Page 1

TOSHIBA Thermal Printer

B-SX6T/SX8T SERIES

System Mode Manual

Document No. EO13-33002

Original Mar., 2006

(Revised )

PRINTED IN JAPAN

Page 2

EO13-33002

(Revision Date: Jul. 24, 2008)

TABLE OF CONTENTS

Page

1. INTRODUCTION----------------------------------------------------------------------------------------------------- 1- 1

1.1 Key Operation Flow ----------------------------------------------------------------------------------------------1- 1

1.2 Operation Panel ---------------------------------------------------------------------------------------------------1- 2

2. SYSTEM MODE ----------------------------------------------------------------------------------------------------- 2- 1

2.1 Self-diagnostic Test----------------------------------------------------------------------------------------------2- 3

2.1.1 Printing Mode Selection----------------------------------------------------------------------------------------- 2- 4

2.1.2 Dispensing Mode Selection ------------------------------------------------------------------------------------ 2- 4

2.1.3 Maintenance Counter/Parameter Settings Printing Out ------------------------------------------------- 2- 5

2.1.4 Self-Diagnostic Test and Result Print Out ----------------------------------------------------------------- 2-11

2.1.5 Print Head Element Check ------------------------------------------------------------------------------------ 2-17

2.2 Parameter Setting------------------------------------------------------------------------------------------------2-18

2.2.1 Character Code Selection ------------------------------------------------------------------------------------- 2-19

2.2.2 Character Zero Selection -------------------------------------------------------------------------------------- 2-20

2.2.3 Baud Rate Selection -------------------------------------------------------------------------------------------- 2-20

2.2.4 Data Length Selection ------------------------------------------------------------------------------------------ 2-21

2.2.5 Stop Bit Length Selection-------------------------------------------------------------------------------------- 2-21

2.2.6 Parity Selection--------------------------------------------------------------------------------------------------- 2-22

2.2.7 Flow Control Code Selection---------------------------------------------------------------------------------- 2-22

2.2.8 LCD Language Selection -------------------------------------------------------------------------------------- 2-23

2.2.9 Auto Forward Wait Selection---------------------------------------------------------------------------------- 2-23

2.2.10 Head Up Cut Selection ----------------------------------------------------------------------------------------- 2-24

2.2.11 Ribbon Save Function Selection ----------------------------------------------------------------------------- 2-24

2.2.12 Control Code Selection----------------------------------------------------------------------------------------- 2-25

2.2.13 Ribbon Type Selection ----------------------------------------------------------------------------------------- 2-26

2.2.14 Strip Wait Status Selection ------------------------------------------------------------------------------------ 2-26

2.2.15 FEED Key Function Selection -------------------------------------------------------------------------------- 2-27

2.2.16 KANJI Code Selection------------------------------------------------------------------------------------------ 2-27

2.2.17 EURO Code Selection------------------------------------------------------------------------------------------ 2-27

2.2.18 Auto Print Head Check Selection ---------------------------------------------------------------------------- 2-28

2.2.19 Centronics Interface ACK/BUSY Timing Selection ------------------------------------------------------ 2-28

2.2.20 Web Printer Function Selection ------------------------------------------------------------------------------ 2-29

2.2.21 Media Sensor Selection---------------------------------------------------------------------------------------- 2-29

2.2.22 Input Prime Selection ------------------------------------------------------------------------------------------- 2-30

2.2.23 Expansion I/O Interface Type Selection-------------------------------------------------------------------- 2-30

2.2.24 Plug & Play Selection------------------------------------------------------------------------------------------- 2-31

2.2.25 Label End/Ribbon End Selection ---------------------------------------------------------------------------- 2-31

2.2.26 Pre-Strip Selection----------------------------------------------------------------------------------------------- 2-33

2.2.27 Reverse Feed Speed Selection ------------------------------------------------------------------------------ 2-33

2.2.28 Maxi Code Specification Selection -------------------------------------------------------------------------- 2-33

2.2.29 Strip Motor Torque Selection --------------------------------------------------------------------------------- 2-34

2.2.30 Stabilizer Function Selection---------------------------------------------------------------------------------- 2-34

Page 3

EO13-33002

(Revision Date: Jul 24, 2008)

Page

2.3 Printer Parameter Fine Adjustment ----------------------------------------------------------------- 2-35

2.3.1 Feed Amount Fine Adjustment ------------------------------------------------------------------------------- 2-37

2.3.2 Cut/Strip Position Fine Adjustment -------------------------------------------------------------------------- 2-38

2.3.3 Reverse Feed Amount Fine Adjustment ------------------------------------------------------------------- 2-41

2.3.4 X Coordinate Fine Adjustment-------------------------------------------------------------------------------- 2-42

2.3.5 Print Tone Fine Adjustment (Thermal Transfer/Thermal Direct Print) ------------------------------ 2-44

2.3.6 Ribbon Motor Voltage Fine Adjustment (Feed/Take-up Motor) -------------------------------------- 2-45

2.3.7 Threshold Manual Fine Adjustment (Black Mark/Feed Gap Sensor) ------------------------------- 2-46

2.4 Test Print------------------------------------------------------------------------------------------------------------2-47

2.4.1 Specifying the Print Condition for the Test Print --------------------------------------------------------- 2-49

2.4.2 Test Print Pattern Selection ----------------------------------------------------------------------------------- 2-52

2.4.3 Slant Line (1 dot)------------------------------------------------------------------------------------------------- 2-53

2.4.4 Slant Line (3 dots) ----------------------------------------------------------------------------------------------- 2-54

2.4.5 Characters--------------------------------------------------------------------------------------------------------- 2-55

2.4.6 Barcode ------------------------------------------------------------------------------------------------------------ 2-55

2.4.7 Non-Printing------------------------------------------------------------------------------------------------------- 2-56

2.4.8 Factory Test------------------------------------------------------------------------------------------------------- 2-56

2.4.9 Auto Print ---------------------------------------------------------------------------------------------------------- 2-57

2.5 Sensor Adjustment ----------------------------------------------------------------------------------------------2-58

2.5.1 Sensor Status Display ------------------------------------------------------------------------------------------ 2-59

2.5.2 Black Mark Sensor Adjustment------------------------------------------------------------------------------- 2-59

2.5.3 Feed Gap Sensor Adjustment -------------------------------------------------------------------------------- 2-60

2.5.4 Black Mark Sensor and Feed Gap Sensor Adjustment (Paper End Level)------------------------ 2-60

2.6 RAM Clear ----------------------------------------------------------------------------------------------------------2-61

2.6.1 RAM Clear Menu Selection ----------------------------------------------------------------------------------- 2-62

2.6.2 No RAM Clear ---------------------------------------------------------------------------------------------------- 2-62

2.6.3 Maintenance Counter Clear----------------------------------------------------------------------------------- 2-62

2.6.4 Printer Parameter Clear---------------------------------------------------------------------------------------- 2-63

2.7 IP Address Setting-----------------------------------------------------------------------------------------------2-66

2.7.1 Printer IP Address, Gateway IP Address, and Subnet Mask Settings ------------------------------ 2-67

2.7.2 Socket Port Setting ---------------------------------------------------------------------------------------------- 2-68

2.7.3 DHCP and DHCP ID Settings -------------------------------------------------------------------------------- 2-68

2.7.4 DHCP Host Name Setting ------------------------------------------------------------------------------------- 2-69

2.8 BASIC Setting -----------------------------------------------------------------------------------------------------2-70

2.8.1 Basic Specification Selection Mode ------------------------------------------------------------------------- 2-71

2.8.2 Basic File Browser----------------------------------------------------------------------------------------------- 2-71

2.8.3 Basic Trace Selection Mode ---------------------------------------------------------------------------------- 2-71

2.8.4 Basic Expansion Mode (Execution of Basic Program)-------------------------------------------------- 2-72

2.9 RFID Module Setting --------------------------------------------------------------------------------------------2-73

2.9.1 RFID Read Test-------------------------------------------------------------------------------------------------- 2-74

2.9.2 RFID Module Type Selection --------------------------------------------------------------------------------- 2-75

2.9.3 RFID Tag Type Selection -------------------------------------------------------------------------------------- 2-76

2.9.4 RFID Error Tag Delection-------------------------------------------------------------------------------------- 2-76

2.9.5 Maximum Number of RFID Issue Retries------------------------------------------------------------------ 2-77

2.9.6 Maximum Number of RFID Read Retries------------------------------------------------------------------ 2-78

2.9.7 RFID Read Retry Time-out------------------------------------------------------------------------------------ 2-79

Page 4

EO13-33002

A

(Revision Date: Jul 24, 2008)

Page

2.9.8 Maximum Number of RFID Write Retries ------------------------------------------------------------------ 2-80

2.9.9 RFIDWritre Retry Time-out------------------------------------------------------------------------------------ 2-81

2.9.10 RFID Adjustment for Retry ------------------------------------------------------------------------------------ 2-82

2.9.11 RFID Wireless Power Level Setting------------------------------------------------------------------------- 2-83

2.9.12 RFID AGC Threshold ------------------------------------------------------------------------------------------- 2-83

2.9.13 RFID Module Q Value Setting -------------------------------------------------------------------------------- 2-84

2.9.14 AGC Threshold for Data Write Setting---------------------------------------------------------------------- 2-85

2.9.15 AGC Threshold Lower Limit for Retry Setting ------------------------------------------------------------ 2-86

3. ON LINE MODE ------------------------------------------------------------------------------------------3- 1

3.1 Automatic Threshold Setting ---------------------------------------------------------------------------------3- 4

3.2 Reset Operation ---------------------------------------------------------------------------------------------------3- 5

3.3 Dump Mode ---------------------------------------------------------------------------------------------------------3- 6

3.4 BASIC Expansion Mode ----------------------------------------------------------------------------------------3- 8

3.5 Automatic Calibration Setting --------------------------------------------------------------------------------3- 9

3.6 LAN Enable/Disable Setting ----------------------------------------------------------------------------------3-11

3.7 Real Time Clock (RTC) Setting ------------------------------------------------------------------------------3-12

4. PROGRAM DOWN LOAD -----------------------------------------------------------------------------4- 1

4.1 Outline of Features -----------------------------------------------------------------------------------------------4- 1

4.2 Download Program Installation ------------------------------------------------------------------------------4- 1

4.2.1 System Requirements ------------------------------------------------------------------------------------------- 4- 1

4.2.2 Setup----------------------------------------------------------------------------------------------------------------- 4- 2

4.3 Firmware Download ----------------------------------------------------------------------------------------------4- 2

5. RFID ANALYZE TOOL ---------------------------------------------------------------------------------5- 1

5.1 System Requirement---------------------------------------------------------------------------------------------5- 1

5.2 Set up -----------------------------------------------------------------------------------------------------------------5- 2

5.3 Application Functions -------------------------------------------------------------------------------------------5- 3

5.3.1 Main Menu---------------------------------------------------------------------------------------------------------- 5- 3

5.3.2 File Menu ----------------------------------------------------------------------------------------------------------- 5- 4

5.3.3 Tool Menu ---------------------------------------------------------------------------------------------------------- 5- 7

5.3.4 Help Menu --------------------------------------------------------------------------------------------------------- 5-12

5.4 Operating Procedure--------------------------------------------------------------------------------------------5-13

CAUTION!

1. This manual may not be copied in whole or in part without prior written permission of TOSHIBA

TEC.

2. The contents of this manual may be changed without notification.

Copyright © 2006

by TOSHIBA TEC CORPORATION

ll Rights Reserved

570 Ohito, Izunokuni-shi, Shizuoka-ken, JAPAN

Page 5

1. INTRODUCTION EO13-33002

g

•

(Revision Date: Jul. 24, 2008)

