Page 1

TEC Electronic Computing Scale

SL-5900 (US. Version)

Owner's Manual

Document No. EM1-31015

TEC

Table of Contents

TOKYO ELECTRIC CO., LTD.

Page 2

TABLE OF CONTENTS

Page

• INTRODUCTION ....................................................................................................................................... 1

1. SPECIFICATIONS ...................................................................................................................................... 5

2. OVERVIEW ............................................................................................................................................... 7

3. REMOTE DISPLAY ..................................................................................................................................... 7

4. KEY LAYOUT ............................................................................................................................................. 8

5. KEY FUNCTIONS ..................................................................................................................................... 10

6. LAMP FUNCTIONS .................................................................................................................................. 13

7. CONTROL LOCK....................................................................................................................................... 14

8. LEVEL ADJUSTMENT ............................................................................................................................. 15

9. CLEANING THE PRINT HEAD ................................................................................................................ 15

EM1-31015D

10. REMOVAL AND REPLACEMENT OF LABEL ROLL

11. REPORT PAPER THREADING ................................................................................................................ 17

12. BEFORE STARTING OPERATION .......................................................................................................... 17

13. OPERATING PROCEDURES ................................................................................................................... 18

13.1 Weighed Commodity Registration ........................................................................................... 18

13.2 Fix Price Registration ............................................................................................................... 21

13.3 By Count Registration (standard function) .............................................................................. 22

13.4 By Count Registration (optional function by initial setting) ................................................... 24

13.5 Tare Function Procedures ........................................................................................................ 27

13.6 SAVE Key Operation Sample......................................................................................................... 28

13.7 VOID Key Operation Sample .................................................................................................... 29

13.8 Date Change ................................................................................................................................... 29

13.9 Calling And Printing A Grade Line .......................................................................................... 30

13.10 Entry By Clerk ........................................................................................................................... 31

13.11 Add Entry By Clerk

13.12 Multiple Weight ............................................................................................................................ 33

................................................................................................................ 32

.............................................................................

16

Page 3

Page

14. TOTAL OPERATION PROCEDURES....................................................................................................... 34

14.1 Hourly Total Report .................................................................................................................. 34

14.2 Grand Total Report......................................................................................................................... 35

14.3 PLU Total Report ....................................................................................................................... 36

14.4 Clerk Total Report ..................................................................................................................... 40

15. LIST UP OF PLU DATA ........................................................................................................................... 42

16. PROGRAMMING PROCEDURES ............................................................................................................ 45

• Selection of Programming Menu ..................................................................................................... 45

EM1-31015D

Menu No. 0 : Changing Unit Price or Price

......................................................................

46

Menu No. 1 : Setting or Changing PLU Data .................................................................... 47

Menu No. 2 : Setting Store Address or Commercial Message

........................................

52

Menu No. 3 : Adjusting Print Position for Label .............................................................. 53

Menu No. 4 : Setting Date, Time, Machine Number, and Store Number ......................... 54

Menu No. 5 : CMT Operations ........................................................................................... 55

Menu No. 7 : Changing Bar Code Format

Menu No. 8 : Assigning Speed Keys

Menu No. 11 : Setting Ingredient (for SL-5900-36 only)

Menu No. 12 : Issuing Confirmation Label (for SL-5900-35/36 only)

........................................................................

................................................................................

...................................................

...............................

57

60

61

63

Menu No. 13 : Switching On-Line/Local (for SL-5900-35/36 only) .................................... 64

Menu No. 17 : Setting Grade Line (for SL-5900-36 only) ................................................... 65

Menu No. 18 : Memory Card (for SL-5900-36 only) ............................................................ 66

Menu No. 20 : Transmitting PLU File or Unit Price (FUN System)

...................................

69

Menu No. 21 : Setting Clerk Name (for SL-5900-36 only) .................................................. 70

Menu No. 40 : Setting Print Item #1 ON/OFF....................................................................... 72

Menu No. 41 : Setting Print Item #2 ON/OFF....................................................................... 73

17. ERROR MESSAGE TABLE ..................................................................................................................... 74

18. BEFORE YOU CALL FOR SERVICE ...................................................................................................... 75

CAUTION:

1. This manual may not be copied in whole or in part without prior written permission.

2. The contents of this manual may be changed without prior notice.

3. Please refer to your local Authorized Service representative with regard to any queries you may

have in this manual.

Copyright ^ 1996

by TEC CORPORATION

All Rights Reserved

1-14-10 Uchikanda, Chlyoda-ku, Tokyo, JAPAN

Page 4

EM1-31015D

• INTRODUCTION

We thank you very much for purchasing the TEC Electronic Computing Scale SL-5900 Series.

This scale has been designed with TEC reliability and offers a cost efficient system for a modest

investment.

The SL-5900 (with thermal printer) takes advantage of the latest technology in microprocessors and

because of this, the decreased cabinet size permits the system to be placed virtually anywhere in

your store.

Your deli, and specialty departments can enjoy these high quality reliable TEC products. Improve

your operating effectiveness and watch the enhanced utilization of your front end scanning

investment. This electronic Load Cell scale eliminates all moving parts and furnishes an accurate

digital display of all information.

We believe that your needs will now be fully satisfied, and you will have total reliability in price

calculation. Should you have any questions concerning the scale, please refer to this manual. Be

sure to keep this manual for future reference.

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications.

Operations of this equipment in a residential area is likely to cause harmful interference in which case

the user will be required to correct the interference at his own expense. (for USA only)

Changes or modifications not expressly approved by manufacturer for compliance could void the user’s

authority to operate the equipment.

“This Class A digital apparatus meets all requirements of the Canadian Interference-Causing Equipment

Regulations.”

“Cet appareil numérique de la classe A respecte toutes les exigences du Règlement sur le matériel

brouilleur du Canada.”

(for CANADA only)

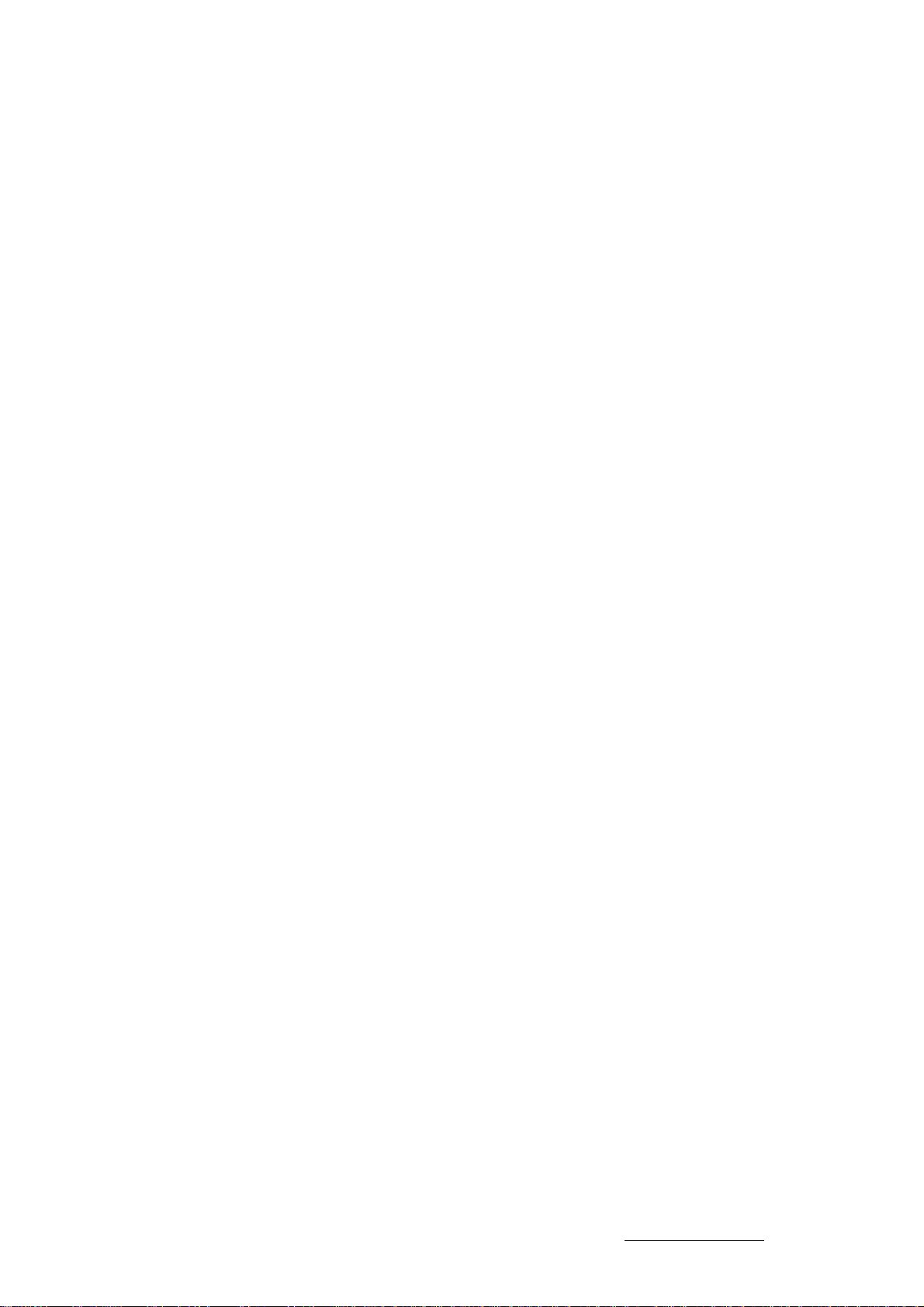

Safety Summary

Personal safety in handling or maintaining the equipment is extremely important. Warnings and

Cautions necessary for safe handling are included in this manual. All warnings and cautions contained

in this manual should be read and understood before handling or maintaining the equipment.

Do not attempt to effect repairs to this equipment. If a fault occurs that cannot be rectified using the

procedures described in this manual, turn off the power, unplug the machine, then contact your

authorised TEC representative for assistance.

Page 5

EM1-31015D

Safety Precautions

This Owner's Manual and the products (machines) which you have purchased contain indications which

should be observed in order to use the machines safely and prevent harm to yourself and others and

damage to property. The meanings of these indications and symbols are given below.

Read these indications and become familiar with their contents before reading this Owner's Manual.

The following safety precaution will help to ensure proper use of the scale.

• Unplug the printer whenever you are working inside the scale.

• Keep your work environment static free.

Meanings of Each Symbol

This symbol indicates warning items (including cautions).

Specific warning contents are drawn inside the Asymbol.

(The symbol on the left indicates a general caution.)

This symbol indicates prohibited actions (prohibited items).

Specific prohibited contents are drawn inside or near the 0 symbol.

(The symbol on the left indicates "no disassembling".)

Prohibited

This symbol indicates actions which must be performed.

Specific instructions are drawn inside or near the •symbol.

(The symbol on the left indicates "disconnect the power cord plug from the outlet".)

WARNING

■ Do not plug in or unplug the power

cord plug with wet hands as this may

cause electric shock.

■ If the machines share the same

outlet with any other electrical

appliances which consume large

amounts of power, the voltage will

fluctuate widely each time these

appliances operate. Be sure to

provide an exclusive outlet for the

machine as this may cause the

machines to malfunction.

This indicates tfiat there is the risk of death or serious injury if fhe

machines ar|^i|tjprogerly handled confrary to this indication.

0

Any other than the

specified AC voltage is

prohibited. A/v.]0| I©)

0

Prohibited

■ Do not use voltages other than the

voltage (AC) specified on the rating

plate, as this may cause fire or

electric shock.

■ Do not place metal objects or

water-filled containers such as flower

vases, flower pots or mugs, etc. on

top of the machines. If metal objects

or spilled liquid enter the machines,

this may cause fire or electric

shock.

■ Do not insert or drop metal,

flammable or other foreign objects into

the machines through the ventilation

slits, as this may cause fire or electric

shock.

-2-

■ Do not remove covers, repair or

modify the machine by yourself. You

may be injured by high voltage, very

hot parts or sharp edges inside the

machine.

