Page 1

TEC Two -Color Printer

Table of Contents

CB-426-T3-QQ

Owner’s Manual

Page 2

W e, TOSHIBA TEC Corporation of 570 Ohito Ohito-cho T agata-Gun Shizuoka-Ken 410-2323 JAP AN,

declare in our sole responsibility that this product has been tested and found to comply with the limits

for a Class A digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This accordance with the instruction manual, may cause harmful interference

to radio communications. Operations of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his own expense.

(for USA only)

Changes or modifications not expressly approved by manufacturer for compliance could void the

user’s authority to operate the equipment.

“This Class A digital apparatus meets all requirements of the Canadian Interference-Causing Equipment

Regulations.”

“Cet appareil numérique de la classe A respecte toutes les exigences du Règlement sur le matériel

brouilleur du Canada.” (for CANADA only)

CAUTION:

1.This manual may not be copied in whole or in part without prior written permission of TOSHIBA

TEC.

2.The contents of this manual may be changed without notification.

3.Please refer to your local Authorized Service representative with regard to any queries you may

have in this manual.

Trademark:

• Microsoft, Windows, Windows NT, and the Windows Logo are either registered trademarks or

trademarks of Microsoft Corporation in the United States.

• All other brands and names are the property of their respective owners.

Copyright © 2000

by TOSHIBA TEC CORPORATION

All Rights Reserved

570 Ohito, Ohito-cho, Tagata-gun, Shizuoka-ken, JAPAN

Page 3

Safety Precautions

Safety Precautions

Safety Summary

Meanings of Symbols

Personal safety in handling or maintaining the equipment is extremely

important. Warnings and Cautions necessary for safe handling are

included in this manual. All warnings and cautions contained in this

manual should be read and understood before handling or maintaining

the equipment.

Do not attempt to effect repairs or modifications to this equipment.

If a fault occurs that cannot be rectified using the procedures described

in this manual, turn off the power, unplug the machine, then contact

your authorized TOSHIBA TEC representative for assistance.

This symbol indicates warning items (including cautions).

Specific warning contents are drawn inside the symbol.

(The symbol on the left indicates a general caution.)

This symbol indicates prohibited actions (prohibited items).

Specific prohibited contents are drawn inside or near the

(The symbol on the left indicates “no disassembling”.)

This symbol indicates actions which must be performed.

Specific instructions are drawn inside or near the symbol.

(The symbol on the left indicates “disconnect the power cord plug

from the outlet”.)

symbol.

i

Page 4

Safety Precautions

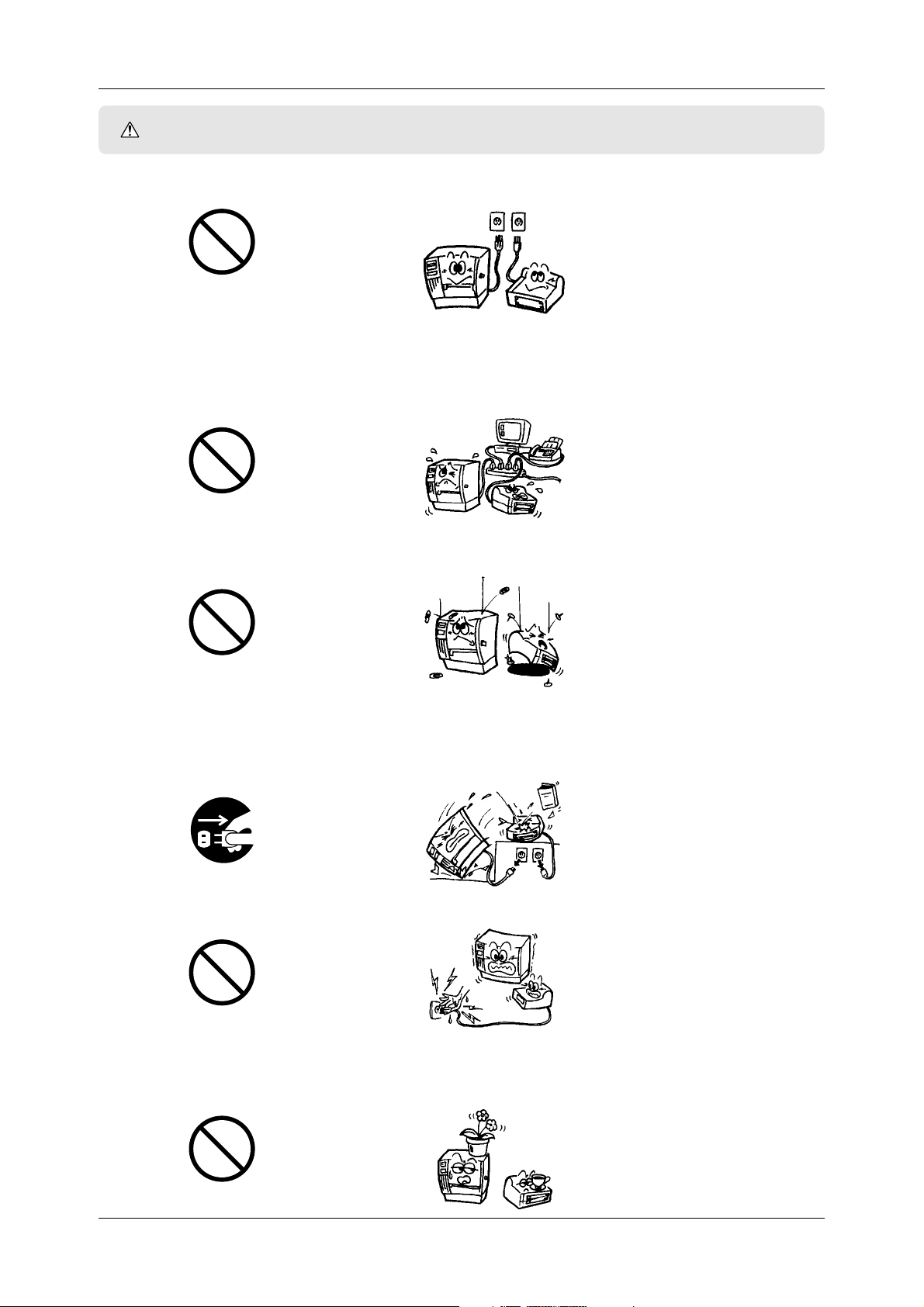

WARNING

Any other than the specified AC voltage

is prohibited.

Prohibited

This indicates that there is the risk of death or serious injury if the

machines are improperly handled contrary to this indication.

■ Do not use voltages other than the voltage (AC) specified on the

rating plate, as this may cause fire or electric shock.

■ If the machines share the same outlet with any other electrical

appliances which consume large amounts of power, the voltage

will fluctuate widely each time these appliances operate. Be sure

to provide an exclusive outlet for the machine as this may cause

the machines to malfunction.

■ Do not insert or drop metal, flammable or other foreign objects

into the machines through the ventilation slits, as this may cause

fire or electric shock.

Prohibited

Disconnect the plug.

Prohibited

■ If the machines are dropped or their cabinets damaged, first turn

off the power switches and disconnect the power cord plugs from

the outlet, and then contact your authorized TOSHIBA TEC

representative for assistance. Continued use of the machine in

that condition may cause fire or electric shock.

■ Do not plug in or unplug the power cord plug with wet hands as

this may cause electric shock.

■ Do not place metal objects or water-filled containers such as flower

vases, flower pots or mugs, etc. on top of the machines. If metal

objects or spilled liquid enter the machines, this may cause fire or

electric shock.

Prohibited

ii

Page 5

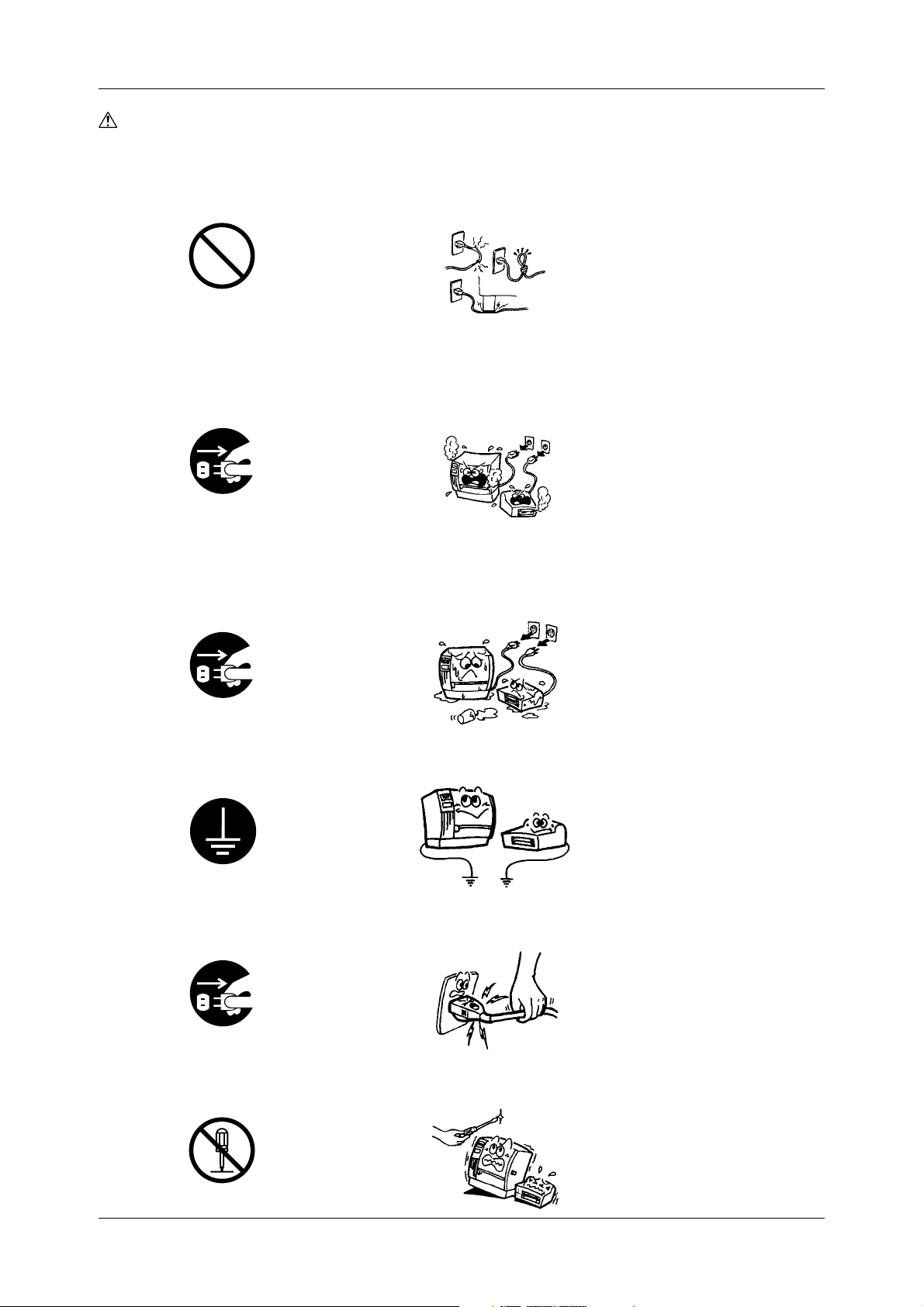

WARNING (Cont.)

Prohibited

Disconnect the plug.

Safety Precautions

■ Do not cut, damage or modify the power cords. Also, do not

place heavy objects on, pull on, or excessively bend the cords, as

this may cause fire or electrical shock.

■ Continued use of the machines in an abnormal condition such as

when the machines are producing smoke or strange smells may

cause fire or electric shock. In these cases, immediately turn off

the power switches and disconnect the power cord plugs from the

outlet. Then, contact your authorized TOSHIBA TEC representative

for assistance.

■ If foreign objects (metal fragments, water, liquids) enter the

machines, first turn off the power switches and disconnect the

power cord plugs from the outlet, and then contact your authorized

TOSHIBA TEC representative for assistance. Continued use of

the machine in that condition may cause fire or electric shock.

Disconnect the plug.

Connect a grounding wire.

Disconnect the plug.

■ Ensure that the equipment is properly grounded. Extension cables

should also be grounded. Fire or electric shock could occur on

improperly grounded equipment.

■ When unplugging the power cords, be sure to hold and pull on

the plug portion. Pulling on the cord portion may cut or expose

the internal wires and cause fire or electric shock.

■ Do not remove covers, repair or modify the machine by yourself.

Y ou may be injured by high voltage, very hot parts or sharp edges

inside the machine.

No disassembling.

iii

Page 6

CAUTION

Safety Precautions

This indicates that there is the risk of personal injury or damage to

objects if the machine is improperly handled contrary to this

indication.

The following precautions will help to ensure that this machine will

continue to function correctly.

• Try to avoid locations that have the following adverse conditions:

* Temperatures out of the specification

* Direct sunlight * High humidity

* Shared power source * Excessive vibration

* Dust/Gas

• The cover should be cleaned by wiping with a dry cloth or a cloth

slightly dampened with a mild detergent solution. NEVER USE

THINNER OR ANY OTHER VOLATILE SOLVENT on the

plastic covers.

• USE ONLY TOSHIBA TEC SPECIFIED paper and ribbons.

• DO NOT STORE the paper or ribbons where they might be exposed

to direct sunlight, high temperatures, high humidity, dust, or gas.

• Ensure the printer is operated on a level surface.

• Any data stored in the memory of the printer could be lost during

a printer fault.

• Try to avoid using this equipment on the same power source as

high voltage equipment or equipment likely to cause electrical

interference.

• Unplug the machine whenever cleaning or working inside it.

• Keep the work environment static free.

• Do not place heavy objects on top of the machines, as these items

may become unbalanced and fall causing injury.

• Do not block the ventilation slits of the machines, as this will

cause heat to build up inside the machines and may cause fire.

• Do not lean against the machine. It may fall and cause injury.

• Care must be taken not to injure yourself with the printer paper cutter.

• Unplug the machine when it is not used for a long period of time.

iv

Request Regarding

Maintenance

• Utilize our maintenance services.

After purchasing the machine, contact your authorized TOSHIBA

TEC representative for assistance once a year to have the inside

of the machine cleaned. Otherwise, dust will build up inside the

machines and may cause a fire or a malfunction. Cleaning is

particularly effective before humid rainy seasons.

• Our preventive maintenance service performs the periodic checks

and other work required to maintain the quality and performance

of the machines, preventing accidents beforehand.

For details, please consult your authorized TOSHIBA TEC

representative for assistance.

• Do not expose the machines to insecticides or other volatile

solvents. This will cause the cabinet or other parts to deteriorate

or cause the paint to peel.

Page 7

Table of Contents

TOC 2

Contents

Table of Contents

1. Product Overview ................................................................................................................................................... 1

1.1 Introduction ...................................................................................................................................................... 1

1.2 Features ............................................................................................................................................................ 1

1.3 Unpacking ........................................................................................................................................................ 1

1.4 Accessories and Options ................................................................................................................................. 2

1.4.1 Accessories ............................................................................................................................................. 2

1.4.2 Cool Release Enhancement Kit ............................................................................................................... 3

1.4.3 Options .................................................................................................................................................... 3

1.5 Appearance ...................................................................................................................................................... 4

1.5.1 Dimensions .............................................................................................................................................. 4

1.5.2 Front View ............................................................................................................................................... 4

1.5.3 Rear View ................................................................................................................................................ 4

1.5.4 Operation Panel ...................................................................................................................................... 5

1.5.5 Interior ..................................................................................................................................................... 5

2. Printer Installation .................................................................................................................................................. 6

2.1 Installing the Accessories ................................................................................................................................. 6

2.1.1 Fan Filters ................................................................................................................................................ 6

2.1.2 Media Slide ............................................................................................................................................. 6

2.1.3 Supply Shaft Holder ................................................................................................................................ 6

2.2 Connecting the Printer to Your Computer ........................................................................................................ 7

2.3 Connecting the Power Cord ............................................................................................................................. 8

2.4 Turning on/off the Printer.................................................................................................................................. 9

2.4.1 Turning on the Printer .............................................................................................................................. 9

2.4.2 Turning off the Printer ............................................................................................................................ 10

2.5 Loading the Media .......................................................................................................................................... 11

2.5.1 Additional Information ........................................................................................................................... 16

2.6 Sensor Adjustments ....................................................................................................................................... 17

2.6.1 Black Mark Sensor ................................................................................................................................ 17

2.6.2 Feed Gap Sensor .................................................................................................................................. 18

2.6.3 Media Sensor Sensitivity Adjustment ................................................................................................... 19

2.7 Loading the Ribbons (for Hot Release Ribbons) ............................................................................................ 21

2.7.1 Ribbon Positions ................................................................................................................................... 21

2.7.2 Loading Procedure ................................................................................................................................ 21

2.8 Loading the Ribbons (for Cold Release Ribbons) .......................................................................................... 24

2.8.1 Precautions ........................................................................................................................................... 24

2.8.2 Installing the Ribbon Plate .................................................................................................................... 25

2.8.3 Installing the SP Ribbon Guides ........................................................................................................... 26

2.8.4 Installing the Ribbon Tension Sheet ...................................................................................................... 27

2.8.5 Loading the Cold Release Ribbons....................................................................................................... 28

3. Printing .................................................................................................................................................................. 29

3.1 Installing the Printer Driver ............................................................................................................................. 29

3.1.1 System Requirements ........................................................................................................................... 29

