Page 1

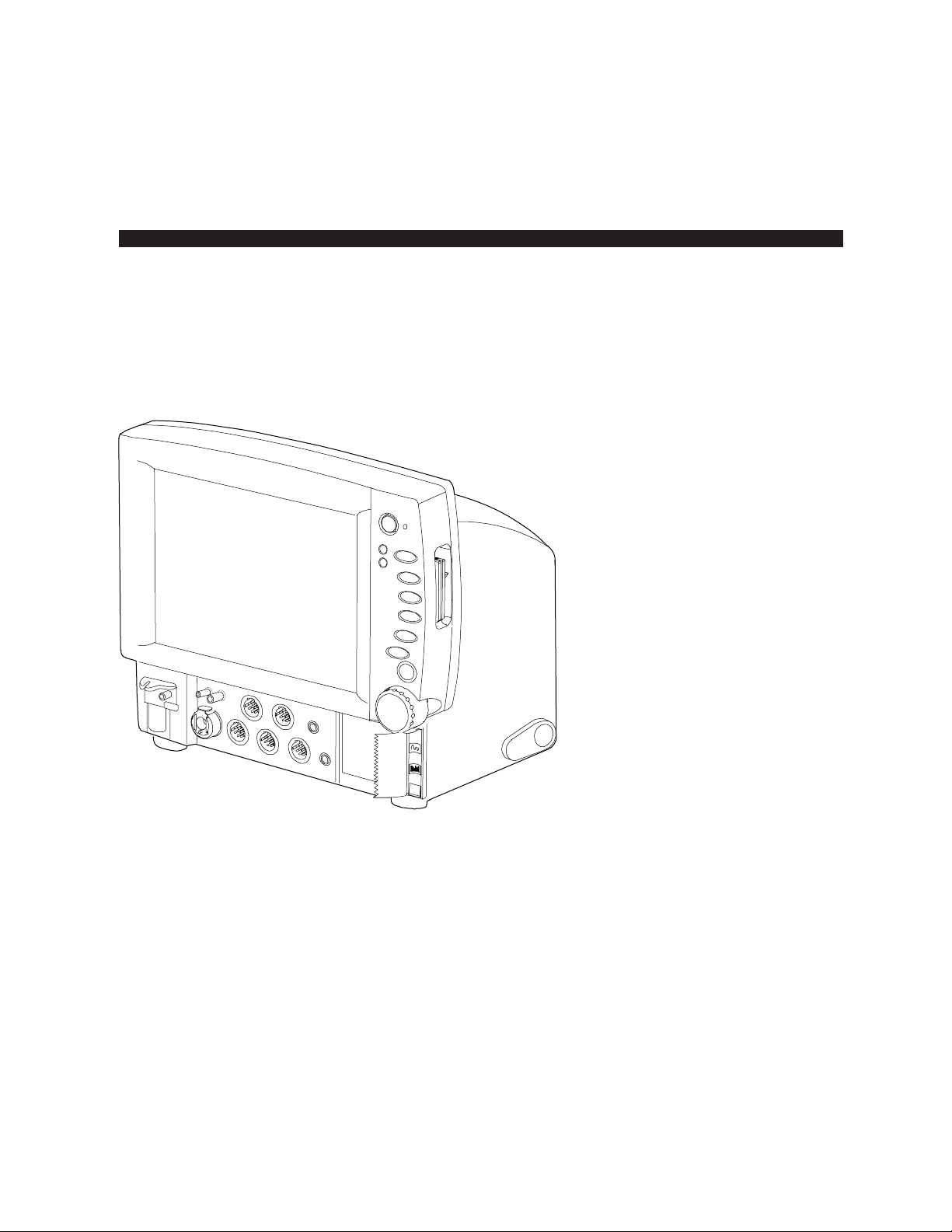

Datex-Ohmeda Cardiocap™/5

Technical Reference Manual

Document Number M1031914

nd

edition

2

9 May 2007

Datex-Ohmeda, Inc.

P.O. Box 7550, Madison

WI 53707-7550, USA

Tel. +1-608-221-1551

Fax +1-608-222-9147

GE Healthcare Finland Oy

Helsinki, Finland

P.O. Box 900

FI-00031 GE

Tel. +358 10 39411 Fax +358 9 146 3310

www.gehealthcare.com

Copyright © 2007 General Electric company. All rights reserved.

Page 2

NOTICE

Intended use

The Datex-Ohmeda Cardiocap/5 and accessories are indicated for indoor monitoring of hemodynamic (ECG,

impedance respiration, NIBP, temperature, SpO

rate, anesthetic agent, and agent identification), ventilatory (airway pressure, volume, and flow), and relaxation

status (NMT) of all hospital patients.

With the N-XOSAT option, monitoring of arterial oxygen saturation includes monitoring hospital patients during

conditions of clinical patient motion.

Cardiocap/5 is indicated for patients weighing 5 kg (11 lb.) or more.

Impedance respiration measurement is indicated for patients ages 3 years and older.

The monitor is indicated for use by qualified medical personnel only.

, and invasive pressure), respiratory (CO2, O2, N2O, respiration

2

CAUTION: US Federal law restricts this device to sale by or on the order of a licensed medical

practitioner. Outside the USA, check local laws for any restriction that may apply.

Classifications

IEC 60601-1:

• Type of protection against electric shock: Class I equipment.

• Degree of protection against electric shock (indicated by a symbol on the panel beside each connector):

Type BF applied part or Type CF applied part.

• The equipment is not suitable for use in the presence of a flammable anesthetic mixture with air or with

oxygen or nitrous oxide.

• Mode of operation: Continuous.

• CISPR 11: Group 1, c lass A

IEC 60529 (degree of protection against harmful ingress of water): IPX1

EU Medical Device Directive: IIb

Responsibility of the manufacturer

GE Healthcare Finland Oy (GE) is responsible for the safety, reliability and performance of the equipment only if:

• Assembly, operation, extensions, readjustments, modifications, service, and repairs are carried out by

personnel authorized by GE.

• Electrical installation complies with appropriate requirements.

• The equipment is used in accordance with the Cardiocap/5 User’s Guide and serviced and maintained in

accordance with the Cardiocap/5 Technical Reference Manual.

GE Healthcare assumes no responsibility for the use or reliability of its software on equipment that is not

furnished by GE Healthcare.

Trademarks

Datex®, Ohmeda®, and other trademarks (Cardiocap/5, AS/3, CS/3, S/5, S/5 Light, D-lite, Pedi-lite, D-fend,

D-fend+, MemCard, ComWheel, EarSat, FlexSat, OxyTip, Patient O

GE Healthcare Finland Oy.

Nellcor® is a registered trademark of Mallinckrodt Inc.

All other product and company names are the property of their respective owners.

, and Patient Spirometry) are trademarks of

2

Product availability

Some of the products mentioned in this manual may not be available in all countries. Please, consult your local

representative for the availability.

Page 3

Cardiocap/5 Technical Reference Manual

Part I – General Service Guide

Overview

Monitor Structure

Safety Precautions

Product Specifications

Installation and Functional Check

Installation

Interfacing

Functional Check

Functional Check Form

Planned Maintenance

Planned Maintenance Instructions

Planned Maintenance Form

Troubleshooting

Messages

Troubleshooting Charts

Part II – Product Service Guide

1

2

3

4

Frames and Software

Hemodynamic Frame (F-MX)

Hemodynamic with Airway Gases Frame (F-MXG)

Anesthesia and Critical Care Software

Measurement Parameters

Parameter Unit (NESTPR)

Invasive Pressures and Second Temperature Option (N-XP)

Nellcor Pulse Oximetry Option (N-XNSAT)

Datex-Ohmeda Enhanced Pulse Oximetry Option (N-XOSAT)

Airway Gas Options (N-XC, N-XCO, N-XCAiO)

Patient Spirometry Option (N-XV)

NeuroMuscular Transmission Option (N-XNMT)

Service Procedures

Repair and Replacement

Checks, Adjustments, and Calibration

Service Menus

Spare Parts 9

5

6

7

8

Page 4

Page 5

Chapter 1. Overview

1.1 About this manual ................................................................ 1-1

Related documentation............................................................................... 1-1

1.2 Cardiocap/5 models and features ......................................... 1-2

1.2.1 Options for hemodynamic model (F-MX)....................................................... 1-2

1.2.2 Options for hemodynamic model with airway gas measurement (F-MXG)......... 1-2

1.2.3 Data collection and management options (for F-MX and F-MXG)..................... 1-2

1.3 Monitor structure ................................................................. 1-3

1.3.1 Measurement parameter units..................................................................... 1-3

NESTPR unit ............................................................................................... 1-3

PVX unit for Patient Spirometry (N-XV option)................................................. 1-4

CAiO unit (N-XC, N-XCO, and N-XCAiO options).............................................. 1-4

Datex-Ohmeda enhanced pulse oximetry (N-XOSAT option)............................ 1-4

Nellcor® compatible pulse oximetry (N-XNSAT option)................................... 1-4

NeuroMuscular Transmission (N-XNMT option) .............................................. 1-4

