Page 1

TOSHIBA Barcode Printer

B-SX600 SERIES

Document No. EO10-33021

Original Sep., 2008

(Revised )

Product Description

Page 2

EO10-33021

(Revision Date: Nov. 21, 2008)

TABLE OF CONTENTS

Page

1. OUTLINE -------------------------------------------------------------------------------------------------1- 1

1.1 PRINTER SPECIFICATIONS ---------------------------------------------------------------------------1- 1

1.2 DESCRIPTION OF MODEL NUMBER --------------------------------------------------------------- 1- 2

1.3 PART NAMES NAD FUNCTIONS -------------------------------------------------------------------- 1- 3

1.4 OPERATION PANEL-------------------------------------------------------------------------------------- 1- 5

1.5 DIMENSIONS (APPROXIMATE) ---------------------------------------------------------------------- 1- 6

1.6 OPERATING ENVIRONMENT -------------------------------------------------------------------------1- 6

1.7 BASIC SPECIFICATIONS ------------------------------------------------------------------------------- 1- 7

1.8 CUTTER UNIT SPECIFICATIONS (B-SX600-HC11/HC12-QM-R model) ------------------1- 8

1.9 STRIP UNIT SPECIFICATIONS (B-SX600-HH11/HH12-QM-R MODEL)------------------- 1- 8

1.10 MECHANICAL BLOCK ----------------------------------------------------------------------------------- 1- 9

1.10.1 Mechanism ----------------------------------------------------------- 1- 9

1.10.2 Outline of the Mechanical Block ------------------------------------------------------------- 1-12

1.10.3 Print Head Block --------------------------------------------------------------------------------- 1-13

1.10.4 Media Roll Holder -------------------------------------------------------------------------------- 1-14

1.10.5 Lower Unit ----------------------------------------------------------------------------------------- 1-15

1.10.6 Strip Unit ------------------------------------------------------------------------------------------- 1-16

1.10.7 Cutter Unit ----------------------------------------------------------------------------------------- 1-17

1.10.8 Position of various sensors ------------------------------------------------------------------- 1-18

2. ELECTRONIC SPECIFICATIONS -----------------------------------------------------------------2- 1

2.1 ELECTRONIC BLOCK------------------------------------------------------------------------------------ 2- 1

2.2 BLOCK DIAGRAM -----------------------------------------------------------------------------------------2- 2

2.3 DESCRIPTION OF THE MAIN PC BOARD---------------------------------------------------------2- 3

2.3.1 Parts Side Layout--------------------------------------------------------------------------------- 2- 3

2.3.2 Solder Side Layout -------------------------------------------------------------------------------2- 4

2.3.3 Outline of the ICs and Connectors ----------------------------------------------------------- 2- 5

2.4 DESCRIPTION OF THE DRIVER PC BOARD---------------------------------------------------- 2-10

2.4.1 PC Board Layout -------------------------------------------------------------------------------- 2-10

2.4.2 Outline of the ICs and Connectors ---------------------------------------------------------- 2-11

3. MEDIA AND RIBBON SPECIFICATIONS -------------------------------------------------------3- 1

3.1 SUPPLY SPECIFICATIONS ---------------------------------------------------------------------------- 3- 1

3.2 DIE-CUT LABEL-------------------------------------------------------------------------------------------- 3- 2

3.3 NOTCHED MEDIA----------------------------------------------------------------------------------------- 3- 3

3.4 LABEL WITH BLACK MARKS-------------------------------------------------------------------------- 3- 4

3.5 GUARANTEED PRINT AREA --------------------------------------------------------------------------3- 5

3.6 STORAGE OF MEDIA AND RIBBONS -------------------------------------------------------------- 3- 6

3.7 UNACCEPTABLE MEDIA AND RIBBONS---------------------------------------------------------- 3- 6

Page 3

EO10-33021

(Revision Date: Nov. 21, 2008)

4. INTERFACE ---------------------------------------------------------------------------------------------4- 1

4.1 Expansion I/O Interface-----------------------------------------------------------------------------------4- 1

4.1.1 Scope------------------------------------------------------------------------------------------------ 4- 1

4.1.2 Basic System Configuration and Scope of Application ---------------------------------4- 1

4.1.3 General Description of the Expansion I/O Interface of this Printer------------------- 4- 1

4.1.4 Mode of the Expansion I/O Interface --------------------------------------------------------4- 2

4.1.5 External Signal Connector --------------------------------------------------------------------- 4- 2

4.1.6 Pin Layout ------------------------------------------------------------------------------------------ 4- 3

4.1.7 PIN Description -----------------------------------------------------------------------------------4- 3

CAUTION!

1. This manual may not be copied in whole or in part without prior written permission of TOSHIBA

TEC.

2. The contents of this manual may be changed without notification.

Copyright © 2008

by TOSHIBA TEC CORPORATION

A

ll Rights Reserved

570 Ohito, Izunokuni-shi, Shizuoka-ken, JAPAN

Page 4

1. OUTLINE EO10-33021

1.1 PRINTER SPECIFICATIONS

1-1

1. OUTLINE

1.1 PRINTER SPECIFICATIONS

1) High quality and resolution

• The resolution in the media feed direction is 1200 dpi, the highest resolution for label printers.

• This printer can precisely print on a 3-mm long label, also can peel off 10-mm long label.

• Prevents change of the ribbon tension which causes ribbon wrinkles.

• Prevents an imbalance contact of the print head with the media and blurred print at the media edges.

2) Interface

• Use of the printer driver eliminates the need of learning any printer specific commands. Also, it is

possible to develop a general-purpose system according to the standard specification.

• Bi-directional communication feature and status monitor API enable the host application to correctly

obtain a end of print job status even when using the printer driver.

• For network printing, the standard print protocol (LPR, Raw) has been adopted.

Bi-directional communication feature of Raw enables obtaining an end of print job status via network.

Like the USB interface model, it realizes complete management of print jobs. Network printing can

be performed without any special printing software.

3) User friendliness

• Very easy supply loading due to the pop-up mechanism of the print head block.

• Easy-to-understand operation menus enable user intuitive operations.

• Large LCD panel displays the printer status or operating procedures. (Language is selectable

between Japanese and English.)

• Print head and platen roller can be replaced without any tools.

• Simple driver installer enables easy and secure installation of the printer driver.

4) Safety and environment consciousness

Interlock switch:

While the cover is opened, printing operation is stopped and the power supply to the print head is shut

down.

User protection:

This printer is designed so that users cannot touch the moving parts such as the platen roller or the cutter

unit.

EMC (Electromagnetic compatibility):

Emission of electromagnetic noise, which influences other electronics devices, is reduced. Also, the

immunity to electromagnetic noise generated by surrounding devices is enhanced.

No use of hazardous chemical substances

Compliance with EU RoHS directive

5) Option

A variety of options are provided to meet your needs.

• Cutter module (Factory option)

• Strip module (Factory option)

• Network adapter (Factory option)

Network interface: 10BASE-T/100BASE-TX (Automatic sensing), Protocol: TCP-IP

Notes:

1. B-SX600 Series does not support TPCL (TEC Printer Command Language).

2. Printable bar code, two-dimensional code, and font type depend on PC’s operating environment and

application software.

3. In the Low Power Mode, the fan motor pauses as a proper operation.

4. When the power is on, the ribbon motor works for applying proper tension to the ribbon.

Page 5

1. OUTLINE EO10-33021

1.2 DESCRIPTION OF MODEL NUMBER

1-2

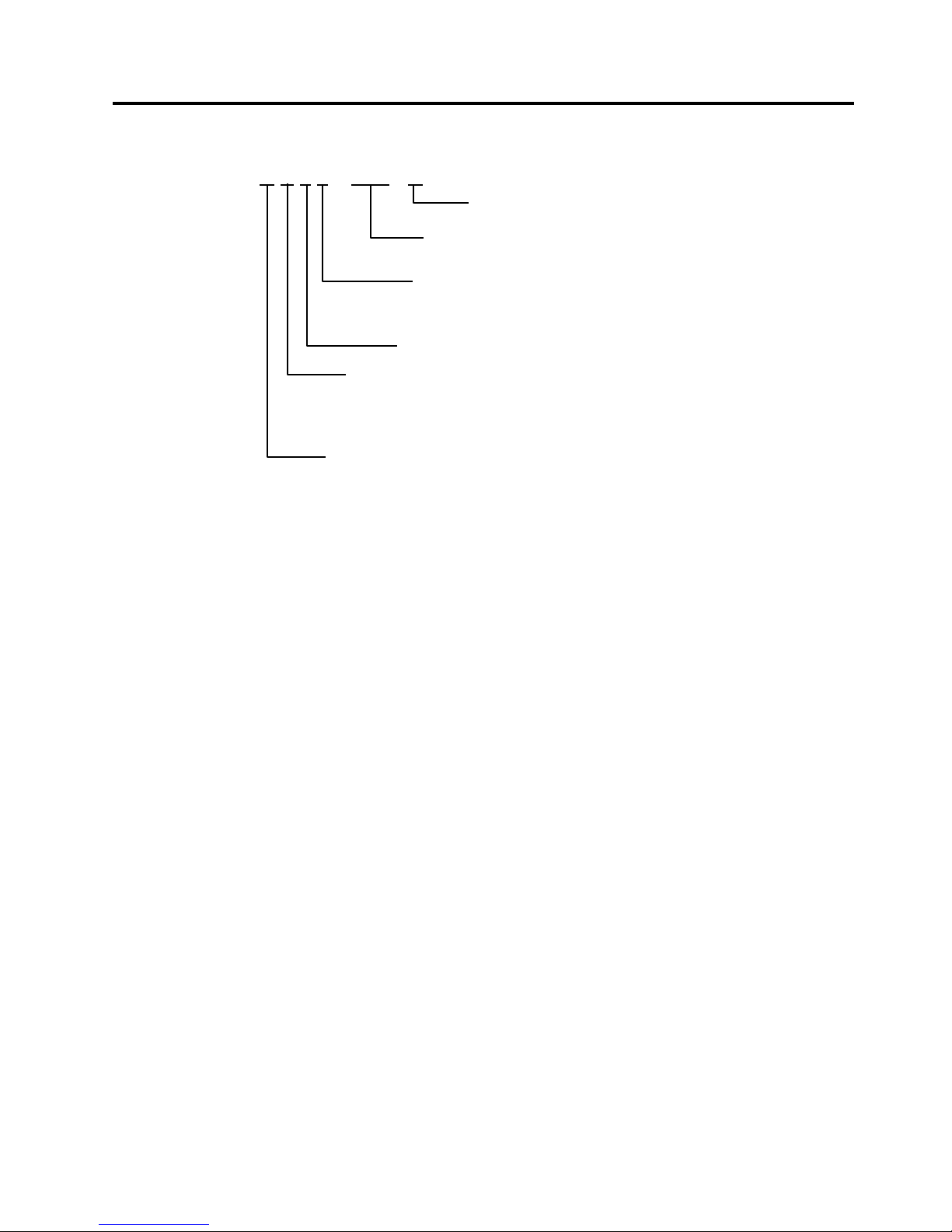

1.2 DESCRIPTION OF MODEL NUMBER

B – S X 6 0 0 – H

S 1 1 – Q M - R

RoHS compliance model

Destination Code

QM: Standard for World Wide

Issue Mode

S: Batch

H: Strip

C: Cut

Resolution

H: 600 dpi

Interface

1: USB

2: LAN

Machine Version

Page 6

1. OUTLINE EO10-33021

1.3 PART NAMES AND FUNCTIONS

1-3

1.3 PART NAMES AND FUNCTIONS

Side Cover

Opened when the media o

r

ribbon is loaded or replaced.

