Page 1

Operations Manual

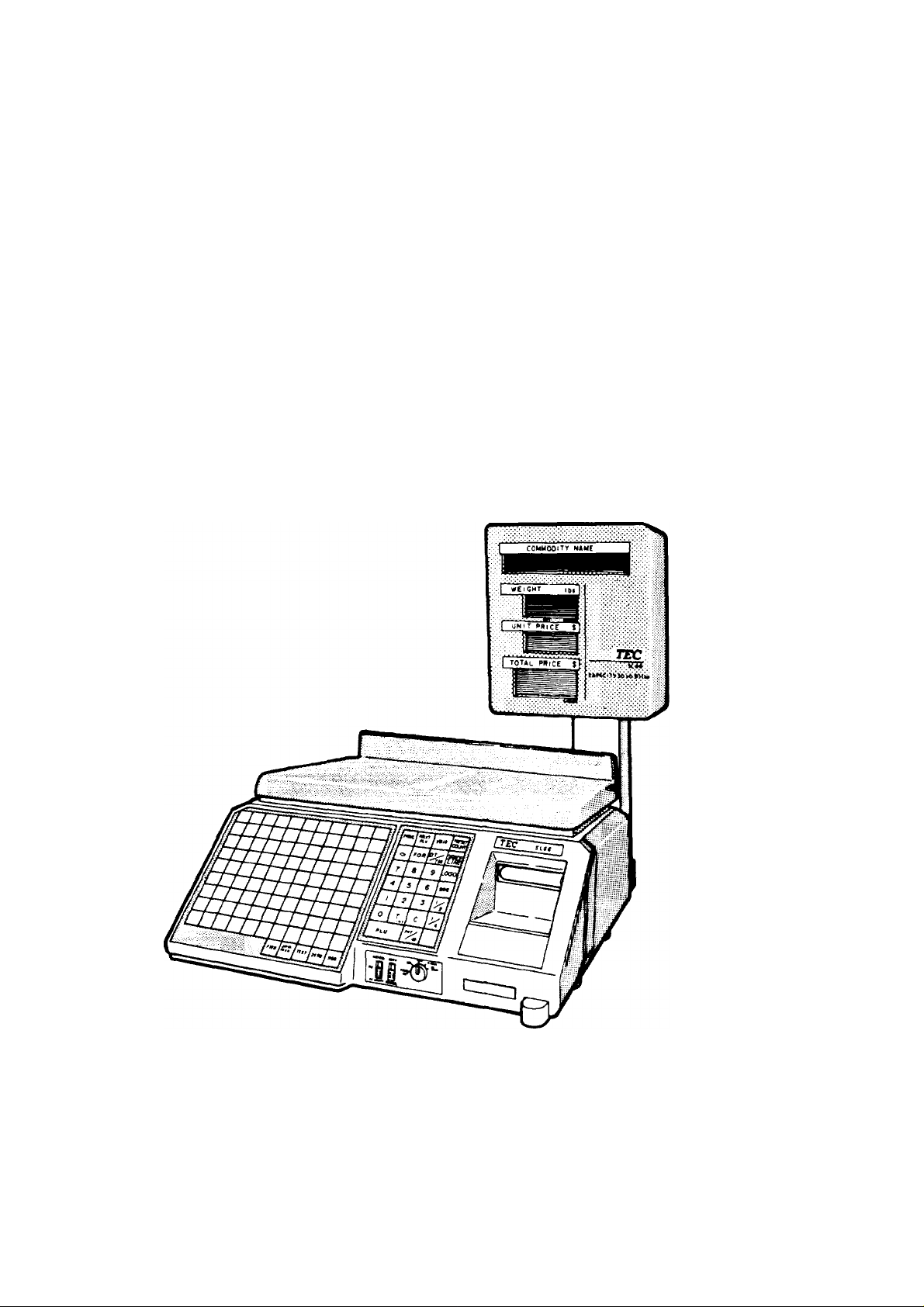

TEC LOAD CELL SCALE

(WITH LABEL PRINTER)

MODEL SLS6 SERIES

(US-V Version)

TEC TEC CORPORATION

Page 2

EMI-31055

------------------------------------- WARNING

This equipment generates, uses, and can radiate radio frequency energy and if not installed

and used in accordance with the instruction manual, may cause interference to radio

communications. It has been tested and found to comply with the limits for a Class A

computing device pursuant to Subpart J of Part 15 of FCC Rules, which are designed to

provide reasonable protection against such interference when operated in a commercial

environment. Operation of this equipment in a residential area is likely to cause interference

in which case the user at his own expense will be required to take whatever measures may

be required to correct the interference.

--------------------------------------

Page 3

TABLE OF CONTENTS

Page

• INTRODUCTION ................................................................................................................................. 1

• PRECAUTIONS .................................................................................................................................... 1

1. SPECIFICATIONS ...................................................................................................................................... 2

2. OVERVIEW ................................................................................................................................................. 3

3. REMOTE DISPLAY .................................................................................................................................... 3

4. KEY LAYOUT ............................................................................................................................................... 4

5. KEY AND LAMP FUNCTIONS .............................................................................................................. 4

6. CONTROL LOCK ....................................................................................................................................... 7

7. LEVEL ADJUSTMENT ............................................................................................................................... 8

8. CLEANING THE PRINT HEAD .............................................................................................................. 8

9. REMOVAL AND REPLACEMENT OF LABEL ROLL ........................................................................ 9

10. NOTES BEFORE STARTING OPERATIONS ................................................................................... 10

11. OPERATION PROCEDURE ................................................................................................................. 11

11 - 1. Weighed Article Registration ....................................................................................... 11

11- 2. By Count Registration ...................................................................................................... 13

11- 3. Fix Price Registration ........................................................................................................ 15

11 - 4. Preset Count Registration and Operation ................................................................ 17

11- 5. Issuing Net Weight Label ................................................................................................ 22

11- 6. Tare Function Procedure ...................................................................................................... 24

11 - 7. SAVE Key Operation Sample

11 - 8. VOID Key Operation Sample ......................................................................................... 28

11 - 9. Date Change ......................................................................................................................... 29

11-10. Selection of Print Item on Registration Label

11-11. Setting Automatic Display Switching Time ................................................................. 31

11-12. Calling and Printing Grade Line ........................................................................................ 32

11-13. Calling and Printing Logo ................................................................................................. 33

11- 14. FUN Automatic Reception ............................................................................................... 34

12. TOTAL OPERATION PROCEDURES ................................................................................................ 36

12- 1. Hourly Report .......................................................................................................................... 36

12- 2. Grand Total Report ................................................................................................................. 37

12- 3. PLU Report................................................................................................................................... 38

12- 4. Combination Report ............................................................................................................... 42

13. ACTION FOR ERROR MESSAGES .................................................................................................... 44

14. LABEL PRINT FORMATS ..................................................................................................................... 46

15. BEFORE YOU CALL FOR SERVICE.................................................................................................. 50

16. APPENDIX ....................................................................................................................................... 51

.........................................................................................

..............................................................

27

30

EMI-31055

Copyright ® 1995

by TEC Corporation

All Rights Reservad

1 »14-10 Uchikanda, Chiyoda-ku, Tokyo. JAPAN

Page 4

EMI-31055

INTRODUCTION

We thank you very much for purchasing the TEC Electronic SL66 Series Scale.

This series has been designed with TEC reliability to offer a cost efficient system for a modest

investment.

The SL66 (with thermal printer) takes advantage of the latest technology in microprocessors. Because

of this, the decreased cabinet size permits the system to be placed virtually anywhere in your store.

Your deli and specialty departments can enjoy these high quality reliable TEC products. Improve your

operating effectiveness and watch the increased utilization of your front end scanning investment. This

electronic Load Cel! scale eliminates all moving parts and furnishes an accurate digital display of all

information.

We believe that your needs will now be fully satisfied, and you will have total reliability in price

calculation. Should you have any questions concerning the scale, please refer to this manual. Be sure

to keep this manual for future reference.

PRECAUTIONS

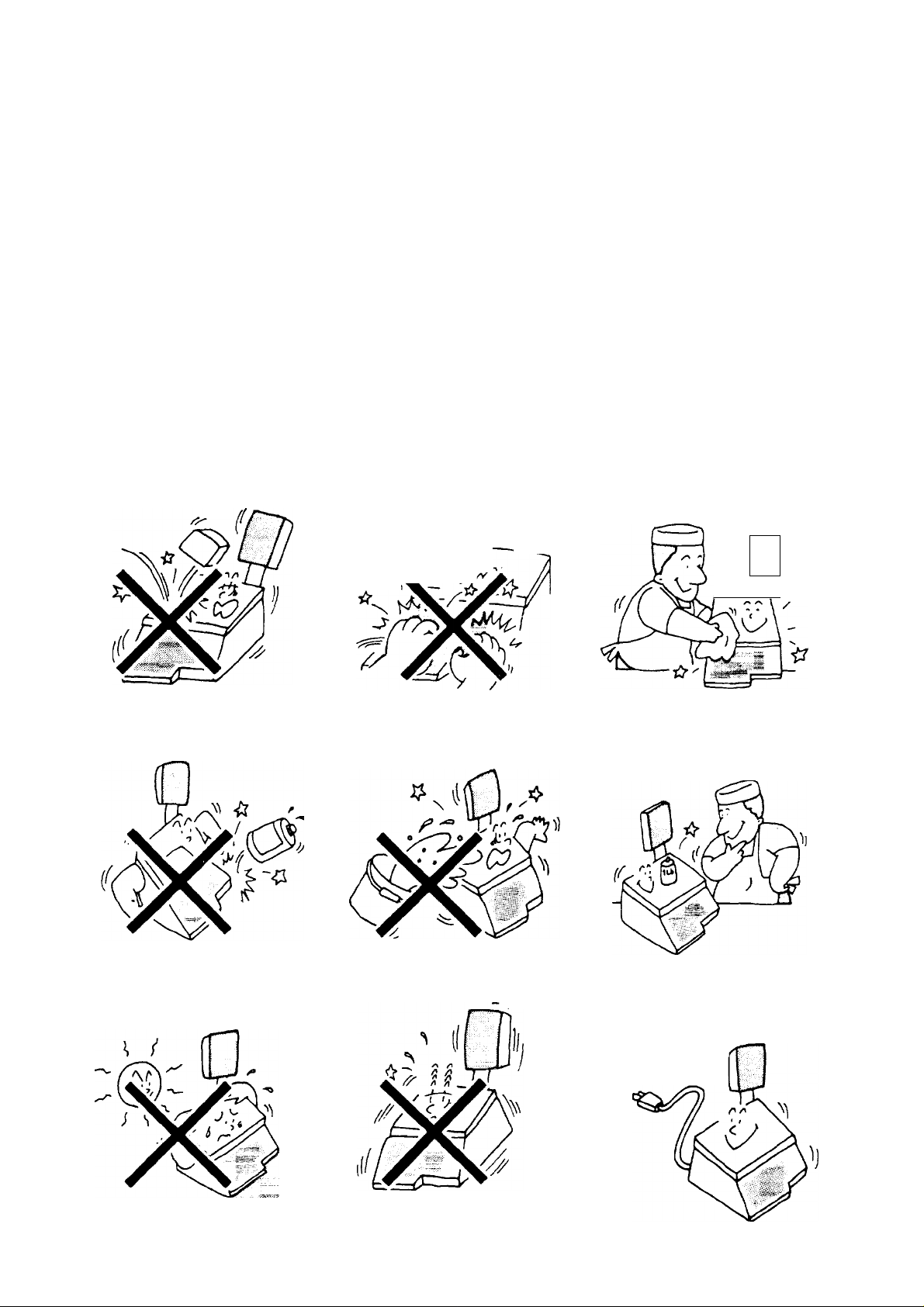

1. DONT SUBJECT the weighing

platter to SUDDEN SHOCKS.