1.3.2 Communication.......................................................................................... 1-4

1.3.3 CPU board.................................................................................................. 1-4

Distributed processing................................................................................. 1-5

1.3.4 Display ...................................................................................................... 1-5

1.3.5 I/O board................................................................................................... 1-5

1.3.6 DC/DC board ............................................................................................. 1-5

1.3.7 AC/DC unit................................................................................................. 1-5

1.3.8 Recorder (N-XREC option)............................................................................ 1-5

Contents

1.4 Symbol definitions................................................................ 1-6

Symbols on equipment................................................................................ 1-6

Symbols on screens ....................................................................................1-7

Symbols on transport packaging ..................................................................1-7

1.5 Safety precautions ............................................................... 1-8

1.5.1 Warnings.................................................................................................... 1-8

Installation ................................................................................................. 1-8

Power connection ....................................................................................... 1-8

External connection..................................................................................... 1-8

Electrical shock hazard................................................................................ 1-9

Fuse replacement ....................................................................................... 1-9

Explosion hazard......................................................................................... 1-9

Patient safety.............................................................................................. 1-9

Temperature probes .................................................................................... 1-9

Cleaning and service ................................................................................... 1-9

Accessories.............................................................................................. 1-10

1.5.2 Cautions ..................................................................................................1-10

General.................................................................................................... 1-10

Installation............................................................................................... 1-10

Before use................................................................................................ 1-10

Page 6

Cardiocap/5 Technical Reference Manual

Airway gas measurement ........................................................................... 1-10

Autoclaving and sterilizing..........................................................................1-10

Cleaning and service .................................................................................1-10

Batteries...................................................................................................1-11

Special components and modifications ......................................................1-11

Storage and transport................................................................................1-11

1.5.3 ESD precautionary procedures...................................................................1-11

ESD precautionary procedure training.........................................................1-12

1.5.4 Disposal...................................................................................................1-12

1.5.5 Points to note ...........................................................................................1-12

1.6 Specifications.................................................................... 1-12

1.6.1 F-MX and F-MXG frames ............................................................................1-12

Power supply ............................................................................................1-12

Environmental conditions...........................................................................1-12

Mechanics................................................................................................1-13

LCD display...............................................................................................1-13

Battery .....................................................................................................1-13

1.6.2 NIBP ........................................................................................................1-13

1.6.3 Temperature.............................................................................................1-13

1.6.4 ECG .........................................................................................................1-13

1.6.5 Impedance respiration ..............................................................................1-14

1.6.6 Pulse oximetry, standard............................................................................1-14

1.7 Specifications for options ................................................... 1-14

1.7.1 Classifications .......................................................................................... 1-14

According to IEC 60601-1 .........................................................................1-14

Classification according to EU Medical Device Directive ...............................1-15

1.7.2 Pulse oximetry, Datex-Ohmeda enhanced (N-XOSAT) ...................................1-15

1.7.3 Pulse oximetry, Nellcor compatible (N-XNSAT) ............................................. 1-16

1.7.4 Invasive blood pressure (N-XP)...................................................................1-16

1.7.5 Airway gases (N-XC, N-XCO, and N-XCAiO)...................................................1-16

General ....................................................................................................1-16

Respiration rate (RR)..................................................................................1-17

Carbon Dioxide (CO2), Oxygen (O2), and Nitrous Oxide (N2O) .........................1-17

Anesthetic agents (AA)............................................................................... 1-17

Agent identification ...................................................................................1-17

MAC.........................................................................................................1-18

Normal conditions.....................................................................................1-18

Conditions exceeding normal .....................................................................1-18

1.7.6 Patient Spirometry (N-XV) ..........................................................................1-19

Conditions exceeding normal .....................................................................1-20

1.7.7 NeuroMuscular Transmission (N-XNMT).......................................................1-20

NMT stimulation modes .............................................................................1-20

Stimulator.................................................................................................1-21

Regional block mode.................................................................................1-21

1.7.8 Recorder (N-XREC) ....................................................................................1-21

Page 7

Table of Figures

Figure 1-1. Cardiocap/5 monitor structure........................................................................ 1-3

Contents

Page 8

Page 9

1. OVERVIEW

1.1 About this manual

The Technical Reference Manual is for use by service personnel who are qualified to perform service

and maintenance procedures on the Datex-Ohmeda Cardiocap/5. The information in this manual is

believed to be accurate and reliable, however, the manufacturer assumes no responsibility for its use.

The manual is organized as follows:

• Part I (chapter 1 – chapter 4) provides a general overview of the Cardiocap/5, including the

information needed to install, checkout, and maintain the monitor. Part I also includes

information for troubleshooting problems that may occur while using the monitor or that you may

encounter while perfoming procedures in this manual, such as the Functional Check, for example.

• Part II (chapter 5 – chapter 9) contains detailed functional descriptions of the Cardiocap/5

hardware and software, including measurement principles and components for each

measurement parameter. Procedures for replacing parts and making adjustments are also

included. Part II also contains illustrations and detailed descriptions of all service screens used

during checkout, maintenance, and other service-related activities. A list of parts with illustrations

is located at the end of Part II.

Overview

Read the entire manual and make sure you understand the procedures described before installing,

repairing, or adjusting the monitor. To avoid risks concerning safety or health, strictly observe all safety

precautions.

This manual relates to the monitor versions 6051-0000-164..00 and ..01.

Related documentation

For information about using the monitor, refer to the following:

Cardiocap/5 for Anesthesia User’s Guide

Cardiocap/5 for Critical Care User’s Guide

Cardiocap/5 for Anesthesia User’s Reference Manual

Cardiocap/5 for Critical Care User’s Reference Manual

For PCA drawings, circuit diagrams, and component lists, order the PCA Drawings Service Kit. See the

Spare Parts chapter.

1-1

Page 10

Cardiocap/5 Technical Reference Manual

1.2 Cardiocap/5 models and features

The Cardiocap™/5 is a configured monitor that is intended for indoor monitoring of the hemodynamic,

respiratory, relaxation, and ventilatory status of the patient. Two models of the monitor are available:

hemodynamic (F-MX) and hemodynamic with airway gas measurement (F-MXG). Both models can be

equipped with built-in options.

• All measurement parameter options (and the Recorder option, N-XREC) are factory-configured

and cannot be added after purchase.

• Data collection and management options (N-XNET and N-XDNET) can be added later, if the CPU

board supports Network functionality.

1.2.1 Options for hemodynamic model (F-MX)

The F-MX measures NIBP, ECG (3-lead and 5-lead), pulse oximetry (SpO2), temperature (T1), and

impedance respiration. The F-MX can be configured with the following built-in options:

N-XP Two invasive pressure channels and second temperature (T2)

N-XREC Recorder

The F-MX model can also be configured with one of the following built-in options:

N-XNSAT Nellcor® compatible pulse oximetry (SpO

N-XOSAT Datex-Ohmeda enhanced pulse oximetry (SpO

)

2

)

2

1.2.2 Options for hemodynamic model with airway gas measurement (F-MXG)

The F-MXG measures NIBP, ECG (3-lead and 5-lead), pulse oximetry (SpO2), temperature (T1),

impedance respiration, and airway gases. Gas measurement depends on which airway gas option is

installed (N-XC, N-XCO, or N-XCAiO):

N-XC Carbon Dioxide (CO

N-XCO CO

N-XCAiO CO

, N2O, and Patient Oxygen (O2)

2

, anesthetic agents, agent identification, N2O, and O2

2

The F-MXG can also be equipped with each of these built-in options:

N-XP Two invasive pressure channels and second temperature (T2)

N-XV Patient Spirometry (N-XCO or N-XCAiO option required)

N-XREC Recorder

The F-MXG can also be configured with one of the following options:

N-XNSAT Nellcor® compatible pulse oximetry (SpO

N-XOSAT Datex-Ohmeda enhanced pulse oximetry (SpO

N-XNMT NeuroMuscular Transmission (NMT) for relaxation measurement (N-XCAiO option required)

)

2

)

2

)

2

1-2

1.2.3 Data collection and management options (for F-MX and F-MXG)

For both models, these options can be factory-built or added later as upgrades, if the CPU board

supports Network functionality:

N-XNET Network

N-XDNET Data card and Network

Page 11

1.3 Monitor structure

The Cardiocap/5 can be equipped with several factory-configured options. The block diagram and

descriptions that follow represent the maximum functionality of the monitor with all options installed.

Overview

Figure 1-1. Cardiocap/5 monitor structure

The main software and measurement technologies are based on AS/3 hardware and software. Some

parameter-measuring unit boards are interchangeable with AS/3 module boards, however, the units

cannot be replaced with the corresponding modules as the hardware of the assemblies is different.

1.3.1 Measurement parameter units

The maximum Cardiocap/5 parameter measurement configuration consists of the NESTPR, PVX, and

CAiO units plus ONE of the following units: NMT or NSAT or OSAT.

The NESTPR, CAiO, and NMT units are connected to the CPU through the Mother board and

communicate with the CPU over a standard AS/3 module bus. The NSAT or OSAT pulse oximetry unit is

also connected to the CPU through the Mother board and communicates with the CPU over a standard

AS/3 module bus, which is located on the SpO

Each parameter measurement board contains a CPU that processes measurement data for the

parameter(s) associated with that board before sending the data to the main CPU.

