Toshiba B-SX600 SERIES, B-SX600-HS11, B-SX600-HH11, B-SX600-HC11-QM-R Product Description

TOSHIBA Barcode Printer

B-SX600 SERIES

Document No. EO10-33021

Original Sep., 2008

(Revised )

Product Description

EO10-33021

(Revision Date: Nov. 21, 2008)

TABLE OF CONTENTS

Page

1. OUTLINE -------------------------------------------------------------------------------------------------1- 1

1.1 PRINTER SPECIFICATIONS ---------------------------------------------------------------------------1- 1

1.2 DESCRIPTION OF MODEL NUMBER --------------------------------------------------------------- 1- 2

1.3 PART NAMES NAD FUNCTIONS -------------------------------------------------------------------- 1- 3

1.4 OPERATION PANEL-------------------------------------------------------------------------------------- 1- 5

1.5 DIMENSIONS (APPROXIMATE) ---------------------------------------------------------------------- 1- 6

1.6 OPERATING ENVIRONMENT -------------------------------------------------------------------------1- 6

1.7 BASIC SPECIFICATIONS ------------------------------------------------------------------------------- 1- 7

1.8 CUTTER UNIT SPECIFICATIONS (B-SX600-HC11/HC12-QM-R model) ------------------1- 8

1.9 STRIP UNIT SPECIFICATIONS (B-SX600-HH11/HH12-QM-R MODEL)------------------- 1- 8

1.10 MECHANICAL BLOCK ----------------------------------------------------------------------------------- 1- 9

1.10.1 Mechanism ----------------------------------------------------------- 1- 9

1.10.2 Outline of the Mechanical Block ------------------------------------------------------------- 1-12

1.10.3 Print Head Block --------------------------------------------------------------------------------- 1-13

1.10.4 Media Roll Holder -------------------------------------------------------------------------------- 1-14

1.10.5 Lower Unit ----------------------------------------------------------------------------------------- 1-15

1.10.6 Strip Unit ------------------------------------------------------------------------------------------- 1-16

1.10.7 Cutter Unit ----------------------------------------------------------------------------------------- 1-17

1.10.8 Position of various sensors ------------------------------------------------------------------- 1-18

2. ELECTRONIC SPECIFICATIONS -----------------------------------------------------------------2- 1

2.1 ELECTRONIC BLOCK------------------------------------------------------------------------------------ 2- 1

2.2 BLOCK DIAGRAM -----------------------------------------------------------------------------------------2- 2

2.3 DESCRIPTION OF THE MAIN PC BOARD---------------------------------------------------------2- 3

2.3.1 Parts Side Layout--------------------------------------------------------------------------------- 2- 3

2.3.2 Solder Side Layout -------------------------------------------------------------------------------2- 4

2.3.3 Outline of the ICs and Connectors ----------------------------------------------------------- 2- 5

2.4 DESCRIPTION OF THE DRIVER PC BOARD---------------------------------------------------- 2-10

2.4.1 PC Board Layout -------------------------------------------------------------------------------- 2-10

2.4.2 Outline of the ICs and Connectors ---------------------------------------------------------- 2-11

3. MEDIA AND RIBBON SPECIFICATIONS -------------------------------------------------------3- 1

3.1 SUPPLY SPECIFICATIONS ---------------------------------------------------------------------------- 3- 1

3.2 DIE-CUT LABEL-------------------------------------------------------------------------------------------- 3- 2

3.3 NOTCHED MEDIA----------------------------------------------------------------------------------------- 3- 3

3.4 LABEL WITH BLACK MARKS-------------------------------------------------------------------------- 3- 4

3.5 GUARANTEED PRINT AREA --------------------------------------------------------------------------3- 5

3.6 STORAGE OF MEDIA AND RIBBONS -------------------------------------------------------------- 3- 6

3.7 UNACCEPTABLE MEDIA AND RIBBONS---------------------------------------------------------- 3- 6

EO10-33021

(Revision Date: Nov. 21, 2008)

4. INTERFACE ---------------------------------------------------------------------------------------------4- 1

4.1 Expansion I/O Interface-----------------------------------------------------------------------------------4- 1

4.1.1 Scope------------------------------------------------------------------------------------------------ 4- 1

4.1.2 Basic System Configuration and Scope of Application ---------------------------------4- 1

4.1.3 General Description of the Expansion I/O Interface of this Printer------------------- 4- 1

4.1.4 Mode of the Expansion I/O Interface --------------------------------------------------------4- 2

4.1.5 External Signal Connector --------------------------------------------------------------------- 4- 2

4.1.6 Pin Layout ------------------------------------------------------------------------------------------ 4- 3

4.1.7 PIN Description -----------------------------------------------------------------------------------4- 3

CAUTION!

1. This manual may not be copied in whole or in part without prior written permission of TOSHIBA

TEC.

2. The contents of this manual may be changed without notification.

Copyright © 2008

by TOSHIBA TEC CORPORATION

A

ll Rights Reserved

570 Ohito, Izunokuni-shi, Shizuoka-ken, JAPAN

1. OUTLINE EO10-33021

1.1 PRINTER SPECIFICATIONS

1-1

1. OUTLINE

1.1 PRINTER SPECIFICATIONS

1) High quality and resolution

• The resolution in the media feed direction is 1200 dpi, the highest resolution for label printers.

