Page 1

BSI(Service Note) TOSHIBA

TOSHIBA TEC CORPORATION

2-4-1, Shibakoen, Minato-ku, TOKYO, 105-8524 JAPAN

BSI No

F97F933

SUBJECT

Change of Adjustment of the RADF Reversing Roller Belt Tension

MODEL

CATEGORY

Treatment in the field, To

improve the productivity

From Jul. 1997

CONTENT

For easier adjustment of the RADF reversing roller driving belt tension, the tension spring has been

changed to a stronger one.

The method of adjusting this part has been omitted from the Service Manual ; the new adjustment

method is shown below together with the current one.

5560, 6560, 7550, 7560, 7650, 7660, A75

FIELD APPLICATION

To be applied when necessary

FACTORY APPLICATION

UNIT

ADF

Date

97/08/22

DTM-F7513

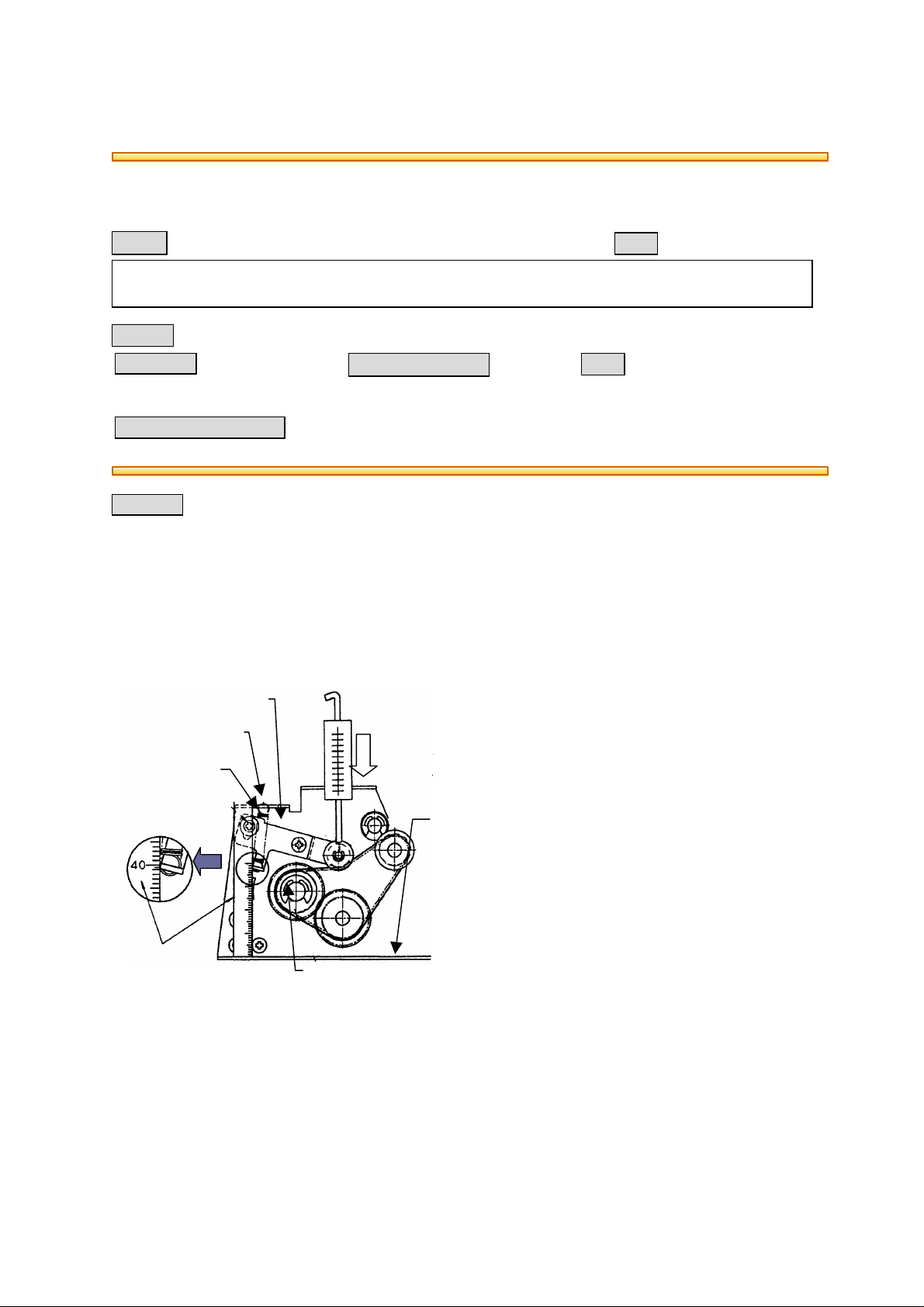

[ Current tension adjustment method - applied before the spring change ]

Retighten the fixing screw while pushing the top edge of the tension lever with a force of 1kg.