NESTPR unit

The NESTPR unit contains three boards for measuring hemodynamic parameters:

• The ECG board measures ECG (3-lead and 5-lead) and impedance respiration.

• The STP board measures oxygen saturation, temperature, and invasive blood pressure.

interface board.

2

• The NIBP board measures noninvasive blood pressure.

1-3

Page 12

Cardiocap/5 Technical Reference Manual

PVX unit for Patient Spirometry (N-XV option)

The PVX unit connects to the CAiO unit and measures the patient’s airway flow and pressure (Patient

Spirometry).

CAiO unit (N-XC, N-XCO, and N-XCAiO options)

The CAiO unit measures airway gases. It is capable of measuring CO2, N2O, O2, anesthetic agents (AA)

and also identifying the present anesthetic agent.

Datex-Ohmeda enhanced pulse oximetry (N-XOSAT option)

The OSAT unit measures oxygen saturation and pulse rate using Datex-Ohmeda enhanced pulse

oximetry technology.

Nellcor® compatible pulse oximetry (N-XNSAT option)

The NSAT unit measures oxygen saturation and pulse rate using signal processing electronics and

software that are based on Nellcor stand-alone oximeters.

NeuroMuscular Transmission (N-XNMT option)

The NMT unit measures the relaxation status (TOF, DBS, and ST) of patients. When used with a regional

block cable, the unit acts as a nerve locator.

1.3.2 Communication

The CPU communicates with the hemodynamic parameters measuring unit (NESTPR) and airway gas

measuring unit (CAiO) over a standard AS/3 module bus. It is based on the widely used industry

standard RS485, which uses a differential serial method to transfer data and is quite robust.

RS485 serial communication supports multidrop or party line connections. This means all units

connected to the module bus use the same two physical wires for communication purposes. The

module bus uses a 500 kbps data transfer rate.

Communication with the I/O board and the DC/DC board takes place over an internal synchronous

serial bus. The same bus also controls display brightness and audio signals by means of D/A

converters located on the CPU board.

Communication with the Net takes place over a separate synchronous serial channel. Communication

with the Net is possible, if the CPU board is equipped with an Ethernet controller.

Communication with the Recorder takes place over an asynchronous serial channel.

1.3.3 CPU board

The control functions of the monitor are centralized on the CPU board. The CPU:

• Controls the power on/off sequencing.

• Controls the brightness of the LCD screen by means of the Backlight board.

• Controls the Inverter board that provides the high voltage for the display backlights.

1-4

• Reads input from the keyboard and ComWheel.

• Controls the serial channels and I/O functions of the monitor.

Two PCMCIA-compatible data card slots on the board are for loading software and transferring data.

Page 13

Distributed processing

The parameter and airway measuring units contain their own microprocessor systems for performing

low level functions, such as waveform filtering and pneumatics control. At the same time, the main

CPU performs higher level tasks (trending and alarm control, for example).

1.3.4 Display

The main CPU directly controls the monitor display, a 10.4 inch color LCD. Supply voltages for the

display are connected via the CPU board and the Backlight board. The Inverter board provides high

voltage for the display backlights. The CPU controls the display brightness by adjusting the backlight

voltage.

1.3.5 I/O board

The I/O board contains D/A converters for analog outputs and the audio output amplifier. It also

contains connectors for the network identification plug, serial I/O, analog output, and external

keyboard.

Analog outputs are created by transferring digital data from the CPU to the D/A converters on the I/O

board through the internal synchronous serial bus. The network identification plug is connected to the

CPU over a separate synchronous serial channel.

Overview

1.3.6 DC/DC board

The DC/DC board converts 15 VDC coming from the AC/DC unit to different supply voltages for the

monitor. All outputs are short-circuit and over-voltage protected. The CPU controls the output voltages.

If the mains voltage drops, the 12 VDC back-up battery automatically supplies power to the monitor.

The battery will run the monitor for at least 15 minutes. The battery is always charged when mains

voltage is connected. The temperature sensor that measures the monitor’s internal temperature is

located on the board. The DC/DC board communicates with the CPU over the internal synchronous

serial bus.

1.3.7 AC/DC unit

The AC/DC unit converts the mains voltage to 15 VDC that is fed to the DC/DC board. The input

voltage range of the unit is 100 to 240 VAC. The DC/DC board shuts down the AC/DC unit when there

is over voltage detected on the 15 VDC output. The shutdown mode is reset by detaching the mains

power cord for 30 seconds.

1.3.8 Recorder (N-XREC option)

The Recorder prints trend data and record parameter waveforms. It connects to the CPU through an

asynchronous serial channel. Recorder supply voltages connect through a Recorder board that is

permanently attached to the recorder mounting box. The board contains a voltage filter and a delay

circuit for 12 V.

1-5

Page 14

Cardiocap/5 Technical Reference Manual

1.4 Symbol definitions

Symbols on equipment

Attention! Read accompanying instructions, including all warnings and cautions,

before using this device.

This symbol has the following meanings when it appears on the screen:

• On the front panel indicates that protection against cardiac defibrillator discharge is

due in part to the accessories for pulse oximetry (SpO

invasive pressure (P) measurement.

), temperature (T) and

2

Pb

Pb

• When displayed beside the O

value, indicates that the FiO2 low-alarm limit is set

2

below 21%.

• When displayed next to the HR value, indicates that there is a risk that the monitor

counts pacemaker spikes (pacer is set ON R) or the monitor counts T-waves (a wide

QRS is selected).

Type BF applied part (IEC 60601-1). Defibrillator-proof protection against electric shock.

Type CF applied part (IEC 60601-1). Defibrillator-proof protection against electric shock.

Main Menu. Located beside the ComWheel to indicate you can open the Main Menu by

pressing the ComWheel when no other menu is displayed.

Power On/Standby.

This battery contains lead. Separate from other waste for disposal according to local

regulations.

This battery contains lead and can be recycled.

1-6

Dangerous voltage.

Gas outlet (in airway gas models only).

Ethernet connectors.

Equipotentiality. Monitor can be connected to potential equalization conductor.

Alternating current.

Fuse.

Page 15

ESD warning symbol for electrostatic sensitive devices. Pins of connectors identified

with the ESD warning symbol should not be touched. Connections should not be

made to these connectors unless ESD precautionary procedures are used. See

"Safety precautions: ESD precautionary procedures" in the “User’s Reference

Manual” for details.

Symbol for non-ionizing electromagnetic radiation. Interference may occur in the

vicinity of equipment marked with the symbol.

This symbol indicates that the waste of electrical and electronic equipment must not

be disposed as unsorted municipal waste and must be collected separately. Please

contact an authorized representative of the manufacturer for information concerning

the decommissioning of your equipment.

Symbols on screens

When displayed on the upper left corner of the screen, indicates alarms are silenced.

When in the menu or digit fields, indicates that the alarm source has been turned off.

Sub menu. Selecting an alternative with this symbol in a menu opens a new menu.

Overview

The monitor is connected to the Monitor Network.

Data card (green) and/or Menu card (white) is inserted.

Indicates the beats detected.

Respiration rate is measured using impedance respiration measurement.

Back-up battery operation and remaining capacity.

Back-up battery charging.

Symbols on transport packaging

The contents of the package are fragile and have to be handled with care.

Indicates the correct upright position of the transport package.

The package must be kept in a dry environment.

The package should be kept within the indicated temperature limitations.

1-7

Page 16

Cardiocap/5 Technical Reference Manual

1.5 Safety precautions

1.5.1 Warnings

Refer to the User’s Reference Manual for additional warnings to be observed while monitoring a patient.

A WARNING indicates a situation in which the user or the patient may be in danger of injury or

death.

Installation

The monitor or its components should not be used adjacent to or stacked with other equipment. If

adjacent or stacked use is necessary, the monitor and its components should be observed to verify

normal operation in the configuration in which it will be used.

Pins of connectors identified with the ESD warning symbol should not be touched. Connections should

not be made to these connectors unless ESD precautionary procedures are used. For details, see

section “1.5.3 ESD precautionary procedures”.

After transferring or reinstalling the monitor, always check that it is properly connected and all parts

are securely attached. Pay special attention to this in case of stacked mounting.

Do not use the monitor in high electromagnetic fields (for example, during MRI).

A printer or computer must be supplied from an additional transformer providing at least basic

isolation (isolating or separating transformer).

If you accidentally drop the monitor, have it checked by authorized service personnel prior to clinical

use.

To avoid explosion hazard, do not use the monitor in presence of flammable anesthetics. The monitor

measures only non-flammable anesthetics.

Do not touch the patient, table, instruments, modules or the monitor during defibrillation.

Power connection

Before connecting the power cord to the mains outlet, check that the local voltage and frequency

rating corresponds with the rating stated on the device plate on the rear panel of the monitor.

Use only hospital-grade grounded power outlets and power cord. Do not remove the grounding pin

from the power plug.

Use only an intact power cord. Replace the cord if it is cracked, frayed, broken, or otherwise damaged.

