Page 1

TEC Electronic Computing Scale

SL-6600 (US. Version)

Owner’s Manual

TEC CORPORATION

Page 2

Page 3

EM 1-31059

TABLE OF CONTENTS

Page

1. INTRODUCTION ................................................................................................................................................ 1-1

2. SPECIFICATIONS .............................................................................................................................................. 2-1

3. NAME AND FUNCTION OF EACH PART ......................................................................................................... 3-1

3.1 OVERVIEW .............................................................................................................................................. 3-1

3.2 REMOTE DISPLAY .................................................................................................................................. 3-1

3.3 CONTROL LOCK ...................................................................................................................................... 3-2

3.4 KEY LAYOUT ............................................................................................................................................ 3-3

4. PROCEDURE BEFORE OPERATION ............................................................................................................... 3-8

5. LEVEL ADJUSTMENT ....................................................................................................................................... 5-1

6. REMOVAL AND REPLACEMENT OF LABEL ROLL

........................................................................................

5-1

7. PROGRAMMING PROCEDURES ..................................................................................................................... 6-1

Menu No. 0: Changing Unit Price .............................................................................................................. 7-2

Menu No. 1: Setting PLU Data .................................................................................................................. 7-3

Menu No. 2: Setting Store Address or Commercial Message ................................................................... 7-9

Menu No. 3: Setting Label Format and Adjusting Print Position

Menu No. 4: Setting Date, Time, Machine Number, and Store Number

.............................................................

.................................................

7-10

7-17

Menu No. 5: CMT/PL-3 Operations ......................................................................................................... 7-18

Menu No. 6: Initial Setting.................................................................................................................................. 7-21

Menu No. 7: Changing Bar Code Format ................................................................................................ 7-28

Menu No. 8: Setting Speed Key .............................................................................................................. 7-30

Menu No. 9: Setting Combination Report ............................................................................................... 7-31

Menu No. 10: Changing Displayed Titles .................................................................................................. 7-35

Menu No. 11: Setting Ingredient Description ............................................................................................. 7-42

Menu No. 12: Issuing Confirmation Label ................................................................................................. 7-43

Menu No. 13: Switching In-line/Off-line ............................................................................................................. 7-44

Menu No. 14: Setting Special Information........................................................................................................ 7-45

Menu No. 15: Setting Department Number........................................................................................................ 7-46

Menu No. 16: Transferring Logo Data ....................................................................................................... 7-47

Menu No. 17: Setting Grade Line .............................................................................................................. 7-48

Menu No. 18: Memory Card Operation ..................................................................................................... 7-49

Menu No. 20: Transmitting PLU File, Unit Price, Address or Speed Key

(FUN System) ....................................................................................................................... 7-55

Menu No. 21: Changing Printing Title of Period of Relish ............................................................................... 7-56

Copyright 'Q 1995

by TEC Corporation

All Rights Reserved

1-14-tO Uchikanda, Chlyoda-ku. Tokyo, JAPAN

Page 4

EMI-31059

8. VERIFICATION OF PROGRAMMED REPORTS ........................................................................................... 8-1

9. OPERATING PROCEDURES ......................................................................................................... 9-1

9.1 WEIGHED COMMODITY OPERATION ............................................................................................... 9-1

9.2 FIX PRICE OPERATION ...................................................................................................................... 9-2

9.3 BY COUNT OPERATION ......................................................................................................... 9-3

9.4 PRESET COUNT OPERATION ................................................................................................................ 9-4

9.5 ISSUING LABELS WITH NET WEIGHT STATEMENT ........................................................................ 9-9

9.6 TARE FUNCTION PROCEDURES ........................................................................................................ 9-11

9.7 SAVE KEY OPERATION SAMPLE ........................................................................................................... 9-13

9.8 VOID KEY OPERATION SAMPLE ............................................................................................................ 9-14

9.9 CALLING AND PRINTING GRADE LINE.............................................................................................. 9-14

9.10 SELECTION OF PRINT OR NOT PRrNT ITEM ON LABEL

9.11 DATE CHANGE ...................................................................................................................................... 9-16

9.12 CALLING AND PRINTING LOGO.................................................................................................. 9-17

9.13 FUN AUTOMATIC RECEPTION............................................................................................................. 9-17

..........................................................

9-15

10. TOTAL OPERATION PROCEDURES..............................................................................................................10-1

10.1 HOURLY REPORT.................................................................................................................................10-1

10.2 GRAND TOTAL REPORT .....................................................................................................................10-1

10.3 PLU REPORT ........................................................................................................................................10-1

10.4 COMBINATION REPORT ......................................................................................................................10-4

11. LABEL PRINT FORMATS ...............................................................................................................................11-1

12. ERROR MESSAGE TABLE .............................................................................................................................12-1

13. CLEANING THE PRINT HEAD ........................................................................................................................13-1

14. BEFORE YOU CALL FOR SERVICE ............................................................................................................ 14-1

15. APPENDIX .............................................................................................. 15-1

CAUTION

1. This manual may not be copied in whole or in part without prior written permission.

2. The contents of this manual may be changed without prior notice.

3. Please refer to a TEC representative regarding questions or misprints.

Page 5

1. INTRODUCTION

EMI-31059

1. INTRODUCTION

1. INTRODUCTION

We thank you very much for purchasing the TEC Electronic Computing Scale SL-6600 Series.

This series has been designed with TEC reliability and offers a cost efficient system for a modest

investment.

The Advanced TEC SL-6600 combines a scale and full-feature UPC printer into an integrated,

compact unit with expanded PLU capabilities. The SL-6600 can automatically and instantly program

the printer for 15 different label sizes and formats. Unlike other systems, you do not have to key

select the scale every time you change labels. Each SL-6600 label cassette has 4 binary switches

on the back which you set once to a specific code for each label. The System is quick and

convenient to use for increased productivity, plus it provides a wide range of management controls

and accurate, time-saving reports.

We believe that your needs will now be fully satisfied, and you will have total reliability in price

calculation. Should you have any questions concerning the scale, please refer to this manual. Be

sure to keep this manual for future reference.

This equipment generates, uses, and can radiate radio frequency energy and if not installed and

used in accordance with the instruction manual, may cause interference to radio communications. It

has been tested and found to comply with the limits for a Class A computing device pursuant

Subpart J of Part 15 of FCC Rules, which are designed to provide reasonable protection against

such interference when operated in a commercial environment. Operation of this equipment in a

residential area is likely to cause interference in which case the user at his own expense will be

required to take whatever measures may be required to correct the interference.

The product that you have purchased contains a rechargeable battery.

The battery is recyclable. At the end of it’s useful life, under various state and local laws, it may be

illegal to dispose of this battery into the municipal waste stream. Check with your local solid waste

officials for details in your area for recycling options or proper disposal.

APPLICABLE MODEL

SL-6600-30-C4-US-V

The description of the model number is as follows:

SL-6600-30-C4-US-V

---------Software Spec.

V: Variable Length Label Spec.

Period of Relish

Multi-intervai

Destination Code

Region Number ---------------------

3: North America

Communication Method

0: Stand-alone

Display Type

4; LCD + Remote Display

Max. Capacity

C: 30 lbs

1- 1

Page 6

1. INTRODUCTION

Installing Precaution

Place the TEC Electronic Computing Scale on a flat, stable surface.

EMI-31059

Installing Precaution

1. DON’T SUBJECT the weighing

platter to SUDDEN SHOCKS.

4. NEVER USE THINNER OR

OTHER VOLATILE SOLVENT for

cleaning.

7. When in use, avoid locations subject to vibration and direct sunlight

2. DONT PRESS THE KEYS TOO

HARD.

Keys will operate correctly if they

are merely touched lightly.

5. DON’T POUR WATER directly on

scale.

Clean the cover and platter by

wiping with a dry cloth or a cloth

soaked with detergent and wrung

out thoroughly.

To ensure the scale is CHierating

correctly, place a known weight on

the platter and check for correct

computing.

After the end of daily work, turn the

power OFF, then clean and inspect

the exterior of the scale to allow

you to use the scale at its best

condition.

If the scale uses the same power source as a high voltage electric appliance,

the voltage to the scale will vary each time the appliane is activated.

Use the special power source to avoid an error operation.

1- 2

10. Use a grounded electrical outlet.

(Do not use a adaption plug.)

Page 7

2. SPECIFICATIONS

2. SPECIFICATIONS

Item SL-6600-30-C4-US-V

Maximum Capacity 30 lbs.

Minimum Scale Division 0.01 lbs.

Display Range

Tare Up to 30 lbs.

Unit Price Presettable $ 0.01 ~ 99.99

Minimum Price Display

Remote Display:

Weight 4 digits

Unit Price

Total

LCD (Message Display)

Display Designations NET, PREPACK, INLINE, ERROR

Remote Display Mode

Capacity of PLU Memory

Print Head Thermal Print Head

Available Printing Width

Label Issue Method

Label

Report Paper

Interface

Power Requirement

Current Consumption

Temperature Limits 32°F ~ 104“F

Relative Humidity

Dimensions (approx.)

Weight (approx.)

0 ~ 30.05 lbs.

$ 0.01

4 digits

5 digits

16 characters (5x7 dot matrix)

Dual sides

840 PLUS (standard), 2520 PLUs max. (option)

1.65”

On-demand/Batch

RICOH 120LA or equivalent

RICOH 115F (black) or equivalent

RS-232C

AC 120V ±10%, 60 Hz

120V-1A, 60Hz

35% ~ 85% RH (No condensation)

15.7” (width) X 16.5” (depth) X 18.5” (height)

32 lbs.

