Toshiba CARRIER RAV-SP180CT-UL, CARRIER RAV-SP300CT-UL, CARRIER RAV-SP240CT-UL, CARRIER RAV-SP360CT-UL, CARRIER RAV-SP420CT-UL Installation Manual

Page 1

AIR CONDITIONER (SPLIT TYPE)

Installation Manual

Indoor Unit

Model name:

Under Ceiling Type

RAV-SP180CT-UL

RAV-SP240CT-UL

RAV-SP300CT-UL

RAV-SP360CT-UL

RAV-SP420CT-UL

Not accessible to the general public

Vente interdite au grand public

Installation Manual

Air conditioner

Manuel d’installation

Climatiseur

(Split type) 1

(Type split) 33

English

Français

Page 2

Under Ceiling Type

Please read this Installation manual carefully before installing the Air Conditioner.

• This Manual describes the installation method of the indoor unit.

• For installation of the outdoor unit, follow the Installation Manual attached to the outdoor unit.

Installation Manual

ADOPTION OF NEW REFRIGERANT

This Air Conditioner uses R410A an environmentally friendly refrigerant.

Contents

1 ACCESSORY PARTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2 PRECAUTIONS FOR SAFETY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3 SELECTION OF INSTALLATION PLACE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4 REFRIGERANT PIPING AND EVACUATING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5 DRAIN PIPING WORK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6 ELECTRICAL CONNECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

7 APPLICABLE CONTROLS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

8 TEST RUN. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

9 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

1-EN

–1–

Page 3

Under Ceiling Type

Installation Manual

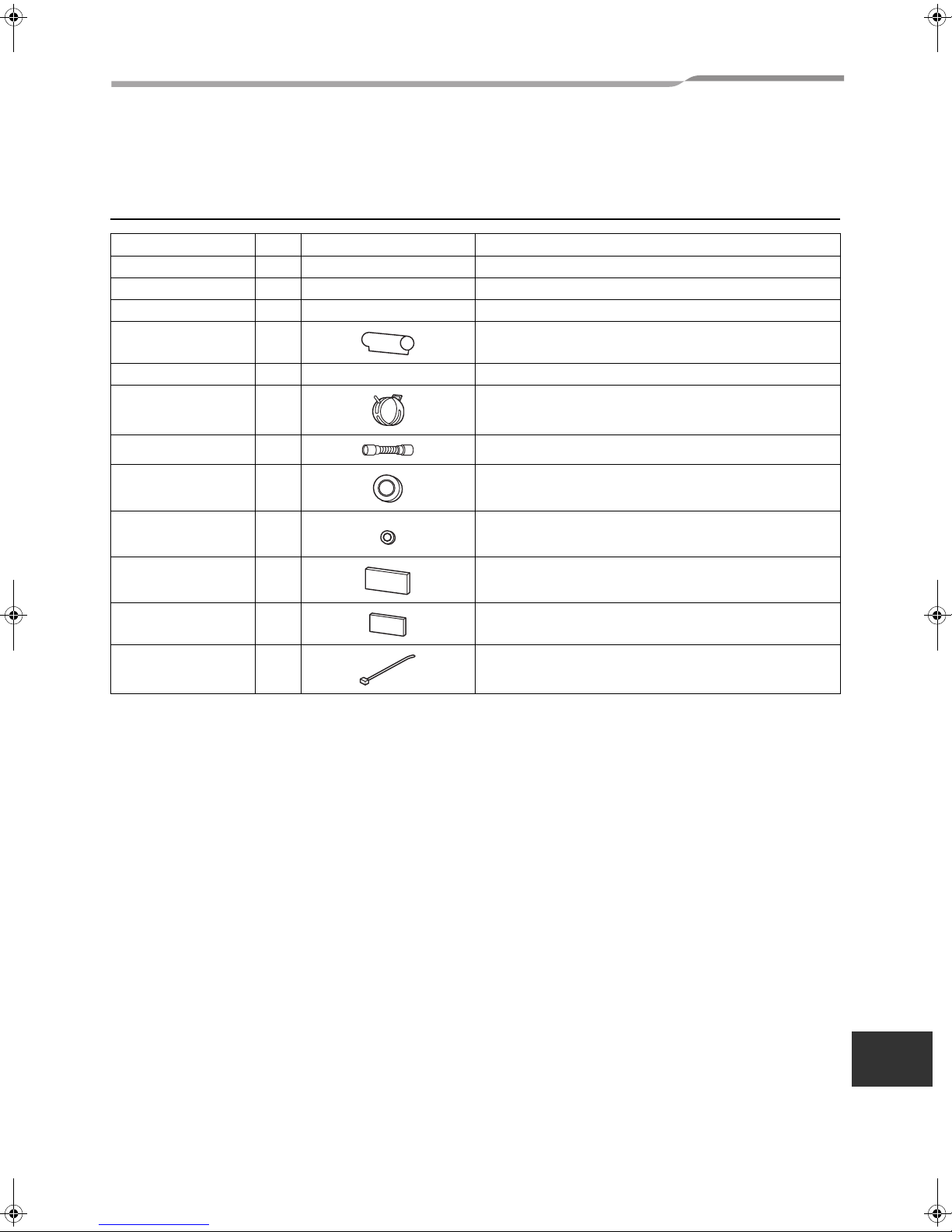

1 ACCESSORY PARTS

Accessory parts

Part name Q’ty Shape Usage

Owner’s Manual 1 – –

Installation Manual 1 This manual –

Installation pattern 1 – Drawing-out port of hanging bolt pipe

Thermal insulation pipe 2 For thermal insulation of pipe connecting section

Washer 4 3/8” (M10) × Ø1.0” (25 mm) For holding down unit

Hose band 2 For connecting drain pipe

Drain hose 1 For connecting drain pipe

Bushing Ø2.2” (Ø56) 1 For protection of edge at hole for remote control wires

Bushing Ø1.1” (Ø28) 1 For sealing the back side conduit hole

Thermal insulator 1

Thermal insulator of top

plate

Banding band 2 For prevention of open of drain hose thermal insulator

1

For thermal insulation of drain hose

(0.4” - thickness × 7.9” × 7.9” (10 - thickness × 200 × 200 mm))

For upper pipe hole of indoor unit

(0.2” - thickness × 5.1” × 6.3” (6 - thickness × 130 × 160 mm))

–2–

EN

2-EN

Page 4

Under Ceiling Type

Installation Manual

2 PRECAUTIONS FOR SAFETY

Installing, starting up, and servicing air--conditioning equipment can be hazardous due to system pressures,

electrical components, and equipment location (roofs, elevated structures, etc.).

Only trained, qualified installers and service mechanics should install, start--up, and service this equipment.

Untrained personnel can perform basic maintenance functions such as cleaning heat exchanger. All other

operations should be performed by trained service personnel.

When working on the equipment, observe precautions in the literature and on tags, stickers, and labels attached

to the equipment.

Follow all safety codes.Wear safety glasses and work gloves. Keep quenching cloth and fire extinguisher nearby

when brazing. Use care in handling, rigging, and setting bulky equipment.

Read these instructions thoroughly and follow all warnings or cautions included in literature and attached to the

unit. Consult local building codes and National Electrical Code (NEC) for special requirements. Recognize safety

information. This is the safety--alert symbol . When you see this symbol on the unit and in instructions or

manuals, be alert to the potential for personal injury.Understand these signal words: DANGER, WARNING, and

CAUTION. These words are used with the safety--alert symbol.

DANGER identifies the most serious hazards which will result in severe personal injury or death. WARNING

signifies hazards which could result in personal injury or death. CAUTION is used to identify unsafe practices which

may result in minor personal injury or product and property damage. NOTE is used to highlight suggestions which

will result in enhanced installation, reliability, or operation.

WARNING

• Ask an authorized dealer or qualified installation professional to install (including moving)/maintain the air

conditioner.

Inappropriate installation may result in water leakage, electric shock or fire.

• Be sure to connect ground wire. (grounding work)

Incomplete grounding cause an electric shock.

Do not connect ground wires to gas pipes, water pipes, lightning rods or ground wires for telephone wires.

• Turn off the circuit breaker before attempting any electrical work.

Make sure all circuit breaker is off. Failure to do so may cause electric shock.

• Install the refrigerant pipe securely during the installation work before operating the air conditioner.

If the air conditioner is operated with the valve open and without the refrigerant pipe, the compressor sucks air and

the refrigeration cycle is overpressurized, which may cause a burst or injury.

• When moving the air conditioner for the installation into another place, be very careful not to enter any

gaseous matter other than the specified refrigerant into the refrigeration cycle.

If air or any other gas is mixed in the refrigerant, the gas pressure in the refrigeration cycle becomes abnormally high

and it resultingly causes pipe burst and injuries on persons.

• Perform installation work properly according to the Installation Manual.

Inappropriate installation may result in water leakage, electric shock or fire.

• When the air conditioner is installed in a small room, provide appropriate measures to ensure that the

concentration of refrigerant leakage occur in the room does not exceed the critical level.

• Install the air conditioner securely in a location where the base can sustain the weight adequately.

• Perform the specified installation work to guard against an earthquake.

If the air conditioner is not installed appropriately, accidents may occur due to the falling unit.

• If refrigerant gas has leaked during the installation work, ventilate the room immediately.

If the leaked refrigerant gas comes in contact with fire, noxious gas may generate.

• After the installation work, confirm that refrigerant gas does not leak.

If refrigerant gas leaks into the room and flows near a fire source, such as a cooking range, noxious gas might

generate.

• Electrical work must be performed by a qualified electrician in accordance with the Installation Manual. Make

sure the air conditioner uses an exclusive power supply.

An insufficient power supply capacity or inappropriate installation may cause fire.

• Use the specified wires for wiring connect the terminals securely fix.

To prevent external forces applied to the terminals from affecting the terminals.

3-EN

–3–

Page 5

Under Ceiling Type

• Conform to the regulations of the local electric company when wiring the power supply.

Inappropriate grounding may cause electric shock.

• For the refrigerant recovery work (collection of refrigerant from the pipe to the compressor), stop the

compressor before disconnecting the refrigerant pipe.

If the refrigerant pipe is disconnected while the compressor is working with the valve open, the compressor sucks air

and the refrigeration cycle is overpressurized, which may cause a burst or injury.

Installation Manual

CAUTION

• THIS AIR CONDITIONER ADOPTS THE NEW HFC REFRIGERANT (R410A) WHICH DOES NOT DESTROY

OZONE LAYER.

• The characteristics of R410A refrigerant are ; easy to absorb water, oxidizing membrane or oil, and its pressure is

approx. 1.6 times higher than that of refrigerant R22. Accompanied with the new refrigerant, refrigerating oil has also

been changed. Therefore, during installation work, be sure that water, dust, former refrigerant, or refrigerating oil does

not enter the refrigerating cycle.