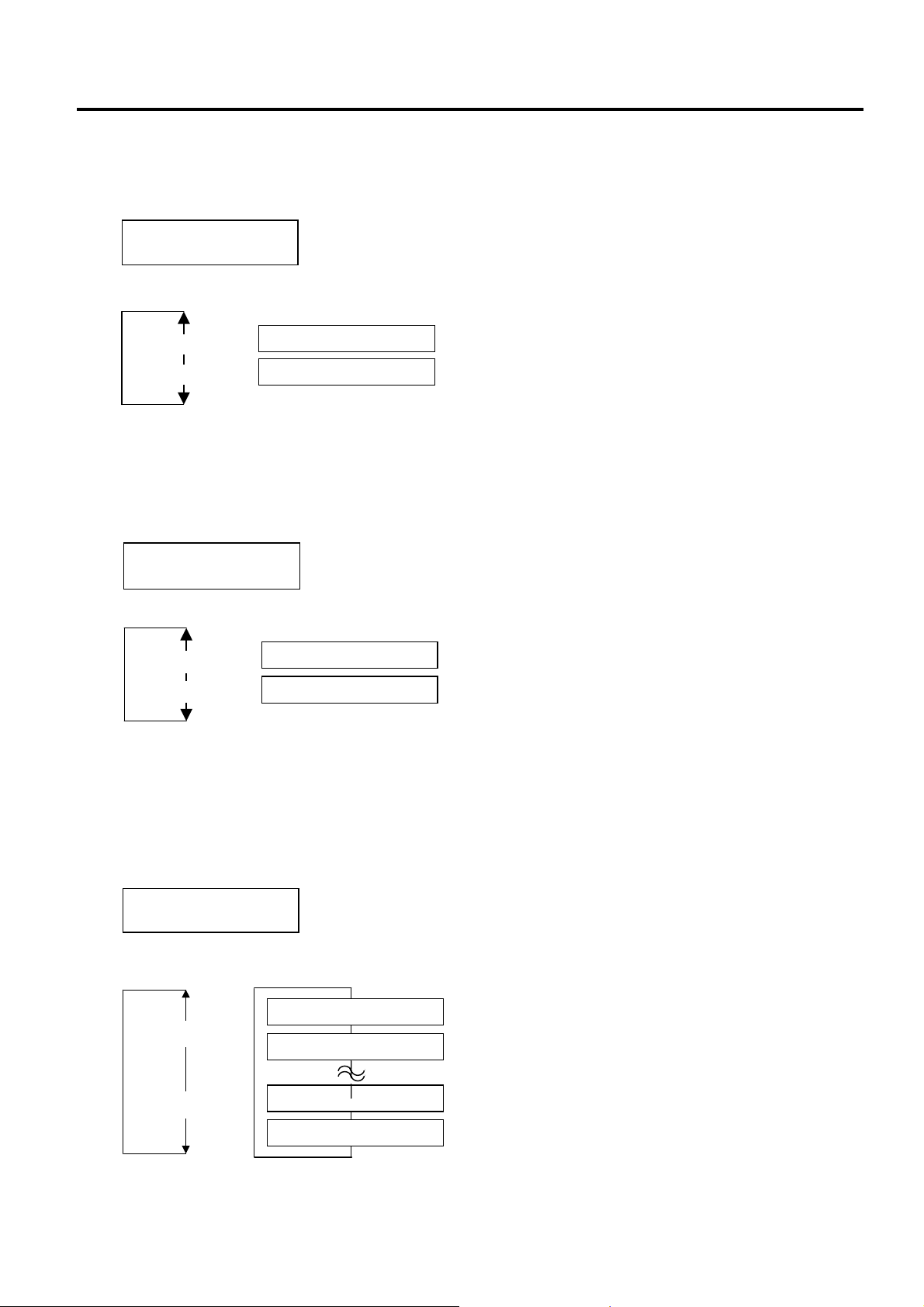

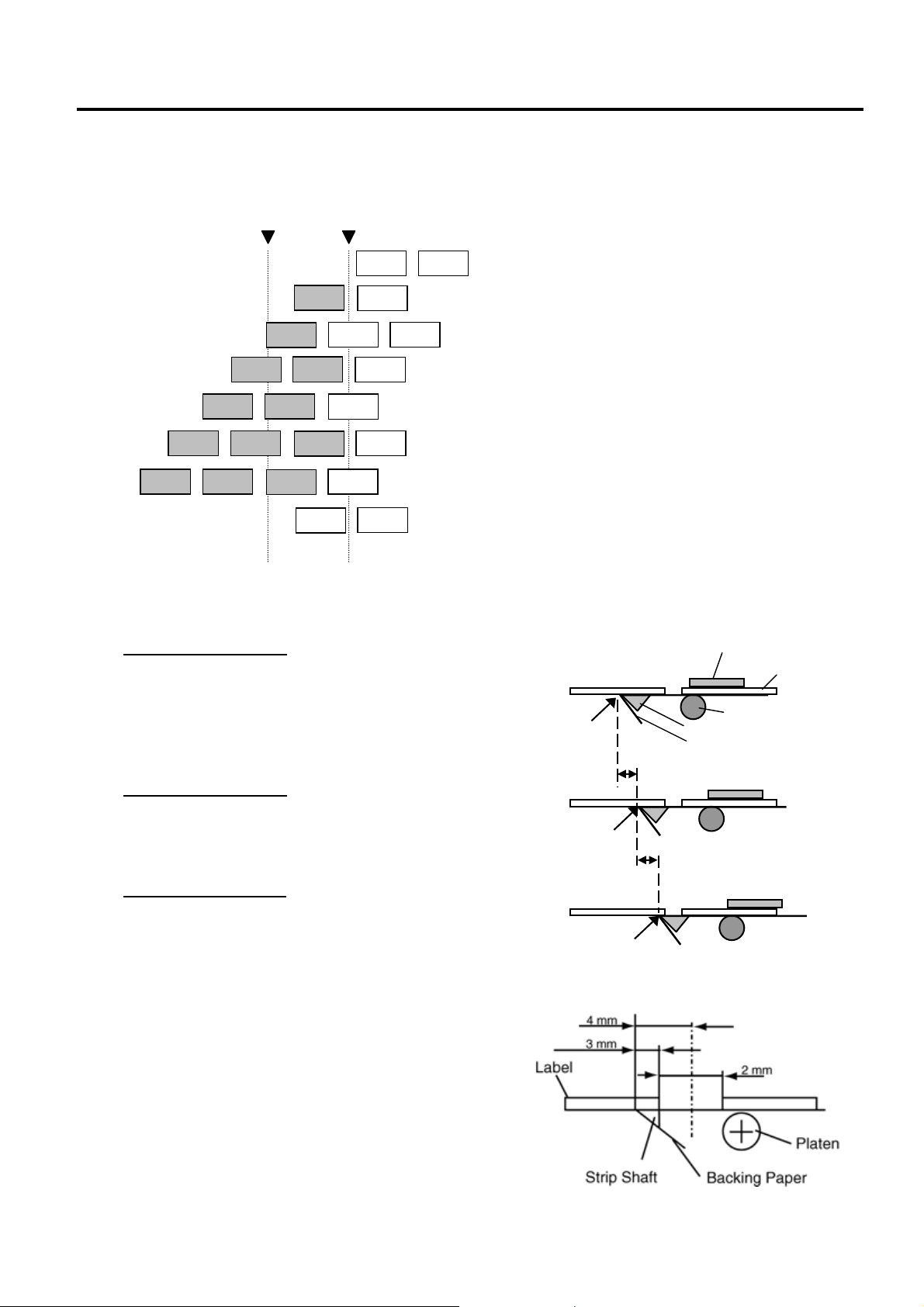

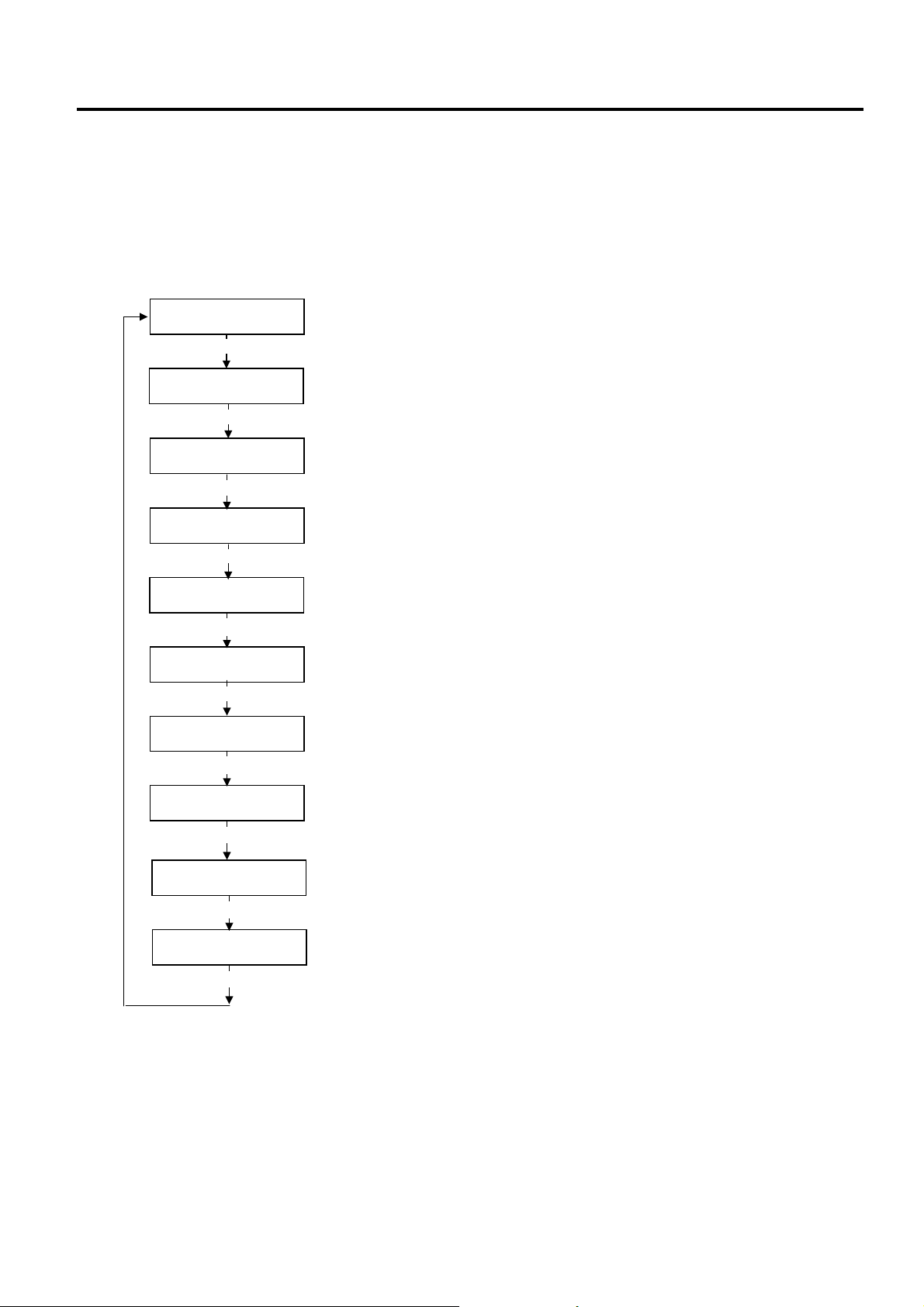

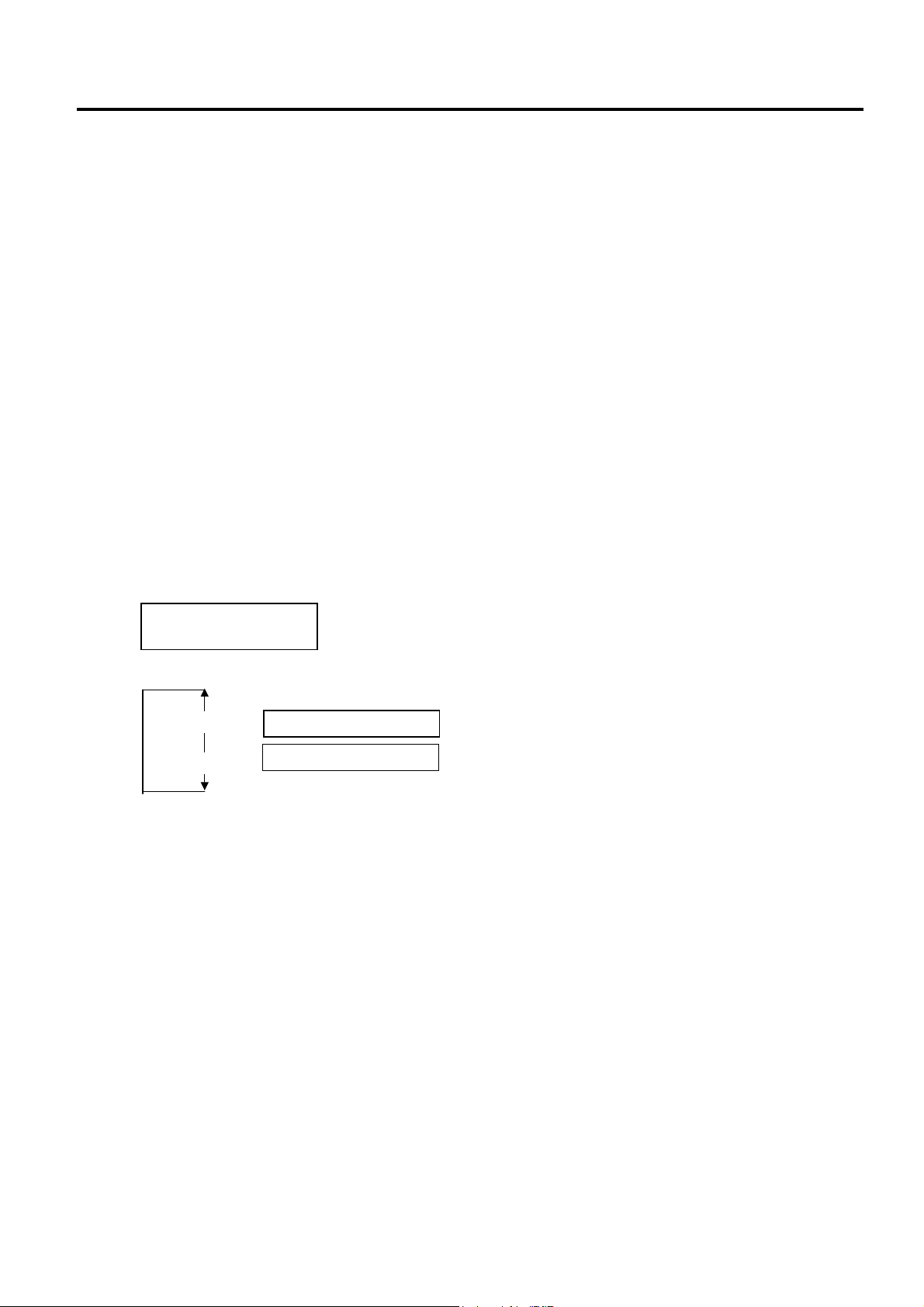

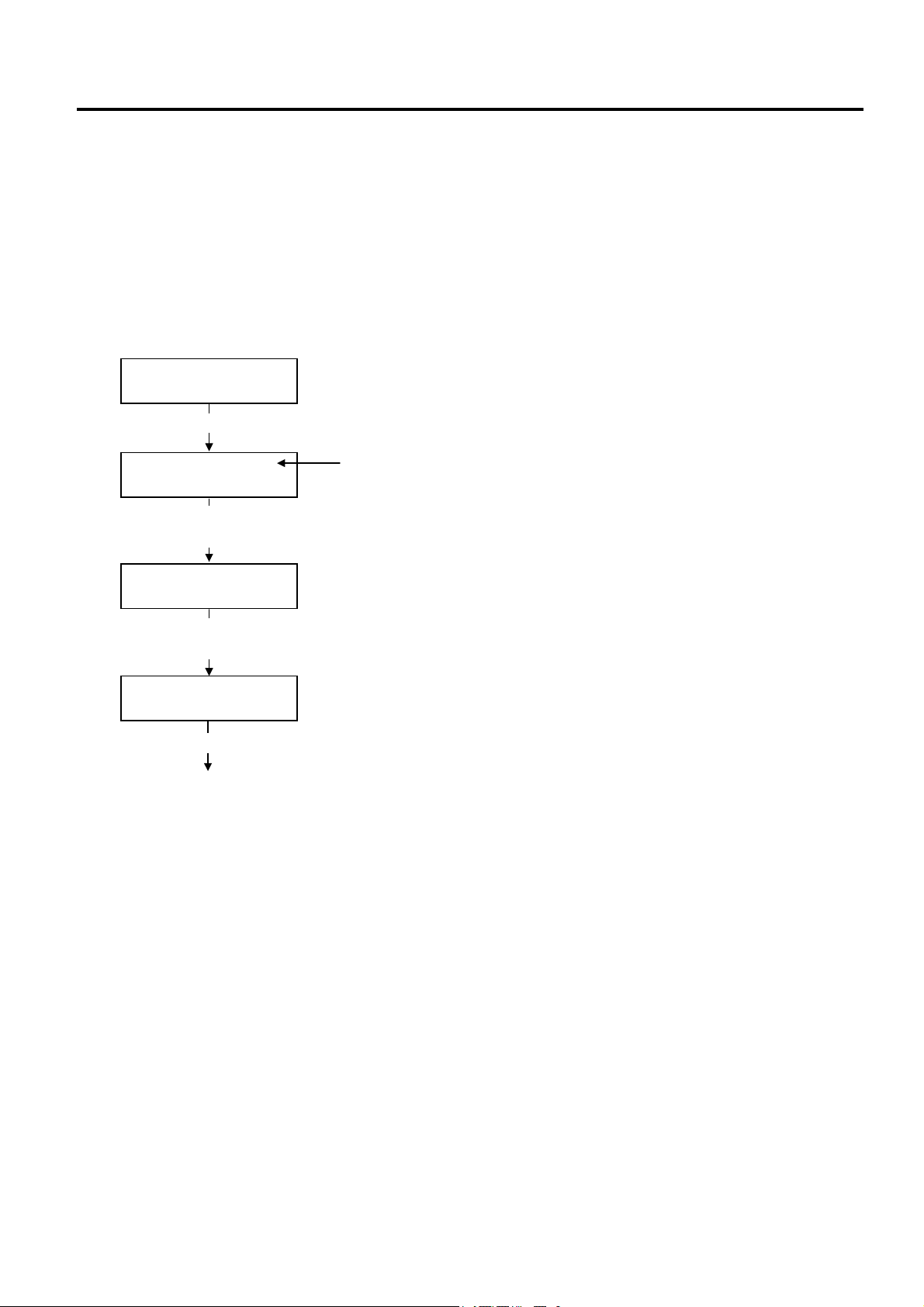

1.1 Key Operation Flow

1. INTRODUCTION

This document describes key operations using the keys and LCD display on the printer that you can operate

on a printer alone. Key operations are performed in the following four printer setting modes:

• Online mode where a pause, reset, automatic threshold setting, etc. are performed.

• Download mode where a firmware downloading is performed.

• System mode for service personnel where a self-diagnosis, printer parameter settings, RAM clear, IP

address setting etc. are performed.

• System mode for end user where a self-diagnosis, printer parameter settings, fine adjustment, etc.,

which are same functions as those in System mode for service personnel, are performed.

NOTE: This document uses the B-SX8T for examples of the display.

1.1 Key Operation Flow

Power OFF

Turn the power on.

Online mode

Online

[FEED] key

[PAUSE] key

While holding down the [FEED],

[RESTART], and [PAUSE] keys,

turn the power on.

While holding down the [FEED] and [RESTART]

keys, turn the power on.

Feeds one label.

Pause

Hold down the [PAUSE] key

for a few seconds.

Hold down the [RESTART] key

for a few seconds.

System mode for service personnel

While holding down the

[FEED] and [PAUSE]

keys, turn the power on.

• Self-test

• Parameter setting

• Fine adjustment

• Test print

• Sensor adjustment

• RAM clear

• IP Address setting

• Basic setting

• For factory

• RFID Module Settin

[RESTART] key

Feed gap sensor automatic threshold setting

[FEED] key or [RESTART] key

Black mark sensor threshold setting

• Reset

• Parameter Setting

• Fine adjustment

• Dump mode

• Expand mode (Basic expansion mode)

• Automatic calibration mode

• LAN Enable/Disable

• RTC Setting

Download mode

System mode for end users

• Self-test

• Parameter setting

• Fine adjustment

Test print

1- 1

Page 6

1. INTRODUCTION EO13-33002

1.2 Operation Panel

1.2 Operation Panel

The figure below illustrates the Operation Panel and key functions.

