Page 1

CD731a

DIGITAL MULTIMETER

取扱説明書

INSTRUCTION MANUAL

Page 2

CONTENTS

SAFETY PRECAUTIONS:Before use, read the following safety precautions

【1】

1-1 Explanation of Warning Symbols …………………………027

1-2 Warning Instruction for safe use …………………………027

1-3 Maximum Overload Protection Input ……………………028

【2】APPLICATION AND FEATURES

2-1 Application……………………………………………………029

2-2 Features………………………………………………………029

【3】NAME OF COMPONENT UNITS

3-1 Display ………………………………………………………029

3-2 Multimeter, Test leads ……………………………………030

【4】Description of Functions

4-1 Switch and description ……………………………………031

4-2 How to Use the Stand………………………………………032

【5】MEASUREMENT PROCEDURE

5-1 Start-up Inspection …………………………………………033

5-2 Voltage Measurement………………………………………034

5-3 Resistance Measurement (Ω) ……………………………035

5-4 Testing Diode ( ) …………………………………………035

5-5 Checking Continuity ( ) ……………………………………036

5-6 Capacity Measurement ( ) ………………………………037

5-7 Current Measurement (μA・mA・A) ……………………038

5-7-1 Current Measurement (μA・mA) ……………………038

5-7-2 Current Measurement (A) ……………………………039

5-8 How to use optional products ……………………………040

5-8-1 AC Clamp Probe (CL-20D) ……………………………040

5-8-2 DC・AC Clamp Probe (CL-22AD)………………………040

5-8-3 DC Clamp Probe (CL33DC) ……………………………041

5-8-4 HV Probe (HV-60) ………………………………………041

【6】MAINTENANCE

6-1 Maintenance and inspection ………………………………042

6-2 Calibration ……………………………………………………042

6-3 How to Replace Battery and Fuse ………………………043

6-4 Cleaning and Storage ………………………………………044

【7】SPECIFICATIONS

7-1 Measurement Range and Accuracy ………………………045

7-2 General Specifications………………………………………046

7-3 Optional accessories General Specifications ……………047

【8】After-Sales Service

8-1 Warranty and Provision ……………………………………047

8-2 Repair…………………………………………………………048

8-3 SANWA web site ……………………………………………048

Page 3

【1】

SAFETY PRECAUTIONS : Before use, read the following safety precautions

This instruction manual explains how to use your multimeter

CD731a safely. Before use, please read this manual thoroughly.

After reading it, keep it together with the product for reference to it

when necessary.

The instruction given under the heading " WARNING" " CAUTION"

must be followed to prevent accidental burn or electrical shock.

1-1 Explanation of Warning Symbols

The meaning of the symbols used in this manual and attached to

the product is as follows.

: Very important instruction for safe use.

・The warning messages are intended to prevent accidents to

operating personnel such as burn and electrical shock.

・The caution messages are intended to prevent damage to

the instrument.

: Dangerous voltage (Take care not to get an electric shock in

voltage measurement.)

: DC 〜 :AC Ω :Resistance

: Buzzer 〜 : Diode 〜:Ground

: Plus :Minus 〜 : Fuse

+

: Double insulation

1-2 Warning Instruction for safe use

To ensure that the meter is used safely, Be sure to observe

the instruction when using the instrument.

01. Never use meter on the electric circuit that exceed 6k VA.

02. Pay special attention when measuring the voltage of AC 33

Vrms (46.7 Vpeak) or DC 70V or more to avoid injury.

03. Never apply an input signals exceeding the maximum rating

input value.

04. Never use meter for measuring the line connected with

equipment (i.e. motors) that generates induced or surge

voltage since it may exceed the maximum allowable voltage.

−

WARNING

−27−

Page 4

05.

Never use meter if the meter or test leads are damaged or broken.

06. Never use uncased meter.

07.

Be sure to use a fuse of the specified rating or type. Never use

a substitute of the fuse or never make a short circuit of the fuse.

08. Always keep your fingers behind the finger guards on the

probe when making measurements.

09. Be sure to disconnect the test pins from the circuit when

changing the function or range.

10. Never use meter with wet hands or in a damp environment.

11. Never open tester case except when replacing batteries or

fuse. Do not attempt any alteration of original specifications.

12. To ensure safety and maintain accuracy, calibrate and check

the tester at least once a year.

13. Indoor use.

1. Correct measurement may not be performed when using the

CAUTION

meter in the ferromagnetic / intense electric field such as

places near a transformer, a high-current circuit, and a radio.

2. The meter may malfunction or correct measurement may not

be performed when measuring special waveform such as that

of the inverter circuit.

