Toshiba Carrier RAS-09 12EK, Carrier RAS-12EK, Carrier RAS-09 12EA, Carrier RAS-09EK, Carrier RAS-09EA Installation Manual

...

ENGLISH

ESPAÑOL

FRANÇAIS

Indoor unit

RAS-09, 12EK Series

Outdoor unit

RAS-09, 12EA Series

AIR CONDITIONER (SPLIT TYPE)

INSTALLATION MANUAL

1110251291-1

1110251291-1 EN.indd 11110251291-1 EN.indd 1 11/13/13 2:52 PM11/13/13 2:52 PM

CONTENTS

DIMENSION .................................................................................................1

SYSTEM REQUIREMENTS .........................................................................3

Piping (Field supplied) ..............................................................................3

Power supply Connection and Connecting Cable ....................................3

PRECAUTIONS FOR SAFETY ....................................................................4

INSTALLATION DIAGRAM OF INDOOR AND OUTDOOR UNITS ............6

Field Supplied Installation Parts ...............................................................6

OUTDOOR UNIT ..........................................................................................7

Installation Location ..................................................................................7

Precautions about Installation in Regions with Snowfall and

Cold Temperatures ...................................................................................7

Refrigerant Piping Connection ..................................................................7

Wiring Connection ....................................................................................7

Electrical Work ..........................................................................................7

INDOOR UNIT ..............................................................................................8

Installation Location ..................................................................................8

Cutting a Hole and Mounting the mounting Plate .....................................8

Wiring Connection ....................................................................................9

Piping and Drain Hose Installation ...........................................................9

Indoor Unit Fixing ...................................................................................10

Drainage ................................................................................................. 11

Remote Control A-B Selection ................................................................ 11

EVACUATING ............................................................................................ 11

Evacuating ............................................................................................. 11

OTHERS .....................................................................................................12

Gas Leak Test .........................................................................................12

Test Operation .......................................................................................12

Auto Restart Setting ..............................................................................12

Troubleshooting (Check Point) ..............................................................12

EN

CONTENIDOS

ES

DIMENSIONES ............................................................................................1

REQUISITOS DE INSTALACIÓN ................................................................3

Tuberías (Suministradas específi camente) ..............................................3

Conexión de la fuente de alimentación y cable ........................................3

PRECAUCIONES SOBRE SEGURIDAD ....................................................4

DIAGRAMA DE INSTALACIÓN DE LA UNIDAD INTERIOR Y EXTERIOR

..6

Piezas de Instalación Opcional ...............................................................6

UNIDAD EXTERIOR ....................................................................................7

Situación de Instalación ............................................................................7

Precauciones sobre Instalación en Regiones con Nieve y

Temperaturas Frías ..................................................................................7

Conexión de la Tubería Refrigerante ........................................................7

Conexión de Cables .................................................................................7

Trabajo Eléctrico ......................................................................................7

UNIDAD INTERIOR .....................................................................................8

Situación de Instalación ............................................................................8

Corte de un Orifi cio y Montaje de la Placa de Montaje ............................8

Conexión de Cables .................................................................................9

Instalación la Tubería y el Tubo de Desagüe ..........................................9

Instalación de la Unidad Interior .............................................................10

Drenaje ..................................................................................................11

Mando a distancia A-B Selección ...........................................................11

EVACUACIÓN ............................................................................................ 11

Evacuación ............................................................................................11

OTROS .......................................................................................................12

Comprobación de Fugas ........................................................................12

Prueba de Operación ............................................................................12

Ajuste de Reinicio Automático ...............................................................12

Troubleshooting (Check Point) ..............................................................12

SOMMAIRE

DIMENSIONS ...............................................................................................1

CONFIGRATION SYSTEME REUQISE .......................................................3

Tuyauterie (Fournie sur chantier) .............................................................3

Connexion de la source d’alimentation et du câble de connexion ............3

MESURES DE SÉCURITÉ ...........................................................................4

PLAN D’INSTALLATION DES UNITÉS INTÉRIEURE ET EXTÉRIEURE ..6

Pièces d’Installation en Option ................................................................6

UNITÉ EXTÉRIEURE ...................................................................................7

Lieu d’Installation ......................................................................................7

Précautions à prendre pour l’installation dans les régions sujettes aux

chutes de neige et aux températures froides ...........................................7

Connexion du Tuyau Réfrigérant ..............................................................7

Connexion des Câbles .............................................................................7

Travaux Electriques .................................................................................7

UNITÉ INTÉRIEURE ....................................................................................8

Lieu d’Installation ......................................................................................8

Ouverture du trou et montage de la plaque de montage ..........................8

Connexion des Câbles .............................................................................9

Installation de la Conduite et du Tuyau de Purge ....................................9

Installation de l’Unité Intérieure ..............................................................10

Drainage ................................................................................................11

Sélection de télécommande A-B ............................................................11

EVACUATION ............................................................................................ 11

Evacuation ............................................................................................. 11

AUTRES .....................................................................................................12

Test de Fuite Gaz ...................................................................................12

Opération du Test ..................................................................................12

Réglage de la Remise en Marche Automatique ....................................12

Troubleshooting (Check Point) ..............................................................12

FR

1110251291-1 EN.indd 21110251291-1 EN.indd 2 11/13/13 2:52 PM11/13/13 2:52 PM

EN

SI

1

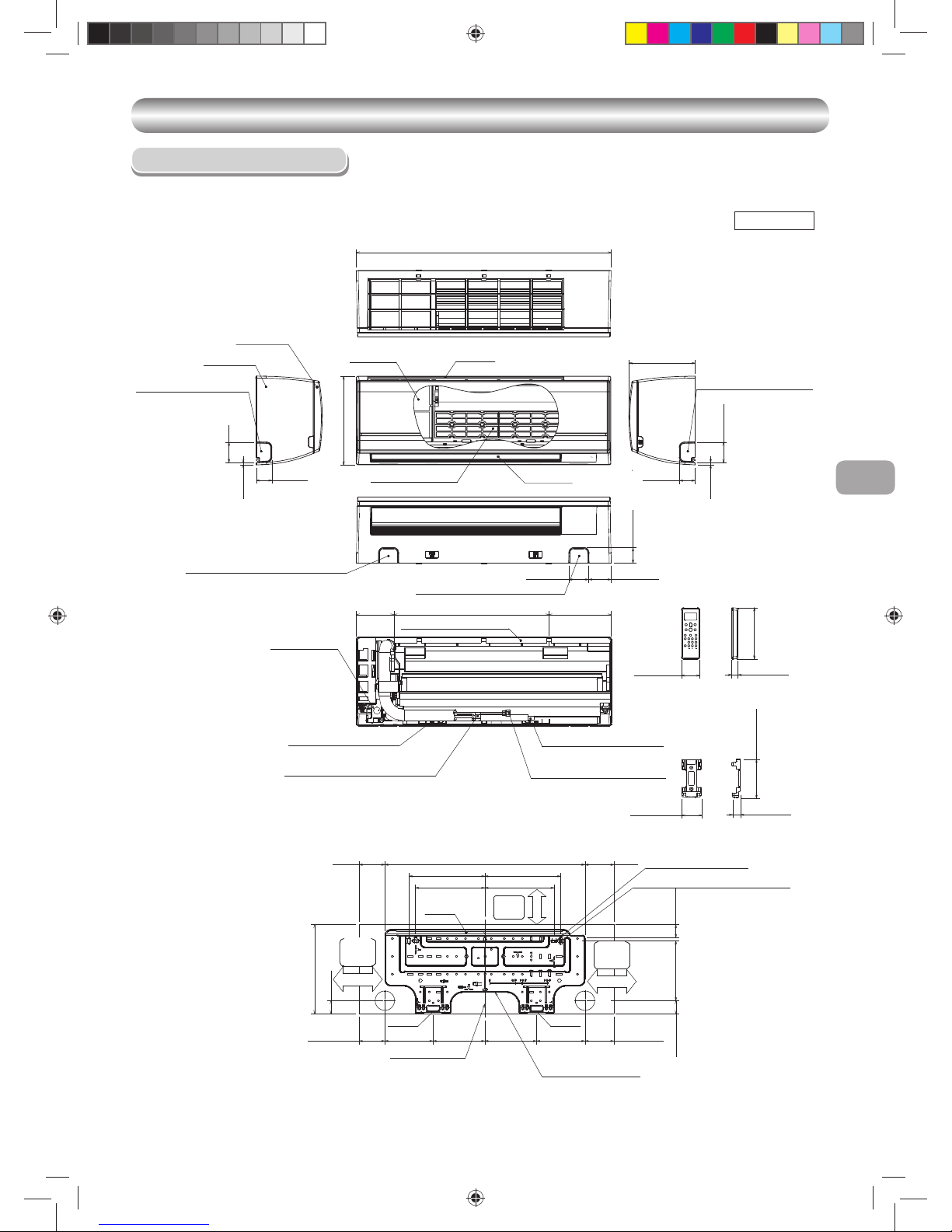

DIMENSION

DIMENSION

Indoor Unit

Unit : Inch (mm)