LCD Message

Display

POWER LED

(Green)

ERROR LED

(Red)

ON LINE LED

(Green)

[FEED] key

[RESTART] key

[PAUSE] key

The LCD Message Display is a 16-character x 2-line display, which shows messages in alphanumeric

characters and symbols to indicate the printer’s status. .

There are three LEDs on the Operation Panel.

LED Illuminates when…

POWER

The printer is turned on.

ON LINE The printer is ready to print.

ERROR The printer is in an error state.

The [FEED], [RESTART] and [PAUSE] keys function as described below.

FEED

Feeds or ejects one media.

Adjusts media to a proper position if the media is not properly positioned by feeding

one or two blank media before printing.

Prints data in the image buffer on one media according to the system mode setting.

In system mode, this key is used to select various parameters or to set a fine

adjustment value in the negative direction (-).

RESTART

Resumes printing when the printer is in a pause state or an error state.

Restores the same state as when the power is turned off and on again.

In system mode, this key is used to select various parameters or to set a fine

adjustment value in the positive direction (+).

PAUSE

Stops printing temporarily.

Programs threshold values.

In system mode, this key is used as an enter key.

1- 2

Page 7

2. SYSTEM MODE EO13-33002

A

2. SYSTEM MODE

2. SYSTEM MODE

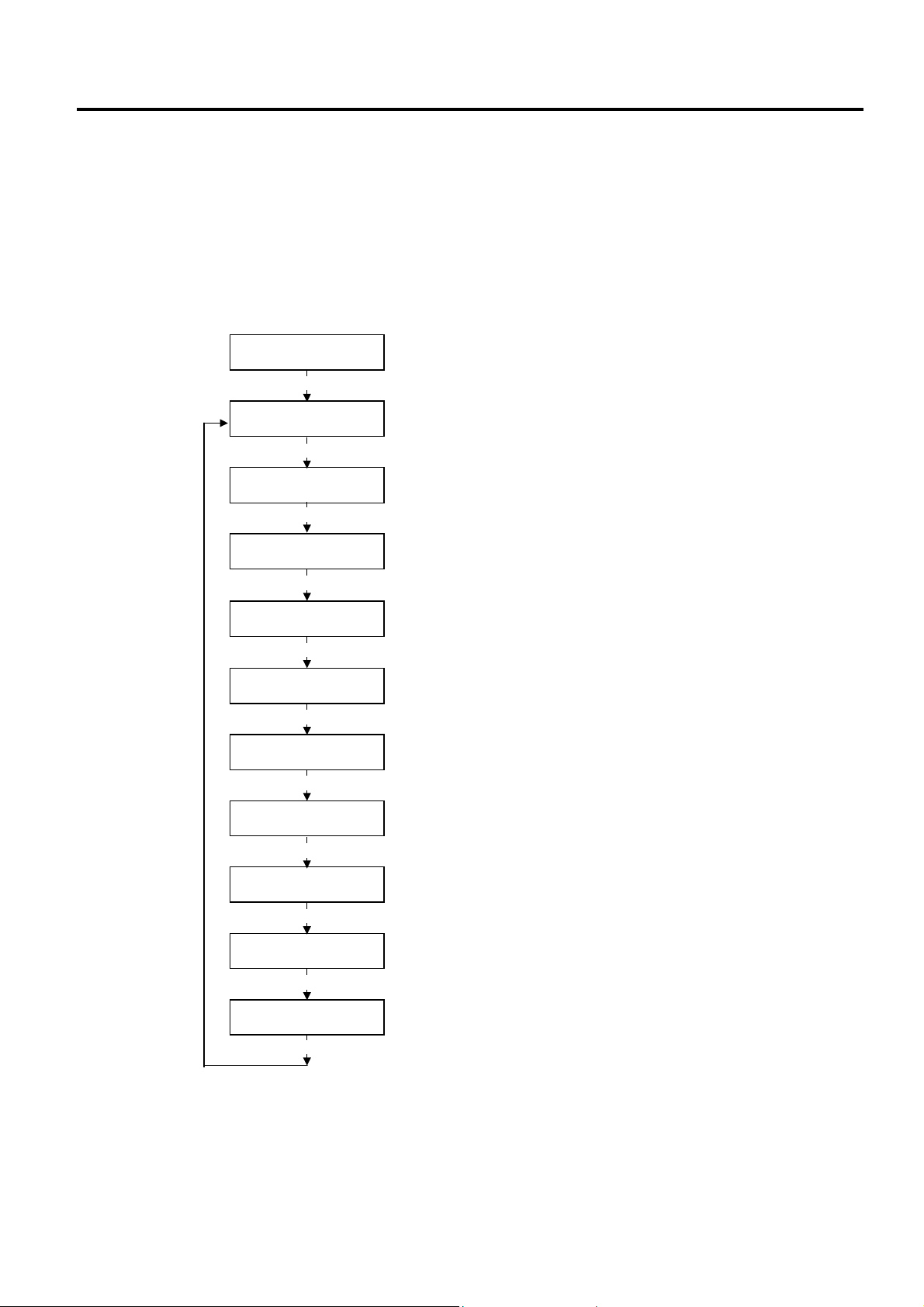

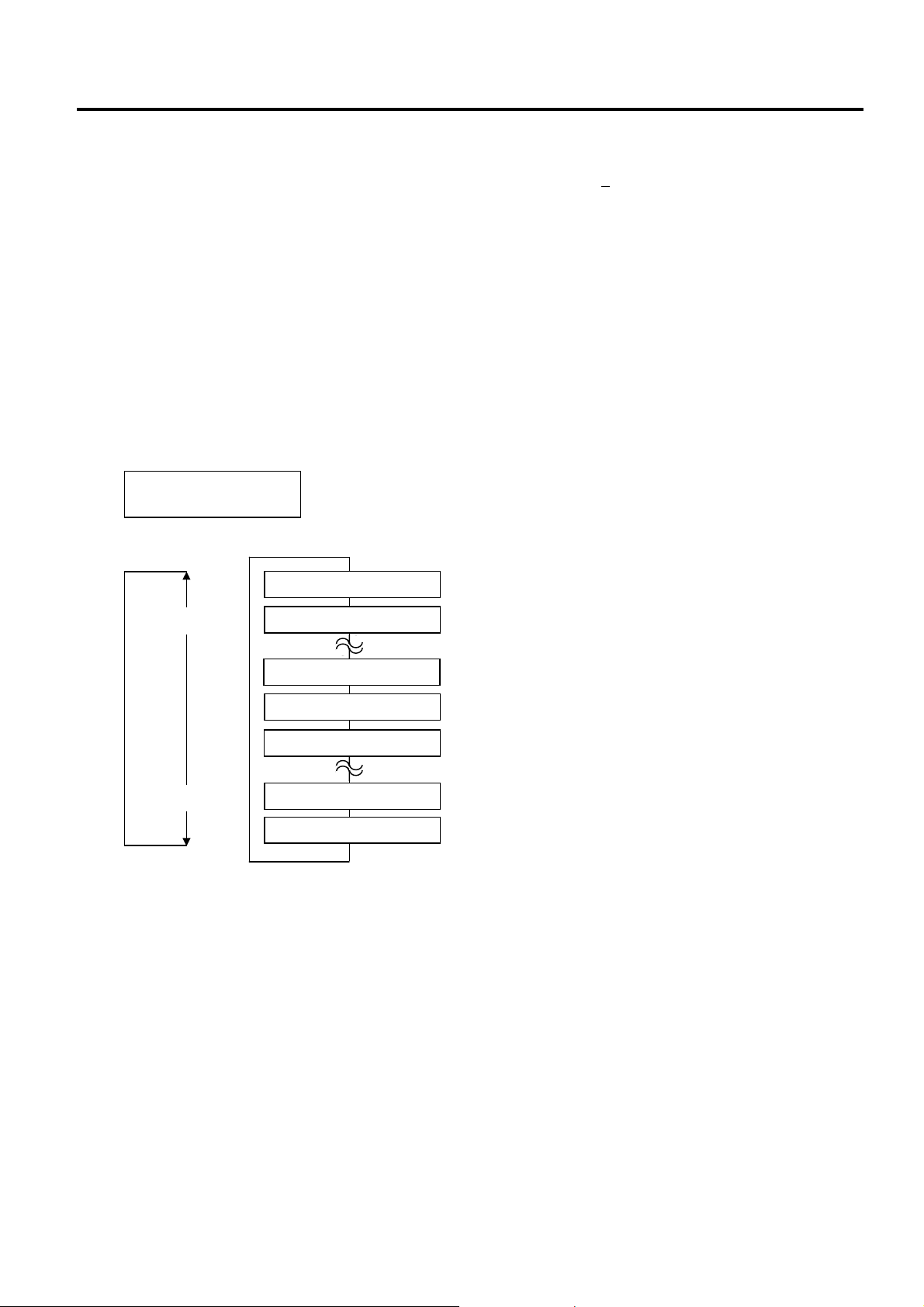

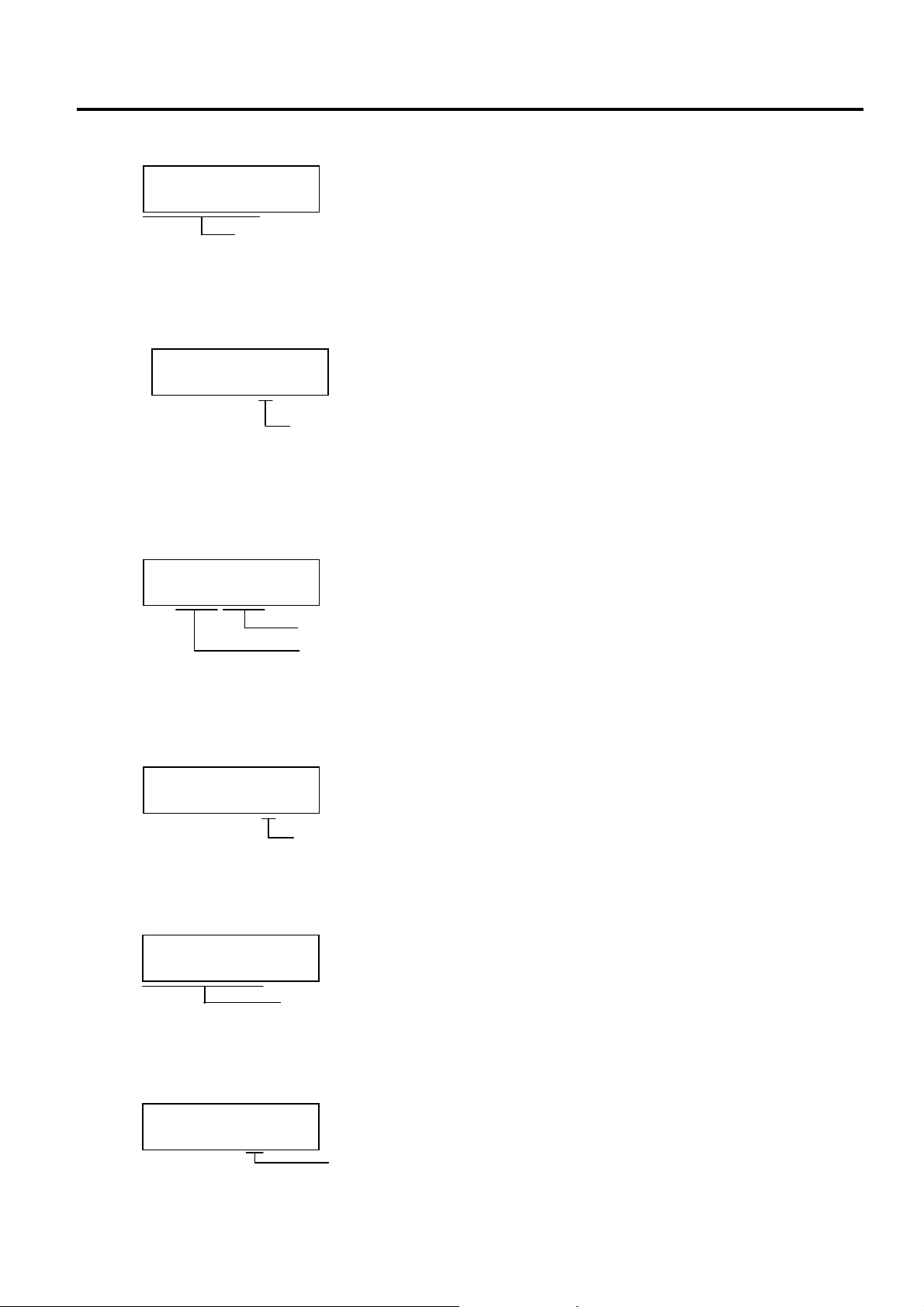

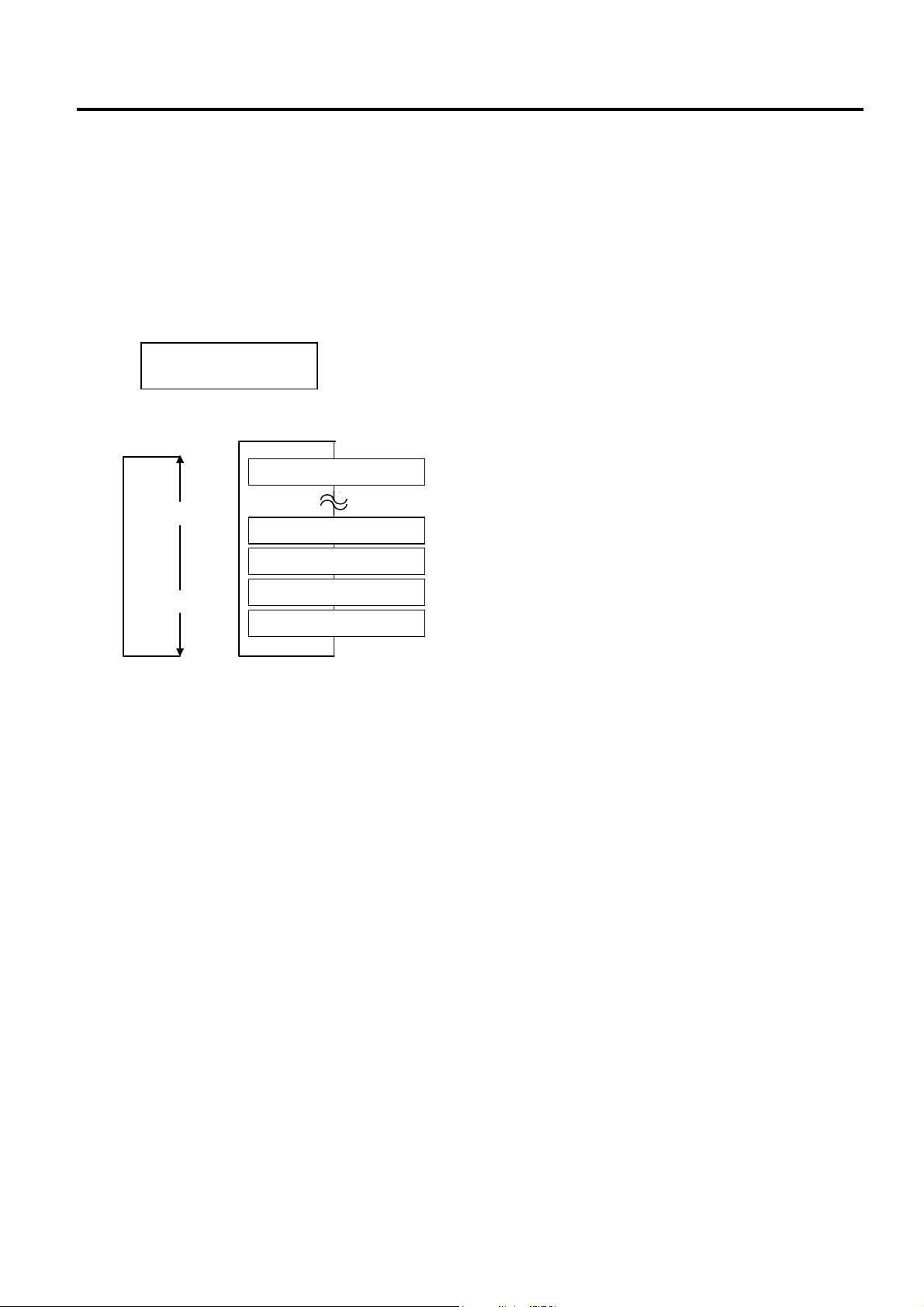

System mode consists of ten main menus: Self-diagnostic test, Parameter setting, Printer parameter fine

adjustment, Test print, Sensor adjustment, RAM clear, IP address setting, Basic setting, and Factory mode.