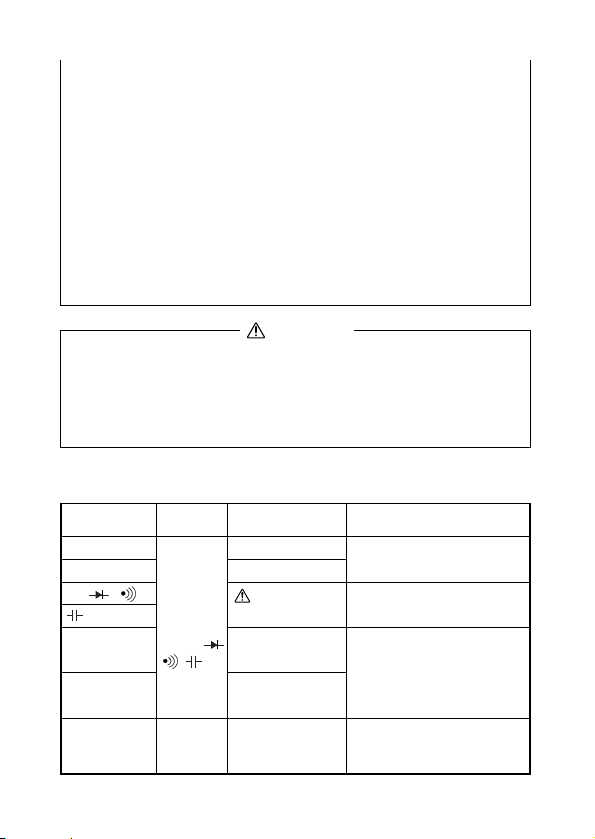

1-3 Maximum Overload Protection Input

Function Input

DCV

ACV

Ω/ /

●

DC/AC

400・4000μA

DC/AC

40・400mA

DC/AC

4・20A

V, Ω, ●

μA, mA

(+)

COM(−)

4・20A

COM

(−)

:

:

:

, ●

:

Maximum rating

input value

DC1000V

AC750V

Voltage and current

●

input prohibited

DC,AC

4000μA

DC, AC

400mA

DC, AC

20A

−28−

Maximum overload

protection value

DC1000V,AC750V

or peak max. 1000V

DC500V,AC500V

or peak max.700V

500mA/250V Fuse

protection

20A/250V Fuse

protection

Page 5

【2】APPLICATION AND FEATURES

2-1 Application

This instrument is portable multimeter designated for measurement

of weak current circuit.

2-2 Features

・4000 counts disply.

・Auto power save 30min.

・With the capacity measurement function.

・The current function is the semi auto ranges.

・Main unit case and the circuit board is made of fire retarding

materials.

・The instrument has been designed in accordance with the safety

standard IEC 61010-1.(See P46 "Safety")

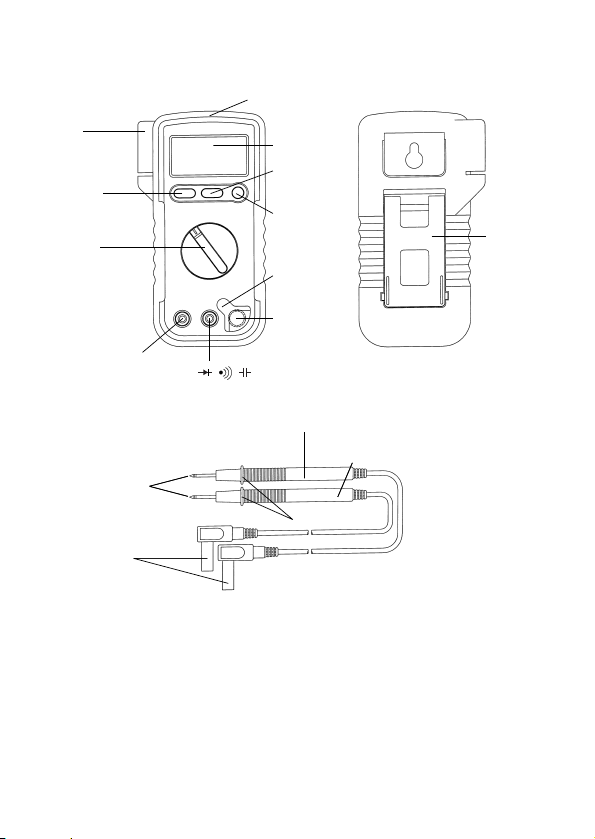

【3】NAME OF COMPONENT UNITS

3-1 Display

Auto mode display

DC mearsurement display

AC measurement display

Minus polarity display

for numeral data

Testing diode

display

Decimal point

Numeral data display

−29−

Data hold displayChecking countinuity display

Relative

display

Battery dischage

warning display

Measurement

unit display

〔Fig 1〕

Page 6

3-2 Multimeter, Test leads

Test lead

Fix

Range hold

switch

Power switch

and function

switch

COM − input

terminal

Test pins

Plug

V, Ω,● , ●, ●,μA,mA

+ input terminal

Test lead (TL-21)