• To prevent charging an incorrect refrigerant and refrigerating oil, the sizes of connecting sections of charging port of

the main unit and installation tools are changed from those for the conventional refrigerant.

• Accordingly the exclusive tools are required for the new refrigerant (R410A).

• For connecting pipes, use new and clean piping designed for R410A, and please care so that water or dust does not

enter.

• Tighten the flare nut with a torque wrench in the specified manner.

Excessive tightening of the flare nut may cause a crack in the flare nut after a long period, which may result in

refrigerant leakage.

• Wear heavy gloves during the installation work to avoid injury.

• The installation fuse must be used for the power supply line of this conditioner.

–4–

EN

4-EN

Page 6

Under Ceiling Type

Installation Manual

3 SELECTION OF INSTALLATION PLACE

WARNING

• Install the air conditioner at enough strong place

to withstand the weight of the unit.

If the strength is not enough, the unit may fall down

resulting in injury.

• Install the air conditioner at a height 8’ (2.4 m) or

more from the floor.

If you insert your hands or others directly into the unit

while the air conditioner operates, it is dangerous

because you may contact with revolving fan or active

electricity.

CAUTION

• Do not install the air conditioner in a location

subject to a risk of exposure to a combustible gas.

If a combustible gas leaks and stays around the unit,

a fire may occur.

Upon approval of the customer, install the air

conditioner in a place that satisfies the

following conditions.

• Place where the unit can be installed horizontally.

• Place where a sufficient servicing space can be

ensured for safety maintenance and check.

• Place where drained water will not cause any

problem.

Avoid installing in the following places.

• Place exposed to air with high salt content (seaside

area), or place exposed to large quantities of sulfide

gas (hot spring).

(Should the unit be used in these places, special

protective measures are needed.)

• Place exposed to oil, vapor, oil smoke or corrosive

gas.

• Place where organic solvent is used nearby.

• Place close to a machine generating high frequency.

• Place where the discharged air blows directly into

the window of the neighbor house. (Outdoor unit)

• Place where noise of the outdoor unit is easily

transmitted.

(When install the outdoor unit on the boundary with

the neighbor, pay due attention to the level of noise.)

• Place with poor ventilation. (Before air ducting work,

check whether value of fan speed, static pressure

and duct resistance are correct.)

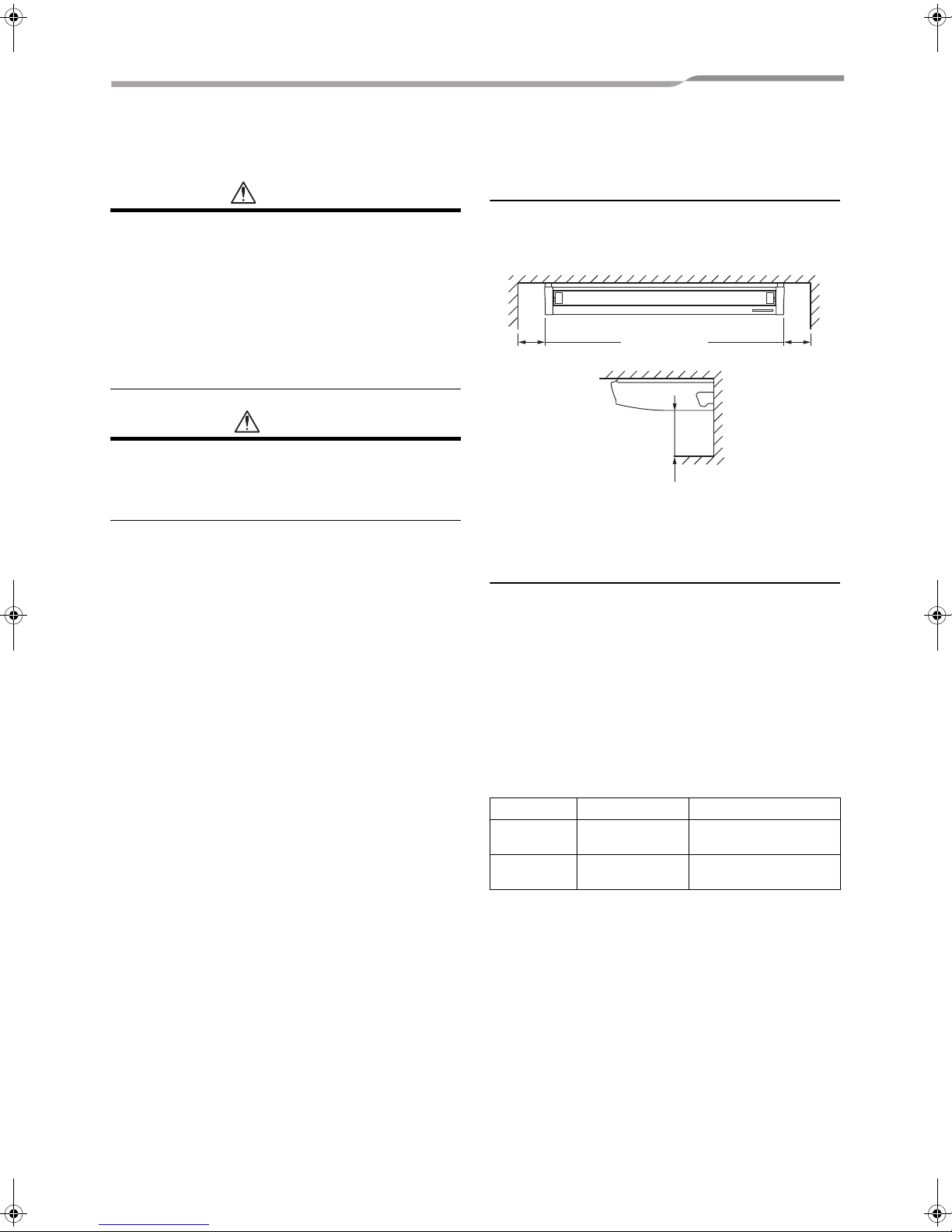

Installation space

Secure the specified space in the figure for

installation and servicing.

Unit: in (mm)

9.8” (250)

or more

19.7” (500) or more

9.8” (250)

or more

Height of ceiling

Set the installable height of the ceiling within 13’1” (4

m), otherwise the air distribution will become poor.

If height of ceiling exceeds 11’6” (3.5 m), hot air

becomes difficult to reach the floor surface, and then

the change of setup of high ceiling is necessary.

For the change method of high ceiling, refer to the

application control, “In case of installation to high

ceiling” and “In case of incorporating filter sold

separately” in this Manual.

List of installable ceiling height

Setup data

0000

0001 High ceiling 1

According to the conditions of installation, setup time of

turning-on of filter sign (notification of filter cleaning) of

the remote control can be changed.

When it is difficult to warm up the room due to

installation place or structure of the room, the detection

temperature of heating can be raised.

For change the setup time, refer to the application

control, “Change of filter sign turning-on time” and

“How to increase the heating effect” in this Manual.

Standard

(Factory default)

11’6” (3.5 m) or less

more than 11’6” (3.5 m)

up to 13’1” (4.0 m)

5-EN

–5–

Page 7

Under Ceiling Type

Installation Manual

Wireless remote control

Decide the position which remote control is operated

and the installation place.

And then refer to the Installation Manual of the wireless

remote controller kit sold separately.

(The signal of the wireless type remote control can be

received within approx. 23’ (7 m). This distance is a

criterion and varies a little according to capacity of the

battery, etc.)

• To prevent malfunction, select a place where is not

affected by a fluorescent lamp or direct sunlight.

• Two or more (up to 6 units) wireless-type indoor units

can be set in a room.

A

p

p

r

o

x

.

2

3

’

(

7

m

)

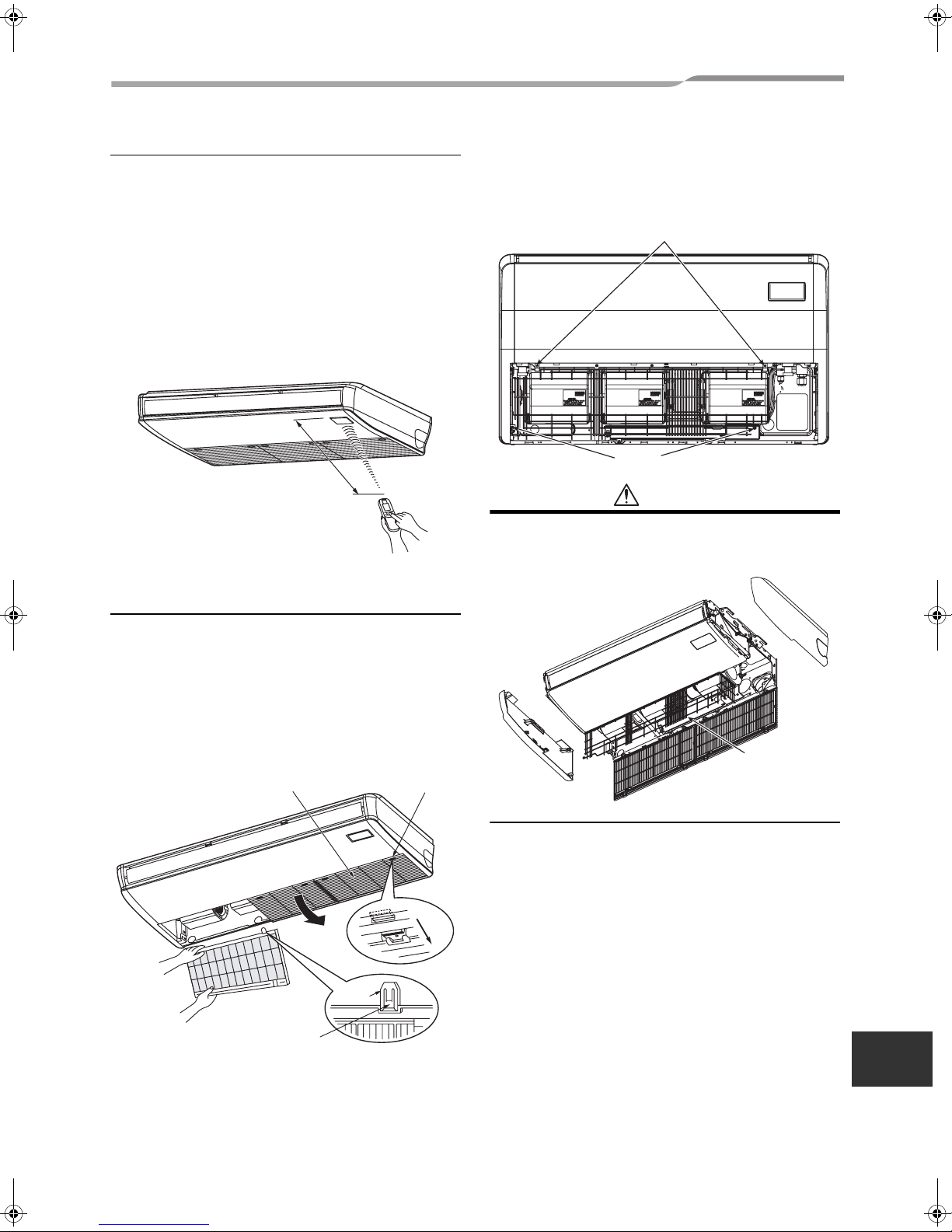

2 Removing wire guard

Remove the screws (2 pcs.) which are fixing the

wire guard.