Each menu is used for the following purposes:

• To check and print the system status, the Maintenance Counter, and the Print Head Element.

• To set the parameters for the communication with the host computer, and the printer functions such as

the language for LCD message, Feed key function, etc.

• To make fine adjustment related to the media issue.

• To perform a test print for checking print quality.

• To check the status of the sensors and to set the threshold of the media sensor for pre-printed media.

• To perform a Maintenance Counter clear and Parameter clear.

• To set the IP address

• To set the Basic setting

• To perform the factory mode

To enter System mode, turn on the printer while pressing the [FEED] and [PAUSE] keys at the same time.

Hold both keys until “<1>DIAG. Vx.x” message appears on the display.

<1>DIAG. Vx.x

[FEED]

[RESTART]

[PAUSE]

This is the start of the Self-Diagnostic Test

menu. → Section 2.1

<2>PARAMETER SET

[PAUSE]

[FEED]

<3>ADJUST SET

[FEED]

<4>TEST PRINT

[FEED]

<5>SENSOR ADJ.

[RESTART]

[PAUSE]

[RESTART]

[PAUSE]

[RESTART]

[PAUSE]

[FEED]

<6>RAM CLEAR

[RESTART]

[PAUSE]

[FEED]

<7>IP ADDRESS

[FEED]

[RESTART]

[PAUSE]

[RESTART]

This is the start of the Parameter Setting

menu. → Section 2.2

This is the start of the Printer Parameter Fine

djustment menu. → Section 2.3

This is the start of the Test Print menu.

→ Section 2.4

This is the start of the Sensor Adjustment

menu. → Section 2.5

This is the start of the RAM Clear menu.

→ Section 2.6

This is the start of the IP Address Setting

menu. → Section 2.7

Continued on the next page.

2- 1

Page 8

2. SYSTEM MODE EO13-33002

(Revision Date: Jul. 24, 2008)

2. SYSTEM MODE

Continued from the previous page.

<8>BASIC

[FEED]

<9>FOR FACTORY

[RESTART]

[PAUSE]

[PAUSE]

This is the start of the Basic Setting menu.

→ Section 2.8

This is the start of the Factory Mode menu.

[FEED]

<10>RFID

[FEED]

[RESTART]

[PAUSE]

This is the RFID Module Setting menu.

→ Section 2.9

NOTES: 1. System Mode menu can be selected with the [RESTART] or [FEED] key.

2. Pressing the [PAUSE] key allows you to enter the sub menus of each System Mode menu.

Flowcharts of each menu’s sub menus are provided on the following pages.

3. “x.x” of “DIAG. Vx.x” indicates firmware version and revision.

2- 2

Page 9

2. SYSTEM MODE EO13-33002

2.1 Self-diagnostic Test

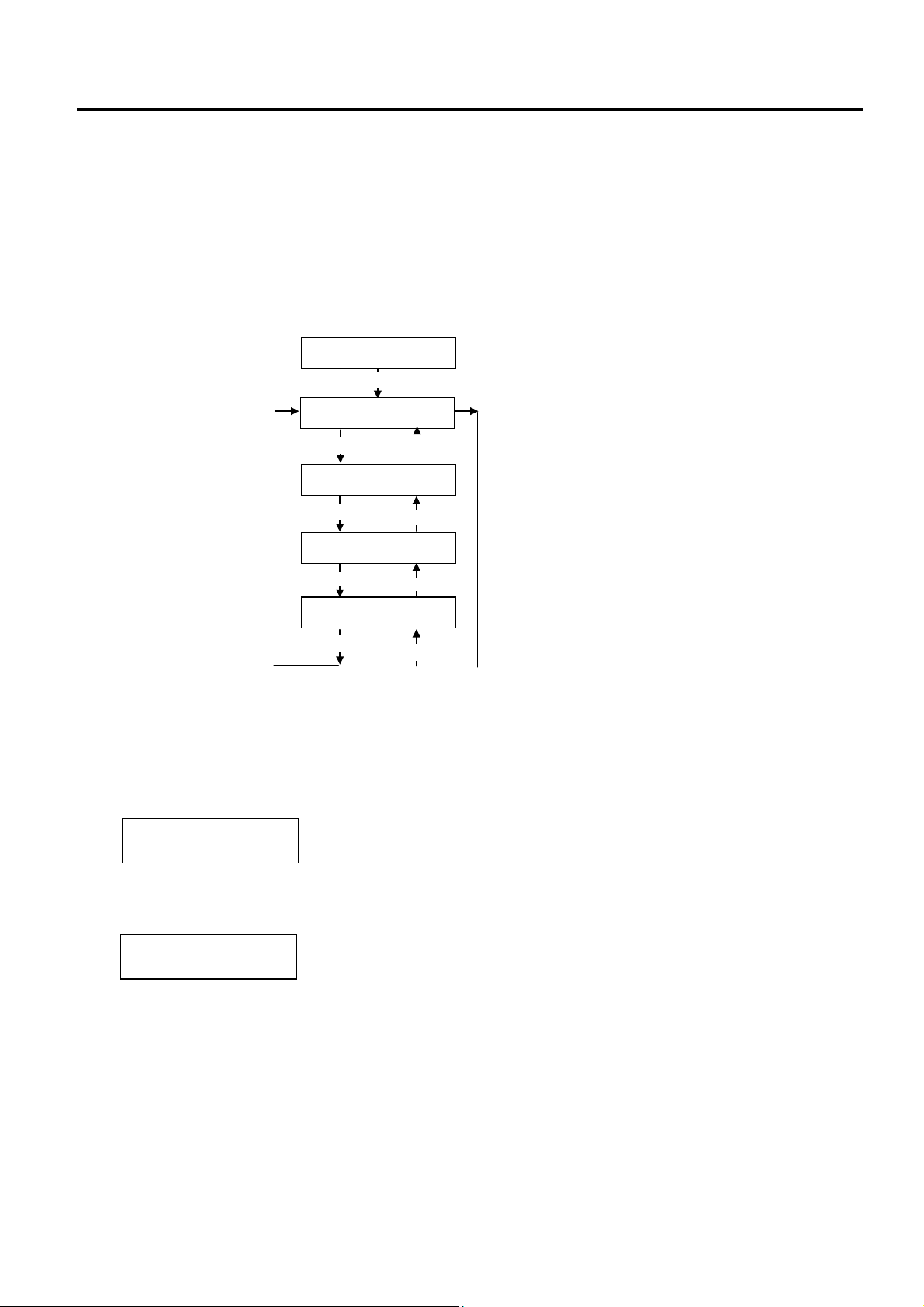

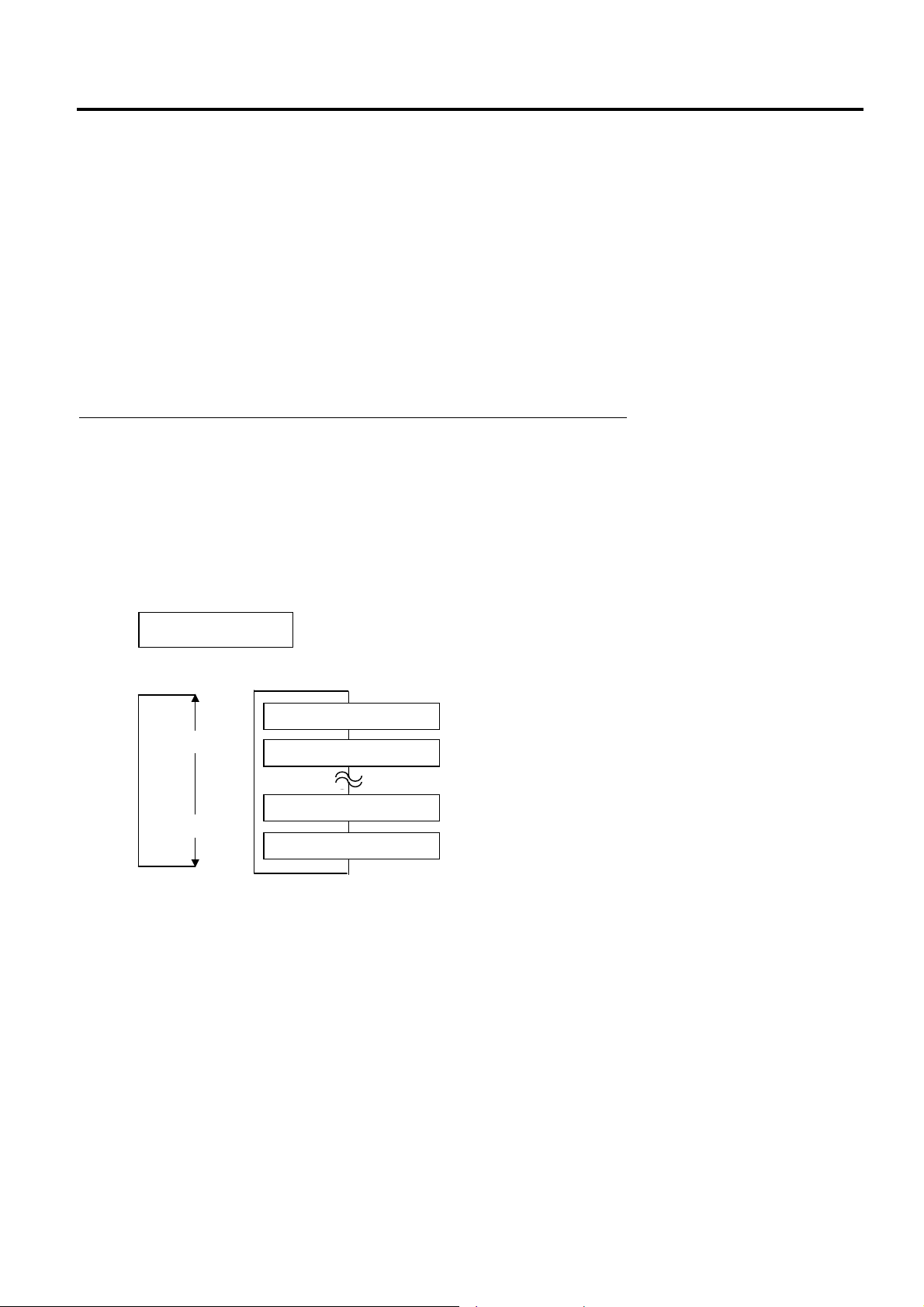

2.1 Self-diagnostic Test

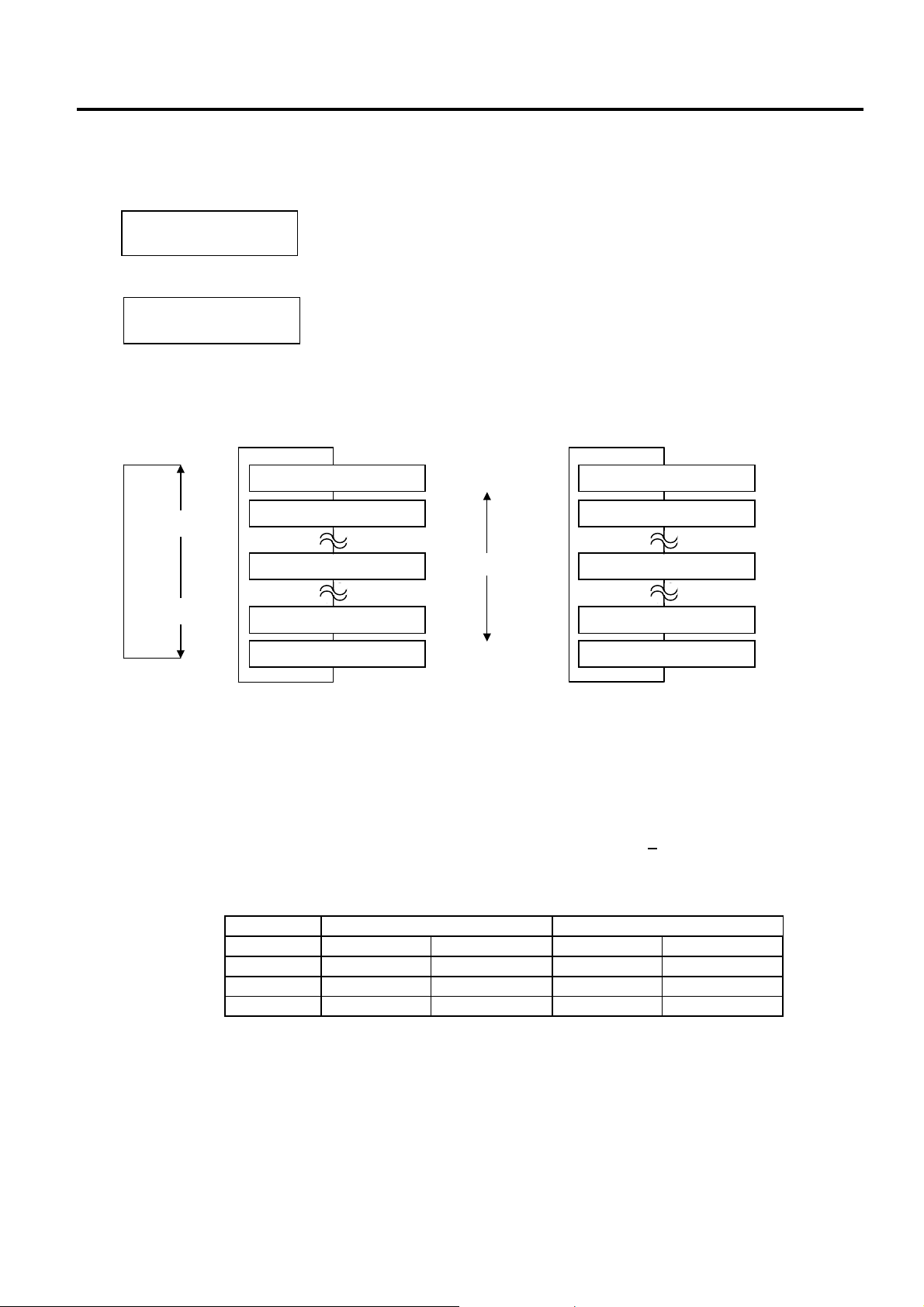

Outline of Self-diagnostic Test

In the Self-diagnostic test mode, the printer automatically checks and prints out the printer system

information such as the sensor status or interface, and the maintenance counter. Also it performs a print

head broken element check.

The Self-diagnostic test contains the following sub menus:

NOTE: Use the [FEED] or [RESTART] key to select a desired option.

How to Enter Self-diagnostic Test Mode

Turn on the printer while pressing the [FEED] and [PAUSE] keys at the same time. Hold both keys until the

“<1>DIAG. Vx.x” message appears in the display.

<1>DIAG. Vx.x

[PAUSE]

<1>DIAG. Vx.x

PRT TYPE TRANSFR

[PAUSE]

<1>DIAG. Vx.x

TYPE[S] NO CUT

[PAUSE]

<1>DIAG. Vx.x

MAINTENANCE CONT.

[FEED]

<1>DIAG. Vx.x

AUTO DIAGNOSTIC

[FEED]

<1>DIAG. Vx.x

HEAD CHECK

[FEED]

<1>DIAG. Vx.x

[RESTART]

[RESTART]

[RESTART]

[PAUSE]

[PAUSE]

[PAUSE]

Selection of the printing mode.

Selection of the dispensing mode.

Prints out the Maintenance Counter /Parameter Settings.

Performs a Self-Diagnostic Test, and prints out the result.

Checks to see if there is any problem with the print head.