EMI-31059

2, SPECIFICATIONS

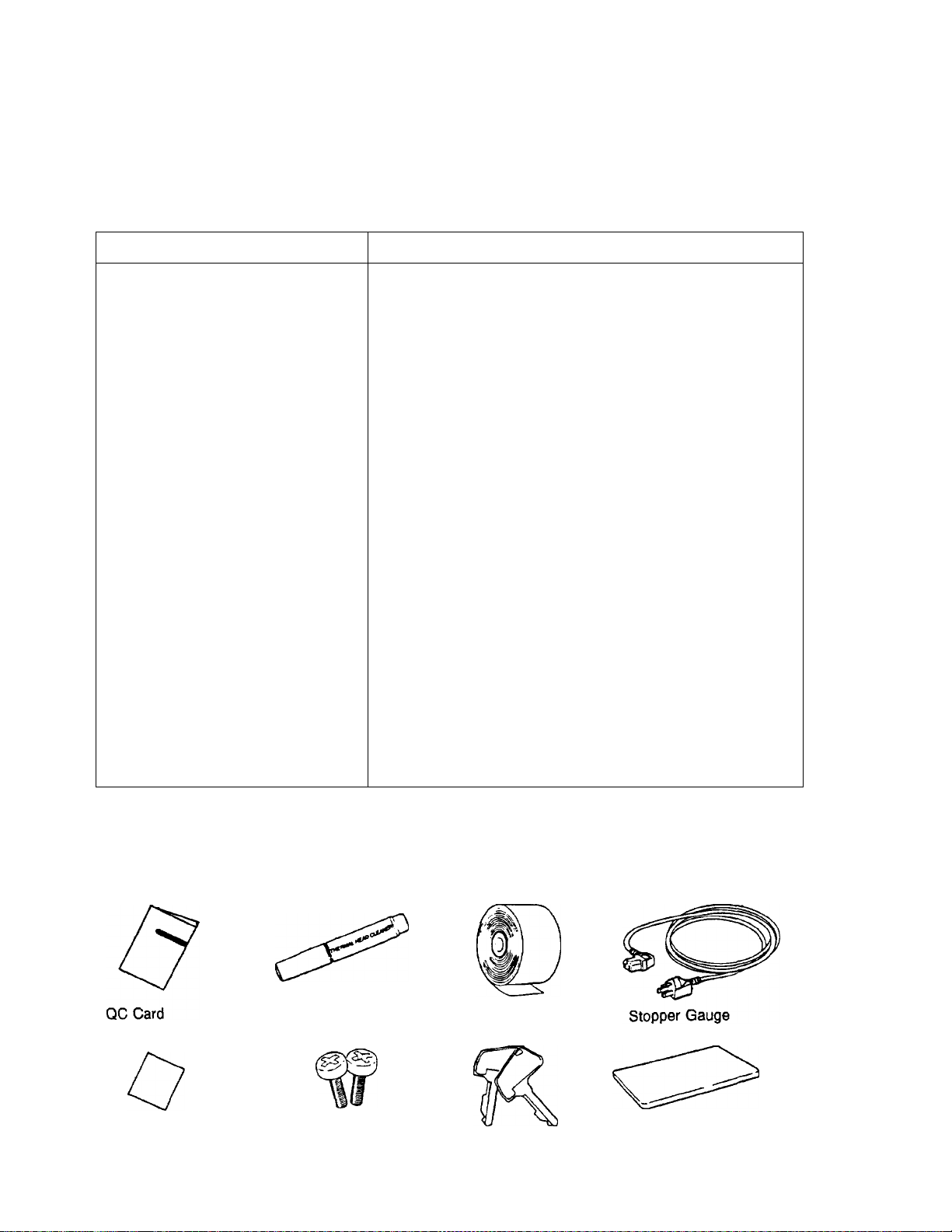

Accessories

Owner’s Manual Thermal Head Cleaner

Remote Attaching Screw

M4x8

MA and SE Keys

2- 1

Label

Power Cord

Page 8

2. SPECIFICATIONS

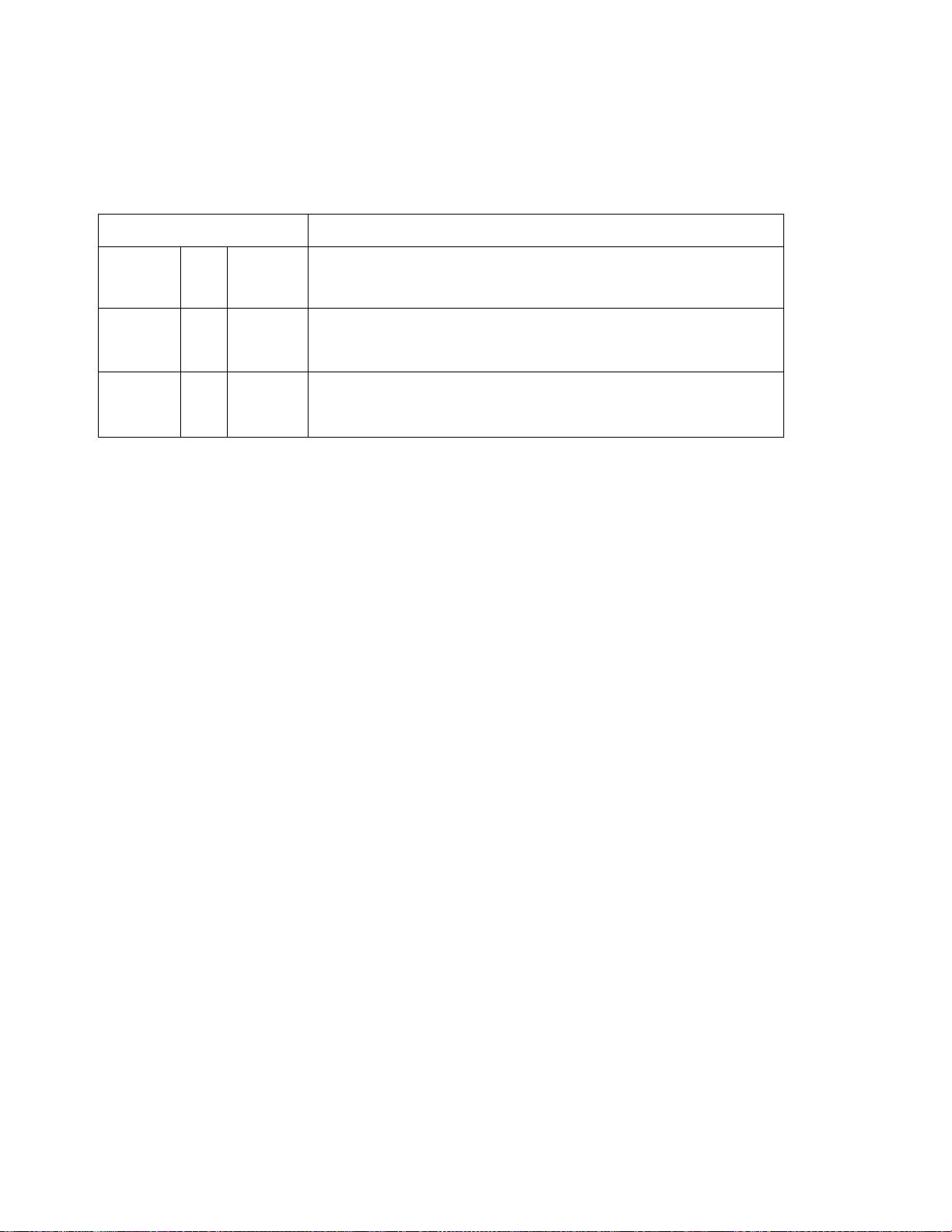

Option Kit and Device

EM1-31059

Option KH and Device

Model Name

DR-1 CMT Loader Used to load the CMT with PLU file,

PL-3

PL-3S

PC-XT

FKB-2381-001

FKB-2381-101

OP-66-32K Expansion RAM Kit

OP-66-PL

OP-66-PL-TMCC Program Loader Kit with

OP-66-FUN-

TMCC

MC-128-EX

MC-256-EX

OP-66-PCKEY

KS-60-1

Program Loader Used to load the FDK with PLU file,

Scale System FDK and RS232C Cable

PC Keyboard Used to enter the programming menu. IBM

Program Loader Kit

Communication l/F (TMCC-3)

FUN System with

Communication l/F (TMCC-3)

Memory Card

PC Keyboard Adapter

Label Cassette Case

Option KIT Name

Ingredient file and other data.

Ingredient file and other data.

A floppy disk and a cable for the PL-3.

Used to extend PLUs and ingredient

messages. (32KB xi Opes, contained)

PC Board for use of a memory card.

PC Board for use of a memory card

and the In-line system.

PC Board for use of the FUN system

and the In-line system.

Used to load PLU file. Ingredient file

and LOGO file into.

Used to connect a PC Keyboard.

It is convenient to change several kinds

of labels.

Description

Maker

AIWA

TEC

TEC

FUJITSU

FUJITSU

TEC

TEC

TEC

TEC

TEC

TEC

TEC

TEC

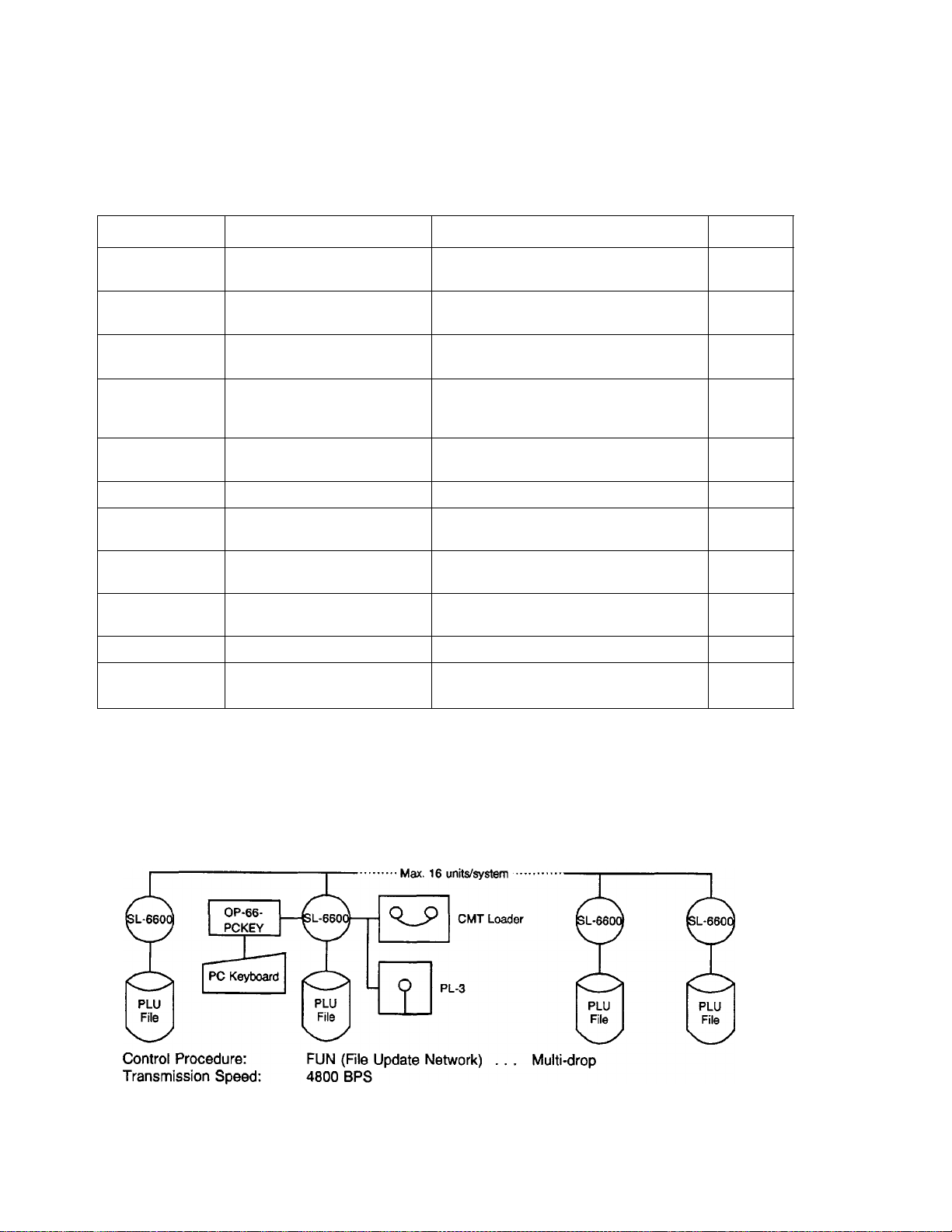

■ FUN System

The File Update Network (F.U.N. System) connector is standard with the SL66. The F.U.N. System

allows up to 16 units to be connected using standard telephone cables for the purpose of PLU file

maintenance. The operator may send PLU and price change information from any scale in the

network to all other scales quickly and simply.

■ System Configuration

Number of unit/system: Max. 16 units

2- 2

Page 9

3. NAME AND FUNCTION OF EACH PART

3. NAME AND FUNCTION OF EACH PART

3.1 OVERVIEW

EMI-31059

3.1 OVERVIEW

3.2 REMOTE DISPLAY

CAPACITY 30x0.01 lbs

WEIGHT lbs

NET PREPACK

UNIT PRICE $

TOTAL PRICE $

INLINE ERROR

TEC

SL-6600

WEIGHT DISPLAY

• NET Lamp: Lights when tare is subtracted

• PREPACK Lamp: Lights when the

depressed.

UNIT PRICE DISPLAY

TOTAL PRICE DISPLAY

• INLINE Lamp: Lights when the scale is in the

IN-LINE mode.

• ERROR Lamp: Lights when this scale is

improperly operated or there is a

function error.

SAVE

key is

3-1

Page 10

3. NAME AND FUNCTION OF EACH PART

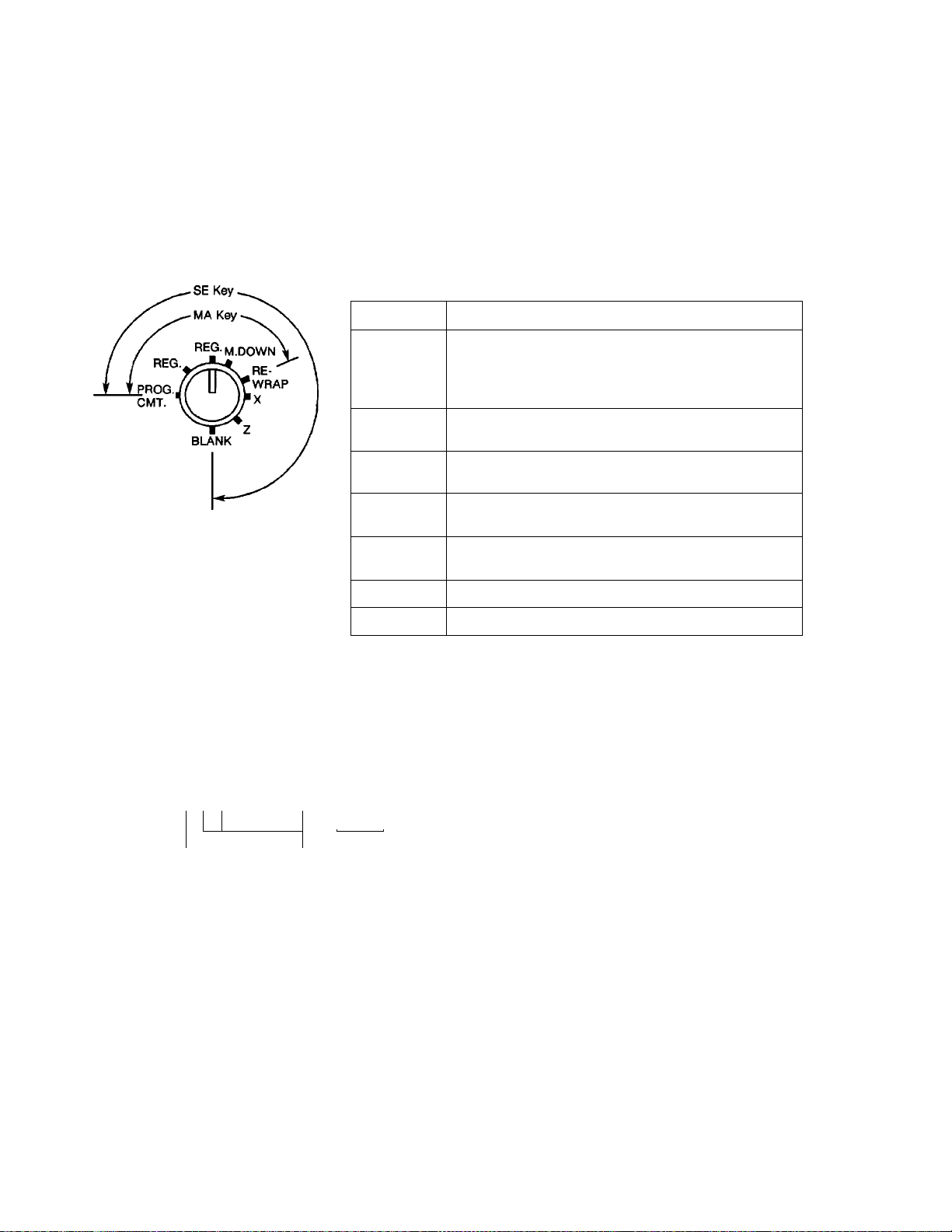

3.3 CONTROL LOCK

The control lock has seven marked positions.

There are two control keys which will operate these locks.

Each of the following positions on the control lock serves a

different function.

EM 1-31059

3.3 CONTROL LOCK

Mode Switch

Mode Switch (1)

AUTO

MANUAL

Position

PROG.

CMT.

REG.

M. DOWN

REWRAP

X (Read) This position is used to read all the accumulated

Z (Reset) This position is used to reset all item file totals.

BLANK

“AUTO”

When the weight becomes stable, the label will automatically be issued.

position:

“MANUAL"

eight becomes stable, the label will be issued by depressinc

the

PRT/*

key.

With the manager key in this position, it is available

to program data in the PLU file. Store Address,

Printing Position, Date, Time, Initial Set, and Bar

Code Format, etc., may also be programmed.

This position is the normal control lock position

which allows the issuance of printed label.

In the Markdown position, it is available to

designate an item for discount pricing.

In the Rewrap position, it is available to designate

an item for rewrapping products.

sales totals stored in the total memory.

No function.

position:

Function

Mode Switch (2)

WEIGH

FIX

BY COUNT

“WEIGH”

This position is used in_ the weighing function of the SL-6600.

“FIX”

The Unit Price is entered directly as the Total Price on calling up the

PLU item and that the Total Price cannot be changed by any

subsequent weighing (Fix Price function).