2-15/32(63)

7-15/32(190)

6-5/16(161) 5-1/2(150)

10-13/16(275)

1-9/16(40)

1-9/16(40)

1-3/4(45)

7-19/32(193)18-7/8(480)

2-7/16(62) 2-11/16(69)

1-7/8(48)

2-15/32(63)

9/32(7)

1-7/8(48)

4-9/16(116)

10-25/32(275)

1-7/8(48)

9/32(7)

24-7/16(621)

8-1/16(205)

31-1/8(790)

8-7/16(215)

9-1/4(235)

9-1/4(235)

8-7/16(215)

6-5/16(161)5-1/2(150)

Front panel

Knockout for leftward piping

Air fi lter Air inlet

Heat exchanger

Knockout for rightward piping

Knockout for bottom leftward piping

Knockout for bottom rightward piping

Installation plate hanger

Conduit hole

(Ø7/8(22) hole)

Connecting pipe (18-5/8(0.40m))

(Flare Ø1/4(6.35))

Installation plate hanger

Connecting pipe (13-25/32(0.35m))

(Flare Ø3/8(9.52))

Wireless remote controller

Drain hose (19-11/16(0.50m))

Remote controller holder

3-5/16(84.5)

3-5/16(84.5)

3-5/16(84.5)3-5/16(84.5)

Hanger

Hanger

Hanger

Center line

Installation plate outline

Minimum

distance

to wall

Minimum

distance

to wall

Minimum

distance

to wall

6-11/16(170)or more

6-11/16(170)or more

2-9/16(65)or more

Grille Inlet

Air outlet

For stud bold (Ø2-1/4(6))

For stud bold (Ø5/16(8)~Ø13/32(10))

31/32 (26)

3/4 (19)

2-15/32 (63)

2-3/16 (56)

4-29/32 (125)

6-3/4 (157)

1110251291-1 EN.indd 11110251291-1 EN.indd 1 11/13/13 2:52 PM11/13/13 2:52 PM

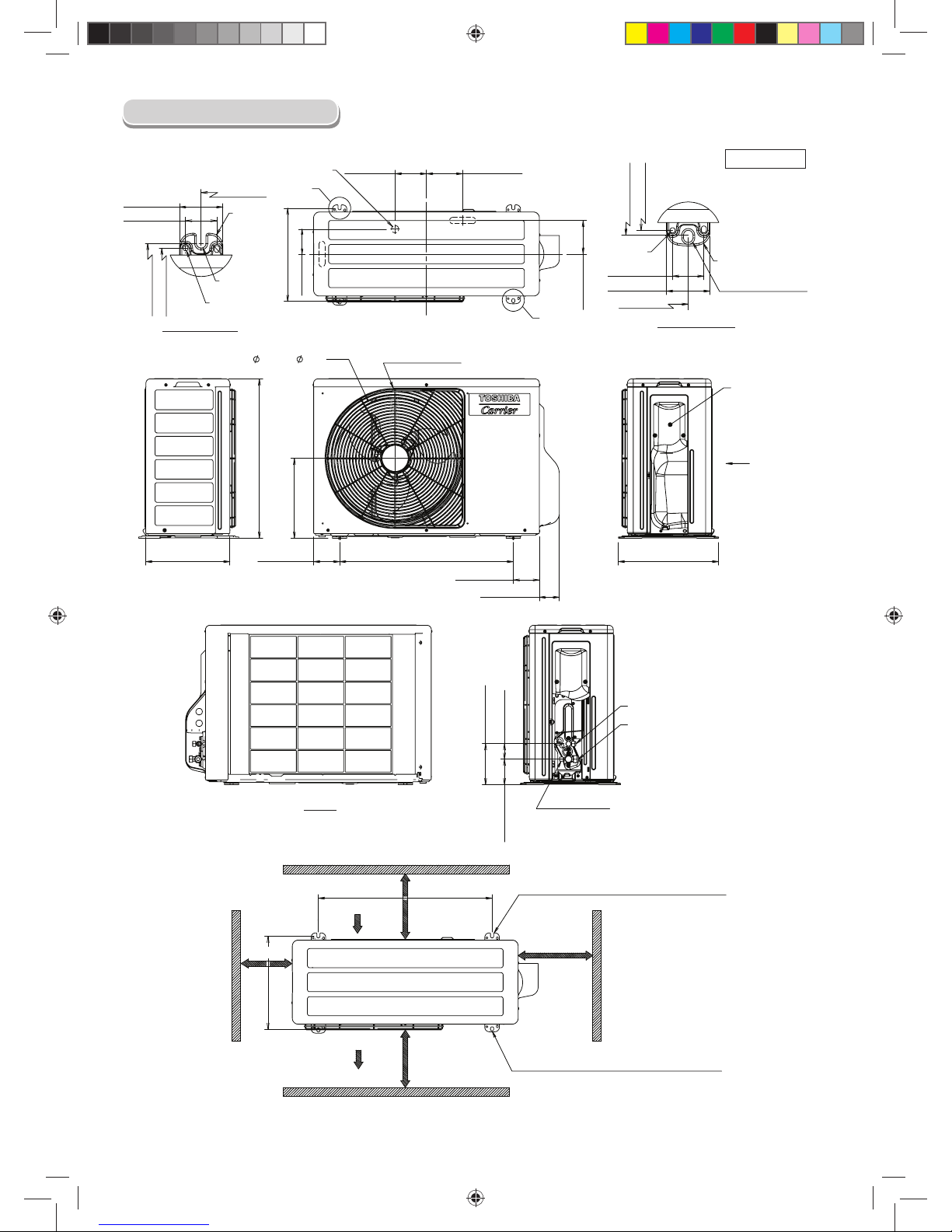

2-23/32 (69)

)572( 8/7-01

3-17/32 (90)

3-17/32 (90)

23-5/8 (

600

)

17-5/32 (

436

)

)023( 23/91-21

4-1/4 (

108

)

4-15/16 (

125

)

( 8/3-3

68

)

( 61/9-4

611

)

A

B

13-1/2 (342)

( 61/11-12

055

)

11-7/16 (

290

)

( 2

3/3-2

35

)

(

23/5

1

3

88

)

( 6

1/9-5

141

)

1-27/64 (36)

1-31/32 (50)

(R15)

R19/32

)023( 23/91-21

23-5/8 (600)

)603( 46/3-21

1-27/64 (36)

1-31/32 (50)

R19/32 (R15)

23-5/8 (600)

)023( 23/91-21

)603( 4

6/3-21

23-5/8 (

600

)

)

0

23(

23/9

1

-21

2

Ø1 (Ø25) Water Drain Outlet

Detail-A (Rear Leg)

R7/32

(R5.5)

Ø1/4 Hole

(Ø6) Hole

Ø1/4 Hole

(Ø6) Hole

Ø7/16x9/16 Oval-Hole

(Ø11x14) Oval-Hole

Detail-B (Front Leg)

COVER

PACKED VALVE

View Z

WIRE GUARD

View Z

Liquid side

(Flare Nut : Ø1/4 (Ø6.35))

Gas side

(Flare Nut : Ø3/8 (Ø9.52))

Service Port

Air Inlet

Air Outlet

3-15/16 or more

(100 mm or more)

23-5/8 or more

(600 mm or more)

2-R7/32x43/64L (R5.5x17L) U-Shape

(For Ø5/16~ Ø13/32 (Ø8~ Ø10) Anchor Bolt)

2-Ø7/16x9/16 (Ø11x14) Oval-Hole

(For Ø5/16~Ø13/32 (Ø8~Ø10) Anchor Bolt)

3-15/16 Inch or more

(100 mm or more)

23-5/8 Inch or more

(600 mm or more)

Unit : Inch (mm)

