Page 1

TEC Electronic Computing Scale

SL-9000-ESB SERIES

Owner’s Manual

Page 2

Page 3

Safety Summary

Safety Summary

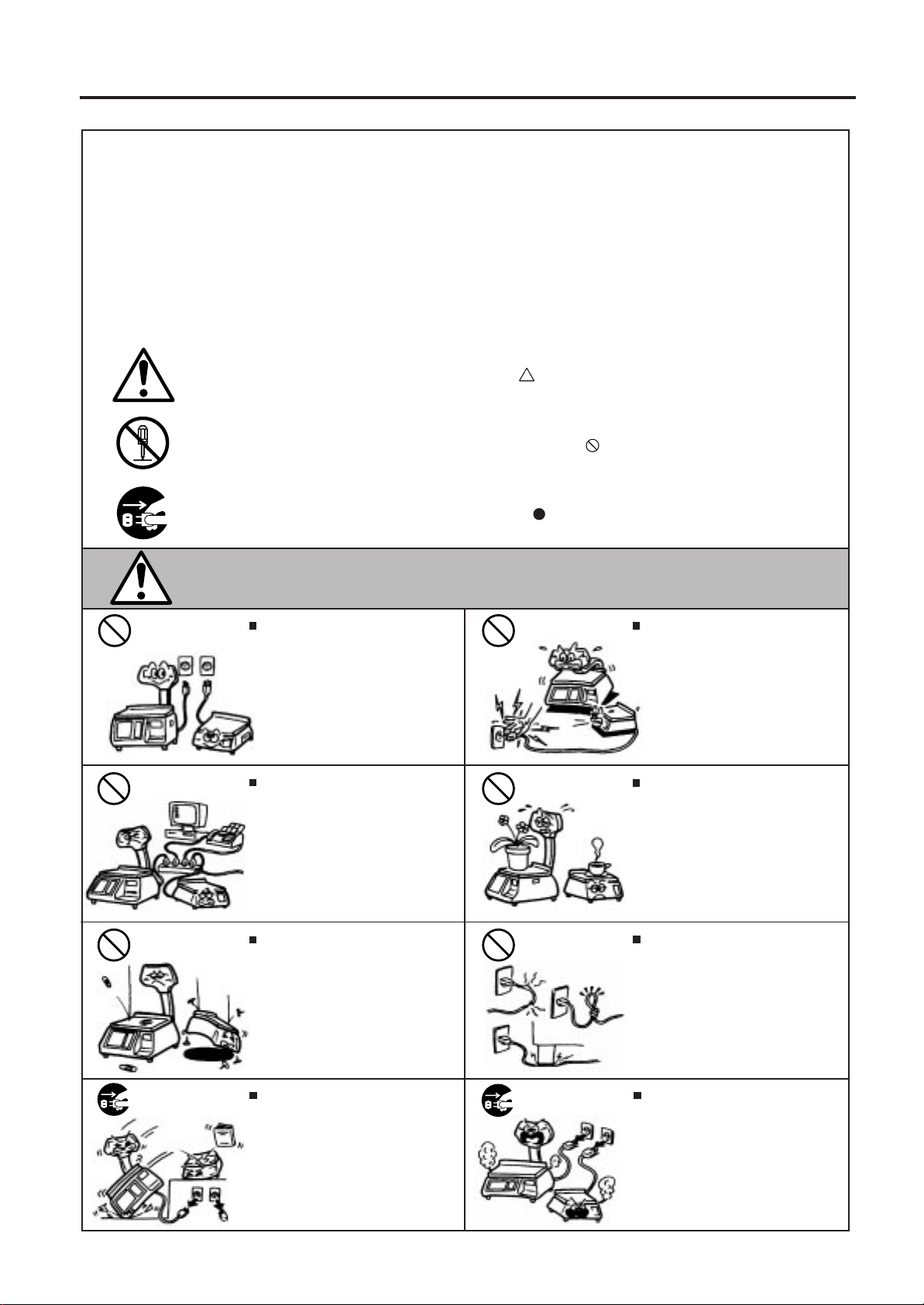

Personal safety in handling or maintaining the equipment is extremely important. Warnings and Cautions

necessary for safe handling are included in this manual. All warnings and cautions contained in this

manual should be read and understood before handling or maintaining the equipment.

Do not attempt to effect repairs or modifications to this equipment. If a fault occurs that cannot be rectified

using the procedures described in this manual, turn off the power, unplug the machine, then contact your

authorized TOSHIBA TEC representative for assistance.

Meanings of Each Symbol

This symbol indicates warning items (including cautions).

Specific warning contents are drawn inside the symbol.

(The symbol on the left indicates a general caution.)

This symbol indicates prohibited actions (prohibited items).

Specific prohibited contents are drawn inside or near the symbol.

(The symbol on the left indicates “no disassembling”.)

This symbol indicates actions which must be performed.

Specific instructions are drawn inside or near the symbol.

(The symbol on the left indicates “disconnect the power cord plug from the outlet”.)

WARNING

Any other than the

specified AC voltage

is prohibited.

Prohibited

Prohibited

Do not use voltages other than the

voltage (AC) specified on the rating

plate, as this may cause fire or

electric shock.

If the machines share the same

outlet with any other electrical

appliances which consume large

amounts of power, the voltage will

fluctuate widely each time these

appliances operate. Be sure to

provide an exclusive outlet for the

machine as this may cause the

machines to malfunction.

Do not insert or drop metal,

flammable or other foreign objects into

the machines through the ventilation

slits, as this may cause fire or electric

shock.

This indicates that there is the risk of death or serious injury if the

machines are improperly handled contrary to this indication.

Prohibited

Prohibited

Prohibited

Do not plug in or unplug the power

cord plug with wet hands as this may

cause electric shock.

Do not place metal objects or

water-filled containers such as flower

vases, flower pots or mugs, etc. on

top of the machines. If metal objects

or spilled liquid enter the machines,

this may cause fire or electric

shock.

Do not scratch, damage or modify

the power cords. Also, do not place

heavy objects on, pull on, or excessively bend the cords, as this may

cause fire or electrical shock.

Disconnect

the plug.

If the machines are dropped or their

cabinets damaged, first turn off the

power switches and disconnect the

power cord plugs from the outlet, and

then contact your authorized

TOSHIBA TEC representative for

assistance. Continued use of the

machine in that condition may cause

fire or electric shock.

(i)

Disconnect

the plug.

Continued use of the machines in an

abnormal condition such as when the

machines are producing smoke or

strange smells may cause fire or elec-

tric shock. In these cases, immediately turn off the power switches and

disconnect the power cord plugs from

the outlet. Then, contact your authorized TOSHIBA TEC representative for

assistance.

Page 4

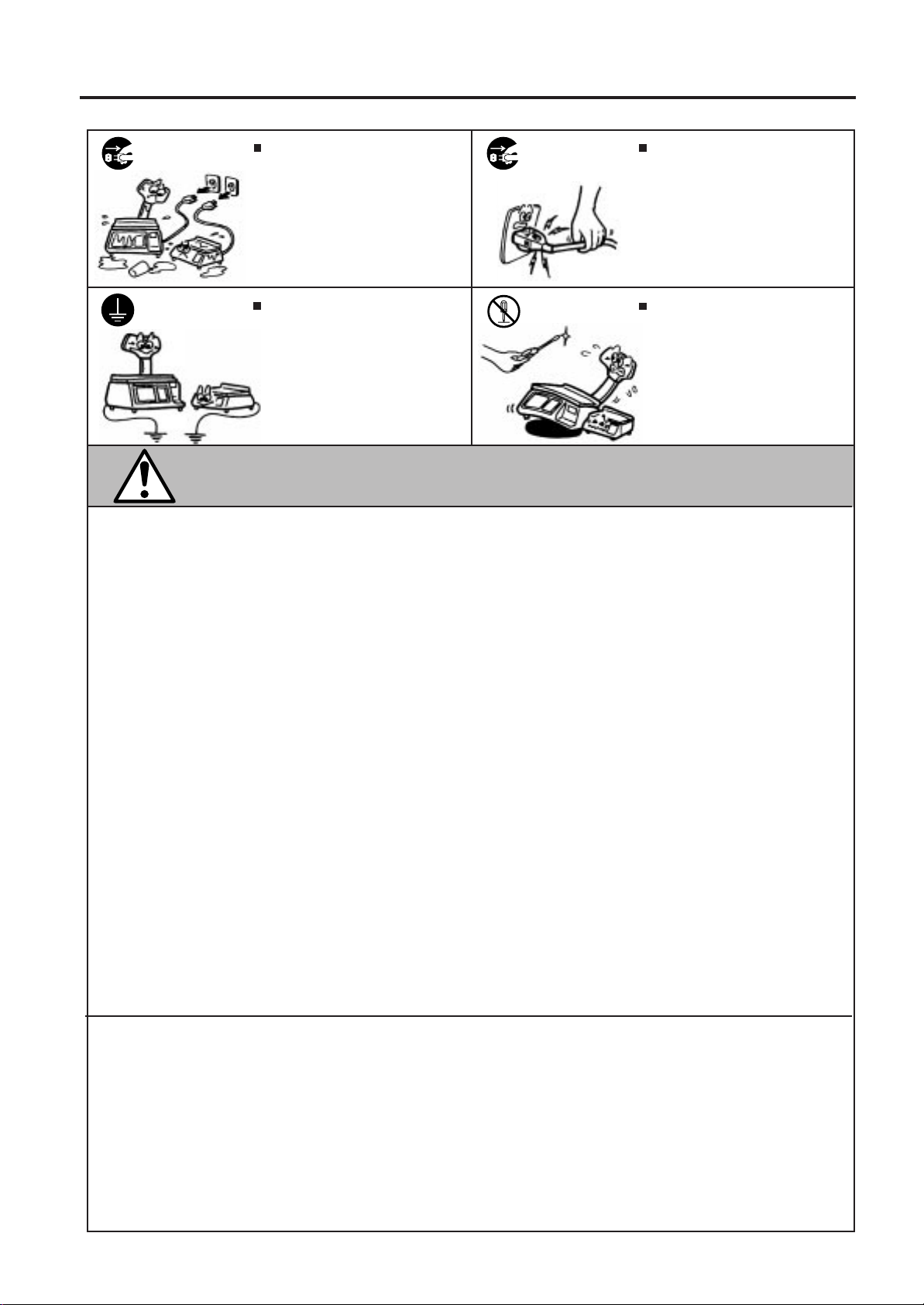

Safety Summary

Disconnect

the plug.

Connect a

grounding

wire.

If foreign objects (metal fragments,

water, liquids) enter the machines,

first turn off the power switches and

disconnect the power cord plugs from

the outlet, and then contact your

authorized TOSHIBA TEC representative for assistance. Continued

use of the machine in that condition

may cause fire or electric shock.

Ensure that the equipment is

properly grounded. Extension cables

should also be grounded. Fire or

electric shock could occur on

improperly grounded equipment.

Disconnect

the plug.

No disassembling.

When unplugging the power cords,

be sure to hold and pull on the plug

portion. Pulling on the cord portion

may cut or expose the internal wires

and cause fire or electric shock.

Do not remove covers, repair or

modify the machine by yourself. You

may be injured by high voltage, very

hot parts or sharp edges inside the

machine.

This indicates that there is the risk of personal Injury or damage to

CAUTION

objects if the machines are improperly handled contrary to this indication.

Precautions

The following precautions will help to ensure that this machine will continue to function correctly.

• Try to avoid locations that have the following adverse conditions:

* Temperatures out of the specification * Direct sunlight * High humidity

* Shared power source * Excessive vibration * Dust/Gas

• Do not subject the machine to sudden shocks.

• Do not press the keys too hard. Keys will operate correctly if they are touched lightly.

• Clean the cover and keyboard, etc. by wiping with a dry cloth or a cloth soaked with detergent and wrung out

thoroughly. Never use thinner or other volatile solvent for cleaning.

• To ensure that the scale is operating correctly, place a known weight on the platter and check it for correct

weight measurement. This should be done every morning before starting normal operations.

• When moving the machine, take hold of the case and lift the machine. Never hold the remote unit.

• Do not place the machines on unstable or slanted surfaces, as they may drop or fall and cause injury.

• USE ONLY TOSHIBA TEC SPECIFIED paper.

• DO NOT STORE the paper or ribbons where they might be exposed to direct sunlight, high temperatures, high

humidity, dust, or gas.

• Ensure the machine is operated on a level surface.

• Any data stored in the memory of the machine could be lost during a machine fault.

• Try to avoid using this equipment on the same power supply as high voltage equipment or equipment likely to

cause mains interference.

• Unplug the machine whenever you are working inside it or cleaning it.

• Keep your work environment static free.

• Do not place heavy objects on top of the machines, as these items may become unbalanced and fall causing

injury.

• Do not block the ventilation slits of the machines, as this will cause heat to build up inside the machines and

may cause fire.

• Do not lean against the machine. It may fall on you and could cause injury.

• Care must be taken not to injure yourself with the printer paper cutter.

• Unplug the machine when it is not used for a long period of time.

Request Regarding Maintenance

• Utilize our maintenance services.

After purchasing the machine, contact your authorized TOSHIBA TEC representative for assistance once a

year to have the inside of the machine cleaned. Otherwise, dust will build up inside the machines and may

cause a fire or a malfunction. Cleaning is particularly effective before humid rainy seasons.

• Our preventive maintenance service performs the periodic checks and other work required to maintain the

quality and performance of the machines, preventing accidents beforehand.

For details, please consult your authorized TOSHIBA TEC representative for assistance.

• Using insecticides and other chemicals

Do not expose the machines to insecticides or other volatile solvents. This will cause the cabinet or other parts

to deteriorate or cause the paint to peel.

(ii)

Page 5

Page 6

Page 7

TABLE OF CONTENTS

Page

1.INTRODUCTION ............................................................................................. 1-1

1.1 APPLICABLE MODEL........................................................................... 1-2

1.2 ACCESSORIES .................................................................................... 1-2

2.SPECIFICATION ............................................................................................. 2-1

2.1 SCALE................................................................................................... 2-1

2.2 OPTION................................................................................................. 2-1

3.APPEARANCE ................................................................................................ 3-1

4.DISPLAY.......................................................................................................... 4-1

4.1 US TYPE ............................................................................................... 4-1

4.2 CA TYPE ............................................................................................... 4-1

4.3 QR TYPE............................................................................................... 4-2

5.KEY LAYOUT .................................................................................................. 5-1

5.1 PROGRAMMING KEYBOARD ............................................................. 5-1

5.2 OPERATION KEYBOARD AND SPEED KEYBOARD.......................... 5-3

6.PROCEDURE BEFORE OPERATION ............................................................ 6-1

7.INSTALLATION PROCEDURE ....................................................................... 7-1

8.LEVEL ADJUSTMENT .................................................................................... 8-1

9.REMOVAL AND REPLACEMENT OF MEDIA ................................................ 9-1

10.OUTLINE OF OPERATION ............................................................................. 10-1

11.PROGRAMMING PROCEDURES .................................................................. 11-1

11.1 UNIT PRICE CHANGE.......................................................................... 11-5

11.2 PLU DATA SETTING ............................................................................ 11-6

11.3 INGREDIENT MESSAGE ..................................................................... 11-9

11.4 NUTRITION FACTS .............................................................................. 11-10

11.5 PLU VERIFYING LABEL....................................................................... 11-14

11.6 ADDRESS SETTING ............................................................................ 11-15

11.7 SPECIAL INFORMATION ..................................................................... 11-16

11.8 GRADE LINE......................................................................................... 11-16

11.9 SPEED KEY SETTING ......................................................................... 11-17

11.10 PRINT FORMAT.................................................................................... 11-18

11.11 DATE/TIME SETTING........................................................................... 11-21

11.12 CMT/PL-3 .............................................................................................. 11-21

11.13 ON-LINE/LOCAL ................................................................................... 11-24

11.14 BAR CODE FORMAT ........................................................................... 11-25

11.15 TITLES .................................................................................................. 11-27

11.16 TRANSFERRING LOGO DATA ............................................................ 11-28

11.17 IDIOM SETTING.................................................................................... 11-29

11.18 VENDOR SETTING .............................................................................. 11-29

11.19 FREE FORMAT..................................................................................... 11-30

Page 8

Page

12.PROGRAMMED DATA VERIFICATION REPORTS ....................................... 12-1

13.PASSWORD SECURITY ................................................................................. 13-1

13.1 SETTING PASSWORD AND PROTECT MENU................................... 13-1

13.2 CALLING MENU BY ENTERING PASSWORD .................................... 13-3

14.OPERATING PROCEDURES ......................................................................... 14-1

14.1 WEIGHING OPERATION...................................................................... 14-2

14.2 FIX PRICE OPERATION (FOR US TYPE ONLY)................................. 14-3

14.3 BY COUNT OPERATION...................................................................... 14-4

14.4 PRINT COUNT OPERATION................................................................ 14-6

14.5 ISSUING LABELS WITH NET WEIGHT STATEMENT

(FOR US TYPE ONLY) ......................................................................... 14-9

14.6 TARE/SAVE FUNCTION PROCEDURES ............................................ 14-11

14.7 CALLING AND PRINTING GRADE LINES ........................................... 14-12

14.8 CALLING AND PRINTING LOGOS ...................................................... 14-13

14.9 SELECTING PRINT ITEM AND ADJUSTING

THE LCD BRIGHTNESS....................................................................... 14-14

14.10 DATE CHANGE .................................................................................... 14-15

14.11 BATCH PRINT MODE (with 30 Items Run Assignment)....................... 14-16

14.12 FLOATING VENDOR ............................................................................ 14-19

15.TOTAL OPERATION ....................................................................................... 15-1

15.1 HOURLY TOTAL REPORT................................................................... 15-2

15.2 GRAND TOTAL REPORT..................................................................... 15-2

15.3 PLU TOTAL REPORT........................................................................... 15-2

15.4 VENDOR TOTAL REPORT................................................................... 15-3

16.ERROR MESSAGE TABLE............................................................................. 16-1

17.CLEANING THE PRINT HEAD ....................................................................... 17-1

18.TROUBLESHOOTING..................................................................................... 18-1

CAUTION:

1. This manual may not be copied in whole or in part without prior written permission of TOSHIBA TEC.

2. The contents of this manual may be changed without notification.

3. Please refer to your local Authorized Service representative with regard to any queries you may

have in this manual.

Copyright © 2001

by TOSHIBA TEC CORPORATION

All Rights Reserved

570 Ohito, Ohito-cho, Tagata-gun, Shizuoka-ken, JAPAN

Page 9

1. INTRODUCTION

1. INTRODUCTION

1. INTRODUCTION

Thank you for purchasing the TEC SL-9000-ESB Series electronic computing scale. As you will discover,

the TEC SL-9000-ESB series has many features and functions designed for user friendliness as well as

complete customer satisfaction.

The 7-segment fluorescent display which indicates transaction information such as weights, unit prices,

total prices, etc. and the liquid crystal display used to display commodity names and programming

messages are provided with the scale. The 140 speed keys realize a higher degree of operability, and

the 3 inch/sec. print speed ensures fast and clear printing.

Password security prevents unauthorized access to the PROG., M.DOWN, REWRAP, READ and

RESET mode.

We believe that your needs will now be fully satisfied, and you will have total reliability in price calculations.

Should you have any questions concerning the scale, please refer to this manual. Be sure to keep this

manual for future reference.

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications.

Operations of this equipment in a residential area is likely to cause harmful interference in which case

the user will be required to correct the interference at his own expense. (for USA only)

Changes or modifications not expressly approved by manufacturer for compliance could void the

user’s authority to operate the equipment.

“This Class A digital apparatus meets all requirements of the Canadian Interference-Causing

Equipment Regulations.”