Page 6

EM1-31015D

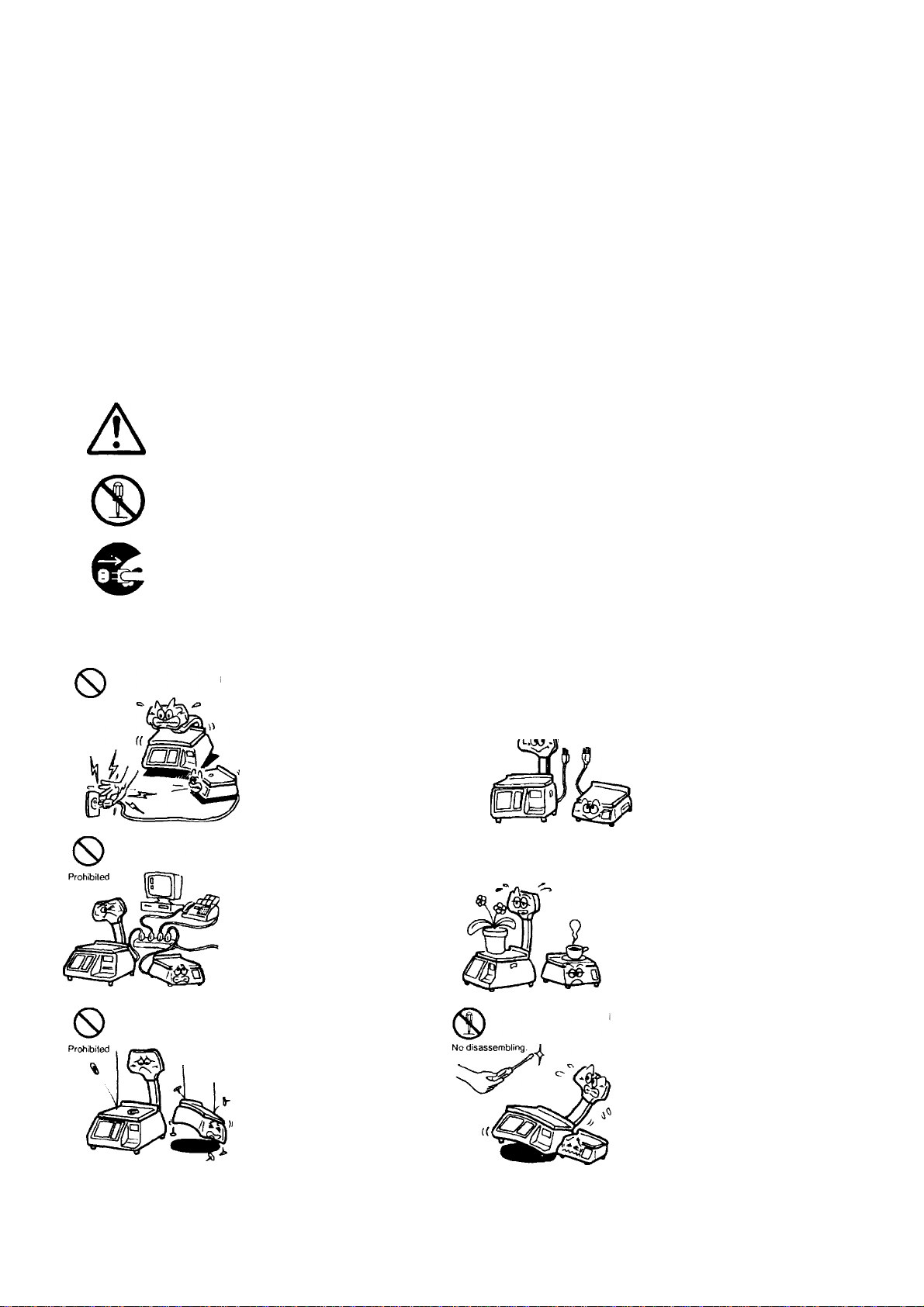

0

Prohibited

■ Do not scratch, damage or modify

the power cords. Also, do not place

heavy objects on. pull on, or exces

sively bend the cords, as this may

cause fire or electrical shock.

■ If foreign objects (metal fragments,

water, liquids) enter the machines, first

turn off the power switches and

disconnect the power cord plugs from

the outlet, and the contact your sales

agent (or maintenance and service

agent). Continued use of the machine

in that condition may cause fire or

electric shock.

■ Ensure that the equipment is

properly grounded. Extension cables

should also be grounded. Fire or

electric shock can occur on improp

erly grounded equipment.

Disconnect the plug.

■ Continued use of the machines in

an abnormal condition such as when

the machines are producing smoke or

strange smells may cause fire or

electric shock. In these cases,

immediately turn ofi the power

switches and disconnect the power

cord plugs Irom the outlet. Then,

contact your sales agent (or mainte

nance and service agent).

■ If the machines are dropped or their

cabinets damaged, first turn off the

power switches and disconnect the

power cord plugs from the outlet, and

the contact your sales agent (or

maintenance and service agent).

Continued use of the machine in that

condition may cause fire or electric

shock.

/f\ CAUTION

0

Prohibited

This Indicates that there is the risk of personal Injury or damage to objects if the

machines arejmproperly handled contrary to this indication.

■ Do not install the machines where

they might be exposed to direct

sunlight, high humidity, or dust.

Otherwise fire or electric shock

could occur.

■ Do not place heavy objects on top of

the machines, as these items may

become unbalanced and fall causing

Injury.

Prohibile

0

Prohibited

[Precautions During installation]

■ Do not place the machines on

unstable or slanted surfaces, as they

may drop or fall and cause injury.

■ Do not block the ventilation slits of

the machines, as this will cause heat

to build up inside the machines and

may cause fire.

-3

Page 7

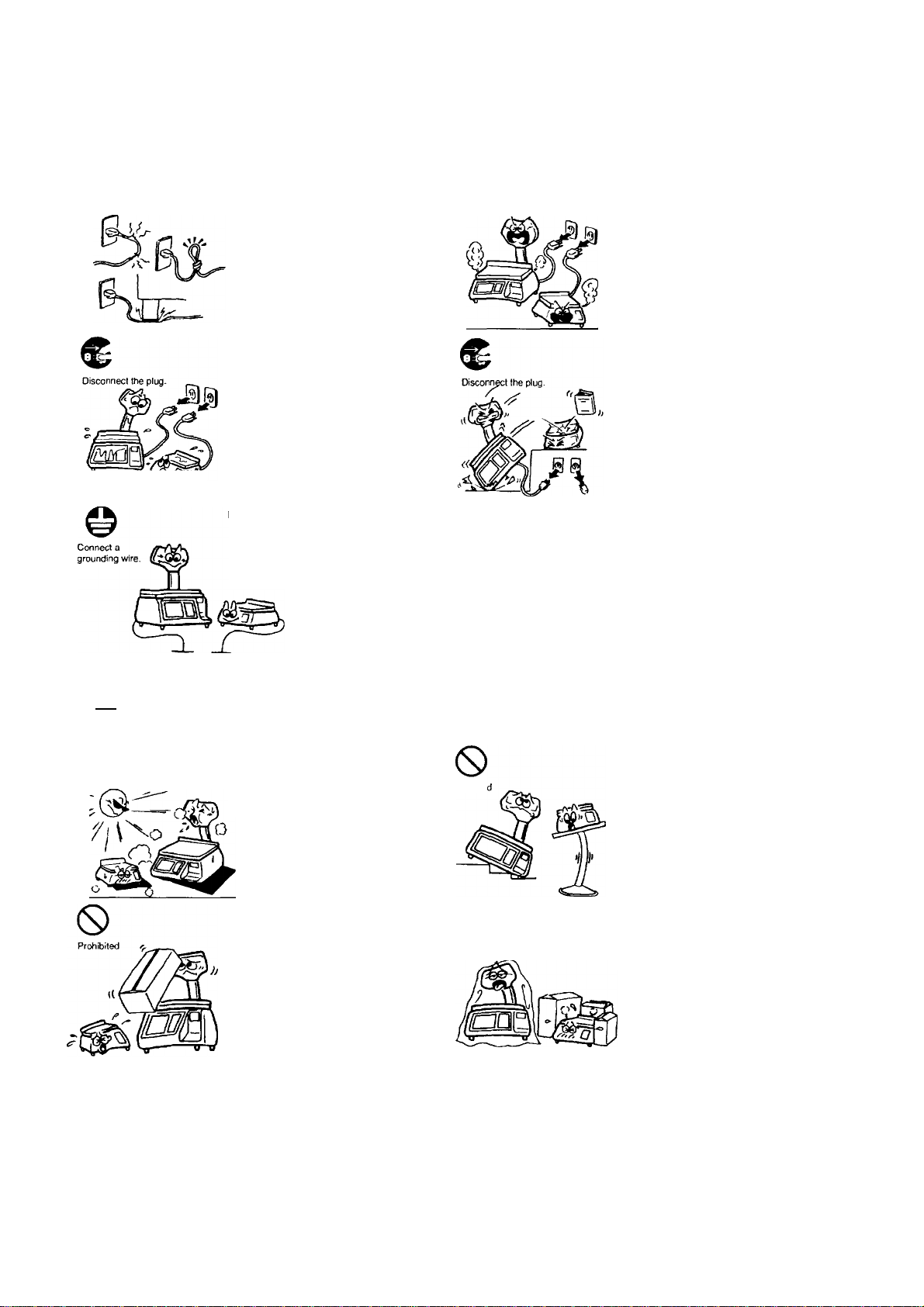

EM1-31015D

Disconnect the plug.

[Precautions When Moving the

Machines]

■ When moving the machines, be

sure to first unplug the power cords.

Moving the machines with the power

cords plugged in may damage the

cords and cause fire or electric

shock.

■ Do not lean against the machine. It

may fall and be damaged.

■ Be sure to move large scale

machines with two or more people. In

addition, machines should be mobed

after first confirming that connecting

wires between machines and

externally connected wires, etc. have

been removed. Failure to observe

these precautions may result in injury.

Disconnect the plug.

■ When unplugging the power cords,

be sure to hold and puli on the plug

portion. Pulling on the cord portion

may cut or expose the internal wires

and cause fire or electric shock.

■ When opening the cash drawer, be

careful not to let the drawer hit

children's heads, etc., as this may

cause injury.

Precaution

The following precautions will help to ensure that this machine will continue to function correctly.

® Try to avoid locations that have the following adverse conditions:

* Temperatures below 0°C and above 40°C * Direct sunlight

* Shared power socket * Excessive vibration

(2) Do not subject the weighing platter to sudden shocks.

(§) Do not press the keys too hard. Keys will operate correctly if they are touched lightly.

0 Clean the cover and weighing platter by wiping with a dry cloth or a cloth soaked with detergent

and wrung out thoroughly. Never use thinner or other volatile solvent for cleaning.

© To ensure that the scale is operating correctly, place a known weight on the platter and check it

for correct weight measurement. This should be done every morning before starting normal

operations.

© At the end of the day, turn the power OFF, then clean and inspect the exterior of the scale.

0 Try to avoid using this equipment on the same power supply as high voltage equipment or

equipment likely to cause mains interference (freezer cabinets etc.).

© USE ONLY TEC SPECIFIED media.

© DO NOT STORE the media where they might be exposed to direct sunlight, high temperatures,

high humidity, dust, or gas.

® When moving the scale, take hold of the case and lift the scale. Never hold the remote unit.

-4-

Page 8

1. SPECIFICATIONS

EM 1-31015D

Item

Maximum Capacity

Minimum Scale Division

Display Range

Tare

Unit Price Presettable

Minimum Price Display

Remote Diasplay :

Weight

Unit Price

Total Price

Message Display (option)

Display Designations

Remote Display Mode

Capacity of PLU Memory

Print Head

Label Issue Method

Available Printing Width

Label

Report Paper

Power Requirement

Current Consumption

Temperature Limits

Relative Humidity

Dimensions (approx.)

Weight (approx.)

Memory Card

30-C2

30 lbs.

0.01 lb.

0-30.05 lbs.

Up to 30 lbs.

$0.01 -99.99

35-C2

35-C4 36-C4

$0.01

4 digits

4 digits

5 digits

16 characters (5x7 dot matrix)

NET, PREPACK, INLINE, ERROR, ACCM, ITEMS

Dual sides

400 PLUS (standard), 1240 PLUs max. (option)

Thermal Print Head

On-demand

1.65”

RICOH 120LA or equivalent

RICOH 115F (black) or equivalent

AC 120V ±10%, 60Hz

120V-1A, 60Hz

0°C-+40”C (32”F-104'>F)

35%—85%RH (No condensation)

15.7” (W) x 16.2”(D) x 18.7”(H)

29 lbs.

MC-128KB

Interface :

CMT Loader l/F

FUN System l/F

PC Keyboard l/F

TMCC l/F

Memory Card l/F

Standard

Standard

Standard

Option Kit and Device

Cassette Magnetice Tape Loader : AIWA DR-1

PC Keyboard (for programming) :

Programming Keyboard :

Programming Keyboard Adapter :

Message Display Kit ;

TMCC Cable Kit ;

IBM PC-XT Keyboard, FUJITSU FKB-2831-001, FUJITSU FKB2831-101

For use of other keyboards, please conteact your TEC

representative.

TEC RK-3

TEC OP-57-RK-3

OP-LCDFIU-US (Except SL-5900-35-C4-US)

OP-5900-TMCC

- 5

Standard

Standard

Standard

Standard

Standard

Standard

Standard

Standard

Standard

Standard

Standard

Standard

Standard

Page 9

EM1-31015D

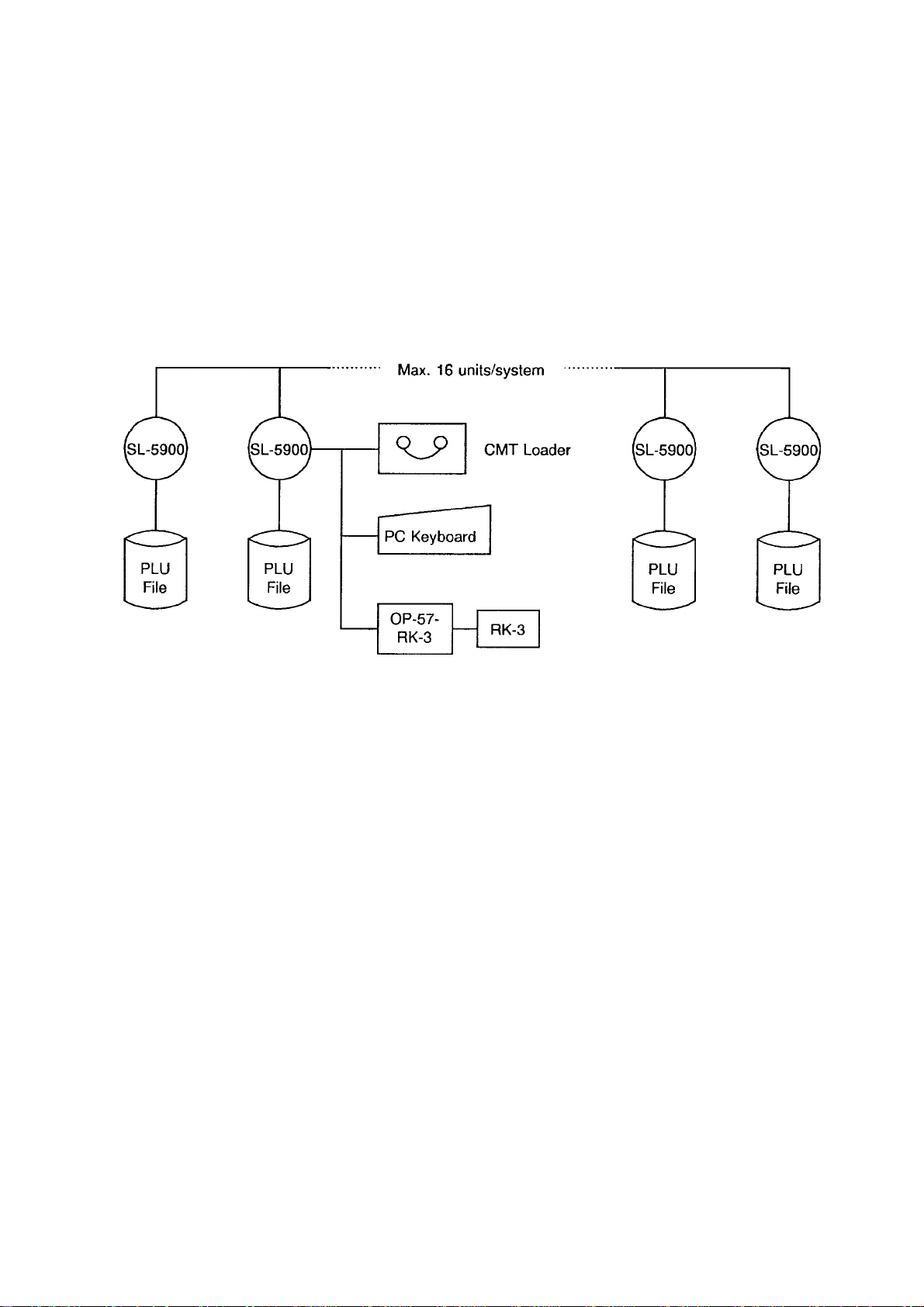

■ FUN System

The SL-5900 is based on the FUN (File Update Network) system, which is a simplified networking

system unique to TEC. This system can accommodate up to 16 terminals as a multi-drop, and

allows any terminal in the system to transfer its PLU file or UNIT PRICE data to other terminals for

verification.

System Configuration

Control Procedure :

Transmission Speed :

Number of unit/system

FUN (File Update Network) • Multi-drop

4800 BPS

Max. 16 units

-6 -

Page 10

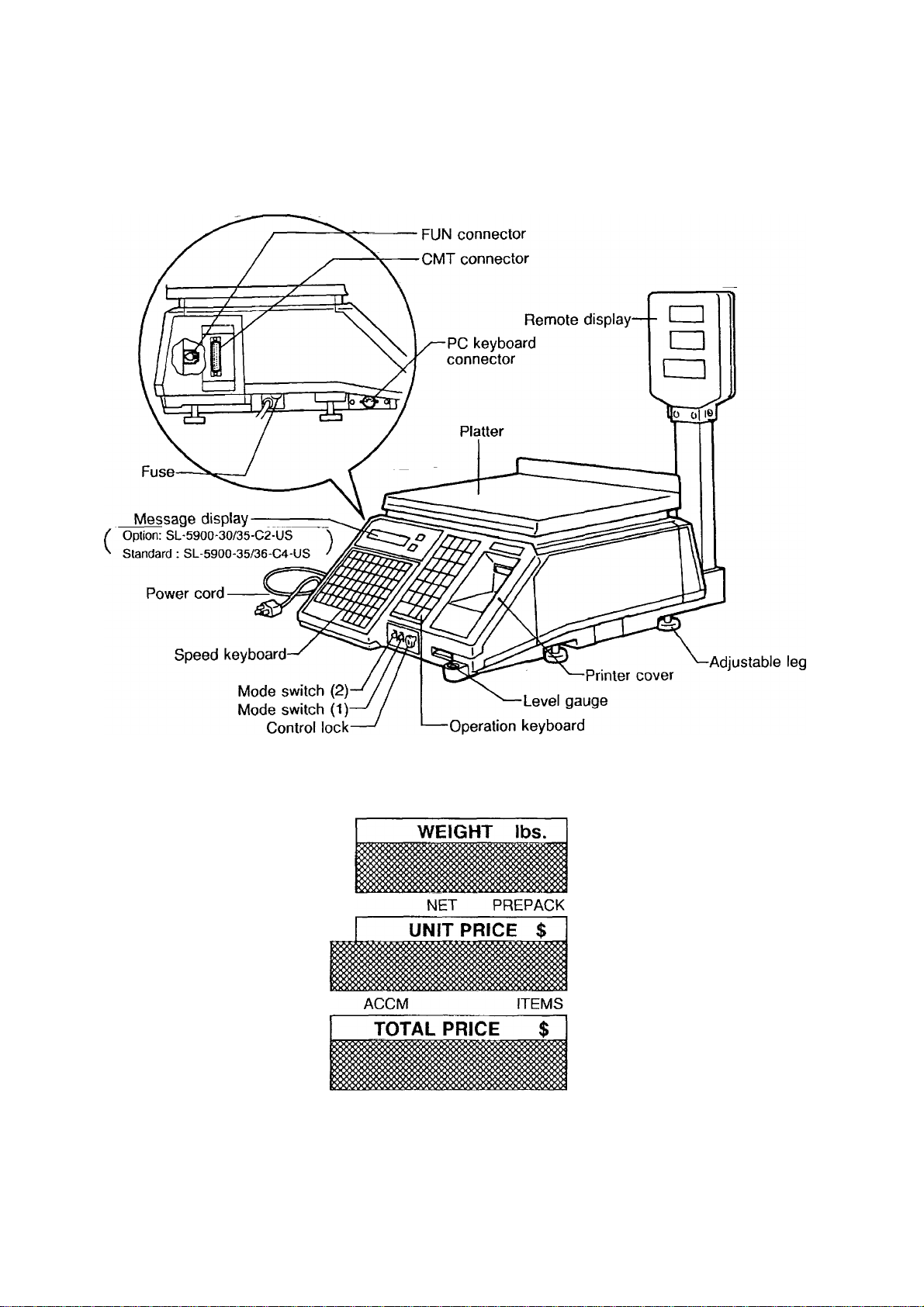

2. OVERVIEW

EM1-31015D

3. REMOTE DISPLAY

1b FOR

CAPACITY 30X0.01 lbs

INLINE ERROR

TEC

SL-5900

- 7 -

Page 11

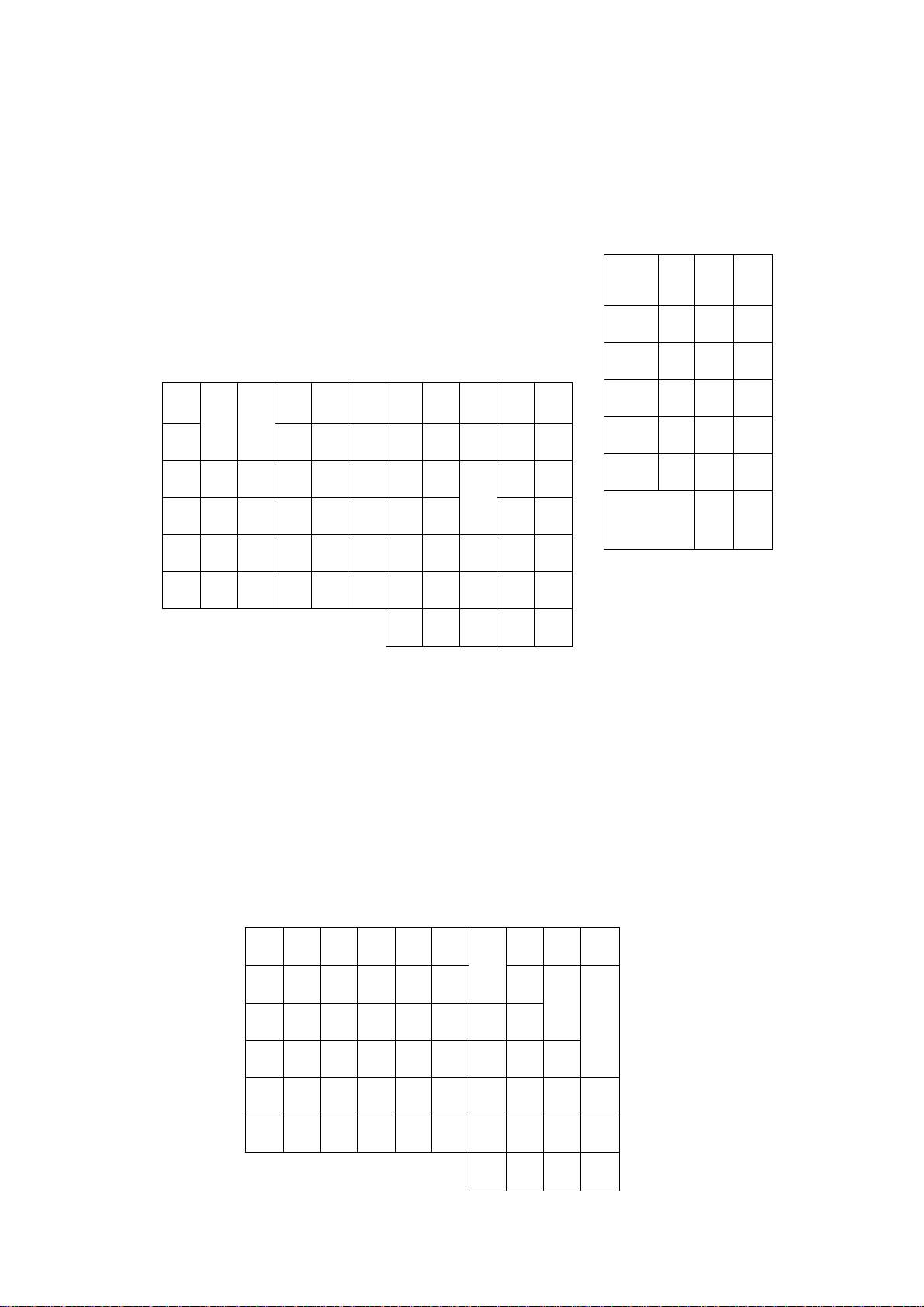

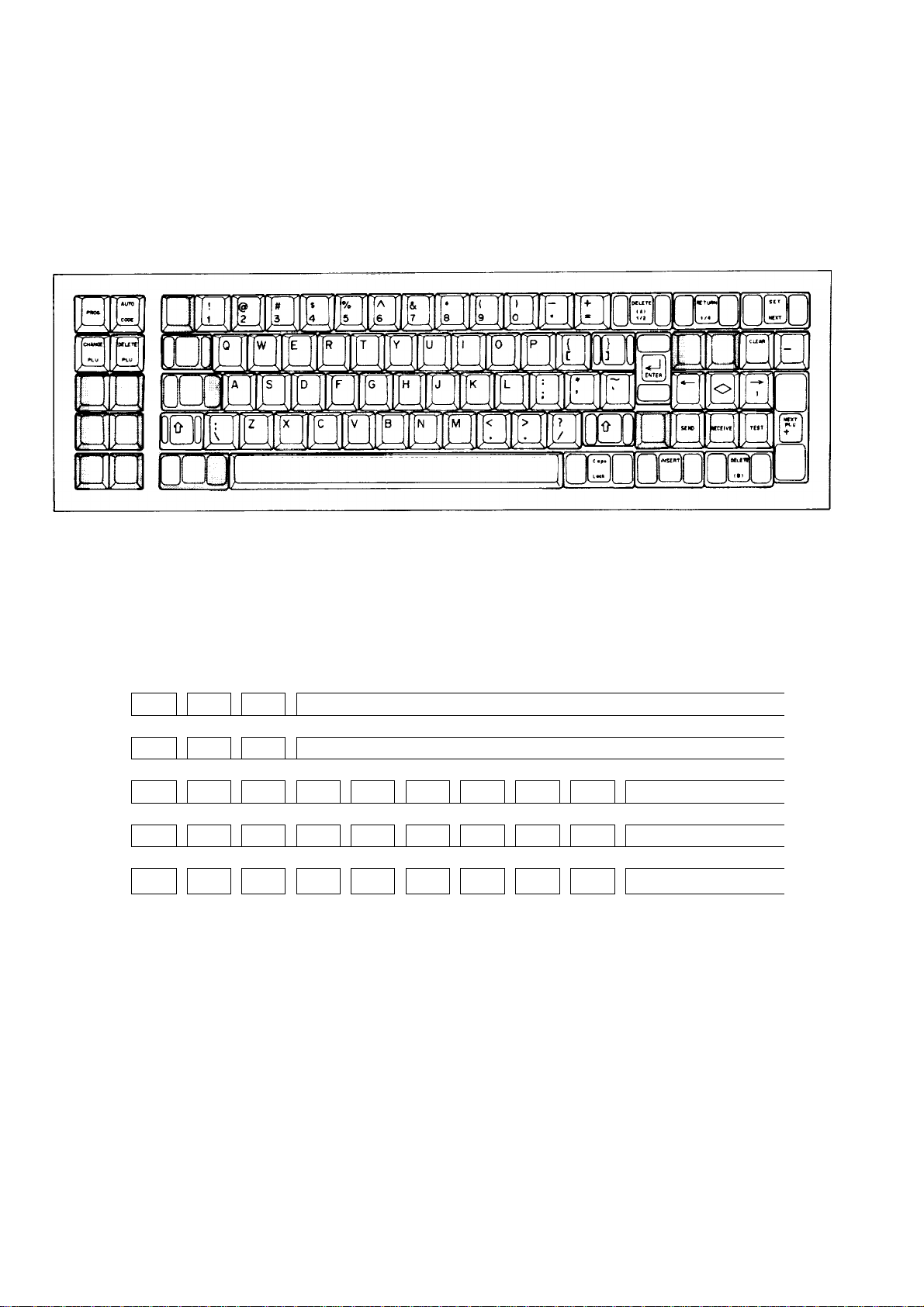

4. KEY LAYOUT

■ Operation Keyboard

EM1-31015D

COMMODITY NAME

DARK

— CONTRAST

NEXT

PLU

■ o FOR

VOID

DT^

L

R 1

G. i

LINE 1

LIGHT

8 9

5 6

2

T (Tr)

SAVE

1/2

3

1/4

C

PRT^

OFF M.DOWN

= g / TWRAP

1 2 3 4 5

11 12

21 22

31

41

51

32

42

52

14

13

24

23

34

33

44 45

43

54

53

15 16

25 26

35 36

55 56

1 ^

7 8

6

17

27

37

47

46

57

9 10 Cl

18 19 20

29

28

38

39

48 49

59 60

58

30 C3

40

50

1

C2

1 ^

1 °

C4

C5

C6

1

W^H A^O RE;

=IX ~ I-T I PfOG \ / X

J ^ z

FEED

NOTE : The characters (1~60) indicated on the speed keys are shown for the convenience of

explanation in this manual. The indications on the actual unit are not as shown in this

illustration.

TEST

ZERO

COUNT^ MANUAL

Programming Keyboard

/r=

COMMODITY NAME

SET

CLEAR SHIFT

PROG

o

}

1

*

W E R T Y

Q

I

\

A

E

Z X

2

f

5 D

E A E

NEXT

ENTER

#

3

c

NEXT

(

1

AUTO

CODE

PLU

-

% &

$

4

5

l <

)

—

F

G

-»

V

B N

SEND

1

6 7

{

H

DARK

LIGHT

RECEIVE

DEtETE

(A) 1/2

FEED

CHANGE

PLU

INSERT

U

J

M SPACE

—CONTRAST

DELETE

PLU

DELETE

(B)

7

8

9

_

1

0

} 0

K

L

t

▼

TEST

RETURN

1/4

@

0

>

p

A

ZERO

Page 12

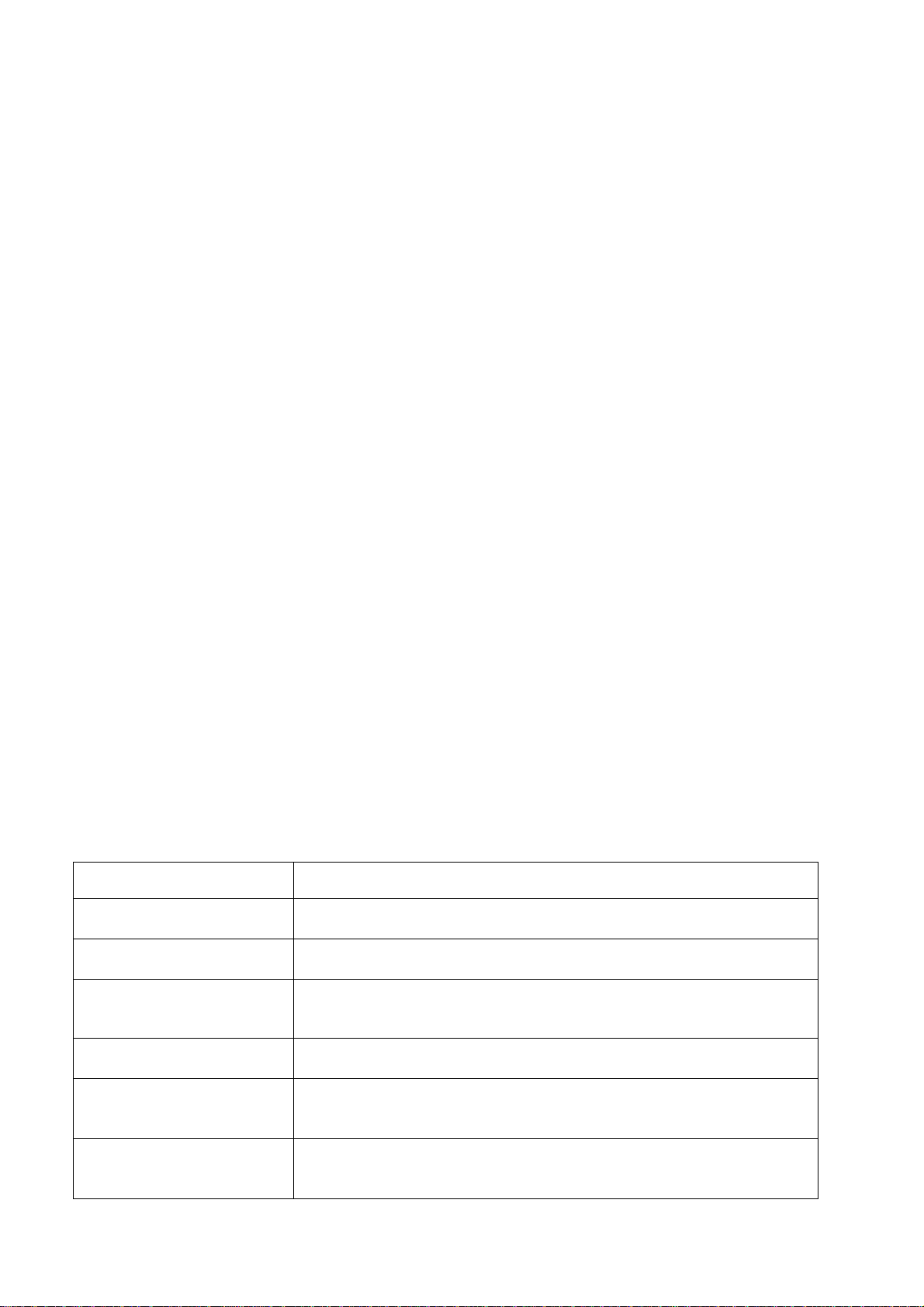

PC Keyboard (for programming)

EMI-31015D

RK-3 (with OP-57-RK-KS) Keyboard (for programming)

FROG

1

- i

*

Q

[

A

z X

o

ENTER

2

+

w

\

s

1

_0__E__G_[_H_1_J_1K L INSERT

—

$

4

_1_

CAPS LOCK

1

[_J 1 ^ i

%

NPq PLUAUTO CODE

&

5

T

/

6

1

_i_/U

_c__V__B__N__

CHANG DELETE

<

1 0

?

9

CLEARSHIFT

@

0

SEND

n

>

p

^1

SPACE DELETEiB\

OP-57-RK-KS

RECEIVE

—f

1

DELETE(A)

1 /?

II II 1

RETURN

1/4

Page 13

5. KEY FUNCTIONS

■ For Operation Keyboard

EMI-31015D

Switch & Key

Mode Switch (1)

AUTO

■— MANUAL

Mode Switch (2)

WEIGH

FIX

BY COUNT

CLEAR Key

DATE & TIME Key

/rtM

Function

“AUTO” position:

This position is used to issue regular scale labels.

When the weight becomes stable, the label will automatically be issued.

“MANUAL” position:

When the weight becomes stable, the label will be issued by depressing

the PRINT key.

“WEIGH” position:

This position is used in the weighing function of the SL-5900.

“FIX” position:

The unit price is entered directly to the total price on calling up PLU,

and that total price cannot be changed by any subsequent weighing.

“BY COUNT” position:

It is available to produce labels which contain information on quantity

pricing, instead of weight.

This key is used for dear-entry of numeric keys. It is also used to

release the scale from the save mode and/or error mode.

This key is used to indicate the date on a remote display and for

temporary date changes.

FEED Key

FOR Key

NEXT PLU Key

NUMERIC Keys

Per 1/2 Key

FEED

FOR

NEXT

PLU

1/2

This key is used to feed labels or report paper.

In the “X” or “Z” control lock position, this key is used to generate the

zone total report.

This key is used to call out the next PLU #, and forward the operation

step to the next step.

These keys are used to enter numeric data (PLU#, unit price, tare

weight, etc.).

This key is used to calculate the unit price by 1/2 lbs.

-10

Page 14

EM 1-31015D

Switch & Key

Per 1/4 Key

PLU Key

PRINT Key

SAVE Key

SPEED Keys

1

TARE Key

1/4

PLU

"7.

SAVE

(Tr)

60

Function

This key is used to calculate the unit price by 1/4 lbs.

This key is used to select a PLU number or return to the initial mode.

If the Mode Switch (1) is set to the MANUAL position, it has the function

of label issue.

This key is used for issuing total labels.

This key is used to save tare and unit price after removing the

commodity from the platter.

These keys are used to set and call the PLU data of frequently used

commodities.

This key is used to subtract tare weight.

TEST Key

TEST

VOID Key

VOID

ZERO Key

ZERO

o

GRADE LINE key

G LINE

LABELS REPORT PAPER

key

%

This key is used to issue test labels.

This key is used to cancel only one commodity’s data by depressing

this key after its registration.

This key is used to adjust the “ZERO” point.

This key is used to subtract an item which was entered previously in the

sale or to cancel all the items entered in the sale.

In the “X” or “Z” control lock position, this key is used to genetate the

block total report.

This key is used to call the Grade Line message.

This key is used to select label printout or report paper printout.

CLERK keys

01

06

These keys are used for entry operation by clerk and add entry

operation by clerk.

- 11 -

Page 15

For Programming Keyboards

Key

This key allows the clearing of numeric entries prior to the depression

CLEAR

of another function key. It is also used to release the scale from the

error mode.

Function

LO

o

0.

tn

O o

EM1-31015D

<V

«

oc

o

I

SEND

SHIFT

SET

NEX

NEXT

PLU

AUTO

CODE

RECEIVE

CHANGE

PLU

This key is used to select the upper or lower character indicated on

the keytop when setting the commodity name or store address.

While this key is pressed down, press a character key to set the small

letter of alphabet, or upper-case character indicated on the upper

area of the keytop. When this key is released, the shifted status is

cancelled.

This key is used to recall the next PLU # (+1) of the PLU # currently

recalled.

This key is used to recall the PLU # which is registered next to the

current recalled PLU #. It is also used to skip the digit when setting

the bar code format.

This key is used to set the auto code for UPC #.

These keys are not used. (No function)

This key is used to change the PLU # currently recalled.

O o

O

o o

o o

o

o o o

o o o

o o o

DELETE

PLU

TEST

PROG.

o

ENTER

When a PLU is no longer to be maintained in the PLU file, this key is

used to delete such PLU data.

This key is used to print out the data set in the currently recalled

PLU.

This key is used to access each programming menu.

This key is used to select selectable items.

During programming, data is input to the SL-5900 system using this

key.

This key is used to set the free zone of the auto code for UPC #,

back the digit when setting the bar code format, and return the setting

line to the first line while setting the second line and during the setting

of the commodily name or store address.

12

o

o o

o

o

o

o o o

o

o o

O o o

o

o o

Page 16

Key

Function

o>

CO

EM1-31015D

>

8

0)

in

f

_l

O

OL

9

cc

DELETE

(A) 1/2

INSERT

DELETE

(B)

RETURN

1/4

CPAS

LOCK

This key is used to back the digit when setting the commodity name

or store address.

This key is used to skip the digit when setting the commodity name or

store address.

This key is used to delete a character when setting the commodity

name or store address. When setting the unit price for the weighed

PLU, this key is used to set the unit price to the price per 1/2 lbs.

This key is used to insert a space at the digit when setting the

commodity name or store address.

This key is used to clear all characters on the current setting line

when setting the commodity name or store address.

This key is used to move the setting line when setting the commodity

name or store address. When setting the unit price for the weighed

PLU, this key is used to set the unit price to the unit price per 1/4 lbs.

Press this key to lock the keyboard into the shifted status. While this

key is pressed down, press a character key to set the small letter of

alphabet. When this key is released, the shifted status is cancelled.

o o o

o o o

o o o

o o o

o o o

o o

o

o o

NOTE : When the power is turned off or control lock is switched, the PC keyboard or RK-3 keyboard

will be initialized to select capital letters.

6. LAMP FUNCTIONS

NET Lfi

PREPACK

INLINE

ERROR

ACCM

ITEMS

Lamp

^ I ^

Lights when tare is subtracted.

Lights when the SAVE key is pressed.

Lights when the PLU or unit price file is updated.

Lights when the scale (for SL-5900-35/36) is in the IN-LINE mode.

Lights when the scale is improperly operated or there is a function error.

This lamp lights when items are being added to the specific CLERK

memory in the add entry by clerk mode (for SL-5900-36).

This lamp lights when items are being added to any CLERK memory in

the sub-total operation in the add entry by clerk mode (for SL-5900-36).