“BY COUNT”

It is available to produce labels which contain information on quantity

pricing, instead of weight.

position:

position:

position:

3-2

Page 11

3. NAME AND FUNCTION OF EACH PART

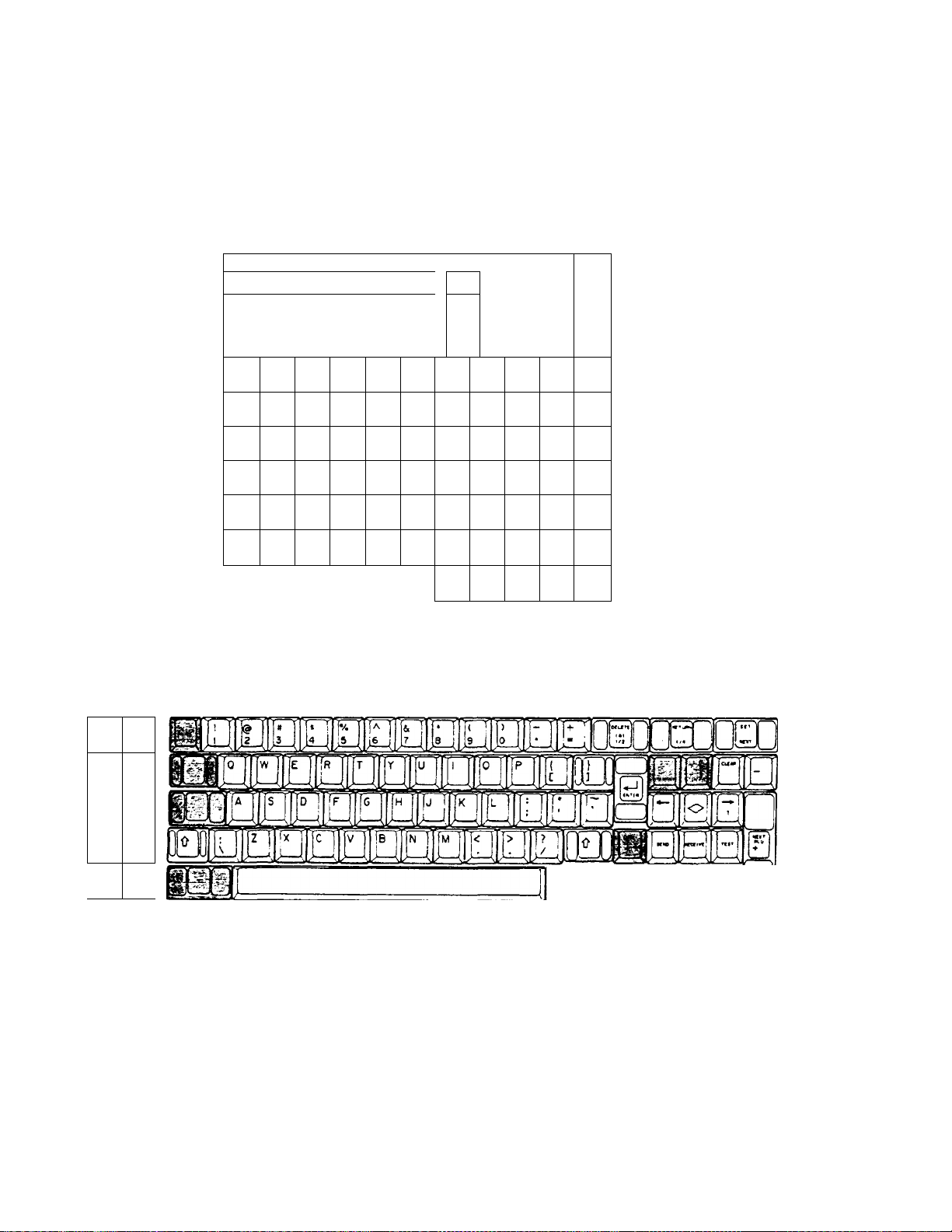

3.4 KEY LAYOUT

■ Programming Keyboard

EMI-31059

3.4 KEY LAYOUT

PC Keyboard

CLEAR

PROG.

1

1 2

Q

!

A\s

ZiX

COMMODITY NAME

SET

SHIFT

NEXT

ENTER

O

#

3

+

W(E)R

]

DAF G{H

A

C

NEXT

AUTO

CODE

PLU

4—

—

%

$

4

5

/

T

£

V B N

SEND

ft

6

Y U

DARK

LIGHT

RECEI

VE

DELE

TE

1/2 (A)

/

7

1

J

i

M

FEED

J-CONTRAST

CHAN

DELE

GE

PLU

DELE

INSERT

TE (B)

\

8

<

I

>

K L

t

SPACE

TE

PLU

7

9

0

T A

TEST

RETU

RN 1/4

<9

0

>

P

la

ZERO

,d

0MMt|

►u- I

J

UT-1

i

NOTE: This key layout is for the keyboard being used with a scale.

3-3

Page 12

3. NAME AND FUNCTION OF EACH PART

• Programming Key Functions

EMI-31059

3.4 KEY LAYOUT

Key

CLEAR

SHIFT

SET

NEXT

NEXT

PLU

AUTO

CODE

CHANGE

DELETE

PLU

PLU

Function

This key allow the clearing of numeric entries prior to the depression of

another function key.

It is also used to release the scale from the error mode.

This key is used to select the upper or lower character indicated on the

keytop when setting a commodity name, ingredient message, etc.

(on scale)

This key use to recall the next PLU# ( +1) of the PLU# currently recalled.

It is also used for label format # setting when labels are issued in

succession. When this key is pressed, three labels are issued

automatically.

This key is used to recall the PLU# which is registered next to the currently

recalled PLU#.

It is also used to skip the digit when setting the bar code format.

This key is used to set the auto code for UPC#.

This key is used to change the PLU# currently recalled.

It is also used to set label format #.

When a PLU is no longer to be maintained in the PLU file, this key is used

to remove it. When an ingredient is no longer to be maintained in the

ingredient file, this key is used to remove it.

TEST

ENTER

DELETE

1/2 (A)

This key is used to print out the data set in the currently recalled PLU.

It is also used to check for the laber print position.

During programming, this key is used to enter data.

This key is used to set the free zone of the auto code for UPC#, back the

digit when setting the bar code format, and return the setting line to the first

line while setting the second line and during the setting of the commodity

name, store address or ingredient message, etc.

This key is used to back the character when setting the commodity name,

ingredient message, etc.

This key is used to skip the character when setting the commodity name,

ingredient message, etc.

When setting the unit price for the weighed PLU, this key is used to select

the unit of weight. (100 g or kg)

This key is used to delete a character when setting the commodity name,

ingredient message, etc.

3-4

Page 13

3. NAME AND FUNCTION OF EACH PART

Key Function

EM1-31059

3.4 KEY LAYOUT

INSERT

PELETE

(B)

RETURN

1/4

t

ISPACE

PROG.

O

SEND

RECEIVE

This key is used to insert a space at the digits when setting the commodity

name, ingredient message, etc.

This key is used to clear all characters on the current setting line when

setting the commodity name, ingredient message, etc.

This key is used to move the setting line when setting commodity name,

store address, or ingredient message, etc.

This key is used to insert blank spaces in descriptors.

This key is used to access each programming menu.

This key is used to select selectable items.

This key is used to store ingredient message setting data temporarily in the

work buffer during setting an ingredient message with programming menu

#11.

This key is used to recall the data, which has been stored in the work buffer

by the [send I key.

While this key is pressed down, press a character key to set the small letter

of alphabet, or upper-case character indicated on the upper area of the

(on PC Key)

Character Keys

keytop. When this key is released, the shifted status is cancelled.

Character keys are used to set the upper or lower-case character indicated

on the keytop.

NOTE: When setting alphabet data such as commodity name, ingredient message, etc., through the

PC Keyboard, either small or capital letters can be selected by pushing CAPS/LOCK key.

Pushing the | ^ | key will reverse the characters.

When the power is turned off or control lock is switched, the PC keyboard will be initialized to

select capital letters.

3- 5

Page 14

3. NAME AND FUNCTION OF EACH PART

Speed Key and Operation Keyboard

EMI-31059

3.4 KEY LAYOUT

COMMODITY NAME

1 2

12

11

22

21

32

31

41 42 43 44 45 46 47

52 53 54

51

4 5 6 7 8

3

14 15

13

24

23

33

25 26

34

35 36

55

16

56

FEED TEST

DARK

LIGHT

17

27

37

57

ONTRAST

9

18 19 20

29 30

28

38 39

49

48

59 60

58

ZERO

NEXT

PROG.

PLU

FOR

o

7

10

8 9 LOGO

4

5 6

1 2 3

40

50

0

T

PLU

WEIGH AUTO

FIX

BfB

;OUNT M

BY COUNT ^ MANUAL

VOID

V

^TM

C

PR^

REG

PROG.,

CMT.

PRESET

COUNT

GRADE

LINE

SAVE

1/2

1/4

RE-I

WRAP

U

NOTE; The characters (1~60) indicated on the speed keys are shown for the convenience of

explanation in this manual. The indications on the actual unit are not as shown in this

illustration

• Operation Key Functions

Name of Key Function

Numeric Keys

CLEAR Key

TARE Key

PLU Key

PRINT Key

PLU

PRT/*

These keys are used to enter numeric data (PLU#, unit price, tare

weight, etc.).

This key is used to ciear an entry of numeric keys, return the scale

condition to the normal weighing mode, release the scale from the

SAVE or ERROR mode, and suspend batch printing.

This key is also used to stop the label issue.

This key is used to subtract tare weight.

This key is used to recall a PLU number or return to the initial display.

This key is used for issuing total reports.

If the Mode Switch (1) is set to the MANUAL position, it has the

function of label issue.

It is also used to resume batch printing if it has been suspended.

3- 6

Page 15

3. NAME AND FUNCTION OF EACH PART

EMI-31059

3.4 KEY LAYOUT

Name of Key

1/2 Key, 1/4 Key

1/2

SAVE Key

SAVE

DATE & TIME Key

DT^

GRADE LINE Key

GRADE

LINE

FOR Key

FOR

VOID Key

VOID

NEXT PLU Key

NEXT

PLU

Function

These Keys are used to calculate the unit price per 1/2 lb or 1/4 lb.

1/4

This key is used after placement of the tare or entry of unit price.

This key is used to indicate the date on the remote display and for

temporary date changes.

TM

This key is used to call the grade line message.

This key is used to generate the zone total report when control lock is

set to the “X” or “Z” position.

This key is used to cancel only one commodity’s data by depressing

this key after its registration.

It is also used to return the operation step to the previous step.

This key is used to call out the next PLU#, and forward the operation

step to the next step.

O

PROGRAM Key

PROG.

PRESET COUNT Key

PRESET

COUNT

LOGO Key

LOGO

SPEED Keys

1

60

In “X” or “Z” control lock position, this key is used to generate the

block total report.

In “REG.” control lock position, this key is used to select whether the

data should be printed on the label or not.

This key Is used to change the unit price and to select a print item for

label print. This key is also used when issuing a combination report

of X (READ) and Z (RESET).

This key is used to preset the number of issuing labels.

This key is used to call the logo data.

These keys are used to call the PLU data of frequently used

commodities.

3- 7

Page 16

3. NAME AND FUNCTION OF EACH PART

EM1-31059

3.4 KEY LAYOUT

Name of Key

FEED Key

TEST Key

ZERO Key

This key is used to feed labels or report paper.

FEED

This key is used to issue test labels.

TEST

This key is used to adjust the ZERO point.

ZERO

Function

4. PROCEDURE BEFORE OPERATION

1. Connect the Power Cord to the AC inlet on the scale and plug in.

2. Adjust the Level Gauge. (See page 5-1.)

3. Connect a PC Keyboard if necessary. (See page 7-1.)

4. Turn on the power.

5. Load the Label or Receipt. (See page 6-1.)

6. Check the status of initial setting and bar code format, then programming menu No. 3, 1 and

4.

If required, execute the programming menu No. 2, 8, 9, 11, 14, 15, 17 and so on.

7. Check the date of the scale before operation every day. (See page 7-17.)

8. Make a test print before operation every day.

(1) Turn the control key to REG. position.

(2) Press

9. Recall the PLU which contains the unit price used in weighing mode, and place a weight on

the platter and check a correct price is displayed for the preset unit price.

10. Label issued is ready.

TEST

Key, and the test label is issued.

3- 8

Page 17

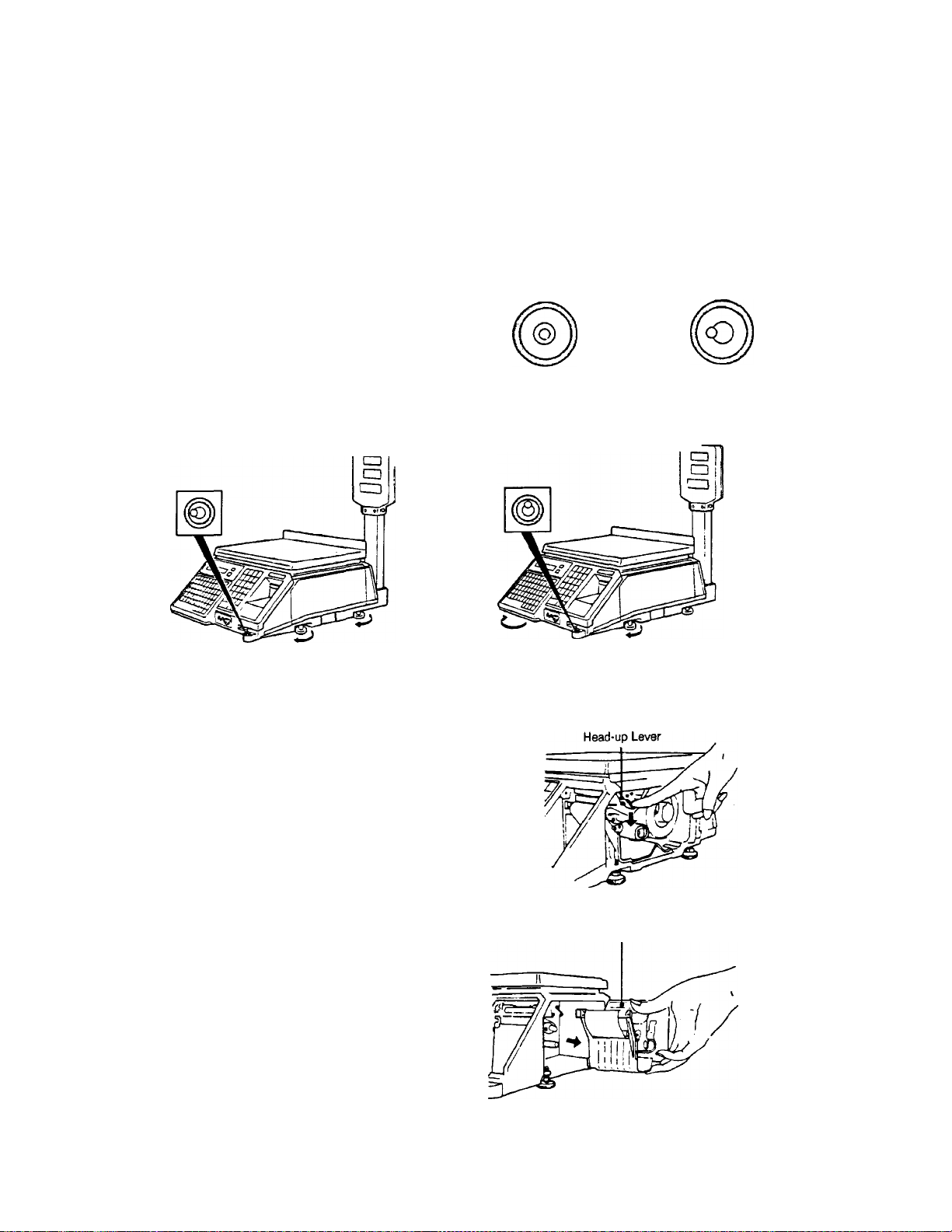

5. LEVEL ADJUSTMENT

5. LEVEL ADJUSTMENT

Set the scale on a stable and level surface.

Level the scale by turning the adjustable legs so

that the air bubble is inside the center circle.

EM1-31059

5. LEVEL ADJUSTMENT

Level Gauge

Correct incorrect

When the air bubble moves toward the left side,

turn the right adjustable legs clockwise.

When the air bubble moves toward rear, turn the

front adjustable legs clockwise.

1

6. REMOVAL AND REPLACEMENT OF LABEL ROLL

1. Remove the printer cover and right side

cover. Then push the head-up lever in the

direction indicated by the arrow.