2- 3

Page 10

2. SYSTEM MODE EO13-33002

2.1 Self-diagnostic Test

2.1.1 Printing Mode Selection

While “PRT TYPE TRANSFR” is displayed on the LCD, press the [PAUSE] key. The type of printing mode

can be selected:

“TRANSFR” (Thermal transfer) or “DIRECT” (Thermal direct).

After selecting the printing mode to be used, press the [PAUSE] key.

[RESTART]

NOTE: When using the ribbon, be sure to select “Thermal Transfer”. When using the thermal media, be sure to

[FEED]

select the “Thermal Direct”.

<1>DIAG. Vx.x

PRT TYPE TRANSFR

<1>DIAG. Vx.x

PRT TYPE NO TRAN

<1>DIAG. Vx.x

PRT TYPE DIRECT

Thermal transfer: When transparent ribbon is used.

Thermal transfer: When non-transparent ribbon is used.

Thermal direct: When thermal paper is used.

2.1.2 Dispensing Mode Selection

When “TYPE[S] NO CUT” is displayed, press the [PAUSE] key. The type of dispensing mode can be

selected:

“[S] NO CUT” (Batch issue) or “[C] WITH CUT” (Cut issue)

After selecting the dispensing mode to be used, press the [PAUSE] key.

[RESTART]

NOTE: When using the cutter module, be sure to select “[C] WITH CUT”. When the cutter module is not

installed, be sure to select “[S] NO CUT”.

[FEED]

<1>DIAG. Vx.x

TYPE[S] NO CUT

<1>DIAG. Vx.x

TYPE[C] WITH CUT

[S] NO CUT (Batch issue): To issue media in batch

mode.

[C] WITH CUT (Cut issue): When an optional cutter

module is installed.

2- 4

Page 11

2. SYSTEM MODE EO13-33002

A

A

2.1 Self-diagnostic Test

2.1.3 Maintenance Counter/Parameter Settings Print Out

When “MAINTENANCE CONT” is displayed, the printer is ready to print out the Maintenance

Counter/Parameter Settings. Press the [PAUSE] key to start.

<1>DIAG. Vx.x

MAINTENANCE CONT

• Print Sample

[PAUSE]

(1)

TOTAL FEED 1.1km [QM]

(2)

FEED 1.1km

(3)

PRINT 0.5km

(4)

CUT 96

(5)

HEAD U/D 12320

(6)

RIBBON 3h

(7)

SOLENOID 2h

(8)

232C ERR 255

(9)

SYSTEM ERR 0

(10)

POWER FAIL 0

[PC] [KEY]

(11)

FEED +2.0mm FEED +0.0mm

(12)

CUT +0.0mm CUT +1.0mm

(13)

BACK +0.0mm BACK +0.0mm

(14)

TONE(T) +0 step TONE(T) +0 step

(15)

TONE (D) +0 step TONE(D) +0 step

(16)

RBN(FW) -10 RBN (FW) -8

(17)

RBN (BK) +0 RBN (BK) +0

(18)

X ADJ. +0.0mm

(19)

THRESHOLD (R) 1.0V

(20)

THRESHOLD (T) 1.4V

(21)

FONT [PC-850] [0]

(22)

SPEED [9600]

(23)

DATA LENG. [8]

(24)

STOP BIT [1]

(25)

PARITY [EVEN]

(26)

CONTROL [XON+READY AUTO]

(27)

MESSAGE [ENGLISH]

(28)

FORWARD WAIT [ON] +0.0mm

(29)

HEAD UP CUT [ON]

(30)

RIBBON SAVE [ON:LABEL]

(31)

CODE [AUTO]

(32)

RIBBON [TRANS]

(33)

PEEL OFF STATUS [ON]

(34)

FEED KEY [FEED]

(35)

KANJI [TYPE1]

(36)

EURO CODE [B0]

(37)

(38)

(39)

(40)

(41)

(42)

(43)

(44)

(45)

(46)

(47)

(48)

UTO HD CHK [OFF]

CK/BUSY [TYPE1]

WEB PRINTER [OFF]

SENSOR POSITION [CENTER]

INPUT PRIME [ON]

EX. I/O MODE [TYPE1]

PLUG & PLAY [OFF]

LBL/RBN END [TYPE1]

PRE PEEL OFF [ON] +0.0mm

BACK SPEED [STD]

MAXI CODE SPEC. [TYPE1]

PEEL OFF TRQ [R3]

------------------------------------------------------------------------------

<1>DIAG. Vx.x

CHECKING & PRINT

<1>DIAG. Vx.x

2- 5

Page 12

2. SYSTEM MODE EO13-33002

A

(Revision Date: Jul. 24, 2008)

2.1 Self-diagnostic Test

-------------------------------------------------------------------------------

(49)

STABILIZER [ON]

(50)

(51)

(52)

(53)

(54)

(55)

(56)

(57)

(58)

(59)

(60)

(61)

(62)

(63)

(64)

(65)

(66)

(67)

(68)

(69)

(70)

(71)

(72)

(73)

(74)

(75)

(76)

(77)

(78)

(79)

(80)

(81)

UTO CALIB. [OFF]

LAN [ON SNMP ON]

PRTR IP ADDRESS [192.168.010.020]

GATE IP ADDRESS [000.000.000.000]

SUBNET MASK [255.255.255.000]

MAC ADDRESS [00-80-91-34-00-CC]

TTF AREA [1280KB]

EXT CHR AREA [ 256KB]

BASIC AREA [ 128KB]

PC SAVE AREA [ 128KB]

SOCKET PORT [OFF][08000]

BASIC [OFF]

BASIC TRACE [OFF]

DHCP [OFF]

DHCP ID [FFFFFFFFFFFFFFFFFFFF]

[FFFFFFFFFFFF]

DHCP HOST NAME [ ]

RTC BATT. CHK [ON]

RTC RENEWAL [PAGE]

RFID MODULE [U2]

RFID TAG TYPE [NONE ]

RFID ERR CHECK [OFF]

RFID RETRY [ 3]

RFID RD CYCLE [ 5] [2.0sec]

RFID WT CYCLE [ 5] [2.0sec]

RFID ADJ RETRY [+00mm]

RFID POWER LEV [ 18]

RFID AGC THR. [0]

RFID Q VAL [0]

RFID WT AGC [ 0]

RFID WT AGC MIN [ 0]

RFID WT OK TAGS 0

RFID VOID PRINT TAGS 0

NOTE: Print conditions:

Print speed: 4”/sec., Sensor: No sensor, Printing mode: Thermal transfer/Direct thermal

length: 240 mm, Issue mode: Batch printing

(*1) Depends on the printing mode setting.

(*1)

, Media

2- 6

Page 13

2. SYSTEM MODE EO13-33002

(Revision Date: Jul. 24, 2008)

2.1 Self-diagnostic Test

• Descriptions of the Maintenance Counter

# Item Count Condition Range

(1) Total media distance

covered

(2) Media distance

covered

(3) Print distance Counts while printing. (Reverse feed is not counted.) See NOTE 3. 0.0 to 200.0 km

(4) Cut count Counts every cut. See NOTE 4. 0 to 1000000 times

(5) Head up and down

cycle count

(6) Ribbon motor driving

time

(7) Solenoid drive time for

head up

(8) RS-232C hardware

error count

(9) System error count Counts when a system error occurs. 0 to 15 times

(10) Momentary power

failure count

(80) Number of successful

RFID write

(81) Number of failure in

RFID write

Counts when the feed motor is driven to feed, print or issue media.

(Counted also during a reverse feed.) See NOTE 2.

Destination printed on the same line indicates one selected for a

parameter clear.

Counts every head up and down cycle by means of the solenoid which

is used for the ribbon save function. See NOTE 4.

Counts when the ribbon motor is driven to feed, print or issue media.

(The driving time is also counted during a reverse feed.) See NOTE 5.

Counts when the ribbon save function is activated. See NOTE 5. 0 to 1000 hours

Counts when a parity, overrun or framing error occurs. See NOTE 6. 0 to 255 times

Counts when a momentary power interruption occurs. 0 to 15 times

Counts when an RFID write has succeeded. 0 to 9999999 times

Counts when an RFID write has failed. 0 to 9999999 times

0.0 to 3200.0 km

0.0 to 3200.0 km

0 to 2000000 times

0 to 2000 hours

NOTES:

1. Item from (2) through (10) are initialized to “0” after RAM clear.

2. If the media distance covered is 50.0 cm or less, it is rounded down and no data is added to the memory at power off.

3. If the print distance is 5.5 m or less, it is rounded down and no data is added to the memory at power off.

4. If the count is 31 or less, it is rounded down and no data is added to the memory at power off.

5. If the driving time is 27 sec. or less, it is rounded down and no data is added to the memory at power off.

6. When a sent command results in an error, the same number as the data capacity of the command is counted by byte.

2- 7

Page 14

2. SYSTEM MODE EO13-33002

(Revision Date: Mar. 26, 2009)

2.1 Self-diagnostic Test

• Descriptions of the Parameters

Item # Description Specification

FEED (11) Print start position fine adjustment (PC), (KEY) -50.0 mm to +50.0 mm

CUT (12) Cut/strip position fine adjustment (PC), (KEY) -50.0 mm to +50.0 mm

BACK (13) Reverse feed amount fine adjustment (PC), (KEY) -9.9 mm to +9.9 mm

TONE(T) (14) Print tone fine adjustment (Thermal transfer), (PC), (KEY) -10 step to +10 step

TONE(D) (15) Print tone fine adjustment (Thermal direct), (PC), (KEY) -10 step to +10 step

RBN(FW) (16) Ribbon take-up motor driving voltage fine adjustment

(PC), (KEY)

RBN(BK) (17) Ribbon feed motor driving voltage fine adjustment (PC),

(KEY)

X ADJ. (18) X coordinate fine adjustment -99.9 mm to +99.9 mm

THRESHOLD<R> (19) Threshold manual fine adjustment for the black mark

sensor

THRESHOLD<T> (20) Threshold manual fine adjustment for the feed gap sensor 0.0V to 4.0V

FONT (21)

SPEED (22) Baud rate 2400: 2400 bps 19200: 19200 bps

DATA LENG. (23) Data length 7: 7 bits

STOP BIT (24) Stop bit length selection 1: 1 bit

PARITY (25) Parity NON: None

CONTROL (26) Flow control code XON/XOFF: XON/XOFF

MESSAGE (27) Language selection for LCD message ENGLISH: English

FORWARD WAIT (28) Auto forward wait ON: Available

HEAD UP CUT (29) Head up cut in cut issue mode ON: Activated

RIBBON SAVE (30) Ribbon saving function ON(TAG): Activated

CODE (31) Control code selection AUTO: Automatic selection

Character code PC-850 PC-851 PC-1252 LATIN9 PC-852

Character “0” 0: without slash

-15 step to +0 step

-15 step to +10 step

0.0V to 4.0V

PC-855 PC-1253 Arabic PC-857 PC-1250

PC-1254 PC-8 PC-1251 PC-1257 PC-866

UTF-8

0: with slash

4800: 4800 bps 38400: 38400 bps

9600: 9600 bps 115200: 115200 bps

8: 8 bits

2: 2 bits

ODD: ODD

EVEN: EVEN

READY/BUSY: READY/BUSY (DTR)

XON+READ AUTO:

XON/XOFF+READY/BUSY (DTR)

XON/XOFF AUTO: XON/XOFF

READY/BUSY RTS: RTS

GERMAN: German

FRENCH: French

DUTCH: Dutch

SPANISH: Spanish

JAPANESE: Japanese

ITALIAN: Italian

OFF: Unavailable

NOTE: The stop position fine adjustment

value is also printed out.

OFF: Not activated

(When the head lever is set to

the tag position.)

ON(LBL): Activated

(When the head lever is set to

the label position.)

OFF: Not activated

ESC LF NUL: ESC LF NUL mode

{ | }: Mainframe mode

xx xx xx: Optional code

(The values are given in HEX.)

2- 8

Page 15

2. SYSTEM MODE EO13-33002

(Revision Date: Mar. 26, 2009)

2.1 Self-diagnostic Test

Item # Description Specification

RIBBON (32) Ribbon type selection TRANS: Transparent ribbon

NON TRANS: Non transparent ribbon

PEEL OFF STATUS (33) Strip wait status selection ON: Available

OFF: Unavailable

FEED KEY (34) Feed key function FEED: Feeds one label

PRINT: Prints image buffer on one label

KANJI (35) Kanji code type (Not supported by QM model) TYPE 1: Windows code

TYPE 2: Original code

EURO CODE (36) Euro font code 20H to FFH

AUTO HD CHK (37) Auto print head broken element check ON: Available

OFF: Unavailable

ACK/BUSY (38) Centronics interface ACK/BUSY timing setting TYPE1: A rise of ACK signal and a release

of BUSY occur at the same time.

TYPE2: A fall of ACK signal and a release

of BUSY occur at the same time.

WEB PRINTER (39) Web printer function ON: Available

OFF: Unavailable

SENS POSI (40) Media sensor CENTER: Fixed sensor

EDGE: Movable sensor

INPUT PRIME (41) Input prime selection

(Reset operation when INIT signal is ON)

EX. I/O MODE (42) Expansion I/O interface operating mode TYPE1: Standard mode

PLUG&PLAY (43) Plug & Play setting ON: Available

LBL/RBN END (44) Print processing setting at the label/ribbon error detection TYP1: Printing is paused in the middle of

PRE PEEL OFF (45) Pre-Strip setting OFF: Unavailable

BACK SPEED (46) Reverse Feed Speed setting STD: 3”/second

MAXI CODE SPEC. (47) MAXI code specification selection TYPE1: Compatible with the current

PEEL OFF TRQ (48) Strip motor torque R0: Standard

STABILIZER (49) Stabilizer function ON: Stabilizer function is used.

AUTO CALB. (50) Automatic calibration OFF: Disabled

LAN (51) Enabling or disabling the LAN ON SNMP ON: LAN Enabled

PRTR IP ADDRESS (52) Printer IP address ***.***.***.***

GATE IP ADDRESS (53) Gateway IP address ***.***.***.***

SUBNET MASK (54) Subnet mask ***.***.***.***

MAC ADDRESS (55) MAC (Media Access Control) address for LAN controller

on the MAIN PC Board

TTF AREA (56) True type font registration area size 0 KB to 3072 KB (unit of 128 KB)

EXT CHR AREA (57) External character registration area size 0 KB to 3072 KB (unit of 128 KB)

BASIC AREA (58) BASIC file store area size 0 KB to 1792 KB (unit of 128 KB)

PC SAVE (59) PC saving area size 0 KB to 3072 KB (unit of 128 KB)

SOCKET PORT (60) Socket port number ON: Available

ON: Available

OFF: Unavailable

TYPE2: Inline mode

OFF: Unavailable

printing.

TYP2: Printing is paused after the label is

issued.

LOW: 2”/second

version

TYPE2: Special specification

OFF: Stabilizer function is not used.

ON TRANS: Enabled with the transmissive

sensor

ON REFLECT: Enabled with the reflective

sensor

SNMP Enabled

ON SNMP OFF: LAN Enabled

SNMP Disabled

OFF: LAN Disabled

¶¶-¶¶-¶¶-¶¶-¶¶-¶¶

OFF: Unavailable

Port No. 0 to 65535

2- 9

Page 16

2. SYSTEM MODE EO13-33002

(Revision Date: Mar. 26, 2009)

2.1 Self-diagnostic Test

Item # Description Specification

BASIC (61) BASIC interpreter setting ON: Available

OFF: Unavailable

BASIC TRACE (62) BASIC interpreter trace setting ON: Available

OFF: Unavailable

DHCP (63) DHCP function setting ON: Available

OFF: Unavailable

DHCP ID (64) DHCP ID setting Max. 16 characters

DHCP HOST NAME (65) DHCP host name Max. 16 characters

RTC BATT. CHK (66) RTC Low Battery Check setting ON: Available

OFF: Unavailable

RTC RENEWAL (67) RTC data renewal timing BATCH: per batch

PAGE: per page

RFID MODULE (68) RFID module type NONE: No RFID kit is installed.

U2: U2 B-SX708-RFID-U2-EU-R,

B-SX708-RFID-U2-CN-R

RFID TAG TYPE (69) RFID tag type NONE: 11

EPC C1 Gen2: 24

RFID ERR CHECK (70) RFID error tag detection ON: An error tag detection is performed.

