Toshiba Carrier MMD-AP0074SPH2UL, Carrier MMD-AP0124SPH2UL, Carrier MMD-AP0154SPH2UL, Carrier MMD-AP0184SPH2UL, Carrier MMD-AP0094SPH2UL Installation Manual

Page 1

AIR CONDITIONER (MULTI TYPE)

Installation Manual

Indoor Unit

Model name:

Slim Duct Type

MMD-AP0074SPH2UL

MMD-AP0094SPH2UL

MMD-AP0124SPH2UL

MMD-AP0154SPH2UL

MMD-AP0184SPH2UL

For commercial use

Pour usage commercial

Installation Manual 1

Manuel d’installation 22

English

Français

Page 2

–1–

Please read this Installation Manual carefully before installing the Air Conditioner.

• This Manual describes the installation method of the indoor unit.

• For installation of the outdoor unit, follow the Installation Manual attached to the outdoor unit.

ADOPTION OF NEW REFRIGERANT

This Air Conditioner uses R410A an environmentally friendly refrigerant.

Contents

1 Precautions for safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2 Accessory parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

3 Selection of installation place. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

4 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

5 Drain piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

6 Duct design. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

7 Refrigerant piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

8 Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

9 Applicable controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

10 Test run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

11 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1-EN 2-EN

1 Precautions for safety

Installing, starting up, and servicing air--conditioning equipment can be hazardous due to system pressures,

electrical components, and equipment location (roofs, elevated structures, etc.).

Only trained, qualified installers and service mechanics should install, start--up, and service this equipment.

Untrained personnel can perform basic maintenance functions such as cleaning heat exchanger. All other

operations should be performed by trained service personnel.

Before working on the equipment, observe precautions in the literature and on tags, stickers, and labels attached

to the equipment.

Follow all safety codes.Wear safety glasses and work gloves. Keep quenching cloth and fire extinguisher nearby

during brazing. Use care in handling, rigging, and setting bulky equipment.

Read these instructions thoroughly and follow all warnings or cautions included in literature and attached to the

unit. Consult local building codes and National Electrical Code (NEC) for special requirements. Recognize safety

information. This is the safety--alert symbol . When you see this symbol on the unit and in instructions or

manuals, be alert to the potential for personal injury.Understand these signal words: DANGER, WARNING, and

CAUTION. These words are used with the safety--alert symbol.

DANGER identifies the most serious hazards which will result in severe personal injury or death. WARNING

signifies hazards which could result in personal injury or death. CAUTION is used to identify unsafe practices which

may result in minor personal injury or product and property damage. NOTE is used to highlight suggestions which

will result in enhanced installation, reliability, or operation.

The manufacturer shall not assume any liability for the damage caused by not observing the description of this

manual.

WARNING

• Only a qualified installer or service person is allowed to do installation work.

Inappropriate installation may result in water leakage, electric shock or fire.

• Do not use any refrigerant different from the one specified for complement or replacement.

Otherwise, abnormally high pressure may be generated in the refrigeration cycle, which may result in a

failure or explosion of the product or an injury to your body.

• Connect ground wire. (grounding work)

Incomplete grounding may cause an electric shock.

Do not connect ground wires to gas pipes, water pipes, lightning rods or ground wires for telephone wires.

• Turn off all the circuit breaker before attempting any electrical work.

Failure to do so may cause electric shock.

• Install the refrigerant pipe securely during the installation work before operating the air conditioner.

If the air conditioner is operated with the valve open and without the refrigerant pipe, the compressor sucks air and

the refrigeration cycle is overpressurized, which may cause a burst or injury.

• When moving the air conditioner for the installation into another place, do not enter any gaseous matter

other than the specified refrigerant into the refrigeration cycle.

If air or any other gas is mixed in the refrigerant, the gas pressure in the refrigeration cycle becomes abnormally high

and it resultingly causes pipe burst and injuries on persons.

• Perform installation work properly according to the Installation Manual.

Inappropriate installation may result in water leakage, electric shock or fire.

• When the air conditioner is installed in a small room, provide appropriate measures to ensure that the

concentration of refrigerant leakage occur in the room does not exceed the critical level.

• Install the air conditioner securely in a location where the base can sustain the weight adequately.

• Perform the specified installation work to guard against an earthquake.

If the air conditioner is not installed appropriately, accidents may occur due to the falling unit.

• Install the air conditioner at a height 8’ (2.4 m) or more from the floor.

If you insert your hands or others directly into the unit while the air conditioner operates, it is dangerous because you

may contact with revolving fan or active electricity.

• If refrigerant gas has leaked during the installation work, ventilate the room immediately.

If the leaked refrigerant gas comes in contact with fire, noxious gas may generate.

• After the installation work, confirm that refrigerant gas does not leak.

If refrigerant gas leaks into the room and flows near a fire source, such as a cooking range, noxious gas might

generate.

• Electrical work must be performed by a qualified electrician in accordance with the Installation Manual. Use

an exclusive power supply for the air conditioner at the rated voltage.

An insufficient power supply capacity or inappropriate installation may cause fire.

Page 3

• Use the specified wires for wiring connect the terminals. Securely fix them to prevent external forces applied

to the terminals from affecting the terminals.

• Conform to the regulations of the local electric company when wiring the power supply.

• For the refrigerant recovery work (collection of refrigerant from the pipe to the compressor), stop the

compressor before disconnecting the refrigerant pipe.

If the refrigerant pipe is disconnected while the compressor is working with the valve open, the compressor sucks air

and the refrigeration cycle is overpressurized, which may cause a burst or injury.

• Before carrying out the installation, maintenance, repair or removal work, set the circuit breaker to the OFF

position.

Otherwise, electric shocks may result.

• Do not touch the aluminium fin of the unit. You may injure yourself if you do so. If the fin must be touched

for some reason, first put on protective gloves and safety work clothing, and then proceed.

• Install the air conditioner securely in a location where the base can sustain the weight adequately. If the

strength is not enough, the unit may fall down resulting in injury.

• The unit can be accessed from the service panel.

• Install a circuit breaker that meets the specifications in the installation manual and the stipulations in the

local regulations and laws.

• Install the circuit breaker where it can be easily accessed by the agent.

• Under no circumstances the power wire must not be extended. Connection trouble in the places where the

wire is extended may give rise to smoking and/or a fire.

• Upon completion of the installation work, tell the user where the circuit breaker is located. If the user does

not know where the circuit breaker is, he or she will not be able to turn it off in the event that trouble has

occurred in the air conditioner.

CAUTION

• This air conditioner adopts the new HFC refrigerant (R410A) which does not destroy ozone layer.

• The characteristics of R410A refrigerant are; easy to absorb water, oxidizing membrane or oil, and its pressure is

approx. 1.6 times higher than that of refrigerant R22. Accompanied with the new refrigerant, refrigerating oil has also

been changed. Therefore, during installa tion work, be sure that water, dust, former refrigerant, or refrigerating oil does

not enter the refrigerating cycle.

• To prevent charging an incorrect refrigerant and refrigerating oil, the sizes of connecting sections of charging port of

the main unit and installation tools are changed from those for the conventional refrigerant.

• Accordingly the exclusive tools are required for the new refrigerant (R410A).

• For connecting pipes, use new and clean piping designed for R410A, and please care so that water or dust does not

enter.

• Tighten the flare nut with a torque wrench in the specified manner.

Excessive tightening of the flare nut may cause a crack in the flare nut after a long period, which may result in

refrigerant leakage.

• Wear heavy gloves during the installation work to avoid injury.

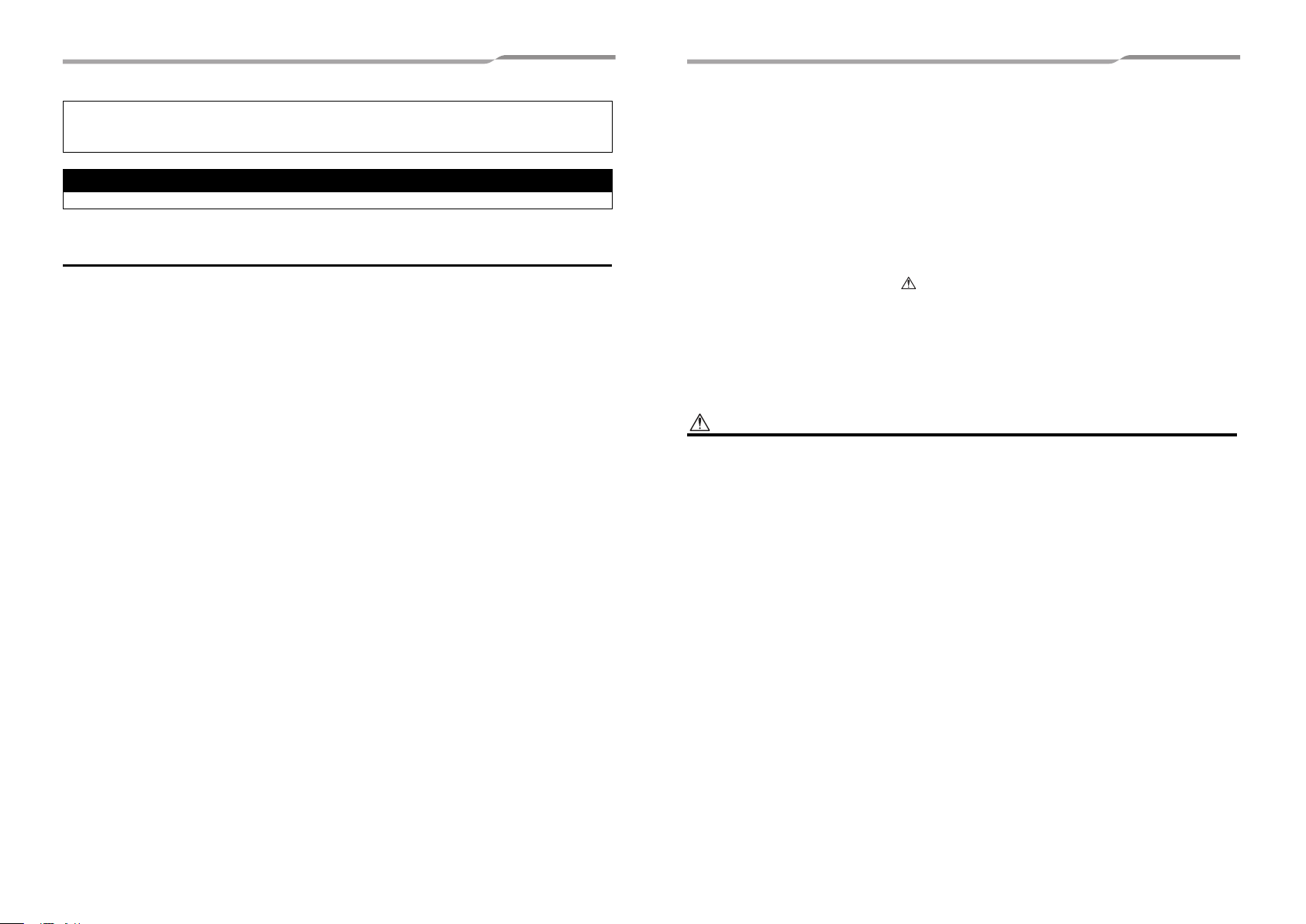

2 Accessory parts

Part name Q’ty Shape Usage

Installation Manual 1 This manual (Hand over to customers)

Heat insulating pipe 2 For heat insulation of pipe connecting section

Washer 8 For hanging-up unit

Hose band 1 For connecting drain pipe

Flexible hose 1 For adjustment of drain pipe centering

Heat insulator 1 For insulating drain connecting section

1

Drain socket

1

Banding band 2 For fixing of pipe connecting heat insulator

Air intake port flange 1 For connecting a duct when air intake is from the back

For connect drain pipe

EN

3-EN 4-EN

–2–

Page 4

–3–

3 Selection of installation place

Avoid installing in the following places

Select a location for the indoor unit where the cool or warm air will circulate evenly.

Avoid installation in the following kinds of locations.

• Saline area (coastal area).

• Locations with acidic or alkaline atmospheres (such as areas with hot springs, factories where chemicals or

pharmaceuticals are made and places where the exhaust air from combustion appliances will be sucked into the

unit).

Doing so may cause the heat exchanger (its aluminum fins and copper pipes) and other parts to become

corroded.

• Locations with atmospheres with mist of cutting oil or other types of machine oil.

Doing so may cause the heat exchanger to become corroded, mists caused by the blockage of the heat

exchanger to be generated, the plastic parts to be damaged, the heat insulators to peel off, and other such

problems to result.

• Locations where vapors from food oils are formed (such as kitchens where food oils are used).

Blocked filters may cause the air conditioner’s performance to deteriorate, condensation to form, the plastic parts

to be damaged, and other such problems to result.

• Places where iron or other metal dust is present. If iron or other metal dust adheres to or collects on the interior

of the air conditioner, it may spontaneously combust and start a fire.

• Locations near obstructions such as ventilation openings or lighting fixtures where the flow of the blown air will

be disrupted (a disruption of the air flow may cause the air conditioner’s performance to deteriorate or the unit to

shut down).

• Locations where an in-house power generator is used for the power supply.

The power line frequency and voltage may fluctuate, and the air conditioner may not work properly as a result.

• On truck cranes, ships or other moving conveyances.

• The air conditioner must not be used for special applications (such as for storing food, plants, precision

instruments or art works).

(The quality of the items stored may be degraded.)

• Locations where high frequencies are generated (by inverter equipment, in-house power generators, medical

equipment or communication equipment).

(Malfunctioning or control trouble in the air conditioner or noise may adversely affect the equipment’s operation.)

• Locations where there is anything under the unit installed that would be compromised by wetness.

(If the drain has become blocked or when the humidity is over 80 %, condensation from the indoor unit will drip,

possibly causing damage to anything underneath.)

• In the case of the wireless type of system, rooms with the inverter type of fluorescent lighting or locations

exposed to direct sunlight.

(The signals from the wireless remote control may not be sensed.)

• Locations where organic solvents are being used.

• The air conditioner cannot be used for liquefied carbonic acid cooling or in chemical plants.