Pull out the label cassette and remove the

core of the label roll and the label backing

paper.

NOTE:

To remove the label backing paper,

loosen the paper by turning the

paper winding shaft

counterclockwise and remove the

paper stopper.

Label Cassette

5- 1

Page 18

6. REMOVAL AND REPLACEMENT OF LABEL ROLL

REMOVAL AND REPLACEMENT OF LABEL ROLL

EMI-31059

3. Referring to the figure on the right, set the

label roll on the label cassette.

4. Set the label cassette.

Push down the print head, and close the

covers.

NOTE:

When the label roll was replaced,

press the feed key to confirm that

the label is issued correctly.

Roll Stopper

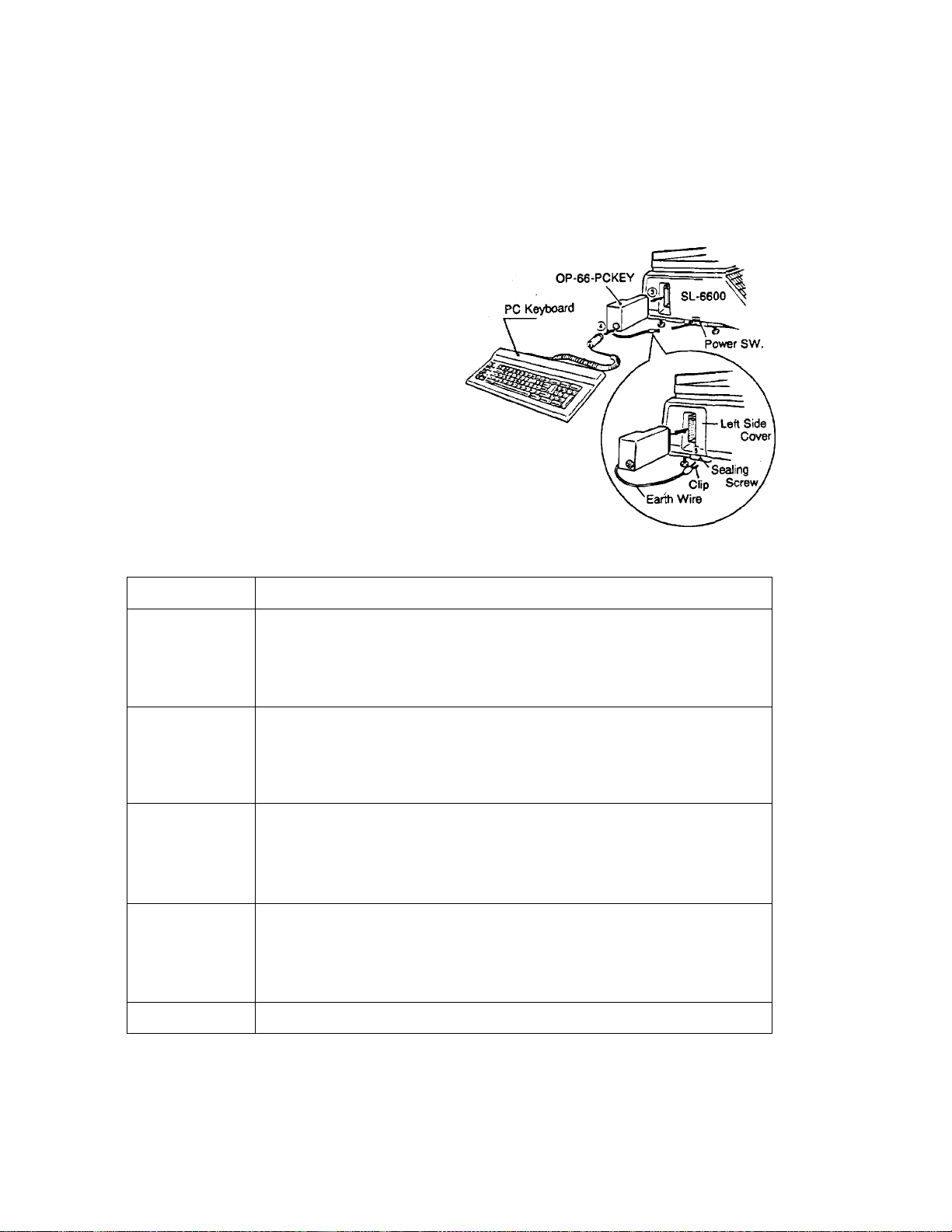

7. PROGRAMMING PROCEDURES

• Selection of Programming Menu

Programming can be done through the Programming Keyboard on the SL-6600 or a PC Keyboard via

the OP-66-PCKEY. The Operation Keyboard cannot be used for programming.

6-1

Page 19

7. PROGRAMMING PROCEDURES

HOW TO CONNECT THE PC KEYBOARD

(1) Prepare option kit “OP-66-PCKEY”.

(2) Turn the power switch of the scale to the

OFF position.

(3) Connect the OP-66-PCKEY to the CMT or

PL-3 connector of the scale.

(4) Connect the PC Keyboard plug into the socket

of the OP-66-PCKEY.

(5) Hook the clip of the earth wire to the sealing

screw.

Table 1: Programming Menu Numbers and Their Items

EMI-31059

HOW TO CONNECT THE PC KEYBOARD

Menu No.

0 Changing Unit Price

1

2 Setting Store Address and Commercial Message

3 Setting Print Format Number and Adjusting Print Position

4

5 CMT/PL-3 Operations

6

7

8 Setting Speed Key

9 Setting Combination Report

10

11 Setting Ingredient Description

12

13 Switching In-iine/Off-line

14

15 Setting Department Number

16

17

18 Memory Card Operation

20

21

Setting PLU Data

Setting Date, Time, Machine Number, and Store Number

Initial Setting

Changing Bar Code Format

Changing Displayed Titles

Issuing Confirmation Label

Setting Special Information

Transferring Logo Data

Setting Grade Line

Transmitting PLU File, Unit Price, Address and Speed Key (FUN System)

Changing Printing Title for Period of Relish

Item

7- 1

Page 20

7. PROGRAMMING PROCEDURES

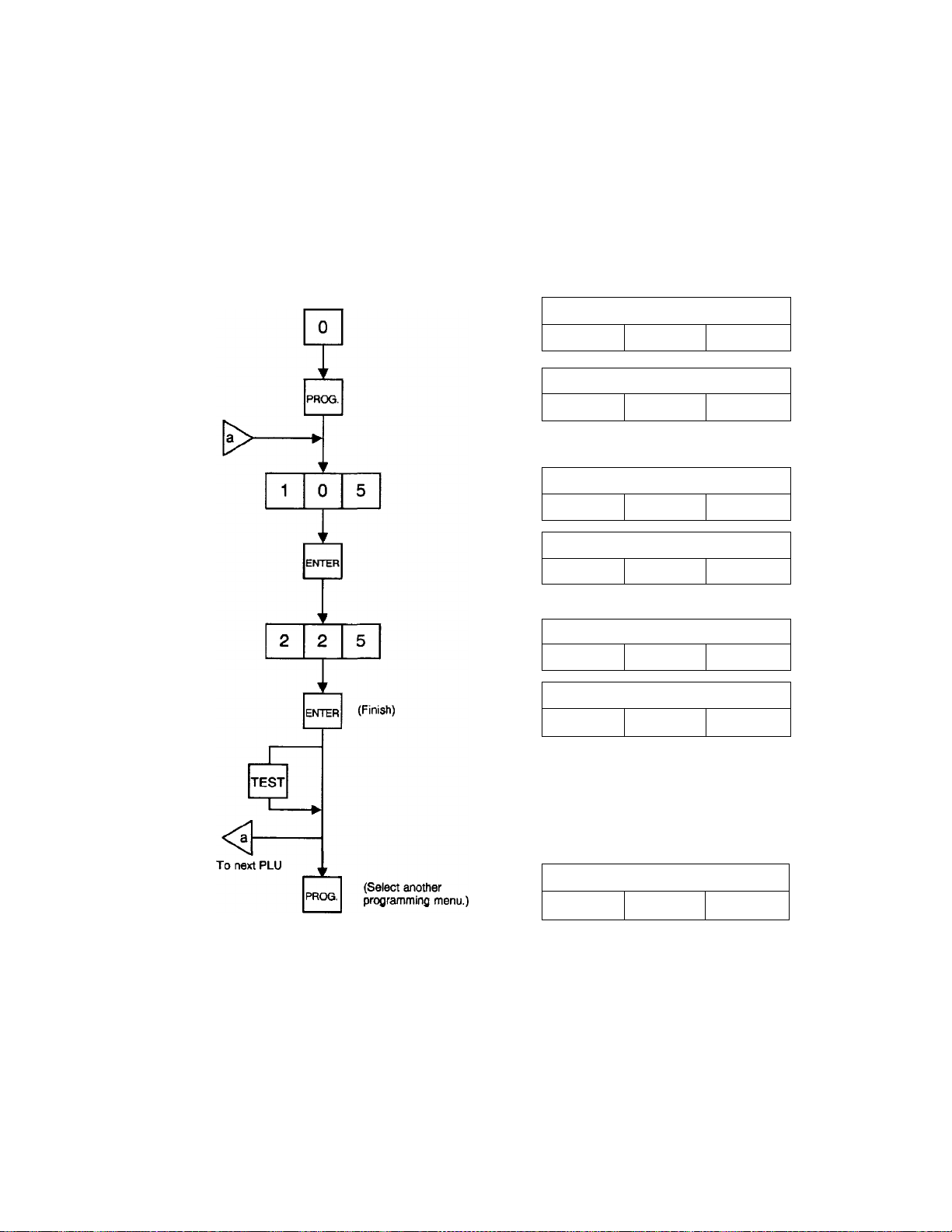

Menu No. 0

• Changing Unit Price

The unit price in the PLU that are previously stored can be changed with this menu.

EM1-31059

Menu No. 0

Select programming

menu #0.

Enter the PLU#.

(Max. 6 digits)

Enter the new unit

price.

(Max. 4 digits)

PLU DATA

EDIT

P

ENTER PLU

#

PO 1

The smaliest PLU# in the

fiie is displayed.

ENTER PLU #

PO

ENTER U.PRICE

PO

Unit price

ENTER U.PRICE

PO

ENTER PLU #

PO 105

_______

2.50

_______

2.25

0

T

105

T

The setting iabel is

issued.

PLU DATA EDIT

NOTES; 1. Recalling a PLU# that has not been stored in the PLU file will result in an error.

2. It is not available to change the unit price of a PLU if it has been set to “open price”.

7- 2

P

0

Page 21

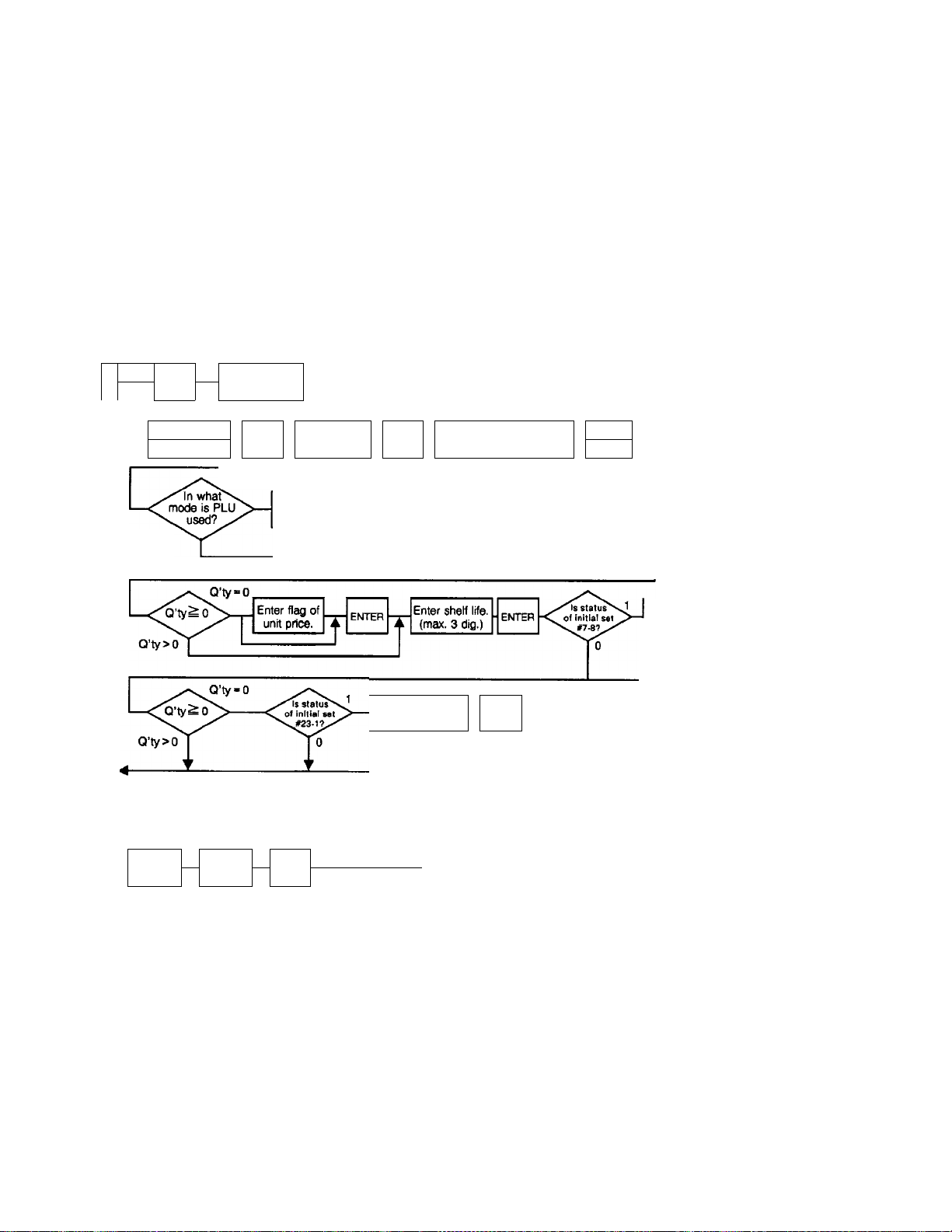

7. PROGRAMMING PROCEDURES

Setting PLU Data

1

PRCX3.

EM1-31059

Menu No. 1

Menu No. 1

->

AUTO Set auto code

CODE

Enter PLU#.

(max. 6 dig.) (max. 6 dig.)

WEIGH

or FIX

CHANGE

PLU

for the UPC #.

ENTER

BY COUNT

Enter quantity for that

price, (max. 2 dig.)

Enter current

PLU #.

ENTER

Enter UPC#.

ENTER

Enter tare weight

Enter new

PLU #.

Enter commodity name.

(mas. 26 chars, x 2 lines)

ENTER - - enter

(max. 4 dig.)

ENTER

(max. 4 dig.)

ENTER

{Refer to Chart ^.)

Enter PERIOD OF

RELISH (Max. 3 dig.)

ENTER

- TEST

◄

PROG.