4. NEVER USE THINNER OR OTHER

VOLATILE SOLVENT for cleaning.

2. DONT PRESS THE KEYS TOO

HARD.

Keys will operate correctly if they

are merely touched lightly.

/1 ^ ■

XT

5. DONT POUR WATER directly on

scale.

3. Clean the cover and platter by

wiping with a dry cloth or a

cloth soaked with detergent

and wrung out thoroughly.

•Ù"

\ 1

T

6. To ensure the scale is operat

ing correctly, place a known

weight on the platter and

check for correct computing.

7. When in use, avoid locations subject to vibration and direct sunlight.

1 -

8. After the end of daily work, turn

the power OFF, then clean and

inspect the exterior of the scale

to allow you to use the scale at

its best condition.

Page 5

1. SPECIFICATIONS

EMI-31055

Items

Maximum Capacity

Minimum Scale Division

Using Weight Range

Display Range

Tare

Unit Price presettable

Minimum Price Display

Power Requirement

Current Consumption

Temperature Limits

Relative Humidity

Dimensions (approx.)

Weight

Remote Display

Weight

Unit Price

Total Price ■

Message

Display Designations

Remote Display Mode

Capacity of PLU Memory

Print Head

Label Issuing Method

Label

Interface Device (option):

Cassette Magnetic Tape Loader

PC Keyboard

SL66-30L-US-V

30 lbs

0.01 lbs.

0.20 ' 30 lbs.

0 ~ 30.05 lbs

0.01 - 30 lbs.

$0.01 ' 99.99

$0.01

AC 120V ± 10%, 60 Hz

120V 1.5A 60 Hz

32° ~ 104°F

35% ~ 85% RH (No condensation)

15.7" (W) X 17.2" (D) X 18.7" (H)

33.1 lbs.

4 digits

4 digits

5 digits

22 charactors (16 x 176 dot matrix)

NET. PREPACK, ERROR

Dual sides

Refer to below table.

Thermal Print Head

On-demand/Batch

RICOH 120LA or equivalent

AIWA DR-1

A FUJITSU PC Keyboard (FKB-2831-001) instead of the

IBM PC-XT Keyboard can be used. For use of other units,

please contact your TEC representative.

Capacity of PLU Memory

Type

us-v

Capacity of PLU

Max. 1400 PLUS

Option Kits

Name of Kit

Purpose

OP-66-32K Expansion RAM Kit

OP-66-TMCC

Communication l/F Kit

(TMCC-3)

OP-66-PCKEY

IBM PC-XT keyboard connec

tion adapter

KS-60-1

OP-66-PL

OP-66-PL-TMCC

Label cassette case

Program Loader

Program Loader with Com

munication l/F (TMCC-3)

OP-66-PIGGY

MC-128-EX

MC-256-EX

Expansion RAM board

Memory Card (128 KB)

Memory Card (256 KB)

TMCC — TEC Multi-drop

Communication Control

- 2 -

Page 6

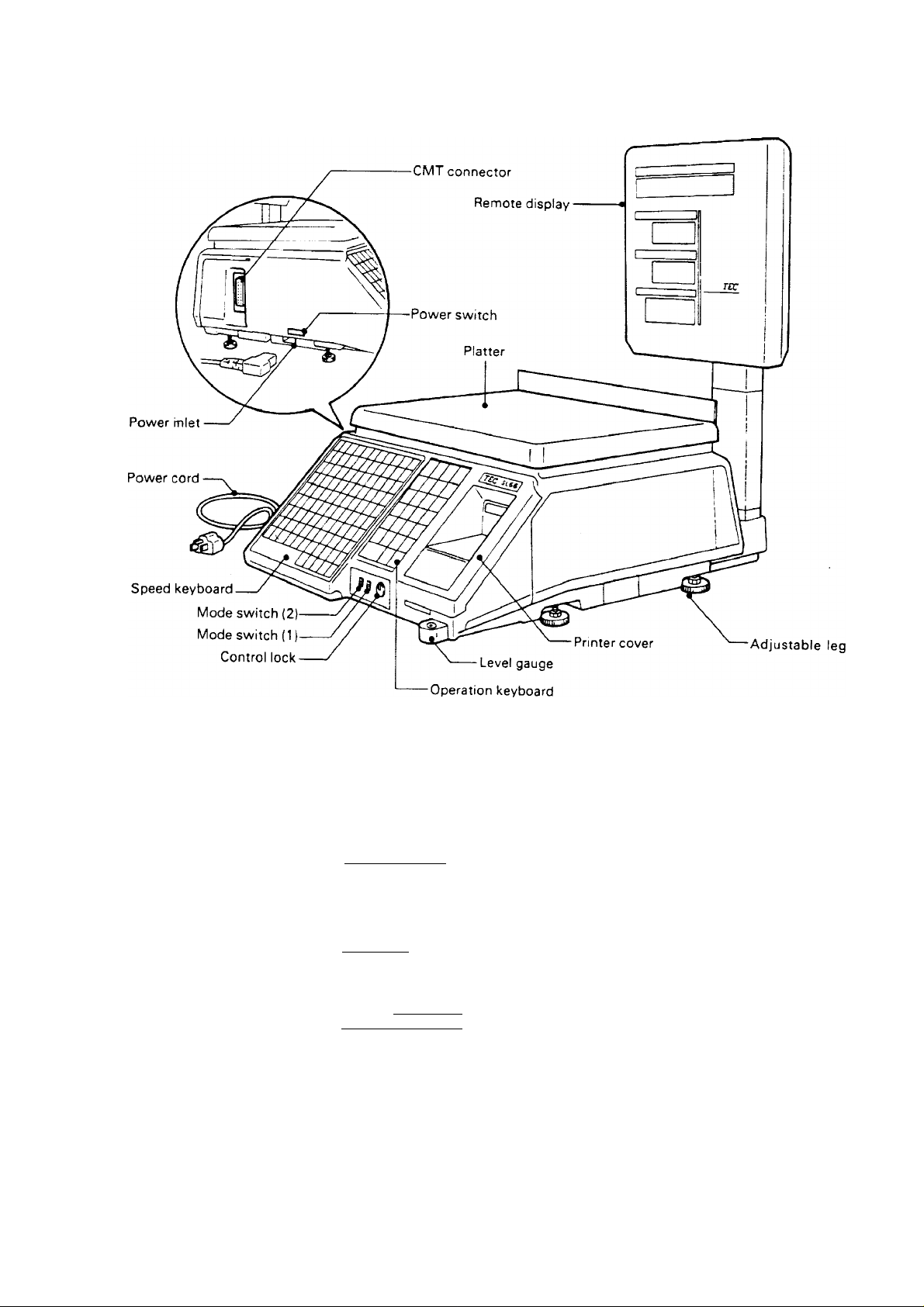

2. OVERVIEW

EMI-31055

3. REMOTE DISPLAY

COMMODITY NAME

WEIGHT lbs

■■HET PtItWCK

UNIT PRICE $]

I

TOTAL price $1

TEC

Sl66

CAPACITY 30i0 Oil»*

- 3 -

Page 7

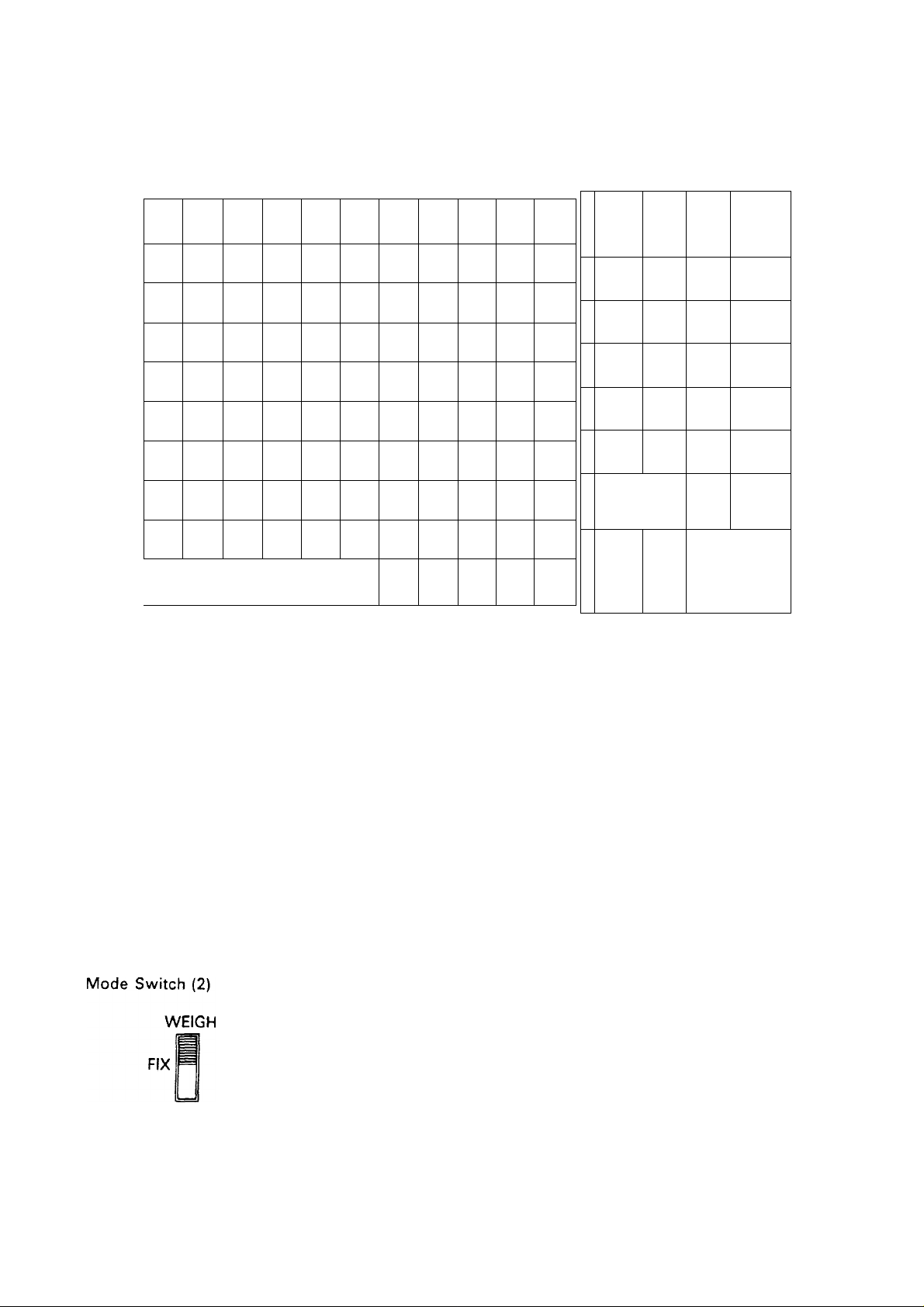

4. KEY LAYOUT

EMI-31055

2 3 4

11

12 13 14

21 22

31

41

51 32 53 54

6t 62

71 72

61 02 63 84

23

33

32

42

43 44

«3 64

73 74

24

34

3

6

15

16

25

26 27

35

36

45

46

53 56

65 66

75

76

85 86 87

FEED

7

17

37

47

57 56

67

77

JRNL

FEED

8 9

19 20

18

29 30

28

36 39 40

46

49

59 60

68 69

79

76

89 90

86

TEST

ZERO

10

NEXT

PROG.

PLU

FOR

O

7 8

50

4 5

1 2

70

60

MSG

T

0

(Tf)

PLU

6H AUT

FIX "

BYC

VOID

DT^

9

6

3

c

PRT>

■ ^¥r

PRESET

COUNT

GRADE

LINE

LOGO

SAVE

1 /

^4

R£G. «.DOWN

NOTE; The characters (1 ~ 90) indicated on the speed keys are shown for the convenience of

explanation in this manual. The indications on the actual unit are not as shown in this illustration.

5. KEY AND LAMP FUNCTIONS

Name of Key & Lamp

Mode Switch (1)

AUTO

L-MANUAL

BY COUNT

"AUTO" position:

This position is used to issue regular scale labels.

When the weight becomes stable, the label will automatically be

issued.

"MANUAL" position:

When the weight becomes stable, the label will be issued by

depressing the Imt-I Key.

"WEIGHT" position:

This position is used in the weighing function of the SL66.

"FIX" position:

The Unit Price is entered directly to the Total Price on calling up

PLU, and that

Total Price cannot be changed by any subsequent weighing.

"BY COUNT" position:

It is possible to produce labels which contain information on quantity

pricing, instead of weight.

Function

NUMERIC Keys

These keys are used to enter PLU Number, Unit Price, and Tare weight.

Page 8

EM1-310S5

Name of Key & Lamp

CLEAR Key

TARE Key

T

J1Ù.

PLU Key

PLU

PRINT/VERIFY Key

PRT/-

1/2 Key

1/2

1/4 Key

1/4

Function

This key is used for dear-entry of numeric keys, return the scale

condition to the normal weighing mode, release the scale from the

SAVE or ERROR mode, and suspend batch printing.

This key is used to subtract tare weight.

This key is used to select a PLU number or return to the initial mode.

For issuing Total labels.

If the Label issue mode switch is set to the MANUAL position, it has

the function of label issue.

It is also used to resume batch printing if it has been suspended.

These keys are used to calculate the unit price by 1/2lbs or 1/4lbs.

SAVE Key

SAVE

DATE & TIME Key

GRADE LINE Key

GRADE

LINE

FOR Key

FOR

VOID Key

VOID

NEXT PLU Key

NEXT

PLU

This key is used to save tare and unit price after removing the

commodity from the platter.

This key is used for temporary date changes.

This key is used to call the grade line message.

In the "X" or ”2" control lock position, this key is used to generate the

Zone Total Report.

One article's data can be cancelled by depressing this key after its

registration.

It is also used to return the operation step to the previous step.

This key is used to call out the next PLU #■, and forward the operation

step to the next step.

<>

PROGRAM Key

PROG.

In the "X"or "Z" control lock position, this key is used to generate the

Block Total Report.

In the "REG.” control lock position, this key is used to select whether

the data should be printed on the label or not.

This key is used to set the various programs.

- 5

Page 9

EMI-31055

Name of Key & Lamp

SPEED Key

1

FEED Key

FEED

JOURNAL FEED Key

JRNL

FEED

TEST Key

TEST

ZERO Key

ZERO

MESSAGE Key

MSG

Function

These keys are used to set and call the PLU numbers of frequently used

90

articles.

This key is used to feed labels or journal paper.

This key is not used. (No function)

This key is used to issue Test Labels.

This key is used to adjust the ZERO point.

This key is not used. (No function)

PRESET COUNT Key

PRESET

COUNT

LOGO Key

LOGO

NET Lamp

PREPACK Lamp

ERROR Lamp

-V-

▼ V

/ T N

-V-

This key is used to preset the number of issuing labels.

This key is used to call the logo data.

Lights when tare is subtracted.

Lights when the SAVE key is depressed.

Lights when this machine is improperly operated or there is a function

error.

Page 10

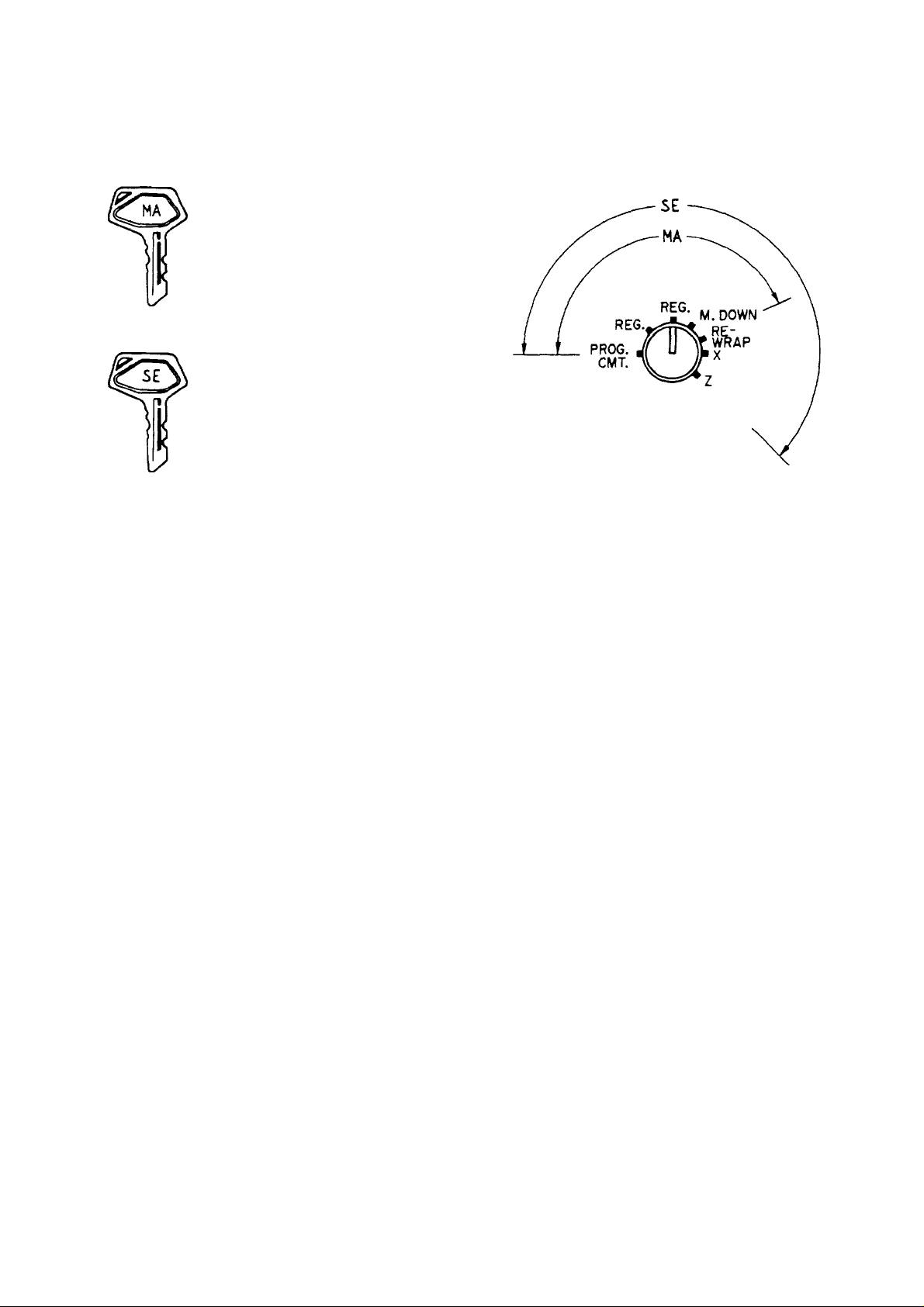

6. CONTROL LOCK

The control lock has seven marked positions.

There are two control keys which will operate these locks.

• Manager Key

This key (MA) will access the

PROG/CMT, REG, M, DOWN,

and REWRAP positions.

• SE Key

This key (SE) will access al

seven positions.

EMI-31055

Each of the following positions on the control lock serves a different function.

PROG. CMT.

---------

With the manager key in this position, it is possible to program data in the PLU

file. Store Address, Message, Printing Position, Date, Time, Initial Set, and Bar

Code Format, etc., may also be programmed.

REG.

These positions are the normal control lock positions which allow the issuance

of printed labels.

M. DOWN

REWRAP

X(Read)

In the Markdown position, it is possible to designate an item for discount pricing.

In the Rewrap position, it is possible to designate an item for rewrapping products.

This position is used to read all the accumulated sales totals stored in the unit.

These totals include individual item totals, group totals, hourly totals, and the entire

file totals. ■

Z (Reset)

This position is used to reset all item file totals.

- 7

Page 11

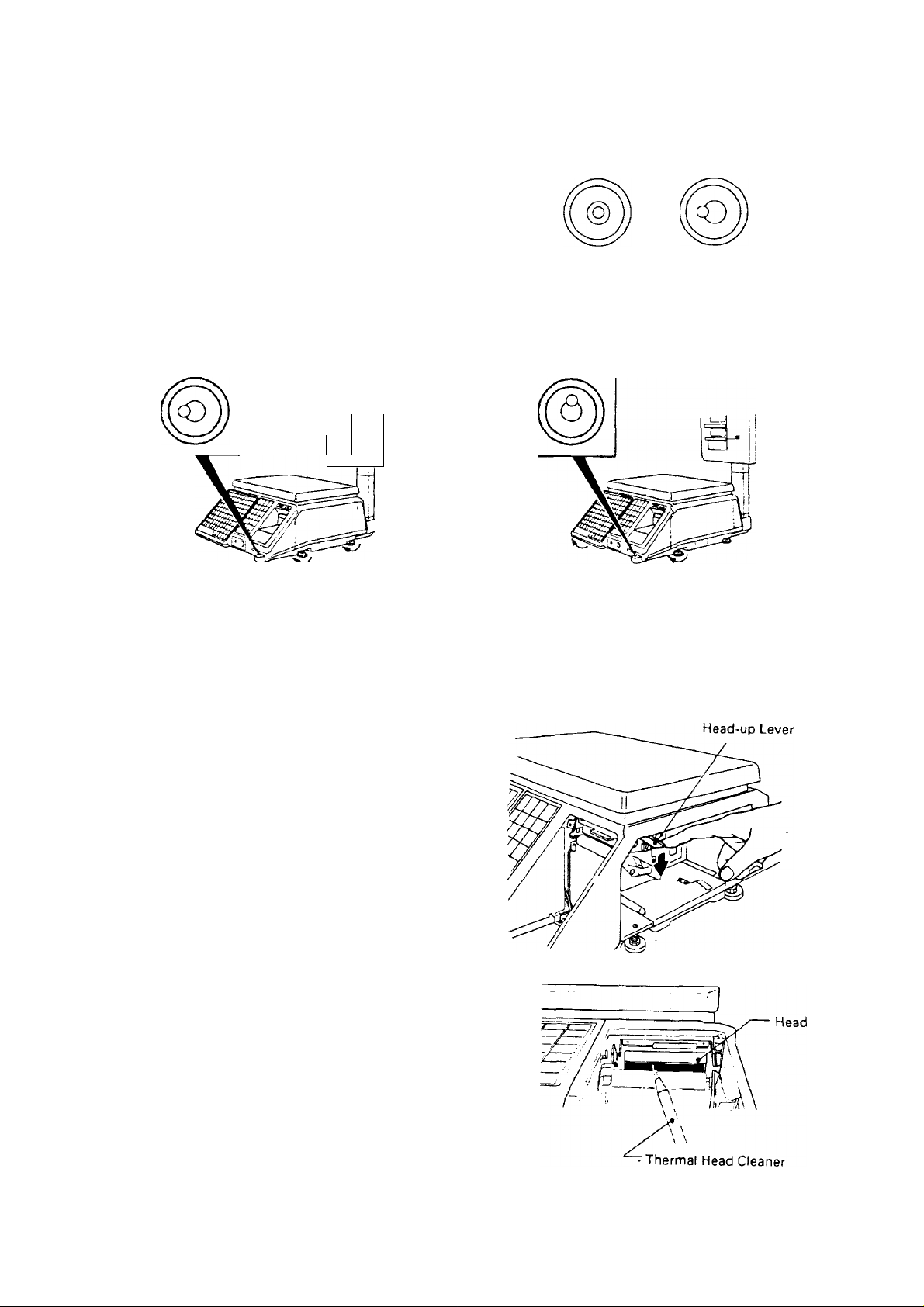

7. LEVEL ADJUSTMENT

EMI-31055

Set the scale on a stable and level surface. Level

the scale by turning the adjustable legs so that

the air bubble is inside the center circle.

When the air bubble moves toward the left side,

turn the right adjustable legs clockwise.

“* 1 i

1 '

___i

Level Gauge

Correct

Incorrect

When the air bubble moves toward rear, turn the

front adjustable legs clockwise.

8. CLEANING THE PRINT HEAD

If the print head is dirty, clear printing will not be produced. It is recommended to clean the head with

the thermal head cleaner every day before starting operation using the following procedure:

1. Remove the printer cover and label cassette.

Then push the head-up lever in the direction

indicated by the arrow.

2. Wipe off the dirt on the darkened portion in the

diagram with the thermal head cleaner.

Then set the label cassette, and push down the

print head.

NOTE: Be careful not to damage the print head

when cleaning.

- 8 -

Page 12

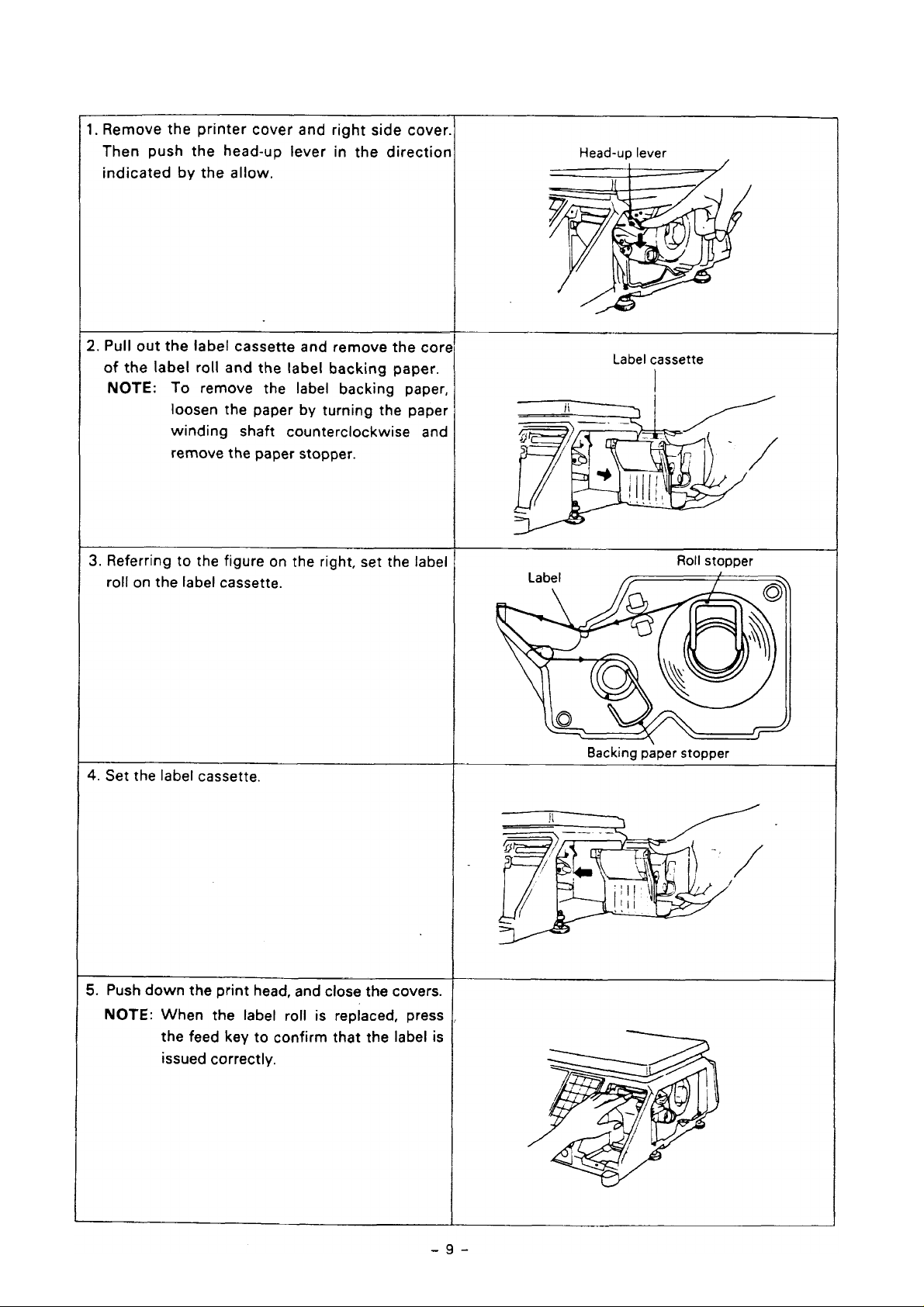

9. REMOVAL AND REPLACEMENT OF LABEL ROLL (for On-demand printing mode)

EMI-31055

Page 13

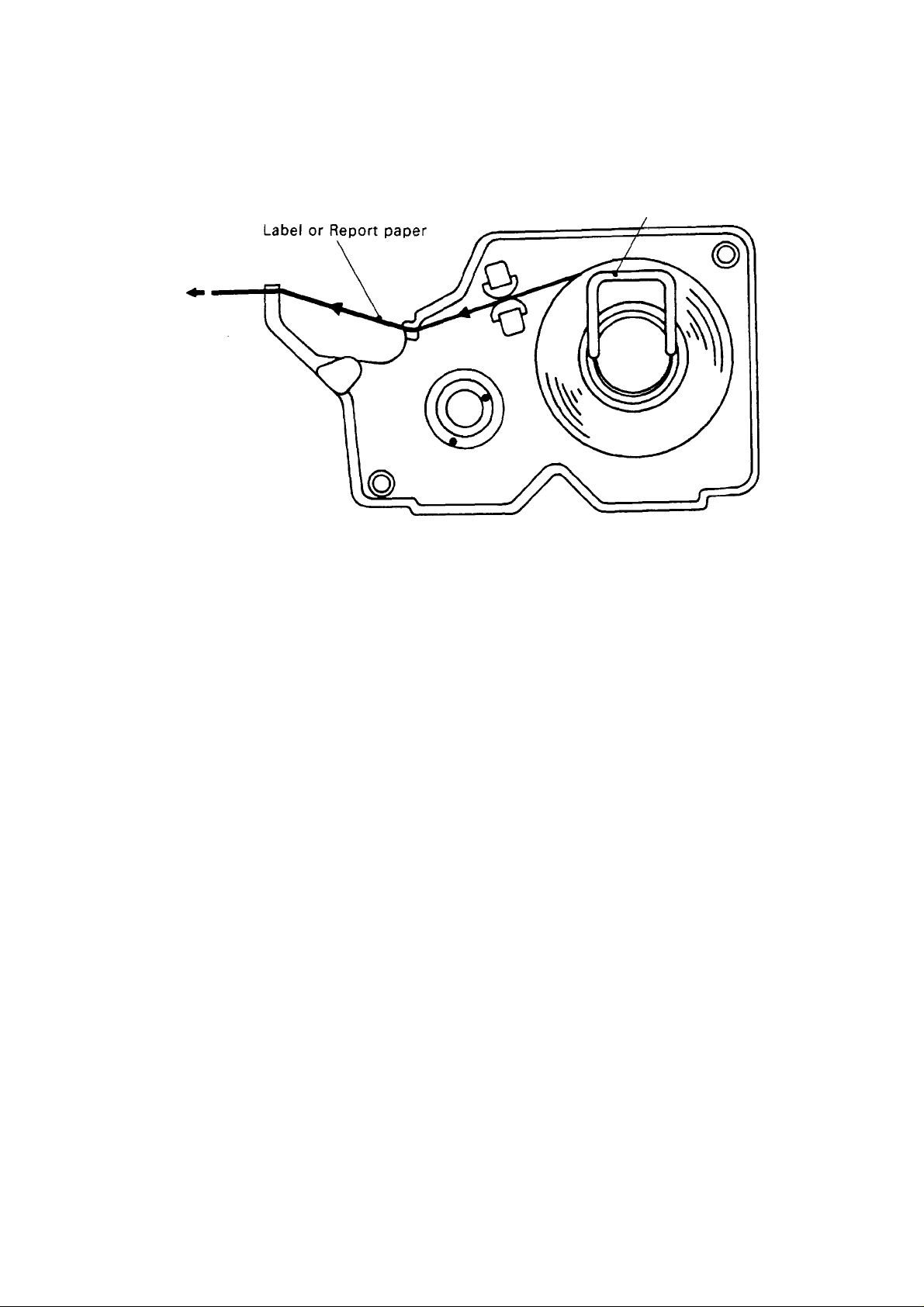

• Label (for Batch printing mode) and Report Paper Threading

EMi-31055

Roll stopper

10. NOTES BEFORE STARTING OPERATION

(1) Be sure to plug the power plug into an AC outlet.

(2) When the power switch is turned on, the scale goes through the test scanning sequence, such as

0000, 0000, 0000, then 1111, 1111, 1111 1

(3) While the scale is in the test sequence, do not put anything on the platter.

(4) Do not move the unit while it is in operation. Should it become necessary to move it at any time,

turn the power switch to the OFF position and be sure to readjust the level indicator after relocaitng

the scale.

(5) Should a power failure occur during operation, remove the commodity from the platter and insert

the power plug into an AC outlet again when power is restored.

(6) If the scale is used with an unrated power source, inaccurate scaling or other errors may occur.

(7) If the Zero Point has shifted during scaling, and no tare is displayed, adjust the Zero Point by

depressing the Zero key.

......

and zeros appear on the displays.

- 10 -

Page 14

11 OPERATION PROCEDURE

11-1. Weighed Article Registration

Control lock : REG, M.DOWN, or REWRAP

Mode SW(2) : WEIGH

Example A) In the case of an article for which PLU ^ 100 and a unit price of $3.00/lb are set in speed

key □ .

ENTER THE PLU #

EMI-31055

AUTO

MANUAL

Depress the speed key.

Place an article on.

(Ex. 5.00 lbs)

; AUTO

1

u

The label is issued.

▼

0.00 P

1

T-BONE STEAK

0.00 3.00

T-BONE STEAK

5.00

MANUAL:

3.00

n

m

PRT/.

The label is issued.

000000

0.00

15.00

AUTO

MANUAL

T- B O N E S T E i K

PAC

PACKED ON

Al

AUG 25

2002d5'315000

5.00 3.00

NETWT S? PRiCE/ibiJ

«IdOI-A BANKERS CIRCLE AT

(Sample label)

NOTE: Depressing a speed key which is not stored in PLU data beforehand causes the scale to enter

an error mode.