• Location near doors or windows where the air conditioner may come into contact with high-temperature, highhumidity outdoor air.

(Condensation may occur as a result.)

• Locations where special sprays are used frequently.

Installation under high-humidity atmosphere

In some cases including the rainy season, especially inside of the ceiling may become high-humidity atmosphere

(dew-point temperature: 73 °F (22.8 °C) or higher).

1. Installation to inside of the ceiling with tiles on the roof

2. Installation to inside of the ceiling with slated roof

3. Installation to a place where inside of the ceiling is used for pathway to intake the fresh air

4. Installation to a kitchen

• In the above cases, additionally attach the heat insulator to all positions of the air conditioner, which come to

contact with the high-humidity atmosphere. In this case, arrange the side plate (Check port) so that it is easily

removed.

• Apply also a sufficient heat insulation to the duct and connecting part of the duct.

[Reference] Condensation test conditions

Indoor side:

Air volume: Low air volume, operation time 4 hours

80 °F (26.7 °C) dry bulb temperature

75 °F (23.9 °C) wet bulb temperature

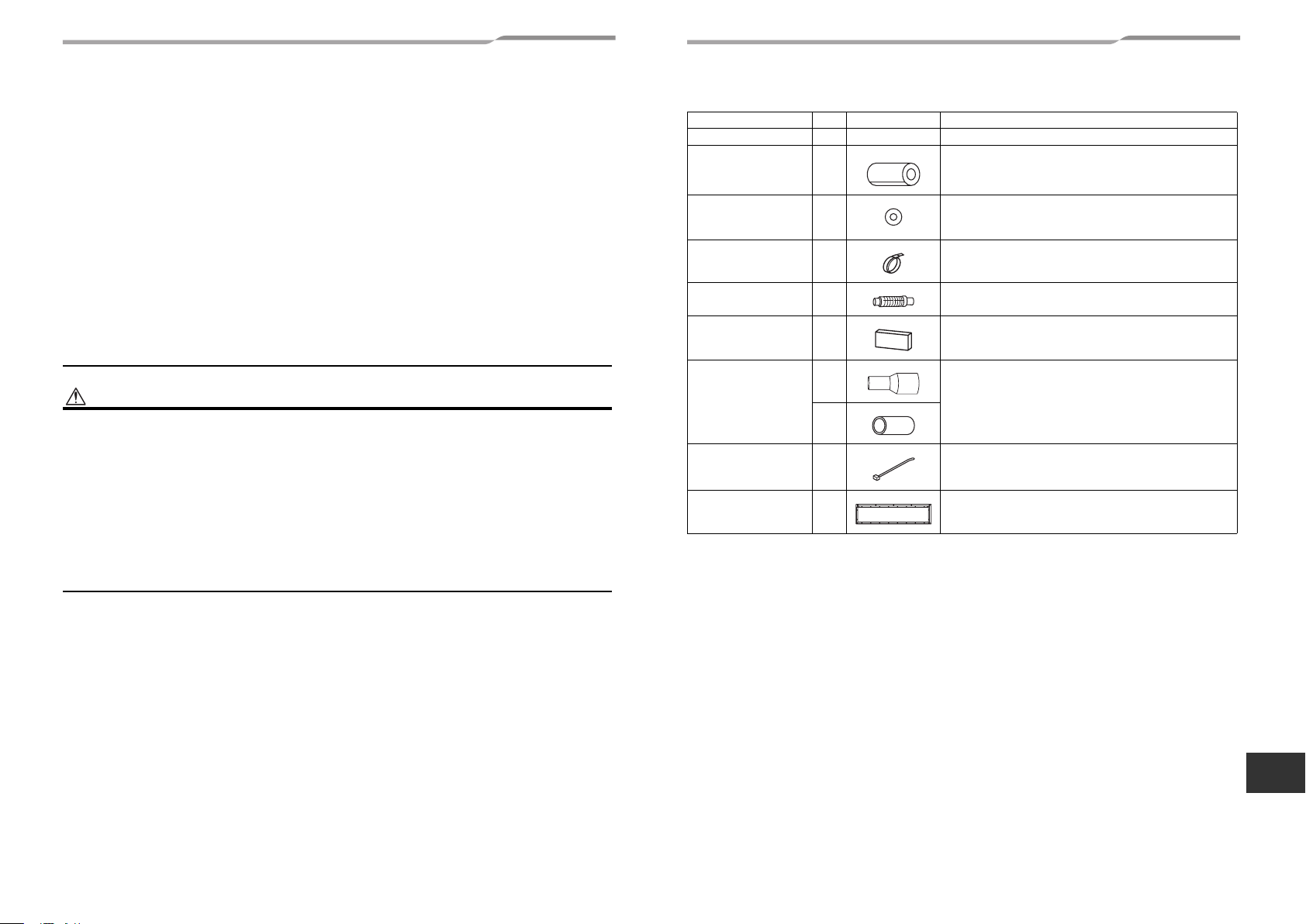

Preparation before installation

CAUTION

The air intake port flange is attached upside down for product protection during shipping. Be sure to reattach the flange

in the correct orientation in order to connect to the duct.

During shipping To install (correct orientation)

Flange Flange

Indoor unit Indoor unit

Screw (10 pieces)

5-EN 6-EN

Page 5

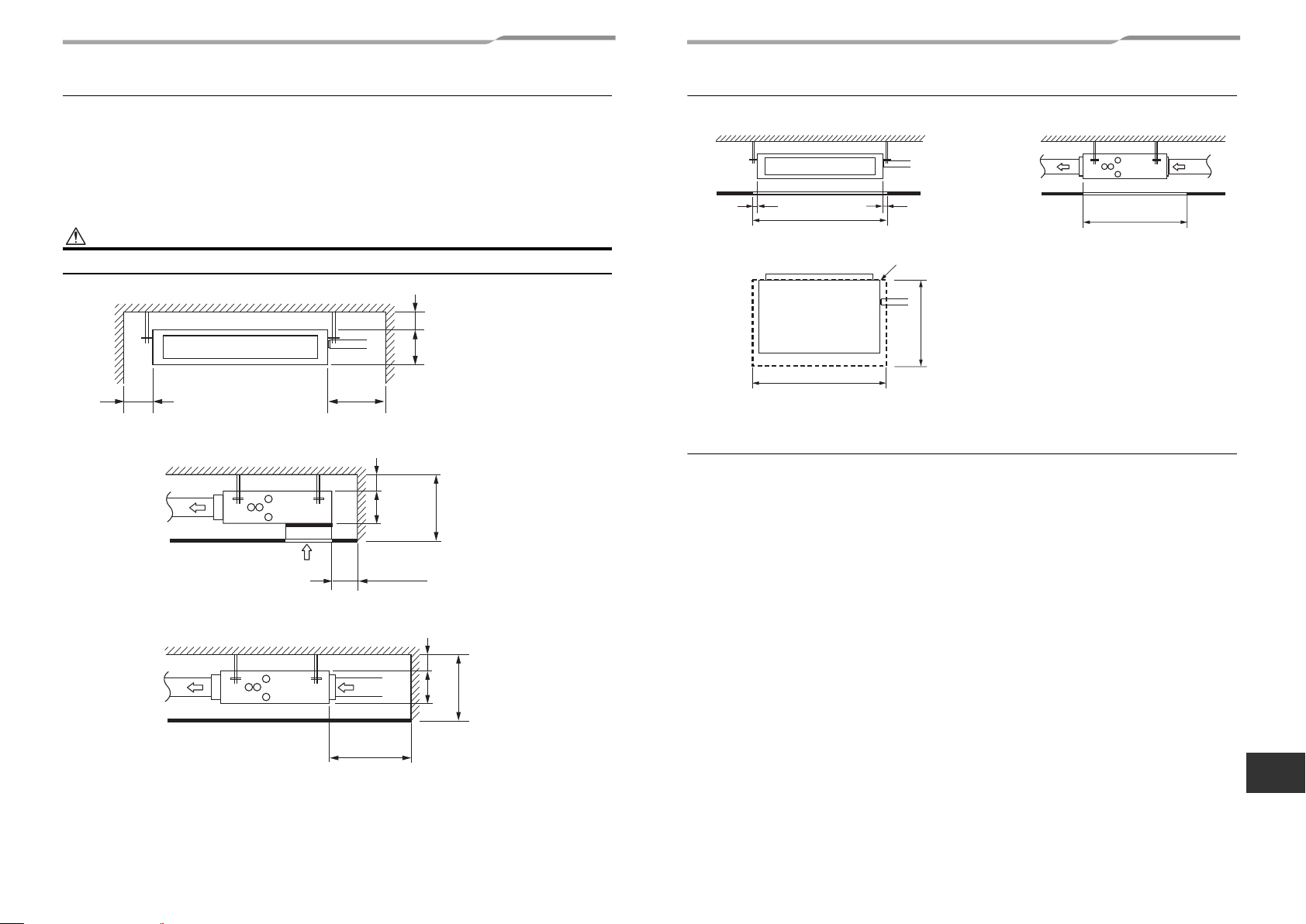

Installation space Unit: in (mm)

Reserve sufficient space required for installation or service work.

The indoor unit does not have a built-in air filter.

The type of air filters required will be specified by applicable codes and requirements for the indoor unit installation.

All filters are locally procured.

Always install the air filter (Local procure) in a location that permits easy maintenance, such as behind the intake

grille. (If no air filter is installed, dust will collect in the heat exchanger, which may cause the air conditioner to fail

or to leak.)

CAUTION

Leave sufficient space to remove the air filter when you attach it.

Service space Unit: in (mm)

Reserve sufficient space required for installation or service work.

Air discharge

Ceiling

2” (50)

39.2” (995)

3.9” (100)

29.3” (745)

Ceiling opening size

<Under air intake>

<Back air intake>

Air discharge

3.9” (100) or more

Ceiling

Ceiling

Air intake

15.8” (400) or

more

0.2” (5) or

more

8.3” (

3.9” (100) or more

Air intake

11.8” (300) or more

0.2” (5) or more

8.3” (

210)

210)

11.2” (285) or more

0.2” (5) or more

8.3”

9.3” (235) or

(

210)

more

29.3” (745)

39.2” (995)

Filter cleaning sign term setting

The lighting term setup of the filter sign (Notification of filter cleaning) of the remote control can be changed

according to the condition of installation.

For setup method, refer to “Filter sign setting” in the Applicable controls of this Manual.

EN

7-EN 8-EN

–4–

Page 6

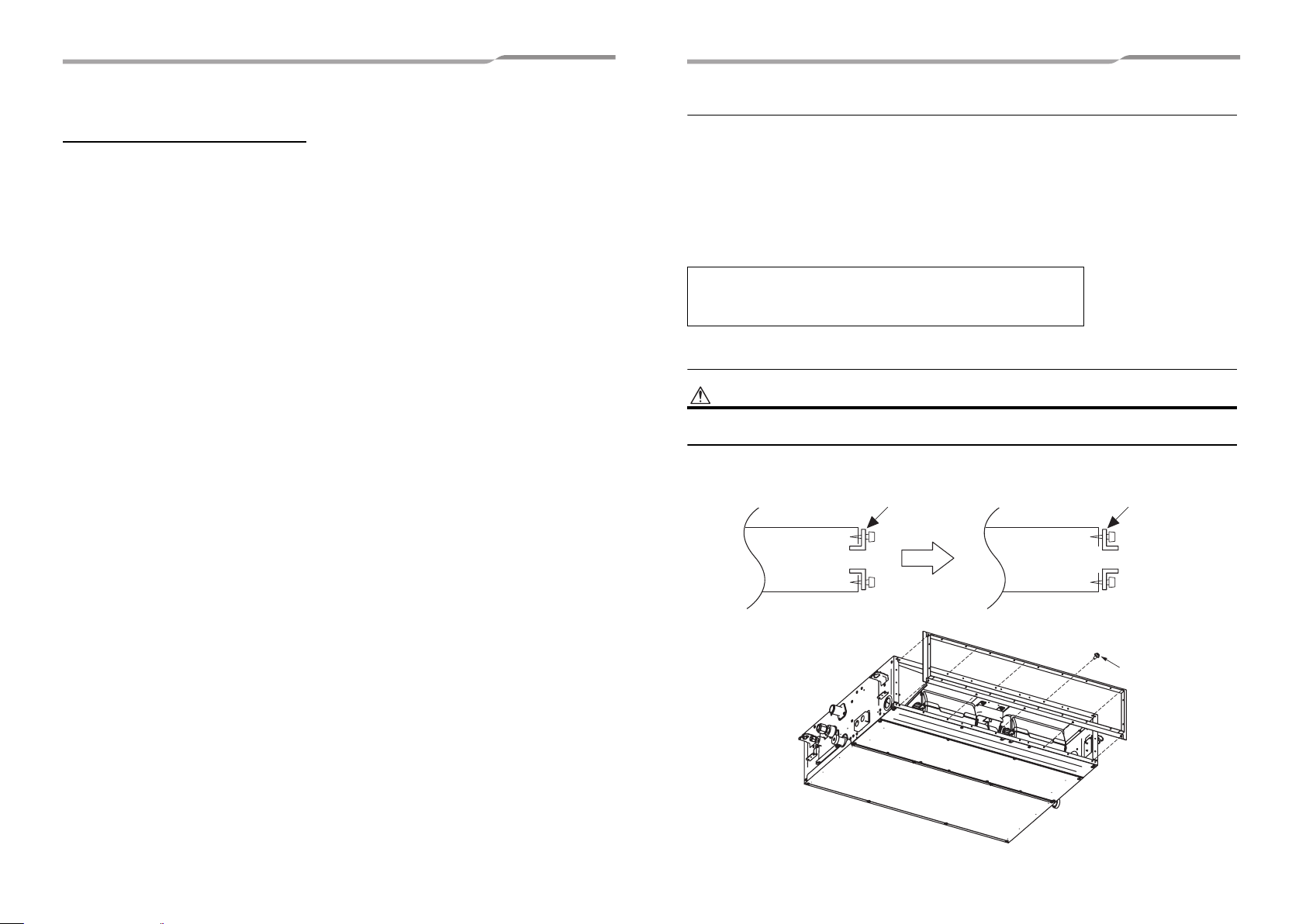

4 Installation

–5–

WARNING

• Install the air conditioner certainly at a place to sufficiently withstand the weight.