Do not apply tension to the power cord otherwise the cord may get damaged.

Do not use an additional multiple socket outlet, extension cord or adapters of any kind.

Before starting to use the system, ensure that the whole combination complies with the international

standard IEC 60601-1-1 and with the requirements of the local authorities. Do not connect any

external devices to the system other than those specified.

1-8

To avoid the risk of electric shock, this equipment must only be connected to a supply mains with

protective earth.

External connection

Do not connect any external devices to the monitor other than those specified.

Page 17

Overview

Electrical shock hazard

When you connect equipment to the Cardiocap/5 input and output connectors, you are configuring a

medical system and are responsible for ensuring that the system complies with IEC/EN 60601-1-1

and with local requirements.

Do not touch any exposed wire or conductive surface while covers are off and the monitor is energized.

The voltages present can cause injury or death.

Always perform an electrical safety check and leakage current test of the monitor after service.

Fuse replacement

Replace a fuse only with one of the same type and rating.

Explosion hazard

To avoid explosion hazard do not use the monitor in the presence of flammable anesthetics.

Patient safety

Do not perform any testing or maintenance on the monitor while it is being used on a patient.

Never install the monitor so that it is above the patient.

The monitor must not be used without manufacturer approved mounting attached.

Operation of the monitor outside the specified values may cause inaccurate results.

To prevent erroneous readings, do not use physically damaged sensors or sensor cables. Discard a

damaged sensor or sensor cable immediately. Never repair a damaged sensor or cable; never use a

sensor or cable repaired by others. A damaged sensor or a sensor soaked in liquid may cause burns

during electrosurgery.

PATIENTS WITH PACEMAKERS OR ARRHYTHMIAS: Monitor may count the pacemaker pulses as heart

beats during cardiac arrest, some arrhythmias, and with certain types of pacemakers particularly in

ON R mode. Do not rely entirely upon rate meter alarms. Keep patients with pacemakers and

arrhythmias under close surveillance.

PACEMAKER PATIENTS: The impedance respiration measurement may cause rate changes in Minute

Ventilation Rate Responsive Pacemakers. In this case, set the pacemaker rate responsive mode off or

turn the monitor impedance respiration measurement off.

Temperature probes

To prevent injury, use Datex-Ohmeda temperature probes only.

Cleaning and service

Only trained personnel with proper tools and test equipment should perform the tests and repairs

described in this manual. Unauthorized service may void the monitor warranty.

Always unplug the monitor before cleaning or service. After cleaning or service ensure that every part

of the monitor is dry before reconnecting it to the power supply.

Do not touch any exposed wire or conductive surface while any cover is removed and the monitor is

energized. The voltages present can cause injury or death.

Pins of connectors identified with the ESD warning symbol should not be touched. Connections should

not be made to these connectors unless ESD precautionary procedures are used. For details, see

section “1.5.3 ESD precautionary procedures”.

1-9

Page 18

Cardiocap/5 Technical Reference Manual

Always perform an electrical safety check and a leakage current test on the monitor after service.

Handle the water trap and its contents as you would any body fluid. Infectous hazard may be present.

Accessories

Use only accessories, mounts and defibrillator-proof cables and invasive pressure transducers

approved by GE Healthcare. For a list of approved supplies and accessories, see the "Supplies and

Accessories" catalog. Other cables, transducers and accessories may cause a safety hazard, damage

the equipment or system, result in increased emissions or decreased immunity of the equipment or

system or interfere with the measurement. Protection against cardiac defibrillator discharge is due in

part to the accessories for pulse oximetry (SpO

measurement.

Single-use accessories are not designed to be reused. Reuse may cause a risk of contamination

and/or affect the measurement accuracy.

1.5.2 Cautions

Refer to the User’s Reference Manual for additional cautions to be observed while monitoring a patient.

A CAUTION indicates a condition that may lead to equipment damage or malfunction.

), temperature (T) and invasive pressure (P)

2

General

US Federal law restricts this device to sale by or on the order of a licensed medical practitioner.

Do not apply pressurized air to any outlet or tubing connected to the monitor. Pressure may destroy

sensitive elements.

Turn off the power before making any rear panel connections.

Use only cables and accessories approved by GE Healthcare. Other cables and accessories may

damage the system or interfere with measurement.

Vibrations during transport may disturb SpO

, ECG, impedance respiration, and NIBP measurements.

2

Installation

Leave space for air circulation to prevent the monitor from overheating.

Before use

Allow two minutes for warm-up and note any error messages or deviations from normal operation.

Airway gas measurement

Strong scavenging suction may change the operating pressure of the monitor and cause inaccurate

readings or internal damage.

Autoclaving and sterilizing

Do not steam autoclave or gas sterilize the monitor.

1-10

Cleaning and service

Do not use hypochlorite, ammonia-based, phenol-based, or acetone-based cleaners. These cleaners

may damage the surface of the monitor.

Do not immerse any part of the monitor in liquid or allow liquid to enter the interior.

Page 19

Overview

Do not apply pressurized air to any outlet or tubing connected to the monitor.

Clean the fan dust filter on the rear panel once a month or whenever necessary.

Electrostatic discharge through the PC boards may damage the components. Before handling printed

circuit boards, wear a static control wrist strap. Handle all boards by their nonconductive edges and

use antistatic containers when transporting them.

Do not break or bypass the patient isolation barrier when testing PC boards.

If liquid has accidentally entered the system or its parts, disconnect the power cord from the power

supply and have the equipment serviced by authorized service personnel.

Batteries

• A lithium battery on the CPU Board. Dispose of the faulty IC containing the battery

according to local regulations.

The battery package of the power supply unit in this device contains lead, which is hazardous to the

environment. Dispose of the battery according to local regulations.

To replace the batteries safely, please refer to the instructions in this manual.

• Do not short-circuit the battery terminals. Short-circuiting the battery may produce a very high

current, which damages the battery and may cause injury to personnel.

• Do not dispose of the battery into open flame, nor put the battery near fire, as it may explode.

• Do not disassemble the battery. It contains electrolyte, which may damage clothing or cause

injury to skin or eyes. If exposed to electrolyte, wash the injured area with plenty of water and

contact a doctor.

See Symbols on equipment earlier in this chapter.

Special components and modifications

Special components used in this monitor are vital to assure reliability and safety. GE Healthcare

assumes no responsibility for damage if replacement components not approved by GE Healthcare are

used.

The manufacturer accepts no responsibility for modifications made to the monitor outside the factory.

Storage and transport

Do not store or transport the monitor outside the specified temperature, pressure and humidity

ranges:

Temperature -10 to +50 °C (14 to 122°F)

Ambient pressure 660 to 1060 hPa (500 to 800 mmHg)

660 to 1060 mbar

Relative humidity 0 to 85 % non-condensing

1.5.3 ESD precautionary procedures

• To avoid electrostatic charges building up, it is recommended to store, maintain and use the

equipment at a relative humidity of 30% or greater. Floors should be covered by ESD

dissipative carpets or similar. Non-synthetic clothing should be used when working with the

component.

• To prevent applying a possible electrostatic discharge to the ESD sensitive parts of the

equipment, one should touch the metallic frame of the component or a large metal object

1-11

Page 20

Cardiocap/5 Technical Reference Manual

located close to the equipment. When working with the equipment and specifically when the

ESD sensitive parts of the equipment may be touched, a grounded wrist strap intended for

use with ESD sensitive equipment should be worn. Refer to the documentation provided with

the wrist straps for details of proper use.

ESD precautionary procedure training

• It is recommended that all potential users receive an explanation of the ESD warning symbol

and training in ESD precautionary procedures.

• The minimum contents of an ESD precautionary procedure training should include an

introduction to the physics of electrostatic charge, the voltage levels that can occur in normal

practice and the damage that can be done to electronic components if they are touched by

an operator who is electrostatically charged. Further, an explanation should be given of

methods to prevent build-up of electrostatic charge and how and why to discharge one’s

body to earth or to the frame of the equipment or bond oneself by means of a wrist strap to

the equipment or the earth prior to making a connection.

1.5.4 Disposal

Dispose of the whole device, parts of it, its packing material and this manual in accordance with local

environmental and waste disposal regulations.

1.5.5 Points to note

Medical electrical equipment needs special precautions regarding electromagnetic compatibility and

needs to be installed and put into service by qualified personnel according to the electromagnetic

compatibility information provided in Chapter 2.

Portable and mobile RF communications equipment can affect the medical electrical equipment.

Service and reparations are allowed for authorized service personnel only.

1.6 Specifications

All product specifications are subject to change without prior notice.