Outdoor Unit

1110251291-1 EN.indd 21110251291-1 EN.indd 2 11/13/13 2:52 PM11/13/13 2:52 PM

EN

SI

3

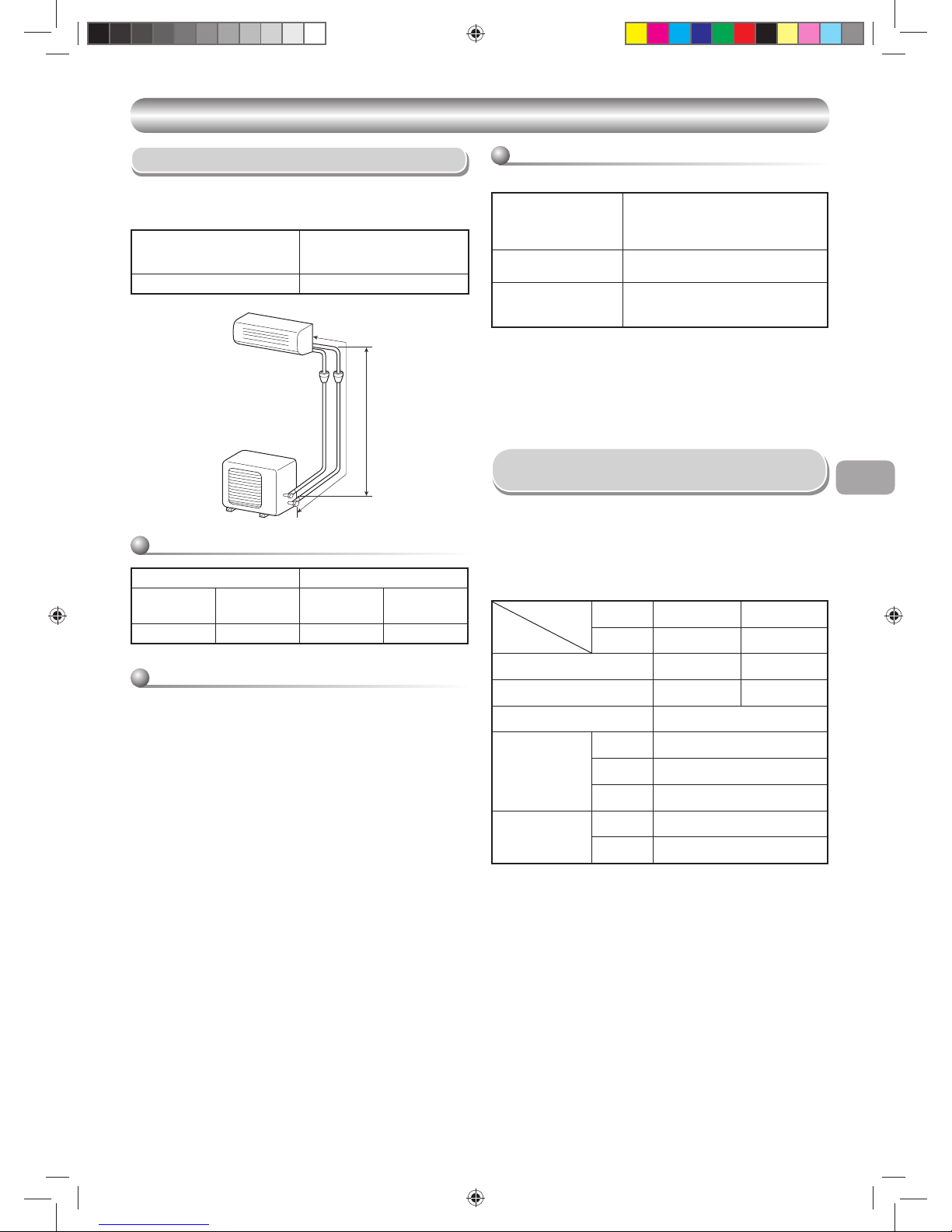

Piping (Field supplied)

• Minimum refrigerant line length between the outdoor unit and indoor unit is

6.6ft. (2m).

• Maximum pipe lengths

SYSTEM REQUIREMENTS

SYSTEM REQUIREMENTS

Allowable

Pipe length T

(ft (m))

Height difference

(Indoor – Outdoor H)

(ft (m))

66 (20) 33 (10)

Refrigerant pipe sizes

HT

Liquid side Gas side

Outer Diameter

In. (mm)

Thickness

In. (mm)

Outer diameter

In. (mm)

Thickness

In. (mm)

Ø1/4 (6.35) 0.03 (0.8) Ø3/8 (9.52) 0.03 (0.8)

Insulation

Both lines need to be insulated. Use a minimum 5/16 in (8mm) wall

thickness.

Refrigerant charge

Unit : ft (m)

Refrigerant charge

Length of refrigerant Pipe

connected to Indoor/

outdoor unit

Additional refrigerant

6.6-50

(2-15m)

None

50-66

(15-20m)

Add 0.22oz/ft (20g/m) of

Refrigerant for piping that exceeds

50ft (15m) up to 66ft (20m)

* Caution during addition of refrigerant

Max. amount of additional refrigerant is 0.22 lbs (100g).

Charge the system accurately. Overcharging may cause serious trouble

to the compressor.

* Minimum refrigerant pipe is 6.6ft (2m).

Using pipe shorter than that may cause a malfunction of the compressor

or other components.

• The power supply shall be connected to the outdoor unit by 3 wires.

• The connecting cable between the indoor unit and outdoor unit needs to

have 4 wires. This cable provides the power for the indoor unit and the

communication signal between the outdoor unit and indoor unit.

• Consult local building codes, NEC (National Electrical Code) or CEC

(Canadian Electrical Code) for special requirements.

• The following are the electrical requirements.

Power supply Connection and

Connecting Cable

Product

Model

Item

FCU RAS-09EK Series RAS-12EK Series

CDU RAS-09EA Series RAS-12EA Series

MCA 10 13

MOCP (MAX Fuse/CB) 15 20

Breaker 15A

Power supply cord

(Not provide)

Connect to

FCU/CDU

CDU

No. of Core 3 (L1, L2, i)

Size AWG14

Interconnecting

cable between FCU

& CDU (Not provide)

No. of Core 4 (L1, L2, S, i)

Size AWG14

MCA = Minimum Circuit Amps

MOCP = Maximum Over Protection Device Amps.

1110251291-1 EN.indd 31110251291-1 EN.indd 3 11/13/13 2:52 PM11/13/13 2:52 PM

4

PRECAUTIONS FOR SAFETY

PRECAUTIONS FOR SAFETY

New refrigerant air conditioner installation

CAUTION

• THIS AIR CONDITIONER USES THE NEW HFC REFRIGERANT (R410A), WHICH DOES NOT DESTROY THE OZONE LAYER.

R410A refrigerant is affected by impurities such as water and oils because the pressure of R410A refrigerant is approx. 1.6 times of refrigerant R22.

ALSO NEW OILS ARE USED WITH R410A, THUS ALWAYS USE NEW REFRIGERANT PIPING AND DO NOT ALLOW MOISTURE OR DUST TO

ENTER THE SYSTEM.

To avoid mixing refrigerant and refrigerant machine oil, the sizes of charging port on the main unit is different than those used on R22 machines and

different tools will be required.

• EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in equipment damage or improper operation.

Do not bury more than 36 in. (914 mm) of refrigerant pipe in the ground. If any section of pipe is buried, there must be a 6 in. (152 mm) vertical rise to

the valve connections on the outdoor units. If more than the recommended length is buried, refrigerant may migrate to the cooler buried section during

extended periods of system shutdown. This causes refrigerant slugging and could possibly damage the compressor at start-up.

DANGER

• FOR USE BY QUALIFIED PERSONS ONLY.

• TURN OFF MAIN POWER SUPPLY BEFORE ATTEMPTING ANY ELECTRICAL WORK. MAKE SURE ALL POWER SWITCHES ARE OFF.

FAILURE TO DO SO MAY CAUSE ELECTRIC SHOCK.

• CONNECT THE CONNECTING CABLE CORRECTLY. IF THE CONNECTING CABLE IS CONNECTED WRONGLY, ELECTRIC PARTS MAY BE

DAMAGED.

• CHECK THAT THE EARTH WIRE IS NOT BROKEN OR DISCONNECTED BEFORE INSTALLATION.

• DO NOT INSTALL THE UNIT NEAR CONCENTRATIONS OF COMBUSTIBLE GAS OR GAS VAPORS.

FAILURE TO FOLLOW THIS INSTRUCTION CAN RESULT IN FIRE OR EXPLOSION.

• TO PREVENT OVERHEATING THE INDOOR UNIT AND CAUSING A FIRE HAZARD, PLACE THE UNIT WELL AWAY (MORE THAN 2 M) FROM

HEAT SOURCES SUCH AS RADIATORS, HEATERS, FURNACE, STOVES, ETC.