• This printer can precisely print on a 3-mm long label, also can peel off 10-mm long label.

• Prevents change of the ribbon tension which causes ribbon wrinkles.

• Prevents an imbalance contact of the print head with the media and blurred print at the media edges.

2) Interface

• Use of the printer driver eliminates the need of learning any printer specific commands. Also, it is

possible to develop a general-purpose system according to the standard specification.

• Bi-directional communication feature and status monitor API enable the host application to correctly

obtain a end of print job status even when using the printer driver.

• For network printing, the standard print protocol (LPR, Raw) has been adopted.

Bi-directional communication feature of Raw enables obtaining an end of print job status via network.

Like the USB interface model, it realizes complete management of print jobs. Network printing can

be performed without any special printing software.

3) User friendliness

• Very easy supply loading due to the pop-up mechanism of the print head block.

• Easy-to-understand operation menus enable user intuitive operations.

• Large LCD panel displays the printer status or operating procedures. (Language is selectable

between Japanese and English.)

• Print head and platen roller can be replaced without any tools.

• Simple driver installer enables easy and secure installation of the printer driver.

4) Safety and environment consciousness

Interlock switch:

While the cover is opened, printing operation is stopped and the power supply to the print head is shut

down.

User protection:

This printer is designed so that users cannot touch the moving parts such as the platen roller or the cutter

unit.

EMC (Electromagnetic compatibility):

Emission of electromagnetic noise, which influences other electronics devices, is reduced. Also, the

immunity to electromagnetic noise generated by surrounding devices is enhanced.

No use of hazardous chemical substances

Compliance with EU RoHS directive

5) Option

A variety of options are provided to meet your needs.

• Cutter module (Factory option)

• Strip module (Factory option)

• Network adapter (Factory option)

Network interface: 10BASE-T/100BASE-TX (Automatic sensing), Protocol: TCP-IP

Notes:

1. B-SX600 Series does not support TPCL (TEC Printer Command Language).

2. Printable bar code, two-dimensional code, and font type depend on PC’s operating environment and

application software.