1.6.1 F-MX and F-MXG frames

Power supply

Rated voltages and frequencies: 100 to 240 VAC 60/50 Hz

Allowed voltage fluctuations: ± 10%

Maximum power consumption: 80 VA

Fuses (2): T2AH/250V

Environmental conditions

Operating temperature: +10 to +40 °C (50 to 104 °F)

Storage and transport temp: –10 to +50 °C (14 to 122 °F)

Relative humidity: 10 to 85 % noncondensing, in airway 0 to 100 % condensing

Atmospheric pressure: 660 to 1060 hPa (500 to 800 mmHg)

1-12

Page 21

Mechanics

Dimension: 330 mm × 220 mm × 300 mm (width × depth × height)

Weight: <11.2 kg / <24.8 lbs (F-MXG with all options); <10.2 kg / <22.6 lbs (F-MX with all options)

LCD display

Display size: 10.4 inch

Display type: Active matrix color LCD display

Resolution: 640 × 480

Battery

Type: 12V 2.6AH, lead acid

Back-up battery time: at least 15 minutes when fully charged

Charging time: 5 hours (typical)

The green battery charge status LED is On when the battery is fully charged, on the holding voltage. The

LED flashes when the battery is being charged.

1.6.2 NIBP

Measurement range:

Pulse rate range accepted: 30 to 250 bpm

Typical measuring time: adults 23 seconds, infants 20 seconds

Overview

adult 25 to 260 mmHg (3.3 to 34.7 kPa)

child 25 to 195 mmHg (3.3 to 26.0 kPa)

infant 15 to 145 mmHg (2.0 to 19.3 kPa)

1.6.3 Temperature

Measurement range: 10 to 45°C (50 to 113°F)

Measurement accuracy: 25 to 45.0 °C ± 0.1 °C (77 to 113 °F ± 0.2 °F)

10 to 24.9 °C ± 0.2 °C (50 to 76.8 °F ± 0.4 °F)

Probe type: Compatible with Datex-Ohmeda temperature probes only

1.6.4 ECG

Waveform display (with 50 Hz power supply frequency):

Monitoring filter: 0.5 to 30 Hz

ST filter: 0.05 to 30Hz

Diagnostic filter: 0.05 to 100 Hz

Waveform display (with 60 Hz power supply frequency):

Monitoring filter: 0.5 to 40 H

ST filter: 0.05 to 40 Hz

Diagnostic filter: 0.05 to 100 Hz

Heart rate

Measurement range: 30 to 250 bpm

Measurement accuracy: ± 5% or ± 5

Pacemaker pulse detection level: 2 to 500 mV

Pacemaker pulse duration: 0.5 to 2 ms

1-13

Page 22

Cardiocap/5 Technical Reference Manual

1.6.5 Impedance respiration

Respiration range: 4 to 120 respirations/minute

Accuracy: ± 5% or ± 5 bpm

1.6.6 Pulse oximetry, standard

Display update time: 5 seconds

Averaging time: adjustable

Plethysmographic waveform scaling: adjustable

SpO2

Calibration range: 50 to 100%

Calibrated against functional saturation

Measurement range: 40 to 100%

Measurement accuracy (% SpO

80 to 100% ± 2 digits;

50 to 80% ± 3 digits;

Below 50% unspecified

NOTE: SpO

measurement accuracy is based on deep hypoxia studies using Datex-Ohmeda FingerSat

2

sensors on volunteered subjects. Arterial blood samples were analyzed by a Radiometer OSM

CO-oximeter. Refer to the sensor instructions for specific SpO

±1 SD):

2

accuracy data.

2

Pulse rate

Measurement range: 30 to 250 bpm

Measurement accuracy: ± 5% or ± 5 bpm

Default alarm limits

: high Off, low 90%

SpO

2

Pulse rate: high 160, low 40

NOTE: Limits are adjustable.

Sensor emitter wavelength ranges

Red LED: 660 nm

Infrared LED: 900 nm

1.7 Specifications for options

1.7.1 Classifications

According to IEC 60601-1

• CLASS I EQUIPMENT and INTERNALLY POWERED EQUIPMENT according to the type of

protection against electrical shock.

• TYPE BF or CF equipment according to the degree of protection against electric shock is

indicated by a symbol beside each patient connector.

1-14

• Degree of protection against harmful ingress of water as detailed in the IEC 60529:

Monitor: IPX1, vertically falling water drops shall have no harmful effects (applicable when the

monitor is in upright position, or tilted backwards). In the protective case IPX4, splash proof,

only when the case is closed properly, the monitor is intact and operates on battery power.

Page 23

Power adapter: IPX0, ordinary equipment.

Power adapter for Transport Vehicles: IPX1.

• EQUIPMENT not suitable for use in the presence of a FLAMMABLE ANAESTHETIC MIXTURE with

air or with oxygen or nitrous oxide.

• CONTINUOUS OPERATION according to the mode of operation.

• CISPR 11: Group 1, Class A.

Group 1 contains all ISM (Industrial, scientific and medical) equipment in which there is

intentionally generated and/or used conductively coupled radio-frequency energy which is

necessary for the internal functioning of the equipment itself.

Class A equipment is suitable for use in all establishments other than domestic and those

directly connected to the public low-voltage power supply network that supplies buildings used

for domestic purposes.

Classification according to EU Medical Device Directive

• The monitor is classified as IIb.

1.7.2 Pulse oximetry, Datex-Ohmeda enhanced (N-XOSAT)

Display update time: 5 seconds

Averaging time: 12 seconds

Plethysmographic waveform scaling: automatic

Overview

SpO

2

Calibration range: 70 to 100%

Calibrated against functional saturation

Measurement range: 1 to 100%

Measurement accuracy (% SpO

±1 SD):

2

70 to 100% ± 2 digits

70 to 100% ± 3 digits during conditions of clinical patient motion

Below 70% unspecified

NOTE: SpO

measurement accuracy is statistically derived and correlated to simultaneous arterial

2

blood gases measured on a Radiometer OSM3 CO-oximeter. Refer to the sensor instructions for

specific accuracy data.

Pulse rate

Measurement range: 30 to 250 bpm

Measurement accuracy: ± 2% or ± 2 bpm (whichever is greater)

Default alarm limits

: high Off, low 90%

SpO

2

Pulse rate: high 160, low 40

NOTE: Limits are adjustable.

Sensor emitter wavelength ranges

Red LED: 650 to 665 nm

Infrared LED: 930 to 950 nm

Average power: ≤ 1 mW

1-15

Page 24

Cardiocap/5 Technical Reference Manual

1.7.3 Pulse oximetry, Nellcor compatible (N-XNSAT)

Display update time: 5 seconds

Averaging time: 5 to 7 seconds

Plethysmographic waveform scaling: automatic

SpO

2

Calibrated against functional saturation

Measurement range: 1 to 100%

Measurement accuracy (% SpO

70 to 100% (± 2 digits to ± 3.5 digits, depending on the sensor)

Below 70% unspecified

See the User's Reference Manual (Pulse Oximetry chapter) for a list of approved sensors and accuracy

details.

NOTE: SpO

Pulse rate

Measurement range: 30 to 250 bpm

Measurement accuracy: ± 3 digits

measurement accuracy is based on testing healthy adult volunteers in induced hypoxia

2

studies.

±1 SD):

2

Default alarm limits

SpO

: high Off, low 90%

2

Pulse rate: high 160, low 40

NOTE: Limits are adjustable.

Sensor emitter wavelength ranges

Red LED: 660 nm

Infrared LED: 920 nm

1.7.4 Invasive blood pressure (N-XP)

Measurement range: –40 to 320 mmHg (-5.3 to 42.7 kPa)

Measurement accuracy: ± 5% or ± 2 mmHg

Transducer sensitivity: 5 µV/V/mmHg, 5 Vdc, max 20 mA

Pulse rate

Measurement range: 30 to 250 bpm

Accuracy: ± 5% or ± 5 bpm

1.7.5 Airway gases (N-XC, N-XCO, and N-XCAiO)

Accuracy specifications apply in normal conditions.

General

Airway humidity: 0 to 100%, condensing

Sampling rate: 200 ± 20 ml/min. (sampling line 2, 3 and 6 m, normal conditions)

Sampling delay: 2.5 seconds typical with a 3 m sampling line

3.4 seconds typical with a 6 m sampling line

Total system response time: 2.9 seconds typical with a 3 m sampling line, including sampling delay

and rise time

4.4 seconds typical with a 6 m sampling line

Value update rate: breath-by-breath

1-16

Page 25

Overview

Automatic compensation for pressure, CO2-N2O and CO2-O2 collision broadening effect

Warm-up time:

2 minutes for operation with CO

, O2, and N2O

2

5 minutes for operation of anesthetic agents

30 minutes for full specifications

Autozeroing interval:

immediately after “Calibrating gas sensor” message and

2, 5, 10, 15, 30, 45, 60 minutes after start-up, then every 60 minutes

Respiration rate (RR)