• WHEN RELOCATING THE AIR CONDITIONER, BE VERY CAREFUL NOT TO MIX THE SPECIFIED REFRIGERANT (R410A) WITH ANY OTHER

GASEOUS BODY INTO THE REFRIGERATION CYCLE. IF AIR OR ANY OTHER GAS IS MIXED WITH THE REFRIGERANT, THE GAS PRESSURE

IN THE REFRIGERATION CYCLE BECOMES ABNORMALLY HIGH AND IT RESULTINGLY CAUSES BURST OF THE PIPE AND INJURIES ON

PERSONS.

• IN THE EVENT OF REFRIGERANT LEAKAGE DURING INSTALLATION, ALLOW FRESH AIR INTO THE ROOM IMMEDIATELY. IF THE

REFRIGERANT GAS IS HEATED BY FIRE OR OTHER MEAN, IT GENERATES POISONOUS GAS.

Installing, staring up, and servicing air-conditioning equipment can be hazardous due to system pressures, electrical components, and equipment location

(roofs, elevated structures, etc.).

Only trained, qualifi ed installers and service mechanics should install, start-up, and service this equipment.

Untrained personnel can perform basic maintenance functions such as cleaning coils. All other operations should be performed by trained service personnel.

When working on the equipment, observe precautions in the literature and on tags, stickers, and labels attached to the equipment.

Follow all safety codes, Wear safety glasses and work gloves. Keep quenching cloth and fi re extinguisher nearby when brazing. Use care in handling,

rigging, and setting bulky equipment.

Read these instructions thoroughly and follow all warnings or cautions included in literature and attached to the unit. Consult local building codes and

National Electrical Code (NEC) for special requirements. Recognize safety information. This is the safety-alert symbol å. When you see this symbol on

the unit and in instructions or manuals, be alert to the potential for personal injury. Understand these signal words: DANGER, WARNING, and CAUTION.

These words are used with the safety-alert symbol.

DANGER identifi es the most serious hazards which will result in severe personal injury or death. WARNING signifi es hazards which could result in personal

injury or death. CAUTION is used to identify unsafe practices which would result in minor personal injury or product and property damage. NOTE is used to

highlight suggestions which will result in enhanced installation, reliability, or operation.

• Before installation, please read these precautions for safety carefully.

• Be sure to follow the precautions provided here to avoid safety risks. The symbols and their meanings are shown below.

1110251291-1 EN.indd 41110251291-1 EN.indd 4 11/13/13 2:52 PM11/13/13 2:52 PM

EN

SI

5

CAUTION

• Exposure of unit to water or other moisture before installation could result in electric shock. Do not store it in a wet basement or expose to rain or water.

• After unpacking the unit, examine it carefully for possible damage. Report any damages to your distributor.

• Do not install in a place that can increase the vibration of the unit. Do not install in a place that can amplify the noise level of the unit or where noise and

discharged air might disturb neighbors.

• Please read this installation manual carefully before installing the unit. It contains further important instructions for proper installation.

• This appliance must be connected to the main power supply by means of a circuit breaker depending on the place where the unit is installed. Failure to do

so may cause electrical shock.

• Follow the instructions in this installation manual to arrange the drain pipe for proper drainage from the unit. Ensure that drained water is discharged.

Improper drainage can result in water leakage, causing water damage to furniture.

• Tighten the fl are nut with a torque wrench using the prescribed method. Do not apply excess torque. Otherwise, the nut may crack after a long period of

usage and it may cause the leakage of refrigerant.

• Wear gloves (heavy gloves such as cotton gloves) for installation work. Failure to do so may cause personal injury when handling parts with sharp edges.

• Do not touch the air intake section or the aluminum fi ns of the outdoor unit. It may cause injury.

• Do not install the outdoor unit in a place which can be a nest for small animals. Small animals could enter and contact internal electrical parts, causing a

failure or fi re.

• Request the user to keep the place around the unit tidy and clean.

• Make sure to conduct a trial operation after the installation work, and explain how to use and maintain the unit to the customer in accordance with the

manual. Ask the customer to keep the operation manual along with the installation manual.

• The manufacturer shall not assume any liability for the damage caused by not observing the description of this manual.

WARNING

• ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury or death.

Main electrical disconnect switch must be in the OFF position before installing, modifying, or servicing the system. There may be more than 1 disconnect

switch. Lock out and tag switch with a suitable warning label.

• Never modify this unit by removing any of the safety guards or bypassing any of the safety interlock switches.

• Installation work must be performed by qualifi ed personnel only.

• Specifi ed tools and pipe parts for model R410A are required, and installation work must be done in accordance with the manual. HFC type refrigerant

R410A has 1.6 times more pressure than that of conventional refrigerant (R22). Use the specifi ed pipe parts, and ensure correct installation, otherwise

damage and/or injury may be caused. At the same time, water leakage, electrical shock, and fi re may occur.

• Be sure to install the unit in a place that can suffi ciently bear its weight. If the load bearing of the unit is not enough, or installation of the unit is improper,

the unit may fall and result in injury.

• Electrical work must be performed by trained, qualifi ed installers and service mechanics in accordance with the code governing such installation work,

internal wiring regulations, and the manual. A dedicated circuit and the rated voltage must be used. Insuffi cient power supply or improper installation

may cause electrical shock or fi re.

• Use a cabtyre cable to connect wires in the indoor/outdoor units. Midway connection is not allowed. Improper connection or fi xing may cause a fi re.

• Wiring between the indoor unit and outdoor units must be well shaped so that the cover can be fi rmly placed. Improper cover installation may cause

increased heat, fi re, or electrical shock at the terminal area.

• Be sure to use only approved accessories or the specifi ed parts. Failure to do so may cause the unit to fall, water leakage, fi re or electrical shock.

• After the installation work, ensure that there is no leakage of refrigerant gas. If the refrigerant gas leaks out of the pipe into the room and is heated by

fi re or something else from a fan heater, stove or gas range, it causes generation of poisonous gas.

• Make sure the equipment is properly grounded. Do not connect the ground wire to a gas pipe, water pipe, lightning conductor, or telephone earth wire.

Improper earth work may be the cause of electrical shock.

• Do not install the unit where fl ammable gas may leak. If there is any gas leakage or accumulation around the unit, it can cause a fi re.

• Do not select a location for installation where there may be excessive water or humidity, such as a bathroom. Deterioration of insulation may cause

electrical shock or fi re.

• Installation work must be performed following the instructions in this installation manual. Improper installation may cause water leakage, electrical shock

or fi re. Check the following items before operating the unit.

- Be sure that the pipe connection is well placed and there are no leaks.

- Check that the service valve is open. If the service valve is closed, it may cause overpressure and result in compressor damage. At the same time, if

there is a leak in the connection part, it may cause air suction and overpressure, resulting in damage to the unit or injury.

• In a pump-down operation, be sure to stop the compressor unit before removing the refrigerant pipe. If removing the refrigerant pipe while the

compressor is operating with the service valve opened, it may cause air suction and overpressure, resulting in damage to the unit or injury.

• Do not modify the power cable, connect the cable midway, or use a multiple outlet extension cable. Doing so may cause contact failure, insulation

failure, or excess current, resulting in fi re or electrical shock.

• If you detect any damage, do not install the unit. Contact your dealer immediately.

• Do not use any refrigerant different from the one specifi ed for complement or replacement.

Otherwise, abnormally high pressure may be generated in the refrigeration cycle, which may result in a failure or explosion of the product or an injury to

your body.