3. In the Low Power Mode, the fan motor pauses as a proper operation.

4. When the power is on, the ribbon motor works for applying proper tension to the ribbon.

1. OUTLINE EO10-33021

1.2 DESCRIPTION OF MODEL NUMBER

1-2

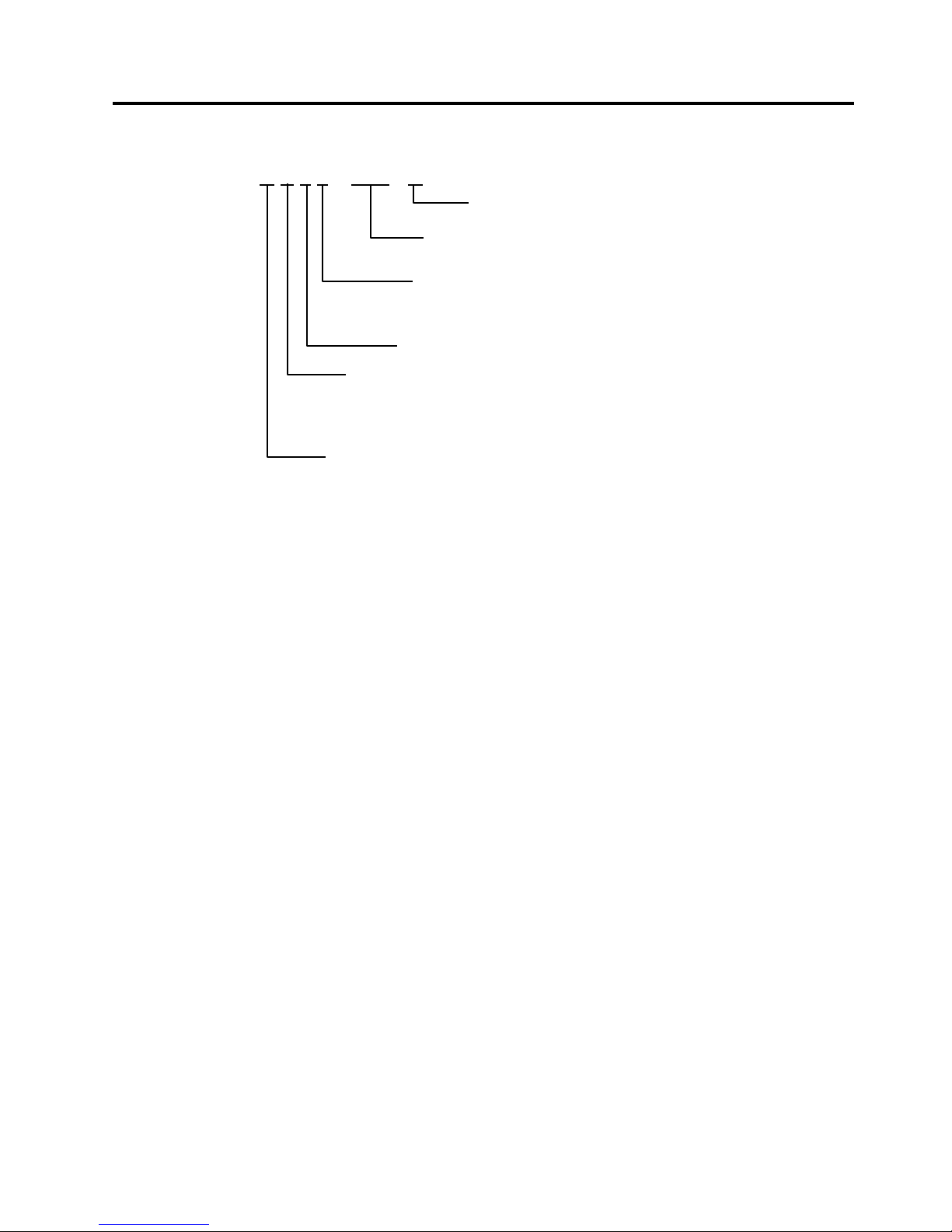

1.2 DESCRIPTION OF MODEL NUMBER

B – S X 6 0 0 – H

S 1 1 – Q M - R

RoHS compliance model

Destination Code

QM: Standard for World Wide

Issue Mode

S: Batch

H: Strip

C: Cut

Resolution

H: 600 dpi

Interface

1: USB

2: LAN

Machine Version

1. OUTLINE EO10-33021

1.3 PART NAMES AND FUNCTIONS

1-3

1.3 PART NAMES AND FUNCTIONS

Side Cover

Opened when the media o

r

ribbon is loaded or replaced.

Supply Window

A

remaining quantity of the

media or ribbon can be

checked through the Supply

Window.

Front Cover Unlock Button

Used to open the Front Cover.

Side Cover Grip

Used to open the Side Cover.

Media Outlet

Printed outputs are ejected

through the Media Outlet.

Front Cove

r

Opened when the

media is loaded o

r

replaced.

Power Switch

Used to turn the

p

rinter on/off.

Front View

Standard model or Cutter model

Strip model

Front Cover Unlock Button

Used to open the Front Cover.

Front Cover

Opened when the media is

loaded or replaced.

Strip Unit

Media Holding Roller

Strip Senso

r

Operation Panel

Used to following.

•Select a menu

•Printer Setting

•Display Message

etc.

(For details, refer to

section 1.4)