Remove the clamp fixing screws and remove the

wire guard.

Clamps

Screw

CAUTION

Attach back the wire guard once indoor unit is installed.

Remove the 2 screws fixing the wire guard and hung the

wire guard with the clamps during a service.

Before installation

1 Removal of suction grille

Slide the suction grille fixing knobs (2 positions)

toward the arrow direction, and then open the

suction grille.

Under the condition of suction grille opened, push

the hook section of hinges (2 positions) at the rear

side, and then pull out the suction grille.

Hinge

Suction grille

fixing knob

Suction grille

Pull out suction grille

while pushing hook.

Wire guard

S

l

i

d

e

EN

–6–

6-EN

Page 8

Under Ceiling Type

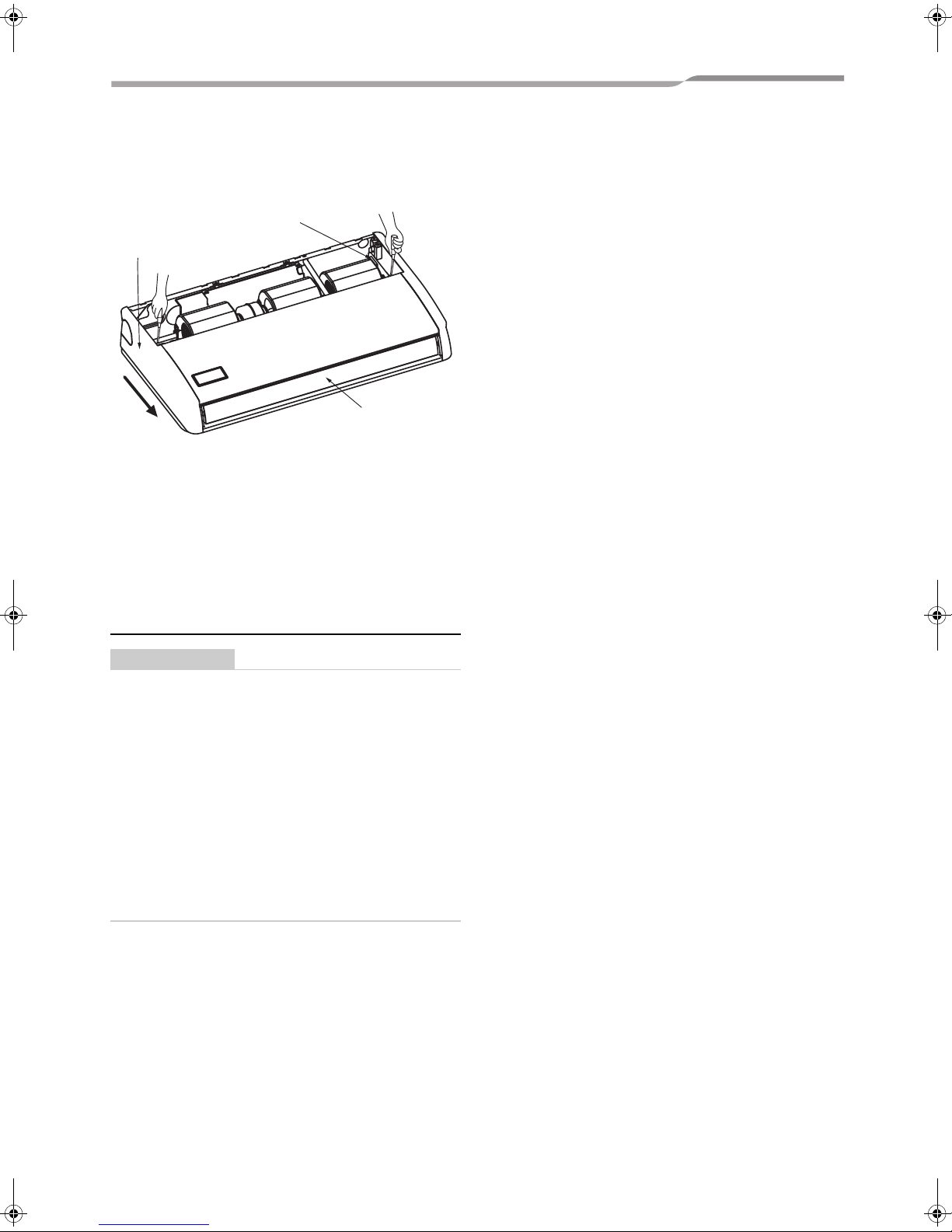

3 Removal of side panel

After removing the side panel fixing screws (1

each at right and left), slide the side panel forward

and then remove it.

Protector

Side panel

Level louver

Slide forward.

4 Removal of protective vinyl

Peel out the protective vinyl on the level louver.

Installation Manual

5 Removal of protector

Remove the protector (1 pcs.) of the fan.

(RAV-SP240CT only)

External view

REQUIREMENT

Strictly comply with the following rules to prevent

damage of the indoor units and human injury.

• Do not put a heavy article on the indoor unit. (Even

units are packaged)

• Carry in the indoor unit as it is packaged if possible.

If carrying in the indoor unit unpacked by necessity,

be sure to use buffering cloth, etc. to not damage

the unit.

• Do not apply force to the other parts (refrigerant

pipe, drain pan, foamed parts, or resin parts, etc.).

• Carry the package by two or more persons, and do

not bundle it with plastic band at positions other

than specified.

7-EN

–7–

Page 9

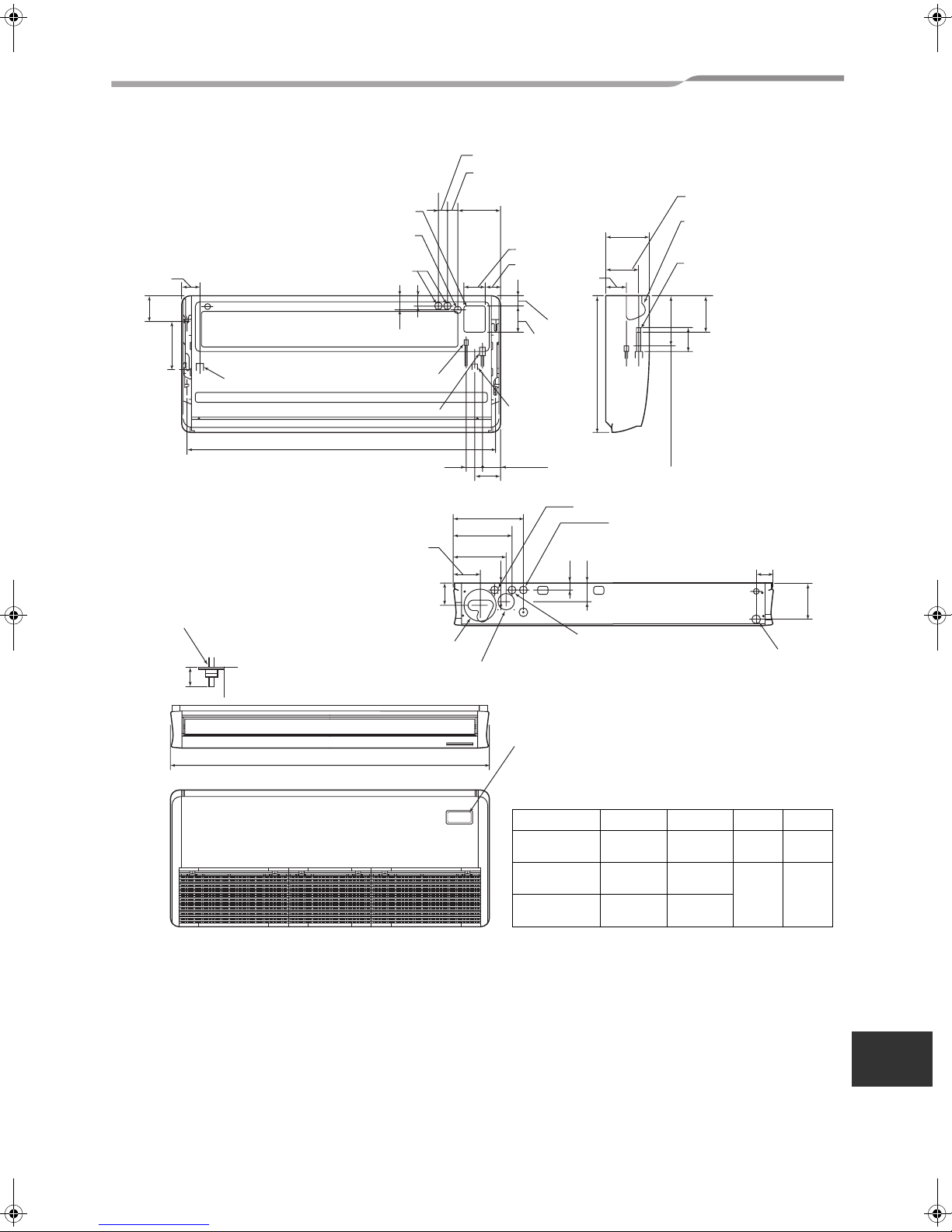

Under Ceiling Type

Upper pipe draw-out port (knockout)

Hole for remote control wires (knockout)

3.3” (84)

6.7” (170)

(Hole for power supply cable. knockout)

12.6” (320)

Left drain size

Conduit hole

2.8”

(70)

Refrigerant pipe

(Liquid side ØC)

Refrigerant pipe (Gas side ØD)

B (Hanging position)

3.0” (75)

5.3” (135)

2.1”

(53)

12.2” (311)

10.3” (262)

1.5” (39)

2.0” (52)

8.5” (216)

5.7” (146)

13.7” (347)

3.5”

(90)

4.3” (110)

3.0” (76)

4.1” (105)

5.1” (130)

Drain pipe

connecting

port

3.8” (97)

8.3” (210)

2.0” (50)

26.8” (680)

7.9” (200) (Liquid pipe)

Hole for remote control wires

Conduit hole

(knockout)

3.6” (92)

1.3” (32)

Installation Manual

Unit: in (mm)

6.6” (167)

Pipe draw-out port

(knockout)

Drain port VP20

(Inner dia. Ø1.0” (26), hose

attached)

4.5” (114)

5.6” (141)

8.5” (216) (Gas pipe)

3.3” (84)

Hanging bolt

Within

2.0” (50)

Ceiling surface

Unit

Pipe hole on wall

(Ø3.9” (100) hole)

A

Outside air take-in port (Duct sold separately)

Knockout hole Ø3.6” (92))

5.7” (145)

Hole for power supply cable

Left drain pipe

draw-out port

(knockout)

Wireless sensor

mounting section

Unit: in (mm)

Model name A B C D

180CT

240CT

300CT, 360CT

to 420CT

35.8”

(910)

46.5”

(1180)

62.8”

(1595)

33.7”

(855)

44.3”

(1125)

60.6”

(1540)

Ø1/4”

(6.4)

Ø3/8”

(9.5)

Ø1/2”

(12.7)

Ø5/8”

(15.9)

Considering pipe/wire connecting work inside the ceiling after the indoor unit has been hanged, select an

installation place and determine piping direction.