Holster

Display

Data hold

switch

Select

switch

Safety cover

4・20A input

terminal

Test probe (Red)

Test probe (Black)

finger guards

Stand

〔Fig 2〕

−30−

Page 7

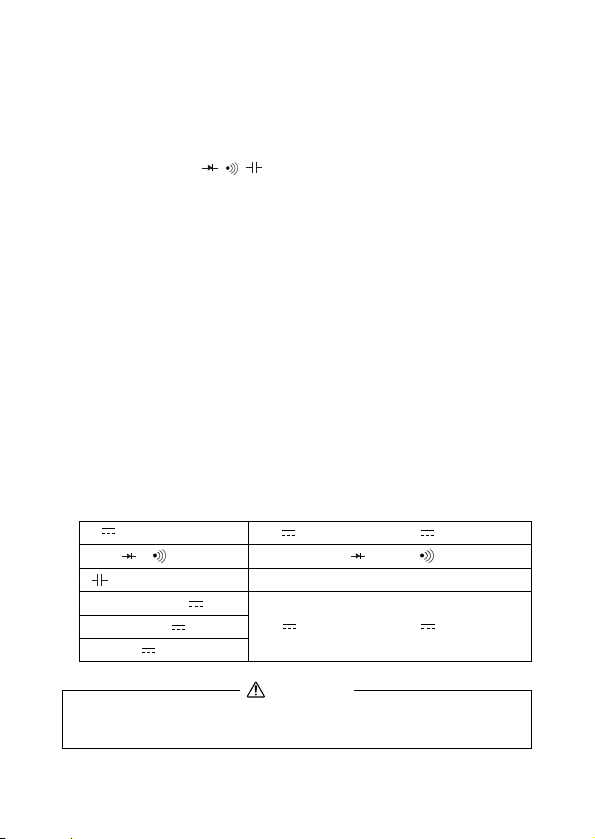

【4】Description of Functions

4-1 Switch and description

○Power switch and function switch

Turn this switch to turn on and off the power and to select the

functions of V, Ω/● /●,● , μA, mA, A.

○Range hold switch

Pressing this switch once sets the manual mode and the range is

fixed. ("AUTO" on the display disappears)

Once the manual mode is set, the range moves each time this

switch is pressed. Checking the unit on the display and the place

of the decimal point, select a desired range. To return to the auto

mode, keep pressing this switch until "AUTO" on the display

appears.

○Data hold switch

When this switch is pressed, the data display at that time

continues ("DH" lights on the display). When the measuring input

changes, the display will not change.

When this switch is pressed again, the hold status is canceled you

can return to the measuring status. ("DH" on the display disappears.)

○Select switch

When this switch is pressed (→), the each modes change as

follows.

V●/〜

Ω/●/●

●

400・4000μA●/〜

40・400mA●/〜

4・20A●/〜

● →〜→ ● →〜

Ω→● → ● →Ω

(See 5-6 Capacity Measurement)

● →〜→● →〜

WARNING

Do not change over the function switch with a voltage applied

to the measuring terminals.

−31−

Page 8

○Auto power off, Auto powersave

This device incorporates auto-power-off function that turns off

the display in about 30 minutes to save battery draining. There is

a little battery draining even if the auto power save function is

activated, therefore be sure to return the Power/Function knob to

OFF after measurement. Press the data hold switch before the

auto-power-save function is activated to use the devise

continuously. To deactivate the auto-power-save function, turn

the meter ON while pressing the SELECT button.

○Over Limit (O.L) indication

In case of excess input to this device, the indicator displays O.L.

If O.L is displayed during the voltage function, stop the input

immediately.

4-2 How to Use the Stand

Please use the stand that there is on the side of rear case like a

figure.

〔Fig 3〕

−32−

Page 9

【5】MEASUREMENT PROCEDURE

5-1 Start-up Inspection

WARNING

1. Never use meter if the meter or test leads are damaged or

broken.

2. Make sure that the test leads are not cut or otherwise damaged.

START

▼

Main unit and

test leads

damaged?

No damage

Check continuity of

test leads.

①

②

③Set the function

▼

▼

Connect the test lead

of black plug to the

COM − terminal.

▼

Connect the test

lead of red plug to

the + terminal.