1. OUTLINE EO10-33021

1.3 PART NAMES AND FUNCTIONS

1-4

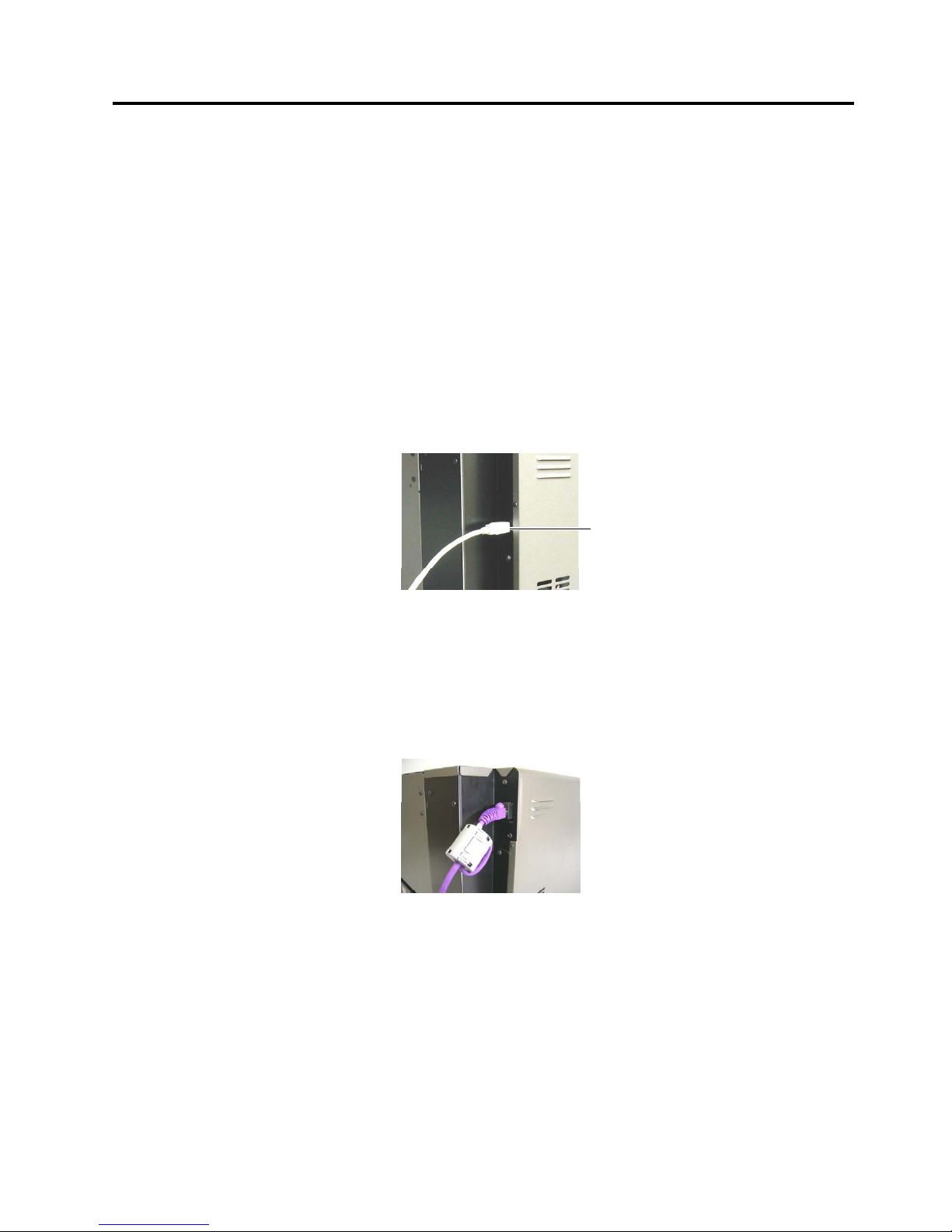

Rear View

USB Interface Connecto

r

Used to connect the printer to a PC

with a USB cable.

(USB Interface model only)

Ventilation Slot

Lets trapped heat pass out of the printer.

Expansion I/O Interface Connecto

r

Used to interface with an external

equipment (Refer to Section 4.)

A

C Power Inlet

Fanfold Paper Slot

A

llows fanfold paper to

feed into the printer from

the printer back.

LAN Interface Connecto

r

Used to connect the printer to a PC

with a LAN cable.

(LAN Interface model only)

Left Side Panel

Reset Switch

Used to reset the print server to the

factory default by the insertion of the

reset pin into the hole.

1. OUTLINE EO10-33021

1.4 OPERATION PANEL

1-5

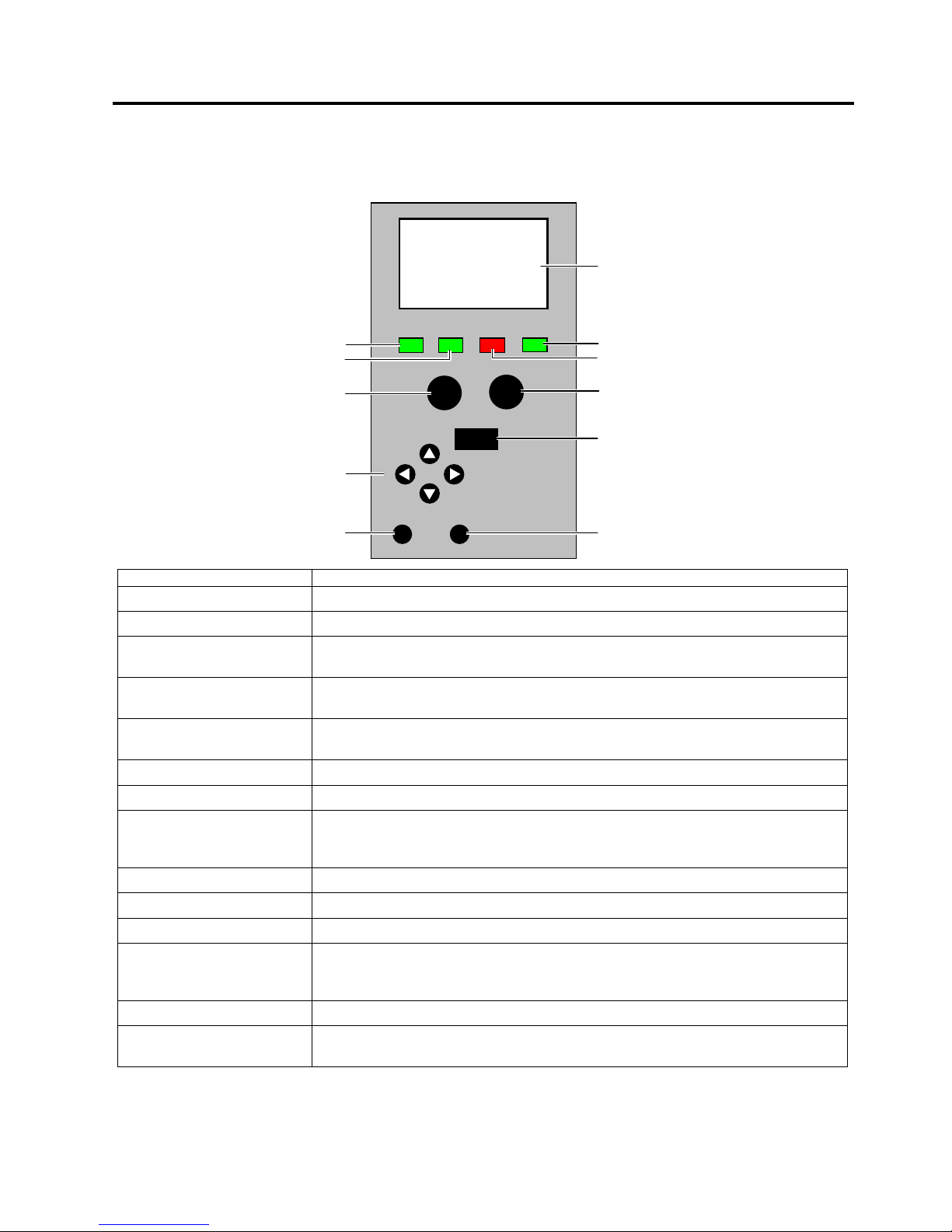

1.4 OPERATION PANEL

The Operation Panel is equipped with the LCD Message Display, which is used to indicate the state of the

printer, 4 LED’s, and 9 keys. Please see the table below for details.

Name Functions (Purposes)

LCD Message Display Shows the menu or error information.

Power LED Illuminates in green when the printer is turned on.

Ready LED Illuminates in green when the printer is ready, and goes out when the printer is in

a pause state or while the menu is being displayed.

Error LED Illuminates in red when an error occurs, and flashes in red in the event of a

warning.

Data LED Flashes in green when data is received, and illuminates in green when data is in

the receive buffer.

[Pause] key Used to place the printer in a pause or ready state.

[Feed] key Used to feed the media for a single page or label length.

[Menu] key Used to display the menu when the printer is in a ready or pause state. When

held down, the [Menu] key will be locked, and when held down again, it will be

unlocked.

◄key

Used to choose an item on the left while the menu is being displayed.

►key

Used to choose an item on the right while the menu is being displayed.

▲key

Used to choose an item above while the menu is being displayed.

▼key

Used to choose an item below while the menu is being displayed.

When the model with the Cutter Unit is used, holding down this key in a ready or

pause state causes the media to be cut.

[Enter] key Used to determine the settings while the menu is being displayed.

[Cancel] key Used to clear an error when it occurs.

When held down, print data is cleared.

LCD Message Display

Error LED

[

Feed]Key

[

Menu] Key

[

Cancel] Key

Ready

No. 00000

Power

Ready

Error Data

Ente

r

Menu

Pause

Feed

Cancel

Data LED

Power LED

Ready LED

[PAUSE] Key

Cursor Keys

(◄ ► ▲ ▼)

[Enter] Key

1. OUTLINE EO10-33021

1.5 DIMENSIONS (APPROXIMATE)

1-6

A

cceptable operating

range

Print quality

guaranteed range

10 20 30 40

20

40

60

80

%RH

℃

5℃90%

29℃90%

5℃

55%

40℃39%

40℃10%

18℃

60%

28℃

60%

28℃

40%

18℃

40%

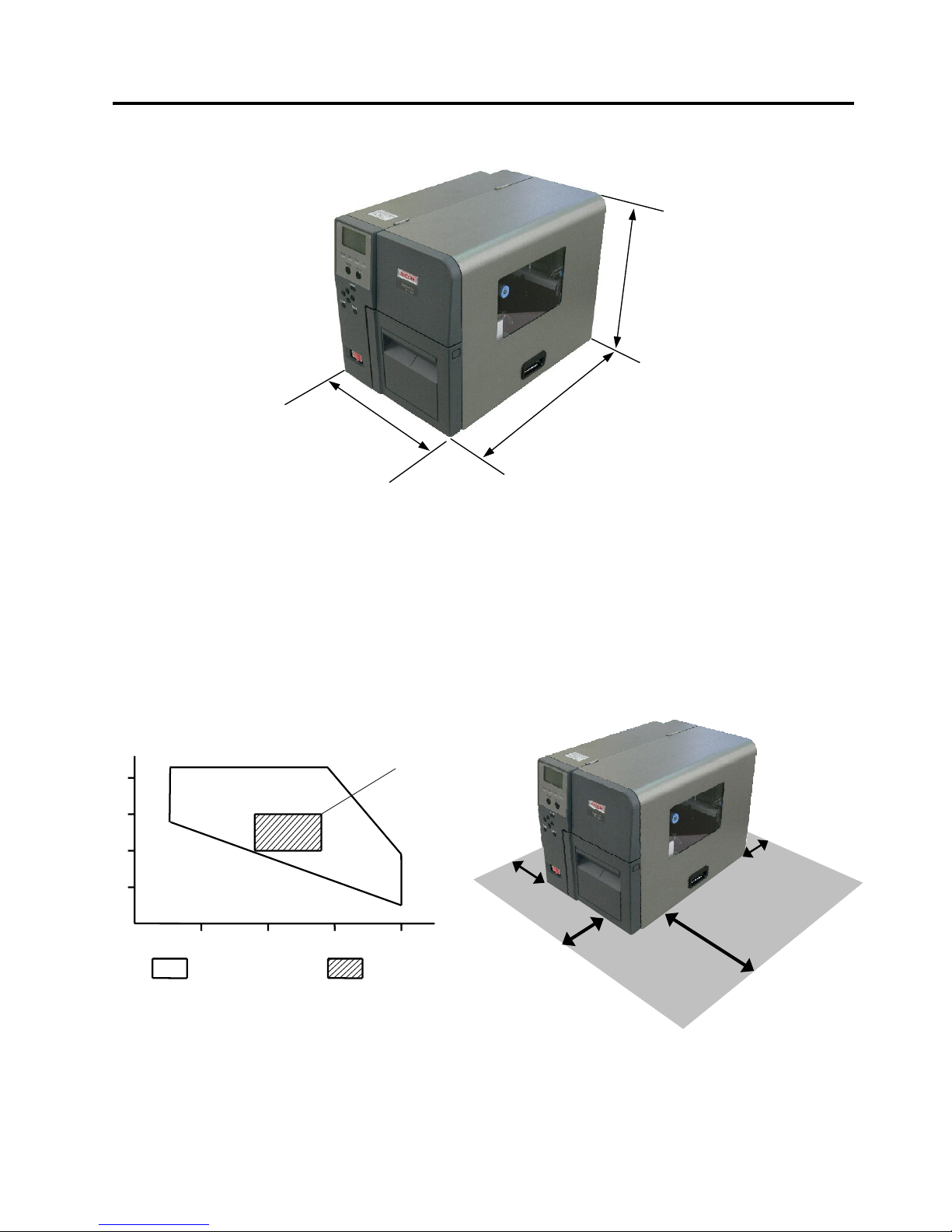

1.5 DIMENSIONS (APPROXIMATE)

1.6 OPERATING ENVIRONMENT

Install the printer in a place where ample space is reserved for the operation. Also, place the printer on a

well ventilated, smooth, level desk or rack specifically designed for the printer. Make sure that the 4 feet of

the printer make full contact with the surface of the desk or rack.

Be sure that there is sufficient space around the printer, as illustrated below.

Depth: 455mm

Width: 300mm

Height: 353.5mm

(including the rubber feet)

Min 15cm

Min 30cm

Min 5cm

Min 10cm

1. OUTLINE EO10-33021

1.7 BASIC SPECIFICATIONS

1-7

1.7 BASIC SPECIFICATIONS

(1) Printing method: Thermal direct printing or thermal transfer printing

(2) Resolutions (dot density): 600 dpi (23.6 dots/mm)

(3) Print speed: Max. 150 mm/second (6ips)

There are limitations on a print speed depending on the media or ribbon

type and an image to print.

Note: Print speed is selectable from 1 ips to 6 ips by the printer driver.

(4) Media alignment: Center

(5) Max. effective print width: 104 mm (Approximate 4”)

(6) Max. print length: 1,000 mm

(7) Available media width: 15 to 120 mm

(8) Host interface: USB model: B-SX600-HS11/HH11/HC11-QM-R

• USB 2.0 High Speed

LAN model: B-SX600-HS12/HH12/HC12-QM-R

• 10BASE-T / 100BASE-TX (IEEE802.3)

• Print Protocol: LPR, PORT9100 (unidirectional), PORT9100

(bi-directional)

• LPR queue name: lp

• Control protocol: HTTP

(9) Operating system: Windows 2000, Windows XP, Windows Server 2003, Windows Vista

(10) Weight: 20.6 kg (USB model: B-SX600-HS11/HH11/HC11-QM-R)

21.0 kg (LAN model: B-SX600-HS12/HH12/HC12-QM-R)

(11) Rating: Input Voltage: 100 VAC to 240 VAC

Frequency: 50/60 Hz (48 to 62 Hz)

Power consumption: 250 W or less under normal operation

20W or less under low power mode operation

Type B

1. OUTLINE EO10-33021

1.8 CUTTER UNIT SPECIFICATIONS (B-SX600-HC11/HC12-QM-R MODEL)

1-8

(12) Noise: 75 dB or less

(13) Operating temperature range: 5 to 40 °C (Print quality guaranteed at temperatures between 18 and 28

°C)

(14) Relative humidity: 10 to 90% (Print quality guaranteed at humidity between 40 and 60%)

(15) Storage temperature range: -20 to 70 °C

(16) Storage humidity range: 5 to 90%

(17) Safety and EMC Standard: CE, TÜV GS, C-Tick, UL, CUL, FCC, ICE, CCC

(18) Environmental standard: RoHS Directive compliant

1.8 CUTTER UNIT SPECIFICATIONS (B-SX600-HC11/HC12-QM-R MODEL)

(1) Acceptable media thickness: 0.08 mm to 0.26 mm

(2) Acceptable label pitch: 10 mm to 1,000 mm

(3) Cut mode: Continuous cut

Cut after printing

Batch cut

(4) Restrictions: Cutting self-adhesive labels is not allowed.

Cutting within 1 mm around perforation is not allowed.

Cutting fabrics or films is not allowed.

Note: The cutter unit is a factory option.

1.9 STRIP UNIT SPECIFICATIONS (B-SX600-HH11/HH12-QM-R MODEL)

(1) Effective print speed: 101.6 mm/second or less (same as a feed speed)

(2) Peeling method: Tensioning

(3) Peeling detection system: A reflective photo sensor is used to detect a label.

(4) Restrictions: Peel-off operation is not allowed when:

Perforated labels are used

Fanfold labels are used.

Fabrics or films are used

Outside wound labels are used

Labels other than rectangular die-cut labels are used.

Note: The strip unit is a factory option.

1. OUTLINE EO10-33021

1.10 MECHANICAL BLOCK

1-9

1.10 MECHANICAL BLOCK

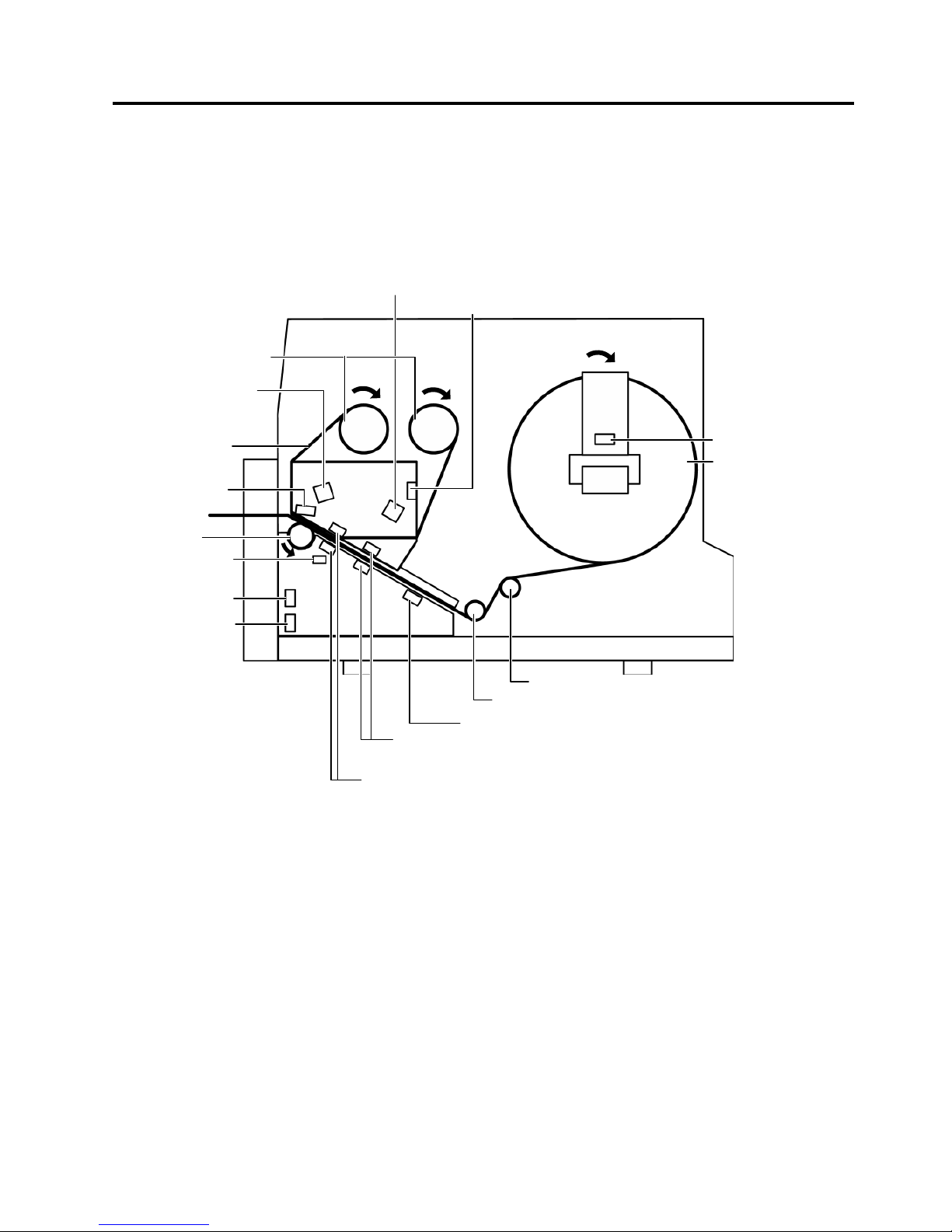

1.10.1 Mechanism

(1) Batch Mechanism (HS11/HS12 model)

This is the standard mechanism which lets the printer print continuously until the number of media specified

in the label issue command has been printed.

Media

Media Near End Sensor

Ribbon End Sensor

Ribbon Encoder Sensor

(Ribbon slit Sensor, Feed)

Ribbon

Ribbon Shaft

Front Cove

r

Open Senso

r

Side Cove

r

Open Senso

r

Media End Sensor

Movable Media Sensor (Feed Gap Sensor),

Reflective Media Sensor (Black Mark Sensor)

Print Head

Ribbon Encoder Senso

r

Ribbon slit Sensor, Take-up)

Print Head

O

p

en Senso

r

Fixed Media Sensor (Feed Gap Sensor)

Platen

Media Roll Damper

Media Roll Guide

1. OUTLINE EO10-33021

1.10 MECHANICAL BLOCK

1-10

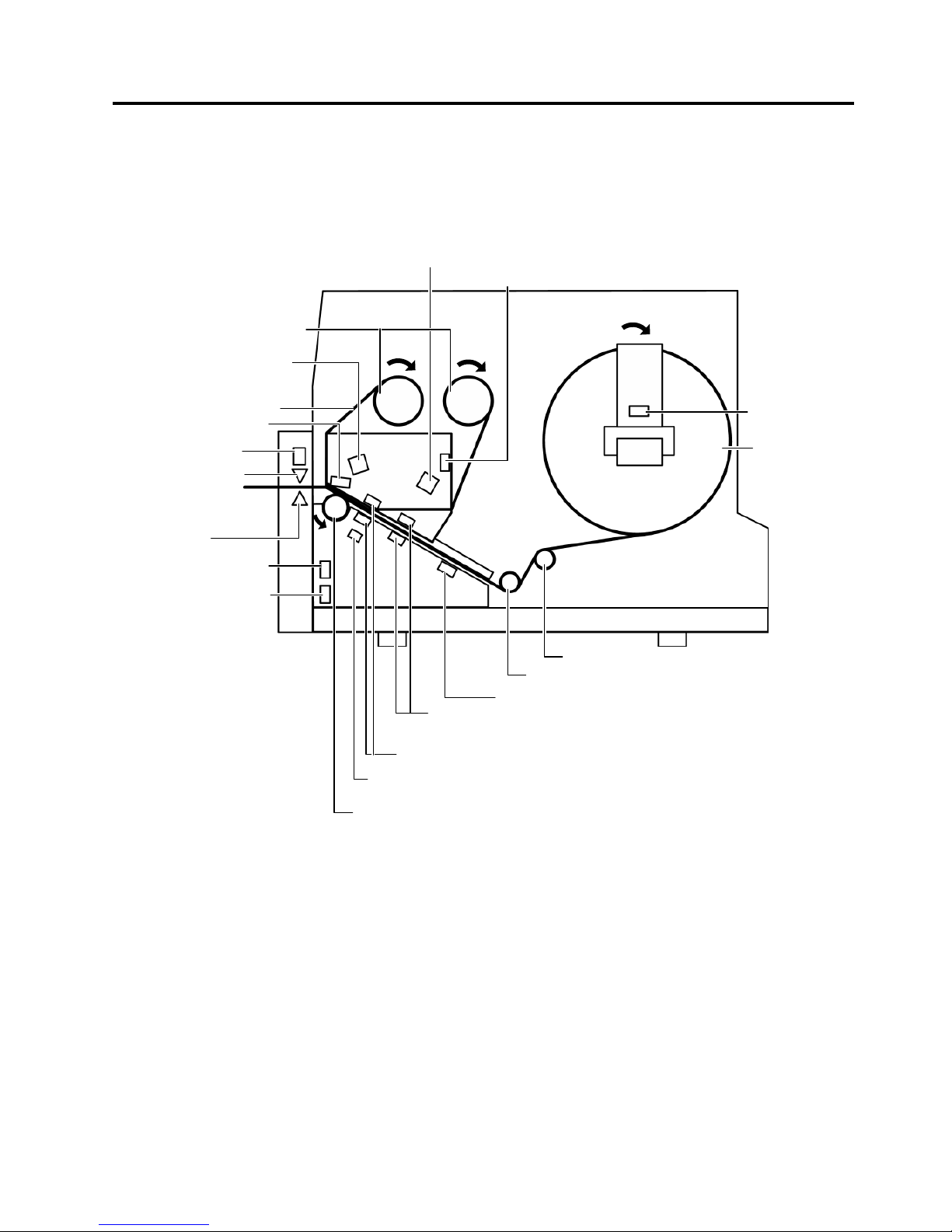

(2) Strip Mechanism (HH11/HH12 model)

When an factory optional strip module is attached, a label is stripped from the backing paper by the strip

shaft, and the backing paper is drawn into the strip module. The nextlabel will not be printed until the

preceding label is removed, as a presence of the label at the strip shaft is monitored by the strip sensor.

Media

Media Near End Sensor

Ribbon End Sensor

Ribbon

Ribbon Shaft

Front Cove

r

Open Senso

r

Feed Roller (Black)

Media End Sensor

Print Head

Print Head Open Sensor

Platen

Pinch Roller (White)

Strip senso

r

Backing Pape

r

Side Cove

r

Open Senso

r

Media Holding

Rolle

r

Media Roll Damper

Media Roll Guide

Strip Plate

Movable Media Sensor (Feed Gap Sensor),

Reflective Media Sensor

(

Black Mark Sensor

)

Fixed Media Sensor (Feed Gap Sensor)

Ribbon Encoder Sensor

(Ribbon slit Sensor, Feed)

Ribbon Encoder Senso

r

Ribbon slit Sensor, Take-up)

1. OUTLINE EO10-33021

1.10 MECHANICAL BLOCK

1-11

3) Cutter Mechanism (HC11/HC12 model)

When an factory optional Cutter module is attached, printed media is fed to the cutter unit and cut off from

the media roll.

Media

Media Near End

Sensor

Ribbon End Sensor

Ribbon

Ribbon Shaft

Front Cove

r

Open Senso

r

Media End Sensor

Print Head

Print Head Open Sensor

Platen

Cutter Blade

Media Roll Damper

Media Roll Guide

Side Cove

r

Open Senso

r

Cutter Carriage

Position Senso

r

Cutter Carriage Unit

Transmissive Media Edge Sensor (Feed Gap Sensor, Movable)

Reflective Media Sensor (Black Mark Sensor)

Transmissive Media Center Sensor (Feed Gap Sensor, Fixed)

Ribbon Encoder Sensor

(Ribbon slit Sensor, Feed)

Ribbon Encoder Senso

r

(Ribbon slit Sensor, Take-up)

Loading...

Loading...