1110251291-1 EN.indd 51110251291-1 EN.indd 5 11/13/13 2:52 PM11/13/13 2:52 PM

6

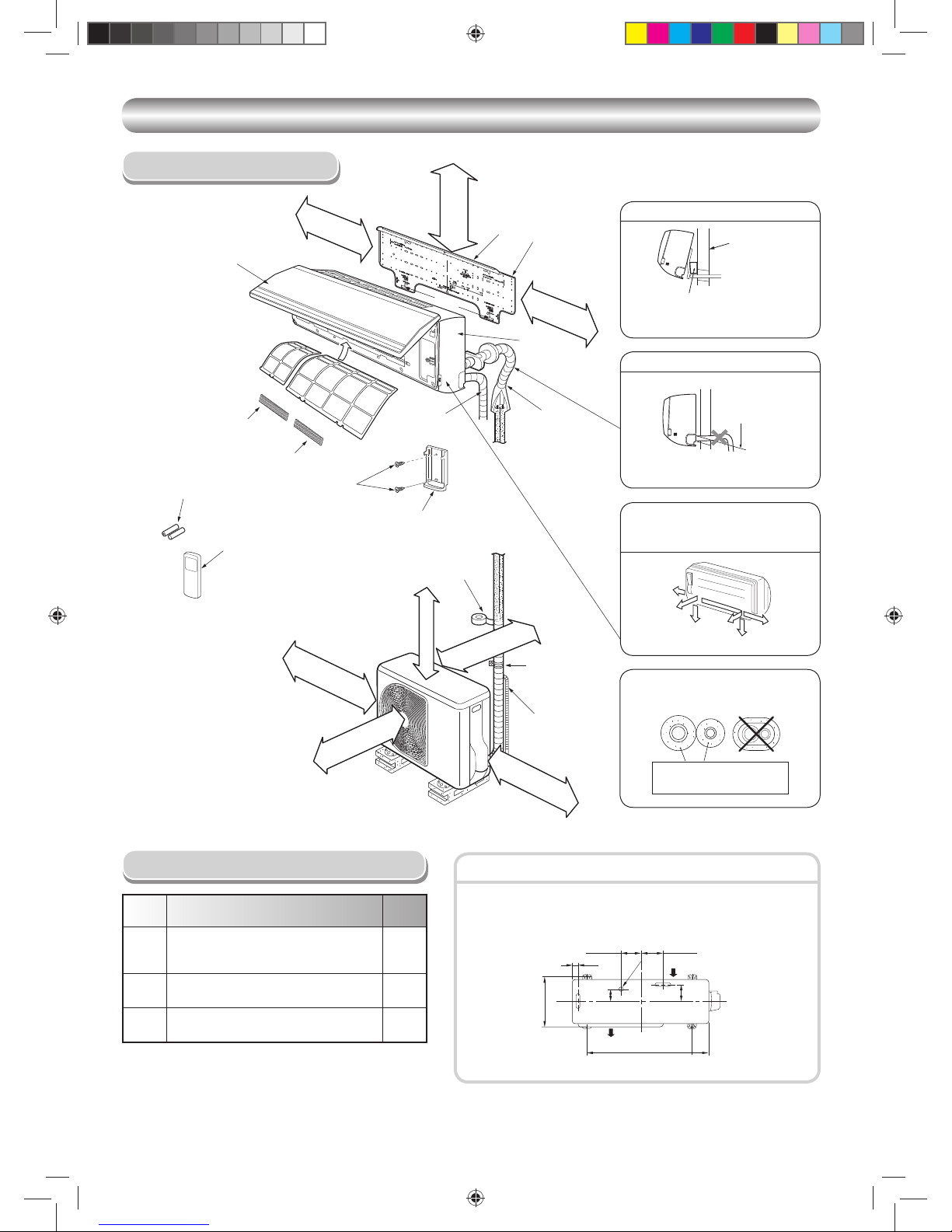

INSTALLATION DIAGRAM OF INDOOR AND OUTDOOR UNITS

INSTALLATION DIAGRAM OF INDOOR AND OUTDOOR UNITS

Part

code

Parts name Q’ty

A

Refrigerant piping

Liquid side : Ø1/4 in. (Ø6.35 mm)

Gas side : Ø3/8 in. (Ø9.52 mm)

One

each

B

Pipe insulating material

(polyethylene foam, 5/16 in. (8 mm) thick)

1

C

Putty, PVC tapes

One

each

Field Supplied Installation Parts

• Secure the outdoor unit with fi xing bolts and nuts if the unit is likely to be

exposed to a strong winds.

• Use Ø5/16 in. (Ø8 mm) or Ø3/8 in. (Ø10 mm) anchor bolts and nuts.

Fixing bolt arrangement of outdoor unit

Insulate the refrigerant pipes separately,

not together.

2

3

8

4

Insert the cushion between the indoor

unit and wall, and tilt the indoor unit for

better operation.

For the rear left and left piping

Wall

Make sure to run the drain hose sloped

downward.

Do not allow the drain hose to get slack.

Cut the piping

hole slightly

sloped downward.

The auxiliary piping can be connected to

the left, rear left, rear right, right, bottom

right or bottom left.

Right

Rear

right

Bottom

right

Rear

left

Bottom left

Left

5/16 in. (8 mm) thick heat

resisting polyethylene foam

1

Batteries

Flat head

wood screw

Remote control holder

Vinyl tape

Apply after carrying

out a drainage test.

Wireless remote control

Saddle

Extension drain hose

(Not available,

provided by installer)

Shield pipe

(Attach to the front panel.)

Air fi lter

Installation

plate

2-9/16 in. (65 mm)

or more

7 in. (170 mm)

or more

3-15/16 in. (100 mm)

or more

3-15/16 in. (100 mm)

or more

23-5/8 in. (600 mm)

or more

23-5/8 in. (600 mm)

or more

6

5

Filter

Filter

Hook

Hook

24 in. (600 mm) or more

only when unobstructed to

the front and both sides.

4-1/4 in.

(108 mm)

1-1/8 in.

(28 mm)

4-15/16 in.

(125 mm)

Ø1 in.

(25 mm)

Air inlet

Air outlet

3-3/8 in.

(86 mm)

4 in.

(102 mm)

12-19/32 in.

(320 mm)

23-5/8 in.

(600 mm)

3-17/32 in.

(90 mm)

7 in. (170 mm)

or more

Conduit

Front

panel

Air inlet grille

CLEARANCES

Remark :

• Details of accessory and installation parts can

be found in the accessory section.

1110251291-1 EN.indd 61110251291-1 EN.indd 6 11/13/13 2:52 PM11/13/13 2:52 PM

EN

SI

7

OUTDOOR UNIT

OUTDOOR UNIT

Installation Location

• A location which provides enough spaces around the outdoor unit as

shown in the diagram above.

• A location which can bear the weight of the outdoor unit and does not

allow an increase in noise level and vibration.

• A location where the operation noise and discharged air do not disturb

your neighbors.

• A location which is not exposed to a strong winds.

• A location free of combustible gases leaks.

• A location which does not block a passage.

• A location where drain water does not cause any problems.

• Depending on snow level, use a fi eld fabricated ice or snow stand.

• When the outdoor unit is to be installed in an elevated position, be sure to

secure its feet as described in the section above.

CAUTION

1. Install the outdoor unit in a location where there are no obstructions

near its air intake or air outlet.

2. When the outdoor units is installed in a place that is always exposed

to strong winds like on the coast or on a high story of a building, use

a fi eld fabricated wind baffl e. To minimize the effect of strong winds,

specially in windy areas, install the unit as shown below.

Strong

wind

90

Refrigerant Piping Connection

1. Make sure you have enough pipe to reach to the indoor unit.

2. Cut the pipe with a pipe cutter.

Flaring

Obliquity Roughness Warp

3. Insert a fl are nut into the pipe and fl are the pipe.

Wiring Connection

1. MOUNT THE OUTDOOR UNIT POWER DISCONNECT.

2. RUN POWER WIRING FROM MAIN BOX TO DISCONNECT PER NEC

AND LOCAL CODES.

3. Remove the valve cover and the cord clamp from the outdoor unit.

4. Fix conduit connector to conduit plate by lock nut and secure it tightly.

Connect the power supply and connecting cables to the terminal block as

shown in the fi gure below and secure it tightly with screws.

5. You should not have extra cables.

6. Secure the power cord and the connecting cable with the cord clamp.

7. Attach the electric parts cover and the valve cover to the outdoor unit.

8. RUN PIPING AND INTERCONNECTING CABLE TO THE INDOOR

UNIT.

Electrical Work

WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury or death.

The unit cabinet must have an uninterrupted or unbroken ground

to minimize personal injury if an electrical fault should occur. The

ground may consist of electrical wire or metal conduit when installed in

accordance with existing electrical codes.

Make sure main power switch is turned OFF before performing service or

maintenance.

All wiring and connections must comply with NEC, CEC, and local codes.

• Connect all wires to the correct terminal on the wiring terminal blocks.

• Make sure that all connectors are secure.

• Size connectors per the ratings listed in the system requirement section.

• System interconnections should be minimum AWG14.

NOTE

CAUTION

Align the centers of the connecting pipes and tighten the fl are nut as far as

possible with your fi ngers. Then tighten the nut with a two wrenches as show

below.

Tightening connection

Do not apply excess torque. Otherwise, the nut may crack depending on

the conditions.

Outer dia. of copper pipe Tightening torque

Ø1/4 in. (Ø6.35 mm) 10 to 13 lbf.ft (14 to 18 N·m)

Ø3/8 in. (Ø9.52 mm) 24 to 31 lbf.ft (33 to 42 N·m)

• Tightening torque for connection of fl are pipe

The pressure of R410A is higher than

R22. (Approx. 1.6 times.) Therefore

securely tighten the fl are pipes

which connect the outdoor unit and

the indoor unit with the specifi ed

tightening torque using a torque

wrench.

Half union Flare nut

Externally

threaded side

Internally

threaded side

Flare at

indoor unit side

Flare at

outdoor unit side

Use a wrench to secure. Use a torque wrench to tighten.

• Do not use the supplied drain nipple for draining water. Drain the water

from all drain holes directly.

• To protect the outdoor unit from snow accumulation, install a holding

frame, and attach a snow protection hood and plate.

* Do not use a double-stacked design.

Precautions about Installation in Regions

with Snowfall and Cold Temperatures

Snow protection plate

Snow protection hood

Snow accumulation line

Holding frame

At least

19-11/16 in. (500 mm)

Install the unit at least

19-11/16 in. (500 mm)

above the snow

accumulation line.

Anchor

bolts

Front

1110251291-1 EN.indd 71110251291-1 EN.indd 7 11/13/13 2:52 PM11/13/13 2:52 PM

8

Stripping length of the Power supply cord and

Interconnecting cable

L1

L2

L1

L2

S

Interconnecting cable

Power supply cord

Terminal block

Unit : inch (mm)

L1

L2

L1

L2

S

Ground line

Connecting cable Power cord

Ground line

3/8 (10)

3/8 (10)

1-3/16 (30)

2-12/16 (70)

3/8 (10)

3/8 (10)

1-3/16 (30)

1-9/16 (40)

Conduit plate

Connector

Lock nut

Valve cover

NOTE : Interconnecting cable

• Wire type : minimum AWG14

CAUTION

• Wrong wiring connection may cause some electrical parts burn out.

• Be sure to comply with LOCAL CODES.

• Every wire must be connected fi rmly.

• If incorrect or incomplete wiring is carried out, it will cause an ignition

or smoke.

INDOOR UNIT

INDOOR UNIT

Installation Location

• Direct sunlight to the indoor unit’s wireless receiver should be avoided.

• The microprocessor in the indoor unit should not be too close to RF

noise sources.

(For details, see the owner’s manual.)

NOTE

• When drilling a wall that contains a metal lath, wire lath or metal plate, be

sure to use a pipe hole brim ring sold separately.

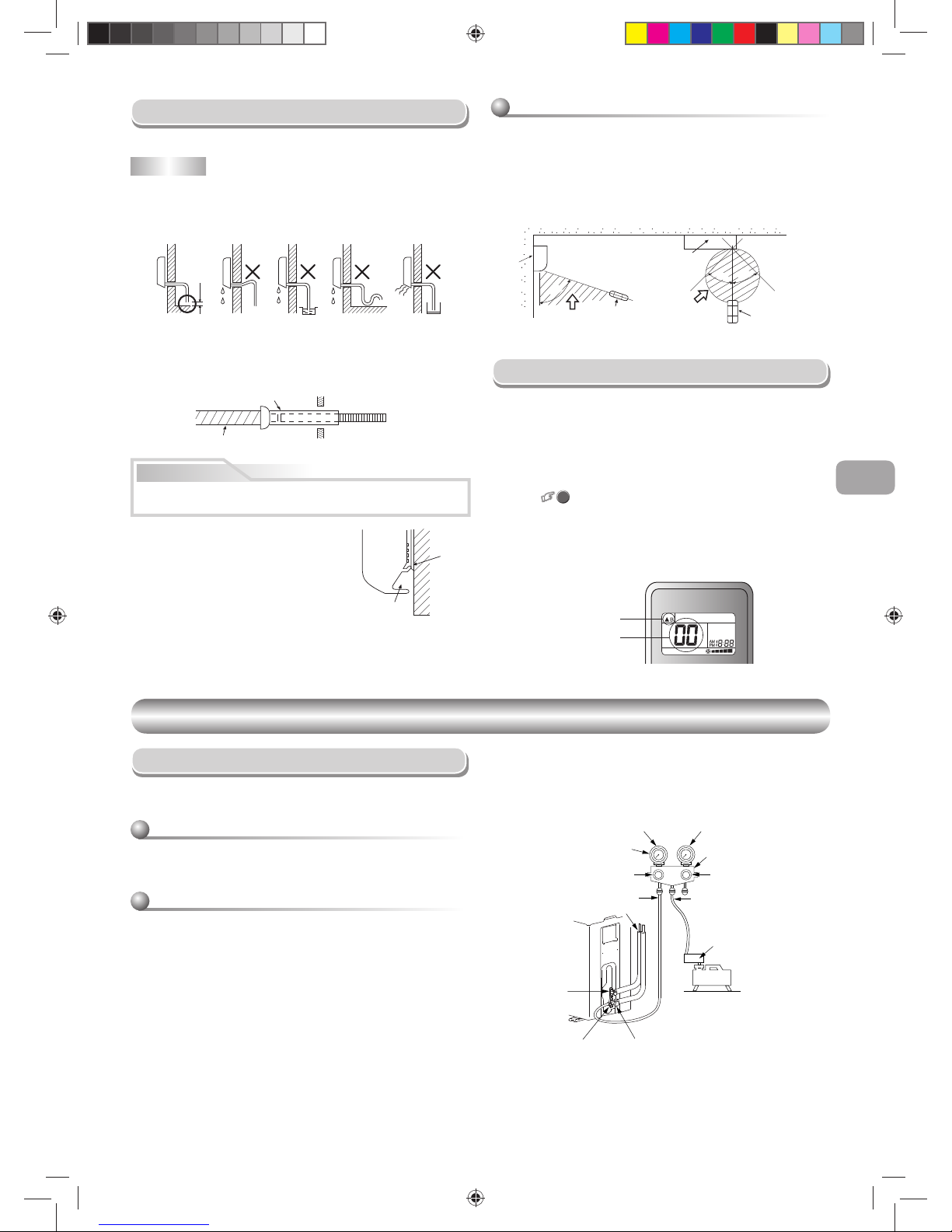

Cutting a hole

When installing the refrigerant pipes from the rear

After determining the pipe hole position on the mounting plate (➡), drill the

pipe hole Ø2-9/16 in. (Ø65 mm) at a slight downward slant to the outdoor

side.

• A location which provides the clearances around the indoor unit as shown

in the diagram in the “CLEARANCES” section.

• A location where there are no obstacles near the air inlet and outlet

• A location which allows easy installation of the piping to the outdoor unit

• A location which allows the front panel to be opened

• The indoor unit shall be installed such that the top of the indoor unit

comes to at least 6.6 ft (2 m) height. Also avoid putting anything on the top

of the indoor unit.

• A location that will bear the weight of the unit.

CAUTION

80 100 180

The center of the pipe

hole is above the arrow.

Pipe hole

Ø2-9/16 in. (65 mm)

3-15/16 in.

(100 mm)

Cutting a Hole and Mounting the

mounting Plate

Mounting the mounting plate

When the mounting plate is directly mounted to

the wall

1. To hook up the indoor unit, securely fi t the mounting plate onto the wall by

screwing it in the upper and lower parts.

2. To mount the mounting plate on a concrete wall with, anchor bolts, drill the

anchor bolt holes as illustrated in the fi gure shown below.

3. Make sure the mounting plate is leveled.

1

7

Anchor bolt holes

Hook

Hook

Hook

Pipe hole Pipe hole

Mounting

plate

Mounting screw

Weight

Indoor unit

Thread

6.6 ft (2 m) or more

from fl oor

7 in.

(170 mm)

3-11/32 in.

(85 mm)

2-29/64 in.

(62 mm)

3-17/64 in.

(82.5 mm)

1. The supply voltage must be the same as the rated voltage of the air

conditioner.

2. Prepare the power source for exclusive use with the air conditioner.

NOTE : Power supply cord

• Wire type : minimum AWG14

CAUTION

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment damage or improper

operation.

Unit failure as a result or of improper line voltage application or excessive

phase imbalance constitutes abuse and may cause damage to electrical

components. Such operation could void any applicable warranty.

1110251291-1 EN.indd 81110251291-1 EN.indd 8 11/13/13 2:52 PM11/13/13 2:52 PM

EN

SI

9

3

1

2

Wiring Connection

1. Open the air inlet grille upward.

2. Remove the screws securing the front panel.

3. Slightly open the lower part of the front panel, then pull the upper part of

the front panel toward you to remove it from the rear plate.

4. Insert the conduit pipe (according to local codes) into the pipe hole on

the wall.

5. Remove the conduit mount by loosening the fi xing screw (Fig. 1)

6. Fix conduit pipe to conduit mount with the lock nut.

7. Pull out the connecting wire through the conduit pipe and process the

wire. (Fig. 3)

8. Take out the wire to the front and fi x it to the terminal block.

Be careful not to mis-wire. (Fig. 2)

9. Firmly tighten the terminal screws to prevent them from loosening.

Tightening torque: 0.9 lbf.ft (1.2 N·m). After tightening, pull the wires

lightly to confi rm that they do not move.

10. Secure the connecting wire with the cord clamp.

11. Fix the conduit mount back to the body by fi xing a screw.

12. Fix the front panel, terminal cover and air inlet grille to the indoor unit.

How to connect the connecting cable

NOTE

• Use stranded wire only.

• Wire type : minimum AWG14

CAUTION

S

L

2

L1

Ground

line

4-5/16 in. (110 mm)

3-5/32 in. (80 mm)

13/16 in. (20 mm)

3/8 in. (10 mm)

• Be sure to refer to the system wiring

diagram located inside the front panel.

• Check local electrical codes and also

any specifi c wiring instructions or

limitations.

Fig. 3

Fig. 2 Wiring

L

1

L

2

S

L

1

L

2

S

Cord clamp

Terminal block

Terminal cover

Screw

Ground line

Screw

Connecting cable

Screw

Front panel

CAUTION

Failure to fi rmly install the unit may result in personal injury and property

damage if the unit falls.

• In case the unit is to be installed in a block, brick, concrete or similar type

walls, make 3/16 in. (5 mm) dia. holes in the wall.

• Insert clip anchors for appropriate mounting screws 7.

NOTE

• Secure four corners and lower parts of the mounting plate with 4 to 6

mounting screws to install it.

7

CAUTION

Installation plate

(Keep horizontal direction.)

3/16 in. (5 mm) dia. hole

Mounting screw

Ø5/32 in. × 1 in.

(Ø4 mm × 25 mm)

Clip anchor

(fi eld supplied parts)

Anchor bolt

Projection

9/16 in. (15 mm)

or less

When installing the mounting plate with a mounting screw, do not use the

anchor bolt holes. Otherwise, the unit may fall down and result in personal

injury and property damage.

Air inlet grille

Front panel

Conduit pipe

Conduit mount

Fixing screw

Lock nut

Interconnecting

cable

Fig. 1 Construction

Piping and Drain Hose Installation

INSULATE BOTH LINES.

Piping and drain hose forming

Rear right

Rear left

Bottom left

Left

Bottom right

Right

Die-cutting

front panel slit

Changing

drain hose

Piping preparation

Right

Rear right

Bottom

right

Rear

left

Bottom left

Left

How to install the air inlet grille on the indoor

unit

• When attaching the air inlet grille,

perform the same process as for

removal but in reverse order.

1110251291-1 EN.indd 91110251291-1 EN.indd 9 11/13/13 2:52 PM11/13/13 2:52 PM

10

Firmly insert the drain hose and drain cap; otherwise, water may leak.

In case of right or left piping

• After making slits of the front panel with a

knife or a making-off pin, cut them with a

pair of nippers or an equivalent tool.

In case of bottom right or bottom left piping

• After making slits of the front panel with a

knife or a making-off pin, cut them with a

pair of nippers or an equivalent tool.

Left-hand connection with piping

• Bend the connecting pipe so that it is laid within 1-5/8 in. (43 mm) above

the wall surface. If the connecting pipe is laid exceeding 1-5/8 in. (43 mm)

above the wall surface, the indoor unit may set on the wall unstably.

When bending the connecting pipe, make sure to use a spring bender to

avoid crushing the pipe.

Bend the connecting pipe within a radius of 1-3/16 in. (30 mm).

To connect the pipe after the unit has been installed (fi gure)

CAUTION

Slit

Slit

80

Liquid side

Gas side

(To the forefront of fl are)

Outward form of indoor unit

R 1-3/16 in. (R 30 mm) (Use polisin

(polyethylene) core or the like for

bending pipe.)

Use the handle of a screwdriver, etc.

6-11/16 in.

(170 mm)

1-5/8 in.

(43 mm)

10-5/8 in.

(270 mm)

How to remove the drain cap

Clip the drain cap with needle-nose

pliers and pull out.

How to fi x the drain cap

1) Insert a hexagon wrench

3/16 in. (4 mm) in the

center head of the cap.

2) Firmly insert the drain cap.

3/16 in.

(4 mm)

No gap

Do not apply lubricating oil

(refrigerant machine oil) when

inserting the drain cap. Application

causes deterioration and drain

leakage from the plug.

Insert a hexagon

wrench 3/16 in.

(4 mm).

How to remove the drain hose

• The drain hose can be removed by removing the

screw securing the drain hose and then pulling out

the drain hose.

• When removing the drain hose, be careful of any

sharp edges the steel plate may have. Sharp

edges can cause injuries.

• To install the drain hose, insert the drain hose

fi rmly until the connection part contacts the heat

insulator, and then secure it with the original

screws.

Heat insulator

Drain hose

NOTE

If the pipe is bent incorrectly, the indoor unit may set on the wall unstably.

After passing the connecting pipe through the pipe hole, connect the

connecting pipes to the refrigerant line and wrap facing tape around them.

CAUTION

• Bind the refrigerant lines (two) and connecting cable with facing tape

tightly. In case of leftward piping and rear-leftward piping, bind the

refrigerant lines (two) only with facing tape.

Indoor unit

Connecting cable

Refrigerant lines

Installation plate

• Carefully arrange pipes such that none of them stick out of the rear

plate of the indoor unit.

• Carefully connect the refrigerant lines and connecting pipes to one

another and cut off the insulating tape wound on the connecting pipe

to avoid double-taping at the joint; moreover, seal the joint with vinyl

tape, etc.

• Check for gas leaks before insulating.

Indoor Unit Fixing

• To detach the indoor unit from the

mounting plate, pull the indoor unit toward

you while pushing its bottom up as shown

in the fi gure.

1

2

1

1. Pass the pipe through the hole in the wall and hook the indoor unit on the

upper hook of the installation plate.

2. Swing the indoor unit to the right and left to confi rm that it is fi rmly hooked

up to the mounting plate.

3. While pressing the indoor unit onto the wall, hook it to the lower section

of the mounting plate. Pull the indoor unit toward you to confi rm that it is

fi rmly hooked up to mounting plate.

Hook here.

Installation plate

Hook

Press

(unhook)

Push Push

1. Die-cutting front panel slit

With a pair, of nippers, cut out the slit on the leftward or right side of the

front panel for the left or right connection, and the slit on the bottom left or

right side of the front panel for the bottom left or right connection.

2. Changing drain hose

For leftward connection, bottom-leftward connection and rearleftward

connection’s piping, it is necessary to change the drain hose and drain

cap.

1110251291-1 EN.indd 101110251291-1 EN.indd 10 11/13/13 2:52 PM11/13/13 2:52 PM

EN

SI

11

Drainage

1. Run the drain hose slopping downward.

NOTE

• The hole should be made at a slight downward slant on the outdoor side.

• The drain is internally trapped. An external trap is not required.

Do not rise the

drain hose.

Do not form the

drain hose into

a wavy shape.

2 in.

(50 mm)

or more

Do not put the

drain hose end

into water.

Do not put the

drain hose end

in the drainage ditch.

2. Put water in the drain pan and make sure that the water is drained out.

3. When connecting an extension drain hose, insulate it with shield pipe.

Shield pipe

Drain hose

Extension drain hose

Inside the room

Arrange the drain pipe for proper drainage from the unit.

Improper drainage can result in dew-dropping.

This air conditioner has the structure designed

to drain water collected from dew, which forms

on the back of the indoor unit, to the drain pan.

Therefore, do not store the power cord and other

parts at a height above the drain guide.

CAUTION

Wall

Drain

guide

Space for pipes

Remote control

• Place the remote control away from obstacles (such as curtain) that may

block the signal coming from the remote control.

• Do not install the remote control in a place exposed to direct sunlight or

close to a heating source such as a stove.

• Keep the remote control at least 3.3 ft (1 m) apart from the nearest TV set

or stereo equipment. (This is necessary to prevent image disturbances or

noise interference.)

• The location of the remote control should be determined as shown below.

54 °

4

5°

5

7

°

Indoor unit

(Side view)

(Top view)

Indoor unit

Remote

control

Remote

control

Reception

range

Reception range

Remote Control A-B Selection

In case of two systems operating nearby, follow the instructions below to set

the remote control to operate with one indoor unit at a time.

Remote Control B Setup.

1. Press RESET button on the indoor unit to turn the air conditioner ON.

2. Point the remote control at the indoor unit.

3. Push and hold CHK ● button on the Remote Control with the tip of a

pencil. “00” will be shown on the display.

4. Press

MODE

while pushing CHK ●. “B” will show on the display and

“00” will disappear and the air conditioner will turn OFF. B is now

memorized.

Note: 1. Repeat above step to reset Remote Control back to A.

2. Remote Control does not display “A”.

3. Default setting of Remote Control from factory is A.

“B” Display

“00” Display

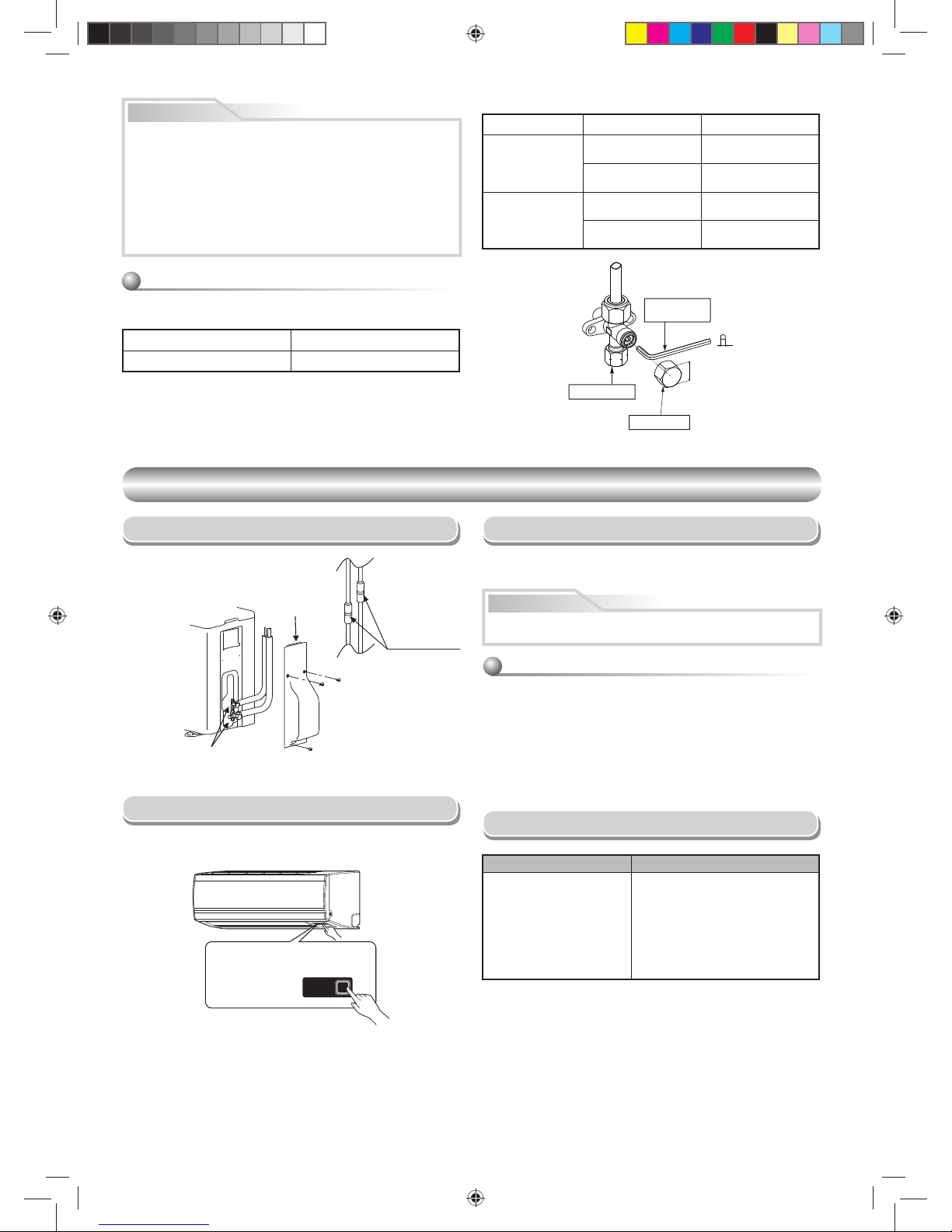

Evacuating

After the piping has been connected to the indoor unit, you vacuum both

units at once.

Be sure to use a vacuum pump with counter-fl ow prevention function so

that inside oil of the pump does not fl ow backward into pipes of the air

conditioner when the pump stops.

(If oil inside of the vacuum pump enters the air conditioner, which uses

R410A, refrigeration cycle trouble may happen.)

1. Connect the charge hose from the manifold valve to the service port of

the packed valve at the gas side.

2. Connect the charge hose to the port of the vacuum pump.

3. Open fully the low pressure side handle of the manifold valve gauge.

4. Operate the vacuum pump to start evacuating. Perform evacuation for

about 15 minutes if the piping length is 66 feet (20 m). (assuming a

pump capacity of 27 liters per minute) Then confi rm that the compound

pressure gauge reading is –101 kPa (–76 cmHg).

Using a vacuum pump

Evacuate the air in the connecting pipes and in the indoor unit using a

vacuum pump. Do not re-use the refrigerant in the outdoor unit. For details,

see the vacuum pump manual.

VACUUMING

EVACUATING

EVACUATING

Packed valve at

liquid side

Service port (Valve core

(Setting pin))

Packed valve at gas side

Vacuum

pump

Vacuum pump adapter for

counter-fl ow prevention

(For R410A only)

Charge hose

(For R410A only)

Handle Hi

(Keep full closed)

Manifold valve

Pressure gauge

Compound pressure gauge

Handle Lo

Charge hose

(For R410A only)

Connecting pipe

–101 kPa

(–76 cmHg)

5. Close the low pressure side valve handle of the manifold valve gauge.

6. Open fully the valve stem of the packed valves (both gas and liquid

sides).

7. Remove the charging hose from the service port.

8. Securely tighten the caps of packed valves.

1110251291-1 EN.indd 111110251291-1 EN.indd 11 11/13/13 2:52 PM11/13/13 2:52 PM

12

Packed valve handling precautions

• Open the valve stem all the way out, but do not try to open it beyond the

stopper.

• Securely tighten the valve cap with torque in the following table:

Pipe size of Packed Valve Size of Hexagon wrench

1/2 in. (12.7 mm and smallers) A = 3/16 in. (4 mm)

Cap Cap Size (H) Torque

Valve Rod Cap

43/64 in. - 3/4 in.

(H17 - H19)

10 to 13 Ibf.ft

(14~18 N·m)

55/64 in. - 1-3/16 in.

(H22 - H30)

24 to 31 Ibf.ft

(33~42 N·m)

Service Port Cap

35/64 in.

(H14)

37 to 46 Ibf.ft

(50~62 N·m)

43/64 in.

(H17)

10 to 13 Ibf.ft

(14~18 N·m)

A

H

Hexagon wrench

is required.

Service Port Cap

Valve Rod Cap

OTHERS

OTHERS

Gas Leak Test

Test Operation

Troubleshooting (Check Point)

To switch the TEST RUN (COOL) mode, press RESET button for 10 seconds.

(The beeper will make a short beep.)

Auto Restart Setting

The product was shipped with Auto Restart function in the ON position.

Turn it OFF if this function is not required.

How to cancel the Auto Restart

Check the fl are nut

connections for the

gas leak with a gas

leak detector or

soap water.

This product is designed so that after a power failure it can restart

automatically in the same operating mode as before the power failure.

1. Press and hold the RESET button on the indoor unit for 3 seconds to

cancel the ope

ration. (3

beeps will

sound but OPERATION lamp does not

blink)

2. Press and hold the RESET button on the indoor unit for 3 seconds to set

the operation. (3 beeps will sound and OPERATION lamp blink 5 time/

sec for 5 seconds)

• Do not operate ON timer and OFF timer.

Note : Default setting of auto restart operation is ON.

Check places with

fl are nut connections

(indoor unit)

Check places for

the outdoor unit.

Valve cover

Information

RESET

RESET button

The unit does not operate. Cooling or Heating is abnormally low.

• The power main switch is

turned off.

• The circuit breaker is tripped.

• ON timer is set.

• The fi lters are blocked with dust.

• The temperature has been set

improperly.

• Windows or doors are open.

• The air inlet or outlet of the outdoor

unit is blocked.

• The fan speed is too low.

• The operation mode is FAN or DRY.

CAUTION

• 5 IMPORTANT POINTS FOR PIPING WORK.

(1) Take away dust and moisture (inside of the connecting pipes).

(2) Tighten the connections (between pipes and unit).

(3) Evacuate the air in the connecting pipes using a VACUUM PUMP.

(4) Check gas leak (connected points).

(5) Be sure to fully open the packed valves before operation.

• UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment damage or

improper operation.

Never use the system compressor as a vacuum pump.

1110251291-1 EN.indd 121110251291-1 EN.indd 12 11/13/13 2:52 PM11/13/13 2:52 PM

Loading...

Loading...