Page 1

TEC P ortable Printer

Table of Contents

B-210 SERIES

Owner’s Man ual

Document No. EM1-33043D

T O SHIBA TEC C O RPORATION

Page 2

DECLARATION OF

CONFORMI TY

Manufact ur er

Address

Product Nam e

model

options

Safety

EMC

Supplementary Informat ion

The product herewith complies with the

requirements of the Low Voltage Directive 73/

23/EEC. and the E M C directi ve 89/ 336/EEC.

The product was tested in a ty pical set up

1)

TEC personnel advocated.

2) The following technical documentation has

been filed for r eview.

• Factory Inspection Certificate by TUV

Rheinland

• Owner's Manual

• Schematic

• Certificates and Test Repor ts

: TEC Corporat ion

: 570 Ohi t o. Ohito- Cho.

Tagata-Gun, S hizuoka-Ken,

41 D-23 Japan

declares that foll owing

product

: Bar Code Pri nter

: B-210 Seri es

: All

Conforms to the following

Product Specifi c ations

: EN 60 950

: EN 56 022

IEC 801 -2

IEC 801-3

Page 3

EM1-33043A

TOC 2

TABLE OF CONTENTS

Page

1. INTRODUCTION ........................1-1

1.1 APPLICABLE MODEL ...........1-10

1.2 ACCESSORIES .....................1-11

2. SPECIFICATIONS ......................2-1

2.1 PRINTER ..............................2-1

2.2 SERIAL INTERFACE

(RS-232C) ...................................2-2

2.3 RADIO INTERFACE .............2-2

2.4 IrDA INTERFACE...................2-3

2.5 MEDIA ..................................2-4

3. APPEARANCE ............................3-1

3.1 FRONT/REAR VIEW .............3-1

3.2 OPERATION PANEL .............3-2

4. INSTALLING THE PRINTER ......4-1

4.1 LOADING THE BATTERY.....4-1

4.2 INSTALLING THE

MEDIA GUIDE ......................4-3

5. LOADING THE MEDIA ................5-1

6. SECURING THE PRINTER

TO YOUR WAIST ........................6-1

7. ISSUING THE MEDIA ..................7-1

8. CARE/HANDLING

OF THE MEDIA ...........................8-1

Page 4

EM1-33043A

TOC 1

Page

9. GENERAL MAINTENANCE ..........9-1

9.1 CLEANING ............................. 9-1

9.2 COVERS AND

OPERATION PANEL ..............9-3

9.3 REMOVING JAMMED

MEDIA .................................... 9-4

10. TROUBLESHOOTING ................10-1

CAUTION:

1. This manual may not be c opied in whole or in

part without

TEC.

2. The content s of this manual may be c hanged

without not ification.

3. Please refer to your local Author ized Service

representative with regard t o any quer ies y ou

may have in this manual.

Copyright © 1997

by TEC CORPORATI ON

All Rights Reserved

570 Ohito. O hito-cho. Tagat a- gun. Shizuoka-ken. JAPAN

the

prior written permi ssion of

Page 5

1. INTRODUCTION

EM1-33043D

1. INTRODUCTION

1. INTRODUCTION

Thank you for purchasing the TEC B-210

series portable printer.

The B-210 printer displays its high

performance with extraordinarily high

speed printing up to 50.8 mm/sec. It has a

considerably compact and light body of 88

mm in height, 128 mm in width and 50 mm

in depth, weighing about 460 g.

As data communication method, minute

radio communication (for GH11 and

GH12 models) or IrDA (GH24 model),

which requires no cable for data

transmission between a handy terminal

and the printer, is adopted.

Owing to a low power consumption design

and use of a chargeable lithium battery as

a power source, this printer can issue 300

pieces of 40-mm pitch labels with a fullycharged battery.

Loading a label roll is very simple; just put

a label roll into the printer and close the

media cover. A belt holder provided on the

rear of the printer enables the printer to be

held hands-free at your waist for improved

productivity.

This manual contains general set-up and

maintenance information and should be

read carefully to help gain maximum

performance and life from your printer. For

most queries please refer to this manual

and keep it safe for future reference.

1- 1

Page 6

1. INTRODUCTION

EM1-33043D

1. INTRODUCTION

FCC Notice

This equipment has been tested and

found to comply with the limits for a

Class B digital device, pursuant to Part

15 of the FCC Rules. These limits are

designed to provide reasonable

protection against harmful interference

in a residential installation. This

equipment generates, uses, and can

radiate radio frequency energy and, if

not installed and used in accordance

with the instructions, may cause harmful

interference to radio communications.