“Cet appareil numéique de la classe A respecte toutes les exigences du Rèlement sur le matériel

brouilleur du Canada.”

(for CANADA only)

Some procedures described in this manual may be illegal in various state jurisdictions. When there

are optional settings to enable various functions or to disable functions. Please ensure that the optional

settings for scale operation meet the local requirements of weights and measures. If you are uncertain

of specific items, contact the state or county office of weights and measures for clarification.

1-1

Page 10

1. INTRODUCTION

1.1 APPLICABLE MODEL

• SL-9000-30M-ESB-US

• SL-9000-15M-ESB-CA

• SL-9000-15M-ESB-QR

The description of the model number is as follows.

S L - 9 0 0 0 - 3 0 M - E S B - U S

Max. Capacity

30M: 30 lbs (decimal

pound/multi-interval)

15M: 15 Kg (multi-interval)

1.1 APPLICABLE MODEL

1. INTRODUCTION

Destination Code

ex.) US, CA, QR etc.

Keyboard Type

B: Built-in keyboard

Display Type/Other Spec.

Display: Liquid Crystal Display and 7 Segment Dsiplay

Spec.: Standalone

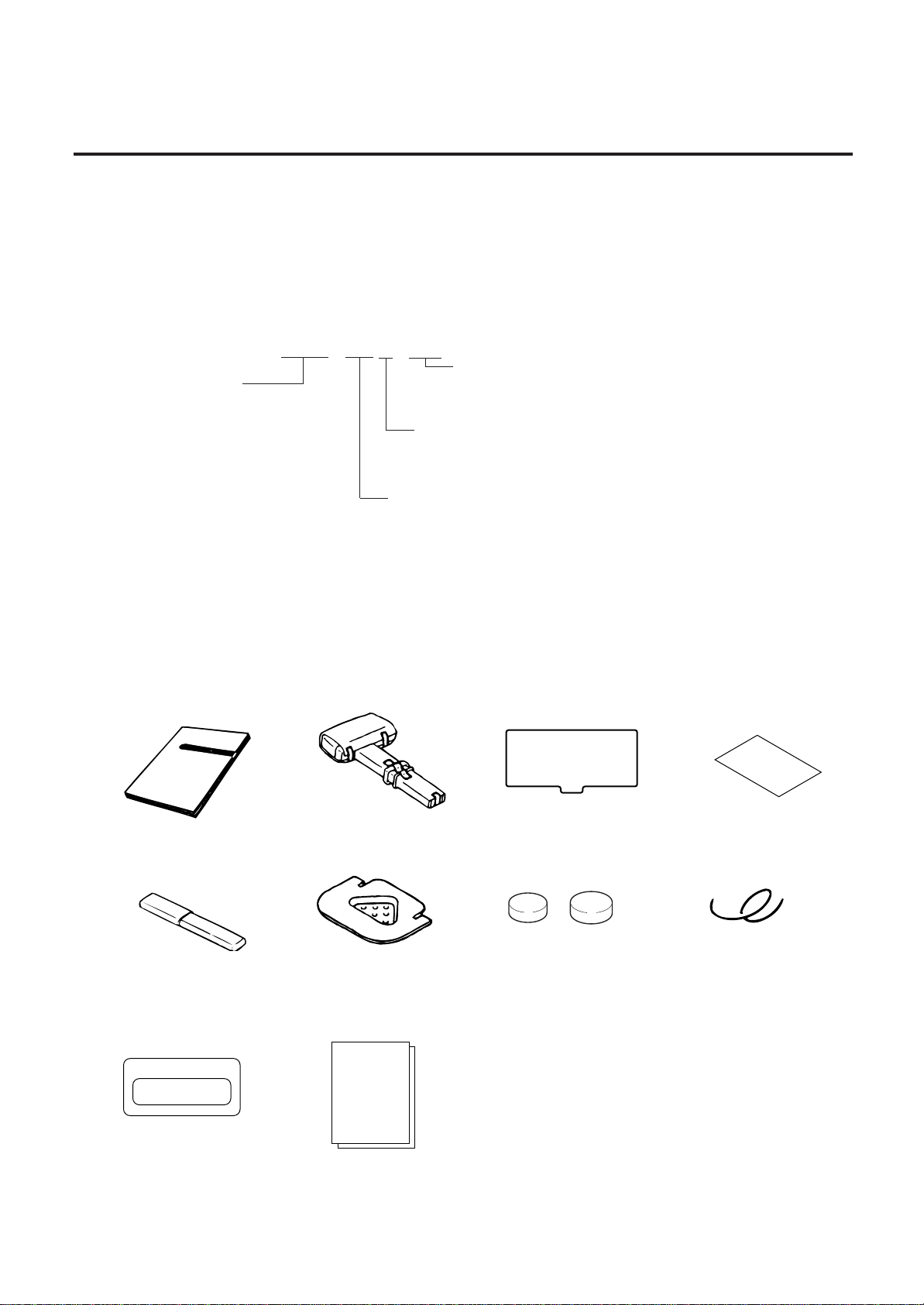

1.2 ACCESSORIES

Owner's Manual

(EM1-31074)

Print Head Cleaner

(24089500013)

Remote Display Sheet

(CA Type only)

Remote Display Speed Key Sheet Quality Control Report

(US type only)

Remote Blind Plate Sealing Lead Stranded Wire

Remote Display Sticker

(QR Type only)

NOTE: Check that there are no missing or incorrect parts in the accessories.

1-2

Page 11

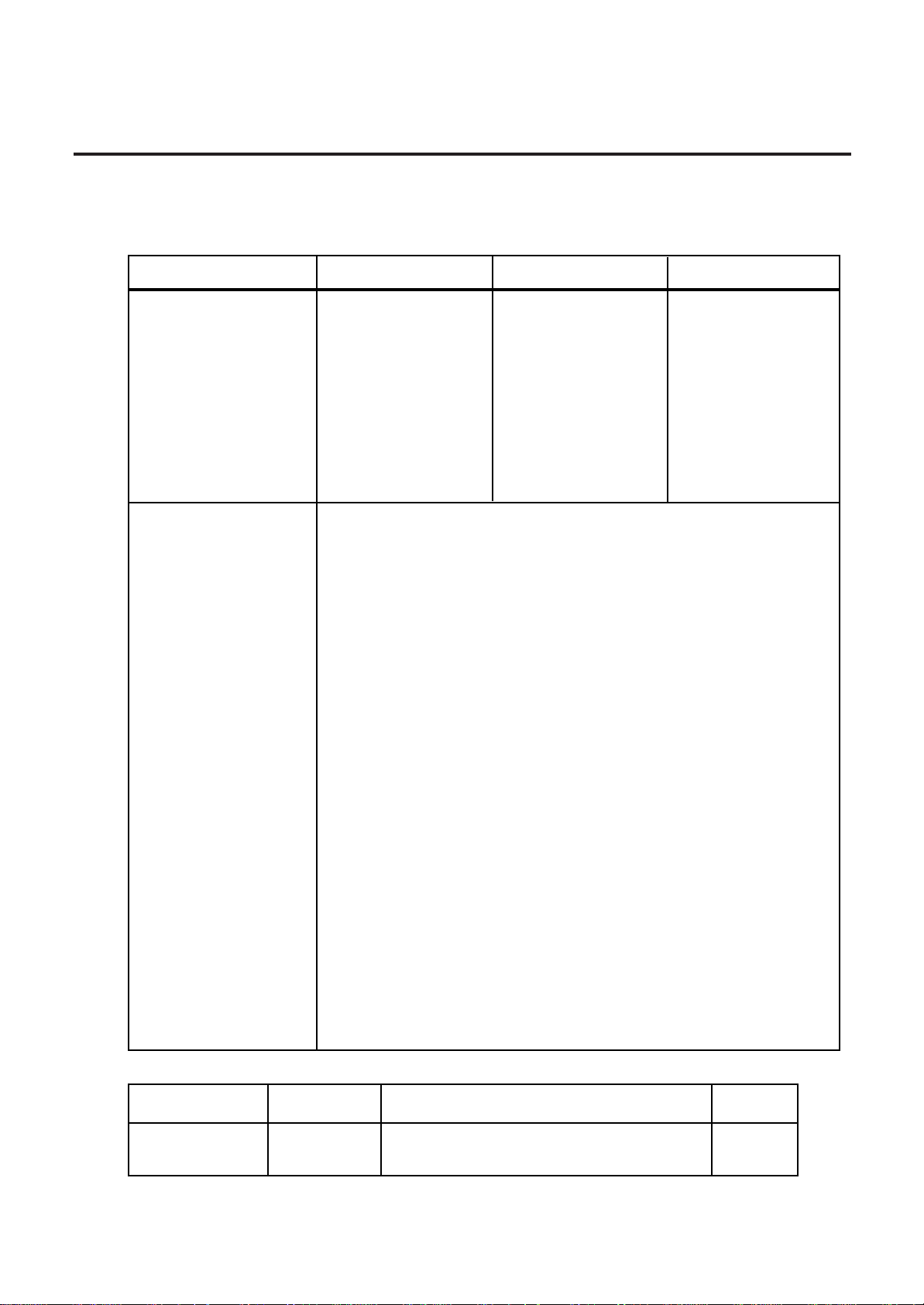

2. SPECIFICATION

2. SPECIFICATION

2.1 SCALE

2.1 SCALE

Item US CA

Maximum Capacity 30 lb 15 Kg (30 lb) 15 Kg

Minimum Scale Division 0.005 lb (0~15 lb) 0.002 Kg (0 ~ 6 Kg) 0.002 Kg (0~6 Kg)

0.005 Kg (6 ~ 15 Kg) 0.005 Kg (6~15 kg)

0.01 lb (15~30 lb) 0.005 lb (0 ~ 15 lb)

0.01 lb (15 ~ 30 lb)

Maximum Tare 2.000 lb 1.000 Kg (2.205 lb) 1.000 Kg

Display Range 0 ~ 30.05 lb 0 ~ 15.025 Kg 0~15.000 Kg

(0 ~ 30.05 lb)

Unit Price Presettable $0.01 ~ 99.99 $0.01 ~ 99.99 0~99999

Minimum Price Display $0.01 $0.01 1

Power Requirement AC 120 V ± 10%, 60 Hz (US/CA type)

AC 220 V ± 10%, 50/60 Hz (QR type)

Power Consumption US/CA: 70 W, 1 A (Standby: 25 W, 0.4 A)

QR: 70 W, 0.66 A (Standby: 25 W, 0.3 A)

Temperature Limits 32°F ~ 104°F (0°C ~ 40°C)

Relative Humidity 35% ~ 85% (No condensation)

Message Display Remote display: 18 digits 7 segments Fluorescent display

Liquid Crystal Display: 5x7 dots 16 characters 1 line LCD

Weight 5 digits (US/CA type), 5 digits (QR type)

Unit Price 4 digits (US/CA type), 5 digits (QR type)

Total Price 5 digits(US/CA type), 6 digits (QR type)

Remote Display Mode Dual sides

Capacity of PLU Memory 560 PLUs (Standard), 240 PLUs when LOGO is available.

Print Head Thermal Print Head (2 inch wide)

Media Issue Method On-demand/Batch

Dot Density 193 dots/inch (7.6 dots/mm)

Print Speed 3 inch/sec. (76.2 mm/sec.)

Available Printing Width 1.89 inch (48 mm), 2.24 inch (57 mm)

Recommended Media

Thermal Label VHTS, VLTB (OSP)/Outer diameter: Ø93 mm (Max.)

Variable Length Label VHTS, VLTB (OSP)/Outer diameter: Ø90 mm (Max.)

Thermal Receipt 120 FC (RICOH)/Outer diameter: Ø81 mm (Max.)

Interface CMT/PL-3 interface (Program Loader)

Drawer Interface

Dimensions (approx.) 17.2 inch (width)x16.8 inch (depth) x 18.7 inch (height)

436 mm (width)x426 mm (depth) x 474 mm (height)

Weight 33 lb (15 Kg)

QR

2.2 OPTION

Option Name

Label Cassette

NOTE: Contact TOSHIBA TEC H.Q. or your nearest TOSHIBA TEC representative.

Model No.

or Part No.

OP-9000CASSETTE

Description Source

It is covenient to change several kinds

of labels.