Measurement range: 4 to 60 breaths/minute

Detection criteria: 1 % variation in CO2

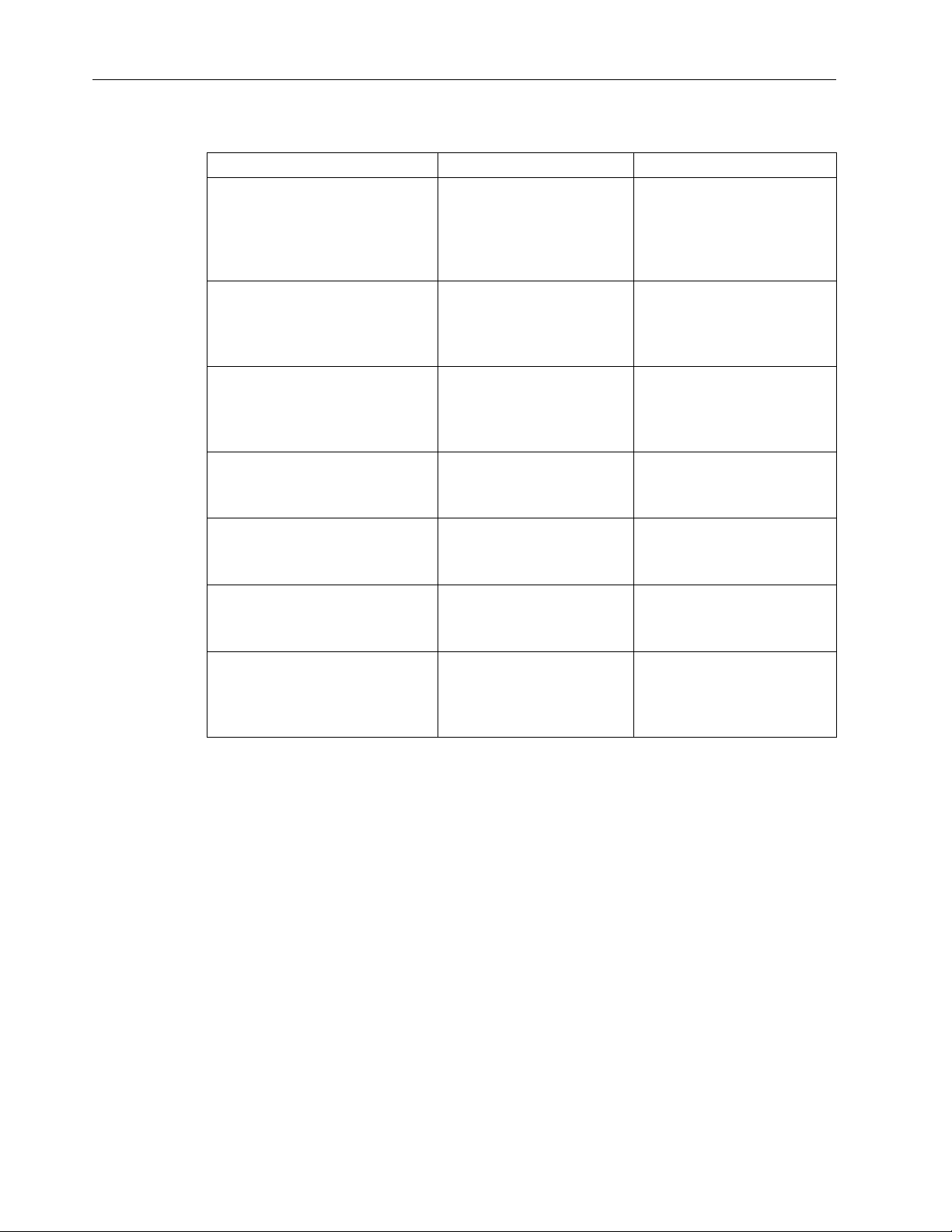

Carbon Dioxide (CO2), Oxygen (O2), and Nitrous Oxide (N2O)

Measurement Carbon Dioxide (CO2) Oxygen (O2) Nitrous Oxide (N2O)

Range

Rise time

Accuracy

(typical value)

Gas cross effects

0 to 15 vol%, (0 to 15 kPa)

(0 to 113 mmHg)

< 400 ms typical < 400 ms typical < 400 ms typical

± (0.2 vol% + 2 % of reading) ± (1 vol% + 2 % of

< 0.2 vol%

(O

, N2O, and anesthetic agents)

2

0 to 100% 0 to 100%

± (2 vol% + 2% of reading)

reading)

< 1 vol% (anesthetic

agents);

< 2 vol% (N2O)

(0%< N2O<85%)

± (2 vol% + 8% of reading)

(85%< N2O<100%)

(anesthetic agents)

< 2 vol%

NOTE:

• If CO

• O

concentration is below 0.1%, 0.0% is displayed.

2

Fi-Et difference: resolution 0.1 vol%

2

Anesthetic agents (AA)

Resolution is two digits when the AA concentration is below 1.0 vol%.

If AA concentration is below 0.1 vol%, 0.0% is displayed.

Measurement Halothane, Isoflurane, Enflurane Sevoflurane Desflurane

Range

Rise time

Accuracy

(typical value)

Gas cross effects

< 600 ms (<1 000 ms for Hal)

typically with a 3 m sampling line

< 650 ms (<1 050 ms for Hal)

typically with a 6 m sampling line

± (0.15 vol% + 5 % of reading) ± (0.15 vol% + 5 % of

0 to 6% 0 to 8% 0 to 20%

< 600 ms typically with

a 3 m sampling line

< 650 ms typically with

a 6 m sampling line

reading)

< 0.15 vol% N2O < 0.15 vol% N2O < 0.15 vol% N2O

< 600 ms typically with

a 3 m sampling line

< 650 ms typically with

a 6 m sampling line

± (0.15 vol% + 5 % of

reading)

Agent identification

Identification threshold: 0.15 vol% typically

Identification time: < 20 seconds (for pure agents)

Mixture identification threshold for 2nd agent: 0.2 vol% +10% of total conc.

1-17

Page 26

Cardiocap/5 Technical Reference Manual

MAC

Range: 0 to 9.9 MAC

Equation:

MAC( AA) =

%(ETAA)

x(AA)

%

+

2

ETN O

100

where x(AA): Hal = 0.75%, Enf = 1.7%, Iso = 1.15%, Sev = 2.05%, Des = 6.0%.

Normal conditions

After 30-minute warm-up period:

Ambient temperature: 18 to 28 °C, within ± 5 °C of calibration

Ambient pressure: 500 to 800 mmHg, ± 50 mmHg of calibration

Ambient humidity: 20 to 80% RH, ± 20% RH of calibration

Non-disturbing gases:

Ethanol C

Acetone (< 0.3%)

Methane CH

Nitrogen N

Carbon monoxide CO

Nitric oxide NO (< 200 ppm)

Water vapor

Maximum effect on readings:

< 0.2 vol%

CO

2

O2, N2O < 2 vol%

Anesthetic agents < 0.15 vol%

Effect of helium: decreases CO

decreases O

Effect of Xenon: decreases CO

Effect of anesthetic agents to monitors without anesthetic measurement:

decreases CO

OH (< 0.3%)

2H5

(< 0. 3%)

4

2

readings < 0.6 vol% typically

2

readings < 3 vol% typically

2

readings < 0.4 vol% typically

2

readings < 0.5 vol% typically

2

1-18

Conditions exceeding normal

Accuracy specifications under conditions n o p q:

n Ambient temperature: 10 to 40 °C, within ± 5 °C of calibration

Ambient pressure: 500 to 800 mmHg, ± 50 mmHg of calibration

Ambient humidity: 10 to 98% RH, ± 20% RH of calibration (non-condensing)

Respiration rate: 35 to 60 breaths per minute

o During warm-up, 2 to 10 minutes (anesthetic agents 5-10 minutes) under normal conditions

p During warm-up, 10 to 30 minutes under normal conditions

O > 85%

q N

2

Page 27

Overview

Parameter

CO2

O2

N2O

Agents (Des, Enf, Hal, Iso, Sev)

Parameter

CO2

O2

N2O

Agents (Des, Enf, Hal, Iso, Sev)

Parameter

CO2

O2

Accuracy under Condition

n

± (0.3 vol% + 4% of reading); at 5 vol% error ± 0.5 vol%

± (2 vol% + 2% of reading)

± (3 vol% + 3% of reading

± (0.2 vol% + 10% of reading)

Accuracy under Condition

o

± (0.4 vol% + 7% of reading); at 5 vol% error ± 0.75 vol%

± (3 vol% + 3% of reading)

± (3 vol% + 5% of reading)

± (0.3 vol% + 10% of reading)

Accuracy under Condition

p

± (0.3 vol% + 4% of reading); at 5 vol% error ± 0.5 vol%

± (2 vol% + 2% of reading)

N2O

Agents (Des, Enf, Hal, Iso, Sev)

Parameter

N2O

1.7.6 Patient Spirometry (N-XV)

Accuracy specifications apply in normal conditions.