DELETE

PLU

-----------

(Select another programming menu.)

Enter

PLU #.

The setting iabel is issued.

ENTER

(Refer to chart Z.)

7- 3

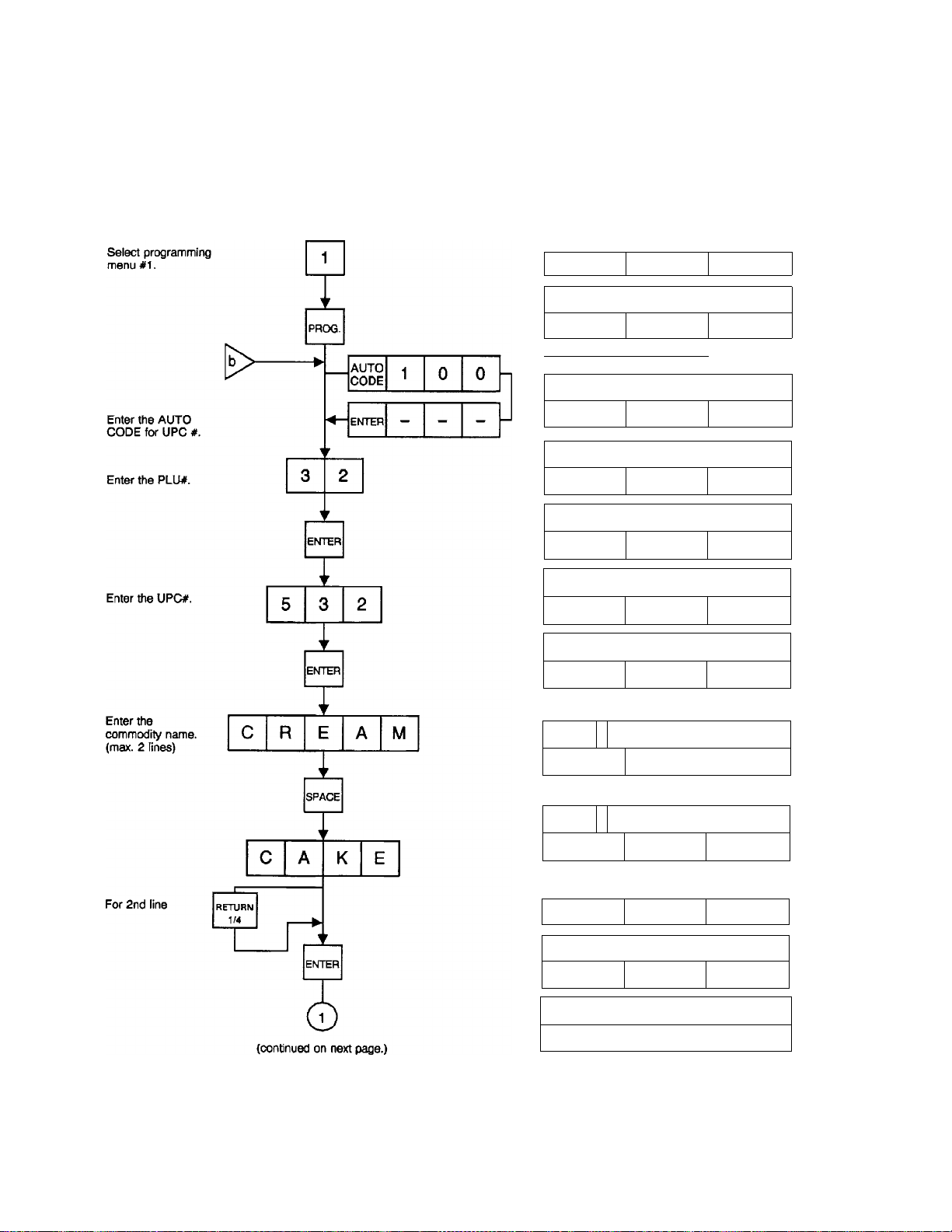

Page 22

7. PROGRAMMING PROCEDURES

EM 1-31059

Menu No. 1

[Example]

PLU DATA

P

ENTER PLU #

PI 1 1

AUTO CODE

PI

ENTER PLU #

PI 1

ENTER UPC #

PI 2

ENTER UPC #

PI 2

ENTER 1ST LINE

t

1 100

1

-----

32

532

Line No.

CREAM

Number of characters

CREAM

CREAM CAKE

ENTER 2ND

ENTER PIECES

PI 3

PI 3 1 5

PI 3

PI

LINE

PI

PI

3 1

3

4

1 0

1 6

2

10

0

0

7-4

Page 23

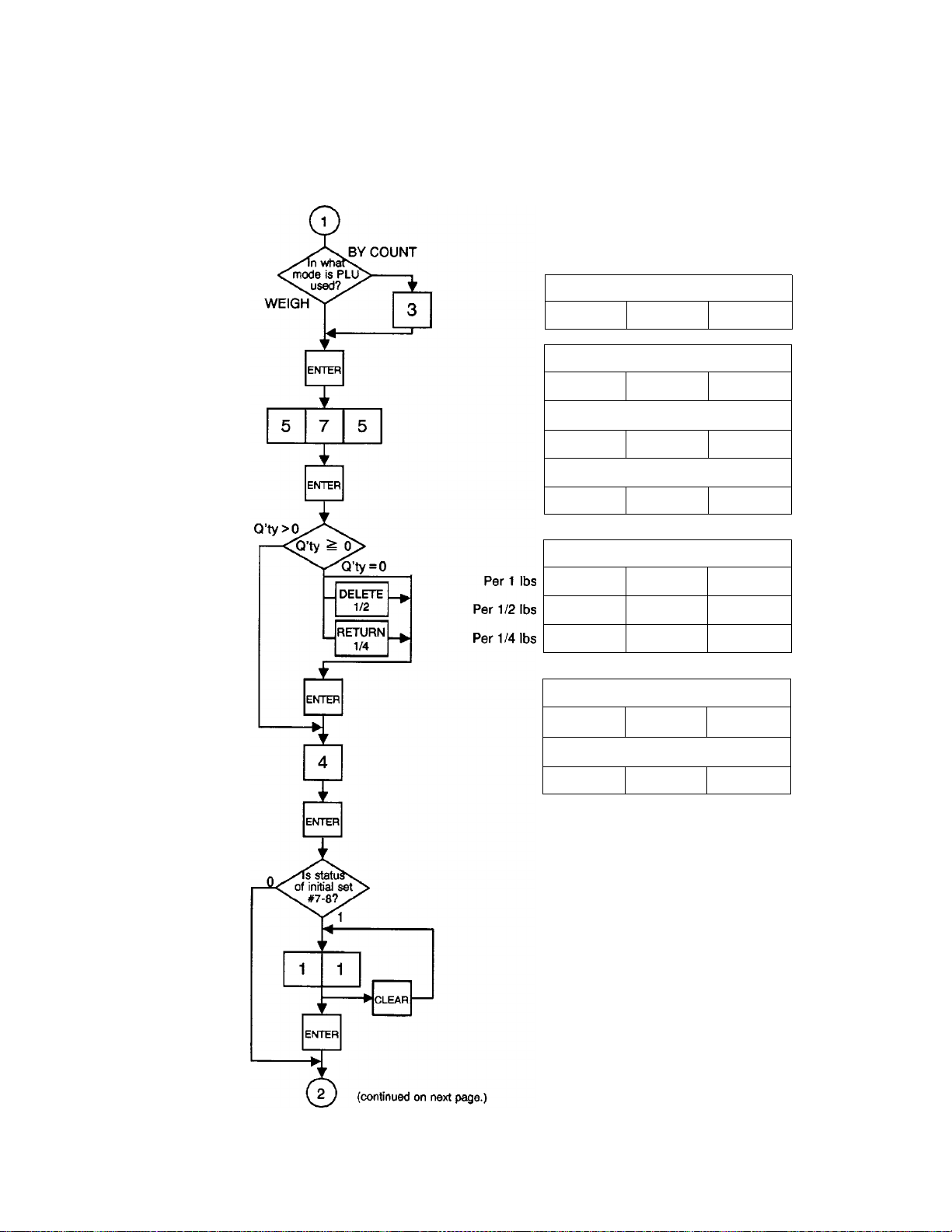

7. PROGRAMMING PROCEDURES

EM 1-31059

Menu No. 1

Enter the quantity,

(max. 2 digits)

Enter the unit price,

(max. 4 digits)

Enter the unit price

Enter the shelf life,

(max. 3 digits)

ENTER PIECES

PI 4

ENTER U.PRICE

PI 4

ENTER U.PRICE

PI 4

ENTER F.PRICING

PI 4

ENTER F.PRICING

PI 4

PI 4 L-2

PI

ENTER SHELF LIFE

PI 5

ENTER SHELF LIFE

PI 5 4

3

0.00

5.75

L-1

L-1

4 L-4

Enter the period of

relish.

(max. 3 digits)

ENTER RELISH

PI 5 h

ENTER RELISH

PI 5 1- 11

7- 5

Page 24

7. PROGRAMMING PROCEDURES

EMI-31059

Menu No. 1

NOTES: 1. UPC# is set after overwriting with the data of AUTO CODE.

Ex. 1) Input : 4 5 6 Ex. 2) Input 4 5 6 7

AUTO CODE : 1 2 3--------------- AUTO CODE : 1 2 3

UPC# 123456 UPC# 123567

In the case that just one line of print is used, it is available to program up to 20

characters, including any space with capital letters.

A two line commodity name can also be printed on a label with up to 52 characters

with capital letter (small size) by using the

3. PERIOD OF RELISH can be set when the initial set #7-$ is set to 1.

CHEESE 8 ONION BUNS

PACKED 0«

JUL II

sea BY

Quantity

PLU # -J- 000808 1.05 020808 -|- upc # Tare Weieht

(Setting label for PLU of BY COUNT mode)

NETWT Jg PWCE/tta ————^

TEC FOOD MART

\P1A I INCOIN AVF

3 flKB

2

TOTALPRICE^

—Commodity Name

-

Shelf Life

Price per pieces

RETURN 1/4

PLU #

--------------------------------

key.

BEEF LIVER

PACKED ON

JUL II

sai BY

----

000105

— T0.50 0.80 030105-—UPC#

NETWT E? PRICE/lbt3

TEC FOOD MART

I23i LINCOLN AVF

(Setting label for PLU of WEIGHT Mode)

3 -

TOTAL PRICE gg

-Shelf Life

-Unit Price

7- 6

Page 25

7. PROGRAMMING PROCEDURES

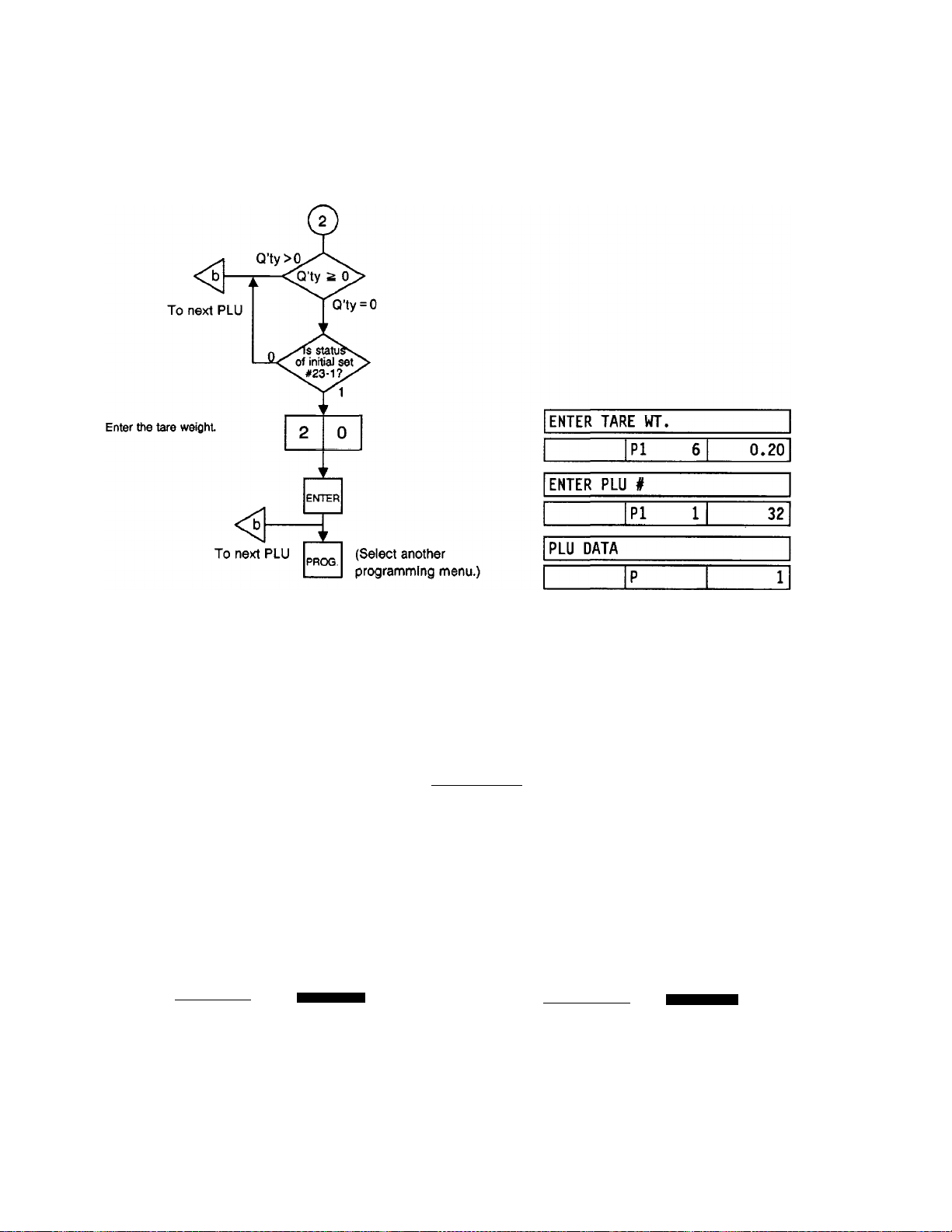

Chart 1: Changing PLU Number

EMI-31059

Menu No. 1

fife is displayed.

NOTE; It is not available to change to a PLU # which has already been used in the PLU file.