- 11 -

1^30

$1 5. 0 0

TOTAL PRICER

Page 15

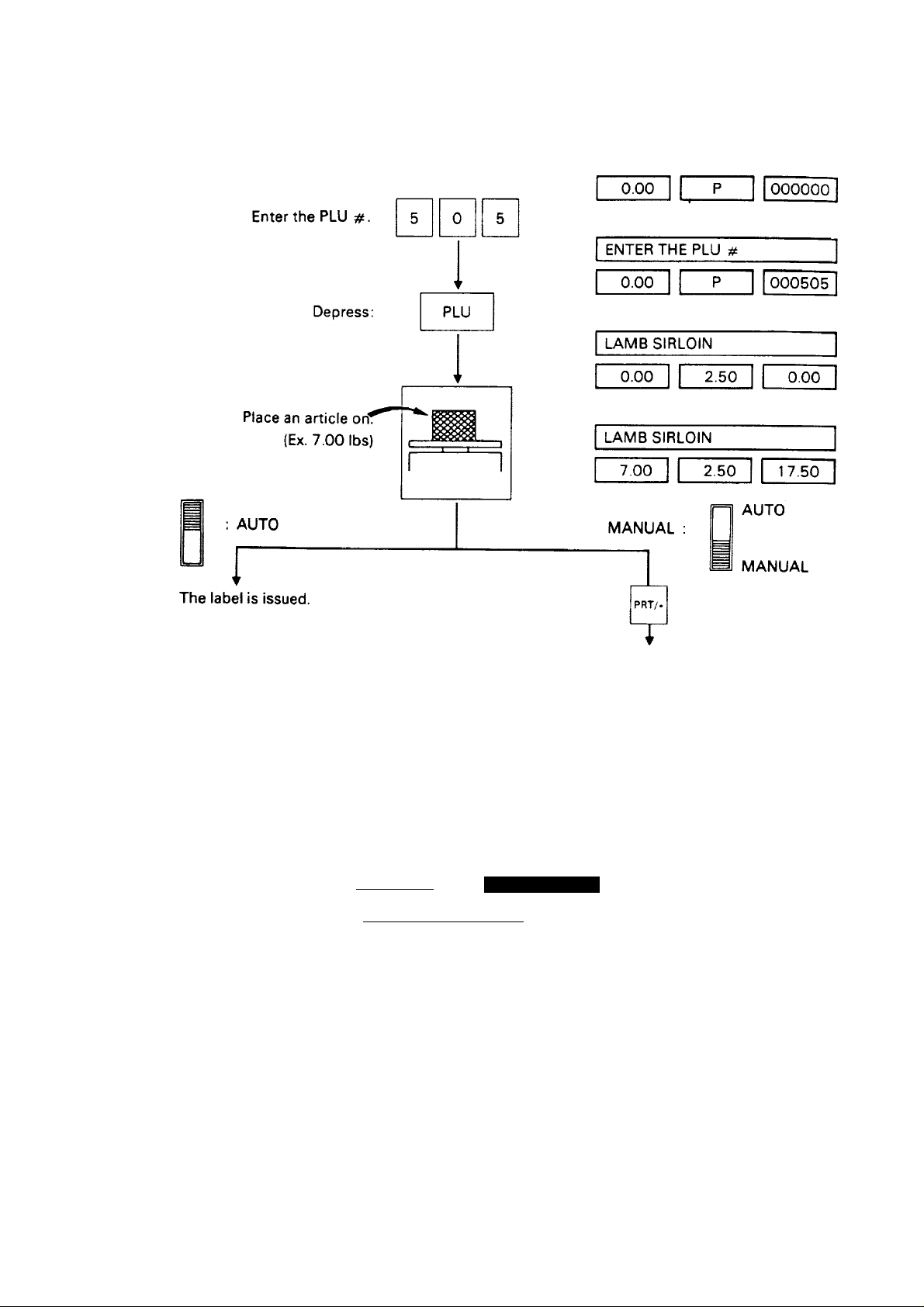

Example B) In the case of an article for which a unit price of $2.50/lb is set for PLU # 505.

ENTER THE PLU #

EMI-31055

AUTO

MANUAL

LA № S I R L O I N

PACKED ON

AU6 25

SELL BY

2040211

017505

7.00 2.50

NETwT igg PRiCE/tb ; 3

4401-* BANKERS CIRCLE AT

AUG 29

$1 7. 5 0

^OTAtPRICtgg

The label is issued.

(Sample label)

- 12 -

Page 16

11 -2. By Count Registration

Control lock : REG, M.DOWN, or REWRAP

Mode SW(2) : BY COUNT

Example A) In the event that a price of $ 1.80/12 pcs is set for PLU #106.

Enter the PLU#. 1 0

EM1-31055

ENTER THE PLU#

000000

Press to cancel

label issue.

AUTO

PLU

PRT/*

CRUSTY ROLLS

MANUAL

P 12

1.80

PLU data is

returned to

the PLU file.

PLU

- 13

CR U S T Y R O L L S

PACKED ON

AUG 21

SELL BY

0Ó0010

12

rats $1.80

NETWr iIS PRICE/it>S5

TEC BAKERY (TEL)888-II 11

4401-A BANKERS CIRCLE AT.

000069

(Sample label)

AUG 27

TOTALPRICEga

Page 17

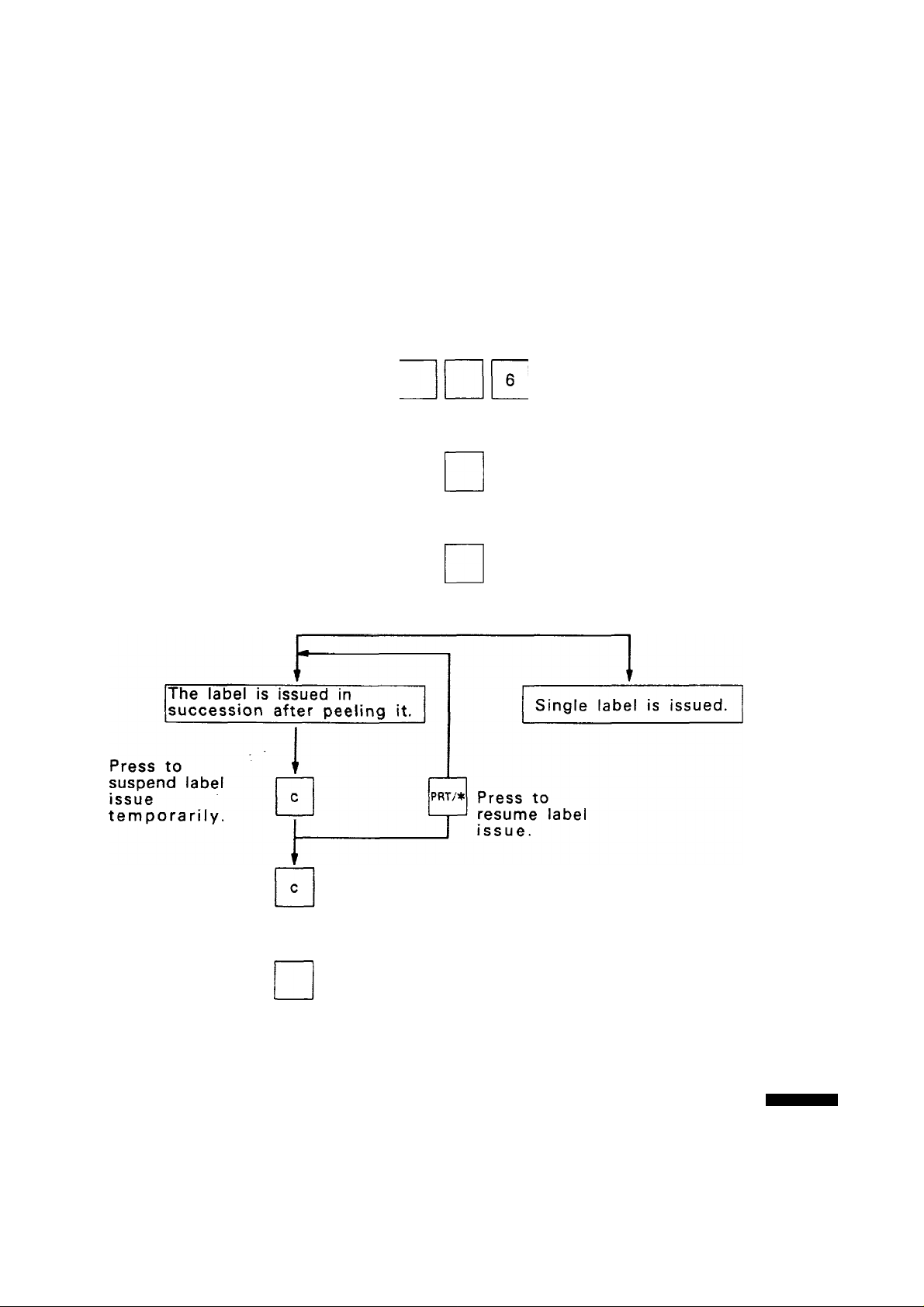

Example B) In the case of purchasing 20 pcs of an article for $ 1.00 of price for 4 pcs. (In the event

that a price of $ 1.00/4 pcs is set for PLU # 113.)

...........................................................

SPLIT PRICE

EMI-31055

Enter the PLU#

Enter the quantity of

purchase.

(Max.2 digits)

AUTO

The label is issued in

succession after peeling it.

113

2 0

ENTER THE PLU#

000000

DONUTS

PLU

P 4 000000

20 1.00

20 5.00

MANUAL

Single label is issued.

DO N U T S

AUG 21

dóóó i i 000037

20 PlfCfS

NETWT igg pRicE/is;a

TEC BAKERY (TEL)888-H1I

4401-A BANKERS CIRCLE AT.

$5 .0 0

TOTALPRtCEB

(Sample label)

PACKED ON

SELL BY

- 14 -

Page 18

11 -3. Fix Price Registration

Control lock : REG, M.DOWN, or REWRAP

Mode SW(2) : FIX

Example A) In the event that PLU #^3036 and a unit price of $3.80/lb are set in speed key Q] ■

ENTER THE PLU #

EMI-31055

Depress the speed key.

Place an article on.

(Ex. 2.00 lbs)

AUTO

r

The label is issued.

0.00

SMOKED SALMON CHUNKS

0.00

''

SMOKED SALMON CHUNKS

2.00

MANUAL

PRT/.

000000

3.80

3.80

T

The label is issued.

SK O K E D S A L H O I I C H U N K S

PACKED ON

m 25

sac BY

"206

003807

2. 00 $3 .8 0

NETwT isg PRicE/!b;i

4401-A BANKERS CIRCLE AT

(Sample label)

- 15 -

SE P 4

Page 19

Example B) In the event that an open unit price is set for PLU #205.

EMl-31055

ENTER THE PLU #

Enter the PLU #.

Depress:

Enter i;he price.

Place an article on.

(Ex. 1.50 lbs)

AUTO

Î

PLU

11 2

0.00 P

0

PORK LOIN RIB CHOPS

’

0.00

PORK LOIN RIB CHOPS

0.00

PORK LOIN RIB CHOPS

1.50

MANUAL

000000

0.00

1.25

1.25

The label is issued.

PO R K L O I N R I B C H O P S

PACKED ON

AU6 25

sac BY

?.02036

301254

Ì.50

NETWT is* PRiCE/^3

4401-A BANKERS CIRCLE AT

{Sample label)

AUG 29

$1 .2 5

TOTAL PRICE

PRT/.

T

The label is issued.

- 16 -

Page 20

11 -4. Preset Count Registration and Operation

Control lock ; REG, M.DOWN, or REWRAP

Mode SW(2) : WEIGH, BY COUNT, or FIX

Example A) When Mode SW. (2) is at the "WEIGH" position

EMl-31055

ENTER THE PLU #

Depress:

Place the shrimps on,

(Ex. 1.50 lbs)’

PRESET

COUNT

i

11.j.

0.00

PRESET COUNT

PRESET COUNT

0 0

50

ENTER THE PLU #

0.00

SHRIMPS

0.00

0.90

SHRIMPS

0.00

0.90

-Tc

PREPACK

SHRIMPS

1,50

0.90

->fc

PREPACK

000000

BALANCE

BALANCE

000000

0.00

0.00

1.35

0

©

(continued on next page)

17

(Sample label)

Page 21

©

EMI-31055

Remove the shrimps.

SHRIMPS

0.00 0.90

-)rr

PREPACK

0.00

When all the specified num

bers of labels are issued.

Clear the preset count.

PRESET COUNT

0.00

PRESET COUNT

50

0 0

BALANCE

000000

BALANCE

<3

Depress:

PRT/.

CAUTION: If the setting of the Control Lock or Mode SW. (2) is changed during operation, the specified

number of the label is cleared.

ENTER THE PLU#.

0.00

P

000000

0

- 18 -

Page 22

EMI-31055

NOTE; To check the remaining number of the specified label during operation or to cancel the specified

number of the label.

SHRIMPS

MANUAL:

Depress:

Depress:

Cancel the

preset count.

1.50 0.90

ENTER THE PLU#

0.00

PRESET COUNT

PRESET COUNT

50

0

1.35

000000

balance

BALANCE

27

27

Depress:

Enter the PLU # again.

Depress: PLU

Place the shrimps on.

MANUAL;

3 0

PRT/.

V

9

:AUTO

ENTER THE PLU#

0.00

000000

1

SHRIMPS

0.00

0.90

0.00

SHRIMPS

1.00 0.90 0.90

The label is issued.

- 19

Page 23

Example B) When Mode SW. (2) is at the "FIX" position.

EMI-31055

ENTER THE PLU #

Depress:

Set the number of labels.

(Max. 99 labels)

Depress:

Enter the PLU #.

Depress:

Depress:

2

1

PRESET

COUNT

r

PR

r

'

PLU

SAVE

0.00

PRESET COUNT

’

PRESET COUNT

5

0

25

000000

balance

BALANCE

0

0

ENTER THE PLU#

0.00

000000

5

MILD CHEDDAR

0.00

0.80

When all the specified num

bers of labels are issued.

Clear the preset count.

MILD CHEDDAR

1.32

-▼r

PREPACK

HI L D C H E D D A R

201320

1.32

NETWT ’ig* PRtCE/ib;j

ddOl-A BANKERS CIRCLE AT

PRESETCOUNT

0.00

PRESETCOUNT

200808"

(Sample label)

25

0

0.80

PACKED ON

AUG 26

sac Br

SEP I

BALANCE

000000

BALANCE

0

0

Depress:

PRT/.

- 20

ENTER THE PLU#

0.00 000000

Page 24

Example C) When Mode SW. (2) is at the "BY COUNT" position.

2

PRESET

COUNT

5

Depress:

Set the number of labels.

(Max. 99 labels)

1

Depress:

PRT/.

Enter the PLU #.

ENTER THE PLU #

PRESET COUNT

PRESET COUNT

0

25

ENTER THE PLU#

CHEESECAKE

000000

BALANCE

BALANCE

000000

EMI-31055

0

0

Depress:

When all the specified numbers

of labels are issued.

PLU

PRESET COUNT

1 0.80

25 0

BALANCE

000000

Clear the preset count.

Depress:

PRT/.

21 -

PRESET COUNT

0 0

ENTER THE PLU#

BALANCE

P 000000

Page 25

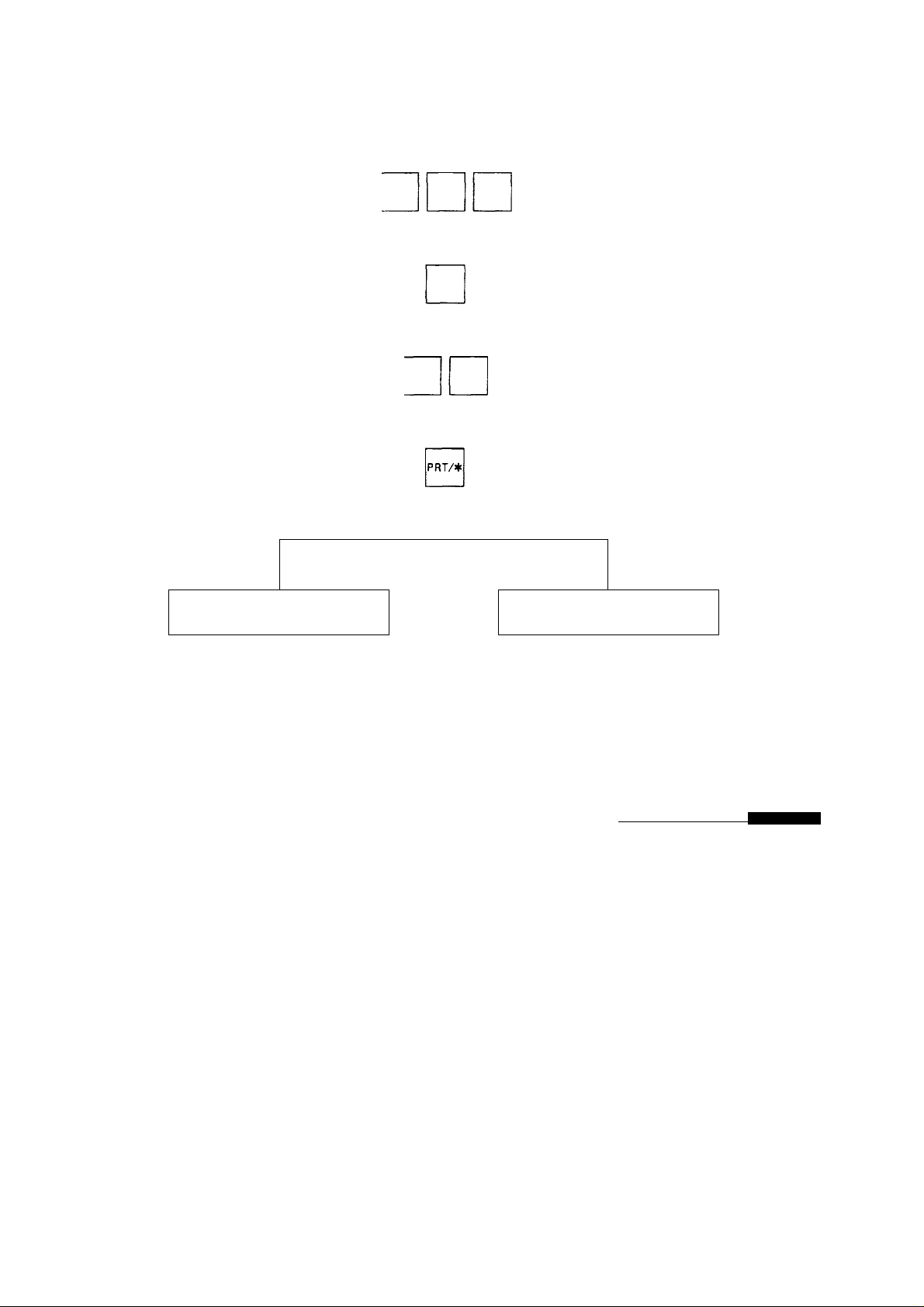

11-5. Issuing Net Weight Label (initial set change will be required)

The unit price and tare weight those are programmed in the PLU will be used as Price and Net

Weight.

The value of the price and net weight could be changed by numeric keys entry.

Control lock : REG, M.DOWN, or REWRAP

Mode SW(2) : FIX

Example) In the event that a unit price of $2.10 and tare weight of 1 lb are set for PLU #116.

EMI-31055

Enter the PLU#

Enter the new price.

Enter the new weight.

1 1

PLU

2 0 0

PRT/«

13 0

ENTER THE PLU#

0.00 000000

ENTER PRICE ($) 2.10

ENTER PRICE ($) 2.00

ENTER WT. 1 LB 0 02

ENTER WT. 1 LB 30 02

AUTO

The label is issued in

succession after peeling it.

Press to

suspend I _

label issue U

temporarily.I-

Press to

cancel label [ Q

issue.

PLU data

is returned

to the

PLU file.

MANUAL

22 -

Page 26

NOTE 1; With this procedure, the tare weight programmed in the PLU is displayed and printed.

EM 1-31055

Example) Tare Weight: 1 lb

The weight which is entered to change the tare weight is printed out as it is.

Example) Weight: 1.30 lbs NET WT. 46 OZ (1LB 30 OZ)

NET WT. 16 OZ (1LB OOZ)

______________

I correct weight

correct weight 2LB140Z

LE H O N M E R I N G U E P I E

Ж5Е=52. $ис«:зг. $оа=гг.

PACKED ON

AUG 21

SEUL BY

200 n 6

NETWT В О TOTAL PRICE O

202002

AUG 25

$

2.00

NET I I T. 46 0 Z( 1L B 30 0 Z)

TEC BAKERY (TEL)888-nil

<1401-A BANKERS CIRCLE AT.

(Sample label)

NOTE 2: The NET WT. label can be issued by setting initial set #2-7 to one of "1" to "4", #5-3 to "1'

and # 7-1 to "0".

23 -

Page 27

EMl-31055

11-6. Tare Function Procedure

There are two kinds of tare subtraction procedures, one is "Direct tare", the other is "Preset tare".

1) Direct tare subtraction

WEIGHT

UNIT

PRICE

TOTAL

PRICE

Put on the tare.

(Ex.0.20 lbs)

Depress:

Weighing operation

(Ex. Depress speed key Q.

and place an article on.)

T

i

1

1

3.00 lbs

0.00

0.20

0.00

NET

0.00

NET

3.00

-Tr

NET

000000

000000

p

3.00

000000

0.00

3.00 9.00

MANUAL:

PRT/*

:AUTO

The label is issued.

0.00

000000

Remove the article

together with the tare.

The tare weight is cleared automatically.

NOTE: Tare weight subtraction is available up to 30 lbs. When tare weight subtraction is in operation,

however, the scalable range for net weight becomes less by the amount of the tare.

(Net weight = Gross weight — Tare weight)

- 24 -

Page 28

2) Preset tare subtraction

Enter the tare weight.

(Ex. 0.20 lbs)

WEIGHT

0.00

0.00

UNIT

PRICE

P

P 000020

EMI-31055

TOTAL

PRICE

000000

Depress:

Put on the tare.

Weighing operation

(Ex. Depress speed key Q

and place an article on

T

I

- 0.20

-▼c

NET

0.00

NET

0.00

NET

5.00

“T'"

NET

P

P

000000

000000

2.00 0.00

2.00

10.00

The tare weight is

cleared automatically.

The tare weight is

cleared automatically.

25 -

0.00

-Tc

NET

0.00

2.00

0.00

000000

Page 29

3) Preset tare subtraction (PLU including tare weight)

(only for backroom type)

Enter the PLU #.

WEIGHT

0.00

UNIT

PRICE

P

EM 1-31055

TOTAL

PRICE

000000

Depress:

Temporarily change the

Tare weight.

New Tare weight.

PLU

T

’

2 5

r

T

-I

- 0.50

NET

0.00

0.25

- 0.25

NET

0.00

NET

0.80

0.80

0.80

0.00

Remove the article

together with the tare.

The tare weight is not

cleared automatically.

1.50 0.80

NET

- 0.50

NET

1.20

0.80

- 26 -

Page 30

11-7. SAVE Key Operation Sample

The SAVE key is used to save the tare weight and unit price after taking the article off the platter.

WEIGHT

0.00

UNIT

PRICE

P

Place the tare on.

(Ex. 0.50 lbs)

0.50

P

EMI-31055

TOTAL

PRICE

000000

000000

Depress:

Enter the PLU #.

Depress:

The unit price and

tare are fixed.

Place an article on.

(Ex. 5.00 lbs)

0.00

-ir-

NET

0.00

7Tr

NET

0.00

‘7'

NET

0.00

-▼c

-▼c

NET PREPACK

5.00

NET PREPACK

P 000000

P

000100

3,00 0.00

3.00 0.00

3.00 15.00

Clear the tare weihgt.

1

0

PLU

- 27 -

- 5.00

-Vc -Vc

NET PREPACK

- 0.50

-▼ 7

NET

0.00

0.00 P

3.00

3.00

3.00

0.00

000000

Page 31

11-8. VOID Key Operation Sample

On depressing the VOID key, the data of the last registration is subtracted from the memory.

ENTER THE PLU #

EMI-31055

Depress the speed key.

0.00

T-BONE STEAK

0.00

T-BONE STEAK

5.00

T-BONE STEAK

000000

3.00

3.00 15.00

0.00

Depress:

VOID

T-BONE STEAK

5.00 3.00 15.00

- 28 -

Page 32

11-9. Date Change

The date can be changed temporarily.

Control lock ; REG, M.DOWN, or REWRAP

Mode SW(2) : WEIGH, BY COUNT, or FIX

EMI-31055

ENTER THE PLU #

Month

Day

Year

0.00

DATE

(Current setting date) ■

DATE

DATE

ENTER THE PLU #

000000

082589

000009

091589

- 29

0.00

DATE

DATE

ENTER THE PLU#

000000

091589

082589

Page 33

EMI-31055

11-10. Selection of Print Item on Registered Label

This operation specifies whether each print item on the issued in registration labels is to be printed

or not.

Control lock; REG, M.DOWN, or REWRAP

Mode SW(2): WEIGH, BY COUNT, or FIX

When using VARIABLE LENGTH LABEL (option), select Initial Set #4-6:0 and 2-8:4.

When using PERIOD OF RELISH (3rd DATE), select Initial Set #7-8:1.

ENTER THE PLU #

Depress:

Select the item.

(Refer to NOTE.)

Print •—• No print

Depress:

NOTE;

Entry Item

PROG

O

PRT/-

ON: Print

OFF: No print

Entry Item

PACKED ON DATE

PACKED ON DATE

ENTER THE PLU #

0.00

ON

OFF

000000

Packed on date

Sell by date

Commodity name

Weight

Print/No print Total price

Print/No print

PrInt/No print Store code

Print/No print

Unit price Print/No print

- 30 -

Print/No print

Bar code Print/No print

Print/No print

Ingredient message Print/No print

10 Piece count

11

Cooked by date

Print/No print

Print/No print

Page 34

11-11. Setting Automatic Display Switching Time

When initial set #6-4 is set to "2” (standard), it is available to specify the time before a scrolling

message appears automatically on hte commodity name display after a label has been issued

or after "ENTER THE PLU#" has been displayed.

Control lock: REG, M.DOWN, or REWRAP

Mode SW(2); WEIGH, BY COUNT, or FIX

EM 1-31055

Depress:

Enter the special code "20'

PROG.

PACKED ON DATE

02

ENTER THE TIME

ON

ENTER THE TIME 40

ENTER THE PLU #

Set the time.

(1 ~ 99 sec.)

Depress:

Current setting time

ENTER THE TIME

ENTER THE TIME

PRT/*

3

15

15

ENTER THE PLU #

NOTE: Automatic display switching occurs provided the control lock is set to "REG", "MARK DOWN'

or "REWRAP". It does not occur if the unit price has been saved.

- 31 -

Page 35

11-12. Calling and Printing Grade Line

Control lock : REG,M.DOWN, or REWRAP

Mode SW (2) ; WEIGH, BY COUNT, or FIX

Enter the PLU#.

EMl-31055

ENTER THE PLU#

000000

Enter the grade line#.

PLU

PRT/*

PRT/*

The label is issued.

CHEESE AND ONION BANS

P 3 1.05

ENTER THE G.LINE#

CHEESE AND onICn buns

BARGAIN SPECIAL

P 3 1.05

CHEESE & ONION BUNS

BARGA

N SPECIAL

PACKED ON

saL BY

000010

3 P11CIS $1.05

NETWT IE? PRICE/Ib¿3

TEC BAKERY (TED888-I 111

4401-A BANKERS CIRCLE AT.

000052

TOTAU PRICE 63

AUG 21

AUG 28

- 32 -

(Sample label)

Page 36

11-13. Calling and Printing Logo

When the initial set # 10-7 is set to " 1" (option), the logo containing picture, mark, POP message, etc.

can be printed on the ingredient label which having 12 lines or more.

Logo data is created on the PC and stored into the memory through the CMT interface.

EMI-31055

Control lock

Mode SW (2)

Enter the logo#.

(1-1 3)

REG,M.DOWN, or REWRAP

WEIGH, BY COUNT, or FIX

LOGO

PRT/*

Start the label issue

operation.

ENTER THE LOGO#

ENTER THE PLU#

000000

NOTE: The called logo is effective till it is canceled.

LOGO

PRT/*

ENTER THE LOGO# 10

ENTER THE PLU#

P 000000

- 33 -

Page 37

11.14 FUN Automatic Reception

Control Lock ; REG, M.DOWN or REWRAP

Mode Switch (2) ; WEIGH or BY COUNT

EMI-31055

ENTER THE PLU #

IN PROCESS

d

ENTER THE PLU #

No

DATA ERROR

Yes

ENTER THE PLU #

ENTER THE PLU #

0.00

0.00

0.00

0.00

F -

F -

000000

000000

See NOTE.

ERROR

000000

000000

- 34 -

Page 38

NOTES: 1.

—„^Description

Error Name

Error Name

HARD ERROR

DATA ERROR

TIME OUT

ERROR

Error Description

7-seg.

Parity error

01

02 Overrun error

04 Framing error

Verify error

08

Character over error

10

BCC error

20

Data error

40

80 Timeout error

Received Text *1

SEND

P U Ml М2

О

X

о

X о

О

О : Error occurs

X : No error occurs

X

RECEIVE

Р и Ml

О

О

X о X

О

EM1-31055

Cause

М2

Hard error

Compared contents do not

correspond.

Hard error

BCC is not correct

•3

Text with designated time has not

been received.

P:

U;

Ml:

М2:

When several error occur at the same time, all relevant data are added and

*2

PLU + ING

UNIT PRICE

MISC. 1 (ADDRESS, LOGO)

MISC. 2 (SPEED KEY)

displayed in the 7-segment display.

*3

Cause of Errors

Q RAM for LOGO does not exist when LOGO is selected in initial set.

(D Transmitted LOGO data exceeds the number of dots to be colored selected in

the initial set.2.

2. Data is automatically received in registration mode. However, scale operation stops

during reception.

3. After clearing an error, the registration initial display is shown. Data other than head

data is not received.

4. When the header text is received, all contents previously set are cleared.

- 35 -

Page 39

12. TOTALOPERATION PROCEDURES

When the control lock is set to the "X" or "Z” position, it is available to issue READ or RESET reports.

Both kinds of reports can be issued on labels or report paper.

Control lock: X or Z

"X" position: READ

The totals will not be cleared as they are printed on labels or report paper.

"Z" position; RESET

The totals will be cleared as they are printed on labels or report paper.

12-1. Hourly Report

REPORTS READ

1

EMI-31055

The labels of hourly report are issued consecutively.

4

PRT/.

HOURLY REPORT

IN PROCESS

1

(Sample labels)

- 36

Page 40

12-2. Grand Total Report

Select the total memory.

Day total:

PRT/-

EM1-31055

REPORTS READ (RESET)

GRAND TOTAL

SELECT DATA FILE

1

NORMAL 1

Mark Down total:

Rewrap total:

PRT/-

2

3

Total label including total weight, items, and amounts is issued

Day total:

GRANO TOTAL

PACKED ON

NO 5Q.U BY

282.20 567

№TWT 'S' PPICE/Idij

ddOI-ft BANKERS CIRCLE AT

AU6 25

904.92

TOTALPRICEgg

(Sample label)

Mark Down total:

GRAND TOTAL

PACKED ON

NO

AUG 25

SEU. BV

MARK DOWN 2

REWRAP 3

GRAND TOTAL

NOIHL R£f€

nOCHINEtag

STOREI 31

COUNT «EIGHT OOLLflfiS

TOTH 365 207.49 604.08

(Sample report)

AUG2S8Ì

17i43

Rewrap total:

40.26 9 62.38

NET WT lE? PRICE/® 55

4401-A BAMkERS CIRCLE AT

* QTAt PRICE

(Sample label)

GRAND TOTAL

PACKED ON

OK AUG 25

RP SELL BY

17.40 48 54.75

NETWT P9IC£/ib55

4401-A BANKERS CIRCLE AT

(Sample label)

'OTAL PRICE

-37

Page 41

12-3. PLU Report

Select the total memory.

Day total:

PRT/-

-►

EMI-31055

REPORTS READ (RESET)

GRAND TOTAL

SELECT DATA FILE

1

NORMAL

1

Mark Down total:

Rewrap total:

Select the search code.

PLU#

UPC#

PRT/-

2

MARK DOWN 2

REWRAP

ENTER THE SEARCH CODE

- 38 -

Page 42

@ Individual Total

Ex.) Individual PLU Total (PLU # 100)

EMI-31055

PLU#

PLU TOTAL

PACKED ON

AUG 25

PLU# SELL BY

000100

73.90 26 221.70

netwt igg ppicE/ibii

dd01-A BANKERS CIRCLE AT

(Sample label)

(§) Block Total

Ex.) UPC Block Totai(UPC#200 ~ 299)

0

0

1

PRT/.

PLU#

IN PROCESS

TOO

PLU REPORT

PLU I 000100 NOmi

nRCHIHEtSS

STOREI31

PLU I COmT ICIGNT DOLLARS

000100 r-MHE STEAK

26 73.90 221.70 100.0

t OF GRAND (DOaARSi 36.7

(Sample report)

UPC#

READ

AUG 25 86

17:45

iX

2 —

PLU TOTAL

PACKED ON

UPC HO sell by

0002-

122.30 34

NETWT gg PBlCE/lbj? ^

ddOI-A BANKERS CIRCLE AT

(Sample label)

AUG 25

328.46

'ALOOiCEg^

2

PRT/>

O

O

UPC#

IN PROCESS

PLU REPORT

UPC 0002- lOWl READ

UPCCOUNT

000245

000249

000267

TOTAL

AACHIICI88

STOREI 31

NEIBIT

26 73.90

4

23.20

4

25.20

34

122.30

OF GRAND (DOLLARS)

AUG 25 86

17:45

DOLLARS

$ ■/,

221.70 67.5

5.7

18.56

26.9

88.20

100.0

328.46

54.4

(Sample report)

NOTE: The key represents 0 through 9. Most significant digit in starting number followed by

appropriate number of the keys.

- 39

Page 43

Zone Total

Ex.)PLU Zone Total (PLU#3001-309 1)

EM1-3105S

PLU#

PLU TOTAL

PLU# Md SQ.L BY

003001-003091

P*CKED ON

0

FOR

3

0 9

PRT/.

1

PLU# 3001

3001 -

3001 - 3091

IN PROCESS

46.54 15 105.06

NETWT 'JS PPIC£/IDi3

<1<101'A BANKERS CIRCLE AT

-Q'A^oRlCi 63

(Sample label)

- 40

Page 44

(B) Entire PLU Total

EMI-31055

PRT/-

PLU TOTAL

PACKED ON

PLU# N4 SELL BV

ALL

200.73 362 601.68

NETWT 'S? PWCE/ib

ddOl-A BANKERS CIRCLE AT

(Sample label)

AU6 25

PLU 1 HL

iMOINEI 88

SrOREl 51

PLU 1 CflUKT «EIGHT

00003S

CHEESECfltt

000059

000052 REDOELICIOIË APPLES

000077

000100

000105 BEEF LIVER

000108

000205

000721

000781

55 0.00

ajTTER COORIE

70 0.00

PSOOUCE Of U.S.fl.

HOVEL ORONGES

i-SONE 5TE0R

SlRLOiH STEOK

m

LOIN RIB CHOPS

CHKXEN «ING

TURXEr DRUISTICRS

NO№OL

U 0.00

72 O.M

26 75.90

t 25.20

A 25.20

4 25.20

67 Q.DO

5 6.69

OUG

DOLLORS 1 V.