OFF: An error tag detection is not

performed.

RFID RETRY (71) Maximum number of RFID issue retries 0 to 255

RFID RD CYCLE (72)

RFID WT CYCLE (73)

RFID ADJ RETRY (74) RFID adjustment for retry -99 mm to +99 mm

RFID POWER LEV (75) RFID wireless power level setting 9 to 18

RFID AGC THR. (76) RFID AGC Threshold Setting 0 to 15

RFID Q VAL (77) RFID Q VAL (Q value) 0 to 5

RFID WT AGC (78) RFID WT AGC (AGC threshold for data write) 0 to 15

RFID WT AGC MIN (79) RFID WT MIN AGC (AGC threshold lower limit for retry) 0 to 15

Maximum number of RFID read retries

RFID read retry time-out

Maximum number of RFID write retries

RFID write retry time-out

0 to 255

0 sec. to 9.9 sec.

0 to 255

0 sec. to 9.9 sec.

2- 10

Page 17

2. SYSTEM MODE EO13-33002

(Revision Date: Jul. 24, 2008)

2.1 Self-diagnostic Test

2.1.4 Self-Diagnostic Test and Result Print Out

When the Maintenance Counter/Parameter Settings is printed, the message returns to “<1>DIAG. Vx.x”.

Press the [PAUSE] key twice.

The Self-Diagnostic Test is ready. Press the [PAUSE] key to start.

The printer starts a self-diagnosis, and prints out the result. During printing, the message below appears on

the display.

After printing is completed, the display returns to “<1>DIAG. Vx.x”.

NOTE: If an error occurs, an error message appears, the printer stops printing. After clearing the error, press the

• Print Sample

<1>DIAG. Vx.x

AUTO DIAGNOSTIC

<1>DIAG. Vx.x

CHECKING & PRINT

[PAUSE] key to return the display to “<1>DIAG.Vx.x”. The printer does not restart printing automatically.

PROGRAM B-SX8T

(1)

MAIN 15OCT2005 V1.0A: 1A00

BOOT 20SEP2005 V1.0: 8500

FONT AD00

(2)

KANJI GOTHIC :9F00

(3)

MINCHO :7400

EEPROM OK

(4)

SDRAM 16MB

(5)

SENSOR1 00000000, 00000111

(6)

SENSOR2 [H]23°C [A]22°C

(7)

[R]4.2V [T]2.5V

PE LV. [R]1.2V [T]4.3V

(8)

M THRE. [R]5.0V [T]5.0V

(9)

[RANK]1 305DPI

EXP.I/O NG

(10)

EX.232C NG

(11)

SIO NG NG

(12)

STRIP NG

(13)

RFID OK #00RV972 (EU0)

(14)

NOTES: 1. Print conditions: Print speed: 4”/sec., Sensor: No sensor, Printing method: Thermal transfer/Direct

(*1) Depends on the printing mode setting.

2. Software version No., Part No. of ROM and checksum vary according to the

software version of PROGRAM ROM.

3. The last two digits of the checksum are usually “00”.

4. When Kanji ROM is not installed, the checksum becomes “0000”.

5. The symbol “°” of “°C” may not be printed depending on the type of character code.

thermal

(*1)

, Media length: 87 mm, Issue mode: Batch printing

2-11

Page 18

2. SYSTEM MODE EO13-33002

2.1 Self-diagnostic Test

• Descriptions

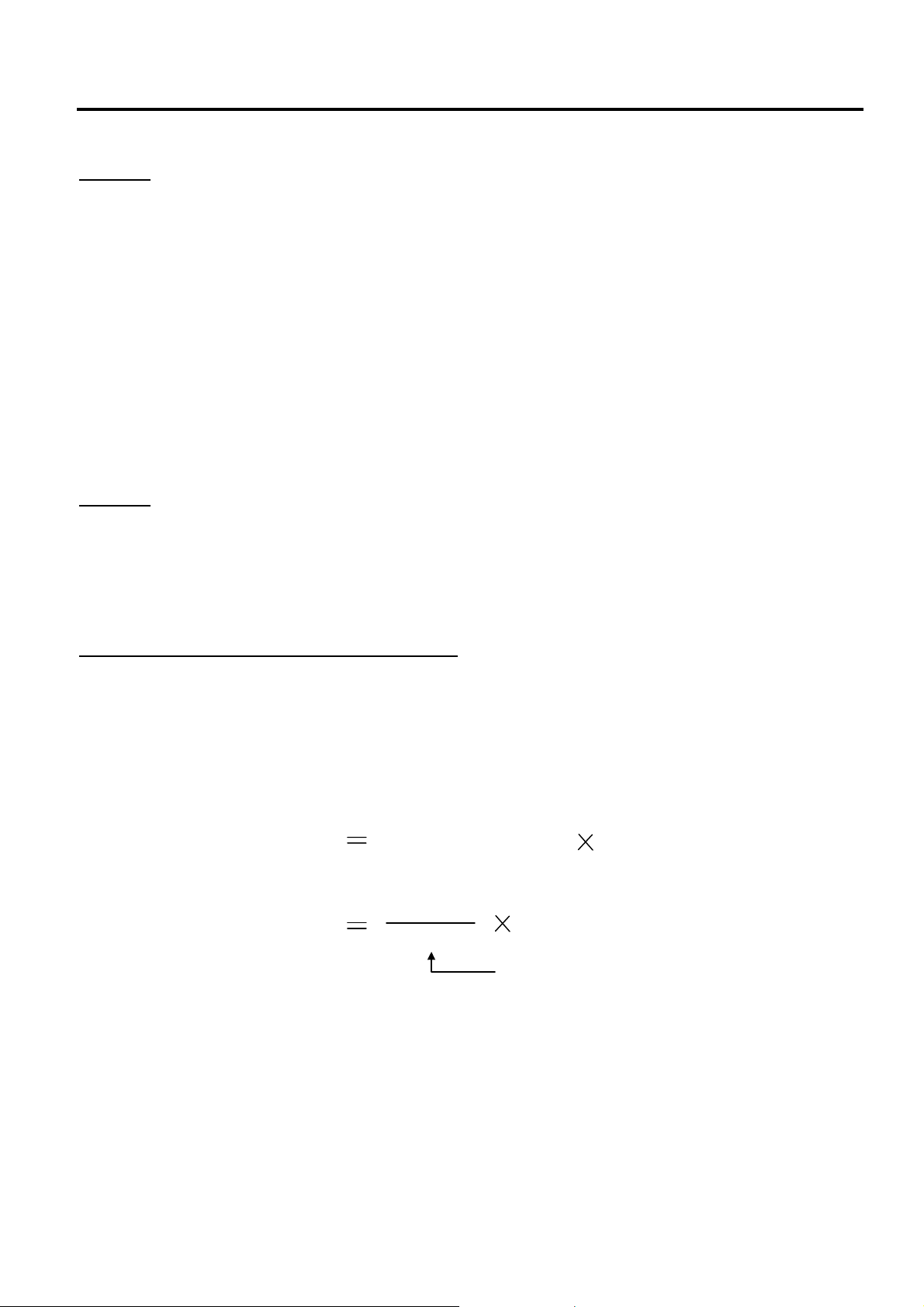

(1) Program ROM Check (Model Name, Date, Version, Part number, Checksum)

PROGRAM B-SX8T

Program area

Model name

MAIN

Main area

Creation date

Software version No.

BOOT

Boot area

Creation date

Software version No.

(2) Alphanumeric Font ROM Check

FONT 5600

Font area

(3) Kanji ROM Check

15OCT2002 V1.0 A : 1A00

Checksum

Revision No.: Space or A to Z

20SEP2002 V1.0: 8500

Checksum

Checksum of Font area

KANJI NONE : 0000

Kanji area

NONE: Kanji ROM is not installed.

GOTHIC: Gothic bit map Kanji ROM is installed.

NONE

: 0000

NONE: Kanji ROM is not installed.

MINCHO: Mincho bit map Kanji ROM is installed.

CHINESE: Chinese character bit map Kanji ROM is installed.

(4) EEPROM Check

EEPROM OK

EEPROM (Backup Memory)

OK: Data in the check area can be properly read/written.

NG (No good): Data in the check area cannot be properly read/written.

Checksum

Checksum

2-12

Page 19

2. SYSTEM MODE EO13-33002

2.1 Self-diagnostic Test

(5) SDRAM Capacity

SDRAM 16MB

System/drawing memory

Capacity of DRAM

(6) Sensor 1 Check

The status of the Strip Sensor, Ribbon Feed Motor Sensor, Ribbon Take-up Motor Sensor, Cutter

Home Position Switch, Head Up Sensor, and Pinch Roller Sensor are printed.

SENSOR1 00000000, 0 1 1 1 0 0 1 1

Fixed to 0.

Pinch roller sensor status

1: The pinch roller is closed.

NOTE: If either the pinch roller or the print head

is opened, printing is not performed.

Head up sensor status

1: The print head is closed.

NOTE: If either the pinch roller or the print head

is opened, printing is not performed.

Cutter home position sensor status

0: Home position

1: Other position

Fixed to 0.

Ribbon take-up motor sensor status

0: The detecting point is positioned outside the slit.

1: The detecting point is positioned inside the slit.

Ribbon feed motor sensor status

0: The detecting point is positioned outside the slit.

1: The detecting point is positioned inside the slit.

Fixed to 0.

Strip sensor status

0: The label is not detected.

1: The label is detected.

Sensor/Switch Print status description

Pinch roller sensor Detects the Open or Close status of the pinch roller. Only when

the pinch roller and the print head are both closed, printing is

performed.

Head up sensor Detects the Open or Close status of the print head. Only when

the pinch roller and the print head are both closed, printing is

performed.

Cutter home position sensor Indicates whether or not the cutter is at the home position.

Ribbon take-up motor sensor

Ribbon feed motor sensor

Controls ribbon motor rotation by detecting the slit on the ribbon

take-up motor and the ribbon feed motor. Indicates the position

of the slit sensor.

Strip sensor Detects whether or not the label is at the paper outlet in strip

printing mode. When the label is not detected, the printer feeds

the label at the print start position.

2-13

Page 20

2. SYSTEM MODE EO13-33002

2.1 Self-diagnostic Test

(7) Sensor 2 Check

The status of the Print Head Thermistor, Ambient Temperature Thermistor, Black Mark Sensor, and

Feed Gap Sensor, Print Head resistance rank, and print head resolution are printed.

SENSOR2 [H]23°C [A]22°C [R]4.2V [T]2.5V

Ambient temperature thermistor status:

0°C to 86°C

If it is undetectable, “--°C “ is printed.

Black mark sensor status:

0.0 to 5.0V

Feed gap sensor status:

0.0 to 5.0V

Print head thermistor status:

0°C to 86°C

Sensor/Thermistor Print status description

Print head thermistor A thermistor built in the print head detects a print head

temperature. The current supplied to the print head (= print tone)

is controlled on the basis of this temperature.

When the print head overheats (80°C or over), the printer

displays “EXCESS HEAT TEMP” message and stops printing to

protect the print head.

Ambient temperature thermistor Temperature inside the printer (around the media) is detected.

The current supplied to the print head (= print tone) is controlled

on the basis of this temperature. When the temperature of 61°C

is detected, an error message, “EXCESS HEAT TEMP”, is

displayed and the printer stops.

Black mark sensor Real time voltage detected by the black mark sensor is

displayed/printed.

Feed gap sensor Real time voltage detected by the feed gap sensor is

displayed/printed.

Print head resistance rank There is individual variability in average resistance of the thermal

element. The current supplied to the print head is controlled on

the basis of this value to obtain the optimal print tone.

(8) Paper End Level Check

PE LV. [R]1.2V [T]4.3V

Paper End Level

Reflective sensor no paper level:

0.0 to 5.0 V

2-14

Transmissive sensor no paper level:

0.0 to 5.0 V

Page 21

2. SYSTEM MODE EO13-33002

2.1 Self-diagnostic Test

(9) Manual Threshold Check

M THRE. [R]5.0V [T]5.0V [RANK]1 305DPI

Thermal head resistance rank:

(See the table below.)

Resolution of head installed

Manual Threshold Check

Reflective sensor manual threshold level:

0.0 to 5.0 V

Transmissive sensor manual threshold level:

0.0 to 5.0 V

Resistance

rank

Average resistance

(ohm)

Resistance

rank

Average resistance

(ohm)

0 1432 to 1454 8 1242 to 1265

1 1409 to 1431 9 1219 to 1241

2 1385 to 1408 10 1195 to 1218

3 1361 to 1384 11 1171 to 1194

4 1337 to 1360 12 1147 to 1170

5 1314 to 1336 13 1124 to 1146

6 1290 to 1313 14 1100 to 1123

7 1266 to 1289 15 1076 to 1099

(10) Expansion I/O Interface Check

Result of a loop back check performed on an expansion I/O interface, which may connect to an

external equipment like a labeller, is printed.

EXP.I/O OK

Expansion I/O PC board

Loopback test

OK: The circuit has no problem.

NG (Not good): The circuit has a problem or loopback jig is not

attached.

Connect the jig like below to the Expansion I/O PC board’s connector and perform a loop back check.

R

R

R

R

R

R

12111098764 531 2

2423222120191816 171513 14

Vcc

GND

LED

R

R = 300 ohms

Connector: FCN-781P024-G/P

2-15

Page 22

2. SYSTEM MODE EO13-33002

j

(Revision Date: Jul. 24, 2008)

2.1 Self-diagnostic Test

(11) Internal Serial Interface Check

EX.232C NG

OK: The circuit has no problem.

NG (Not good): The circuit has a problem or loopback jig is not

attached.

Internal Serial Interface

Connect the jig like below to the serial interface connector and perform a loop back check.

(12) SIO Interface check

Result of optional serial interface check is printed.

SIO NG NG

DIN OK: The circuit has no problem.

NG (Not good): The circuit has a problem or loopback jig

is not attached.

DSUB OK: The circuit has no problem.

NG (Not good): The circuit has a problem or loopback jig is not

attached.

Optional Serial Interface

(13) Strip sensor check

Result of a check of the strip sensor on optional strip module is printed.

STRIP

NG

OK: No problem

NG (Not good): There is a problem or a jig is not attached.

Strip sensor

(14) RFID module check

Results of a RFID module check is printed.

RFID

OK #00RV972 (EU0)

Destination EU0: Europe

RFID module version (Printed only when the result is OK.)

OK: The RFID module has no problem.

NG (No good): The RFID module has a problem or loop back

ig is not attached.

RFID module

2-16

Page 23

2. SYSTEM MODE EO13-33002

2.1 Self-diagnostic Test

2.1.5 Print Head Element Check

This function is used to check for any broken thermal elements of the print head.

If blurred print or missing dots occurs, this check helps you find whether the thermal elements are actually

broken or the print head is just stained.

Also, use this check just after a replacement of a print head to find an initial failure.

When the Self-Diagnostic Test result is printed, the message returns to “<1>DIAG. Vx.x”. Press the

[PAUSE] key three times and [FEED] key twice.

The printer is ready to check the print head to see if there is any problem with the print head. Press the

[PAUSE] key to start.

If there is no problem with the print head, the print head check is complete. Press the [PAUSE] key to

return to “<1>DIAG. Vx.x”.

If there is a problem with the print head, the following message is displayed.

Press the [PAUSE] key to return to “<1>DIAG. Vx.x”.

NOTES: 1. Make sure that the Top Cover is closed before starting the print head check.

2. If “HEAD ERROR” appears, the print head element may be damaged. Replace the print head.

3. The print head element check can be performed at the power on time.

For selecting this function, refer to Section 2.2 Parameter Setting.