However, there is no guarantee that

interference will not occur in a particular

installation. If this equipment does cause

harmful interference to radio or television

reception, which can be determined by

turning the equipment off and on, the

user is encouraged to try to correct the

interference by one or more of the

following measures:

• Reorient or relocate the receiving

antenna.

• Increase the separation between the

equipment and receiver.

• Connect the equipment into an outlet

on a circuit different from that to which

the receiver is connected.

• Consult the dealer or an experienced

radio/TV technician for help.

1- 2

Page 7

1. INTRODUCTION

EM1-33043D

1. INTRODUCTION

Changes or modifications not expressly

approved by manufacturer for compliance

could void the user's authority to operate

the equipment.

CAUTION

To avoid injury, be careful not to catch or

jam your fingers while opening or closing

the cover.

CAUTION

Do not touch moving parts. To reduce the

risk that fingers, jewelry, clothing, etc., be

drawn into the moving parts, push the

switch in the "O" position to stop

movement.

Safety Summary

Personal safety in handling or maintaining

the equipment is extremely important.

Warnings and Cautions necessary for

safe handling are included in this manual.

All warnings and cautions contained in

this manual and written inside or outside

of the printer should be read and

understood before handling or maintaining

the equipment.

Do not attempt to effect repairs to this

equipment. If a fault occurs that cannot

be rectified using the procedures

described in this manual, turn off the

power, then contact your authorised

TOSHIBA TEC representative for

assistance.

1- 3

Page 8

1. INTRODUCTION

EM1-33043D

1. INTRODUCTION

Safety Precautions

This Owner's Manual and the products

(machines) which you have purchased

contain indications which should be

observed in order to use the machines

safely and prevent harm to yourself and

others and damage to property. The

meanings of these indications and

symbols are given below.

Read these indications and become

familiar with their contents before reading

this Owner's Manual.

This indicates that there is the risk

WARNING

of death or serious injury if the

machines are improperly handled

contrary to this indication.

• If water or any other liquid enters the

machine, turn off the power.

Continuous use of the machine under

such conditions may cause fire or

electric shock.

• If the enclosure is damaged when

dropped or subject to shock, turn off

the power. Continuous use of the

machine under such conditions may

cause fire or electric shock.

• Avoid continuous exposure to direct

sunlight or high temperature as this

may cause fire.

• Do not remove covers or modify the

machine by yourself. Doing so may

cause fire or electric shock.

1- 4

Page 9

1. INTRODUCTION

EM1-33043D

1. INTRODUCTION

• Avoid water, operation with wet hands

or cleaning with a moistened cloth.

Failure to do this may cause fire or

electric shock.

• Do not wipe the machine with a cloth

moistened with thinner or other volatile

solvent as this may cause fire or electric

shock.

• Use the specified battery only. Failure

to do this may cause fire or electric

shock.

• Danger of explosion if the battery is

incorrectly replaced. Replace the

battery only with 'TOSHIBA TEC

Corporation, Battery Pack Type B-213BT, 7.2 V 1350 mAh Li-ion'.

Discard used batteries according to

the manufacturer's instruction.

• ATTENTION:

II ya denger d'explosion s'il ya

remplacement incorrect de la batterrie.

Remplacer uniquement avec une

batterie du même type ou d'un type

équivalent recommandé par le

constructeur.

Mettre au rebut les batteries usagées

conformément aux instructions du

fabricant.

• Do not disassemble and modify the

battery because it has a protection unit

in it. Doing so may break the protection

unit, causing the battery to heat up,

burst or burn.

1- 5

Page 10

1. INTRODUCTION

EM1-33043D

• If the battery gets wet, dry it completely.

Using a wet battery may cause fire or

electric shock.

• Be aware of the following precautions

when using batteries. Otherwise they

could heat up, burst or burn.

■ Do not throw the battery into fire or

heat it with a microwave or oven,

etc.

■ Do not load the battery with the

electrodes reversed.

■ Do not connect the electrodes with

metal objects like wire. Do not

carry or store the battery along with

metal objects such as necklaces,

hairpins, etc.

■ Do not stick a needle into, hammer,

step on, or drop the battery.

■ Do not solder the battery.

■ Do not leave the battery where the

temperature is more than 60°

centigrade, such as inside a car or

1- 6

Page 11

1. INTRODUCTION

CAUTION

This indicates that there is the risk of

personal injury or damage to objects

if the machines are improperly

handled contrary to this indication.

EM1-33043D

1. INTRODUCTION

• Keep away from flame or other sources

of heat. Failure to do this may cause

fire or machine failure.

• Do not drop or shock the machine as

this may cause machine failure.

• During lightening, turn off and keep

away from the machine because of

danger of electric shock and machine

failure.

• Avoid locations subject to rapid change

in temperature as this causes

condensation, causing electric shock

or machine failure.

• Do not damage the print head, platen

or strip roller with a sharp object. Doing

so may cause machine failure.

• Do not touch or contact the print head

element with a metal object. Doing so

may cause machine failure.

• Use the specified media only. Failure to

do this may cause machine failure.

• Be sure to turn off the machine before

replacing the battery, or machine failure

may occur.

• Do not charge the battery near flame or

under direct sunlight. High temperature

may activate or damage the protection

unit of the battery, disabling the electric

charge or causing it to overheat, burst, or

burn.

1- 7

Page 12

1. INTRODUCTION

EM1-33043D

1. INTRODUCTION

• Unload the battery when the machine will

not be used for a long time. Failure to do

this may cause machine failure.

• Keep the battery away from flame, a heat

source or other locations subject to high

temperature.

Failure to do this may cause it to over

heat or burn.

• Use the specified battery charger only.

Failure to do this may cause the battery

to overheat, burst or burn.

• Do not force the battery into the machine

or battery charger. Doing so may cause

the battery to overheat, burst or burn.

Check for the correct electrode.

• Do not connect the battery to a power

outlet or a car cigarette lighter jack as this

may cause the battery to overheat, burst

or burn.

• Because the B-213-BT battery is

exclusively for the B-210 printer, do not

use the battery in other machines. Doing

so may damage the battery or affect the

performance and life of the battery.

1- 8

Page 13

1. INTRODUCTION

EM1-33043D

1. INTRODUCTION

Precautions

The following precautions will help to

ensure that this machine will continue to

function correctly.

1 Try to avoid locations that have the

following adverse conditions:

* Temperatures below -5°C and

above 40°C

* Direct sunlight

* Excessive vibration

2 The cover should be cleaned by

wiping with a dry cloth or a cloth

slightly dampened with a mild

detergent solution. NEVER USE

THINNER OR ANY OTHER

VOLATILE SOLVENT on the

plastic covers.

3 USE ONLY TOSHIBA TEC

SPECIFIED media.

4 DO NOT STORE the media where

they might be exposed to direct

sunlight, high temperatures, high

humidity, dust, or gas.

5 Any data stored in the memory of

the printer could be lost during a

printer fault.

6 DO NOT open the media cover

and battery cover during operation.

Doing so will stop printer operation.

7 DO NOT scratch the surface of

printed labels or receipt with a sharp

object.

1- 9

Page 14

1. INTRODUCTION

1.1 APPLICABLE MODEL

1.1 APPLICABLE MODEL

• B-210 Series

Model name description

B - 2 1 1 - G H 1 1 - G B

Destination

GB: Great Britain

QP: Europe

QM: Other countries

Interface

11: Radio (418 MHz)

+ RS-232C

12: Radio (433 MHz)

+ RS-232C

23: RS-232C

24: RS-232C + IrDA

Issue mode

H: Batch/Strip mode

Dot density of the print head

G: 8 dots/mm

EM1-33043D

NOTE: The B-211-GH11-GB model is

for exclusive use in Great Britain.

1- 10

Page 15

1. INTRODUCTION

EM1-33043D

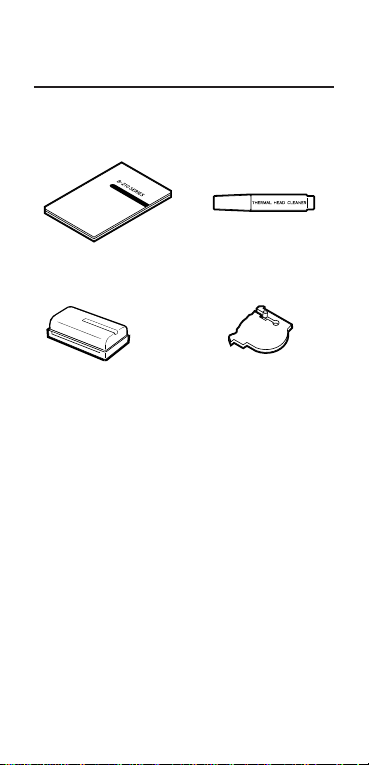

1.2 ACCESSORIES

1.2 ACCESSORIES

Owner’s Manual Print Head Cleaner

Battery Media Guide

1- 11

Page 16

2. SPECIFICATIONS

EM1-33043D

2.1 PRINTER

2. SPECIFICATIONS

2.1 PRINTER

Item

Dimensions

Weight

Operating temperature

Operating humidity

Issue mode

Print head

Print method

Print head dot density

Print speed

Effective print width

Fonts

Bar code types

Interface

Power source

∗: Available only on the GH23 model.

Description

128 mm (W) x 88 mm (H)

x 50 mm (D)

Approximate 460 g, 450 g∗

(Including a battery)

-5°C ~ 40°C

25%~ 85% RH

(No condensation)

Batch mode/Strip mode

Thermal print head

Thermal direct

8 dots/mm (203 dpi)

Max. 50.8 mm/sec.

48 mm

Standard characters and

characters under bar codes:

Writable characters:

Times Roman: 21 point

Helvetica: 18 point

Letter Gothic: 14.3 point

Courier: 15 point

Presentation: 27 point

NW7, EAN 8, EAN 13,

CODE 39, Interleave 2 of 5

PDF417, EAN128,

CODE128

• GH11 model

RS-232C or radio (418

MHz)

• GH12 model

RS-232C or radio (433

MHz)

• GH23 model

RS-232C

• GH24 model

RS-232C + IrDA

Lithium ion battery 7.2V

1350mA (official)

12x24 dots

24x24 dots

2- 1

Page 17

2. SPECIFICATIONS

2.2 SERIAL INTERFACE (RS-232C)

EM1-33043D

2.2 SERIAL INTERFACE

(RS-232C)

Item

Baud rate

Protocol

Signals

9600 bps

XON/XOFF, 8 bit data, Even parity,

Stop bit = 1 bit

TXD, RXD, RTS, CTS

Description

2.3 RADIO INTERFACE

The following specification is applicable

only to the GH11 and GH12 models.

Item

Type

Receiving frequency

Communication method

Transmission speed

Protocol

Communicating

distance

∗: GH11 model

∗∗: GH12 model

NOTE: The RS-232C interface cable

must be disconnected when using

the radio communication.

Description

FM superhet UHF radio

telemetry receiver

(Complies with

MPT1340∗, ETS300220∗∗)

418 MHz∗, 433.92 MHz∗∗

Unidirectional

(Receive only)

4800 bps

8 bit data, non parity,

stop bit = 1 bit

3 m

2- 2

Page 18

2. SPECIFICATIONS

EM1-33043D

2.4 IrDA INTERFACE

2.4 IrDA INTERFACE

The following specification is applicable

only to the GH24 model.

Item Description

Type Physical layer

Transmission speed 19200 bps

Communicable distance 0.3 m max.

Peak wavelength of 850 to 900 nm

the infrared ray

Communicable angle ±15° degrees max.

Ambient light immunity 1,000 lx max. (under a

Intensity of emission Min. 36mW/SR (θh,

Receivable infrared ray Min. 7µW/cm2 (θh,

Protocol Start-stop synchroniza-

conforming to IrDA-SIR

V1.0

fluorescent lamp or

incandescent lamp)

θv≤ ± 15°)

θv≤ ± 15°)

tion, Half duplex

transmission

Start bit = 1 bit, Stop bit

= 1 bit, 8 bit data, Non

parity

2- 3

Page 19

2. SPECIFICATIONS

2.5 MEDIA

Label

I

H

G

D

C

Receipt paper

Black Mark

(on reverse side)

EM1-33043D

E

A

B

Feed direction

Receipt

2.5 MEDIA

H

G

D

B

A

F

Fig. 2-1

2- 4

Page 20

2. SPECIFICATIONS

EM1-33043D

2.5 MEDIA

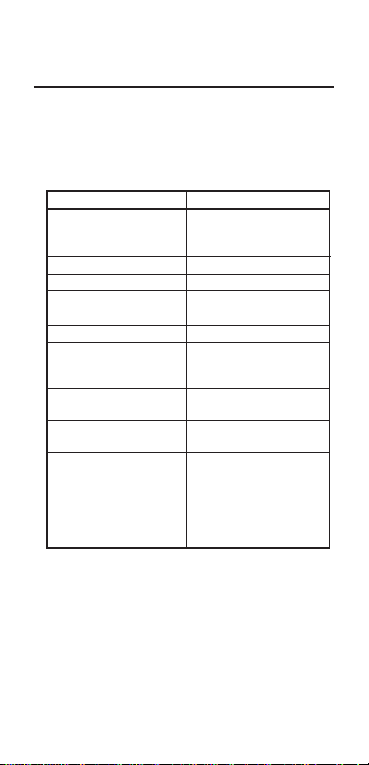

Item

A

B

C

D

E

F

G

H

Outer roll diameter ø34 (Max.)

Roll way The print side facing

Thickness Label 111µm

Issue mode

Label/Receipt 10.0 ~ 167.0 13.0 ~ 67.0

Pitch

Label/Receipt 7.0 ~ 160.0 10.0 ~ 60.0

length

Width including 34, 37, 40, 43, 46, 49,

backing paper 52, 55±0.5

Media width Label 31.0 ~ 52.0

Receipt 34, 37, 40, 43, 46, 49

52, 55±0.5

Gap length 3.0 ~ 7.0

Black mark length 3.0 ~ 7.0

Effective print width ~ 48.0

Effective print length 7.0 ~ 160.0

Margin 1.0 (gap = 7 mm) ~

I

5.0 (gap = 3 mm)

inside

Receipt 65µm

(Unit: mm)

Strip modeBatch mode

NOTE: Do not use media other than the above

to ensure print quality and print head life.

2- 5

Page 21

3. APPEARANCE

3.1 FRONT/REAR VIEW

3. APPEARANCE

3.1 FRONT/REAR VIEW

Front View

IrDA Interface Window

(GH24 model only)

Media Cover

Media Cover

Release Catch

Media Outlet

Rear View

Belt Holder

REPRINT Button

Status Indicator

Backing Paper Outlet

Serial Interface Connector

EM1-33043D

Power Switch

Battery Cover

Release Catch

Battery Cover

3- 1

Fig. 3-1

Page 22

3. APPEARANCE

3.2 OPERATION PANEL

3.2 OPERATION PANEL

REPRINT Button

Each time this button is pressed,

REPRINT

STATUS

the printer issues the same label as

the previous one. When the button

is held, the printer issues labels

continuously.

Receipts are fed for 20 mm by

I

pressing this button once.

STATUS Indicator (Red)

The status indicator lights, and then

goes off at power on.

The indicator which does not light or

stays lit indicates the loaded battery

is uncharged.

Power Switch

A slide power switch

EM1-33043D

3- 2

Page 23

4. INSTALLING THE PRINTER

4.1 LOADING THE BATTERY

EM1-33043D

4. INSTALLING THE

PRINTER

4.1 LOADING THE BATTERY

CAUTION:

1. Be sure to turn off the printer before

loading the battery.

2. Use the specified battery only. Failure

to do this may cause fire or electric

shock.

3. In the United States, used lithium ion

batteries should be returned to the

store where you bought the machine.

(USA only)

4. LITHIUM ION BATTERY

DISPOSE OF PROPERLY

Caution: Do not handle damaged or

leaking lithium ion battery.

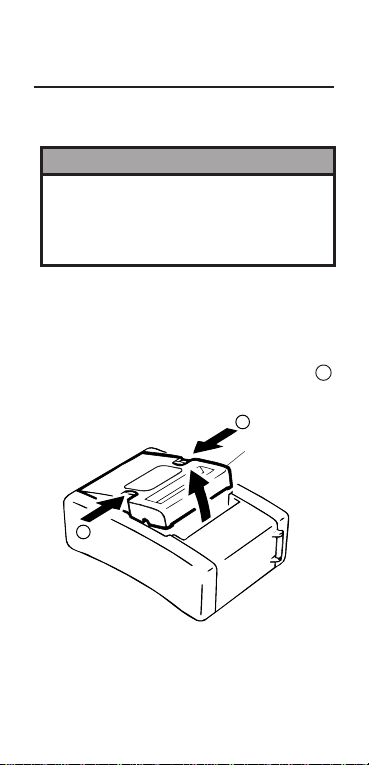

1) Slide the battery cover release catch

toward the direction indicated by the

arrow and open the battery cover.

4- 1

Battery Cover

Fig. 4-1

Page 24

4. INSTALLING THE PRINTER

4.1 LOADING THE BATTERY

EM1-33043D

2) Load a fully charged battery into the

printer.

NOTE: Remove the battery pack cover

from the battery, and then load

the battery in the correct

orientation as indicated in the

following figure.

Battery

Battery Pack

Cover

Fig. 4-2

3) Close the battery cover completely.

4) Turn on the printer and the status

indicator will blink, then go off. The

status indicator which does not light

or stays lit indicates that the battery is

uncharged.

4- 2

Page 25

4. INSTALLING THE PRINTER

4.2 INSTALLING THE MEDIA GUIDE

EM1-33043D

4.2 INSTALLING THE MEDIA

GUIDE

NOTE: The media guide is not required

1) Slide the media cover release catches

2) Fit the media guide into a slot which

for a 55 mm wide label roll.

and open the media cover.

WARNING!

A cutter is attached to the inside of the

media cover. Care should be take not to

injure your hand with the cutter when

opening the cover.

corresponds to the width of media to

be used. First insert portion 1 , then

2 until it snaps in position.

Media Guide

2

1

4- 3

Fig. 4-3

Page 26

4. INSTALLING THE PRINTER

4.2 INSTALLING THE MEDIA GUIDE

EM1-33043D

Unit: mm

Slot 1st 2nd 3rd 4th 5th 6th 7th

Media 52 49 46 43 40 37 34

Width

3) To remove or relocate the media guide,

push up the pin on the media guide

with a screw driver or equivalent, and

remove the media guide from the

printer.

Media Guide

Pin

Fig. 4-4

4- 4

Page 27

5. LOADING THE MEDIA

5. LOADING THE MEDIA

EM1-33043D

5. LOADING THE MEDIA

WARNING!

A cutter is attached to the inside of the

media cover. Care should be taken not

to injure your hand with the cutter when

opening the cover.

This printer prints both labels and receipts.

1. Turn off the printer.

2. Slide the media cover release catches

in the direction indicated by arrows A

and open the media cover.

A

Media Cover

A

Fig. 5-1

5- 1

Page 28

5. LOADING THE MEDIA

5. LOADING THE MEDIA

EM1-33043D

3. Put a label roll or a receipt roll into the

media holder unit in the orientation as

shown below.

Media Roll

Media Holder Unit

Fig. 5-2

• Batch issue

1. Insert the leading edge of the label

roll into the media outlet.

5- 2

Fig. 5-3

Page 29

5. LOADING THE MEDIA

5. LOADING THE MEDIA

EM1-33043D

2. Close the media cover completely.

Make sure that the media cover

release catches snap back into

position.

Fig. 5-4

3. Turn on the printer and press the

REPRINT button. The printer will

align the print start position for the

label. When using receipts, the

printer will feed for 20 mm.

5- 3

Page 30

5. LOADING THE MEDIA

5. LOADING THE MEDIA

EM1-33043D

• Strip issue

1. Unroll the label roll a little and remove

a label.

Fig. 5-5

2. Close the media cover completely.

Make sure that the media cover

release catches snap back into

position.

5- 4

Fig. 5-6

Page 31

5. LOADING THE MEDIA

5. LOADING THE MEDIA

EM1-33043D

3. Turn on the printer and press the

REPRINT button. The printer will

align the print start position.

NOTES:

1. Be sure to take up any slack in the

media roll before closing the media

cover. An incompletely closed cover

will cause a media skew, print position

misalignment, poor print quality, paper

jam, etc.

2. If the media cover is closed while the

printer is turned on, the printer will

automatically feed a label to align the

print position.

5- 5

Page 32

6. SECURING THE PRINTER TO

YOUR WAIST

6. SECURING THE PRINTER TO YOUR WAIST

6.

SECURING THE PRINTER

EM1-33043D

TO YOUR WAIST

CAUTION:

Care should be taken not to drop the

printer when securing it to your waist.

1) Lift the belt holder.

Belt Holder

2) Insert the belt holder into your belt and

lower the printer to secure it to your

waist.

Belt Holder

6- 1

Belt

Fig. 6-1

Fig. 6-2

Page 33

7. ISSUING THE MEDIA

7. ISSUING THE MEDIA

EM1-33043D

7. ISSUING THE MEDIA

CAUTIONS:

1. Radio communication between a

handy terminal and the B-210 printer

is guaranteed when the handy

terminal is in the operator’s hand and

the printer is secured at the waist.

Proper radio communication may not

be obtained when used in other

conditions and in areas subject to

noise and radio interference.

2. Be sure to disconnect the RS-232C

interface cable from the printer before

performing radio communication or

IrDA.

3. To perform the radio communication

or IrDA, the printer must be

synchronized with the handy terminal.

4. IrDA is available on the condition

indicated below. The following

performance is obtained under the

fluorescent lamp (max. 1000 lx). Care

must be taken to prevent direct

sunlight from coming into the IrDA

interface window.

Handy

Terminal

max. 30 cm

Printer

Printer

Handy

Terminal

max. 30 cm

7- 1

Page 34

7. ISSUING THE MEDIA

7. ISSUING THE MEDIA

EM1-33043D

1. Turn on the printer.

2. Send data from the handy terminal to

the printer. (Regarding the operation

of the handy terminal, please refer to

the handy terminal’s operating manual.)