▼

switch at Ω //

and select the

select switch at .

Damaged

Stop using it and

have it repaired.

④Short the red and

▼

No problem.

Start measurement.

〔Fig 4〕

−33−

▼

▼

black test pins.

▼

Display shows

00.0〜1.0?

Yes

▼

①

▼

No

④

③

②

Page 10

Voltage Measurement Maximum rating input value 1000VDC or 750VAC

5-2

WARNING

1. Never apply an input signals exceeding the maximum rating

input value.

2. Be sure to disconnect the test pins from the circuit when

changing the function.

3. Always keep your fingers behind the finger guards on the probe

when making measurements.

1) Applications

DCV : Measures batteries and DC circuits.

ACV : Measures sine-wave AC voltage as lighting voltages.

2) Measuring ranges

DCV : 400mV〜1000V (5 ranges)

ACV : 4V〜750V (4 ranges)

3) Measurement procedure (See Fig 5 or 6, page 9)

①Connect the black plug of the test lead to the COM − input

terminal and the red plug to the + input terminal.

②Set the function switch at "V /〜 " function.

③Select the select switch at " " (DC) or "〜" (AC).

④Apply the black test pin to the negative potential side of the circuit

to measure and the red test pin to the positive potential side.

⑤Read the value on the display.

⑥After measurement, remove the red and black test pins from

the circuit measured.

⑦Turn the function switch to the position of OFF.

●In the AC4V range, a figure of about 3~9 counts will stay on even

if no input signal is present. But it is not malfunction.

●In the manual mode of the ACV function, the CD731a can be set

to the 400mV range and shows an approximate value. But its

accuracy is not guaranteed.

●Since this instrument employs the means value system for its

AC voltage measurement circuit, AC waveform other than sine

wave may cause error.

−34−

Page 11

5-3 Resistance Measurement (Ω)

WARNING

Never apply voltage to the input terminals.

1) Application

Resistance of resistors and circuits are measured.

2) Measuring ranges

400Ω〜40MΩ (6 ranges)

3) Measurement procedure (See Fig 7, page 10)

①Connect the black plug of the test lead to the COM − input

terminal and the red plug to the + input terminal.

②Set the function switch at "Ω//" function.

③Select the select switch at "Ω" (MΩ).

④Apply the black and red test pin to measured circuit.

⑤Read the value on the display.

⑥After measurement, remove the red and black test pins from the

circuit measured.

⑦Turn the function switch to the position of OFF.

●If measurement is likely to be influenced by noise, shield the object

to measure with negative potential (test lead black).

●If a test pin is touched by a finger during measurement, measurement

will be influenced by the resistance in the human body to result in

measurement error.

●The input terminals release voltage is about 0.4V.

5-4 Testing Diode ( )

WARNING

Never apply voltage to the input terminals.

1) Application

The quality of diodes is tested.

2) Measurement procedure (See Fig 8, page 11)

①Connect the black plug of the test lead to the COM − input

terminal and the red plug to the + input terminal.

②Set the function switch at "Ω/ / " function.

−35−

Page 12

③Select the select switch at " ".

④Apply the black test pin to the cathode of the diode and the red

test pin to the anode.

⑤Make sure that the display shows a diode forward voltage drop.

⑥Replace the red and black test pins, make sure that the display

is the same as that when the test leads are released.

⑦After measurement, release the red and black test pins from the

object measured.

⑧Turn the function switch to the position of OFF.

Judgement

When the items ⑤ and ⑥ are normal, the diode is good.

●The input terminals release voltage is about 1.1〜1.5V.

5-5 Checking Continuity ( )

WARNING

Never apply voltage to the input terminals.

1) Application

Checking the continuity of wiring and selecting wires.

2) Measurement procedure (See Fig 9, page 12)

①Connect the black plug of the test lead to the COM − input

terminal and the red plug to the + input terminal.

②Set the function switch at "Ω// " function.

③Select the select switch at " " .

④Apply the red and black test pins to a circuit or conductor to

measure.

⑤The continuity can be judged by whether the buzzer sounds or

not.

⑥After measurement, release the red and black test pins from the

object measured.

⑦Turn the function switch to the position of OFF.

●The buzzer sounds when the resistance in a circuit to measure is

less than about 10〜120Ω.

●Even if the buzzer does not sound, a resistance value up to 10〜

120Ω will be displayed.

−36−

Page 13

●The input terminals release voltage is about 0.4V.

●When a resistance value is in a range of 20 and 40Ω, noise will

be mixed in the buzzer sound. But it is not malfunction.