7- 7

Page 26

7. PROGRAMMING PROCEDURES

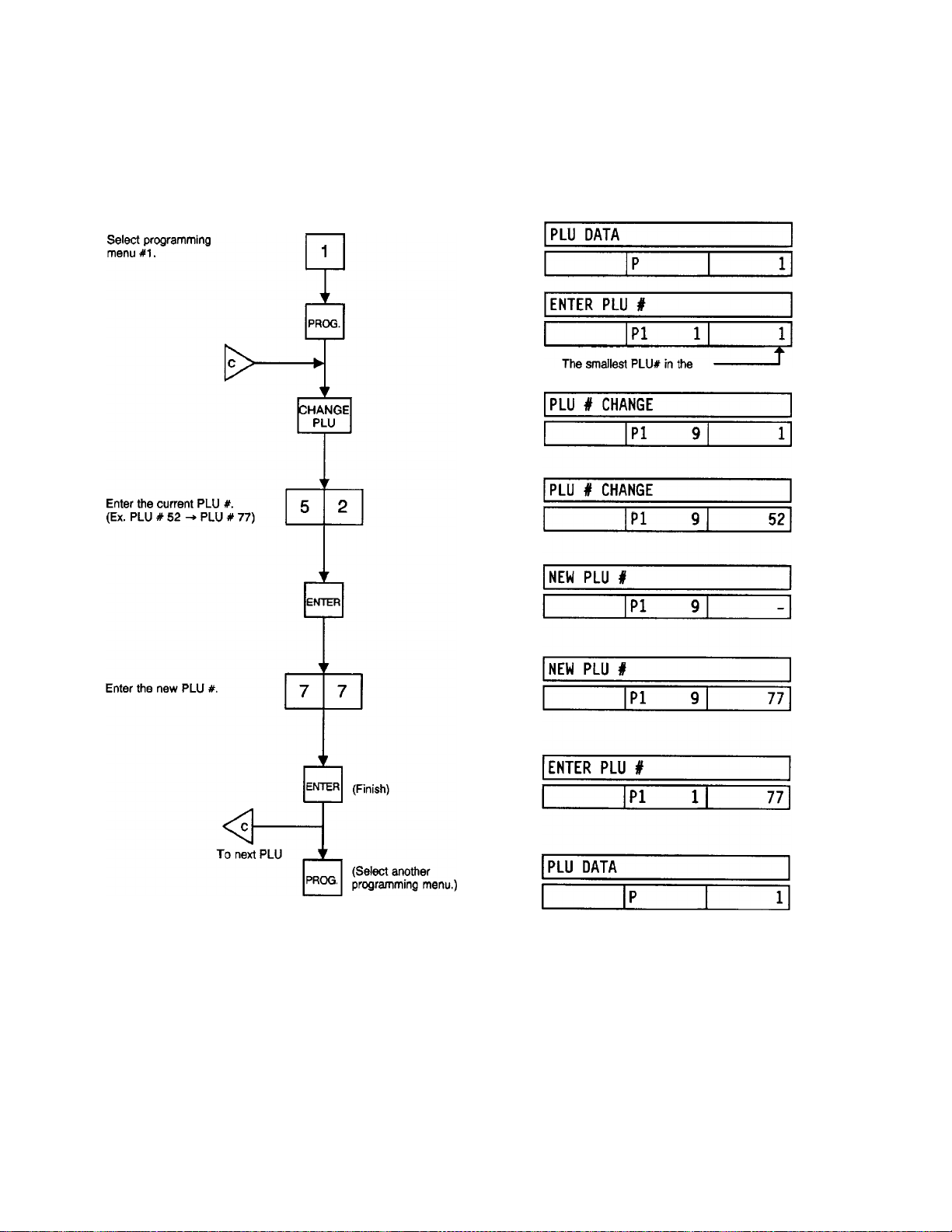

Chart 2: Deleting PLU Data

Ex.) PLU #512 needs to be deleted from the PLU file.

EM1-31059

Menu No. 1

Select programming

menu #1.

Enter the PLU #.

PROG.

DELETE

PLU

ENTER

PROG.

(Finish)

(Select another

programming menu.)

PLU DATA

ENTER PLU #

PLU DELETE

PLU DELETE

ENTER PLU #

PLU DATA

P

PI 1

PI 8

PI 8

PI 1

P

1

1

512

1

1

NOTES: 1. PLU *512 in the PLU We is deleted.

2. If the designated PLU number has not been preset, the procedure will result in an

error.

3. If an error occurs during a PLU deletion, no data will be deleted.

7- 8

Page 27

7. PROGRAMMING PROCEDURES

Menu No. 2

• Setting Store Address or Commercial Message

With the SL-6600 scale, the store address or a commercial message can be set in the memory.

EMI-31059

Menu No. 2

Select programming

menu #2.

Enter the address or

commercial

message.

PROG.

4

C L

RETURN

SHIFT

4 0

I

I

1r

r

1

(

ADDRESS PROG.

ENTER 1ST LINE

P2 1 0

Line No. ^

Number of characters

4 s

440;":

P2 1 3

4401-A BANKERS CIRCLEij

E

ENTER 2ND

P2 1 21

LINE

P2 2

0

ENTER 2ND LINE

P2 2

0

(Li

P2 2

1

r

1

SHIFT

+

T

E

L

(TEL) 404-449-3040

P2

1

0

PROG.

NOTE: The store address or a commercial message can be set in two lines. Each line can contain up to

26 characters including spaces. Before setting the second line, depress the RETURN 1/4 [^ey.

0

(Select another

programming menu.)

7- 9

ADDRESS PROG.

P

18

2

Page 28

EMI-31059

7. PROGRAMMING PROCEDURES

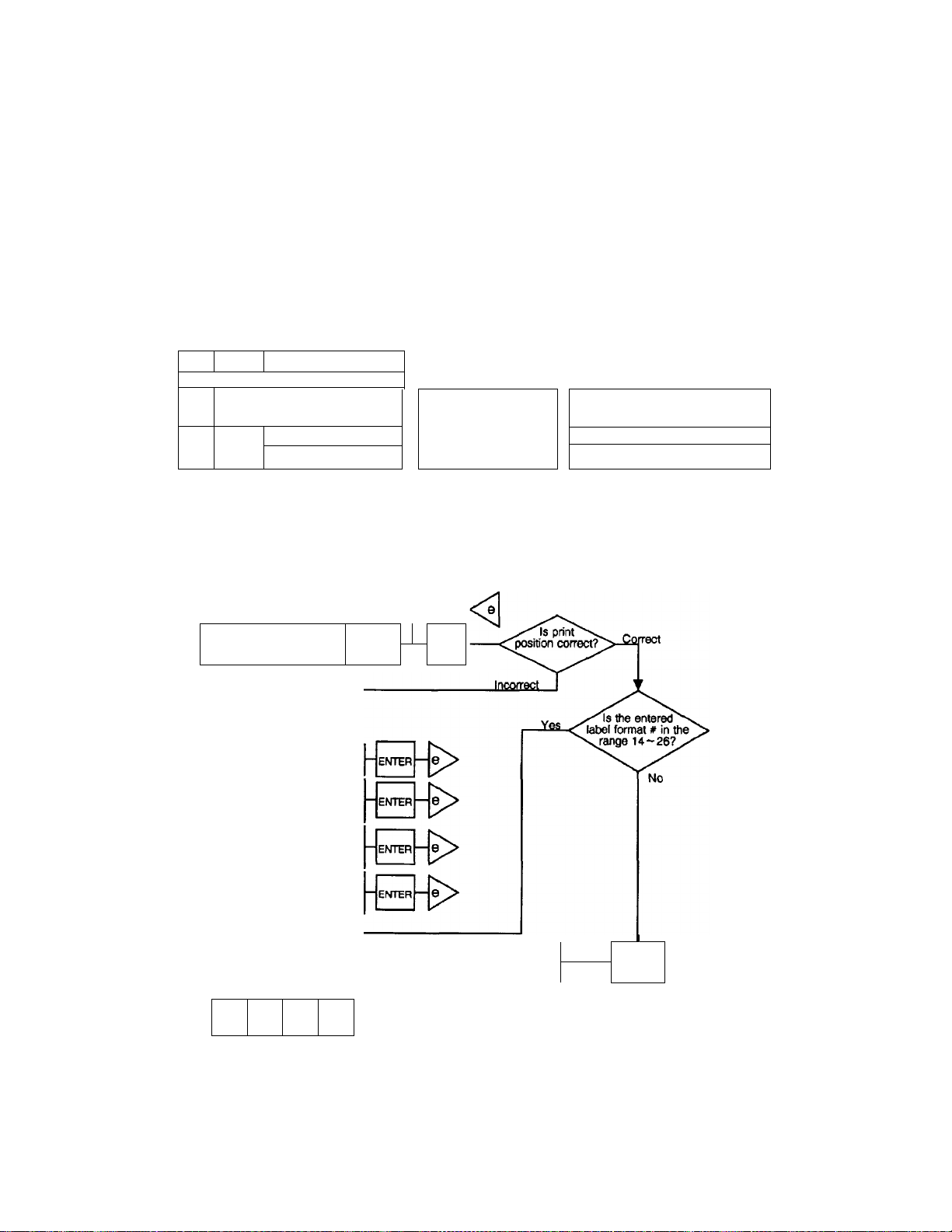

Menu No. 3

Menu No. 3

• Setting Label Format Number and Adjusting Print Position

When the initial set #4-6 is set to “1”, the label format can be set for each of up to 14 cassette #.

When the label format is set for a cassette #, the print position for the format is also set

automatically.

[Outline]

Switch over the

adjusting position.

1 gradation -

0.154mm (1 dot)

1 gradation ■

0.462mm (3 dots)

1 gradation ■

0.462mm (3 dots)

Only when using

the bar code

change label with

pref^ area

a

— PROG.

Select the cassette # which

allocates the label format #

T

by^

or -

NEXT PLU key

key.

NEXT

key:

PLU

key:

Enter the label format #.

(Refer to table 2.)

o

Enter the comect label feed

value. (Range: 0 ~ 199)

Enter the correct value for

commodity name position.

(Range: 0~9)

Enter the correct value for

address position.

(Range: 0~15)

Enter the correct value for

pre feed area

(Range: 0~65)

|-►C#0

'

-----

C#14

I—C#0 '

l-►C#14

CHANGE

PLU

Set the cassette #

Set the label to the selected

which is selected by cassette and attach it to the

cassette switch. scale. Then press the FEED

(Refer to table 3.)

C#1 —► C#2 —► C#4

C#13 i—C#12 4-

C#1 i—C#2 i—C#4

C#13—►C#12

r

1

TEST

---------------

------------------------

key to issue several labels.

► C#7

C#8^

-C#7 4-1

>08—I

Be sure to

perform this

adjustment when

the label format

# of the batch

printing label is

selected.

O o

(for format# 14-22)

o

o o

(for format # 23 - 26)

o

Three labels are

issued automatically.

Set the next label

format #.

CHA

NGE

PI

-U

o

PROG.

7-10

(Select another

programming menu)

Page 29

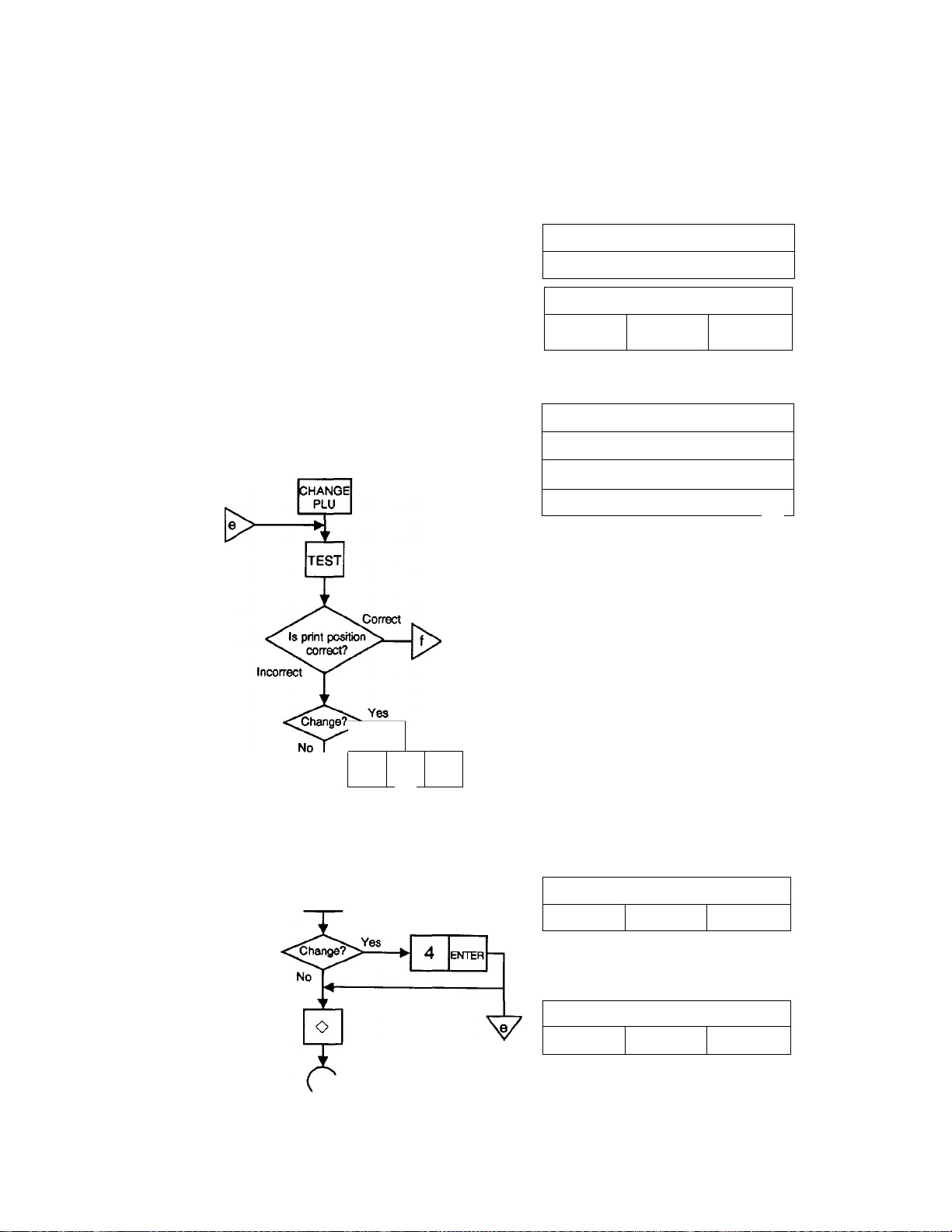

7. PROGRAMMING PROCEDURES

EMI-31059

Menu No. 3

• Rowchart of Print Position Adjustment ®

Select programming

menu #3.

PROG.

Select the cassette #.

Enter the label

format #.

(Refer to table 2)

NEXT

PLU

or

...

In case an initial set #4-6 is set to “1 ”

PRT LOCATION

P

CASSETTE #

Cassette

-------------

Current setting format #.

for cassette #0.

CASSETTE #

P3 2

LABEL FEED

P3 LI

Feed value

(standard)

P3 0

3

d k.

31

A k.

31

100

T

Change the label

feed value?

Switch over the

adjusting position.

Change the

commodity name

position?

r

1

1

1

ENTER

o

2 j (continued on next page.)

(Range; 0~9)

1 gradation - 3 dots

= 0.462 mm

7-11

(Range: 0~199)

0

1 gradation = 1 dot

“0.154 mm

COMMODITY NAME

P3 L2

Standard value

ADDRESS

P3 L3

Standard value

------------

5

Î

5

Page 30

7. PROGRAMMING PROCEDURES

EMI-31059

Menu No. 3

7-12

Page 31

7. PROGRAMMING PROCEDURES

EM 1-31059

Menu No. 3

• Rowchart of Print Position Adjustment ®

Select programming

menu #3.