• If the strength is insufficient, the unit may fall down resulting in human injury.

• Perform a specified installation work to guard against an earthquake.

• An incomplete installation can cause accidents by the units falling and dropping.

• Do not install the indoor unit in the way that it takes in the air in the ceiling and provides it into the room. The indoor

unit must be installed in the way that it takes in the air from the room and returns it back to the room.

GOOD NO GOOD NO GOOD

CAUTION

Strictly comply with the following rules to prevent damage of the indoor units and human injury.

• Do not put a heavy article on the indoor unit or let a person get on it. (Even units are packaged)

• Carry in the indoor unit as it is packaged if possible. If carrying in the indoor unit unpacked by necessity, use buffering

cloth or other material to not damage the unit.

• To move the indoor unit, hold the hooking brackets (4 positions) only.

Do not apply force to the other parts (refrigerant pipe, drain pan, foamed parts, resin parts or other parts).

• Carry the package by two or more persons, and do not bundle it with plastic band at positions other than specified.

• To install vibration isolation material to hanging bolts, confirm that it does not increase the unit vibration.

1 room

• This unit and it’s ducting (supply and return air) are intended for use in one room only.

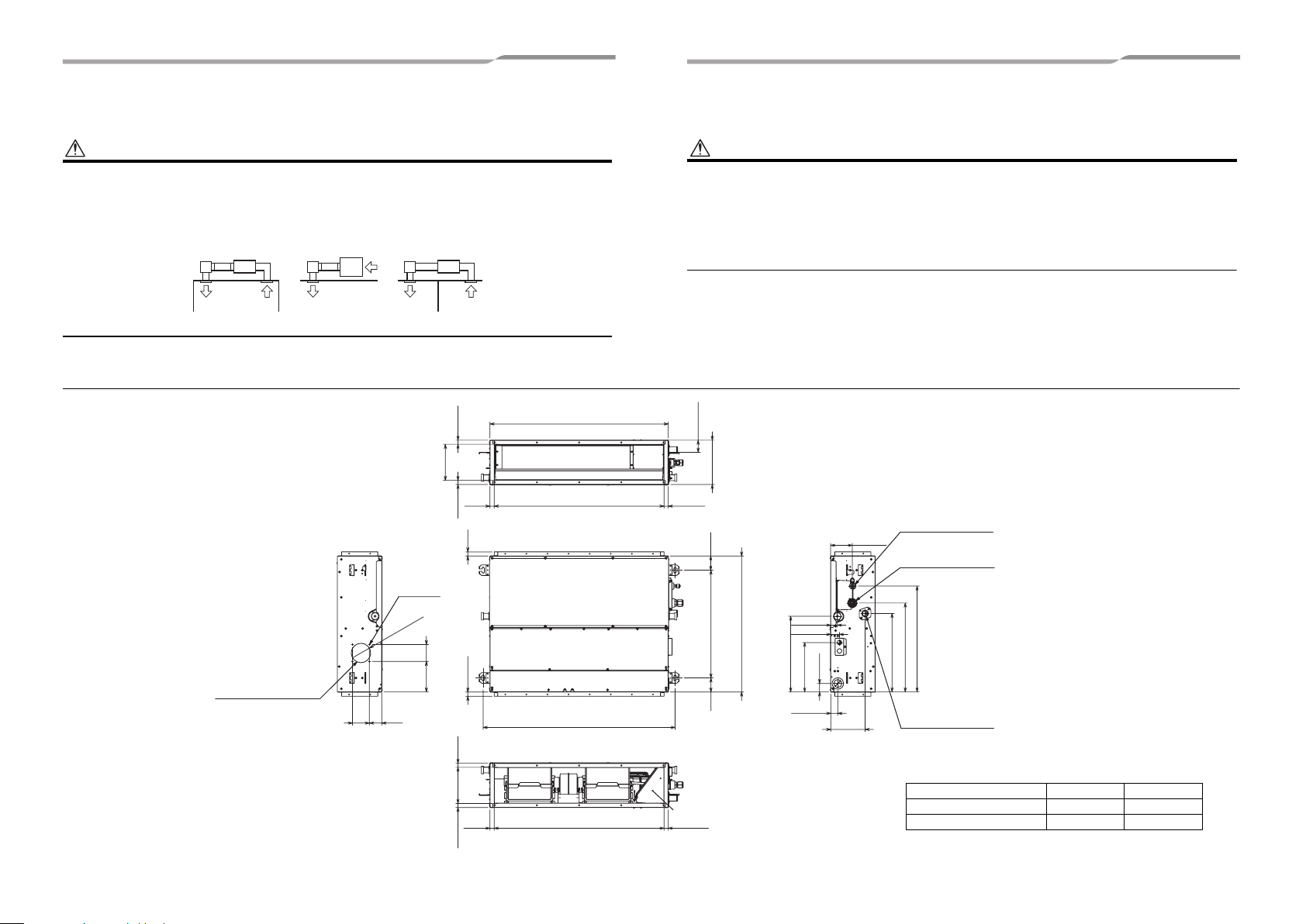

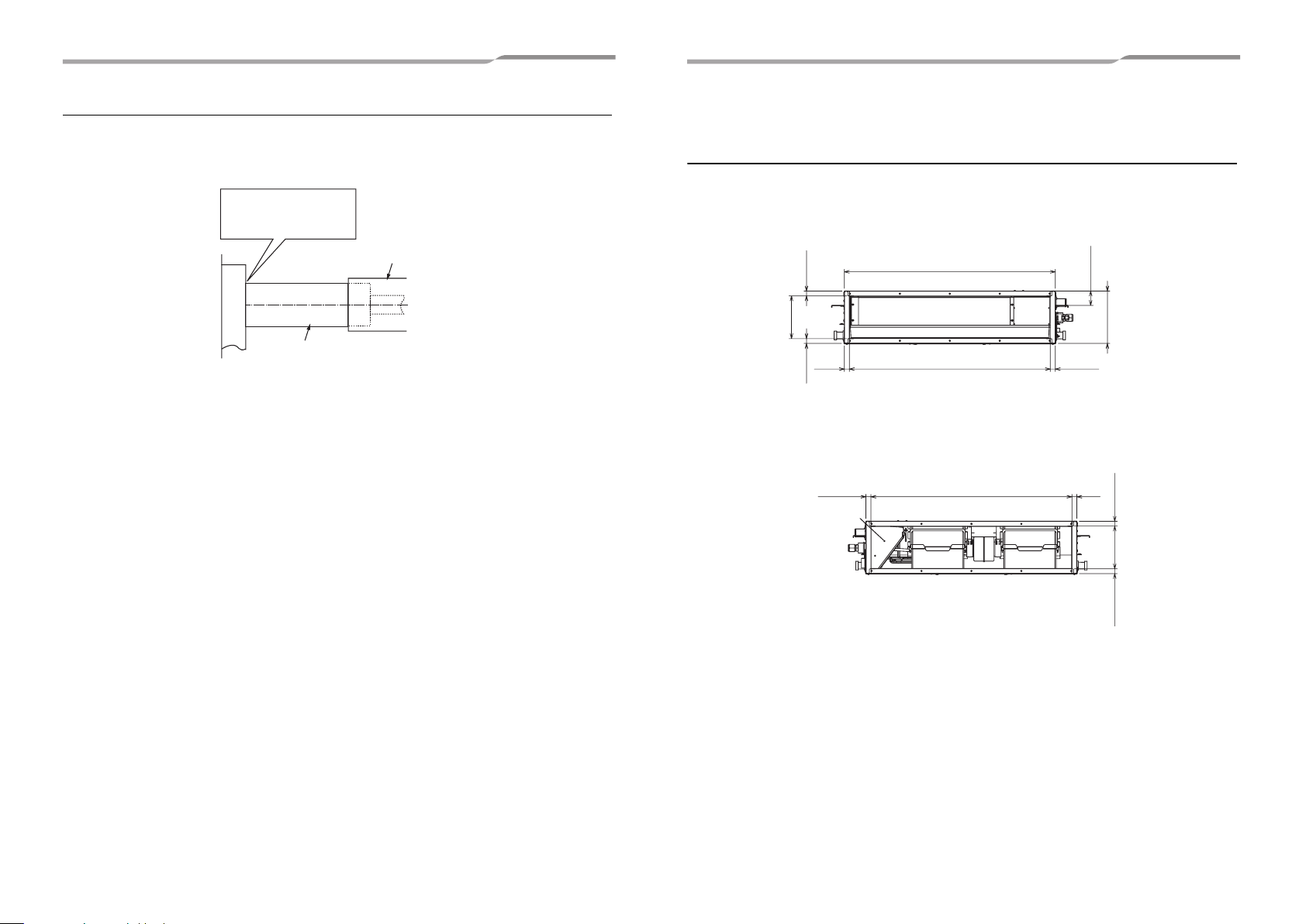

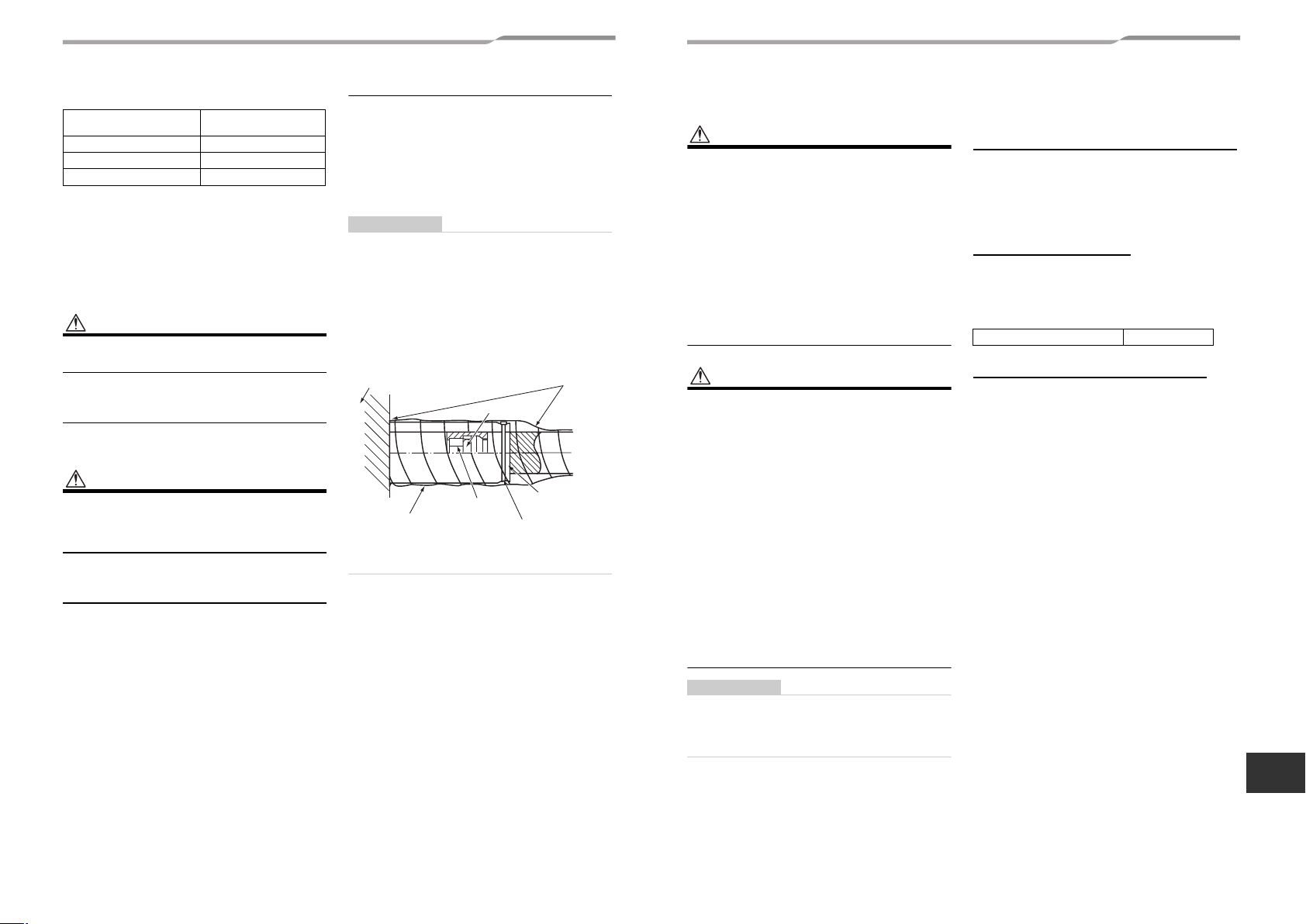

External dimensions Unit: in (mm)

Fresh air intake

(knock-out hole)

3.1”

(80)

3.3”

(59)

3

∅

4-∅0.2”(4)

)

2

9

(

”

6

.

3.1”

(80)

5.7”

(145)

(outside)

6.8”(171.4)

0.8”

0.8”(19.3)

(19.30)

0.8”(20)

0.8”(20)

0.8”

(20)

Unit external dimension 33.3”(845)

Air discharge flange outside

31.7”(805)

Hanging bolt pitch 35.8”(910)

0.8”(20)

2.2”(57)

2.6”

Hanging bolt pitch

2.6”

8.3”(210)

(67)

20.1”(511)

(67)

Refrigerant pipe

connecting port ∅B

4.1”(103)

1.2”(31)

14.1”(359)

1.6”(41)

9.2”(234)

1.3”(33)

1.6”(40)

6.4”(163)

25.4”(645)

Unit external dimention

(Liquid side)

Refrigerant pipe connecting

port ∅A

(Gas side)

19.8”(502)

14.6”(372)

16.6”(422)

Drain-up port

0.8”

(19.3)

6.8”

0.8”

(171.4)

0.8”

(20)

(19.3)

Air intake flange outside

31.7”(805)

Electrical control box

0.8”(20)

Model MMD- A B

AP007, AP009, AP012 3/8” (9.5) 1/4” (6.4)

AP015, AP018 1/2” (12.7) 1/4” (6.4)

9-EN 10-EN

Page 7

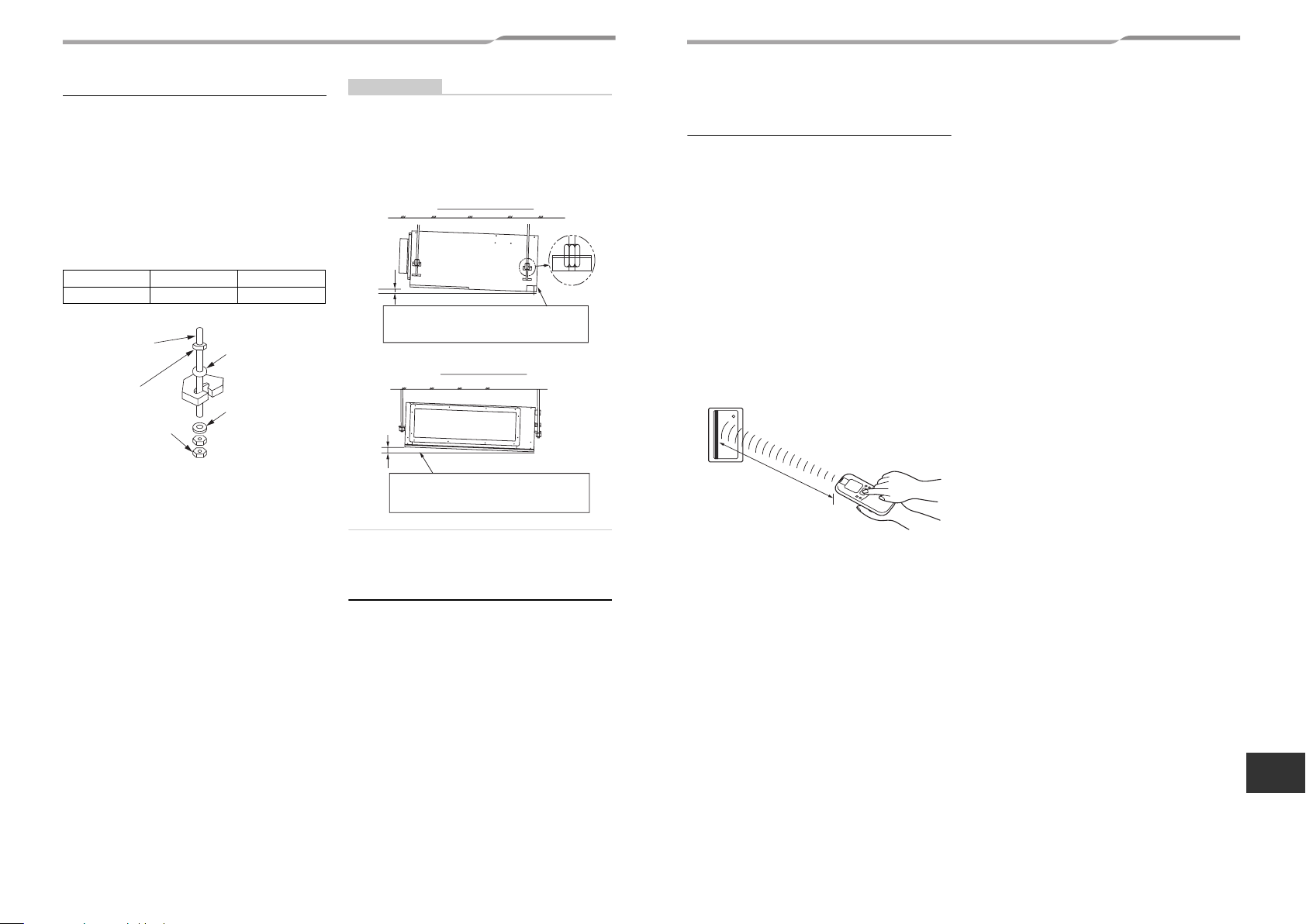

Installation of the indoor unit

All issues related to locating the unit above the ceiling,

hanging the unit from the building structure, routing/

suspending the unit refrigerant piping, routing/

suspending the unit wiring and penetrating the ceiling

for supply and return air connections to the indoor unit

must comply with all applicable codes and regulations.

The indoor unit should be hung above

the ceiling utilizing minimum 3/8" x 16

bolts, or threaded rod (4 pieces required) along with 3/

8" x 16 nuts, 3/8" flat washers and 3/8" lock washers.

All material locally procured.

Hanging bolt W3/8” (M10) 4 pieces

Nut W3/8” (M10) 12 pieces

Hanging bolt

(W3/8” (M10))

Nut

(W3/8” (M10))

Nut

(W3/8” (M10))

The unit should be positioned level and plumb without

pitch in any direction. The bolts, or threaded rod should

be attached to the building structure in compliance with

all applicable codes and regulations. The spacing for

the support bolts, or rods should match the dimensions

provided on the unit External dimensions in this

manual.

• Check that four sides are horizontal with a level

gauge. (Horizontal degree: Within 0.2” (5 mm))

M10 flat washer

(Accessory)

M10 flat washer

(Accessory)

REQUIREMENT

• Hang the unit in a horizontal position.

When unit is hanged to slant, it may cause overflow of

drainage.

• Install the unit within the dimension according to the

figure below.

• Use level gauge to confirm whether the unit is hang

horizontally.

Side view

0.2” (5 mm)

or less

Set the drain pipe connecting port side within

0.2” (5 mm) lower than opposite side.

Front view

0.2” (5 mm) or

less

Set the air intake and air discharge sides are

within 0.2” (5 mm) with each other.

Installation of wired remote

control (sold separately)

For installation of the wired remote control refer to the

instructions that are supplied with the control. The

connection point for the control wiring and the entrance

point for the control wiring are clearly marked in the

instructions.

Installation of wireless

remote control

(sold separately)

For installation of the wireless remote control refer to

the instructions that are supplied with the control. The

connection point for the control wiring and the entrance

point for the control wiring are clearly marked in the

instructions.

The sensor of indoor unit with wireless remote control

can receive a signal by distance within approx. 26.2’ (8

m).

Based upon it, determine a place where the remote

control is operated and the installation place.

• Keep 3.3’ (1 m) or more from the devices such as

television, stereo.

(Disturbance of image or noise may generate.)

• To prevent a malfunction, select a place where is not

influenced by a fluorescent light or direct sunlight.

• Two or more (Up to 6 units) indoor units with wireless

type remote control can be installed in the same

room.

2

6

.

2

’

(

8

m

)

o

r

l

e

s

s

EN

11-EN 12-EN

–6–

Page 8

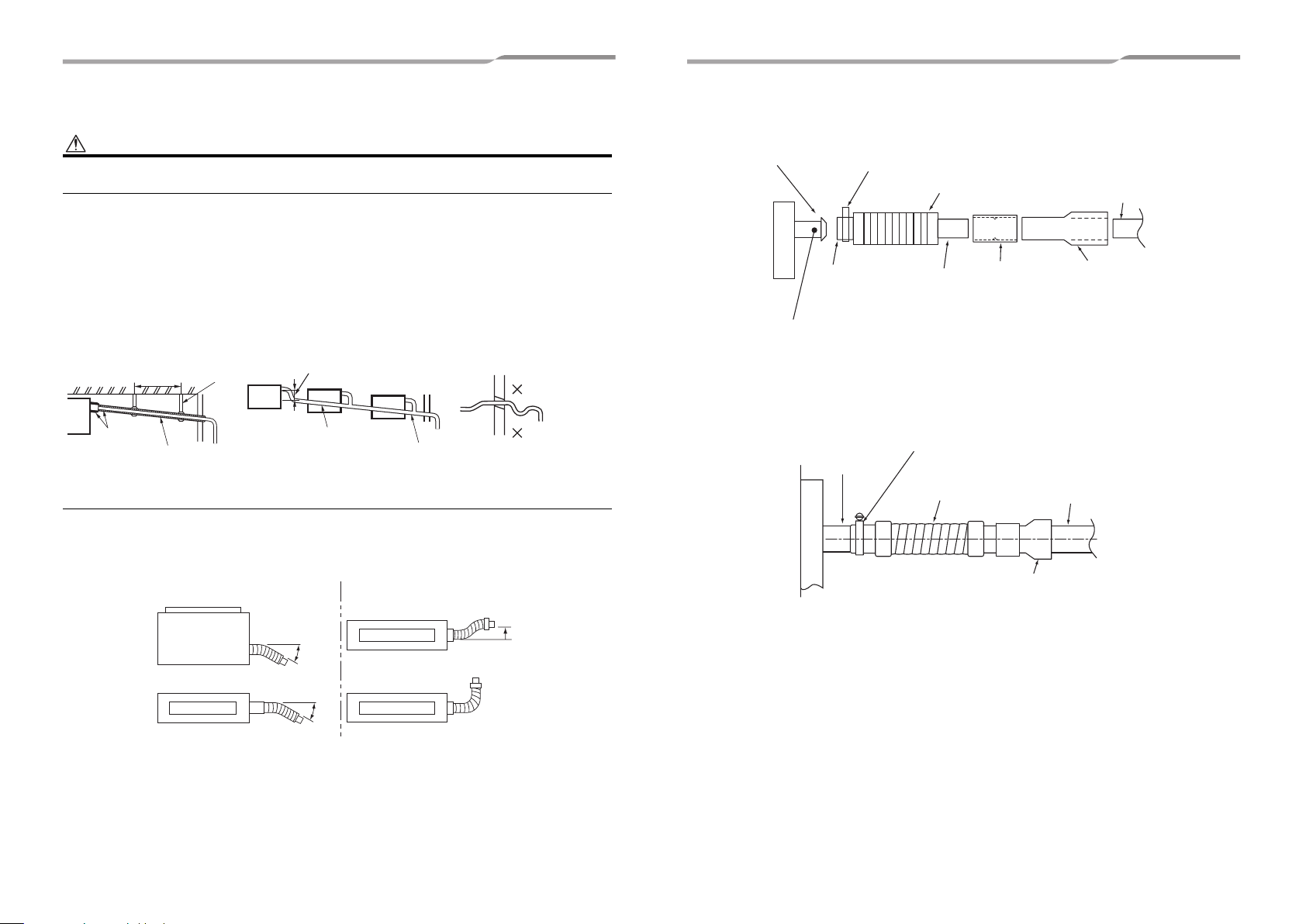

5 Drain piping

–7–

CAUTION

Condensate drain piping installation and material must comply with applicable codes and regulations for the

specific indoor installation.

The condensate drain piping must be insulated to prevent sweating. All material used in the plenum space above

the ceiling must comply with applicable codes and regulations. If the condensate drain exits the unit downward

(gravity flow) the slope and suspension methods used for the condensate drain piping must comply with applicable

codes and regulations.

• The drain pipe must be sloping downward (at an angle of 1/100 or more), and do not run the pipe up and down

(arched shape) or allow it to form traps. Doing so may cause abnormal sounds.

• Restrict the length of the traversing drain pipe to 65.6’ (20 m) or less. For a long pipe, provide support brackets

at intervals of 4’11” to 6’7” (1.5 to 2 m) to prevent flapping.

• Install the collective piping as shown in the following figure.

• Do not provide any air vents. Otherwise, the drain water will spout, causing water to leak.

• Do not allow any force to be applied to the connection area with the drain pipe.

Heat

insulator

4’11” to 6’7”

(1.5 to 2 m)

Downward slope

1/100 or more

Support

bracket

(Collective

piping)

As long as possible

(Approx. 3.9” (100 mm))

Downward slope

1/100 or more

VP30

Arched shape

Trap

Incorrect

Flexible hose

Use the attached flexible hose to adjust centre discrepancy of the hard vinyl chloride pipe or to adjust the angle.

• Do not use the flexible hose as stretched, or do not deform it more extent than that in the following figure.

• Fix the soft end of the flexible hose with the attached hose band.

• Use the flexible hose on a horizontal level.

OK

Top view

Side view

Air discharge

max

45°

max

45°

NO GOOD

Side view

Air discharge

Side view

Air discharge

Riser (Trap)

90° Bend

Condensate drain connection

for ducted indoor unit, metric

size (not suitable for US size)

PVC stub.

Indoor unit

Adhesive inhibited:

Use the attached flexible hose and hose band for connecting the

drain hose to the clear drain socket.

If applying the adhesive, socket will be damaged and cause water

leakage.

Attached hose

band

Soft socket

Drain pipe

connecting port

(Transparent)

Indoor unit

Attached flexible

hose

Hard socket

Align the attached hose band to

the end of hose, set the

tightening position upward, and

then tighten it.

Flexible hose

(Accessory)

Standard 1" PVC drain pipe installed

by field. Can also be converted at the

adapter to any other size/material

that may be required to comply with

applicable codes, or regulations.

Attached drain

socket

Standard 1" PVC drain pipe installed by

field. Can also be converted at the

adapter to any other size/material that

may be required to comply with

applicable codes, or regulations.

Condensate drain connection

for ducted indoor unit, metric

size (not suitable for US size)

PVC stub.

Condensate drain connection

adapter (provided with indoor

unit). converts metric size unit

drain connection to standard

1" US size PVC connection.

(Hard socket)

13-EN 14-EN

Page 9

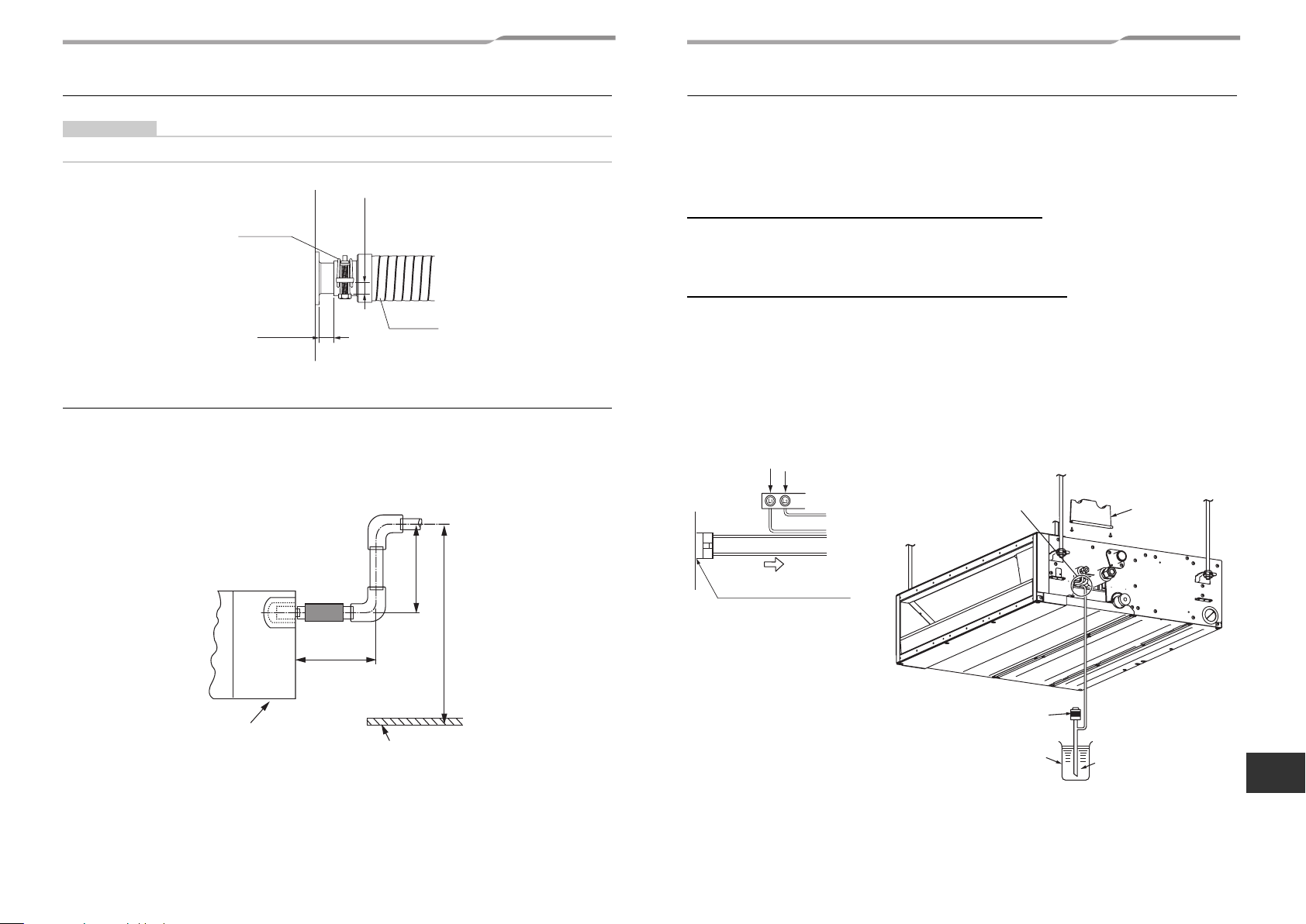

Connecting drain pipe

Insert flexible drain hose into upper drain pipe of main unit as far as it will go. Fix it with hose band.

REQUIREMENT

Mount the flexible drain hose using the hose band without using adhesive.

Check the condensate drain system

When all piping and wiring is completed the condensate drain system (including the pump) should be checked for

correct operation and leaks. If there are any abnormal sounds, leaks, or if the condensate water does not flow

normally, the problem should be diagnosed and corrected before the system is certified for operation.

In the test run, check that water drain is properly performed and water does not leak from the connecting part of

the pipes. When doing this, also check that no abnormal sounds are heard from the drain pump motor. Check

draining also when installed in heating period.

Hose band

Indoor unit

0.6” (15 mm) or less

10 to 12 mm)

(

0.4” to 0.5”

Flexible

drain hose

Drain up (condensate pumped up from unit)

When gravity drainage cannot be provided directly from the indoor unit condensate exit the piping can be arranged

for upward condensate discharge. The vertical leg of the drain line must be a maximum of 15.8”(400 mm) or less

from the indoor condensate exit and the total vertical height of the leg must be a maximum of 33.5”(850 mm) or

less before the drain enters a gravity flow line. These dimensions are specified by the indoor unit condensate pump

limitations. As specified for the gravity flow installation all materials and suspension methods must comply with

applicable codes and regulations.

Rising up

23.1”(587 mm)

or less

15.8”(400 mm)

or less

When the electrical and wiring work has been completed

Pour some water by following the method shown in the following figure. Then, while performing a cooling operation,

check that the water drains from the drain pipe connecting port (transparent) and that no water is leaking from the

drain pipe.

When the electrical and wiring work has not been completed

• Disconnect the float switch connector (3P: Red) from the connector (CN34: Red) on the printed circuit board

inside the electrical control box. (Before doing this, the power must be turned off.)

• Connect a 208 / 230 V supply voltage to (L1) and (L2) on the power supply terminal block. (Do not apply a 208

/ 230 V voltage to (A), (B) of the terminal block. Otherwise, the printed circuit board may be damaged.)

• Pour the water by following the method shown in the following figure. (Amount of water poured: 0.4 to 0.5 gal

(1500 to 2000 cc))

• When the power is turned on, the drain pump automatically starts running. Check whether the water is draining

from the drain pipe connecting port, and check that no water is leaking from the drain pipe.

• After checking that the water drains and there are no water leaks, turn off the power, connect the float switch

connector to its original location (CN34) on the printed circuit board, and return the electrical control box to its

original position.

208 / 230-1-60

White

Black

Black

Pull out connector CN34 (Red)

from P.C. board.

Red

Insert the edge of hose into the

drain pan and bend it downward.

Cover plate

Rising up 33.5”(850 mm) or less

Pump

Indoor unit

Underside of ceiling

15-EN 16-EN

–8–

Vessel

Water

(0.4 to 0.5 gal

(1500 to 2000 cc))

EN

Page 10

–9–

Condensate drain pipe insulation

• As shown in the figure, cover the flexible hose and hose band with the attached heat insulator up to the bottom

of the indoor unit tightly.

• Cover the drain pipe tightly with a heat insulator locally procured so that it overlaps with the attached heat

insulator.

Wrap the attached heat

insulator tightly from the

surface of the indoor unit.

Heat insulator

(locally procured)

Indoor unit

Heat insulator of the drain

connecting section

(Accessory)

6 Duct design

Arrangement Unit: in (mm)

Referring to the following dimensions, manufacture duct at the local site.

<Air discharge>

Unit external dimension 33.3”(845)

0.8”(20)

0.8”

(20)

2.2”(57)

8.3”(210)

0.8”(19.3)

<Back air intake>

0.8”(19.3)

outside

6.8”(171.4)

0.8”

(20)

0.8”

(19.30)

0.8”(20)

Electrical control box

Air discharge flange outside

31.7”(805)

31.7”(805)

6.8”(171.4)

0.8”(19.3)

17-EN 18-EN

Page 11

<Under air intake>

31.7”(805)

0.3”(8.2) or less

1.6”(41.5)

3.9”(100)

10.5”(266)

0.5”(12.5)

3.9”(100)

3.9”(100)

3.9”(100)

3.9”(100)

32.5”(825)

3.9”(100)

3.9”(100)

3.9”(100)

3.9”(100)

0.5”(12.5)

11.3”(286.8)

3.9”(100)

1.8”(45.3)

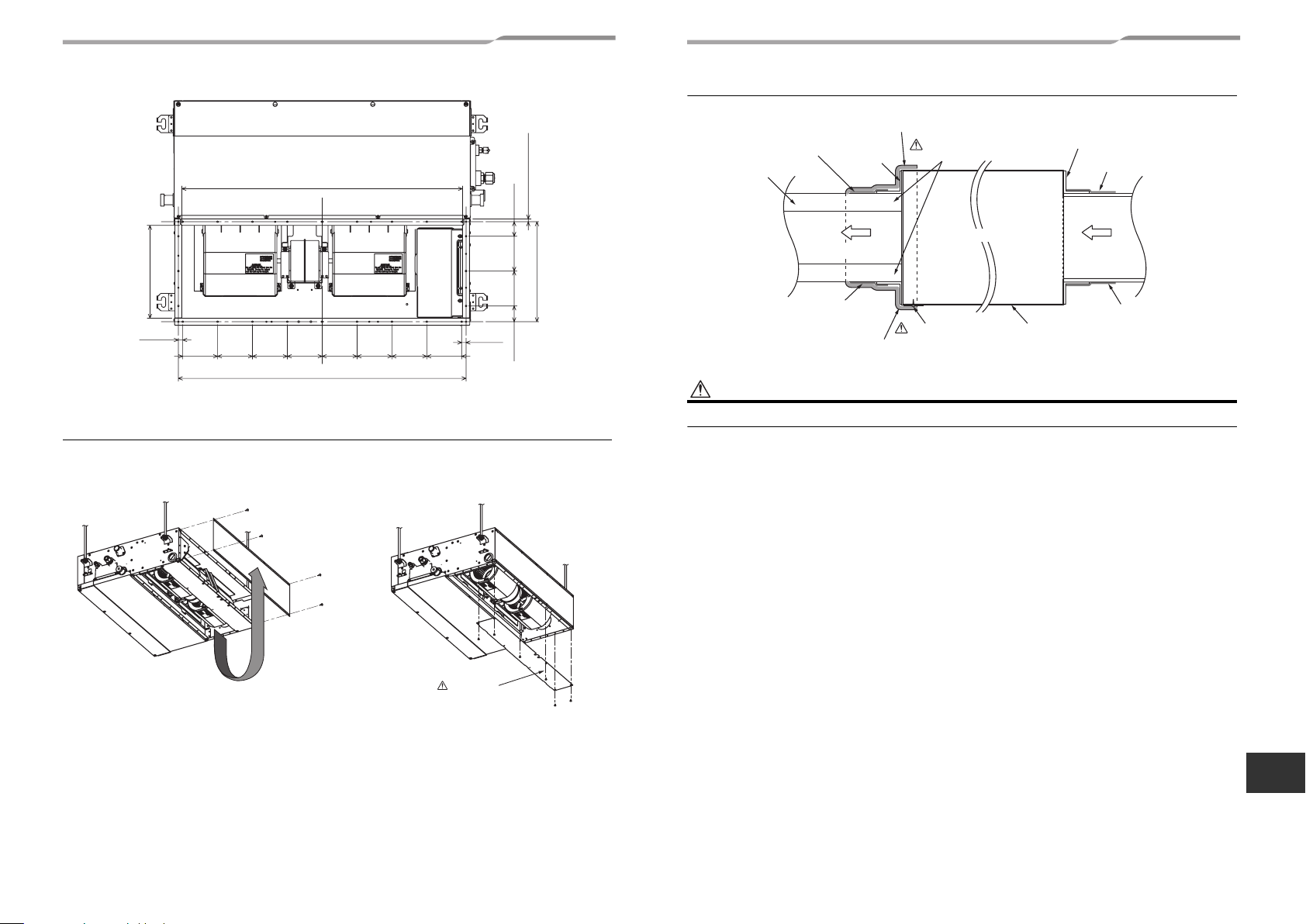

Alteration from the back air intake to the underside air intake

Remove the cover plate from underside. Attach the cover plate to back air intake side.

The intake flange provided (for air intake from the back) cannot be used for air intake from the underside.

Connecting method of the duct

Heat insulator with sticking material (locally procured)

Aluminum tape (locally procured)

Duct: Insulation

materia

(locally procured)

Aluminum tape

(locally procured)

Heat insulator with sticking material (locally procured)

Flange

Air discharge side

Connect a duct to the

inside of the flange

Indoor unit

Cover a screw

CAUTION

Incomplete heat insulation of the supply air flange and sealing may occur dewing resulted in falling of water drop.

Flange

Aluminum tape (locally procured)

Air intake side

Aluminum tape (locally procured)

Under surface

Remove the cover plate and then fix

it to the air intake side

CAUTION

Take out this cover

plate.

EN

19-EN 20-EN

–10–

Page 12

–11–

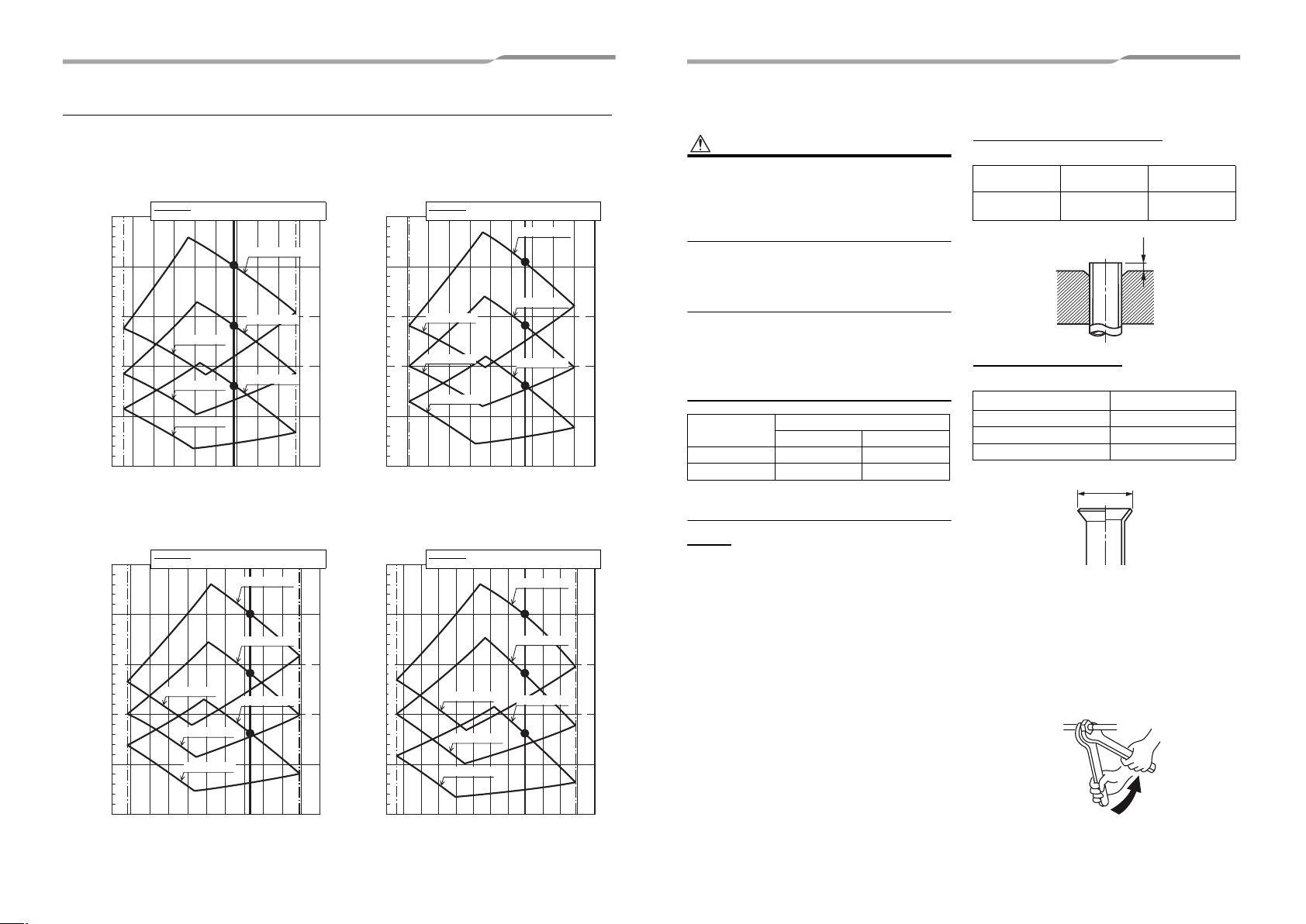

Fan characteristics

◆ No filter

AP007, AP009 AP012

Standerd air flow rate: 317.8 (cfm)

Dotted line: Upper limit of external static pressure

0.250

0.200

0.150

0.100

Air flow rate lower limit

External static pressure (in.WG)

0.050

0.000

200 220 240 260 280 300 320 340 360 380 400

AP015 AP018

0.250

0.200

0.150

0.100

Air flow rate lower limit

External static pressure (in.WG)

0.050

Lower limit of external static pressure

High (0.20 in.WG)

High (0.14 in.WG)

Low (0.20 in.WG)

Low (0.14 in.WG)

Low (0.80 in.WG)

Air flow rate (cfm)

Standerd air flow rate: 406.1 (cfm)

Dotted line: Upper limit of external static pressure

Lower limit of external static pressure

Low (0.20 in.WG)

Low (0.14 in.WG)

Low (0.80 in.WG)

High (0.08 in.WG)

High (0.20 in.WG)

High (0.14 in.WG)

High (0.08 in.WG)

Air flow rate upper limit

External static pressure (in.WG)

Air flow rate upper limit

External static pressure (in.WG)

Standerd air flow rate: 353.1 (cfm)

Dotted line: Upper limit of external static pressure

0.250

0.200

0.150

0.100

Air flow rate lower limit

0.050

0.000

220 240 260 280 300 320 340 360 380 420400

0.250

0.200

0.150

0.100

Air flow rate lower limit

0.050

Lower limit of external static pressure

High (0.20 in.WG)

Low (0.20 in.WG)

Low (0.14 in.WG)

Low (0.80 in.WG)

Air flow rate (cfm)

Standerd air flow rate: 459.0 (cfm)

Dotted line: Upper limit of external static pressure

Low (0.20 in.WG)

Low (0.14 in.WG)

Low (0.80 in.WG)

High (0.14 in.WG)

High (0.08 in.WG)

Lower limit of external static pressure

High (0.20 in.WG)

High (0.14 in.WG)

High (0.08 in.WG)

7 Refrigerant piping

CAUTION

When the refrigerant pipe is long, provide support

brackets at intervals of 8’2” to 9’10” (2.5 to 3 m) to clamp

the refrigerant pipe. Otherwise, abnormal sound may be

generated.

Use the flare nut attached with the indoor unit or R410A

flare nut.

Permissible piping length and

height difference

They vary depending on the outdoor unit. For details,

refer to the Installation Manual attached to the outdoor

unit.

Air flow rate upper limit

Pipe size Unit: in (mm)

Model MMD-

AP007 to AP012 3/8” (9.5) 1/4” (6.4)

AP015 to AP018 1/2” (12.7) 1/4” (6.4)

Pipe size

Gas side Liquid side

Connecting refrigerant piping

Flaring

1 Cut the pipe with a pipe cutter.

Remove burrs completely. (Remaining burrs may

cause gas leakage.)

2 Insert a flare nut into the pipe, and flare the

pipe.

Use the flare nut provided with the unit or the one

used for the R410A refrigerant. The flaring

dimensions for R410A are different from the ones

used for the conventional R22 refrigerant. A new

flare tool manufactured for use with the R410A

refrigerant is recommended, but the conventional

Air flow rate upper limit

tool can still be used if the projection margin of the

copper pipe is adjusted to be as shown in the

following table.

Projection margin in flaring: B

Unit: in (mm)

Outer dia. of

copper pipe

1/4” to 1/2”

(6.4 to 12.7)

R410A tool used

0 to 0.02”

(0 to 0.5)

Conventional

tool used

0.04” to 0.06”

(1.0 to 1.5)

B

Flaring diameter size: A

Unit: in (mm)

Outer dia. of copper pipe A

1/4” (6.4) 0.36” (9.1)

3/8” (9.5) 0.52” (13.2)

1/2” (12.7) 0.65” (16.6)

A

* In case of flaring for R410A with the conventional

flare tool, pull it out approx. 0.02” (0.5 mm) more than

that for R22 to adjust to the specified flare size. The

copper pipe gauge is useful for adjusting projection

margin size.

• The sealed gas was sealed at the atmospheric

pressure so when the flare nut is removed, there will

no “whooshing” sound: This is normal and is not

indicative of trouble.

• Use two wrenches to connect the indoor unit pipe.

+0

–0.02” (0.4)

0.000

260 280 300 320 340 360 380 480400 420 440 460

Air flow rate (cfm)

0.000

300 480 500 520320 340 360 380 540400 420 440 460

Air flow rate (cfm)

Work using double spanner

21-EN 22-EN

Page 13

• Use the tightening torque levels as listed in the

following table.

Outer dia. of connecting

pipe (in (mm))

1/4” (6.4) 10 to 13 (14 to 18)

3/8” (9.5) 24 to 31 (33 to 42)

1/2” (12.7) 37 to 46 (50 to 62)

• Tightening torque of flare pipe connections.

Pressure of R410A is higher than that of R22.

(Approx. 1.6 times) Therefore, using a torque

wrench, tighten the flare pipe connecting sections

which connect the indoor and outdoor units of the

specified tightening torque.

Incorrect connections may cause not only a gas leak,

but also an error of the refrigeration cycle.

Tightening torque

(ft•lbs (N•m))

CAUTION

Tightening with an excessive torque may crack the nut

depending on installation conditions.

Airtight test / air purge, etc.

For air tightness test, adding refrigerant, refer to the

Installation Manual attached to the outdoor unit.

CAUTION

Do not supply power to the indoor unit until the airtight

test and vacuuming are completed. (If the indoor unit is

powered on, the pulse motor valve is fully closed, which

extends the time for vacuuming.)

Open the valve fully

Open the valve of the outdoor unit fully.

Heat insulation process

Apply heat insulation for the pipes separately at liquid

side and gas side.

• For the heat insulation to the pipes at gas side, use

the material with heat-resisting temperature 248 °F

(120 °C) or higher.

• To use the attached heat insulation pipe, apply the

heat insulation to the pipe connecting section of the

indoor unit securely without gap.

REQUIREMENT

• Apply the heat insulation to the pipe connecting

section of the indoor unit securely up to the root

without exposure of the pipe. (The pipe exposed to the

outside causes water leak.)

• Wrap heat insulator with its slits facing up (ceiling

side).

• Apply heat insulating materials to both the gas side

and liquid side as shown:

To cover the pipe and the

indoor unit with a heat

insulator, do not make a

Indoor unit

Wrap the insulator

with adhesive tale.

(locally procured)

gap between them.

Flare nut

Union

Heat insulator

of the pipe

Banding band

(Accessory)

8 Electrical connection

WARNING

1. Use predefined wire and connect them certainly.

Keep the connecting terminal free from external

force.

Improper wire connection or clamping may result in

exothermic, fire or malfunction.

2. Connect ground wire. (grounding work)

Incomplete grounding cause an electric shock.

Do not connect ground wires to gas pipes, water

pipes, lightning rods or ground wires for telephone

wires.

3. Install appliance in accordance with national

wiring regulations.

Capacity shortage of circuit breaker or incomplete

installation may cause an electric shock or a fire.

CAUTION

• Consult local building codes, NEC (National Electrical

Code) or CEC (Canadian Electrical Code) for special

requirements.

• If incorrect / incomplete wiring is carried out, it will

cause an electrical fire or smoke.

• Install circuit breaker is not tripped by shock waves.

If circuit breaker is not installed, an electric shock may

be caused.

• Use the cord clamps attached to the product.

• Do not damage or scratch the conductive core and

inner insulator of power and control wires when

peeling them.

• Use the power cord and control wire of specified

thickness, type, and protective devices required.

• Do not connect 208 / 230 V power to the terminal

blocks (U1, U2, A, B etc.) for control wiring.

(Otherwise, the system will fail.)

• Perform the electric wiring so that it does not come to

contact with the high-temperature part of the pipe.

The coating may melt resulting in an accident.

• Do not turn on the circuit breaker of the indoor unit

until vacuuming of the refrigerant pipes completes.

Power supply wire and

control wires specifications

Power supply wire and control wires are locally

procured.

For the power supply specifications, follow to the table

below. If capacity is little, it is dangerous because

overheat or seizure may be caused.

Indoor unit power supply

For the power supply of the indoor unit, prepare the

exclusive power supply separated from that of the

outdoor unit.

▼ Power supply

Power supply 208 / 230-1-60

Control wiring, Central control wiring

• 2-core with non-polarity wires are used for the

control wiring between indoor unit and outdoor unit

and Central control wiring.

• To prevent noise trouble, use 2-core shielded wire.

• The length of the communication line means the total

length of the control wire length between indoor and

outdoor units added with the central control wire

length.

REQUIREMENT

• For power supply wiring, strictly conform to the Local

Regulation in each country.

• Run the refrigerant piping line and control wir ing line in

the same line.

EN

23-EN 24-EN

–12–

Page 14

–13–

Power supply wire

Recommended wire diameter and wire length for power supply wire.

Power supply wiring

▼ Electric characteristics

Model Power Supply

MMD-AP0074SPH2UL

MMD-AP0094SPH2UL 0.73 15

MMD-AP0124SPH2UL 0.75 15

MMD-AP0154SPH2UL 0.88 15

MMD-AP0184SPH2UL 1.00 15

208 / 230 V-1-60 Hz 187 253

Wire size: 2 × AWG14

Ground 1 × AWG14 or thicker

MOCP : Maximum Overcurrent Protection (Amps)

Up to 164’1” (50 m)

MCA : Minimum Circuit Amps

Voltage Range (V) MCA MOCP

Min Max (A) (A)

0.73 15

Control wire

Control wiring between indoor units, and outdoor unit (2-core

shielded wire)

Wire size

(Up to 3280’10” (1000 m)) AWG16

(Up to 6561’8” (2000 m)) AWG14

Remote control wiring

2-core with non-polarity wire is used for wiring of the remote control wiring and group remote controls wiring.

Remote control wiring, remote control inter-unit wiring Wire size: AWG20

Total wire length of remote control wiring and remote control

inter-unit wiring = L + L1 + L2 + … Ln

Total wire length of remote control inter-unit wiring = L1 + L2 + … Ln Up to 656’2” (200 m)

Remote

control

wiring

Indoor unit

L

Remote

control

Indoor unit Indoor unit Indoor unit

L1

Remote control inter-unit wiring

NOTE

• Use copper supply wire.

• Use UL wire rated 600 V for the power supply.

• Use UL wire rated 300 V for the remote control wires and control wires.

In case of wired type only Up to 1640’5” (500 m)

In case of wireless type included Up to 1312’4” (400 m)

L2 Ln

(Max. 8 units)

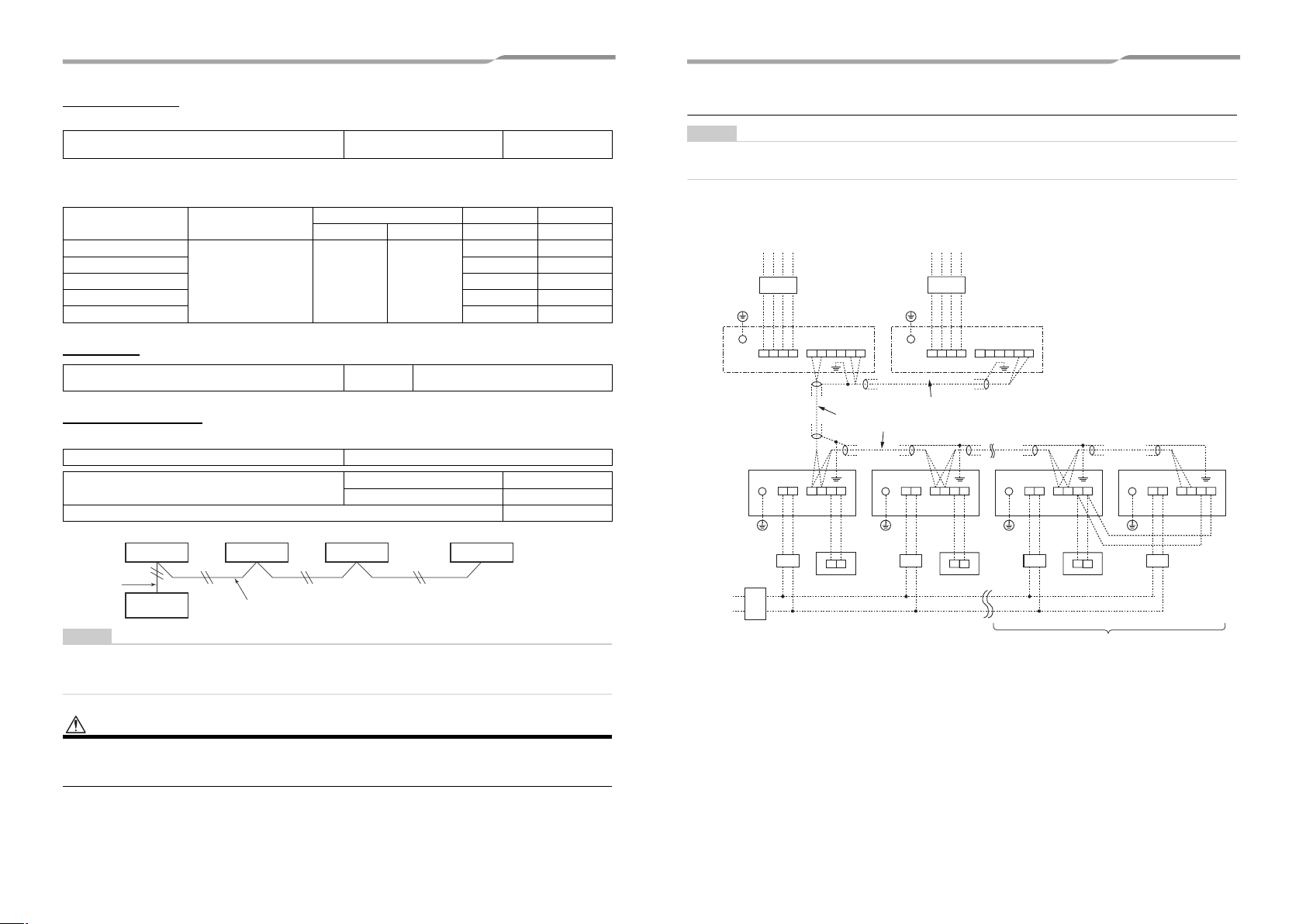

Wiring between indoor and outdoor units

NOTE

An outdoor unit connected with control wiring between indoor and outdoor units wire becomes automatically the header

unit.

▼ Wiring example

Disconnect

switch per NEC

Indoor

power

supply

208 /

230-1-60

Outdoor Power supply

Circuit breaker Circuit breaker

Header outdoor unit

Ground

terminal

Indoor unit

Ground Ground Ground Ground

Circuit

breaker

U1U2U3U4L1 L2L3 N U5U6

Control wiring between indoor and outdoor units

Control wiring between indoor units

U1U2

L1L2 A BU1U2L1L2 A B U1U2L1L2 A B U1U2L1L2 A B

A B

Remote

control

Outdoor Power supply

Follower outdoor unit

Ground

terminal

Control wiring between outdoor units

Indoor unit Indoor unit

Disconnect

switch per

NEC

U1U2U3U4L1 L2L3 N U5U6

Disconnect

A B A B

switch per

NEC

Remote

control

Remote

control

Group control

Indoor unit

Disconnect

switch per

NEC

CAUTION

The remote control wire (Communication line) and AC208 / 230 V wires cannot be parallel to contact each other and

cannot be stored in the same conduits. If doing so, a trouble may be caused on the control system due to noise or other

factor.

25-EN 26-EN

Page 15

Wire connection

REQUIREMENT

• Connect the wires matching the terminal numbers.

Incorrect connection causes a trouble.

• Pass the wires through the bushing of wire connection

holes of the indoor unit.

• The low-voltage circuit is provided for the remote

control. (Do not connect the high-voltage circuit)

• Remove the underside cover plates (2 plates).

Remove the two screws from the electrical control

box cover and then remove the cover from the hook

on which it is hanging.

• Remove the conduit plate from the side plate and

attach the conduit to the conduit plate.

Next, attach the conduit plate to the side plate.

• Tighten the screws of the terminal block, and fix the

wires with cord clamp attached to the electrical

control box.

(Do not apply tension to the connecting section of the

terminal block.)

• Mount the cover of the electrical control box without

pinching wires.

Conduit plate

Electrical control box

Power supply wire

and ground wire

Cord

clamp

Ground

screw

Electrical control box cover

fixed screw

Hook

Remote

control wire

Electrical control box

cover

Cord clamp

Control

wire (2core

shielded

wire)

Power supply wires and

ground wire

1 Strip the wire ends.

Power supply wire: 0.4” (10 mm)

Ground wire: 0.8” (20 mm)

2 Match the wire colors with the terminal

numbers on the indoor units’ and circuit

breakers’ terminal blocks and firmly screw

the wires to the corresponding terminals.

3 Secure the ground wire with the ground

screw.

4 Fix the wires with a cord clamp.

Unit: in (mm)

0.8” (20)

L1 L2

Ground wire

1.2” (30)

0.4” (10)

Address setup

Set up the addresses as per the Installation Manual

supplied with the outdoor unit.

LL

B A

CAUTION

Firmly tighten the screws of the terminal block.

Keep the wire length as shown in figure below when it

is connected to the terminal block.

Remove

cover plate

0.08” (2) or less

Power supply wires and control

wire

Bushing of control

Conduit

27-EN 28-EN

Conduit

plate

and remote

control wires

–14–

EN

Page 16

–15–

9 Applicable controls

REQUIREMENT

When the air conditioner is used for the first time, it will

take some moments after the power has been turned on

before the remote control becomes available for

operations: This is normal and is not indicative of trouble.

• Concerning the automatic addresses (The automatic

addresses are set up by performing operations on the

outdoor interface circuit board.)

While the automatic addresses are being set up, no

remote control operations can be performed. Setup

takes up to 10 minutes (usually about 5 minutes).

• When the power is turned on after automatic address

setup

It takes up to 10 minutes (usually about 3 minutes) for

the outdoor unit to start operating after the power has

been turned on.

Before the air conditioner was shipped from the factory,

all units are set to [STANDARD] (factory default). If

necessary, change the indoor unit settings.

The settings are changed by operating the wired remote

control.

* The settings cannot be changed using only a

wireless remote control, simple remote control or

group control remote control by itself so install a

wired remote control separately as well.

Basic procedure for changing

settings

Change the settings while the air conditioner is not

working. (Stop the air conditioner before making

settings.)

CAUTION

Set only the CODE No. shown in the following table: Do

NOT set any other CODE No.

If a CODE No. not listed is set, it may not be possible to

operate the air conditioner or other trouble with the

product may result.

1

3

4

6

5

1

2

1 Push and hold button and “TEMP.”

button simultaneously for at least 4

seconds. After a while, the display flashes

as shown in the figure. Confirm that the

CODE No. is [01].

If the CODE No. is not [01], push button to clear

the display content, and repeat the procedure from

the beginning. (No operation of the remote control

is accepted for a while after button is pushed.)

(While air conditioners are operated under the

group control, “ALL” is displayed first. When

is pushed, the indoor unit number

displayed following “ALL” is the header unit.)

2 Each time button is pushed, indoor

unit numbers in the control group change

cyclically. Select the indoor unit to change

settings for.

The fan of the selected unit runs and the

louvers start swinging. The indoor unit for

change settings can be confirmed.

3 Specify CODE No. [ ] with “TEMP.” /

buttons.

4 Select SET DATA [ ] with “TIME” /

buttons.

5 Push button. When the display changes

from flashing to lit, the setup is completed.

• To change settings of another indoor unit,

repeat from Procedure

• To change other settings of the selected indoor

unit, repeat from Procedure

Use button to clear the settings. To make

settings after button was pushed, repeat from

Procedure

2.

2.

3.

6 When settings have been completed, push

button to determine the settings.

When button is pushed, flashes and

then the display content disappears and the air

conditioner enters the normal stop mode.

(While is flashing, no operation of the

remote control is accepted.)

(* Display content varies with the indoor unit

model.)

29-EN 30-EN

Page 17

External static pressure settings

Set up a tap change based upon the external static pressure of the duct to be connected.

To set up a tap change, follow to the basic operation procedure (

• Specify [5d] to the CODE No. in procedure

• For the SET DATA of procedure

following table.

<Change on wired remote controller>

SET DATA External static pressure

0001 0.003 psi (20 Pa) Standard (Factory default)

0003 0.005 psi (35 Pa) High static pressure 2

0006 0.007 psi (50 Pa) High static pressure 3

With a remote controller-less system (group control)

Besides the switching method using the wired remote controller as a way to establish the external static pressure

switching is also possible by changing over the jumper block settings on the indoor P.C. board as shown in the

following table.

* However, once these settings are changed, it is necessary to reset the SET DATA to 0001 that placing the

jumper block back to the factory default position and rewriting the SET DATA back to 0001 with wired remote

controller (sold separately).

• Change over the jumper blocks on the indoor P.C. board, and select the desired setting.

Jumper block positions (CN112, CN111 and CN110 from the left)

Jumper block position

Short

Open

SET DATA 0001 0003 0006

External static pressure

4, select a SET DATA of the external static pressure to be set up from the

CN112 CN111 CN110

0.003 psi (20 Pa) 0.005 psi (35 Pa) 0.007 psi (50 Pa)

(Factory default)

3.

Standard

1 → 2 → 3 → 4 → 5 → 6).

CN112 CN111 CN110

High static Pressure 2 High static Pressure 3

CN112 CN111 CN110

Filter sign setting

According to the installation condition, the filter sign

term (Notification of filter cleaning) can be changed.

Follow to the basic operation procedure

1 → 2 → 3 → 4 → 5 → 6).

(

• For the CODE No. in Procedure

• For the [SET DATA] in Procedure

DATA of filter sign term from the following table.

SET DATA Filter sign term

0000 None

0001 150 H

0002

0003 5000 H

0004 10000 H

3, specify [01].

4, select the SET

2500 H

(Factory default)

To secure better effect of

heating

When it is difficult to obtain satisfactory heating due to

installation place of the indoor unit or structure of the

room, the detection temperature of heating can be

raised. Also use a circulator or other machinery to

circulate heat air near the ceiling.

Follow to the basic operation procedure

1 → 2 → 3 → 4 → 5 → 6).

(

• For the CODE No. in Procedure

• For the set data in Procedure

DATA of shift value of detection temperature to be

set up from the following table.

SET DATA Detection temperature shift value

0000 No shift

0001 1.8 °F (+1 °C)

0002

0003 5.4 °F (+3 °C)

0004 7.2 °F (+4 °C)

0005 9.0 °F (+5 °C)

0006 10.8 °F (+6 °C)

3, specify [06].

4, select the SET

3.6 °F (+2 °C)

(Factory default)

Remote control sensor

The temperature sensor of the indoor unit senses room

temperature usually. Set the remote control sensor to

sense the temperature around the remote control.

Select items following the basic operation procedure

1 → 2 → 3 → 4 → 5 → 6).

(

• Specify [32] for the CODE No. in Procedure

• Select the following data for the SET DATA in

Procedure

SET DATA 0000 0001

remote control

sensor

When flashes, the remote control sensor is

defective.

Select the SET DATA [0000] (not used) or replace the

remote control.

4.

(Factory default)

Not used

3.

Used

Group control

In a group control, a remote control can control up to

maximum 8 units.

• The wired remote control only can control a group

control. The wireless remote control is unavailable

for this control.

• For wiring procedure and wires of the individual line

(Identical refrigerant line) system, refer to “Electrical

connection” in this Manual.

• Wiring between indoor units in a group is performed

in the following procedure.

• Connect the indoor units by connecting the remote

control wires from the remote control terminal blocks

(A, B) of the indoor unit connected with a remote

control to the remote control terminal blocks (A, B) of

the other indoor unit. (Non-polarity)

• For address setup, refer to the Installation Manual

attached to the outdoor unit.

EN

31-EN 32-EN

–16–

Page 18

–17–

10Test run

Before test run

• Before turning on the power supply, carry out the

following procedure.

1) By using 500 V-megger, check that resistance

of 1 MΩ or more exists between the terminal

1 to L2 and the earth (grounding).

block L

If resistance of less than 1 MΩ is detected, do

not run the unit.

2) Check the valve of the outdoor unit being

opened fully.

• To protect the compressor at activation time, leave

power-ON for 12 hours or more before operating.

• Do not press the electromagnetic contactor to

forcibly perform a test run. (This is very dangerous

because the protective device does not work.)

• Before starting a test run, set addresses by following

the Installation Manual supplied with the outdoor

unit.

Execute a test run

Operate the unit with the wired remote control as usual.

For the procedure of the operation, refer to the

attached Owner’s Manual to the outdoor unit.

A forced test run can be executed in the following

procedure even if the operation stops by thermostatOFF.

In order to prevent a serial operation, the forced test

run is released after 60 minutes have passed and

returns to the usual operation.

Wired remote control

2, 4

3

1,5

1 Push button for 4 seconds or more.

[TEST] is displayed on the display part and

the selection of mode in the test mode is

permitted.

2 Push button.

3 Select the operation mode with

button, [ Cool] or [ Heat].

• Do not run the air conditioner in a mode other

than [ Cool] or [ Heat].

• The temperature controlling function does not

work during test run.

• The detection of error is performed as usual.

Wireless remote control

1 Remove a small screw which fixes the

nameplate of the receiver unit.

Remove the nameplate of the sensor section

by inserting a flat-blade screwdriver into the

notch at the bottom of the plate, and set the

Dip switch to [TEST RUN ON].

2 Execute a test operation with ON / OFF

button on the wireless remote control.

• , , and LED flash during test operation.

• Under status of [TEST RUN ON], the

temperature adjustment from the wireless

remote control is invalid.

Do not use this method in the operation other than

test operation because the equipment is

damaged.

3 Use either Cool or Heat operation mode for a

test operation.

• The outdoor unit does not operate approx. 3

minutes after power-ON and operation stop.

4 After the test operation finished, stop the air

conditioner from the wireless remote

control, and return Dip switch of the receiver

section as before.

(A 60-minutes timer clearing function is attached

to the receiver section in order to prevent a

continuous test operation.)

Receiver unit

M4 × 25 screw

(2 pieces)

Spacer

If a test run cannot be

properly performed

If a test run is performed before the outside duct is

installed, the protective control works to stop the unit,

and the check code “P12” appears. This is not a

malfunction.

(The current control works and heating protection

control due to the characteristics of the DC motor

employed as the indoor fan motor of this model.)

If performing a test run before installing the outside

duct, set the air volume to LOW, or block the air vent.

CAUTION

Do not use the forced test run for cases other than the

test run because it applies an excessive load to the

devices.

4 After the test run, push button to

stop a test run.

(Display part is same as procedure 1.)

5 Push button to cancel (release from) the

test run mode.

([TEST] disappears on the display and the status

returns to a normal.)

33-EN 34-EN

Small

screw

Notch

Nameplate

Page 19

11Troubleshooting

Confirmation and check

When an error occurred in the air conditioner, the

check code and the indoor UNIT No. appear on the

display part of the remote control.

The check code is only displayed during the operation.

If the display disappears, operate the air conditioner

according to the following “Confirmation of error log” for

confirmation.

Check code Indoor UNIT No. in

which an error occurred

Confirmation of error log

When an error occurred on the air conditioner, the error

log can be confirmed with the following procedure.

(The error log is stored in memory up to 4 errors.)

The log can be confirmed from both operating status

and stop status.

2

3

1

Procedure 2

Push button. The error log stored in memory is

displayed in order.

The numbers in CODE No. indicate CODE No. [01]

(latest) → [04] (oldest).

REQUIREMENT

Do not push button because all the error log of the

indoor unit will be deleted.

Procedure 3

Push button to return to the usual display after

confirmation.

1. Check the errors according to the above procedure.

2. Ask an authorized dealer or qualified service

(maintenance) professional to repair or maintain the

air conditioner.

Procedure 1

Push and buttons simultaneously for 4 seconds

or more, the following display appears.

If [Service check] is displayed, the mode enters in

the error log mode.

•[01: Order of error log] is displayed in CODE No.

window.

• [Check code] is displayed in CHECK window.

• [Indoor unit address in which an error occurred] is

displayed in Unit No.

EN

35-EN 36-EN

–18–

Page 20

–19–

Check codes and parts to be checked

Check method

On the remote control (Wired remote control, Central control remote control) and the interface P.C. board of the

outdoor unit (I/F), a check display LCD (Remote control) or 7-segment display (on the outdoor interface P.C. board)

to display the operation is provided. Therefore the operation status can be known. With this self-diagnosis function,

a trouble or position with error of the air conditioner can be found as shown in the table below.

Check code list

The following list shows each check code. Find the check contents from the list according to part to be checked.

• To check from indoor remote control: See “Wired remote control display” in the list.

• To check from outdoor unit: See “Outdoor 7-segment display” in the list.

• To check from indoor unit with a wireless remote control: See “Sensor block display of receiving unit” in the list.

Check code Wireless remote control

Wired remote

control display

E01 — —

E02 — — Remote control transmission error Remote control

E03 — —

E04 — —

E06 E06

—E07 —

E08 E08 Duplicated indoor addresses Duplicated indoor addresses Indoor / I/F

E09 — — Duplicated header remote controls Remote control

E10 — — Communication error between indoor MCU Indoor

E12 E12

E15 E15 — Indoor is nothing during automatic addressing I/F

E16 E16

E18 — — Communication error between indoor units Indoor

E19 E19

E20 E20

E23 E23 —

E25 E25 — Duplicated follower outdoor addresses I/F

E26 E26

E28 E28 Detected outdoor unit number Follower outdoor unit error I/F

Outdoor 7-segment display

Auxiliary code

No. of indoor units in which

sensor has been normally

received

01: Indoor / Outdoor

communication

02: Communication between

outdoor units

00: Capacity over

01 ~:No. of connected units

00: Header is nothing

02: Two or more header units

01: Outdoor of other line

connected

02: Indoor of other line connected

No. of outdoor units which

received signal normally

Sensor block display of

receiving unit

Operation

Timer

IPDU : Intelligent Power Drive Unit

: Lighting, : Flashing, : Goes off

ALT : Flashing is alternately when there are two flashing LED.

SIM : Simultaneous flashing when there are two flashing LED.

Check code name Judging device

Ready

Flash

Communication error between indoor and remote

control

(Detected at remote control side)

Communication error between indoor and remote

control (Detected at indoor side)

Communication circuit error between indoor /

outdoor (Detected at indoor side)

Decrease of No. of indoor units I/F

Communication circuit error between indoor /

outdoor (Detected at outdoor side)

Automatic address start error I/F

Capacity over / No. of connected indoor units

Combined capacity of indoor units exceeds 120 %

of combined capacity of outdoor units.

Outdoor header units quantity error I/F

Other line connected during automatic address I/F

Sending error in communication between outdoor

units

Decrease of No. of connected outdoor units I/F

Remote control

Indoor

Indoor

I/F

I/F

I/F

Wired remote

control display

E31 E31 IPDU communication error I/F

F01 — — ALT Indoor TCJ sensor error Indoor

F02 — — ALT Indoor TC2 sensor error Indoor

F03 — — ALT Indoor TC1 sensor error Indoor

F04 F04 — ALT TD1 sensor error I/F

F05 F05 — ALT TD2 sensor error I/F

F06 F06

F07 F07 — ALT TL sensor error I/F

F08 F08 — ALT TO sensor error I/F

F10 — — ALT Indoor TA sensor error Indoor

F12 F12 — ALT TS1 sensor error I/F

F13 F13

F15 F15 — ALT Outdoor temp. sensor miswiring (TE1, TL) I/F

F16 F16 — ALT Outdoor pressure sensor miswiring (Pd, Ps) I/F

F22 F22 — ALT TD3 error I/F

F23 F23 — ALT Ps sensor error I/F

F24 F24 — ALT Pd sensor error I/F

F29 — — SIM Indoor other error Indoor

F31 F31 — SIM Indoor EEPROM error I/F

H01 H01

H02 H02

H03 H03

H05 H05 — TD1 miswiring I/F

H06 H06 — Low pressure protective operation I/F

H07 H07 — Oil level down detective protection I/F

H08 H08

H15 H15 — TD2 miswiring I/F

Check code Wireless remote control

Outdoor 7-segment display

Auxiliary code

A3-IPDU

123

01 c

02 c

03 cc

04 c

05 cc

06 cc

07 ccc

08 c

09 cc

0A cc

0B cc c

0C cc

0D ccc

0E cc c

0F ccc c

c : IPDU error

TE1 sensor

TE2 sensor

01: Comp. 1 side

02: Comp. 2 side

03: Comp. 3 side

01: Comp. 1 side

02: Comp. 2 side

03: Comp. 3 side

01: Comp. 1 side

02: Comp. 2 side

03: Comp. 3 side

01: Comp. 1 side

02: Comp. 2 side

03: Comp. 3 side

01: TK1 sensor error

02: TK2 sensor error

03: TK3 sensor error

04: TK4 sensor error

Sensor block display of

Operation

Fan

IPDU

receiving unit

Timer

Ready

Flash

ALT

ALT TH sensor error IPDU

Check code name Judging device

TE1 sensor error

TE2 sensor error

Compressor break down IPDU

Compressor trouble (lock) IPDU

Current detect circuit system error IPDU

Oil level detective temp sensor error I/F

I/F

37-EN 38-EN

Page 21

Check code Wireless remote control

Wired remote

control display

H16 H16

H25 H25 — TD3 miswiring I/F

L03 — — SIM Indoor center unit duplicated Indoor

L04 L04 — SIM Outdoor line address duplicated I/F

L05 — — SIM

L06 L06 No. of indoor units with priority SIM

L07 — — SIM Group line in individual indoor unit Indoor

L08 L08 — SIM Indoor group / Address unset Indoor, I/F

L09 — — SIM Indoor capacity unset Indoor

L10 L10 — SIM Outdoor capacity unset I/F

L17 L17 — SIM Outdoor unit model unmatch error I/F

L20 — — SIM Duplicated central control addresses Indoor

L28 L28 — SIM Over No. of connected outdoor units I/F

L29 L29 SIM No. of IPDU error I/F

L30 L30 Detected indoor address SIM Indoor outside interlock Indoor

— L31 — — Extended I/C error I/F

P01 — — ALT Indoor fan motor error Indoor

P03 P03 — ALT Discharge temp. TD1 error I/F

P04 P04

P05 P05

P07 P07

P10 P10 Detected indoor address ALT Indoor overflow error Indoor

P12 — — ALT Indoor fan motor error or duct setting miss Indoor

P13 P13 — ALT Outdoor liquid back detection error I/F

P15 P15

P17 P17 — ALT Discharge temp. TD2 error I/F

Outdoor 7-segment display

Auxiliary code

01: TK1 oil circuit system error

02: TK2 oil circuit system error

03: TK3 oil circuit system error

04: TK4 oil circuit system error

A3-IPDU

123

01 c

02 c

03 cc

04 c

05 cc

06 cc

07 ccc

08 c

09 cc

0A cc

0B cc c

0C cc

0D ccc

0E cc c

0F ccc c

c : IPDU error

01: Comp. 1 side

02: Comp. 2 side

03: Comp. 3 side

00: Detected phase loss

01: Comp. 1 side

02: Comp. 2 side

03: Comp. 3 side

01: Comp. 1 side

02: Comp. 2 side

03: Comp. 3 side

01: TS condition

02: TD condition

39-EN 40-EN

Sensor block display of

Operation

Fan

IPDU

receiving unit

Timer

Ready

Check code name Judging device

Flash

Oil level detective circuit error I/F

Duplicated indoor units with priority

(Displayed in indoor unit with priority)

Duplicated indoor units with priority

(Displayed in unit other than indoor unit with priority)

ALT High-pressure SW system operation IPDU

Phase loss error / interruption of power supply

ALT

Inverter DC voltage (Vdc) error

ALT Heat sink overheat error IPDU, I/F

ALT Gas leak detection I/F

I/F

I/F

I/F

–20–

Wired remote

control display

P18 P18 — ALT Discharge temp. TD3 error I/F

P19 P19 Detected outdoor unit number ALT 4-way valve inverse error I/F

P20 P20 — ALT High-pressure protective operation I/F

P22 P22

P26 P26

P29 P29

P31 P31 — ALT

Error detected by TCC-LINK central control device

Wired remote

control display

C05 — — — Sending error in TCC-LINK central control device TCC-LINK

C06 — — — Receiving error in TCC-LINK central control device TCC-LINK

C12 — — —

P30

TCC-LINK : TOSHIBA Carrier Communication Link.

Check code Wireless remote control

Outdoor 7-segment display

Auxiliary code

0 : IGBT circuit

1 : Location detection circuit

error

3 : Motor lock-up error

4 : Motor current was

detected.

C :Abnormal temperature was

detected by the TH sensor.

D :TH sensor error

E : Inverter DC voltage error

(outdoor unit fan)

Caution)

Although letters 0 to F appear at

locations indicated by “ ”,

please ignore them.

01: Comp. 1 side

02: Comp. 2 side

03: Comp. 3 side

01: Comp. 1 side

02: Comp. 2 side

03: Comp. 3 side

Check code Wireless remote control

Outdoor 7-segment display

Auxiliary code

Differs according to error contents of unit with occurrence of alarm Group control branching unit error

— — (L20 is displayed) Duplicated central control addresses

Sensor block display of

receiving unit

Operation

Timer

Ready

Sensor block display of

receiving unit

Operation

Timer

Ready

Check code name Judging device

Flash

ALT Outdoor fan IPDU error IPDU

ALT G-TR short protection error IPDU

ALT Comp position detective circuit system error IPDU

Other indoor unit error

(Group follower unit error)

Check code name Judging device

Flash

Batch alarm of general-purpose equipment control

interface

Indoor

General-purpose

equipment I/F

TCC-LINK

EN

Page 22

Warnings on refrigerant leakage

–21–

Check of Concentration Limit

The room in which the air conditioner is to be installed

requires a design that in the event of refrigerant gas

leaking out, its concentration will not exceed a set limit.

The refrigerant R410A which is used in the air conditioner is

safe, without the toxicity or combustibility of ammonia, and is

not restricted by laws to be imposed which protect the ozone

layer. However, since it contains more than air, it poses the

risk of suffocation if its concentration should rise excessively.

Suffocation from leakage of R410A is almost non-existent.

With the recent increase in the number of high concentration

buildings, however, the installation of multi air conditioner

systems is on the increase because of the need for effective

use of floor space, individual control, energy conservation by

curtailing heat and carrying power etc.

Most importantly, the multi air conditioner system is able to

replenish a large amount of refrigerant compared with

conventional individual air conditioners. If a single unit of the

multi conditioner system is to be installed in a small room,

select a suitable model and installation procedure so that if

the refrigerant accidentally leaks out, its concentration does

not reach the limit (and in the event of an emergency,

measures can be made before injury can occur).

In a room where the concentration may exceed the limit,

create an opening with adjacent rooms, or install mechanical

ventilation combined with a gas leak detection device.

The concentration is as given below.

Total amount of refrigerant (lbs (kg))

Min. volume of the indoor unit installed room (ft

≤ Concentration limit (lbs/ft

The concentration limit of R410A which is used in multi air

conditioners is 0.019 lbs/ft

NOTE 1 :

If there are 2 or more refrigerating systems in a single

refrigerating device, the amounts of refrigerant should be as

charged in each independent device.

e.g.,

charged amount

(22 lbs (10 kg))

Room A Room B Room C Room D Room E Room F

For the amount of charge in this example:

The possible amount of leaked refrigerant gas in rooms A,

B and C is 22 lbs (10 kg).

The possible amount of leaked refrigerant gas in rooms

D, E and F is 33 lbs (15 kg).

3

(0.3 kg/m3).

3

Outdoor unit

e.g.,

charged amount

(33 lbs (15 kg))

Indoor unit

(kg/m3))

3

(m3))

NOTE 2 :

The standards for minimum room volume are as

follows.

(1) No partition (shaded portion)

(2) When there is an effective opening with the adjacent

room for ventilation of leaking refrigerant gas (opening

without a door, or an opening 0.15 % or larger than the

respective floor spaces at the top or bottom of the door).

(3) If an indoor unit is installed in each partitioned room and

the refrigerant piping is interconnected, the smallest

room of course becomes the object. But when a

mechanical ventilation is installed interlocked with a gas

leakage detector in the smallest room where the density