Supply Window

A

remaining quantity of the

media or ribbon can be

checked through the Supply

Window.

Front Cover Unlock Button

Used to open the Front Cover.

Side Cover Grip

Used to open the Side Cover.

Media Outlet

Printed outputs are ejected

through the Media Outlet.

Front Cove

r

Opened when the

media is loaded o

r

replaced.

Power Switch

Used to turn the

p

rinter on/off.

Front View

Standard model or Cutter model

Strip model

Front Cover Unlock Button

Used to open the Front Cover.

Front Cover

Opened when the media is

loaded or replaced.

Strip Unit

Media Holding Roller

Strip Senso

r

Operation Panel

Used to following.

•Select a menu

•Printer Setting

•Display Message

etc.

(For details, refer to

section 1.4)

Page 7

1. OUTLINE EO10-33021

1.3 PART NAMES AND FUNCTIONS

1-4

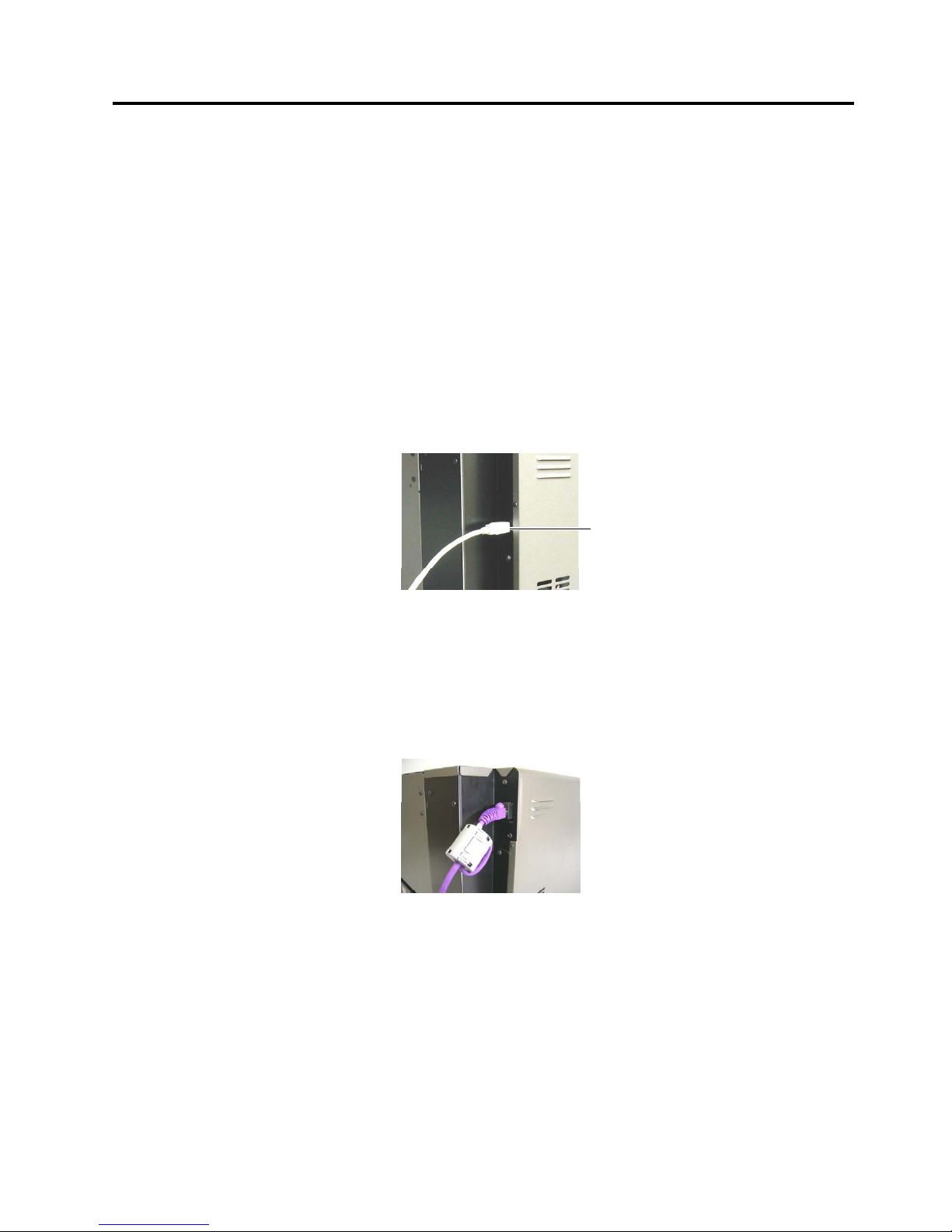

Rear View

USB Interface Connecto

r

Used to connect the printer to a PC

with a USB cable.

(USB Interface model only)

Ventilation Slot

Lets trapped heat pass out of the printer.

Expansion I/O Interface Connecto

r

Used to interface with an external

equipment (Refer to Section 4.)

A

C Power Inlet

Fanfold Paper Slot

A

llows fanfold paper to

feed into the printer from

the printer back.

LAN Interface Connecto

r

Used to connect the printer to a PC

with a LAN cable.

(LAN Interface model only)

Left Side Panel

Reset Switch

Used to reset the print server to the

factory default by the insertion of the

reset pin into the hole.

Page 8

1. OUTLINE EO10-33021

1.4 OPERATION PANEL

1-5

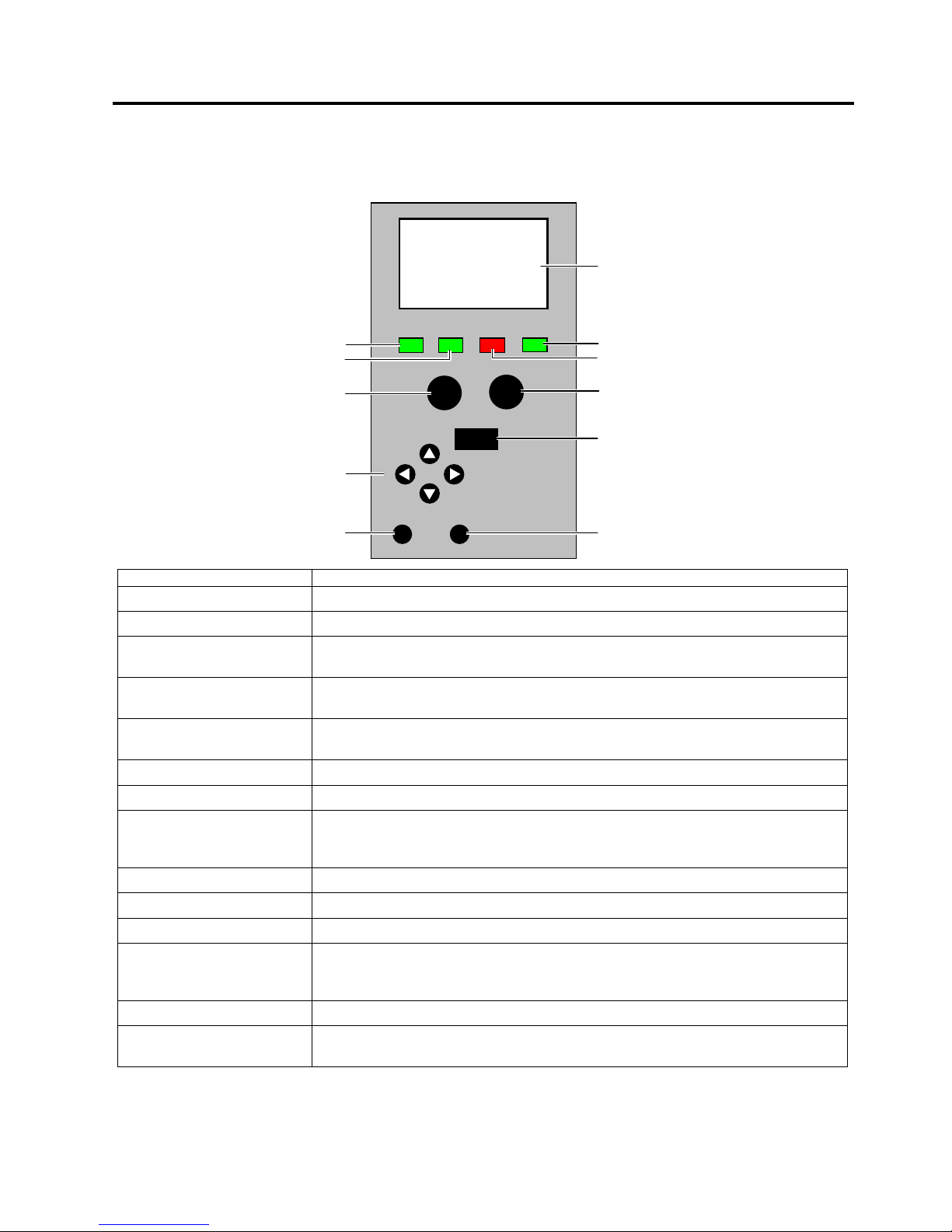

1.4 OPERATION PANEL

The Operation Panel is equipped with the LCD Message Display, which is used to indicate the state of the

printer, 4 LED’s, and 9 keys. Please see the table below for details.