Change the label

feed value?

................................

In case an initial set #4-6 is set to “0”

Switch over the

adjusting position.

Change the

commodity name

position?

Change the address

position?

7-13

Page 32

7. PROGRAMMING PROCEDURES

PRE FEED

(Range; 0~65)

1 gradation » 3 dots

= 0.462 mm

EMI-31059

Menu No. 3

P3 L4 0

Standard value

7-14

PRT LOCATION

P

3

Page 33

7. PROGRAMMING PROCEDURES

Table 2: Label Format Number Table

Select the label format number for the label to be used by referring to the table below.

EMI-31059

Menu No. 3

NOTES:

1.

Casseffe #3

2.

The pre-feed area adjustment is available only for the bar code change label.

3.

When the label format 10 or ^ 23 is selected, the pre-feed area adjustment value

should be within the range from 0 through 29 or from 56 through

set within the range from 30 through 55, the label cannot be issued with the label

format if 10 onf 23.)

4.

When the label format 11 or ff 24 is selected, the pre-feed area adjustment value

should be within the range from 31 through

from 0 through 30, the label cannot be issued with the label format if 11 or #24.)

5.

When the initial set ff 4-6 is set to “0”, the label format is determined by the initial set

#2-7, 2-8, 4-7, and 5-3. (Refer to the function table of initial set.)

6.

Do not select the label format number other than those listed in Table 2.

is designed for report paper and the labei format if setting is not required.

65.

65.

(If the value is set within the range

(If the value is

7-15

Page 34

7. PROGRAMMING PROCEDURES

Table 3: Cassette Number Table

EM1-31059

Menu No. 3

Cassette

0

(for label)

1

(for label)

2

(for label)

3

(for report

paper)

#

Switching Position Cassette

r

IBBI /7V n

^ o /

8

(for label)

i SBBB /?V n

9

^ o /

f

BBBB /7V

n

(for label)

10

^ o /

i

BBBB /7V

n

(for label)

11

^ o /

(for label)

#

f BBBB /7V n

'

f BBBB /7V n

i

Switching Position

BBBB /7V

n

^ o /

^ o /

^ o /

BBBB //V n

^ o /

4

(for label)

5

(for label)

6

(for label)

7

(for label)

i

BBBB /7V n

^ o /

^ o /

^

BBBB/7V n

^ o /

'o^>/

12

(for label)

13

(for label)

14

(for label)

^ o /

BBBB /7V

^ 0 /

i

BBBB /7V n

^ o /

n

7-16

Page 35

7. PROGRAMMING PROCEDURES

Menu No. 4

• Setting Date, Time, Machine Number, and Store Number

Select programming

menu #4.

DATE

TIME

EM1-31059

Menu No. 4

Set date

(Dec. 15. 1992)

Set time

(13:10)

Set machine No.

(Max. 6 digits)

Set store No.

(Max. 5 digits)

PROG.

ENTER

ENTER

ENTER

DATE

Current setting date

DATE

TIME

Current setting date

TIME

MACHINE #

MACHINE #

STORE #

STORE #

P

P4 1

P4

P4

P4

P4

P4 1

P4 2

P4 2

121092

-------------------

121592

1530

-------------------

1310

4

^

^

88

31

ENTER

(Select another

programming menu.)

NOTES: 1. Express all time in a 24 hour military format.

2. The SL-6600 will check details of date (time) input, and any wrong date (time) will resuh

in error mode. The correct date (time) should be re-entered after depressing the CLEAR

key.

Even when Initial Set 8-4, 8-5 or 8-6 is set to the “Julian Date” side, the way to enter the

date in the date setting operation is the same as in the ordinary case.

PROG.

(Finish)

7-17

DATE

DATE TIME

P4

121592

Page 36

EMI-31059

7. PROGRAMMING PROCEDURES

Menu No. 5

Menu No. 5

• CMT Operations

The SL-6600 is designed to interface with a Cassette Magnetic Tape loader. This loader allows the

transfer of the entire PLU file, ingredient file and other data from the SL-6600 to tapes. This can be

accomplished in a number of operation steps.

In turn, Information from the tape can also be transferred to another SL-6600 or TEC SL-5900 Scale.

CMT

p

ENTER THE NUMBER

P5

WRITE PLU TO CMT

P5

VERFY PLU=CMT

P5 2

READ PLU FM CMT

P5

WRITE PLU TO CMT

P5 11

VERFY PLU

= CMT

P5

READ PLU

FM CMT

P5

5

1

3

12

13

IN PROCESS

P5 nn

through the above steps.

2. Use the metal cassette tape which is commercially available and has a capacity of 45 or

60 minutes recording.

3. For operations of the CMT loader, refer to the instruction manual provided with the CMT

loader.

7-18

P

Page 37

7. PROGRAMMING PROCEDURES

■ PL-3 Operation

Connect the PL-3 to the SL-6600 by using RS-232C Cable, then on turn the power of the SL-6600

and the PL-3.

Insert a data disc into the PL-3 and adjust the transmission rate to the SL-6600 (

or I 713 1: 2400 BPS) by using the rotary SW.

Press the | SAVE key of the PL-3, then check whether the SAVE LED is on.

Program the file number of the data disc by using the rotary switch.

ogra

: File No. 1, : File No. 2,

LLl

: File No. 8,

; File No. 9)

EMI-31059

Menu No. 5

: 4800 BPS

Select programming

menu #5.

Save (SL-6600 -<• PL-3)

Verily

(SL-6600 = PL-3 • SL66 STD)

Load

(SL-6600-^PL-3«-SL66 STD)

Save

(SL-6600 -» PL-3 -► SL-5900)

Verify

(SL-6600 = PL-3 - SL-5900)

Load

(SL-6600*-PL-3'^-SL-5900)

1 1

1 2

1 3

CMT

P

ENTER THE

NUMBER

P5

WRITE PLU TO CMT

P5 1

VERIFY PLU=CMT

P5 2

READ PLU FROM CMT

P5 3

WRITE PLU TO CMT

P5

VERIFY PLU=CMT

P5

READ PLU FM CMT

5

11

12

Press either SAVE

or LOAD key on the

PL-3.

Press ENTER key

on the SL-6600.

(See NOTES: 1)

SAVE

or

i

ENTER

PROG.

LOAD

7-19

P5

SAVE

7 seg. display

LOAD/COMPARE 3

7 seg. display

7 seg. display

13

Page 38

7. PROGRAMMING PROCEDURES

NOTES: 1. In the event Enter Key is not depressed within 10 seconds after] SAVE or LOAD

key is depressed, the Time Out Error results.

2. After depressing the

7 seg. display and LAMP goes off. Remove the data disc and turn the power off.

Be sure to start up the PL-3 before this procedure.

3.

ENTER key, the operation ends when “00” appears in the

Error Code during PL-3 Operations

7SEG. LED

EM 1-31059

Menu No. 5

Error Code

0

FDC ERROR

1

NO FDK ERROR

2 UNAVAILABLE FDK ERROR

1

3 DISCREPANCY ERROR

4 FDK MEMORY FULL ERROR

WRITE PROTECT ERROR

5

NO SEARCH FILE ERROR F

6

LOAD

0

1

TIME OUT ERROR 1

2

LOAD ERROR

3

NOTES: 1. When the error code in FF, this system enters stop status. (Turn the power off Ion

3 FDK ERROR

4 BUSY

5 POWER FAIL ERROR

6

OVERRUN ERROR

for release.)

2. When the error code is F2 or FE, perform the status clear (99).

Phenomena Error Code

0

E 2

C

Phenomena

7

FRAMING ERROR

PARITY ERROR

8

DATA ERROR

0

1 STATUS ERROR

TIME OUT ERROR

3 FDK READAVRITE ERROR

INCORRECT KEY ERROR

0

RAM READ/WRITE ERROR

ROM CRC ERROR

2

RAM BACK UP BATTERY ERROR

3 FDC DIAG LEVEL 0 ERROR

E SYSTEM FDK LOADING ERROR

F SYSTEM ERROR

7-20

Page 39

EMI-31059

7. PROGRAMMING PROCEDURES

Menu No. 6

Menu No. 6

• Initial Setting

The function of this scale depends on initial setting as follows.

Numbers 0 to 26 are available for the initial setting (however, initial set numbers 11 to 19 are not

used at present). The initial setting is available only when the DIP Switch #2-5 installed in the SL6600 is set to the OFF position. To set the initial settings for numbers 20 to 26 DIP Switch #3-2

must be set to the ON position.

Select programming

menu

Select the initial set #.

(#11-19 are not used.)

Select the item #.

(1~8)

Select the status #.

(Refer to function

table.)

PROG.

0 2

ENTER

T

or PLU

(left)

(right)

i

±

EMTER

NEXT

6

(Finish)

INITIAL SET

ENTER THE NUMBER

ENTER THE NUMBER

ex.

INITIAL

ex.

INITIAL

ex.

INITIAL

ex.

ENTER THE NUMBER

P

P6

P6 0

P6 0

Item #

Status # - ■''

P6 0

_____

1-0

T“

4-0

P6 0 4-1

P6

6

INITIAL SET

PROG.

(Select another

programming menu.)

.IMPORTANT.

Be sure to set to “0” for the blank status of the function in the function table.

7-21

P

6

Page 40

■ Table 4: Function Table of Initial Setting

1) Initial set #0

''''''^-„„Status No.

Item

Function

No.

No function

1

No function

2

Dots of thermal head

3

(dots/mm)

CMT baud rate (BPS) 2400 BPS

4

PC Keyboard baud rate

5

#1 (BPS)

PC Keyboard baud rate

6

#2 (BPS)

No function

7

dots/mm

9600 BPS

9600 BPS 9470 BPS 9191 BPS 8929 BPS 8681 BPS 8446 BPS 8224 BPS

7.6

0

□

6 dots/mm

4800 BPS

10080 BPS

0

10416 BPS

3

10776 BPS 11161 BPS 11574 BPS

0

NOTE: When a speed other than 9600 BPS is selected with PC

5 6

Keyboard baud rate #1, the status No. of #2 must be set

to “0”.

When a speed other than 9600 BPS is selected with PC

Keyboard baud rate #2. the status No. of #1 must be set

to “0".

0 0 0

8013 BPS 7813 BPS 7622 BPS

Standard

Status No.

0

0

0

0

0

0

0

■0

31

O

o

31

>

3

S

z

o

TJ

n

o

o

m

O

c

XI

m

(O

No function

8

IV)

to

2) Initial set #1

Item

No.

-------- No.

Function

RAM capacity of PLU

1

file

Setting or Changing of

2

PLU data

Reset operations Available

3

Change of PLU data while the

data is present in total

4

menxMy

Switching of modes

5

(WEIGH/BY COUNT)

The method of inputting

quantity in BY COUNT

6

mode

Entry of the number of

7

NETVVT

Print the unit price on net

8

weight statement labels

0

Available

Not

available

Slide SW.

Input in the

process of

Issuing labels

Not

available

Non (Mint

□

32 KB

Not

available

Not

available

Available

Set mode

flag to PLU

data

Included in

PLU data

Available

Print

2

96 KB

3

160 KB 224 KB

0

5 6

288 KB 352 KB

NOTE: When this unit is to be used on-line system,

set the status No. to “1”.

0 0

416 KB 544 KB

9

672 KB

0

Standard

Status No.

2

0

0

0

0

1

0

0

s

¿>

o

«1

<o

Page 41

u

7J

O

a

73

>

s

s

z

o

TJ

n

o

o

m

o

c

73

m

(O

K)

Oi

4) Initial set #3

Item

Function

No.

1 Print of bar code flag

Print of numerals under

2

bar code

COOKED BY when

3

RELISH is 0

4 Print of “M”, “R" mark Print Non print

Print of sell by date when

5

shelf life data is 0

Printing position of

6

grade line

7 No function

AUTO print condition in

8

weighing mode

0

Non print

Print Non print

Non print

Non print

Lower right

of C/N

T. Price = 0 T. Price >0

Q

Print

Print

Print 0

Upper left

of C/N

2

0 0 0

6

0 0

NOTE: C/N = Commodity Name

9

Status No.

Standard

0

0

0

0

0

0

1

3:

CD

z

o

O

cn

(O

Page 42

ro

5) Initial set #4

Item

"''"-^.^^^atus No.

No.

Function

1

Time mode on print

Temporary charrge of

2

date

No function

3

4 No function

No function

5

Selecting method of

6

label format

7 Label issuing method

Variable length label

8

Print Delay Time

0

12 hrs. 24 hrs.

Available

Initial Set

On-

demand

Standard

0.3 sec.

□

availaUa

Cassette

Number

Batch

0.0 sec. 0.1 sec 0.2 sec.

Not

2

0 0 0

6

0 0 0

Standard

Status No.

1

0

TI

3

O

O

3

>

s

)

s

Z

o

TJ

31

o

o

m

O

c

31

m

(0

0.3 sec.

0.4 sec. 0.5 sec. 0.6 sec.

0

0

0

0

0

0.7 sec. 0.8 sec. 0

2 5

o 2

z>

z 2

o o

Page 43

го

СП

"D

Я

О

а

л

>

г

S

Z

о

■ о

я

о

о

m

О

с

я

m

(О

Z

о

о

сл

(О

Page 44

9) Initial set #8

Item

Function

No.

Each country spree.

Each country spee.

No function

Type of PACKED ON

DATE

Type of SELL BY

DATE

Type of COOKED BY

DATE

No function

No function

Status No.

us

Dominical

year

Dominical

year

Dominical

year

m

CA

Julian Date

Julian Date

Juiian Date

0

US-B CA-B

AU

NOTES: 1. The ‘Julian Dale' means the date expressed in the calendar system that only uses the day

numbers but not months. The Julian Date value corresponds to the month-and-day ol the

dominical year as in the following table.

Dominical year

Month/Day

Ordinary Year

Julian

Date

Leap Year

2. Even when the ‘Julian Date' option is selecled, the way lo enter the date in the dale setting

operation is the same as in the ordinary case.

3. Whan the ‘Julian Dale’ option is selecled, ‘PACKED ON' date, 'SELL BY' data or ‘COOKED

BY' date is automatically calculated from the dale of entry.

4. The Julian Dale value will never exceed 366. Whan ‘SELL BY* dale or ‘COOKED BY' date

turns out to be in the next year, the date value will start from 1 again, (For example, January 1 will

be ‘1*.)

1/2

1/1

1

2

1

2 59 60

0 0

2Ka 2C9 3/1

59 60

61 315 316 366

11/10

314

Others

Others

11/11

315 365

12/31

Standard

Status No.

‘U

3D

O

o

3D

>

s

s

z

o

■o

3D

O

o

m

a

c

3D

m

to

ro

CD

10) Initial set #9

''''''^-..„,__^tus No.

Item

Function

No.

