SERVICE MANUAL

MULTIFUNCTIONAL DIGITAL SYSTEMS

e-STUDIO200L/230/280

e-STUDIO202L/232/282

e-STUDIO203L/233/283

Model: DP-2020/2050/2320/2330/2340/2820/2830/2840

Publish Date: June 2004

File No. SME040009J0

R04022142802-TTEC

Ver10_2010-01

Trademarks

• The official name of Windows 95 is Microsoft Windows 95 Operating System.

• The official name of Windows 98 is Microsoft Windows 98 Operating System.

• The official name of Windows Me is Microsoft Windows Millennium Edition Operating System.

• The official name of Windows 2000 is Microsoft Windows 2000 Operating System.

• The official name of Windows XP is Microsoft Windows XP Operating System.

• Microsoft, Windows, Windows NT and the brand names and product names of other Microsoft products are trademarks or registered trademarks of Microsoft Corporation in the U.S. and/or other countries.

• Apple, AppleTalk, Macintosh, and Mac are trademarks of Apple Computer, Inc. in the U.S. and other

countries.

• PostScript is a trademark of Adobe Systems Incorporated.

• NOVELL, NetWare, and NDS are trademarks or registered trademarks of Novell, Inc.

• Molykote is a registered trademark of Dow Corning Corporation.

• FLOIL is a registrated trademark of Kanto Kasei Ltd. CORPORATION.

• Mylar is a registered trademark of DuPont Teijin Films U.S. Limited Partnership.

• TopAccess is a trademark of Toshiba Tec Corporation.

• Felica is a trademark of Sony Corporation.

• iCLASS is a trademark of HID Corporation.

• MIFARE is a trademark of Royal Philips Electronics.

• Other company names and product names in this manual are the trademarks of their respective

companies.

©2004 - 2010 TOSHIBA TEC CORPORATION All rights reserved

Under the copyright laws, this manual cannot be reproduced in any form without prior written permission

of TOSHIBA TEC CORPORATION. No patent liability is assumed, however, with respect to the use of the

information contained herein.

10/01

GENERAL PRECAUTIONS REGARDING THE SERVICE FOR

e-STUDIO200L/202L/203L/230/232/233/280/282/283 SERIES

The installation and service should be done by a qualified service

technician.

1) Transportation/Installation

- When transporting/installing the equipment, employ two persons and be sure to hold the posi-

tions as shown in the figure.

The equipment is quite heavy and weighs approximately 75 kg (165.34 lb.) therefore pay full

attention when handling it.

- Be sure not to hold the movable parts or units (e.g. the control panel, ADU or RADF) when trans-

porting the equipment.

- Be sure to use a dedicated outlet with AC 110 V / 13.2 A, 115 V or 127 V / 12 A, 220-240 V or 240

V / 8 A for its power source.

- The equipment must be grounded for safety.

- Select a suitable place for installation. Avoid excessive heat, high humidity, dust, vibration and

direct sunlight.

- Provide proper ventilation since the equipment emits a slight amount of ozone.

- To insure adequate working space for the copying operation, keep a minimum clearance of 80

cm (32”) on the left, 80 cm (32”) on the right and 10 cm (4”) on the rear.

- The equipment shall be installed near the socket outlet and shall be accessible.

- Be sure to fix and plug in the power cable securely after the installation so that no one trips over

it.

07/11

2) General Precautions at Service

- Be sure to turn the power OFF and unplug the power cable during service (except for the service

should be done with the power turned ON).

- Unplug the power cable and clean the area around the prongs of the plug and socket outlet once

a year or more. A fire may occur when dust lies on this area.

- When the parts are disassembled, reassembly is the reverse of disassembly unless otherwise

noted in this manual or other related documents. Be careful not to install small parts such as

screws, washers, pins, E-rings, star washers in the wrong places.

- Basically, the equipment should not be operated with any parts removed or disassembled.

- The PC board must be stored in an anti-electrostatic bag and handled carefully using a wristband

since the ICs on it may be damaged due to static electricity.

Caution: Before using the wristband, unplug the power cable of the equipment and

make sure that there are no charged objects which are not insulated in the

vicinity.

- Avoid expose to laser beam during service. This equipment uses a laser diode. Be sure not to

expose your eyes to the laser beam. Do not insert reflecting parts or tools such as a screwdriver

on the laser beam path. Remove all reflecting metals such as watches, rings, etc. before starting

service.

- Be sure not to touch high-temperature sections such as the exposure lamp, fuser unit, damp

heater and areas around them.

- Be sure not to touch high-voltage sections such as the chargers, developer, high-voltage trans-

former, exposure lamp control inverter, inverter for the LCD backlight and power supply unit.

Especially, the board of these components should not be touched since the electric charge may

remain in the capacitors, etc. on them even after the power is turned OFF.

- Make sure that the equipment will not operate before touching potentially dangerous places (e.g.

rotating/operating sections such as gears, belts pulleys, fans and laser beam exit of the laser

optical unit).

- Be careful when removing the covers since there might be the parts with very sharp edges

underneath.

- When servicing the equipment with the power turned ON, be sure not to touch live sections and

rotating/operating sections. Avoid exposing your eyes to laser beam.

- Use designated jigs and tools.

- Use recommended measuring instruments or equivalents.

- Return the equipment to the original state and check the operation when the service is finished.

- Be very careful to treat the touch panel gently and never hit it. Breaking the surface could cause

malfunctions.

3) Important Service Parts for Safety

- The breaker, door switch, fuse, thermostat, thermofuse, thermistor, IC-RAMs including lithium

batteries, etc. are particularly important for safety. Be sure to handle/install them properly. If

these parts are short-circuited and their functions become ineffective, they may result in fatal

accidents such as burnout. Do not allow a short-circuit or do not use the parts not recommended

by Toshiba TEC Corporation.

4) Cautionary Labels

- During servicing, be sure to check the rating plate and cautionary labels such as “Unplug the

power cable during service”, “CAUTION. HOT”, “CAUTION. HIGH VOLTAGE”, “CAUTION.

LASER BEAM”, etc. to see if there is any dirt on their surface and if they are properly stuck to the

equipment.

06/09

5) Disposal of the Equipment, Supplies, Packing Materials, Used Batteries and IC-RAMs

- Regarding the recovery and disposal of the equipment, supplies, packing materials, used batter-

ies and IC-RAMs including lithium batteries, follow the relevant local regulations or rules.

Caution:

Dispose of used batteries and IC-RAMs including lithium batteries according to this manual.

Attention:

Se débarrasser de batteries et IC-RAMs usés y compris les batteries en lithium selon ce manuel.

Vorsicht:

Entsorgung der gebrauchten Batterien und IC-RAMs (inclusive der Lithium-Batterie) nach diesem Handbuch.

05/11

CONTENTS

e-STUDIO200L/230/280

1. SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES ................................... 1-1

1.1 Specifications....................................................................................................................... 1-1

1.2 Accessories ......................................................................................................................... 1-6

1.3 Options ................................................................................................................................ 1-7

1.3.1 e-STUDIO200L/230/230L/280/280S ........................................................................ 1-7

1.3.2 e-STUDIO202L/203L/232/232S/233/282/282S/283/283S ....................................... 1-8

1.4 Supplies............................................................................................................................. 1-10

1.4.1 e-STUDIO200L/230/230L/280/280S ...................................................................... 1-10

1.4.2 e-STUDIO202L/232/232S/282/282S ...................................................................... 1-10

1.4.3 e-STUDIO203L/233/283/283S ............................................................................... 1-10

1.5 System List ........................................................................................................................ 1-11

1.5.1 e-STUDIO200L/230/230L/280/280S ...................................................................... 1-11

1.5.2 e-STUDIO202L/203L/232/232S/233/282/282S/283/283S ..................................... 1-17

2. OUTLINE OF THE MACHINE ....................................................................................... 2-1

2.1 Sectional View ..................................................................................................................... 2-1

2.2 Electric Parts Layout............................................................................................................ 2-4

2.3 Symbols and Functions of Various Components............................................................... 2-17

2.4 General Description........................................................................................................... 2-26

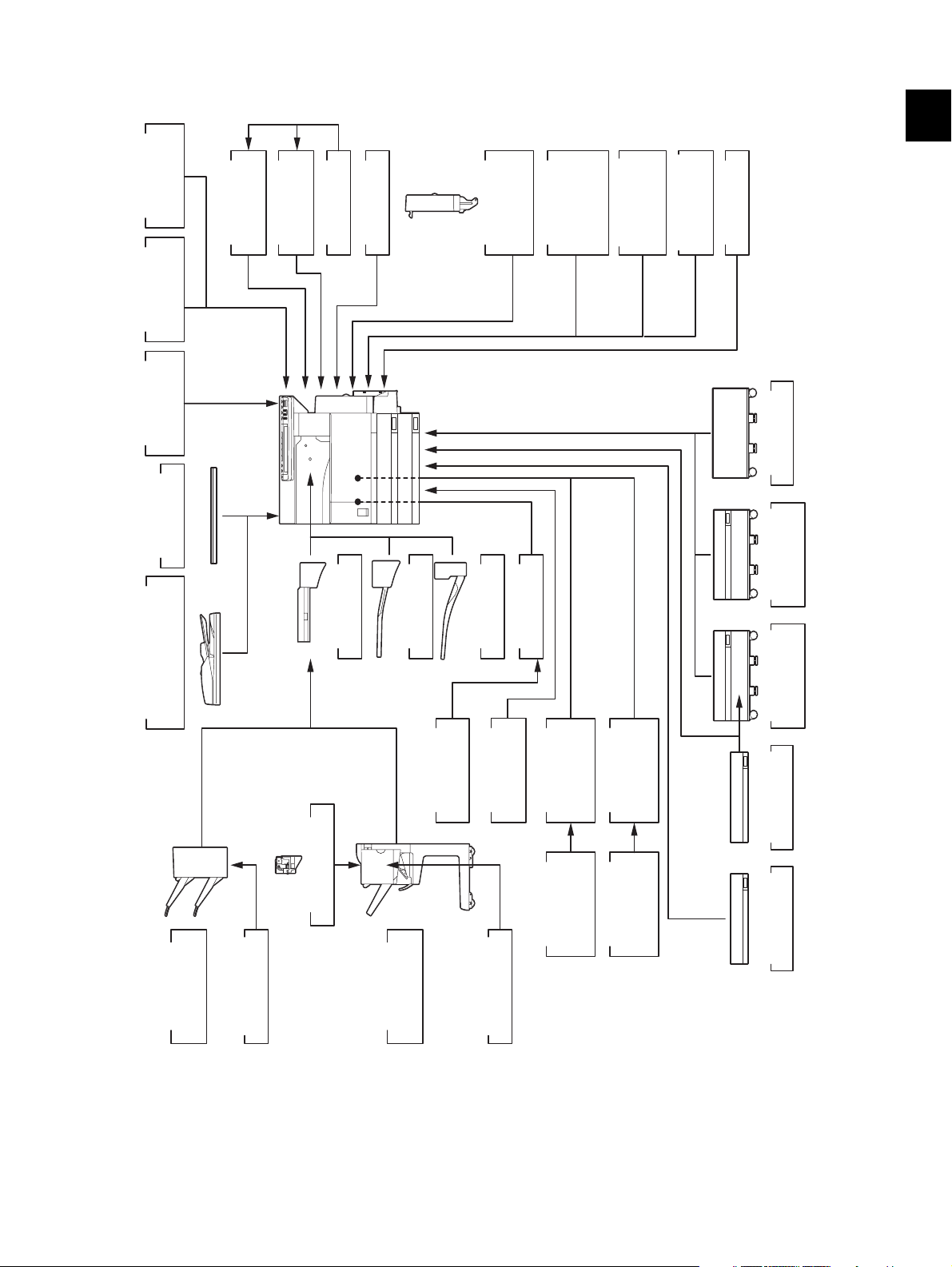

2.4.1 System block diagram ............................................................................................ 2-26

2.4.2 Construction of boards ........................................................................................... 2-28

2.5 Installation and Replacement of Covers and PC Boards................................................... 2-30

2.5.1 Covers .................................................................................................................... 2-30

2.5.2 PC boards .............................................................................................................. 2-41

2.6 Installation and Replacement of Options ........................................................................... 2-51

3. COPY PROCESS ..........................................................................................................3-1

3.1 General Description of Copying Process............................................................................. 3-1

3.2 Details of Copying Process.................................................................................................. 3-2

3.3 Comparison with e-STUDIO350/450 ................................................................................. 3-13

4. GENERAL OPERATION............................................................................................... 4-1

4.1 Overview of Operation ......................................................................................................... 4-1

4.2 Description of Operation...................................................................................................... 4-2

4.2.1 Warming-up .............................................................................................................. 4-2

4.2.2 Ready state (ready for copying) ............................................................................... 4-2

4.2.3 Drawer feed copying (Upper drawer paper feeding) ................................................ 4-3

4.2.4 Bypass feed copying ................................................................................................ 4-5

4.2.5 Interruption copying .................................................................................................. 4-5

4.3 Detection of Abnormality...................................................................................................... 4-6

4.3.1 Types of abnormality ................................................................................................ 4-6

4.3.2 Description of abnormality ........................................................................................ 4-7

4.4 Flow Chart ......................................................................................................................... 4-12

4.4.1 Immediately after the power is turned ON .............................................................. 4-12

4.4.2 Automatic paper feed copying ................................................................................ 4-14

5. CONTROL PANEL........................................................................................................ 5-1

5.1 Control Panel and Display Panel ......................................................................................... 5-1

5.2 Items Shown on the Control Panel ...................................................................................... 5-2

5.2.1 Display...................................................................................................................... 5-3

5.3 Relation between the Equipment State and Operator’s Operation...................................... 5-8

5.4 Description of Operation.................................................................................................... 5-12

5.4.1 Dot matrix LCD circuit ............................................................................................ 5-12

5.4.2 LED display circuit .................................................................................................. 5-15

© 2004 - 2010 TOSHIBA TEC CORPORATION All rights reserved e-STUDIO200L/202L/203L/230/232/233/280/282/283

1

05/11

CONTENTS

5.5 Disassembly and Replacement ......................................................................................... 5-16

6. SCANNER ..................................................................................................................... 6-1

6.1 Function............................................................................................................................... 6-1

6.2 Construction......................................................................................................................... 6-2

6.3 Description of Operation...................................................................................................... 6-4

6.3.1 Scan motor ............................................................................................................... 6-4

6.3.2 Scanning drive circuit ............................................................................................... 6-5

6.3.3 Initialization at power-ON ......................................................................................... 6-7

6.4 Control of Exposure Lamp................................................................................................... 6-8

6.4.1 General description .................................................................................................. 6-8

6.4.2 Exposure lamp ......................................................................................................... 6-9

6.4.3 Control circuit for the exposure lamp...................................................................... 6-10

6.5 General Description of CCD Control.................................................................................. 6-11

6.5.1 Opto-electronic conversion..................................................................................... 6-11

6.5.2 Shading correction ................................................................................................. 6-11

6.6 Automatic Original Size Detection Circuit .......................................................................... 6-12

6.6.1 Principle of original size detection .......................................................................... 6-12

6.6.2 Process of detection of original size ....................................................................... 6-13

6.7 Disassembly and Replacement ......................................................................................... 6-17

7. IMAGE PROCESSING .................................................................................................. 7-1

7.1 General Description............................................................................................................. 7-1

7.2 Configuration ....................................................................................................................... 7-3

7.3 SLG Board........................................................................................................................... 7-4

7.3.1 Features ...................................................................................................................7-4

7.3.2 Functions of image processing circuit ...................................................................... 7-4

7.4 LGC Board........................................................................................................................... 7-7

7.4.1 Features ...................................................................................................................7-7

7.4.2 Functions of image processing circuit ...................................................................... 7-7

7.5 Laser Driving PC Board.......................................................................................................7-8

8. LASER OPTICAL UNIT ................................................................................................ 8-1

8.1 General Description............................................................................................................. 8-1

8.2 Structure .............................................................................................................................. 8-3

8.3 Laser Diode ......................................................................................................................... 8-6

8.4 Polygonal Motor................................................................................................................... 8-7

8.5 Internal cooling fan-2 ........................................................................................................... 8-8

8.6 Disassembly and Replacement ........................................................................................... 8-9

9. PAPER FEEDING SYSTEM.......................................................................................... 9-1

9.1 Functions ............................................................................................................................. 9-1

9.2 Operation............................................................................................................................. 9-5

9.2.1 Operation of bypass pickup roller ............................................................................. 9-5

9.2.2 Operation of drawer pickup roller ............................................................................. 9-6

9.2.3 Separation of paper .................................................................................................. 9-7

9.2.4 Operation of clutch ................................................................................................... 9-8

9.2.5 General operation..................................................................................................... 9-9

9.3 Drive Circuit of Tray-up Motor............................................................................................ 9-11

9.4 Disassembly and Replacement ......................................................................................... 9-13

10. DRIVE SYSTEM .......................................................................................................... 10-1

10.1 General Description ........................................................................................................... 10-1

10.2 Functions ........................................................................................................................... 10-2

10.3 Main Motor......................................................................................................................... 10-3

10.3.1 Main motor drive..................................................................................................... 10-3

10.3.2 Control signals........................................................................................................ 10-4

10.4 Disassembly and Replacement ......................................................................................... 10-5

e-STUDIO200L/202L/203L/230/232/233/280/282/283 © 2004 - 2010 TOSHIBA TEC CORPORATION All rights reserved

CONTENTS

2

11. DRUM RELATED SECTION....................................................................................... 11-1

11.1 Configuration ..................................................................................................................... 11-1