After 10-minute warm-up period

Ambient temperature: 10 to 40 °C

Ambient pressure: 500 to 800 mmHg

Ambient humidity: 10 to 98% RH

Airway humidity: 10 to 100% RH

Respiration rate: 4 to 35 breaths/minute (adult); 4 to 50 breaths/minute (pediatric)

I:E ratio: 1:4.5 to 2:1

Intubation tube: 5.5 to 10 mm (adult); 3 to 6 mm (pediatric)

± (3 vol% + 3% of reading

± (0.2 vol% + 10% of reading)

Accuracy under Condition

q

± (2 vol% + 8% of reading)

1-19

Page 28

Cardiocap/5 Technical Reference Manual

Detection through D-lite™ or Pedi-lite™ flow sensor and gas sampler:

Measurement D-lite flow sensor (adult) Pedi-lite flow sensor (pediatric)

Tidal volume

Measurement range

Resolution

Accuracy (typical value)

Minute volume

Measurement range

Resolution

Accuracy (typical value)

Airway pressure (Paw)

Measurement range

Resolution

Accuracy (typical value)

Airway flow

Measurement range

(for both directions)

Compliance

Measurement range

Resolution

Airway resistance (Raw)

Measurement range

Resolution

150 to 2000 ml

1 ml

± 6% or 30 ml (whichever is

larger)

2 to 20 l/minute

0.1 l/minute

± 6%

–20 to +100 cmH

0.5 cmH

O

2

O

2

± 1 cmH2O

1.5 to 100 l/minute

4 to 100 ml/cmH

O

2

1 ml/cmH2O

O/ l/s

2

O/l/second

2

0 to 40 cm H

1 cmH

15 to 300 ml

1 ml

± 6% or 4 ml (whichever is

larger)

0.5 to 5 l/minute

0.1 l/minute

± 6%

–20 to +100 cmH

0.5 cmH

O

2

O

2

not applicable

0.25 to 25 l/minute

1 to 100 ml/cmH

O

2

0.1 ml/cmH2O

0 to 40 cm H

1 cmH

O/ l/s

2

O/l/second

2

Sensor specifications

Dead space

Resistance at 30 l/minute

Resistance at 10 l/minute

9.5 ml

0.5 cmH

O

2

not applicable

Conditions exceeding normal

Accuracy specifications during warm-up (first 2 to 10 minutes after power is turned on):

Airway pressure (P

) accuracy: ± 2 cmH2O

aw

Tidal volume accuracy: ± 10% or 100 ml (adult); ± 10% or 10 ml (pediatric)

1.7.7 NeuroMuscular Transmission (N-XNMT)

NMT stimulation modes

Stimulation modes

Train of four (TOF)

Double burst, 3.3 (DBS)

Single twitch (ST)

50 Hz tetanic + post tetanic count (PTC)

Measurement intervals (TOF and DBS): manual; 10 seconds, 12 seconds, 15 seconds, 20 seconds,

1 minute, 5 minutes, 15 minutes

Measurement intervals (ST): manual; 1 second, 10 seconds, 20 seconds

2.5 ml

not applicable

1.0 cmH

O

2

1-20

Page 29

Stimulator

Stimulus pulse: Square wave, constant current

Pulse width: 100, 200 or 300 µs

Stimulus current range (supramax and manual): 10 to 70 mA with 5 mA steps

Stimulus current accuracy: 10% or ±3 mA (whichever is greater)

Maximum load: 3 kΩ

Maximum voltage: 300 V

Regional block mode

Stimulation modes: Single twitch

Intervals: 1 second, 2 seconds, 3 seconds

Stimulus pulse: Square wave, constant current

Pulse width: 40 µs

Stimulus current range: 0 to 5.0 mA with 0.1 mA steps

Stimulus current accuracy: 20% or 0.3 mA (whichever is greater)

1.7.8 Recorder (N-XREC)

Principle: thermal array

Print resolution

Vertical: 8 dots/mm (200 dots/inch)

Horizontal: 32 dots/mm (800 dots/inch) at speed of 25 mm/second and slower

Paper width: 50 mm, printing width 48 mm

Traces: selectable; 1, 2, or 3 traces

Print speed: 1, 6.25, 12.5, 25 mm/second

Overview

1-21

Page 30

Cardiocap/5 Technical Reference Manual

1-22

Page 31

Chapter 2. Installation and Functional Check

2.1 Introduction......................................................................... 2-1

2.2 Installation .......................................................................... 2-1

2.2.1 Front panel components.............................................................................. 2-1

Patient connectors panel (F-MX)................................................................... 2-2

Patient connectors panel (F-MXG) ................................................................ 2-3

2.2.2 Rear panel ................................................................................................. 2-4

2.2.3 Connection to network ................................................................................ 2-5

2.2.4 Sample gas exhaust connections................................................................. 2-5

2.2.5 Scavenging through the ventilator reservoir................................................... 2-5

2.2.6 Scavenging through the anesthesia gas scavenging system ........................... 2-6

2.2.7 Connecting directly to a vacuum scavenging system...................................... 2-6

2.2.8 Returning gas to the patient circuit ............................................................... 2-7

2.3 Choosing the location ........................................................... 2-7

Contents

2.4 Interfacing........................................................................... 2-7

2.4.1 Interfacing a printer..................................................................................... 2-7

2.4.2 Interfacing a computer................................................................................ 2-8

2.4.3 Interfacing other devices using the analog/digital output connector................ 2-8

Digital outputs ............................................................................................ 2-8

Analog outputs ........................................................................................... 2-9

2.4.4 Setting the analog output signals............................................................... 2-10

2.5 Connector pin assignments................................................. 2-11

2.5.1 Analog/digital output connector (X1)..........................................................2-11

2.5.2 RS-232 serial communication interface/local printer connector (X2) ............2-12

2.5.3 Network identification plug connector (X3).................................................. 2-12

2.5.4 Ethernet connector (X4)............................................................................. 2-13

2.5.5 Remote Control connector (X5) .................................................................. 2-13

2.6 Functional check................................................................ 2-14

Using the Functional Check Form................................................................ 2-14

Recommended tools................................................................................. 2-14

2.6.1 Functional inspection................................................................................ 2-15

Recorder test (if N-XREC option is included) ................................................ 2-17

Memory card (PCMCIA) test (if N-XDNET option is included).......................... 2-17

Network test (if N-XNET or N-XDNET option is included).................................2-18

ECG board test.......................................................................................... 2-19

STP board test ..........................................................................................2-19

NIBP board test......................................................................................... 2-20

Pulse oximetry test (if N-XOSAT or N-XNSAT option is included) .....................2-20

Gas measurement and spirometry test........................................................ 2-21

NeuroMuscular Transmission (NMT) test (if N-XNMT option is included) ......... 2-22

2.6.2 Performance checks ................................................................................. 2-24

Page 32

Cardiocap/5 Technical Reference Manual

Table of Figures

Figure 2-1. Cardiocap/5 monitor (F-MXG) .........................................................................2-1

Figure 2-2. Patient connections—Hemodynamic (F-MX)......................................................2-2

Figure 2-3. Patient connections—Hemodynamic with gas (F-MXG).......................................2-3

Figure 2-4. Rear panel (F-MXG).........................................................................................2-4

Figure 2-5. Scavenging through ventilator reservoir ............................................................ 2-5

Figure 2-6. Connecting sample gas outlet directly to an anesthesia gas scavenging system... 2-6

Figure 2-7. Gas return to patient circuit in AS/3 ADU.......................................................... 2-7

Page 33

2. INSTALLATION AND FUNCTIONAL CHECK

2.1 Introduction

This chapter includes the information needed to install and check the monitor. Information for

connecting other equipment, such as a printer or computer, is also included. If you need assistance

concerning the installation, please contact your authorized distributor.

2.2 Installation

2.2.1 Front panel components

Installation and Functional Check

Figure 2-1. Cardiocap/5 monitor (F-MXG)

(1) Power On/standby key

(2) External power indicator / Battery charge status LED

(3) Alarm indicators

(4) Insertion slots for memory cards (Data card and Menu card)

A cover for the slots is available. See the Spare Parts chapter later in this manual.

(5) Direct access keys

(6) Adjustable rear support

(7) ComWheel

2-1

Page 34

Cardiocap/5 Technical Reference Manual

(8) Recorder (N-XREC option)

NOTE: The two-button recorder (shown) is for Cardiocap/5 monitors using software version 3.0

or higher. A one-button recorder was available previously.

(9) Patient connectors

(10) Spirometry connectors

(11) NIBP connector

(12) D-fend housing (F-MXG only)

Patient connectors panel (F-MX)

T2

NIBP

ECG SpO2

1 2 3 4 5 6 7

P1

P2 T1

Figure 2-2. Patient connections—Hemodynamic (F-MX)

(1) NIBP

(2) ECG

(3) SpO

2

NOTE: Connector type depends on which SpO

option is installed:

2

Connector for Datex-Ohmeda

standard pulse oximetry

Connector for Datex-Ohmeda

enhanced pulse oximetry

Connector for Nellcor® compatible

pulse oximetry

2-2

(4) Invasive pressure, P1 (N-XP option)

(5) Invasive pressure, P2 (N-XP option)

(6) Temperature, T2 (N-XP option)

(7) Temperature, T1

Page 35

Patient connectors panel (F-MXG)

1 2 3 4

Installation and Functional Check

NIBP

Spiromet ry

NMT

ECG

SpO2

P2

T2

P1

T1

569 8 710

Figure 2-3. Patient connections—Hemodynamic with gas (F-MXG)

(1) Spirometry (N-XV option)

(2) NMT (N-XNMT option)

(3) Invasive pressure, P2 (N-XP option)

(4) Temperature, T2 (N-XP option)

(5) Temperature, T1

(6) Invasive pressure, P1 (N-XP option)

(7) SpO

2

NOTE: Connector type depends on which SpO

Connector for Datex-Ohmeda

standard pulse oximetry

option is installed:

2

(8) ECG

(9) NIBP

(10) D-fend housing

Connector for Datex-Ohmeda

enhanced pulse oximetry

Connector for Nellcor® compatible

pulse oximetry

2-3

Page 36

Cardiocap/5 Technical Reference Manual

2.2.2 Rear panel

1

13

12

Figure 2-4. Rear panel (F-MXG)

(1) Built-in handle

(2) Gas outlet (F-MXG only), X6

(3) Remote Control connector, X5

(4) Ethernet connector, X4

(5) Network connection LEDs

(6) Network identification plug connector, X3

(7) Serial communication interface/local printer connector, X2

(8) Analog/digital output connector, X1

(includes nurse call and defibrillator synchronization signals)

2

3

4

567891011

2-4

(9) Mounting attachment

(10) Dust filter

(11) Potential equalization

(12) Fuse and voltage information

(13) Receptacle for mains power cord and fuses

WARNING: Electrical shock hazard. Connect the power cord to a three-wire, grounded, hospitalgrade receptacle only.