Name Functions (Purposes)

LCD Message Display Shows the menu or error information.

Power LED Illuminates in green when the printer is turned on.

Ready LED Illuminates in green when the printer is ready, and goes out when the printer is in

a pause state or while the menu is being displayed.

Error LED Illuminates in red when an error occurs, and flashes in red in the event of a

warning.

Data LED Flashes in green when data is received, and illuminates in green when data is in

the receive buffer.

[Pause] key Used to place the printer in a pause or ready state.

[Feed] key Used to feed the media for a single page or label length.

[Menu] key Used to display the menu when the printer is in a ready or pause state. When

held down, the [Menu] key will be locked, and when held down again, it will be

unlocked.

◄key

Used to choose an item on the left while the menu is being displayed.

►key

Used to choose an item on the right while the menu is being displayed.

▲key

Used to choose an item above while the menu is being displayed.

▼key

Used to choose an item below while the menu is being displayed.

When the model with the Cutter Unit is used, holding down this key in a ready or

pause state causes the media to be cut.

[Enter] key Used to determine the settings while the menu is being displayed.

[Cancel] key Used to clear an error when it occurs.

When held down, print data is cleared.

LCD Message Display

Error LED

[

Feed]Key

[

Menu] Key

[

Cancel] Key

Ready

No. 00000

Power

Ready

Error Data

Ente

r

Menu

Pause

Feed

Cancel

Data LED

Power LED

Ready LED

[PAUSE] Key

Cursor Keys

(◄ ► ▲ ▼)

[Enter] Key

Page 9

1. OUTLINE EO10-33021

1.5 DIMENSIONS (APPROXIMATE)

1-6

A

cceptable operating

range

Print quality

guaranteed range

10 20 30 40

20

40

60

80

%RH

℃

5℃90%

29℃90%

5℃

55%

40℃39%

40℃10%

18℃

60%

28℃

60%

28℃

40%

18℃

40%

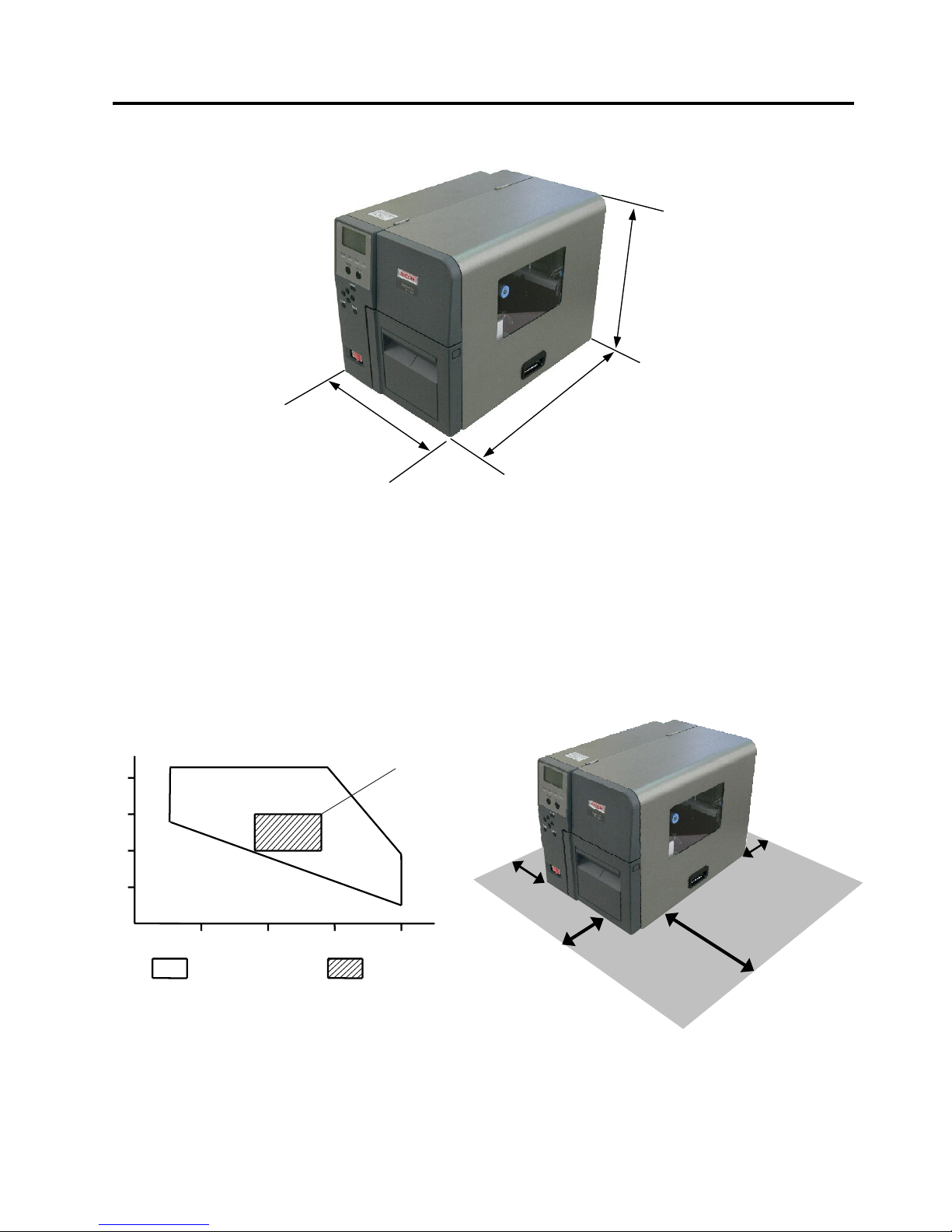

1.5 DIMENSIONS (APPROXIMATE)

1.6 OPERATING ENVIRONMENT

Install the printer in a place where ample space is reserved for the operation. Also, place the printer on a

well ventilated, smooth, level desk or rack specifically designed for the printer. Make sure that the 4 feet of

the printer make full contact with the surface of the desk or rack.

Be sure that there is sufficient space around the printer, as illustrated below.

Depth: 455mm

Width: 300mm

Height: 353.5mm

(including the rubber feet)

Min 15cm

Min 30cm

Min 5cm

Min 10cm

Page 10

1. OUTLINE EO10-33021

1.7 BASIC SPECIFICATIONS

1-7

1.7 BASIC SPECIFICATIONS

(1) Printing method: Thermal direct printing or thermal transfer printing

(2) Resolutions (dot density): 600 dpi (23.6 dots/mm)

(3) Print speed: Max. 150 mm/second (6ips)

There are limitations on a print speed depending on the media or ribbon

type and an image to print.

Note: Print speed is selectable from 1 ips to 6 ips by the printer driver.

(4) Media alignment: Center

(5) Max. effective print width: 104 mm (Approximate 4”)

(6) Max. print length: 1,000 mm

(7) Available media width: 15 to 120 mm

(8) Host interface: USB model: B-SX600-HS11/HH11/HC11-QM-R

• USB 2.0 High Speed

LAN model: B-SX600-HS12/HH12/HC12-QM-R

• 10BASE-T / 100BASE-TX (IEEE802.3)

• Print Protocol: LPR, PORT9100 (unidirectional), PORT9100

(bi-directional)

• LPR queue name: lp

• Control protocol: HTTP

(9) Operating system: Windows 2000, Windows XP, Windows Server 2003, Windows Vista

(10) Weight: 20.6 kg (USB model: B-SX600-HS11/HH11/HC11-QM-R)

21.0 kg (LAN model: B-SX600-HS12/HH12/HC12-QM-R)

(11) Rating: Input Voltage: 100 VAC to 240 VAC

Frequency: 50/60 Hz (48 to 62 Hz)

Power consumption: 250 W or less under normal operation

20W or less under low power mode operation

Type B

Page 11

1. OUTLINE EO10-33021

1.8 CUTTER UNIT SPECIFICATIONS (B-SX600-HC11/HC12-QM-R MODEL)

1-8

(12) Noise: 75 dB or less

(13) Operating temperature range: 5 to 40 °C (Print quality guaranteed at temperatures between 18 and 28

°C)

(14) Relative humidity: 10 to 90% (Print quality guaranteed at humidity between 40 and 60%)

(15) Storage temperature range: -20 to 70 °C

(16) Storage humidity range: 5 to 90%

(17) Safety and EMC Standard: CE, TÜV GS, C-Tick, UL, CUL, FCC, ICE, CCC

(18) Environmental standard: RoHS Directive compliant

1.8 CUTTER UNIT SPECIFICATIONS (B-SX600-HC11/HC12-QM-R MODEL)

(1) Acceptable media thickness: 0.08 mm to 0.26 mm

(2) Acceptable label pitch: 10 mm to 1,000 mm

(3) Cut mode: Continuous cut

Cut after printing

Batch cut

(4) Restrictions: Cutting self-adhesive labels is not allowed.

Cutting within 1 mm around perforation is not allowed.

Cutting fabrics or films is not allowed.

Note: The cutter unit is a factory option.

1.9 STRIP UNIT SPECIFICATIONS (B-SX600-HH11/HH12-QM-R MODEL)

(1) Effective print speed: 101.6 mm/second or less (same as a feed speed)

(2) Peeling method: Tensioning

(3) Peeling detection system: A reflective photo sensor is used to detect a label.

(4) Restrictions: Peel-off operation is not allowed when:

Perforated labels are used

Fanfold labels are used.

Fabrics or films are used

Outside wound labels are used

Labels other than rectangular die-cut labels are used.

Note: The strip unit is a factory option.