11.2 Functions ........................................................................................................................... 11-2

11.3 High-Voltage Transformer Output Control Circuit.............................................................. 11-4

11.3.1 General description ................................................................................................ 11-4

11.3.2 Description of Operation......................................................................................... 11-5

11.4 Drum Temperature Detection Circuit ................................................................................. 11-6

11.4.1 General description ................................................................................................ 11-6

11.4.2 Construction ........................................................................................................... 11-6

11.5 Temperature/Humidity Detection Circuit............................................................................ 11-7

11.5.1 General description ................................................................................................ 11-7

11.5.2 Construction .......................................................................................................... 11-7

11.6 Disassembly and Replacement ......................................................................................... 11-8

12. DEVELOPMENT SYSTEM..........................................................................................12-1

12.1 Configuration ..................................................................................................................... 12-1

12.2 Functions ........................................................................................................................... 12-2

12.2.1 General description ................................................................................................ 12-2

12.2.2 Recovered toner supply mechanism ...................................................................... 12-3

12.3 Drive Circuit of Toner Motor............................................................................................... 12-4

12.4 Auto-Toner Circuit.............................................................................................................. 12-6

12.4.1 General description ................................................................................................ 12-6

12.4.2 Function of auto-toner sensor ................................................................................ 12-7

12.5 Disassembly and Replacement ......................................................................................... 12-9

13. FUSER UNIT ...............................................................................................................13-1

13.1 General Description ........................................................................................................... 13-1

13.2 Operation ........................................................................................................................... 13-2

13.3 Functions ........................................................................................................................... 13-3

13.4 Heater Control Circuit ........................................................................................................ 13-5

13.4.1 Configuration .......................................................................................................... 13-5

13.4.2 Temperature detection section............................................................................... 13-6

13.5 Disassembly and Replacement ....................................................................................... 13-11

14. PAPER EXIT SECTION .............................................................................................. 14-1

14.1 General Description ........................................................................................................... 14-1

14.2 Functions ........................................................................................................................... 14-2

14.3 Control Circuit of Exit Motor...............................................................................................14-3

14.4 Exit Motor Drive ................................................................................................................. 14-4

14.5 Disassembly and Replacement ......................................................................................... 14-5

15. AUTOMATIC DUPLEXING UNIT (ADU) (OPTION: MD-0102) .................................. 15-1

15.1 General Description ........................................................................................................... 15-1

15.2 Description of Operations .................................................................................................. 15-2

15.3 Drive of ADU...................................................................................................................... 15-7

15.4 Flow Chart ......................................................................................................................... 15-8

15.5 Disassembly and Replacement ....................................................................................... 15-10

16. POWER SUPPLY UNIT .............................................................................................. 16-1

16.1 Construction....................................................................................................................... 16-1

16.2 Operation of DC Output Circuits ........................................................................................ 16-2

16.3 Output Channel ................................................................................................................. 16-3

16.4 Fuse................................................................................................................................... 16-5

16.5 Configuration of Power Supply Unit................................................................................... 16-6

16.6 Sequence of Power Supply ............................................................................................... 16-7

16.7 AC Wire Harness ............................................................................................................... 16-8

17. PC BOARDS ............................................................................................................... 17-1

© 2004 - 2010 TOSHIBA TEC CORPORATION All rights reserved e-STUDIO200L/202L/203L/230/232/233/280/282/283

3

CONTENTS

e-STUDIO200L/202L/203L/230/232/233/280/282/283 © 2004 - 2010 TOSHIBA TEC CORPORATION All rights reserved

CONTENTS

4

1. SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES

1.1 Specifications

Values in { } are for e-STUDIO200L/202L/203L and values in [ ] are for e-STUDIO280/280S/282/

282S/283/283S in case that the specification is different among e-STUDIO200L/202L/203L, eSTUDIO230/230L/232/232S/233 and e-STUDIO280/280S/282/282S/283/283S.

Copy process Indirect electrophotographic process (dry)

Type Desktop type (console type: when paper feed pedestal (PFP) and large

capacity feeder (LCF) are installed)

Original table Fixed type (the left rear corner used as guide to place originals)

Accepted originals Sheet, book and 3-dimensional object. The reversing automatic document

feeder (RADF) only accepts paper which are not pasted or stapled. Carbon

paper are not acceptable either.

Maximum size: A3/LD

Single - sided original Double - sided original

MR-3016

MR-3018

50 ~ 127 g/m

35 ~ 157 g/m

2

(13 lb. Bond - 34 lb. Bond) 50 ~ 105 g/m2 (13 lb. Bond - 28 lb. Bond)

2

(9.3 lb. Bond - 58 lb. Cover) 50 ~ 157 g/m2 (13 lb. Bond - 58 lb. Cover)

1

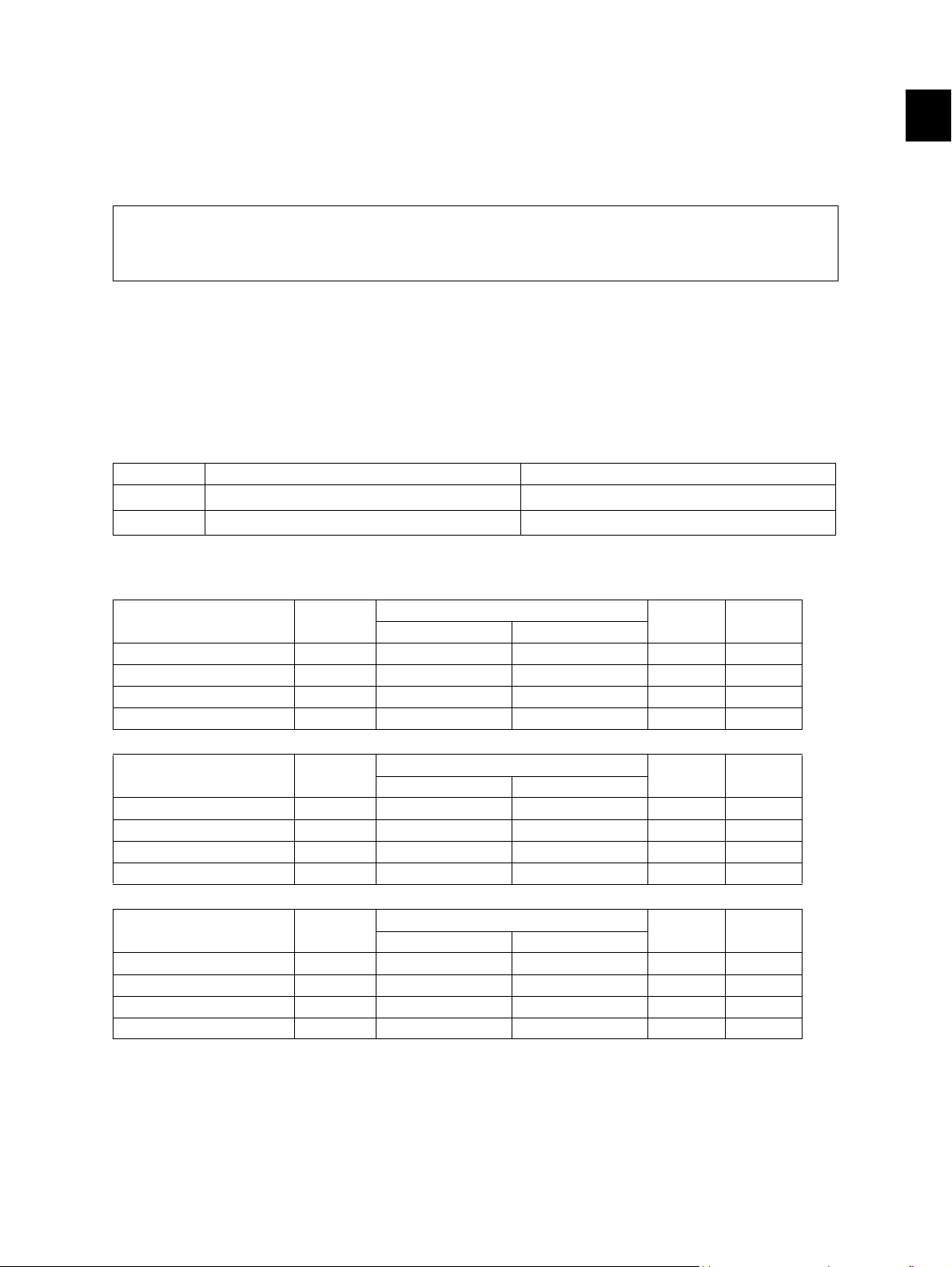

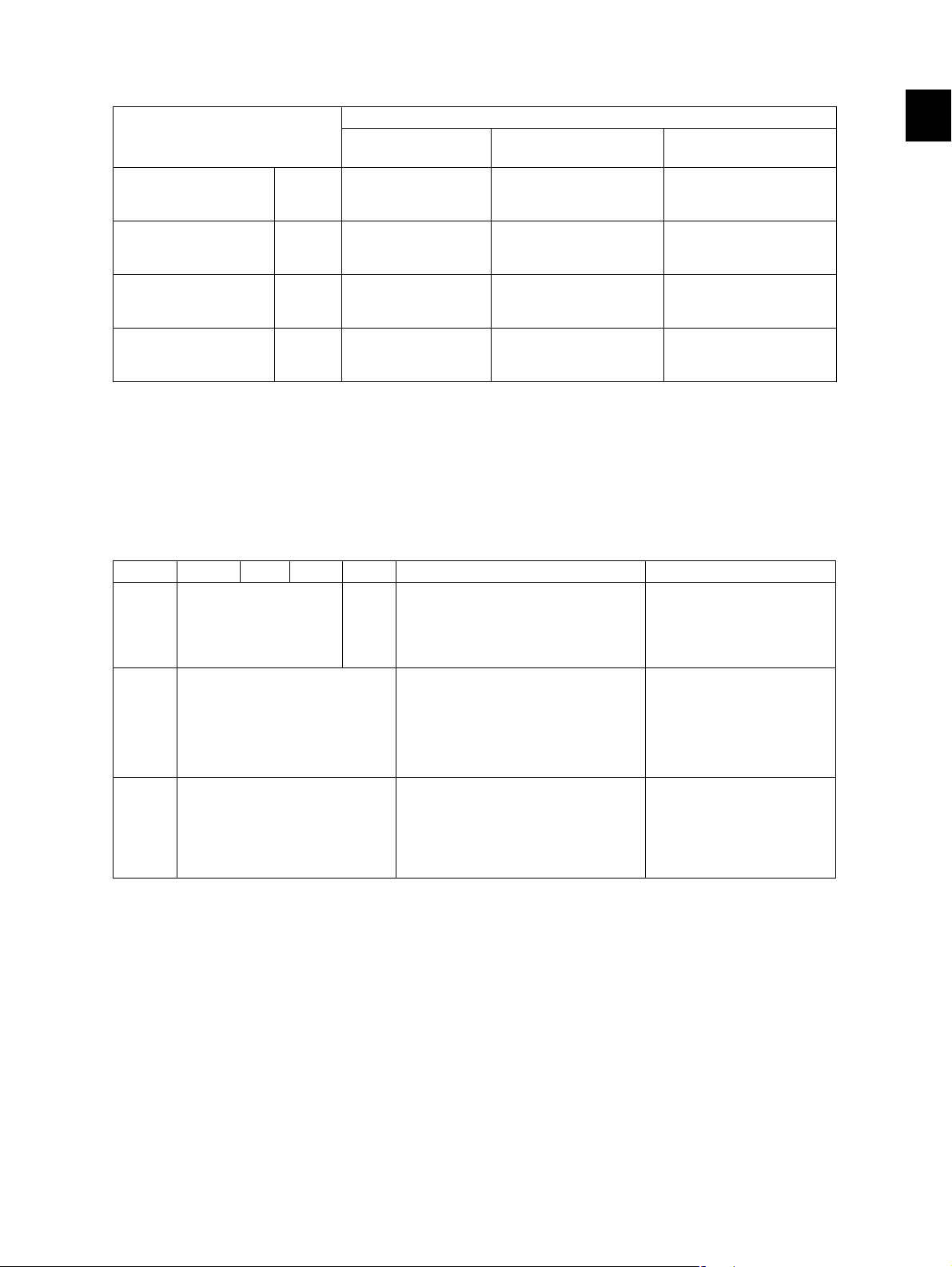

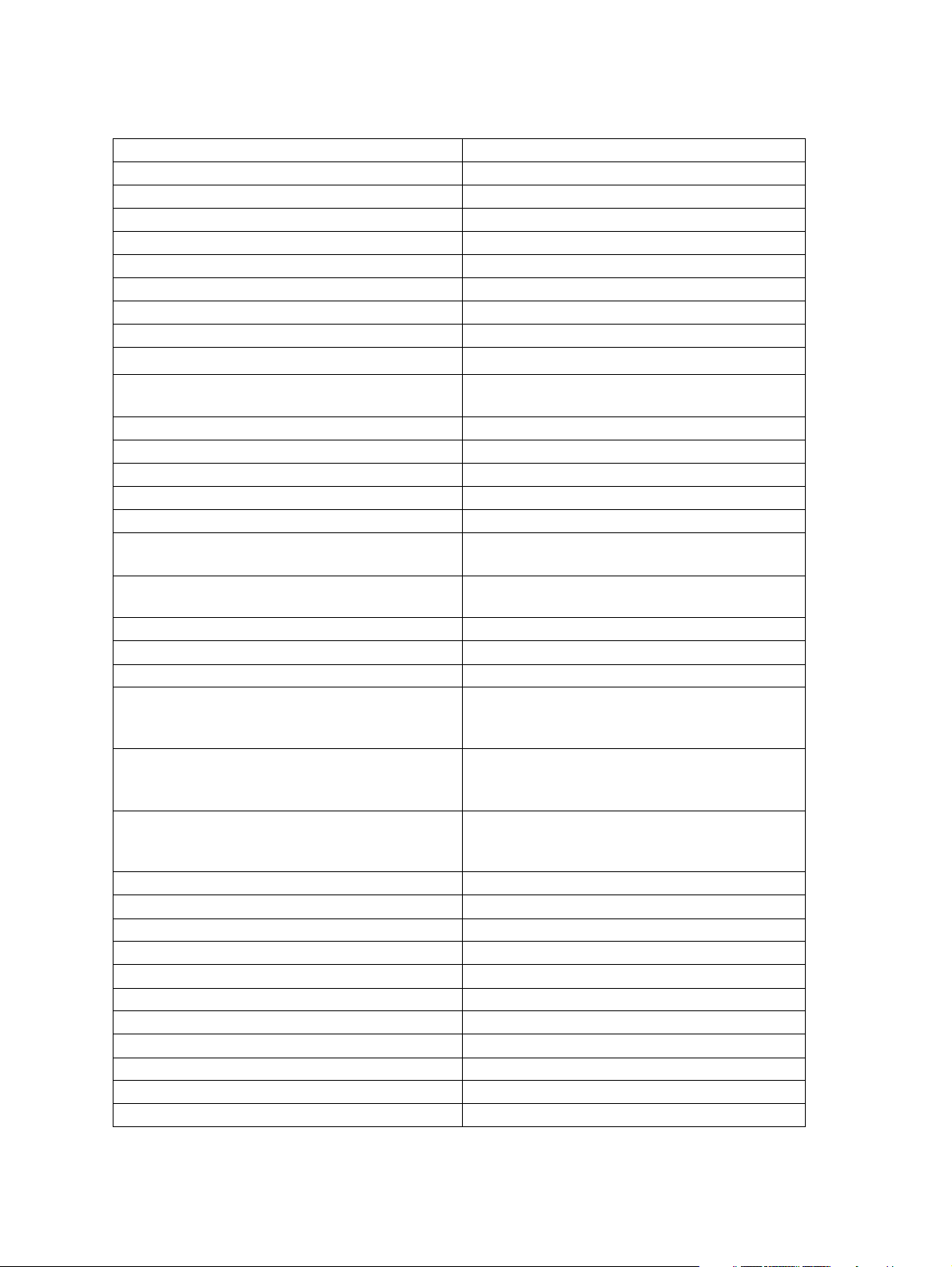

Copy speed (Copies/min.)

e-STUDIO200L/202L/203L

Paper size Drawer

A4, LT, B5, A5-R, ST-R 20 20 16 20 20

A4-R, B5-R, LT-R 19 19 16 19 –

B4, LG 18 18 16 18 –

A3, LD 16 16 16 16 –

Size specified Size not specified

Bypass feed

PFP LCF

e-STUDIO230/230L/232/232S/233

Paper size Drawer

A4, LT, B5, A5-R, ST-R 23 23 16 23 23

A4-R, B5-R, LT-R 21.5 21.5 16 21.5 –

B4, LG 18 18 16 18 –

A3, LD 16 16 16 16 –

Size specified Size not specified

Bypass feed

PFP LCF

e-STUDIO280/280S/282/282S/283/283S

Paper size Drawer

A4, LT, B5, A5-R, ST-R 28 28 16 28 28

A4-R, B5-R, LT-R 21.5 21.5 16 21.5 –

B4, LG 18 18 16 18 –

A3, LD 16 16 16 16 –

Size specified Size not specified

Bypass feed

PFP LCF

* “–” means “Not acceptable”.

* The copy speed in the above table are available when originals are manually placed for single side,

multiple copying.

© 2004 - 2010 TOSHIBA TEC CORPORATION All rights reserved e-STUDIO200L/202L/203L/230/232/233/280/282/283

1 - 1

07/11

SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES

* When the RADF is used, the copy speed of {20}23[28] sheets per minute is only available under the

following conditions:

• Original/Mode: Single side original/A4/LT size. APS/automatic density are not selected.