2-1

See

Note 1

Page 12

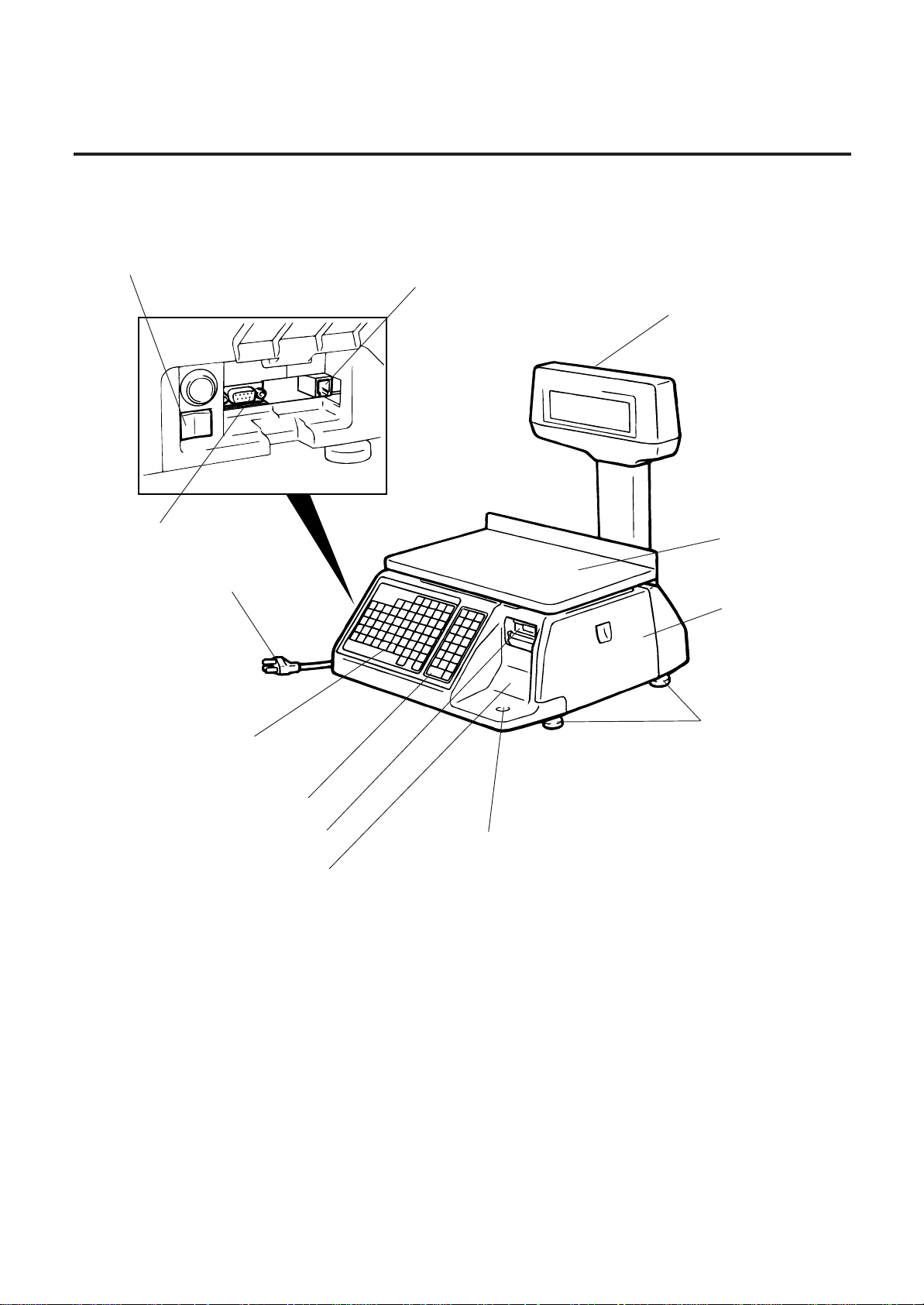

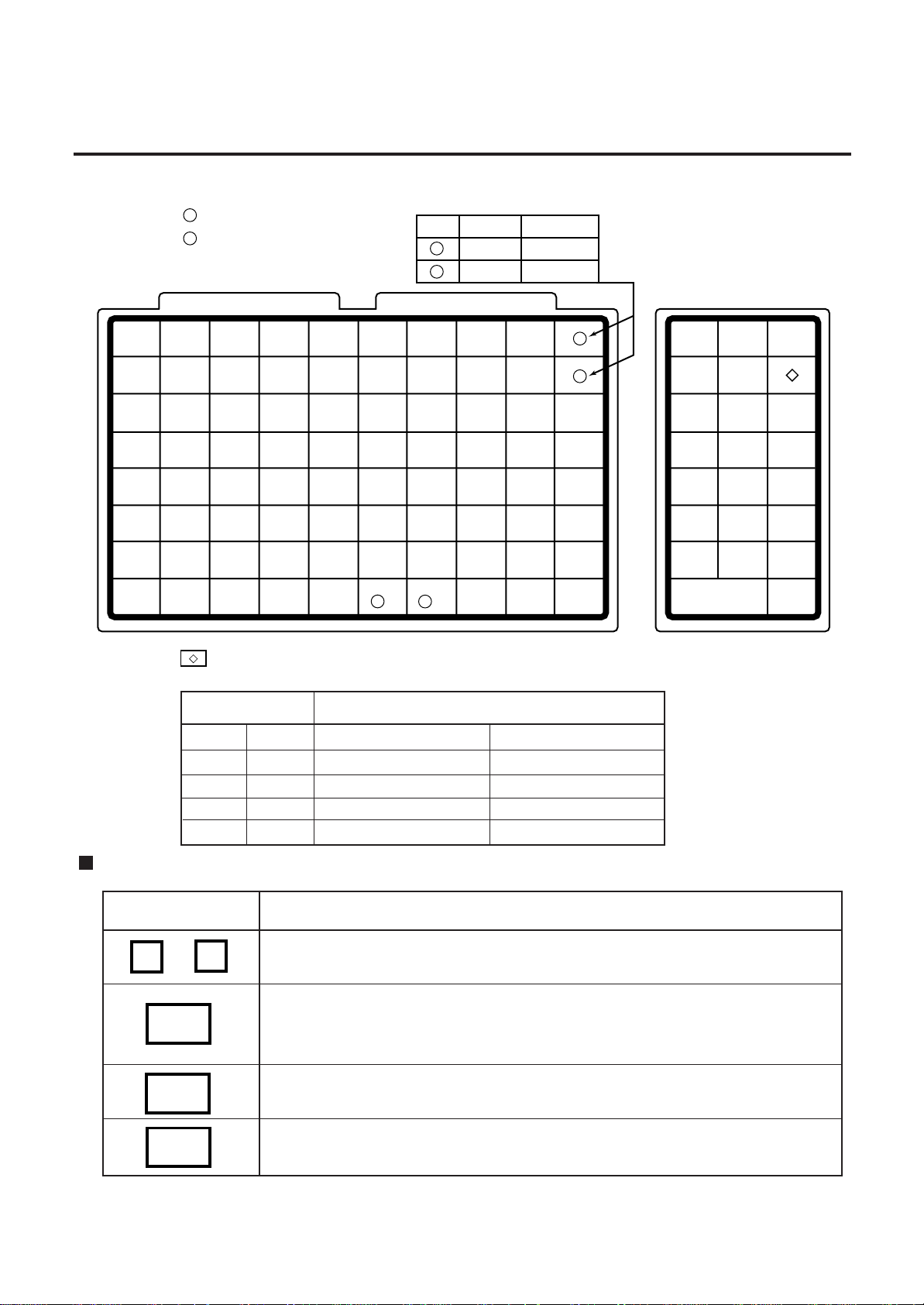

3. APPEARANCE

3. APPEARANCE

3. APPEARANCE

Main Power Switch

CMT/PL-3 I/F

Power Cord

Drawer I/F

Remote Display

Meat Platter

Right Cover

Speed Keyboard and

Programming Keyboard

Operation Keyboard

Print Head

Liquid Crystal Display

Adjustable Legs

Level Gauge

3-1

Page 13

4. DISPLAY

4. DISPLAY

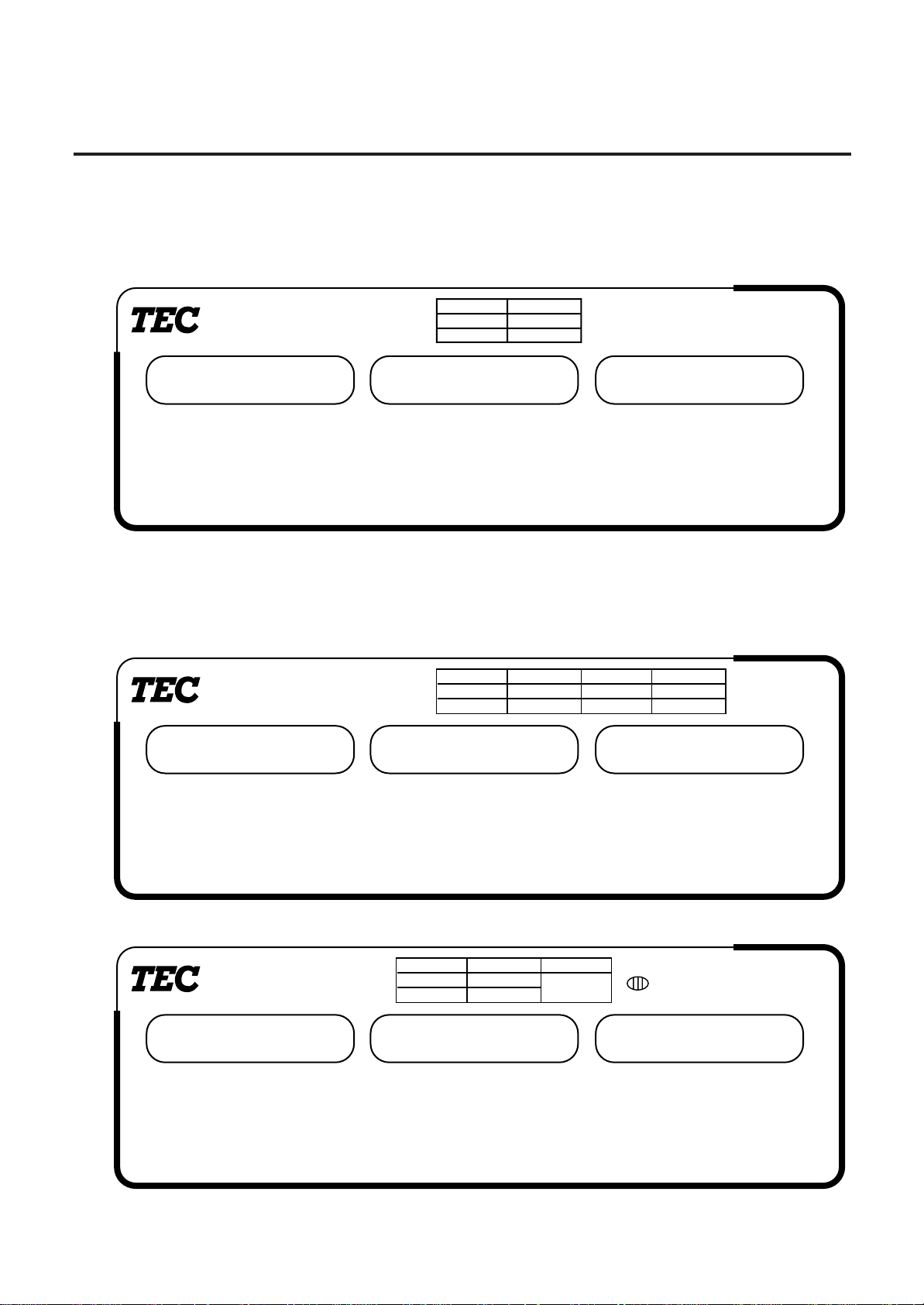

4.1 US TYPE

• US (UNITED STATES)

4.1 US TYPE

SL-9000

WEIGHT lb

%/T NET REG. M/D R/W PREPACK X Z ERROR

CAPACITY

WEIGHT

0 ~ 15 lb

15 ~ 30 lb

PRICE/lb $ TOTAL PRICE $

e=d

0.005 lb

0.01 lb

4.2 CA TYPE

Since the following two remote display sheets are enclosed with the CA machine, select one and affix

it to the remote display. (Refer to Section 7 How to affix the remote display sheet.)

• CA (CANADA)

SL-9000

WEIGHT/POIDS

CAPACITY

CAPACITÉ

WEIGHT

0 ~ 6 Kg

6 ~ 15 Kg

PRICE/PRIX $ TOTAL $

e=d

0.002 Kg

0.005 Kg

WEIGHT

0 ~ 15 lbs

15 ~ 30 lbs

e=d

0.005 lbs

0.01 lbs

ZERO/ %/T NET kg lb

ZERO

• MX (MEXICO)

PESO kg PRECIO TOTAL $

CERO NETO REG. M/D R/W 100g FIJO X Z ERROR

SL-9000

REG. M/D R/W 100g PREPACK/

PRÉ-EMBALLÉ ERREUR

WEIGHT

0 ~ 6 Kg

6 ~ 15 Kg

e=d

0.002 Kg

0.005 Kg

TARE

T=-1 Kg

PRECIO UNITARIO $/kg

4-1

ERROR/X Z

Max. 15 Kg

Min 0.04 Kg

Page 14

4. DISPLAY

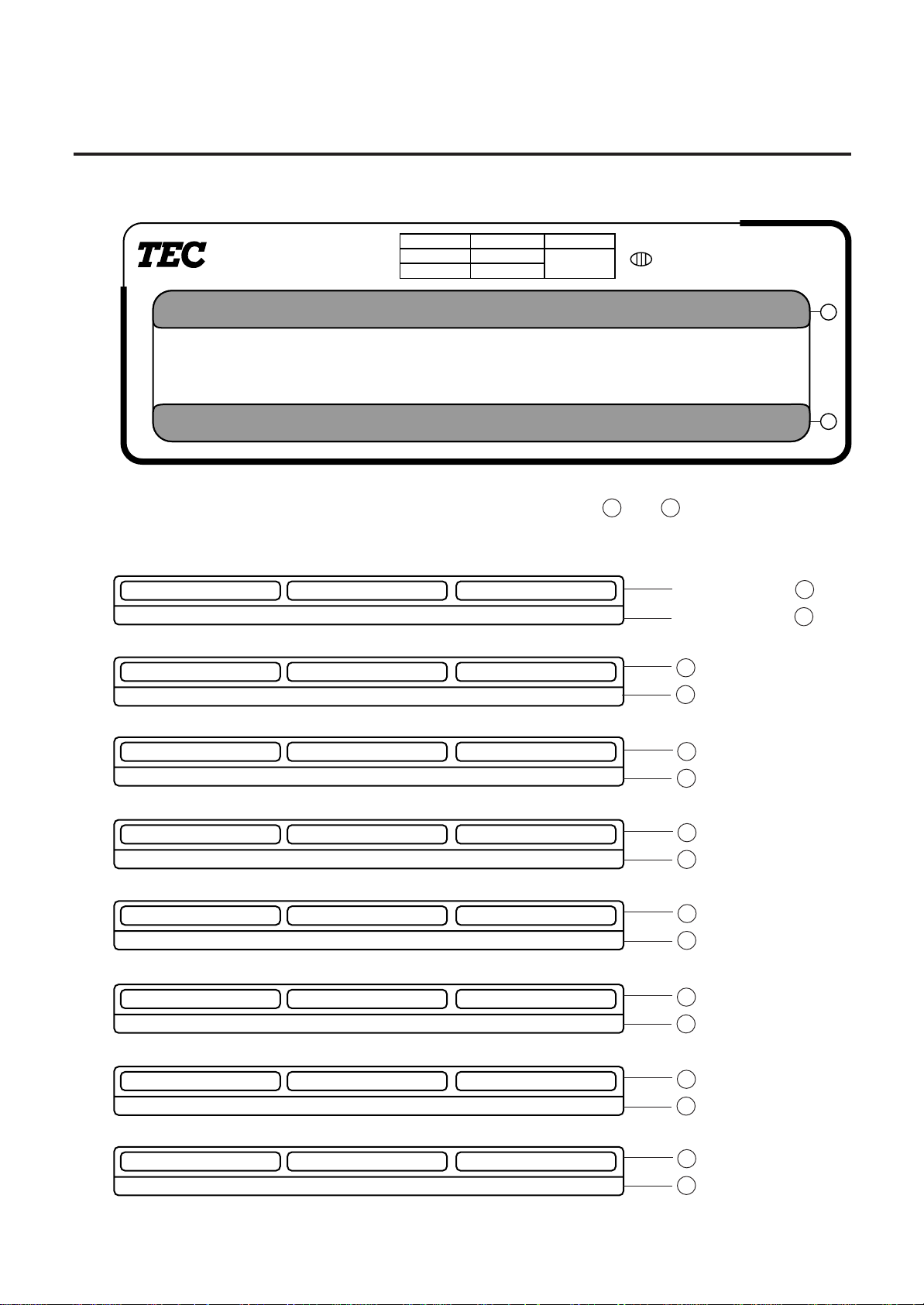

4.3 QR TYPE

4.3 QR TYPE

SL-9000

WEIGHT

0 ~ 6 Kg

6 ~ 15 Kg

e=d

0.002 Kg

0.005 Kg

TARE

T=-1 Kg

Max. 15 Kg

Min 0.04 Kg

For the QR machine, the following multi-linqual display stickers are provided to adapt machines to

use in various countries. Select one of them and affix it to positions A and B on the remote display. (Refer to Section 7 How to affix the remote display sheet.)

• AG/CL (ARGENTINA/CHILE)

PESO kg

CERO NETO REG. M/D R/W 100g FIJO X Z LON LINEA ERROR

PRECIO UNITARIO $/kg

PRECIO TOTAL $

Affix to position A

Affix to position B

• BN/SG (BRUNEI/SINGAPORE)

WEIGHT kg UNIT PRICE $/kg

ZERO NET REG. M/D R/W 100g FIX X Z LON INLINE ERROR

TOTAL PRICE $

A

B

A

B

• IN (INDONESIA)

WEIGHT kg UNIT PRICE Rp/kg

ZERO NET REG. M/D R/W 100g FIX X Z LON INLINE ERROR

TOTAL PRICE Rp

• MY (MALAYSIA)

WEIGHT kg UNIT PRICE RM/kg

ZERO NET REG. M/D R/W 100g FIX X Z LON INLINE ERROR

TOTAL PRICE RM

• PH (PHILIPPINES)

WEIGHT kg UNIT PRICE PHP/kg

ZERO NET REG. M/D R/W 100g FIX X Z LON INLINE ERROR

TOTAL PRICE PHP

• SD (SAUDI ARABIA)

WEIGHT kg UNIT PRICE S.R./kg

ZERO NET REG. M/D R/W 100g FIX X Z LON INLINE ERROR

TOTAL PRICE S.R.

• TH (THAILAND)

WEIGHT kg UNIT PRICE BT/kg

ZERO NET REG. M/D R/W 100g FIX X Z LON INLINE ERROR

TOTAL PRICE BT

• ZA (SOUTH AFRICA)

WEIGHT kg UNIT PRICE R/kg

ZERO NET REG. M/D R/W 100g FIX X Z LON INLINE ERROR

TOTAL PRICE R

A

B

A

B

A

B

A

B

A

B

A

B

4-2

Page 15

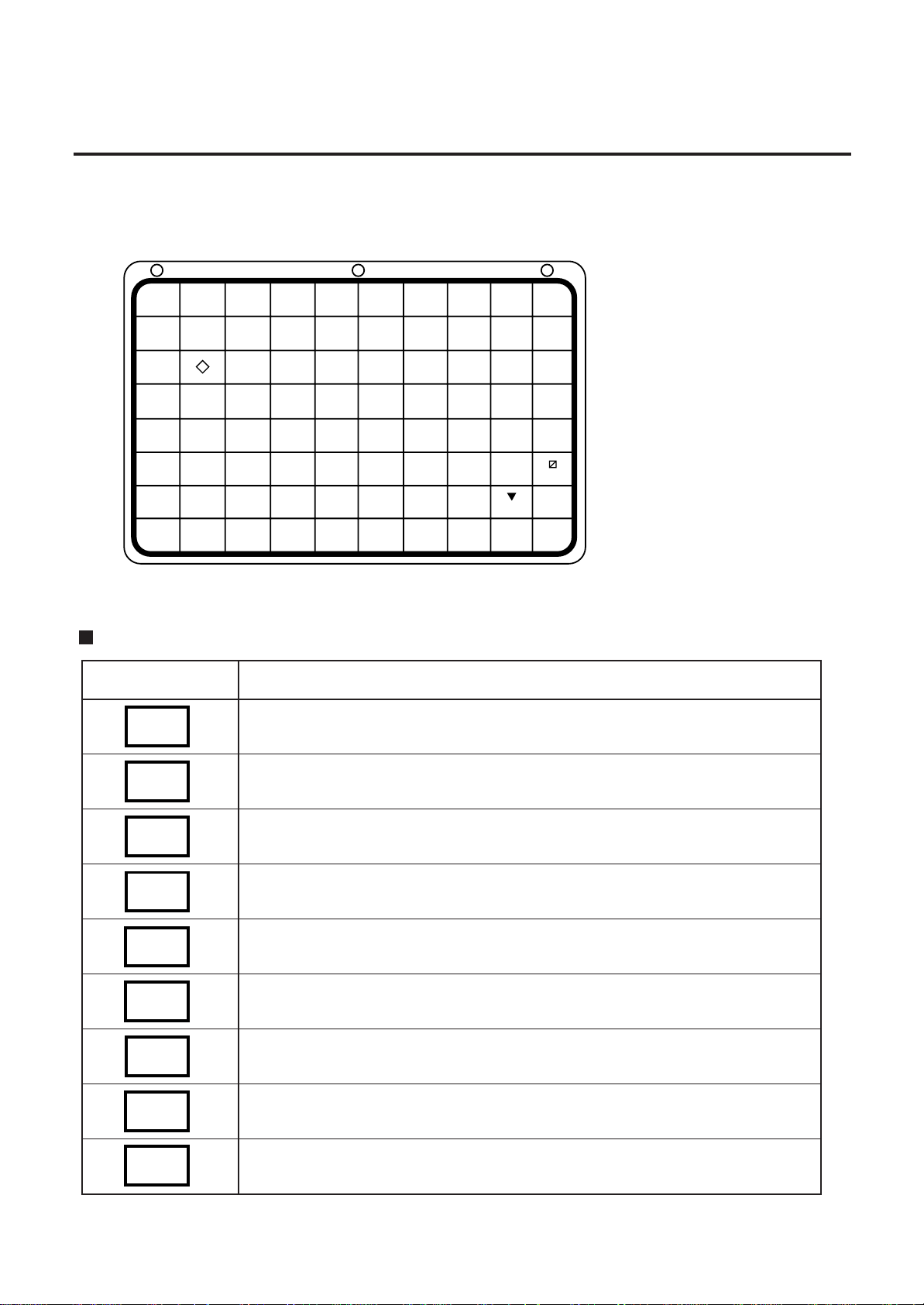

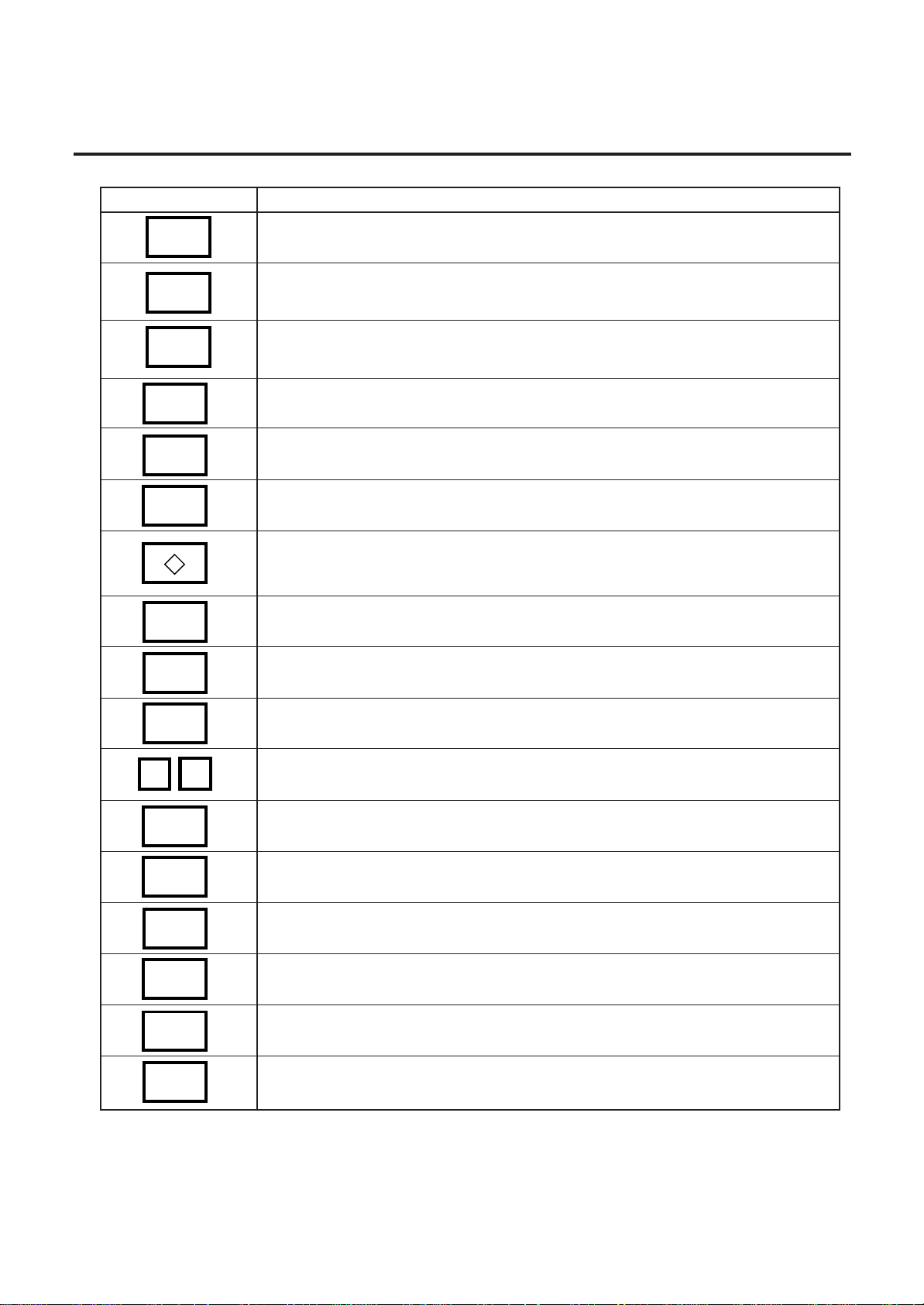

5. KEY LAYOUT

5. KEY LAYOUT

5.1 PROGRAMMING KEYBOARD

CLEAR

RECEIVE

PROG.

!