Page 12

1. OUTLINE EO10-33021

1.10 MECHANICAL BLOCK

1-9

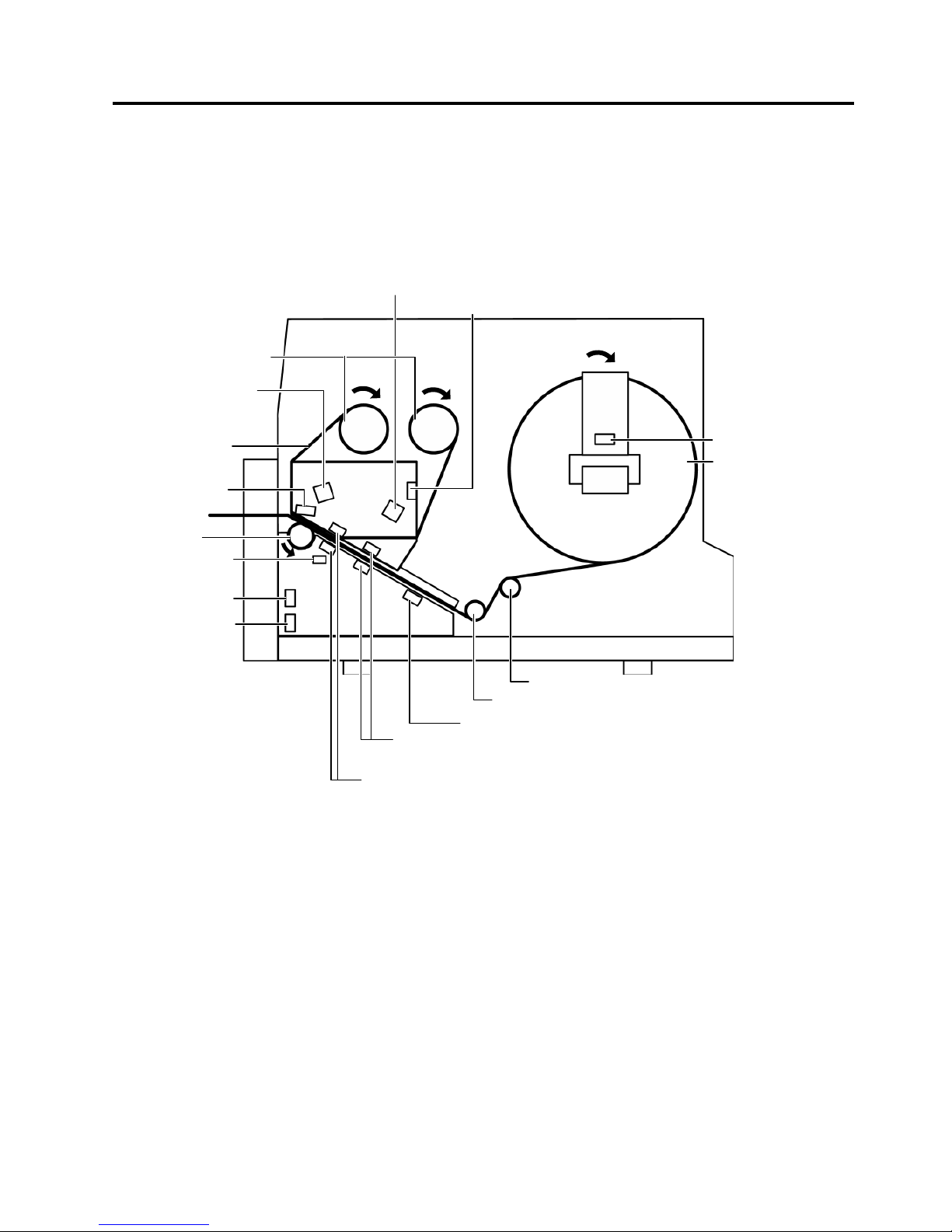

1.10 MECHANICAL BLOCK

1.10.1 Mechanism

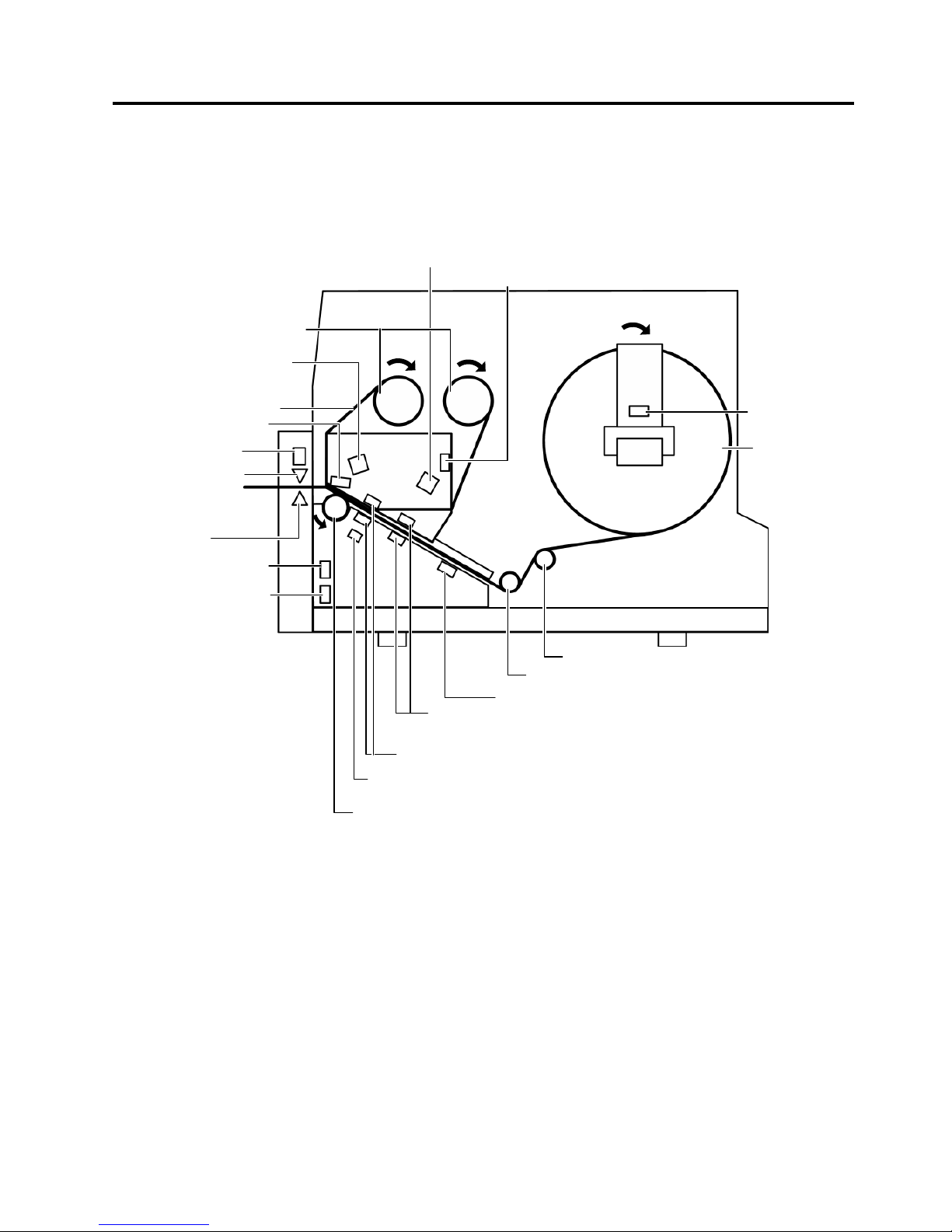

(1) Batch Mechanism (HS11/HS12 model)

This is the standard mechanism which lets the printer print continuously until the number of media specified

in the label issue command has been printed.

Media

Media Near End Sensor

Ribbon End Sensor

Ribbon Encoder Sensor

(Ribbon slit Sensor, Feed)

Ribbon

Ribbon Shaft

Front Cove

r

Open Senso

r

Side Cove

r

Open Senso

r

Media End Sensor

Movable Media Sensor (Feed Gap Sensor),

Reflective Media Sensor (Black Mark Sensor)

Print Head

Ribbon Encoder Senso

r

Ribbon slit Sensor, Take-up)

Print Head

O

p

en Senso

r

Fixed Media Sensor (Feed Gap Sensor)

Platen

Media Roll Damper

Media Roll Guide

Page 13

1. OUTLINE EO10-33021

1.10 MECHANICAL BLOCK

1-10

(2) Strip Mechanism (HH11/HH12 model)

When an factory optional strip module is attached, a label is stripped from the backing paper by the strip

shaft, and the backing paper is drawn into the strip module. The nextlabel will not be printed until the

preceding label is removed, as a presence of the label at the strip shaft is monitored by the strip sensor.

Media

Media Near End Sensor

Ribbon End Sensor

Ribbon

Ribbon Shaft

Front Cove

r

Open Senso

r

Feed Roller (Black)

Media End Sensor

Print Head

Print Head Open Sensor

Platen

Pinch Roller (White)

Strip senso

r

Backing Pape

r

Side Cove

r

Open Senso

r

Media Holding

Rolle

r

Media Roll Damper

Media Roll Guide

Strip Plate

Movable Media Sensor (Feed Gap Sensor),

Reflective Media Sensor

(

Black Mark Sensor

)

Fixed Media Sensor (Feed Gap Sensor)

Ribbon Encoder Sensor

(Ribbon slit Sensor, Feed)

Ribbon Encoder Senso

r

Ribbon slit Sensor, Take-up)

Page 14

1. OUTLINE EO10-33021

1.10 MECHANICAL BLOCK

1-11

3) Cutter Mechanism (HC11/HC12 model)

When an factory optional Cutter module is attached, printed media is fed to the cutter unit and cut off from

the media roll.

Media

Media Near End

Sensor

Ribbon End Sensor

Ribbon

Ribbon Shaft

Front Cove

r

Open Senso

r

Media End Sensor

Print Head

Print Head Open Sensor

Platen

Cutter Blade

Media Roll Damper

Media Roll Guide

Side Cove

r

Open Senso

r

Cutter Carriage

Position Senso

r

Cutter Carriage Unit

Transmissive Media Edge Sensor (Feed Gap Sensor, Movable)

Reflective Media Sensor (Black Mark Sensor)

Transmissive Media Center Sensor (Feed Gap Sensor, Fixed)

Ribbon Encoder Sensor

(Ribbon slit Sensor, Feed)

Ribbon Encoder Senso

r

(Ribbon slit Sensor, Take-up)

Page 15

1. OUTLINE EO10-33021

1.10 MECHANICAL BLOCK

1-12

1.10.2 Outline of the Mechanical Block

The main Mechanical Blocks are as follows.

Front Cover (HS11/HS12)

Cutter Unit (HC11/HC12)

Strip Unit (HH11/HH12)

Upper Uni

t

Media Roll Holder and

Damper Unit

Lower unit

Page 16

1. OUTLINE EO10-33021

1.10 MECHANICAL BLOCK

1-13

1.10.3 Print Head Block

The main parts of the Print Head Block are as follows.