• Number of sheets: {20}23[28] or more.

• Reproduction ratio: 100%

Copy speed for thick paper (Copies/min.)

e-STUDIO200L/202L/203L/230/232/233/280/282/283 series

Thick 1 (81 g/m

Paper size Drawer

A4, LT, B5, A5-R, ST-R {20} 23 [27] {20} 23 [27] {15} 16 [16] {20} 23 [27] {20} 23 [27]

A4-R, B5-R, LT-R {19} 21 [21] {19} 21 [21] {15} 16 [16] {19} 21 [21] {-} - [-]

B4, LG {18} 18 [18] {18} 18 [18] {15} 16 [16] {18} 18 [18] {-} - [-]

A3, LD {15} 16 [16] {15} 16 [16] {15} 16 [16] {15} 16 [16] {-} - [-]

Thick 2 (106 g/m

Paper size Drawer

A4, LT, B5, A5-R, ST-R {-} - [-] {20} 23 [27] {15} 16 [16] {-} - [-] {-} - [-]

A4-R, B5-R, LT-R {-} - [-] {19} 21 [21] {15} 16 [16] {-} - [-] {-} - [-]

B4, LG {-} - [-] {18} 18 [18] {15} 16 [16] {-} - [-] {-} - [-]

A3, LD {-} - [-] {15} 16 [16] {15} 16 [16] {-} - [-] {-} - [-]

2

to 105 g/m2, 21.3 lb. Bond to 28 lb. Bond)

Bypass feed

Size specified Size not specified

2

to 163 g/m2, 28 lb. Bond to 90 lb. Index)

Bypass feed

Size specified Size not specified

PFP LCF

PFP LCF

Thick 3 (164 g/m

Paper size Drawer

A4, LT, B5, A5-R, ST-R {-} - [-] {20} 23 [27] {15} 16 [16] {-} - [-] {-} - [-]

A4-R, B5-R, LT-R {-} - [-] {19} 21 [21] {15} 16 [16] {-} - [-] {-} - [-]

B4, LG {-} - [-] {18} 18 [18] {15} 16 [16] {-} - [-] {-} - [-]

A3, LD {-} - [-] {15} 16 [16] {15} 16 [16] {-} - [-] {-} - [-]

2

to 209 g/m2, 90 lb. Index to 115.7 lb. Index)

Bypass feed

Size specified Size not specified

PFP LCF

* Only A4/LT size is available for the LCF.

* The tolerance is within ±2.

e-STUDIO200L/202L/203L/230/232/233/280/282/283 © 2004 - 2010 TOSHIBA TEC CORPORATION All rights reserved

SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES

1 - 2

07/11

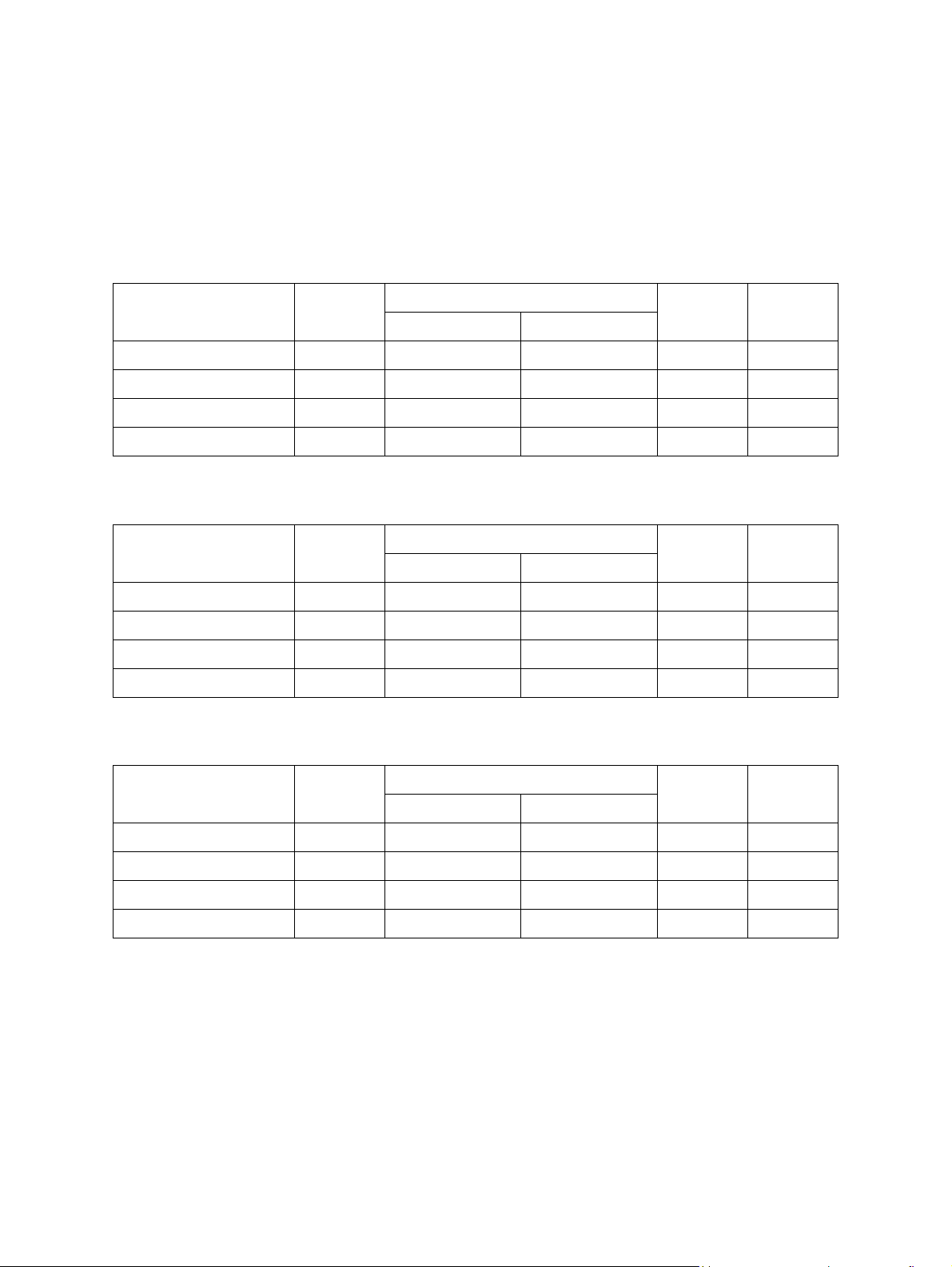

* System copy speed

Sec.

Copy mode

Single-sided originals

↓

Single-sided copies

Single-sided originals

↓

Double-sided copies

Double-sided originals

↓

Double-sided copies

Double-sided originals

↓

Single-sided copies

1 set

3 sets

5 sets

1 set

3 sets

5 sets

1 set

3 sets

5 sets

1 set

3 sets

5 sets

e-STUDIO200L/

202L/203L

34.18

95.53

154.28

37.44

96.81

155.54

70.26

188.48

306.64

64.65

184.73

302.58

e-STUDIO230/230L/

232/232S/233

31.5

84.8

136.2

34.5

85.9

137.4

64.8

167.7

270.6

57.8

163.1

266.1

e-STUDIO280/280S/

282/282S/283/283S

27.6

72.2

114 .0

31.6

73.4

116 .4

58.9

143.8

228.5

50.5

137.3

222.1

* The system copy speed, including scanning time, is available when 10 sheets of A4/LT size original

are set on RADF and one of the copy modes in the above table is selected. The period of time from

pressing [START] to the paper exit completely out of the equipment based on the actually measured

value.

* Upper drawer is selected and copying is at the non-sort mode.

* Automatic copy density, APS/AMS are turned off.

* Finisher is not installed.

Copy paper

Drawer ADU PFP LCF Bypass copy Remarks

Size A3 to A5-R, LD to ST-R,

FOLIO, COMPUTER,

13"LG, 8.5" x 8.5", 8K,

16K, 16K-R

Weight

Special

paper

64 to 105 g/m

17 to 28 lb. Bond

– Tracing paper, labels,

A4, LT A3 to A5-R, LD to ST-R, FOLIO,

COMPUTER, 13"LG, 8.5" x 8.5", 8K,

16K, 16K-R

(Non-standard or user-specified

sizes can be set.)

2

64 to 209 g/m

Index

(Continuous feeding)

50 to 209 g/m2, 13 lb. Bond to 110 lb.

Index

(Single paper feeding)

OHP film

(thickness: 80 µm or thicker),

tab paper, envelope

(COM10, Monarch, DL, CHO-3,

YOU-4)

2

, 17 lb. Bond to 110 lb.

These special papers recommended by Toshiba Tec

CHO-3: 92 mm x 235 mm

YOU-4: 105 mm x 235 mm

1

First copy time ......................... Approx. 5.4 sec. or less

(A4/LT, upper drawer, 100%, original placed manually)

Warming-up time ..................... Approx. 25 sec. (temperature: 20°C)

Multiple copying....................... Up to 999 copies; Key in set numbers

Reproduction ratio ................... Actual ratio: 100±0.5%

Zooming: 25 to 400% in increments of 1%

(25 to 200% when using RADF)

Resolution/Gradation............... Scanning: 600 dpi x 600 dpi

Printing: Equivalent to 2400 dpi x 600 dpi

Gradation: 256 steps

© 2004 - 2010 TOSHIBA TEC CORPORATION All rights reserved e-STUDIO200L/202L/203L/230/232/233/280/282/283

1 - 3

07/11

SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES

Eliminated portion.................... Leading edges: 3.0±2.0 mm, Side/trailing edges: 2.0±2.0 mm (copy)

Leading / trailing edges: 5.0±2.0 mm, Side edges: 5.0±2.0 mm (print)

Paper feeding .......................... Standard drawers:

1 or 2 drawers (stack height 60.5 mm, equivalent to 550 sheets;

64 to 80 g/m

2

(17 to 22 lb. Bond)): Depends on destinations or

versions.

PFP:

Option (One drawer or two: stack height 60.5 mm, equivalent to

550 sheets; 64 to 80 g/m

2

(17 to 22 lb. Bond))

LCF:

Option (Stack height 137.5 mm x 2: equivalent to 2500 sheets;

64 to 80 g/m

2

(17 to 22 lb. Bond))

Bypass feeding:

Stack height 11 mm: equivalent to 100 sheets; 64 to 80 g/m

2

(17

to 22 lb. Bond)

Capacity of originals in the reversing automatic document feeder (Option)

.................................................. A3 to A5-R, LD to ST-R:

100 sheets / 80 g/m

2

(Stack height 16 mm or less)

Automatic duplexing unit (ADU is available as standard equipment for some destinations or versions.)

.................................................. Stackless, Switchback type

Toner supply ............................ Automatic toner density detection/supply

Toner cartridge replacing method (There is a recovered toner supply

mechanism.)

Density control......................... Automatic density mode and manual density mode selectable in 11

steps

Weight ..................................... Approximately 75 kg (165.34 lb.): e-STUDIO200L/230/230L/280/280S

Approximately 77 kg (169.75 lb.): e-STUDIO202L/203L/232/232S/233/

282/282S/283 (include the developer material and drum) (The ADU

and Drawer module are installed.)

Power requirements ................ AC 110 V / 13.2 A, 115 V or 127 V / 12 A

220-240 V or 240 V / 8 A (50/60 Hz)

* The acceptable value of each voltage is ±10%.

Power consumption................. 1.5 kW or less (115 V series, 200 V series)

* The electric power is supplied to the RADF, (ADU), Finisher, Job Separator, Offset Tray, PFP and

LCF through the equipment.

Total counter ............................ Electronical counter

e-STUDIO200L/202L/203L/230/232/233/280/282/283 © 2004 - 2010 TOSHIBA TEC CORPORATION All rights reserved

SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES

1 - 4

07/11

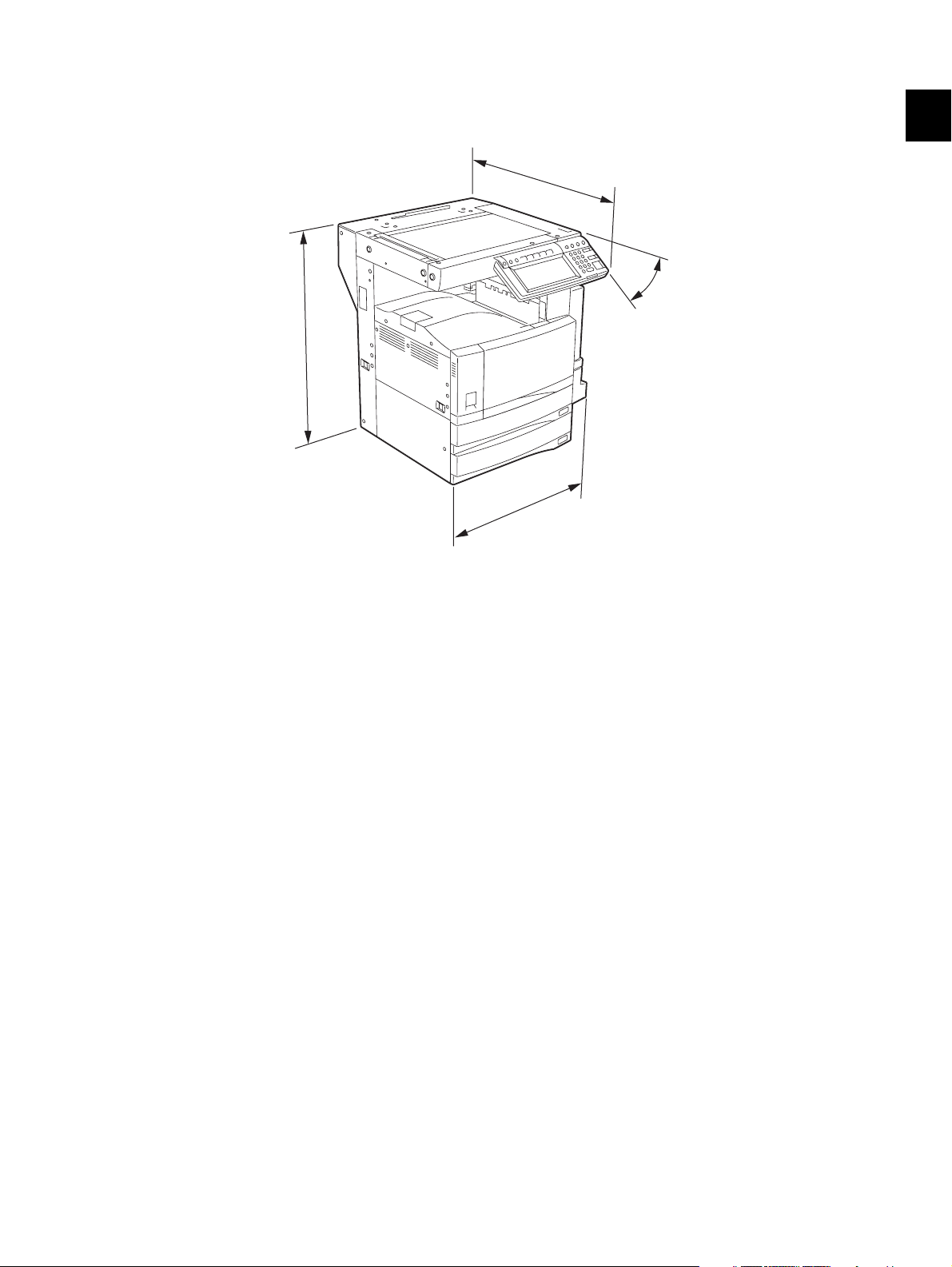

Dimensions of the equipment...................... See the figure below (W 637 x D 719 x H 739 (mm))

* When the tilt angle of the control panel is 45 degrees.

719

45°

739

637

1

Fig. 1-1

© 2004 - 2010 TOSHIBA TEC CORPORATION All rights reserved e-STUDIO200L/202L/203L/230/232/233/280/282/283

1 - 5

04/09

SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES

1.2 Accessories

Unpacking/setup instruction 1 set

Operator’s manual 3 pcs. (except for MJD)

Operator's manual pocket 1 pc.

Power cable 1 pc.

Warranty sheet 1 pc. (for NAD)

Setup report 1 set (for NAD and MJD)

Customer satisfaction card 1 pc. (for MJD)

Drum (installed inside of the equipment) 1 pc.

Toner cartridge 1 pc. (except for NAD, MJD)

Developer material 1 pc. (except for NAD, MJD)

Control panel stopper 1 pc.

Blind seal 1 pc.

Rubber plug 5 pcs.

CD-ROM

Transfer charger wire cleaner

(installed inside of the transfer cover)

Paper stopper

Stopper bracket

*1

*1

4 pcs.

1 pc.

1 pc.

1 pc.

*2

Machine version

NAD: North America

ARD: Argentina

ASD: Central and South America / Hong Kong

AUD: Australia

MJD: Europe

ASU: Asia

SAD: Saudi Arabia

IRD: Iran

CND: China

TWD: Taiwan

JPD: Japan

KRD: Korea

*1: e-STUDIO200L/230/230L/280/280S only

*2: In e-STUDIO202L/203L/232/232S/233/282/282S/283, 2 discs are included.

e-STUDIO200L/202L/203L/230/232/233/280/282/283 © 2004 - 2010 TOSHIBA TEC CORPORATION All rights reserved

SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES

1 - 6

07/11

1.3 Options

1.3.1 e-STUDIO200L/230/230L/280/280S

Platen Cover KA-3511 PC/PC-C

Reversing Automatic Document Feeder (RADF) MR-3016

Drawer Module MY-1021/-C

Paper Feed Pedestal (PFP) KD-1011/-C

Large Capacity Feeder (LCF) KD-1012 A4/LT/A4-C

Finisher (Hanging type) MJ-1022/-C

Saddle stitch Finisher MJ-1025/-C

Hole Punch Unit

MJ-6005 N/E/F/S

Staple Cartridge STAPLE-1600 (for MJ-1022)

STAPLE-2000 (for MJ-1025)

Bridge Kit KN-3520/-C

Job Separator MJ-5004/-C

Offset Tray MJ-5005/-C

Key copy Counter, Key copy counter socket MU-8, MU-10

Work Tray KK-3511

Damp Heater MF-2320 U/E

Fax Board GD-1150 NA/AU/EU/TW/C/AS

2nd Line for Fax Board GD-1160 NA/EU/TW/C

Wireless LAN Adapter GN-1010

PCI Slot GO-1040/C

Scrambler Board GP-1030

Printer Kit GM-1020/GM-1030

Printer/Scanner Kit GM-2020/GM-2030

Scanner upgrade Kit GM-3020/GM-3030

Parallel interface kit GF-1140

Desk MH-1700

Harness kit for coin controller GQ-1020

Automatic Duplexing Unit (ADU) MD-0102

Slot cover KE-2330

NIC board GF-1150

Data overwrite kit GP-1050

*1

1

* 1) N: North America E: Europe F: France S: Sweden

Notes:

• The bridge unit (KN-3520) is necessary for installation of the finisher (MJ-1022, MJ-1025).

• The finisher (MJ-1025) is necessary for installation of the hole punch unit (MJ-6005N/E/F/S).

• The PCI slot (GO-1040) is necessary for installation of the scrambler board (GP-1030) and

parallel interface kit (GF-1140).

• GM-1030/GM-2030/GM-3030 are exclusive for e-STUDIO200L.

They do not operate with e-STUDIO230/230L/280/280S.

© 2004 - 2010 TOSHIBA TEC CORPORATION All rights reserved e-STUDIO200L/202L/203L/230/232/233/280/282/283

1 - 7

05/11

SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES

1.3.2 e-STUDIO202L/203L/232/232S/233/282/282S/283/283S

Platen Cover KA-3511PC/-C

Reversing Automatic Document Feeder (RADF) MR-3020

Automatic Duplexing Unit (ADU) MD-0102

Drawer module MY-1021/-C

Slot cover KE-2330

Paper Feed Pedestal (PFP) KD-1011/-C

Large Capacity Feeder (LCF) KD-1012LT/A4/A4-C

Finisher (Hanging type) MJ-1022/-C

Finisher (Console saddle stitcher type) MJ-1025

Hole punch unit (for MJ-1025)

MJ-6005N/E/F/S

Staple cartridge STAPLE-1600 (for MJ-1022)

STAPLE-2000 (for MJ-1025)

Bridge kit KN-3520/-C

Job separator MJ-5004/-C

Offset tray MJ-5005/-C

Work tray KK-3511/-C

Damp heater MF-2320U/E

Fax board GD-1150NA/EU/AU/AS/C/TW

GD-1151NA/EU/AU/AS/C/TW

2nd line for fax board GD-1160NA/EU-N/C/TW

GD-1260NA/EU/C/TW

Printer kit GM-1070/1071/1080U/1081U

Printer/Scanner kit GM-2070/2071/2080U/2081U

Scanner kit GM-4070/GM-4080U

Printer ELK GM-1130 (e-STUDIO232/232S/233/282/282S/

283/283S)

GM-1140U (e-STUDIO202L/203L)

Printer/Scanner ELK GM-2130 (e-STUDIO232/232S/233/282/282S/

283/283S)

GM-2140U (e-STUDIO202L/203L)

Scanner ELK GM-4130 (e-STUDIO232/232S/233/282/282S/

283/283S)

GM-4140U (e-STUDIO202L/203L)

Memory GC-1230

Scrambler board GP-1040

Wireless LAN module GN-1041

Bluetooth module GN-2010

Antenna GN-3010

Data overwrite kit GP-1060

PCI slot GO-1060

e-BRIDGE ID Gate (HID iClass) KP-2004

e-BRIDGE ID Gate (MIFARE) KP-2005

Desk MH-1700

Harness kit for coin controller GQ-1020

*1

* 1) N: North America E: Europe F: France S: Sweden

e-STUDIO200L/202L/203L/230/232/233/280/282/283 © 2004 - 2010 TOSHIBA TEC CORPORATION All rights reserved

SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES

1 - 8

10/01

Notes:

• The bridge kit (KN-3520) is necessary for installation of the finisher (MJ-1022 or MJ-1025).

• The saddle stitch finisher (MJ-1025) is necessary for installation of the hole punch unit

(MJ-6005N/E/F/S).

• The PCI slot (GO-1060) is necessary for installation of the scrambler board (GP-1040).

• The antenna (GN-3010) is necessary to enable the wireless LAN module (GN-1041) and

Bluetooth module (GN-2010).

• When the wireless LAN module (GN-1041) and the Bluetooth module (GN-2010) are

installed, only 1 antenna (GN-3010) can be connected to each.

• GM-1080U / GM-2080U / GM-4080U are exclusive to e-STUDIO202L. They do not operate

with e-STUDIO232/232S/282/282S.

• GM-1081U / GM-2081U / GM-4080U are exclusive to e-STUDIO202L/203L. They do not

operate with e-STUDIO232/232S/233/282/282S/283.

• The Printer kit (GM-1070/1080U) or Printer/Scanner kit (GM-2070/2080U) does not have a

function for printing an XPS file.

• To enable an XPS file to be printed by the Printer kit (GM-1071/1081U) or Printer/Scanner kit

(GM-2071/1081U), the Memory (GC-1230) is required to be installed.

• To enable an XPS file to be printed by the Printer ELK (GM-1130/1140U) or Printer/Scanner

ELK (GM-2130/2140U), the Memory (GC-1230) is required to be installed.

1

© 2004 - 2010 TOSHIBA TEC CORPORATION All rights reserved e-STUDIO200L/202L/203L/230/232/233/280/282/283

1 - 9

10/01

SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES

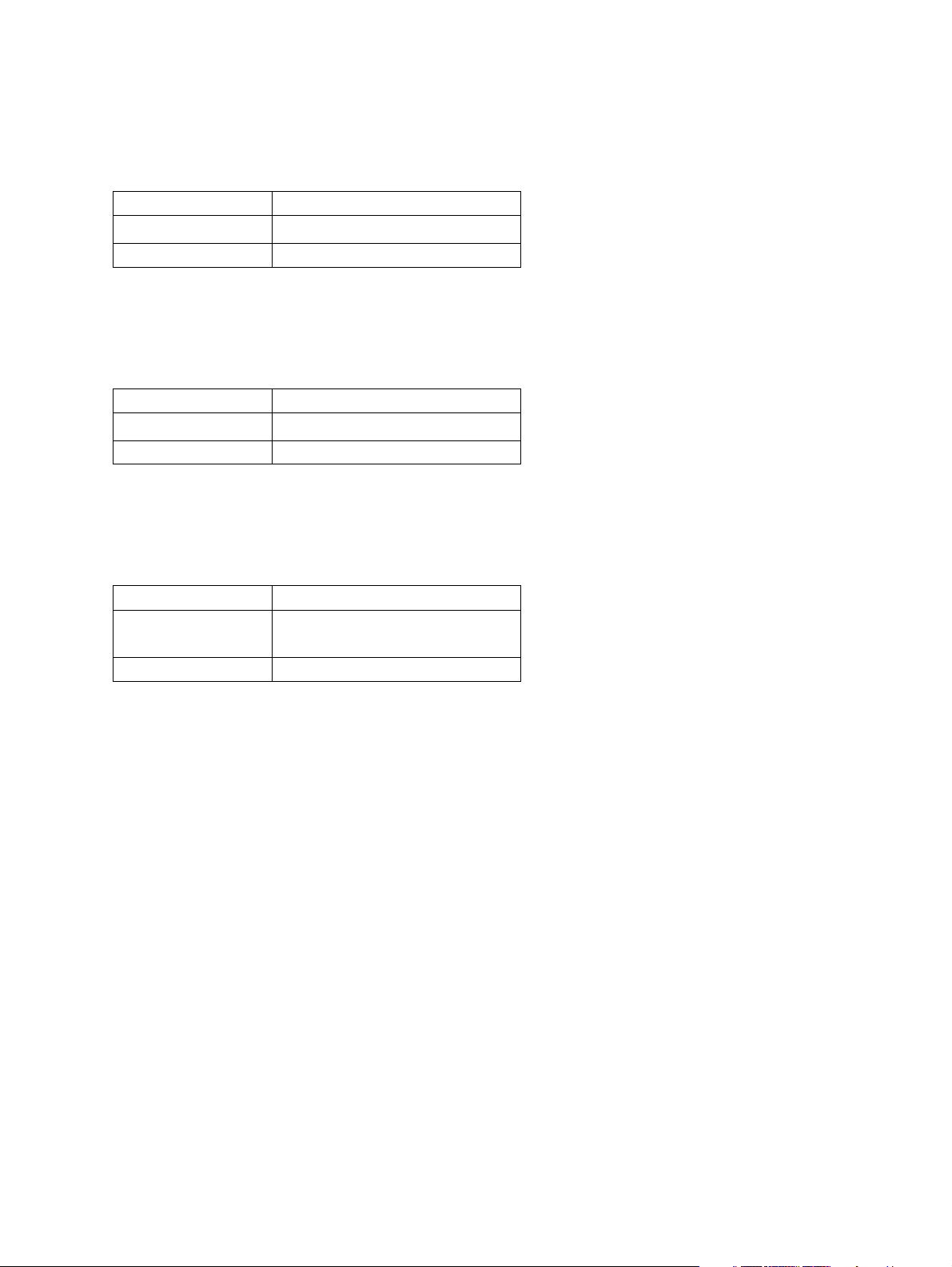

1.4 Supplies

1.4.1 e-STUDIO200L/230/230L/280/280S

Drum OD-1600

Toner cartridge

Developer D-2320 /C

PS-ZT2320 /T/D/C/E

* 1) T: Taiwan D: Asia C: China E: Europe NONE: North America

1.4.2 e-STUDIO202L/232/232S/282/282S

Drum OD-1600

Toner cartridge

Developer D-2340 /C

PS-ZT2340 /T/D/C/E

* 1) T: Taiwan D: Asia C: China E: Europe NONE: North America

1.4.3 e-STUDIO203L/233/283/283S

*1

*1

Drum OD-1600

Toner cartridge

Developer D-2340 /C

PS-ZT2840 /E

PS-ZT2340C

*1

*1

* 1) C: China E: Europe NONE: North America

e-STUDIO200L/202L/203L/230/232/233/280/282/283 © 2004 - 2010 TOSHIBA TEC CORPORATION All rights reserved

SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES

1 - 10

07/11

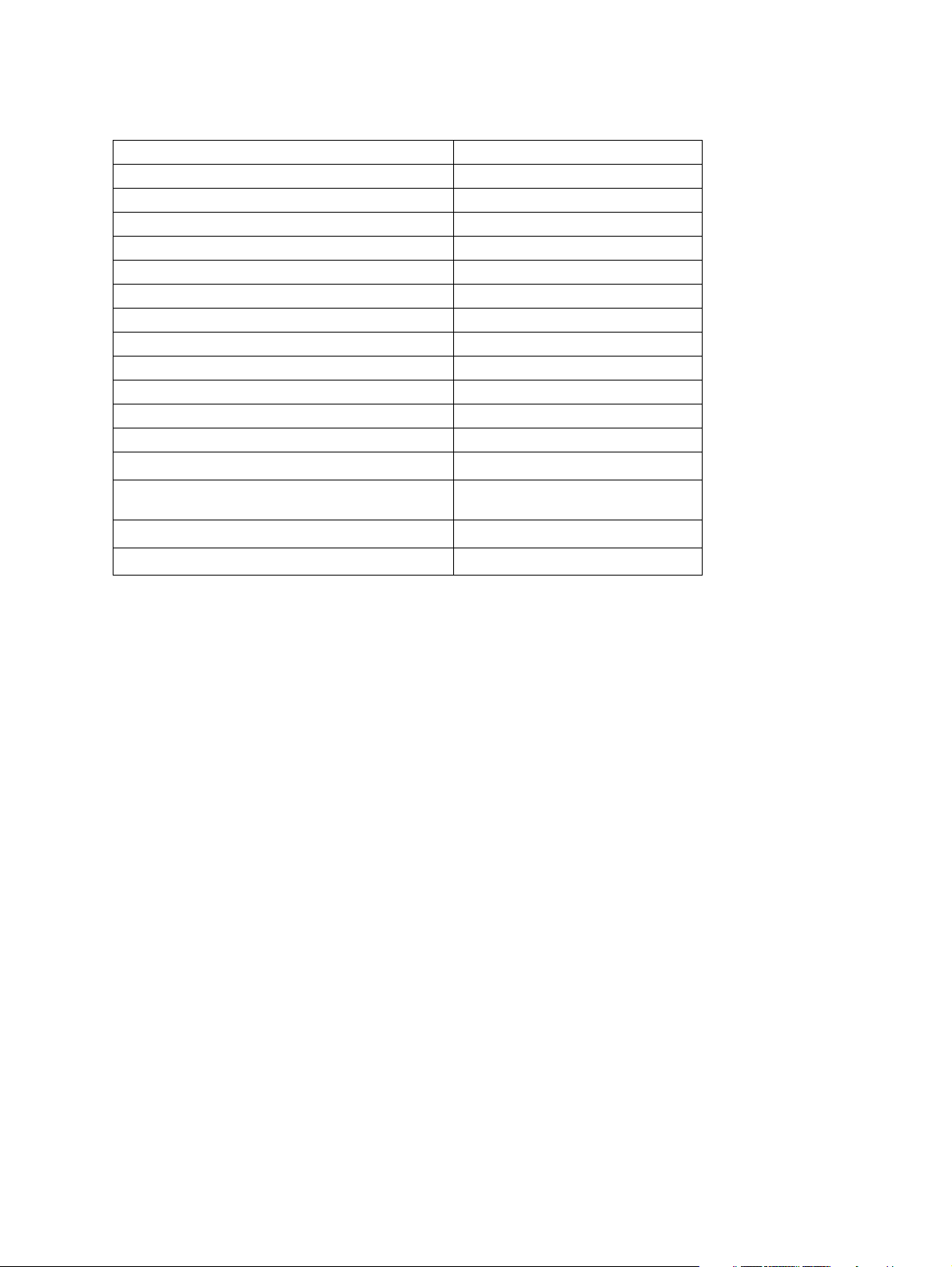

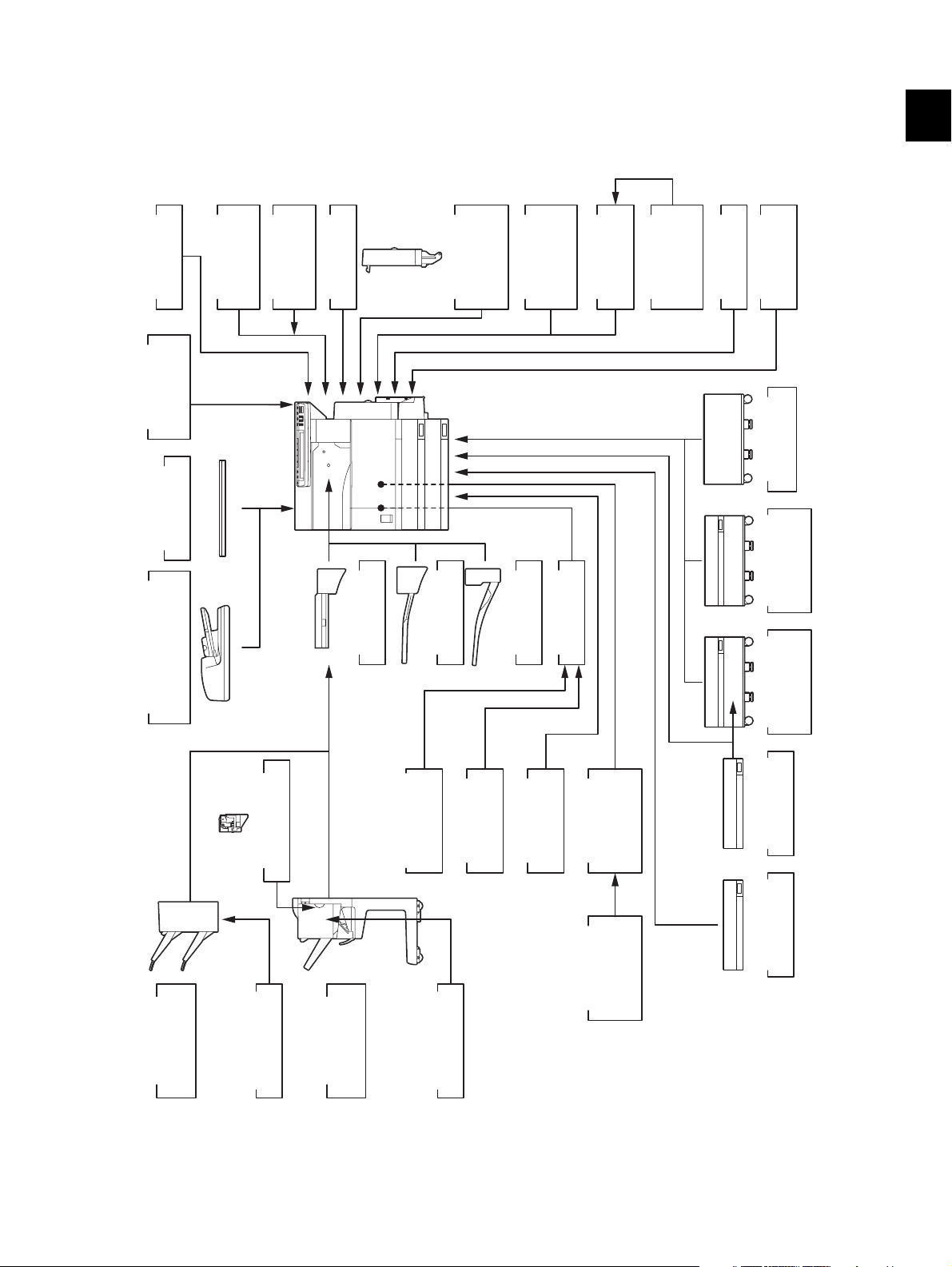

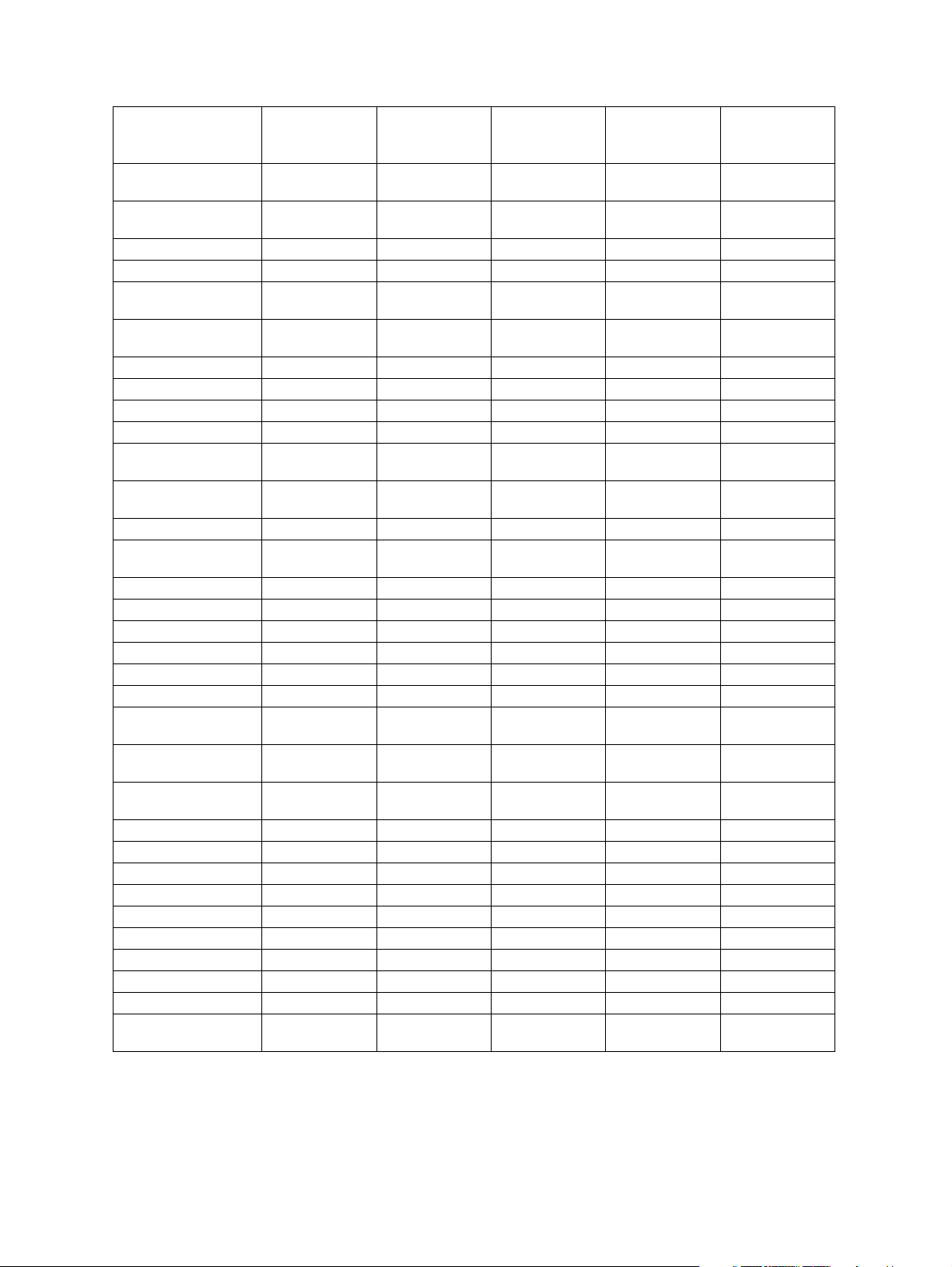

1.5 System List

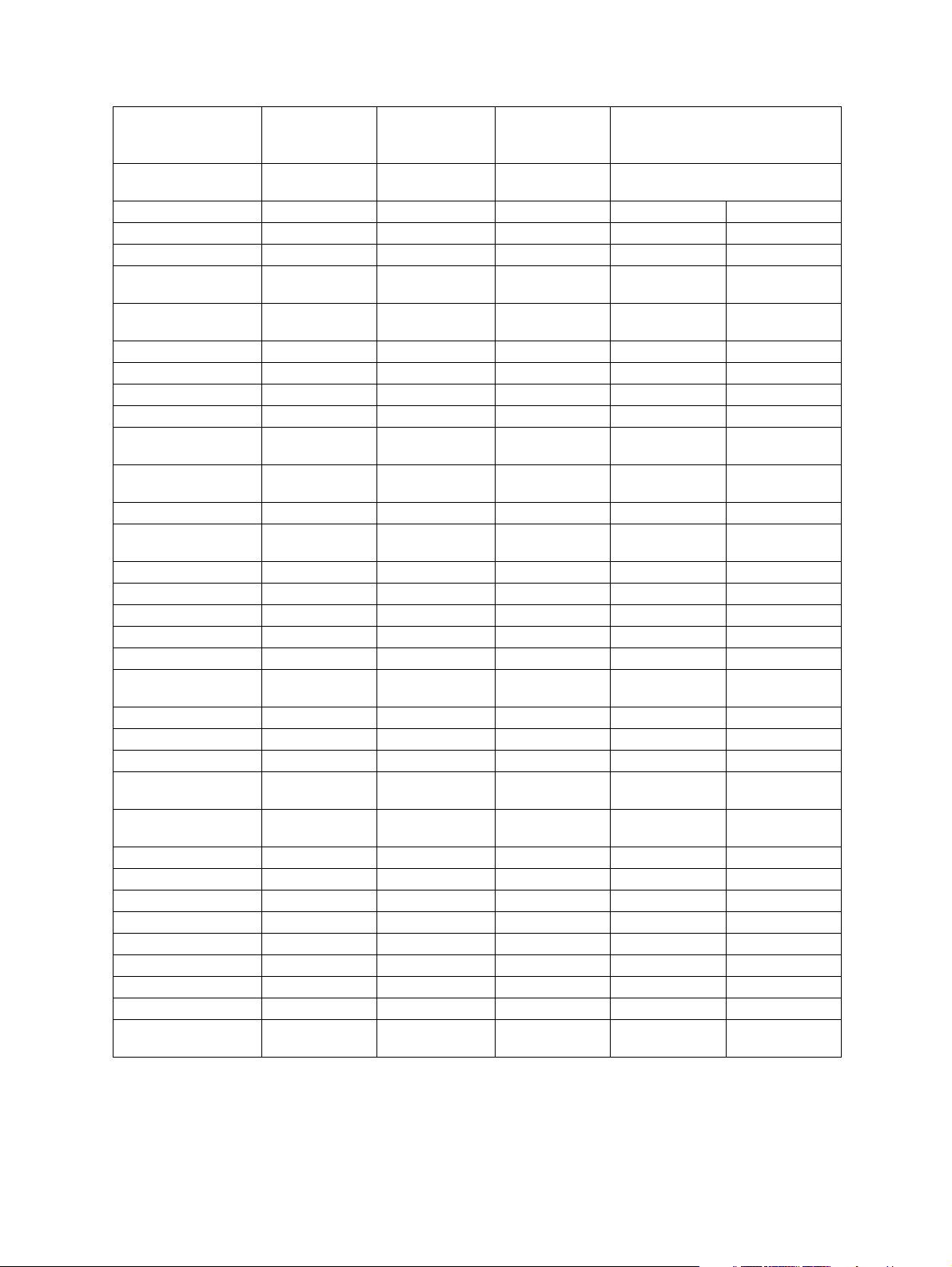

1.5.1 e-STUDIO200L/230/230L/280/280S

)

KK-3511

Work Tray

GQ-1020

coin controller

Harness kit for

KA-3511

Platen Cover

MU-8

Counter

Key Copy

MU-10

Key Copy

Counter Socket

MF-2320 U/E

Damp Heater

ADU

(

MD-0102

Automatic

Duplexing Unit

Printer/

GM-2020/

Scanner Kit

GM-2030

Printer Kit

Scanner

GM-1030

GM-1020/

GM-3030

GM-3020/

Upgrade Kit

Data

GF-1150

NIC board

GP-1050

overwrite kit

Desk

MH-1700

1

)

RADF

(

MR-3016

Reversing Automatic

Document Feeder

)

Hole Punch Unit

MJ-6005 N/E/F/S

KN-3520

Bridge Kit

MJ-5004

Job Separator

kit

Parallel interface

GF-1140

Scrambler

Board

MJ-5005

Offset Tray

GP-1030

Wireless LAN

PCI Slot

Adapter

GN-1010

GO-1040

GD-1150

FAX Board

FAX Board

2nd Line for

TW/C/AS

NA/AU/EU/

GD-1160

NA/EU/TW/C

Feeder (LCF)

Large Capacity

KD-1012 A4/LT

KD-1011

Paper Feed

Pedestal (PFP)

MY-1021

Drawer Module

KE-2330

Slot cover

Finisher

MJ-1022

Hanging type

(

STAPLE-1600

Staple Cartridge

Finisher

MJ-1025

Saddle stitch

STAPLE-2000

Staple Cartridge

Fig. 1-2

© 2004 - 2010 TOSHIBA TEC CORPORATION All rights reserved e-STUDIO200L/202L/203L/230/232/233/280/282/283

SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES

1 - 11

05/11

e-STUDIO280/280S

Central and

Area North America

Machine version

(destination)

NAD

(115V)

Model name e-STUDIO280 e-STUDIO280 e-STUDIO280 e-STUDIO280 e-STUDIO280

Platen cover KA-3511PC KA-3511PC KA-3511PC KA-3511PC KA-3511PC

RADF MR-3016 MR-3016 MR-3016 MR-3016 MR-3016

Drawer module

(for Equipment)

Drawer module

(for PFP)

Standard MY-1021 Standard Standard MY-1021

MY-1021 MY-1021 MY-1021 MY-1021 MY-1021

Slot cover - Standard - - KE-2330

ADU Standard MD-0102 Standard Standard MD-0102

PFP KD-1011 KD-1011 KD-1011 KD-1011 KD-1011

LCF KD-1012LT KD-1012A4 KD-1012A4 KD-1012A4 KD-1012A4

Finisher

(Hanging type)

Staple cartridge

(for MJ-1022)

MJ-1022 MJ-1022 MJ-1022 MJ-1022 MJ-1022

STAPLE-1600 STAPLE-1600 STAPLE-1600 STAPLE-1600 STAPLE-1600

Saddle stitch finisher MJ-1025 MJ-1025 MJ-1025 MJ-1025 MJ-1025

Staple cartridge

(for MJ-1025)

STAPLE-2000 STAPLE-2000 STAPLE-2000 STAPLE-2000 STAPLE-2000

Hole punch unit MJ-6005N MJ-6005E MJ-6005E MJ-6005E/F/S MJ-6005E

Bridge kit KN-3520 KN-3520 KN-3520 KN-3520 KN-3520

Job separator MJ-5004 MJ-5004 MJ-5004 MJ-5004 MJ-5004

Offset tray MJ-5005 MJ-5005 MJ-5005 MJ-5005 MJ-5005

Key copy counter MU-8 MU-8 MU-8 MU-8 MU-8

Key copy counter

socket

MU-10 MU-10 MU-10 MU-10 MU-10

Work tray KK-3511 KK-3511 KK-3511 KK-3511 KK-3511

Damp heater MF-2320U Standard Standard MF-2320E Standard

Fax board GD-1150NA GD-1150AS GD-1150AU GD-1150EU GD-1150AS

2nd line for Fax

board

Wireless LAN

adapter

GD-1160NA GD-1160EU GD-1160EU GD-1160EU GD-1160EU

GN-1010 GN-1010 GN-1010 GN-1010 GN-1010

PCI slot GO-1040 GO-1040 GO-1040 GO-1040 GO-1040

Scrambler board GP-1030 GP-1030 GP-1030 GP-1030 GP-1030

Parallel interface kit GF-1140 GF-1140 GF-1140 GF-1140 GF-1140

NIC board Standard GF-1150 Standard Standard GF-1150

Printer/Scanner kit GM-2020 GM-2020 GM-2020 GM-2020 GM-2020

Printer kit GM-1020 GM-1020 GM-1020 GM-1020 GM-1020

Scanner upgrade kit GM-3020 GM-3020 GM-3020 GM-3020 GM-3020

Desk MH-1700 MH-1700 MH-1700 MH-1700 MH-1700

Harness kit for coin

controller

GQ-1020 GQ-1020 GQ-1020 GQ-1020 GQ-1020

South America/

Hong Kong

ASD

(220-240V)

Australia Europe Asia

AUD

(220-240V)

MJD

(220-240V)

ASU

(220-240V)

e-STUDIO200L/202L/203L/230/232/233/280/282/283 © 2004 - 2010 TOSHIBA TEC CORPORATION All rights reserved

SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES

1 - 12

04/09

Area Saudi Arabia Iran China Taiwan

Machine version

(destination)

SAD

(127V)

IRD

(220-240V)

CND

(220-240V)

TWD

(110V)

Model name e-STUDIO280 e-STUDIO280 e-STUDIO280S e-STUDIO280 e-STUDIO280

Platen cover KA-3511PC KA-3511PC Standard Standard KA-3511PC

RADF MR-3016 MR-3016 MR-3016 MR-3016 MR-3016

Drawer module

(for Equipment)

Drawer module

(for PFP)

MY-1021 Standard Standard Standard Standard

MY-1021 MY-1021 MY-1021 MY-1021 MY-1021

Slot cover KE-2330 - - - -

ADU MD-0102 Standard MD-0102 Standard MD-0102

PFP KD-1011 KD-1011 KD-1011 KD-1011 KD-1011

LCF KD-1012A4 KD-1012A4 KD-1012-C KD-1012-C KD-1012A4

Finisher

(Hanging type)

Staple cartridge

(for MJ-1022)

MJ-1022 MJ-1022 MJ-1022-C MJ-1022-C MJ-1022

STAPLE-1600 STAPLE-1600 STAPLE-1600 STAPLE-1600 STAPLE-1600

Saddle stitch finisher MJ-1025 MJ-1025 MJ-1025 MJ-1025 MJ-1025

Staple cartridge

(for MJ-1025)

STAPLE-2000 STAPLE-2000 STAPLE-2000 STAPLE-2000 STAPLE-2000

Hole punch unit MJ-6005E MJ-6005E MJ-6005E MJ-6005E MJ-6005E

Bridge kit KN-3520 KN-3520 KN-3520-C KN-3520-C KN-3520

Job separator MJ-5004 MJ-5004 MJ-5004-C MJ-5004-C MJ-5004

Offset tray MJ-5005 MJ-5005 MJ-5005-C MJ-5005-C MJ-5005

Key copy counter MU-8 MU-8 MU-8 MU-8 MU-8

Key copy counter

socket

MU-10 MU-10 MU-10 MU-10 MU-10

Work tray KK-3511 KK-3511 KK-3511 KK-3511 KK-3511

Damp heater Standard Standard Standard Standard Standard

Fax board GD-1150NA N/A GD-1150C GD-1150C GD-1150TW

2nd line for Fax

board

Wireless LAN

adapter

GD-1160NA N/A GD-1160C GD-1160C GD-1160TW

GN-1010 GN-1010 GN-1010 GN-1010 GN-1010

PCI slot GO-1040 GO-1040 GO-1040C GO-1040C GO-1040

Scrambler board GP-1030 GP-1030 GP-1030 GP-1030 GP-1030

Parallel interface kit GF-1140 GF-1140 GF-1140 GF-1140 GF-1140

NIC board GF-1150 Standard GF-1150 Standard Standard

Printer/Scanner kit GM-2020 Standard GM-2020 Standard GM-2020

Printer kit GM-1020 GM-1020 GM-1020 GM-1020 GM-1020

Scanner upgrade kit GM-3020 GM-3020 GM-3020 GM-3020 GM-3020

Desk MH-1700 MH-1700 MH-1700 MH-1700 MH-1700

Harness kit for coin

controller

GQ-1020 GQ-1020 GQ-1020 GQ-1020 GQ-1020

1

© 2004 - 2010 TOSHIBA TEC CORPORATION All rights reserved e-STUDIO200L/202L/203L/230/232/233/280/282/283

1 - 13

04/09

SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES

e-STUDIO230/230L

Central and

Area North America

Machine version

(destination)