1

*

Q

[

A

È

Z

SEND

TEST

ENTER

#

"

3

2

+

E

W

\

D

S

Â

É

C

X

-

$

4

)

(

R

ˆ

]

F

Ê

V

↑

←

&

%

6

5

:

/

Y

T

{

H

G

←

→

N

B

SHIFT

↓

→

´

7

;

U

J

↓

M

--

SET

NEXT

CHANGE

PLU

DELETE

1/2

`

8

<

|

}

K

↑

SPACE

(A)

NEXT

PLU

DELETE

PLU

INSERT

1

?

9

=

O

~

L

,

AUTO

CODE

RETURN

1/4

DELETE

(B)

@

0

>

P

-

>

.

5.1 PROGRAMMING KEYBOARD

NOTE: Blank keys have no function.

Programming Keyboard Function

Name of Key

CLEAR

SHIFT

SET

NEXT

NEXT

PLU

AUTO

CODE

1. Clears preceding numeric data.

2. Releases the scale from the error mode.

Toggles between the upper characters or lower characters.

Calls the next PLU data item.

Sets the media transarency on the sensor.

1. Calls the next PLU #.

2. Selects a programming item.

Sets "AUTO CODE."

ZERO

Function

FEED

CHANGE

PLU

DELETE

PLU

TEST

ENTER

Changes the PLU # currently called.

Deletes PLU.

Prints data set in the currently called PLU.

Inputs data to the SL-9000 system during programming.

5-1

Page 16

5. KEY LAYOUT

5.1 PROGRAMMING KEYBOARD

Name of Key

_

←

→

DELETE

(A)

1/2

INSERT

1

DELETE

(B)

RETURN

1/4

Function

1. Displays the preceding PLU data.

2. Used to set an auto code.

3. Calls the preceding label format # when setting the print position.

4. Selects a prgramming item.

Moves the cursor to the left.

Moves the cursor to the right.

1. Deletes a selected character.

2. Sets a unit price per 1/2 lb.

1. Inserts a space when entering characters.

2. Toggles between 100 g and Kg, or used to select Lb when setting unit price.

Deletes all characters on the selected line.

1. Displays the next line.

2. Sets a unit price per 1/4 lb.

↑

SPACE

SEND

RECEIVE

↑

↓

PROG.

Inserts a blank space in descriptors.

Stores "Ingredient data" in the temporaty memory.

Calls "ingredient data" from the temporaty memory.

Sets the preceding item.

Sets the following item.

Returns to the programming menu.

1. Selects programming menu group.

2. Toggles between capitals and small letters.

3. Sorts the file when setting PLU data, ingredient data and nutrition data.

4. Sets a block PLU # using the confirmation label procedure.

5. Toggles between the scrolling message and fixed message.

6. Calls the second half of the speed keys and sets a department #.

Other Keys

The other 39 keys are used to set the character.

5-2

Page 17

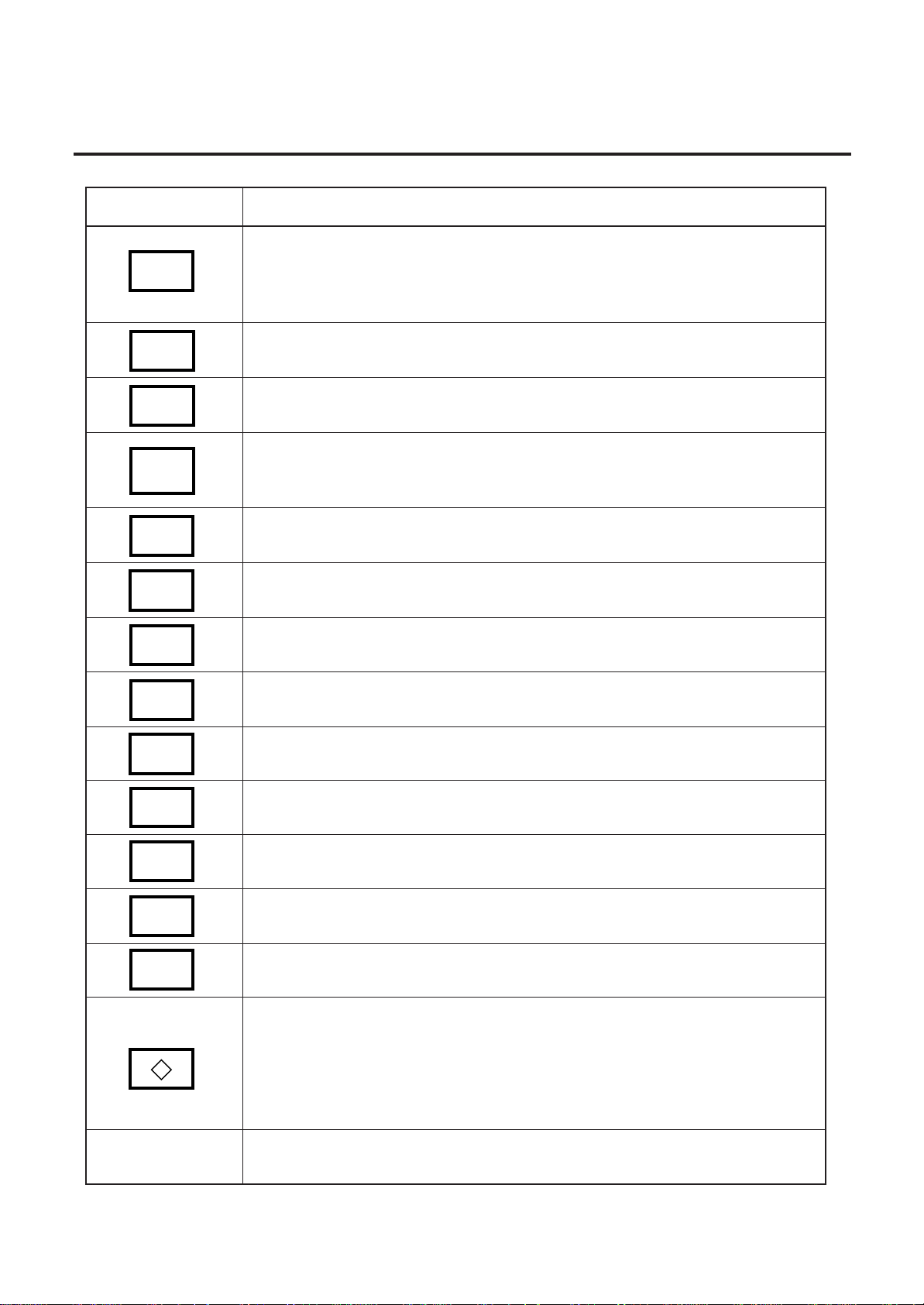

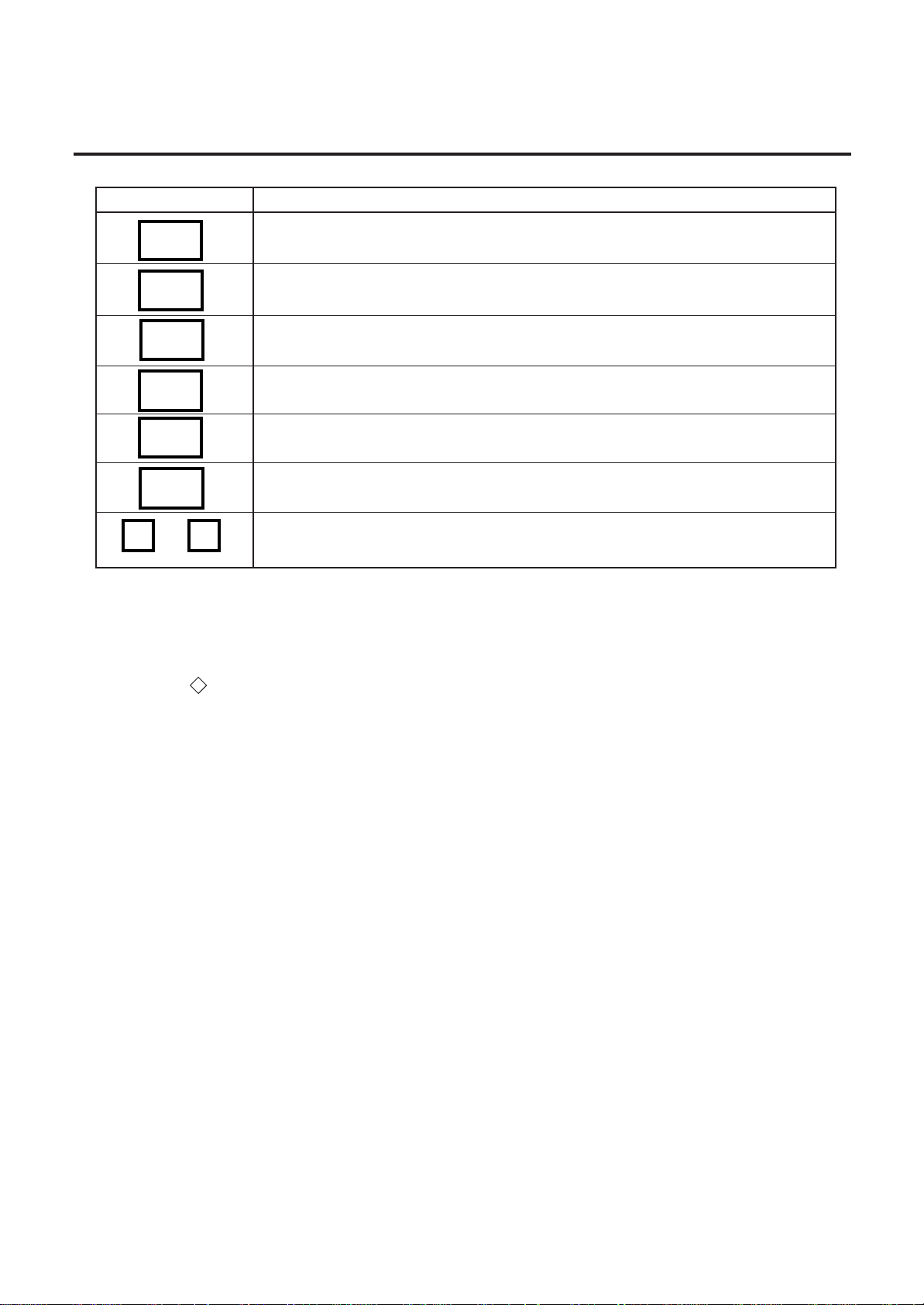

5. KEY LAYOUT

5.2 OPERATION KEYBOARD AND SPEED KEYBOARD

5.2 OPERATION KEYBOARD AND SPEED KEY BOARD

1

Primary function

2

Secondary function

US type

1

2

1/2

1/4

CA/QR type

100 g

LB/kg

9

1

18

2

27

PRESET

COUNT

36

GRADE

LINE

45

LOGO

54

GROUP#

63

ST

TESTZERO

FEED

ESC.

PROG.

NEXT

PLU

SAVE FOR DT/TM

789

456

123

0

PLU PRT/*

POWER

VOID

TC

10

19

28

37

46

55

64

1

2

11

20

29

38

47

56

65

3

12

21

30

39

48

57

66

4

13

22

32

40

49

58

67

5

14

23

32

41

50

59

68

6

15

24

33

42

51

60

69

4

7

16

25

34

43

52

61

70

3

8

17

26

35

44

53

62

NOTES: 1. The numbers 1~70 indicate the speed key layout, but the actual keys have no number. Pressing the

key enables another 70 PLUs assignment.

2. The functions of the 3 and 4 keys can be changed according to the initial settings as follows.

Initial Setting #

8-7

0

0

1

1

12-8

0

1

0

1

69 (4)

Speed key #69

Speed key #69

Speed key #69

AUTO/MANUAL key

Speed key #

70 (3)

Speed key #70

AUTO/MANUAL key

Tare % key

Tare % key

Operation Keyboard Function

Name of Key

Enters numeric data such as PLU #, unit price and tare.

1. Clears numeric entries.

2. Releases the scale from error mode.

3. Releases the scale from SAVE mode.

Subtracts tare.

Calls a PLU or clears displayed PLU.

to

9

0

C

T

PLU

Function

5-3

Page 18

5. KEY LAYOUT

5.2 OPERATION KEYBOARD AND SPEED KEYBOARD

Name of Key

PRT/*

SAVE

FOR

DT/TM

NEXT

PLU

VOID

ESC.

Function

Prints the customer label.

Saves tare and unit price after taking off the commodity from a platter.

Sets the quantity of commodity in "BY COUNT" mode.

Displays the date.

1. Selects the item for change Print/OFF.

2. Selects a programming item and a main menu.

1. Cancels preceding data.

2. Selects a programming item and a main menu.

1. Enables calling the other 70 speed keys.

2. Selects the function for change Print/OFF.

3. Selects a menu group.

Returns to the main menu.

PROG.

POWER

1/4

1/2

100g

LB/kg

PRESET

COUNT

GRADE

LINE

LOGO

GROUP

#

Accesses print item, auto message timer, print format and issue mode

selection mode.

Turns the display on/off when the scale power is on.

Changes between 1/2 lb and 1/4 lb (US type only).

Changes the unit of measure to 100g (CA/QR type only).

Changes the unit of measure between lb and kg (CA type only).

Sets the number of labels to print.

Prints a grade line.

Calls a logo.

No function

5-4

Page 19

5. KEY LAYOUT

5.2 OPERATION KEYBOARD AND SPEED KEYBOARD

Name of Key

Displays a total amount.

ST

This key is used for item or subtotal discount by entering a percentage.

%

(Optional key by initial setting)

Feeds the label.

FEED

Issues a test label.

TEST

Adjusts the zero point.

ZERO

AUTO/

MANUAL

1

70

Changes the label issue mode between Automatic issue and manual

issue. (Optional key by initial setting)

Calls the PLU frequently used.

to

NOTE: In ESB limited specification mode

Function

Speed key (70 keys with no shift function)

"

" key is no-function as following mode.

1) Page change in speed-key program mode

2) Page change in unit-price-change mode at PLU DATA EDIT

3) Second page print in speed-key report at read mode

4) Page change in PLU calling by speed-key at Reg. mode

5-5

Page 20

6. PROCEDURE BEFORE OPERATION

6. PROCEDURE BEFORE OPERATION

6. PROCEDURE BEFORE OPERATION

1. Unpack the accessories and scale from the carton.

2. Install the remote display on the scale. (See Page 7-1.)

3. Refer to safety Precautions in this manual and set up the scale in a proper location.

4. Load the label or receipt. (See Page 9-1.)

5. Be sure to insert the power cord plug into an AC outlet.

6. Adjust the level gauge. (See page 8-1.)

7. Turn the power on and then press the power key. (See page10-1.)

8. Set the following program menus:

Menu Group ITEM No. Programming Name

2 0 PRINT FORMAT

2 1 DATE/TIME SETTING

1 1 PLU DATA SETTING

If necessary, set the following program menus:

Menu Group ITEM No. Programming Name

1 2 INGREDIENT MESSAGE

1 3 NUTRITION SETTING

1 5 ADDRESS SETTING

1 7 SPECIAL INFORMATION

1 8 GRADE LINE

1 9 SPEED KEY SET

9. Call a PLU to be sold in weighing mode, and place a weight on the platter to check a correct price

is displayed.

10. The scale is ready to issue labels.

6-1

Page 21

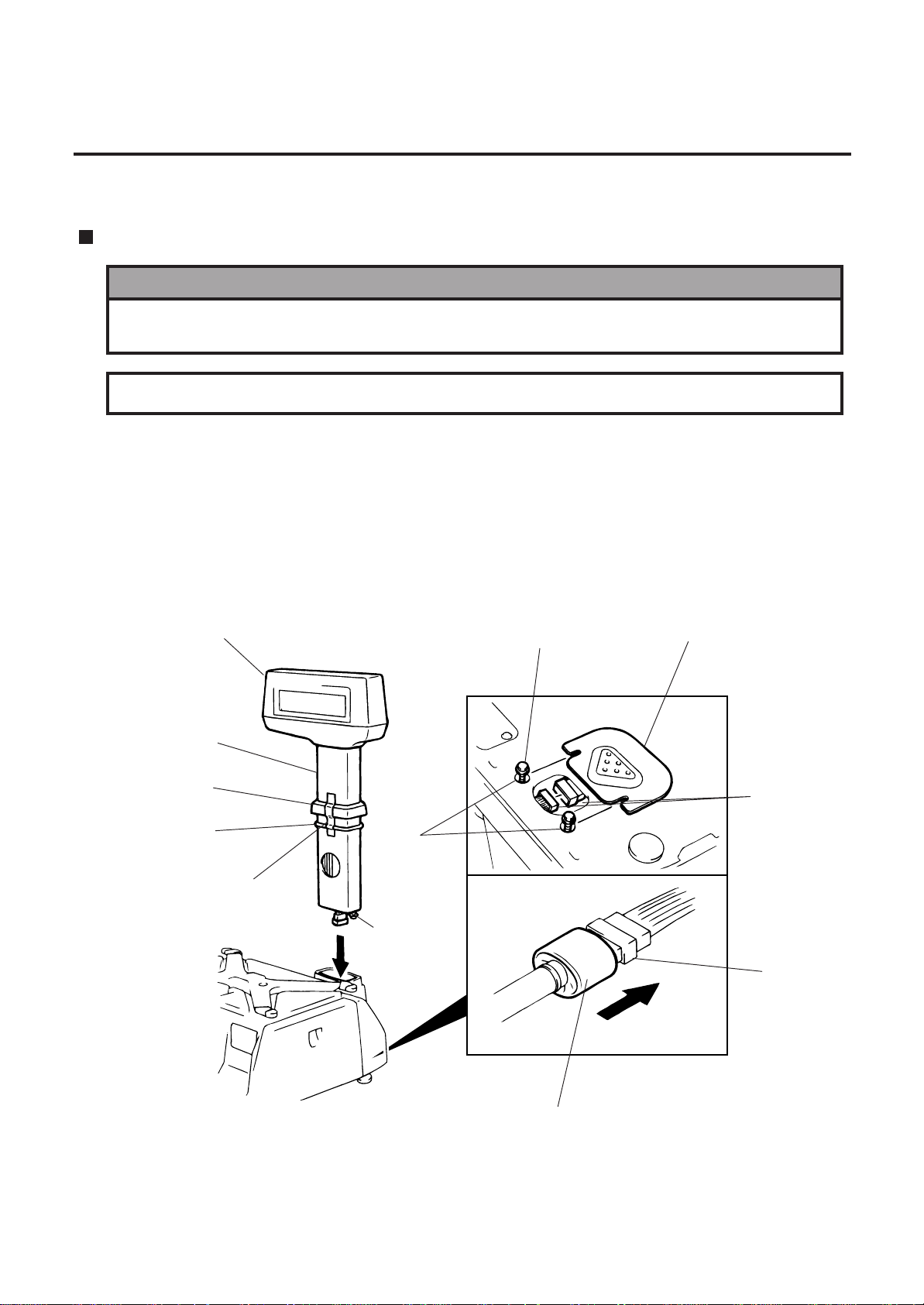

7. INSTALLATION PROCEDURE

7. INSTALLATION PROCEDURE

7. INSTALLATION PROCEDURE

Remote Display

WARNING!

Be sure to cover the connectors with the connector cover because of high voltage and current.

If the connectors are exposed to water, a leakage may result.

CAUTION: Never place the scale upside down. Doing so will cause a malfusction.

1. To install the remote display, insert the two screws on the bottom of the remote pipe into the holes

provided on the scale base.

2. Connect the connectors, pull down the connector cover, and install the remote blind plate.

Then tighten the screws to secure the remote display.

