Toshiba CN36V51, CZ36V61, CZ32V61, 36V61 Schematic

SAFETY PRECAUTIONS

SERVICE WARNING

Only qualified service technicians who are familiar with safety checks

and guidelines should perform service work. Before replacing parts,

disconnect power source to protect electrostatically sensitive parts. Do

not attempt to modify any circuit unless so recommended by the

manufacturer. When servicing the receiver, use an isolation transformer

between the line cord and power receptacle.

SERVICING THE HIGH VOLTAGE AND CRT

Use EXTREME CAUTION when servicing the high voltage circuits. To

discharge static high voltage, connect a 10K ohms resistor in series with a

test lead between the receiver ground and CRT anode lead. DO NOT lift

the CRT by the neck. Always wear shatterproof goggles when handling

the CRT to protect eyes in case of implosion.

X-RAY RADIATION AND HIGH VOLTAGE LIMITS

Be aware of the instructions and procedures covering X-ray radiation. In

solid-state receivers and monitors, the CRT is the only potential source of

X-rays. Keep an accurate high voltage meter available at all times. Check

meter calibration periodically. Whenever servicing a receiver, check the

high voltage at various brightness levels to be sure it is regulating

properly. Keep high voltage at rated value, NO HIGHER. Excessive high

voltage may cause X-ray radiation or failure of associated components.

DO NOT depend on protection circuits to keep voltage at rated value.

When troubleshooting a receiver with excessive high voltage, avoid close

contact with the CRT. DO NOT operate the receiver longer than

necessary. To locate the cause of excessive high voltage, use a variable

AC transformer to regulate voltage. In present receivers, many electrical

and mechanical components have safety related characteristics which are

not detectable by visual inspection. Such components are identified by a

# on both the schematic and the parts list. For SAFETY, use only

equivalent replacement parts when replacing these components.

GENERAL GUIDELINES

Perform a final SAFETY CHECK before returning receiver to customer.

Check repaired area for poorly soldered connections, and check entire

circuit board for solder splashes. Check board wiring for pinched wires or

wires contacting any high wattage resistors. Check that all control knobs,

shields, covers, grounds, and mounting hardware have been replaced. Be

sure to replace all insulators and restore proper lead dress.

SAFETY CHECKS FIRE AND SHOCK HAZARD

Cold Leakage Checks for Receivers with Isolated Ground

Unplug the AC cord, connect a jumper across the plug prongs, and turn

the power switch on (if applicable). Use an ohmmeter to measure the

resistance between the jumped AC plug and any exposed metal cabinet

parts such as antenna screw heads, control shafts, or handle brackets.

Exposed metal parts with a return path should measure between 1M

ohms and 5.2M ohms. Parts without a return path must measure infinity.

Hot Leakage Current Check

Plug the AC cord directly into an AC outlet. DO NOT use an isolation

transformer. Use a 1500 ohms, 10W resistor in parallel with a .15µF

capacitor to connect between any exposed metal parts on the receiver and

a good earth ground. (See figure below.) Use an AC voltmeter with at

least 5000 ohms per volt sensitivity to measure the voltage across the

resistor. Check all exposed metal parts and measure voltage at each point.

Voltage measurements should not exceed .75VAC, 500µA. Any value

exceeding this limit constitutes a potential shock hazard and must be

corrected. If the AC plug is not polarized, reverse the AC plug and repeat

exposed metal part voltage measurement at each point.

5266

INDEXINDEX

INDEX

INDEXINDEX

SET 5266

High Voltage Shutdown Test ....................1

Important Parts Information ..................... 1

Miscellaneous Adjustments ..................... 1

Parts List ...................................................4

Placement Chart ....................................... 1

Safety Precautions .................................... 1

Schematic Component Location ..............3

Schematic Notes ....................................... 2

Schematics

A/V Switching ................................... 3

CRT ................................................... 2

PIP Control ........................................ 2

Power Supply .................................... 2

System Control .................................. 4

Television .......................................... 2

Test Equipment ......................................... 1

Tuner Information ....................................1

5266

Technical Service Data

TOSHIBA

Model CZ36V61 (Chassis TAC9922)

Representative Model

Essential coverage

for servicing a television receiver...

Schematics

5266

HIGH VOLTAGE SHUTDOWN TEST

Apply 120VAC and turn receiver on. Set all digital customer controls for normal operation. Momentarily

short test point X to test point R. Receiver should lose raster and sound. If the receiver does not lose raster

and sound, the shutdown circuit should be repaired. To resume normal operation, remove AC power and

wait 30 seconds. After restoring AC power, the receiver should power up automatically.

The listing of any available replacement part herein in no case constitutes a recommendation, warranty, or guarantee by

SAMS Technical Publishing, LLC as to the quality and suitability of such replacement part. The numbers of the listed parts

have been compiled from information furnished to SAMS Technical Publishing, LLC by the manufacturers of the specific

type of replacement part listed.

Reproduction or use, without express permission, of editorial or pictorial content, in any manner, is prohibited. No patent

liability is assumed with respect to the use of the information contained herein.

© 2007 SAMS Technical Publishing, LLC

9850 E. 30th St.

Indianapolis IN 46229

www.samswebsite.com

Printed in the United States of America 5 4 3 2 1 07PF03377

Page 1 SET 5266

!IBCGC|05266S

MODEL CZ36V61 (CHASSIS TAC9922)

TOSHIBA

For a Complete List of Manuals,

Visit www.samswebsite.com

Component locations

Parts list

Coverage includes this additional model and chassis:

Model Chassis

CZ32V61 TAC9920

JUNE 2007 SET 5266

3

Page 1 SET 5266

TUNER INFORMATION

Important Parts Information

MAIN TUNER VOLTAGE CHART

Pin VHF Low Band VHF High Band UHF Band

1 (AGC) 1.7V 1.7V 1.6V

3 (A) 4.6V 4.6V 4.6V

4 (SCL) 4.3V 4.3V 4.3V

5 (SDA) 4.3V 4.3V 4.3V

6 (MB) 0V 0V 0V

7 (+5V) 5.0V 5.0V 5.0V

9 (+32V) 32.7V 32.7V 32.7V

11 (IF) 0V 0V 0V

NOTE: VHF Low Band voltages taken on channel 2.

VHF High Band voltages taken on channel 7.

UHF Band voltages taken on channel 14.

PIP TUNER VOLTAGE CHART

Pin VHF Low Band VHF High Band UHF Band

1 (NC) 0V 0V 0V

2 (+32V) 32.7V 32.7V 32.7V

3 (SCL) 4.4V 4.4V 4.4V

4 (SDA) 4.3V 4.3V 4.3V

5 (NC) 0V 0V 0V

6 (ADS) 0V 0V 0V

7 (+5V) 5.0V 5.0V 5.0V

8 (AGC) 3.4V 3.6V 3.2V

9 (9V) 8.7V 8.7V 8.7V

10 (A OUT) 0V 0V 0V

11 (GND) 0V 0V 0V

12 (AFT) 1.8V 1.8V 2.0V

13 (NC) 0V 0V 0V

14 (GND) 0V 0V 0V

15 (V OUT) 4.4V 4.4V 4.4V

NOTE: VHF Low Band voltages taken on channel 2.

VHF High Band voltages taken on channel 7.

UHF Band voltages taken on channel 14.

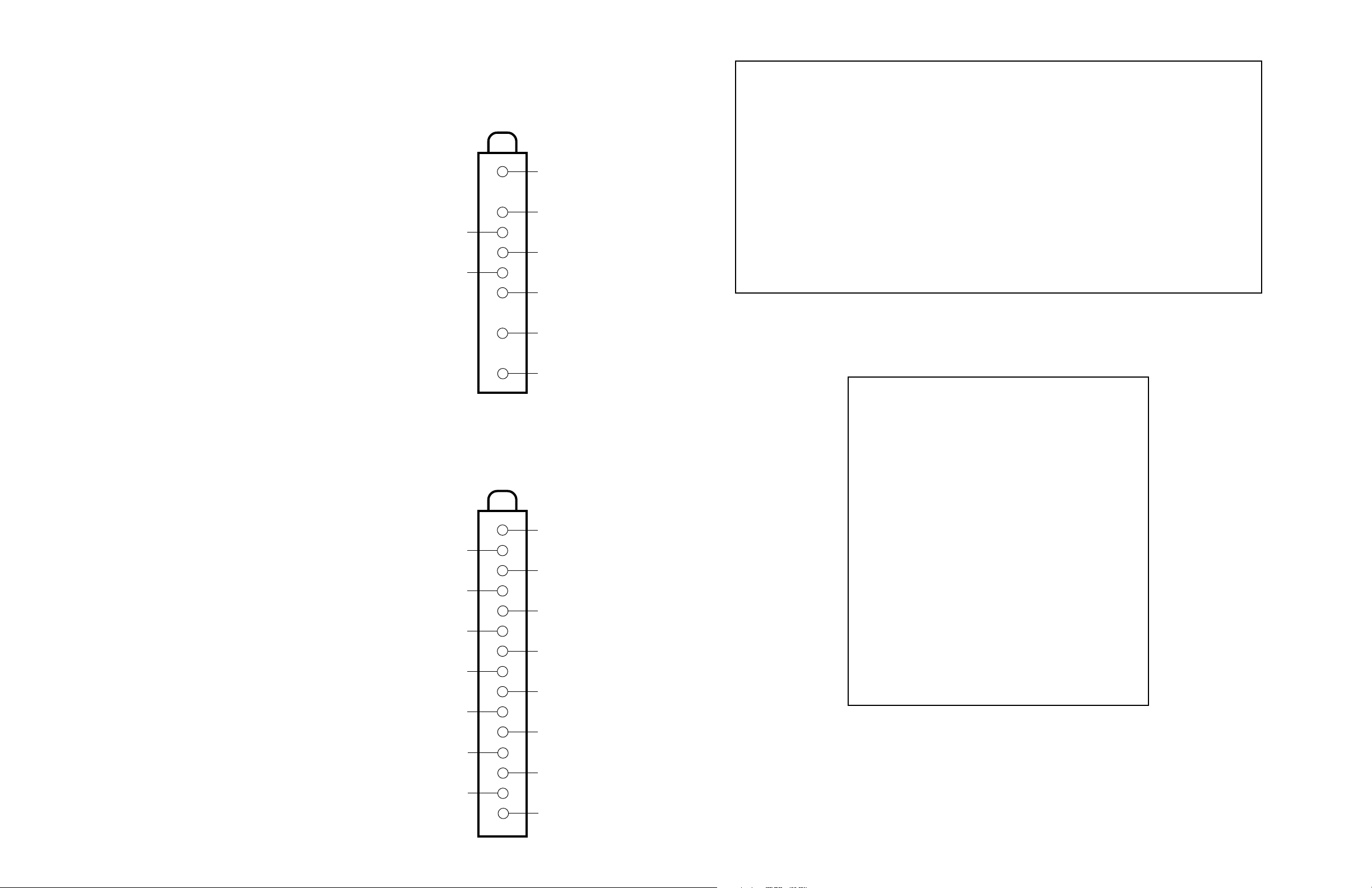

MAIN TUNER TERMINAL GUIDE

(1)

(3)

(4)

(5)

(6)

(7)

(9)

(11)

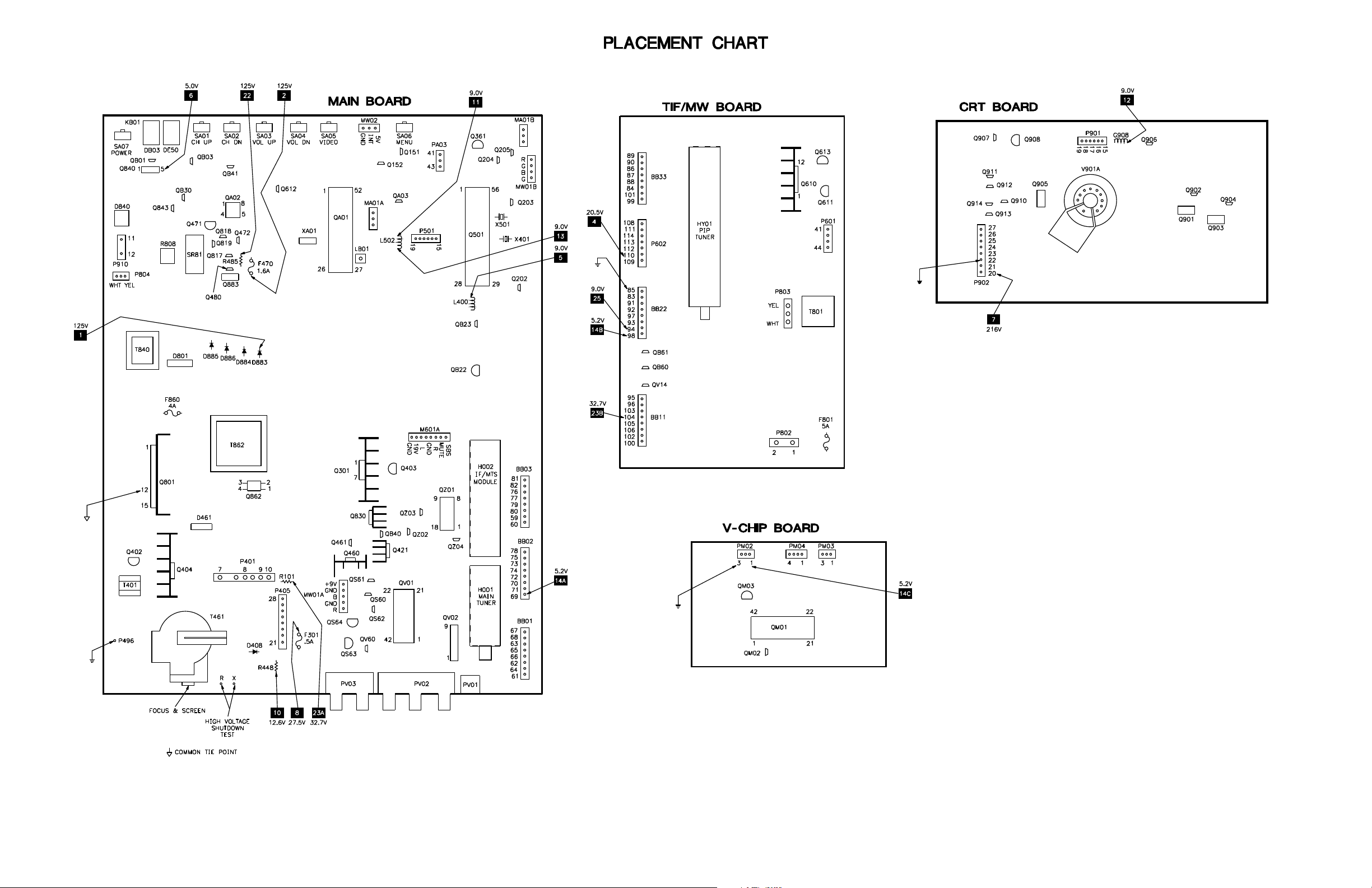

PIP TUNER TERMINAL GUIDE

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(10)

n Parts not listed in the parts list are commonly available at your local electronics parts retailer.

n The parts listed here are those not usually available from a well-stocked supply cabinet or bin.

n On the parts lists, safety items are marked with a # to remind you that only exact replacements are recommended for

these items.

n When ordering parts, state the model number, part number, and description.

Obtaining Parts

Many of these parts are available from your local Sams authorized distributor or the manufacturer of the equipment. Call

Sams for the name of your nearest distributor:

800-428-7267

TEST EQUIPMENT

Test equipment listed by participating manufacturer illustrates typical or

equivalent equipment used by Sams engineers to obtain measurements.

This equipment is compatible with most types used by field service

technicians.

Equipment Sencore No.

Oscilloscope SC3100

Generators

RGB CM2125

Multiburst Signal VG91

Color Bar VG91

TV Stereo VG91

Digital VOM SC3100

Frequency Meter SC3100

Hi-Voltage Probe HP200

Accessory Probes TP212

Isolation Transformer PR570

Capacitance Analyzer LC102

CRT Analyzer CR7000

AC Leakage Tester PR570

Inductance Analyzer LC102

Flyback Yoke Tester TVA92

Field Strength Meter SL753

Transistor Tester TF46

Horizontal Analyzer HA-2500

Video Analyzer VG91, TVA92

(12)

(14)

(11)

(13)

(15)

MISCELLANEOUS ADJUSTMENTS

SET 5266 Page 1

HIGH VOLTAGE CHECK

Tune in a picture. Set brightness, contrast, and color to minimum. Connect a high

voltage probe to the CRT anode. Model CZ32V61: high voltage should read 31kV

to 32.4kV. Model CZ36V61: high voltage should read 31.9kV to 33.3kV.

ENTERING THE SERVICE AND DESIGN MODES

To enter the service mode, press the mute button on the remote. Press the mute

button again and keep pressing while simultaneously pressing the menu button on

the receiver. The letter S will appear on the screen indicating that the receiver is in

the service mode.

To enter the design mode, enter the service mode and press and hold the recall

button while simultaneously pressing the menu button on the receiver. The letter D

will appear on the screen indicating that the receiver is in the design mode. No

items are to be adjusted according to the manufacturer. No information available

for option codes.

When in the service mode or design mode, press the menu button on the receiver to

display the adjustment menu. To select the item to be adjusted, press the channel up

or down button. To adjust the reference value, press the volume up or down button.

To exit from the service mode or the design mode, press the power button to turn

off the receiver.

TEST SIGNAL SELECTION

Enter the service mode. Press the menu button on the receiver to display the

adjustment menu. Press the TV/video button on the remote to display the built-in

test patterns in the following order:

Normal picture, red raster, green raster, blue raster, black screen, white screen,

black screen with white window, black cross bar, white cross bar, black crosshatch,

white crosshatch, black crossdot, white crossdot, white h signal, black h signal,

black cross bar on green raster, and back to normal picture. In some models the

audio test signal may not work with the white h signal, black h signal, black cross

bar on green raster test patterns.

NOTE: If a video cable is connected to the video input jack, the built-in test

patterns will not be displayed on the screen.

SELF DIAGNOSTIC FUNCTION

Enter the service mode. Press the 9 button on the remote to check for proper

execution of IC interfacing. The following is an explanation of what is displayed on

screen:

Display Explanation

[SELF CHECK] Self diagnostic function.

No. 23905036 Part number of QA01.

POWER : 000 Operation number of protecting circuit.

000 display is normal.

BUS LINE : OK BUS line check. OK is normal.

SCL-GND indicates a short to ground of

the SCL signal. SDA-GND indicates a

short to ground of the SDA signal.

SCL-SDA indicates a short between

SCL and SDA signals.

BUS CONT : OK Bus line acknowledge check. OK is

normal. A location number is NG.

QA02 NG indicates QA02 is bad.

BLOCK : UV V1 V2 Green display is normal. Cyan display is

QV01 QV01S no check. Red display is NG. UV is TV

mode, V1 is Video 1 mode, and

V2 is Video 2 mode. UV, V1, and V2

may not be used in some models.

To initialize the self diagnostic data, press and hold the recall button on the remote

while simultaneously pressing the channel down button on the receiver.

INITIALIZATION OF QA02

NOTE: QA02 must be initialized after replacement. Do not initialize QA02 unless

it has been replaced.

Enter the service mode. Press and hold the recall button on the remote while

simultaneously pressing the channel up button on the receiver. The initialization of

QA02 is complete. Program channels into memory.

ITEM BUTTONS

The following is a list of the buttons on the remote that will go to an item or

perform a different function of the service mode:

1 RCUT 5 COLC

2 GCUT 6 TNTC

3 BCUT 8 Toggles audio test signal on and off.

4 SCNT 9 Self diagnostics

SUB COLOR (COLC) & SUB TINT (TNTC)

Tune in a color bar pattern. Set contrast to maximum and brightness to midrange.

Connect an oscilloscope to the red cathode. Enter the service mode. Select item

COLC and adjust reference value to obtain 150Vp-p. Tune in an active channel.

Select item TNTC and adjust reference value for proper flesh tones.

SUB BRIGHTNESS (BRTC)

Tune in a picture. Set contrast to minimim and brightness to center. Enter the

service mode. Select item BRTC, adjust reference value until vertical retrace line

just disappears. Adjust contrast for normal picture. Perform Height (HIT)

adjustment.

HORIZONTAL POSITION (HPOS) /

VERTICAL POSITION (VPOS)

Enter the service mode. Press the TV/video button on remote until a crossbar

pattern is displayed. Select item HPOS or VPOS and adjust reference value for the

horizontal and vertical position alternately until the pattern is centered on the

screen. Check the position of the picture with off-air signal.

HEIGHT (HIT)

Enter the service mode. Press the TV/video button on remote until a crosshatch

pattern is displayed. Select item HIT and adjust reference value for slight

underscan. Advance the data value by 9 steps and check the vertical position of the

picture.

WIDTH (WID)

Enter the service mode. Press the TV/video button on reme until a crosshatch

pattern is displayed. Select item WID, adjust reference value for slight underscan.

Advance the reference value by 7 steps. Check for proper horizontal position of the

picture.

E-W PARABOLA (DPC)

Enter the service mode. Press the TV/video button on remote until a crosshatch

pattern is displayed. Select item DPC, adjust reference value for straight vertical

lines on both sides of the pattern.

WHITE BALANCE (RCUT, GCUT, BCUT, GDRV, BDRV)

Turn receiver on. Allow a 10 to 30 minute warm up time. Adjust contrast to center

and brightness to maximum. Enter the service mode. Press the TV/video button on

remote until the white screen pattern is displayed. Select items RCUT, GCUT,

BCUT, GDRV, and BDRV and set the reference value for each to 40H. Press the

TV/video button on the receiver to obtain a single horizontal line. Advance the

screen control until a faint line of one predominant color appears on the screen.

Adjust the other two cutoff items to obtain a dim white line. Press the TV/video

button on the receiver to get full deflection. Select items GDRV and BDRV and

adjust reference value of each for the best black and white picture on screen.

COLOR PURITY / CONVERGENCE

The yoke is bonded to the CRT. Color purity and convergence adjustments are not

recommended.

STEREO

Enter the service mode.

Attenuator (ATT)

Select item ATT. Input a 1kHz, 30% modulated signal. Connect a RMS meter to

pin 12 of H002. Adjust reference value to obtain a reading of 130mVrms.

Stereo VCO (STVC)

Select item STVC. Connect a frequency counter to pin 12 of H002 and connect pin

9 to ground. Adjust reference value to obtain a reading of 62.936kHz.

SAP VCO (SAVC)

Select item SAVC. Input 78.67kHz, 147mVrms to pin 9 of H002. Input a mono

signal. Adjust reference value for a reading in the center of the range for STA7=0

and STA8=1.

Stereo Filter (STRF)

Select item STRF. Input 9.4kHz, 600mVrms to pin 9 of H002. Input a mono signal.

Adjust reference value for a reading in the center of the range for STA3=1.

SAP Filter (SAPF)

Select item SAPF. Input 88kHz, 110mVrms to pin 9 of H002. Input a mono signal.

Adjust reference value for a reading in the center of the range for STA4=1.

Stereo Separation (WBAN) / Spectral (SPEC)

Select item WBAN. Input 300Hz, right channel signal. Select stereo mode on

receiver. Connect an oscilloscope to pin 14 of H002. Adjust reference value for

minimum amplitude of waveform. Select item SPEC. Input 3kHz, right channel

signal. Adjust reference value for minimum amplitude of waveform.

Audio Test Signal

Enter the service mode. Press the 8 button on remote transmitter to toggle the audio

test signal (1kHz) on and off.

SERVICE MODE ADJUSTMENT CHART

Adjustment Direct Preset 32 36

Item Name Button Value Value Value

RCUT Red Cutoff 1 40H 40H 40H

GCUT Green Cutoff 2 40H 40H 40H

BCUT Blue Cutoff 3 40H 40H 40H

GDRV Green Drive - 40H 40H 40H

BDRV Blue Drive - 40H 40H 40H

SCNT Sub Contrast 4 08H 08H 08H

BRTC Sub Brightness - 40H 40H 40H

COLC Sub Color 5 40H 40H 40H

TNTC Sub Tint 6 40H 40H 40H

SAVC SAP VCO - 88H 88H 88H

ATT Attenuator - 08H 08H 08H

SAPF SAP Filter - 88H 88H 88H

STVC Stereo VCO - 1CH 1CH 1CH

STRF Stereo Filter - 16H 16H 16H

SPEC Spectral - 30H 30H 30H

WBAN Stereo Separation - 22H 22H 22H

HPOS Horizontal Position - 16H 16H 16H

VPOS Vertical Position - 03H 03H 03H

HIT Height - 1EH 1EH 1EH

LIN Vertical Linearity - 07H 06H 06H

VSC Vertical S Correction - 01H 04H 04H

VPS Vertical Shift - 1BH 1BH 1BH

VCP Vertical Compensation - 03H 03H 03H

WID Width - 37H 18H 35H

DPC E-W Parabola - 17H 0AH 17H

CNR E-W Corner - 07H 07H 09H

TRAP Trapezium - 0EH 09H 08H

HCP Horizontal Compensation - 00H 00H 00H

VFC Vertical F Correction - 0FH 0FH 0FH

PCOL (1) PIP Color - 08H 08H 08H

PHUE (1) PIP Tint - 00H 00H 00H

DAC - - 03H 03H 03H

PGOF (1) - - 00H 00H 00H

PROF (1) - - 0AH 0AH 0AH

PBOF (1) - - 0AH 0AH 0AH

(1) Adjust to match PIP brightness, white balance, tint, and color to main screen.

TOSHIBA MODEL CZ36V61 (CHASSIS TAC9922)

PHILIPS MODEL 32PT5441/37 (CHASSIS L04.1UAA)

SET 5266 Page 1

Loading...

Loading...