No function

1

No function

2

No function

3

4 No function

Number of TR # digits

5

No function

6

No function

7

No function

8

----------------

____

0 0

3 digits 1 digit

2

3

0

5

6

0

8

9

Standard

Status No.

0

0

0

0

0

0

0

0

s 5

a S

3

Z ¿

o o

o> <o

. 4

Ü1

Page 45

11) Initial set #10

Item

'' No.

Function

No.

1 No function

2 No function

0 CD

2

3

E B

6

B

8 9

standard

Status No.

0

0

■B

3J

O

O

30

>

■vl

'-j

Open PLU

3

Print 13th digit under

4

bar code

No function

5

The number of digits

6

for PLU

7 Logo print Non print

Possible thermal dots per

8

row when printing logo

Not

available

Print Non print

6 digits 4 digits

50 dots or

less

Available

Print 0

100 dots or

less

150 dots or

less

200 dots or

less

No limit

0

0

0

0

0

o

TJ

30

o

o

m

O

c

30

m

</>

<s 3.

3 -b

I

o o

a> <D

Ü1

Page 46

7. PROGRAMMING PROCEDURES

Menu No. 7

• Changing Bar Code Format

With the SL-6600 scale, two kinds of bar code formats are available; Weighing format and the By

Count format. These formats can be changed freely.

BAR CODE FORMAT

EM1-31059

Menu No. 7

ENTER THE NUMBER

WEIGHT

BY COUNT

FIX

01 FLAG FLAG-0

Digit#

Current setting item #

01 UPC #

ex.)

03 UPC # UPC # -2

P

P7

P7

P7 2

P7

P7 1

-------

Item#

Format data

FLAG-0

P7 1

3

7

1

3

1 1-0

1-0

7-28

ex.)

09 UPC # PRICE-1

09 PRICE

ex.)

13 PRICE C/D -1

ex.)

ENTER THE NUMBER

BAR CODE

P7 3

P7 9

PRICE-1

P7 9

P7 13

P7

FORMAT

P

3

3-2

3

5-1

5

5-1

5 7-1

7

Page 47

7. PROGRAMMING PROCEDURES

EMI-31059

Menu No. 7

NOTES;

1.

In this scale, the preciously set bar code format is cleared by RAM clear, and can be

switched to the following formats. Therefore, it is necessary to set the bar code format

again after RAM clear.

Bar Code Format by Initialization:

0 Weighing Format^lX Format

Lo

0 By Count Format

2.

When the ENTER key is depressed, format check is executed, resulting in an error in

the following cases.

2 C2

0 0 C2 C3 C4

0 Check digit (C/D) is at other than digit-13.

0 Price check digit (PC/D) cannot be calculated.

0 Price is not set serially beginning from Pi (Pi to P4, or Pi to P5).

® Weight is not set serially beginning from W1 (Wl to W4, or W1 to W5).

3. Calculated from weight if price is not set for price check digit (PC/D).

4. The usable keys to set the column are as follows:

FLAG

PLU#

UPC#

PC/D

PRICE

WEIGHT

C/D

C3

C4

C5 C6 PC/D PI P2

C5 0 0 0 0

0 -[I]

m -n]

D] -HI

m

HI -'ll]

D] ~[I]

m

P3

P4 C/D 1

C/D

C6

5. Digits and display

PLU# 1 2

i i

Display 2-1 2-2

7. Digits

Price $

Display 5-1 5-2

9. Setting items

and display

1 2 .

i 4

^ 1

* FLAG

of PLU #.

3 4 5

i i i i

2-3 2-4 2-5

of price.

3 4

i i

5-3 5-4

► 2 3 .

* PLU#

C/D .

7 ^

6 UPC# 1 2

2-6

WEIGHT . PRICE .

6

7-29

6. Digits and display of UPC #.

3 4 5 6

1 i

Display

8. Digits and display of weight.

Weight 1 2 .

Display

UPC# '

3-1 3-2

i

6-1

4

PC/D

^ 5

3-3 3-4 3-5 3-6

1 1 ;

6-2

6-3 6-4

1 Ir 1 i

3 4

Page 48

7. PROGRAMMING PROCEDURES

Menu No. 8

• Setting Speed Key

The SL-6600 has 60 PLU speed keys which are very convenient to call a PLU quickly.

Example: Set PLU # 100 to speed key Dl-

EMI-31059

Menu No. 8

Select programming

menu #8.

Enter the speed key

#.

Set PLU# 100.

(Max. 6 digits)

8

PROG.

ENTER

ENTER

(Finish)

SPEED KEY SET

P

SPEED KEY #

P8

SPEED KEY #

P8 12

SPEED KEY #

P8 12

SPEED KEY #

P8 12

SPEED KEY #

P8

8

100

PROG.

NOTE: When “0” is set on the speed key, if this speed key is pressed in the REG, M.DOWN, or

REWRAP mode, the scale enters an error status (PLU NOT FOUND). Press the|

to release the error mode.

(Select another

programming menu.)

SPEED KEY SET

P

c

| key

7-30

8

Page 49

EMI-31059

7. PROGRAMMING PROCEDURES

Menu No. 9

Menu No. 9

• Setting Combination Report

In the Read P<)/Reset (Z) mode on the SL-6600, a format of the report to be printed can be

previously set for operation ease. A format contains 8 tables, and up to 8 kinds of report data can be

set for each table.

Select programming

menu #9.

Select the table #.

(1 ~ 8)

Select the table menu.

(Refer to next page.)

REPORT COMBI.

P

ENTER THE NUMBER

P9

ENTER THE NUMBER

P9 1

Table #

REPORTS

P9 1

9

ENTER THE NUMBER

REPORT COMBI.

CAUTION

When the table # is selected, pressing the ENTER | key clears all report data set in

the table #. For this, it is convenient for the operations above to have all the setting

tables for the combination report listed in the READ

contents of the table.

(X) mode before changing the

7-31

P9

P

9

Page 50

7. PROGRAMMING PROCEDURES

Select a table menu #.

EM 1-31059

Menu No. 9

HOURLY REPORT

Hourly total report.

Grand total report

PLU total report

PLU programmed data report

Commodity description report

Speed key programmed data

report

Combination report format

Commodity and ingredient

description report

Grade line description report.

5

5

5 3

5

5

5

1

GRAND TOTAL

2

PLU REPORT

3

PLU PROG. DATA

1

-0

51

COMMODITY DESCRI

2

52

SPEED KEY REPORT

53

4

REPORT COMBI.

54

5

“0)

COMMO. & INGRE.

55

6

G. LINE REPORT

ENTER

V

56

REPORTS

P9 1

7-32

Page 51

7. PROGRAMMING PROCEDURES

® Set the data of PLU Total Report

EMI-31059

Menu No. 9

Select the total memory.

Mark Down total;

Select the search code.

Day total:

Rewrap total:

PLU #:

UPC #:

A

i

ENTER

£

ENTER

ENTER

PLU REPORT

3

SELECT DATA FILE

3 -

NORMAL

3 1

MARK DOWN

3 2

REWRAP

3 3

SEARCH CODE

3 n-

(n = 1~3)

PLU #

3 n 1

UPC #

3 n2

Individual Total

(EX. PLU # 100)

Block Total

(EX. PLU # 30 ~ 39)

Zone Total

(EX. PLU # 100 ~ 108)

Entire PLU Total

EN1PER

V

1

NEXT

PLU

o

0

1 0

PLU #

3 nx □

(x= 1 or 2)

PLU #

3 n X □

0

PLU #

3 nx □

8

PLU #

3 nx □

100

3-

100

PLU #

3 nx □

108

REPORTS

P9 1

7-33

Page 52

7. PROGRAMMING PROCEDURES

Set the data of Grand Total Report

EM 1-31059

Menu No. 9

GRAND TOTAL

2

SELECT DATA FILE

2 -

NORMAL

2 1

MARK DOWN

2 2

REWRAP

2 3

REPORTS

P9 1

Set the data of Each Programmed Report

Select the individual PLU #.

(Ex. PLU # 100)

Set the block PLU #.

(Ex. PLU # 30 ~ 39)

Set the zone PLU #.

(Ex. PLU# 100 ~ 108)

Set the entire PLU #.

7-34

Page 53

EM 1-31059

7. PROGRAMMING PROCEDURES

Menu No. 10

Menu No. 10

• Changing Displayed Titles

With the SL-6600, the title indicated in each control lock position can be changed. The title changed

with the procedure below will be stored in "EEPROM". When a “All Clear" or “EEPROM Clear” is

executed, all these titles will be cleared and the initial will resume. To allow this programming, initial

set # 7-3 must be set to “1”.

NOTE: These titles are indicated on the message display.

Select programming

menu #10.

TITLE PROG.

P

ENTER THE NUMBER

PIO

ENTER 1ST LINE

PIO

Title#

-------------------

Number of character

10

1

^

9

7-35

Page 54

EMI-31059

7. PROGRAMMING PROCEDURES

Menu No. 10

When the initial set # 6-8 is set to “1”, the “PIECES” field printed on the BY COUNT label can be

changed.

Enter the title # 249.

7-36

Page 55

7. PROGRAMMING PROCEDURES

■ Table 5: Title Number and Name Table

Status clear mode

I N I T I A L S E

0

1 R A M

2 E E

3

4 A R E A

5

6

7 P L

8

9

10

11 D A T E T I M E

12

13

14 B A R

15

16

17 T I T L E P R

18

Not used

19

20

21 INL I N E

22 E N T E R P L U

23 E N T E R

24

25

P R0M

P A N

s

Z E R 0

P A N

S

U

P

L U D A T A

A D D R E

P R T L

M T

C

I N I T I A L

SPE E

R E

P 0

I NGR

G R A D E L I N E

L A

B E L F 0 R M A T

E N T E R

E N T

L E A

C

L E A R

C

D A T A E D I T

S

s

0

c

C 0 D E F 0 R M A T

D

K E Y

R T

D I

E

U •

S H E L F L I F E

E R T A R E

T

R

L E A R

C

P R

0 G •

A T I 0 N

E T

S

s

M

C 0

E

0 G •

N T

P R

B I •

#

I

L R

C

E T

P R 0 G

E

C

W T

•

Programming menu #1

E N T E R UPC

26

27 E N T E R F •

N T E R

E

28

E N T E R T A R E W T •

29

E N T E R D E P T

30

P L

31

32 N E w P L U

33

34 A U T 0 C 0 0 E

Programming menu #5,

35

36

37 M E

38

39

40

41 M E

42 M E

•

43

44 M E

45

46

47 L A B E L F

48 C

49

Programming menu #4 & REG mode

50

Programming menu #4

51

52 M A

53

Programming menu #5

54 w

55

56

u

P L

u

E N T E R THE N U M B E R

A D D R E

S

s

M E

S

s

M E

s s

M E

s s

s s

s s

M E

s s

s s

R0L L

s

C

F I X E D M E

0 M M0D I T

A D D R E

D A T E

T I M E

H I N

c

s

T 0 R E

R I T E P

V E R I

R E A D

P R I

H E L F L I F E

S

C H ANG

#

#

D E L E T E

10 and 11

9.

6.

S S

AGE

AGE

A G E

AGE

A G E

A G E

AGE

A

G E

M ESS A G E

S SAG E

EED

Y N A M E

S S

E

#

#

L u T

F Y P L

P L

U F M

U

EMI-31059

Menu No. 10

#

C

* #

E

0

=

I N

c

c

c

M T

G

M T

M

T

7-37

Page 56

7. PROGRAMMING PROCEDURES

EMI-31059

Menu No. 10

Programming menu #5 & READ/RESET modes

57 I N P R 0 c E

Programming menu #6 Programming menu #9 & READ mode

I N

58

Programming menu #7 & REG mode

W E I

59

Programming menu #7

B Y

60

F I X P R I

61

FLA

62

P

63

64

C

Programming menu #8

65 P R E S s S P E E D K E Y 94 M A R K D 0 W N

66 S

Programming menu #9

67 E N T E R T H E N

68 E N T E R T H E N u M B E R

E N T E R T H E N

69

E N

70

71 E N

72 E N T

E N T E R T H E NuM

73

74 E N T E R

R

75

H

76

Programming menu #9 & READ/RESET modes

77 G R A N D

P L

78

79 SEL E C T D A

80 S E A R

Programming menu #9

81 u P C

Programming menu #9 & READ/RESET modes

82 D E P

Programming menu #9 & READ mode

P

83

84 P L

T I A L

I

H T

G

0

C

G

D

C

/

D D E p T

/

P E E D K E Y

T E R T H E N

T E R T H E N

E

N T

u

R

T H E NuM B

T H E NuM B E R

E p 0 R T

R

0 u

U R E p

A

L

U

U

s

L Y R E P 0 R T

T 0 T A L

H

C

#

R

T M

P

R 0

#

S

s

E

c

p

L u

p R I

R

0

#

E

c

•

#

# 95

uMB

u M B E R

M B

u

M

u

T

A

T

F

C 0 D E

E N T

G • D A T A

U P

W E 92

E R

E R

B E R

E R

B E R

I L E 107

Programming menu #9

M M

C 0

85

86 S

87 R

88 C

89 U

90 G •

91

93

p

E

P

E

0 M M

P

C

L I N E R E p

D E P T

Programming menu #9

D

E P A R T M E N T

Programming menu #9 & READ/RESET modes

N 0 R M A L

D I T Y D E

0

E D K E Y R E P0R T

0 R T C 0 M B I •

0 • &

I N

R E P0R T

R E P0R T

•

R E W R A P

P L

96

97 U P c

Programming menu #9

98

Programming menu #11

99

REG mode

100 E N T E R T H E

101

102 E N T E R T

103

104 P A

105 S E L L 6 Y 0 A T E

106 C 0MM 0 D I T Y N

108

109

110 0 N

u #

#

D E p

A R T M E N T

E N T E R T

E N T E R

E N TER

K E D

c

M E

T H E

U N I T P R I

T

0 T A L P R I

B A

R

C 0

D E

H E

S s

H E L

N

0

E

C

C

G

A

G *

0 A T E

E

G

R T

0

#

P L U

G

0 G 0

A M E

0 F F

S C

R E

L I

E

L I N

R I

•

N E

#

#

#

E

7-38

Page 57

7. PROGRAMMING PROCEDURES

EM 1-31059

Menu No. 10

READ/RESET modes

111 R E P 0 R T S

H

112

C 0 M B I • R

113

114

S

A N A L Y B Y

115

A N A L Y B Y W E I G H T

116

A N A L Y

117

RESET mode

R E P

118

Edit mode

E N T E R L I N

119

120 S

System checking mode

121 W R I T E

122 V E R I F Y E E P

REA

123

REG mode

124

ST0

File sorting mode

125 S0R T I N G P L

READ/RESET modes

126 T A B L E N

Character generator

127

5

7

128

1

129

READ mode

130 G • L I N E R

Resistor Change

P R

131

132 P R

P R

133

NETWT statement

140 E N T

141

E N T E

R L Y R E P0R T

0 U

EQU E NcE R E P 0 R T

R T

0

T N D R D T H

D E E P F M

R