3. Remove the tape from the remote packing and remote cap and lower to fit them to the scale.

Remote Display

Remote Pipe

Remote Cap

Remote Packing

Tape

Hole

Screw

Screw

Remote Blind Plate

Connector

Connector

Connector Cover

7-1

Page 22

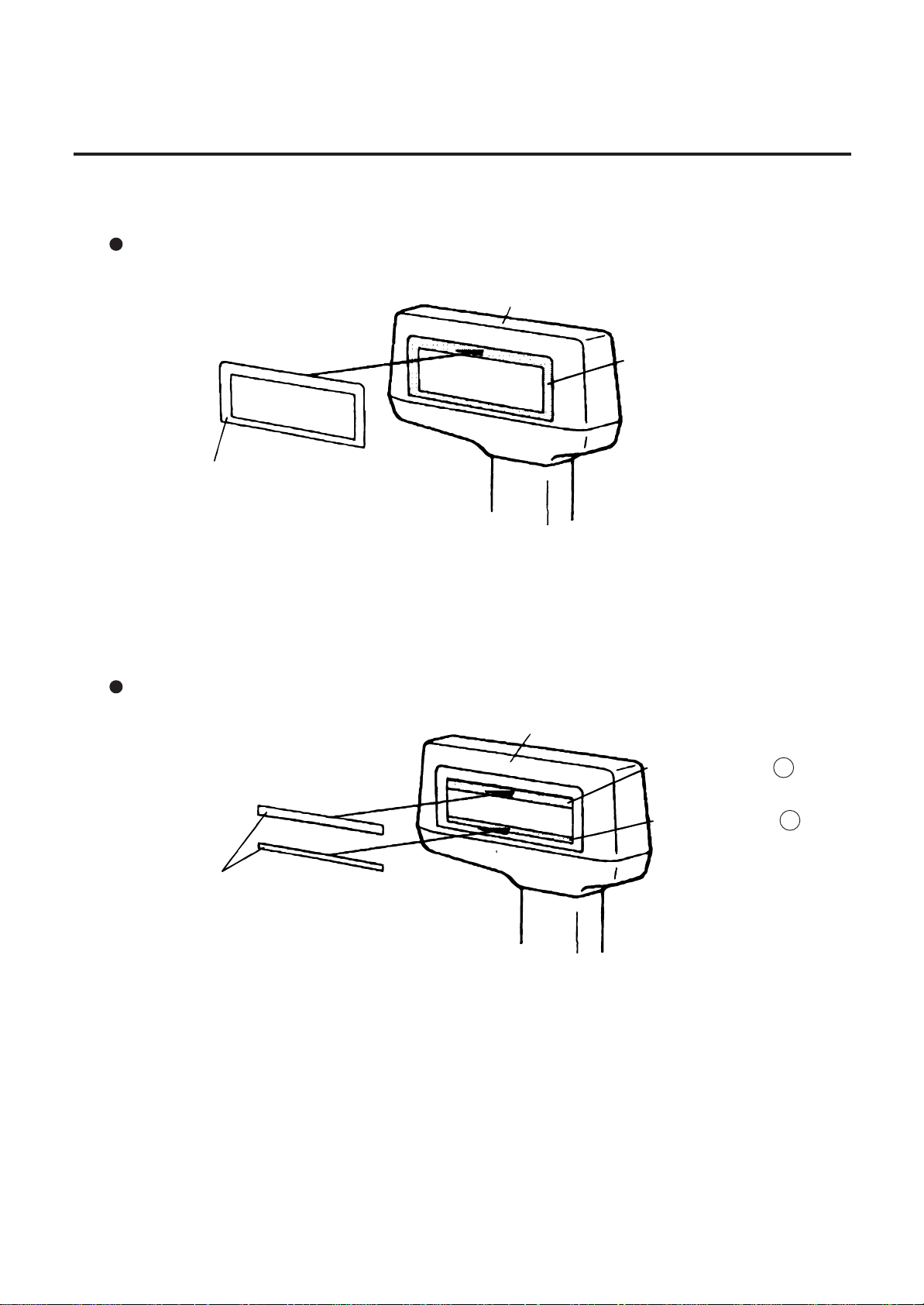

7. INSTALLATION PROCEDURE

7. INSTALLATION PROCEDURE

4. For the CA type, affix the remote display sheets to the remote display.

Be sure to wipe the remote display surface clean before affixing the sheet or sticker.

CA Type

Remote Display

Affix here.

Remote Display Sheet

Affix the remote display sheets to the depressed area of the remote display on both sides.

(Operator side and customer side)

QR Type

Remote Display

Affix to position A

Affix to position B

Remote Display Sticker

Affix the remote display stickers to the inner edge of the remote display sheet. (The sticker

should be affixed on both the operator side and customer side)

7-2

Page 23

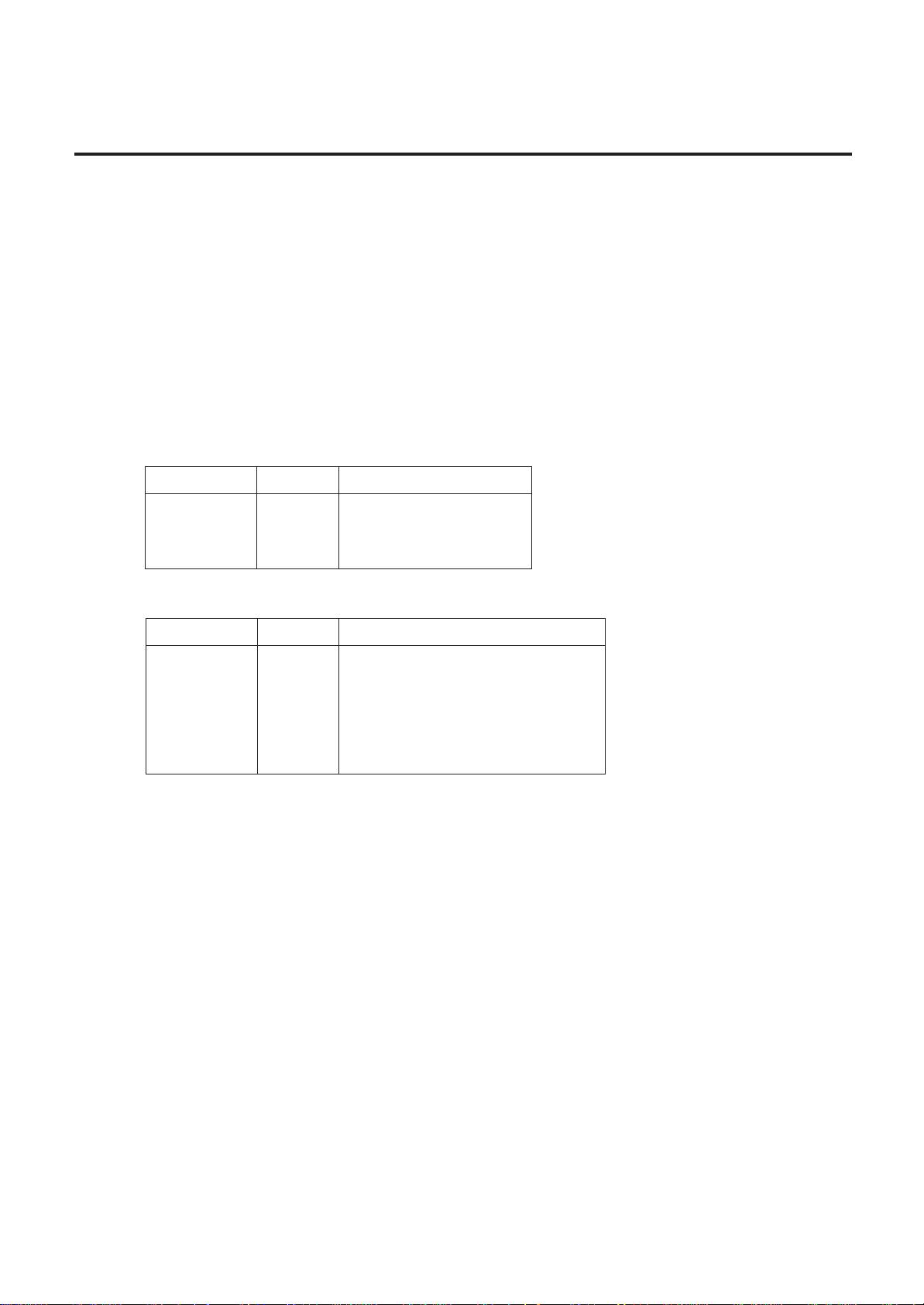

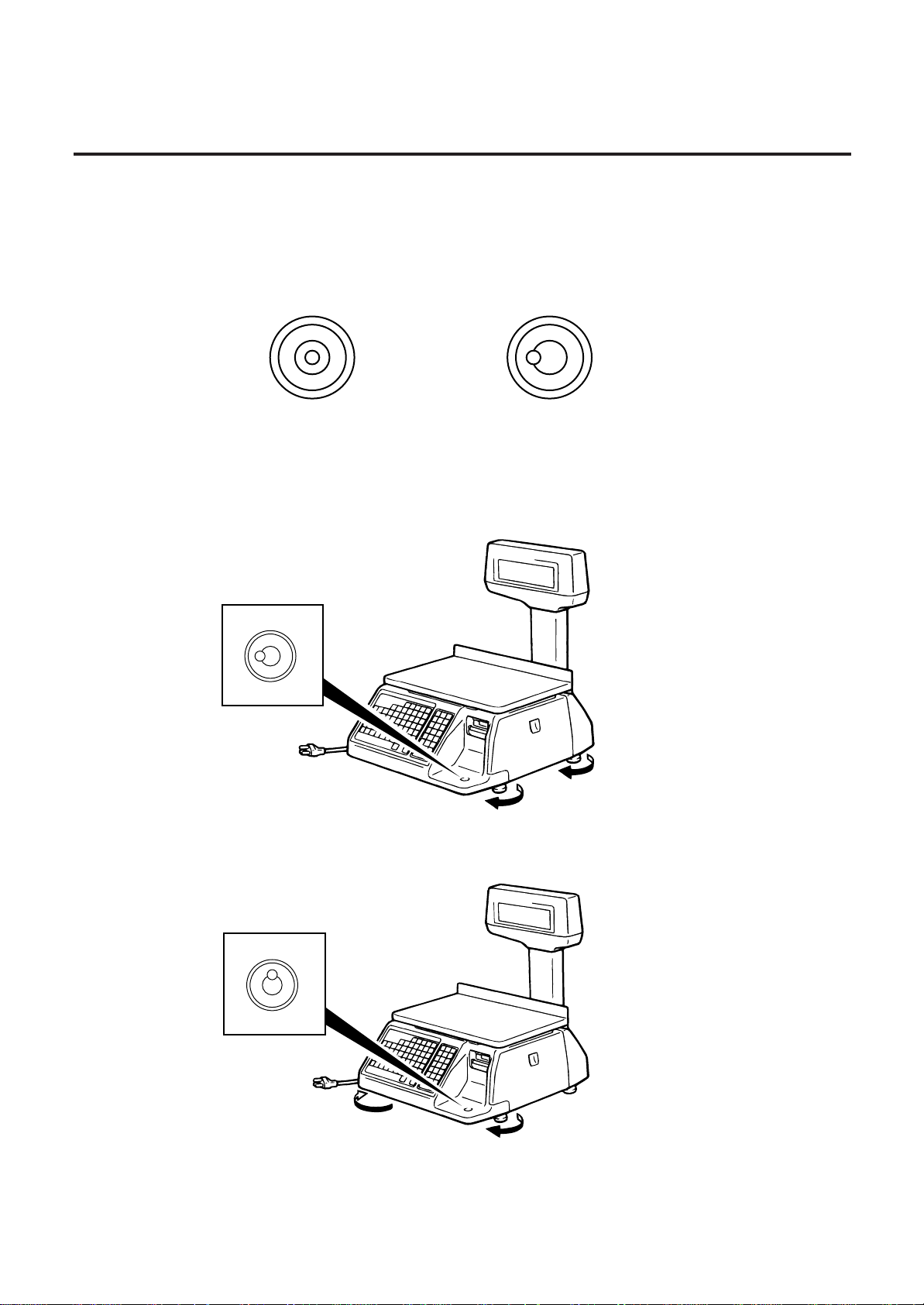

8. LEVEL ADJUSTMENT

8. LEVEL ADJUSTMENT

8. LEVEL ADJUSTMENT

1. Level Gauge

Set the scale on a stable and level surface. Level the scale by turning the adjustable legs so that the

air bubble is inside the center circle.

Correct

2. Adjustment Procedure

1 When the air bubble moves toward the left side, turn the right adjustable legs clockwise.

2 When the air bubble moves toward rear, turn the front adjustable legs clockwise.

Incorrect

8-1

Page 24

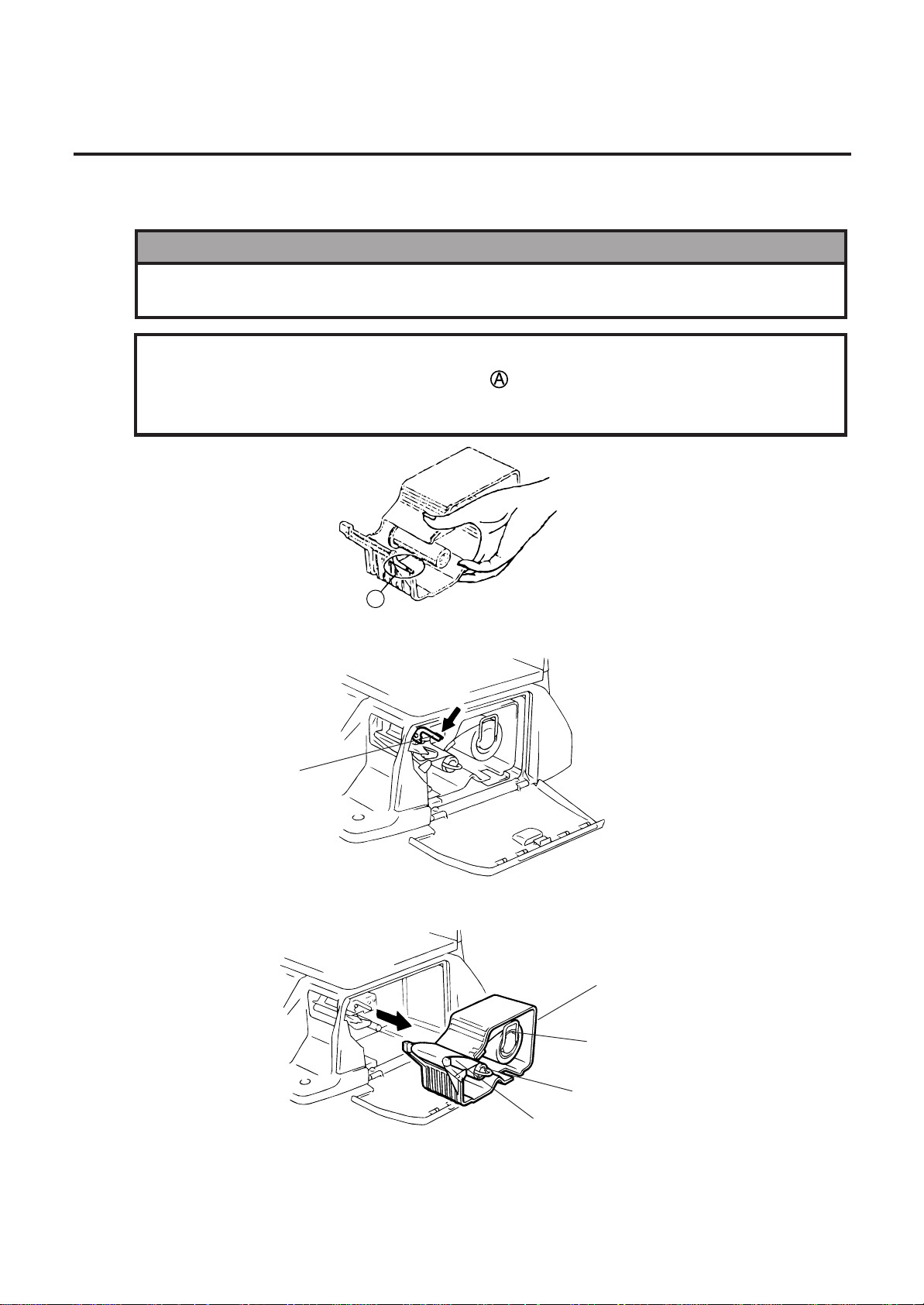

9. REMOVAL AND REPLACEMENT OF MEDIA

9. REMOVAL AND REPLACEMENT OF MEDIA

9. REMOVAL AND REPLACEMENT OF MEDIA

WARNING!

Since there is a cutter at the paper outlet, be careful not to injure your fingers when replacing

media.

CAUTION:

Do not hold the label cassette by the portion

. Doing so may deform the label cassette,

causing damage when setting it in position. Please be sure to hold the label cassette as the

following figure shows.

A

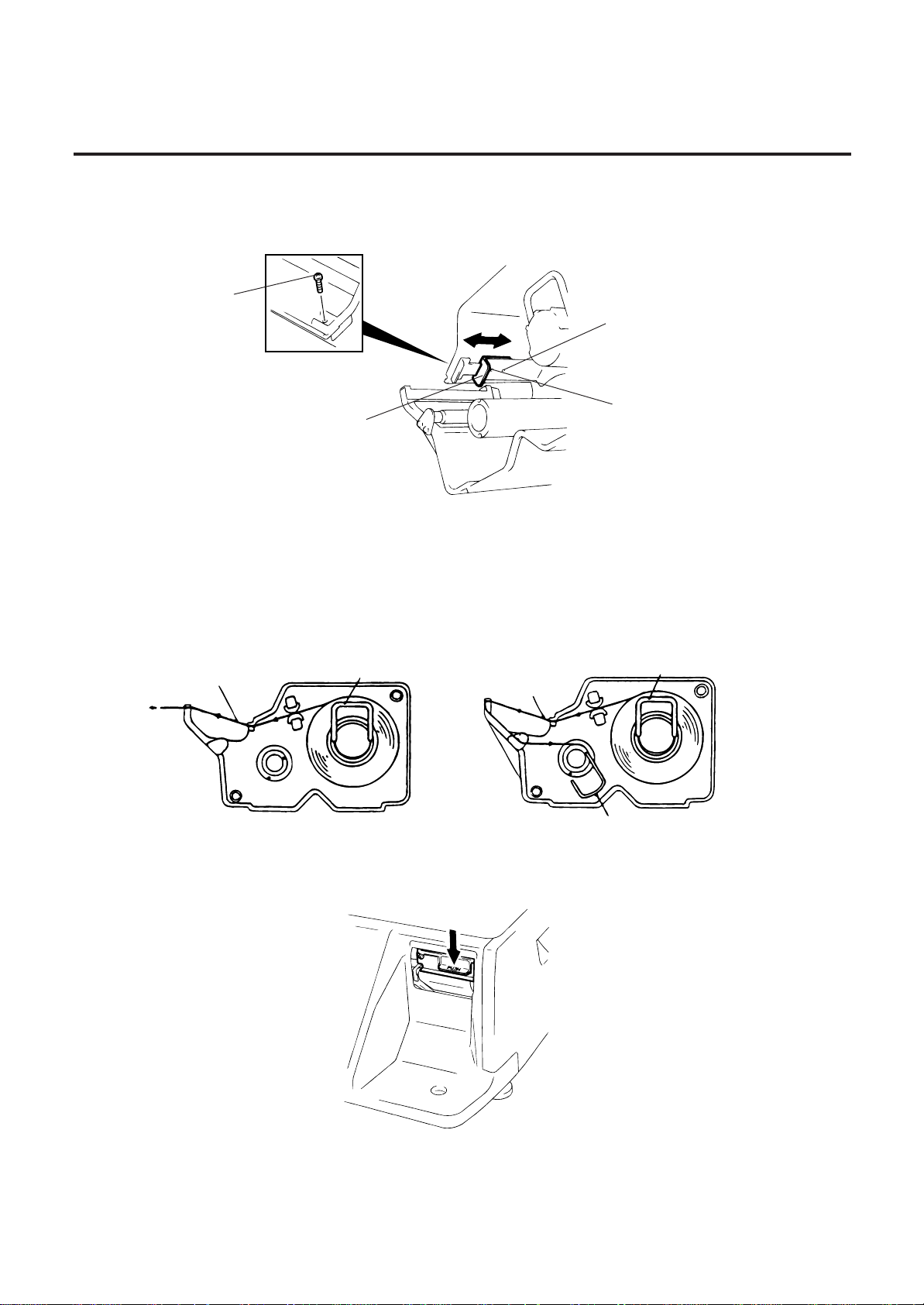

1. Open the right cover. Then push the head-up lever in the direction indicated by the arrow.

Head-up Lever

2. Pull out the label cassette.

3. Pull out the roll stopper and the backing paper stopper, and remove the media core with backing

paper.