5-6 Capacity Measurement ( )

WARNING

1. Never apply voltage to the input terminals.

2. Be sure to discharge the capacitor prior to measurement.

1) Application

Measures capacitance of capacity.

2) Measuring ranges

40nF*〜100μF (5 ranges) *1000nF=1μF

3) Measurement procedure (See Fig 10, page 13)

①Connect the black plug of the test lead to the COM − input

terminal and the red test lead to the + input terminal.

②Set the function switch at " " function.

③Press the select switch to make the display show 00.00nF.

(The "REL" mark illuminates in the upper right area of the display.)

④Apply the red and black test pins to capacitor.

⑤Read the value on the display.

⑥After measurement, release the red and black test pins from the

object measured.

⑦Turn the function switch to the position of OFF.

●The " " function can be set to the auto range, but not to the

manual range.

●In 4nF and 40nF ranges, large value is left, especially when

disconnecting measuring terminals. This is not malfuction.

●For measurement of 100nF (0.1μF) or below, the display will not

stabilize due to the influence of ambient noise and floating

capacity. It is therefore recommended that an object to measure

(capacitor) be directly connected between the (+) and (−)

measuring terminals of the CD731a.

●As the capacitance increases, the measuring time becomes longer.

Example: 2 to 4 seconds at 10μF5 to 8 seconds at 50μF

Example: 13 to 16 seconds at 100μF

−37−

Page 14

5-7 Current Measurement (μA, mA, A)

WARNING

1. Never apply voltage to the input terminals.

2. Be sure to make a series connection via load.

(please see to above drawing)

3. Do not apply an input exceeding the maximum rated current

to the input terminals.

Power Power

Load Load

〔×〕

Wrong connection

〔○〕

Right connection

〔Fig 5〕

5-7-1 Current Measurement (μA, mA)

Maximum rating input value DC/AC 4000μA・400mA

1) Applications

Current in DC and AC circuit is measured.

2) Measuring ranges

DCA:400・4000μA, 40・400mA (4 ranges)

ACA:400・4000μA, 40・400mA (4 ranges)

3) Measurement procedure (See Fig 12, page 15)

①Connect the black plug of the test lead to the COM − input

terminal and the red plug to the + input terminal.

②Set the function switch at "400・4000μA" or "40・400mA" function.

③Select the select switch at " " (DC) or "〜" (AC).

④Apply the black test pin to the negative potential side of the circuit

to measure and the red test pin to the positive potential side.

−38−

Page 15

⑤Read the value on the display.

⑥After measurement, remove the red and black test pins from

the circuit measured.

⑦Turn the function switch to the position of OFF.

●If the display will not change when an input signal is applied

(measurement is not possible), a probable cause is a blown fuse.

●Since this instrument employs the means value system for its

AC voltage measurement circuit, AC waveform other than sine

wave may cause error.

5-7-2

Current Measurement (A) Maximum rating input value DC/AC 20A

WARNING

1. Never apply voltage to the input terminals.

2. Finish measurement within 10 seconds to prevent heat

generation.

3. Provide intervals 5 minutes or longer between measurements

to prevent heat generation. (Continuous measurement:max 5A)

4. Perform measurement with the leads kept straight to prevent

overheat.

1) Applications

Current in DC and AC circuit is measured.

2) Measuring ranges

DCA: 4・20A (2 ranges), ACA: 4・20A (2 ranges)

3) Measurement procedure (See Fig 13, page 16)

①Slide the safety cover of the CD731a to the left and insert the

red plug of the test leads to the 4・20A measuring terminal and

the black plug to the COM (−) terminal.

②Set the function switch at "4・20A /〜" function.

③Select the select switch at " " (DC) or "〜" (AC).

④Apply the black test pin to the negative potential side of the

circuit to measure and the red test pin to the positive potential

side.

⑤Read the value on the display.

⑥After measurement, remove the red and black test pins from

the circuit measured.

⑦Turn the function switch to the position of OFF.

−39−

Page 16

●If the display will not change when an input signal is applied

(measurement is not possible), a probable cause is a blown fuse.

●Since this instrument employs the means value system for its

AC voltage measurement circuit, AC waveform other than sine

wave may cause error.

5-8 How to use optional products

WARNING

Never apply an input signals exceeding the maximum rating

input value of optional products.

5-8-1

AC Clamp Probe (CL-20D) Maximum measurement value AC200A

<Measurement procedure> (See Fig 14, page 17)

①Connect the black plug of the current probe to the COM − input

terminal and the red plug to the + input terminal.

②Set the function switch at "V /〜" function.

③Select the select switch at "〜" and set the 4V range with the

range hold switch.

④Select either 20A or 200A with selector knob of clamp probe.

⑤Open the clamp part, have electric line (one line) clamped.

⑥Read the value on the display in A unit and when current probe

of the 20A range after multiplying indicated value by 10, and the

200A range after multiplying indicated value by 100.

⑦After measurement, open the clamp part and release clamp probe

from the electric wire.

⑧Turn the function switch to the position of OFF.

5-8-2

DC・AC Clamp Probe (CL-22AD) Maximum measurement value DC/AC200A

<Measurement procedure> (See Fig 15, page 18)

①Connect the black plug of the current probe to the COM −

terminal and the red plug to the + terminal.

②Set the function switch at "V /〜" function.

③Select the select switch at " " (DC) or "〜" (AC).

④Set the 400mV range (at DC measurement) or 4V range (at AC

measurement) with range hold switch.

⑤Select either 20A or 200A with selector knob of clamp probe.

probe to make the display of the CD731a show "000.0".

⑥Open the clamp part, have electric wire (one line) clamped.

−40−

Page 17

⑦Read the value on the display as follows.

DC20A : multiplying by 0.1 AC20A : multiplying by 100

DC200A : multiplying by 1 AC200A : multiplying by 1000

⑧After measurement, open the clamp part and release clamp probe

from the electric wire.

⑨Turn the function switch of multimeter and selector knob of

clamp probe to the position of OFF.

5-8-3

DC Clamp Probe (CL33DC) Maximum measurement value DC300A

<Measurement procedure> (See Fig 16, page 19)

①Connect the black plug of the current probe to the COM − input

terminal and the red plug to the + input terminal.

②Set the function switch at "V /〜" function.

③Select the select switch at " " (DC) and set the 400mV range

with the range hold switch.

④Select either 30A or 300A with selector knob of clamp probe.

⑤Open the clamp part, have electric line (one line) clamped.

⑥Read the value on the display in A unit and when current probe

of the 30A range after multiplying indicated value by 0.1, and the

300A range after multiplying indicated value by 1.

⑦After measurement, open the clamp part and release clamp probe

from the electric wire.

⑧Turn the function switch of multimeter and selector knob of

clamp probe to the position of OFF.

5-8-4 HV Probe (HV-60)Maximum measured voltage: DC30kV

<Measurement procedure> (See Fig 17, page 20)

WARNING

1.The probe is designed for the measurement of very small DC

circuit. Never use the probe to measure high voltage in power Iines,

Such as transmission and distribution lines; it is very dangerous.

2.Never apply an input signals exceeding the maximum

rating(30kV)of HV prove.

3.Be sure to disconnect the test pins from the circuit when

changing the function.

4.Always keep your fingers behind the finger guards on the

probe when making measurement.

−41−

Page 18

1) Measurement item

Anode voltage of cathode ray tube, high focusing voltage, and

voltage of high-impedance circuit

2) Measurement range : DC1000V range

(Set manually in the manual mode)

3) Measuring method

①Insert the red plug of the high-voltage probe into the V input

terminal and the black plug into the COM terminal.

②

Set the function switch to V, select DC with the SELECT

switch, and set the RANGE HOLD switch to the 1000 V range.

③

Connect the black clip to the ground line of the circuit under test and

touch the measuring position with the pin at the end of the probe.

④Read the indicator and multiply the reading by 0.1 for kV.

⑤After measurement, release the pin from the circuit under

test and then remove the clip.

●HV-60 cannot be used for AC voltage measurement.

【6】MAINTENANCE

WARNING

1. This section is very important for safety. Read and understand

the following instruction fully and maintain your instrument

properly.

2. The instrument must be calibrated and inspected at least once

a year to maintain the safety and accuracy.

6-1 Maintenance and inspection

1. Appearance

・Is the appearance not damaged by falling?

2. Test leads

・Is the cord of the test leads not damaged?

・Is the core wire not exposed at any place of the test leads?

If your instrument falls in any of the above items, do not use it and

have it repaired or replace it with a new one.

●Make sure that the test leads are not cut, referring to the section.

6-2 Calibration

The calibration and inspection may be conducted by the dealer.

For more information, please contact the dealer.

−42−

Page 19

6-3 How to Replace Battery and Fuse (See Fig 18, page 22)

WARNING

1. If the rear case is removed with input applied to the input

terminals, you may get electrical shock. Before starting the work,

always make ure that no inputs is applied.

2. Be sure to use the fuse is same rating so as to ensure safety

and performance of tester.

3. When operator remove the rear case, do not touch the internal

parts or wire with hand.

<How to replace the battery>

①Remove the holster.

②Remove the rear case screw with a screwdriver.

③Remove the rear case.

④Take out the battery and replace it with a new one.

⑤Attach the rear case and fix it with the the screw.

⑥Attach the holster.

* Do not use mix new and old batteries together.

<How to replace the fuse>

Fuse of the Specified Rating and Type

(Fuse with arc-extinguishing agent)

500mA/250Vφ5×20mm Blowout capacity:1500A

20A/250V φ6.3×32mm Blowout capacity:200kA

①Remove the holster.

②Remove the rear case screw with a screwdriver.

③Remove the rear case.

④Pull out the fuse out of holder on the circuit board and replace it.

⑤Put back rear case where it was and tighten the screw.

⑥Check and see whether or not indications of respective ranges

are normal.

⑦Attach the holster.

−43−

Page 20

6-4 Cleaning and Storage

CAUTION

1. The panel and the case are not resistant to volatile solvent and

must not be cleaned with thinner or alcohol.

For cleaning, use dry, soft cloth and wipe it lightly.

2. The panel and the case are not resistant to heat. Do not place

the instrument near heat-generating devices (such as a soldering

iron).

3. Do not store the instrument in a place where it may be subjected

to vibration or from where it may fall.

4. For storing the instrument, avoid hot, cold or humid places or

places under direct sunlight or where condensation is anticipated.

Following the above instructions, store the instrument in good

environment.

−44−

Page 21

【7】SPECIFICATIONS

7-1 Measurement Range and Accuracy

Accuracy assurance range : 23±5˚C 80%RH MAX. No condensaition.

Function

DCV

ACV

DCA

ACA

400.0mV

400.0μA,

40.00mA,

400.0mA

400.0μA,

40.00mA,

400.0mA

Ω

4.000M

40.00M

rdg:reading dgt:digits

CAUTION:

If there is presence of strong magnetic field generated by conductor fed large

current, motors or strong radio wave, a measurement may not be accurate.

Specifications and external appearance of the product described

above may be revised for modification without prior notice.

Input Resistance

Range Accuracy

≧100M

Approx. 11MΩ

4.000V

40.00V

Approx. 10MΩ

400.0V

1000V

Approx. 11MΩ

4.000V

40.00V

Approx. 10MΩ

400.0V

750V

20.00A

20.00A

400.0

Ω

Ω

Ω

Ω

Ω

Ω

Approx. 100Ω

Approx. 1Ω

Approx. 0.01Ω

Approx. 100Ω

Approx. 1Ω

Approx. 0.01Ω

4000μA

4.000A,

4000μA

4.000A,

4.000k

40.00k

400.0k

40.00nF

400.0nF

4.000μF

40.00μF

100.0μF

±(0.5%rdg+2dgt)

Ω

±(0.9%rdg+2dgt)

±(1.0%rdg+2dgt)

±(1.2%rdg+9dgt)

±(1.2%rdg+5dgt)

±(1.5%rdg+5dgt)

±(1.5%rdg+2dgt)

±(2.0%rdg+2dgt)

±(1.8%rdg+5dgt)

±(2.5%rdg+5dgt)

±(1.5%rdg+5dgt)

±(1.2%rdg+4dgt)

±(1.8%rdg+2dgt)

±(3.0%rdg+2dgt)

Open voltage Approx

Buzzer sound at approx. 10〜120

Open voltage Approx 1.5V

±(5.0%rdg+6dgt)

Remarks

Accuracy in the cace of sin

wave

40〜500Hz

20A range :

Continuous measurement :

max 5A

Accuracy in the cace of sin

wave

40〜500Hz

20A range :

Continuous measurement :

max 5A

Open voltage Apporox 0.4V

Ω max.

Auto range only

−45−

Page 22

7-2 General Specifications

Measuring Method

Display : 4000 counts

Range selection : Auto and manual ranges

Over display : "O.L" is displayed

Polarity : Automatic selection (only "−" is displayed)

Battery discharge display

Sampling rate : Approx. 3 times/sec.

Accuracy assurance temperature /humidity range

Operating temperature /humidity range

Storage temperature /humidity range

Environmental condition

Power supply : R6 (IEC) dry battery, 2 pieces

Power consumption

Battery life : Approx. 400 hours at DCV

Fuse protection : 500mA/250V Fast acting fuse (φ5×20mm)

Fuse with

arc-extinguishing

( )

agent

Dimension and weight

Safety : IEC 61010-1 (EN61010-1)

EMC :

Accessories :

: △Σmethod

(except DC/AC20A, DC1000V, AC750V ranges)

: If the internal battery has been consumed and the

voltage drops, the display shows.

:23±5˚C 80%RH max. No condensation.

:0〜40˚C 80%RH max. No condensation.

: -10〜50˚C 70%RH max. No condensation.

: Operating altitude <2000m, pollution degree Ⅱ

: Approx. 7mW TPY. (at DCV)

Blowout capacity, 1500A

20A/250V Fast acting fuse (φ6.3×32mm)

Blowout capacity, 200kA

: 167(H) × 90(W) × 48(D)mm

Approx. 315g (holster attached.)

≦DC・AC 600V : Measurement category Ⅲ (CAT.Ⅲ

requirement of IEC 61010-1, Pollution degree Ⅱ.

≦DC1000V・AC 750V : Measurement category Ⅱ (CAT.Ⅱ)

requirement of IEC 61010-1, Pollution degree Ⅱ.

EN50081-1 (EN55022) EN50082-1(EN61000-4-2)

EN50082-1 (EN61000-4-3) EN50082-1(EVN50204)

Instruction manual, Test leads(TL-21), Holster (H-70)

)

−46−

Page 23

MEASUREMENT CATEGORY

・CATⅠ:Secondary electrical circuit connected to an AC

electrical outlet through a transfomer or similar device.

・CATⅡ:Primary electrical circuits in equipment connected to

an AC electrical outlet by a power cord.

・CATⅢ:Primary electrical circuits of heavy equipment

connected directly to the distribution panel, and

feeders from the distribution panel to outlets.

Factory -preinstalled built-in battery

A battery for monitoring is preinstalled before shipping, therefore it

may run down sooner than the battery life specified in the

instruction manual.

※The "battery for monitoring" is a battery to inspect the functions

and specifications of the product.

7-3 Optional accessories

・Clip adapter CL-11・HV probe HV-60

・Corrent probe CL-20D, CL-22AD, CL33DC・Carrying case C-SP

【8】After-Sales Service

8-1 Warranty and Provision

Sanwa offers comprehensive warranty services to its end-users and to its

product resellers. Under Sanwa's general warranty policy, each instrument

is warranted to be free from defects in workmanship or material under

normal use for the period of one (1) year from the date of purchase.

This warranty policy is valid within the country of purchase only, and

applied only to the product purchased from Sanwa authorized agent

or distributor.

Sanwa reserves the right to inspect all warranty claims to determine

the extent to which the warranty policy shall apply. This warranty shall

not apply to fuses, disposables batteries, or any product or parts,

which have been subject to one of the following causes:

1. A failure due to improper handling or use that deviates from

the instruction manual.

2. A failure due to inadequate repair or modification by people

other than Sanwa service personnel.

3. A failure due to causes not attributable to this product such as

fire, flood and other natural disaster.

−47−−47−

Page 24

4. Non-operation due to a discharged battery.

5. A failure or damage due to transportation, relocation or

dropping after the purchase.

8-2 Repair

Customers are asked to provide the following information when

requesting services:

1. Customer name, address, and contact information

2. Description of problem

3. Description of product configuration

4. Model Number

5. Product Serial Number

6. Proof of Date-of-Purchase

7. Where you purchased the product

1) Prior to requesting repair,please check the following:

Capacity of the built-in battery, polarity of installation and

discontinuity of the test leads.

2) Repair during the warranty period:

The failed meter will be repaired in accordance with the conditions

stipulated in 8-1 Warranty and Provision.

3) Repair after the warranty period has expired:

In some cases, repair and transportation cost may become higher

than the price of the product. Please contact Sanwa authorized

agent / service provider in advance.

The minimum retention period of service functional parts is 6 years

after the discontinuation of manufacture. This retention period is the

repair warranty period. Please note, however, if such functional parts

become unavailable for reasons of discontinuation of manufacture,

etc., the retention period may become shorter accordingly.

4) Precautions when sending the product to be repaired:

To ensure the safety of the product during transportation, place the

product in a box that is larger than the product 5 times or more in

volume and fill cushion materials fully and then clearly mark ”Repair

Product Enclosed” on the box surface. The cost of sending and

returning the product shall be borne by the customer.

8-3 SANWA web site

http://www.sanwa-meter.co.jp

E-mail: exp_sales@sanwa-meter.co.jp

−48−

Page 25

本社=東京都千代田区外神田2−4−4・・電波ビル

郵便番号=101-0021・・電話=東京(03)3253−4871(代)

大阪営業所=大阪市浪速区恵美須西2−7−2

郵便番号=556-0003・・電話=大阪(06)6631−7361(代)

SANWA ELECTRIC INSTRUMENT CO.,LTD.

Dempa Bldg, 4-4 Sotokanda2-Chome Chiyoda-Ku,Tokyo,Japan

大豆インキを使用しています。

02-080220402040

Loading...

Loading...