Ribbon Tensioner

Print Head Block Handle

Ribbon Stopper

Ribbon Stoppe

r

Ribbon Shaft

(Supply Side)

Ribbon Shaft

(Take up side)

Print Head

Release Leve

r

Upper Unit

Unlock Lever

Print Head Ass’

y

Print Head Pressure

Selection Lever

Page 17

1. OUTLINE EO10-33021

1.10 MECHANICAL BLOCK

1-14

1.10.4 Media Roll Holder

The main parts of the Media Holder Block are as follows.

Note: The on or off status of the media near end sensor can be switched with the Lever. Move the lever

into OFF position for using the fanfold paper. If it remains in ON position, a media near end error is

detected, causing that no print operation is performed.

Unlock Lever

Media Roll Holder Unit

Media Near End Sensor

By adopting a reflective

sensor, this sensor detects

a media near end state

when the media is reduced

under the sensor window.

OFF position

ON position

Lever

Sensor Window

Page 18

1. OUTLINE EO10-33021

1.10 MECHANICAL BLOCK

1-15

1.10.5 Lower Unit

The main parts of the Lower Unit are as follows.

Media Roll Damper

Media Roll Guide

Media Guide

Media Holder

Media End Sensor

Fixed Media Sensor (Fixed Feed Gap Sensor)

Movable Media Sensor

(Movable Feed Gap Sensor)

Reflective Media Sensor

(Black Mark Sensor)

Platen

Page 19

1. OUTLINE EO10-33021

1.10 MECHANICAL BLOCK

1-16

1.10.6 Strip Unit

The main parts of the Strip Module are as follows.

Strip Module

Pinch Roller

(White)

Feed Roller

(Black)

Media Holding

Roller

Strip Sensor

Page 20

1. OUTLINE EO10-33021

1.10 MECHANICAL BLOCK

1-17

1.10.7 Cutter Unit

The main parts of the Cutter Unit are as follows.

Cutter Motor

Cutter Carriage

Position Senso

r

Cutter Carriage

Unit

Cutter Blade

Page 21

1. OUTLINE EO10-33021

1.10 MECHANICAL BLOCK

1-18

1.10.8 Position of various sensors

Cutter Carriage Position Sensor

• It detects the position of the

cutter.

Front Cover Open Sensor

(1) Cover open

It detects the open or close

status of the front cover.

(2) Interlock function

It performs as a safety

interlock switch.

Print Head Open Sensor

• It detects the open or

close status of the print

head by working with the

home position sensor.

Print Head Thermistor

• It measures the

temperature of the print

head.

Side Cover Open Sensor

(1) Cover open

It detects the open or

close status of the

side cover.

(2) Interlock function

It performs as a safety

interlock switch.

Ribbon Encoder Sensor

• It monitors the rotation of the ribbon shaft.

• It detects the tear of the ribbon.

Ribbon End Sensor

• It detects a ribbon end.

Media Near End Sensor

• It detects the remaining

number of media.

(1) Transmissive Media Edge

Sensor Sensor

(2) Reflective Media Sensor

(3) Transmissive Media Center

Sensor

• The above sensors optically

measure potential difference

of the media to measure the

media length.

Home Position Sensor (Print Head Open Sensor)

• It detects the open or close status of the print

head by working with the print head open sensor.

Media End Sensor

• It detects a media end.

Environmental Temperature

Thermistor

• It measures the operating

temperature of the printer

to adjust print energy.

Page 22

1. OUTLINE EO10-33021

1.10 MECHANICAL BLOCK

1-19

Note:

The sensor is selectable from Movable Media Sensor, Reflective Media Sensor, and Fixed Media Sensor by the

printer driver.

Refer to Owner’s Manual or Printer Driver Users Manual.

Fixed Media Sensor (Fixed Feed Gap Sensor)

This sensor detects the tag paper in which

center a round hole (3 mm in diameter) is

provided.

Page 23

2. ELECTRONIC SPECIFICATIONS EO10-33021

(Revision Date: Nov. 21, 2008)

2.1 ELECTRONIC BLOCK

2-1

2. ELECTRONIC SPECIFICATION

2.1 ELECTRONIC BLOCK

The main parts of the Electronic Block are as follows.

Ribbon Motor

(Take up)

Driver PC

Board

Stepping motor

Main PC

Board

Fan Moto

r

Ribbon Motor

(Supply)

LAN Unit

(LAN model only)

Cutter Control PC Board

(HC11/HC12 model)

5V Power

Supply Unit

24V Power

Supply Unit

Noise Filter

PC Board

Operation Panel

PC Board

LCD Panel

Page 24

2. ELECTRONIC SPECIFICATIONS EO10-33021

(Revision Date: Nov. 21, 2008)

2.2 BLOCK DIAGRAM

2-2

2.2 BLOCK DIAGRAM

Page 25

2. ELECTRONIC SPECIFICATIONS EO10-33021

(Revision Date: Nov. 21, 2008)

2.3 DESCRIPTION OF THE MAIN PC BOARD

2-3

2.3 DESCRIPTION OF THE MAIN PC BOARD

2.3.1 Parts Side Layout

CN2

Print Head

(Print Data, Control

Si

g

nal

)

CN7 (Not used)

CN4 (Panel PC Board)

CN11 CPLD JTAG (Joint Test Action Group)

Not used, for Developer

CN8 H-UDI Interface

Not used, for Develope

r

FU2 Fuse

FU1 Fuse

IC22 PROM (Not installed)

CN10 FPGA JTAG (Not installed)

IC19 FPGA

IC3

Buffer

IC5

Buffer

SW1 (CPLD)

Not installed

IC4 CPLD

(Complex

Programmable

Logic Device)

IC16 IC17 IC18

128M bit SDRAM

IC8 32 bit

RISC CPU

SH7206

SW2 (for FPGA)

Not used

IC21

Buffer

IC20

Buffer

OSC3 Oscillator

33.33MHz

IC15

16M bit Flash ROM

IC14

Buffer

IC9

Buffer

IC7 Reset IC

CN1 USB

CN5 5VDC

(Not used)

FU3 Fuse

CN9 AUD (Advanced User Debugger)

Not used

IC1 DC/DC Converter (3.3V)

FU4 Fuse

FU5 Fuse

IC2 DC/DC Converter (1.2V, 1.25V)

OSC1 Oscillato

r

24MHz

IC6 USB Controlle

r

OSC2 Oscillator

12.5MHz

IC11

IC10

IC13

IC12

Multiplexe

r

CN6 VFR Interface

(Not installed)

Page 26

2. ELECTRONIC SPECIFICATIONS EO10-33021

(Revision Date: Nov. 21, 2008)

2.3 DESCRIPTION OF THE MAIN PC BOARD

2-4

2.3.2 Solder Side Layout

IC27 Reset IC

PST9246N

REG2 Regulator

(1.5V)

IC26 16M bit Flash ROM

IC25

Buffer

IC23

Buffer

IC24

Buffer

REG3 Regulato

r

(2.5V)

CN3 Driver

PC Board

REG1 Regulato

r

(1.8V)

Not installed

Page 27

2. ELECTRONIC SPECIFICATIONS EO10-33021

(Revision Date: Nov. 21, 2008)

2.3 DESCRIPTION OF THE MAIN PC BOARD

2-5

2.3.3 Outline of the ICs and Connectors

The Main PC board functions as a central part of the printer and controls the operation of print head.

This PC board is comprised of the following major components:

Main Electronic parts

CPU (IC8): 32bit RISC CPU

Type: SH7206

Clock: Max. 200MHz

This IC is a central part of the electric system, which performs the following

processing.

Controlling the data bus and address bus

Controlling the serial interface

Controlling the interruption

Performing as the A/D converter

Performing as the D/A converter

Flash ROM (IC15, 26): 32Mbit Flash ROM

Type: S29AL016D70

Various setting values of firmware program, sensor setting, etc. are written

into this memory.

SDRAM (IC16, 17, 18): 128Mbit SDRAM

Type: EDS1216AATA-75-E

This memory is used for drawing the print data.

It is not possible to store writable characters, etc. into the printer which

does not support TEC Printer Command Language.

FPGA (IC19): Type: XC3S1500

This IC is a Field Programmable Gate Array (FPGA), which performs

controlling the devices such as cutter, print head, ribbon motor, and

sensors.

Page 28

2. ELECTRONIC SPECIFICATIONS EO10-33021

(Revision Date: Nov. 21, 2008)

2.3 DESCRIPTION OF THE MAIN PC BOARD

2-6

CPLD (IC4): Type: EPM3128ATC100

This IC is a Complex Programmable Logic Device (CPLD).

USB Controller (IC6) Type: M66592WG

This IC is used for controlling the USB interface.

DC/DC Converter (IC1, 2): Type: TPS54380PWPG4

These ICs are DC/DC converters. From +5V, IC1 generates +3.3V and

IC2 generates +1.25V and +1.2V, respectively.

+3.3V is used as the operating voltage for logic devices such as CPU.

+1.25V is used as the supply voltage for the CPU.

+1.2V is used as the operating voltage for the FPGA (IC19).

Regulator (REG2, 3): Type: PQ070XH02ZPH

They are regulator ICs.

From +3.3V, REG2 generates +1.5V and REG3 generates +2.5V,

respectively.

+1.5V is used for the USB controller (IC6).

+2.5V is used as the operating voltage for the FPGA (IC19).

Page 29

2. ELECTRONIC SPECIFICATIONS EO13-33001

(Revision Date: Nov. 21, 2008)

2.3 DESCRIPTION OF THE MAIN PC BOARD

2-7

Connectors

CN1

CN4

Signal I/O Pin No.

USB_GND --- 1

D+ I/O 2

D- I/O 3

VBUS --- 4

Signal I/O Pin No.

PANEL_VDD_O O 1

PANEL_RESERVE2 I 2

PANEL_BUZZER O 3

PANEL_RESERVE1 O 4

PANEL_SDI I 5

PANEL_SDO O 6

PANEL_LCD_CS_N O 7

PANEL_LCD_A0 O 8

PANEL_SCLK O 9

GND --- 10

This is a USB interface connector.

The model with a USB interface is connected to a PC via the

connector.