Label Cassette

Roll Stopper

Backing Paper Stopper

Backing Paper

NOTE: When removing the backing paper, loosen the paper by turning the paper winding shaft

counterclockwise.

9-1

Page 25

9. REMOVAL AND REPLACEMENT OF MEDIA

9. REMOVAL AND REPLACEMENT OF MEDIA

4. Loosen the P-2.6x6 screw and move the label guide plate according to the media width.

5. Secure the label guide plate with the P-2.6x6 screw.

Screw (P-2.6x6)

48-mm label dowel

57-mm label dowel

Label Guide Plate

NOTE: Ensure that the label guide plate aligns with the dowel.

6. Refer to the figure below and set the media on the label cassette.

7. Insert the roll stopper into the media core fully.

8. Set the backing paper stopper in the proper orientation.

Label or Report Paper

Roll Stopper

Label

Roll Stopper

Backing Paper Stopper

9. Assemble the label cassette to the scale and remove slack of the media.

Push down the print head, and close the right cover.

NOTE: After replacing the media, press the feed key to confirm that the media is issued correctly.

*Use of other model’s label cassette in the SL-9000 may cause a label skew.

9-2

Page 26

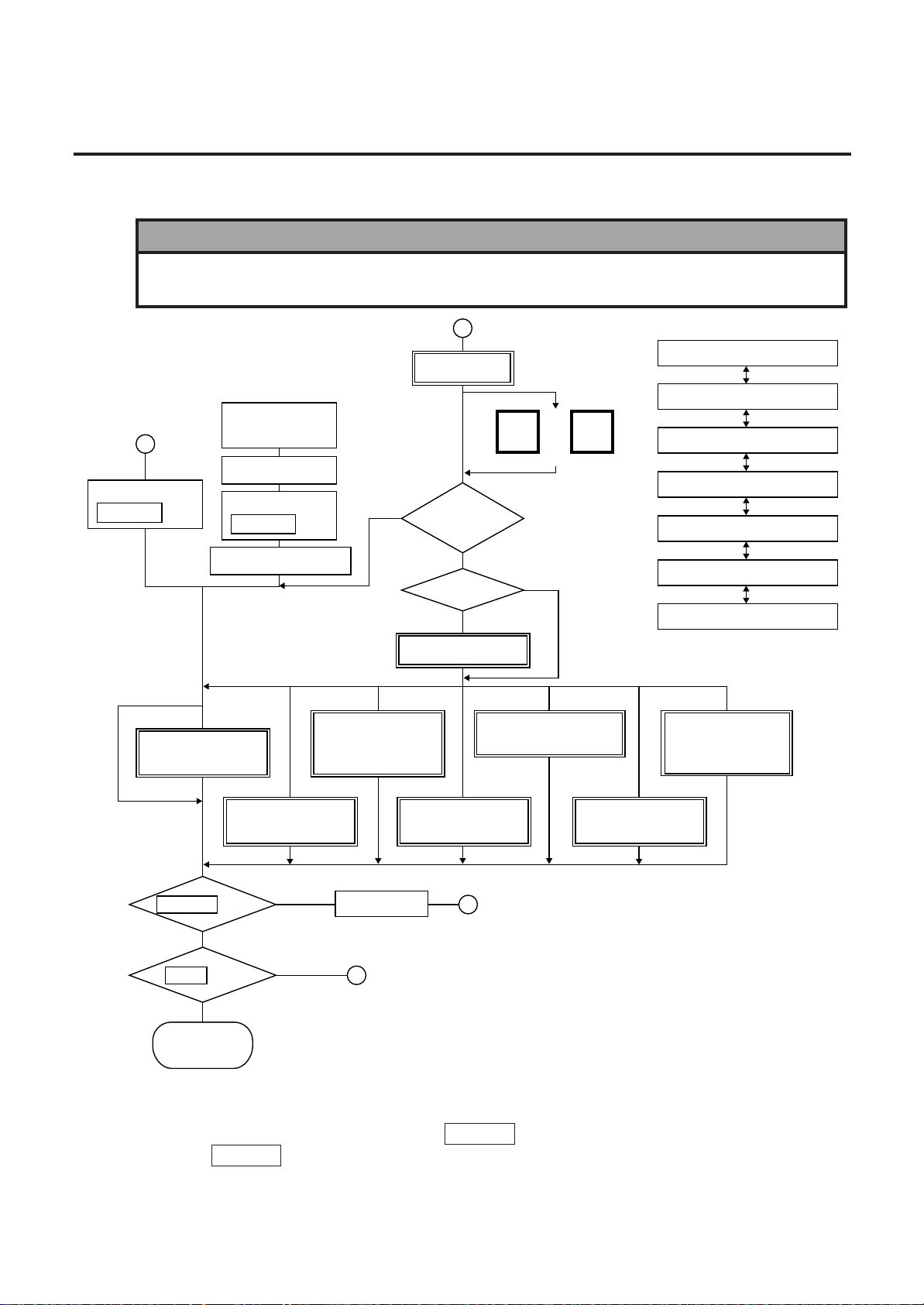

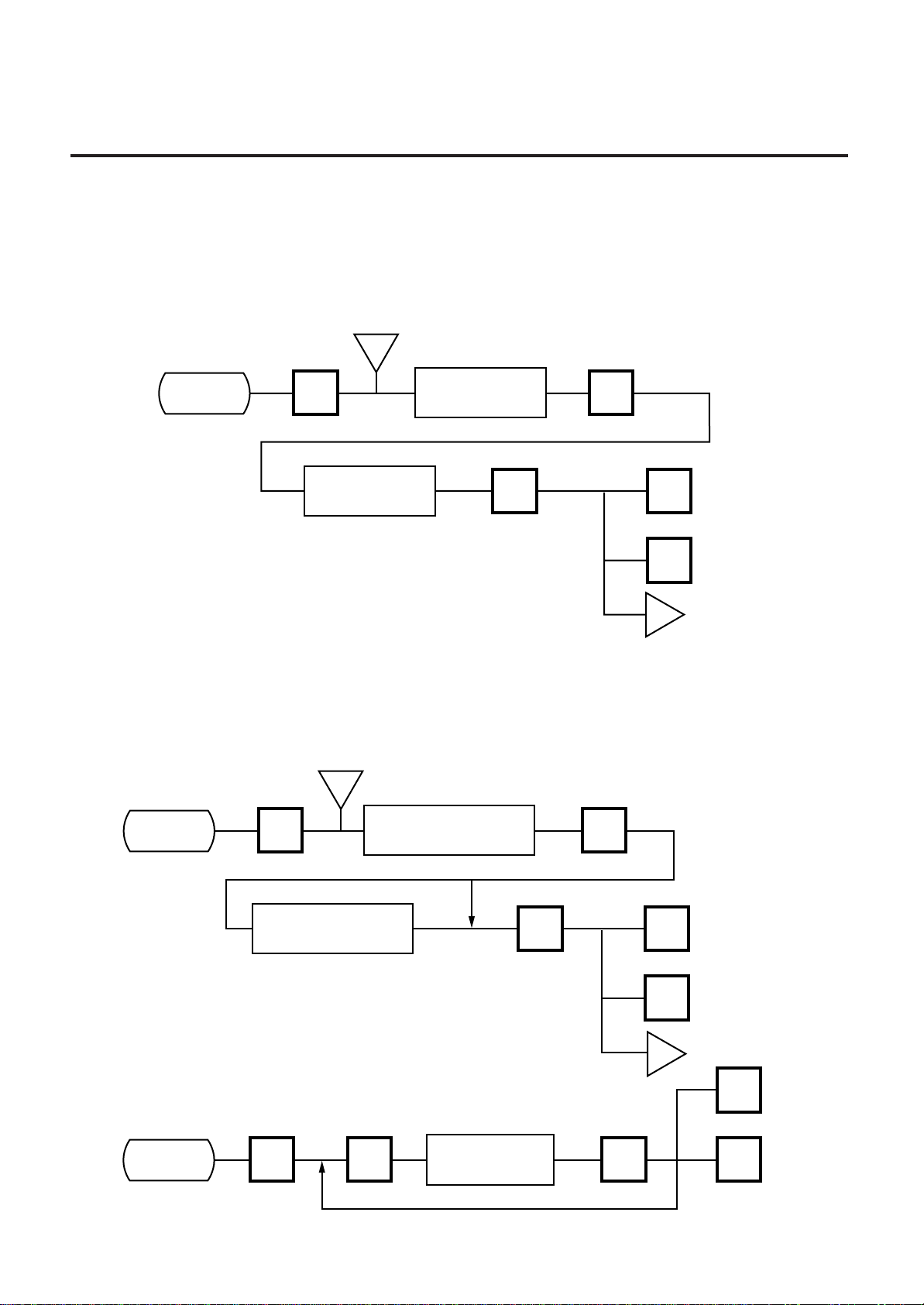

10. OUTLINE OF OPERATION

10. OUTLINE OF OPERATION

WARNING!

Since there is a cutter at the paper outlet, be careful not to injure your fingers when issuing

labels.

10. OUTLINE OF OPERATION

1

Press the

POWER key

REG Menu

(Refer to Section 14)

Main Power

Switch ON

Display OFF

Press the

POWER key

Scanning Display

Menu No. 1

Menu #1

Necessary

Password Input

Menu No. 2

MARK DOWN

Menu

(Refer to Section 14)

2

Main Menu

Increment

Select the

Menu #

Other than Menu #1.

Password

(Refer to Section 12, 15)

NEXT

PLU

Unnecessary

or

Decrement

Menu No. 5

READ Menu

VOID

Menu selection

PROG. 0

REG. 1

MARK DOWN 2

REWRAP 3

SECURITY 4

READ 5

RESET 6

Menu No. 4

SECURITY

Menu

(Refer to Section 13)

POWER key

No Press

ESC. key

No Press

Menu No. 3

REWRAP Menu

(Refer to Section 14)

Press

Press

(Refer to Section 11)

Display OFF

2

Menu No. 0

PROG Menu

1

RESET Menu

(Refer to Section 15)

Menu No. 6

Return to

each mode

NOTES:

1. You can register a password to prohibit unauthorized access to each menu expect for REG. menu.

2. To avoid wasteful use of the display, press the

Pressing the

POWER

key again allows you to enter REG. mode without scanning.

POWER

key to turn the display off while being unused.

3. Refer to respective sections for explanation each menu enclosed by a double rectangle.

10-1

Page 27

11. PROGRAMMING PROCEDURES

11. PROGRAMMING PROCEDURES

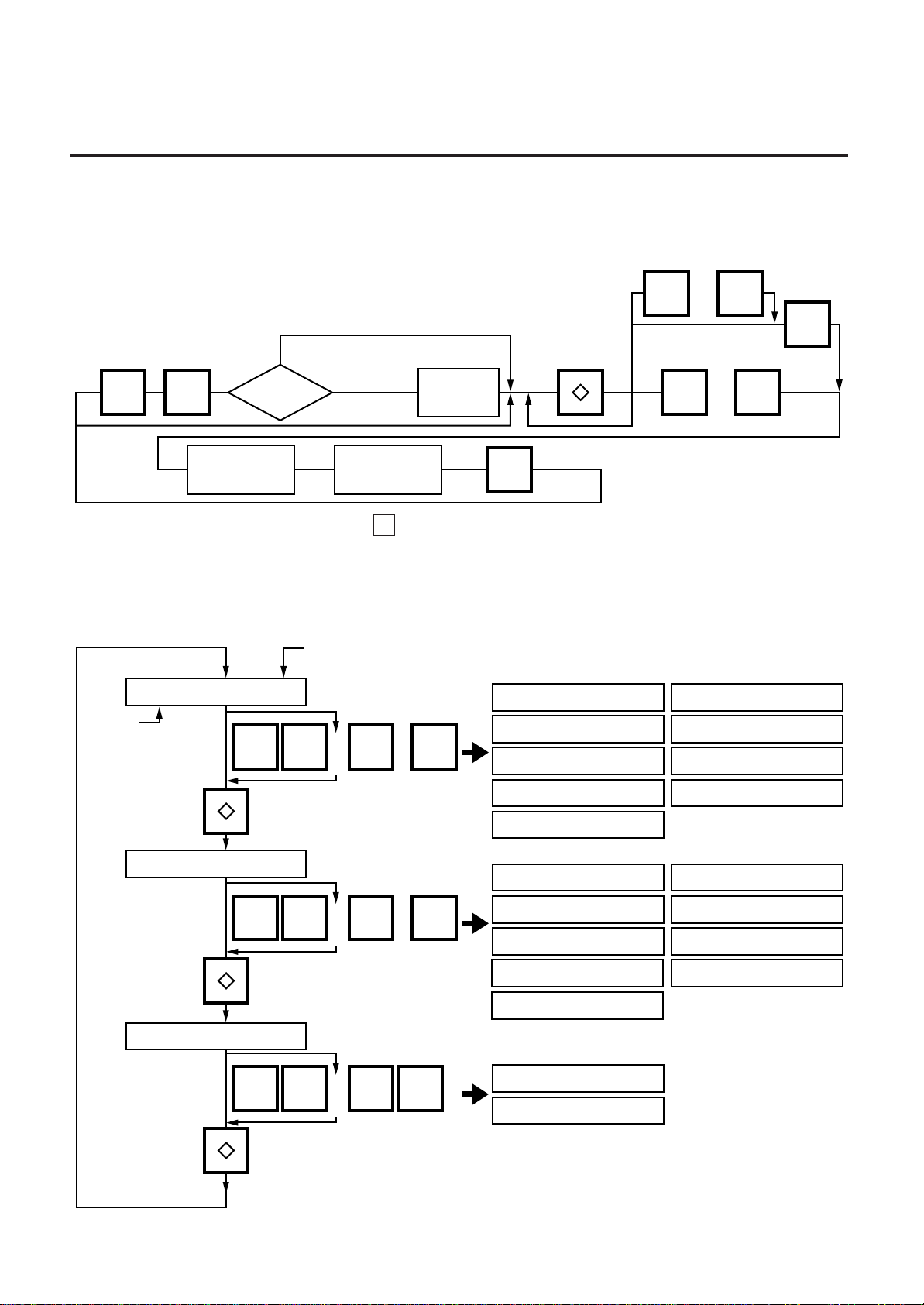

(1) Normal Mode

(1) Normal Mode

■ How to access the Programming Menu

Enter a

menu number

ESC.

Programming

starts

unnecessary

Password

neccesary

Programming

completes

Select the

programming

menu group.

Enter the

Password

PROG.

Item # selection

Increment

NEXT

or

PLU

Select an item No.

(See next page.)

00 9

Decrement

VOID

ENTER

~

NOTES: 1. When the selected menu ( 0 ) is protected from an access, refer to Section 13.2 and enter

the password.

2. In Sections 11.1, 11.2 and 11.3, items which have been sold on that day cannot be called

unless they are reset or the Initial Setting #1-4 is set to 1.

■ How to Select Menu and Item No.

Item No.

<Menu Group 1>

PLU DATA EDIT 0

TITLE

NEXT

PLU

Liquid Crystal Display

VOID

or

0

~

~

9

<Item No.>

PLU DATA EDIT 0

PLU DATA 1

INGREDIENT 2

ADRESS 5

SPECIAL INFO. 7

GRADE LINE 8

<Menu Group 2>

PRT LOCATION 0

<Menu Group 3>

VENDOR 0

NEXT

PLU

NEXT

PLU

VOID

VOID

or

or

NUTRITION 3

CONF. LABEL 4

<Item No.>

PRT LOCATION 0

9

~

0

0

1

DATE TIME 1

CMT 2

ON-LINE/LOCAL 3

INITIAL SET 5

<Item No.>

VENDOR NAME 0

FREE FORMAT 1

SPEED KEY SET 9

BAR CODE FORM. 6

TITLE 7

LOGO 8

IDIOM 9

11-1

Page 28

11. PROGRAMMING PROCEDURES

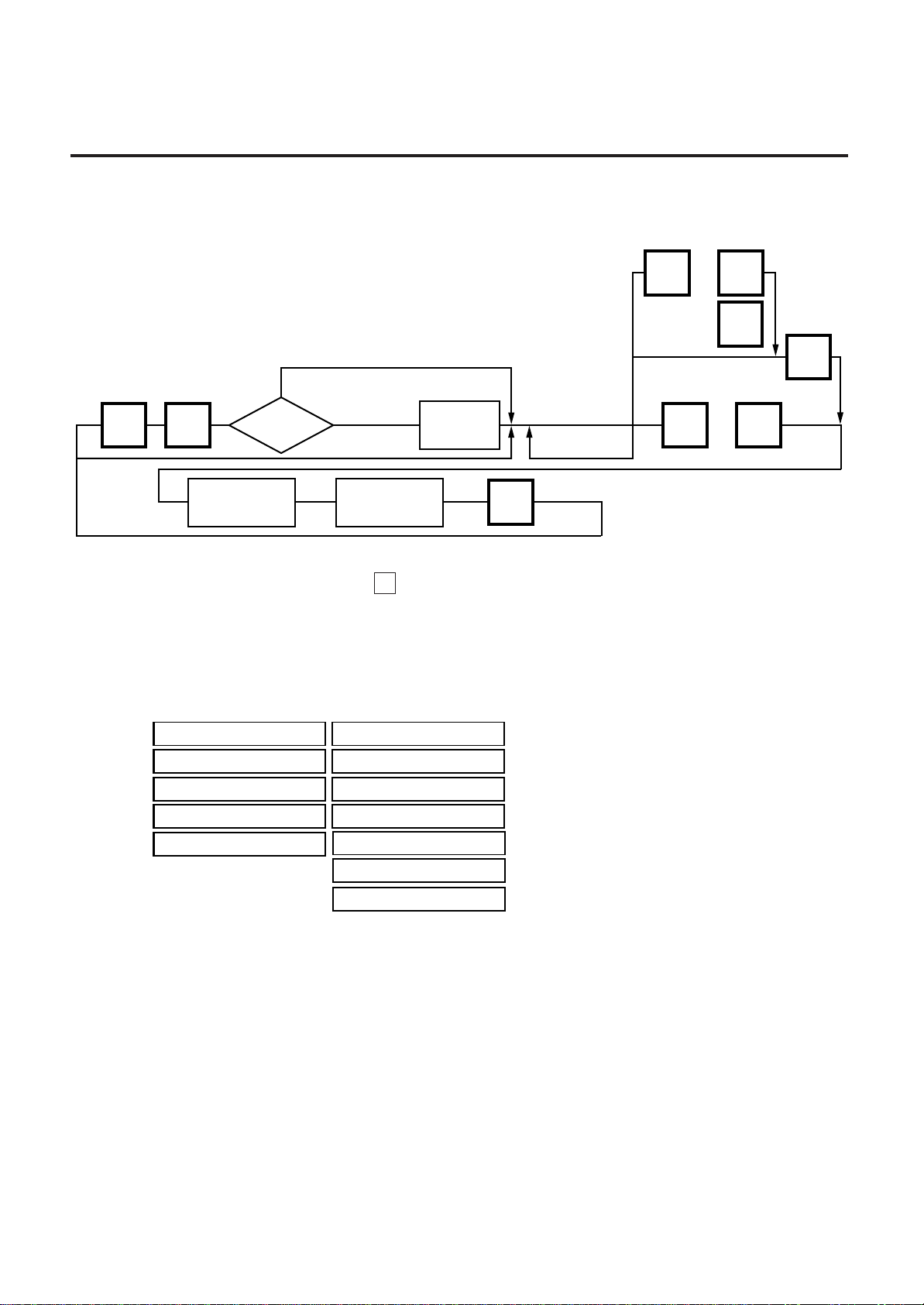

(2) ESB Limited Specification

■ How to access the Programming Menu

Item # selection

(Refer to NOTE3)

Increment

NEXT

PLU

(2) ESB Limited Specification

Decrement

VOID

or

-

PROG.