Tension lever

Tension spring

1 Kg

Fixing screw

39.0~39.5mm

(Reference value)

Scale

Reversing roller shaft

Lower frame

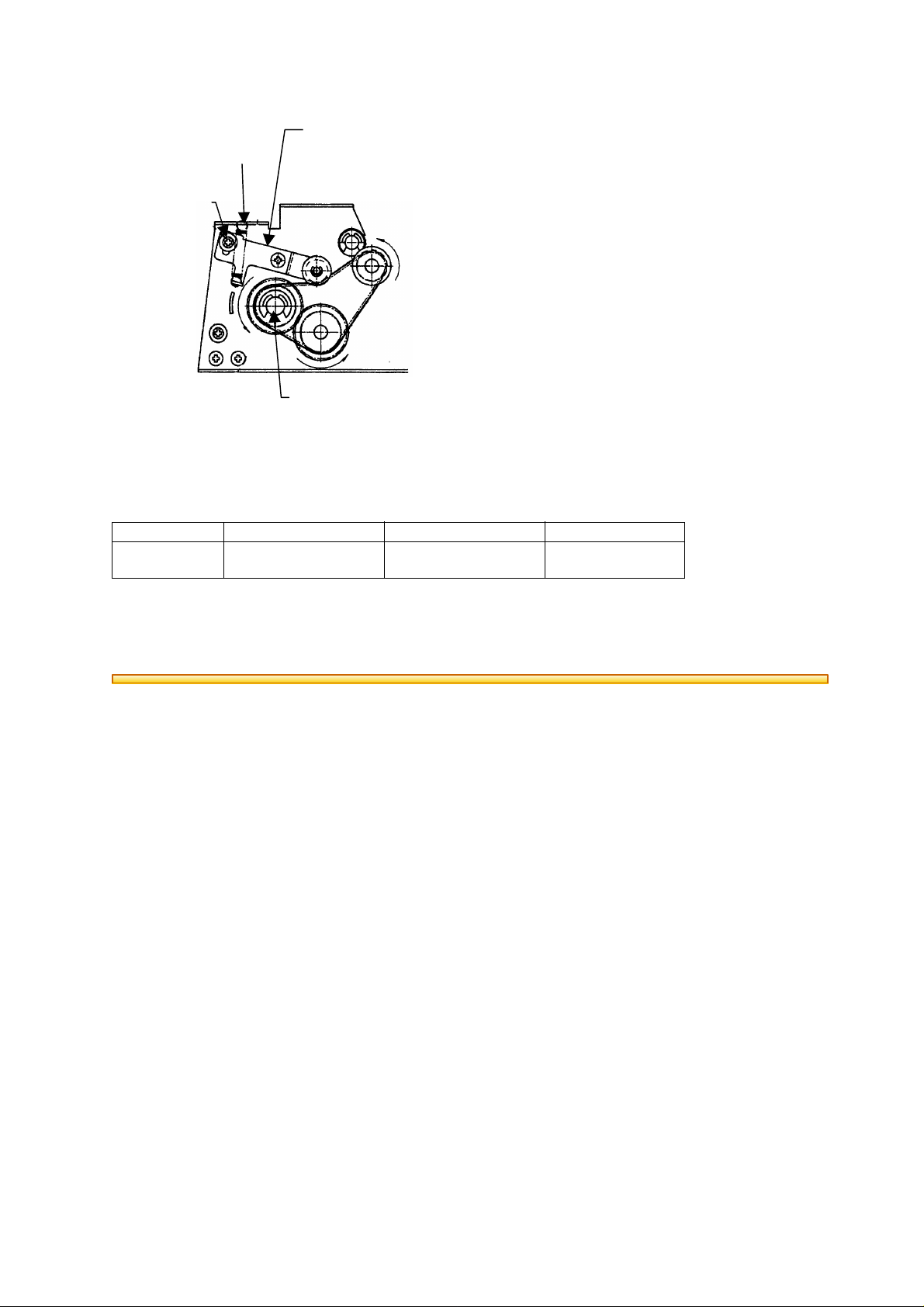

[ New tension adjustment method - applied after the spring change ]

Retighten the fixing screw with the tension lever pulled by the tension spring.

Page 2

BSI No. F97F933 Page 2

Tension spring

Fixing screw

Tension lever

Reversing roller shaft

[ For distinction between the new spring and the current one ]

The tension spring of copiers to which the new adjustment method is applied is marked in blue.

( Be careful as the new tension springs supplied as service parts are not marked in blue.)

[ Change of Part ]

Part Name Current New Interchangeability

Tension spring 4401791530

SPE054-035-0162

4401914880

SPE067-070-0181

B

[ Note ]

The current tension spring is used in the 6550 (RADF), but for this model the new adjustment

method has already been used, so the new stronger tension spring is not required. When

changing parts or readjusting, be careful not to make an error.

Loading...

Loading...