<1>DIAG. Vx.x

HEAD CHECK

<1>DIAG. Vx.x

NORMAL END

<1>DIAG. Vx.x

HEAD ERROR

[PAUSE]

<1>DIAG. Vx.x

CHECKING

2-17

Page 24

2. SYSTEM MODE EO13-33002

A

[

[

[

[

[

[

[

A

A

A

[

]

[

]

[

]

[

]

[

]

[

]

[

]

[

]

[

]

[

]

[

]

[

]

p

[

[

[

]

[

]

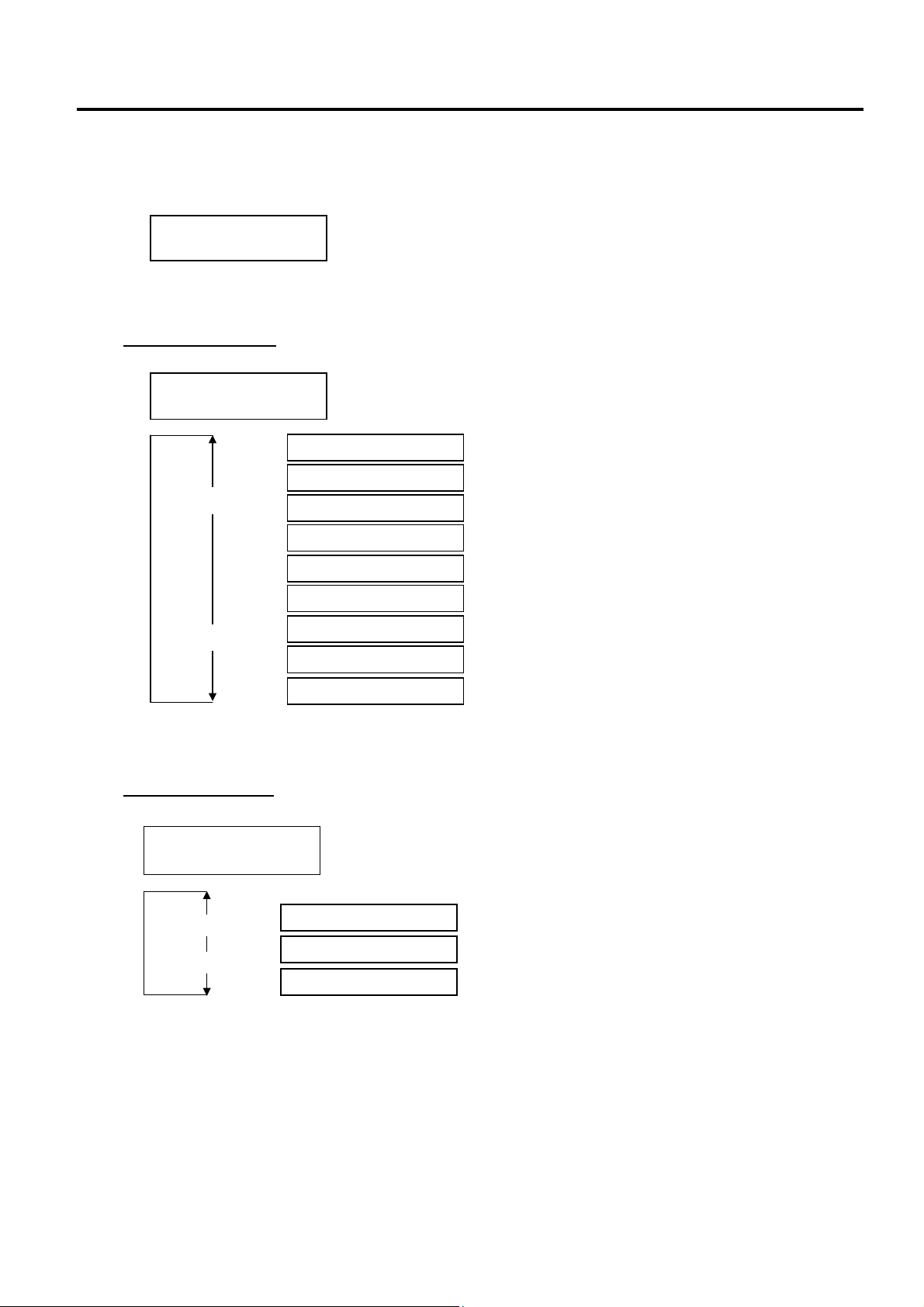

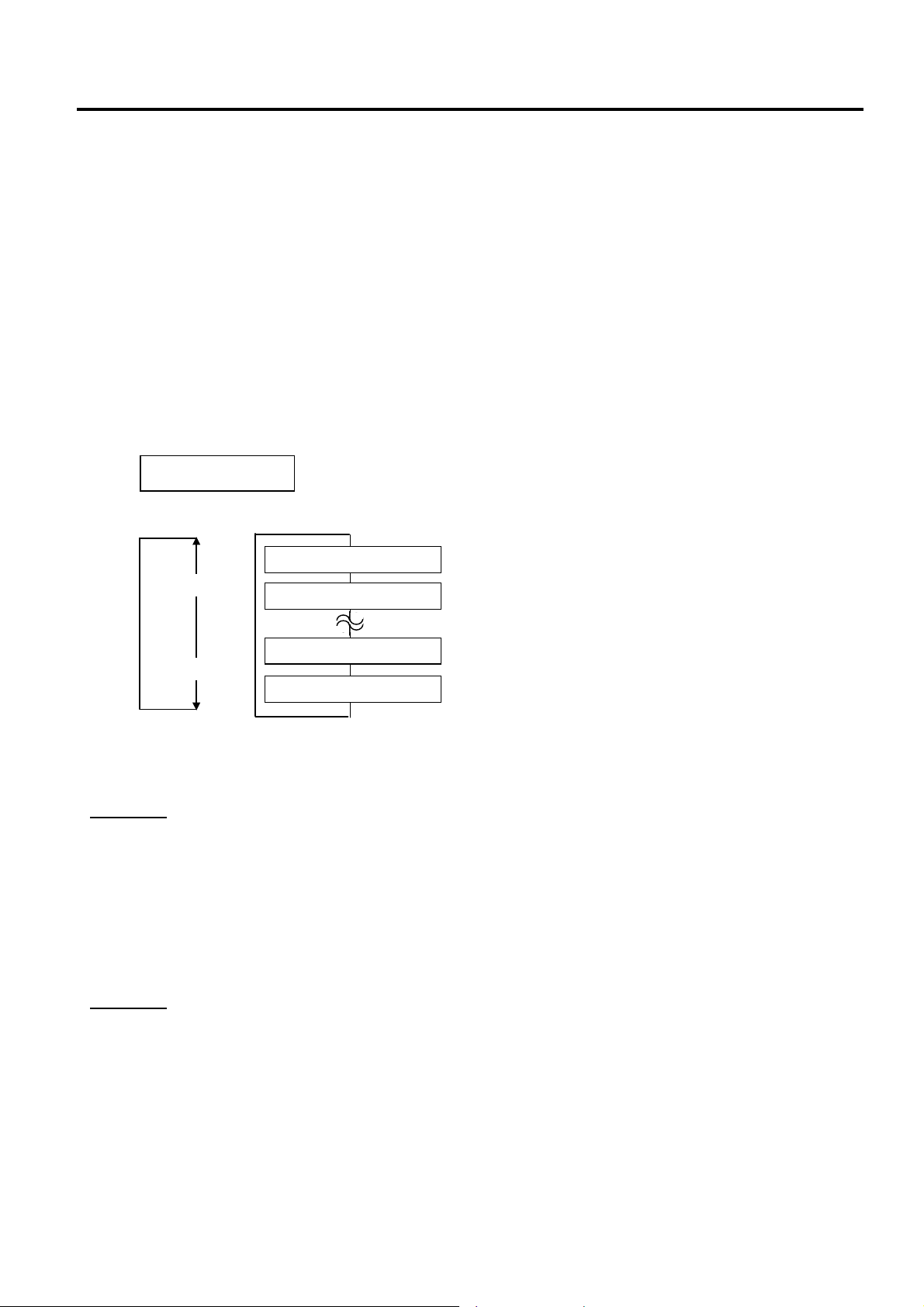

2.2 Parameter Setting

2.2 Parameter Setting

Outline of Parameter Setting

In the Parameter Setting mode, various kinds of parameters, such as communication, key, LCD, etc. can be set.

This will allow a use of the printer to comply with your operating conditions.

The Parameter Setting menu contains the following:

<2>PARAMETER SET

<2>PARAMETER SET

FONT CODE PC-850

<2>PARAMETER SET

ZERO FONT 0

<2>PARAMETER SET

SPEED 9600bps

<2>PARAMETER SET

DATA LENG. 8bits

<2>PARAMETER SET

STOP BIT 1bit

<2>PARAMETER SET

PARITY EVEN

<2>PARAMETER SET

XON+READY AUTO

<2>PARAMETER SET

LCD ENGLISH

<2>PARAMETER SET

FORWARD WAIT OFF

<2>PARAMETER SET

HEAD UP CUT OFF

<2>PARAMETER SET

RBN SAVE ON (TAG)

<2>PARAMETER SET

CODE ESC,LF,NUL

<2>PARAMETER SET

RIBBON NON TRANS

<2>PARAMETER SET

PEEL OFF STS OFF

PAUSE]

PAUSE]

PAUSE]

[PAUSE]

PAUSE]

[PAUSE]

[PAUSE]

PAUSE]

PAUSE]

PAUSE]

PAUSE]

PAUSE]

[PAUSE]

[PAUSE]

[PAUSE]

Character code selection

Character zero selection

Baud rate selection

Data length selection

Stop bit length selection

Parity selection

Flow control code selection

LCD language selection

uto forward wait selection

Head up cut selection

Ribbon save function selection

Control code selection

Ribbon type selection

Strip wait status selection

<2>PARAMETER SET

FEED KEY FEED

[PAUSE]

<2>PARAMETER SET

KANJI CODE TYPE1

[PAUSE]

<2>PARAMETER SET

EURO CODE B0

PAUSE

<2>PARAMETER SET

UTO HD CHK OFF

PAUSE

<2>PARAMETER SET

CK/BUSY TYPE1

PAUSE

<2>PARAMETER SET

WEB PRINTER OFF

PAUSE

<2>PARAMETER SET

SENS POSI CENTER

PAUSE

<2>PARAMETER SET

INPUT PRIME OFF

PAUSE

<2>PARAMETER SET

EX.I/O TYPE1

PAUSE

<2>PARAMETER SET

PLUG & PLAY OFF

PAUSE

<2>PARAMETER SET

LBL/RBN END TYPE1

PAUSE

<2>PARAMETER SET

PRE PEEL OFF OFF

PAUSE

<2>PARAMETER SET

BACK SPEED STD

PAUSE

<2>PARAMETER SET

MAXI CODE TYPE1

PAUSE

<2>PARAMETER SET

PEEL OFF TRQ R0

PAUSE

<2>PARAMETER SET

STABILIZER ON

PAUSE

Feed key function selection

Kanji code selection

Euro code selection

uto print head check selection

Centronics ACK/BUSY timing

selection

Web printer function selection

Media sensor selection

Input prime selection

Expansion I/O interface type

selection

Plug & Play selection

Label end/Ribbon end selection

Pre-strip selection

Reverse feed speed selection

Maxi code specification selection

motor torque selection

Stri

Stabilizer function selection

NOTE: Baud rate, Data length, Parity, and Transmission control code should be set to the same values as those of the host

computer. Failure to do this causes improper operation.

2-18

Page 25

2. SYSTEM MODE EO13-33002

2.2 Parameter Setting

How to Enter Parameter Setting Mode

Turn on the printer while pressing the [FEED] and the [PAUSE] keys at the same time. Hold both keys

until the “<1>DIAG. Vx.x” message appears.

<1>DIAG. Vx.x

Press the [FEED] key. The printer is at the start of the Parameter Setting menu.

<2>PARAMETER SET

2.2.1 Character Code Selection

This parameter is to choose a character code used for printing. Printed characters differ depending on a

chosen character code and font. For details of characters, refer to the B-SX6T/SX8T Series External

Equipment Interface Specification (Printer Command Manual).

When “<2>PARAMETER SET” appears, press the [PAUSE] key.

<2>PARAMETER SET

FONT CODE PC-850

Use the [FEED] or [RESTART] key to select a desired option.

[RESTART]

[FEED]

After selecting a character code, press the [PAUSE] key.

NOTES: 1. When pressing the [FEED] and [RESTART] keys at the same time in the parameter setting, the

message returns to “<2>PARAMETER SET”.

2. If holding the [FEED] or [RESTART] key for 0.5 seconds or longer in the parameter setting the key

is entered continuously.

3. A changed parameter becomes effective by pressing the [PAUSE].

FONT CODE PC-8

FONT CODE PC-857

FONT CODE PC-852

FONT CODE PC-850

FONT CODE Arabic

FONT CODE LATIN9

FONT CODE PC1257

FONT CODE PC1254

FONT CODE PC1253

FONT CODE PC1252

FONT CODE PC1251

FONT CODE PC1250

FONT CODE PC-850

FONT CODE PC-851

FONT CODE PC-866

FONT CODE UTF-8

2-19

Page 26

2. SYSTEM MODE EO13-33002

2.2 Parameter Setting

2.2.2 Character Zero Selection

This parameter is to choose the way to indicate zero between “0” and “Ø”.

When “<2>PARAMETER SET” appears, press the [PAUSE] key twice.

<2>PARAMETER SET

ZERO FONT 0

Use the [FEED] or [RESTART] key to select a desired option.

After selecting a character zero, press the [PAUSE] key.

NOTE: The following fonts do not support a zero with slash.

Bit Map Font: OCR-A, OCR-B, GOTHIC 725 Black, Kanji, Chinese

Outline Font: Price Font 1, Price Font 2, Price Font 3, DUTCH 801 Bold, BRUSH 738 Regular, GOTHIC

[RESTART]

[FEED]

ZERO FONT 0

ZERO FONT Ø

725 Black, True Type Font

(Without slash)

(With slash)

2.2.3 Baud Rate Selection

This parameter is to choose a baud rate of the RS-232C interface. When the printer communicates with a

host computer by serial interface, be sure to match the setting with the host.

When “<2>PARAMETER SET” appears, press the [PAUSE] key until the following display appears.

<2>PARAMETER SET

SPEED 9600bps

Use the [FEED] or [RESTART] key to select a desired option.

[RESTART]

[FEED]

After selecting a baud rate, press the [PAUSE] key.

SPEED 115200 bps

SPEED 38400 bps

SPEED 19200 bps

SPEED 9600 bps

SPEED 4800 bps

SPEED 2400 bps

2-20

Page 27

2. SYSTEM MODE EO13-33002

2.2 Parameter Setting

2.2.4 Data Length Selection

This parameter is to choose a communication data length of the RS-232C interface.

7 bits is used when transmitting alphanumeric data only. 8 bits is used to when transmitting special

characters. Be sure to match a setting with a host computer.

When “<2>PARAMETER SET” appears, press the [PAUSE] key until the following display appears.

<2>PARAMETER SET

DATA LENG. 8bits

Use the [FEED] or [RESTART] key to select a desired option.

[RESTART]

[FEED]

After selecting a data length, press the [PAUSE] key.

DATA LENG. 8bits

DATA LENG. 7bits

2.2.5 Stop Bit Length Selection

This parameter is to choose a stop bit length of the RS-232C interface.

Be sure to match a setting with a host computer.

When “<2>PARAMETER SET” appears, press the [PAUSE] key until the following display appears.

<2>PARAMETER SET

STOP BIT 1bit

Use the [FEED] or [RESTART] key to select a desired option.

[RESTART]

[FEED]

After selecting a stop bit, press the [PAUSE] key.

STOP BIT 1bit

STOP BIT 2bits

2-21

Page 28

2. SYSTEM MODE EO13-33002

2.2 Parameter Setting

2.2.6 Parity Selection

This parameter is to choose the parity of the RS-232C interface.

When “<2>PARAMETER SET” appears, press the [PAUSE] key until the following display appears.

<2>PARAMETER SET

PARITY NONE

Use the [FEED] or [RESTART] key to select a desired option.

[RESTART]

[FEED]

After selecting the parity, press the [PAUSE] key.

PARITY EVEN

PARITY ODD

PARITY NONE

2.2.7 Flow Control Code Selection

This parameter is to choose a flow control code of the RS-232C interface.

When “<2>PARAMETER SET” appears, press the [PAUSE] key until the following display appears.

<2>PARAMETER SET

XON+READY AUTO

Use the [FEED] or [RESTART] key to select a desired option.

[RESTART]

[FEED]

XON/XOFF AUTO

XON+READY AUTO

READY/BUSY

XON/XOFF

READY/BUSY RTS

After selecting a flow control code, press the [PAUSE] key.

