Toshiba e-STUDIO 3005AC, e-STUDIO 2008A, e-STUDIO 4505AC, e-STUDIO 5005AC, e-STUDIO 3508A Hardware Troubleshooting Manual

...

MULTIFUNCTIONAL DIGITAL COLOR SYSTEMS /

MULTIFUNCTIONAL DIGITAL SYSTEMS

Hardware Troubleshooting

Guide

©2016 TOSHIBA TEC CORPORATION All rights reserved

Under the copyright laws, this manual cannot be reproduced in any form without prior written permission of TTEC.

Preface

Thank you for purchasing TOSHIBA Multifunctional Digital Systems. This manual describes how to troubleshoot the

problems that could occur while you are using the equipment. Keep this manual within easy reach, and use it to

configure an environment that makes the best use of the e-STUDIO’s functions.

This equipment provides the scanning/printing function as an option. However, this optional scanning/printing

function is already installed in some models.

How to read this manual

Symbols in this manual

In this manual, some important items are described with the symbols shown below. Be sure to read these items

before using this equipment.

Indicates a potentially hazardous situation which, if not avoided, could result in death, serious

injury, or serious damage, or fire in the equipment or surrounding objects.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury, partial damage to the equipment or surrounding objects, or loss of data.

Indicates information to which you should pay attention when operating the equipment.

Describes handy information that is useful to know when operating the equipment.

Pages describing items related to what you are currently doing. See these pages as required.

Target audience for this manual

This is a manual that is aimed at general users and administrators.

Model and series names in this manual

In this manual, each model name is replaced with the series name as shown below.

Model name Series name in this manual

e-STUDIO2000AC/2500AC e-STUDIO5005AC Series

e-STUDIO2505AC/3005AC/3505AC/4505AC/5005AC

e-STUDIO2008A/2508A/3008A/3508A/4508A/5008A e-STUDIO5008A Series

Options

For the available options, refer to the Quick Start Guide for this equipment.

Screens in this manual

The details on the screens may differ depending on your model and how the equipment is used, such as the status

of the installed options, the OS version and the applications.

The illustration screens used in this manual are for paper in the A/B format. If you use paper in the LT format, the

display or the order of buttons in the illustrations may differ from that of your equipment.

Preface 3

Abbreviations in this manual

In this manual, “Dual Scan Document Feeder” is referred to as “DSDF” and “Reversing Automatic Document Feeder”

as “RADF”, and they are collectively referred to as “Automatic Document Feeder” (ADF).

Trademarks

For trademarks, refer to the Safety Information.

4 Preface

CONTENTS

Preface................................................................................................................................................. 3

How to read this manual ............................................................................................................................................ 3

Chapter 1 TROUBLESHOOTING FOR THE HARDWARE

When This Screen Is Displayed................................................................................................................ 9

Messages Displayed on the Touch Panel ................................................................................................ 13

Clearing a Paper Misfeed...................................................................................................................... 18

Locating a paper misfeed .......................................................................................................................................... 18

Clearing a paper misfeed........................................................................................................................................... 19

ADF.............................................................................................................................................................................. 21

Drawer feeding portion ............................................................................................................................................. 27

Large Capacity Feeder ............................................................................................................................................... 28

Paper Feed Pedestal .................................................................................................................................................. 28

Drawers (e-STUDIO2000AC/2500AC)......................................................................................................................... 29

Drawers (Except for e-STUDIO2000AC/2500AC) ....................................................................................................... 30

Envelope Drawer........................................................................................................................................................ 31

Large Capacity Feeder ............................................................................................................................................... 31

Bypass tray ................................................................................................................................................................. 32

Automatic duplexing unit .......................................................................................................................................... 33

Paper transport path ................................................................................................................................................. 34

Fuser unit.................................................................................................................................................................... 35

Job Separator ............................................................................................................................................................ 38

Bridge Kit.................................................................................................................................................................... 39

Finisher and Hole Punch Unit.................................................................................................................................... 39

Saddle Stitch Finisher and Hole Punch Unit............................................................................................................. 45

Saddle Stitch unit of the Saddle Stitch Finisher....................................................................................................... 48

Inner Finisher and Hole Punch Unit .......................................................................................................................... 54

Clearing paper misfeeds caused by a wrong paper size setting.............................................................................. 57

Clearing a Staple Jam .......................................................................................................................... 63

Finisher....................................................................................................................................................................... 63

Saddle Stitch unit ...................................................................................................................................................... 68

Replacing a Toner Cartridge ................................................................................................................. 70

Color models .............................................................................................................................................................. 70

Monochromatic models............................................................................................................................................. 72

Replacing a “Near Empty” toner cartridge ............................................................................................................... 74

Replacing the Waste Toner Box (Color Models)....................................................................................... 77

Refilling With Staples .......................................................................................................................... 79

Finisher....................................................................................................................................................................... 79

Saddle Stitch unit ...................................................................................................................................................... 82

Cleaning the Inside of the Equipment.................................................................................................... 85

The Main Chargers and LED Print Heads (e-STUDIO2000AC/2500AC) .................................................................... 85

The Main Chargers and Slit Glass (e-STUDIO2505AC/3005AC/3505AC/4505AC/5005AC)....................................... 88

The Main Chargers (e-STUDIO5008A Series)............................................................................................................. 92

Cleaning the Hole Punch Dust Bin ......................................................................................................... 93

Finisher / Saddle Stitch Finisher Hole Punch Unit ................................................................................................... 93

Inner Finisher Hole Punch Unit ................................................................................................................................. 93

When Printed Sheets Overflow from the Exit Tray .................................................................................. 96

Chapter 2 WHEN SOMETHING IS WRONG WITH THE EQUIPMENT

When You Think Something Is Wrong With the Equipment ...................................................................... 98

General operations .................................................................................................................................................... 98

CONTENTS 5

Originals and paper ................................................................................................................................................... 99

Regular Maintenance..........................................................................................................................101

INDEX .........................................................................................................................................................103

6 CONTENTS

1.TROUBLESHOOTING FOR THE HARDWARE

This chapter describes how to troubleshoot problems with paper, toner and other finishing processes.

This chapter also describes how to supply the paper, toner and staples.

When This Screen Is Displayed.............................................................................................9

Messages Displayed on the Touch Panel .............................................................................13

Clearing a Paper Misfeed...................................................................................................18

Locating a paper misfeed ....................................................................................................................................18

Clearing a paper misfeed.....................................................................................................................................19

ADF........................................................................................................................................................................21

Drawer feeding portion .......................................................................................................................................27

Large Capacity Feeder .........................................................................................................................................28

Paper Feed Pedestal ............................................................................................................................................28

Drawers (e-STUDIO2000AC/2500AC)...................................................................................................................29

Drawers (Except for e-STUDIO2000AC/2500AC) .................................................................................................30

Envelope Drawer..................................................................................................................................................31

Large Capacity Feeder .........................................................................................................................................31

Bypass tray ...........................................................................................................................................................32

Automatic duplexing unit ....................................................................................................................................33

Paper transport path ...........................................................................................................................................34

Fuser unit..............................................................................................................................................................35

Job Separator ......................................................................................................................................................38

Bridge Kit..............................................................................................................................................................39

Finisher and Hole Punch Unit..............................................................................................................................39

Saddle Stitch Finisher and Hole Punch Unit.......................................................................................................45

Saddle Stitch unit of the Saddle Stitch Finisher.................................................................................................48

Inner Finisher and Hole Punch Unit ....................................................................................................................54

Clearing paper misfeeds caused by a wrong paper size setting........................................................................57

Clearing a Staple Jam .......................................................................................................63

Finisher.................................................................................................................................................................63

Saddle Stitch unit ................................................................................................................................................68

Replacing a Toner Cartridge ..............................................................................................70

Color models ........................................................................................................................................................70

Monochromatic models.......................................................................................................................................72

Replacing a “Near Empty” toner cartridge .........................................................................................................74

Replacing the Waste Toner Box (Color Models)....................................................................77

Refilling With Staples........................................................................................................79

Finisher.................................................................................................................................................................79

Saddle Stitch unit ................................................................................................................................................82

Cleaning the Inside of the Equipment.................................................................................85

1.TROUBLESHOOTING FOR THE HARDWARE

The Main Chargers and LED Print Heads (e-STUDIO2000AC/2500AC) ..............................................................85

The Main Chargers and Slit Glass (e-STUDIO2505AC/3005AC/3505AC/4505AC/5005AC) ................................88

The Main Chargers (e-STUDIO5008A Series) ......................................................................................................92

Cleaning the Hole Punch Dust Bin.......................................................................................93

Finisher / Saddle Stitch Finisher Hole Punch Unit ............................................................................................. 93

Inner Finisher Hole Punch Unit ...........................................................................................................................93

When Printed Sheets Overflow from the Exit Tray ...............................................................96

8

0.When This Screen Is Displayed

Various screens are displayed on the touch panel depending on the state of the equipment. This section describes

how to solve problems with some of the screen examples.