NAD

(115V)

Model name e-STUDIO230 e-STUDIO230 e-STUDIO230 e-STUDIO230 e-STUDIO230L

Platen cover KA-3511PC KA-3511PC KA-3511PC KA-3511PC KA-3511PC

RADF MR-3016 MR-3016 MR-3016 MR-3016 MR-3016

Drawer module

(for Equipment)

Drawer module

(for PFP)

Standard MY-1021 Standard Standard MY-1021

MY-1021 MY-1021 MY-1021 MY-1021 MY-1021

Slot cover - Standard - - Standard

ADU Standard MD-0102 Standard Standard MD-0102

PFP KD-1011 KD-1011 KD-1011 KD-1011 KD-1011

LCF KD-1012LT KD-1012A4 KD-1012A4 KD-1012A4 KD-1012A4

Finisher

(Hanging type)

Staple cartridge

(for MJ-1022)

MJ-1022 MJ-1022 MJ-1022 MJ-1022 MJ-1022

STAPLE-1600 STAPLE-1600 STAPLE-1600 STAPLE-1600 STAPLE-1600

Saddle stitch finisher MJ-1025 MJ-1025 MJ-1025 MJ-1025 MJ-1025

Staple cartridge

(for MJ-1025)

STAPLE-2000 STAPLE-2000 STAPLE-2000 STAPLE-2000 STAPLE-2000

Hole punch unit MJ-6005N MJ-6005E MJ-6005E MJ-6005E/F/S MJ-6005E

Bridge kit KN-3520 KN-3520E KN-3520 KN-3520 KN-3520

Job separator MJ-5004 MJ-5004 MJ-5004 MJ-5004 MJ-5004

Offset tray MJ-5005 MJ-5005 MJ-5005 MJ-5005 MJ-5005

Key copy counter MU-8 MU-8 MU-8 MU-8 MU-8

Key copy counter

socket

MU-10 MU-10 MU-10 MU-10 MU-10

Work tray KK-3511 KK-3511 KK-3511 KK-3511 KK-3511

Damp heater MF-2320U Standard Standard MF-2320E MF-2320E

Fax board GD-1150NA GD-1150AS GD-1150AU GD-1150EU GD-1150EU

2nd line for Fax

board

Wireless LAN

adapter

GD-1160NA GD-1160EU GD-1160EU GD-1160EU GD-1160EU

GN-1010 GN-1010 GN-1010 GN-1010 GN-1010

PCI slot GO-1040 GO-1040 GO-1040 GO-1040 GO-1040

Scrambler board GP-1030 GP-1030 GP-1030 GP-1030 GP-1030

Parallel interface kit GF-1140 GF-1140 GF-1140 GF-1140 GF-1140

NIC board Standard GF-1150 Standard Standard GF-1150

Printer/Scanner kit GM-2020 GM-2020 GM-2020 GM-2020 GM-2020

Printer kit GM-1020 GM-1020 GM-1020 GM-1020 GM-1020

Scanner upgrade kit GM-3020 GM-3020 GM-3020 GM-3020 GM-3020

Desk MH-1700 MH-1700 MH-1700 MH-1700 MH-1700

Harness kit for coin

controller

GQ-1020 GQ-1020 GQ-1020 GQ-1020 GQ-1020

South America/

Hong Kong

ASD

(220-240V)

Australia Europe

AUD

(220-240V)

MJD

(220-240V)

e-STUDIO200L/202L/203L/230/232/233/280/282/283 © 2004 - 2010 TOSHIBA TEC CORPORATION All rights reserved

SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES

1 - 14

04/09

Area Asia Saudi Arabia China Taiwan

Machine version

(destination)

ASU

(220-240V)

SAD

(127V)

CND

(220-240V)

TWD

(110V)

Model name e-STUDIO230 e-STUDIO230 e-STUDIO230 e-STUDIO230

Platen cover KA-3511PC KA-3511PC Standard KA-3511PC

RADF MR-3016 MR-3016 MR-3016 MR-3016

Drawer module

(for Equipment)

Drawer module

(for PFP)

MY-1021 MY-1021 Standard Standard

MY-1021 MY-1021 MY-1021 MY-1021

Slot cover KE-2330 KE-2330 - -

ADU MD-0102 MD-0102 Standard MD-0102

PFP KD-1011 KD-1011 KD-1011 KD-1011

LCF KD-1012A4 KD-1012A4 KD-1012A4 KD-1012A4

Finisher

(Hanging type)

Staple cartridge

(for MJ-1022)

MJ-1022 MJ-1022 MJ-1022-C MJ-1022

STAPLE-1600 STAPLE-1600 STAPLE-1600 STAPLE-1600

Saddle stitch finisher MJ-1025 MJ-1025 MJ-1025 MJ-1025

Staple cartridge

(for MJ-1025)

STAPLE-2000 STAPLE-2000 STAPLE-2000 STAPLE-2000

Hole punch unit MJ-6005E MJ-6005E MJ-6005E MJ-6005E

Bridge kit KN-3520 KN-3520 KN-3520-C KN-3520

Job separator MJ-5004 MJ-5004 MJ-5004-C MJ-5004

Offset tray MJ-5005 MJ-5005 MJ-5005-C MJ-5005

Key copy counter MU-8 MU-8 MU-8 MU-8

Key copy counter

socket

MU-10 MU-10 MU-10 MU-10

Work tray KK-3511 KK-3511 KK-3511 KK-3511

Damp heater Standard Standard Standard Standard

Fax board GD-1150AS GD-1150NA GD-1150C GD-1150TW

2nd line for Fax

board

Wireless LAN

adapter

GD-1160EU GD-1160NA GD-1160C GD-1160TW

GN-1010 GN-1010 GN-1010 GN-1010

PCI slot GO-1040 GO-1040 GO-1040C GO-1040

Scrambler board GP-1030 GP-1030 GP-1030 GP-1030

Parallel interface kit GF-1140 GF-1140 GF-1140 GF-1140

NIC board GF-1150 GF-1150 Standard Standard

Printer/Scanner kit GM-2020 GM-2020 Standard GM-2020

Printer kit GM-1020 GM-1020 GM-1020 GM-1020

Scanner upgrade kit GM-3020 GM-3020 GM-3020 GM-3020

Desk MH-1700 MH-1700 MH-1700 MH-1700

Harness kit for coin

controller

GQ-1020 GQ-1020 GQ-1020 GQ-1020

1

© 2004 - 2010 TOSHIBA TEC CORPORATION All rights reserved e-STUDIO200L/202L/203L/230/232/233/280/282/283

1 - 15

04/09

SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES

e-STUDIO200L

Area North America

Machine version

(destination)

NAD

(115V)

Model name e-STUDIO200L e-STUDIO200L

Platen cover KA-3511PC KA-3511PC

RADF MR-3016 MR-3016

Drawer module

(for Equipment)

Drawer module

(for PFP)

MY-1021 MY-1021

MY-1021 MY-1021

Slot cover Standard Standard

ADU MD-0102 MD-0102

PFP KD-1011 KD-1011

LCF KD-1012LT KD-1012A4

Finisher

(Hanging type)

Staple cartridge

(for MJ-1022)

MJ-1022 MJ-1022

STAPLE-1600 STAPLE-1600

Saddle stitch finisher MJ-1025 MJ-1025

Staple cartridge

(for MJ-1025)

STAPLE-2000 STAPLE-2000

Hole punch unit MJ-6005N MJ-6005E

Bridge kit KN-3520 KN-3520

Job separator MJ-5004 MJ-5004

Offset tray MJ-5005 MJ-5005

Key copy counter MU-8 MU-8

Key copy counter

socket

MU-10 MU-10

Work tray KK-3511 KK-3511

Damp heater MF-2320 Standard

Fax board GD-1150NA GD-1150AS

2nd line for Fax

board

Wireless LAN

adapter

GD-1160NA GD-1160EU

GN-1010 GN-1010

PCI slot GO-1040 GO-1040

Scrambler board GP-1030 GP-1030

Parallel interface kit GF-1140 GF-1140

NIC board GF-1150 GF-1150

Printer/Scanner kit GM-2030 GM-2030

Printer kit GM-1030 GM-1030

Scanner upgrade kit GM-3030 GM-3030

Desk MH-1700 MH-1700

Harness kit for coin

controller

GQ-1020 GQ-1020

Central and

South America

ASD

(220-240V)

e-STUDIO200L/202L/203L/230/232/233/280/282/283 © 2004 - 2010 TOSHIBA TEC CORPORATION All rights reserved

SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES

1 - 16

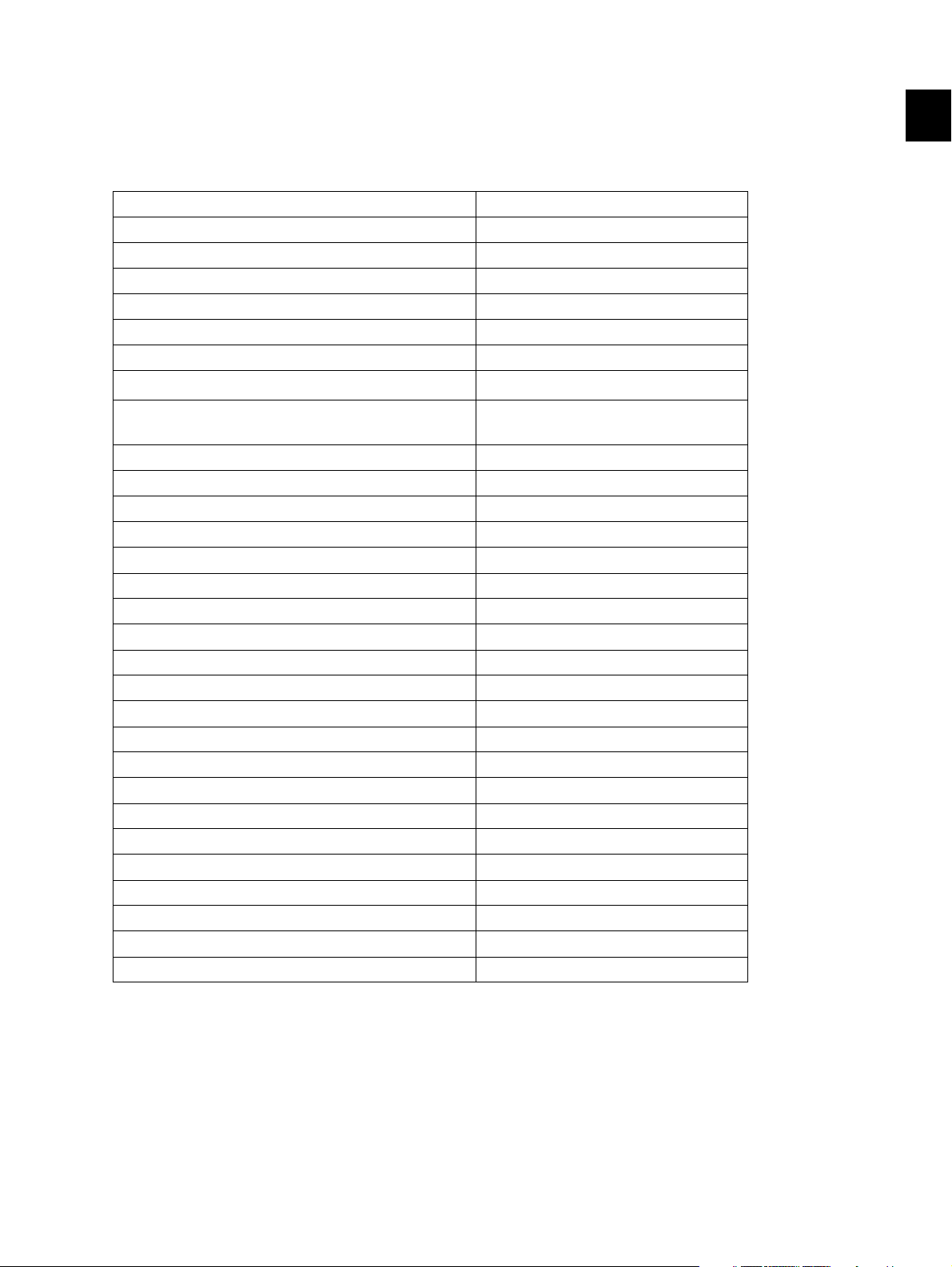

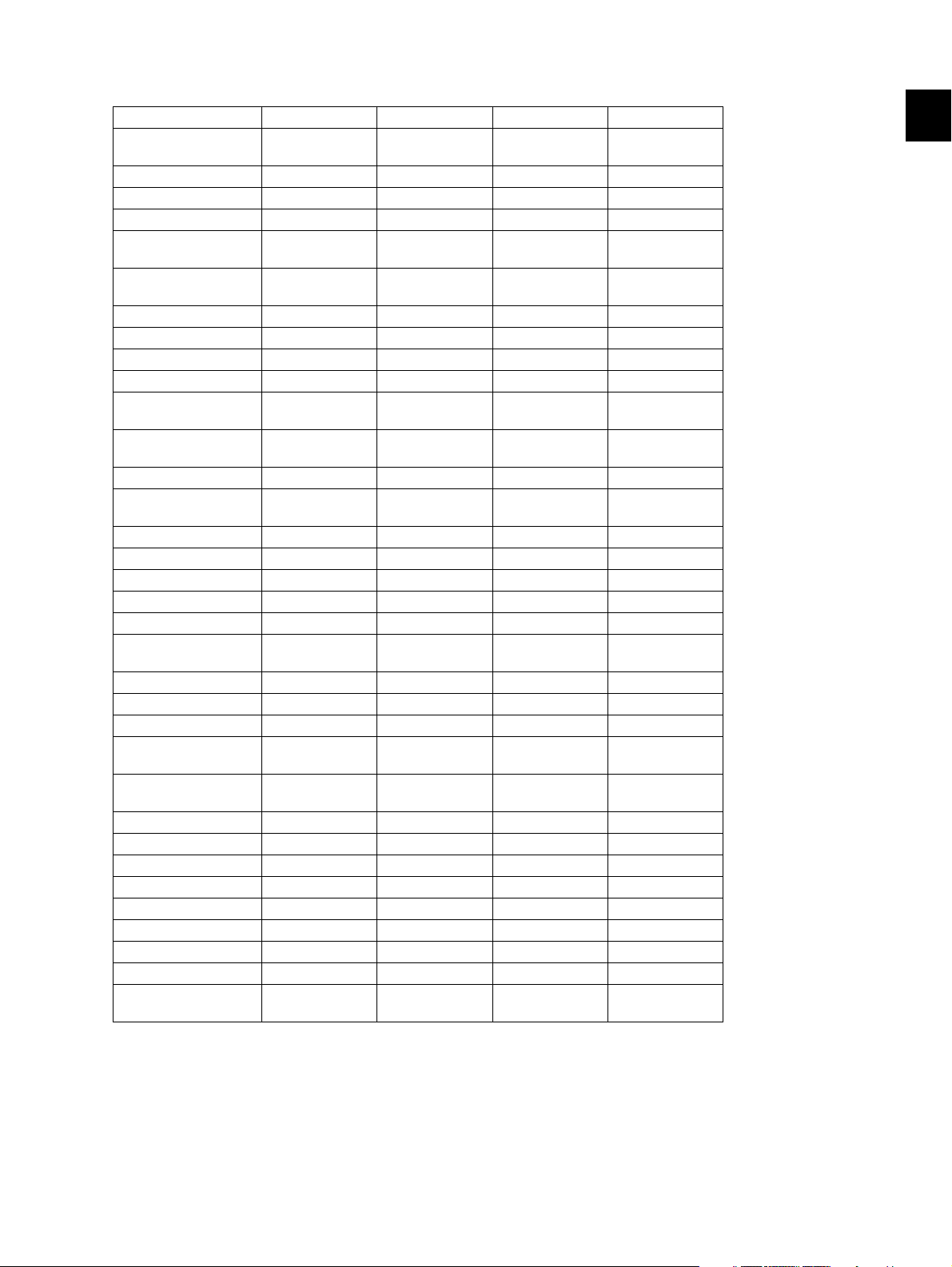

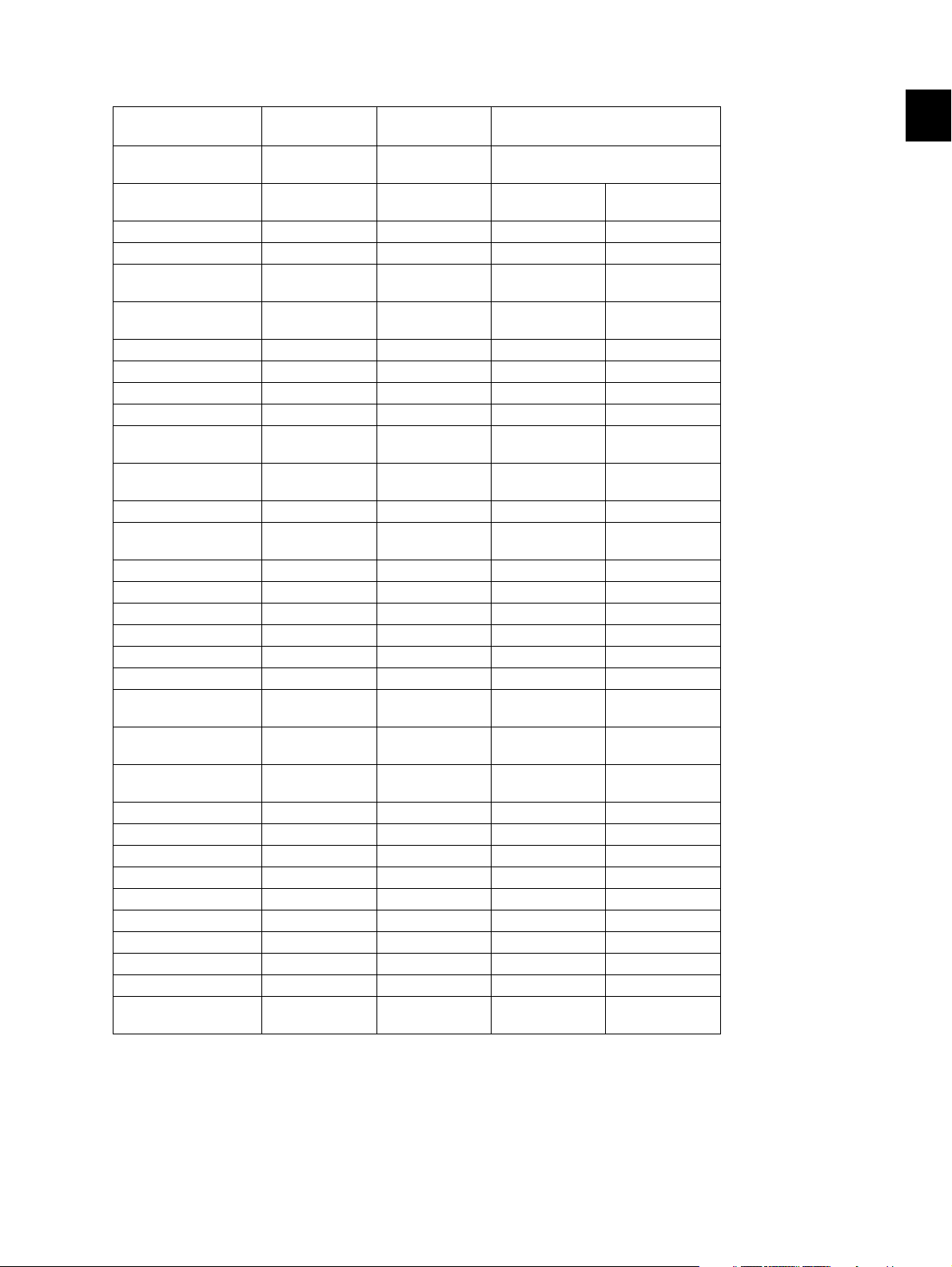

1.5.2 e-STUDIO202L/203L/232/232S/233/282/282S/283/283S

1

ID Gate

KP-2005

e-BRIDGE

ID Gate

KP-2004

e-BRIDGE

GQ-1020

coin controller

Harness kit for

KA-3511

Platen Cover

)