42.40

5.50 0.6

19.50 3.2

56.00

221.70 36.8

18.56

88.20

45.56

18.40

3.x

PLU REPORT

REOO

25 86

19:45

7.0

6.0

5.1

14.7

7.5

3.1

0.5

COO FILETS

005001

SHORED SOLHON

005051

lOTH

SHÎIHPS

562 200.75

% OF OfifM) tOOLLORS) 100.0

005091

(Sample report)

5 5.26

CHUNRS

4 25.20

i 16.08

0.3

2.10

15.9

95.76

1.2

7.20

601.68 1X.0

- 41

Page 45

12-4. Combination Report

The total reports or setting reports are printed in the order of the specified tables (max. 8 tables).

Depress:

Select the table:

Table # 1

Table #2

Table #3

EM1-31055

Table #7

Table #8

Depress;

NOTE 1; If an error occurs while the combination reports are being printed, the data which is not printed

out is printed as the "Canceled report” after the combination reports are printed.

NOTE2: With the control lock set to the "Z” position, only the total reports are printed out.

- 42 -

Page 46

HOURLV REPORT

REPO

HOUR

16-17

17-18

18-19

19-X

X-21

rOTPL

I1ACHINEÌ88

STOREI 31

COUNT

31

78

160

92

61

422

PX 5 86

HEIGHT

15.61

$

30.64

J

XI. 22

$

6.76

s

10.92

i

265.15

17:47

OOLLPRS

18.60

H 2.6

109.92

X

15.2

506.43

t X.2

43.60

X

6.0

42.66

^ 5.9

721.21

GRAND TOTAL

NORML

nACHIHEI38

STORE« 31

REX

PX586

17:47

PROOUCE

Of

y.S.P.

000077 NWa ORPNGES

XOtX T-BONE STEPK

0X105 XEF LIVER

0X1X 5IIS.0IN STEW

0X205 PORK LOIN RIB CHOPS

0X724 CHICKEN UING

0X781 TURKET ORUHSilCXS

W O.X 19.50 3.2

72

0.® 36.x 6.0

26 73.x 221.70 36.7

4 23.x 18.56 3.1

4 25.x 88.x 14.6

4 S.X 45.36 7.5

67 O.X 18.40 3.0

3 6.69 3.x 0.5

X3X1 CX FILETS

3 5.26 2.10 0.3

X3036 SitiKEO SPLnON CHUNKS

X3091 SDIHPS

TOTX

4 5.x 95.76 15.9

8 16.K 7.x 1.2

365 X7.49

'/.OFORPNO

604.x 1X.0

(OXLPRS) IX.0

EM1-310S5

TOTPL

COUNT

365

HEIGHT

X7.49

DOLLARS

604.x

GRAND TOTAL

NORKDOUN REX

TOlPL

nPCHINEI88

STOREI 31

COUNT

HEIGHT

9

40.26

PX586

17:47

XLLPI5

62.38

GRAND TOTAL

TOTPL

REHRPP

nPCHIHEi S

STOREI 31

COUNT

HEIGHT

48

17.40

REX

PX586

17:47

OXLPRS

54.5

PLU REPORT

PEU I PEL HORdPL IKPO

POCHINEI S8 PUG 5 86

SIOREI 31 17:47

aoi caiir i€iar ooll*s

OQOOIS RILD CHEDDPfi

01)035 OCESECaff

3 6,76

53 0.00

'ifTER COOKIE

7.40 0.4

42.40 7.0

PLU 1 XL

PLUl

COUNT 1CIGHT

000505

0X724

TOTX

nXHINEI X

STOREI 31

LPX SIRLOIN

CHICKEN HIX

H OFGRPNO

REHRPP

OXLPRS

3 17.40

45 fl.X

48 17.40

iOOLLPRSl

PLU REPORT

UPC X

PLU REPORT

,L

NPCHINEI X

IK

COUNT HEIGHT

X0267

X0315

X2X5

Torx

6 34.x

9 40.26

( Sa mp l e r e po r t)

STOREI 31

2 5.46

1 O.X 2.x 4.0

7. OFGRfN)

XRKOONN

OOLLPRS

(OOLLPRS) 1X.0

PUG 586

43.50

11.5

54.75

PX 5X

16

.x

43.M

62

.x

REX

17:47

5

79.5

X.5

1X.0

1X.0

REX

17:47

$

X

26.3

69.7

IX.O

X

- 43 -

Page 47

EMI-31055

13. ACTION FOR ERROR MESSAGES

Take the following action if an error message appears on the commodity name display with the buzzer

sounding.

• Label Issue Mode

Control lock: REG./MARK DOWN/REWRAP

Message

DATA ENTRY ERROR

PLU NOT FOUND

Error in key input.

The PLU# being called out is not

Cause Solution

registered.

TOTALS OVERFLOW

GRAND TOTAL or PLU TOTAL

memory has overflowed at the

time of issuing a label.

PLU DATA ERROR

PRT FAILURE DETECTED

Error of PLU data.

Printer trouble. 1. Check that the label and printer

CASSETTE ERROR Label cassette is not set correct

ly.

Cassette switch is not set cor

rectly.

Depress the 0 key, and re-input.

Depress the [C] key, and check

the PLU data.

Depress the key, and turn the

control lock at "Z" position. Then

sum up the overflowing memory.

Depress the [C] key, and check

the PLU data.

head are set correctly.

2. If the label home position is

misaliqned. press the iFEEDI

key.

Set the cassette correctly.

Set the cassette switch

correctly.

LABEL SENSE ERROR

Setting of control lock position

and cassette switch is not cor

rect.

The label interrupts the sensors.

When control lock position is set to

other than "X" or "Z", set the cas

sette switch to "LABEL POSITION".

Depress the [C] key, then the

IFEEDI kev. and remove the label.

- 44 -

Page 48

• Read and Reset Mode

EMI-31055

Control lock; X (read)/Z (reset)

Message

PLU NOT FOUND

Corresponding PLU # or UPC is

not registered.

NO REGISTED REPORTS

There is no combination report

setting data.

PRT FAILURE DETECTED Printer trouble

CASSETTE ERROR

Label cassette is not set correct

ly.

LABEL SENSE ERROR

The label interrupts the sensors.

Cause

Solution

Depress the key, and enter the

correct PLU#,

Depress the[C]key, and check the

combination report tables.

Same as in the label issue mode.

Set the cassette correctly.

Depress the [C] key, then the

(FEEDI kev, and remove the label.

45

Page 49

14. LABEL PRINT FORMATS

1) Weighing Label

EMI-31055

46

Page 50

4) Ingredient and Period of Relish Label

EMI-31055

5) Net Weight Label

CHOCOUTE

n«IW ilOklDC.IHIttri« fumTw

tcii m i/ts V n nitssi» sawit

rnkmim.

m ¡MKirantst.tfKTMLE OK W

wTiiB.

6030"80300l

n t

an fl№T ui.iitcii.

AUG 27

Moca M

AUG 30

$3l’

KT WT m WICt/>

taiAl PRICE i5

NETKT.580Z( 3LB100Z)

dd01-A BANKERS CIRCLE AT

Commodity Name

Ingredient Message

Price

Net Weight

47 -

Page 51

6) Bar Code Change Label

EM1-3105S

CHEESECAKE

....

iiif3irMI:lbMtSflll( IHR.VITIKII ll>

1lt!.»eui№№.

NOV 29 DEC 2

Nr*~B PRiC£/a B

eHT.360Z( uBzoozi

1"200?2r'6C

4dOI-A BANKERS CIRCLE

-Commodity Name

-Ingredient Message

-Price

-Net Weight

-Bar Code

-Store Address

- 48 -

Page 52

7) Read & Reset Mode

• Hourly report

EMI-31055

"READ" mark(*; RESET)

Total Weight-

------

NETWT igg PHicE/ib;3 '

4401-A BANKERS CIRCLE AT

• Grand total report

Total Memory mark

N: Day Total .

(

M: Mark Down Total i

R: Rewrap Total '

HOURLY REPORT

I PACKED ON

,P A AU6 25

17-18 0 3Y

-Total Items

r

30.64 78

109.92-

-Total Amounts

'AlFPiCE^B

GRAND TOTAL

•NO

282.20 567 904.92

NETWT PR!CE,';b;3

4401-A BANKERS CIRCLE AT

PACKED ON

AUG 25

SELL BY

TOTAL PRICE ga

HOURLY REPORT

PACKED ON

TOTAL

265.15 422 721.21

NETWT 'JI? PRlCE/lbja

4401-A BANKERS CIRCLE AT

AUG 25

SELL BY

'O-^ALfRICEg?

PLU total report

Search code

PLU #100-

Zone #

3001 - 3091

Individual PLU Total

PLU TOTAL

PLU# N0

000100

73.90 26

NETWT igg PBiCE/ib;3 *

4401-A BANKERS CIRCLE AT

Zone Total

PLU TOTAL

PLU# N4

-003001-00309!

46.54 15

NETWT 'JS PRICE/lbjj

PACKED ON

AUG 25

SELL BY

221.70

*ALFRlCEgB

PACKED ON

AUG 25

SELL BY

___

105.06

..............

-Q-ALPR'CEgg

Search code -

Block #200 ~ 299-

Block Total

PLU TOTAL

-| PACKED ON

I AUG 25

WPC N4 SELL BY

0002-

122.30 34

NETWT '15? PRiCE/ibSa '

4401-A BANKERS CIRCLE AT

Entire PLU Total

PLU TOTAL

PLU# N4 saL BY

ALL

200.73 362 601.68

NETWT 'E? PRICE/lb¿3

328.46

Q-AL PRICE gg

PACKED ON

AUG 25

^OTAtFFtCL^B

4401-A BANKERS CIRCLE AT

4401-A BANKERS CIRCLE AT

49 -

Page 53

EMI-31055

15. BEFORE YOU CALL FOR SERVICE

It is our primary concern to give you full satisfaction and better service. If, however, any problem arises in

connection with the operation of this scale, please check the following points before calling for service.

A) Is the power plug fully plugged into an AC outlet?

B) Is the power switch turned ON ?

C) Is AC power being properly supplied to the outlet? (Check it using another electric appliance.)

D) Check the circuit breaker.

E) Has there been a power failure of any sort ?

F) Has the operation been carried out in the correct order ?

This scale has been manufactured under strict quality control. If you have any trouble, however, DO NOT

ATTEMPT TO FIX IT BY YOURSELF. Pull the power plug out of the AC outlet, and contact your TEC

representative.

NOTE: The specifications are subject to change without notice.

- 50 -

Page 54

16. APPENDIX

SL66 Seríes Bilingual Specification

us type; Owner’s Manual at page 32

NOTE: The print position of the grade line is selectable by setting the Initial #3-6.

EMi-31055

No. of lines for commodity name

1 line (No print in the 2nd, 3rd-.

and 4th line.)

2 lines (No print in the 3rd and

4th line.)

3 lines (No print in the 4th line.)

4 lines

#3-6

1

0

1

0

Print position of the grade line

• A grade line is printed in the 1st line. (Left-justification)

• A commodity name is printed from the 2nd line.

• A commodity name is printed from the 1st to the 3rd line.

• A grade line is printed in the 4th line.

(Right-justification)

• A grade line is printed in the 1st line. (Left-justification)

• A commodity name is printed from the 2nd line to the 5th

line,’ provided that the total number of lines of the grade

line + commodity name + Ing. line does hot exceed the

max. line of the label when using the Ing. label.

• A commodity name is printed from the 1st line to the 4th

line.

• A grade fine is printed in the 4th line, provided that the

total number of characters of commodity name + grade line

does not exceed 26 characters. (Right-justification)

- 51

Page 55

TOSHIBA TEC CORPORATION

PRINTED IN JAPAN

Loading...

Loading...