(Radio Communication Sample)

Fig. 7-1

3. Issuing labels

1) The number of labels are specified

when issuing labels in batch mode.

To re-issue the label, press the

REPRINT button.

2) The printer prints labels one by one

in strip mode by pressing the

REPRINT button.

To issue more than one label,

remove the printed label before

issuing the next one.

NOTE: Trim off the backing paper

coming from the backing paper

outlet.

7- 2

Page 35

7. ISSUING THE MEDIA

7. ISSUING THE MEDIA

EM1-33043D

3) After printing the receipt, press the

REPRINT button to feed it to the

position where it is easily cut. Each

time the REPRINT button is pressed,

the receipt is fed for 20 mm.

4. Trim off the printed media upward or

downward with the cutter.

NOTE: Do not pull the media toward

the feed direction, as this will

misalign the print position of

the next media.

Media

Fig. 7-2

7- 3

Page 36

8. CARE/HANDLING OF

THE MEDIA

8. CARE/HANDLING OF THE MEDIA

EM1-33043D

8. CARE/HANDLING OF

THE MEDIA

CAUTION:

Be sure to read carefully and understand

the Supply Manual. Use only media

which meet specified requirements. Use

of non-specified media may shorten the

head life and result in problems with bar

code readability or print quality. All media

should be handled with care to avoid any

damage to the media or printer. Read the

following guideline carefully.

• Do not store the media for longer than

the manufactures recommended shelf

life.

• Store media rolls on the flat end, do not

store them on the curved sides as this

might flatten that side causing erratic

media advance and poor print quality.

• Store the media in plastic bags and

always reseal after opening.

Unprotected media can get dirty and the

extra abrasion from the dust and dirt

particles will shorten the print head life.

• Store the media in a cool, dry place.

Avoid areas where they would be

exposed to direct sunlight, high

temperature, high humidity, dust or gas.

8- 1

Page 37

8. CARE/HANDLING OF

THE MEDIA

8. CARE/HANDLING OF THE MEDIA

EM1-33043D

• The thermal paper used for direct thermal

printing must not have the specifications

which exceed Ca++ 800 ppm, Na+ 800

ppm, K+ 800 ppm and CL- 600 ppm.

• Some ink used on pre-printed labels

may contain components which shorten

the print head's product life. Do not use

labels pre-printed with ink which contains

hard substances such as carbonic

calcium (CaCO3) and kaolin (Al2O3,

2SiO2, 2H2O).

For further information please contact your

local distributor or your media manufacturer.

8- 2

Page 38

9. GENERAL MAINTENANCE

9.

GENERAL MAINTENANCE

EM1-33043D

9.1 CLEANING

9.1 CLEANING

WARNING!

Care should be taken not to injure your

hand with the cutter when cleaning.

To help retain the high quality and

performance of your printer it should be

regularly cleaned. The greater the usage

of the printer, the more frequent the

cleaning. (i.e. low usage = weekly: high

usage = daily).

1. Turn off the printer.

2. Open the media cover.

3. Remove the media roll from the printer.

4. Clean the print head element with the

print head cleaner.

5. Wipe the cutter platen and strip roller

with a soft cloth moistened with alcohol.

Remove dust or foreign substances from

the internal parts of the printer, if any.

9- 1

Page 39

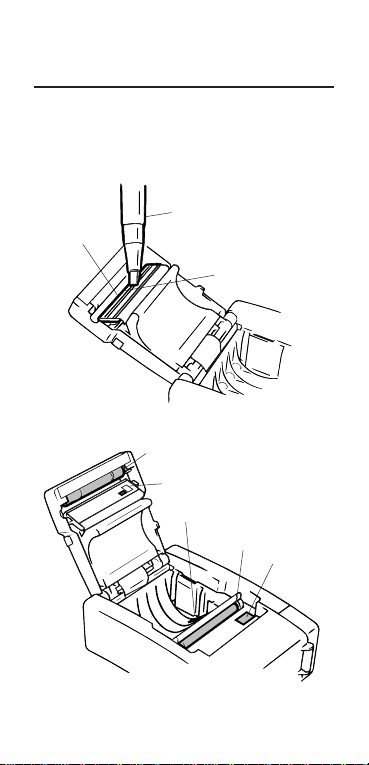

9. GENERAL MAINTENANCE

EM1-33043D

9.1 CLEANING

6. Remove paper particles or stains from

the feed gap sensor, black mark sensor,

and the batch/strip sensor with a soft

cloth.