The model with a LAN interface, not provided with the

connector, is connected to the printer server via the cable

directly installed into the PC board.

This connector is connected to the panel PC board.

The signals output from the connector are used fo

r

controlling the LCD display, buzzer, and so on.

Page 30

2. ELECTRONIC SPECIFICATIONS EO13-33001

(Revision Date: Nov. 21, 2008)

2.3 DESCRIPTION OF THE MAIN PC BOARD

2-8

CN2

Signal I/O Pin No.

HEAD_TEMP I 1

GND --- 2

HEAD_TRS5 I 3

HEAD_TRS6 I 4

HEAD_TRS3 I 5

HEAD_TRS4 I 6

HEAD_TRS1 I 7

HEAD_TRS2 I 8

HEAD_DATA13 O 9

GND --- 10

HEAD_DATA12 O 11

GND --- 12

HEAD_DATA11 O 13

GND --- 14

HEAD_DATA10 O 15

GND --- 16

HEAD_DATA9 O 17

GND --- 18

HEAD_DATA8 O 19

GND --- 20

HEAD_DATA7 O 21

GND --- 22

HEAD_DATA6 O 23

GND --- 24

HEAD_DATA5 O 25

GND --- 26

HEAD_DATA4 O 27

GND --- 28

HEAD_DATA3 O 29

GND --- 30

HEAD_DATA2 O 31

GND --- 32

HEAD_DATA1 O 33

GND --- 34

HEAD_STROBE2_N O 35

GND --- 36

HEAD_STROBE1_N O 37

GND --- 38

HEAD_CLOCK O 39

GND --- 40

HEAD_LATCH_N O 41

GND --- 42

HEAD_B_E_O O 43

GND --- 44

+5V O 45

GND --- 46

+5V O 47

GND --- 48

+5V O 49

GND --- 50

This connector is connected to the print head.

+5V, print data (HEAD DATA1 to HEAD DATA13), and

the strobe, clock, and latch signals which control the print

head are output from the connector.

A

lso, the thermistor signal (HEAD TEMP) which is used

for detecting the internal temperature of the print head

and the print head element resistance rank detect signal

(HEAD TRS1 to HEAD TRS6) are input into the

connector.

Page 31

2. ELECTRONIC SPECIFICATIONS EO13-33001

(Revision Date: Nov. 21, 2008)

2.3 DESCRIPTION OF THE MAIN PC BOARD

2-9

CN3

Signal I/O

Pin

No.

Signal I/O

Pin

No.

GND --- 1 GND --- 51

GND --- 2 GND --- 52

GND --- 3 GND --- 53

GND --- 4 GND --- 54

+5V I 5 +5V I 55

+5V I 6 +5V I 56

+5V I 7 +5V I 57

+5V I 8 +5V I 58

+5V I 9 +5V I 59

+5V I 10 +5V I 60

CO_VM_MONITOR I 11 CO_FAN_REVOLUTION I 61

CO_VTH_MONITOR I 12 CO_N_DISCHARGE O 62

CO_N_PSU_REMOTE O 13 EX_IF_LABEL_END O 63

EX_IF_ERROR O 14 EX_IF_CMP_NRMLTY O 64

EX_IF_CMP_ABNRMLTY O 15 EX_IF_READY_N_PAUSE O 65

EX_IF_PRINT_DATA O 16 EX_IF_RIBBON_END O 66

EX_IF_RESERVE_OUT O 17 EX_IF_PAUSE I 67

EX_IF_BACK_FEED I 18 EX_IF_RESERVE_IN I 68

EX_IF_PRINT_START I 19 CO_N_HEAD_ENABLE O 69

CO_N_HEAD_CHECK O 20 CUTE_M_CW_CCW O 70

CUTE_M_CLOCK O 21 CUTE_M_MODE_1 O 71

CUTE_M_POWER O 22 CUTE_M_MODE_3 O 72

CUTE_M_MODE_2 O 23 CO_OPT_SIG1 I 73

CUTE_M_RESET O 24 CO_OPT_SIG2 I 74

LF_MO_CLOCK O 25 LF_MO_CW_CCW O 75

LF_MO_POWER_1 O 26 LF_MO_POWER_2 O 76

LF_MO_MODE_1 O 27 LF_MO_MODE_2 O 77

LF_MO_MODE_3 O 28 LF_MO_RESET O 78

RB_M_WAND_UP_ENABLE O 29 RB_M_DELIVER_ENABLE O 79

RB_M_WAND_UP_MODE O 30 RB_M_DELIVER MODE O 80

RB_M_WAND_UP_PAHSE O 31 RB_M_DELIVER_PAHSE O 81

RB_M_WAND_UP_PFD_1 O 32 RB_M_DELIVER_PFD_1 O 82

RB_M_WAND_UP_PFD_2 O 33 RB_M_DELIVER_PFD_2 O 83

GND --- 34 GND --- 84

GND --- 35 GND --- 85

RB_M_WND_UP_REF O 36 RB_M_DELIVER_REF O 86

SEN_CENTER_HOLE I 37 SEN_HEAD_RESISTOR I 87

SEN_INTERRUPTER I 38 SEN_REFLECTIVE I 88

SEN_THERMISTOR I 39 SEN_RBN_END I 89

GND --- 40 GND --- 90

GND --- 41 GND --- 91

SEN_CUT_HP_LEFT_PEL I 42 SEN_CUT_HP_RIGHT I 92

SEN_PAPER_NEAR_END I 43 SEN_SIDE_COVER_OPEN I 93

SEN_HEAD_LATCH_OPEN I 44 SEN_HEAD_OPEN I 94

SEN_PAPER_END I 45 SEN_FRONT_COVER_OPN I 95

SEN_RBN_WAND_UP_ENC I 46 SEN_RBN_DELIVER_ENC I 96

SEN_RBN_PINCH I 47 LEDS_PULSE_INT O 97

LEDS_PULSE_CENTER O 48 LEDS_PULSE_REF O 98

RESERVE_IN_1 I 49 POWER_ON_IN I 99

RESERVE_OUT_1 O 50 POWER_ON_OUT O 100

This connector, which is

connected to the driver PC

board, performs the

input/output of the control

signals for the motor,

sensors, and so on.

A

lso, +5V, the operating

voltage for each logic

device, is supplied from

the connector.

Page 32

2. ELECTRONIC SPECIFICATIONS EO1033021

(Revision Date: Nov. 21, 2008)

2.4 DESCRIPTION OF THE DRIVER PC BOARD

2-10

2.4 DESCRIPTION OF THE DRIVER PC BOARD

2.4.1 PC Board Layout

In addition, the following PC boards are used in the printer.

24V Power Supply PC Board: Generate +24VDC

5V Power Supply PC Board: Generate +5VDC

Cutter Control PC Board: Control of the cutter

Operation Panel PC Board: Control of the operation panel.

Noise Filter PC Board: Reduce a noise of the power supply.

CN3 Ribbon Motor (Rewind)

CN8 Print Head

(Power)

CN5 Stepping

Motor

CN6

Cutter Drive

PC Board

FU4 Fuse

IC5 Stepping Motor

Driver

Heat Sink

FU6 Fuse

CN4 Ribbon Motor (Feed)

FU7 Fuse

CN2 Sensors

Ribbon End Sensor

Media Sensor (Movable Media sensor, Reflective Media

sensor, Fixed Media sensor)

Environmental Temperature Thermistor

CN1 Sensors

Media End Sensor

Media Near End Sensor

Print Head Open Sensor

Home Position Sensor (Print Head Open Sensor)

Front Cover Open Sensor

Side Cover Open Sensor

Ribbon Encoder Sensor (Ribbon Feed, Ribbon Rewind)

FU8 Fuse

CN7

MAIN PC Board

CN9 5VPS Unit

CN10 LAN Module

(LAN model only)

Q1 FET

(Power Switching)

CN14 24VPS Unit

IC8 IC9 IC10

Inverte

r

IC6 Motor Driver IC

(Rewind)

IC2

Op. AMP

IC7 Motor Driver IC

(Feed)

PC1PC2PC3

Photo Couple

r

IC3 Reset IC

IC4

DC/DC Converte

r

Q9

(Power Switch)

FU5 Fuse

FU1 Fuse

CN13 Fan Motor

IC1 Reset IC

CN11

Expansion I/O

Interface

CN12 5VPS Unit and 24VPS Unit

FU2 Fuse

FU3 Fuse

Page 33

2. ELECTRONIC SPECIFICATIONS EO1033021

(Revision Date: Nov. 21, 2008)

2.4 DESCRIPTION OF THE DRIVER PC BOARD

2-11

2.4.2 Outline of the ICs and Connectors

The Driver PC board controls devices such as stepping motor and DC motor, detects the sensor status, and

generates a voltage to work devices such as print head and motors.

Motor Driver IC (IC6, 7): Type: A3959SLP

These ICs generate the operating voltage for the ribbon motor.

IC6 generates the RIBBON_WAND_OUT_A and RIBBON_WAND_OUT_B

signals from +36V and the RBN_M_WAND_UP_PFD_1 and

RBN_M_WAND_UP_PFD_2 signals output from the CPU PC board, and

then it outputs these signals to the ribbon motor (rewind).

IC7 generates the RIBBON_DELIVER_OUT_A and

RIBBON_DELIVER_OUT_B signals from +36V and the

RBN_M_DELIVER_UP_PFD_1 and RBN_M_DELIVER_UP_PFD_2

signals output from the CPU PC board, and then it outputs these signals to

the ribbon motor (feed).

Stepping Motor Driver (IC5): Type: SLA7078MR

This is a driver IC which controls the stepping motor.

It generates the A, B, N_A, and N_B signals from +36V and the

LF_M_MODE and LF_M_CLOCK signals output from the CPU PC board,

and then it outputs these signals to the stepping motor.

NOTE:

The IC is provided with the heat sink. Never touch the IC which may

become hot immediately after the operation. Doing so may burn your

fingers or hands.

Photo Coupler (PC1 to PC3): Type: TLP281-4

These ICs are used as the input/output circuits of each signal for the

external I/O interface.

DC/DC Converter (IC4): Type: R1223N332G

This IC is a DC/DC converter which generates 3.3V from +5V.

3.3V is used as the operating voltage for each circuit, and so on.