• If the ceiling has already been set before hanging the main unit, prepare refrigerant pipe, drain pipe, indoor

connecting wire, remote control cord, etc. up to the place where pipe and wire can be connected.

• Check the size of the indoor unit, and match the indoor unit size using the attached installation pattern.

6.7” (171)

EN

–8–

8-EN

Page 10

Under Ceiling Type

Installation Manual

Using attached installation pattern

Ceiling surface

Wall face

Installation pattern

Using the pattern, positioning of the hanging bolt and

pipe hole can be performed.

* As an error to some degree may generate on the

pattern size due to temperature and humidity, be

sure to confirm the size.

Installation of hanging bolts

Use 3/8” (M10) hanging bolts (4 pcs, to be local

procure).

Matching to the existing structure, set pitch according

to size in the unit external view as shown below.

New concrete slab

Install the bolts with insert brackets or anchor bolts.

Rubber

(Blade type

bracket)

Use existing angles or install new support angles.

(Slide type

bracket)

Steel flame structure

Hanging bolt

Anchor bolt

(Pipe hanging

anchor bolt)

Pipe knockout hole

• Piping from rear side

* Cut off the groove section with a plastic cutter, etc.

Rear cover

100

Opened when

Grooves

Opened when only drain pipe is

taken out from the rear side

• Piping from right side

* Cut off the groove section with a metal saw or

plastic cutter, etc.

• Piping from left side

Taking pipe from left side is applied only to the

drain pipe.

The refrigerant pipe cannot be taken out from the

left side.

* Cut off the groove section with a metal saw or

plastic cutter, etc.

refrigerant pipe is

taken out from the

rear side

Groove

Side panel (Right side)

Hanging bolt Support angle

Existing concrete slab

Use a hole-in anchors, hole-in plugs, or a hole-in bolts.

Draw-out direction of pipe/

wire

• Decide installation place of the unit and draw-out

direction of pipe and wire.

9-EN

Groove

• Piping from upper side

Taking pipe from upper side is applied only to

the refrigerant pipe.

When taking out the drain pipe from the upper

side, use a drain up kit sold separately.

Open the upper pipe draw-out port (Knockout hole)

shown in the external view.

(Knockout hole of thin plate)

After piping, cut off the attached thermal insulator of

the top plate to pipe shape, and then seal the

knockout hole.

–9–

Side panel (Left side)

Page 11

Under Ceiling Type

Installation Manual

Installation of indoor unit

• Preparation before holding down main unit

* Confirm the presence of the ceiling material

beforehand because the fixing method of hanging

metal when the ceiling material is set differs from

that when the ceiling material is not set.

▼ There is ceiling material

Hanging bolt

(Procured locally)

Indoor

unit

Hanging metal

Nut

(Procured locally)

Indoor

unit

Hanging metal

* Tighten the hanging metal with upper/lower nuts

as shown in the figure.

▼ There is no ceiling material

Indoor

unit

• Holding down of main unit

(1) Attach washer and nuts to the hanging bolt.

Ceiling surface

Ceiling surface

Washer (Accessory)

Double nut

(Procured locally)

Hanging bolt

(Procured locally)

Ceiling surface

Washer (Accessory)

Double nut

(Procured locally)

Hanging bolt

(Procured locally)

Washer

(Procured locally)

Washer (Accessory)

Double nut

(Procured locally)

2.0” (50 mm)

(2) Hang the unit to the hanging bolt as shown the

figure below.

(3) As shown in the figure below, fix the ceiling material

securely with the double nuts.

REQUIREMENT

• The ceiling surface may not be horizontal. Be

sure to confirm that width and depth directions

are level.

Installation of remote control

(Sold separately)

For installation of the wired remote control, follow the

Installation Manual attached with the remote control.

• Pull out the remote control cord together with the

refrigerant pipe or drain pipe.

Be sure to pass the remote control cord through

upper side of the refrigerant pipe and drain pipe.

• Do not leave the remote control at a place exposed

to the direct sunlight and near a stove.

• Operate the remote control, confirm that the indoor

unit receives a signal surely, and then install it.

(Wireless type)

• Keep 3’3” (1 m) or more from the devices such as

television, stereo, etc.

(Disturbance of image or noise may generate.)

(Wireless type)

Washer

(Accessory)

Hanging bolt

Double nut

(Procured locally)

0.8” - 1.2”

(20 - 30 mm)

–10–

EN

10-EN

Page 12

Under Ceiling Type

Installation Manual

4 REFRIGERANT PIPING AND EVACUATING

Refrigerant Piping

• The connecting sections of the refrigerant pipes are

provided at the positions in the figure below.

Upper side

Right

Rear side

1. Use copper pipe with 0.03” (0.8 mm) or more

thickness.

(In case pipe size is Ø5/8” (15.9 mm), with 0.04” (1.0

mm) or more.)

2. Flare nut and flare works are also different from

those of the conventional refrigerant.

Take out the flare nut attached to the main unit of the

air conditioner, and use it.

REQUIREMENT

When the refrigerant pipe is long, provide support

brackets at intervals of 8’2” - 9’10” (2.5 - 3 m) to clamp

the refrigerant pipe. Otherwise, abnormal sound may

be generated.

* When using the drain

pump kit sold separately,

the pipe can be drawn out

only from the upper side.

Permissible Piping Length

and Height Difference

They vary according to the outdoor unit.

For details, refer to the Installation Manual attached to

the outdoor unit.

Flaring

• Cut the pipe with a pipe cutter.

Remove burrs completely.

Remaining burrs may cause gas leakage.

• Insert a flare nut into the pipe, and flare the pipe.

As the flaring sizes of R410A differ from those of

refrigerant R22, the flare tools newly manufactured

for R410A are recommended.

However, the conventional

tools can be used by adjusting

projection margin of the

copper pipe.

▼ Projection margin in

flaring: B (Unit: in (mm))

Rigid (Clutch type)

Outer dia. of

copper pipe

1/4” - 5/8”

(6.4 - 15.9)

R410A tool used

0 - 0.02”

(0 - 0.5)

Conventional

tool used

0.04” - 0.06”

(1.0 - 1.5)

B

CAUTION

IMPORTANT 4 POINTS FOR PIPING WORK

1. Remove dust and moisture from the inside of the

connecting pipes.

2. Tight connection (between pipes and unit)

3. Evacuate the air in the connecting pipes using

VACUUM PUMP.

4. Check the gas leakage. (Connected points)

Pipe size

Model

name

Pipe size

RAV-

Gas side

Liquid side

SP180

type

1/2"

(12.7 mm)

1/4"

(6.4 mm)

SP240, SP300,

SP360, SP420

type

5/8"

(15.9 mm)

3/8"

(9.5 mm)

Outer dia. of copper pipe

1/4” (6.4) or 3/8” (9.5) 0.06” - 0.08” (1.5 - 2.0)

1/2” (12.7) or 5/8” (15.9) 0.08” - 0.1” (2.0 - 2.5)

Imperial

(Wing nut type)

▼ Flaring dia. meter size: A (Unit: in (mm))

Outer dia. of copper pipe A

1/4” (6.4) 0.36” (9.1)

3/8” (9.5) 0.52” (13.2)

1/2” (12.7) 0.65” (16.6)

5/8” (15.9) 0.78” (19.7)

+0

-0,02" (–0.4)

* In case of flaring for R410A with the

conventional flare tool, pull it out approx.

0.02” (0.5 mm) more than that for R22 to

adjust to the specified flare size.

The copper pipe gauge is useful for

adjusting projection margin size.

A

11-EN

–11–

Page 13

Under Ceiling Type

Installation Manual

Tightening connection

CAUTION

• Do not apply excessive torque. Otherwise, the nut

may crack depending on the conditions.

(Unit: ft•lbs (N•m))

Outer dia. of copper

▼

Tightening torque of flare pipe connections

pipe

1/4” (6.4 mm) 10 -13 (14 - 18)

3/8” (9.5 mm) 24 - 31 (33 - 42)

1/2” (12.7 mm) 37 - 46 (50 - 62)

5/8” (15.9 mm) 46 - 57 (63 - 77)

Pressure of R410A is higher than that of R22.

(Approx. 1.6 times)

Therefore, using a torque

wrench, tighten the flare pipe

connecting sections which

connect the indoor and

outdoor units of the specified

tightening torque.

Incorrect connections may

cause not only a gas leak, but

also a trouble of the

refrigeration cycle.

Align the centres of the connecting pipes and tighten

the flare nut as far as possible with your fingers. Then

tighten the nut with a spanner and torque wrench as

shown in the figure.

Tightening torque

Flare at

outdoor

unit side

Flare at

indoor

unit side

Evacuation

Using a vacuum pump, perform vacuuming from the

charge port of valve of the outdoor unit.

For details, follow to the Installation Manual attached to

the outdoor unit.

• Never use the refrigerant sealed in the outdoor unit

for air purge.

REQUIREMENT

For the tools such as charge hose, etc., use those

manufactured exclusively for R410A.

Refrigerant amount to be added

For addition of the refrigerant, add refrigerant “R410A”

referring to the attached Installation Manual of outdoor

unit.

Be sure to use a scale to charge the refrigerant of

specified amount.

REQUIREMENT

• Charging an excessive or too little amount of

refrigerant causes a trouble of the compressor.

Be sure to charge the refrigerant of specified

amount.

• A personnel who charged the refrigerant should

write down the pipe length and the added

refrigerant amount in the nameplate attached to the

service panel of the outdoor unit. It is necessary to

troubleshooter the compressor and refrigeration

cycle malfunction.

Half union Flare nut

Externally

threaded side

Use a wrench to secure. Use a torque wrench to tighten.

REQUIREMENT

Tightening with an excessive torque may crack the nut

depending on installation conditions.

Tighten the nut within the specified tightening torque.

Piping with outdoor unit

• Shape of valve differs according to the outdoor unit.

For details of installation, refer to the Installation

Manual of the outdoor unit.

Internally

threaded side

Open the valve fully

Open the valve of the outdoor unit fully.

For details, refer to the Installation Manual attached to

the outdoor unit.

Gas leak check

Check with a leak detector or soap water whether gas

leaks or not, from the pipe connecting section or cap of

the valve.

REQUIREMENT

Use a leak detector manufactured exclusively for HFC

refrigerant (R410A, R134a, etc.).

–12–

EN

12-EN

Page 14

Under Ceiling Type

Thermal insulation process

Apply thermal insulation for the pipes separately at

liquid side and gas side.

For the thermal insulation to the pipes at gas side, be

sure to use the material with heat-resisting

temperature 248 °F (120 °C) or higher.

Using the attached thermal insulation material, apply

the thermal insulation to the pipe connecting section of

the indoor unit securely without gap.

REQUIREMENT

• Apply the thermal insulation to the pipe connecting

section of the indoor unit securely up to the root

without exposure of the pipe. (The pipe exposed to

the outside causes water leak.)

• Wrap heat insulator with its slits facing up (ceiling

side).

Wrap the pipe with the attached heat insulator

without any gap between the indoor unit.

Indoor unit

The seam must be faced upward

(ceiling side).

Installation Manual

Heat insulation

pipe

(Accessory)

Union

Flare nut

Heat insulator

of the pipe

13-EN

–13–

Page 15

Under Ceiling Type

5 DRAIN PIPING WORK

Installation Manual

CAUTION

• Following the Installation Manual, perform the

drain piping work so that water is properly

drained, and apply a heat insulation so as not to

cause a dew dropping.

Inappropriate piping work may result in water

leakage in the room and wet of furniture.

Piping/Heat insulating

material

Require the following materials for piping and heat

insulating at site.

Piping

Heat insulator

REQUIREMENT

• Be sure to perform heat insulation of the drain pipes

of the indoor unit.

• Never forget to perform heat insulation of the connecting

part with the indoor unit.

An incomplete heat insulation causes dew dropping.

• Set the drain pipe with downward slope (1/100 or

more), and do not make swelling or trap on the

piping. It may cause an abnormal sound.

• For length of the traversing drain pipe, restrict 65’7”

(20 m) or less.

In case of a long pipe, provide support brackets with

interval of 4’11” - 6’7” (1.5 - 2 m) in order to prevent

waving.

Hard vinyl chloride pipe VP20

(Outer dia.: Ø1.0” (26 mm))

Foam polyethylene:

Thickness 0.4” (10 mm) or more

4’11” - 6’7” (1.5 - 2 m)

1/100 or more

downward

Support

bracket

• Set the collective piping as shown in the below

figure.

As long as possible

(3.9” (100 mm))

VP20

VP30 or more

VP20 VP20

Downward slope

1/100 or more

<Collective piping>

Extended

ventilating

pipe

• Be sure not to apply force to the connecting part of

the drain pipe.

• The hard vinyl-chloride pipe cannot be directly

connected to the drain pipe connecting port of the

indoor unit.

For connection with the drain pipe connecting port,

be sure to use/fix the attached flexible hose with the

hose band, otherwise a damage or water leak is

caused on the drain pipe connecting port.

Drain pipe connecting

port (Hard socket)

Drain pan

Adhesive agent

prohibited

Attached flexible hose

Attached hose bandAttached hose band

Soft socketSoft socket

VP20 vinyl chloride pipe

(procured locally)

Adhesive inhibited:

Use the attached flexible hose and hose band for

connecting the drain hose to the clear drain socket.

If applying the adhesive, socket will be damaged and

cause water leakage.

Thermal insulator

Arched shape

Trap

NO

GOOD

Drain up

When not securing down slope on the drain pipe, use

a Drain pump kit sold separately.

Also refer to the “Drain pump kit installation manual”.

The drain pipe can be raised 23.6” (600 mm) from the

top face of the main unit.

* When using Drain pump kit, both drain pipe and

refrigerant pipe can be taken only from upper side.

* VP25 PVC pipe is needed when a drain pump is

used.

–14–

EN

14-EN

Page 16

Under Ceiling Type

Installation Manual

Connection of drain hose

• Insert the attached drain hose into the drain pipe

connecting port on the drain pan up to the end.

• Fit the attached hose band to the end of the pipe

connecting port, and then tighten it securely.

REQUIREMENT

• Be sure to fix the drain hose with the attached hose

band, and set the tightening position upward.

• As the draining is the natural water draining,

arrange the pipe outside of the unit on the down

slope.

• If piping is performed as shown in the figure, drain

cannot be discharged.

NO GOOD

Drain pipe

Fit the attached hose band to the end of the hose, lay

down the knob, and then tighten hose band.

Refrigerant pipe

Drain pipe

Connection of drain pipe

• Connect the hard vinyl chloride pipe (procured

locally) to the mounted drain hose which was

attached.

• Piping from left side

• In case of taking pipe from the left side, exchange

the plug from left to right. Push in the plug of which

end is not sharp up to the end.

Drain pan

Plug

Drain pan

Attached drain hose

Confirm that soft hose is pushed

in up to the end of the drain pan.

Thermal insulating process

• Using the attached drain hose thermal insulator, lap

the connecting section and the drain hose without

clearance, and then tighten with two handing band

so that thermal insulator does not open.

• Covering the attached drain hose thermal insulator,

lap the thermal insulator (procured locally) to the

drain pipe without clearance.

Lap covering connecting section

between drain pan and drain hose.

Drain hose

Drain

pan

Hose band

* Tighten the banding band so that

attached thermal insulator is not

pushed excessively.

Banding band

Attached thermal insulator

Hose band

Thermal insulator

(procured locally)

Lap the attached

thermal insulation

so that the one

end is put on the

other end at the

upper side.

15-EN

–15–

Page 17

Under Ceiling Type

6 ELECTRICAL CONNECTION

Installation Manual

WARNING

1. Using the specified wires, ensure to connect the

wires, and fix wires securely so that the external

tension to the wires do not affect the connecting

part of the terminals.

Incomplete connection or fixation may cause a fire,

etc.

2. Be sure to connect ground wire. (grounding work)

Incomplete grounding cause an electric shock.

Do not connect ground wires to gas pipes, water

pipes, lightning rods or ground wires for telephone

wires.

3. Appliance shall be installed in accordance with

national wiring regulations.

Capacity shortage of circuit breaker or incomplete

installation may cause an electric shock or a fire.

CAUTION

• Consult local building codes, NEC (National Electrical

Code) or CEC (Canadian Electrical Code) for special

requirements.

• This indoor unit has no power cord.

• If incorrect/incomplete wiring is carried out, it will

cause an electrical fire or smoke.

• Be sure to install circuit breaker is not tripped by shock

waves.

If circuit breaker is not installed, an electric shock may

be caused.

• Be sure to use the cord clamps attached to the

product.

• Do not damage or scratch the conductive core and

inner insulator of power and system interconnection

wires when peeling them.

• Use the power cord and system interconnection wire

of specified thickness, type, and protective devices

required.

REQUIREMENT

• For power supply wiring, strictly conform to the

Local Regulation in each country.

• For wiring of power supply of the outdoor units,

follow the Installation Manual of each outdoor unit.

• Never connect 208/230 V power to the terminal

blocks (A, B etc.) for control wiring.

(Otherwise, the system will fail.)

• Perform the electric wiring so that it does not come

to contact with the high-temperature part of the

pipe.

The coating may melt resulting in an accident.

• Run the refrigerant piping line and control wiring line

in the same line.

• Do not turn on the circuit breaker of the indoor unit

until vacuuming of the refrigerant pipes completes.

Remote control wiring

• For single system, use 2 x AWG20 non polarity wire

is used for the remote control wiring.

Wiring

1. Connect the connecting wire to the terminal as

identified with their respective numbers on the

terminal block of indoor and outdoor unit.

(4

x AWG12)

2. Insulate the unsheathed redundant cords

(conductors) with electrical insulation tape.

Process them so that they do not touch any electrical

or metal parts.

3. For inter-unit wiring, do not use a wire jointed to

another on the way.

Wire Quantity x size

Indoor unit - Outdoor unit *1 3 x AWG12 (polar)

Ground 1 x AWG12 or thicker

Remote control 2 x AWG20 (non-polar)

*1 :Length of the system interconnection wires.

RAV- SP180AT2 SP240AT2

Wire

length

164’1” (50

m) or less

229’8” (70

m) or less

–16–

SP300AT2 -

SP420AT2

246’1” (75 m) or

less

EN

16-EN

Page 18

Under Ceiling Type

CAUTION

Use the same size wire for the field power supply wire

and system interconnection wires when the outdoor unit

is RAV-SP180AT2.

NOTE

• Use copper supply wires.

• Use UL wires rated 600 V for the system

interconnection wires.

• Use UL wires rated 300 V for the remote control

wires.

Installation Manual

17-EN

–17–

Page 19

Under Ceiling Type

Installation Manual

Wire connection

REQUIREMENT

• Be sure to connect the wires matching the terminal numbers. Incorrect connection causes a trouble.

• The low-voltage circuit is provided for the remote control. (Do not connect the high-voltage circuit)

• Loosen the cover mounting screws (2 positions) of the electric parts box, and then remove the cover.

• Attach the conduit pipe to the conduit hole with a lock nut.

• Slit the film of bushing attached to the hole for remote control wire, and then pass through wires.

• Connect the system interconnection wires and the remote control wire to the terminal block of the electric parts

box. Secure the ground wire with the ground screw.

• Tighten screws of the terminal block securely, and fix the wires with code clamp attached to the electric parts

box. (Do not apply tension to the connecting section of the terminal block.)

• Mount the cover of the electric parts box so that it does not pinch the wires.

Electric parts box

Terminal block for

wired remote

control

Wire partition plate

Pass the remote control wire through the

hole for remote control wire and behind

this wire partition plate.

Two screws

A

B

P.C. board

Terminal block for system

interconnection

L

1

L

2

S

Terminal block

Ground screw

System interconnection

wires and ground wire

Cord clamp

Remote control wires

Hole for Remote control wires

Conduit hole

–18–

EN

18-EN

Page 20

Under Ceiling Type

Installation Manual

CAUTION

Fix the system interconnection wires and the remote control wires separately with the cord clamps as shown below.

Connected at backside

Cord clamp

Conduit pipe

Cord clamp

Hole for

remote control wires

Connected at upside

Conduit hole for

system

interconnection wires

Conduit hole (knockout)

for system

interconnection wires

Hole for

remote control wires

(knockout)

Attach the supplied

bushing to cover the

hole edge.

19-EN

Cord clamp

Attach the supplied

bushing to seal the

back side conduit hole.

–19–

Cord Clamp

Cord Clamp

Page 21

Under Ceiling Type

Installation Manual

System interconnection

Wires and Ground Wire

1. Strip wire ends.

System interconnection wire : 0.4” (10 mm).

Ground wire : 0.8” (20 mm)

2. Match wire colours with terminal numbers on indoor

and outdoor units’ terminal blocks and firmly screw

wires to the corresponding terminals.

3. Secure the ground wire with the ground screw.

4. Fix the wire with cord clamp.

Unit: in (mm)

0.8” (20)

Ground wire

0.4” (10)

Connecting wire

L

1

S

L

2

CAUTION

Remote Control Wiring

• Strip off approx. 0.4” (9 mm) the wire to be

connected.

• Non polarity, 2 x AWG20 wire is used for wiring of the

remote control.

Terminal block for

remote control wiring

of indoor unit

A

B

Remote control wire

(Procured locally)

Terminal block

Remote

A

control

B

unit

Wiring Diagram

▼ Single system

Indoor unit

Low voltage

A B

Remote

control

Outdoor

unit

208/230-1-60

L

1

L

2

S

High voltage

L

1

L

2

S

• Firmly tighten the screws of the terminal block.

Keep the wire length as shown in figure below when it

is connected to the terminal block.

0.08” (2 mm) or less

System

interconnection wire

EN

–20–

20-EN

Page 22

Under Ceiling Type

7 APPLICABLE CONTROLS

Installation Manual

REQUIREMENT

• When you use this air conditioner for the first time,

it takes approx. 5 minutes until the remote control

becomes available after power-on. This is normal.

<When power is turned on for the first time after

installation>

It takes approx. 5 minutes until the remote control

becomes available.

Approx. 5 minutes

Power

on

<When power is turned on for the second (or

later) time>

It takes approx. 1 minute until the remote control

becomes available.

Power

on

• Normal settings were made as factory default.

Change the indoor unit settings as required.

• Use the wired remote control to change the

settings.

* The settings cannot be changed using the

“SETTING”

flashes

“SETTING”

flashes

wireless remote control, sub remote control,

or remote-controlless system (for central

remote control only). Therefore, install the

wired remote control to change the settings.

“SETTING”

goes out

Approx. 1 minutes

“SETTING”

goes out

Remote

control is

available

Remote

control is

available

Changing applicable control

setting

Basic procedure for changing settings

Change the settings while the air conditioner is not

working.

(Be sure to stop the air conditioner before making

settings.)

4

6

1

Procedure 1

When pushing , , and buttons simultaneously

for 4 seconds or more, after a while, the display part

flashes as shown in the figure.

Check that the displayed CODE No. is [10].

• If the CODE No. indicates other than [10], push

button to erase the display, and then retry the

operation from the first step.

(For some time after button has been pushed, the

operation of the remote control cannot be accepted.)

(In a group control, the firstly displayed indoor UNIT

No. becomes the master unit.)

3

5

2

21-EN

(* Display content varies with

the indoor unit model.)

Procedure 2

Every pushing button, the indoor UNIT No. in

the group control is displayed successively.

Select an indoor unit of which setup to be changed.

In this time, the position of the indoor unit of which

setup to be changed can be confirmed because the fan

and the louver of the selected indoor unit work.

Procedure 3

Using temp. setup / buttons, specify CODE

No. [ ].

Procedure 4

Using timer time / buttons, select SET DATA [

].

–21–

Page 23

Under Ceiling Type

Installation Manual

Procedure 5

Push button. In this time, if the display changes

from flashing to lighting, the setup completes.

• To change the setup of an indoor unit other than the

selected one, start operation from Procedure

• To change the setup of another setup in the selected

indoor unit, start operation from Procedure

Pushing button clears the set up contents which

have been already set. In this case, retry from

Procedure

2.

2.

3.

Procedure 6

When settings have been completed, push button

to determine the settings.

When button is pushed, “SETTING” flashes and

then the display content disappears and the air

conditioner enters the normal stop mode.

(While “SETTING” is flashing, no operation of the

remote control is accepted.)

Installation to high ceiling

When the height of the ceiling to be installed exceeds

3.5 m (11’6”), adjustment of fan speed is necessary.

Set up the high ceiling.

• Set according to the basic operation procedure

(

1 → 2 → 3 → 4 → 5 → 6).

• Item code in Procedure specifies [5d].

• Select [SET DATA] in Procedure from “List of

installable ceiling height” in this Manual.

• For the item code in Procedure

• For the SET DATA in Procedure

data of static pressure to be set up from the table on

the right.

(Exchange by wired remote control)

3, specify [5d].

4, select the setup

Using wireless remote control

Change the high ceiling setting with the DIP switch on

the P.C. board of the signal receiving part.

Refer to the installation manual of the wireless remote

controller kit for the details.

High ceiling setting can be changed by arranging the

jumper block on the indoor unit micro computer P.C.

board as shown in the table below as well.

* However, once the setting is changed, it is

necessary to reset the setting back to 0000 that

placing the jumper block back to the factory default

position and rewriting the setting data back to 0000

with wired remote control (sold separately). (The

setting can be changed to 0001, 0003 and 0006

without resetting.)

• Select by exchange of jumper block on indoor

microcomputer P.C. board.

jumper block

position

SET DATA Note

Short Open

0000

0001 High static pressure 1

• Jumper block position

(CN112, CN111, CN110 from the left)

Standard filter

(Factory default)

SET DATA

0000

0001 High static pressure 1

Standard

(Factory default)

11’6” (3.5 m) or less

more than 11’6” (3.5 m)

up to 13’1” (4.0 m)

–22–

EN

22-EN

Page 24

Under Ceiling Type

Installation Manual

Filter sign setting

According to the installation condition, the lighting time

of the filter sign (Notification of filter cleaning) can be

changed.

Follow to the basic operation procedure

(

1 → 2 → 3 → 4 → 5 → 6).

• For the CODE No. in Procedure

• For the [SET DATA] in Procedure

3, specify [01].

4, select the setup

data of filter sign lighting time from the following

table.

Setup data Filter sign lighting time

0000 None

0001 150H

0002 2500H (Factory default)

0003 5000H

0004 10000H

To secure better effect of

heating

When it is difficult to obtain satisfactory heating due to

installation place of the indoor unit or structure of the

room, the detection temperature of heating can be

raised. Also use a circulator, etc. to circulate heat air

near the ceiling.

Follow to the basic operation procedure

(

1 → 2 → 3 → 4 → 5 → 6).

• For the CODE No. in Procedure

• For the SET DATA in Procedure

data of shift value of detection temperature to be set

up from the table below.

Setup data Detection temp shift value

0000 No shift

0001 +1.8 °F (+1 °C)

0002

0003 +5.4 °F (+3 °C)

0004 +7.2 °F (+4 °C)

0005 +9.0 °F (+5 °C)

0006 +10.8 °F (+6 °C)

+3.6 °F (+2 °C)

(Factory default)

3, specify [06].

4, select the setup

Group control

Group control for system of multiple units

One remote control can control maximum 8 indoor

units as a group.

▼ Group control in single system

Outdoor

unit

Indoor

unit

Remote

control

Outdoor

unit

Indoor

unit

Finish of address setup by

power-ON

Outdoor

unit

Indoor

unit

• For wiring procedure and wiring method of the

individual line (Identical refrigerant line) system,

follow to “Electric work”.

• Wiring between lines is performed in the following

procedure.

Connect the terminal block (A/B) of the indoor unit

connected with a remote control to the terminal

blocks (A/B) of the indoor units of other indoor units

by wiring the inter-unit wire of the remote control.

• When the power supply has been turned on, the

automatic address setup starts and “ ” display

which indicates that address is being set up flashes

on the display part. During setup of automatic

address, the remote control operation is not

accepted.

Required time up to the finish of automatic

addressing is approx. 5 minutes.

NOTE

In some cases, it is necessary to change the address

manually after setup of the automatic address

according to the system configuration of the group

control.

Procedure example 1

Manual address setup procedure

While the operation stops, change the setup.

(Be sure to stop the operation of the unit.)

Outdoor

unit

Indoor

unit

Outdoor

unit

Indoor

unit

(Max. 8 units)

23-EN

–23–

Page 25

Under Ceiling Type

3

-2,

4

-2,

5

-2

7

3

4

5

Installation Manual

Indoor UNIT No. before setup change is displayed.

-1,

-1,

-1,

7

2,61

Procedure 1

Push simultaneously + + buttons for 4

seconds or more. After a while, the display part flashes

as shown below. Check the displayed CODE No. is

[10].

• When the CODE No. is other than [10], push

button to erase the display and repeat procedure

from the first step.

(After pushing

control is not accepted for approx. 1 minute.)

(For a group control, No. of the firstly displayed

indoor unit becomes the header unit.)

Procedure 2

Every pushing button, the indoor UNIT No. in

the group control is displayed in order. Select the

indoor unit of which setup is changed.

In this time, the position of the indoor unit of which

setup is changed can be confirmed because fan and

louver of the selected indoor unit operate.

Procedure 3

1. Using temp. setup / buttons, specify CODE

No. [12].

(CODE No. [12]: Line address)

2. Using timer time / buttons, change the line

address from [3] to [2].

3. Push button.

In this time, the setup finishes when the display

changes from flashing to lighting.

button, operation of the remote

(* Display changes according to

the model No. of indoor unit.)

3

4

5

-3,

-3,

-3,

Procedure 4

1. Using temp. setup / buttons, specify CODE

No. [13].

(CODE No. [13]: Indoor address)

2. Using timer time / buttons, change the indoor

address from [3] to [2].

3. Push button.

In this time, the setup finishes when the display

changes from flashing to lighting.

Indoor UNIT No. before setup change is displayed.

Procedure 5

1. Using temp. setup / buttons, specify CODE

No. [14].

(CODE No. [14]: Group address)

2. Using timer time / buttons, change the setup

data from [0001] to [0002].

(Setup data [Header unit: 0001] [Follower unit:

0002])

3. Push button.

In this time, the setup finishes when the display

changes from flashing to lighting.

Indoor UNIT No. before setup change is displayed.

–24–

EN

24-EN

Page 26

Under Ceiling Type

Procedure 6

If there is other indoor unit to be changed, repeat

procedure

When the above setup has finished, push to

select the indoor UNIT No. before change of setup,

specify CODE No. [12], [13], [14] in order with temp.

setup / buttons, and then check the changed

contents.

Address change check Before change:

[3-3-1] → After change: [2-2-2]

2 to 5 to change the setup.

1,3

Installation Manual

1

2

Pushing button clears the contents of which setup

was changed.

(In this case, procedure from

Indoor UNIT No. before setup change is displayed.

2 is repeated.)

Procedure 7

After check of the changed contents, push button.

(Setup is determined.) When pushing

display disappears and the status becomes the usual

stop status. (When pushing

from the remote control is not accepted for approx.

1 minute.)

* If the operation from the remote control is not

accepted even 1 minute or more passed after

pushing

setup is incorrect.

In this case, the automatic address must be again

set up.

Therefore repeat procedure of the setup change

from the Procedure

button, it is considered that the address

button the operation

1.

button, the

To recognize the position of the

corresponding indoor unit though the

indoor UNIT No. is known

Check the position during operation stop.

(Be sure to stop operation of the set.)

Procedure 1

Push simultaneously + buttons for 4 seconds

or more.

After a while, the display part flashes and the display

appears as shown below.

In this time, the position can be checked because fan

and louver of the indoor unit operate.

• For the group control, the indoor UNIT No. is

displayed as [ ] and fans and louvers of all the

indoor units in the group control operate.

Check the displayed CODE No. is [01].

• When the CODE No. is other than [01], push

button to erase the display and repeat procedure

from the first step.

(After pushing

control is not accepted for approx. 1 minute.)

button, operation of the remote

(* Display changes according to

the model No. of indoor unit.)

Procedure 2

In the group control, every pushing button, the

indoor UNIT No. in the group control is displayed in

order.

In this time, the position of the indoor unit can be

confirmed because only fan of the selected indoor unit

operate.

(For a group control, No. of the firstly displayed indoor

unit becomes the header unit.)

Procedure 3

After confirmation, push button to return the mode

to the usual mode.

When pushing

the status becomes the usual stop status.

(When pushing

remote control is not accepted for approx. 1 minute.)

button, the display disappears and

button the operation from the

25-EN

–25–

Page 27

Under Ceiling Type

Installation Manual

Remote control switch

monitoring function

This function is available to call the service monitor

mode from the remote control during a test run to

acquire temperatures of sensors of the remote control,

indoor unit, and outdoor unit.

1. Push and

4 seconds to call the service monitor mode.

The service monitor indicator lights up and the

header indoor unit number is displayed first. CODE

No. is also displayed.

2. Pushing TEMP. buttons, select the

number of sensor, etc. (CODE No.) to be monitored.

(See the following table.)

3. Pushing

indoor unit to be monitored. The sensor

temperatures of indoor units and their outdoor unit in

the control group are displayed.

4. Push

button to return to the normal display.

buttons simultaneously for at least

(left side of the button), select an

Outdoor unit data

CODE No. Data name

60

61 Outside air temperature (TO)

62 Compressor discharge air temperature (TD)

63 Compressor intake air temperature (TS)

64 —

65 Heatsink temperature (THS)

6A Operating current (x1/10)

F1

Outdoor unit heat exchanger temperature

(TE)

Compressor cumulative operating hours

(x100h)

2

4

13

Indoor unit data

CODE No. Data name

01 Room temperature (remote control)

02 Indoor unit intake air temperature (TA)

03

04

F3

F8 Indoor unit discharge air temperature

Indoor unit heat exchanger temperature

(TCJ)

Indoor unit heat exchanger temperature

(TC)

Indoor unit fan cumulative operating hours

(x1 h)

–26–

EN

26-EN

Page 28

Under Ceiling Type

8 TEST RUN

Installation Manual

Before test run

• Before turning on the circuit breaker, carry out the

following procedure.

1) Using 500V-megger, check 1MΩ or more exists

between the terminal block L

ground.

If 1MΩ or less is detected, do not run the unit. Do

not apply to the remote control circuit.

2) Check the valve of the outdoor unit being opened

fully.

• To protect the compressor at activation time, leave

power-ON for 12 hours or more be for operating.

1 to L2 and the

Execute a test run

Using the remote control, operate the unit as usual.

For the procedure of the operation, refer to the

attached Owner’s Manual.

A forced test run can be executed in the following

procedure even if the operation stops by thermo.-OFF.

In order to prevent a serial operation, the forced test

run is released after 60 minutes have passed and

returns to the usual operation.

CAUTION

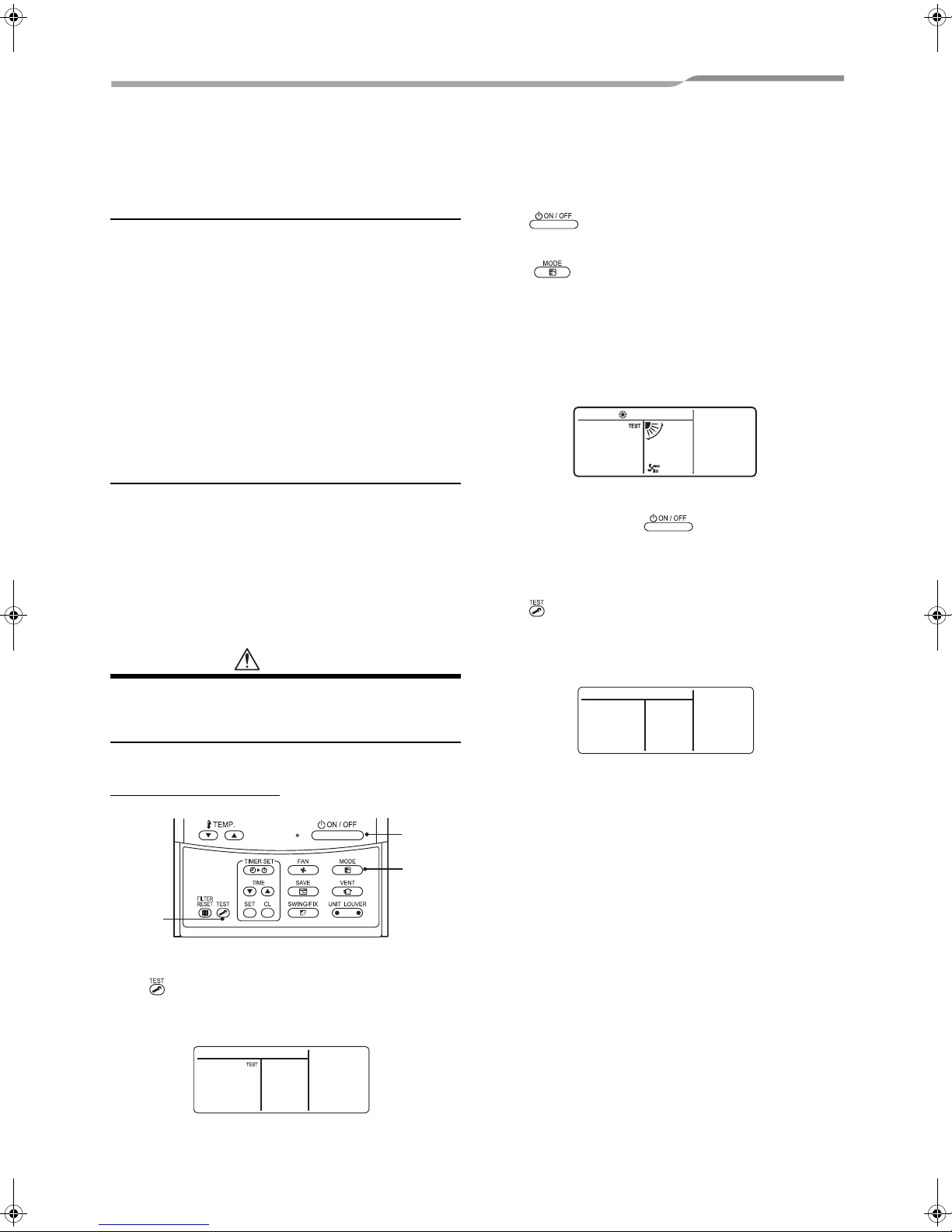

Procedure 2

Push button.

Procedure 3

Using button, select the operation mode,

[COOL] or [HEAT].

• Do not run the air conditioner in a mode other than

[COOL] or [HEAT].

• The temperature controlling function does not work

during test run.

• The detection of error is performed as usual.

Procedure 4

After the test run, push button to stop a test

run.

(Display part is same as procedure 1.)

Procedure 5

Push check button to cancel (release from) the test

run mode.

([TEST] disappears on the display and the status

returns to a normal.)

• Do not use the forced test run for cases other than the

test run because it applies an excessive load to the

devices.

Wired remote control

2, 4

3

1,5

Procedure 1

Keep button pushed for 4 seconds or more. [TEST]

is displayed on the display part and the selection of

mode in the test mode is permitted.

27-EN

–27–

Page 29

Under Ceiling Type

Installation Manual

Wireless remote control

Procedure 1

Turn on the circuit breaker of the air conditioner.

The operation is not accepted for 5 minutes when

circuit breaker is turned on at first time after installation,

and 1 minute when circuit breaker is turned on at the

next time and after. After the specified time has

passed, perform a test operation.

Procedure 2

Push “ON/OFF” button on the remote control, select

[COOL] or [HEAT] with “MODE” button, and then select

[HIGH] with “FAN” button.

Procedure 3

Cooling test run Heating test run

Set the temperature to 64°F

(18°C) with the temp. setup

buttons.

Procedure 4

Cooling test run Heating test run

After confirming a signal

receiving sound “beep”

immediately set the

temperature to 66 °F (19°C)

with the temp. setup buttons.

Set the temperature to 86 °F

(30°C) with the temp. setup

buttons.

After confirming a signal

receiving sound “beep”

immediately set the

temperature to 84 °F (29°C)

with the temp. setup buttons.

▼ Heating test run:

ON/OFF → 86 °F (30°C) → 84 °F (29°C) → 86 °F

(30°C) → 84 °F (29°C) → 86 °F (30°C) → 84 °F (29°C)

→ 86 °F (30°C) → (test run) → ON/OFF

Always select

[HIGH] fan

speed.

2

3, 4,

5, 6

2

2,7

Procedure 5

Cooling test run Heating test run

After confirming a signal

receiving sound “beep”

immediately set the

temperature to 64 °F (18°C)

with the temp. setup buttons.

After confirming a signal

receiving sound “beep”

immediately set the

temperature to 86 °F (30°C)

with the temp. setup buttons.

Procedure 6

Repeat procedures 4 → 5 → 4 → 5.

Indicators “Operation” (green), “Timer” (green), and

“Ready” (orange) in the wireless receiver section flash

in approx. 10 seconds, and the air conditioner starts

operation. If any of these indicators does not flash,

repeat procedures

2 to 5.

Procedure 7

Upon completion of the test run, push “ON/OFF” button

to stop operation.

<Overview of test run operations using the

wireless remote control>

▼ Cooling test run:

ON/OFF → 64 °F (18 °C) → 66 °F (19°C) → 64 °F

(18°C) → 66 °F (19°C) → 64 °F (18°C) → 66 °F (19°C)

→ 64 °F (18°C) → (test run) → ON/OFF

EN

–28–

28-EN

Page 30

Under Ceiling Type

9 TROUBLESHOOTING

Installation Manual

Confirmation and check

When a trouble occurred in the air conditioner, the

check code and the indoor UNIT No. appear on the

display part of the remote control.

The check code is only displayed during the operation.

If the display disappears, operate the air conditioner

according to the following “Confirmation of error

history” for confirmation.

Check code

Indoor UNIT No. in

which an error occurred

Confirmation of error history

When a trouble occurred on the air conditioner, the

trouble history can be confirmed with the following

procedure. (The trouble history is stored in memory up

to 4 troubles.)

The history can be confirmed from both operating

status and stop status.

Procedure 2

Every pushing of button used to set

temperature, the trouble history stored in memory is

displayed in order.

The numbers in CODE No. indicate CODE No. [01]

(latest) → [04] (oldest).

REQUIREMENT

Do not push button because all the trouble history

of the indoor unit will be deleted.

Procedure 3

After confirmation, push button to return to the

usual display.

1. Check the troubles according to the above

procedure.

2. Ask an authorized dealer or qualified service

(maintenance) professional to repair or maintain the

air conditioner.

2

3

Procedure 1

When pushing and buttons at the same time for

4 seconds or more, the following display appears.

If [Service check] is displayed, the mode enters in

the trouble history mode.

•[01: Order of trouble history] is displayed in CODE

No. window.

• [Check code] is displayed in CHECK window.

• [Indoor unit address in which an error occurred] is

displayed in Unit No..

1

29-EN

–29–

Page 31

Under Ceiling Type

Check codes and parts to be checked

Installation Manual

Wired

remote

control

display

Indication

E01

E02

E03

E04

E08

E09

E10

E18

E31

F01 ALT

F02 ALT

F04 ALT

F06 ALT

F07

(F06)

F08 ALT

F10 ALT

F12

(F06)

F13

(L29)

F15

(F06)

F29 SIM

Wireless remote control

Sensor block display of

receiving unit

Operation Timer Ready

GR GR OR

Main defective parts

Flashing

No header remote

control

Remote control

communication error

Remote control

transmission error

Indoor unit-remote

control regular

communication error

Indoor unit-outdoor

unit serial

communication error

IPDU-CDB

communication error

Duplicated indoor

addresses

Duplicated header

remote controls

CPU-CPU

communication error

Header indoor unitindoor follower unit

regular communication

error

IPDU communication

error

Indoor unit heat

exchanger sensor

(TCJ) error

Indoor unit heat

exchanger sensor (TC)

error

Outdoor unit discharge

temp. sensor (TD)

error

Outdoor unit temp.

sensor (TE/TS) error

ALT TL sensor error Outdoor

Outdoor unit outside

air temp. sensor error

Indoor unit room temp.

sensor (TA) error

ALT TS sensor error Outdoor

ALT Heat sink sensor error Outdoor

Temp. sensor

ALT

connection error

Indoor unit, other P.C.

board error

Judging

device

Remote

control

Remote

control

Indoor

Indoor

Indoor

Remote

control

Indoor

Indoor

Outdoor Communication error between IPDU and CDB Entire stop

Indoor

Indoor

Outdoor

Outdoor

Outdoor

Indoor

Outdoor Temp. sensor (TE/TS) may be connected incorrectly. Entire stop

Indoor Indoor P.C. board --- EEPROM error Auto-reset

Parts to be checked / error description

Incorrect remote control setting --- The header remote

control has not been set (including two remote controls).

No signal can be received from the indoor unit.

System interconnection wires, indoor P.C. board, remote

control

--- No signal can be sent to the indoor unit.

Remote control, network adapter, indoor P.C. board --No data is received from the remote control or network

adapter.

System interconnection wires, indoor P.C. board,

outdoor P.C. board --- Serial communication error

between indoor unit and outdoor unit

Indoor address setting error --- The same address as the

self-address was detected.

Remote control address setting error --- Two remote

controls are set as header in the double-remote control

control.

(* The header indoor unit stops raising alarm and follower

indoor units continue to operate.)

Indoor P.C. board --- Communication error between main

MCU and motor microcomputer MCU

Indoor P.C. board --- Regular communication is not

possible between header and follower indoor units or

between twin header (main) and follower (sub) units.

Heat exchanger sensor (TCJ) , indoor P.C. board --Open-circuit or short-circuit of the heat exchanger sensor

(TCJ) was detected.

Heat exchanger sensor (TC), indoor P.C. board --- Opencircuit or short-circuit of the heat exchanger sensor (TC)

was detected.

Outdoor temp. sensor (TD), outdoor P.C. board --- Opencircuit or short-circuit of the discharge temp. sensor was

detected.

Outdoor temp. sensors (TE/TS), outdoor P.C. board --Open-circuit or short-circuit of the heat exchanger temp.

sensor was detected.

TL sensor may be displaced, disconnected or shortcircuited.

Outdoor temp. sensor (TO), outdoor P.C. board --- Opencircuit or short-circuit of the outdoor air temp. sensor was

detected.

Room temp. sensor (TA), indoor P.C. board --- Opencircuit or short-circuit of the room temp. sensor (TA) was

detected.

TS sensor may be displaced, disconnected or shortcircuited.

Abnormal temperature was detected by the temp. sensor

of the IGBT heat sink.

Air

conditioner

status

*

*

Auto-reset

Auto-reset

Auto-reset

*

Auto-reset

Auto-reset

Auto-reset

Auto-reset

Entire stop

Entire stop

Entire stop

Operation

continued

Auto-reset

Entire stop

Entire stop

EN

–30–

30-EN

Page 32

Under Ceiling Type

Installation Manual

F31

(L29)

H01

H02

H03

H04

(P04)

H06

L03 SIM

L07 SIM

L08 SIM

L09 SIM

L10

(L29)

L20 SIM

L29 SIM

L30 SIM

L31 SIM

P01 ALT Indoor unit fan error Indoor

P03 ALT

P04 ALT

P05

(P04)

P07 ALT Heat sink overheat Outdoor

P10 ALT

P15

(L29)

P19

(L29)

P20

(P04)

Outdoor unit P.C.

SIM

board

Outdoor unit

compressor

breakdown

Outdoor unit

compressor lock

Outdoor unit current

detect circuit error

Case thermostat

operation

Outdoor unit lowpressure system error

Duplicated header

indoor units

Group line in individual

indoor unit

Indoor group address

not set

Indoor power level not

set

Outdoor unit P.C.

SIM

board

LAN communication

error

Other outdoor unit

error

Abnormal external

input into indoor unit

(interlock)

Phase sequence error,

etc.

Outdoor unit discharge

temp. error

Outdoor unit highpressure system error

ALT Open phase detected Outdoor

Indoor unit water

overflow detected

ALT Gas leakage detected Outdoor

ALT 4-way valve error

High-pressure

ALT

protective operation

Outdoor Outdoor P.C. board ---- In the case of EEPROM error. Entire stop

Outdoor

Outdoor

Outdoor

Outdoor Malfunction of the case thermostat Entire stop

Outdoor

Indoor

Indoor

Indoor

Indoor Indoor power level has not been set. Entire stop

Outdoor

Network

adapter

central

control

Outdoor

Indoor

Outdoor

Outdoor

Outdoor

Indoor

Outdoor

(Indoor)

Outdoor High-pressure protection Entire stop

Current detect circuit, power voltage --- Minimum

frequency was reached in the current releasing control or

short-circuit current (Idc) after direct excitation was

detected

Wiring error of compressor (open phase)

Compressor circuit --- Compressor lock was detected.

Wiring error of compressor (open phase)

Current detect circuit, outdoor unit P.C. board --Abnormal current was detected in AC-CT or a phase loss

was detected.

Current, high-pressure switch circuit, outdoor P.C. board

--- Ps pressure sensor error was detected or low-pressure

protective operation was activated.

Indoor address setting error --- There are two or more

header units in the group.

Indoor address setting error --- There is at least one

group-connected indoor unit among individual indoor

units.

Indoor address setting error --- Indoor address group has

not been set.

In the case of outdoor P.C . board jumper wire (for service)

setting error

Address setting, central control remote control, network

adapter --- Duplication of address in central control

communication

Other outdoor unit error Entire stop

1) Communication error between IPDU MCU and CDB

MCU

2) Abnormal temperature was detected by the heat sink

temp. sensor in IGBT.

External devices, outdoor unit P.C. board --- Abnormal

stop due to incorrect external input into CN80

Power supply phase sequence, outdoor unit P.C. board -

-- Abnormal phase sequence of the 3-phase power

supply

Indoor fan motor, indoor P.C. board --- Indoor AC fan

error (fan motor thermal relay activated) was detected.

An error was detected in the discharge temp. releasing

control.

High-pressure switch --- The IOL was activated or an

error was detected in the high-pressure releasing control

using the TE.

The power cable may be connected incorrectly. Check

open phase and voltages of the power supply.

Abnormal temperature was detected by the temp. sensor

of the IGBT heat sink.

Drain pipe, clogging of drainage, float switch circuit,

indoor P.C. board --- Drainage is out of order or the float

switch was activated.

There may be gas leakage from the pipe or connecting

part. Check for gas leakage.

4-way valve, indoor temp. sensors (TC/TCJ) --- An error

was detected due to temperature drop of the indoor unit

heat exchanger sensor when heating.

Entire stop

Entire stop

Entire stop

Entire stop

Entire stop

Entire stop

Entire stop

Entire stop

Auto-reset

Entire stop

Entire stop

Operation

continued

(thermostat

OFF)

Entire stop

Entire stop

Entire stop

Entire stop

Entire stop

Entire stop

Entire stop

Auto-reset

(Auto-reset)

31-EN

–31–

Page 33

Under Ceiling Type

Installation Manual

P22 ALT Outdoor unit fan error Outdoor

P26 ALT

P29 ALT

P31 ALT Other indoor unit error Indoor

Check codes in parentheses ( ) are displayed when connected to an outdoor unit other than the new SDI series.

: Lighting : Flashing : OFF : The air conditioner automatically enters the auto-address setting mode.

ALT: When two LEDs are flashing, they flash alternately. SIM: When two LEDs are flashing, they flash in synchronization.

Receiving unit display OR: Orange GR: Green

Outdoor unit inverter

Idc activated

Outdoor unit position

error

Outdoor