ESC.

Enter a

menu number

Programming

starts

unnecessary

Password

neccesary

Programming

completes

Enter the

Password

PROG.

Select an item No.

(See next page.)

to

00 9

NOTES: 1. When the selected menu ( 0 ) is protected from an access, refer to Section 13.2 and enter

the password.

2. In Sections 11.1, 11.2 and 11.3, items which have been sold on that day cannot be called

unless they are reset or the Initial Setting #1-4 is set to 1.

3. Select the programming menu by referring to the following item numbers.

<Item No.>

PLU DATA EDIT 0

PLU DATA 1

ADDRESS 2

CMT 5

INITIAL SET 6

BAR CODE FORM. 7

PRT LOCATION 3

DATE TIME 4

SPEED KEY SET 8

INGREDIENT 11

CONF. LABEL 12

ON-LINE/LOCAL 13

11-2

Page 29

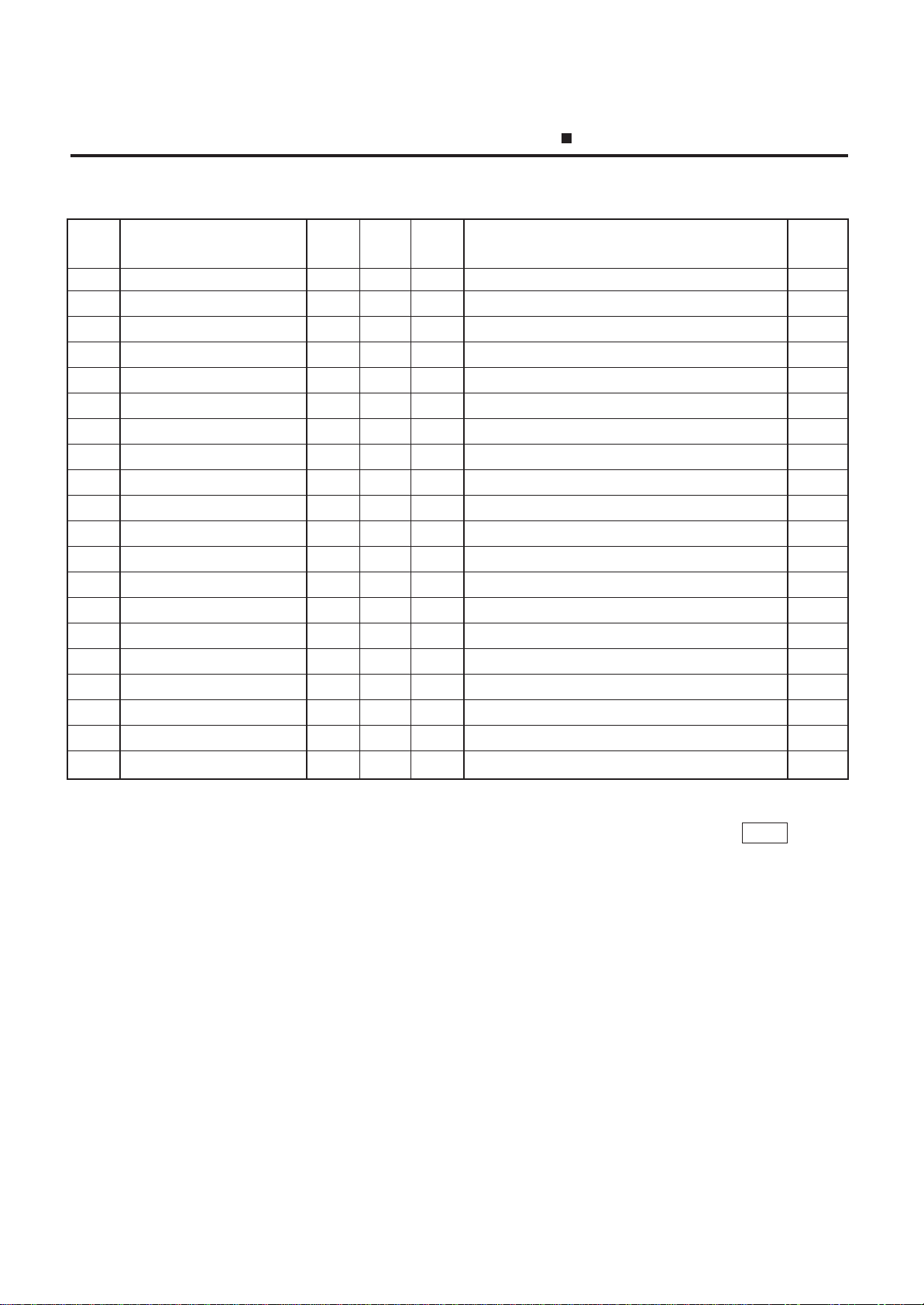

11. PROGRAMMING PROCEDURES

■ Table 1: Title and Contents of Programming Menu

Table 1: Title and Contents of Programming Menu

NO. TITLE MENU CONTENTS Page

GROUP

1 PLU DATA EDIT 1 0 0 CHANGE UNIT PRICE 11-5

2 PLU DATA 1 1 1 PROGRAM/CHANGE/DELETE PLU 11-6

3 INGREDIENT MESSAGE 1 2 11 PROGRAM/CHANGE INGREDIENT 11-9

4 NUTRITION FACTS 1 3 - PROGRAM/CHANGE NUTRITION FACTS TABLE 11-10

5 CONFIRMATION LABEL 1 4 12 VERIFY THE PROGRAMMING DATA OF PLU 11-14

6 ADDRESS SETTING 1 5 2 PROGRAM ADDRESS 11-15

7 SPECIAL INFO. 1 7 - PROGRAM SPECIAL INFORMATION 11-16

8 GRADE LINE 1 8 - PROGRAM GRADE LINE 11-16

9 SPEED KEY SETTING 1 9 8 ASSIGN COMMON PLU TO SPECIFIC SPEED KEY 11-17

10 PRT LOCATION 2 0 3 SELECT LABEL FORMAT AND ADJUST 11-18

11 DATE/TIME SETTING 2 1 4 PROGRAM DATE/TIME/MACHINE #/STORE CODE 11-20

12 CMT/PL-3 2 2 5

13 ON-LINE/LOCAL 2 3 13 SET PARAMETERS FOR TMCC 11-24

15 INITIAL SET 2 5 6 SET INITIAL PARAMETERS 16 BAR CODE FORMAT 2 6 7 PROGRAM BARCODE FORMAT 11-25

17 TITLE 2 7 - PROGRAM/CHANGE TITLE ON DISPLAY/PRINT 11-27

18 LOGO 2 8 - SEND/RECIEVE LOGO DATA 11-28

19 IDIOM 2 9 - PROGRAM IDIOM 11-29

20 VENDOR 3 0 - VENDOR NAME 11-29

21 FREE FORMAT 3 1 - PROGRAM FREE FORMAT 11-30

ITEM

No.

NOTE 2

ITEM

No.

NOTE 3

BACK-UP /LOAD DATA OF PLU/ING/NUTRI./SPEED KEY

11-20

NOTES: 1. Menu No. 15 is program for use of dealers. Connect a TOSHIBA TEC representative if you

desire to use them. When you enter one of these menus by mistake, press

ESC.

key to

return to Main Menu.

2. Nornal Mode (Initial Setting #13-8 is 0)

3. ESB Limited Specification Mode (Initial Setting #13-8 is 1)

4. If you would like to switch the Initial Setting #13-8 please contact your authorized TOSHIBA

TEC representative.

The default initial setting #13-8 for each model is as follows.

US model: 1

CA/QR/MX model: 0

11-3

Page 30

11. PROGRAMMING PROCEDURES

How to enter characters

■ How to enter characters

Use the following procedure to enter a commodity name, address and ingredient message.

Example) 1st line: TEC STORE

2nd line: (TEL) 0123-45-6789

T

EC

SHIFT (

SPACE

1st line content

SHIFT

TEE 6789

STOR

2nd line content

NOTES: 1. ← and → keys are the cursor keys.

2. To insert a space, move the cursor to the next character to the space to be inserted, and

press

3. To delete a line, press

INSERT

key.

DELETE (B)

key.

4. To move the cursor to the preceding line, press

5. Pressing the

key toggles between capitals and small letters.

6. When entering a commodity name, press

RETURN 1/4

7. Pressing the

key to return.

CHANGE PLU

key toggles the type font between normal and boldface.

8. To call a preset ingredient message idiom, follow the procedure below:

E

DELETE

(A) 1/2

-

RETURN

1/4

L

key, or ↑ key.

ENTER

or ↓ key instead of the

NEXT

PLU

Enter the idiom #.

RETURN

1/4

9. To skip a line when entering an ingredient message, follow the procedure below:

SET

NEXT

Enter the line #.

11-4

RETURN

1/4

Page 31

11. PROGRAMMING PROCEDURES

11.1 UNIT PRICE CHANGE

11.1 UNIT PRICE CHANGE

Normal Mode ESB Limited Spec. Mode

Menu Group: 1 Item No.: 0

Item No.: 0

Unit prices stored in PLU can be changed under this menu.

In this procedure, use the operation keys (except when calling a PLU by using a speed key).

<MENU>

Group 1

a

0

Change the unit price

(max. 4 digit)

Enter the PLU #.

NEXT

Speed key

1st half 2nd half

PLU

or

VOID

Enter the Speed key #

PRT

PRT

*

a

PROG.

<MENU>

*

TEST

ESC.

<MENU>

NOTES: 1. Calling a PLU# that has not been stored in the PLU file results in an error.

2. Under this Menu (Menu No. 0), “open-price” PLU’s price cannot be changed.

Group 1

Main

11-5

Page 32

11. PROGRAMMING PROCEDURES

11.2 PLU DATA SETTING

Normal Mode ESB Limited Spec. Mode

Menu Group: 1 Item No.: 1

Item No.: 1

Setting or changing the contents of PLU (PLU#, UPC#, Commodity Name, etc.).

b

Set tare limit.

#8-2?

1

Max. 2 lb (US)

Max. 1Kg/2.205 lb (CA)

0

ENTER

<MENU>

Group 1

SET

NEXT

1

NEXT

PLU

AUTO

CODE

Set auto code

for the UPC#

ENTER

Is status

of initial set

or

11.2 PLU DATA SETTING

Enter PLU#

(max. 6 dig.)

Is status

of initial set

#1-6?

Is status

of initial set

#26-4?

0

Is status

of initial set

#23-1?

Is status

of initial set

#1-5?

CHANGE

PLU

ENTER ENTER

1

0

1

1

0

1

0

Enter current

PLU#

Enter UPC#

(max. 6 dig.)

BY COUNT

In what

mode is PLU

used?

WEIGH

or FIX

Enter flag of

unit price.

(Refer to NOTE4)

Enter tare weight.

Max. 2 lb (US)

Max. 1Kg/2.205 lb (CA)

Selection Mode Flag

0: Weight

1: By Count

2: Fix Price

ENTER

Enter quantity for that

price. (Max. 2 dig.)

ENTER

ENTER

ENTER

Enter new

PLU#

ENTER

Enter commodity name.

(max. 32 chars.x4 lines)

Enter shelf life.

(Max. 3 dig.)

Is status

of initial set

#10-5?

0

ENTER

ENTER

1

ENTER

Enter unit price.

(max. 4 dig)

Is status

of initial set

#7-8?

0

Safe Handing

Instruction

0: Non Print

1: Print

ENTER

1

Enter PERIOD OF

RELISH (Max. 3 dig.)

Select

compulsory tare

ENTER

Is status

of initial set

#8-7?

0

2

Is status

of initial set

#8-1?

1

ENTER

0 or 1

Set tare %

(Max. 99.9%)

(Price %)

ENTER

DELETE

TEST

Enter

PLU

PLU#

The setting label is issued.

b

<MENU>

PROG.

ESC.

<MENU>

Group1

Main

ENTER

or

Y N

(Sorting)

Y

Any key

except Y

(Not Sorting)

The memory file is sorted

when a memory full error

occurs.

11-6

Is status

of initial set

#12-4?

0 or 1

Is status

of initial set

#9-4?

0

2

(Price: Max. 5 digit

Rate: Max. 3 digit)

1

Enter discount

price or rate.

Enter LOGO #.

(#0 - 26)

ENTER

ENTER

Page 33

11. PROGRAMMING PROCEDURES

11.2 PLU DATA SETTING

Pressing the ↓ key instead of the

ENTER

key proceeds to the next menu. Pressing the ↑ key

returns to the preceding menu.

Verification label of PLU data

Commodity Name

Mode Flag

Preset Tare

Quantity

PLU#

T1.000

NET WT.

PACKED ON

SELL BY

PRICE lb

TEC STORE

(TEL) 0123-45-6789

C

T15.0%

Compulsory Tare

Shelf Life

Preset % Tare

Price

UPC#

NOTES:

1. A UPC code is made up of a combination of an entered code and an AUTO CODE. Be sure

to add some - characters to the end of the AUTO CODE, or all entered codes will be

ignored and an AUTO CODE will become an UPC code (see ex. 1).

ex. 1) enter code: 456 ex. 2) enter code 4567 ex. 3) enter code: 123456

AUTO CODE: 123.... AUTO CODE: 123.... AUTO CODE: 987

↓

↓

↓

code#: 123456 code#: 123567 code#: 987

2. When there is no area to store PLU data, an error occurs when pressing the ENTER key.

3. Changing a PLU# to number to which other PLU data is set will result in an error.

4. Unit price flag may be selected as follows:

1) In case of lb scale

a. INSERT1 key : $ per lb

b. DELETE (A) 1/2 key : $ per 1/2 lb

c. RETURN 1/4 key : $ per 1/4 lb

2) In case of kg scale

a. INSERT 1 key : $ per 100 g or Kg (CA/QR type only)

5. Tare limit should be a multiple of 5 (5, 10, 15...), up to 2.000 lb for US type and a mutiple of 2

(2, 4, 6, 8...), up to 1.000 Kg for CA/QR type.

6. Safe handing instructions can be printed on 57-mm wide labels only. Safe handing

instructions are printed on labels formatted for ingredient messages. Only ingredient

message labels with 13 or more lines can be used to print safe handling instructions.

Available print formats are as follows:

13 (63), 15 (65), 16 (66), 23 (73), 25 (75), 26 (76), 33 (83), 35 (85), 36 (86), 41, 42, 43, 48

and 49.

7. Tare % indicates a percentage of tare in gross weight, which is available when the Initial

Setting #8-7 is set to 1.

8. When setting open price in the count mode (Initial Setting #1-6: 1), set zeros as quantity and

unit price.

11-7

Page 34

11. PROGRAMMING PROCEDURES

Scanning

REG

POWER POWER

POWER SW : ON

POWER

9. In ESB limited specification mode

Open PLU

(1) "OPEN PLU" (PLU#.999999) is created automatically when RAM clear is performed.

(2) "OPEN PLU" (PLU#.999999) is called automatically with U.P = $0.00 when registration

mode is selected.

(3) Memory addition for "OPEN PLU" is same as normal PLU.

(4) Key operation is as following.

OPEN PLU DATA

PLU# 999999 tare 000000

UPC# 000000 shelf life 000

DEPT# 0000 3rd Date 000

comm. 1st OPEN PLU piece cnt. 00

comm. 2nd (space) mode flag 00

comm. 3rd (space) Bold/SH flag 00

comm. 4th (space) % Tare 0000

unit price flag 11 Discount 000000

unit price 000000 Total memory all zero

11.2 PLU DATA SETTING

OPEN PLU

0.000 0.00 0.00

11-8

Page 35

11. PROGRAMMING PROCEDURES

11.3 INGREDIENT MESSAGE

11.3 INGREDIENT MESSAGE

Normal Mode ESB Limited Spec. Mode

Menu Group: 1 Item No.: 11

Item No.: 2

Ingredient messages can be printed on a label with a maximum of 54 characters per line in small letters

or 32 characters per line in boldfaced small letters, by up to 38 lines.

C

<MENU>

Group 1

Enter the ingredient message

(Refer to Page 11-4.)

Pressing the key

calls data stored by pressing

the key.

Pressing the key

temporarily stores data into

the work buffer.

SEND

2

RECEIVE

SEND

NEXT

PLU

Enter the PLU#

(max. 6 dig.)

or

ENTER

The memory file

is sorted when a

memory full error

occurs.

ENTER

TEST

Sorting

Y

Any key

except Y

C

Not Sorting

PROG.

ESC.

<MENU>

Group 1

Main

<MENU>

NOTES: 1. When no data is programmed for the PLU, ingredient cannot be set.

2. When a selected PLU is not stored in the PLU file, a “PLU NOT FOUND” error occurs.

3. Once you exit this menu and enter again, data stored in the work buffer is cleared.

4. When there is no area to store ingredient data, a “MEMORY FULL” error occurs.

5. PLUs cannot share ingredient data. (PLU and ingredient data are in pairs.)

11-9

Page 36

11. PROGRAMMING PROCEDURES

11.4 NUTRITION FACTS

11.4 NUTRITION FACTS

In ESB Limited specification mode, this programming is unavailable.

Menu Group: 1

Item No.:3

Using the following procedure, nutrition information and caloric intake can be set.

Serving Size and Servings Per Container consist must of maximum of a 18 characters. However, total

number of characters including title characters must not exceed 30.

<MENU>

Group 1

f

d

3

NEXT

PLU

Enter the

Serving Size.

Enter the Calories.

(0~9999)

Additional Information.

Area 1 (0~9999)

Enter the Total Fat.

(0~99999 or 0.0~999.9)

ENTER

Enter the PLU#

(max. 6 dig.)

or

Enter the Servings

Per Container.

ENTER

ENTER

ENTER ENTER

Enter the Calories

from Fat.

(0~9999)

Enter the Saturated Fat.

(0~99999 or 0.0~999.9)

ENTER

ENTER

ENTER

Enter the cholesterol.

(0~99999 or 0.0~999.9)

Enter the Total

Carbohydrate.

(0~99999 or 0.0~999.9)

Enter Sugar.

(0~99999 or 0.0~999.9)

A

ENTER ENTER

ENTER ENTER

ENTER ENTER

Enter the Sodium.

(0~99999 or 0.0~999.9)

Enter the Dietary Fiber.

(0~99999 or 0.0~999.9)

Enter Protein.