IC5

Heat Sink

Page 34

2. ELECTRONIC SPECIFICATIONS EO1033021

(Revision Date: Nov. 21, 2008)

2.4 DESCRIPTION OF THE DRIVER PC BOARD

2-12

CN1

CN2

Signal I/O

Pin

No.

GND --- 1

R_PINCH_VDD O 2

SENS_RBN_OPN I 3

GND --- 4

D_RENC_VDD O 5

SENS_D_ENC I 6

GND --- 7

W_RENC_VDD O 8

SENS_W_ENC I 9

GND --- 10

SCVR_OPN_VDD O 11

SENS_NEAR_E I 12

GND --- 13

HEAD_UP_VDD O 14

SENS_HEAD_UP I 15

GND --- 16

P_NEND_VDD O 17

SENS_SCVR_OPN I 18

GND --- 19

P_END_VDD O 20

SENS_P_END I 21

GND --- 22

TH_OPEN_VDD O 23

SENS_TH_OPN I 24

GND --- 25

FCVR_OPN_VDD O 26

SENS_FCVR_OPN I 27

GND --- 28

RSRV_VDD O 29

SENS_RSRV I 30

This connector is connected to the sensors as follows. The

sensor control and sensor status signals are input into the

connector.

• Media End Sensor

• Media Near End Sensor

• Print Head Open Sensor

• Home Position Sensor (Print Head Open Sensor)

• Front Cover Open Sensor

• Side Cover Open Sensor

• Ribbon Encoder Sensor (Ribbon Feed, Ribbon Rewind)

Signal I/O

Pin

No.

A-GND --- 1

LED_CENT O 2

A-GND --- 3

CENT_SIG_VDD O 4

SENS_CENT_SIG I 5

A-GND --- 6

LED_REF O 7

SENS_REF_SIG I 8

A-GND --- 9

A-VDD1 O 10

SENS_THERMISTOR_SIG I 11

A-GND --- 12

A-GND --- 13

A-VDD2 O 14

SENS_A_RSRV I 15

A-GND --- 16

LED_INT O 17

A-GND --- 18

A-GND --- 19

INT_GIG_VDD O 20

SENS_INT_SIG I 21

A-GND --- 22

A-VDD3 O 23

SENS_RIBN_END_SIG I 24

This connector is connected to the sensors as follows. The

sensor control and sensor status signals are input into the

connector.

• Ribbon End Sensor

• Media Sensor (Transmissive Sensor, Reflective Sensor)

• Transmissive Media Center Sensor

• Environmental Temperature Thermistor

Page 35

2. ELECTRONIC SPECIFICATIONS EO1033021

(Revision Date: Nov. 21, 2008)

2.4 DESCRIPTION OF THE DRIVER PC BOARD

2-13

CN3

CN4

CN5

CN6

Signal I/O

Pin

No.

RIBBON_WAND_OUT_A O 1

RIBBON_WAND_OUT_B O 2

Signal I/O

Pin

No.

RIBBON_DELIVER_OUT_A O 1

RIBBON_DELIVER_OUT_B O 2

Signal I/O

Pin

No.

COM_A O 1

COM_B O 2

A O 3

N_A O 4

B O 5

N_B O 6

Signal I/O

Pin

No.

36V O A1

3.3V O A2

OPT_CUT_M_CLOCK O A3

OPT_CUT_M_RESET O A4

5V_P_3 O A5

OPT_CON_SIG_1 I A6

OPT_CON_SIG_2 I A7

OPT_CUT_M_MODE_1 O A8

OPT_CUT_M_MODE_2 O A9

OPT_CUT_M_MODE_3 O A10

CUT_M_HP_RIGHT I B1

CUT_M_HP_LEFT I B2

OPT_PEEL I B3

GND --- B4

GND --- B5

GND --- B6

OPT_CUT_M_POWER O B7

OPT_CUT_M_CW_CCW O B8

GND --- B9

GND --- B10

This connector is connected to the cutter drive PC board.

(It is used only for the model with the cutter, but unused for the

standard model and the model with the strip module.)

This connector is connected to the ribbon motor (rewind).

The RIBBON_WAND_OUT_A and RIBBON_WAND_OUT_B

signals generated from the motor driver IC (IC6) are output

from the connector.

This connector is connected to the ribbon motor (feed).

The RIBBON_DELIVER_OUT_A and

RIBBON_DELIVER_OUT_B signals generated from the moto

r

driver IC (IC7) are output from the connector.

This connector is connected to the stepping motor.

The COM_A and COM_B, operating voltage for the stepping

motor, are output from the pins 1 and 2, respectively.

The control signals A, N_A, B, and N_B are output from the

pins 3, 4, 5, and 6, respectively.

Page 36

2. ELECTRONIC SPECIFICATIONS EO1033021

(Revision Date: Nov. 21, 2008)

2.4 DESCRIPTION OF THE DRIVER PC BOARD

2-14

CN8

CN9

CN10

CN11

Signal I/O

Pin

No.

24V_TH O 1

24V_TH O 2

24V_TH O 3

24V_TH O 4

P_GND --- 5

P_GND --- 6

P_GND --- 7

P_GND --- 8

This connector is connected to the print head.

The 24V, operating voltage for the print head, is supplied

from the connector.

Signal I/O

Pin

No.

P_GND --- 1

GND --- 2

36V O 3

5V_P_1 O 4

This connector is connected to the print server.

The +5V and 36V, operating voltage for the print server is

supplied from the connector.

Signal I/O

Pin

No.

24V_EXIT_IN I 1

GND_EXT --- 2

EXT_BACK_FEED I 3

EXT_PRINT_START I 4

EXT_PAUSE I 5

EXT_RESERVE_IN I 6

EXT_ERROR O 7

EXT_PRINT_DATA O 8

GND_EXT --- 9

EXT_COMP_NORMALITY O 10

EXT_COMP_ABNORMALITY O 11

EXT_READY_PAUSE O 12

EXT_RIBBON_END O 13

EXT_LABEL_END O 14

EXT_RESERVE_OUT O 15

This connector is used for the external interface.

It is connected to the 15-pin D-sub connector on the back o

f

the printer.

For each signal, refer to Section 4.1.7. PIN Description.

Signal I/O

Pin

No.

GND --- 1

GND --- 2

5V I 3

5V I 4

P_GND --- 5

VM I 6

This connector is connected to the 5V power supply unit.

The +5V and VM (36V), operating voltage for the ICs and

devices such as stepping motor and ribbon motor, are input

into the connector.

The VM and +5V are protected by the fuses FU3 and FU5,

respectively.

For safety VM (36V) is supplied only when the interlock

switches of the right side cover and the front cover are on

(cover close).

Page 37

2. ELECTRONIC SPECIFICATIONS EO1033021

(Revision Date: Nov. 21, 2008)

2.4 DESCRIPTION OF THE DRIVER PC BOARD

2-15

CN12

CN13

CN14

Signal I/O

Pin

No.

P_GND --- 1

P_GND --- 2

P_GND --- 3

P_GND --- 4

P_GND --- 5

24V I 6

24V I 7

24V I 8

24V I 9

This connector is connected to the 24V power supply unit.

The 24V is input into the connector.

Signal I/O

Pin

No.

PSU2_VH_REMOTE_VCC O 1

PSU2_VH_REMOTE O 2

PSU1_VM_REMOTE_VCC O 3

PSU1_VM_REMOTE_GND O 4

Signal I/O

Pin

No.

FAN_VH O 1

FAN_REV I 2

P_GND --- 3

This connector is connected to the fan motor.

The FAN_VH functions as the operating voltage +24V.

This connector is connected to the 5V power supply unit and

the 24V power supply unit.

The control signals are output from the connector.

Page 38

2. ELECTRONIC SPECIFICATIONS EO1033021

(Revision Date: Nov. 21, 2008)

2.4 DESCRIPTION OF THE DRIVER PC BOARD

2-16

CN7

Signal I/O

Pin

No.

Signal I/O

Pin

No.

GND --- 1 GND --- 51

GND --- 2 GND --- 52

GND ---- 3 GND --- 53

GND --- 4 GND --- 54

+5V O 5 +5V O 55

+5V O 6 +5V O 56

+5V O 7 +5V O 57

+5V O 8 +5V O 58

+5V O 9 +5V O 59

+5V O 10 +5V O 60

VM_MONITOR O 11 FAN_REVOLUTION O 61

VTH_MONITOR O 12 N_DISCHARGE I 62

N_PSU_REMOTE I 13 EXT_IF_LABEL_END I 63

EXT_IF_ERROR I 14 EXT_IF_CMP_NRMLTY I 64

EXT_IF_CMP_ABNRMLTY I 15 EXT_IF_READY_N_PAUSE I 65

EXT_IF_PRINT_DATA I 16 EXT_IF_RIBBON_END I 66

EXT_IF_RESERVE_OUT I 17 EXT_IF_PAUSE O 67

EXT_IF_BACK_FEED O 18 EXT_IF_RESERVE_IN O 68

EXT_IF_PRINT_START O 19 N_HEAD_ENABLE I 69

N_HEAD_CHECK I 20 CUT_M_CW_CCW I 70

CUT_M_CLOCK I 21 CUT_M_MODE_1 I 71

CUT_M_POWER I 22 CUT_M_MODE_3 I 72

CUT_M_MODE_2 I 23 OPT_SIG_1 O 73

CUT_M_RESET I 24 OPT_SIG_2 O 74

LF_M_CLOCK I 25 LF_M_CW_CCW I 75

LF_M_POWER_1 I 26 LF_M_POWER_2 I 76

LF_M_MODE_1 I 27 LF_M_MODE_2 I 77

LF_M_MODE_3 I 28 LF_M_RESET I 78

RBN_M_WAND_UP_ENABLE I 29 RBN_M_DELIVER_ENABLE I 79

RBN_M_WAND_UP_MODE I 30 RBN_M_DELIVER MODE I 80

RBN_M_WAND_UP_PAHSE I 31 RBN_M_DELIVER_PAHSE I 81

RBN_M_WAND_UP_PFD_1 I 32 RBN_M_DELIVER_PFD_1 I 82

RBN_M_WAND_UP_PFD_2 I 33 RBN_M_DELIVER_PFD_2 I 83

GND --- 34 GND --- 84

GND --- 35 GND --- 85

RBN_M_WND_UP_REF I 36 RBN_M_DELIVER_REF I 86

SENS_CENTER_HOLE O 37 SENS_HEAD_RESISTOR O 87

SENS_INTERRUPTER O 38 SENS_REFLECTIVE O 88

SENS_THERMISTOR O 39 SENS_RIBBON_END O 89

GND --- 40 GND --- 90

GND --- 41 GND --- 91

SENS_CUT_HP_LEFT_PEL O 42 SENS_CUT_HP_RIGHT O 92

SENS_PAPER_NEAR_END O 43 SENS_FRONT_COVER_OPN O 93

SENS_HEAD_OPEN O 44 SENS_HEAD_LATCH_OPN O 94

SENS_PAPER_END O 45 SENS_SIDE_COVER_OPN O 95

SENS_RBN_WAND_UP_ENC O 46 SENS_RBN_DELIVER_ENC O 96

SENS_RBN_PINCH O 47 LED_PULSE_INT I 97

LED_PULSE_CENTER I 48 LED_PULSE_REF I 98

RESERVE_IN_1 O 49 RESERVE_IN_2 O 99

RESERVE_OUT_1 I 50 POWER_ON_MAIN I 100

This connector is connected to the MAIN PC board. It performs the input/output of the control signals

for the motors, sensors, and so on. Also, it outputs +5V, operating voltage for each circuit, to the CPU

PC board.