Function

13 -

Page 17

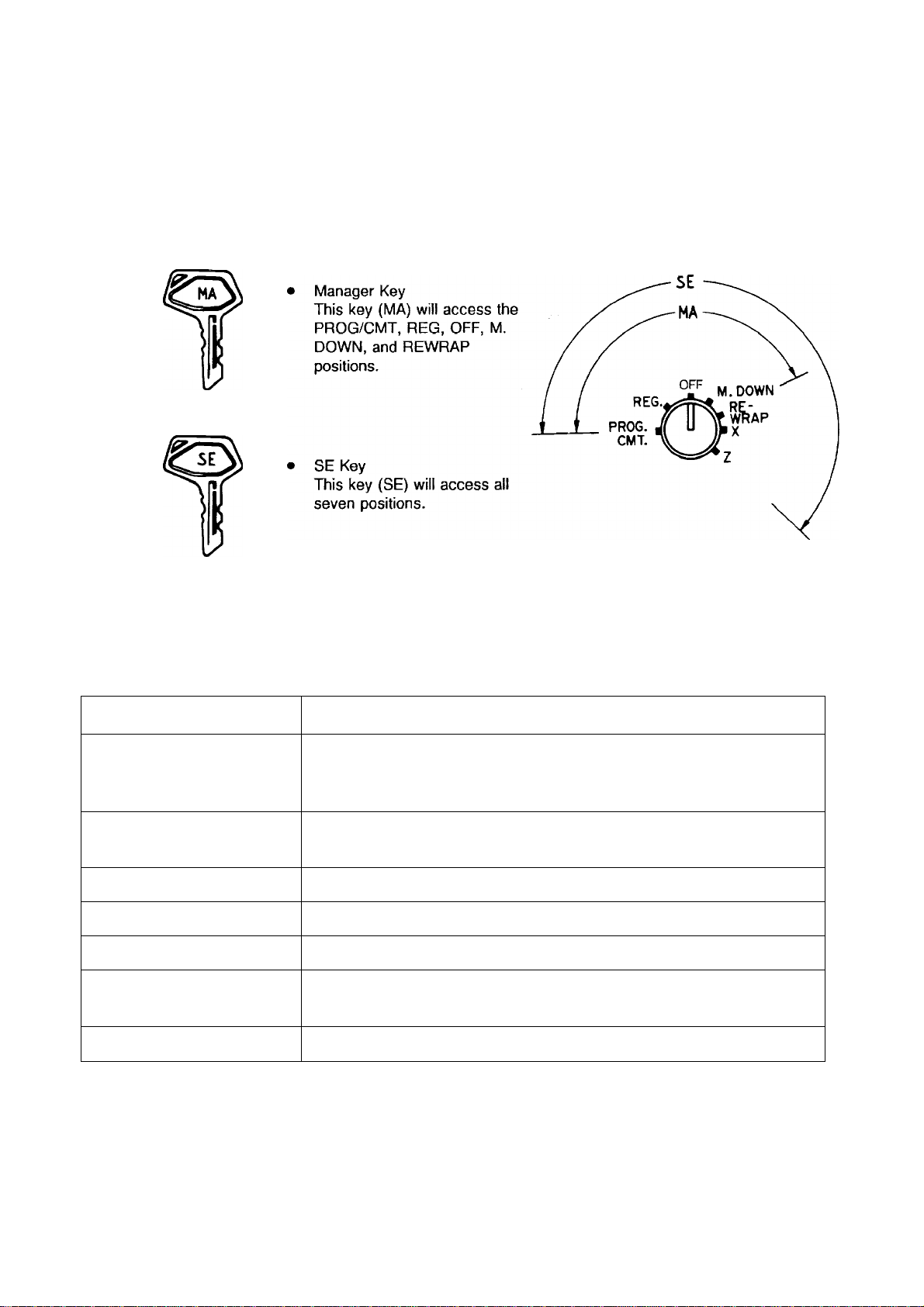

7. CONTROL LOCK

The control lock has seven marked positions.

There are two control keys which will operate these locks.

EM1-31015D

Each of the following positions on the control lock serves a different function.

Position

PROG. CMT.

REG.

OFF

M. DOWN This position is used to designate an item for discount pricing.

REWRAP

X(Read) This position is used to read all the accumulated sales totals stored in

Z (Reset) This position is used to reset all item file totals.

This position is used to set the data of the PLL), store address, printing

position, date, time, bar code format, etc. It is also used to transfer the

PLU file using a CMT loader.

This position is the normal control lock position which allow the issuance

of printed labels.

This position is used to lock the scale power.

This position is used to designate an item for rewrapping products.

the total memory.

Function

14 -

Page 18

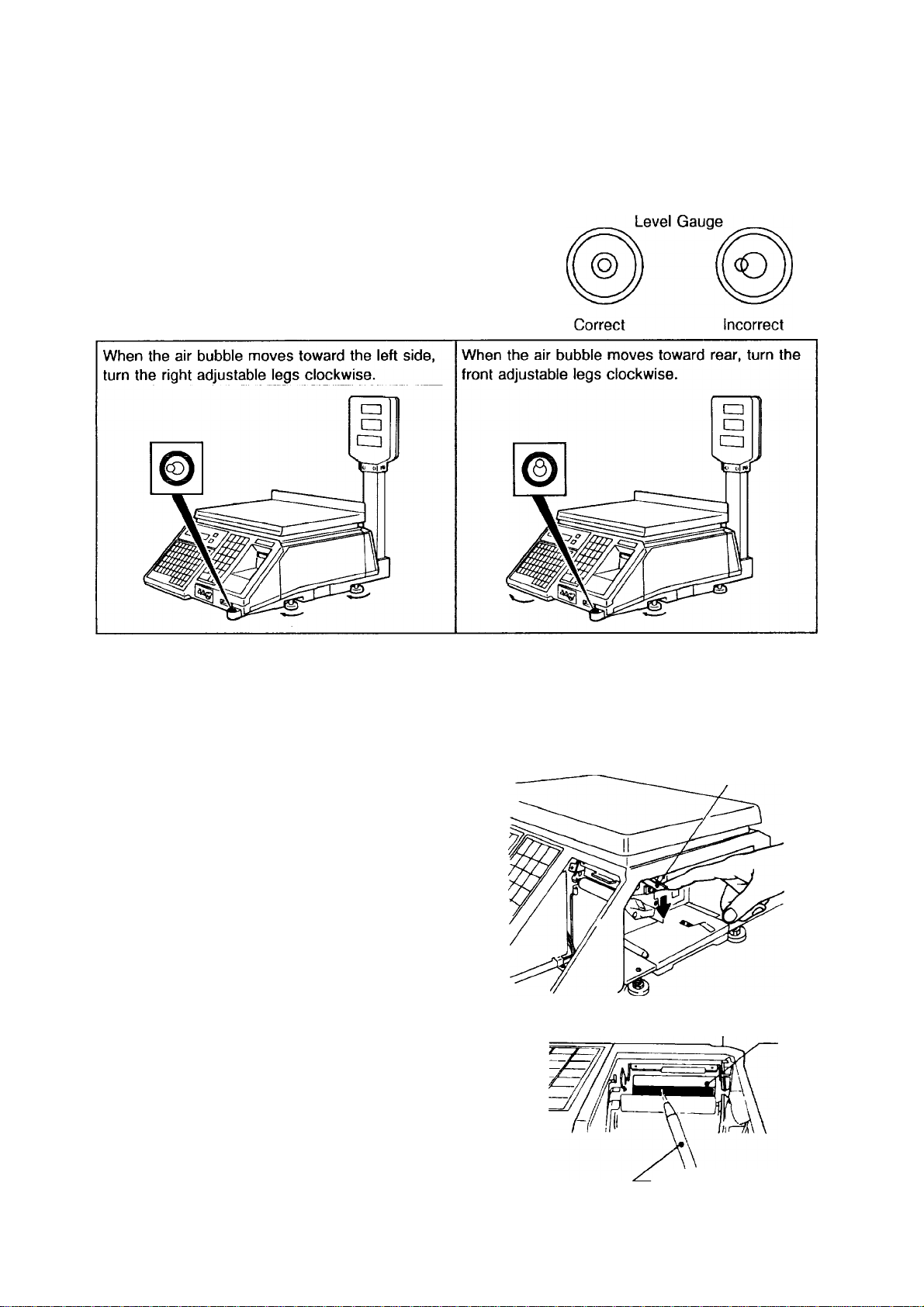

8. LEVEL ADJUSTMENT

Set the scale on a stable and level surface. Level

the scale by turning the adjustable legs so that the

air bubble is inside the center circle.

EMI-31015D

9. CLEANING THE PRINT HEAD

If the print head is dirty, clear printing will not be produced. It is recommended to clean the head

with thermal head cleaner everyday before starting operation using the following procedure:

1. Remove the printer cover and label cassette.

Then push the head-up lever in the direction

indicated by the allow.

2. Wipe off the dirt on the blackened portion in

the figure to the right with the thermal head

cleaner.

Then set the label cassette, and push down the

print head.

NOTE: Be careful not to damage the print head

when cleaning.

Head-up Lever

Head

- 15 -

Thermal Head Cleaner

Page 19

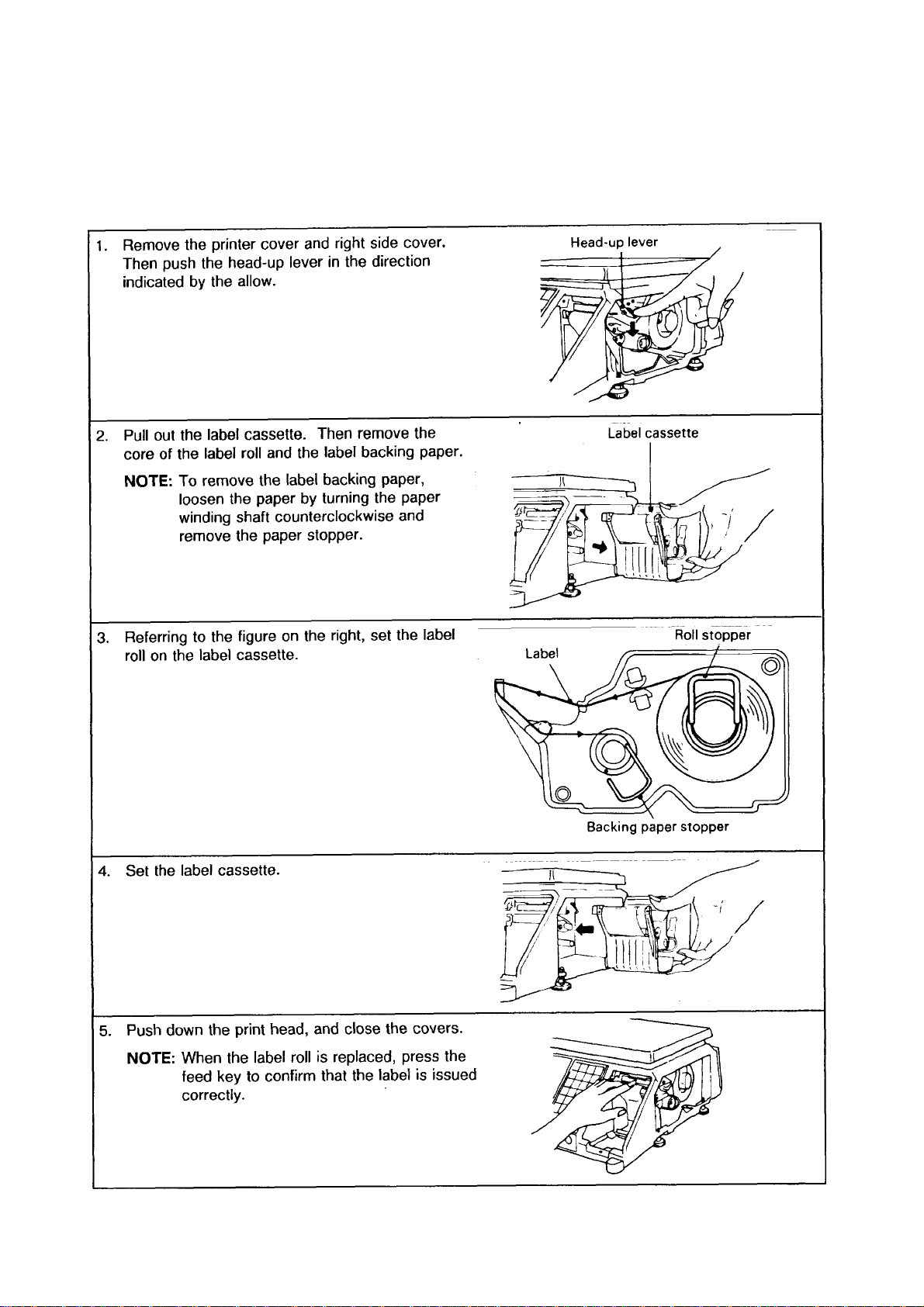

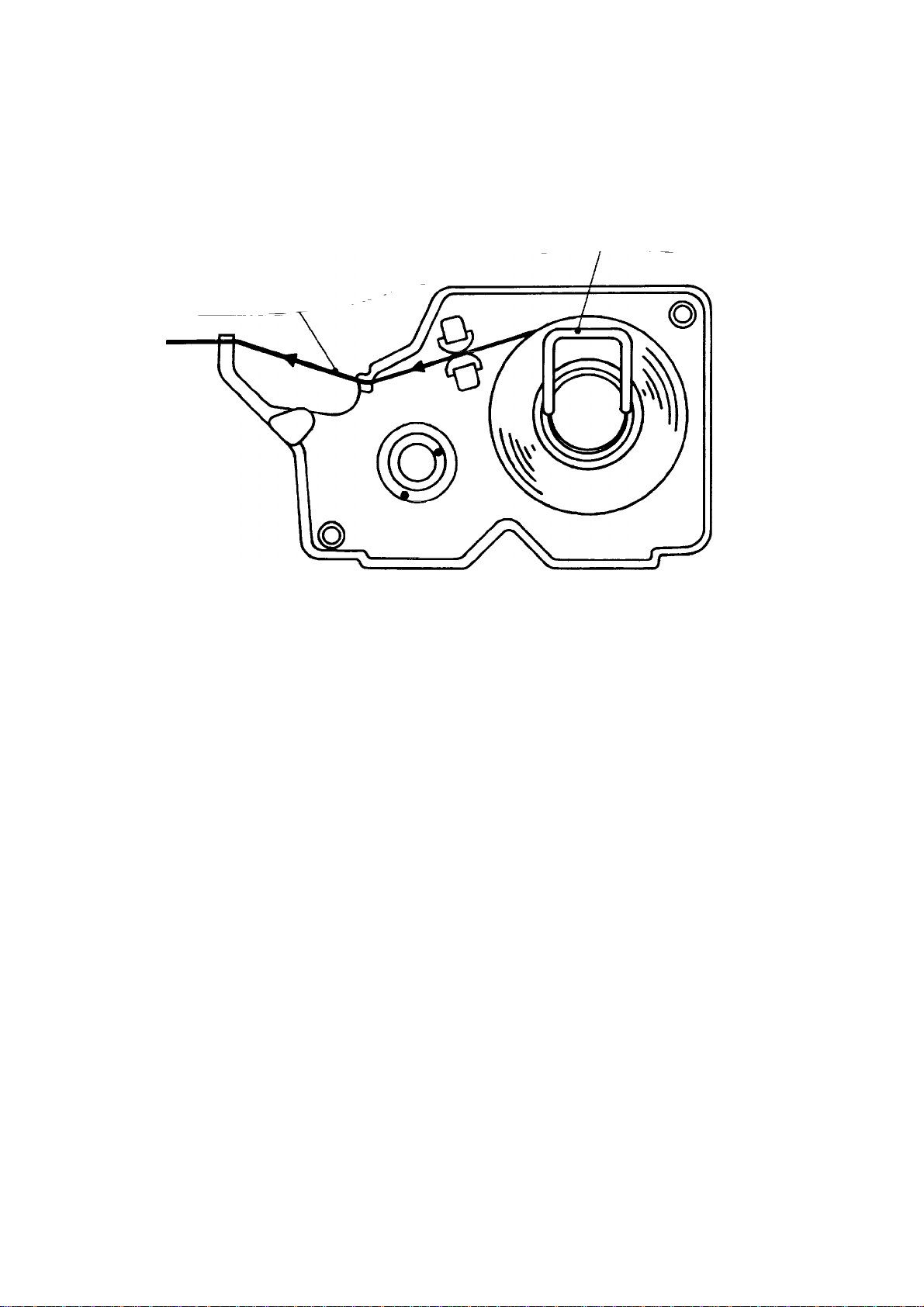

10. REMOVAL AND REPLACEMENT OF LABEL ROLL

EM1-31015D

- 16 -

Page 20

11. REPORT PAPER THREADING

Report paper

EM1-31015D

Roll stopper

12. BEFORE STARTING OPERATION

(1) Be sure to plug the power plug into an AC outlet.

(2) When the control lock is turned from OFF to REG position, the scale goes through the test

scanning sequence, such as 0000, 0000, 00000, then 1111, 1111, 11111

appear on the weight and total price displays. When the control lock is turned from OFF to

REG over 16 seconds after the power plug is plugged into an AC outlet, all “8”s appear on ail

displays for a moment, then zeros appear on the displays and the scale is ready for use.

(3) While the scale is in the test sequence, do not pul anything on the platter.

(4) Do not move the scale while it is in operation. Should it become necessary to move it at any

time, turn the power OFF and be sure to readjust the level indicator after relocating the scale.

(5) Should a power failure occur during operation, remove the commodity from the platter and plug

the power plug into an AC outlet again when power is restored.

(6) If the scale is used with an unrated power source, inaccurate scaling or other errors may occur.

(7) If the Zero Point has shifted during scaling, and no tare is displayed, adjust the Zero Point by

depressing the ZERO key.

.............................

and zeros

17-

Page 21

13. OPERATING PROCEDURES

13.1 WEIGHED COMMODITY REGISTRATION

Control lock : REG, M.DOWN, or REWRAP

Mode SW (2) : WEIGH

[Example A] In the event that an unit price of $3.00 is set for PLU#100.

Step

Ho,

1

2

3

Procedure

Enter the PLU# .

Depress the PLU key.

Place a commodity on the platter.

(ex. 2 lbs.)

ModeSW(l): AUTO

The label is issued automatically.

Mode SW (1) ; MANUAL

The label is issued after depressing

the PRINT key.

WEIGHT

0.00 P

0.00

2.00 3.00

2201Ö0

2.00

NETWT. EB PRICE/IbBB

19250 VAN NESS AVE.

TEL 213(320)8900

UNIT

PRICE

f-BONE STEAK

306004

3.00

TOTAL

000100

3.00 0.00

6.00

PACKED ON

iJ,

DEC 6

$

6. 00

TOTALPraCEH

i»-;

N

L.E..

EMI-31015D

!

A

T

C

iiii:

C

M

M

s

Remove the commodity from the

platter.

PLU data is returned to the PLU file.

NOTE : Recalling a PLU# that has not been set in the PLU file w/ill result in an error. In this case,

depress the CLEAR key, then enter a correct PLU#.

0.00

000000

18

Page 22

[Example B] In the event that PLU#100 and an unit price of $3.00 are set in the speed key #1.

EM1-31015D

(

Step

Ho.

Depress the speed key #1.

Place a commodity on the platter.

(ex. 2 lbs.)

SW (1) : AUTO

The label is issued automatically.

Mode SW (1) ; MANUAL

The label is issued after depressing

the PRINT key.

Procedure

WEIGHT

0.00

2.00

220IÖ0

2.00

NETOT. tsg

19250 VAN NESS AVE.

TEL 213(320)8900

Remove the commodity from the

platter.

PLU data is returned to the speed key

and PLU file.

NOTE : Depressing a speed key to which no PLU data has been assigned will result in an error. In

this case, depress the CLEAR key, then depress a speed key to which PLU data has been

assigned.

0.00

UNIT

PRICE:

3.00

3.00

TOTAL

PRICE

0.00

6.00

T-BONE STEAK

PACKED ON

15 J,

306004

3.00

PRCE/lb^

DEC 6

$

6.00

TOTAIPRICEB

000000

list:

:i|N:

.f

....

A

C

C

M

[Example C] In the event that an open unit price is set for PLU#103.

Step

No

1

2

3

Enter the PLU# .

Depress the PLU key.

Enter the unit price, (ex. $1.25)

Place a commodity on the platter.

(ex. 2 lbs.)

Mode SW (1) : AUTO

The label is issued automatically.

Mode SW (1) : MANUAL

The label is issued after depressing

the PRINT key.

Procedure

WEIGHT

0.00

0.00

0.00

2.00

GROUND BEEF

220 03 702506'

2.00 1.25 $2.50

NETWT. USB PRCE/1bS3 A/tW-lisrlftljsl

19250 VAN NESS AVE.

TEL 213(320)8900

UNIT

PRICE

P

0.00

1.25

1.25

TOTAL

PRICE

000103

0.00

0.00

2.50

PACKED ON

•iJv

DEC S

A

c

C

M

mvi

T

M

s

E

19 -

Page 23

EM1-31015D

[Example D] In the event that an unit price is $1.50

(optional function by initial setting)

Step

No

Depress the PLU key.

2

Enter the unit price, (ex. $1.50)

Place a commodity on the platter.

3

(ex. 3 lbs.)

ModeSW(1): AUTO

The label is issued automatically.

Mode SW (1) : MANUAL

The label is issued after depressing

the PRINT key.

NOTES;

1. This operation is available only when the Random Item PLU is set to “Available” in initial

setting.

Procedure

WEIGHT

0.00

0.00

3.00

200000 904500

3.00 1.50

NETVrr. ISg PRICE/bE3

19250 VAN NESS AVE.

TEL 213(320)8900

Random Item PLU

UNIT

PRICE

0.00

1.50

1.50

TOTAL

PRICE

PACKED ON

iii

$4.50

TOTALPRCE®

0.00

0.00

4.50

ifiSi:

ilNSi:;:

iiLSs.

sfiSiS

A

C

C

m

2. Although the Random Item PLU is handled as PLU^O in the REG mode, it is handled as

PLU# 999999 in the PLU file.

20-

Page 24

13.2 FIX PRICE REGISTRATION

Control lock : REG, M.DOWN, or REWRAP

Mode SW (2) ; FIX

[Example A] In the event that an unit price of $1.25 is set for PLU#33.

^lililí

No.

Procedure

WEIGHT

PRICE

UNIT

TOTAL

PRICE

EMI-31015D

t

A

Mi

T

C

E

C

M

S

N

E

3

Enter the PLU#.

1

Depress the PLU key.

2

Place a commodity on the platter,

3

(ex. 1 lb.)

ModeSW(l): AUTO

4

The label is issued automatically.

Mode SW (1) : MANUAL

The label is issued after depressing

the PRINT key.

[Example B] In the event that an open unit price is set for PLU#32.

No,

1

Enter the PLU#.

Procedure

3

0.00

0.00

1.00

CREAH CAKE

290033"301254

1.00

NETWT. gjS

9250 VAN NESS AVE.

TEL 213(320)8900

WEIGHT

0.00

FflICE/Ibgg

íliiiiiií

P

000033

1.25

1.25

PACKED ON

BY

DEC 4

$1,25

TOTALPRICE®

TOTAL

PRICE

000032

(

A

N

E

m

T

C

e

c

M

M

2

Depress the PLU key.

Enter the price, (ex. $2.00)

3

Place a commodity on the platter.

4

(ex. 1 lb.)

ModeSW(l): AUTO

The label is issued automatically.

Mode SW (1) ; MANUAL

The label is issued after depressing

the PRINT key.

0.00

0.00

1.00

CHOCOLATE

HERIN6UE PIE

290032

1.00 ^2.00

NFT'ilfr. (5B PRICE/lbSa

19250 VAN NESS AVE.

TEL 213(320)8900

21-

202002

0.00

2.00

2.00

PACKED ON

IL BY

DEC 5

TOTALPRICE®

Page 25

13.3 BY COUNT REGISTRATION (standard function)

Control lock : REG, M.DOWN, or REWRAP

Mode SW (2) : BY COUNT

[Example A] In the event that PLU#302 and a price of $3.00 per 6 pieces are set in the speed key

)5f2l.

EM1-31015D

Step

No

1

2

Procedure

Enter the speed key #21.

Depress the PRINT key.

WEIGHT

UNIT

PRICE

?TOTAi:i:?

PRICE

3.00

CHICKEN LEGS

$3.00

P

PACKED ON

DEC 1

SELL BY

DEC 5

TOTALPRICEB

TOTAL

PRICE

000303

I

Tf

f

N

iiM

ModeSW(l): AUTO

3

Labels are issued in succession

after they are peeled.

Mode SW (1) : MANUAL

Single label is issued.

NOTE : When Mode SW (1) is in the “AUTO” position, the desired number of identical labels can be

obtained by just depressing the PRINT key to issue the first label, then a next label will be

issued once after peeling it until depressing the CLEAR key.

[Example B] In the event that a price of $2.50 per 12 pieces is set for PLU#303.

Step

No.

Enter the PLU#.

Procedure

3 0 3

002030"000029

6 f\m

NETv/T. mg PHce/ibsa

19250 VAN NESS AVE.

TEL 213(320)8900

WEIGHT

UNIT

PRICE

A

C

C

Mii

A

C

C

2

Depress the PLU key.

Depress the PRINT key.

3

Mode SW (1) ; AUTO

Labels are issued in succession

after they are peeled.

Mode SW (1) : MANUAL

Single label is issued.

P 12

CHICKEN KING

PACKED ON

002030

12 PlfClS $2.50

NETWT. IBB PPJCE/ibSa

19250 VAN NESS AVE.

TEL 213(320)8900

-22

000036

DEC 6

TOTALPflICE®

2.50

BY

Page 26

[Example C] In case of purchasing 10 pieces of commodity at a price of $1.00 per 6 pieces

.......

(In the event that a price of $1.00 per 6 pieces is set for PLU#39.)

Step

No

Proc('<iiite

WEIGHT

PRICE i

TOTAL

PRICE

N

F

SPLIT PRICE

EM1-31015D

l

A

T

C

E

C

M

M

m

1

Enter the PLU #.

Depress the PLU key.

2

Enter the quantity of purchase,

3

(ex. 10 pieces) ••• max. 2 digits

Depress the PRINT key.

4

Mode SW (1) : AUTO '

5

Labels are issued in succession

after they are peeled.

Mode SW (1) : MANUAL

Single label is issued.

P

P 6

10

P 10

DONUTS

009003'000093

10 FifCIS

NETWT. IBB PRICE/Ibga

19250 VAN NESS AVE.

TEL 213(320)8900

000039

1.00

1.00

1.68

PACKED ON

DEC 4

$

1. 68

TOTALPRICE®

23

Page 27

13.4 BY COUNT REGISTRATION (optional function by initial

setting)

Control lock ; REG. M.DOWN, or REWRAP

Mode SW (2) ; BY COUNT

[Example A] In the event that an unit price of $1.75 is set for PLU#31.

EM1-31015D

Step

No.

1

2

3

4

5

6

Ptoceduio WEIGHT

Enter the PLU #.

Depress the PLU key.

Enter the quantity of purchase,

(ex. 2 pieces)

Depress the FOR key.

Depress the PRINT key.

ModeSW(1): AUTO

Labels are issued in succession

after they are peeled.

Mode SW (1) : MANUAL

Single label is issued.

2

TOTAL

PRICE

000031

0.00

1.75

1.75

UNIT

PRICÉ

1.75

BLUEBERRY PIE

llllllllllllllllllllll backed ON

I

I

II llll IIIIIIIIIIII DEC 5

2 Pits $1.75

NETWT. IBB PRICE/lbga

19250 VAN NESS AVE.

TEL 213(320)8900

TOTALPfflCE®

N

r

i:Tí5

A

C

G

Mi

24

Page 28

[Example B] In case of purchasing 6 pieces of commodity at a price of $2.75 per 3 pieces

.......

(In the event that PLU#826 and a price of $2.75 are set in the speed key #40.)

EM1-31015D

SPLIT PRICE

Step

Mo

1

2

3

4

5

6

7

Ptoc‘>duio

Depress the speed key #40.

Enter the quantity of purchase.

(ex. 6 pieces)

Depress the FOR key.

Enter the quantity for that price.

Depress the FOR key.

Depress the PRINT key.

ModeSW(l): AUTO

Labels are issued in succession

after they are peeled.

Mode SW (1) : MANUAL

Single label is issued.

WEIGFIT

UNIT

PRICE

2.75

P 6

P 3

P 6

6

3

TOTAL

PRICE

0.00

2.75

2.75

2.75

2.75

5.50

LARGE SHRIHPS

PACKED ON

ii,V

005082

6

NFTWT. GS PRCE/lb53

19250 VAN NESS AVE.

TEL 213(320)8900

000061

pitcfs

$5.50

DEC 5

TOTALPRICEH

A

G

C

M

- 25

Page 29

13.5 TARE FUNCTION PROCEDURES

Control lock : REG, M.DOWN, or REWRAP

Mode SW (2) : WEIGH or FIX

There are two kinds of tare subtraction procedures, one is “Direct tare”, the other is “Preset tare”.

1) Direct tare subtraction

EM 1-31015D

Step

Place the tare on the platter,

(ex. 0.20 lbs.)

2

Depress the TARE key.

Weighing operation,

3

ex.) Enter the PLU#.

Depress the PLU key.

Place a commodity on.

Depress the PRINT key.

Remove the commodity together with

the tare.