RADF

(

module

GN-1041

Wireless LAN

Bluetooth

module

GN-2010

Antenna

GN-3010

KN-3520

Bridge Kit

MF-2320 U/E

Damp Heater

Job Separator

MJ-5004

)

ADU

(

Automatic

Duplexing Unit

PCI Slot

MJ-5005

Offset Tray

.

Printer/

MD-0102

GO-1060

ELK

GM-2070/2071

Scanner Kit

GM-2130/2140U

GM-2080U/2081U

ELK

.

Printer Kit

GM-1070/1071

GM1130/1140U

GM-1080U/1081U

ELK

.

Memory

Scanner Kit

GM-4070/4080U

GM-4130/4140U

GC-1230

Desk

MH-1700

Feeder (LCF)

Large Capacity

KD-1012 A4/LT

MR-3020

Reversing Automatic

Document Feeder

)

Finisher

MJ-1022

Hanging type

(

Hole Punch Unit

STAPLE-1600

Staple Cartridge

MJ-6005 N/E/F/S

Saddle stitch

Finisher

MJ-1025

Board

GP-1040

Scrambler

Fig. 1-3

kit

GP-1060

Data overwrite

Staple Cartridge

FAX Board

2nd Line for

STAPLE-2000

GD-1150

AS/C/TW

NA/EU/AU/

GD-1160

FAX Board

NA/EU-N/TW/C

GD-1151

AS/C/TW

FAX Board

NA/EU/AU/

GD-1260

FAX Board

2nd Line for

NA/EU/TW/C

KD-1011

Paper Feed

Pedestal (PFP)

MY-1021

Drawer Module

KE-2330

Slot cover

© 2004 - 2010 TOSHIBA TEC CORPORATION All rights reserved e-STUDIO200L/202L/203L/230/232/233/280/282/283

SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES

1 - 17

10/01

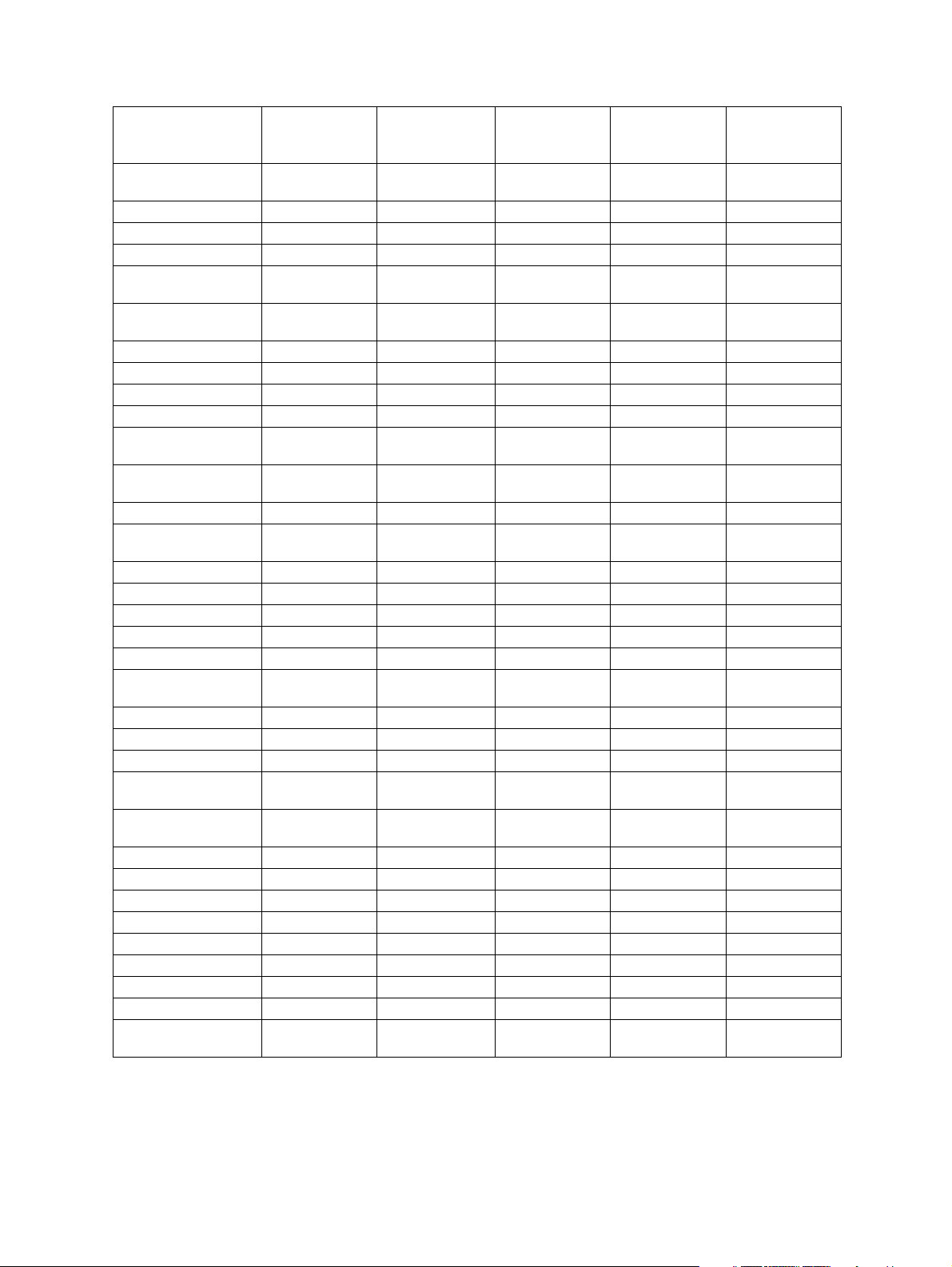

e-STUDIO282/282S/283/283S

Central and

Area North America

Machine version

(destination)

NAD

(115V)

Model name e-STUDIO

282/283

Platen cover KA-3511PC KA-3511PC KA-3511PC KA-3511PC KA-3511PC

RADF MR-3020 MR-3020 MR-3020 MR-3020 MR-3020

Drawer module

(for Equipment)

Drawer module

(for PFP)

Standard MY-1021 MY-1021 Standard Standard

MY-1021 MY-1021 MY-1021 MY-1021 MY-1021

Slot cover - Standard Standard - -

ADU Standard MD-0102 MD-0102 Standard Standard

PFP KD-1011 KD-1011-N KD-1011 KD-1011 KD-1011

LCF KD-1012LT KD-1012A4 KD-1012A4 KD-1012A4 KD-1012A4

Finisher

(Hanging type)

Staple cartridge

(for MJ-1022)

MJ-1022 MJ-1022 MJ-1022 MJ-1022 MJ-1022

STAPLE-1600 STAPLE-1600 STAPLE-1600 STAPLE-1600 STAPLE-1600

Saddle stitch finisher MJ-1025 MJ-1025 MJ-1025 MJ-1025 MJ-1025

Staple cartridge

(for MJ-1025)

STAPLE-2000 STAPLE-2000 STAPLE-2000 STAPLE-2000 STAPLE-2000

Hole punch unit MJ-6005N MJ-6005E MJ-6005E MJ-6005E MJ-6005E/F/S

Bridge kit KN-3520 KN-3520 KN-3520 KN-3520 KN-3520

Job separator MJ-5004 MJ-5004 MJ-5004 MJ-5004 MJ-5004

Offset tray MJ-5005 MJ-5005 MJ-5005 MJ-5005 MJ-5005

Work tray KK-3511 KK-3511 KK-3511 KK-3511 KK-3511

Damp heater MF-2320U Standard Standard Standard MF-2320E

Fax board GD-1150NA

GD-1151NA

2nd line for Fax

board

Wireless LAN

module

GD-1160NA

GD-1260NA

GN-1041 GN-1041 GN-1041 GN-1041 GN-1041

Bluetooth module GN-2010 GN-2010 GN-2010 GN-2010 GN-2010

Antenna GN-3010 GN-3010 GN-3010 GN-3010 GN-3010

PCI slot GO-1060 GO-1060 GO-1060 GO-1060 GO-1060

Scrambler board GP-1040 GP-1040 GP-1040 GP-1040 GP-1040

Printer kit GM-1070/1071 GM-1070/1071 GM-1070/1071 GM-1070/1071 GM-1070/1071

Printer/Scanner kit GM-2070/2071 GM-2070/2071 GM-2070/2071 GM-2070/2071 GM-2070/2071

Scanner kit GM-4070 GM-4070 GM-4070 GM-4070 GM-4070

Data overwrite kit GP-1060 GP-1060 GP-1060 GP-1060 GP-1060

Desk MH-1700 MH-1700 MH-1700 MH-1700 MH-1700

Harness kit for coin

controller

GQ-1020 GQ-1020 GQ-1020 GQ-1020 GQ-1020

South Amer-

Argentina Australia Europe

ica/Hong Kong

ASD

(220-240V)

ARD

(220-240V)

e-STUDIO282 e-STUDIO

282/283

GD-1150AS

GD-1151AS

GD-1160EU-N

GD-1260EU

GD-1150AS

GD-1151AS

GD-1160EU-N

GD-1260EU

AUD

(220-240V)

MJD

(220-240V)

e-STUDIO282 e-STUDIO

282/283

GD-1150AU

GD-1151AU

GD-1160EU-N

GD-1260EU

GD-1150EU

GD-1151EU

GD-1160EU-N

GD-1260EU

e-STUDIO200L/202L/203L/230/232/233/280/282/283 © 2004 - 2010 TOSHIBA TEC CORPORATION All rights reserved

SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES

1 - 18

10/01

Area Asia Saudi Arabia

China

1

Machine version

(destination)

Model name e-STUDIO282 e-STUDIO282 e-STUDIO

ASU

(220-240V)

SAD

(127V)

282/283

CND

(220-240V)

e-STUDIO

282S/283S

Platen cover KA-3511PC KA-3511PC Standard Standard

RADF MR-3020 MR-3020 MR-3020 MR-3020

Drawer module

(for Equipment)

Drawer module

(for PFP)

MY-1021 MY-1021 Standard Standard

MY-1021 MY-1021 MY-1021-C MY-1021-C

Slot cover KE-2330 KE-2330 - -

ADU MD-0102 MD-0102 Standard MD-0102-C

PFP KD-1011 KD-1011 KD-1011-C KD-1011-C

LCF KD-1012 KD-1012A4 KD-1012A4-C KD-1012A4-C

Finisher

(Hanging type)

Staple cartridge

(for MJ-1022)

MJ-1022 MJ-1022 MJ-1022-C MJ-1022-C

STAPLE-1600 STAPLE-1600 STAPLE-1600 STAPLE-1600

Saddle stitch finisher MJ-1025 MJ-1025 MJ-1025 MJ-1025

Staple cartridge

(for MJ-1025)

STAPLE-2000 STAPLE-2000 STAPLE-2000 STAPLE-2000

Hole punch unit MJ-6005E MJ-6005E MJ-6005E MJ-6005E

Bridge kit KN-3520 KN-3520 KN-3520-C KN-3520-C

Job separator MJ-5004 MJ-5004 MJ-5004-C MJ-5004-C

Offset tray MJ-5005 MJ-5005 MJ-5005-C MJ-5005-C

Work tray KK-3511 KK-3511 KK-3511-C KK-3511-C

Damp heater Standard Standard Standard Standard

Fax board GD-1150AS

GD-1151AS

2nd line for Fax

board

Wireless LAN

module

GD-1160EU-N

GD-1260EU

GN-1041 GN-1041 GN-1041 GN-1041

GD-1150NA

GD-1151NA

GD-1160NA

GD-1260NA

GD-1150C

GD-1151C

GD-1160C

GD-1260C

GD-1150C

GD-1151C

GD-1160C

GD-1260C

Bluetooth module GN-2010 GN-2010 GN-2010 GN-2010

Antenna GN-3010 GN-3010 GN-3010 GN-3010

PCI slot GO-1060 GO-1060 GO-1060 GO-1060

Scrambler board GP-1040 GP-1040 GP-1040 GP-1040

Printer kit GM-1070/1071 GM-1070/1071 GM-1070/1071 -

Printer/Scanner kit GM-2070/2071 GM-2070/2071 Standard -

Scanner kit GM-4070 GM-4070 GM-4070 -

Data overwrite kit GP-1060 GP-1060 GP-1060 GP-1060

Desk MH-1700 MH-1700 MH-1700 MH-1700

Harness kit for coin

controller

GQ-1020 GQ-1020 GQ-1020 GQ-1020

© 2004 - 2010 TOSHIBA TEC CORPORATION All rights reserved e-STUDIO200L/202L/203L/230/232/233/280/282/283

1 - 19

10/01

SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES

Area Taiwan Korea

Machine version

(destination)

TWD

(110V)

KRD

(220-240V)

Model name e-STUDIO282 e-STUDIO282

Platen cover KA-3511PC Standard

RADF MR-3020 MR-3020

Drawer module

(for Equipment)

Drawer module

(for PFP)

Standard Standard

MY-1021 MY-1021

Slot cover - -

ADU MD-0102 MD-0102

PFP KD-1011 KD-1011

LCF KD-1012A4 KD-1012A

Finisher

(Hanging type)

Staple cartridge

(for MJ-1022)

MJ-1022 MJ-1022

STAPLE-1600 STAPLE-1600

Saddle stitch finisher MJ-1025 MJ-1025

Staple cartridge

(for MJ-1025)

STAPLE-2000 STAPLE-2000

Hole punch unit MJ-6005E MJ-6005E

Bridge kit KN-3520 KN-3520

Job separator MJ-5004 MJ-5004

Offset tray MJ-5005 MJ-5005

Work tray KK-3511 KK-3511

Damp heater Standard Standard

Fax board GD-1150TW

GD-1151TW

2nd line for Fax

board

Wireless LAN

module

GD-1160TW

GD-1260TW

GN-1041 GN-1041

GD-1150AS

GD-1151AS

GD-1160EU-N

GD-1260EU

Bluetooth module GN-2010 GN-2010

Antenna GN-3010 GN-3010

PCI slot GO-1060 GO-1060

Scrambler board GP-1040 GP-1040

Printer kit GM-1070/1071 GM-1070/1071

Printer/Scanner kit GM-2070/2071 GM-2070/2071

Scanner kit GM-4070 GM-4070

Data overwrite kit GP-1060 GP-1060

Desk MH-1700 MH-1700

Harness kit for coin

controller

GQ-1020 GQ-1020

e-STUDIO200L/202L/203L/230/232/233/280/282/283 © 2004 - 2010 TOSHIBA TEC CORPORATION All rights reserved

SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES

1 - 20

10/01

e-STUDIO232/232S/233

Central and

Area North America

Machine version

(destination)

NAD

(115V)

Model name e-STUDIO

232/233

Platen cover KA-3511PC KA-3511PC KA-3511PC KA-3511PC KA-3511PC

RADF MR-3020 MR-3020 MR-3020 MR-3020 MR-3020

Drawer module

(for Equipment)

Drawer module

(for PFP)