Page 39

3. MEDIA AND RIBBON SPECIFICATIONS EO13-33001

3.1 SUPPLY SPECIFICATIONS

3-1

3. MEDIA AND RIBBON SPECIFICATIONS

3.1 SUPPLY SPECIFICATIONS

Item Batch/Tear-off mode Strip mode Cut mode

Media width (Backing

paper width)

15 mm to 120 mm

Media thickness (total) 0.08 mm to 0.26 mm

Media pitch 5 mm to 1,000 mm 12 mm to 1,000 mm 10 mm to 1,000 mm

Label length - 10 mm to 998 mm

(Note 1)

-

Label width - 10 mm or more Label thickness - 0.05 mm or more Backing paper thickness - 0.1 mm or less Material of backing

paper

- Glassine paper -

Media type (Roll

direction)

Roll (Inside/outside)

Fanfold (Note 2)

Roll (Inside) Roll (Inside/outside)

Fanfold

Max. outside roll

diameter

∅200 mm

Inner core diameter ∅76.2 mm

Ribbon width 30 to 120 mm (A ribbon must be at least 10 mm wider than the loaded

media.)

Ribbon roll direction Ink side faces outside

Ribbon inner core

diameter

∅25.4 mm to ∅ 26.4 mm

End of ribbon Minimum of 200 mm long silver film is attached to the end of the ribbon.

Outside roll diameter ∅70 mm or less (Ribbon length: Approx. 300 m or less)

Notes:

1. If the length of a label is long, place the printer on a surface where an ejected label does not stick

to the printer or floor.

2. Feed fanfold paper from back of the printer. (Refer to section 5.3 of owner’s manual)

3. Use a ribbon that is at least 10 mm wider than the media.

4. In the case of peel-off operation, use of perforated labels is not allowed.

5. Feed fanfold paper through the Fanfold Paper Slot on the printer back.

Page 40

3. MEDIA AND RIBBON SPECIFICATIONS EO13-33001

3.2 DIE-CUT LABEL

3-2

3.2 DIE-CUT LABEL

“Die-cut label” refers to a label stock of which labels are die cut one by one and surroundings are removed,

as illustrated below.

When a die-cut label stock is loaded, either the Transmissive Media Edge Sensor or the Transmissive Media

Center Sensor is used to detect a print position. The Transmissive Media Center Sensor is located at the

centre of the label feed path. (Refer to section 1.3 of owner’s Manual)

Precautions

・ The Transmissive Media Edge Sensor must be placed so that it does not come into contact with the media.

Media feed direction

Label pitch

5 to 1,000 mm

Transmissive Media

Edge Sensor

Page start line

25 mm

Gap

2 to 13 mm

20 mm or less

R2 mm or less

15 to 120 mm

Page 41

3. MEDIA AND RIBBON SPECIFICATIONS EO13-33001

3.3 NOTCHED MEDIA

3-3

3.3 NOTCHED MEDIA

“Notched media” is notched on the left at a regular interval. When notched media is loaded, the

Transmissive Paper Edge Sensor is used.

Precautions

・ The Transmissive Paper Edge Sensor must be placed so that it does not come into contact with the

media.

Media feed direction

Page start line

Notch

4 mm or over

2 to 13 mm

Transmissive Paper Edge Sensor

15 to 120 mm

Page 42

3. MEDIA AND RIBBON SPECIFICATIONS EO13-33001

3.4 LABEL WITH BLACK MARKS

3-4

3.4 LABEL WITH BLACK MARKS

“Label with black marks” refers to a label stock with black marks printed at the back of the backing

paper for the position detection purpose, as illustrated below. When a label stock with black marks is

loaded, the Reflective Media Sensor is used.

Label pitch

10 to 1,000 mm

Page start line

12 mm or over

Reflective Media Sensor

(Located under the media)

Media feed direction

2 to 13 mm

Black mark on

the reverse

side

15 to 120 mm

Page 43

3. MEDIA AND RIBBON SPECIFICATIONS EO13-33001

3.5 GUARANTEED PRINT AREA

3-5

3.5 GUARANTEED PRINT AREA

Printing must be performed within the shaded area as illustrated below.

If a printed image is placed outside this area, the loaded ribbon may be torn or the print quality may be

degraded.

1. Die-cut label

2. Notched media

B

B

A

A

Label width

Media width

Label length

A

= 2 mm or over

B = 1.5 mm (if a label length is 100 mm or less)

B = 2.5 mm (if a label length is more than 100 mm)

B

A

A

B

Media width

A

= 2 mm or over

B = 1.5 mm (if a notch pitch is 100 mm or less)

B = 2.5 mm (if a notch pitch is more than 100 mm)

Page 44

3. MEDIA AND RIBBON SPECIFICATIONS EO13-33001

3.6 STORAGE OF MEDIA AND RIBBONS

3-6

3.6 STORAGE OF MEDIA AND RIBBONS

1. Store the media and ribbon in a cool, dry place. Avoid areas where they would be exposed to direct

sunlight, high temperature, high humidity, dust or gas.

2. Store the media in a plastic bag so as not to collect dust or dirt particles.

3. Store media rolls on the flat end. Do not store them on the curved sides as this might flatten that side

causing erratic media advance and poor print quality.

3.7 UNACCEPTABLE MEDIA AND RIBBONS

4. Wrinkled, folded, or ripped media

5. Media on which dust particles settle on

6. Media or ribbon whose edge is wavy

7. Curled media

8. Damp media or ribbon

9. Media or ribbon already used for printing

10. Media whose surface is treated (except for designated media)

11. Media whose thickness does not meet the specifications

12. Perforated or punched media (except for designated media)

13. Label from which adhesive squeezes out

14. Partially darkened media

15. Media or ribbons of which shelf life is expired

When you purchase media and ribbons

There are a wide variety of media or ribbons depending on what they are made of and how the front and

back surfaces are treated.

Please use only TOSHIBA TEC-approved or recommended media and ribbons in order to ensure the best

print quality.

TOSHIBA TEC shall not be liable for any print failures or defects arising from the use of non-approved media

or ribbons.

Preprinted Media

When preprinted media (for instance, media with a box already printed on it) is used for printing, the Print

Head may be damaged by the ink used for preprinting. Particularly, if pigment-based ink is used for

preprinting, the life of the Print Head will be considerably reduced. Please contact your nearest authorised

TOSHIBA TEC representative for further information before using preprinted media.

If you use media with preprints on the back and have the Reflective Media Sensor (designed to detect black

marks) detect black marks, please consult your nearest authorised TOSHIBA TEC representative. The

Reflective Media Sensor is only applicable to the media with preprints printed with special ink.

Page 45

4. EXPANSION I/O INTERFACE EO13-33001

4.1 Expansion I/O Interface

4-1

4. INTERFACE

4.1 Expansion I/O Interface

4.1.1 Scope

This specification describes the functions provided through the expansion input/output (I/O) interface of the

B-SX600 series (hereinafter referred to as “this printer”) and the control of the signals between this printer

and an external device.

For details, please refer to the Expansion I/O Specifications.

4.1.2 Basic System Configuration and Scope of Application

The following diagram shows the basic system configuration including this printer and peripherals and the

applicable scope of this specification.

4.1.3 General Description of the Expansion I/O Interface of this Printer

To meet the requirements of various external devices of different controls, this printer has three

expansion I/O interface modes.

Each of the expansion I/O interface modes and its function are descried in the following section.

Page 46

4. EXPANSION I/O INTERFACE EO13-33001

4.1 Expansion I/O Interface

4-2

4.1.4 Mode of the Expansion I/O Interface

This printer has three expansion I/O interface modes that are different in the available functions and

operations.

● Expansion I/O interface disabled

The expansion I/O interface is disabled, and input signals from an external device are ignored.

This mode has been selected as the factory default.

● Expansion I/O interface mode 1

It is possible to obtain printer statuses, switch between “Printer ready” and “NOT ready” by an external

device, and cancel data in the printer buffer.

● Expansion I/O interface mode 2

In addition to the functions of mode 1 above, it is also possible to control the start of printing or the start

of a reverse feed by an external device.

This mode can be selected only on the printer with a peel-off module. Be sure to enable the peel-off

issue whenever this mode is selected.

4.1.5 External Signal Connector

This printer is equipped with a D-Sub 15-pin connector for interfacing with the sequencer of an automated

instrument. Since the signals of this connector are isolated from the printer’s internal circuit, it is possible to

send/receive signals to/from an external device only by turning on the external device.

(1) Expansion I/O Interface Connector on the Printer

Manufacturer: DDK Ltd. Connector model: 17DE-13150-C (socket connector)

Connector body 17DE-13150-C D-Sub 15-pin Socket type

Connector contact 17D-303SCR Socket contact

Jack socket 17L-003A3 with M2.6 screw, Depth: 4 mm or less

(2) Recommended Mating Connector

The following connector is recommended as a mating connector.

Manufacturer DDK Ltd.

Connector body 17DE23150-C D-Sub 15-pin Contact type

Connector contact 17D-703PCR Pin contact

Mounting screw M2.6, Depth: 4 mm or less

Loading...

Loading...