Screen Description / Remedy

A message appears on the upper

part of the screen to notify users of a

problem, etc. For the major

examples, see the following pages.

P.13 “Messages Displayed on the

Touch Panel”

TROUBLESHOOTING FOR THE HARDWARE

When This Screen Is Displayed 9

1.TROUBLESHOOTING FOR THE HARDWARE

Screen Description / Remedy

An incorrect paper size or “ ”

indicates an unsuccessful paper size

detection. In this case, check the

following items.

Check if the paper with an

unacceptable size is placed in the

drawer.

For details about the acceptable

paper size, refer to the

Specifications Guide.

Check if the paper with a

non-standard size is placed in the

drawer.

Press [Custom] to set the paper

size manually.

Check if there is too much space

between the paper and the side

and end guides of the drawer.

Set the paper, the side guide and

the end guide to the appropriate

position again.

Check if [Auto (inch)] is selected

even though A/B format paper has

been placed. Check if [Auto (mm)]

is selected even though LT format

paper has been placed.

Press the button which

corresponds to the format of the

paper set in the drawer and then

set the paper again.

If a different paper size is

displayed even though a standard

size paper has been placed, set

the paper size manually. To do so,

the change of the setting by the

administrator is required. For

details, refer to the MFP

Management Guide.

10 When This Screen Is Displayed

1.TROUBLESHOOTING FOR THE HARDWARE

Screen Description / Remedy

The original or copy paper is misfed.

Remove it following the guidance

on the touch panel.

P.18 “Clearing a Paper Misfeed”

A cover is open. Check which cover

on the touch panel and then close it

securely.

TROUBLESHOOTING FOR THE HARDWARE

Toner has run out. Replace the new

toner cartridge.

P.70 “Replacing a Toner

Cartridge”

When This Screen Is Displayed 11

1.TROUBLESHOOTING FOR THE HARDWARE

Screen Description / Remedy

The waste toner box is full. Replace

it following the guidance on the

touch panel.

P.77 “Replacing the Waste Toner

Box (Color Models)”

The equipment requires adjusting

by a service technician.

Contact your service representative

with the error code displayed on the

right side of the touch panel.

Never attempt to repair,

disassemble or modify the

equipment by yourself.

You could cause a fire or get an

electric shock.

Always contact your service

representative for maintenance or

repair of the internal parts of the

equipment.

12 When This Screen Is Displayed

0.Messages Displayed on the Touch Panel

A message appears on the upper part of the screen to notify users of a problem, etc. The major examples of problems

and how to solve them are described in the table below.

Message Problem Description Corrective Action

TROUBLESHOOTING FOR THE HARDWARE

Close *** cover. The cover indicated by *** is

open.

Misfeed in *** Paper misfeed has occurred

inside the equipment.

Install new *** toner cartridge No toner is left. (For color

models, “***” indicates the

applicable color.)

(The colors are shown

abbreviated when two or more

toners are running out: Y:

yellow, M: magenta, C: cyan,

and K: black)

*** Toner Not Recognized

Check the toner cartridge

The toner cartridge indicated by

*** is not installed at all or

improperly so.

The terminal of the toner

cartridge is stained.

The recommended toner

cartridge is not being used.

Check paper size setting on

control panel for drawer N.

Check the direction or size of

the paper.

Paper misfeed has occurred

because of the mismatch

between the paper size placed

in drawer N and the size

registered for the drawer N in

the equipment.

Check the cover on the touch panel and close

it.

Remove the misfed paper following the

guidance displayed on the touch panel.

P.18 “Clearing a Paper Misfeed”

See the color indication on the touch panel

and replace the toner cartridge.

(For color models, about another 50 copies

can be made after this message appears. The

number varies depending on the conditions

of copying.)

P.70 “Replacing a Toner Cartridge”

Install the toner cartridge correctly.

P.70 “Replacing a Toner Cartridge”

Wipe the terminal with a soft cloth.

Use the recommended toner cartridge.

P.70 “Replacing a Toner Cartridge”

Just removing the misfed paper does not

prevent another paper from being misfed. Be

sure to correctly register the paper size in the

equipment.

P.57 “Clearing paper misfeeds caused by a

wrong paper size setting”

Wait (Performing Self-check) The equipment is undergoing

maintenance to keep its

imaging quality.

Adjusting. Wait until printing

resumed.

The equipment is performing

the adjustment of its inside

temperature.

Time for cleaning. Open the

front cover and follow the

guidance.

Check the original and set it

again

The main charger, LED print

head or slit glass needs

cleaning.

The original is misfed inside of

the ADF.

The direction or the size of the

original placed on the ADF is

incorrect.

Change direction of original The orientation of the original

placed on the original glass is

incorrect.

Wait until the adjustment is completed and

the message disappears.

Wait until the adjustment is completed and

the message disappears.

Clean the main charger, LED print head and

slit glass.

P.85 “Cleaning the Inside of the

Equipment”

Remove the misfed original following the

guidance on the touch panel.

P.21 “ADF”

Check the direction and the size of the

original and then replace it on the ADF. Then

reattempt the operation.

Change the orientation of the original by 90

degrees and place it on the original glass.

Messages Displayed on the Touch Panel 13

1.TROUBLESHOOTING FOR THE HARDWARE

Message Problem Description Corrective Action

Cannot print this paper size

Select the other drawer.

Cannot print this paper type

Set the other paper type

Change from this mode

Count over, cannot store

anymore

Ready(*** Toner Not

Recognized)

Check the toner cartridge

Printing was attempted but

failed. The paper could not be

output on the tray selected for

the paper output because of a

mismatch between the paper

size and the tray.

Printing was attempted but

failed.

The paper could not be output

in the tray selected because of a

mismatch between the paper

type and the tray.

(Special paper, thick 4 paper or

thin paper tried to be output on

the lower receiving tray of

MJ-1109/MJ-1110.)

The number of originals to be

scanned has exceeded the limit

specified with the department

or user code during scanning.

The toner cartridge indicated by

*** is not installed at all or

improperly so.

Delete the failed print job, select the

appropriate tray for the paper, and perform

printing again.

For the restrictions of the paper type and the

receiving trays, refer to the Quick Start Guide.

Delete the failed print job, select the

appropriate tray for the paper, and perform

printing again.

Ask your administrator for details of setting

the limit for the number of copies.

Install the toner cartridge correctly.

P.70 “Replacing a Toner Cartridge”

The terminal of the toner

cartridge is stained.

The recommended toner

cartridge is not being used.

Ready (Saddle Stitch Tray Full) The saddle stitch tray of the

finisher is full of paper.

Ready (Check Saddle Stitch

Stapler)

A staple jam has occurred in the

stapler of the saddle stitch unit

or the staple sheet has not been

fed sufficiently.

Ready (Check Saddle Stitch

Stapler)

Staples in the stapler of the

saddle stitch unit have almost

run out or have actually done

so.

Ready (Check Stapler) Staple jam has occurred in the

stapler of the finisher.

Ready (Check Stapler) Staples in the stapler of the

finisher have almost run out or

have actually done so.

Wipe the terminal with a soft cloth.

Use the recommended toner cartridge.

P.70 “Replacing a Toner Cartridge”

Remove the paper from the saddle stitch tray

of the finisher.

Remove the top staple sheet.

P.68 “Saddle Stitch unit”

Replace the staple case of the saddle stitch

unit if stapling is not performed for an output

document even though the stapling function

has been selected.

P.82 “Saddle Stitch unit”

Remove the jammed staples.

P.63 “Clearing a Staple Jam”

Replace the staple case of the finisher if

stapling is not performed for an output

document even though the stapling function

has been selected.

P.79 “Refilling With Staples”

Ready (Hole Punch Dust Bin is

Full)

Hole punch dust bin is full of

paper punchings.

Ready (Finisher Full) The receiving tray of the finisher

is full of paper.

Ready (Inner Tray Full) The exit tray of the equipment is

full of paper.

14 Messages Displayed on the Touch Panel

Remove the paper punchings.

P.93 “Cleaning the Hole Punch Dust Bin”

Remove the paper from the receiving tray of

the finisher.

Remove the paper from the exit tray of the

equipment.

1.TROUBLESHOOTING FOR THE HARDWARE

Message Problem Description Corrective Action

Cannot copy

Check Department Counter

The number of originals to be

scanned has exceeded the limit

specified with the department

code during scanning.

Add paper No paper is left in a drawer or on

the bypass tray.

Call for Service The equipment requires

adjusting by a service

technician.

Examine stapler in the saddle

Stitch unit

Check staple cartridge in the

saddle stitch unit

Staple jam has occurred in the

stapler of the saddle stitch unit.

Staples in the stapler of the

saddle stitch unit have almost

run out or have actually done

so.

Ask your administrator for details of setting

the limit for the number of copies.

Set paper in the drawer or on the bypass tray.

The touch panel indicates which drawer (or

the bypass tray) has no paper.

To set paper, refer to the Copying Guide.

Contact your service representative with the

error code displayed on the right side of the

touch panel.

Never attempt to repair, disassemble or

modify the equipment by yourself.

You could cause a fire or get an electric shock.

Always contact your service representative

for maintenance or repair of the internal parts

of the equipment.

Remove the jammed staples.

P.68 “Saddle Stitch unit”

Replace the staple case of the saddle stitch

unit if stapling is not performed for an output

document even though the stapling function

has been selected.

P.82 “Saddle Stitch unit”

TROUBLESHOOTING FOR THE HARDWARE

Check staple cartridge Staples in the stapler of the

finisher have almost run out or

have actually done so.

Examine Stapler Staple jam has occurred in the

stapler of the finisher.

Saving energy - press Energy

Saver button.

The equipment has entered into

the energy saving mode since it

has not been used for a certain

time.

Change Drawer to Correct Paper

Size

No paper suitable for the

original is set.

The size of the original is not

detected correctly because the

original is sent from the ADF at a

skew.

Time for periodic maintenance The equipment requires

inspection and maintenance by

a service technician.

Power Failure A job was interrupted by a

power failure or some other

reason.

Replace the staple case of the finisher if

stapling is not performed for an output

document even though the stapling function

has been selected.

P.79 “Refilling With Staples”

Remove the jammed staples.

P.63 “Clearing a Staple Jam”

Press [ENERGY SAVER] button to clear the

energy saving mode.

Place the suitable size paper for the original in

the drawer.

Replace the original while aligning the side

guides of the ADF to its width so that it will be

placed straight.

Contact your service representative for

maintenance.

The print or fax job may be incomplete. Press

[Job Status] to check whether any jobs are

unfinished.

To clear the messages, press the [FUNCTION

CLEAR] button twice.

Messages Displayed on the Touch Panel 15

1.TROUBLESHOOTING FOR THE HARDWARE

Message Problem Description Corrective Action

Erasing Data The Data Overwrite Enabler is

clearing the data.

Check paper size setting on

control panel for Bypass. Check

the direction or size of the

paper.

Paper misfeed has occurred

because of a mismatch between

the paper size placed in the

bypass tray and the size

registered for the bypass tray in

the equipment.

Set the paper on the bypass tray

again.

Check the direction or size of

the paper on the bypass tray

and press START

The paper placed on the bypass

tray misfed.

The direction or the size of the

paper placed on the bypass tray

is incorrect.

The side guides of the bypass

tray do not fit the paper length.

Reboot the machine A system-related trouble has

occurred.

Toner near Empty (***) Toner is running out. “***”

indicates the color.

(The colors are shown in

abbreviations when two or

more toners are running out: Y:

yellow, M: magenta, C: cyan,

and K: black)

This message is displayed if the Data

Overwrite Enabler is installed. You can

operate the equipment while the message is

displayed.

Register the paper size correctly. Just

removing the misfed paper does not prevent

another paper from being misfed.

P.57 “Clearing paper misfeeds caused by a

wrong paper size setting”

Remove the misfed paper and set the paper

again.

Check the direction and the size of the paper

and then replace it on the bypass tray.

Align the side guides of the bypass tray to the

paper length.

Press the [POWER] button for at least 5

seconds to shut down the equipment.

Some toner is still left in the toner cartridge

while this message is displayed. You do not

have to replace the toner cartridge yet.

Check the color of the toner on the touch

panel and prepare the toner cartridge.

(About another 1000 copies can be made after

this message appears. Depending on the

conditions of copying, this message may not

appear even when the toner cartridge is near

empty.)

Replace the toner cartridge after the toner

has completely run out. [Install new ***

toner cartridge] is displayed at that time.

If you want to replace the toner cartridge

though some toner is still left, follow the

procedure below:

P.74 “Replacing a “Near Empty” toner

cartridge”

Black and white print is available while the

other colors has run out. Neither color nor

black and white print can be done when the

black toner has run out.

Dispose of used toner The waste toner box is full. Replace the waste toner box following the

guidance displayed on the touch panel.

P.77 “Replacing the Waste Toner Box

(Color Models)”

Please empty hole punch waste The Hole Punch Unit dust bin is

full.

Fax line1 (or line2) is out of

order.

The 1st (or 2nd) line for the fax

unit is not working.

Remove the paper punchings.

P.93 “Cleaning the Hole Punch Dust Bin”

Contact your service representative.

16 Messages Displayed on the Touch Panel

1.TROUBLESHOOTING FOR THE HARDWARE

Message Problem Description Corrective Action

Fax line1 (or line2) is not

installed.

The 1st (or 2nd) line for the fax

unit is not installed.

This original is copy protected An attempt is made to copy a

prohibited original.

DEPARTMENT Quota exceeded.

Contact the Administrator.

The copying, printing or

scanning quota to the

department has reached “0”.

Not enough Work Space to store

originals

Internal memory available ran

out while scanning.

Will you print out stored

originals?

USER Quota exceeded.

Contact the Administrator.

The copying, printing or

scanning quota to the user has

reached “0”.

USER and DEPARTMENT Quota

exceeded.

Contact the Administrator.

Check under the Finisher tray

and reboot the machine.

The number of originals

exceeds the limits.

The scanned data will be

deleted.

The copying, printing or

scanning quota to the user and

department has reached “0”.

An obstruction is placed under

the Finisher tray.

The number of originals to be

scanned has exceeded the limit

of 1000 sheets during scanning.

(The magazine sort or page

number function is used.)

Contact your service representative.

This original cannot be copied.

For details of setting the quota, ask your

administrator.

To print out the data for the originals stored

(scanned) until the message appeared, press

[Yes] on the touch panel. To delete the stored

data, press [No].

For details of setting the quota, ask your

administrator.

For details of setting the quota, ask your

administrator.

Remove the obstruction under the Finisher

tray and reboot the equipment.

Reduce the number of originals to be

scanned, and try again.

TROUBLESHOOTING FOR THE HARDWARE

The number of originals

exceeds the limits.

Will you copy stored originals?

The number of originals to be

scanned has exceeded the limit

of 1000 sheets during scanning.

LAN cable is not detected The LAN cable connection is not

detected.

To print out the data for the originals stored

(scanned) until the message appeared, press

[Yes] on the touch panel. To delete the stored

data, press [No].

Check the following items.

Check that the LAN cable is connected to

the equipment.

Check that there is no damage on the

connector of the LAN cable.

Check that the LAN cable is open circuited.

Check that the LAN cable is connected to

the HUB. Check that there is no damage to

the connector.

Check that the power is ON for the HUB to

which the LAN cable is connected.

Check that the settings of the

communication speed and the Ethernet

method for the equipment and the HUB are

aligned.

Error Codes

The error codes indicating the status of the equipment may appear on the touch panel. For details, please refer to the

Software Troubleshooting Guide.

Messages Displayed on the Touch Panel 17

0.Clearing a Paper Misfeed

Error code

Error message

Paper misfeed symbols

Guidance for

clearing paper misfeeds

1113 12

1

9 78

2 3 4 5 6

10

Locating a paper misfeed

The equipment stops copying when the original or copy paper is misfed. Paper misfeeds are notified on the touch

panel as follows:

The paper misfeed symbol helps you locate the paper misfeed.

1. RADF or DSDF (lower) ( P.21)

2. RADF or DSDF (upper) ( P.21)

3. Job Separator, Offset Tray ( P.38) or Bridge Kit ( P.39)

4. Fuser unit ( P.35)

5. Automatic duplexing unit ( P.33)

6. Bypass tray ( P.32)

7. Drawer feeding portion ( P.27)

8. Large Capacity Feeder ( P.28) or Paper Feed Pedestal ( P.28)

9. Paper transport path ( P.34)

10. Drawers ( P.29, P.30), Envelope Drawer ( P.31) or drawer of the Large Capacity Feeder ( P.31)

11. Saddle stitch unit ( P.48)

12. Finisher ( P.39, P.45, P.54)

13. Hole Punch Unit ( P.39, P.45, P.54)

The picture of the hardware device shown on the touch panel differs depending on the options installed.

18 Clearing a Paper Misfeed

1.TROUBLESHOOTING FOR THE HARDWARE

Clearing a paper misfeed

Clear the paper misfeed.

1

Clear the paper misfeed following the guidance shown on the touch panel. Press or to scroll the pages.

After clearing the misfeed, close all the opened covers.

2

The equipment starts the warm-up. Follow the guidance on the touch panel.

Tips on removing the misfed paper

Note the following points in removing the misfed paper.

TROUBLESHOOTING FOR THE HARDWARE

Remove the misfed paper carefully so as not to tear it.

To avoid tearing the misfed paper, remove the paper slowly with both hands. Using force may tear the paper, making

it more difficult to remove. See also that no pieces of torn paper are left inside the equipment.

When the paper misfeed sign remains after removing the misfed paper:

Depending on the timing of the occurrence, no misfed paper may be found where the paper misfeed sign indicates. If

the sign does not disappear after you have removed the misfed paper, follow the steps as instructed on the touch

panel.

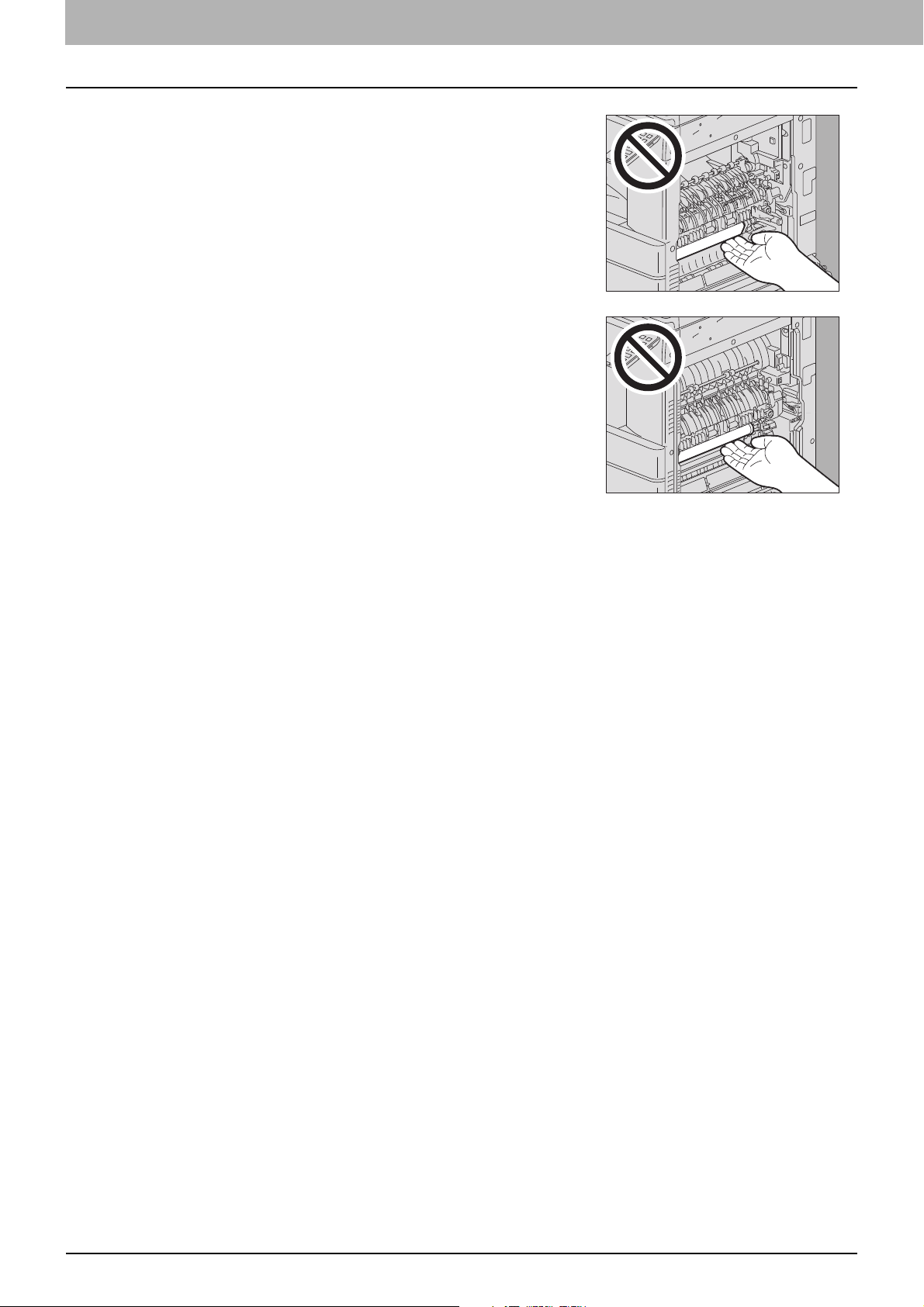

Do not touch the connectors inside the equipment.

This could cause a malfunction.

Do not touch the fuser unit or the metal portion around it.

Do not touch the fuser unit or the metal portion around it when you

remove the paper misfed in the right side of the equipment. This could

burn you or the shock could cause you to get your hand injured in the

machine.

Clearing a Paper Misfeed 19

1.TROUBLESHOOTING FOR THE HARDWARE

(e-STUDIO5005AC Series) Do not touch the transfer belt.

When you remove the paper misfed in the right side of the equipment, be

sure not to touch the transfer belt. This could stain copy images.

(e-STUDIO5008A Series) Do not touch the photoconductive drum.

When you remove paper which has been misfed in the right side of the

equipment, be sure not to touch the photoconductive drum. This could

stain the copy images.

If paper misfeeds occur frequently

The following are the common causes of paper misfeeds. If the problem persists, check for the following situations.

An unsuitable original is placed on the ADF.

Unavailable paper with the equipment is used.

Paper sizes are not consistent between the size in a drawer or the bypass tray and the size registered in the

equipment.

All the misfed paper has not been removed.

There is too much of a gap between the paper and the side or end guide in the drawer.

The amount of paper placed in a drawer exceeds the limit indicated on the side guide of the drawer.

20 Clearing a Paper Misfeed

1.TROUBLESHOOTING FOR THE HARDWARE

ADF

RADF (Lower)

Open the RADF.

1

Lower the green lever, open the reverse cover and remove the original.

2

TROUBLESHOOTING FOR THE HARDWARE

Close the RADF.

3

RADF (Upper)

Raise the lever and open the upper cover.

1

Clearing a Paper Misfeed 21

1.TROUBLESHOOTING FOR THE HARDWARE

Remove the original.

2

Turn the inner green dial and remove the misfed original.

3

Raise the green lever and open the transport guide.

4

Raise the green lever under the transport guide, and remove the original under the guide plate.

5

Close the transport guide.

6

22 Clearing a Paper Misfeed

1.TROUBLESHOOTING FOR THE HARDWARE

Raise the original feeder tray, and remove the original under the tray.

7

Lower the original feeder tray.

8

Close the upper cover.

9

TROUBLESHOOTING FOR THE HARDWARE

DSDF (Lower)

Remove the originals on the DSDF and open it.

1

Push the green button to open the lower cover.

2

Clearing a Paper Misfeed 23

1.TROUBLESHOOTING FOR THE HARDWARE

Turn the inner green dial and remove the misfed original.

3

Remove the misfed originals.

4

Push the green part to close the lower cover.

5

Close the DSDF.

6

24 Clearing a Paper Misfeed

1.TROUBLESHOOTING FOR THE HARDWARE

DSDF (Upper)

Raise the lever and open the upper cover.

1

Remove the misfed originals.

2

TROUBLESHOOTING FOR THE HARDWARE

If it is not easy to remove the misfed originals under the feed roller unit, take it off.

3

Remove the misfed originals under the feed roller unit.

4

Clearing a Paper Misfeed 25

1.TROUBLESHOOTING FOR THE HARDWARE

Attach the feed roller unit.

5

Remove the originals under the original feeder tray.

6

Close the upper cover.

7

Confirm that the lever of the upper cover is closed firmly.

26 Clearing a Paper Misfeed

1.TROUBLESHOOTING FOR THE HARDWARE

Drawer feeding portion

Open the feeder cover on the right side.

1

Remove the misfed paper from the drawer and close the feeder cover.

2

If the paper is misfed on the cover side, remove it as shown in the figure below.

TROUBLESHOOTING FOR THE HARDWARE

Clearing a Paper Misfeed 27

1.TROUBLESHOOTING FOR THE HARDWARE

Large Capacity Feeder

Open the feeder cover of the Large Capacity Feeder on the right.

1

Remove the misfed paper and close the feeder cover.

2

Paper Feed Pedestal

Open the feeder cover of the Paper Feed Pedestal on the right.

1

Remove the misfed paper and close the feeder cover.

2

28 Clearing a Paper Misfeed

1.TROUBLESHOOTING FOR THE HARDWARE

Drawers (e-STUDIO2000AC/2500AC)

The first drawer

Open the drawer, press the paper down until the plate clicks and remove the misfed paper.

1

Check that the guide width is correct, there is no folded/curled paper or overloading (especially

2

for thick paper), and then close the drawer.

TROUBLESHOOTING FOR THE HARDWARE

Be sure that the height of the stacked paper does not exceed the line indicated inside of the side guides. In

particular, be sure that the upper limit for thick paper is not exceeded when placing thick paper in the first

drawer. The amount of thick paper you can load in the drawer is lower than that for plain paper.

The second to fourth drawers

Open the paper source drawer, and remove the misfed paper.

1

Clearing a Paper Misfeed 29

1.TROUBLESHOOTING FOR THE HARDWARE

Check that the guide width is correct, there is no folded/curled paper or overloading, and then

2

close the drawer.

Drawers (Except for e-STUDIO2000AC/2500AC)

Open the paper source drawer, and remove the misfed paper.

1

Check that the guide width is correct, there is no folded/curled paper or overloading, and then

2

close the drawer.

Be sure that the height of the stacked paper does not exceed the line indicated inside of the side guides.

30 Clearing a Paper Misfeed

1.TROUBLESHOOTING FOR THE HARDWARE

Envelope Drawer

Open the paper source drawer, and remove the misfed paper.

1

Check that the guide width is correct, there is no folded/curled paper or overloading, and then

2

close the drawer.

TROUBLESHOOTING FOR THE HARDWARE

Be sure that the height of the stacked paper does not exceed the line indicated inside of the side guides. In

particular, be sure that the upper limit for envelope is not exceeded when placing envelope in the Envelope

Drawer. The amount of envelope you can load in the drawer is lower than that for plain paper.

Large Capacity Feeder

Open the drawer of the Large Capacity Feeder.

1

Pull out the right-hand tray and remove the misfed paper.

2

Clearing a Paper Misfeed 31

1.TROUBLESHOOTING FOR THE HARDWARE

Check that there is no folded/curled paper or overloading, and then close the drawer of the Large

3

Capacity Feeder.

Be sure that the height of the stacked paper does not exceed the line indicated inside of the side guides.

Bypass tray

Move the green paper holding lever toward the outside.

1

The paper can now be removed.

Pull out the misfed paper in the bypass tray.

2

Place paper in the bypass tray again and then move the green paper holding lever toward the

3

inside.

If a sheet of paper is stained, folded or torn, replace it with a new one.

32 Clearing a Paper Misfeed

1.TROUBLESHOOTING FOR THE HARDWARE

Automatic duplexing unit

Be careful not to let your fingers be caught between the equipment and the duplexing unit cover or automatic

duplexing unit cover.

This could injure you.

Open the automatic duplexing unit cover on the right.

1

Except for e-STUDIO2000AC/2500AC and e-STUDIO2008A/2508A/3008A, remove the misfed paper.

2

TROUBLESHOOTING FOR THE HARDWARE

Except for e-STUDIO2000AC/2500AC, while holding the green lever, remove the misfed paper.

3

Lower the green lever carefully and then close the automatic duplexing unit cover.

4

Clearing a Paper Misfeed 33

1.TROUBLESHOOTING FOR THE HARDWARE

AA

2

1

Paper transport path

Be careful not to let your fingers be caught between the equipment and the duplexing unit cover or automatic

duplexing unit cover.

This could injure you.

Open the automatic duplexing unit cover on the right.

1

Remove the misfed paper.

2

e-STUDIO5005AC Series

e-STUDIO5008A Series

Be sure not to touch the transfer belt when removing the misfed paper. This could stain copy images.

Do not clean roller [A] though it may be stained. It will be automatically cleaned at the next printing.

34 Clearing a Paper Misfeed

1.TROUBLESHOOTING FOR THE HARDWARE

open the transport guide toward you and remove the misfed paper.

3

Be sure not to touch the photoconductive drum when removing the misfed paper. This could stain copy images.

Close the automatic duplexing unit cover.

4

Fuser unit

TROUBLESHOOTING FOR THE HARDWARE

Be careful not to let your fingers be caught between the equipment and the duplexing unit cover or

automatic duplexing unit cover.

This could injure you.

Do not touch the fuser unit or the metal portion around it.

Since they are very hot, you could be burned or the shock could cause you to get your hand injured in the machine.

Open the automatic duplexing unit cover on the right.

1

For e-STUDIO2000AC/2500AC and e-STUDIO5008A Series, press down the two green fuser

2

pressure release levers until they stop.

Clearing a Paper Misfeed 35

1.TROUBLESHOOTING FOR THE HARDWARE

Open the transport guide holding the green knob and then release the misfed paper. Pull the

3

misfed paper up or down as shown in the illustrations depending on the position of the paper.

Pulling it up

Pulling it down

Remove the paper from the exit section.

4

When the finisher is installed, open the Bridge Kit cover while holding the handle.

5

36 Clearing a Paper Misfeed

1.TROUBLESHOOTING FOR THE HARDWARE

Remove the misfed paper.

6

When the finisher is installed, close the Bridge Kit cover.

7

TROUBLESHOOTING FOR THE HARDWARE

For e-STUDIO2000AC/2500A and e-STUDIO5008A Series, return the two green fuser pressure

8

release levers to their original position.

Close the automatic duplexing unit cover.

9

Clearing a Paper Misfeed 37

1.TROUBLESHOOTING FOR THE HARDWARE

Job Separator

The procedure below is for e-STUDIO2000AC/2500AC and e-STUDIO2008A/2508A/3008A with the Job Separator

installed. However, it does not apply to e-STUDIO2505AC/3005AC/3505AC/4505AC/5005AC and e-STUDIO3508A/

4508A/5008A with the Job Separator installed.

Be careful not to let your fingers be caught between the equipment and the duplexing unit cover or

automatic duplexing unit cover.

This could injure you.

Do not touch the fuser unit or the metal portion around it.

Since they are very hot, you could be burned or the shock could cause you to get your hand injured in the machine.

Open the automatic duplexing unit cover on the right.

1

Open the cover inside of the equipment.

2

Remove the misfed paper.

3

Close the cover inside of the equipment.

4

Close the automatic duplexing unit cover.

5

38 Clearing a Paper Misfeed

1.TROUBLESHOOTING FOR THE HARDWARE

Bridge Kit

Open the cover holding the handle of the Bridge Kit.

1

Remove the misfed paper inside the Bridge Unit.

2

TROUBLESHOOTING FOR THE HARDWARE

If the misfed paper cannot be removed because the right side is caught by the fuser unit, follow the steps on

P.35 “Fuser unit”.

Close the Bridge Kit cover.

3

Finisher and Hole Punch Unit

Paper misfeed in the upper receiving tray

Raise the lever and open the upper receiving tray of the finisher.

1

Remove the misfed paper.

2

Clearing a Paper Misfeed 39

1.TROUBLESHOOTING FOR THE HARDWARE

Open the cover holding the handle of the Bridge Unit.

3

When the Hole Punch Unit is installed, proceed to step 5.

Remove the misfed paper.

4

Proceed to step 8.

When the Hole Punch Unit is installed

Open the Hole Punch Unit cover.

5

Turn the green knob to get the misfed paper out.

6

Be sure to turn the knob to the direction indicated by the arrow to remove the misfed paper. If you pull out the

paper forcibly without turning the knob, this may tear the paper.

40 Clearing a Paper Misfeed

1.TROUBLESHOOTING FOR THE HARDWARE

Close the Hole Punch Unit cover.

7

Close the Bridge Kit cover.

8

Close the upper receiving tray of the finisher.

9

Place your hands on the near and far side of the lever and push to close the tray until it clicks.

TROUBLESHOOTING FOR THE HARDWARE

Be careful not to let your fingers be caught between the finisher body and the upper tray of the finisher.

This could injure you.

The upper receiving tray can also be closed by pressing the right side of the lever.

Clearing a Paper Misfeed 41

1.TROUBLESHOOTING FOR THE HARDWARE

Paper misfeed in the lower receiving tray

Raise the lever and open the upper receiving tray of the finisher.

1

Remove the misfed paper.

2

Remove the misfed paper.

3

If the paper is caught by the roller in the exit section, remove it by lifting the roller up with your fingers.

42 Clearing a Paper Misfeed

1.TROUBLESHOOTING FOR THE HARDWARE

Open the cover holding the handle of the Bridge Unit.

4

When the Hole Punch Unit is installed, proceed to step 6.

Remove the misfed paper.

5

Proceed to step 9.

TROUBLESHOOTING FOR THE HARDWARE

When the Hole Punch Unit is installed

Open the Hole Punch Unit cover.

6

Turn the green knob to get the misfed paper out.

7

Be sure to turn the knob to the direction indicated by the arrow to remove the misfed paper. If you pull out the

paper forcibly without turning the knob, this may tear the paper.

Clearing a Paper Misfeed 43

1.TROUBLESHOOTING FOR THE HARDWARE

Close the Hole Punch Unit cover.

8

Close the Bridge Kit cover.

9

Close the upper receiving tray of the finisher.

10

Place your hands on the near and far side of the lever and push to close the tray until it clicks.

Be careful not to let your fingers be caught between the finisher body and the upper tray of the finisher.

This could injure you.

The upper receiving tray of the finisher can also be closed by pressing the right side of the lever.

44 Clearing a Paper Misfeed

1.TROUBLESHOOTING FOR THE HARDWARE

Saddle Stitch Finisher and Hole Punch Unit

Raise the lever and open the upper receiving tray of the finisher.

1

Open the cover of the Hole Punch Unit when it is installed.

2

TROUBLESHOOTING FOR THE HARDWARE

Open the front cover of the finisher.

3

Remove the misfed paper from the right or left.

4

Clearing a Paper Misfeed 45

1.TROUBLESHOOTING FOR THE HARDWARE

When the Hole Punch Unit is not installed

When the Hole Punch Unit is installed

Open the cover holding the handle of the Bridge Unit.

5

Remove the misfed paper inside the Bridge Unit.

6

If the paper size is small, turn the knob shown in the following figures to send the paper, and then

7

remove the misfed paper.

When the Hole Punch Unit is installed, open the front cover of the finisher and turn the 2 knobs at the same time.

Be sure to turn the knob to the direction indicated by the arrow to remove the misfed paper. If you pull out the

paper forcibly without turning the knob, this may tear the paper.

46 Clearing a Paper Misfeed

1.TROUBLESHOOTING FOR THE HARDWARE

Remove the misfed paper.

8

If the paper is caught by the roller in the exit section, remove it by lifting the roller up with your fingers.

TROUBLESHOOTING FOR THE HARDWARE

Close the cover of the Bridge Unit.

9

Close the upper receiving tray of the finisher.

10

Place your hands on the near and far side of the lever and push to close the tray until it clicks.

Be careful not to let your fingers be caught between the finisher body and the upper tray of the finisher.

This could injure you.

The upper receiving tray of the finisher can also be closed by pressing the right side of the lever.

Clearing a Paper Misfeed 47

1.TROUBLESHOOTING FOR THE HARDWARE

Close the cover of the Hole Punch Unit when it is installed.

11

Close the front cover of the finisher.

12

Saddle Stitch unit of the Saddle Stitch Finisher

Remove the misfed paper from the exit side of the Saddle Stitch unit.

1

Open the front cover of the finisher.

2

48 Clearing a Paper Misfeed

1.TROUBLESHOOTING FOR THE HARDWARE

When the Hole Punch Unit is not installed

When the Hole Punch Unit is installed

Holding the green knob, move the guide to the right.

3

Raise the lever and open the upper receiving tray of the finisher.

4

TROUBLESHOOTING FOR THE HARDWARE

Open the cover of the Hole Punch Unit when it is installed.

5

Turn the knob shown in the following figures to send the paper, and then remove the misfed

6

paper.

When the Hole Punch Unit is installed, open the front cover of the finisher and turn the 2 knobs at the same time.

Be sure to turn the knob to the direction indicated by the arrow to remove the misfed paper. If you pull out the

paper forcibly without turning the knob, this may tear the paper.

Some misfed paper may get inside of the Saddle Stitch unit depending on the location where the misfeeding

occurs. In this case, follow step 7.

Clearing a Paper Misfeed 49

1.TROUBLESHOOTING FOR THE HARDWARE

Close the upper receiving tray of the finisher.

7

Place your hands on the near and far side of the lever and push to close the tray until it clicks.

Be careful not to let your fingers be caught between the finisher body and the upper tray of the finisher.

This could injure you.

The upper receiving tray of the finisher can also be closed by pressing the right side of the lever.

Turn the green knob to lower the paper until it is hidden.

8

Holding the green knob, return the guide to the left.

9

50 Clearing a Paper Misfeed

1.TROUBLESHOOTING FOR THE HARDWARE

AA

Pull out the Saddle Stitch unit until it stops.

10

Do not put your hands in the opening section (A) which is located behind the Saddle Stitch unit.

Your hands may be caught, resulting in injury.

Open the transport guide on the right side.

11

TROUBLESHOOTING FOR THE HARDWARE

Remove the misfed paper.

12

Remove the paper from the inside of the Saddle Stitch unit.

13

Clearing a Paper Misfeed 51

1.TROUBLESHOOTING FOR THE HARDWARE

Close the transport guide.

14

Holding both green knobs with your fingers, open the transport guide on the left.

15

Lower the two green levers.

16

Remove the paper.

17

Raise the two green levers.

18

52 Clearing a Paper Misfeed

1.TROUBLESHOOTING FOR THE HARDWARE

Holding both green knobs with your fingers, close the transport guide on the left.

19

Return the Saddle Stitch unit to its original position.

20

TROUBLESHOOTING FOR THE HARDWARE

Close the cover of the Hole Punch Unit when it is installed.

21

Close the front cover of the finisher.

22

Clearing a Paper Misfeed 53

1.TROUBLESHOOTING FOR THE HARDWARE

Inner Finisher and Hole Punch Unit

Lift up the control panel and then open the front cover of the finisher.

1

While holding the green lever, move the finisher to the left until it stops.

2

Pull down the green lever on the right-hand unit of the finisher.

3

The paper exit of the equipment opens.

Turn the green dial clockwise to send the paper and remove it.

4

54 Clearing a Paper Misfeed

1.TROUBLESHOOTING FOR THE HARDWARE

Return the green lever to its original position.

5

When the Hole Punch Unit is installed and used for punching holes, while pulling the green dial

6

toward you, turn it to align the yellow marks on the parts.

TROUBLESHOOTING FOR THE HARDWARE

Turn the upper green dial counterclockwise to remove the misfed paper.

7

Turn the upper green dial clockwise to remove the misfed paper.

8

Clearing a Paper Misfeed 55

1.TROUBLESHOOTING FOR THE HARDWARE

Holding the green knob, open the upper cover.

9

Remove the misfed paper and then close the upper cover.

10

While holding the green lever, open the Hole Punch Unit to remove the misfed paper.

11

Return the Hole Punch Unit to its original position.

12

56 Clearing a Paper Misfeed

1.TROUBLESHOOTING FOR THE HARDWARE

Carefully return the finisher to its original position.

13

Do not put your hand or fingers on the top of the finisher when closing it.

They could be caught and this could injure you.

Close the front cover of the finisher.

14

TROUBLESHOOTING FOR THE HARDWARE

Clearing paper misfeeds caused by a wrong paper size setting

Paper misfeeds occur when there is a mismatch between the size of the paper in a drawer or the bypass tray and the

size registered for the corresponding drawer or the bypass tray in the equipment. The message “Check paper size

setting on control panel for drawer N. Check the direction or size of the paper.” or “Check paper size setting on control

panel for Bypass. Check the direction or size of the paper.” appears on the touch panel.

In this case, just clearing the misfed paper does not prevent another paper from being misfed. Be sure to follow the

procedure below.

Troubleshooting differs depending on how the paper misfeed has occurred:

P.58 “Misfeed when making copies or prints (using a drawer)”

P.60 “Misfeed when making copies or prints (using the bypass tray)”

P.61 “Misfeed when printing from the Fax”

Clearing a Paper Misfeed 57

1.TROUBLESHOOTING FOR THE HARDWARE

Misfeed when making copies or prints (using a drawer)

Clear the paper misfeed following the guidance shown on the touch panel.

1

Open the paper source drawer, check that the guide width is correct and there is no folded/curled

2

paper or overloading, and then close the drawer.

Be sure that the height of the stacked paper does not exceed the line indicated inside of the side guides.

In particular, be sure that the upper limit for thick paper is not exceeded when placing thick paper in the first

drawer of the e-STUDIO2000AC/2500AC. The amount of thick paper you can load in the drawer is lower than that

for plain paper.

Close all the drawers or covers.

3

Press [Yes] when “Cancel print job?” appears.

4

The print job is canceled.

If you do not want to cancel the print job

To restart the job without canceling it, replace the paper in the drawer with that corresponding to the size set in

the equipment after the paper misfeed is cleared. Then if you press [No] in step 4, the job can be restarted. In this

case, it is not necessary to follow step 5 and later.

58 Clearing a Paper Misfeed

1.TROUBLESHOOTING FOR THE HARDWARE

Press [User Functions - User-] on the touch panel to access the User Functions menu.

5

Press the [User] tab to enter the User menu and press [Drawer].

6

Press the drawer button indicated in the message.

7

TROUBLESHOOTING FOR THE HARDWARE

Set the paper size again and press [OK].

8

For details about how to set the paper size, refer to “Doing Paper Settings” in Chapter 1 of the Paper Preparation

Guide.

Press the [HOME] button to return to the basic menu. Then press [Copy] to enter the copy menu.

9

Clearing a Paper Misfeed 59

1.TROUBLESHOOTING FOR THE HARDWARE

Confirm that the paper size is correctly detected if you selected [Auto (mm)] or [Auto (inch)] in

10

step 8.

The detected paper size is indicated on the drawer button in the equipment status indication area on the left.

An incorrect paper size or “ ” indicates an unsuccessful detection. In this case, see the following page.

P.9 “When This Screen Is Displayed”

Try copying or printing again.

11

Misfeed when making copies or prints (using the bypass tray)

Clear the paper misfeed following the guidance shown on the touch panel. Then close all the

1

covers.

Press [Yes] when “Cancel print job?” appears.

2

The print job is canceled.

If you do not want to cancel the print job

To restart the job without canceling it, replace the paper on the bypass tray with that corresponding to the size

set in the equipment after the paper misfeed is cleared. Then if you press [No] in step 2, the job can be restarted.

In this case, it is not necessary to follow step 3 and later.

Place the paper on the bypass tray and set the paper size.

3

Try copying or printing again.

4

60 Clearing a Paper Misfeed

1.TROUBLESHOOTING FOR THE HARDWARE

Misfeed when printing from the Fax

Pull out the drawer in which paper misfeeds occurred and remove all the paper from it.

1

If such paper misfeeds occur although [Auto (mm)] or [Auto (inch)] has been selected as the paper size, this is

caused by the incorrect size detection of the paper placed in the drawer. In this case, do not remove the paper

and proceed to step 3.

Place the paper corresponding to the set size in the drawer.

2

TROUBLESHOOTING FOR THE HARDWARE

Check that the guide width is correct and there is no folded/curled paper or overloading, and

3

then close the drawer.

Be sure that the height of the stacked paper does not exceed the line indicated inside of the side guides.

In particular, be sure that the upper limit for thick paper is not exceeded when placing thick paper in the first

drawer of the e-STUDIO2000AC/2500AC. The amount of thick paper you can load in the drawer is lower than that

for plain paper.

Clearing a Paper Misfeed 61

1.TROUBLESHOOTING FOR THE HARDWARE

Clear the paper misfeed following the guidance shown on the touch panel. Then close all the

4

drawers and covers.

Printing resumes.

62 Clearing a Paper Misfeed

0.Clearing a Staple Jam

When a staple jam has occurred in the stapler of the finisher or saddle stitch unit, clear the jam following the

procedure below.

P.63 “Finisher”

P.68 “Saddle Stitch unit”

Finisher

Finisher / Saddle Stitch Finisher

Open the front cover of the finisher.

1

TROUBLESHOOTING FOR THE HARDWARE

Remove the staple cartridge.

2

Lower the guide while holding the knob.

3

Do not touch the stapling area.

The actual needle point could cause you personal injury.

Clearing a Staple Jam 63

1.TROUBLESHOOTING FOR THE HARDWARE

Remove the top staple sheet.

4

Holding the knob, raise the guide, and return it to its original position.

5

Remove the staples if they have fallen between the staple cartridge and the staple case or in the

6

staple receiver.

Fit the staple cartridge into the stapler.

7

When fitting the staple cartridge, hold the green-labeled portion of the bracket securely so that the bracket will

not move.

Insert the cartridge until it is caught by the latch and fixed with a click.

Close the front cover of the finisher.

8

64 Clearing a Staple Jam

1.TROUBLESHOOTING FOR THE HARDWARE

Inner Finisher

Lift up the control panel and then open the front cover of the finisher.

1

While holding the green lever, move the finisher to the left until it stops.

2

TROUBLESHOOTING FOR THE HARDWARE

Open the Hole Punch Unit while pushing the green lever.

3

Remove the staple cartridge.

4

Clearing a Staple Jam 65

1.TROUBLESHOOTING FOR THE HARDWARE

Lower the guide while holding the knob.

5

Do not touch the stapling area.

The actual needle point could cause you personal injury.

Remove the top staple sheet.

6

Holding the knob, raise the guide, and return it to its original position.

7

Remove the staples if they have fallen between the staple cartridge and the staple case or in the

8

staple receiver.

66 Clearing a Staple Jam

1.TROUBLESHOOTING FOR THE HARDWARE

Fit the staple cartridge into the stapler.

9

Insert the cartridge until it is caught by the latch and fixed with a click.

Return the Hole Punch Unit to its original position.

10

TROUBLESHOOTING FOR THE HARDWARE

Carefully return the finisher to its original position.

11

Do not put your hand or fingers on the top of the finisher when closing it.

They could be caught and this could injure you.

Close the front cover of the finisher.

12

Clearing a Staple Jam 67

1.TROUBLESHOOTING FOR THE HARDWARE

Saddle Stitch unit

Open the front cover of the finisher, and pull out the Saddle Stitch unit until it stops.

1

Remove the staple cartridge.

2

Raise the guide while holding the knob.

3

Do not touch the stapling area.

The actual needle point could cause you personal injury.

Remove the top staple sheet.

4

68 Clearing a Staple Jam

1.TROUBLESHOOTING FOR THE HARDWARE

Holding the knob, lower the guide, and return it to its original position.

5

Fit the staple cartridge.

6

Insert the cartridge until it is caught by the latch and secured with a click.

TROUBLESHOOTING FOR THE HARDWARE

Return the Saddle Stitch unit to its original position. Close the front cover of the finisher.

7

Clearing a Staple Jam 69

0.Replacing a Toner Cartridge

Y M C K

When the toner cartridge runs out, the message “Install New *** (color name) toner cartridge” appears. Replace the

toner cartridge following the procedure below when you see this message.

Never attempt to incinerate toner cartridges.

Dispose of used toner cartridges and waste toner boxes in accordance with local regulations.

Do not touch the terminal of the toner cartridge.

This may cause the equipment not to recognize the toner cartridge or

may damage the terminal.

Some toner is still left in the toner cartridge while the message “Toner near Empty” is displayed. You do not have to

replace the toner cartridge yet, but if you choose to do so, follow the procedure P.74 “Replacing a “Near Empty”

toner cartridge”.

Color models

Open the front cover of the equipment.

1

Put your fingers on the right side of the toner cartridge and pull it out supported with your left

2

hand.

Never attempt to incinerate toner cartridges.

70 Replacing a Toner Cartridge

Dispose of used toner cartridges and waste toner boxes in accordance with local regulations.

1.TROUBLESHOOTING FOR THE HARDWARE

Y M C K

Shake the new toner cartridge strongly with its label side down to loosen the toner inside.

3

Pull the seal straight out in the direction of the arrow.

4

TROUBLESHOOTING FOR THE HARDWARE

Align the new toner cartridge to the guide. Insert it up to the black line.

5

Pull out the cleaner until the mark appears and return it. Repeat this 3 times for each of the 4

6

colors.

The cleaner cannot be removed by design. Pulling it out forcibly may cause malfunction.

Replacing a Toner Cartridge 71

1.TROUBLESHOOTING FOR THE HARDWARE

Close the front cover pressing both edges.

7

Monochromatic models

Open the front cover of the equipment.

1

Hold down the green lever.

2

The toner cartridge is slightly pushed out.

Pull out the toner cartridge.

3

Never attempt to incinerate toner cartridges.

Dispose of used toner cartridges in accordance with local regulations.

72 Replacing a Toner Cartridge

1.TROUBLESHOOTING FOR THE HARDWARE

Shake the new toner cartridge strongly with the label surface down to loosen the toner inside.

4

Pull out the seal in the direction of the arrow.

5

TROUBLESHOOTING FOR THE HARDWARE

Insert the toner cartridge along the rail.

6

Insert the toner cartridge until it clicks.

Carefully pull the cleaner out until it comes to a stop, and then carefully reinsert it straight into

7

its original position. Repeat this step a couple of times.

Check that the cleaner’s knob is fully inserted after cleaning.

Replacing a Toner Cartridge 73

1.TROUBLESHOOTING FOR THE HARDWARE

Close the front cover pressing both edges.

8

Replacing a “Near Empty” toner cartridge

The message “Toner near Empty” appears on the touch panel when there is not much toner left in a toner cartridge.

Some toner is still left in the toner cartridge while the message “Toner near Empty” is displayed. You do not have to

replace the toner cartridge yet, but if you choose to do so, follow the procedure below.

Press [Job Status].

1

74 Replacing a Toner Cartridge

1.TROUBLESHOOTING FOR THE HARDWARE

Press the [Toner] tab.

2

Press [Replace Toner Cartridge].

3

TROUBLESHOOTING FOR THE HARDWARE

To replace a toner cartridge, press [Yes]. To cancel, press [No].

4

If you press [Yes], go to the next step. If you press [No], the previous screen appears.

Replacing a Toner Cartridge 75

1.TROUBLESHOOTING FOR THE HARDWARE

For color models, press the button for the color you intend to replace.

5

For color models, to replace the toner cartridge, press [Yes]. To cancel, press [No].

6

If you press [Yes], go to the next step. If you press [No], the previous screen appears.

Replace the toner cartridge.

7

See P.70 “Replacing a Toner Cartridge” for the correct procedure.

Press [Finish].

8

76 Replacing a Toner Cartridge

0.Replacing the Waste Toner Box (Color Models)

When the waste toner box becomes full, the symbol for replacement of the waste toner box blinks and the message

“Dispose of used toner” appears. Replace the waste toner box following the procedure below.

Never attempt to incinerate waste toner boxes.

Dispose of used toner cartridges and waste toner boxes in accordance with local regulations.

Open the front cover of the equipment.

1

Put your fingers in the waste toner box front grooves and take it out toward you pushing down

2

the top latch.

TROUBLESHOOTING FOR THE HARDWARE

Never attempt to incinerate waste toner boxes.

Dispose of used toner cartridges and waste toner boxes in accordance with local regulations.

Place the waste toner box on a large sheet so as not to dirty the floor.

3

Do not place the waste toner box with its collecting port face down.

The waste toner may spill out from the box's collecting port.

Replacing the Waste Toner Box (Color Models) 77

1.TROUBLESHOOTING FOR THE HARDWARE

Take the new waste toner box out of the carton.

4

Put the used waste toner box in the plastic bag and seal it with adhesive tape.

5

Clean the LED print head (for e-STUDIO2000AC/2500AC) or the slit glass (except for

6

e-STUDIO2000AC/2500AC).

e-STUDIO2000AC/2500AC: Perform steps 5 to 11 on P.85 “The Main Chargers and LED Print Heads

(e-STUDIO2000AC/2500AC)”.

Except for e-STUDIO2000AC/2500AC: Perform steps 5 to 9 on P.88 “The Main Chargers and Slit Glass

(e-STUDIO2505AC/3005AC/3505AC/4505AC/5005AC)”.

Push the new waste toner box securely until the upper latches click.

7

Close the front cover pressing both edges.

8

78 Replacing the Waste Toner Box (Color Models)

0.Refilling With Staples

Refill with staples according to the following procedures when the staples in the stapler of the finisher and saddle

stitch unit run out.

P.79 “Finisher”

P.82 “Saddle Stitch unit”

Finisher