3.1.2 Installation Procedure (For Windows

3.1.3 Uninstalling the Printer Driver................................................................................................................ 35

3.2 Properties ....................................................................................................................................................... 37

3.2.1 Displaying Printer Properties ................................................................................................................. 37

3.2.2 Summary of Properties ......................................................................................................................... 38

3.3 Page Setup ..................................................................................................................................................... 39

3.3.1 Selecting a label size ............................................................................................................................. 39

3.3.2 Creating a new label size ...................................................................................................................... 40

3.3.3 Orientation ............................................................................................................................................. 41

3.3.4 Miscellaneous ....................................................................................................................................... 42

3.4 Graphics ......................................................................................................................................................... 46

3.4.1 Dithering ................................................................................................................................................ 46

3.4.2 Color ...................................................................................................................................................... 46

3.4.3 Color Setup ........................................................................................................................................... 47

3.4.4 Color Registration ................................................................................................................................. 50

3.5 Bar Fonts ........................................................................................................................................................ 52

3.5.1 Specifying a New Font Style ................................................................................................................. 53

3.6 Stock .............................................................................................................................................................. 55

3.6.1 Print Method.......................................................................................................................................... 55

®

98) .............................................................................................. 29

v

Page 8

Table of Contents

TOC 1

3.6.2 Sensor ................................................................................................................................................... 55

3.6.3 Label Gap .............................................................................................................................................. 55

3.6.4 Issue Settings ........................................................................................................................................ 56

3.6.5 Fine Adjustment .................................................................................................................................... 57

3.7 Options ........................................................................................................................................................... 58

3.7.1 Transfer Mode ....................................................................................................................................... 58

3.7.2 Print Density Adjustment....................................................................................................................... 58

3.8 Testing ............................................................................................................................................................ 59

3.8.1 Testing ................................................................................................................................................... 59

3.8.2 Maintenance .......................................................................................................................................... 60

3.9 Print Test ......................................................................................................................................................... 61

3.9.1 Procedures ............................................................................................................................................ 61

3.10 Printing a Label .............................................................................................................................................. 62

4. Online Mode .......................................................................................................................................................... 64

4.1 Operation Panel.............................................................................................................................................. 64

4.2 Operation........................................................................................................................................................ 65

4.3 Reset .............................................................................................................................................................. 65

5. Maintenance ......................................................................................................................................................... 66

5.1 Cleaning ......................................................................................................................................................... 66

5.1.1 Print Head/Platen .................................................................................................................................. 66

5.1.2 Pinch Roller/Feed Roller/Media Guide .................................................................................................. 67

5.1.3 Fan Filters .............................................................................................................................................. 67

5.1.4 Covers and Panels ................................................................................................................................ 68

5.1.5 Ribbon Modules .................................................................................................................................... 68

6. Troubleshooting.................................................................................................................................................... 69

6.1 Error Messages .............................................................................................................................................. 69

6.2 Possible Problems.......................................................................................................................................... 71

6.3 Removing Jammed Media ............................................................................................................................. 72

6.3.1 From the Pinch Roller Unit .................................................................................................................... 72

6.3.2 From the Print Head Block .................................................................................................................... 72

6.4 When the Ribbon is Torn Apart ...................................................................................................................... 73

Appendix 1 Specifications......................................................................................................................................... 74

A1.1 Printer ............................................................................................................................................................. 74

A1.2 Options ........................................................................................................................................................... 75

A1.3 Media.............................................................................................................................................................. 75

A1.3.1 Media Type ............................................................................................................................................ 75

A1.3.2 Detection Area of the Transmissive Sensor .......................................................................................... 76

A1.3.3 Detection Area of the Reflective Sensor ............................................................................................... 77

A1.3.4 Effective Print Area................................................................................................................................ 77

A1.4 Ribbon ............................................................................................................................................................ 78

Appendix 2 DIP Switches .......................................................................................................................................... 79

A2.1 DIP Switch A .................................................................................................................................................. 80

A2.2 DIP Switch B .................................................................................................................................................. 81

A2.3 Ribbon Near End Detection ........................................................................................................................... 82

Appendix 3 Quick Reference for Printing ................................................................................................................ 83

Appendix 4 Message and LED .................................................................................................................................. 86

Appendix 5 System Mode.......................................................................................................................................... 88

A5.1 Operation Panel.............................................................................................................................................. 88

A5.2 Overview......................................................................................................................................................... 89

A5.3 Self-Diagnostic Test ....................................................................................................................................... 91

A5.4 Parameter Setting .......................................................................................................................................... 92

A5.5 Test Print ....................................................................................................................................................... 101

A5.6 RAM Clear .................................................................................................................................................... 104

A5.7 Additional Information .................................................................................................................................. 106

A5.7.1 Self-Diagnostic Test Result Sample and Descriptions ........................................................................ 106

A5.7.2 Maintenance Counter/Parameter Check Print Sample and Descriptions........................................... 107

A5.7.3 Cut Operation Example ....................................................................................................................... 108

A5.7.4 Pulse Motor Speed ............................................................................................................................. 108

A5.7.5 X-Coordinate Fine Adjustment ............................................................................................................ 108

A5.7.6 Magnified Views of Slant Line Pattern ................................................................................................ 108

A5.7.7 Initial Values after Clearing the Maintenance Counter (MAINTE.CNT.CLEAR).................................... 109

A5.7.8 Initial Values after Clearing the Parameter (PARAMETER CLEAR)...................................................... 110

A5.7.9 Initial Values after Clearing the Print Distance (PRINT STEP CLEAR)................................................. 111

Appendix 6 Interface................................................................................................................................................ 112

vi

Page 9

1. Product Overview

Chapter 1 Product Overview

1.1 Introduction

1.2 Features

Thank you for choosing the TOSHIBA TEC CB-426-T3 two-color

printer.

This Owner’s Manual describes printer setup and installation

procedures, printer properties, settings and adjustments, and

maintenance information. Thus it should be read carefully to help

gain maximum performance and life from the printer. For further

information please refer to this manual and keep it safe for future

reference.

The CB-426-T3 two-color printer has the following features:

• H igh-speed, quality printing. The printer utilizes Edge Heads that

support the high-performance Hot Release Ribbons to produce a

maximum print speed of approximately 6 in/s (150 mm/s). In addition,

the Cool Release Enhancement Kit is supplied as an accessory, and

allows the popular Cold Release Ribbons to be loaded.

• Fine, sharp color printing. The printer utilizes two high-resolution

(305 dpi) print heads, and uses a variety of spot color ribbons for

solid printing.

• A variety of printer fonts and bar code fonts are built into the

printer to help create a unique colored label.

• Cost efficiency. The automatic ribbon saver is standard and allows

for conservation of individual ribbons. In addition, the media

back feed capability allows you to avoid wasting the media.

1.3 Unpacking

Unpack the printer as per the Unpacking Instructions packed with

the printer.

Important!

• Check for damage or scratches on the printer.

However, please note that TOSHIBA TEC shall have no

liability of any damage of any kind sustained during

transportation of the product.

• Keep the cartons and pads for future transportation of the

printer.

1

Page 10

Chapter 1 Product Overview

1.4 Accessories and

Options

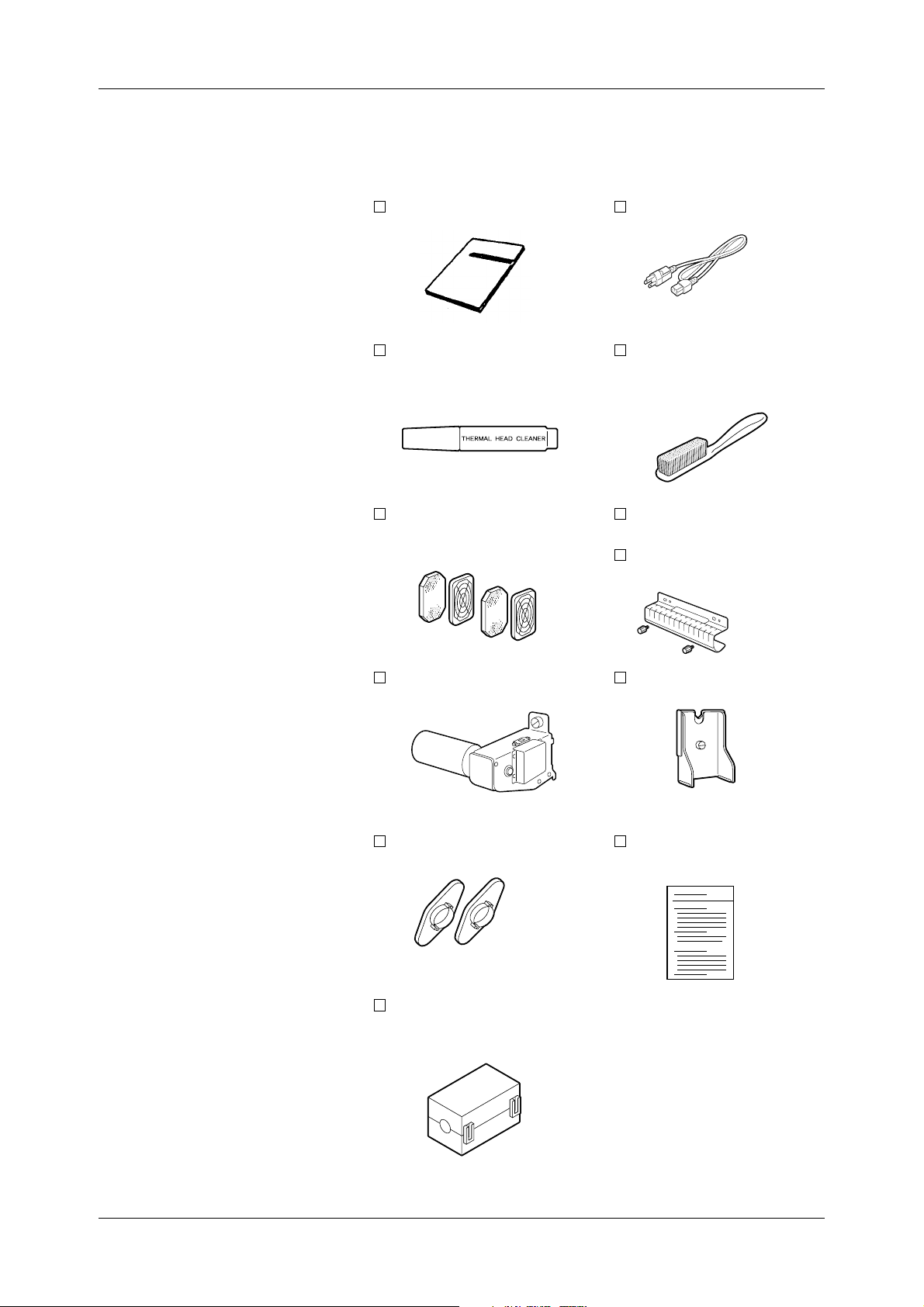

1.4.1 Accessories

When unpacking the printer, please make sure all accessories are

packed with the printer.

✓

Owner’s Manual (1 pc.)

Thermal Head Cleaner (1 pc.)

(24089500013)

Fan Filter (2 sets.)

(FMBB0046401)

Power Cord (1 pc.)

(FBC B0030202)

Feed Roller Brush (1 pc.)

(FMQB0047001)

*To be used exclusively for

the Feed Roller

Media Slide (1 pc.)

(FMCC 0032001)

Black Screw (2 pcs.)

(HAA-0007002)

Supply Shaft Holder (1 pc.)

(FMBD 0038901)

Supply Roll Holder (2 pcs.)

(FMHD0007502)

Ferrite Core (1 pc.)

(HGA-0068001)

*Used for RS-232C

Supply Shaft Holder Stand

(FMBB0047401)

Unpacking Instructions

(1 pc.)

(1pc.)

2

Page 11

Chapter 1 Product Overview

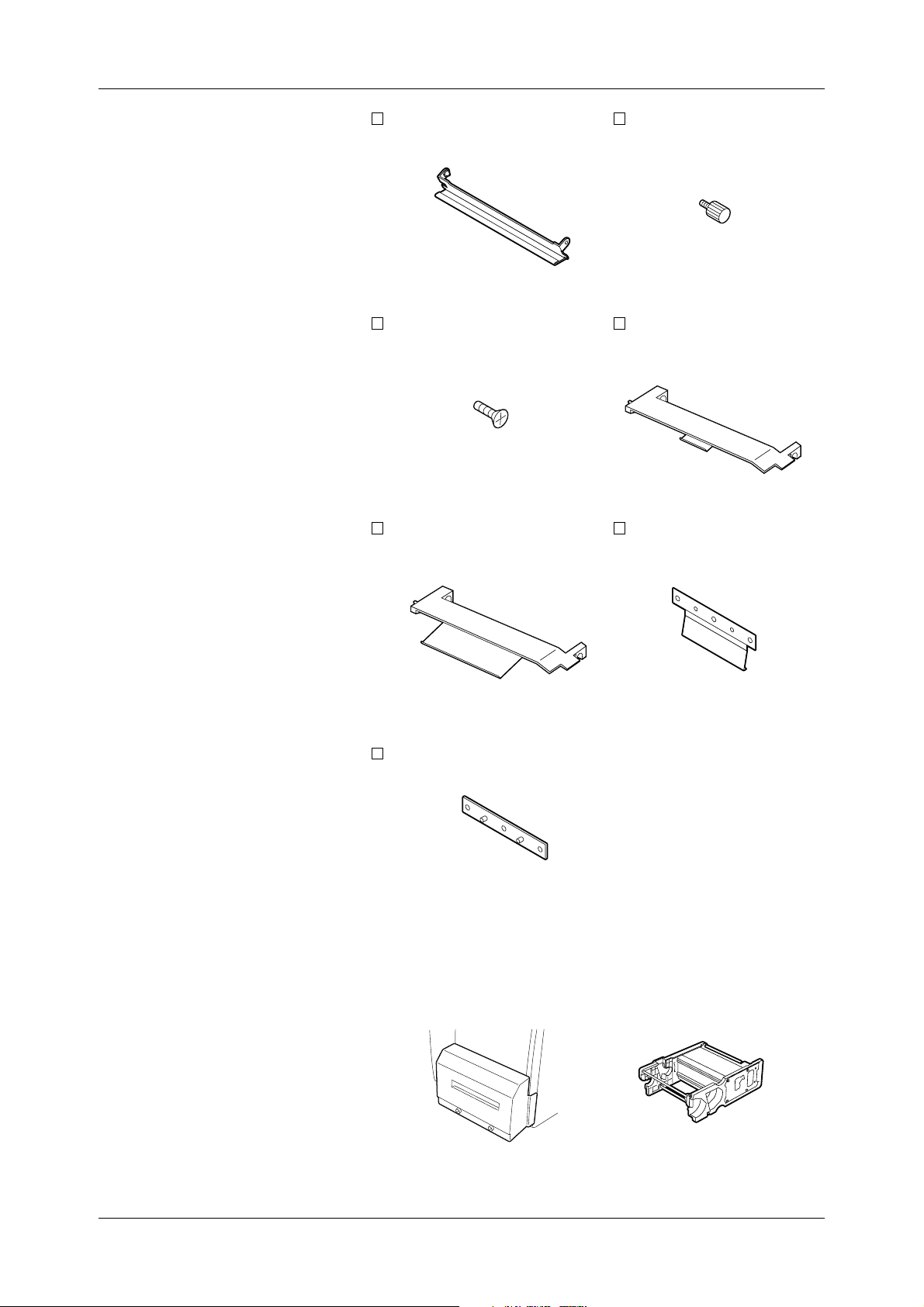

1.4.2 Cool Release

Enhancement Kit

Ribbon Plate (2 pcs.)

(FMCB 0095301)

D-3x5 Screw (6 pcs.)

(X0140305130)

SP Ribbon Guide (B) (1 pc.)

(FMCB0095501)

Mounting Screw (2 pcs.)

(FMDB 0079501)

SP Ribbon Guide

(FMCB0095601)

Ribbon T ension Sheet

(FMQC0035901)

(A) (1 pc.)

(2 pcs.)

1.4.3 Options

Sheet Fixing Plate (2 pcs.)

(FMEB0116901)

The following two options are available for the CB-426-T3 two-color

printer:

• The CB-1204-QM Cutter Module, which is used to cut media

repeatedly.

• The CB-1004-QM Ribbon Module, to be used as a spare ribbon

module.

Cutter Module Ribbon Module

3

Page 12

Chapter 1 Product Overview

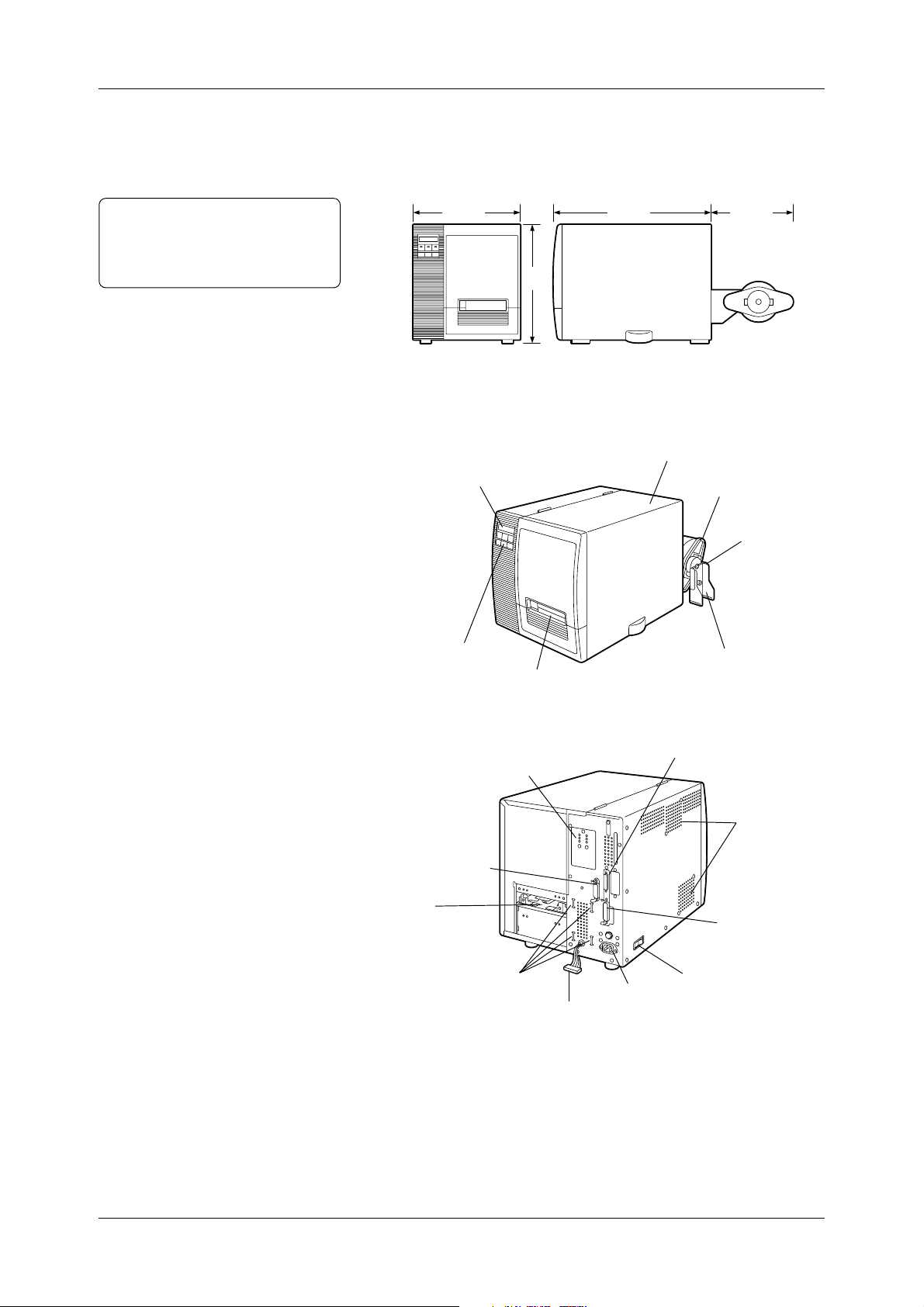

1.5 Appearance

1.5.1 Dimensions

Note:

Depth is 34.4 inches (875mm) when

the Cutter Module is installed on the

printer.

1.5.2 Front View

The names of the parts or units introduced in this section are used in

the following chapters.

13.7(350)

15.1

(385)

20.4(520)

11.0(280)

Dimensions in inches + (mm)

Top Cover

Message Display (LCD)

Supply Roll Holder

Supply Shaft Holder

1.5.3 Rear View

Operation Panel

Media Sensor Adjuster

Expansion I/O

Interface Connector

Media Inlet

Supply Shaft Holder Slots

Supply Shaft Holder Stand

Media Outlet

Serial Interface Connector

(RS-232C)

Air Vents

(Cooling Fans)

Parallel Interface

Connector

(Centronics)

Power Switch

AC Power Inlet

Harness

4

Page 13

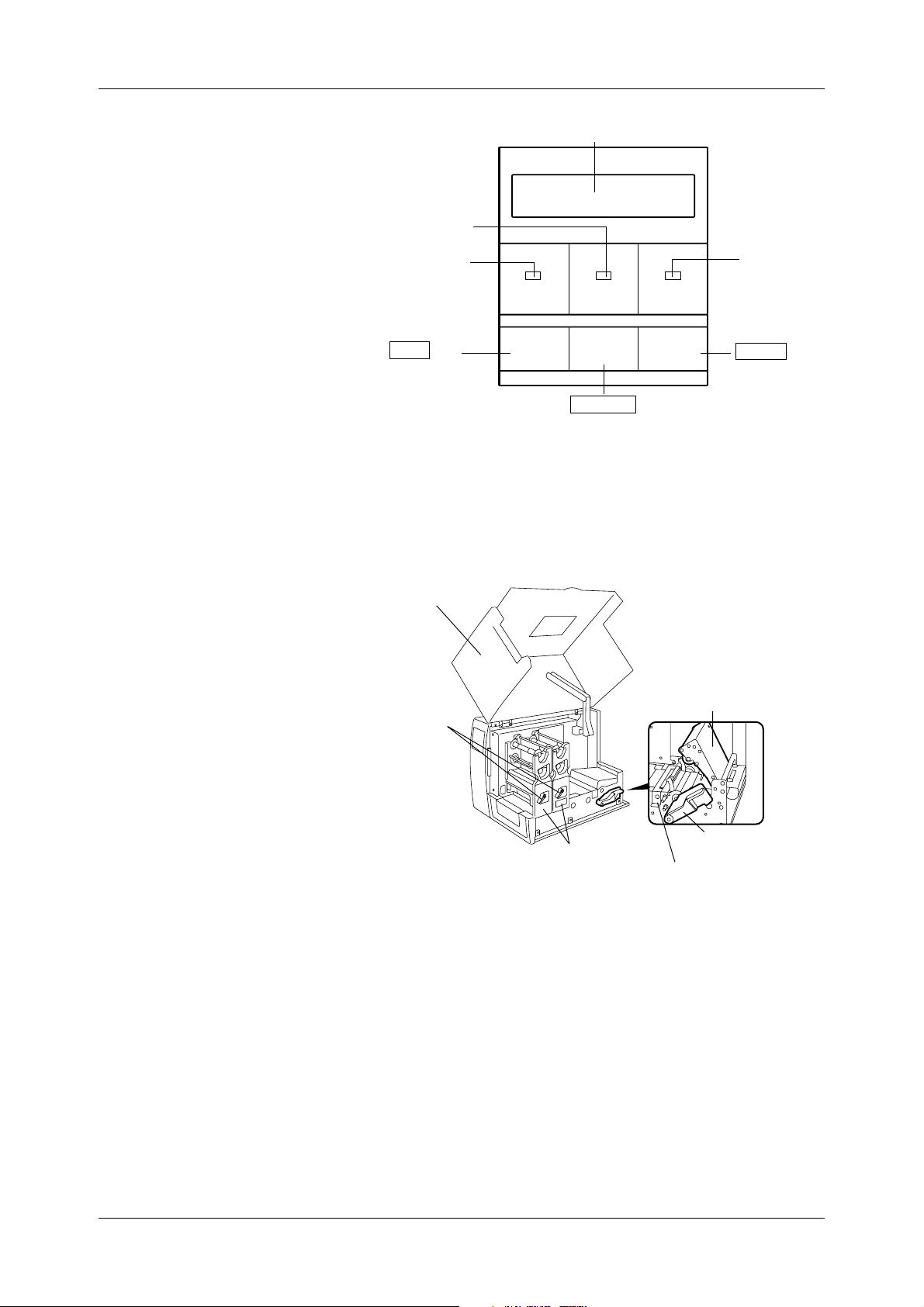

Chapter 1 Product Overview

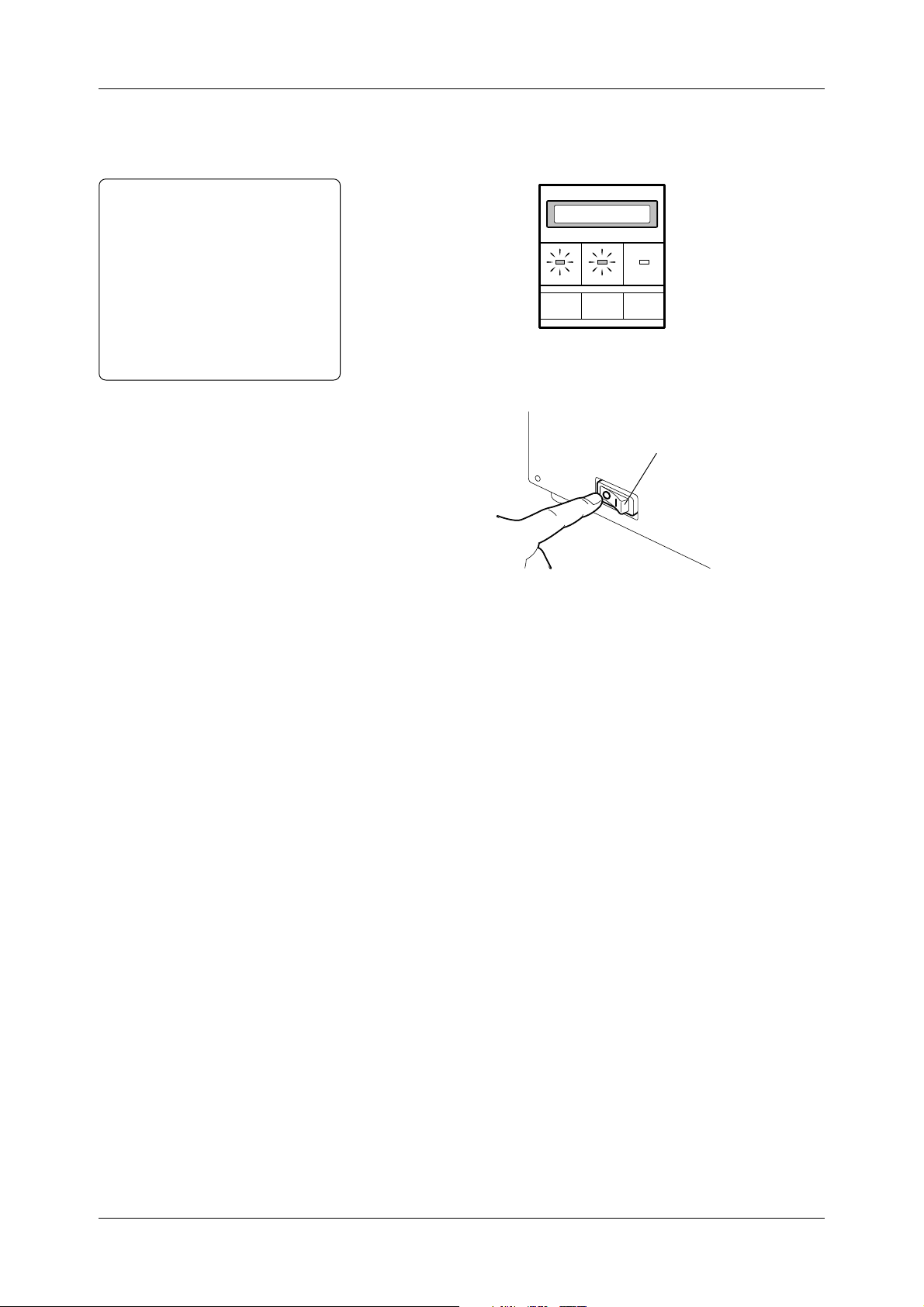

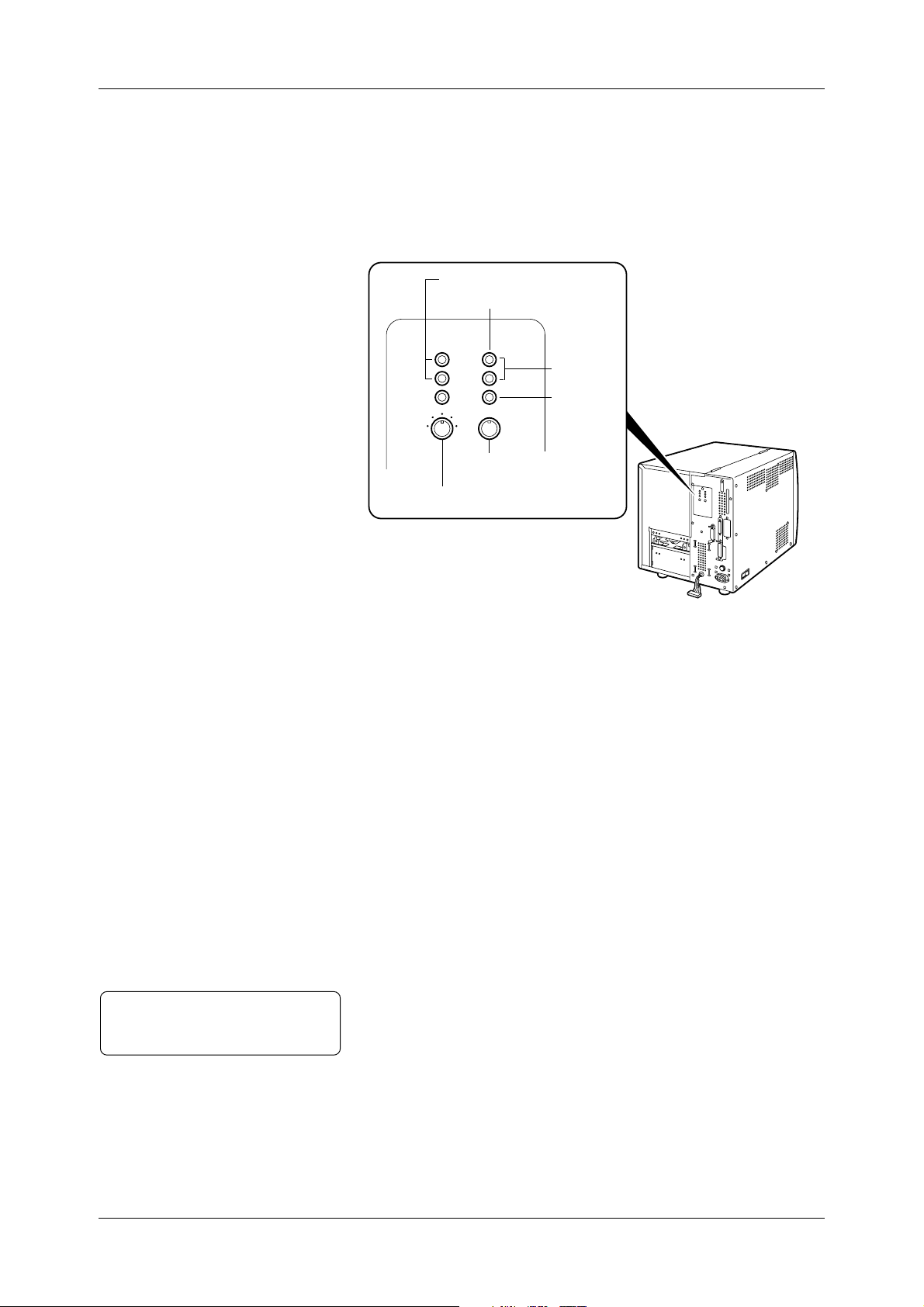

1.5.4 Operation Panel

1.5.5 Interior

Message Display (LCD)

ON LINE LED

(Green)

POWER LED

(Red)

FEED Key

POWER ON LINE ERROR

FEED RESTART PAUSE

RESTART Key

ERROR LED

(Green)

PAUSE Key

Please see Appendix 3 for further information about the Operation

Panel.

Top Cover

Head Lever

Ribbon Module

Pinch Roller Unit

Pinch Roller Lever

Media Pressure Plate

5

Page 14

2. Printer Installation

This chapter describes in detail how to set up the printer to get ready

for printing.

Chapter 2 Printer Installation

2.1 Installing the

Accessories

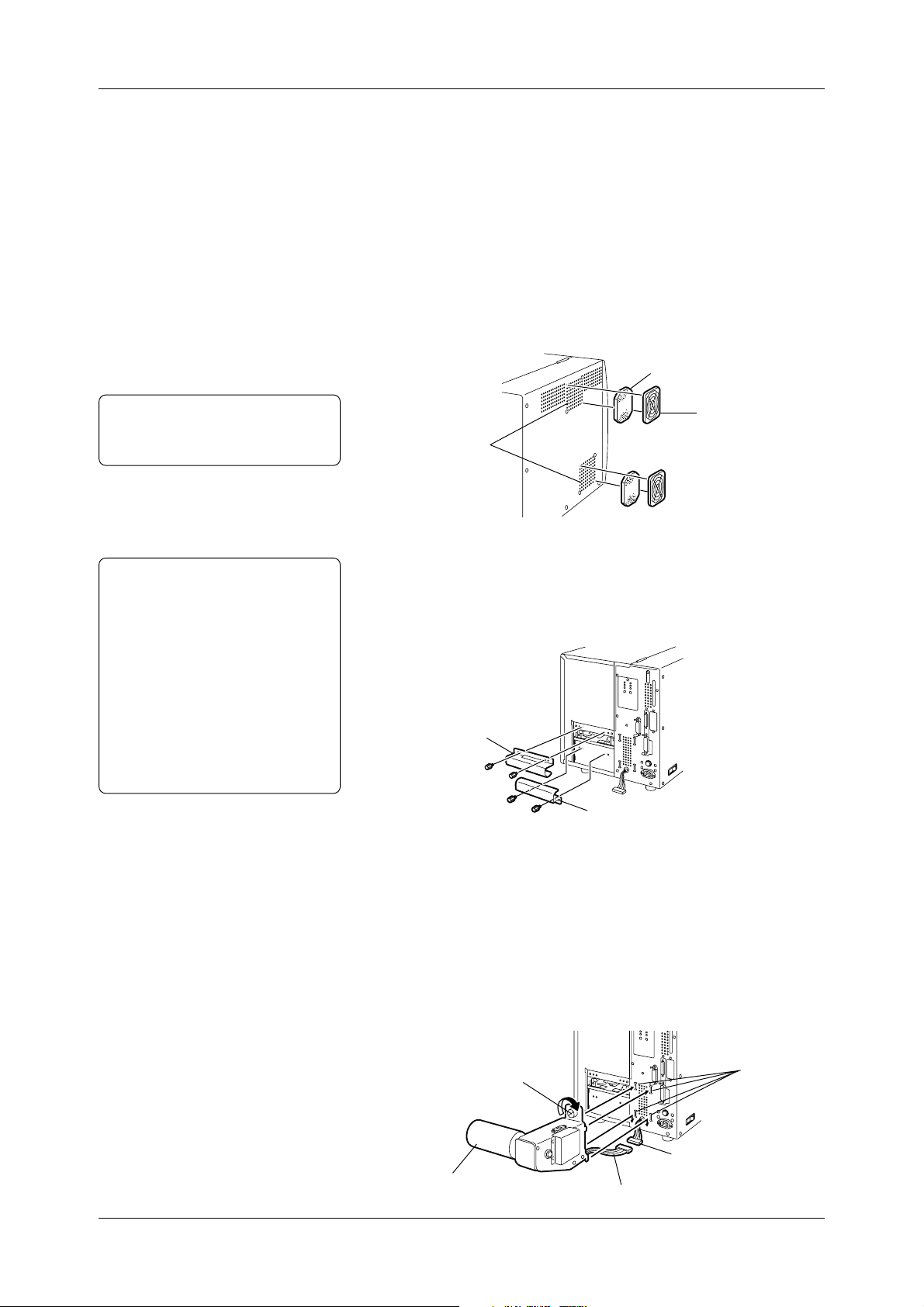

2.1.1 Fan Filters

Note:

Please clean the Filter Pads

periodically. See Section 5.1.3.

2.1.2 Media Slide

Notes:

• Either a roll of labels or tags can

be loaded in the printer.

• In this Owner's Manual, labels and

tags are generically called

"media".

• TOSHIBA TEC recommends that

labels are rolled outside, and the tags

are r olled inside. The media loading

procedur e depends on which type of

media is going to be loaded. See

Section 2.5 for more detail.

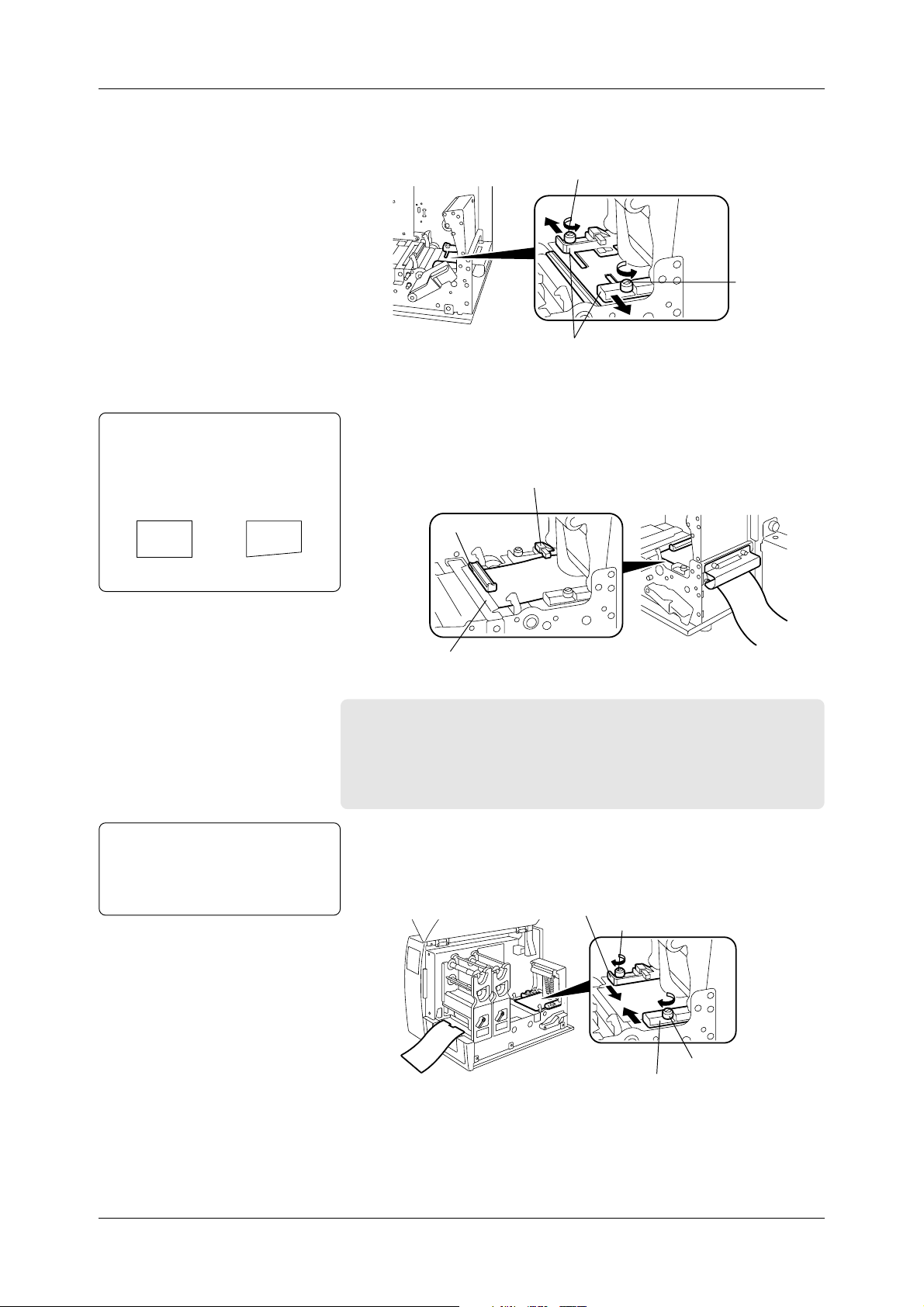

First install the accessories on the printer.

1

Unpack the Fan Filters.

2

Mount the Fan Filters over the Air Vents.

Filter Pad

Filter Retainer

Air Vents

(Cooling Fans)

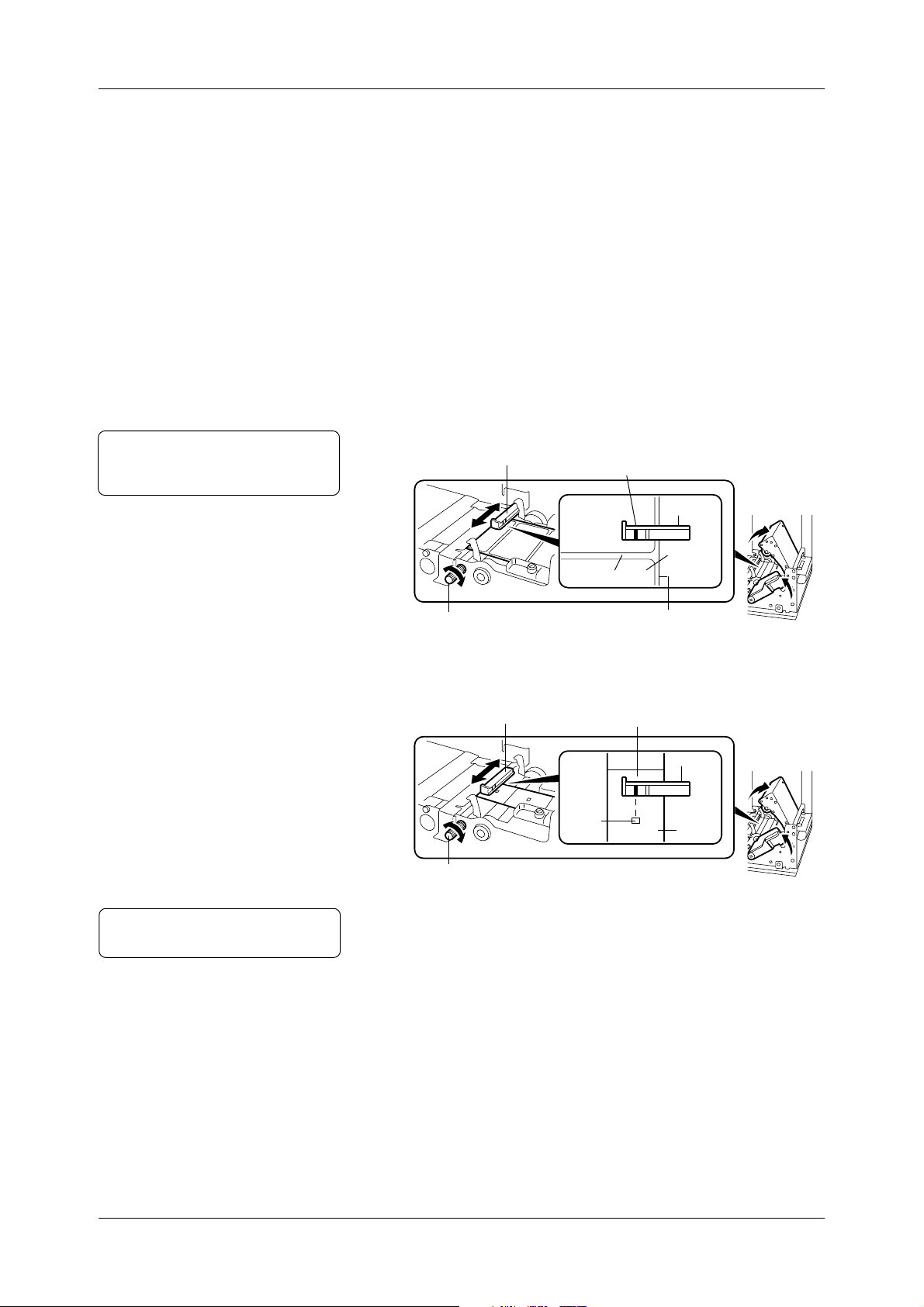

Attach the Media Slide with the two supplied black screws.

When loading a roll of labels, fit the Media Slide on the screw holes

above the Media Inlet.

or

When loading a roll of tags, fit the Media Slide on the screw holes

below the Media Inlet.

Media Slide (for labels)

2.1.3 Supply Shaft Holder

6

Media Slide (for tags)

1

Connect the Supply Shaft Holder Harness to the harness attached

on the rear of the printer.

2

First hook the lower parts of the Supply Shaft Holder into the

lower two Supply Shaft Holder Slots on the rear of the printer.

Then fix the Supply Shaft Holder in place by tightening the screw .

T o remove the Supply Shaft Holder from the printer, just reverse the

installation procedure.

Screw

Harness

Supply Shaft Holder

Supply Shaft Holder Harness

Supply Shaft

Holder Slots

Page 15

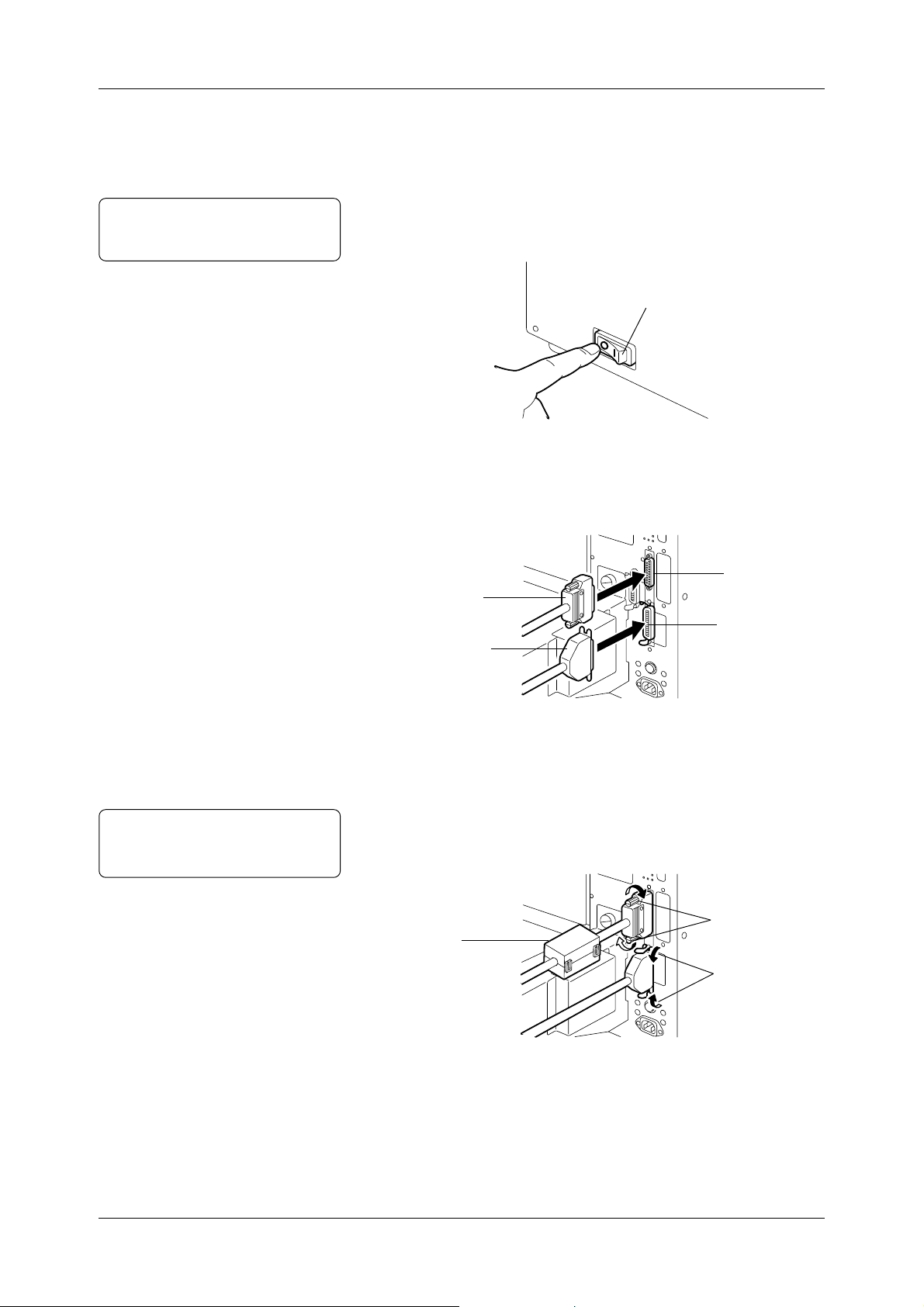

Chapter 2 Printer Installation

2.2 Connecting the

Printer to Your

Computer

Note:

The interface cable is not included

in the accessories.

The printer can be connected to any computer, since it supports both

serial and parallel interface cables. Before connecting the printer,

please make sure which interface cable will be used.

1

Be sure that both printer and computer are turned off.

(o) indicates OFF.

Power Switch

2

Connect the interface cable to the interface connector on the

printer. As illustrated below, connect the interface cable to either

of the interface connectors, depending on which interface cable

will be used.

Note:

Please refer to the user's manual of

the computer.

Serial Interface

Parallel Interface

3

Secure the cable with the clamps or screws.

4

When using the serial interface cable, attach the supplied ferrite

Cable

Cable

Serial Interface

Connector

Parallel Interface

Connector

core to the cable.

5

Connect the interface cable to the interface connector on the

computer.

Screws

Ferrite Core

(For Serial Interface

Cable)

Clamps

7

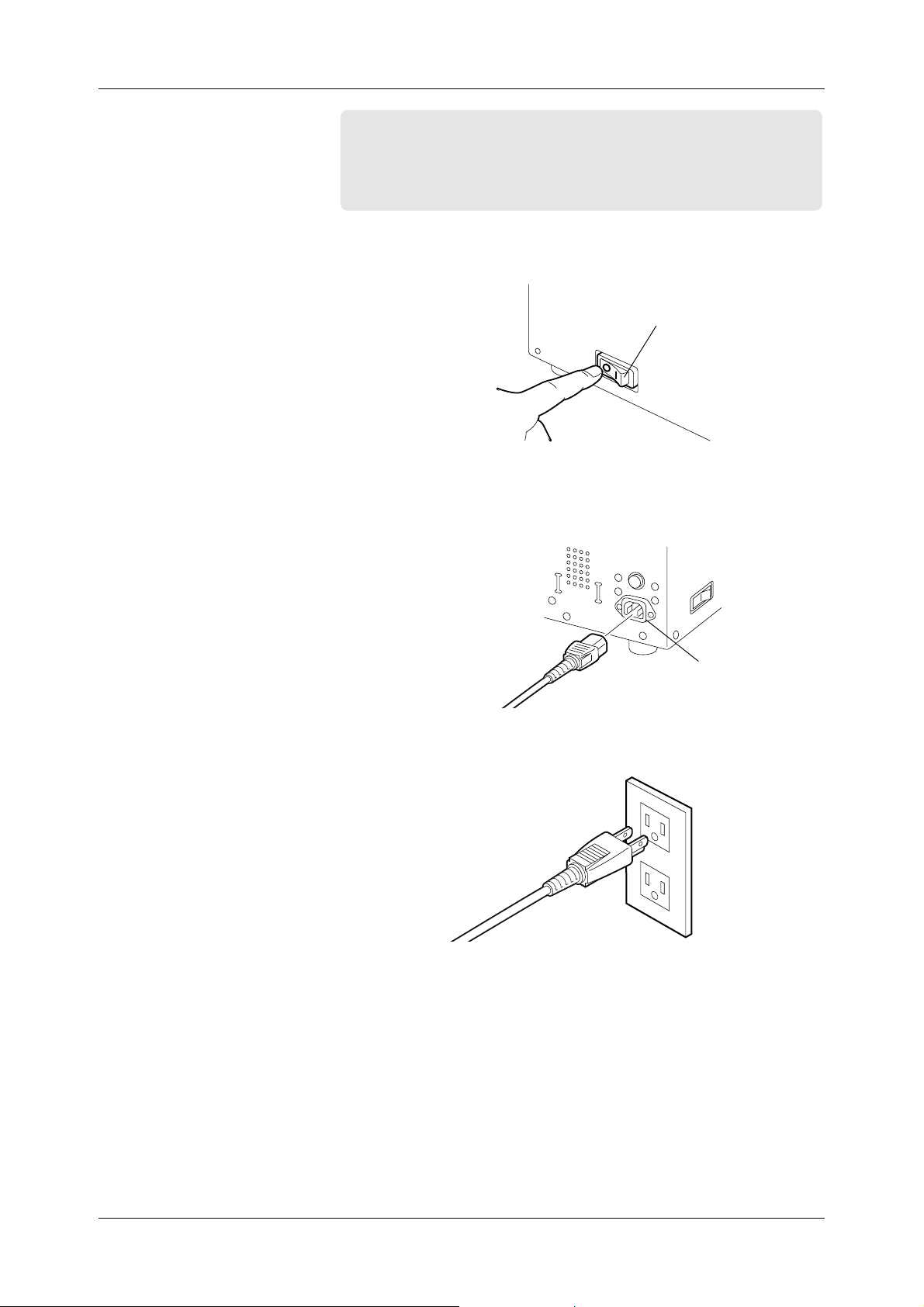

Page 16

Chapter 2 Printer Installation

2.3 Connecting

the Power

Cord

CAUTION!

• Please turn off the printer before connecting the power cord,

as this may cause an electric shock or damage to the printer.

• Please use the supplied power cord only. Use of other cords

may cause an electric shock or a fire.

1

Be sure that both printer and computer are switched OFF.

(o) indicates OFF.

Power Switch

2

Connect the supplied power cord to the AC Power Inlet of the

printer.

3

Plug the power cord in an outlet.

AC Power Inlet

8

Page 17

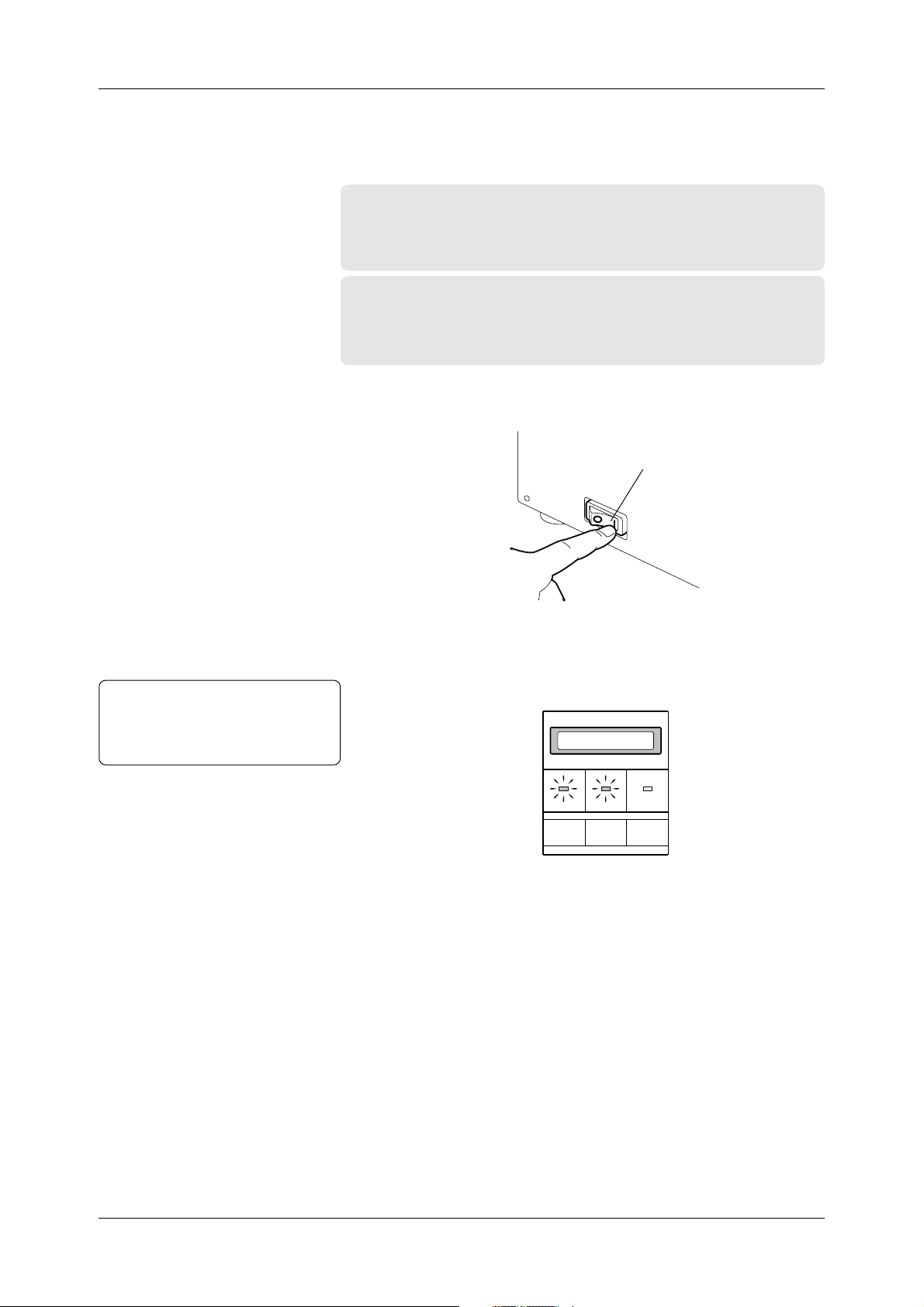

Chapter 2 Printer Installation

2.4 Turning on/off

the Printer

2.4.1 Turning on the

Printer

When turned on, the printer checks the print head and memory.

When turned off, the printer will lose data in non-volatile memory.

CAUTION!

Use the power switch to turn on/off the printer. Unplugging

the power cord for turning on/off the printer may cause a fire,

an electric shock, or damage to the printer.

Important!

When the printer is connected to the computer,

• Turn ON the printer before turning on the computer.

• Turn OFF the computer before turning off the printer.

1

Turn on the printer. ( ❘ ) indicates ON.

Power Switch

Note:

Just in case the printer is not turned

on, or any error message appears,

please see Chapter 6.

2

The “ON LINE” message appears on the Message Display. The

POWER LED illuminates green. Then the ON LINE LED also

illuminates green.

ON LINE

POWER ON LINE ERROR

FEED RESTART PAUSE

9

Page 18

Chapter 2 Printer Installation

2.4.2 Turning off the

Printer

CAUTION!

• Do not turn off the printer

while a label is being issued,

as this may cause a paper jam

or damage to the printer.

• Do not turn off the printer

when the ON LINE LED is

blinking, as this may cause

damage to the computer

connected to the printer.

1

When turning off the printer, make sure of the following:

• The “ON LINE” message is shown on the Message Display.

• Both POWER and ON LINE LED’s are illuminated.

ON LINE

POWER ON LINE ERROR

FEED RESTART PAUSE

2

Turn off the power switch.

Power Switch

10

Page 19

Chapter 2 Printer Installation

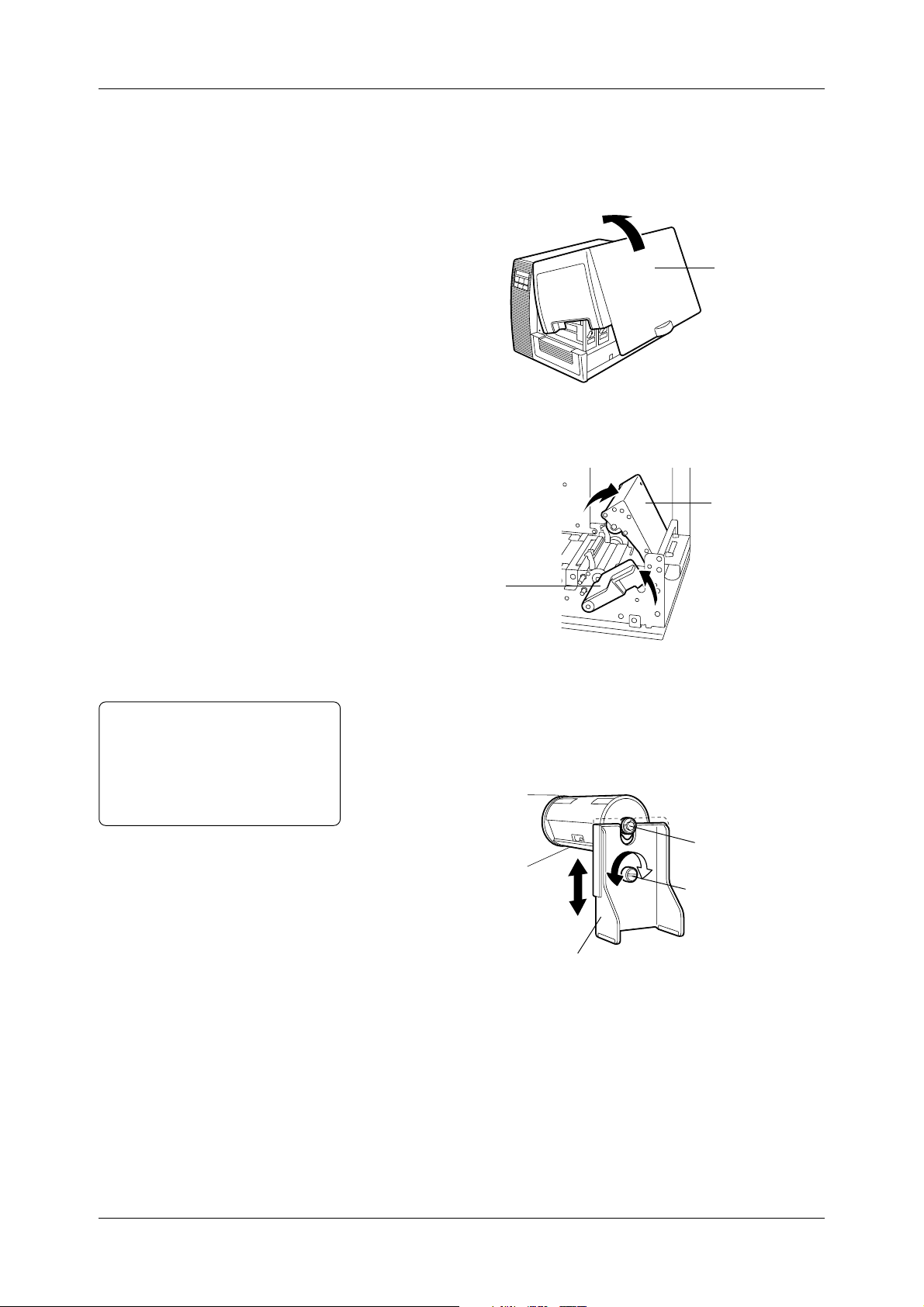

2.5 Loading the

Media

Labels or tags can be loaded in the printer. The media loading

procedure depends on which media is going to be used.

1

Open the Top Cover.

Top Cover

2

Lift the Pinch Roller Lever to the ROLLER RELEASE position

to open the Pinch Roller Unit.

Pinch Roller Unit

Note:

The Supply Shaft cannot be kept level

because of its weight, as the printer

becomes older . So befor e loading the

media, adjust the Supply Shaft so that

it can be kept level.

Pinch Roller Lever

(To ROLLER RELEASE)

3

Loosen the screw on the Supply Shaft Holder Stand.

4

Fit the Supply Shaft Holder Stand to the Supply Shaft, as illustrated

below . The Supply Shaft Holder Stand moves up or down so that

the Supply Shaft is kept level.

Supply Shaft

Screw

Supply Shaft Holder Stand

5

Remove the Supply Shaft Holder Stand from the Supply Shaft,

when adjustment to its height is complete.

11

Page 20

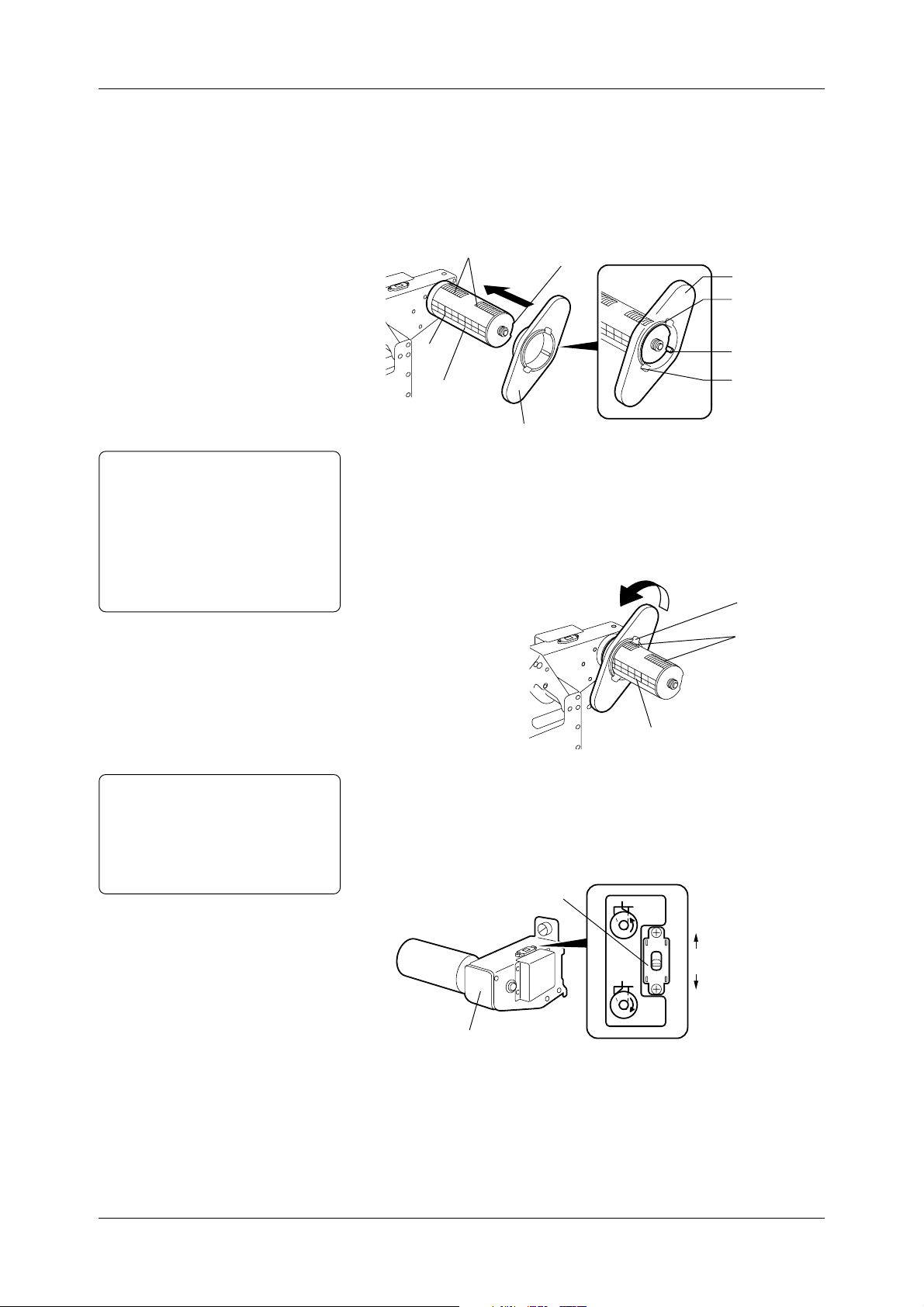

2.5 Loading the

Media (Cont.)

Chapter 2 Printer Installation

6

Turn the Supply Shaft so that the notches face upward, and the

marks face the Media Inlet.

7

To attach the Supply Roll Holder (inside), fit the tooth of the

Supply Roll Holder to the groove of the Supply Roll Shaft. Turn

the Supply Roll Holder clockwise to the end.

CAUTION!

Do not push into the Supply

Roll Holder (inside) with the

claw locked in the notches, as

this may cause damage to the

claw or notches.

See Section 2.5.1 for more

detail.

Notches

Marks

Supply Shaft

8

Push the Supply Roll Holder (inside) to the end of the Supply

Groove

Supply Roll Holder

Claw

Tooth

Claw

Supply Roll Holder

Shaft. Then turn the Supply Roll Holder counterclockwise so

that the claw is locked into the notch. When inserting the Supply

Roll Holder into the Supply Shaft, more pressure should be applied

when passing over the roller on the way to the end of the Supply

Shaft.

Claw

Notches

Note:

The media is rolled either outside or

inside, depending on the type of media

that is loaded. Whichever media is

used, load it with print side facing up.

See Appendix 1 for more detail.

Marks

9

Switch the Back T ension Selector, depending on whether the media

is rolled outside or inside. Switch the Selector to A for the media

rolled outside. Switch it to B for the media rolled inside, as

indicated by the arrows.

Back Tension Selector

A

Media rolled outside

Media rolled inside

B

Supply Shaft Holder

10

Measure width of the media that will be loaded.

12

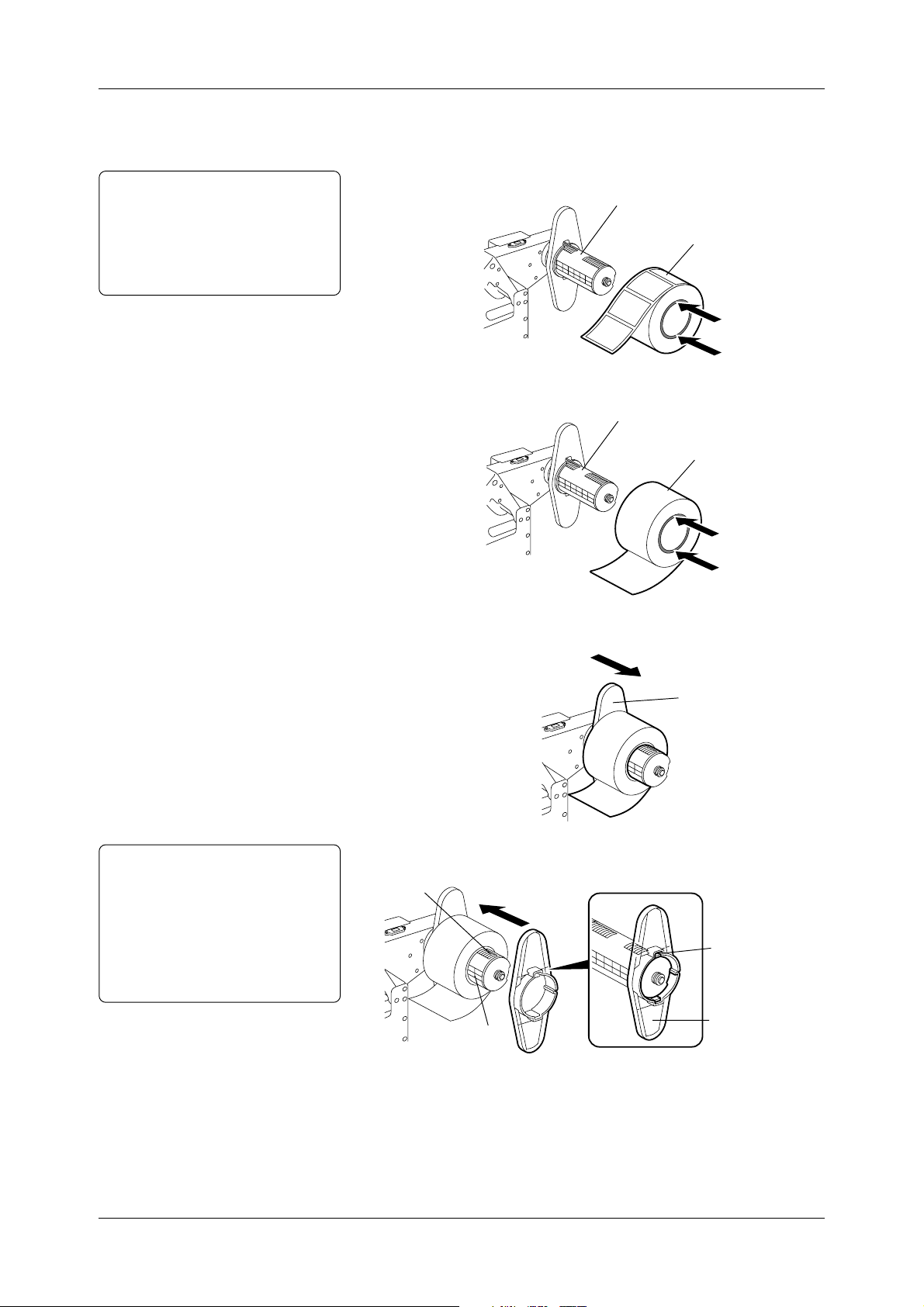

Page 21

2.5 Loading the

Media (Cont.)

Note:

When inserting a roll of labels or

tags, push on the media core only.

Otherwise, core material drags

against the Supply Shaft causing

telescoping of the media supply roll.

Chapter 2 Printer Installation

11

Based on width of the media measured in Step 10, push the media

into the Supply Roll Holder (inside), and place it with reference

to the marks on the Supply Shaft.

• Loading a roll of labels

Supply Shaft

Labels

• Loading a roll of tags

Supply Shaft

Tags

12

Slide the Supply Roll Holder (inside) to the loaded media.

Supply Roll Holder

CAUTION!

To remove the Supply Roll

Holder (outside), turn it to

disengage the claw from the

notches. Otherwise, the claw or

the notches may be damaged.

See Section 2.5.1 for more

detail.

13

Slide the Supply Roll Holder (outside) to the loaded media.

Notches

Claw

Supply Shaft

Supply Roll Holder

(Outside)

13

Page 22

2.5 Loading the

Media (Cont.)

Note:

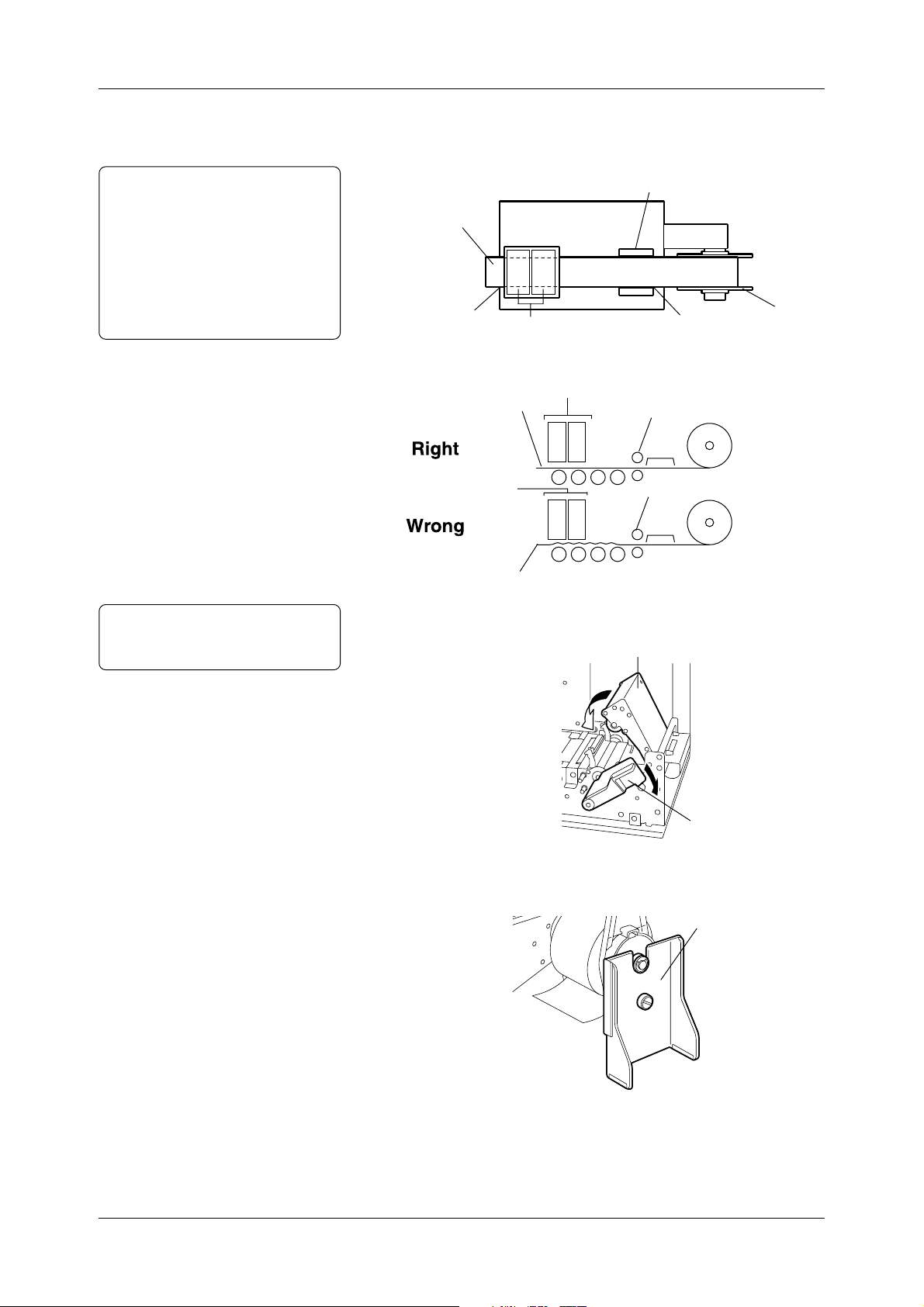

Make sure that the leading edge of

media is cut straight before inserting

the media into the printer , as this may

cause a media jam.

Chapter 2 Printer Installation

14

Loosen the two screws. Slide the Media Guides in the direction

of the arrows below until they stop (completely open).

Screw

Screw

Media Guides

15

Unroll about 1.5 to 2 inches (40 to 50cm) of the media.

16

Insert the media into the Media Inlet. Make sure that the media

passes under the Media End Sensor, the media sensor and the

Media Pressure Plate.

Media End Sensor

Media Sensor

Right Wrong

CAUTION!

Do not over tighten the two

screws, as this may cause

damage to the Media Guides.

Media Pressure Plate

Important!

• According to the media is loaded, adjust the position of the

media sensor. See Section 2.6 for more detail.

• Whenever the type of media is changed, adjust sensitivity

of the media sensor. See Section 2.7 for more detail.

17

Slide the Media Guides in the direction of the arrows below until

both guides come in contact with the media (media should be in

center of media path). Hand tighten the two screws.

Media Guide

Screw

14

Screw

Media Guide

Page 23

2.5 Loading the

Media (Cont.)

Notes:

• Pass the media straight from the

Supply Holder Unit to the Media

Outlet to avoid skewing.

• Use the marks at the Media Slide

and the Media Outlet so that the

media can be centered.

• Be sure to take up any slack in the

media.

Chapter 2 Printer Installation

18

Feed the media to the Media Outlet manually until its leading

edge comes out of the Media Outlet.

(Top View of the Printer)

Media Guide

Media

Media Outlet

Print Head Blocks

Media Inlet

Supply Roll

Holder

Note:

Push down the Pinch Roller Unit

gently on the “PUSH HERE” label.

(Side View of the Printer)

Print Head Blocks

Media

Print Head Blocks

Media

19

Push down the Pinch Roller Unit until it is hooked. Then push

Pinch Roller

Pinch Roller

down the Pinch Roller Lever to the ROLLER LOCK position.

[PUSH HERE]

Pinch Roller Lever

(To ROLLER LOCK)

20

Reinstall the Supply Shaft Holder Stand to the Supply Shaft Holder,

whose level is adjusted in Steps 3 to 5.

Supply Shaft Holder Stand

15

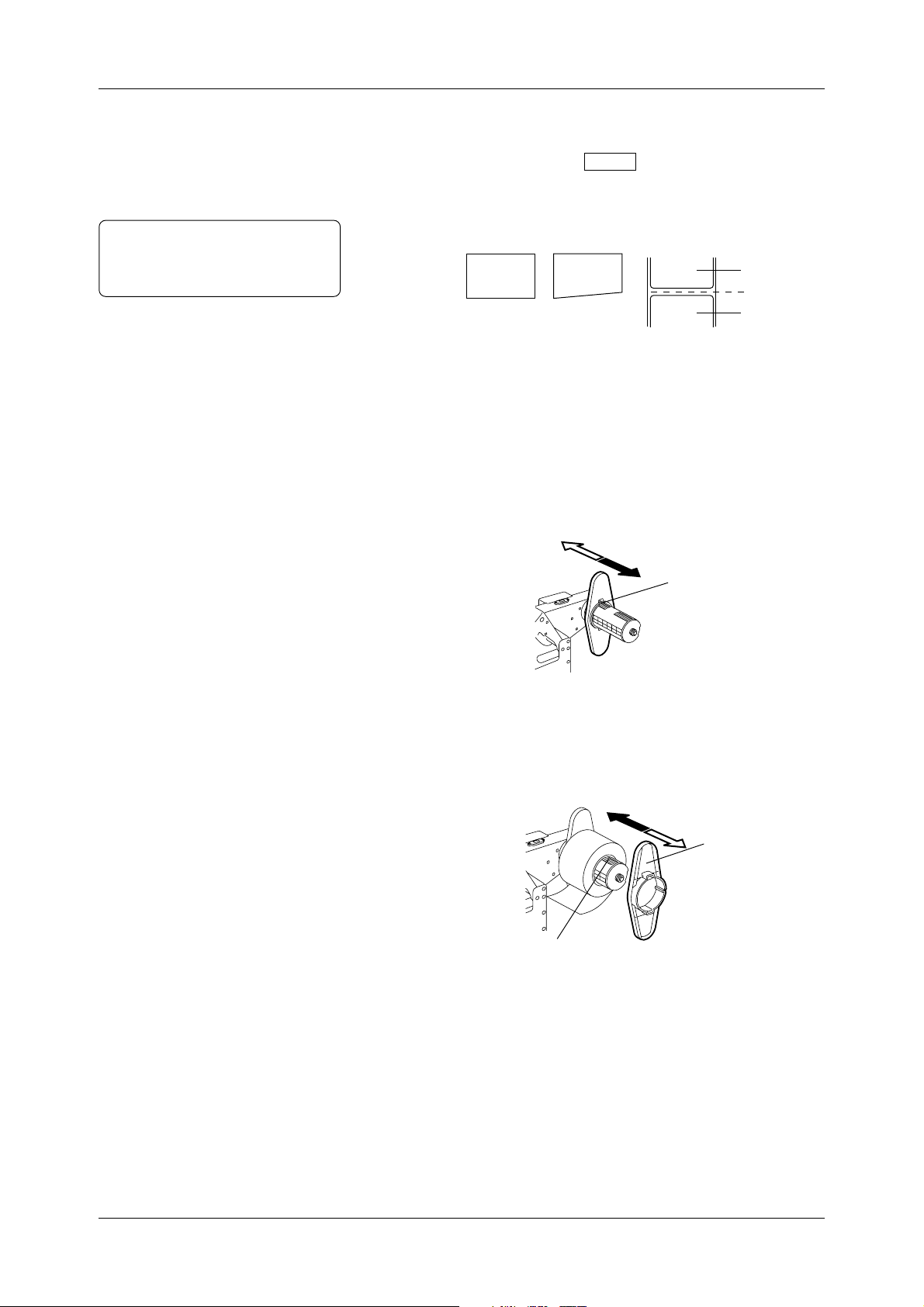

Page 24

2.5 Loading the

Media (Cont.)

Note:

When loading labels, make a straight

cut in the gap area between labels.

Chapter 2 Printer Installation

21

Close the Top Cover gently. Make sure that the POWER LED

and ON LINE LED are illuminated, and that the “ON LINE”

message is shown. Press the FEED key on the Operation Panel

to feed the media about 1 inch (20 to 30cm). Check that the media

is fed successfully.

Label

Cut here.

Right Wrong

Label

2.5.1 Additional

Information

This section contains more information concerning the care that should

be taken when loading the media.

• The figure below indicates the direction the Supply Roll Holder

(inside) can be moved with the claws of the Supply Roll Holder

locked into the notches.

Wrong

Supply Roll Holder

(Inside)

• The figure below indicates the direction the Supply Roll Holder

(outside) can be moved with the claws of the Supply Roll Holder

locked into the notches.

Right

Notches

Right

Wrong

Supply Roll Holder

(Outside)

16

Notches

Page 25

Chapter 2 Printer Installation

2.6 Sensor

Adjustments

2.6.1 Black Mark

Sensor

This section describes in detail how to adjust the media sensor

positions and their sensitivity.

Whenever the type of media is changed, a positional adjustment of

the media sensor is needed. The media sensors are designed to keep

positional alignment of the image on each label or tag when issued.

Important!

NEVER skip the media sensor positional adjustment.

The printer has two types of media sensors: Black Mark Sensor and

Feed Gap Sensor.

The Black Mark Sensor (reflective sensor) is used to detect black

marks on the back of the media by the reflection of light. On the

other hand, the Feed Gap Sensor (transmissive sensor) is used to detect

gaps by the transmission of light.

Which media sensor to adjust depends on the type of media loaded.

When the media with black marks on the BACK is loaded, adjust the

Black Mark Sensor (reflective sensor) position as follows:

1

Open the Top Cover.

2

Lift the Pinch Roller Lever to the ROLLER RELEASE position

to open the Pinch Roller Unit.

Note:

“1” marked on the sensor indicates

the Black Mark Sensor position.

Note:

See A1.3.3 for black mark specifications.

3

Align the Media Guides to the width of the media.

4

Fold the media so that a black mark faces upward.

5

Insert the media into the Media Inlet.

6

Turn the Media Guide Knob, and move the media sensor so that it

is positioned at the center of the black mark.

Media Sensor

Media Guide Knob

7

The Black Mark Sensor Position Adjustment has been completed.

Black Mark detected here

Sensor

Media

Black Mark

17

Page 26

Chapter 2 Printer Installation

2.6.2 Feed Gap Sensor When the media with gaps or rectangular holes is loaded, adjust the

Feed Gap Sensor (transmissive sensor) position as follows:

1

Open the Top Cover.

2

Lift the Pinch Roller Lever to the ROLLER RELEASE position

to open the Pinch Roller Unit.

3

Align the Media Guides to width of the media.

4

Insert the media into the Media Inlet.

• If the media with gaps is loaded, go to Step 5.

• If the media with rectangular holes is loaded, go to Step 6.

5

Turn the Media Guide Knob, and move the media sensor so that

the gap between labels will pass under the sensor.

Note:

“2” marked on the sensor indicates

the Feed Gap Sensor position.

Media Sensor

Gap detected here

Sensor

Note:

See A1.3.2 for gap or hole specifications.

Label

Gap

Media Guide Knob

6

Turn the Media Guide Knob, and move the media sensor so that it

Backing Paper

is positioned at the center of the rectangular hole.

Media Sensor

Media Guide Knob

7

The Feed Gap Sensor Position Adjustment has been completed.

Hole detected here

Hole

Sensor

Media

18

Page 27

Chapter 2 Printer Installation

2.6.3 Media Sensor

Sensitivity

Adjustment

Whenever the type of media is changed, adjust the media sensor

sensitivity.

Please note that the adjustment procedures are slightly different,

depending on which type of media loaded.

Media Sensor Adjustor

Feed Gap Sensor Lamp

Black Mark Sensor Lamp

Green

Red

Black Mark Sensor

Adjusting Knob

Feed Gap Sensor Adjusting Knob

Note:

As soon as the upper two lamps

illuminate green, stop turning the knob.

Black Mark Sensor Sensitivity Adjustment

1

Open the Top Cover.

2

Lift the Pinch Roller Lever to the ROLLER RELEASE position

to open the Pinch Roller Unit.

3

Insert the media with black marks into the Media Inlet so that the

Black Mark Sensor can detect the WHITE part of the media.

4

Lock the Pinch Roller Unit.

5

Turn on the printer.

6

Turn the Black Mark Sensor Adjusting Knob to the left most

position.

7

Keep turning the knob clockwise slowly. When the upper two

Black Mark Sensor Lamps illuminate green, the adjustment is

complete.

19

Page 28

Chapter 2 Printer Installation

2.6.3 Media Sensor

Sensitivity

Adjustment (Cont.)

Note:

As soon as the upper two lamps

illuminate green, stop turning the knob.

Feed Gap Sensor Sensitivity Adjustment

(for Label with Gaps)

1

Open the Top Cover.

2

Lift the Pinch Roller Lever to the ROLLER RELEASE position

to open the Pinch Roller Unit.

3

Insert the label with gaps into the Media Inlet so that the Feed

Gap Sensor can detect the LABEL part.

4

Lock the Pinch Roller Unit.

5

Turn on the printer.

6

Turn the Feed Gap Sensor Adjusting Knob to the left most position.

7

Keep turning the knob clockwise slowly. When the upper two

Feed Gap Sensor Lamps illuminate green, the adjustment is

complete.

Note:

As soon as the upper two lamps

illuminate green, stop turning the knob.

Feed Gap Sensor Sensitivity Adjustment

(for Media with Rectangular Holes)

1

Open the Top Cover.

2

Lift the Pinch Roller Lever to the ROLLER RELEASE position

to open the Pinch Roller Unit.

3

Insert the media with rectangular holes into the Media Inlet so

that the Feed Gap Sensor can detect the PAPER part.

4

Lock the Pinch Roller Unit.

5

Turn on the printer.

6

Turn the Feed Gap Sensor Adjusting Knob to the left most position.

7

Keep turning the knob clockwise slowly. When the upper two

Feed Gap Sensor Lamps illuminate green, the adjustment is

complete.

20

Page 29

Chapter 2 Printer Installation

2.7 Loading the

Ribbons

(for Hot Release

Ribbons)

Note:

Media Width does not include width

of the backing paper.

2.7.1 Ribbon Positions

Important!:

When loading the ribbons, please

do not forget to specify the ribbon

colors in the printer properties.

See Section 3.4.3 for more detail.

This section describes in detail how to load the ribbons in the printer .

Please use the ribbon width corresponding to the media width from

the table shown below.

Ribbon Width

2.7 (68)

3.5 (88)

4.3 (109)

Media Width

2 to 2.6 (50 to 65)

2.6 to 3.4 (65 to 85)

3.4 to 4.4 (85 to 110)

Dimensions in inches + (mm)

There are two types of ribbons: high-performance Hot Release Ribbons

that provide fast, quality print, and the popular Cold Release Ribbons.

This section focuses on how to load the Hot Release Ribbons.

See Section 2.8 for loading procedures of the Cold Release Ribbons.

Also refer to the table in Section 3.8.2 for specific information about

each ribbon type. If the ribbon type to be used cannot be found in the

table, contact an authorized sales representative.

Please load the ribbons, as illustrated below.

2.7.2 Loading

Procedure

Notes:

• Turn the Head Lever to the

OPEN position completely, or

the Ribbon Module cannot be

removed.

• Do not bend, drop, or give any

shock to the Ribbon Module.

Distortion of the Ribbon

Module may cause poor print.

Head 2 (Front)

1

Open the Top Cover.

2

Turn the Head Lever to the OPEN position. Pull out each Ribbon

Head 1 (Back)

Module in the direction of the arrow , and remove it from the printer.

Head Lever

HEAD

LOCK

3

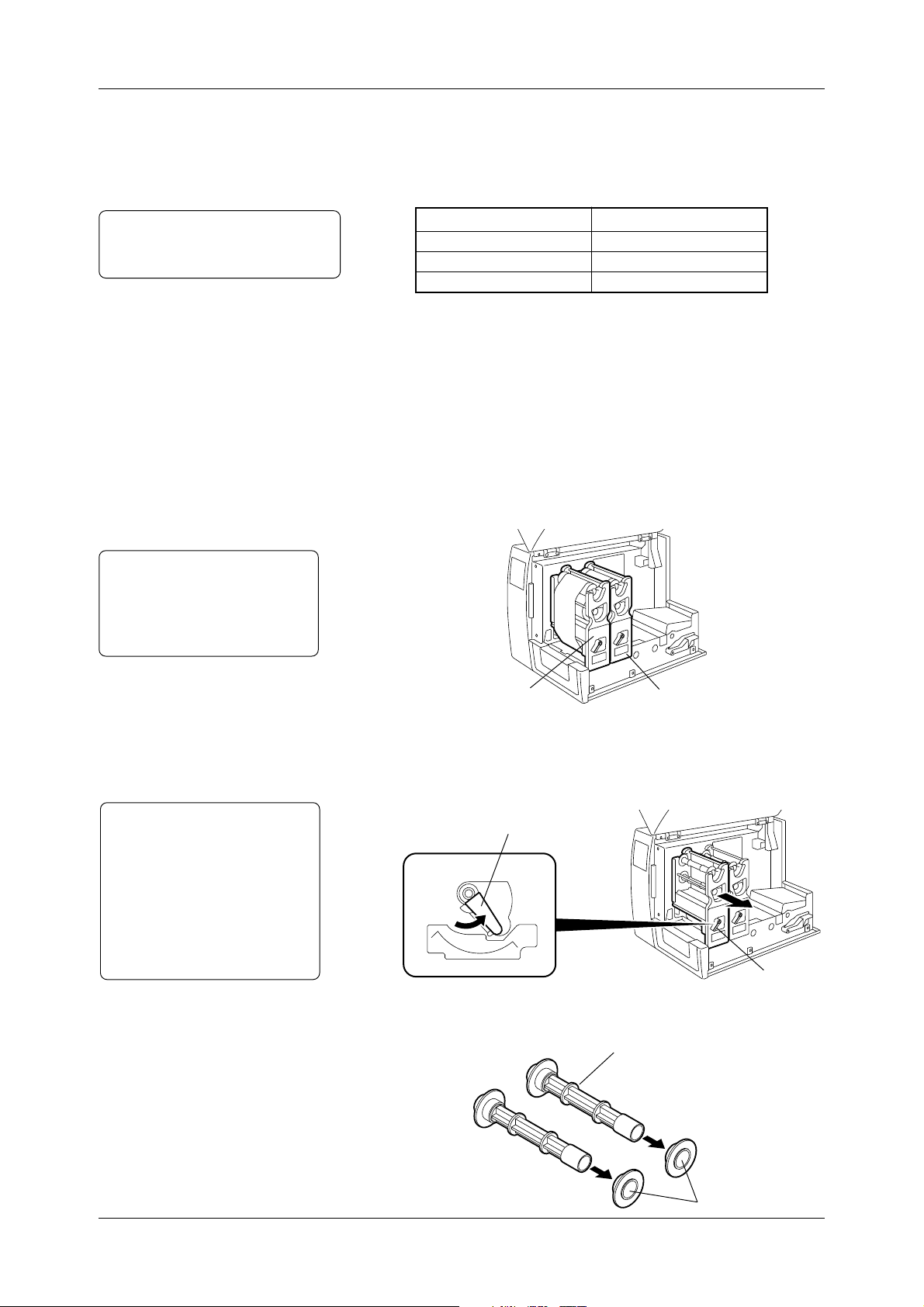

Remove the two Ribbon Shafts from the Ribbon Module. Remove

OPEN

Ribbon Module

the Ribbon Stopper from each Ribbon Shaft.

Ribbon Shaft

Ribbon Stoppers

21

Page 30

2.7.2 Loading

Procedure (Cont.)

Chapter 2 Printer Installation

4

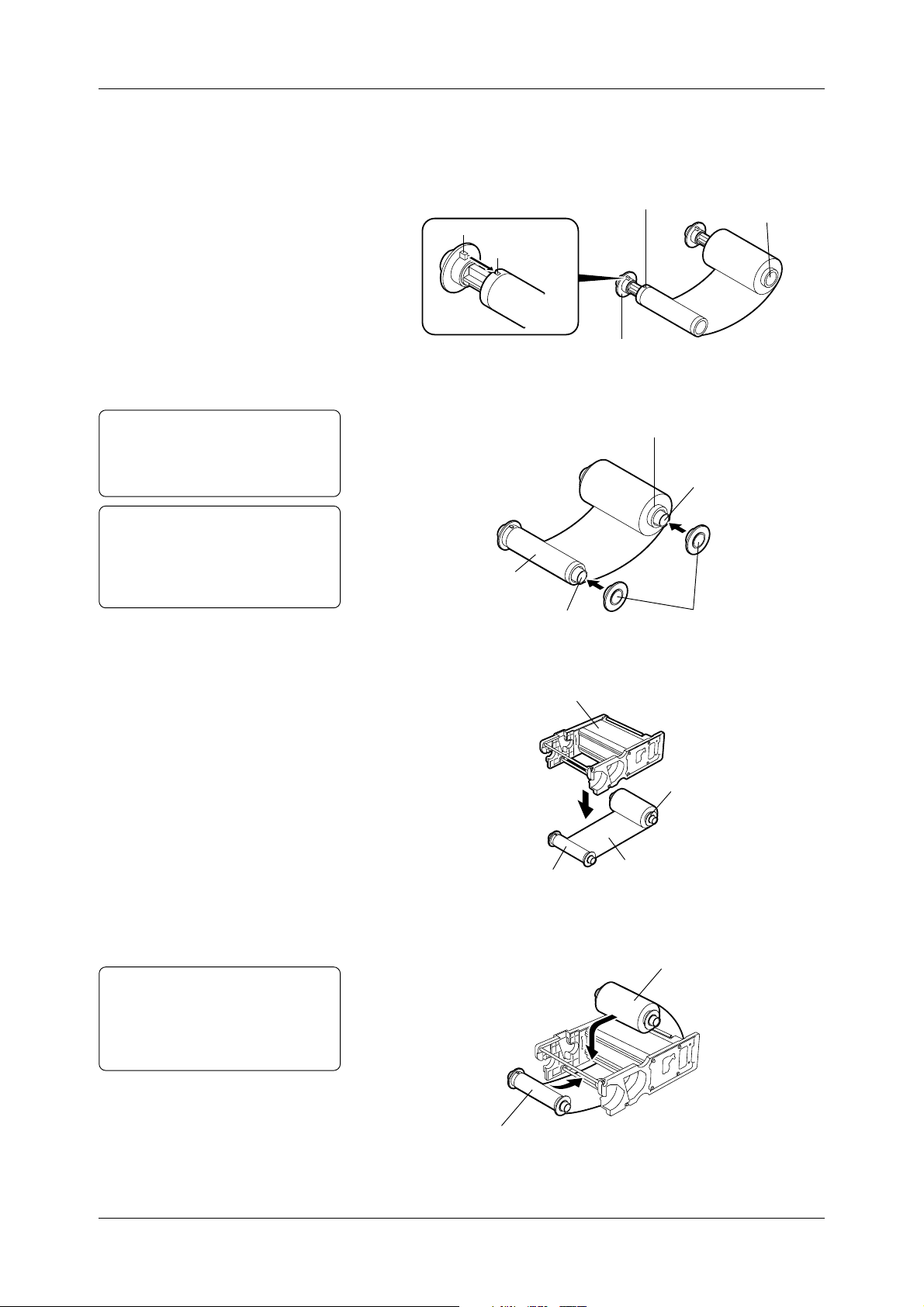

Insert the Ribbon Shaft into the Ribbon Winding Core. Fit the

protrusion of the Ribbon Shaft into the notch of the Ribbon

Winding Core. Insert the other Ribbon Shaft into the Ribbon Feed

Core in the same manner.

Ribbon Winding Core

Protrusion

Notch

Ribbon Shaft

5

Attach the Ribbon Stoppers gently to each Ribbon Shaft.

Ribbon Feed Core

CAUTION!

Push in the Ribbon Stoppers

gently. Otherwise, damage

may occur.

Note:

Please make sure that the Ribbon

Stoppers are completely inserted into

the Ribbon Winding Cor e and Ribbon

Feed Core respectively.

Ribbon Feed Core

Ribbon Shaft

Ribbon Winding Core

Ribbon Shaft

6

Unroll about 1 inch (30cm) of the ribbon. Place the Ribbon Module

Ribbon Stoppers

on the ribbon.

Ribbon Module

Ribbon Feed Core

Ribbon Winding Core

Ribbon

CAUTION!

Loading the ribbon upside

down may cause damage to

the print head, as well as print

failure.

22

7

Insert the Ribbon Feed Core, and then the Ribbon Winding Core

on the Ribbon Module, as illustrated below.

Ribbon Feed Core

Ribbon Winding Core

Page 31

Chapter 2 Printer Installation

2.7.2 Loading

Procedure (Cont.)

8

T ake up any slack in the ribbon. Replace the Ribbon Module into

the print head block by sliding it into the end.

Ribbon Module

Ribbon

Print Head Block

9

Turn the Head Lever to the LOCK position to secure the Ribbon

Module. Take up any ribbon slack one more time by turning the

Ribbon Winding Core.

Ribbon Winding Core

10

Load the other three ribbons in the same manner.

11

Close the Top Cover.

Ribbon Module

23

Page 32

Chapter 2 Printer Installation

2.8 Loading the

Ribbons

(for Cold Release

Ribbons)

Notes:

• Please see Section 1.4.2 for the part

illustrations.

• Installing the Cool Release

Enhancement Kit allows a variety

of ribbons to be loaded.

2.8.1 Precautions

This section describes how to load the popular Cold Release Ribbons.

To identify a ribbon type to be loaded, refer to the table in Section

3.8.2 or contact an authorized sales representative. Before loading

the Cold Release Ribbons, install the Cool Release Enhancement Kit

that is composed of the following accessories.

Part Name

Ribbon Plate

Mounting Screw

D-3x5 Screw

SP Ribbon Guide (A)

SP Ribbon Guide (B)

Ribbon T ension Sheet

Sheet Fixing Plate

1

Depending on the operating temperature or print patterns, ribbon

wrinkles or blurred printing may occur. To solve this problem,

adjust the print density as follows:

• When the ribbons wrinkle, decrease the print density.

• When the blurred printing occurs, increase the print density.

To change the print density, see Section 3.7.2 for more detail.

Quantity

2 pcs.

2 pcs.

6 pcs.

1 pc.

1 pc.

2 pcs.

2 pcs.

2

When using the Cold Release Ribbons in high temperature (about

105°F/40°C), the sound of the ribbon being separated from the media

may be heard. But that does not impact upon print quality .

24

Page 33

Chapter 2 Printer Installation

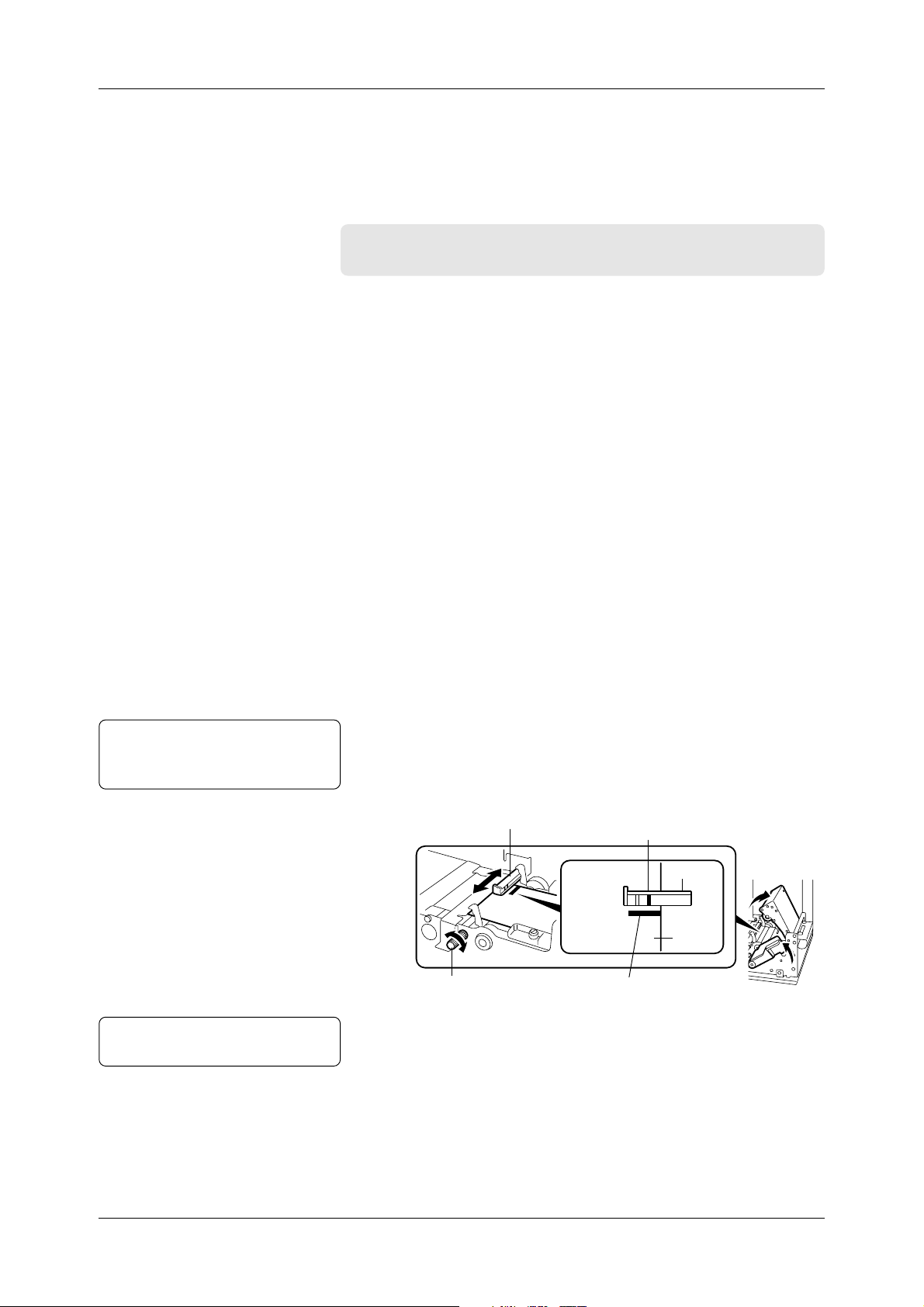

2.8.2 Installing the Ribbon

Plate

WARNING!

During normal printer operations, the print head will become hot. Care

should be used when handling the print head to avoid personal injury.

1

Remove all Ribbon Modules from the print head blocks. Then

lift one of the print head blocks.

Print Head Block

2

Hold the Ribbon Plate with the pin facing inside and downwards,

as illustrated below.

Print Head Block

Print Head Block

Notes:

• Be sure to return the print head to

the original position.

• Tighten the screws so as not to

damage the screw threads.

Ribbon Plate

3

First position the Head Positioning Plate (opposite the pin side),

Pin

into the small rectangular groove. Keep the Head Positioning

Plate flush against the groove, as illustrated below.

When attaching the Ribbon Plate to the print head block, make

sure that the Head Positioning Plate makes full contact with the

small rectangular groove.

Groove

Head Positioning

Plate

Ribbon Plate

Print Head Block

Ribbon Plate

(Side View of Print Head Block and Ribbon Plate)

4

Slide the Ribbon Plate down slightly and insert the pin into the

hole on the back of the print head.

5

After the pin is inserted, slide the Ribbon Plate back in the direction

of the arrow and gently pull down the print head. Secure the Ribbon

Plate to the print head block by tightening the Mounting Screw.

Print Head Block

Mounting Screw

Print Head Block

Ribbon Plate

6

Repeat this procedure for installation of the other three print heads.

Pin

25

Page 34

2.8.3 Installing the SP

Ribbon Guides

Important!

• The SP Ribbon Guide (A) with the

small plastic film is exclusively for

Head 2.

• The SP Ribbon Guide (B) with the

large plastic film is for Head 1.

Chapter 2 Printer Installation

1

Remove the Guide Plates from the printer by lifting and pulling

them in the direction of the arrow.

Guide Plate

2

Install the SP Ribbon Guides (A) and (B) in the reverse order of

removal of the Guide Plates.

SP Ribbon Guide (A)

(for Head 2)

SP Ribbon Guide (B)

(for Head 1)

Plastic Plate (Small)

Plastic Plate (Large)

26

Page 35

Chapter 2 Printer Installation

2.8.4 Installing the Ribbon

Tension Sheet

Note:

Do not reinstall the Ribbon guide

Lever , Ribbon Guide Lever Shaft and

the D-3x6 screw because they ar e not

used after the ribbon tension sheet

has been installed.

1

Remove the Ribbon Guide Lever from the Ribbon Cassette by

removing the screw.

2

Fit the bosses on the Sheet Fixing Plate into the holes of the Ribbon

Tension sheet and the aluminum frame. Secure them with the

three D-3x5 screws.

Ribbon Cassette

D-3x5

Bosses

(A)

Aluminum Frame

D-3x6

(B)

Ribbon Guide Level

Ribbon Guide

Level Shaft

Sheet Fixing Plate

Ribbon Tension Sheet

(A)

(B)

27

Page 36

Chapter 2 Printer Installation

2.8.5 Loading the Cold

Release Ribbons

Note:

Selecting a wrong ribbon type may

cause blurred or blotted printing.

Be sure to select the pr oper ribbon

type.

Note:

Selecting a wrong ribbon motor

voltage may cause ribbon wrinkles

or blurred printing. Be sure to

enter the proper value.

After attaching the Cool Release Enhancement Kit, the Ribbon

Settings need to change. See Section 3.8.2 for more detail.

1

Open the Testing property page on the computer, click Ribbon

Settings, and open the Testing dialog.

2

Click the Type down arrow, and select Premium (either 109mm

or 68mm).

3

The Ribbon Motor Voltage may need to change.

28

Page 37

3. Printing

Chapter 3 Printing

Note:

In this chapter, unless otherwise

specified, “click” means click the left

mouse button once.

3.1 Installing the

Printer Driver

3.1.1 System

Requirements

This chapter explains how to print an image or bar code using the

Windows driver . First, it describes in detail how to install the printer

driver . Then it describes how to modify the printer settings and fine

adjustments to produce the best output. Finally it describes how to

print a label.

The chapter is organized as follows:

1

To install the printer driver, see Section 3.1.

2

To specify the printer properties, see Sections 3.2 to 3.8.

3

T o perform test printing, see Section 3.9.

4

To print an actual label from an application program, see Section

3.10.

To use the CB-426-T3 printer with Windows, the printer driver must

be installed on the computer. Labels or tags can easily be printed

from a variety of application software using the CB-426-T3 printer

driver.

You need an IBM PC/AT-compatible computer with:

Microsoft® Windows® 95/98, Windows NT® V ersion 4.0 W orkstation,

or Windows NT® Version 4.0 Server.

Pentium® 133MHz or greater recommended

16MB of available RAM or more (32MB recommended).

10MB or more of available hard-disk space.

3.1.2 Installation

Procedure

(For Windows

Notes:

•For further information about the

installation procedure for

Windows® NT , please contact your

authorized service representative.

• The printer driver may be upgraded

without notification. For further

information about the download of

the upgraded printer driver, please

access the following URL.

http://barcode.toshibatec.co.jp.

®

98)

This section has step-by-step procedures to install the TEC Printer

Driver Version 6.4 build 33 for Windows®98.

Preparation

Make preparations for the installation of the printer driver as follows:

1

Insert Disk 1 in the floppy disk drive.

2

Click the Start button. Then click Run.

3

Type “a:setup” in Open, and then click OK.

29

Page 38

3.1.2 Installation

Procedure (Cont.)

Chapter 3 Printing

4

TOSHIBA TEC PRINTER DRIVER Setup W izard is initiated.

Click Next.

5

To accept License Agreement, click Yes. If it is not acceptable,

click No. However, the printer driver cannot be installed.

30

6

Choose a destination folder to install COLOR. To install it in

C: \TEC_DRV\COLOR, click Next. The installation of COLOR

begins. To install it in another destination, click Browse.

Page 39

3.1.2 Installation

Procedure (Cont.)

Chapter 3 Printing

7

Remove Disk 1. Then insert the other disks in the floppy disk

drive, as instructed by the dialog box that appears on the screen.

Click OK to continue the set up.

8

Setup Complete appears, when the setup successfully completes.

Click Finish.

9

Start the Windows Explorer. Verify that the Color folder was

created in the TEC_drv folder on the C drive.

31

Page 40

Chapter 3 Printing

3.1.2 Installation

Procedure (Cont.)

Adding the Printer (For Windows®98)

Install the printer driver as follows:

1

Click the Start button. Choose Settings, and click Printers. The

Add Printer icon appears.

2

Double-click the Add Printer icon, and Add Printer W izard is

initiated. Click Next to add the CB-426 printer.

32

3

Choose whether the printer is used as Local Printer or Network

Printer. Then click Next.

Page 41

3.1.2 Installation

Procedure (Cont.)

Chapter 3 Printing

4

Click Have Disk.

5

Type in “C:\TEC_DRV\COLOR”, and click OK.

6

Choose CB-426-T3 from the printer list, and click Next.

33

Page 42

3.1.2 Installation

Procedure (Cont.)

Notes:

• The ECP Printer port is recommended.

• Please refer to the user's manual of

your computer for further information

regarding the setting of the ECP

Printer port.

Note:

If no printer driver has been installed

before, this printer will be used as a

default printer automatically.

Chapter 3 Printing

7

Choose the port that the printer is connected to, and click Next.

8

Type in a printer name that you prefer to use.

9

Select whether the printer will be used as the default printer for

all applications. Then click Finish.

34

10

Finally, make sure that the CB-426-T3 icon has been added in

Printers. Installation of the printer driver has been completed.

Page 43

Chapter 3 Printing

3.1.3 Uninstalling the

Printer Driver

Note:

Start uninstalling the printer driver

after closing all application programs.

Note:

Remove the icon by right-clicking the

icon, and choosing and clicking

Delete.

Perform the following steps to uninstall the printer driver.

1

Click the Start button. Choose Settings, and click Printers.

Choose the CB-426-T3 icon.

2

On the File menu, click Delete. Please be sure that the CB-426T3 icon is removed.

The printer driver is uninstalled now.

35

Page 44

Chapter 3 Printing

3.1.3 Uninstalling the

Printer Driver

(Cont.)

Important!

When upgrading the printer driver, the folder needs to be

deleted as follows:

1

Click the Start button. Choose Settings, and click Control Panel.

2

Double-click the Add/Remove Programs icon.

3

Add/Remove Programs Properties appears. Choose TOSHIBA

TEC PRINTER COLOR, and click Add/Remove.

4

The Confirm File Deletion dialog box appears. Click Yes, and

the removal of the printer driver begins.

5

The printer driver is removed successfully. Click OK.

36

Page 45

Chapter 3 Printing

3.2 Properties

3.2.1 Displaying Printer

Properties

This section summarizes the main properties that can be specified to

ensure the best printer performance.

Please refer to the later sections describing the property settings in

detail.

1

Click the Start button. Choose Settings, and click Printers.

2

On the File menu, click Properties. TEC CB-426-T3 Properties

appears.

37

Page 46

Chapter 3 Printing

3.2.2 Summary of

Properties

Note:

Some of the properties may have to

be set again in the application

programs.

This is a summary of the main properties for CB-426-T3.

• On the Page Setup property page, specify the default label size and

orientation settings. In addition, other label sizes can be created,

then accessed through your application’s page setup dialog.

See Section 3.3 for more detail.

• On the Graphics property page, how text and images will be

printed on the labels or tags can be specified.

See Sections 3.4 for more detail.

• On the Bar Fonts property page, internal bar code fonts can be

added, deleted, modified, imported, exported and viewed.

See Section 3.5 for more detail.

• On the Stock property page, print conditions including selection

of the media sensor to be used, the issue mode and fine adjustments

can be specified.

See Sections 3.6 for more detail.

• On the Options property page, the transfer mode of graphics data

and print density adjustments can be specified.

See Section 3.7 for more detail.

• On the Testing property page, the type of ribbon to be used, can

be specified. The Testing property page is also used for test print

and maintenance purposes.

See Section 3.8 for more detail.

• On the Regional Settings property page, the units of measurement

(inches or centimeters) and the language in which your driver is

displayed can be specified.

• On the About property page, the printer driver information that

includes the version number and licence agreement can be viewed.

38

Page 47

Chapter 3 Printing

3.3 Page Setup

This section describes in detail how to specify the default label size,

orientation and how to create other label sizes that then can be accessed

through an application’s page setup dialog.

Click the Page Setup tab to open the Page Setup property page.

3.3.1 Selecting a label size

Note:

The setting made in this section can

be saved in the file as a preferred

setting for a particular print job.

See Section 3.3.4 for more detail.

Click the Name down arrow to select a desired label size from the

predefined label sizes: 2 x 4, 4 x 4, 4 x 6 or User Defined.

• Use Import Stock List to import previously defined label sizes

from other compatible printer drivers.

• Use Export Stock List to save defined label sizes to a file so they

can later be imported into other printer drivers with this capability .

39

Page 48

Chapter 3 Printing

3.3.2 Creating a new label

size

To create your own label size :

1

Click New, and Edit Label Stock appears.

Note:

User Defined cannot be renamed.

Note:

Delete is grayed out when the

predefined label sizes ar e selected. In

other words, you cannot delete them.

2

Enter a new label stock name in Name.

3

Change Label Size (Width and Height) and Exposed Liner Width

(Left and Right). Click OK to return to the Page Setup property

page.

4

Click Edit to change the label name, label size, or exposed liner

size that is defined in Step 3.

5

To delete a label size that you created, select it in Name, and click

Delete. When the confirmation dialog box appears, click Yes.

40

Page 49

Chapter 3 Printing

3.3.3 Orientation

Notes:

• A preview will be shown, as each

option is selected.

• The setting made in this section can

be saved in the file as a preferred

setting for a particular print job.

See Section 3.3.4 for more detail.

Select the print image orientation to determine the direction that the

print image will be issued

• Click Portrait, and the bottom of the print image comes out of

the printer first.

• Click Landscape, and images are rotated 90° counterclockwise

from the portrait orientation. The left edge of the print image

comes out of the printer first.

• Click Portrait 180 °, and the top of the print image comes out of

the printer first.

• Click Landscape 180°, and images are rotated 90° clockwise from

the portrait orientation. The right edge of the print image comes

out of the printer first.

Note:

• Effects is not available for this

version.

41

Page 50

3.3.4 Miscellaneous

Chapter 3 Printing

Notes:

• When the page setup or print property

changing using the application

software under Windows®95, just in

case any application occurs, please

do not mark the Enable User

Commands checkbox.

• The User Commands specified

here can be saved in the file as the

preferred User Commands for a

particular print job.

See the Printing Prefer ences below .

• Click Copies to enter the default number of copies that the printer

will print.

• Click Advanced Options. The Advanced Options Screen appears

to implement the following functions:

User Commands

Printer commands can be added at the beginning or the end of a print

job.

Please note familiarity with application programs and commands is

required. Otherwise the printer may not function, as desired.

42

Page 51

Chapter 3 Printing

3.3.4 Miscellaneous

(Cont.)

Note:

Regardless of whether the Set Check

box is marked or not, the shaded area

will be enabled when saved as the

preferred settings.

See Sections 3.6.5 and 3.7.2 for more

detail.

Printing Preferences

• In Printing Preferences, the preferred settings can be saved in the

file for a particular print job. If several kinds of print jobs are

performed, it is strongly recommended to use this function to save

the preferred settings in the file for each print job.

When using Printing Preferences, the following settings can be

saved. For more details of each setting, see the section indicated

in the right column of the table below.

Tab

Page Setup

Graphics

Settings

Name

Orientation

User Commands

Dithering

Color Control

Print Method

Sensor

Label Gap

See Section ...

3.3.1

3.3.3

3.3.4

3.4.1

3.4.3

3.6.1

3.6.2

3.6.3

Issue Mode

Stock

Cut

3.6.4

Cut Interval

Feed (Fine Adjustment)

Back feed (Fine Adjustment)

Cut/Strip (Fine Adjustment)

3.6.5

Stop Position (Fine Adjustment)

Options

Transfer Mode

Print Density Adjustment

3.7.1

3.7.2

43

Page 52

Chapter 3 Printing

3.3.4 Miscellaneous

(Cont.)

To save the settings indicated in the table, use the following

procedures: