Page 1

FILE NO. A10-031

SERVICE MANUAL

SPLIT TYPE

INDOOR UNIT <DIGITAL INVERTER>

Compact 4-way Cassette Type

RAV-SM404MUT-E RAV-SM404MUT-TR

RAV-SM454MUT-E RAV-SM454MUT-TR

RAV-SM564MUT-E RAV-SM564MUT-TR

Concealed Duct Type

RAV-SM564BT-E RAV-SM564BT-TR

RAV-SM804BT-E RAV-SM804BT-TR

RAV-SM1104BT-E RAV-SM1104BT-TR

RAV-SM1404BT-E RAV-SM1404BT-TR

Ceiling Type

RAV-SM564CT-E RAV-SM564CT-TR

RAV-SM804CT-E RAV-SM804CT-TR

RAV-SM1104CT-E RAV-SM1104CT-TR

RAV-SM1404CT-E RAV-SM1404CT-TR

R410A

PRINTED IN JAPAN, Apr., 2011 ToMo

Page 2

NOTE

A direct current motor is adopted for indoor fan motor in the Concealed Duct Standard Type air conditioner.

Caused from its characteristics, a current limit works on the direct current motor. When replacing the

high-performance filter or when opening the service board, be sure to stop the fan. If an above action is

executed during the fan operation, the protective control works to stop the unit operation, and the check

code “P12” may be issued. However it is not a trouble. When the desired operation has finished, be sure to

reset the system to clear “P12” error code using the leak breaker of the indoor unit. Then push the

operation stop button of the remote controller to return to the usual operation.

CONTENTS

ORIGINAL INSTRUCTION ................................................................................ 4

WARNING INDICATIONS ON THE AIR CONDITIONER UNIT6

PRECAUTION FOR SAFETY ............................................................................ 7

NEW REFRIGERANT (R410A) ....................................................................... 13

1. Safety Caution Concerned to New Refrigerant .................................................... 13

2. Cautions on Installation/Service............................................................................ 13

3. Pipe Materials .......................................................................................................... 13

1. AIR DUCTING WORK............................................................................... 15

1-1. Static Pressure Characteristics ....................................................................... 15

2. CONSTRUCTION VIEWS (EXTERNAL VIEWS) ...................................... 17

2-1. Compact 4-way Cassette Type ......................................................................... 17

2-2. Concealed Duct Type ........................................................................................ 18

2-3. Ceiling Type ....................................................................................................... 19

3. WIRING DIAGRAM ................................................................................... 20

3-1. Indoor Unit......................................................................................................... 20

4. SPECIFICATIONS OF ELECTRICAL PARTS .......................................... 23

4-1. Compact 4-way Cassette Type ......................................................................... 23

4-2. Concealed Duct Type ........................................................................................ 23

4-3. Ceiling Type ....................................................................................................... 23

5. CONTROL BLOCK DIAGRAM ................................................................. 24

5-1. Indoor Controller Block Diagram ..................................................................... 24

5-2. Control Specifications...................................................................................... 27

5-3. Indoor Print Circuit Board................................................................................ 40

– 2 –

Page 3

6. TROUBLESHOOTING .............................................................................. 42

6-1. Summary of Troubleshooting ........................................................................... 42

6-2. Check Code List (Indoor) ................................................................................. 47

6-3. Diagnostic Procedure for Each Check Code (Indoor Unit)............................ 52

7. REPLACEMENT OF SERVICE P.C. BOARD ........................................... 64

7-1. Indoort Unit ....................................................................................................... 64

8. SETUP AT LOCAL SITE AND OTHERS .................................................. 68

8-1. Indoor Unit......................................................................................................... 68

8-2. Setup at Local Site / Others ............................................................................. 78

8-3. How to Set up Central Control Address Number ........................................... 80

9. ADDRESS SETUP.................................................................................... 82

9-1. Address Setup .................................................................................................. 82

9-2. Address Setup & Group Control ...................................................................... 83

9-3. Address Setup (Manual Setting from Remote Controller) ............................. 86

9-4. Confirmation of Indoor Unit No. Position ....................................................... 87

10. DETACHMENTS ....................................................................................... 88

10-1. Compact 4-Way Cassette Type ........................................................................ 88

10-2. Concealed Duct Type ........................................................................................ 97

10-3. Ceiling Type ..................................................................................................... 100

11. EXPLODED VIEWS AND PARTS LIST .................................................. 104

11-1. Compact 4-way Cassette Type ....................................................................... 104

11-2. Concealed Duct Type ...................................................................................... 108

11-3. Ceiling Type ..................................................................................................... 115

– 3 –

Page 4

Original instruction

Please read carefully through these instructions that contain important information which complies with the

“Machinery” Directive (Directive 2006/42/EC), and ensure that you understand them.

Generic Denomination: Air Conditioner

Definition of Qualified Installer or Qualified Service Person

The air conditioner must be installed, maintained, repaired and removed by a qualified installer or qualified

service person.

When any of these jobs is to be done, ask a qualified installer or qualified service person to do them for you.

A qualified installer or qualified service person is an agent who has the qualifications and knowledge

described in the table below.

Agent

Qualified

installer (∗1)

Qualified service

person (∗1)

Qualifications and knowledge which the agent must have

• The qualified installer is a person who installs, maintains, relocates and removes the air

conditioners made by Toshiba Carrier Corporation.

He or she has been trained to install, maintain, relocate and remove the air conditioners made by

Toshiba Carrier Corporation or, alternatively, he or she has been instructed in such operations by

an individual or individuals who have been trained and is thus thoroughly acquainted with the

knowledge related to these operations.

• The qualified installer who is allowed to do the electrical work involved in installation, relocation

and removal has the qualifications pertaining to this electrical work as stipulated by the local laws

and regulations, and he or she is a person who has been trained in matters relating to electrical

work on the air conditioners made by Toshiba Carrier Corporation or, alternatively, he or she has

been instructed in such matters by an individual or individuals who have been trained and is thus

thoroughly acquainted with the knowledge related to this work.

• The qualified installer who is allowed to do the refrigerant handling and piping work involved in

installation, relocation and removal has the qualifications pertaining to this refrigerant handling

and piping work as stipulated by the local laws and regulations, and he or she is a person who

has been trained in matters relating to refrigerant handling and piping work on the air conditioners

made by Toshiba Carrier Corporation or, alternatively, he or she has been instructed in such

matters by an individual or individuals who have been trained and is thus thoroughly acquainted

with the knowledge related to this work.

• The qualified installer who is allowed to work at heights has been trained in matters relating to

working at heights with the air conditioners made by Toshiba Carrier Corporation or, alternatively,

he or she has been instructed in such matters by an individual or individuals who have been

trained and is thus thoroughly acquainted with the knowledge related to this work.

• The qualified service person is a person who installs, repairs, maintains, relocates and removes

the air conditioners made by Toshiba Carrier Corporation. He or she has been trained to install,

repair, maintain, relocate and remove the air conditioners made by Toshiba Carrier Corporation or,

alternatively, he or she has been instructed in such operations by an individual or individuals who

have been trained and is thus thoroughly acquainted with the knowledge related to these operations.

• The qualified service person who is allowed to do the electrical work involved in installation,

repair, relocation and removal has the qualifications pertaining to this electrical work as stipulated

by the local laws and regulations, and he or she is a person who has been trained in matters

relating to electrical work on the air conditioners made by Toshiba Carrier Corporation or,

alternatively, he or she has been instructed in such matters by an individual or individuals who

have been trained and is thus thoroughly acquainted with the knowledge related to this work.

• The qualified service person who is allowed to do the refrigerant handling and piping work

involved in installation, repair, relocation and removal has the qualifications pertaining to this

refrigerant handling

she is a person who has been trained in matters relating to refrigerant handling and piping

work on the air conditioners made by Toshiba Carrier Corporation or, alternatively, he or she

has been instructed in such matters by an individual or individuals who have been trained

and is thus thoroughly acquainted with the knowledge related to this work.

• The qualified service person who is allowed to work at heights has been trained in matters

relating to working at heights with the air conditioners made by Toshiba Carrier Corporation or,

alternatively, he or she has been instructed in such matters by an individual or individuals who

have been trained and is thus thoroughly acquainted with the knowledge related to this work.

and piping work as stipulated by the local laws and regulations, and he or

– 4 –

Page 5

Definition of Protective Gear

When the air conditioner is to be transported, installed, maintained, repaired or removed, wear protective

gloves and ‘safety’ work clothing.

In addition to such normal protective gear, wear the protective gear described below when undertaking the

special work detailed in the table below.

Failure to wear the proper protective gear is dangerous because you will be more susceptible to injury, burns,

electric shocks and other injuries.

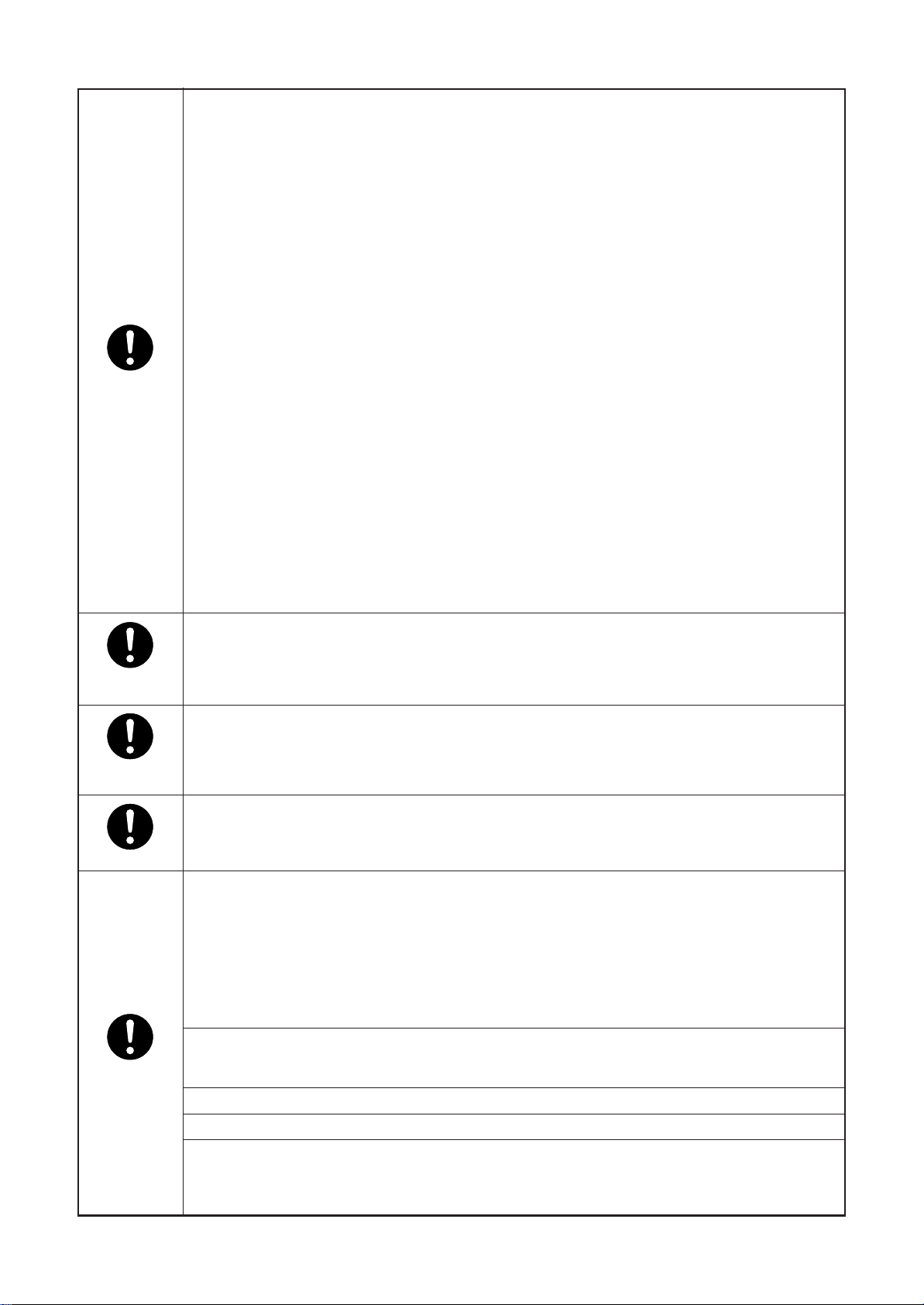

Work undertaken

All types of work

Electrical-related work

Work done at heights (50 cm or more)

Transportation of heavy objects

Repair of outdoor unit

Protective gloves

“Safety” working clothing

Gloves to provide protection for electricians and from heat

Insulating shoes

Clothing to provide protection from electric shock

Helmets for use in industry

Shoes with additional protective toe cap

Gloves to provide protection for electricians and from heat

Protective gear worn

The important contents concerned to the safety are described on the product itself and on this Service Manual.

Please read this Service Manual after understanding the described items thoroughly in the following contents

(Indications/Illustrated marks), and keep them.

[Explanation of indications]

Indication

Explanation

DANGER

WARNING

CAUTION

Indicates contents assumed that an imminent danger causing a death or serious injury of

the repair engineers and the third parties when an incorrect work has been executed.

Indicates possibilities assumed that a danger causing a death or serious injury of the

repair engineers, the third parties, and the users due to troubles of the product after work

when an incorrect work has been executed.

Indicates contents assumed that an injury or property damage (∗) may be caused on the

repair engineers, the third parties, and the users due to troubles of the product after work

when an incorrect work has been executed.

∗ Property damage : Enlarged damage concerned to property, furniture, and domestic animal/pet

[Explanation of illustrated marks]

Mark Explanation

Indicates prohibited items (Forbidden items to do)

The sentences near an illustrated mark describe the concrete prohibited contents.

Indicates mandatory items (Compulsory items to do)

The sentences near an illustrated mark describe the concrete mandatory contents.

Indicates cautions (Including danger/warning)

The sentences or illustration near or in an illustrated mark describe the concrete cautious contents.

– 5 –

Page 6

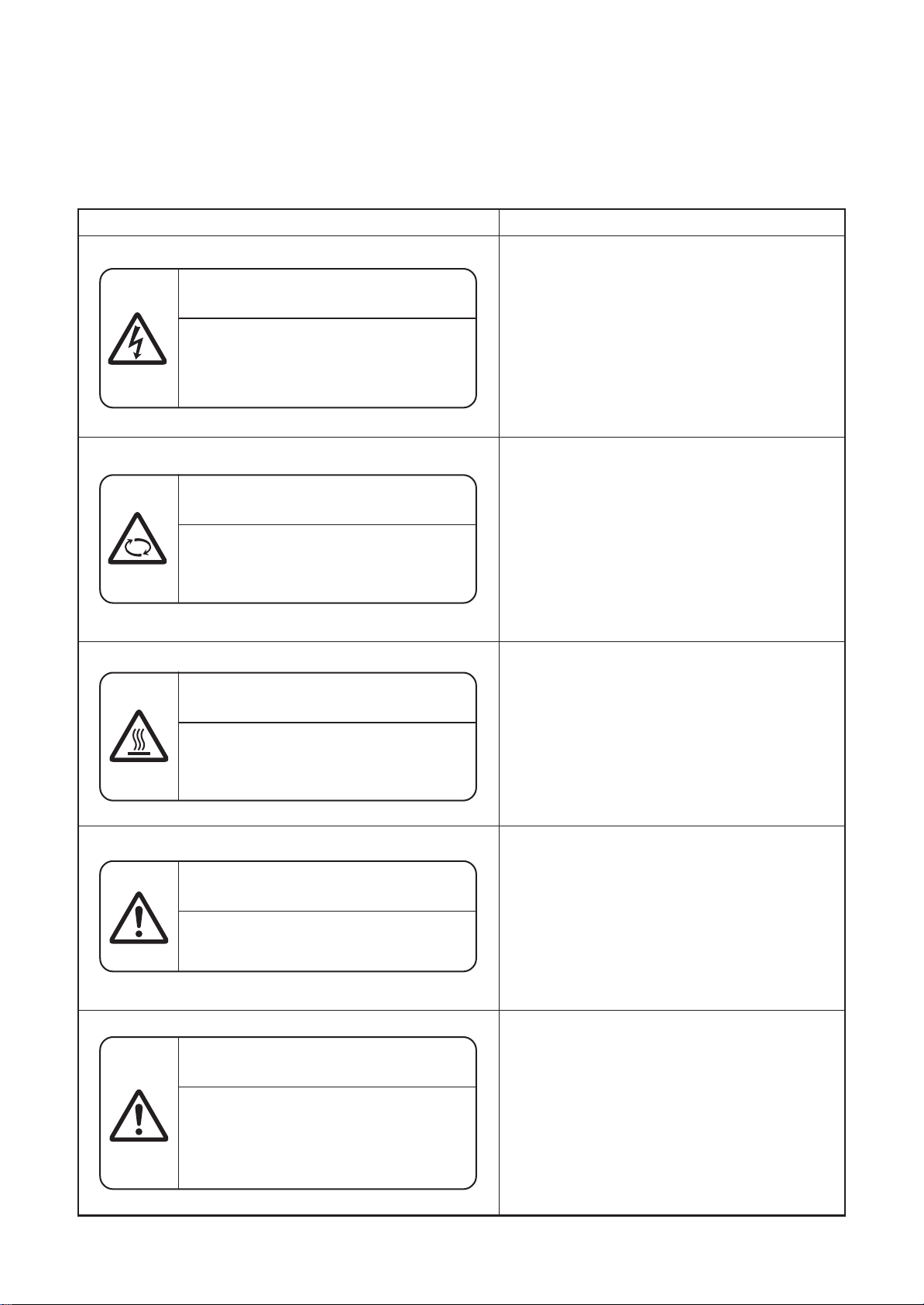

Warning Indications on the Air Conditioner Unit

[Confirmation of warning label on the main unit]

Confirm that labels are indicated on the specified positions

If removing the label during parts replace, stick it as the original.

Warning indication

WARNING

ELECTRICAL SHOCK HAZARD

Disconnect all remote electric

power supplies before servicing.

WARNING

Moving parts.

Do not operate unit with grille removed.

Stop the unit before the servicing.

Description

WARNING

ELECTRICAL SHOCK HAZARD

Disconnect all remote electric power supplies

before servicing.

WARNING

Moving parts.

Do not operate unit with grille removed.

Stop the unit before the servicing.

CAUTION

High temperature parts.

You might get burned when removing

this panel.

CAUTION

Do not touch the aluminum fins of the unit.

Doing so may result in injury.

CAUTION

BURST HAZARD

Open the service valves before the

operation, otherwise there might be the

burst.

CAUTION

High temperature parts.

You might get burned when removing this panel.

CAUTION

Do not touch the aluminum fins of the unit.

Doing so may result in injury.

CAUTION

BURST HAZARD

Open the service valves before the operation,

otherwise there might be the burst.

– 6 –

Page 7

Precaution for Safety

The manufacturer shall not assume any liability for the damage caused by not observing the description of this

manual.

WARNING

Before starting to repair the air conditioner, read carefully through the Service Manual, and repair

the air conditioner by following its instructions.

Only qualified service person (∗1) is allowed to repair the air conditioner.

Repair of the air conditioner by unqualified person may give rise to a fire, electric shocks, injury,

water leaks and/or other problems.

Only a qualified installer (∗1) or qualified service person (∗1) is allowed to carry out the electrical

work of the air conditioner.

Under no circumstances must this work be done by an unqualified individual since failure to carry

out the work properly may result in electric shocks and/or electrical leaks.

Wear protective gloves and safety work clothing during installation, servicing and removal.

When connecting the electrical wires, repairing the electrical parts or undertaking other electrical

jobs, wear gloves to provide protection for electricians and from heat, insulating shoes and

clothing to provide protection from electric shocks.

Failure to wear this protective gear may result in electric shocks.

Use wiring that meets the specifications in the Installation Manual and the stipulations in the local

regulations and laws. Use of wiring which does not meet the specifications may give rise to

electric shocks, electrical leakage, smoking and/or a fire.

Only a qualified installer (∗1) or qualified service person (∗1) is allowed to undertake work at heights

General

using a stand of 50 cm or more or to remove the intake grille of the indoor unit to undertake work.

When working at heights, use a ladder which complies with the ISO 14122 standard, and follow

the procedure in the ladder’s instructions.

Also wear a helmet for use in industry as protective gear to undertake the work.

When working at heights, put a sign in place so that no-one will approach the work location,

before proceeding with the work.

Parts and other objects may fall from above, possibly injuring a person below.

Do not touch the aluminum fin of the outdoor unit.

You may injure yourself if you do so. If the fin must be touched for some reason, first put on

protective gloves and safety work clothing, and then proceed.

Do not climb onto or place objects on top of the outdoor unit.

You may fall or the objects may fall off of the outdoor unit and result in injury.

When transporting the air conditioner, wear shoes with additional protective toe caps.

When transporting the air conditioner, do not take hold of the bands around the packing carton.

You may injure yourself if the bands should break.

This air conditioner has passed the pressure test as specified in IEC 60335-2-40 Annex EE.

DENGER

Before carrying out the installation, maintenance, repair or removal work, be sure to set the circuit

breaker to the OFF position. Otherwise, electric shocks may result.

Before opening the intake grille of the indoor unit or service panel of the outdoor unit, set the

circuit breaker to the OFF position. Failure to set the circuit breaker to the OFF position may result

in electric shocks through contact with the interior parts.

Only a qualified installer (∗1) or qualified service person (∗1) is allowed to remove the intake grille

of the indoor unit or service panel of the outdoor unit and do the work required.

Turn off

breaker.

Before starting to repair the outdoor unit fan or fan guard, be absolutely sure to set the circuit

breaker to the OFF position, and place a “Work in progress” sign on the circuit breaker.

When cleaning the filter or other parts of the indoor unit, set the circuit breaker to OFF without

fail, and place a “Work in progress” sign near the circuit breaker before proceeding with the work.

– 7 –

Page 8

Execute

discharge

between

terminals.

Prohibition

Stay on

protection

WARNING

Check earth

wires.

Even if the circuit breaker has been set to the OFF position before the service panel is removed

and the electrical parts are repaired, you will still risk receiving an electric shock.

For this reason, short-circuit the high-voltage capacitor terminals to discharge the voltage before

proceeding with the repair work.

For details on the short-circuiting procedure, refer to the Service Manual.

You may receive an electric shock if the voltage stored in the capacitors has not been sufficiently

discharged.

Place a “Work in progress” sign near the circuit breaker while the installation, maintenance, repair

or removal work is being carried out.

There is a danger of electric shocks if the circuit breaker is set to ON by mistake.

If, in the course of carrying out repairs, it becomes absolutely necessary to check out the

electrical parts with the electrical parts box cover of one or more of the indoor units and the

service panel of the outdoor unit removed in order to find out exactly where the trouble lies, wear

insulated heat-resistant gloves, insulated boots and insulated work overalls, and take care to

avoid touching any live parts.

You may receive an electric shock if you fail to heed this warning. Only qualified service person

(∗1) is allowed to do this kind of work.

Before troubleshooting or repair work, check the earth wire is connected to the earth terminals of

the main unit, otherwise an electric shock is caused when a leak occurs.If the earth wire is not

correctly connected, contact an electric engineer for rework.

After completing the repair or relocation work, check that the ground wires are connected properly.

Be sure to connect earth wire. (Grounding work) Incomplete grounding causes an electric shock.

Do not connect ground wires to gas pipes, water pipes, and lightning rods or ground wires for

telephone wires.

Do not modify the products.Do not also disassemble or modify the parts.

It may cause a fire, electric shock or injury.

Prohibition of

modification.

Use specified

parts.

Do not bring

a child close to

the equipment.

Insulating

measures

No fire

When any of the electrical parts are to be replaced, ensure that the replacement parts satisfy the

specifications given in the Service Manual (or use the parts contained on the parts list in the

Service Manual).

Use of any parts which do not satisfy the required specifications may give rise to electric shocks,

smoking and/or a fire.

If, in the course of carrying out repairs, it becomes absolutely necessary to check out the

electrical parts with the electrical parts box cover of one or more of the indoor units and the

service panel of the outdoor unit removed in order to find out exactly where the trouble lies, place

"Keep out" signs around the work site before proceeding.

Third-party individuals may enter the work site and receive electric shocks if this warning is not

heeded.

Connect the cut-off lead wires with crimp contact, etc, put the closed end side upward and then

apply a water-cut method, otherwise a leak or production of fire is caused at the users’ side.

When performing repairs using a gas burner, replace the refrigerant with nitrogen gas because

the oil that coats the pipes may otherwise burn.

When repairing the refrigerating cycle, take the following measures.

1) Be attentive to fire around the cycle.

When using a gas stove, etc, be sure to put out fire before work; otherwise the oil mixed with

refrigerant gas may catch fire.

2) Do not use a welder in the closed room.

When using it without ventilation, carbon monoxide poisoning may be caused.

3) Do not bring inflammables close to the refrigerant cycle, otherwise fire of the welder may catch

the inflammables.

– 8 –

Page 9

Refrigerant

Assembly/

Cabling

Insulator

check

Ventilation

Compulsion

The refrigerant used by this air conditioner is the R410A.

Check the used refrigerant name and use tools and materials of the parts which match with it.

For the products which use R410A refrigerant, the refrigerant name is indicated at a position on

the outdoor unit where is easy to see.

To prevent miss-charging, the route of the service port is changed from one of the former R22.

Do not use any refrigerant different from the one specified for complement or replacement.

Otherwise, abnormally high pressure may be generated in the refrigeration cycle, which may

result in a failure or explosion of the product or an injury to your body.

For an air conditioner which uses R410A, never use other refrigerant than R410A.

For an air conditioner which uses other refrigerant (R22, etc.), never use R410A.

If different types of refrigerant are mixed, abnormal high pressure generates in the refrigerating

cycle and an injury due to breakage may be caused.

Do not charge refrigerant additionally.

If charging refrigerant additionally when refrigerant gas leaks, the refrigerant composition in the

refrigerating cycle changes resulted in change of air conditioner characteristics or refrigerant over

the specified standard amount is charged and an abnormal high pressure is applied to the inside

of the refrigerating cycle resulted in cause of breakage or injury.

Therefore if the refrigerant gas leaks, recover the refrigerant in the air conditioner, execute

vacuuming, and then newly recharge the specified amount of liquid refrigerant.

In this time, never charge the refrigerant over the specified amount.

When recharging the refrigerant in the refrigerating cycle, do not mix the refrigerant or air other

than R410A into the specified refrigerant.

If air or others is mixed with the refrigerant, abnormal high pressure generates in the refrigerating

cycle resulted in cause of injury due to breakage.

After installation work, check the refrigerant gas does not leak.

If the refrigerant gas leaks in the room, poisonous gas generates when gas touches to fire such

as fan heater, stove or cocking stove though the refrigerant gas itself is innocuous.

Never recover the refrigerant into the outdoor unit.

When the equipment is moved or repaired, be sure to recover the refrigerant with recovering device.

The refrigerant cannot be recovered in the outdoor unit; otherwise a serious accident such as

breakage or injury is caused.

After repair work, surely assemble the disassembled parts, and connect and lead the removed

wires as before.

Perform the work so that the cabinet or panel does not catch the inner wires.

If incorrect assembly or incorrect wire connection was done, a disaster such as a leak or fire is

caused at user’s side.

After the work has finished, be sure to use an insulation tester set (500V Megger) to check the

resistance is 1MΩ or more between the charge section and the non-charge metal section

(Earth position).

If the resistance value is low, a disaster such as a leak or electric shock is caused at user’s side.

When the refrigerant gas leaks during work, execute ventilation.

If the refrigerant gas touches to a fire, poisonous gas generates.

A case of leakage of the refrigerant and the closed room full with gas is dangerous because a

shortage of oxygen occurs. Be sure to execute ventilation.

When the refrigerant gas leaks, find up the leaked position and repair it surely.

If the leaked position cannot be found up and the repair work is interrupted, pump-down and

tighten the service valve, otherwise the refrigerant gas may leak into the room.

The poisonous gas generates when gas touches to fire such as fan heater, stove or cocking stove

though the refrigerant gas itself is innocuous.

When installing equipment which includes a large amount of charged refrigerant such as a multi

air conditioner in a sub-room, it is necessary that the density does not the limit even if the

refrigerant leaks.

If the refrigerant leaks and exceeds the limit density, an accident of shortage of oxygen is caused.

Tighten the flare nut with a torque wrench in the specified manner.

Excessive tighten of the flare nut may cause a crack in the flare nut after a long period, which may

result in refrigerant leakage.

Nitrogen gas must be used for the airtight test.

The charge hose must be connected in such a way that it is not slack.

For the installation/moving/reinstallation work, follow to the Installation Manual.

If an incorrect installation is done, a trouble of the refrigerating cycle, water leak, electric shock or

fire is caused.

– 9 –

Page 10

Check after

repair

Do not

operate the

unit with the

valve closed.

Check after

reinstallation

Cooling check

Installation

Once the repair work has been completed, check for refrigerant leaks, and check the insulation

resistance and water drainage.

Then perform a trial run to check that the air conditioner is running properly.

After repair work has finished, check there is no trouble. If check is not executed, a fire, electric

shock or injury may be caused. For a check, turn off the power breaker.

After repair work (installation of front panel and cabinet) has finished, execute a test run to check

there is no generation of smoke or abnormal sound.

If check is not executed, a fire or an electric shock is caused. Before test run, install the front

panel and cabinet.

Check the following matters before a test run after repairing piping.

• Connect the pipes surely and there is no leak of refrigerant.

• The valve is opened.

Running the compressor under condition that the valve closes causes an abnormal high

pressure resulted in damage of the parts of the compressor and etc. and moreover if there is

leak of refrigerant at connecting section of pipes, the air is suctioned and causes further

abnormal high pressure resulted in burst or injury.

Only a qualified installer (∗1) or qualified service person (∗1) is allowed to relocate the air

conditioner. It is dangerous for the air conditioner to be relocated by an unqualified individual

since a fire, electric shocks, injury, water leakage, noise and/or vibration may result.

Check the following items after reinstallation.

1) The earth wire is correctly connected.

2) The power cord is not caught in the product.

3) There is no inclination or unsteadiness and the installation is stable.

If check is not executed, a fire, an electric shock or an injury is caused.

When carrying out the pump-down work shut down the compressor before disconnecting the

refrigerant pipe.

Disconnecting the refrigerant pipe with the service valve left open and the compressor still

operating will cause air, etc. to be sucked in, raising the pressure inside the refrigeration cycle to

an abnormally high level, and possibly resulting in reputing, injury, etc.

When the service panel of the outdoor unit is to be opened in order for the compressor or the

area around this part to be repaired immediately after the air conditioner has been shut down, set

the circuit breaker to the OFF position, and then wait at least 10 minutes before opening the

service panel.

If you fail to heed this warning, you will run the risk of burning yourself because the compressor

pipes and other parts will be very hot to the touch. In addition, before proceeding with the repair

work, wear the kind of insulated heat-resistant gloves designed to protect electricians.

When the service panel of the outdoor unit is to be opened in order for the fan motor, reactor,

inverter or the areas around these parts to be repaired immediately after the air conditioner has

been shut down, set the circuit breaker to the OFF position, and then wait at least 10 minutes

before opening the service panel.

If you fail to heed this warning, you will run the risk of burning yourself because the fan motor,

reactor, inverter heat sink and other parts will be very hot to the touch.

In addition, before proceeding with the repair work, wear the kind of insulated heat-resistant

gloves designed to protect electricians.

Only a qualified installer (∗1) or qualified service person (∗1) is allowed to install the air

conditioner. If the air conditioner is installed by an unqualified individual, a fire, electric shocks,

injury, water leakage, noise and/or vibration may result.

Before starting to install the air conditioner, read carefully through the Installation Manual, and

follow its instructions to install the air conditioner.

Do not install the air conditioner in a location that may be subject to a risk of expire to a

combustible gas.

If a combustible gas leaks and becomes concentrated around the unit, a fire may occur.

Install the indoor unit at least 2.5 m above the floor level since otherwise the users may injure

themselves or receive electric shocks if they poke their fingers or other objects into the indoor unit

while the air conditioner is running.

Install a circuit breaker that meets the specifications in the installation manual and the stipulations

in the local regulations and laws.

Install the circuit breaker where it can be easily accessed by the qualified service person (∗1).

Do not place any combustion appliance in a place where it is directly exposed to the wind of air

conditioner, otherwise it may cause imperfect combustion.

– 10 –

Page 11

Explanations given to user

• If you have discovered that the fan grille is damaged, do not approach the outdoor unit but set the circuit

breaker to the OFF position, and contact a qualified service person to have the repairs done. Do not set the

circuit breaker to the ON position until the repairs are completed.

Relocation

• Only a qualified installer (∗1) or qualified service person (∗1) is allowed to relocate the air conditioner.

It is dangerous for the air conditioner to be relocated by an unqualified individual since a fire, electric shocks,

injury, water leakage, noise and/or vibration may result.

• When carrying out the pump-down work shut down the compressor before disconnecting the refrigerant pipe.

Disconnecting the refrigerant pipe with the service valve left open and the compressor still operating will

cause air, etc. to be sucked in, raising the pressure inside the refrigeration cycle to an abnormally high level,

and possibly resulting in reputing, injury, etc.

(∗1) Refer to the “Definition of Qualified Installer or Qualified Service Person.”

Declaration of Conformity

Manufacturer: Toshiba Carrier Corporation

336 Tadehara, Fuji-shi, Shizuoka-ken 416-8521 JAPAN

Authorized Nick Ball

Representative/TCF holder: Toshiba EMEA Engineering Director

Toshiba Carrier UK Ltd.

Porsham Close, Belliver Industrial Estate,

PLYMOUTH, Devon, PL6 7DB.

United Kingdom

Hereby declares that the machinery described below:

Generic Denomination: Air Conditioner

Model/type: RAV-SM404MUT-E RAV-SM404MUT-TR

RAV-SM454MUT-E RAV-SM454MUT-TR

RAV-SM564MUT-E RAV-SM564MUT-TR

RAV-SM564BT-E RAV-SM564BT-TR

RAV-SM804BT-E RAV-SM804BT-TR

RAV-SM1104BT-E RAV-SM1104BT-TR

RAV-SM1404BT-E RAV-SM1404BT-TR

RAV-SM564CT-E RAV-SM564CT-TR

RAV-SM804CT-E RAV-SM804CT-TR

RAV-SM1104CT-E RAV-SM1104CT-TR

RAV-SM1404CT-E RAV-SM1404CT-TR

Commercial name: Digital Inverter Series / Super Digital Inverter Series Air Conditioner

Complies with the provisions of the “Machinery” Directive (Directive 2006/42/EC) and the regulations

transposing into national law.

Complies with the provisions of the following harmonized standard:

EN 378-2: 2008 / A1: 2009

Note: This declaration becomes invalid if technical or operational modifications are introduced without the

manufacturer’s consent.

– 11 –

Page 12

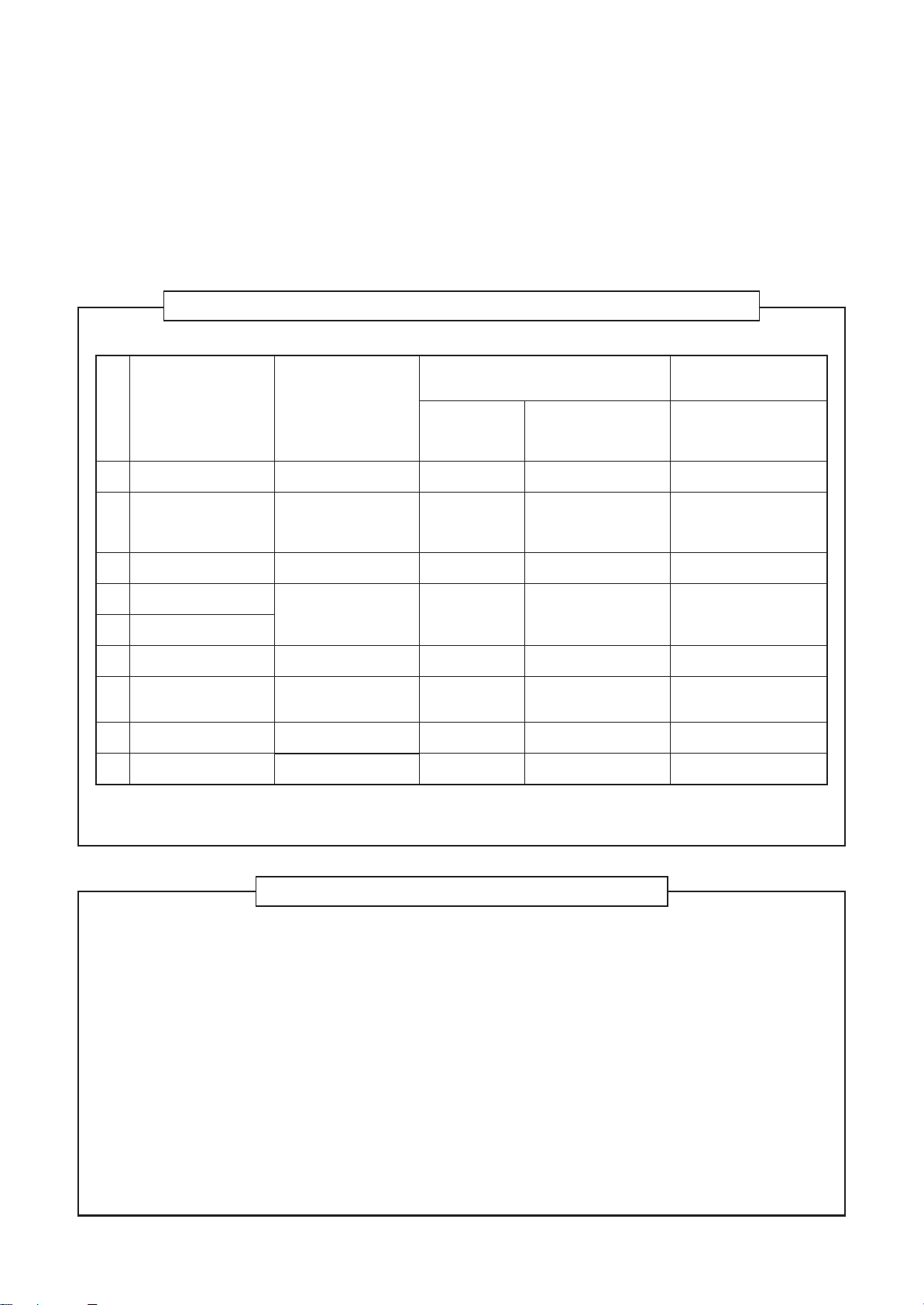

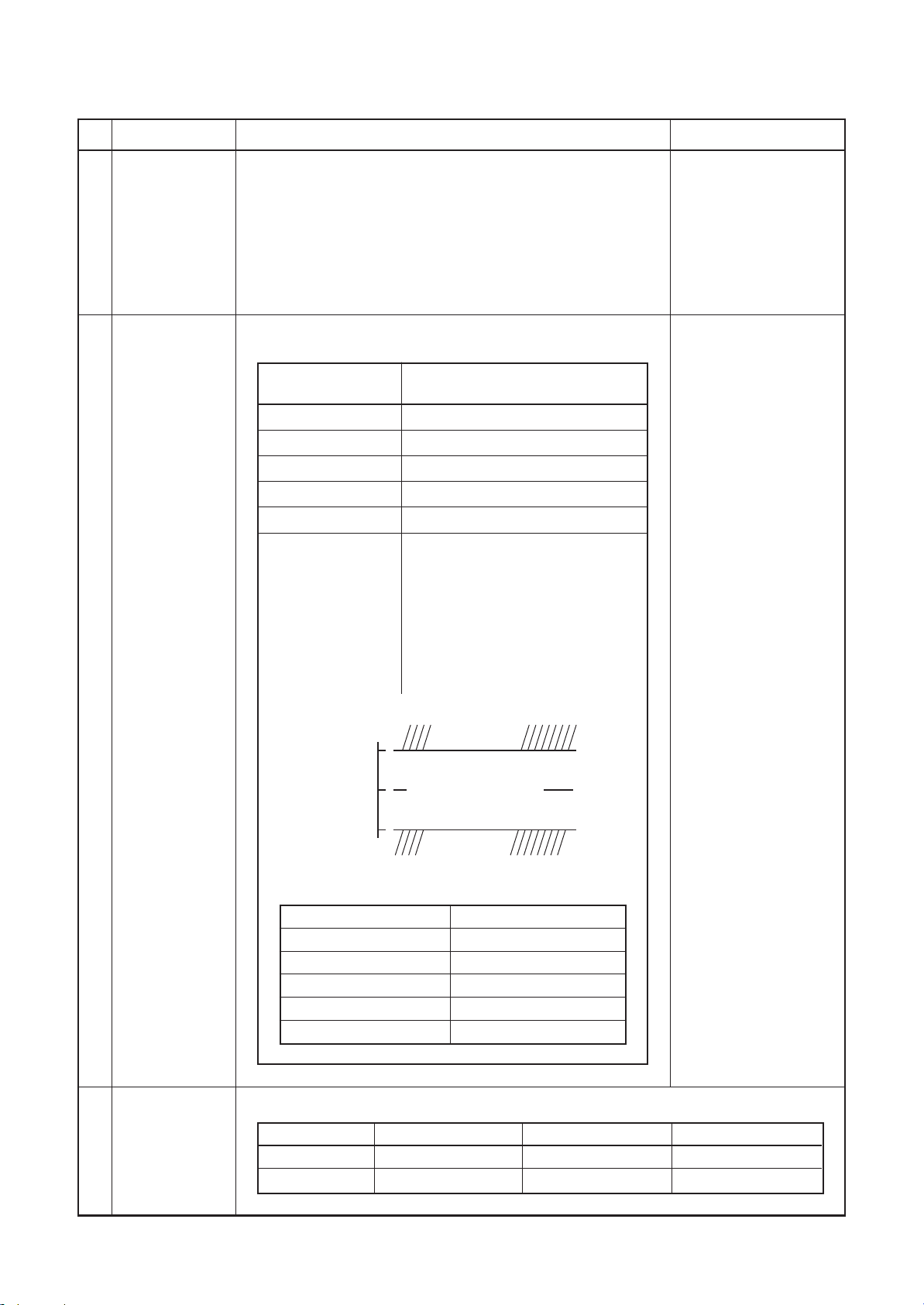

Specifications

Model

RAV-SM404MUT-E

RAV-SM454MUT-E

RAV-SM564MUT-E

RAV-SM404MUT-TR

RAV-SM454MUT-TR

RAV-SM564MUT-TR

RAV-SM564BT-E

RAV-SM804BT-E

RAV-SM1104BT-E

RAV-SM1404BT-E

RAV-SM564BT-TR

RAV-SM804BT-TR

Sound power level (dBA)

Cooling Heating

∗∗

∗∗

∗∗

∗∗

∗∗

∗∗

∗∗

∗∗

∗∗

∗∗

∗∗

∗∗

Weight (kg)

Main unit (Ceiling panel)

16 (3)

16 (3)

16 (3)

16 (3)

16 (3)

16 (3)

30

39

54

54

30

39

RAV-SM1104BT-TR

RAV-SM1404BT-TR

RAV-SM564CT-E

RAV-SM804CT-E

RAV-SM1104CT-E

RAV-SM1404CT-E

RAV-SM564CT-TR

RAV-SM804CT-TR

RAV-SM1104CT-TR

RAV-SM1404CT-TR

: Under 70 dBA

∗

• Other specifications than abovementioned models are equal to current models (2 series).

∗∗

∗∗

∗∗

∗∗

∗∗

∗∗

∗∗

∗∗

∗∗

∗∗

54

54

21

25

33

33

21

25

33

33

– 12 –

Page 13

New Refrigerant (R410A)

This air conditioner adopts a new HFC type refrigerant (R410A) which does not deplete the ozone layer.

1. Safety Caution Concerned to New Refrigerant

The pressure of R410A is high 1.6 times of that of the former refrigerant (R22).

Accompanied with change of refrigerant, the refrigerating oil has been also changed.

Therefore, be sure that water, dust, the former refrigerant or the former refrigerating oil is not mixed into the

refrigerating cycle of the air conditioner with new refrigerant during installation work or service work.

If an incorrect work or incorrect service is performed, there is a possibility to cause a serious accident.

Use the tools and materials exclusive to R410A to purpose a safe work.

2. Cautions on Installation/Service

1) Do not mix the other refrigerant or refrigerating oil.

For the tools exclusive to R410A, shapes of all the joints including the service port differ from those of

the former refrigerant in order to prevent mixture of them.

2) As the use pressure of the new refrigerant is high, use material thickness of the pipe and tools which are

specified for R410A.

3) In the installation time, use clean pipe materials and work with great attention so that water and others

do not mix in because pipes are affected by impurities such as water, oxide scales, oil, etc.

Use the clean pipes.

Be sure to brazing with flowing nitrogen gas. (Never use gas other than nitrogen gas.)

4) For the earth protection, use a vacuum pump for air purge.

5) R410A refrigerant is azeotropic mixture type refrigerant.

Therefore use liquid type to charge the refrigerant. (If using gas for charging, composition of the

refrigerant changes and then characteristics of the air conditioner change.)

3. Pipe Materials

For the refrigerant pipes, copper pipe and joints are mainly used.

It is necessary to select the most appropriate pipes to conform to the standard.

Use clean material in which impurities adhere inside of pipe or joint to a minimum.

1) Copper pipe

<Piping>

The pipe thickness, flare finishing size, flare nut and others differ according to a refrigerant type.

When using a long copper pipe for R410A, it is recommended to select “Copper or copper-base pipe

without seam” and one with bonded oil amount 40mg/10m or less.

Also do not use crushed, deformed, discolored (especially inside) pipes.

(Impurities cause clogging of expansion valves and capillary tubes.)

<Flare nut>

Use the flare nuts which are attached to the air conditioner unit.

2) Joint

The flare joint and socket joint are used for joints of the copper pipe.

The joints are rarely used for installation of the air conditioner.

However clear impurities when using them.

– 13 –

Page 14

4. Tools

1. Required Tools for R410A

Mixing of different types of oil may cause a trouble such as generation of sludge, clogging of capillary,

etc. Accordingly, the tools to be used are classified into the following three types.

1) Tools exclusive for R410A (Those which cannot be used for conventional refrigerant (R22))

2) Tools exclusive for R410A, but can be also used for conventional refrigerant (R22)

3) Tools commonly used for R410A and for conventional refrigerant (R22)

The table below shows the tools exclusive for R410A and their interchangeability.

Tools exclusive for R410A (The following tools for R410A are required.)

Tools whose specifications are changed for R410A and their interchangeability

No.

Q

R

S

T

U

V

W

X

Y

Used tool

Flare tool

Copper pipe gauge

for adjusting

projection margin

Torque wrench

Gauge manifold

Charge hose

Vacuum pump adapter

Electronic balance for

refrigerant charging

Refrigerant cylinder

Leakage detector

Usage

Pipe flaring

Flaring by

conventional flare tool

Tightening of flare nut

Evacuating, refrigerant

charge, run check, etc.

Vacuum evacuating

Refrigerant charge

Refrigerant charge

Gas leakage check

air conditioner installation

Existence of

new equipment

for R410A

Ye s ∗ (Note)

Ye s ∗ (Note)

Ye s N o

Ye s N o

Ye s N o

Ye s Ye s

Ye s N o

Ye s N o

R410A

Whether conventional

equipment can be used

Conventional air

conditioner installation

Whether

conventional equipment

can be used

Ye s

∗ (Note)

No

No

Ye s

Ye s

No

Ye s

(Note) When flaring is carried out for R410A using the conventional flare tools, adjustment of projection

margin is necessary. For this adjustment, a copper pipe gauge, etc. are necessary.

General tools (Conventional tools can be used.)

In addition to the above exclusive tools, the following equipments which serve also for R22 are necessary

as the general tools.

1) Vacuum pump. Use vacuum pump by

attaching vacuum pump adapter. 7) Screwdriver (+, –)

2) Torque wrench 8) Spanner or Monkey wrench

3) Pipe cutter 9) Hole core drill

4) Reamer 10) Hexagon wrench (Opposite side 4mm)

5) Pipe bender 11) Tape measure

6) Level vial 12) Metal saw

Also prepare the following equipments for other installation method and run check.

1) Clamp meter 3) Insulation resistance tester (Megger)

2) Thermometer 4) Electroscope

– 14 –

Page 15

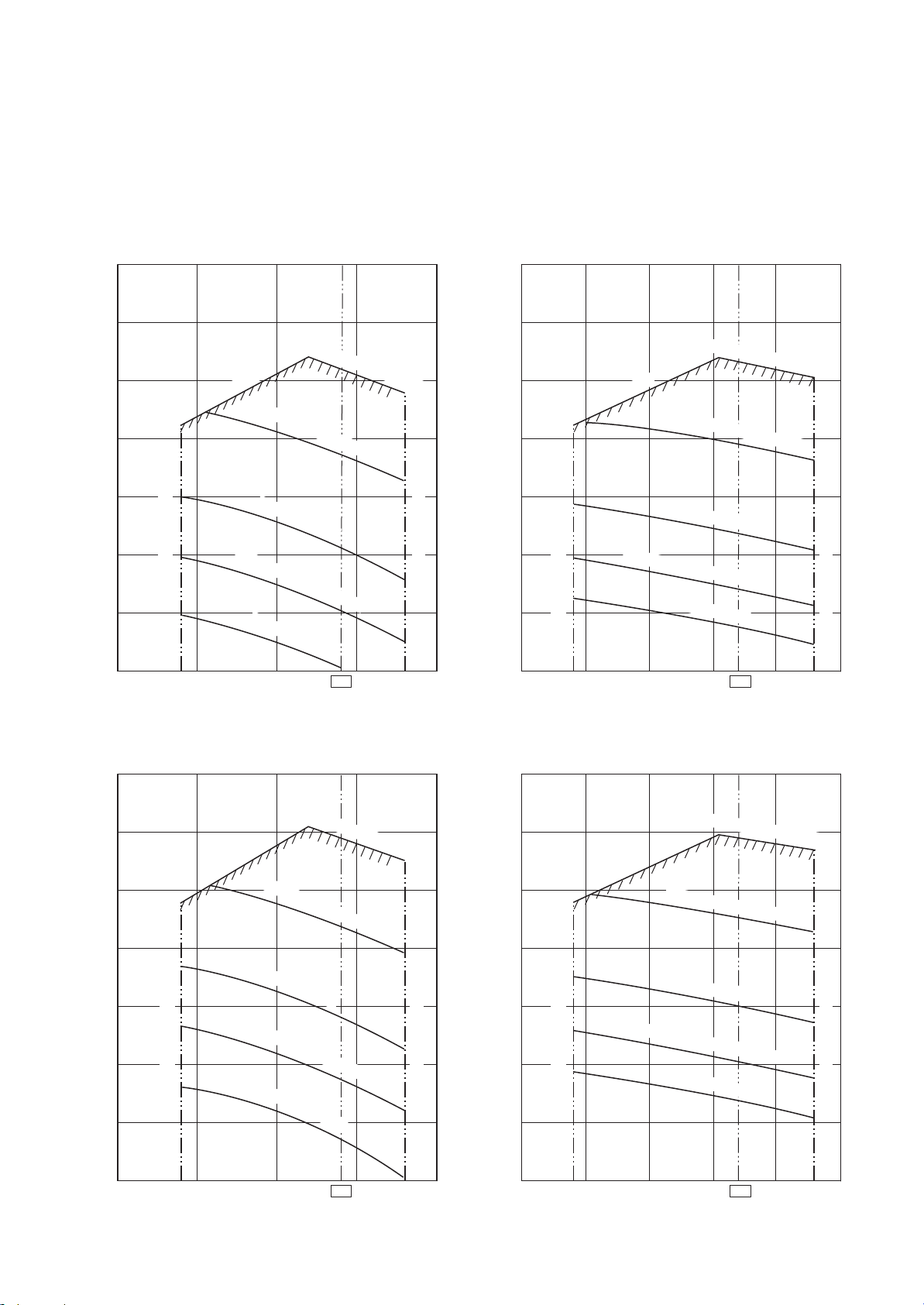

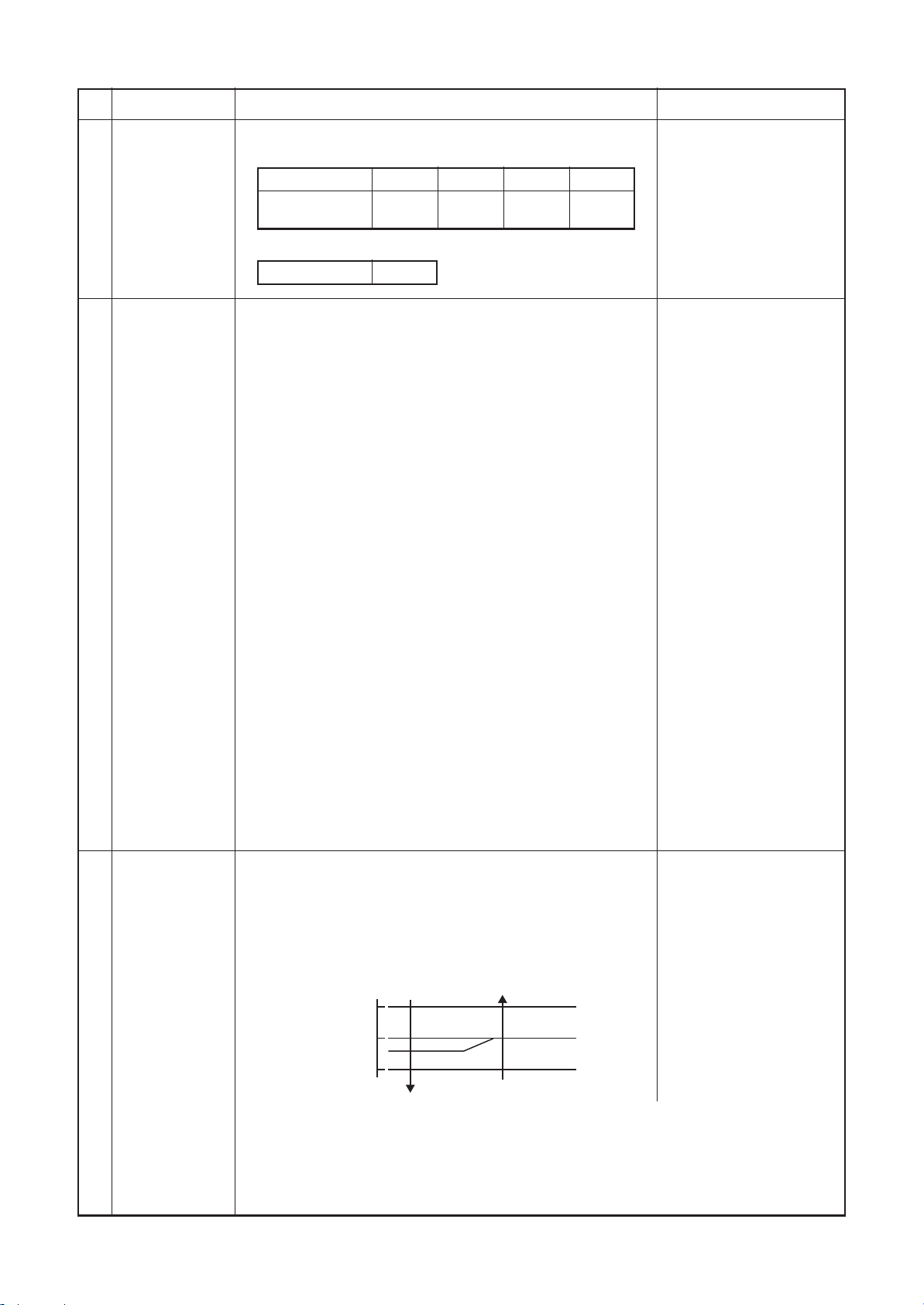

1. AIR DUCTING WORK

1-1. Static Pressure Characteristics

Concealed Duct type

RAV-SN564BT

∗∗

, RAV-SN804BT

∗

∗∗

∗∗

, RAV-SN1104BT

∗

∗∗

∗∗

, RAV-SN1404BT

∗

∗∗

∗∗

∗

∗∗

Fig. 1 SM56 type (Round duct)

140

120

100

Usable limit

80

60

Static pressure (Pa)

40

Air volume limit (Min.)

20

Standard air volume 780m³/h

High static pressure 2H tap

High static pressure 1H tap

Standard H tap

Lo

w static pressure H ta

Standard L tap

140

120

100

Static pressure (Pa)

Air volume limit (Max.)

p

Fig. 3 SM80 type (Round duct)

Standard air volume 1140m³/h

Usable limit

80

60

40

20

Air volume limit (Min.)

High static pressure 1H tap

Standard H tap

Low static pressure H tap

Standard L

High static pressure 2H tap

tap

Air volume limit (Max.)

0

500 700 780

Air volume m³/h

Fig. 2 SM56 type (Square duct)

140

120

108

100

80

60

Static pressure (Pa)

40

20

Usable limit

Air volume limit (Min.)

Standard air volume 780m³/h

High static pressure 2H tap

High static press

Standard H tap

Low static pressure H tap

Standard L tap

ure 1H tap

900

Air volume limit (Max.)

0

800 1000

140

120

100

80

60

Static pressure (Pa)

40

20

12001140 1300

Air volume m³/h

Fig. 4 SM80 type (Square duct)

Standard air volume 1140m³/h

High static pressure 2H tap

Usable limit

Air volume limit (Min.)

High static pressure 1H tap

Standard H tap

Low static pressure H tap

Standard L tap

Air volume limit (Max.)

0

500 700 780

Air volume m³/h

900

– 15 –

0

800 1000

Air volume m³/h

12001140 1300

Page 16

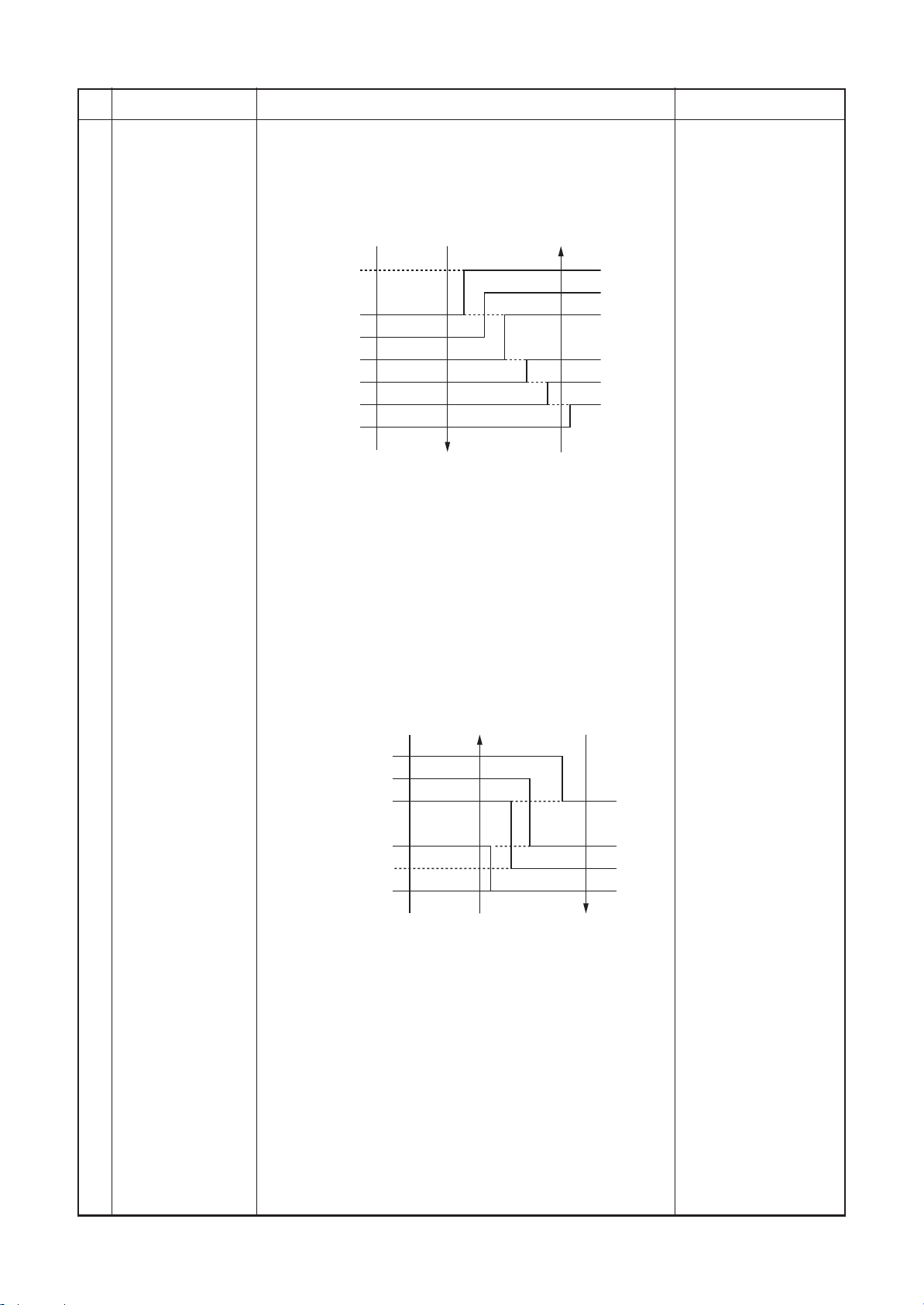

0

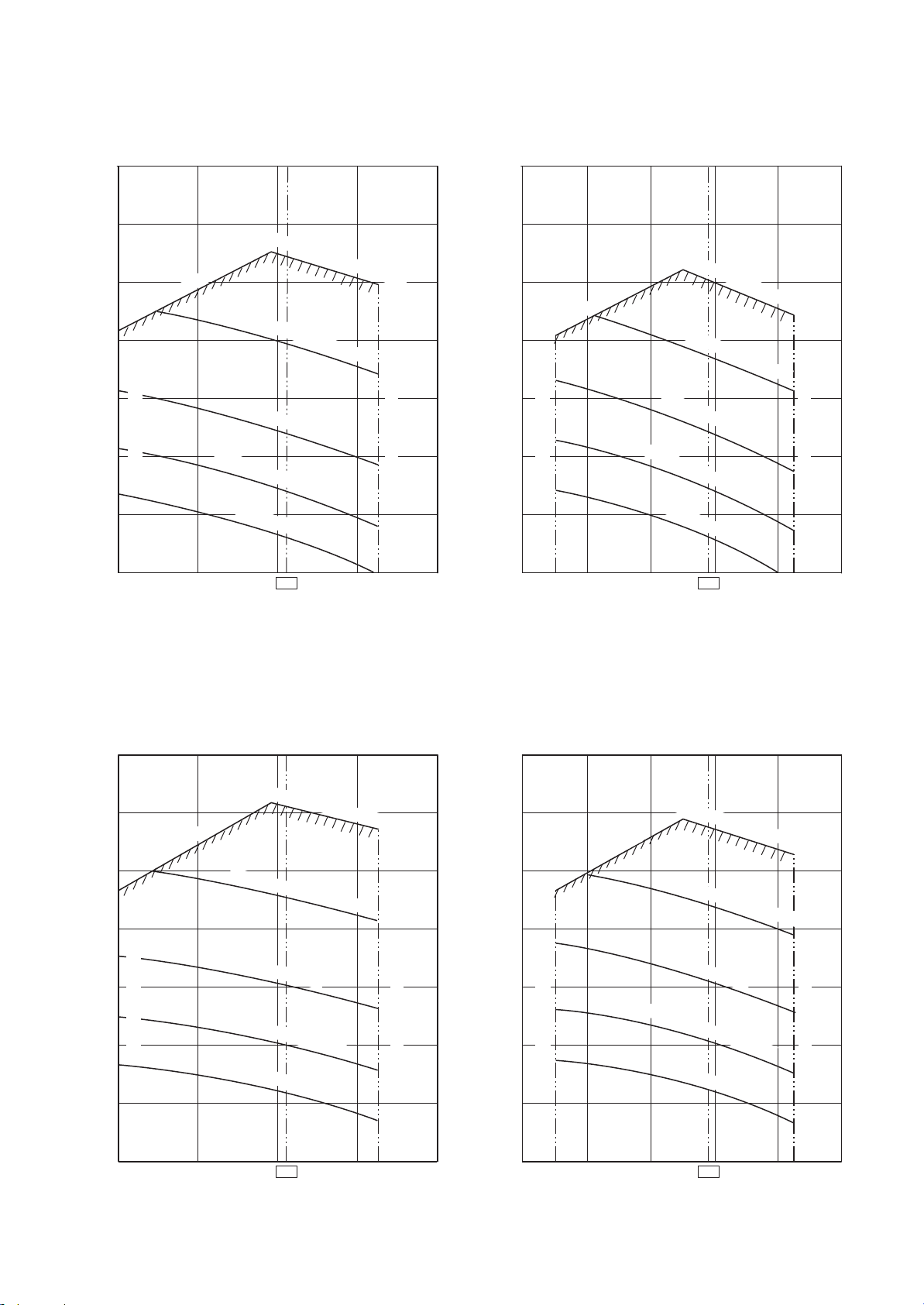

Fig. 5 SM110 type (Round duct)

Fig. 7 SM140 type (Round duct)

140

120

Standard air volume 1620m³/h

140

120

Standard air volume 1980m³/h

High static pressure 2H tap

High static pressure 2H tap

100

100

Usable limit

High static pressure 1H tap

80

60

Standard H tap

Static pressure (Pa)

40

Air volume limit (Min.)

20

0

1200

Low static pressure H tap

Standard L tap

1620

Air volume limit (Max.)

2000

80

60

Static pressure (Pa)

40

20

0

1200 1800

Air volume m³/h

Usable limit

Air volume limit (Min.)

High static pressure 1H tap

Standard H tap

Low static pressure H tap

Standard L tap

1980

Air volume m³/h

Air volume limit (Max.)

2200 2400

Fig. 6 SM110 type (Square duct)

140

Standard air volume 1620m³/h

Fig. 8 SM140 type (Square duct)

140

Standard air volume 1980m³/h

High static pressure 2H tap

120

120

High static pressure 2H tap

Usable limit

100

80

High static pressure 1H tap

100

80

Standard H tap

60

Static pressure (Pa)

40

Air volume limit (Min.)

Low static pressure H tap

Air volume limit (Max.)

60

Static pressure (Pa)

40

Standard L tap

20

20

Usable limit

Air volume limit (Min.)

High static pressure 1H tap

Standard H tap

Low static pressure H tap

Standard L tap

Air volume limit (Max.)

0

1200

1620

Air volume m³/h

2000

– 16 –

0

1200 1800

Air volume hm³/h

1980

2200 240

Page 17

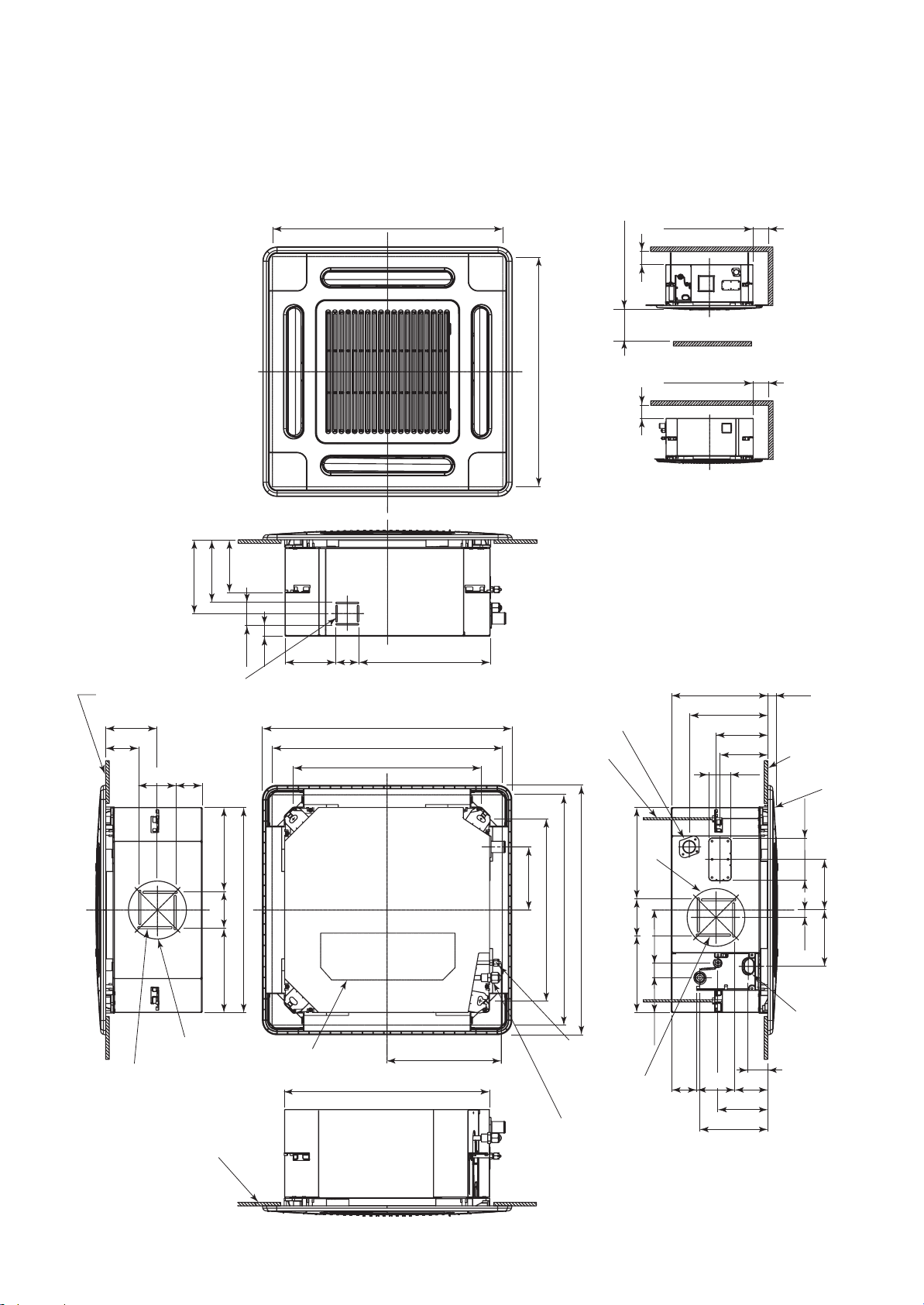

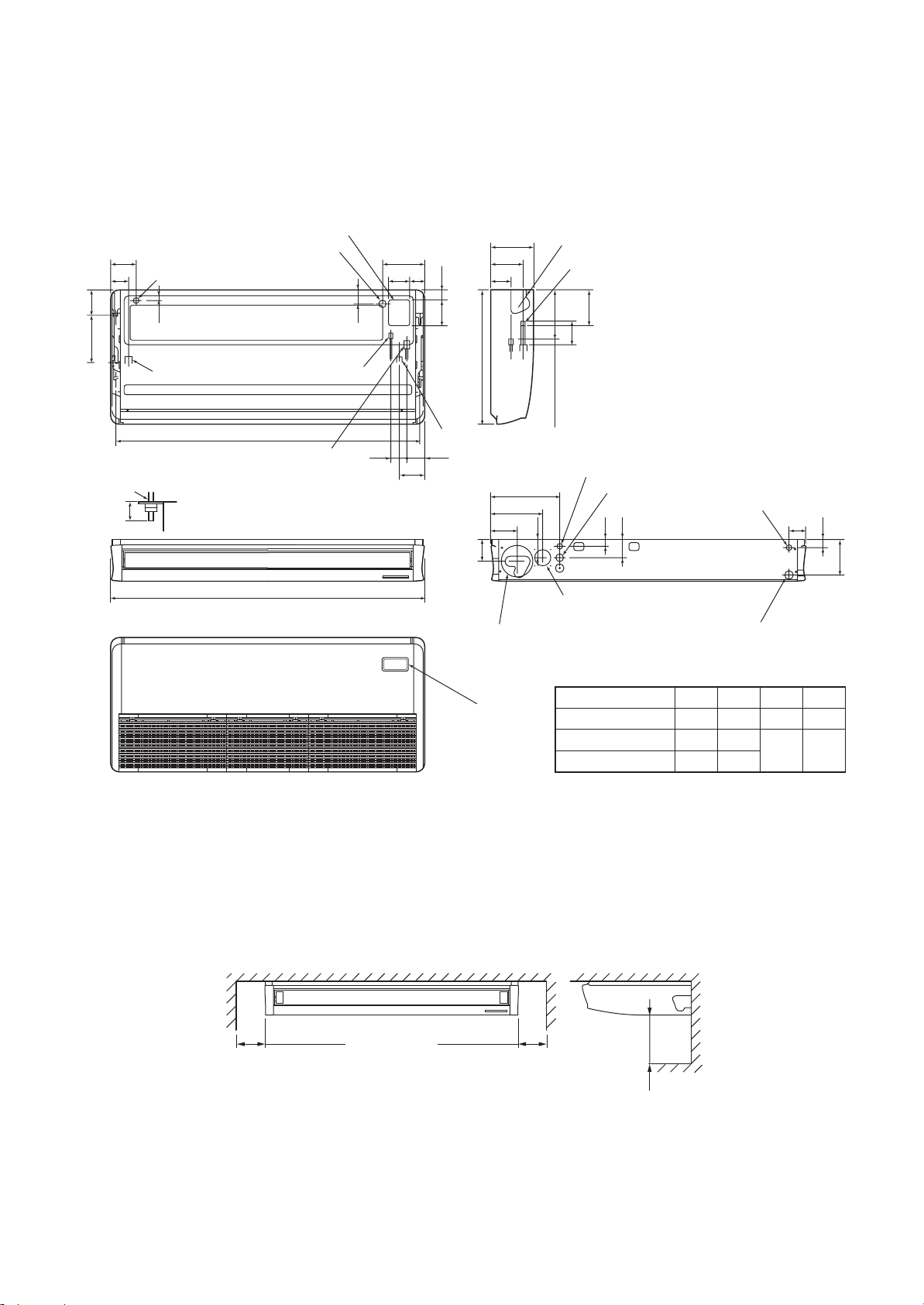

2. CONSTRUCTION VIEWS (EXTERNAL VIEWS)

2-1. Compact 4-way Cassette Type

RAV-SM404MUT

, RAV-SM454MUT

∗∗

∗

∗∗

149

175

207

, RAV-SM564MUT

∗∗

∗

∗∗

595 to 660 Ceiling open dimension

∗∗

∗

∗∗

595 to 660 Ceiling open dimension

1000 or more

15 or more15 or more

1000 or more

Obustacle

1000 or more

Space required for

installation and servicing

Bottom face

of ceiling

145.5

93

105

For branch duct knockout

square hole Ø150

Knockout for flesh

air intake Ø100

70

235

105235

Ø162

Bottom face of ceiling

64

575 Unit external dimension

142 64

29

700 Panel external dimension

595 to 660 Ceiling open dimension

525 Hanging bolt pitch

Electric parts box

575 Unit external dimension

368.5

320.5

Drain discharge port

Hanging bolt

M10 or W3/8

local arrange

Ø162

256

177

148

510 Hanging bolt pitch

700 Panel external dimension

595 to 660 Ceiling open dimension

Refrigerant pipe

(Liquid) Ø6.4

For branch ductt

knockout square

hole Ø150

Refrigerant pipe

(Gas) Ø12.7

214 105

97.5 42

268 27

220.5

145.5

134

63

9310570

139.5

190.5

Bottom face

of ceiling

Ceiling panel

55

120

142

21

158

Wiring

connection

port

– 17 –

Page 18

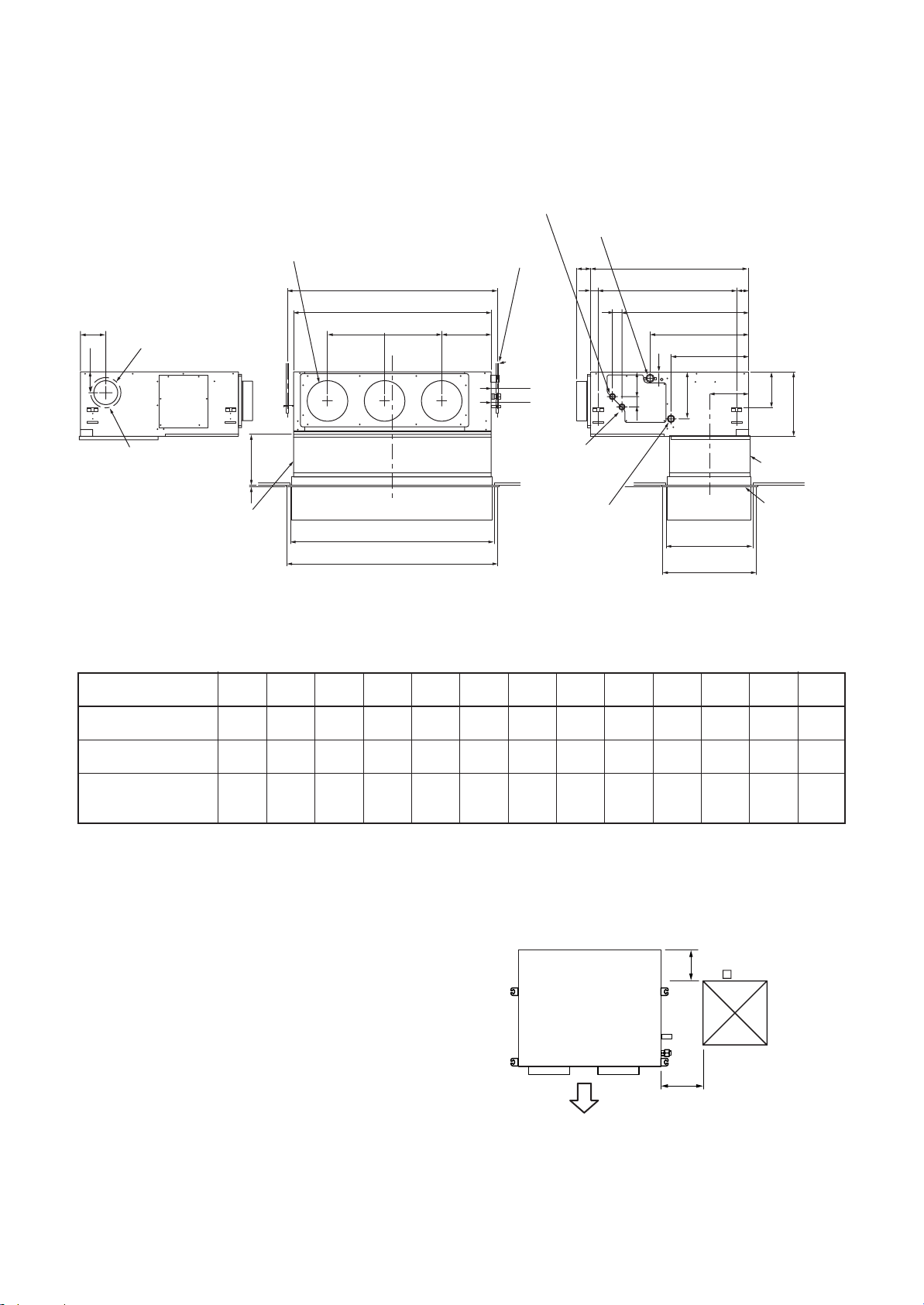

2-2. Concealed Duct Type

RAV-SM564BT

129

110

Knock-out hole Ø125

(Air take-in port)

6-Ø4 Tapping screw

undersized hole Ø160

Suction port canvas

(Separate sold)

, RAV-SM804BT

∗∗

∗

∗∗

Discharge port flange

N-Ø200

60 to 260

9

, RAV-SM1104BT

∗∗

∗

∗∗

Refrigerant pipe connecting port

(Gas side ØF)

Hanging bolt pitch B

Main unit dimension A

J = M x K H

C

Ceiling open size D

Panel external dimension E

, RAV-SM1404BT

∗∗

∗

∗∗

Hanging bolt

4-M10 screw

(Arranged locally)

44

49

Refrigerant pipe

connecting port

(Liquid side ØG)

Ø26 Power supply,

remote controller

cable take-out port

∗∗

∗

∗∗

Drain pipe connecting port

for vinyl chloride pipe

(Inner dia. 32, VP. 25)

75

Main unit dimension 800

Hanging bolt pitch 700

50

638

41

131

50

Ceiling open size

498

393

243

Panel C.L

410

470

Panel external

dimension 500

196

5941

174

Suction port

flange

(Separate sold)

Suction port

panel

(Separate sold)

320

• Dimension

ABCDEFGHJ KMNO

SM56 type

SM80 type

SM110 type

SM140 type

NOTE 1 :

For maintenance of the equipment, be sure to install

a check port A at the position as shown below.

NOTE 2 :

Using the drain up kit sold separately, drain-up by 300 (mm)

from drain pipe draw-out port of the main unit is necessary.

The drain-up over 300mm or more is impossible.

700 766 690 750 780 12.7 6.4 252 280 280 1 2 410

1000 1066 990 1050 1080 15.9 9.5 252 580 290 2 3 410

1350 1416 1340 1400 1430 15.9 9.5 252 930 310 3 4 410

Plane view of main unit

(Pipe side)

Discharge side

Check port A

300

100

450

– 18 –

Page 19

2-3. Ceiling Type

RAV-SM564CT

Power supply cable take-in port (Knockout)

128

Remote controller cable take- in port

(Knockout hole)

84

170320

(Hanging position)

Hanging bolt

50

Within

53

Left drain size

Ceiling surface

Unit

, RAV-SM804CT

∗∗

∗

∗∗

Upper pipe draw-out port (Knockout hole)

B (Hanging position)

Refrigerant pipe (Gas side ØD)

∗∗

∗

∗∗

Refrigerant pipe

(Liquid side ØC)

, RAV-SM1104CT

216 167

110

76

50

70

75 97

130

Drain pipe connecting port

146

, RAV-SM1404CT

∗∗

∗

∗∗

210

105

680

200 (Liquid pipe)

347

262

135 84

90

145

∗∗

∗

∗∗

Pipe draw-out port (Knockout hole)

Drain port VP20

(Inner dia. Ø26, hose attached)

114

41

216 (Gas pipe)

Remote controller cable take- in port

Power supply cable take-in port (Knockout hole)

Remote controller cable take- in port

32

(Knockout hole)

92

32

171

A

Pipe hole on wall (Ø100 hole)

Wireless sensor

mounting section

Outside air take-in port

(Duct sold separately)(Knockout hole Ø92)

Drain left pipe draw-out port (Knockout hole)

Model name A B C D

SM56 type

SM80 type

SM110, 140 type

910

1180

1595

855

1125

1540

Ø6.4 Ø12.7

Ø9.5 Ø15.9

250 or more250 or more

– 19 –

500 or more

Page 20

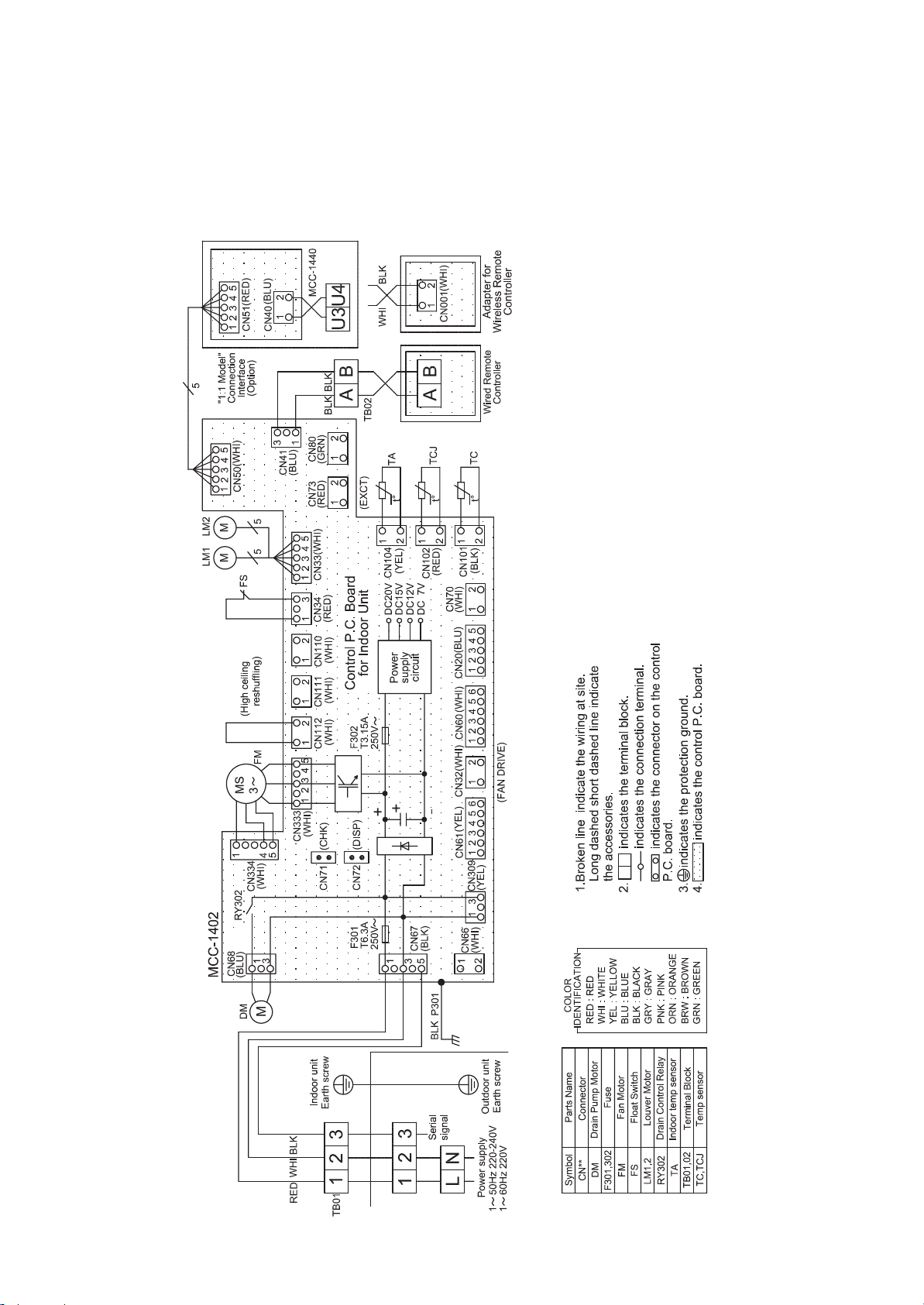

3. WIRING DIAGRAM

3-1. Indoor Unit

3-1-1. Compact 4-way Cassette Type

RAV-SM404MUT

, RAV-SM454MUT

∗∗

∗

∗∗

, RAV-SM564MUT

∗∗

∗

∗∗

∗∗

∗

∗∗

– 20 –

Page 21

3-1-2. Concealed Duct Type

RAV-SM564BT

, RAV-SM804BT

∗∗

∗

∗∗

, RAV-SM1104BT

∗∗

∗

∗∗

, RAV-SM1404BT

∗∗

∗

∗∗

∗∗

∗

∗∗

– 21 –

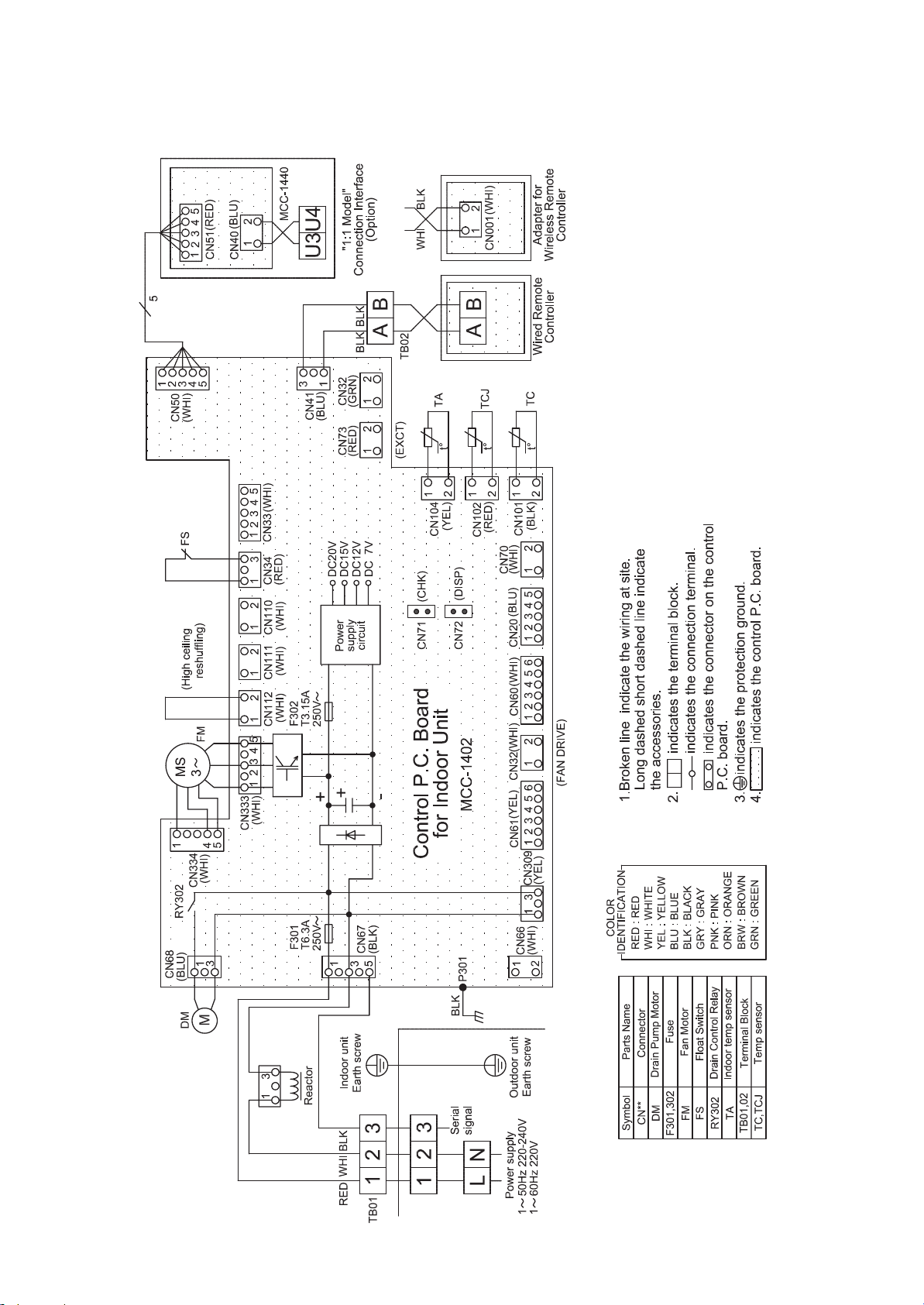

Page 22

3-1-3. Ceiling Type

RAV-SM564CT

, RAV-SM804CT

∗∗

∗

∗∗

, RAV-SM1104CT

∗∗

∗

∗∗

, RAV-SM1404CT

∗∗

∗

∗∗

∗∗

∗

∗∗

– 22 –

Page 23

4. SPECIFICATIONS OF ELECTRICAL PARTS

4-1. Compact 4-way Cassette Type

No.

1

Fan motor (for indoor)

2

Thermo. sensor (TA-sensor)

3

Heat exchanger sensor (TCJ-sensor)

4

Heat exchanger sensor (TC-sensor)

5

Float switch

6

Drain pump motor

Parts name

4-2. Concealed Duct Type

No.

1

Fan motor (SM804BT)

Fan motor

2

(SM564BT/SM1104BT/SM1404BT)

3

Thermo. sensor (TA-sensor)

Parts name

Type

SWF-230-60-1R

155 mm

Ø6 mm, 1200 mm

Ø6 mm, 1200 mm

FS-0218-102

ADP-1409

Type

ICF-280-120-1C

ICF-280-120-2C

618 mm

Specifications

Output (Rated) 60 W, 220–240 V

10 kΩ at 25°C

10 kΩ at 25°C

10 kΩ at 25°C

Specifications

Output (Rated) 120 W, 220–240 V

Output (Rated) 120 W, 220–240 V

10 kΩ at 25°C

4

Heat exchanger sensor (TCJ-sensor)

5

Heat exchanger sensor (TC-sensor)

6

Float switch

7

Drain pump motor

8

Reactor

4-3. Ceiling Type

No.

1

Fan motor (SM564CT)

2

Fan motor (SM804CT)

3

Fan motor (SM1104CT/SM1404CT)

4

Thermo. sensor (TA-sensor)

5

Heat exchanger sensor (TCJ-sensor)

Parts name

Ø6 mm, 1200 mm

Ø6 mm, 1200 mm

FS-0218-102

ADP-1409

CH-43-2Z-T

Type

SWF-280-60-1R

SWF-280-60-2R

SWF-280-120-2R

155 mm

Ø6 mm, 1200 mm

10 kΩ at 25°C

10 kΩ at 25°C

10 mH, 1 A

Specifications

Output (Rated) 60 W, 220–240 V

Output (Rated) 60 W, 220–240 V

Output (Rated) 120 W, 220–240 V

10 kΩ at 25°C

10 kΩ at 25°C

6

Heat exchanger sensor (TC-sensor)

7

Louver motor

8

Reactor

Ø6 mm, 1200 mm

MP24Z2N

CH-43-2Z-T

– 23 –

10 kΩ at 25°C

DC 15V

10 mH, 1 A

Page 24

5. CONTROL BLOCK DIAGRAM

5-1. Indoor Controller Block Diagram

5-1-1. In Case of Connection of Wired (Simple) Remote Controller

Wired (Simple) heder remote controller (Max. 2 units) Central remote controller

Indoor unit

#1 (Heder)

*

None for

Duct type

Louver

motor

Drain

pump

*

Option for

Ceiling type

Indoor

fan motor

DC280V

Display LCD Function setup

Display LED

Remote controller

communication circuit

Indoor control P.C. board (MCC-1402)

Power circuit

DC20V

DC5V

DC12V

TMP88CH47FG

(TMP88PH47FG)

Fan motor

control circuit

Remote controller

communication circuit

CPU

CPU

AB

Driver

External

output

Run

Alarm

Defrost

Thermo. ON

COOL

HEAT

FAN

Key switch

DC5V

Power circuit

CPU

H8/3039

AC

synchronous

signal input circuit

CN2

CN1

∗3

EEPROM

TA sensor

TC sensor

TCJ sensor

Float input

Serial send/

receive circuit

Display LCD LCD driver

CPU

DC5V

HA

Powe r

circuit

Secondary

battery

#2

(Follower)

A B

Same as left

∗2

Function setup

Key switch

#3

(Follower)

A B

Same as left

321

1

∗2

32

∗ “1:1 model” connection interface

Central remote

controller(Option)

U3

U4

communication circuit

(Option)

P.C. board

(MCC-1440)

TCC-LINK

– 24 –

321

321

Outdoor unit

Outdoor unit

Up to 8 units are connectable. ∗1

∗1 However, if “1:1 model connection interface” is

connected when 2 wired (simple) remote controllers

are connected, Max. 7 units are connectable.

∗2 Connect “1:1 model connection interface” to only

1 unit and connect 1 “1:1 model connection

interface” to the header unit.

∗3 It is unavailable to connect the Central remote

controller to the simple wired remote controller.

Outdoor unit

Page 25

5-1-2. In Case of Connection of Wireless Remote Controller

Indoor unit

#1 (Heder)

Wireless remote controller

Receiver P.C. board (MCC-1504)

Display LED

*

None for

Duct type

Louver

motor

Drain

pump

*

Option for

Ceiling type

Indoor

fan motor

DC280V

Receive circuit

Buzzer

DC5V

Powe r

circuit

Indoor control P.C. board (MCC-1402)

DC20V

DC5V

DC12V

TMP88CH47FG

(TVP88PH47FG)

Fan motor

Power circuit

control circuit

Remote controller

communication circuit

Remote controller

communication circuit

CPU

CPU

AB

Driver

External

output

Run

Alarm

Defrost

Thermo. ON

COOL

HEAT

FAN

Function setup SW

Temporary

operation SW

CPU

H8/3039

AC

synchronous

signal input circuit

EEPROM

TA sensor

TC sensor

TCJ sensor

Float input

HA

Serial send/

receive circuit

#2

(Follower)

A B

Same as left

∗2

#3

(Follower)

A B

Same as left

321

1

∗2

32

∗ “1:1 model” connection interface

(MCC-1440)

communication circuit

Central remote

controller (Option)

U3

U4

(Option)

P.C. board

TCC-LINK

– 25 –

321

321

Outdoor unit

Outdoor unit

Up to 8 units are connectable. ∗1

∗1 However, if “1:1 model connection interface” is

connected when 2 wireless remote controllers are

connected, Max. 7 units are connectable.

∗2 Connect “1:1 model connection interface” to only

1 unit and connect 1 “1:1 model connection

interface” to the header unit.

Outdoor unit

Page 26

5-1-3. Connection of Both Wired (Simple) Remote Controller and Wireless Remote Controller

Indoor unit

#1 (Heder)

Receive

circuit

Buzzer

DC5V

Powe r

circuit

Display LED

CPU

Remote controller

communication circuit

Receiver P.C. board

(MCC-1504)

Function setup SW

Temporary

operation SW

Wired (Simple) heder remote controller

communication circuit

(Max. 2 units)

Display

LCD

Display

LED

Remote controller

ABAB

CPU

Function

setup

Key

switch

DC5V

Powe r

circuit

CN2

CN1

∗3

Central remote controllerWireless remote controller

Display

LCD

Powe r

circuit

DC5V

LCD

driver

CPU

Function

setup

Key

switch

Secondary

battery

*

None for

Duct type

Louver

motor

Drain

pump

*

Option for

Ceiling type

Indoor

fan motor

DC280V

Indoor control P.C. board (MCC-1402)

Power circuit

DC20V

DC5V

DC12V

TVP88CH47FG

(TMP88PH47FG)

control circuit

Remote controller

communication circuit

CPU

Fan motor

AB

Driver

External

output

Run

Alarm

Defrost

Thermo. ON

COOL

HEAT

FAN

CPU

H8/3039

AC

synchronous

signal input circuit

321

EEPROM

TA sensor

TC sensor

TCJ sensor

Float input

HA

Serial send/

receive circuit

#2

(Follower)

A B

Same as left

∗2

Outdoor unit

#3

(Follower)

A B

Same as left

321

1

Outdoor unit

∗2

32

∗ “1:1 model” connection interface

(MCC-1440)

Central remote

controller (Option)

U3

U4

communication circuit

(Option)

P.C. board

TCC-LINK

– 26 –

321

Outdoor unit

Up to 8 units are connectable. ∗1

∗1 However, if “1:1 model connection interface” is

connected, Max. 7 units are connectable.

∗2 Connect “1:1 model connection interface” to only

1 unit and connect 1 “1:1 model connection

interface” to the header unit.

∗3 It is unavailable to connect the Central remote

controller to the simple wired remote controller.

Page 27

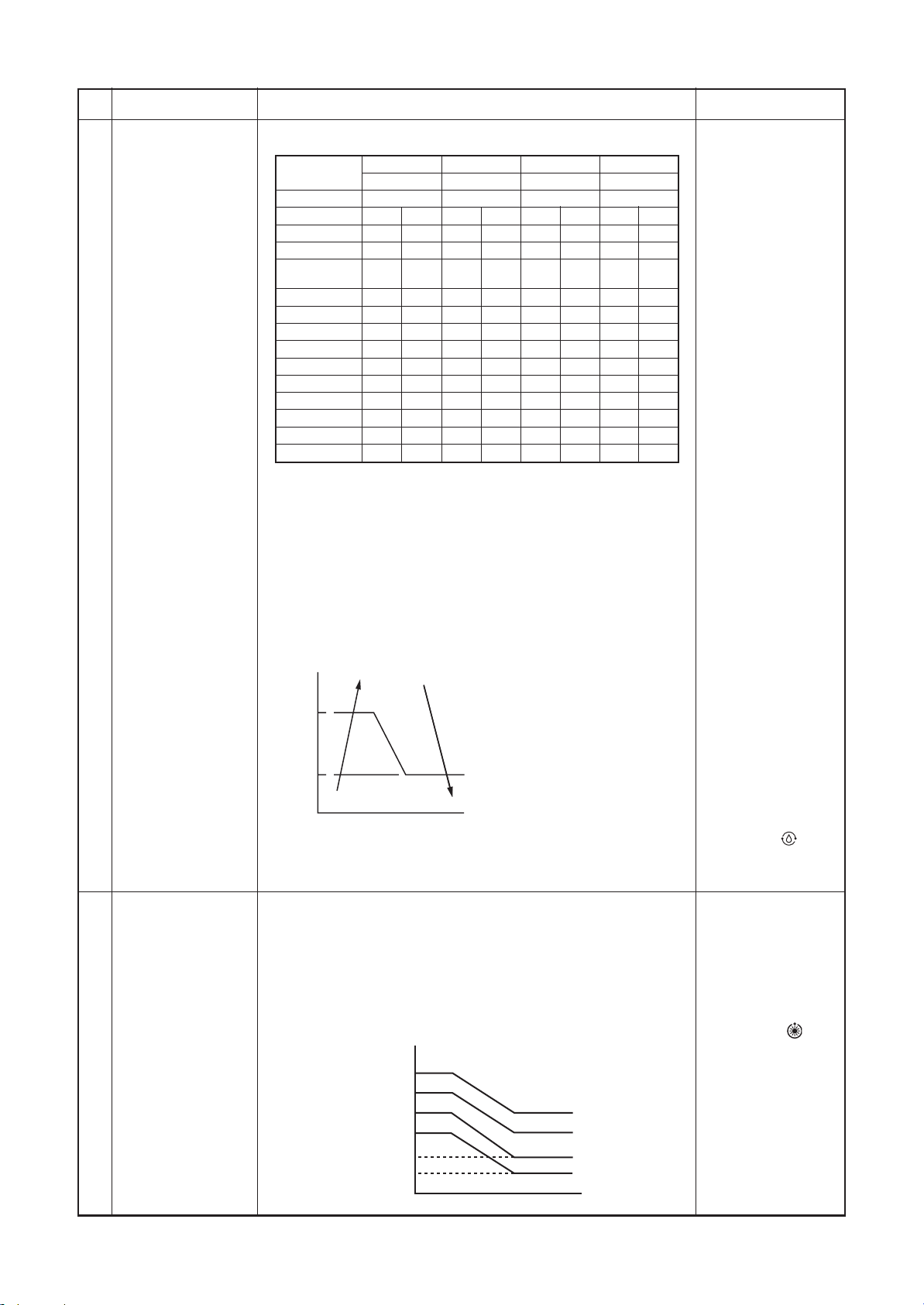

5-2. Control Specifications

No.

1

When power

supply is reset

2

Operation

mode selection

Item

Outline of specifications

1) Distinction of outdoor unit

When the power supply is reset, the outdoors are distin-

guished and the control is selected according to the

distinguished result.

2) Setting of indoor fan speed and existence of air direction

adjustment

Based on EEPROM data, select setting of the indoor fan

speed and the existence of air direction adjustment.

1) Based on the operation mode selecting command from the

remote controller, the operation mode is selected.

Remote controller

command

STOP

FAN

COOL

DRY

HEAT

AUTO

• COOL/HEAT operation mode is

automatically selected by Ta, Ts

and To for operation.

• The operation is performed as

shown in the following figure

according to Ta value at the first

time only. (In the range of Ts +

Control outline

Air conditioner stops.

Fan operation

Cooling operation

Dry operation

Heating operation

α –1 < Ta < Ts + α + 1, Cooling

thermo. OFF (Fan)/Setup air

volume operation continues.)

Remarks

Fan speed (rpm)/

Air direction adjustment

Ta: Room temp.

Ts: Setup temp.

To: Outside temp.

3

Room temp.

control

Cooling

1.0

Ta˚C Ts +

•

α is corrected according to the outside temperature.

α

–1.0

Outside temp.

No To

To ≥ 24°C

24°C > To ≥ 18°C

To < 18°C

To error

operation

Cooling thermo. OFF (Fan)

• Setup air volume

Heating

operation

Correction value (

0K

–1K

0K

+1K

0K

αα

α)

αα

1) Adjustment range: Remote controller setup temperature ( °C )

Wired type

Wireless type

COOL/DRY

18°C to 29°C

18°C to 30°C

HEAT

18°C to 29°C

16°C to 30°C

K = deg

AUTO

18°C to 29°C

17°C to 27°C

– 27 –

Page 28

No.

3

Room temp.

control

(Continued)

4

Automatic

capacity control

(GA control)

Item

Outline of specifications

2) Using the CODE No. 06, the setup temperature in heating

operation can be corrected.

SET DATA

Setup temp.

correction

0246

+0°C +2°C +4°C +6°C

Setting at shipment

SET DATA 2

1) Based on the difference between Ta and Ts, the operation

frequency is instructed to the outdoor unit.

2) Cooling operation

Every 90 seconds, the room temperature difference

between temperature detected by Ta and Ts and the

varied room temperature value are calculated to obtain

the correction value of the frequency command and then

the present frequency command is corrected.

Ta (n) – Ts (n) : Room temp. difference

n : Counts of detection

Ta (n-1) – Ts (n) : Varied room temp. value

n – 1 :

Counts of detection of 90 seconds before

3) Heating operation

Every 1 minute (60 sec.), the room temperature differ-

ence between temperature detected by Ta and Ts and the

varied room temperature value are calculated to obtain

the correction value of the frequency command and then

the present frequency command is corrected.

Ts (n) – Ta (n) : Room temp. difference

n : Counts of detection

Ta (n) – Ta (n – 1) : Varied room temp. value

n – 1 : Counts of detection of 1 minute before

4) Dry operation

The frequency correction control is same as those of the

cooling operation.

However the maximum frequency is limited to approxi-

mately “S6”.

Note) When LOW is set up, the maximum frequency is

limited to approximately “SB”.

Remarks

Shift of suction

temperature in heating

operation

5

Automatic

cooling/heating

control

1) The judgment of selecting COOL/HEAT is carried out as

shown below. When +1.5°C exceeds against Tsh 10

minutes and after thermo. OFF, heating operation

(Thermo. OFF) exchanges to cooling operation.

Description in the parentheses shows an example of

cooling ON/OFF.

Tsc: Setup temp. in

cooling operation

Tsh: Setup temp. in

heating operation

+ temp. correction of

room temp. control

+1.5

–1.5

Cooling

(Cooling ON)

(Cooling OFF)

Heating

Ta ˚C

Tsc or Tsh

When –1.5°C lowers against Tsc 10 minutes and after thermo. OFF, cooling operation

(Thermo. OFF) exchanges to heating operation.

2) For the automatic capacity control after judgment of cooling/heating, see Item 4.

3) For temperature correction of room temp. control in automatic heating, see Item 3.

– 28 –

Page 29

No.

6

Fan speed control

Item

Outline of specifications

1) Operation with (HH), (H), (L) or [AUTO] mode is carried

out by the command from the remote controller.

2) When the fan speed mode [AUTO] is selected, the fan

speed varies by the difference between Ta and Ts.

<COOL>

Remarks

HH > H+ > H > L+ >

L > UL

Ta ˚C

+3.0

+2.5

+2.0

+1.5

+1.0

+0.5

Tsc

–0.5

HH

(HH)

H+ (HH)

H (HH)

L+ (H+)

L (H)

L (H)

L (L+)

A

B

C

D

E

F

G

• Controlling operation in case when thermostat of remote

controller works is same as a case when thermostat of the

body works.

• If the fan speed has been changed once, it is not changed

for 3 minutes. However when the air volume is exchanged,

the fan speed changes.

• When cooling operation has started, select a downward

slope for the fan speed, that is, the high position.

• If the temperature is just on the difference boundary, the

fan speed does not change.

• Mode in the parentheses indicates one in automatic

cooling operation.

<HEAT>

Ta ˚C

(–0.5) –1.0

(0) Tsh

(+0.5) +1.0

(+1.0) +2.0

(+1.5) +3.0

(+2.0) +4.0

L (L+)

L+ (H)

H (H+)

H+

(HH)

HH

(HH)

E

D

C

B

A

Value in the parentheses indicates one when thermostat of

the remote controller works.

Value without parentheses indicates one when thermostat of

the body works.

• If the fan speed has been changed once, it is not changed

for 1 minute. However when the fan speed exchanged, the

fan speed changes.

• When heating operation has started, select an upward

slope for the fan speed, that is, the high position.

• If the temperature is just on the difference boundary, the

fan speed does not change.

• Mode in the parentheses indicates one in automatic

heating operation.

• In Tc ≥ 60°C, the fan speed increases by 1 step.

Tc: Indoor heat

exchanger sensor

temperature

– 29 –

Page 30

No.

6

Fan speed control

(Continued)

Item

Outline of specifications

(Ceiling type)

CODE No.

[5d]

SW501 (1)/(2)

Tap

F1

F2

F3

F4

F5

F6

F7

F8

F9

FA

FB

FC

FD

Standard Type 1 Type 3 Type 6

0000 0001 0002 0003

OFF/OFF ON/OFF OFF/ON ON/ON

HEAT COOL HEAT COOL HEAT COOL HEAT COOL

HH HH HH HH

HH HH

H+ H+, H H+, H

H+

HH H

HH H L+ L+

H+ H+ L L

HL+

HL+L

L+ L

L+ L

L

UL UL UL UL

H+, H H+, H

L+, L L+, L

3) In heating operation, the mode changes to [UL] if thermostat

is turned off.

4) If Ta ≥ 25°C when heating operation has started and when

defrost operation has been cleared, the air conditioner

operates with (H) mode or higher mode for

1 minute after Tc entered in E zone of cool air discharge

preventive control (No. 7).

5) In automatic cooling/heating operation, the revolution

frequency of (HH) is set larger than that in the standard

cooling/heating operation.

Ta ˚C

F5 → F4

Remarks

Selection of high

ceiling type

CODE No.: 5d

However only when

the high ceiling

selection is set to

[Standard]

7

Cool air discharge

preventive control

47

However the revolution frequency

is restricted in the automatic

heating operation as shown in

42

F5

the following figure.

6) Self-clean operation

When performing self-clean operation after stopping the

cooling operation, the mode becomes 210 rpm.

1) In heating operation, the indoor fan is controlled based on

the detected temperature of Tc sensor or Tcj sensor. As

shown below, the upper limit of the revolution frequency is

restricted.

However B zone is assumed as C zone for

6 minutes and after when the compressor activated.

In defrost operation, the control value of Tc is shifted by 6°C.

Tc, Tcj

˚C

HH

32

H

30

28

26

20

16

L

UL

OFF

E zone

D zone

C zone

B zone

A zone

[Self-clean

] is

displayed.

In D and E zones,

the priority is given

to air volume

selection setup of

remote controller.

In A zone while

thermo is ON,

[PRE-HEAT

(Heating ready)] is

displayed.

– 30 –

Page 31

No.

8

Freeze preventive control

(Low temperature release)

Item

Outline of specifications

1) The cooling operation (including Dry operation) is

performed as follows based on the detected

temperature of Tc sensor or Tcj sensor.

When [J] zone is detected for 6 minutes

(Following figure), the commanded frequency is

decreased from the real operation frequency.

After then the commanded frequency changes

every 30 seconds while operation is performed in

[J] zone.

In [K] zone, time counting is interrupted and the

operation is held.

When [ I ] zone is detected, the timer is cleared

and the operation returns to the normal operation.

If the commanded frequency becomes S0

because the operation continues in [J] zone, the

return temperature A is raised from 5°C to 12°C

until [ I ] zone is detected and the indoor fan

operates with [L] mode.

˚C

5

I

A

K

Remarks

Tcj:

Indoor heat exchanger

sensor temperature

2

J

In heating operation, the freeze-preventive control

works if 4-way valve is not exchanged and the

following conditions are satisfied.

(However the temperature for J zone dashing control

is changed from 2°C to –5°C.)

<Conditions>

• When

activation.

Q

R

or R is established 5 minutes after

Q

Tcn ≤ Tc (n – 1) – 5

Tcn < Tc (n – 1) – 1 and Tcn ≤ Ta < 5°C

Tcn:

Tc temperature when 5

minutes elapsed after

activation

Tc (n – 1):

Tc temperature at start

time

– 31 –

Page 32

No.

9

High-temp.

release control

Item

Outline of specifications

1) The heating operation is performed as follows based on the

detected temperature of Tc sensor or Tcj sensor.

• When [M] zone is detected, the commanded frequency is

decreased from the real operation frequency. After then

the commanded frequency changes every 30 seconds

while operation is performed in [M] zone.

• In [N] zone, the commanded frequency is held.

• When [L] zone is detected, the commanded frequency is

returned to the original value by approx. 6Hz every

60 seconds.

Remarks

However this control is

ignored in case of the

follower unit of the twin.

10

Drain pump

control

(The ceiling

type is optional)

Setup at shipment

Control temp. °C

AB

56 (54) 52 (52)

Tc, Tcj

˚C

A

M

N

B

L

NOTE:

When the operation has started or when Tc or Tcj < 30°C at start

of the operation or after operation start, temperature is controlled between values in parentheses of A and B.

1) In cooling operation (including Dry operation), the drain

pump is usually operated.

2) If the float switch works while drain pump drives, the

compressor stops, the drain pump continues the operation,

and a check code is output.

3) If the float switch works while drain pump stops, the

compressor stops and the drain pump operates. If the float

switch keeps operating for approx. 4 minutes, a check code

is output.

Same status as that

when “thermostat-OFF”

(status that the air

conditioner enters in the

room temp. monitor

mode when the

temperature reached the

setup temperature on

the remote controller)

Check code [P10]

11

After-heat

elimination

When heating operation stops, in some cases, the indoor fan

operates with (L) for approx. 30 seconds.

– 32 –

Page 33

No.

12

Louver control:

Compact 4-way

type only

Item

Outline of specifications

1) Louver position setup

• When the louver position is changed, the position moves

necessarily to downward discharge position once to return to

the set position.

The louver position can be set up in the following operation range.

•

In cooling/dry operation In heating/fan operation

• In group twin/triple operation, the louver positions can be set

up collectively or individually.

2) Swing setup

• [SWING] is displayed and the following display is repeated.

In all operations

(Repeats)

Remarks

The swinging

louver moves

usually up to the

ceiling side from

the louver position

of the set time.

• In group twin operation, the louver positions can be set up

collectively or individually.

3) When the unit stopped or the warning was output, the louver is

automatically set to full closed position.

4) When PRE-HEAT

(Heating operation started or defrost operation is performed),

heating thermo is off or self-cleaning is performed, the louver is

automatically set to horizontal discharge position.

∗ The louver which air direction is individually set or the locked

louver closes fully when the unit stops and the louver is

automatically set to horizontal discharge position when

PRE-HEAT

off or self-cleaning is performed.

(Heating ready) is displayed

(Heating ready) is displayed, heating thermo is

– 33 –

Page 34

No.

13

(Continued)

For ceiling type only

Item