Tare weight is cleared automatically,

then PLU data is returned to the PLU

file.

Procedure

I

WEIGHT

0.20

UNIT

Mill

0.00

1

0.00

0.00

1.00

1.50

1.50

TOTAL

PRICE

000000

000000

000101

0.00

1.50

T

▼

T

t

SN

A

C

C

M

BEEF LIVER

PACKED ON

DEC 1

SELL BY

220

1.00

NETWT. HÌB PRICE/liEB

19250 VAN NESS AVE.

TEL 213(320)8900

101509

01

1.50

0.00 000000

DEC 4

$1.50

TOTALPRICE®

NOTE ; Tare weight subtraction is available up to 30 lbs. When tare weight subtraction is in

operation, however, the scalable range for net weight is decreased by the amount of the

tare.

(Net weight = Gross weight - tare weight)

-26

Page 30

2) Preset tare subtraction

Step

No.

1

2

Enter the tare weight, (ex. 0.20 lbs.)

Depress the TARE key.

PruCGCIure

WEIGHT

0.00

- 0.20

UNIT

PRICE

P

P

; OTAL

PRICE

000020

000000

▼

EM 1-31015D

[

m.

mi

T

c

E

c

M

S

N

E

T

3 Place the tare on the platter.

4

Weighing operation.

Remove the commodity together with

5

the tare.

Tare weight is cleared automatically,

then PLU data is returned to the PLU

file.

0.00 P

0.00

P

3) Preset tare subtraction when tare weight is included in PLU data

(optional function by initial setting)

[Example] In the event that tare weight of 0.20 pounds is set for PLU#825.

000000

000000

T

-27-

Page 31

EM 1-31015D

13.6 SAVE KEY OPERATION SAMPLE

Control lock : REG, M.DOWN, or REWRAP

Mode SW (2) : WEIGH, BY COUNT, or FIX

The SAVE key is used to save tare weigh, unit price, and PLU data after taking a commodity off the

platter.

Step

Nq,

Place the tare on the platter,

1

(ex. 0.20 lbs.)

Depress the TARE key. 0.00

2

Enter the PLU#. (ex. PLU#101)

3

Depress the PLU key.

4

Depress the SAVE key.

5

The tare weight and PLU data are

saved.

Place a commodity on. (ex. 1 lb.)

6

Mode SW (1) : AUTO

7

The label is issued automatically.

Mode SW (1) : MANUAL

The label is issued after depressing

the PRINT key.

Proi'Pduro

WEIGHT

0.20

0.00

0.00

0.00 1.50

1.00 1.50

UNIT

PRICE

P 000000

P 000000

P

1.50 0.00

TOTAL

PRICE

000101

0.00

1.50

N

E

T

T

T

▼

T

I-:

I

w.

A

C

G

M

T

Remove the commodity together with

8

the tare.

Depress the CLEAR key.

9

Save mode is cleared.

10 Enter the 0.

Depress the TARE key.

11

The tare weight is cleared.

Depress the PLU key.

12

The sacle is returned to the initial

mode.

- 0.20 1.50

- 0.20

0

0.00 1.50 0.00

0.00

1.50

P

000000

T

T

- 28 -

Page 32

13.7 VOID KEY OPERATION SAMPLE

Control lock : REG, M.DOWN, or REWRAP

Mode SW (2) : WEIGH, BY COUNT, or FIX

On depressing the VOID key, the data of the last registration is subtracted from the memory.

EM1-31015D

Step

No.

1

Enter the PLU#100.

2

Depress the PLU key.

Place a commodity on the platter.

3

ModeSW(l): AUTO

4

The label is issued automatically.

Mode SW (1) ; MANUAL

The label is issued after depressing

the PRINT key.

Depress the VOID key.

5

The data is subtracted from the

memory.

Procedure

13.8 DATE CHANGE

Control lock : REG, M.DOWN, or REWRAP

Mode SW (2) : WEIGH, BY COUNT, or FIX

Vt/EIGHT

0.00

0.00 3.00 0.00

1.00

1.00 3.00

UNIT

PRICE

P

3.00 3.00

TOTAL

PRICE

000100

3.00

N

E

T

p

R

E

1

P

t

A

C

K

N

.e _

:0:T:S

A

c

c

M

T

M

Wm

1

E

The date can be changed temporarily.

Step

No.

Depress the DATE & TIME key.

Enter the new date,

ex.) Dec. 5, 1989

1

Depress the PRINT key.

NOTE ; The SL-5900 will check details of date input, and any wrong date will result in an error mode.

The correct date should be re-entered after depressing the CLEAR key.

Pfocedufe

0

Month (01 to 12)

8

Day (01 to 31)

WEIGHT

“ Year (00 to 99)

0.00

-29-

UNIT

PRICfi

TOTAL

PRICE

120189

120589

000000

N

E

T

A

C

C

M

'■m

M

s

f

Page 33

13.9 CALLING AND PRINTING A GRADE LINE

Control lock : REG, M.DOWN, or REWRAP

Mode SW (2) : WEIGH, BY COUNT, or FIX

A required Grade Line of those programmed (maximum 49 Grade Lines) can be call and printed on

the label to be issued, for the purpose of adding a short message to the commodity name.

P

R

Step

No,

1

Procedure

Enter the PLU#109.

WElGl 11

0.00

UNIT

PRICE

P

TOTAL

PRICE

000109

N

E

T

N

A

c

..fe.

EM1-31015D

1

E

ft

L

R

f

0

R

_

iisitSSS

A

C

■iCo:::

E

M

s

Depress the PLU key.

2

Depress the G.Line key.

3

Enter the required Grade Line #3

4

(Max.49)

Depress the PRINT key.

5

NOTES ; 1. The Grade Line # to be called in this operation must be one of those programmed

beforehand. If a Grade Line # of no programmed data is entered, a “DATA ENTRY

ERROR” will result on the following [PRT/*] key depression.

2. When a Grade Line Entry is operated after a PLU Entry as in the example above, the

Grade Line content is not displayed in the Messasge Window but is printed on the label.

On the contrary, when a Grade Line Entry is operated before a PLU Entry, the Grade

Line content is displayed in the Message Window but is not printed.

3. The Grade Line print position (above or below the Commodity Name line) is determined

by Initial Setting.

4. The maximum number of grade line characters is 26.

--------. - -

-----

...

P 3

GL1 E

GLI E

P 3

1.00

3

1.00

30

Page 34

13.10 ENTRY BY CLERK

Control lock : REG, M.DOWN, or REWRAP

Mode SW (2) : WEIGH, BY COUNT, or FIX

The entry by clerk mode is used to print out clerk sales data on labels.

EM1-31015D

Step

No.

1

Enter the PLU#33.

Depress the PLU key.

2

Place a commodity on the platter.

3

Depress the CLERK key.

4

Depressing the CLERK key allows a

receipt to be printed out.

NOTES : 1. PLUs can also be called by using the Speed key.

2. In the entry by clerk mode, a label is manually issued and its data is recorded in the

CLERK TOTAL memory, regardless of the position of switch (1).

Procedure '

0.00

0.00 2.50

1.00

1.00 2.50 2.50

iillli!

UNIT

PRICE

P

2.50

TOTAL

PRICE

000033

0.00

2.50

P

R

N

E

L

P

E

T

1

A

C

К

N

f

О

В

i

А

т

С

Е

С

М

м

S

31-

Page 35

13.11 ADD ENTRY BY CLERK

Control lock : REG

Mode SW (2) : WEIGH. BY COUNT, or FIX

The add entry by clerk mode is used to print out receipts.

Step

No

1

Enter the L/R key.

PrOCf duiC

WEIGHT

0.00

UNIT

PRICE

P

F

1

R

TOTAL

PRICE

N

E

1

h

£

L

P

A

c

1

:sn;xS-

. e

R

0

R

000000 T

EM1-31015D

t

r

E

C

M

M

Si

Enter the PLU#150.

2

Depress the PLU key.

3

Place a commodity on the platter.

4

ex.) Depress the CLERK key.

Depress the O key.

Enter the PLU#20.

Enter the VOID key.

Enter the PRINT key.

5

0.00

0.00 2.00

cit 3

cit 3

cit 1

cit 2

cit 2

P

000150

0.00

5.00

5.00

1.00

4.00

4.00

NOTES : 1. The Speed key can be used for calling the first PLU but cannot be used after pressing

the O key.

2. Depressing the CLERK key causes the item total to be displayed as “SUB-TOTAL”.

3. There are three kinds of void operations:

1) Item Correct

2) Void

.............................

3) Ail void

..............

........................

Depress the CLERK key, followed by the VOID key.

Deletes an item which was previously added.

Depress the O key, followed by the VOID key.

4. Up to 48 items can be added in the add entry mode.

T

T

T T

T

T T

T T

T T

▼

-32

Page 36

13.12 MULTIPLE WEIGHT

Control lock : REG. M.DOWN, or REWRAP

Mode SW (2) ; WEIGH '

This mode can be used when the option for multiple weight has been selected, and the entry unit

price can be changed or the unit price is open.

p

Stop

No-

1

2

3

4

Procedure

Enter the PLU#60.

Enter the Purchased Quantity.

(Numeric entry = 1 ~9)

Depress the FOR key.

Enter the unit price, (ex. $5.5)

WEIGHT

0.00 1

0.00

0.00

0.00

UNIT

PRICE

3.00 0.00

1

0.03

3 0.00

3 5.50

TOTAL

PRICE

0.00

0.00

0.00

n

N

e

p

E

A

T

C

K

N

L

N

iiesii

EM1-31015D

t

E

h

P

t

0

R

mu

M

i

T

c

E

c

M

s

Place a commodity on the platter.

5

ex) The amount for buying 2lb of a product which costs $5.50 per 3lb is automatically calculated.

2.00

3 5.50

3.68

- 33 -

Page 37

14. TOTAL OPERATION PROCEDURES

When the control lock is set to the “X” or “Z” position, it is available to issue READ or RESET

reports.

When the control lock is set to the “X (READ)” position, the totals will not be cleared as they are

printed on labels (for except the hourly report) or report paper.

When the control lock is set to the “Z (RESET)” position, the totals will be cleared as they printed on

labels (for except the hourly report) or report paper.

NOTE: Before printing out totals on the report paper, change the initial setting.

14.1 HOURLY TOTAL REPORT

The hourly total report is printed on report paper only.

P

1

ft

Step

No.

Procedure

iillll?

UNIT

TOTAL

PRICE

e

ft

A

K

w

siissi;

■¡mi:':

Is

EM1-31015D

h

R

0

R

f

A

T

C

F

C

M

M

5

1

Enter the report #1.

2

Depress the PRINT key.

1

1

P

34

Page 38

14.2 GRAND TOTAL REPORT

Stop

No

1

2

3

4

Enter the report #2.

Depress the PRINT key. 2 -

Enter the total memory #.

#1 : Day total (Normal)

#2 : Mark Down total

#3 : Rewrap total

Depress the PRINT key.

Procedure

wr-K.'ii-ir

UNIT

PRICE

2

21

22

23 -

nn ◄—

TOTAL

PRICE

P

EM1-31015D

F

1

E

N

N

P

t

A

T

a

K

R

L

R

I

0

N

.R

t

A

T

C

E

c

M

M

s

Day total :

Mark Down total

Rewrap total :

GRAND TOTAL

PACKED ON

DEC 1

N9

236.34 390

NETWT. IBS PRICE/lbS3

19250 VAN NESS AVE

TEL 213(320)8900

SELL BY

680.20

TOTALPHicEeai

GRAND TOTAL

PACKED ON

DEC 1

H«

7,98 30

NETWT. gSg PfllCMbSS

19250 VAN NESS AVE.

TEL 213(320)8900

sea BY

27.42

TOTALPRICEea

GRAND TOTAL

PACKED ON

DEC 1

R«

SELL BY

7.54 999856

NETVff. IBB PRICE^l]^

19250 VAN NESS AVE.

TEL 213(320)8900

27,54

TOTALPHICEea

. 35

Page 39

14.3 PLU TOTAL REPORT

1) Individual total

[Example] Individual PLU total (PLU#100) in the day total memory.

EM 1-31015D

Stop

No.

Procedure WEIGHT

1 Enter the report #3.

2 Depress the PRINT key.

Enter the total memory #1. 31

3

4 Depress the PRINT key.

Enter the search code 1.

5

Code 1 : PLU#

Code 2 : UPC#

Depress the PRINT key.

6

7 Enter the PLU#100.

Depress the PRINT key.

8

ililii:

3

3 -

31 -

311

311 □

311 □

311

'sm i

SiMSi

mm

C

yBm,

M

M

s

liiil

mirn

N

E '

iSl-iS:::'

'iM y

100

p

36

Page 40

2) Block total

[Example] UPC block total (UPC#250820~250829) in the mark down total memory.

EM1-31015D

No.

Procedure

1 Enter the report #3.

2 Depress the PRINT key.

Enter the total memory #2.

3

4 Depress the PRINT key.

Enter the search code 2.

5

Depress the PRINT key.

6

7 Enter the UPC#25082.

8 Depress the O

Depress the PRINT key.

9

key.

WEIOHT

UNIT

3

3 -

32

32 -

322

322 □

322 □

322 □

322

Iflllll:;

25082

25082 -

P

IllSiil

mii

E

^mm

mm

vvEiiS;

mm

iiA,.,';:;

mm

myy:

mm

6

mm

'mm

mm

mm

mm

1

r

c

M

&

NOTE : The

appropriate number of the keys.

key represents 0 through 9. Most significant digit in starting number followed by

O

37-

Page 41

3) Zone total

[Example] PLU zone total (PLU#100~303) in the rewrap total memory.

EM 1-31015D

Step

No,

1

Enter the report #3.

2

Depress the PRINT key.

3 Enter the total memory #3.

4

Depress the PRINT key.

Enter the search code 1.

5

6

Depress the PRINT key.

7

Enter the start PLU#100.

8

Depress the FOR key.

9

Enter the end PLU#303.