Print Head Cleaner

Cutter

Print Head

Fig. 9-1

Strip Roller

Feed Gap Sensor

Black Mark Sensor

Platen

Strip Mode

Sensor

9- 2

Fig. 9-2

Page 40

9. GENERAL MAINTENANCE

9.2 COVERS AND OPERATION

EM1-33043D

WARNING!

1. Be sure to turn off the printer prior to

performing any maintenance.

2. Do not use any tool that may damage

the print head.

3. DO NOT POUR WATER directly onto

the printer.

9.2 COVERS AND OPERATION

PANEL

The covers should be cleaned by wiping

with a dry cloth or a cloth slightly dampened

with a mild detergent solution.

NOTE: Clean the printer cover with an

electrostatic free cleaner for

automated office equipment.

CAUTION:

1. DO NOT POUR WATER directly onto

the printer.

2. DO NOT APPLY cleaner or detergent

directly onto any cover or panel.

3. NEVER USE THINNER OR OTHER

VOLATILE SOLVENT on the plastic

covers.

4. DO NOT clean the covers or the

operation panel with alcohol as it

may cause them to discolor, loose

their shape or develop structural

weakness.

9- 3

Page 41

9. GENERAL MAINTENANCE

9.3 REMOVING JAMMED MEDIA

EM1-33043D

9.3 REMOVING JAMMED MEDIA

1. Turn off the printer.

2. Open the media cover.

3. Remove the media roll from the printer.

4. Remove the jammed media. DO NOT

USE any sharp implement or tool as

these could damage the printer.

5. Clean the print head and platen, then

remove any further dust or foreign

substances.

9- 4

Page 42

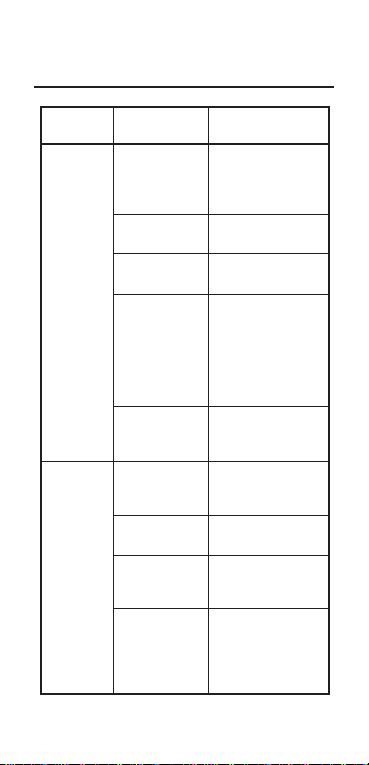

10. TROUBLESHOOTING

10. TROUBLESHOOTING

EM1-33043D

10.TROUBLESHOOTING

WARNING!

If you cannot solve a problem with the

following solutions, do not attempt to

repair it yourself. Turn off the printer,

then contact your TOSHIBA TEC

representative for assistance.

When a problem occurs during operation,

the status indicator will blink or light. Refer

to the following troubleshooting guide and

take corrective action.

Status

Indicator

Blinks

Lights

Cause

Media end

The media cover

is open.

The printer is

jammed with

media.

The print head

element is broken.

A communication

error occurred.

The battery

voltage is low.

Action

Load a new media

roll.

Close the media

cover completely.

Turn off the printer,

remove the jammed

media, and re-load

the media roll

correctly.

Contact a TOSHIBA TEC

service representative for

repair.

Check that the

interface cable is

connected firmly.

Check the

communication

parameters.

Turn off the printer

and replace the

battery with a fully

10- 1

Page 43

10. TROUBLESHOOTING

EM1-33043D

10. TROUBLESHOOTING

Other

problems

The printer

does not

issue media.

Print failure

Check

Did the status

indicator light

and then go off

at power on?

Is the printer

turned on?

Is the media roll

loaded correctly?

Is the status

indicator blinking

or lighting?

Is the media

cover closed

completely?

Is the print head

dirty?

Is the media

discolored?

Is the specified

media used?

Are the media

cover release

catches locked

completely?

Corrective action

Charge the battery

fully.

Turn on the printer.

Re-load the media

roll correctly.

Check the handy

terminal for an error

status, and take

appropriate action

described in the

handy terminal’s

operating manual.

Close the media

cover completely.

Clean the print head

with the attached

print head cleaner.

Replace the media

roll with a new one.

Replace the media

roll with the proper

one.

Close the media

cover so that the

media cover release

catches snap back

into position.

10- 2

Page 44

Page 45

Page 46

PRINTED IN JAPAN

E

EM1-33043D 99010500 GS

Loading...

Loading...