN-ON

C52

CC0.1/25

C70

CC0.1/25

TNR-MOT

DEV-SW

ATS-VIN

DRM-THM

LED-SCK

LED-DAT

LED-LTH

ERS-ON

6712G

ACOFF

EXT-SW

SSR-

SSR+

TH+

TH-

ZC

[TNR-MOT]

[TNR-FULL]

[DEV-SW]

[ATS-VREF]

[ATS-VIN]

[DRM-THM]

[LED-CN-ON]

[LED-SCK]

[LED-DAT]

[LED-LTH]

[ERS-ON]

[6712G]

[ZC]

[SSR-]

[ACOFF]

[EXT-SW]

[SSR+]

[TH+]

[TH-]

J5

10

11

12

13

14

15

16

17

18

19

20

CNTROL-PANEL

FED+RGT_UNIT

21

22

23

24

25

26

27

28

29

30

J8

10

11

12

13

14

15

16

17

18

19

20

21

22

53313-30V

1

2

3

4

5

6

7

8

9

17513222V

1

2

3

4

5

6

7

8

9

VDD

+24V

VDD

GND

A

175132-24

J9

B

PROCESS

C

J3

D

POWER

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

+24V

53324-12

1

2

3

4

5

6

7

8

9

10

11

12

DG

E

175487-7V

J7

FUSER

1

2

3

4

5

6

7

543 678

VDD

+24V

GND

CTR-SIG

CTR-CNT

T-CTR

DSP-DAT

DSP-SCK

DSP-LTH

DSP-RST

DSP-ON0

DSP-ON1

K-RTN0

K-RTN1

K-RTN2

K-RTN3

K-RTN4

K-RTN5

K-RTN6

K-RTN7

SIZ05

SIZ03

SIZ02

SIZ01

RGT-CLT

RGT-SW

FED-CLT

PKUP-CLT

EMP-SW

SCN0

SCN1

SCN2

SCN3

SCN4

SCN5

[CTR-SIG]

[CTR-CNT]

[T-CTR]

[DSP-DAT]

[DSP-SCK]

[DSP-LTH]

[DSP-RST]

[DSP-ON0]

[DSP-ON1]

[SCN0]

[SCN1]

[SCN2]

[SCN3]

[SCN4]

[SCN5]

[K-RTN0]

[K-RTN1]

[K-RTN2]

[K-RTN3]

[K-RTN4]

[K-RTN5]

[K-RTN6]

[K-RTN7]

[SIZ05]

[SIZ03]

[SIZ02]

[SIZ01]

[RGT-CLT]

[RGT-SW]

[FED-CLT]

[PKUP-CLT]

[EMP-SW]

J11

OPTICAL-UNIT

J4

UPPER-UNIT

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

53313-22V

53313-18V

+24V

GND

+24V

12

JMP5

JP1

GND

VDD

MRR-MOT-D

MRR-MOT-C

MRR24V

MRR-MOT-B

MRR-MOT-A

MRR-HOM

AES-VIN

SCN-MOT-D

SCN-MOT-C

SCN-MOT-B

SCN-MOT-A

LNS-MOT-D

LNS-MOT-C

LNS-MOT-B

LNS-MOT-A

LNS-HOM

OPT-FAN-F

OPT-F-ON

EXT-FAN1

EXT-F-ON

EXT-FAN2

K-CTR

CTR-SIG

CRG-HOM

OPT-FAN-R

[MRR-MOT-D]

[MRR-MOT-C]

[MRR24V]

[MRR-MOT-B]

[MRR-MOT-A]

[MRR-HOM]

[AES-VIN]

[SCN-MOT-D]

[SCN-MOT-C]

[SCN-MOT-B]

[SCN-MOT-A]

[LNS-MOT-D]

[LNS-MOT-C]

[LNS-MOT-B]

[LNS-MOT-A]

[LNS-HOM]

[OPT-FAN-F]

[OPT-F-ON]

[EXT-FAN1]

[EXT-F-ON]

[EXT-FAN2]

[K-CTR]

[CTR-SIG]

[CRG-HOM]

[OPT-FAN-R]

A

B

C

D

E

F

GND

781 65423

F

7

8

Page 18

12

543 678

GND

MC74

HC14F

1011

IC19

40p 47p 67p 81p

C50

C43

1

2

1

2

C

C

CC0.1/25

CC0.1/25

C51

C44

1

1

C2

C2

CC0.1/25

CC0.1/25

C46

C62

1

2

C

1

2

C

CC0.1/25

C42

A

1

C2

B

C

7407M

43

A

+24V

GND

VDD

53324-9

MOT-FG

MOT-DIR

PLL-OK

MOT-BRK

MOT-ON

EXP-PWM

EXP-ON

SP-VREF

HVT-SP-ON

HVT-GB-ON

TR-VREF

HVT-TR-ON

G-VREF

HVT-M-ON

M-VREF

DG

[MOT-FG]

[MOT-DIR]

[PLL-OK]

[MOT-BRK]

[MOT-ON]

[EXP-PWM]

[EXP-ON]

[SP-VREF]

[HVT-SP-ON]

[HVT-GB-ON]

[TR-VREF]

[HVT-TR-ON]

[G-VREF]

[HVT-M-ON]

[M-VREF]

J1

SORTER

J2

DF

1

2

3

4

5

6

7

8

9

GND

53324-10

1

2

3

4

5

6

7

8

9

10

SACK

S-REQ

REQ-S

S-CNT

SRXD

STXD

ACKB-S

DFACK

DF-REQ

REQ-DF

DF-CNT

DFRXD

DFTXD

ACKB-DF

[SACK]

[S-REQ]

[REQ-S]

[S-CNT]

[SRXD]

[STXD]

[ACKB-S]

[DFACK]

[DF-REQ]

[REQ-DF]

[DF-CNT]

[DFRXD]

[DFTXD]

[ACKB-DF]

VDD

CC0.1/25

GND

VDD

CC0.1/25

GND

GND

1

C59

C2

90p 100p 110p 120p 130p 150p

1

C61

2

C

C45

CC0.1/25

C47

CC0.1/25

53313-24V

J10

B

MOT_HVT_LRG

C

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

IC18

7407M

65

IC18

10p 20p1p

1

CC0.1/25

2

C

1

CC0.1/25

C2

C60

C56

1

1

2

C2

C

CC0.1/25

CC0.1/25

VDD

CC0.1/25

GND

VDD

CC0.1/25

GND

14p 14p 14p 14p 14p 14p 14p

C63

1

C9

2

C

1

C2

C66

C29

IC-

1

1

2

C2

36p

C

CC0.1/25

CC0.1/25

C35

C18

1

CC0.1/25

2

C

MPUMPU

77p

1

CC0.1/25

C2

C30

C15

1

1

2

C2

7p7p7p

C

CC0.1/25

CC0.1/25

1

C36

C48

CC0.1/25

2

C

7p 7p 7p 7p

1

CC0.1/25

C2

C68

C65

1

1

2

C2

C

CC0.1/25

CC0.1/25

CC0.1/25

CC0.1/25

C20

C57

1

C2

D

1

2

C

E

C38

C16

GND

1

C2

1

C2

+24V

MAINOFF

CE47/16

C6

C4

[MAINOFF]

1

2

CE47/35

1

2

VDD

GND

+24V

DG

DR-SW2

EMP-SW2

FED-SW2

MOT-ON2

SIZ10

SIZ11

SIZ12

SIZ13

FED-CLT2

PKUP-CLT2

RGT-CLT2

SFB-SET

SFB-CLT

SFB-PSW

CST2

[DR-SW2]

[EMP-SW2]

[FED-SW2]

[MOT-ON2]

[CST2]

[SIZ10]

[SIZ11]

[SIZ12]

[SIZ13]

[FED-CLT2]

[PKUP-CLT2]

[RGT-CLT2]

[SFB-SET]

[SFB-CLT]

[SFB-PSW]

J13

MAIN-SW

+24V

CC0.1/50G

DG

VDD

CC0.1/25

GND

53052-2V

1

2

+5VSW

17513218V

J6

D

PFU

E

J12

SFB

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

53324-7

1

2

3

4

5

6

7

VDD

+24V

F

F

GND

8

781 65423

8

Page 19

SFB-CLT

TNR-MOT

SNR-ATS

ERS

MRR-MOT

MRR-HOME

PWA-F-AES

73

1

2

3

4

DRM-THMS

ACC

J532

T-FULL-SW

DCH

1

2

SFB-PSW

321

1234567

1234567

J12

79

5

1

4

2

3

3

2

4

1

5

80

3

3

2

2

1

1

3

3

2

2

1

1

25

SCN-MOT

LNS-MOT

1

3

75

2

2

3

1

76

1

2

74

6

1

5

2

4

3

3

4

2

5

1

6

90

211

2

1

2

3

4

5

6

7

8

9

10

11

21

M/DC-MAIN

1

2

3

4

PS-LRG

PS-HVT

10

11

11

10

11

10

81

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

1

2

3

4

5

77A

9

8

7

6

5

4

3

2

1

122

78

9

8

7

6

5

4

3

2

1

77B

A

J11

11

10

9

8

7

6

5

4

3

2

1

82

B

6

5

4

3

2

1

83

5

4

3

2

1

A

531

7

6

5

4

3

2

1

4

3

2

1

B

502

511

10

9

8

7

6

5

4

3

2

1

11

A

10

9

8

7

6

5

4

3

2

1

1

B

11

10

9

8

7

6

5

4

3

2

1

MRR-MOT-D

1

1

MRR-MOT-C

2

2

MRR-24V

3

3

MRR-MOT-B

4

4

MRR-MOT-A

5

5

GND

6

6

MRR-HOM

7

7

VDD

8

8

+24V

9

9

AES-VIN

10

10

GND

11

11

1

+24V

12

2

SCN-MOT-D

13

3

SCN-MOT-C

14

4

SCN-MOT-B

15

5

SCN-MOT-A

16

6

+24V

17

7

LNS-MOT-D

18

8

LNS-MOT-C

19

9

+24V

20

10

LNS-MOT-B

21

11

LNS-MOT-A

22

J10

MOT-FG

1

1

VDD

2

2

MOT-DIR

3

3

PLL-OK

4

4

MOT-BRK

5

5

MOT-ON

6

6

GND

7

7

VDD

8

8

EXP-PWM

9

9

EXP-ON

10

10

GND

11

11

12

12

13

1

14

2

SP-VREF

15

3

HVT-SP-ON

16

4

HVT-GB-ON

17

5

TR-VREF

18

6

HVT-TR-ON

19

7

DG

20

8

+24V

21

9

G-VREF

22

10

HVT-M-ON

23

11

M-VREF

24

12

J9

+24V-TNR

1

1

TNR-MOT

2

2

TNR-FULL

3

3

GND

4

4

DEV-SW

5

5

GND

6

6

ATS-VREF

7

7

+24V

8

8

ATS-VIN

9

9

DG

10

10

DRM-THMS

11

11

GND

12

12

13

1

LED-CN-ON

14

2

+24V

15

3

GNDE

16

4

+5VE

17

5

LED-SCK

18

6

LED-DAT

19

7

LED-LTH

20

8

GND

21

9

VDD

22

10

+24V

23

11

ERS-ON

24

12

SFB-SET

SIZ04

SIZ05

123456789

J8

123456789

A

5

6

65

GND

4

SIZ-SW

+24V

SIZ02

3

SFB-CLT

GND

SIZ01

1

2

GND

SFB-PSW

+24V

68

VDD

RGT-SW

GND

RGT-CLT

10

10

4

5

2

1

1

2

2

1

1

1

J13

+24V

VDD

11

1213141516171819202122

123456789

11

B

1

2

3

66

5

4

3

1

2

3

69

71

RGT-SW

MAIN-SW

2

2

MAINOFF

67

1

2

2

1

+24V

4

1

70

+24V

FED-CLT

2

3

3

2

1

2

2

1

EMP-SW

GND

PKUP-CLT

10

1

4

2

3

EMP-SW

J8123456789101112

FG

123456789

J112345678

SACK

S-REQ

ERQ-S

VDD

11

1

72

62 63

VDD

EXT-SW

GND

1234567

J7

1234567

321

64

3

2

1

1

2

3

EXT-SW

S-CNT

SSR+

432

1

TH+

2

HTR-

SRXD

TH-

3

THMS

GND

STXD

SSR+1

1

4

GND

9

ACKB-S

ACC

J523

FED-SW2

EMP-SW2

DR-SW2

+5VSW

123456789

J6

123456789

A

A

987654321

J39

123456789

GND

FED-SW

VDD

DR-SW2

GND

1234567

1234567

J36

J8123456789101112

FG

123456789

J212345678910

DFACK

DF-CNT

DF-REQ

REQ-DF

CST2

MOT-ON2

GND

VDD

+24V

BB

+24V

PK2-ON

+24V

RGT2-0

123456789

123456789

J38

SIZ10

SIZ11

101112131415161718

123456789

987654321

101112131415161718

FED2-0

GND

GND

DFRXD

SIZ12

SIZ13

EMP-SW

VDD

GND

DFTXD

+24V

SIZ13

10

ACKB-DI

FED-CLT2

PKUP-CLT

RGT-CLT2

SIZ12

N.C.

SIZ11

101112

101112

ACC

J524

DG

SIZ10

+24V

+24V

DG

DG

VDD

GND

+5VE

GNDE

ZC

SSR+1

SSRACOFF

VDD

LNS-HOM

GND

OPT-FAN-F

OT-F-ON

EXT-FAN1

EXT-F-ON

EXT-FAN2

EXT-F-ON

+24V

K-CTR

STR-SIG

VDD

CRG-HOM

VDD

GND

OPT-FAN-R

OPT-F-ON

CTR-SIG

CTR-CNT

T-CTR

+24V

GND

GND

VDD

VDD

VDD

DSP-DAT

DSP-SCK

DSP-LTH

DSP-RST

DSP-ON0

DSP-ON1

SCN0

SCN1

SCN2

SCN3

SCN4

SCN5

K-RTN0

K-RTN1

K-RTN2

K-RTN3

K-RTN4

K-RTN5

K-RTN6

K-RTN7

PWA-F-PFU

GND

13

13

J3

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

J4

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

1

11

2

12

3

13

4

14

5

15

6

16

7

17

8

18

9

J5

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

13

13

14

14

15

15

16

1

17

2

18

3

19

4

20

5

21

6

22

7

23

8

24

9

25

10

26

11

27

12

28

13

29

14

30

15

PFU-

DG

1

2

1

2

J37

J521

12

12

11

10

9

8

7

6

5

4

3

2

1

1

2

3

K-CTR

CRG-HOME

2

57

60

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

1

2

3

4

5

6

7

8

9

10

11

12

13

14

61

PS-ACC

J523

J524

J522

11

10

9

8

7

6

5

4

3

2

1

3

2

1

59

4

3

2

1

58

3

2

1

211

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

14

13

12

11

10

9

8

7

6

5

4

3

2

1

1

2

1

2

3

1

2

3

4

5152

3

2

1

53

211

211

54

OPT-FANR

18

4

3

2

1

11

10

9

8

7

6

5

4

3

2

1

14

13

12

11

10

9

8

7

6

5

4

3

2

1

+24V

DG

+24V

DG

J532

+24V

+24V

DG

DG

LNS-HOME

2

2

1

2

3

4

16

PWA-F-PNL

17

J88

11

12

J89

11

12

1

2

MAIN-MOT

3

4

OPT-FANF

EXT-FAN

T-CTR

RGT1-CLT

FED1-CLT

CLT

PKUP1-

104

2

1

2

321

2

106

FED-SW2

1

DR-SW2

107

108

1

2

RGT2-CLT

101

1

1

102

2

PKUP2-CLT

103

21321654321

1

2

SIZE-SW2

EMP-SW2

FED2-CLT

PFU-MOT

PFU

MY-1004

Loading...

Loading...