10

Depress the PRINT key.

Procedure . .

WEIGHT

UNIT

PRICE

3

3 -

33

33 -

331

331 □

331 □ 100

331 □ -

331 □

331

TOTAU

PRICE

303

p

A

C

C

M

-38

Page 42

4) Entire total

[Example] Entire PLU total in the day total memory.

EM1-31015D

39

Page 43

14.4 CLERK TOTAL REPORT (for SL-5900-36 only)

1) Clerk total

This is valid only when intial set 11-1 is 1.

EM1-31015D

Step

No

1

Enter the report #4.

2

Depress the PRINT key.

3 Enter the clerk memory #1.

4

Depress the PRINT key.

5 Enter the total memory #.

#1; Day total (Normal)

#2: Mark Down total

#3: Rewrap total

6 Depress the PRINT key.

NOTE: When the option for label has been selected by initial set 9-2, the data for clerks 1 to 6 is printed

on labels in on-demand dispensing mode (a clerk is skipped if its data is 0), and finally the gross

total is printed. For report paper, the data for clerks 1 to 6 and the gross total are printed.

Procedure

WEIGHT

UNIT

PRICE

4

4 -

41

41 -

411

412

413

41 n

TOTAL

PRICE

P

T

E

M

s

40

Page 44

2) Clerk name

With the SL-5900, the setting PLU data can be listed on report paper when the control lock is set to

the “X” position.

EM1-31015D

Step

No

1

Enter the report #4.

2

Depress the PRINT key. 4 -

3 Enter the clerk memory #2.

4

Depress the PRINT key.

• Piocedure ■ ■ ■

WEIGHT

UNIT

iiiliii

4

42

42 -

TOTAL

PRICE

P

N

E

T

R

E

P

A

C

К

1

1st

1

1

0

liSNSSi

R

F

A

C

imm

t

E

S

E

R

R

- 41-

Page 45

EM1-31015D

15. LIST UP OF PLU DATA

With the SL-5900, the setting PLU data can be listed on report paper when the control lock is set to

the “X" position (optional function by initial setting). Before listing, set the report paper on the label

cassette and install it correctly in the scale.

Step

No

Enter the report #51.

Depress the PRINT key.

Enter the PLU #.

ex.1) List up the individual PLU

ex.2)

ex.3)

ex.4) List up the entire PLU report.

List up the block PLU report.

(PLU #820-829)

Enter the PLU #82.

Depress the <> key.

List up the zone PLU report.

(PLU #100-303)

Enter the start PLU #100.

Depress the FOR key.

Enter the end PLU #303.

Procedure WEIGHT

report. (PLU #100)

Enter the PLU #100.

UNIT

PRICE

51

51 □

51 □

51

51

51

51

51

51

□

□

□

□

□

□

TOTAL

PRICE

100

82

82-

100

303

A

C

C

Depress the PRINT key.

51

-42

Page 46

Sample Reports

EM 1-31015D

Ex.1) Individual PLU report

Ex.2) Block PLU report

PLU PROGRAffiD DATA

PLU IQ OO R2 -

hfl CH II Ci I 6

STO RE I?

PLU l

COm OO IT Y DE SC RI PT IO N

000 82 0

000 82 1

000 82 5

000 82 6

D00 82 9

COD S TE MS

IFC 2 50 82 0 JPE R/ l b

T№ 0. 00

COO F IL ET S

IK 25 08 21

TAR E 0. 00

SHR IM PS

UPC 2 58 82 5 JPERW lb

TAR E 0. 20

LAR GE S HR IM PS

UPC 2 50 8^

TAR E 0. 00

SMO KE D SA LM ON C HU NK S

UPC 2 50 82 9

T№ 0. 00

0£C / 1/ 89

SHE LF L IF E

IPE R/ l b 2. 5 0

SIC LF LI FE 3

SIE FL IF E 3

$PE R / lb 2.7 5

SHE LF L IF E

SPE R/ l b 2.2 5

SKL FL IF E 7

I9: A8

2.3 0

3

1.2 5

4

Ex.3) Zone PLU report

PLU PROGRAHED DATA

PLU 1 0 00 10 0- 11 00 38 3

HGC HI NE i 1i DEC / 1/ 89

STO RE I 7 19: 49

PLU t

COt MO IT y DE SC RI PT IG H

000 10 0

000 10 1

000 10 2

000 10 3

000 30 1

000 30 2

000 30 3

T-B OI CS TE M

UPC 1 20 10 0 IP ER / l b 3.0 0

TAR E 0. 00 S HE LF L IF E

8EE F LI VE R

IFC 1 20 10 1 SPER/ l b

TAR E 0. 20 S HE LF L IF E

BEE F SI RL OI N

SI2 21 ER S TE MS

UPC 1 20 10 2 tf ER / l b 3. 50

TAR E 0. 00 S HE LF L IF E 4

GRO UW BE EF

irC 1 20 10 3 SP ER / l b OPEN

TAR E 0. 00 s ap L IF E 4

HAL F CH IC KE NS

UPC 1 20 30 1 SPER /l b

TAR E 0. 00 S HE LF L IF E 4

CHI CK EN L EG S

(PC 1 20 30 2 SP ER / l b 3.00

TAR E 0. 00 S IC LF LI FE 4

CHI CK EN U IN G

UPC 1 20 30 3 SP ER / l b

TAR E 0. 00 S IC LF LI FE

5

1.5 0

3

0.7 5

2.5 0

5

43 -

Page 47

Ex.4) Entire PLU report

PLU PROGRAHED DATA

PLU I ALL

EM1-31015D

nfl CH IN E1 16

ST0 KI 7

PUI I

COH NO OI IY D ES CR IP TI ON

000 03 1

BLU EB ER RY P IE

UPC 1 90 03 1 JPH/ ib

TAR E 0. 00 S HE LF L IF E

D00 03 2

CHO CO LA TE

ICR IH GU E PI E

IK 19 00 32 S PE R / lb

TAR E 0. 00 S HE LF L IF E

000 03 3

CRE AK C AR E

K 1 90 03 3 SP ER / l b

TAR E 0. 00 S IE Lf LI FE

000 03 9

DON UT S

K 1 90 03 9 SP ER / l b

TAR E 0. 00 S KF LI FE

moioo

T-B ON E ST EA R

K 1 20 10 0 SP ER / l b

TAR E 0. 00 S KL FL IF E

D00 1D 1

BSF LI WR

K 1 20 10 1 SPER /l b

TAR E 0. 20 s na p LI FE

TAR E 0. 00 S fi J LI FE

D00 30 1

HAL FC HI OS NS

K 1 20 30 1 SPER /l b 0.75

TAR E 0. 00 H LF LI FE

DOO SI Z

CHI CR BI LE GS

K 1 20 30 2 SP ER / l b 3.0 0

TAR E 0. 00 S HE LF L IF E 4

000 30 3

CHI CR EN U IN G

K 1 20 30 3 SP ER / l b

TAR E 0. 00 S KI FL IF E

000 82 0

COO ST EA RS

K 2 50 82 0 SP ER / l b 2.3 0

TAR E 0. 00 S HE LF L IF E

000 82 1

COO F IL ET S

K 2 50 82 1 SPER /l b

TAR E 0. 00 S HE LF L IF E

000 82 5

SHR II fS

K 2 50 82 5 SP ER 1/ 2l b 1.25

TAR E 0. 20 S IE LF LI FE

000 82 6

LAR GE S HR II fS

K 2 50 82 6 SPER /l b 2 .7 5

TAR E 0. 00 S HE LF L IF E

000 82 9

SHO RE D SA LK ON C HI KS

K 2 50 82 9 SP ER / l b 2.2 5

TAR E 0. 00 S EL F LI FE 7

QQQQQQ

777777

K 0 00 00 0 SP ER / l b OP EN

TAR E O. DO S HE LF L IF E

DEC / 1/ 89

19: 50

1.7 5

4

OPE N

4

1.2 5

3

1.0 0

3

3.0 0

5

1.5 0

3

4

4

2.5 0

5

3

2.5 0

3

3

4

0

- 44 -

Page 48

16. PROGRAMMING PROCEDURES

• Selection of Programming Menu

Step

No

Procedure

WeiGHT

UNIT

PRICE

TOTAL

PRICE

EMI-31015D

p

iifsi:

iSSiss

N

E

P

E

k

iii

r

E

N

mm

l,

R

1

0

N

mtm

A

T

C

£ i

G

M

s

Turn the control lock to “PROG/CMT”

1

position.

Select the menu #. (Refer to table 1.)

2

Depress the PROG key.

3

Start the programming.

4

Depress the PROG key. (Finish)

5

Return the step #2 or select another

6

mode.

P

P

Pn

P

▲

n

L

Me

n

Table 1 : Programming Menu Numbers and Their Functions

Menu No.

0

1 Setting or Changing PLU Data

2 Setting Store Address or Commercial Message

3

4

Changing Unit Price or Price

Adjusting Print Position for Label

Setting Date, Time, Machine Number, and Store Number

Item

nu #

5

7

8

11 Setting Ingredient

12

13 Switching On-Line/Local (for SL-5900-35/36 only)

17 Setting Grade Line (for SL-5900-36 only)

18

20 Transmitting PLU File or Unit Price (FUN System)

21

40

41

CMT Operations

Changing Bar Code Format

Assigning Speed Keys

Issuing Confirmation Label (for SL-5900-35/36 only)

Memory Card (for SL-5900-36 only)

Setting Clerk Name (for SL-5900-36 only)

Setting Print Item #1 ON/OFF

Setting Print Item #2 ON/OFF

- 45

Page 49

Menu No. 0

• Changing Unit Price or Price

The unit price or price in the PLU that is previously stored can be changed with this menu.

EM 1-31015D

Prooddure

WEIGHT

UNir

PRICE

PO

PO

PO

PO

PO

TOTAL

PRICE

31

101

1.50

1.25

101

A

The smallest

PLU# in the

memory is

displayed.

{Select another menu or mode.)

NOTES:

1. Recalling a PLU# that has not been stored in the PLU file will result in an error.

2. It is not available to change the unit price of a PLU if it has been set to “open price”.

46

Page 50

Menu No. 1

• Setting or Changing PLU Data

Setting or changing the contents of PLU (PLU#, UPC#, Commodity Name, etc-)-

EM1-31015D

Menu #.

AUTO CODE

for the UPC#.

PLU#.

Proc$dure

WEIGHT

PI 1

PI 1

UNIT

PRICE

P

PI 1

PI 10

PI 10

TOTAL

PRICE

31

120

120-

101

The smallest

PLU# in the

memory is

displayed.

PI 2

UPC#.

(continued on next page)

PI 2

PI 3

NOTE: UPC# is set after overwriting with the data of AUTO CODE.

ex.1) Input

AUTO CODE 120—

UPC#

101

120101

ex.2) Input

AUTO CODE 120-—

UPC# 120234

-47-

101

0

1234

Page 51

EM1-31015D

Commodity

name.

2ncl line

setting.

Quantity.

Procedure

B

RETURN

1/4

L

BY COUNT/ In what

SPACE

1

0

E E F

1 St line

setting.

V E

used? WEIGH or

FIX

WEIGHT

UNIT

PRICE

TOTAL

PRICE

PI 3 1 4

PI 3

P

R

PI 3

PI 4

PI 4

1 5

2 0

1 10

0

3

Unit price or

price.

Unit price flag.

ENTER

Open price.

Q’ty = 0

(per lb)

(per 1/2 lb)

DELETE

1/2

(per 1/4 lb)

RETURN

1/4

-►

-►

PI 4

PI 4

PI 4

PI 4

PI 4

PI 5

0.00

1.50

L-1

L-2

L-4

0

(continued on next page)

-48 -

Page 52

EM1-31015D

Procedure

WEIGHT

rOTAE

PRICE

P1

PI 6 0.20

PRICE

PI 7

PI 7

P1 7 1

PI 7

PI 1

P

(Selecl another menu or mode.)

NOTES:

1. The commodity name can be set in two lines. Each line can contain up to 26 characters

including spaces. Before setting the second line, depress the RETURN key.

2. When the quantity is 1 or more (PLU in BY COUNT mode), the unit price flag is skipped

automatically.

3. When the quantity is 1 or more (PLU in BY COUNT mode), the tare weight setting is skipped

automatically even if the tare weight setting has been enabled.

0

0

2

101

1

-49

Page 53

Changing PLU Number

EM1-31015D

Menu #.

Current PLU#.

New PLU#.

PriiCe<iur6

WEIGHT

UNIT

PRICE

P

PI 1 31

P1 9

P1 9 33

PI 9

P1 9 35

TOTAL

PRICE

p

mw:t

N

wms

mm

E

smm

T

Sttiifi:

1

-

wm

mmi;

sesi;.:

Sit'-SiSi

N

Mm

iP'vSS

MB

SfiSii

A

c

fS

(

T

e

M

$

PI 1 35

P 1

(Select another menu or mode.)

NOTE: It is not available to change to a PLU# which has already been used in the PLU file.

50 -

Page 54

Deleting PLU Data

EM1-31015D

Menu #.

PLU#.

Procedure

WEIGHT

UNIT

f>RlCE

P1

PI

PI

PI

TOTAL

PRICE

31

103

31

(Select another menu or mode.)

NOTE: All the data programmed for PLU#103 in the PLU file is deleted. If the scale goes into error

during a PLU deletion, it has not been reset or PLU# designated in the above procedure had

not been preset in the PLU file.

51 -

Page 55

Menu No. 2

• Setting Store Address or Commercial Message

With the SL-5900 scale, the store address or a commercial message can be set in the memory.

EM1-31015D

Procftdiirp

Menu #.

(Select another menu or mode.)

NOTE: The store address or a commercial message can be set in two lines.

Each line can contain up to 26 characters including spaces. Before setting the second line,

depress the RETURN key.

WEIGHT

UNIT

PRICE

P2

70TAL

PRfCe

M

- 52

Page 56

EM1-31015D

Menu No. 3