CAUTION: Turn off the power before making any rear panel connections.

Page 37

2.2.3 Connection to network

If either Cardiocap/5 Network option (N-XNET or N-XDNET) is installed, you can connect the

Cardiocap/5 to the Datex-Ohmeda Network and iCentral. Use the Monitor-Network cable to connect

the monitor to the network.

1. Power off the monitor.

2. On the rear panel, connect one of the RJ-45 connectors to connector X4 and connect the

Identification Plug to connector X3.

3. Connect the other RJ-45 connector to the corresponding Datex-Ohmeda iCentral Network

connector on the wall box.

4. Power on the monitor.

5. Confirm that the network symbol and the “Connected to Network” message are displayed on the

upper part of the screen.

NOTE: The network symbol does not appear if the battery symbol is displayed.

Installation and Functional Check

2.2.4 Sample gas exhaust connections

When N2O or volatile anesthetics are used, take precautions against venting these gases into room air.

Return the sample gas to the patient circuit or connect the sample gas outlet of the monitor to the

scavenging system.

CAUTION: Strong scavenging suction may change the operating pressure of the monitor and cause

inaccurate readings or internal damage.

2.2.5 Scavenging through the ventilator reservoir

To scavenge through the ventilator reservoir:

Figure 2-5. Scavenging through ventilator reservoir

• Connect an exhaust line to the sample gas outlet on the rear panel of the monitor.

2-5

Page 38

Cardiocap/5 Technical Reference Manual

•

Attach the other end of the line to the ventilator reservoir. Make sure that the reservoir tube

diameter is at least 2-3 times larger than the exhaust line.

2.2.6 Scavenging through the anesthesia gas scavenging system

Anesthesia machines are equipped with an anesthesia gas scavenging system (AGSS), and in some

machines you can connect the sample gas outlet directly to that.

For example, connect the sample gas outlet to the Datex-Ohmeda S/5 Avance:

2-6

Figure 2-6. Connecting sample gas outlet directly to an anesthesia gas scavenging system

Note: Refer to the anesthesia machine’s documentation to find out where and how the sample gas

can be connected.

2.2.7 Connecting directly to a vacuum scavenging system

To scavenge through a direct connection:

1. Connect the exhaust line (733195, 5/pkg) to the sample gas outlet on the monitor.

2. Connect the exhaust line only to an open scavenging system where gas is removed at room

pressure. Do not connect the monitor directly to a vacuum scavenging system.

Page 39

2.2.8 Returning gas to the patient circuit

In some anesthesia machines, you can return the sample gas to the patient circuit, refer to the

anesthesia machines manuals. For example, if you use the Datex-Ohmeda S/5 Anesthesia Delivery

Unit (ADU), connect an optional adapter (881644, 5/pkg) to the patient breathing tubes.

Figure 2-7. Gas return to patient circuit in AS/3 ADU

Installation and Functional Check

2.3 Choosing the location

The monitor can be placed on a flat surface or hung with the handle from the bed or wall rails. Make

sure that the surface or rail holds up to at least 13 kg/29 lb.

WARNING: The monitor or its components should not be used adjacent to or stacked with other

equipment. If adjacent or stacked use is necessary, the monitor and its components should be

observed to verify normal operation in the configuration in which it will be used.

When choosing the location, refer to the EMC guidance in the appendix later in this document.

2.4 Interfacing

WARNING: Electrical shock hazard. When you connect equipment to the Cardiocap/5 input and

output connectors, you are configuring a medical system and are responsible for ensuring that

the system complies with IEC/EN 60601-1-1 and with local requirements.

2.4.1 Interfacing a printer

You can connect a PCL-5 compatible laser printer to the Cardiocap/5 using the Datex-Ohmeda Light

Monitor–Printer cable. Connect this serial-to-parallel interface cable between the local printer

connector (X2) and the printer. For ordering details, refer to the Datex-Ohmeda Supplies &

Accessories Catalog.

WARNING: Connecting the power supply cord of the printer to the wall socket may cause the

printer leakage current to exceed the limit specified for medical equipment. Always connect the

printer to an appropriate isolation transformer.

2-7

Page 40

Cardiocap/5 Technical Reference Manual

2.4.2 Interfacing a computer

It is possible to interface a computer to the Cardiocap/5. For further information, please contact your

authorized GE Healthcare distributor.

WARNING: Connecting the power supply cord of the computer to the wall socket may cause the

computer leakage current to exceed the limit specified for medical equipment. Always connect

the computer to an appropriate separating transformer.

2.4.3 Interfacing other devices using the analog/digital output connector

The analog/digital output connector (X1) can be used to interface other devices to the Cardiocap/5.

Digital outputs

Defibrillation sync

The ECG generates the defibrillation sync digital output signal. The signal is set to a high state

(logic 1: 2.8 to 5.0 VDC ) when activated. After 10 ms, it is set back to a low state

(logic 0: 0 to 0.8 VDC). The signal is regenerated only after returning to the low state. The delay from

the R-wave peak to the start of the signal is 35 ms maximum.

Nurse call

The nurse call digital output signal is generated by red, yellow, and white alarms. When activated, the

signal is set to a high state and remains at a high state until the alarm situation is over or the Silence

Alarms key is pressed. The high state (logic 1) ranges from 2.8 to 5.0 VDC while the low state (logic 0)

ranges from 0 to 0.8 VDC. The nurse call signal also activates a relay that connects X1 (pins 11 and 12).

2-8

Page 41

Installation and Functional Check

Analog outputs

Each analog output signal is scaled linearly between –5 and +5 volts. The resolution is 4096 steps

over 10 volts, or approximately 0.00244 volts per step. All signal levels are updated every 10 ms.

OFF Default state. No signal is present at the analog output pin.

HR according to selected source (display value)

The original scale of 0 to 300 beats is scaled between 0 and 3 volts.

ECG1, ECG2, ECG3

The original scale of –5000 microvolts to +5000 microvolts is scaled between –5 and +5 volts.

P1 lre, P2 lre (Invasive pressure real-time values, low resolution)

The original scale of –20 mmHg to +320 mmHg (-2.7 to +42.7 kPa) is scaled between –0.2

and +3.2 volts.

P1 hre, P2 hre (Invasive pressure real-time values, high resolution)

The original scale of –20 mmHg to +50 mmHg (-2.7 to +6.7 kPa) is scaled between –2 and

+5 volts.

Pleth The original scale of –100% to 100% is scaled between –5 and +5 volts.

SpO

>40, SpO2>60, SpO2>80 (beat-to-beat, display value, 10 s average)

2

The original scale of 40 to 100% (SpO

(SpO2>80) is scaled between –5 and +5 volts.

>40), 60 to 100% (SpO2>60) or 80 to 100%

2

CO

The original scale of 0% to 10% is scaled between 0 and +5 volts. Values greater than 10%

2

are set to 10%. (Airway gas special indications are applied. See Special indications for

analog outputs below.)

AA (anesthetic agent)

The original scale of 0% to 10% is scaled between 0 and +5 volts. Values greater than 10%

are set to 10%. (Airway gas special indications are applied. See Special indications for

analog outputs below.)

The original scale of 0% to 100% is scaled between 0 and +5 volts. (Airway gas special

O

2

indications are applied. See Special indications for analog outputs below.)

O The original scale of 0% to 100% is scaled between 0 and +5 volts. (Airway gas special

N

2

indications are applied. See Special indications for analog outputs below.)

Paw (airway pressure)

The original scale of –20 cmH

O to +80 cmH2O is scaled between –5 and +5 volts. (Airway

2

gas sensor failure is applied. See Special indications for analog outputs below.)

Flow The original scale of –100 l/minute to +100 l/minute is scaled between –5 and +5 volts.

(Airway gas sensor failure is applied. See Special indications for analog outputs below.)

Volume The original scale of –2.5 liters to +2.5 liters is scaled between –5 and +5 volts. (Airway gas

sensor failure is applied. See Special indications for analog outputs below.)