Standard MY-1021 MY-1021 Standard Standard

MY-1021 MY-1021 MY-1021 MY-1021 MY-1021

Slot cover - Standard Standard - -

ADU Standard MD-0102 MD-0102 Standard Standard

PFP KD-1011 KD-1011-N KD-1011 KD-1011 KD-1011

LCF KD-1012LT KD-1012A4 KD-1012A4 KD-1012A4 KD-1012A4

Finisher

(Hanging type)

Staple cartridge

(for MJ-1022)

MJ-1022 MJ-1022 MJ-1022 MJ-1022 MJ-1022

STAPLE-1600 STAPLE-1600 STAPLE-1600 STAPLE-1600 STAPLE-1600

Saddle stitch finisher MJ-1025 MJ-1025 MJ-1025 MJ-1025 MJ-1025

Staple cartridge

(for MJ-1025)

STAPLE-2000 STAPLE-2000 STAPLE-2000 STAPLE-2000 STAPLE-2000

Hole punch unit MJ-6005N MJ-6005E MJ-6005E MJ-6005E MJ-6005E/F/S

Bridge kit KN-3520 KN-3520 KN-3520 KN-3520 KN-3520

Job separator MJ-5004 MJ-5004 MJ-5004 MJ-5004 MJ-5004

Offset tray MJ-5005 MJ-5005 MJ-5005 MJ-5005 MJ-5005

Work tray KK-3511 KK-3511 KK-3511 KK-3511 KK-3511

Damp heater MF-2320U Standard Standard Standard MF-2320E

Fax board GD-1150NA

GD-1151NA

2nd line for Fax

board

Wireless LAN

module

GD-1160NA

GD-1260NA

GN-1041 GN-1041 GN-1041 GN-1041 GN-1041

Bluetooth module GN-2010 GN-2010 GN-2010 GN-2010 GN-2010

Antenna GN-3010 GN-3010 GN-3010 GN-3010 GN-3010

PCI slot GO-1060 GO-1060 GO-1060 GO-1060 GO-1060

Scrambler board GP-1040 GP-1040 GP-1040 GP-1040 GP-1040

Printer kit GM-1070/1071 GM-1070/1071 GM-1070/1071 GM-1070/1071 GM-1070/1071

Printer/Scanner kit GM-2070/2071 GM-2070/2071 GM-2070/2071 GM-2070/2071 GM-2070/2071

Scanner kit GM-4070 GM-4070 GM-4070 GM-4070 GM-4070

Data overwrite kit GP-1060 GP-1060 GP-1060 GP-1060 GP-1060

Desk MH-1700 MH-1700 MH-1700 MH-1700 MH-1700

Harness kit for coin

controller

GQ-1020 GQ-1020 GQ-1020 GQ-1020 GQ-1020

South Amer-

Argentina Australia Europe

ica/Hong Kong

ASD

(220-240V)

ARD

(220-240V)

e-STUDIO232 e-STUDIO

232/233

GD-1150AS

GD-1151AS

GD-1160EU-N

GD-1260EU

GD-1150AS

GD-1151AS

GD-1160EU-N

GD-1260EU

AUD

(220-240V)

MJD

(220-240V)

e-STUDIO232 e-STUDIO

232/233

GD-1150AU

GD-1151AU

GD-1160EU-N

GD-1260EU

GD-1150EU

GD-1151EU

GD-1160EU-N

GD-1260EU

1

© 2004 - 2010 TOSHIBA TEC CORPORATION All rights reserved e-STUDIO200L/202L/203L/230/232/233/280/282/283

1 - 21

10/01

SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES

Area Asia Saudi Arabia

China

Machine version

(destination)

Model name e-STUDIO232 e-STUDIO232 e-STUDIO

ASU

(220-240V)

SAD

(127V)

CND

(220-240V)

e-STUDIO232S

232/233

Platen cover KA-3511PC KA-3511PC Standard Standard

RADF MR-3020 MR-3020 MR-3020 MR-3020

Drawer module

(for Equipment)

Drawer module

(for PFP)

MY-1021 MY-1021 Standard Standard

MY-1021 MY-1021 MY-1021-C MY-1021-C

Slot cover KE-2330 KE-2330 - -

ADU MD-0102 MD-0102 Standard MD-0102-C

PFP KD-1011 KD-1011 KD-1011-C KD-1011-C

LCF KD-1012 KD-1012A4 KD-1012A4-C KD-1012A4-C

Finisher

(Hanging type)

Staple cartridge

(for MJ-1022)

MJ-1022 MJ-1022 MJ-1022-C MJ-1022-C

STAPLE-1600 STAPLE-1600 STAPLE-1600 STAPLE-1600

Saddle stitch finisher MJ-1025 MJ-1025 MJ-1025 MJ-1025

Staple cartridge

(for MJ-1025)

STAPLE-2000 STAPLE-2000 STAPLE-2000 STAPLE-2000

Hole punch unit MJ-6005E MJ-6005E MJ-6005E MJ-6005E

Bridge kit KN-3520 KN-3520 KN-3520-C KN-3520-C

Job separator MJ-5004 MJ-5004 MJ-5004-C MJ-5004-C

Offset tray MJ-5005 MJ-5005 MJ-5005-C MJ-5005-C

Work tray KK-3511 KK-3511 KK-3511-C KK-3511-C

Damp heater Standard Standard Standard Standard

Fax board GD-1150AS

GD-1151AS

2nd line for Fax

board

Wireless LAN

module

GD-1160EU-N

GD-1260EU

GN-1041 GN-1041 GN-1041 GN-1041

GD-1150NA

GD-1151NA

GD-1160NA

GD-1260NA

GD-1150C

GD-1151C

GD-1160C

GD-1260C

GD-1150C

GD-1151C

GD-1160C

GD-1260C

Bluetooth module GN-2010 GN-2010 GN-2010 GN-2010

Antenna GN-3010 GN-3010 GN-3010 GN-3010

PCI slot GO-1060 GO-1060 GO-1060 GO-1060

Scrambler board GP-1040 GP-1040 GP-1040 GP-1040

Printer kit GM-1070/1071 GM-1070/1071 GM-1070/1071 -

Printer/Scanner kit GM-2070/2071 GM-2070/2071 Standard -

Scanner kit GM-4070 GM-4070 GM-4070 -

Data overwrite kit GP-1060 GP-1060 GP-1060 GP-1060

Desk MH-1700 MH-1700 MH-1700 MH-1700

Harness kit for coin

controller

GQ-1020 GQ-1020 GQ-1020 GQ-1020

e-STUDIO200L/202L/203L/230/232/233/280/282/283 © 2004 - 2010 TOSHIBA TEC CORPORATION All rights reserved

SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES

1 - 22

10/01

Area Taiwan Korea

Machine version

(destination)

TWD

(110V)

KRD

(220-240V)

Model name e-STUDIO232 e-STUDIO232

Platen cover KA-3511PC Standard

RADF MR-3020 MR-3020

Drawer module

(for Equipment)

Drawer module

(for PFP)

Standard Standard

MY-1021 MY-1021

Slot cover - -

ADU MD-0102 MD-0102

PFP KD-1011-TW KD-1011

LCF KD-1012A4 KD-1012A4

Finisher

(Hanging type)

Staple cartridge

(for MJ-1022)

MJ-1022 MJ-1022

STAPLE-1600 STAPLE-1600

Saddle stitch finisher MJ-1025 MJ-1025

Staple cartridge

(for MJ-1025)

STAPLE-2000 STAPLE-2000

Hole punch unit MJ-6005E MJ-6005E

Bridge kit KN-3520 KN-3520

Job separator MJ-5004 MJ-5004

Offset tray MJ-5005 MJ-5005

Work tray KK-3511 KK-3511

Damp heater Standard Standard

Fax board GD-1150TW

GD-1151TW

2nd line for Fax

board

Wireless LAN

module

GD-1160TW

GD-1260TW

GN-1041 GN-1041

GD-1150AS

GD-1151AS

GD-1160EU-N

GD-1260EU

Bluetooth module GN-2010 GN-2010

Antenna GN-3010 GN-3010

PCI slot GO-1060 GO-1060

Scrambler board GP-1040 GP-1040

Printer kit GM-1070/1071 GM-1070/1071

Printer/Scanner kit GM-2070/2071 GM-2070/2071

Scanner kit GM-4070 GM-4070

Data overwrite kit GP-1060 GP-1060

Desk MH-1700 MH-1700

Harness kit for coin

controller

GQ-1020 GQ-1020

1

© 2004 - 2010 TOSHIBA TEC CORPORATION All rights reserved e-STUDIO200L/202L/203L/230/232/233/280/282/283

1 - 23

10/01

SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES

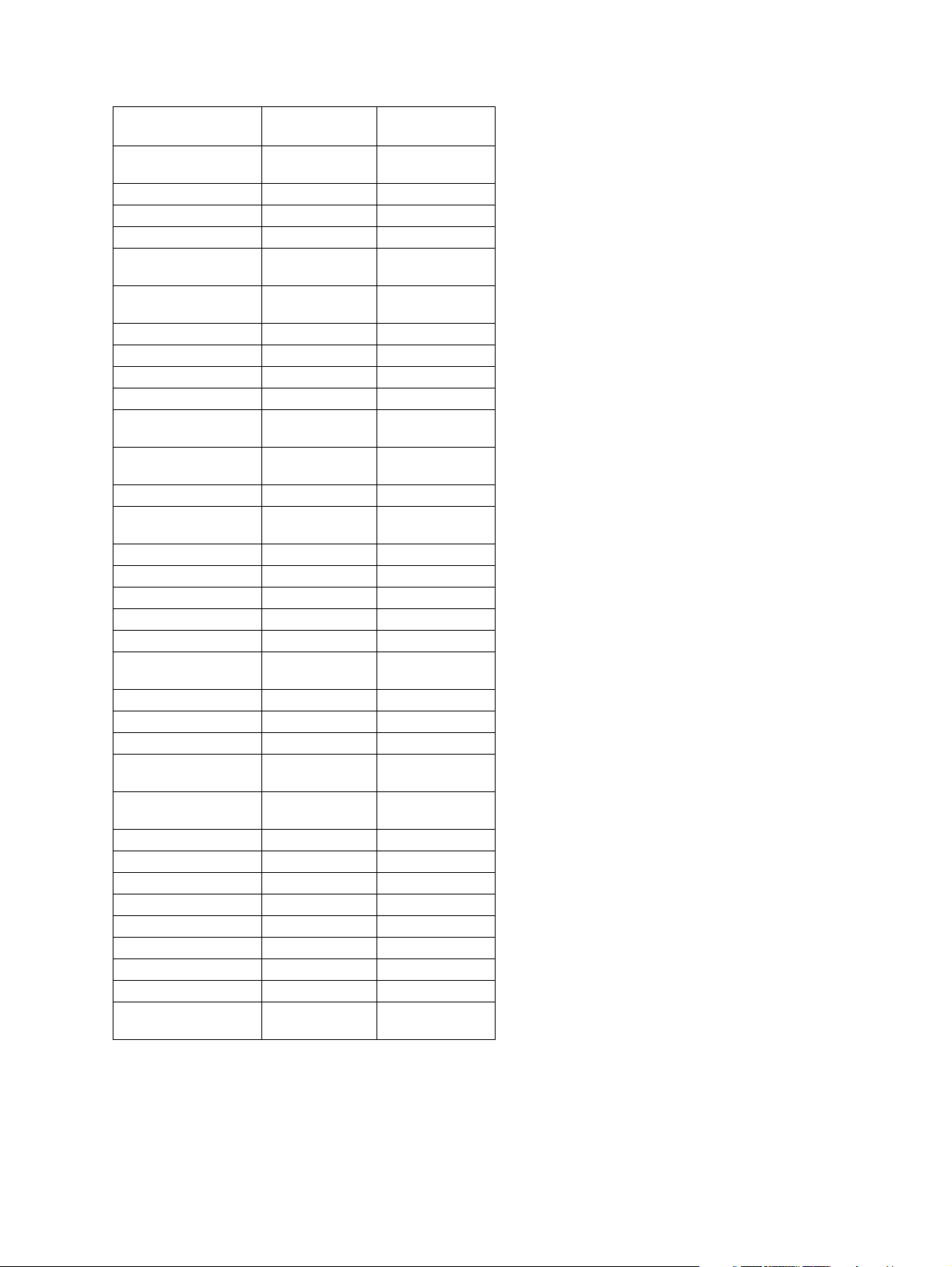

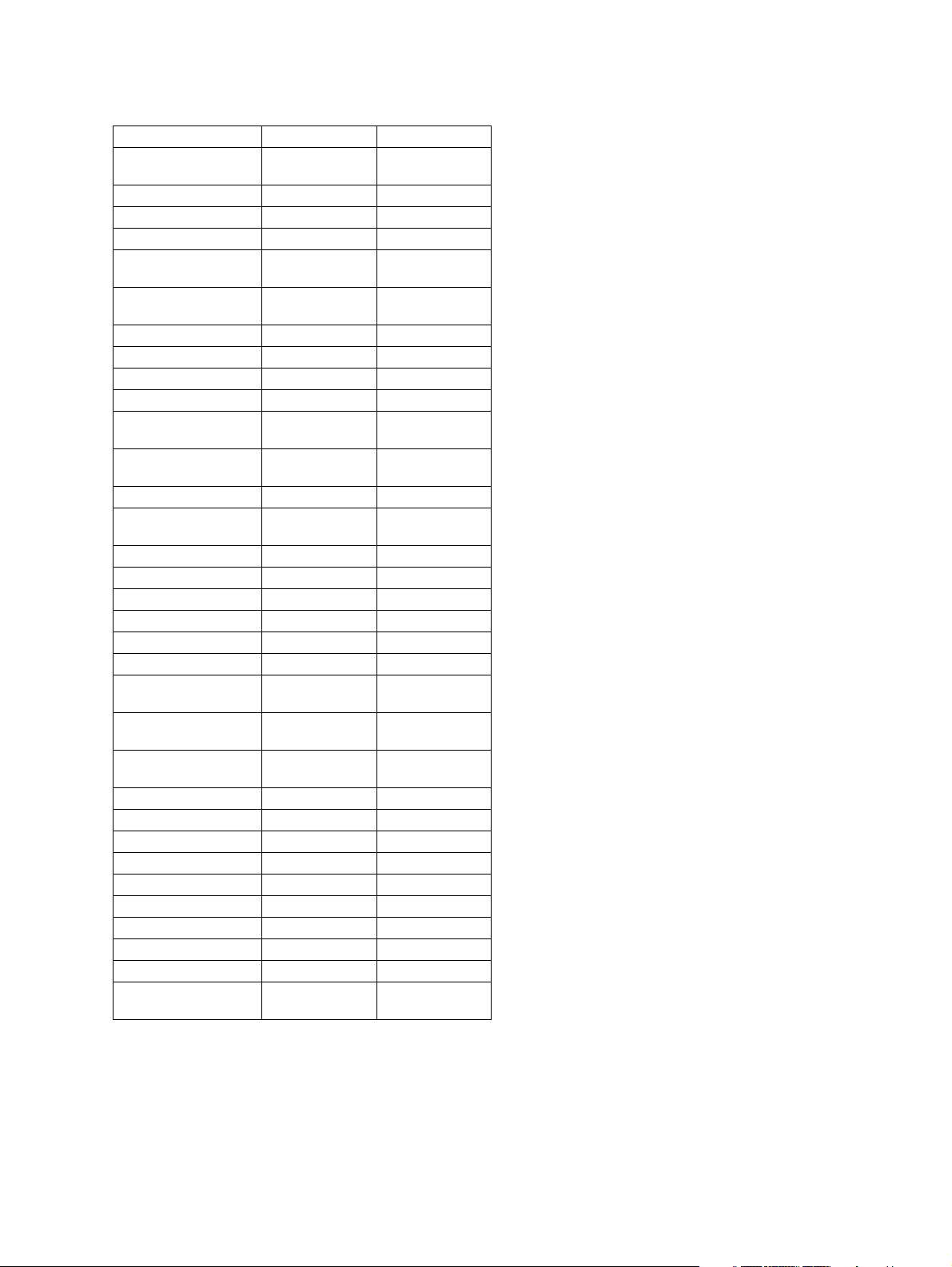

e-STUDIO202L/203L

Area North America Argentina

Machine version

(destination)

Model name e-STUDIO

Platen cover KA-3511PC KA-3511PC

RADF MR-3020 MR-3020

Drawer module

(for Equipment)

Drawer module

(for PFP)

Slot cover Standard Standard

ADU MD-0102 MD-0102

PFP KD-1011 KD-1011-N

LCF KD-1012LT KD-1012A4

Finisher

(Hanging type)

Staple cartridge

(for MJ-1022)

Saddle stitch finisher MJ-1025 MJ-1025

Staple cartridge

(for MJ-1025)

Hole punch unit MJ-6005N MJ-6005E

Bridge kit KN-3520 KN-3520

Job separator MJ-5004 MJ-5004

Offset tray MJ-5005 MJ-5005

Work tray KK-3511 KK-3511

Damp heater MF-2320U Standard

Fax board GD-1150NA

2nd line for Fax

board

Wireless LAN

module

Bluetooth module GN-2010 GN-2010

Antenna GN-3010 GN-3010

PCI slot GO-1060 GO-1060

Scrambler board GP-1040 GP-1040

Printer kit GM-1080U/

Printer/Scanner kit GM-2080U/

Scanner kit GM-4080U GM-4080U

Data overwrite kit GP-1060 GP-1060

Desk MH-1700 MH-1700

Harness kit for coin

controller