(0~99999 or 0.0~999.9)

11-10

Page 37

11. PROGRAMMING PROCEDURES

A

11.4 INUTRITION FACTS

Additional Information Area 2~6.

(0~99999 or 0.0~999.9)

Enter the

Vitamin A.

ENTER ENTER

(0~999)

Enter the

Calcium.

e

(0~999)

ENTER

Additional Information

Area 7~12 (0~999)

PROG.

ESC.

<MENU>

Group 1

Main

Enter the

Vitamin C.

(0~999)

Enter the

Iron.

(0~999)

ENTER

ENTER

ENTER

<MENU>

f

Pressing the ↓ key instead of the ENTER key proceeds to the next menu. Pressing the ↑ returns

to the preceding menu.

NOTES: 1. When a selected PLU# is not stored in the PLU file, an error occurs.

2. Nutrition file is input each time the

on the way, data entered without pressing

ENTER

key is pressed. Thus, if you quit the procedure

ENTER

key is not stored.

3. The additional information can be used only when its title has been registered in Section

11.14.

11-11

Page 38

11. PROGRAMMING PROCEDURES

• Set the Daily Value Table

11.4 INUTRITION FACTS

d

AUTO

CODE

NOTES:

1. DAILY VALUE (Max. 8 digits)

1) The contents of daily value

Contents

No. 1

Percentage of necessary daily intake of

Calories

No. 2

Percentage of necessary daily intake of

Total Fat

No. 3

Percentage of necessary daily intake of

Saturated Fat

No. 4

Percentage of necessary daily intake of

Cholesterol

No. 5

Percentage of necessary daily intake of

Sodium

No. 6

Percentage of necessary daily intake of

Total Carbohydrate

No. 7

Percentage of necessary daily intake of

Dietary Fiber

Enter the

Basic Calories.

(Content No. 1)

Enter the Basic

Saturated Fat.

(Content No. 3)

Enter the

Basic Sodium.

(Content No. 5)

Enter the Basic

Dietary Fiber.

(Content No. 7)

ENTER ENTER

ENTER ENTER

ENTER ENTER

ENTER

upper 4 digits

Enter the

Basic Total Fat.

(Content No. 2)

Enter the

Basic Cholesterol.

(Content No. 4)

Enter the Basic

Total Carbohydrate.

(Content No. 6)

e

e

lower 4 digits

Necessary daily intake of

Calories

Necessary daily intake of

Total Fat

Necessary daily intake of

Saturated Fat

Necessary daily intake of

Cholesterol

Necessary daily intake of

Sodium

Necessary daily intake of

Total Carbohydrate

Necessary daily intake of

Dietary Fiber

2) The necessary daily intake of calories can be changed by changing the above table data,

and percentage will be changed accordingly.

2. Percentage of daily intake

1) Percentage data are printed in right justified 3 digits with zero suppression.

2) On the following conditions, an error occurs and data will be printed as ‘--- %’.

1

Percentage data exceeds 3 digits (999%).

2

Data is entered improperly.

Other than xxxxx or xxx.x

Other than numberals (0 to 9) and a point ‘.’

3. Calculation

(input data) / (necessary daily intake) x 100 = Percentage of daily value

(round the obtained data to one decimal place)

11-12

Page 39

11. PROGRAMMING PROCEDURES

• Deleting Nutrition Data

11.4 INUTRITION FACTS

d

DELETE

PLU

Enter the PLU#.

(max. 6 dig.)

ENTER

e

• Memory file sort

The memory file is sorted when a memory full error occurs.

Sorting

d

Y

Any key

except Y

Not Sorting

Nutrition Facts

Serving Size xxxCUP (xxxxg)

Servings Per Container xxx

Amount Per Serving

Calorier xxxx

Calories from Fat xxxx

xxxxxxxxxxxxxxxxxxxxxx xxxx

% Daily Value*

Total Fat xxxxg xxx%

Saturated Fat xxxxg xxx%

Cholesterol xxxxmg xxx%

Sodium xxxxmg xxx%

Total Carobohydratexxxxg xxx%

Dietary Fiber xxxxg xxx%

Sugers xxxxg

Protein xxxxg

xxxxxxxxxxxxxxxxxx xxxxxx

xxxxxxxxxxxxxxxxxx xxxxxx

xxxxxxxxxxxxxxxxxx xxxxxx

xxxxxxxxxxxxxxxxxx xxxxxx

xxxxxxxxxxxxxxxxxx xxxxxx

e

Additional information area 1

Additional information area 2

Additional information area 3

Additional information area 4

Additional information area 5

Additional information area 6

Nutrition Facts

Serving Size 1234567890123

Servings Per Container 223

Amount Per Serving

Calories 3

Calories from Fat 4

% Daily Value*

Total Fat 5g 8%

Saturated Fat 6g 30%

Cholesterol 7mg 2%

Sodium 8mg 0%

Total Carbohydrate 9g 3%

Dietary Fiber 10g 40%

Sugars 11g

Protein 12g

Vitamin A 13%.Vitamin C 14%

Calcium 15%.Iron 16%

* Percent Daily Values are based on a 2,000

calorie diet.

Vitamin A xxx% Vitamin C xxx%

Calcium xxx% Irom xxx%

xxxxxxxxxx xxx% xxxxxxxxxx xxx%

xxxxxxxxxx xxx% xxxxxxxxxx xxx%

xxxxxxxxxx xxx% xxxxxxxxxx xxx%

* Percent Daily Values are based on a 2,000

calorie diet.

1 st Address - - - - - - - - - - - - - 2 nd Address - - - - - - - - - - - - - -

Area for titles

Area for entry data: Set in this menu (Nutrition Setting procedure.)

Area for data: Calculated on the basis of the entered data in Menu Page 1/Item No. 3

Additional information area 7,8

Additional information area 9,10

Additional information area 11,12

1-0000000000000000000000-1

2-0000000000000000000000-2

(Sample label)

11-13

Page 40

11. PROGRAMMING PROCEDURES

11.5 PLU VERIFYING LABEL

Normal Mode ESB Limited Spec. Mode

Menu Group: 1 Item No.: 12

Item No.: 4

PLU data stored in the scale are verified in the following procedure.

g

11.5 PLU VERIFYING LABEL

<MENU>

Group 1

CLEAR

To interrupt

label issue.

4

1 0 0

Set the individual PLU#. (Ex. PLU #100)

1

Set the block PLU#. (Ex. PLU #100~199)

1 0 0 1 0 8

Set the zone PLU#. (Ex. PLU #100~108)

ENTER

To resume label issue

which has been interrupted.

Set the entire PLU#.

NEXT

PLU

PROG.

ESC.

g

<MENU>

Group 1

Main

<MENU>

ENTER

The

confirmation

label is issued.

NOTES:

1. Labels are printed in both batch mode and on-demand mode.

2. When no PLU is stored in the selected range, an error occurs when the

3. Pressing the

CLEAR

key releases the scale from the error mode and returns to the initial status

of this menu.

4. After clearing a paper jam error, the scale will wait for an entry of PLU# again.

11-14

ENTER

key is pressed.

Page 41

11. PROGRAMMING PROCEDURES

11.6 ADDRESS SETTING

11.6 ADDRESS SETTING

Normal Mode ESB Limited Spec. Mode

Menu Group: 1 Item No.: 2

Item No.: 5

Store addresses and receipt header printed on label can be set within the following character limits.

Address: 32 characters x 2 lines

Receipt Header: 24 characters on the 1st/2nd line and 48 characters in the 3rd line

h

<MENU>

Group 1

5 0

Store Address

9

Receipt Header

Enter a store address

or receipt header.

(Refer to Page 11-4)

PROG.

ESC.

h

<MENU>

Group 1

Main

<MENU>

ENTERENTER

11-15

Page 42

11. PROGRAMMING PROCEDURES

11.7 SPECIAL INFORMATION

11.7 SPECIAL INFORMATION

In ESB Limited Spec. mode, this programming is unavailable.

Menu Group: 1

Item No.:7

When the Net Weight Statement label is selected, 3 lines (32 characters/line) of special information can

be printed on the label position where the net weight data is to be printed. The special information can

be printed in the weigh and By Count mode. In the Fix mode, the net weight data is printed.

<MENU>

Group 1

7

ENTER ENTER

Enter the special

information.

(Refer to page 11-3.)

TEST

PROG.

ESC.

<MENU>

Group 1

Main

<MENU>

11.8 Grade Line

In ESB Limited Spec. mode, this programming is unavailable.

Menu Group: 1

Item No.:8

You can set the maximum 49 kinds of grade lines (max. 32 characters/line), and call one of them to print

it on the label.

<MENU>

Group 1

8

Enter the grade

line#. (1~49)

PROG.

<MENU>

Group 1

ENTER ENTER

Enter characters.

(max. 32 chars./line)

(Refer to NOTE 2)

ESC.

Main

<MENU>

NOTES: 1. Print position of grade line can be changed by initial setting.

2. Refer to page 11-4, for information regarding how to enter the Grade Line.

11-16

Page 43

11. PROGRAMMING PROCEDURES

11.9 SPEED KEY SETTING

11.9 SPEED KEY SETTING

Normal Mode ESB Limited Spec. Mode

Menu Group: 1 Item No.: 8

Item No.: 9

The SL-9000 has a maximum of 70x2 speed keys which are very convenient to call PLUs quickly.

(Refer to page 5-3 regarding the Key Layout.)

i

<MENU>

Group 1

9

Select the 1st half or the

2nd half of the speed keys.

Enter the PLU#.

(max. 6 dig.)

ENTER

Setting Department/Vendor Number

<MENU>

Group 1

Selecting items to be

assigned to speed keys.

(PLU #/VENDOR #/DEPT #)

9

AUTO

CODE

ENTER ENTER

Enter the department #

or vendor #. (1 ~ 99)

Enter the Speed

Key number

(# 1~70 X 2)

NEXT

or

PLU

i

PROG.

ESC.

Enter a default

department #. (1~99)

<MENU>

Group 1

Main

<MENU>

ENTER

ENTER

Enter the speed

key number.

PROG.

ESC.

<MENU>

Group 1

<MENU>

Main

• Department Number

When initial set #10-6 is set to “1”, the six-digit PLU# is divided into two; the upper two digits are assigned to

department #, and the lower four digits to PLU.

The department # is automatically added in front of four-digit PLU# and treated as a six-digit PLU#.

In case of “PROG.”, “Report”, and “Reset” modes, PLU# is treated as a six-digit number. So the upper two digits

are not treated as department #. Consequently the four-digit PLU# is available only in “REG.”, “M.DOWM”, and

“REWRAP” modes.

NOTE: The default Dept. No. is two-digit serial number ranging from 0 to 99. Entering a “0” clears a Dept. No.

• Vendor Number

Vendor numbers can be set when the Initial Setting #11-1 is set to 1.

Vendor numbers are assigned to the speed keys in two ways:

1 Individual vendor number: 00-39

Vendor# is assigned to the speed keys one by one.

2 Group vendor number: 0-, 1-, 2- and 3-

Maximum 10 vendor numbers can be assigned to one speed key, resulting in 4 speed keys in total. When

assigning group vendor numbers to the speed keys, enter the first digit of the vendor key (0, 1, 2 or 3) plus

a bar (-).

Vendor numbers can be called whichever half of the speed keys are selected.

11-17

Page 44

11. PROGRAMMING PROCEDURES

11.10 PRINT FORMAT

11.10 PRINT FORMAT

Normal Mode ESB Limited Spec. Mode

Menu Group: 2 Item No.: 3

Item No.: 0

The SL-9000 can memorize 5 different print formats. After print formats are set, you can call them by

entering the print format number.

<MENU>

Group 2

CHANGE

PLU

Issue method

Batch

0

Select "SENSIBILITY ADJUST"

by pressing the key.

When Batch Printing with backing paper is

selected, the sensitivity of the label sensor will

be set by pressing the key before

issuing label.

Select the Item for adjustment.

1 gradation

= 0.154mm (1 dot)

1 gradation

= 0.462mm (3 dots)

1 gradation

= 0.462mm (3 dots)

Only when using the bar code

change label with pre-feed area.

(This adjustment cannot be made

for the Variable Length Label.)

Select the print format # which

allocates the label format #

by the key or key.NEXT PLU

On-demand

SET NEXT

Enter the correct label feed

value.

(Range: 0~199)

Enter the correct value for

commodity name position.

(Range: 0~9)

Enter the correct value for

address position.

(Range: 0~15)

Enter the correct value for

pre-feed area.

(Range: 0~65)

–

SET

NEXT

Enter the label format #.

(Refer to Table 2)

j

TESTFEED

Incorrect

ENTER

ENTER

ENTER

ENTER

j

j

j

j

Is print

position

correct?

<MENU>

Group 2

Main

<MENU>

Correct

CHANGE

PLU

PROG.

ESC.

NOTES:

1. When a commodity name position is adjusted, an address position will move automatically.

2. When entering the other label format #, fine adjust values are initialized.

3. Selecting label format numbers other than those provided in Table 2 results in an error.

4. When selecting a variable length label format, rectangles are printed instead of print items when

test printing.

5. Pressing the

key allows you to select a print format number from 1 to 5.

6. Be sure to press the SET NEXT key when a label format for batch printing with backing paper

is selected.

11-18

Page 45

11. PROGRAMMING PROCEDURES

Table 2: Label Format Number Table

Select the format # for the label to be used by referring to the table below.

11.10 PRINT FORMAT

Item

Label

Format #

00 (50)

10 (60)

11 (61)

12 (62)

13 (63)

14 (64)

15 (65)

16 (66)

21 (71)

22 (72)

23 (73)

24 (74)

25 (75)

Ingredient

Line

0

0

6

12

18

22

38

37

6

12

18

22

38

Label length (mm)

48 mm

width

30.0

40.0

54.0

68.8

82.6

92.0

69.9

84.1

106.4

57 mm

width

49.2

63.5

92.8

138.1

138.1

85.7

112.7

158.7

Nutrition

Printing

Kind of label

NON-

POS

label

POS

label

Bar code

change

label

Print of the NET WT.

statement

Impossible Possible

26 (76)

31 (81)

32 (82)

33 (83)

34 (84)

35 (85)

36 (86)

41 (91)

42 (92)

43 (93)

48

49

38

6

12

18

22

38

22/38

Programmable

Programmable

Programmable

VARIABLE

21

(ROTATION)

76.2

90.5

104.8

112.7

112.7

Variable

Length

158.7

96.8

123.8

171.4

171.4

Programmable

Programmable

Programmable

Variable

Length

Variable

Length

Free Format (Refer to section 11.18)

Free Format (Refer to section 11.18)

Free Format (Refer to section 11.18)

batch printing method

on-demand printing method

1) The width of label is selected by INITIAL SETTING.

2) The number of commodity lines depends on label width.

48 mm width: 2 lines

57 mm width: 4 lines

: possible

: impossible

11-19

Page 46

11. PROGRAMMING PROCEDURES

11.10 PRINT FORMAT

Label format

In ESB limited specification mode, it is possible to print it is possible to print following labels. (New

label format is not added.)

57 mm width label

48 mm width label

Non-POS

X

O

POS

O

O

Ing. 6line

O

O

V. Length

O

O

Format No.

10,11,48,60,61

00,10,11,48,50,60,61

X: Not possible

O: Possible

11-20

Page 47

11. PROGRAMMING PROCEDURES

11.11 DATE/TIME SETTING

Normal Mode ESB Limited Spec. Mode

Menu Group: 2 Item No.: 4

Item No.: 1

Date, time, machine number, and store code are set in this procedure.

k

11.11 DATE/TIME SETTING

<MENU>

NOTES:

Group 2

Set the machine No.

(max. 6 dig.)

1

Set the date.

(Month, Day, Year)

ENTER ENTER

Set the store No.

(max. 5 dig.)

ENTER

Set the time.

(Hour, Minute)

k

PROG.

ESC.

ENTER

<MENU>

Group 2

Main

<MENU>

1. Express the time in a 24-hour military format.

2. The SL-9000 will check details of date (time) input, and any wrong date (time) will result in an error.

Then the correct date (time) should be re-entered and press the

CLEAR

key.

3. Even when the initial Setting # 8-4, 8-5 or 8-6 is set to the “Julian Date” the way to enter the date

in the date setting operation is the same in the ordinary case.

4. The date display method can be changed by the initial setting.

11.12 CMT/PL-3

Normal Mode ESB Limited Spec. Mode

Menu Group: 2 Item No.: 5

Item No.: 2

CMT OPERATIONS

SL-9000 is designed to interface with a Cassette Magnetic Tape loader. This loader allows the

transfer of the entire PLU file, ingredient file and other data from the SL-9000 to tapes. This can be

accomplished in number of operation steps.

In turn, information from the tape can also be transferred to another SL-9000 scale.

<MENU>

Group 2

2

NOTES:

1. The error mode can be released by pressing the

above steps.

2. Use the metal cassette tape which is commercially available and has a capacity of 45 or 60 minutes

recording.

3. For operations of the CMT loader, refer to the instruction manual provided with the CMT loader.

Set the transmission items.

(Refer to table 4)

NEXT

or

PLU

CLEAR

11-21

ENTER

PROG.

ESC.

<MENU>

Group 2

Main

<MENU>

key, and operated again through the

Page 48

11. PROGRAMMING PROCEDURES

11.12 CMT/PL-3

PL-3 Operation

Connect the PL-3 to the SL-9000 by using RS-232C Cable, then turn on the power of the SL-9000 and

the PL-3.

Insert a data disc into the PL-3 and adjust the transmission rate to the SL-9000 ( 7 2 : 4800 BPS

or 7 3 : 2400 BPS) by using the rotary switch.

Press the SAVE key of the PL-3, then check whether the SAVE LED is on.

Program the file number of the data disc by using the rotary switch.

( 4 1 : File No. 1, 4 2 : File No. 2, ..... 4 8 : File No. 8, 4 9 : File No. 9)

SAVE

<MENU>

Group 2

2

Set the transmission item.

(Refer to table 4)

NEXT

or

PLU

or

LOAD

ENTER

PROG.

ESC.

<MENU>

Group 2

<MENU>

Main

NOTES: 1. Press

2. If the

SAVE

ENTER

or

LOAD

key on the PL-3.

Key is not pressed within 10 seconds after

a time out error will occur.

3. After pressing the

ENTER

key, the operation ends when “00” appears in the 7 seg. display

and LAMP goes off. Remove the data disc and turn the power off.

4. Be sure to start the PL-3 before the main operation.

Table 3: Error code during PL-3 operation

Error Code Error Message

0

FDC ERROR

1

FDK MISINSERTION ERROR

2

UNAVAILABLE FDK INSERTION

1

3

ERROR

3

VOL. LABEL UNMATCH ERROR

4

FDK MEMORY FULL ERROR

5

WRITE PROTECT ERROR

6

NO SEARCH FILE ERROR

1

TIME OUT ERROR

2

LOAD ERROR

3

FDK ERROR

4

BUSY STATUS

5

POWER FAIL ERROR

6

OVERRUN ERROR

SAVE

Error Code Error Message

7

3

E

F

FRAMING ERROR

8

PARITY ERROR

0

DATA ERROR

STATUS ERROR

1

2

TIME OUT ERROR

3

FDK READ/WRITE ERROR

DESIGNATED SELECT KEY

F

ERROR

0

RAM READ/WRITE ERROR

1

ROM CRC ERROR

2

RAM BACK UP BATTERY ERROR

3

FDC DIAG LEVEL 0 ERROR

E

SYSTEM FDK LOADING ERROR

F

SYSTEM ERROR

or

LOAD

key is pressed,

1) When the error code in FF, this system enters stop status. (Turn the power off/on for release.)

2) When the error code is F2 or FE, perform the status clear ( 9 9 ).