NOTE: The following is the detailed descriptions for each transmission control code.

1) XON/XOFF AUTO

At the power on time, the printer outputs XON. At the power off time, the printer outputs XOFF.

2) XON+READY AUTO

At the power on time, the printer outputs XON. At the power off time, the printer outputs XOFF.

3) READY/BUSY

At the power on time, the DTR signal output from the printer turns to High level (READY). At the

power off time, the printer does not output XOFF.

4) ON/XOFF

At the power on time, the printer outputs XON. At the power off time, the printer does not output

XOFF.

5) READY/BUSY RTS

At the power on time, the RTS signal output from the printer turns to High level (READY). At the

power off time, the printer does not output XOFF.

XON/XOFF mode

XON/XOFF+READY/BUSY (DTR) mode

READY/BUSY (DTR) mode

XON/XOFF mode

RTS mode

2-22

Page 29

2. SYSTEM MODE EO13-33002

2.2 Parameter Setting

2.2.8 LCD Language Selection

This parameter is to choose a language in which the LCD message is displayed.

When “<2>PARAMETER SET” appears, press the [PAUSE] key until the following display appears.

<2>PARAMETER SET

LCD ENGLISH

Use the [FEED] or [RESTART] key to select a desired option.

[RESTART]

[FEED]

ENGLISH

ITALIAN

JAPANESE

SPANISH

DUTCH

FRENCH

GERMAN

After selecting a language, press the [PAUSE] key.

2.2.9 Auto Forward Wait Selection

This parameter is to choose whether to activate the Auto Forward Wait function or not.

This function, used in the cut mode, automatically feeds the media forward for about 14 mm if there is more

than 1-second idle time after printing, to prevent the top edge of the media from curling.

When “<2>PARAMETER SET” appears, press the [PAUSE] key until the following display appears.

<2>PARAMETER SET

FORWARD WAIT OFF

Use the [FEED] or [RESTART] key to select a desired option.

[RESTART]

FORWARD WAIT ON

[FEED]

FORWARD WAIT OFF

When ON is selected, pressing the [PAUSE] key will result that the LCD Message Display shows the stop

position fine adjustment value setting screen.

<2>PARAMETER SET

POSITION +0.0mm

[RESTART]

[FEED]

POSITION +5.0mm

POSITION +0.0mm

POSITION -5.0mm

[FEED] key: Pressing the [FEED] key one time causes a –0.1 mm change, up to –5.0 mm.

[RESTART] key: Pressing the [RESTART] key one time causes a +0.1 mm change, up to +5.0 mm.

Activated

Not activated

After selecting an auto forward wait, press the [PAUSE] key.

2-23

Page 30

2. SYSTEM MODE EO13-33002

2.2 Parameter Setting

NOTES: 1. If the printer is not used for a few days, the top edge of the media may become curly, which may

cause a paper jam. The Auto Forward Wait Function prevents this problem since the media feed

amount is increased so that the media stops past the platen.

2. When the Stop Position Fine Adjustment Value is set in + direction, the media will stop past the

media outlet.

When the value is set in – direction, the media will stop inside the media outlet.

3. This setting will be useful to fine adjust the cut position of labels.

2.2.10 Head Up Cut Selection

This parameter is to choose whether to activate the head up action in the cut issue.

This function prevents ribbon smudges by raising the print head during a reverse feed to the print start

position.

When “<2>PARAMETER SET” appears, press the [PAUSE] key until the following display appears.

<2>PARAMETER SET

HEAD UP CUT OFF

Use the [FEED] or [RESTART] key to select a desired option.

[RESTART]

[FEED]

HEAD UP CUT ON

HEAD UP CUT OFF

After selecting the head up action in cut issue, press the [PAUSE] key.

NOTES: 1. For the B-SX6T, this function is available only when an optional ribbon saving module (B-SX908-R-

QM-R) is installed

2. The print head may not be raised depending on the rise of the solenoid’s temperature.

Activated

Not activated

2.2.11 Ribbon Save Function Selection

This parameter is to choose whether to activate the Ribbon Saving function or not.

This function enables reducing the ribbon loss caused by taking up unused ribbon during non-print areas.

When “<2>PARAMETER SET” appears, press the [PAUSE] key until the following display appears.

<2>PARAMETER SET

RBN SAVE ON (TAG)

Use the [FEED] or [RESTART] key to select a desired option.

[RESTART]

[FEED]

RBN SAVE ON (TAG)

RBN SAVE ON (LBL)

RBN SAVE OFF

After selecting the ribbon save function, press the [PAUSE] key.

NOTES: 1. For the B-SX6T, this function is available only when an optional ribbon saving module (B-SX908-R-

QM-R) is installed.

2. If this parameter is set to ON without installing a ribbon saving module, the ribbon will be slack

during paper feed or printing, and as a result, printing cannot be performed properly.

Also, be sure to conform the choice to the actual head lever position. Failure to do this may disable

proper ribbon saving function.

Activated (When the head lever is set to position 2.)

Activated (When the head lever is set to position 1.)

Not activated

2-24

Page 31

2. SYSTEM MODE EO13-33002

2.2 Parameter Setting

3. The ribbon saving function is activated when there is a 20-mm or more non-print area in the media

feed direction.

4. Ribbon saving is enabled up to 4 areas per media.

5. To use the ribbon saving function for more than one area in a label/tag, there should be at least an

8-mm print area between non-print areas where the ribbon saving is performed

2.2.12 Control Code Selection

This parameter is to choose a Control Code.

When “<2>PARAMETER SET” appears, press the [PAUSE] key until the following display appears.

<2>PARAMETER SET

CODE AUTO

Use the [FEED] or [RESTART] key to select a desired option.

[RESTART]

[FEED]

NOTES: 1. This parameter is used to select the Control Code for the communication between the printer and

the host computer.

2. Selecting “Manual” enables you to set the control code.

When “CODE MANUAL” is selected and the [PAUSE] key is pressed, the LCD display will show the setting

screen of CONTROL CODE1 to CONTROL CODE3 as follows.

<2>PARAMETER SET

CONTROL CODE1 1B

[RESTART]

[FEED]

NOTES: 1. Pressing the [FEED] or [RESTART] key causes 1-byte change in the Control Code value.

2. You cannot specify the same control code with the one used for the commands.

3. You cannot use the specified Control Code for the data of the Data Command or Display Command.

CODE AUTO

CODE ESC,LF,NUL

CODE{|}

CODE MANUAL

CONTROL CODE1 FF

CONTROL CODE1 FE

CONTROL CODE1 FD

CONTROL CODE1 02

CONTROL CODE1 01

CONTROL CODE1 00

Automatic selection

Manual selection

Manual selection

Control codes should be specified.

2-25

Page 32

2. SYSTEM MODE EO13-33002

2.2 Parameter Setting

After setting the control code for Control Code 1, press the [PAUSE] key to show the CONTROL CODE2

screen. In a same manner, press the [PAUSE] key after setting the control code for Control Code 2 to

display the CONTROL CODE3 screen.

CONTROL CODE1

CONTROL CODE2

CONTROL CODE3

[PAUSE]

[PAUSE]

Press the [PAUSE] key after setting the control code for Control Code 3.

2.2.13 Ribbon Type Selection

This parameter is to choose a ribbon type to be used.

When “<2>PARAMETER SET” appears, press the [PAUSE] key until the following display appears.

<2>PARAMETER SET

RIBBON TRANS

Use the [FEED] or [RESTART] key to select a desired option.

[RESTART]

[FEED]

After selecting a ribbon type, press the [PAUSE] key.

RIBBON TRANS

RIBBON NON TRANS

Transparent ribbon

Non transparent ribbon

2.2.14 Strip Wait Status Selection

This parameter is to choose when the printer sends a strip wait status (05H) to a host in response to a

status request command.

When “<2>PARAMETER SET” appears, press the [PAUSE] key until the following display appears.

<2>PARAMETER SET

PEEL OFF STS OFF

Use the [FEED] or [RESTART] key to select a desired option.

[RESTART]

PEEL OFF STS OFF

[FEED]

PEEL OFF STS ON

After selecting the Strip Wait Status, press the [PAUSE] key.

A strip wait status is sent when the printer receives the next

issue command and the previously printed label is waiting to

be removed.

A strip wait status is sent when a printed label is waiting to

be removed.

2-26

Page 33

2. SYSTEM MODE EO13-33002

2.2 Parameter Setting

2.2.15 FEED Key Function Selection

This parameter is to choose the function of the [FEED] key.

When “<2>PARAMETER SET” appears, press the [PAUSE] key until the following display appears.

<2>PARAMETER SET

FEED KEY FEED

Use the [FEED] or [RESTART] key to select a desired option.

[RESTART]

[FEED]

FEED KEY FEED

FEED KEY PRINT

The [FEED] key will feed one media when pressed.

The [FEED] key will print the data in the Image Buffer

(The last printed data)

After selecting the FEED key function, press the [PAUSE] key.

2.2.16 KANJI Code Selection

This parameter is to choose a KANJI code.

When “<2>PARAMETER SET” appears, press the [PAUSE] key until the following display appears.

<2>PARAMETER SET

KANJI CODE TYPE1

Use the [FEED] or [RESTART] key to select a desired option.

[RESTART]

[FEED]

KANJI CODE TYPE1

KANJI CODE TYPE2

NOTE: Kanji code selection is not supported by the QM model as the Kanji ROMs are not installed.

Windows code

Original code

After selecting a Kanji code, press the [PAUSE] key.

2.2.17 EURO Code Selection

This parameter is to choose a Euro code (€).

When “<2>PARAMETER SET” appears, press the [PAUSE] key until the following display appears.

<2>PARAMETER SET

EURO CODE B0

Use the [FEED] or [RESTART] key to select a desired option.

[RESTART]

[FEED]

NOTE: Pressing the [FEED] or [RESTART] key causes 1 byte change in the Euro Code value.

After selecting a Euro code, press the [PAUSE] key.

EURO CODE 20

EURO CODE 21

EURO CODE FE

EURO CODE FF

2-27

Page 34

2. SYSTEM MODE EO13-33002

A

2.2 Parameter Setting

2.2.18 Auto Print Head Check Selection

This parameter is to choose whether to perform the Auto Print Head Check function at the power on time.

When “<2>PARAMETER SET” appears, press the [PAUSE] key until the following display appears.

<2>PARAMETER SET

AUTO HD CHK OFF

Use the [FEED] or [RESTART] key to select a desired option.

NOTES: 1. It will take about 2 seconds to perform an Auto Print Head check.

2. It is recommended that this function should be activated when high quality printing such as bar

3. When a broken element is found, the printer stops, displaying “HEAD ERROR”. The error state can

[RESTART]

[FEED]

codes printing is required. Otherwise, choose OFF.

be cleared by pressing the [RESTART] key, but if the broken element affects bar code readability or

actual operations, please replace the print head with a proper one.

AUTO HD CHK OFF

AUTO HD CHK ON

After selecting auto print head check, press the [PAUSE] key.

Auto print head broken element check is not performed.

Auto print head broken element check is performed.

2.2.19 Centronics Interface ACK/BUSY Timing Selection

This parameter is to choose an ACK/BUSY timing of the Centronics interface.

“TYPE1” has been chosen as default, but if a communication error occurs or a communication is not

properly made, change to “TYPE2”.

When “<2>PARAMETER SET” appears, press the [PAUSE] key until the following display appears.

<2>PARAMETER SET

ACK/BUSY TYPE1

Use the [FEED] or [RESTART] key to select a desired option.

[RESTART]

ACK/BUSY TYPE1

[FEED]

ACK/BUSY TYPE2

After selecting an ACK/BUSY timing, press the [PAUSE] key.

rise of ACK signal and a release of BUSY occur at the same

time.

A fall of ACK signal and a release of BUSY occur at the same

time.

2-28

Page 35

2. SYSTEM MODE EO13-33002

2.2 Parameter Setting

2.2.20 Web Printer Function Selection

This parameter is to choose whether to use the printer as a web printer.

When “<2>PARAMETER SET” appears, press the [PAUSE] key until the following display appears.

<2>PARAMETER SET

WEB PRINTER OFF

Use the [FEED] or [RESTART] key to select a desired option.

[RESTART]

[FEED]

After selecting the Web printer function, press the [PAUSE] key.

NOTE: When “WEB PRINTER ON” is selected, the status of the printer connected in a network can be checked

through the Web browser.

WEB PRINTER OFF

WEB PRINTER ON

Unavailable

Available

2.2.21 Media Sensor Selection

This parameter is to choose the media sensor type to be used.

When “<2>PARAMETER SET” appears, press the [PAUSE] key until the following display appears.

<2>PARAMETER SET

SENS POSI CENTER

Use the [FEED] or [RESTART] key to select a desired option.

[RESTART]

[FEED]

After selecting the media sensor type, press the [PAUSE] key.

SENS POSI CENTER

SENS POSI EDGE

Fixed sensor

Movable sensor

2-29

Page 36

2. SYSTEM MODE EO13-33002

2.2 Parameter Setting

2.2.22 Input Prime Selection

This parameter is to choose whether to enable a reset operation when INIT signal is ON.

Normally, when the printer receives a reset request signal (nInit signal) from the host via Centronics

interface, the printer will be reset and turn to the idle state.

When the INPUT PRIME parameter is set to OFF, the printer is reset but does not turn to idle.

When this parameter is set to ON, the host sends an INIT signal and the printer turns to idle each time the

printer is turned on. If you would like to avoid this processing, set this parameter to OFF.

When “<2>PARAMETER SET” appears, press the [PAUSE] key until the following display appears.

<2>PARAMETER SET

INPUT PRIME OFF

Use the [FEED] or [RESTART] key to select a desired option.

[RESTART]

INPUT PRIME OFF

[FEED]

INPUT PRIME ON

After selecting the Input Prime, press the [PAUSE] key.

Unavailable

Available

2.2.23 Expansion I/O Interface Type Selection

This parameter is to choose a type of the Expansion I/O interface operating mode.

This parameter should be set depending on the expansion I/O control specification of the device to be

connected via the expansion I/O interface. For details, refer to the External Equipment Interface

Specification.

When “<2>PARAMETER SET” appears, press the [PAUSE] key until the following display appears.

<2>PARAMETER SET

EX.I/O TYPE1

Use the [FEED] or [RESTART] key to select a desired option.

[RESTART]

[FEED]

After selecting an Expansion I/O Interface type, press the [PAUSE] key.

EX.I/O TYPE1

EX.I/O TYPE2

TYPE1: Standard mode

TYPE2: Inline mode

2-30

Page 37

2. SYSTEM MODE EO13-33002

2.2 Parameter Setting

2.2.24 Plug & Play Selection

This parameter is to choose whether to enable a Plug & Play function.

When “<2>PARAMETER SET” appears, press the [PAUSE] key until the following display appears.

Use the [FEED] or [RESTART] key to select a desired option.

NOTE: If the printer and the PC are connected by USB, plug & play will be automatically enabled, regardless of

After selecting a Plug & Play, press the [PAUSE] key.

<2>PARAMETER SET

PLUG & PLAY OFF

[RESTART]

[FEED]

the setting of this parameter.

PLUG & PLAY OFF

PLUG & PLAY ON

Unavailable

Available

2.2.25 Label End/Ribbon End Selection

This parameter is to choose a printing process when a label end or ribbon end is detected. For details, refer

to NOTE on the following page.

When “<2>PARAMETER SET” appears, press the [PAUSE] key until the following display appears.

Use the [FEED] or [RESTART] key to select a desired option.

After selecting a Label End/Ribbon End type, press the [PAUSE] key.

<2>PARAMETER SET

LBL/RBN END TYP1

[RESTART]

[FEED]

LBL/RBN END TYP1

LBL/RBN END TYP2

TYPE1: When a label/ribbon end is detected in the middle

of printing, printing is immediately paused.

TYPE2: When a label/ribbon end is detected in the middle

of printing, the printer prints the half-finished label as far as

possible, and stops when the next label is at the home

position.

2-31

Page 38

2. SYSTEM MODE EO13-33002

2.2 Parameter Setting

NOTE: Difference between TYPE 1 and TYPE 2

TYPE1: