Page 1

TOSHIBA Barcode Printer

B-SV4D SERIES

Owner’s Manual

Mode d’emploi

Bedienungsanleitung

Manual de instrucciones

Gebruikershandleiding

Manuale Utente

Manual do Utilizador

Page 2

CE Compliance (for EU only)

A

This product complies with the requirements of EMC and Low Voltage Directives including their

amendments.

VORSICHT:

• Schallemission: unter 70dB (A) nach DIN 45635 (oder ISO 7779)

• Die für das Gerät Vorgesehene Steckdose muß in der Nähe des Gerätes und leicht zugänglich sein.

Centronics is a registered trademark of Centronics Data Computer Corp.

Microsoft is a registered trademark of Microsoft Corporation.

Windows is a trademark of Microsoft Corporation.

This equipment has been tested and found to comply with the limits for a Class B digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference in a residential installation. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance with the instructions, may

cause harmful interference to radio communications. However, there is no guarantee that

interference will not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by turning the equipment off

and on, the user is encouraged to try to correct the interference by one or more of the following

measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and receiver.

- Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

- Consult the dealer or an experienced radio/TV technician for help.

(for USA only)

Changes or modifications not expressly approved by manufacturer for compliance could void the

user’s authority to operate the equipment.

“This Class B digital apparatus meets all requirements of the Canadian Interference-Causing

Equipment Regulations.”

“Cet appareil numérique de la classe B respecte toutes les exigences du Règlement sur le matériel

brouilleur du Canada.”

(for CANADA only)

The EA10953 AC adapter should be exclusively used for the B-SV4D Series printer.

The B-SV4D Series printer must be powered by the EA10953 AC adapter.

Waste Recycling information for users:

Following information is only for EU-member states:

The use of the crossed-out wheeled bin symbol indicates that this product may not

be treated as general household waste.

By ensuring this product is disposed of correctly you will help prevent

potential negative consequences for the environment and human health, which could

otherwise be caused by inappropriate waste handling of this product. For more

detailed information about the take-back and recycling of this product, please contact

your supplier where you purchased the product.

< For EU Only >

TOSHIBA TEC Europe Retail Information Systems S.A.

Rue de la Célidée 33 BE-1080 Brussels

Copyright © 2006

by TOSHIBA TEC CORPORATION

ll Rights Reserved

570 Ohito, Izunokuni-shi, Shizuoka-ken, JAPAN

Page 3

TOSHIBA Barcode Printer

B-SV4D SERIES

Owner’s Manual

Page 4

Safety Summary ENGLISH VERSION EO1-33061

W

Safety Summary

Personal safety in handling or maintaining the equipment is extremely important. Warnings and Cautions

necessary for safe handling are included in this manual. All warnings and cautions contained in this manual

should be read and understood before handling or maintaining the equipment.

Do not attempt to effect repairs or modifications to this equipment. If a fault occurs that cannot be rectified

using the procedures described in this manual, turn off the power, unplug the machine, then contact your

authorised TOSHIBA TEC representative for assistance.

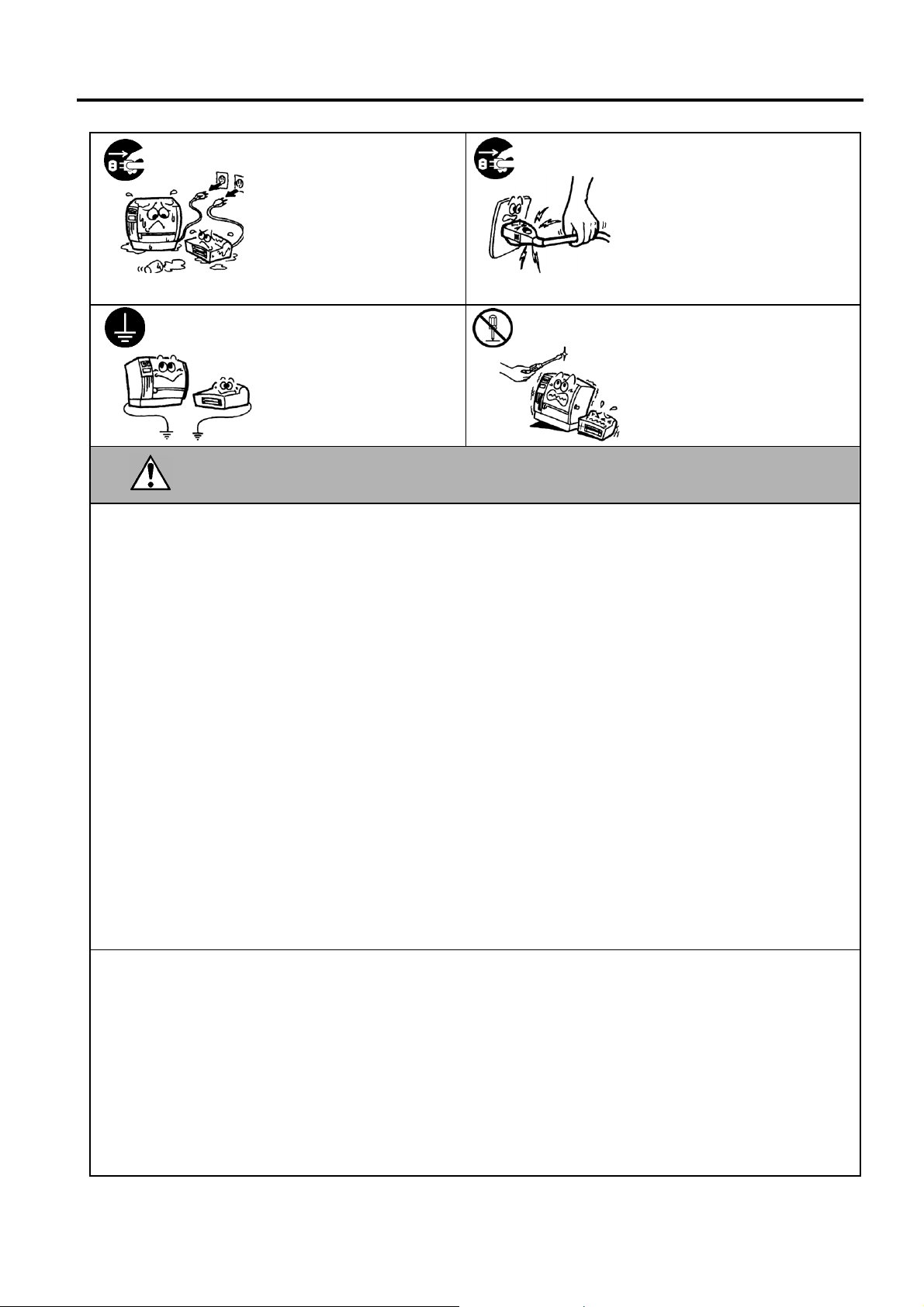

Meanings of Each Symbol

This symbol indicates warning items (including cautions).

Specific warning contents are drawn inside the

(The symbol on the left indicates a general caution.)

This symbol indicates prohibited actions (prohibited items).

Specific prohibited contents are drawn inside or near the

(The symbol on the left indicates “no disassembling”.)

This symbol indicates actions which must be performed.

Specific instructions are drawn inside or near the z symbol.

(The symbol on the left indicates “disconnect the power cord plug from the outlet”.)

symbol.

symbol.

Any other than the

specified AC voltage

is prohibited.

Prohibited

Prohibited

ARNING

Do not use voltages other than

the voltage (AC) specified on the

rating plate, as this may cause

fire or electric shock.

If the machines share the same

outlet with any other electrical

appliances that consume large

amounts of power, the voltage

will fluctuate widely each time

these appliances operate. Be sure

to provide an exclusive outlet for

the machine as this may cause

fire or electric shock.

Do not insert or drop metal,

flammable or other foreign

objects into the machines through

the ventilation slits, as this may

cause fire or electric shock.

This indicates that there is the risk of death or serious injury if the

machines are improperly handled contrary to this indication.

Prohibited

Prohibited

Prohibited

Do not plug in or unplug the power

cord plug with wet hands as this

may cause electric shock.

Do not place metal objects or

water-filled containers such as

flower vases, flower pots or mugs,

etc. on top of the machines. If

metal objects or spilled liquid enter

the machines, this may cause fire

or electric shock.

Do not scratch, damage or modify

the power cords. Also, do not

place heavy objects on, pull on, or

excessively bend the cords, as this

may cause fire or electrical shock.

Disconnect

the plug.

If the machines are dropped or

their cabinets damaged, first turn

off the power switches and

disconnect the power cord plugs

from the outlet, and then contact

your authorised TOSHIBA TEC

representative for assistance.

Continued use of the machine in

that condition may cause fire or

electric shock.

( )

i

Disconnect

the plug.

Continued use of the machines in

an abnormal condition such as

when the machines are producing

smoke or strange smells may cause

fire or electric shock. In these

cases, immediately turn off the

power switches and disconnect the

power cord plugs from the outlet.

Then, contact your authorised

TOSHIBA TEC representative for

assistance.

Page 5

Safety Summary ENGLISH VERSION EO1-33061

Disconnect

the plug.

Connect a

grounding wire.

If foreign objects (metal

fragments, water, liquids) enter

the machines, first turn off the

power switches and disconnect

the power cord plugs from the

outlet, and then contact your

authorised TOSHIBA TEC

representative for assistance.

Continued use of the machine in

that condition may cause fire or

electric shock.

Ensure that the equipment is

properly grounded. Extension

cables should also be grounded.

Fire or electric shock could

occur on improperly grounded

equipment.

Disconnect

the plug.

No

disassembling.

When unplugging the power cords,

be sure to hold and pull on the plug

portion. Pulling on the cord portion

may cut or expose the internal wires

and cause fire or electric shock.

Do not remove covers, repair or

modify the machine by yourself.

You may be injured by high

voltage, very hot parts or sharp

edges inside the machine.

This indicates that there is the risk of personal Injury or damage to

CAUTION

objects if the machines are improperly handled contrary to this indication.

Precautions

The following precautions will help to ensure that this machine will continue to function correctly.

• Try to avoid locations that have the following adverse conditions:

* Temperatures out of the specification * Direct sunlight * High humidity

* Shared power source * Excessive vibration * Dust/Gas

• The cover should be cleaned by wiping with a dry cloth or a cloth slightly dampened with a mild

detergent solution. NEVER USE THINNER OR ANY OTHER VOLATILE SOLVENT on the plastic

covers.

• USE ONLY TOSHIBA TEC SPECIFIED paper and ribbons.

• DO NOT STORE the paper or ribbons where they might be exposed to direct sunlight, high

temperatures, high humidity, dust, or gas.

• Ensure the printer is operated on a level surface.

• Any data stored in the memory of the printer could be lost during a printer fault.

• Try to avoid using this equipment on the same power supply as high voltage equipment or equipment

likely to cause mains interference.

• Unplug the machine whenever you are working inside it or cleaning it.

• Keep your work environment static free.

• Do not place heavy objects on top of the machines, as these items may become unbalanced and fall

causing injury.

• Do not block the ventilation slits of the machines, as this will cause heat to build up inside the machines

and may cause fire.

• Do not lean against the machine. It may fall on you and could cause injury.

• Care must be taken not to injure yourself with the printer paper cutter.

• Unplug the machine when it is not used for a long period of time.

• Place the machine on a stable and level surface.

Request Regarding Maintenance

• Utilize our maintenance services.

After purchasing the machine, contact your authorised TOSHIBA TEC representative for assistance

once a year to have the inside of the machine cleaned. Otherwise, dust will build up inside the machines

and may cause a fire or a malfunction. Cleaning is particularly effective before humid rainy seasons.

• Our preventive maintenance service performs the periodic checks and other work required to maintain

the quality and performance of the machines, preventing accidents beforehand.

For details, please consult your authorised TOSHIBA TEC representative for assistance.

• Using insecticides and other chemicals

Do not expose the machines to insecticides or other volatile solvents. This will cause the cabinet or

other parts to deteriorate or cause the paint to peel.

( )

ii

Page 6

ENGLISH VERSION EO1-33061

TABLE OF CONTENTS

Page

1. PRODUCT OVERVIEW.......................................................................................................... E1-1

1.1 Introduction.................................................................................................................... E1-1

1.2 Features ........................................................................................................................ E1-1

1.3 Unpacking...................................................................................................................... E1-1

1.4 Accessories .................................................................................................................. E1-1

1.5 Appearance...................................................................................................................E1-3

1.5.1 Dimensions.................................................................................................................E1-3

1.5.2 Front View ..................................................................................................................E1-3

1.5.3 Rear View...................................................................................................................E1-3

1.5.4 Interior........................................................................................................................E1-4

1.5.5 Button and Indicator Lamp .........................................................................................E1-4

2. PRINTER SETUP................................................................................................................... E2-1

2.1 Precautions.................................................................................................................... E2-1

2.2 Procedure before Operation.......................................................................................... E2-2

2.3 Turning the Printer ON/OFF .......................................................................................... E2-2

2.3.1 Turning ON the Printer ...............................................................................................E2-2

2.3.2 Turning OFF the Printer..............................................................................................E2-3

2.4 Connecting the Cables to the Printer............................................................................. E2-3

2.5 Connecting the Power Adapter and the Power Cord..................................................... E2-4

2.6 Loading the Media.........................................................................................................E2-5

2.7 Media Sensor Calibration, Self Print Test, and Dump Mode Utilities............................. E2-9

2.7.1 Media Sensor Calibration...........................................................................................E2-9

2.7.2 Self Print Test and Dump Mode..................................................................................E2-9

3. MAINTENANCE ..................................................................................................................... E3-1

3.1 Cleaning ........................................................................................................................ E3-1

3.1.1 Print Head ..................................................................................................................E3-1

3.1.2 Platen/Sensors...........................................................................................................E3-2

3.1.3 Cover..........................................................................................................................E3-2

3.2 Care/Handling of the Media........................................................................................... E3-3

4. TROUBLESHOOTING ........................................................................................................... E4-1

4.1 Troubleshooting Guide.................................................................................................. E4-1

4.2 Removing Jammed Media............................................................................................. E4-1

APPENDIX 1 SPECIFICATIONS ................................................................................................EA1-1

A1.1 Printer..........................................................................................................................EA1-1

A1.2 Options ........................................................................................................................EA1-2

A1.3 Media...........................................................................................................................EA1-2

A1.3.1 Media Type ........................................................................................................... EA1-2

A1.3.2 Detection Area of the Transmissive Sensor.......................................................... EA1-3

A1.3.3 Detection Area of the Reflective Sensor ............................................................... EA1-3

A1.3.4 Effective Print Area ...............................................................................................EA1-4

APPENDIX 2 INTERFACE..........................................................................................................EA2-1

GLOSSARIES

INDEX

CAUTION!

1. This manual may not be copied in whole or in part without prior written permission of TOSHIBA TEC.

2. The contents of this manual may be changed without notification.

3. Please refer to your local Authorized Service representative with regard to any queries you may have in

this manual.

Page 7

1. PRODUCT OVERVIEW ENGLISH VERSION EO1-33061

1. PRODUCT OVERVIEW

1.1 Introduction

1.2 Features

1.3 Unpacking

1. Check for damage or

scratches on the printer.

However, please note that

TOSHIBA TEC shall have no

liability for any damage of

any kind sustained during

transportation of the product.

2. Keep the cartons and pads

for future transportation of

the printer.

NOTES:

1.4 Accessories

Thank you for choosing the TOSHIBA B-SV4D series barcode printer.

This Owner’s Manual contains valuable information from general set-up

to confirming the printer's operation using test prints. You should read it

carefully to help you gain maximum performance and life from your

printer. This manual should be kept close at hand for everyday reference.

Please contact your TOSHIBA TEC representative for further

information concerning this manual.

This printer has the following features:

• This printer is equipped with a 32-bit RISC processor, which offers up

to 5 inches/sec. print speed.

• A standard USB interface for convenient label printing connectivity.

• A 10/100T Base LAN connector is standard on the GS12 model.

• The clamshell design and moveable media sensor enable easy me dia

loading and use of a wide range of media.

• All frequently used bar code formats are available in this printer.

Fonts and bar codes can be printed in any rotation.

• This printer provides a choice of six different type faces of

alphanumeric font, and outline font printing capability.

• The GS type is designed for batch issue and the GC type is for cut

issue. Fitting the optional cutter unit to the GS type enables cut issue.

• This is the most cost-effective and high performance printer in this

class.

Unpack the printer as per the Unpacking Instructions supplied with the

printer.

When unpacking the printer, please check that the following accessories

are supplied with the printer.

CD-ROM (1 copy) Power Adapter (1 pc.)

Media Shaft (1 pc.) Media Holder (2 pcs.)

Media Holder Spacer (2 pcs.)

1.1 Introduction

E1- 1

Page 8

1. PRODUCT OVERVIEW ENGLISH VERSION EO1-33061

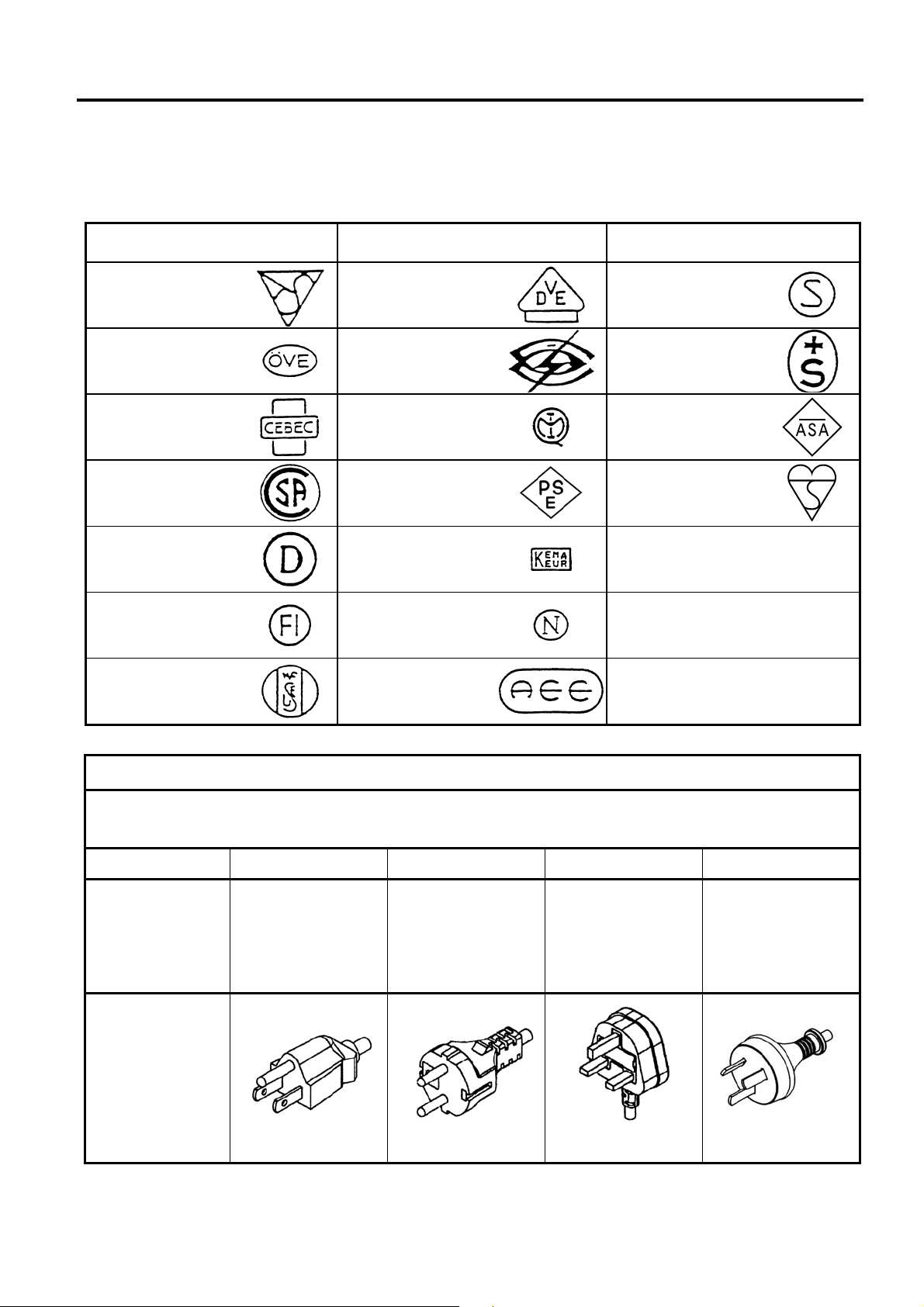

1.4 Accessories

When purchasing the power cord

Since the power cord set is not enclosed in this unit, please purchase an approved one that meets the following

standard from your Authorised TOSHIBA TEC representative.

(As of September 2004)

Country Agency

Australia SAA Germany VDE

Austria OVE

Belgium CEBEC

Canada CSA

Certification

mark

Country Agency

Ireland NSAI

Italy IMQ

Japan METI

Certification

mark

Country Agency

Sweden SEMKKO

Switzerland SEV

UK ASTA

UK BSI

Certification

mark

Denmark DEMKO

Finland FEI

France UTE

Netherlands KEMA

Norway NEMKO

Spain AEE

U.S.A. UL

Europe HAR

Power Cord Instruction

1. For use with 100 – 125 Vac mains power supply, please select a power cord rated Min. 125V, 10A.

2. For use with 200 – 240 Vac mains power supply, please select a power cord rated Min. 250V.

3. Please select a power cord with the length of 4.5m or less.

Country/Region North America Europe United Kingdom Australia

Power Cord

Rated (Min.)

Type

Conductor size

125V, 10A

SVT

No. 3/18AWG

250V

H05VV-F

3 x 0.75 mm

2

250V

H05VV-F

3 x 0.75 mm

250V

AS3191 approved,

2

Light or Ordinary Duty type

3 x 0.75 mm2

(Min.)

Plug Configuration

(locally approved

type)

Rated (Min.)

125V, 10A

250V, 10A

250V, *1

250V, *1

*1: At least, 125% of the rated current of the product.

E1- 2

Page 9

1. PRODUCT OVERVIEW ENGLISH VERSION EO1-33061

r

(

p

C

r

1.5 Appearance

1.5.1 Dimensions

The picture on the right is the G

model’s. The depth of the GS

model is 231.8 mm (9.1 inches).

1.5.2 Front View

1.5.3 Rear View

NOTE:

The names of the parts or units introduced in this section are used in the

following chapters.

Media Outlet

Strip Block

(Option)

Backing Paper Outlet

200 (7.9)

(GS Type)

Cutter Block

Top Cover

Media Outlet

Rear Media Guide

260.8

10.3)

231.8 (9.1)

Dimensions in mm (inches)

(GC Type)

Cover Open Lever

1.5 Appearance

168.5

(6.6)

Indicator Lam

FEED/PAUSE

Button

LAN Interface

Connecto

(GS12 model only)

USB Interface

Connecto

Parallel Interface

Connector (Centronics)

(Not available on the

GS12 model)

E1- 3

Serial Interface Connector (RS-232C)

Power Jack

Power Switch

Page 10

1. PRODUCT OVERVIEW ENGLISH VERSION EO1-33061

r

p

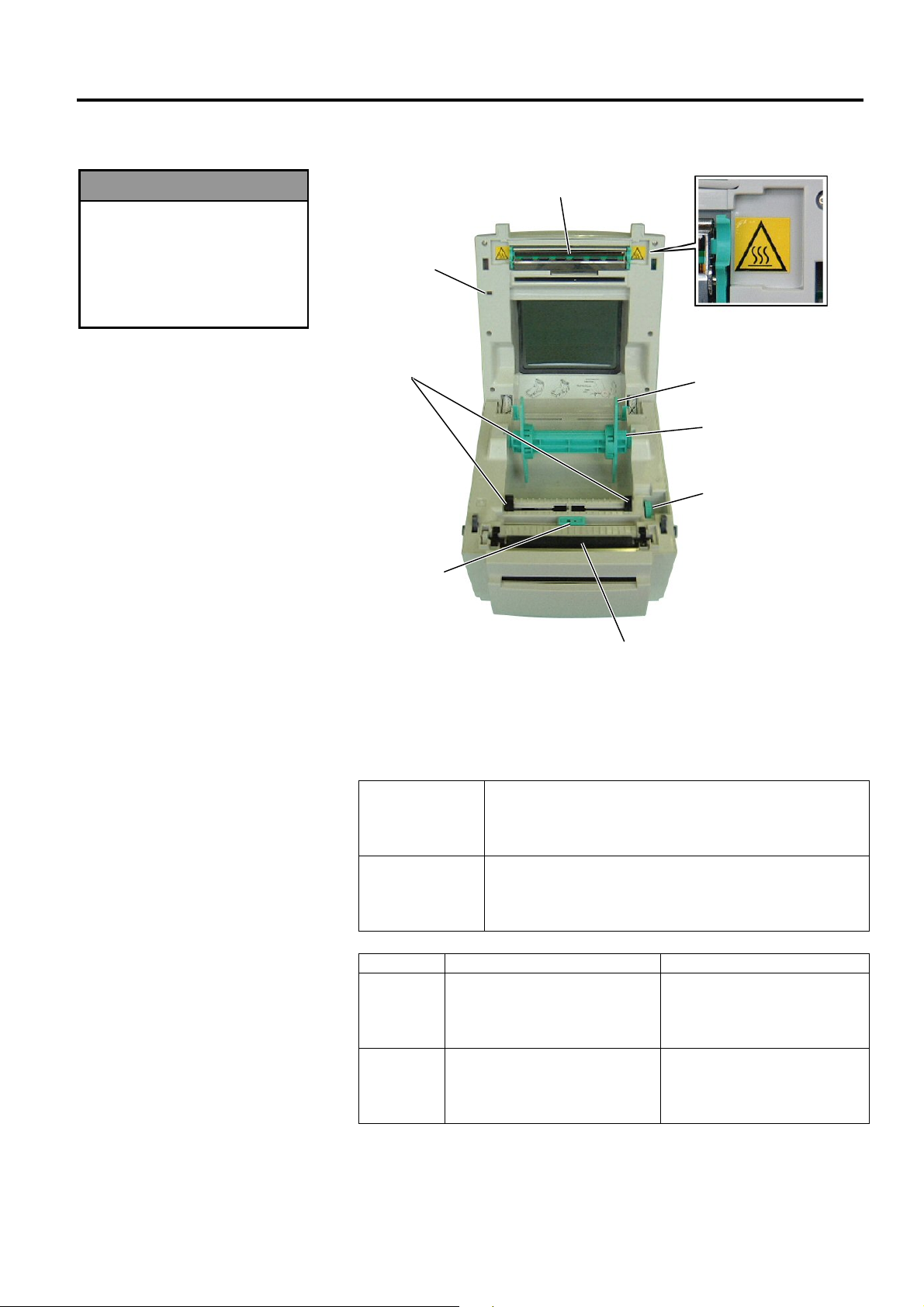

1.5.4 Interior

WARNING!

Do not touch the print head

or around it just after printing.

You may get burned as the

rint head becomes very hot

during printing.

1.5.5 Button and Indicator Lamp

1.5 Appearance

Print Head

Cover Open

Senso

Media Guide

Caution Symbol for the

Print Head (Please refer

to WARNING!)

Media Holder

Media Shaft

Media Guide

Adjustment Knob

Media Sensor

Platen

The FEED/PAUSE Button and the Indicator Lamp have the following

functions:

• Pressing this button when the printer is in online

As the FEED

button

state causes a media feed.

• Pressing this button after removing a cause of

an error returns the printer to online state.

• Pressing this button during printing stops

As the PAUSE

button

printing after completing the current label. The

printer resumes printing when this button is

pressed again.

Color Illuminates when… Flashes when…

RED

• A print error, such as a

memory error, syntax

error, etc.

• There is no label.

• The top cover is opened.

GREEN

• The printer is on-line and

ready to print.

• The button is pressed as

a PAUSE function.

• The printer is

downloading files.

E1- 4

Page 11

2. PRINTER SETUP ENGLISH VERSION EO1-33061

2. PRINTER SETUP

2.1 Precautions

This section outlines the steps necessary to setup your printer prior to its

operation. The section includes precautions, connecting cables,

assembling accessories, loading media, and performing a test print.

To insure the best operating environment, and to assure the safety of the

operator and the equipment, please observe the following precautions.

• Operate the printer on a stable, level, operating surface in a loc ation

• Keep your work environment static free . Static discharges can cause

• Make sure that the printer is connected to a clean source of AC Power

• Ensure that the printer is connected only to AC mains that has a

2.1 Precautions

free from excessive humidity, high temperature, dust, vibration or

direct sunlight.

damage to delicate internal components.

and that no other high voltage devices that may cause line noise

interference are connected to the same mains.

proper ground (earth) connection.

• Do not operate the printer with the cover open. Be careful not to

allow fingers or articles of clothing to get caught into any of the

moving parts of the printer.

• Make sure to turn off the printer power and to remove the power

adapter connector from the printer whenever working on the inside of

the printer or when cleaning the printer.

• For best results, and longer printer life, use only TOSHIBA TEC

recommended media.

• Store the media in accordance with the specifications.

• This printer mechanism contains high voltage components; therefore

you should never remove any of the covers of the machine as you may

receive an electrical shock. Additionally, the printer contains many

delicate components that may be damaged if accessed by unauthorized

personnel.

• Clean the outside of the printer with a clean dry cloth or a clean cloth

slightly dampened with a mild detergent solution.

• Use caution when cleaning the thermal print head as it may become

very hot while printing. Wait until it has had time to cool before

cleaning. Use only the TOSHIBA TEC recommended print head

cleaner to clean the print head.

• Do not turn off the printer power or remove the power plug while the

printer is printing or while the Indictor Lamp is flashing.

E2- 1

Page 12

2. PRINTER SETUP ENGLISH VERSION EO1-33061

f

p

p

I

2.2 Procedure before

Operation

To communicate directly with a

host computer, an RS-232C,

Centronics, or USB cable is

required.

(1) RS-232C cable: 9 pins

(do not use a null modem cable)

(2) Centronics cable: 36 pins

(3) USB cable: V1.1

Use of a Windows Driver will

allow issuing media on the printer

rom a Windows application.

The printer can also be controlled

with its own programming

commands. For details, please

contact your TOSHIBA TEC

reseller.

NOTE:

NOTE:

2.3 Turning the Printer ON/OFF

2.3.1 Turning ON the Printer

Use the power switch to

turn the printer On/Off.

Plugging or unplugging the

ower cord to turn the

rinter On/Off may cause

fire, an electric shock, or

damage to the printer.

f the Red Indicator Lamp is

illuminated, go to Section 4.1,

Troubleshooting Guide.

CAUTION!

NOTE:

2.2 Procedure before Operation

This section describes the outline of the printer setup.

1. Unpack the accessories and printer from the box.

2. Refer to Safety Precautions in this manual and set up the printer at a

proper location.

3. Make sure that the Power Switch is off. (Refer to Section 2.3.)

4. Connect the printer to a host computer with an RS-232C, Centronics

interface, or USB cable. (Refer to Section 2.4.)

5. Connect the Power Adapter to the printer, and then plug the Power

Cord into a properly grounded power outlet. (Refer to Section 2.5)

6. Load the media. (Refer to Section 2.6.)

7. Adjust the position of the Feed Gap Sensor or Black Mark Sensor to

match the media being used. (Refer to Section 2.7.)

8. Turn the Power ON. (Refer to Section 2.3.)

9. Install the Printer Drivers. (Refer to the Printer Driver in the CD-

ROM.)

When the printer is connected to a host computer it is good practice to

turn the printer ON before turning on the host computer and to turn OFF

the host computer before turning off the printer.

1. To turn ON the printer power, press the power switch as shown in the

diagram below. Note that ( ⏐ ) is the power ON side of the switch.

2. Check that the Indicator Lamp is illuminated in green.

Power Switch

E2- 2

Page 13

2. PRINTER SETUP ENGLISH VERSION EO1-33061

F

A

2.3.2 Turning OFF the Printer

1. Do not turn off the printer

power while the media is

being printed as this may

cause a paper jam or

damage to the printer.

2. Do not turn off the printer

power while the Green

Indicator Lamp is flashing

as this may cause damage

to the data being

downloaded.

CAUTION!

2.4 Connecting the Cables to the Printer

NOTE:

or the specifications of the

serial interface cable, refer to

PPENDIX 2, INTERFACE.

2.4 Connecting the Cables to the Printer

1. Before turning off the printer power switch verify that the Indicator

Lamp is illuminated in green, not flashing.

2. To turn OFF the printer power press the power switch as shown in the

diagram below. Note that ( { ) is the power OFF side of the switch.

The following paragraphs outline how to connect the cables from the

printer to your host computer, and will also show how to make cable

connections to other devices. Depending on the application software you

use to print labels, there are three possibilities for connecting the printer

to your host computer. These are:

• A serial cable connection between the printer’s RS-232C serial

connector and one of your host computer’s COM ports.

• A parallel cable connection between the printer’s standard parallel

connector and your host computer’s parallel port (LPT).

• A USB cable connection between the printer’s USB interface

connector and one of your host computer’s USB port.

• A LAN cable connection between the printer’s LAN interface

connector and a hub or your host computer’s LAN port.

The diagram below shows all the possible cable connections to the

current version of the printer.

Power Switch

g

c

d

e f

c USB Interface

d Parallel Interface (Centronics) (Not available on the GS12 model)

e Serial Interface (RS-232C)

f Power Jack

g LAN Interface (GS12 model only)

E2- 3

Page 14

2. PRINTER SETUP ENGLISH VERSION EO1-33061

s

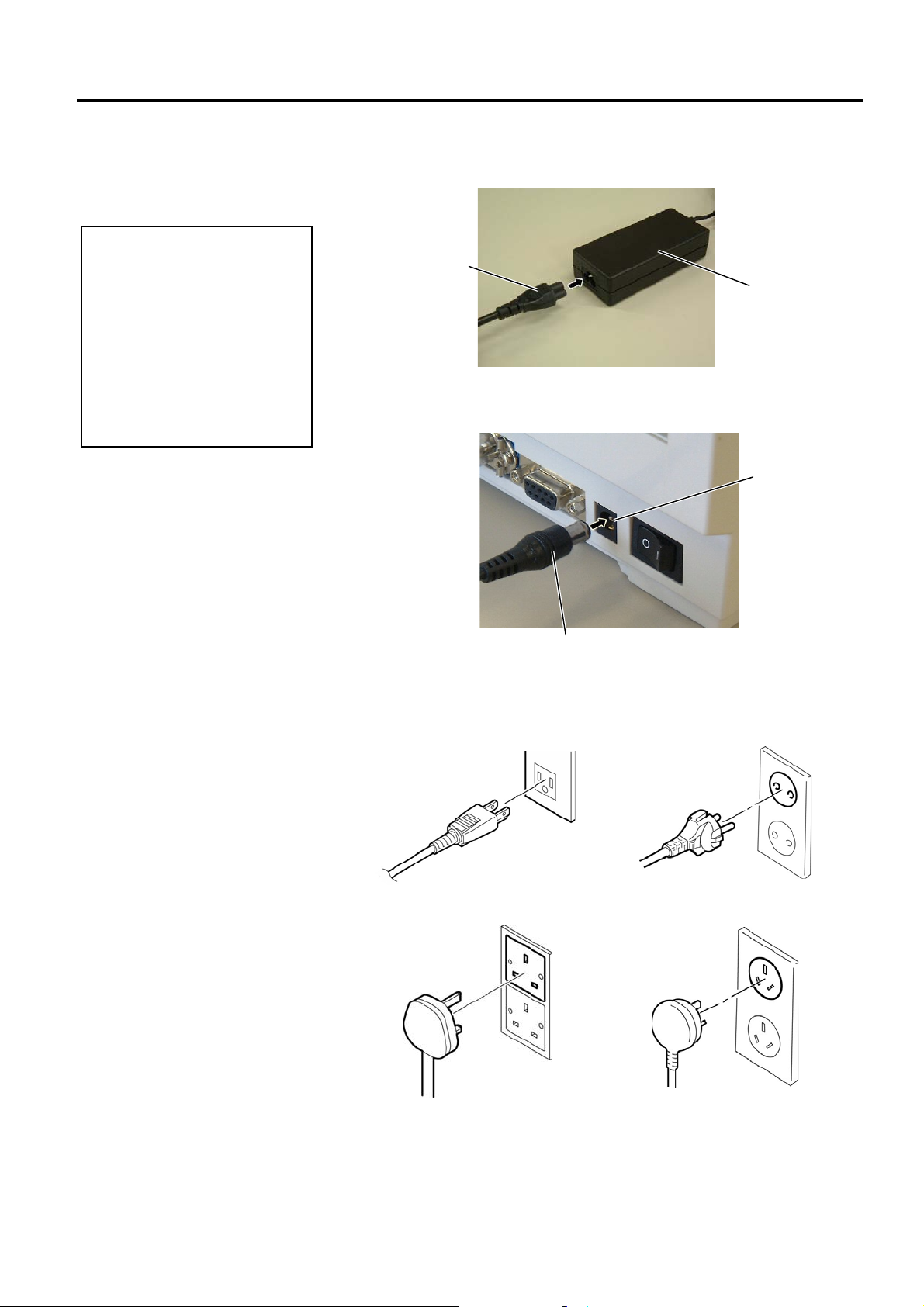

2.5 Connecting the

Power Adapter and

the Power Cord

1. Since the power cord is not

enclosed in thi

purchase a proper one after

referring to page 1-2.

2. The EA10953 AC adapter

should be exclusively used for

the B-SV4D Series printer.

The B-SV4D Series printer

must be powered by the

EA10953 AC adapter.

NOTES:

printer, please

2.5 Connecting the Power Adapter and the Power Cord

1. Make sure that the printer power switch is in the OFF (O) position.

2. Insert the Power Cord into the inlet of the Power Adapter.

Power Cord

Power Adapter

3. Insert the Power Adapter connector into the Power Jack on the rear of

the printer.

Power Jack

Power Adapter Connector

4. Plug the other end of the Power Cord into a grounded outlet as shown

in the figure below.

E2- 4

Page 15

2. PRINTER SETUP ENGLISH VERSION EO1-33061

j

p

F

2.6 Loading the Media

1. Do not touch any moving

parts. To reduce the risk

of fingers, jewellery,

clothing, etc. being drawn

into the moving parts, be

sure to load the media

once the printer has

stopped moving

completely.

2. To avoid in

not to trap your fingers

while opening or closing

the cover.

Be careful not to touch the

Print Head Element when

opening the Top Cover.

Failure to do this may cause

missing dots by static

electricity or other print quality

roblems.

When the outer roll diameter

exceeds 127 mm (5”) or the inner

core diameter exceeds 38.1 mm

(1.5”), an optional External

Media Roll Hanger is required.

or details, refer to page 2-8.

WARNING!

ury, be careful

CAUTION!

NOTE:

2.6 Loading the Media

This section describes in detail how to load the media.

1. Turn OFF the printer and open the Top Cover.

2. When the inner core diameter of the media roll is 25.4 mm (1”),

remove the Media Holder Spacers from the Media Holders. The

Media Holder Spacers are required to print media rolls with 38.1-mm

(1.5”) inner core diameter.

Media Holder

Spacer

(Accessory)

3. Put the media roll onto the Medial Shaft so that the print side faces up

as shown below.

Media Holder

(Accessory)

Media

Media Shaft

(Accessory)

4. Hold the Media Holder with the smooth side facing the media roll,

align the Media Holder’s centre hole with the Media Shaft, and then

install the Media Holder by sliding it onto the Media Shaft. Make

sure that the media roll is positioned at the centre of the Media Shaft.

5. Insert the Media Holder Ass’y into the slots of the printer.

Media Shaft

Media Holder

Slot

Slot

Media Holder

Ass’y

E2- 5

Page 16

2. PRINTER SETUP ENGLISH VERSION EO1-33061

A

2.6 Loading the Media

(Cont.)

When the Media Guide

djustment Knob is turned

backward ( ), the Media

Guides move away from each

other. When it is turned forward

( ), the Media Guides move

toward each other.

1. The Feed Gap Sensor can be

correctly positioned by

engaging the Protrusion of the

Media Sensor with the centre

guide.

2. The Black Mark Sensor is

fully adjustable.

NOTE:

NOTES:

2.6 Loading the Media

6. Feed the media between the Media Guides.

7. Pull the media until it extends past the Media Outlet.

8. Adjust the Media Guide position to the media width by rotating the

Media Guide Adjustment Knob.

9. Make sure that the media path through the printer is straight,

otherwise skew feeding or a paper jam may occur.

10. After loading the media, manually set the Media Sensor to the correct

position. When using the Feed Gap Sensor, position it to the centre

of the printer. When using the Black Mark Sensor, it should be

positioned in line with the centre of the black marks on the reverse

side of the media.

Centre Guide

Media Sensor

Black Mark Sensor

There are three issue modes available on this printer.

Batch mode:

Media Guide

Adjustment Knob

Feed Gap

Sensor

Protrusion

In the batch mode, the media is continuously printed and fed until the

CAUTION!

To separate the printed

media from the media roll in

batch mode, be sure to tear

off the media at the Media

Outlet or cut the media past

the Tear Off Bar. If you tear

off the media at the Print

Head by mistake, be sure to

feed one label (10 mm or

more) with the

FEED/PAUSE Button prior to

next issue. Failure to do this

may cause a paper jam.

number of media specified in the issue command has been printed.

E2- 6

Page 17

2. PRINTER SETUP ENGLISH VERSION EO1-33061

p

F

2.6 Loading the Media

(Cont.)

When the media is correctly set, the

backing paper is supposed to be

inched by the Platen and the Strip

eed Roller as shown below.

Strip Plate

Label

Strip Feed Roller

Backing Paper

1. When attaching or removing

the cutter cover, be sure to

turn off the power. Otherwise,

you may be injured.

2. The cutter is sharp, so care

must be taken not to injure

yourself when handling the

cutter.

1. Be sure to cut the backing

paper of the label. Cutting

labels will cause the glue to

stick to the cutter which may

affect the cutter quality and

shorten the cutter life.

2. Use of tag paper when the

thickness exceeds the specified

value may affect the cutter life.

NOTE:

Platen

WARNING!

CAUTION!

2.6 Loading the Media

Strip mode (Option):

When issued in the strip mode, labels are automatically removed from the

backing paper each time a label is printed.

• How to set the media

When issuing labels in the strip mode, set the label in the following

procedure:

1. Open the Strip Block by the tabs on both sides.

Tab

Strip Block

2. Remove enough labels from the leading edge of the media to leave

about 200 mm of backing paper free.

3. Pass the backing paper over the Platen and the Strip Plate, and insert

the leading edge of the backing paper into the Backing Paper Outlet.

Platen

Strip Feed Roller

Strip Plate

Strip Block

Backing Paper

Backing Paper Outlet

4. Close the Strip Block.

Cut mode:

When the Cutter is fitted, the media is automatically cut.

After loading the media as described on the previous pages, insert the

leading edge of the media into the Media Outlet of the Cutter.

Media Outlet

Cutter Cover

E2- 7

Page 18

2. PRINTER SETUP ENGLISH VERSION EO1-33061

2.6 Loading the Media

(Cont.)

2.6 Loading the Media

When a media roll has an outside diameter exceeding 127 mm (5”) or an

inner core diameter of 38.1 mm (1.5”), the optional External Media Roll

Hanger will be required.

1. Fit the protrusions on the bottom of the printer into the holes in the

External Media Roll Hanger.

External Media Roll

Hanger (Option)

2. Load a media roll onto the printer’s Media Holder Ass’y, and place it

into the cuts of the External Media Roll Hanger.

3. Pull the media forward and insert the leading edge into the printer so

that it passes between the Rear Media Guides.

Media Holder

Ass’y

When the media roll has the inner core diameter of 76.2 mm (3”), use

the 3”-Diameter Media Shaft included in the optional External Media

Roll Hanger.

3”-Diameter

Media Shaft

(Option)

4. Manually move the Rear Media Guides so that the media is centred.

5. Refer to the previous pages to complete the media loading.

6. Close the Top Cover.

E2- 8

Page 19

2. PRINTER SETUP ENGLISH VERSION EO1-33061

A

A

A

2.7 Media Sensor

Calibration, Self Print

Test, and Dump Mode

Utilities

2.7.1 Media Sensor

Calibration

The Transmissive Sensor (Feed Gap

Sensor) has been selected as factory

default.

2.7.2 Self Print Test and

Dump Mode

NOTE:

2.7 Media Sensor Calibration, Self Print Test, and Dump Mode Utilities

This utility is used to calibrate the sensitivity of the Feed Gap/Black

Mark Sensor.

It is necessary to set the media sensors after the media is changed to

different type.

1. First, select the sensor to calibrate in the following procedure.

Open the Top Cover.

The Indicator Lamp blinks in red.

Press and hold the FEED/PAUSE

Button for more than 5 seconds,

and then release.

The Indicator Lamp

illuminates in green.

bout 3 seconds.

The Indicator Lamp

illuminates in orange.

bout 3 seconds.

FEED/PAUSE

Button

FEED/PAUSE

Button

The Indicator Lamp is unlit.

(Reflective (Black Mark)

Sensor is selected.)

The Indicator Lamp is unlit.

(“No sensor” is selected.)

The Indicator Lamp

illuminates in red.

FEED/PAUSE

Button

bout 3 seconds.

The Indicator Lamp is unlit.

(Transmissive (Feed Gap)

Sensor is selected.)

2. Turn off the printer power and install blank media (without pre-

printing) on the printer.

3. To calibrate the Black Mark Sensor, align the sensor position with the

black marks on the media. (Refer to Section 2.6.)

4. Press the FEED/PAUSE Button while turning on the printer.

The Indicator Lamp will be illuminated in the following order:

Orange Orange (Flashing) Red (Flashing)

5. Release the FEED/PAUSE Button when the Indicator Lamp flashes in

red. This completes the Media Sensor calibration.

6. To start the Online operation, turn the printer off, then on again.

1. Turn off the printer power and install a media roll on the printer.

2.

Press the FEED/PAUSE Button while turning on the printer. The

Indicator Lamp will be illuminated in the following order:

Orange Orange (Flashing) Red (Flashing) Green

3. Release the FEED/PAUSE Button when the Indicator Lamp is

illuminated in green.

4. The printer automatically performs a self print test, and then enters the

Dump Mode.

5. To start the Online operation, turn the printer off, then on again.

E2- 9

Page 20

2. PRINTER SETUP ENGLISH VERSION EO1-33061

D

A

2.7.2 Self Print Test and

Dump Mode (Cont.)

NOTE:

The following commands should

not affect the test print issue.

, AX, XS, Z2;1, Z2;2 (without

Y)

2.7 Media Sensor Calibration, Self Print Test, and Dump Mode Utilities

Print test label sample

PRINTER INFO.

PROGRAM VERSION VX.XX XXXX

TONE ADJUST +XX

FEED ADJUST +XX.Xmm

CUT POSITION ADJUST +XX.Xmm

BACKFEED ADJUST +XX.Xmm

PARAMETER [PC-850][0]

[9600][8][1][NONE][0]

[ON][AUTO][FEED][B0]

X-COORDINATE ADJUST +XX.Xmm

SENSOR TRANSMISSIVE [17]

MEMORY [192KB][XXXKB]

TTF AREA [XXXKB][XXXKB]

EXT CHAR AREA [XXXKB][XXXKB]

BASIC AREA [XXXKB][XXXKB]

PC SAVE AREA [XXXKB][XXXKB]

INFORMATION XXXXXXXXXXXXXXXXXXX

TOTAL FEED X.XXKm

IP ADDRESS XXX.XXX.XXX.XXX

SUBNET MASK XXX.XXX.XXX.XXX

GATEWAY XXX.XXX.XXX.XXX

DHCP Enable

The test print contents should be changed by the following commands

and parameters:

PROGRAM VERSION: VX.XX XXXX --- Firmware version and checksum

TONE ADJUST: +XX ------------------------- Print tone fine adjustment value

FEED ADJUST: +XX.Xmm ------------------ Print position fine adjustment value

CUT POSITION ADJUST: +XX.Xmm ----- Cut position fine adjustment value

BACKFEED ADJUST: +XX.Xmm---------- Back feed amount fine adjustment value

PARAMETER: [PC-850][0]----------------- Character code selection and Font “0”

selection

[9600][8][1][NONE][0]--- Baud rate, Data length, Stop bit length,

Parity, and Transmission control of RS232C

[ON][AUTO][FEED][B0] Forward feed wait function, Control code,

Feed key function, and Euro code

X-COORDINTE ADJUST: +XX.Xmm ----- X-coordinate fine adjustment value

SENSOR: TRANSMISSIVE [17] ------------ Sensor selection and sensitivity

MEMORY: [192KB][XXXKB]--------------- Memory capacity of the Main PC Board and

optional memory card (0,1,2,3,4,6,8)

TTF AREA: [XXXKB][XXXKB]------------ True type font storage area, Main PC board

and optional memory card

EXT CHAR AREA: [XXXKB][XXXKB] -- Writable character storage area, Main PC

board and optional memory card

BASIC AREA: [XXXKB][XXXKB] -------- BASIC file storage area, Main PC board and

optional memory card

PC SAVE AREA: [XXXKB][XXXKB]----- PC save storage area, Main PC board and

optional memory card

E2-10

Page 21

2. PRINTER SETUP ENGLISH VERSION EO1-33061

2.7.2 Self Print Test and

Dump Mode (Cont.)

2.7 Media Sensor Calibration, Self Print Test, and Dump Mode Utilities

INFORMATION: ------------------------------- Printed only when some information is

stored in the flash ROM

TOTAL FEED----------------------------------- Total feed distance

IP ADDRESS------------------------------------ IP address

SUBNET MASK-------------------------------- Subnet mask

GATEWAY-------------------------------------- Gateway

DHCP--------------------------------------------- DHCP is enabled or disabled.

E2-11

Page 22

3. MAINTENANCE ENGLISH VERSION EO1-33061

P

3. MAINTENANCE

1. Be sure to turn OFF the

2. To avoid injury, be careful

3. Be careful when handling

4. Do not pour water directly

3.1 Cleaning

3.1.1 Print Head

1. Do not allow any hard

objects to touch the print

head or platen, as this may

cause damage to them.

2. Do not use any volatile

solvents including thinner

and benzene, as this may

cause discoloration of the

cover, print failure, or

breakdown of the printer.

3. Do not touch the print head

element with bare hands,

as static may damage the

print head.

WARNING!

power before performing

maintenance. Failure to

do this may cause an

electric shock.

not to pinch your fingers

while opening or closing

the cover and print head

block.

the print head as it

becomes very hot

immediately after printing.

Allow it to cool before

performing any

maintenance.

onto the printer.

CAUTION!

3.1 Cleaning

This chapter describes how to perform routine maintenance.

To ensure the continuous high quality operation of your printer, you

should perform a regular maintenance routine. For high throughput it

should be done on a daily basis. For low throughput it should be done on

a weekly basis.

To maintain the printer performance and print quality, please clean the

printer regularly, or whenever the media is replaced.

1. Turn the power off.

2. Open the Top Cover.

3. Remove the media.

4. Clean the Print Head Element with a Print Head Cleaner, cotton swab

or soft cloth slightly moistened with ethyl alcohol.

Print Head Element (positioned at the print head edge)

NOTE:

lease purchase the Print Head

Cleaner from the authorized

TOSHIBA TEC service

representative.

E3- 1

Print Head Cleaner

(Part No.: 24089500013)

Page 23

3. MAINTENANCE ENGLISH VERSION EO1-33061

r

3.1.2 Platen/Sensors

3.1.3 Cover

CAUTION!

Do not use any volatile

solvents including thinner and

benzene, as this may cause

discoloration or distortion of

the cover.

3.1 Cleaning

1. Wipe the Platen with a soft cloth moistened with alcohol.

2. Remove dust or paper particles from the Media Sensor and Cover

Open Sensor using an air blower.

Cover Open

Wipe the Cover with a dry soft cloth. Wipe off dirt with a soft cloth

slightly moistened with water.

Senso

Media Sensor

Platen

E3- 2

Page 24

3. MAINTENANCE ENGLISH VERSION EO1-33061

p

3.2 Care/Handling of the Media

Be sure to carefully review and

understand the Supply

Manual. Use only media

which meets specified

requirements. Use of nonspecified media may shorten

the head life and result in

roblems with bar code

readability or print quality. All

media should be handled with

care to avoid any damage to

the media or printer. Read the

guideline in this section

carefully.

CAUTION!

3.2 Care/Handling of the Media

• Do not store media for longer than the manufacturer’s recommended

shelf life

• Store media rolls on the flat end. Do not store them on the curved

sides as this might flatten that side causing erratic media advance and

poor print quality.

• Store the media in plastic bags and always reseal after opening.

Unprotected media can get dirty and the extra abrasion from the dust

and dirt particles will shorten the print head life.

• Store the media in a cool, dry place. Avoid areas where they would be

exposed to direct sunlight, high temperature, high humidity, dust or

gas.

• The thermal paper used for direct thermal printing must not have

specifications which exceed Ca

2+

, K+, Na+ 800 ppm, and Cl- 600 ppm.

• Some ink used on pre-printed media may contain ingredients which

shorten the print head’s product life. Do not use labels pre-printed

with ink which contain hard substances such as carbonic calcium

(CaCO

) and kaolin (Al2O3, 2SiO2, 2H2O).

3

For further information, please contact your local distributor or your

media manufacturer.

E3- 3

Page 25

4. TROUBLESHOOTING ENGLISH VERSION EO1-33061

p

4.1 Troubleshooting Guide

4. TROUBLESHOOTING

This chapter lists the error messages, possible problems, and their solutions.

If a problem cannot be solved by taking actions described in this chapter, do not attempt to repair the

rinter. Turn off and unplug the printer. Then contact an authorised TOSHIBA TEC service

representative for assistance.

4.1 Troubleshooting Guide

Problems Solutions

The Online Indicator Lamp (green) is not

illuminated.

The Online Indicator Lamp (green) is flashing. The printer is in PAUSE state. Press the FEED/PAUSE

The Error Indicator Lamp (red) is illuminated, not

flashing.

The Error Indicator Lamp (red) is flashing. 1. The media has run out. Install a new media roll.

Poor print quality 1. The Top Cover is not closed completely. Close the

4.2 Removing Jammed Media

WARNING!

1. Check that the Power Cord is properly connected.

If the LED on the AC Adapter is not illuminated,

2.

please contact an authorised TOSHIBA TEC service

representative.

Button to return to Online state.

The Top Cover is not closed completely. Close the Top

Cover completely and confirm that the Indicator Lamp

flashes. Then press the FEED/PAUSE Button to return

to Online state.

The Media Sensor cannot detect the print start

2.

position. Retry the Media Sensor calibration.

A paper jam occurred.

3.

A cutter jam occurred.

4.

After removing causes of the problems, press the

FEED/PAUSE Button to return to Online state.

Top Cover completely.

Clean the Print Head.

2.

The media being used is not with in specification.

3.

Use TOSHIBA TEC recommended media only.

This section describes in detail how to remove jammed media from the printer.

CAUTION!

Do not use any tool that may damage the print head.

1. Turn the power off.

2. Open the Top Cover.

3. Remove the media.

4. Remove the jammed media from the printer. DO NOT USE any sharp implements or tools as these could

damage the printer.

5. Clean the Print Head with the Print Head Cleaner and remove dust or paper particles.

6. Load the media and close the Top Cover.

E4- 1

Page 26

APPENDIX 1 SPECIFICATIONS ENGLISH VERSION EO1-33061

N

APPENDIX 1 SPECIFICATIONS

Appendix 1 describes the printer specifications and supplies for use on the B-SV4D printer.

A1.1 Printer

The following are the printer specifications.

Item Specifications

Supply voltage

Power consumption

During a print job

During standby

Power supply

Operating temperature range

Storage temperature range

Relative humidity

Humidity for storage

Ventilation for storage

Resolution

Printing method

Issue mode

Printing speed

In the batch/cut mode

In the strip mode

Available media width

(including backing paper)

Effective print width (max.)

Dimension (W × D × H)

Weight

Available bar code types

Available two-dimensional code

Available bar code font

Rotations

Standard interface

Optional interface LAN Adapter

OTES:

• Data Matrix

• PDF417

• QR Code is a trademark of DENSO CORPORATION.

• Maxi Code is a trademark of United Parcel Service of America, Inc., U.S.

TM

is a trademark of International Data Matrix Inc., U.S.

TM

is a trademark of Symbol Technologies Inc., US.

AC100 to 240V, 50/60 Hz

100 to 120V: 2.7 A, 64.8 W maximum, 200 to 240V: 2.6 A, 62.4 W maximum

100 to 120V: 0.185 A, 4.4 W maximum, 200 to 240V: 0.16 A, 3.8 W maximum

100 to 240V universal switching power supply

5°C to 40°C (40°F to 104°F)

-40°C to 60°C

25% to 85% RH (no condensation)

10% to 90% RH (no condensation)

Free air environment

203 dpi

Thermal direct

Batch (GS/GC model), Strip (GS model option), Cut (GC model, GS model

option)

50.8 mm/sec. (2”/sec.), 76.2 mm/sec. (3”/sec.), 101.6 mm/sec. (4”/sec.),

127 mm/sec. (5”/sec.)

50.8 mm/sec. (2”/sec.), 76.2 mm/sec. (3”/sec.)

25.4 mm (1.0”) to 112 mm (4.4”)

108.0 mm (4.3”)

GS model: 200.0 mm × 231.8 mm × 168.5 mm (7.9” × 9.1” × 6.6”)

GC model: 200.0 mm × 260.8 mm × 168.5 mm (7.9” × 10.3” × 6.6”)

GS model: 2.0 kg (4.4 lb) (Excluding Media)

GC model: 2.5 kg (5.5 lb) (Excluding Media)

EAN8, EAN13, EAN128, EAN and UPC 2(5) digital add-on, UPC-A, UPC-E,

MSI, Interleaved 2 of 5, CODE39, CODE39C, CODE93, CODE128UCC,

CODE128 Subsets A.B.C, CODE11, CODABAR, POSTNET, PLESSEY

Data Matrix, PDF417, QR code, Maxi Code, Micro PDF417

Times Roman (14 point), Helvetica (12 point), Presentation (18 point), Letter

Gothic (9.5 pint), Courier (10 point), Prestige Elite (7 point), Outline font (1

type)

0°, 90°, 180°, 270°

Serial interface (RS-232C)

Parallel interface (Centronics) (Not available on the GS12 model)

USB (V1.1)

10/100 Base LAN (GS12 model only)

A1.1 Printer

EA1- 1

Page 27

APPENDIX 1 SPECIFICATIONS

N

d

ENGLISH VERSION EO1-33061

A1.2 Options

A1.2 Options

Option Name Type Description

Keyboard display unit KB-75-QM-R This module is an external intelligent keyboard

display unit.

Cutter module B-SV204-QM-R

B-SV404-QM-R

A cutter unit that makes stub cuts.

A cutter unit that makes normal cuts.

Strip sensor B-SV904-H-QM-R When attached to the front of the Media Outlet,

this sensor allows the on-demand strip issue by

Memory module B-SV704-E1M-QM-R (1MB)

detecting the presence or lack of a label.

A flash ROM memory PC board

B-SV704-E2M-QM-R (2MB)

B-SV704-E3M-QM-R (3MB)

B-SV704-E4M-QM-R (4MB)

B-SV704-E6M-QM-R (6MB)

B-SV704-E8M-QM-R (8MB)

External media roll hanger B-SV904-PH-QM-R When this option is attached to the printer, a

media roll with an outer roll diameter exceeding

127 mm (5”) can be used.

LAN adapter B-SV704-LAN-QQ-R

(For AC100 to 120V)

This option enables the printer to be used in a

LAN network.

B-SV704-LAN-QP-R

(For AC200 to 240V)

OTE:

The above options are available from your nearest TOSHIBA TEC representative or TOSHIBA TEC Head Quarters.

A1.3 Media

Please make sure that the media to be used is approved by TOSHIBA TEC. The warranties do not apply to

problems caused by using media that is not approved by TOSHIBA TEC.

For information regarding TOSHIBA TEC-approved media, please contact a TOSHIBA TEC authorised

representative.

A1.3.1 Media Type

This direct thermal printer is specifically designed for thermal media. The table below shows the size and shape

of the media that can be used on this printer.

Label

h

Black Mark

(on reverse side)

g

Cut position

Tag paper

h

Black Mark

(on reverse side)

g

e

f

e

c

Feed Direction

EA1- 2

d

c

Page 28

APPENDIX 1 SPECIFICATIONS ENGLISH VERSION EO1-33061

N

A

A1.3 Media

A1.3.1 Media Type (Cont.)

Unit: mm (inch)

Issue mode

Item

Batch mode Strip mode Cut mode

c Width including backing paper 25.4 to 112 (1.0 to 4.4)

d Media width Min. 17 (0.7)

e Media pitch 10 to 609 (0.39 to 24.0) 15 to 609 (0.59 to 24.0)

f Media length Min. 10 (0.39) Min. 15 (0.59)

g Gap length (or black mark length) Min. 2 Min. 6

h Black mark width Min. 8

Thickness 0.06 to 0.19

Max. outer roll diameter

Roll direction

Ø214 (8.4): When the optional External Media Roll Hanger is used.

Outside roll media; Linerless paper (option)

Inner core diameter 25.4, 38.1, or 76.2 (1, 1.5, or 3)

OTES:

1. To ensure print quality and print head life use only TOSHIBA TEC approved media.

2. When using a media roll of 76.2-mm (3”) inner core diameter, the 3”-Diameter Media Shaft included in the

optional External Media Roll Hanger is required.

Ø127 (5)

Either is acceptable.

(See NOTE 2.)

A1.3.2 Detection Area of the Transmissive Sensor

The Transmissive Sensor is positioned 6 mm from the centre.

The Transmissive Sensor detects a gap between labels, as illustrated below.

Sensor position

Min. 2 mm

(Min. 6 mm:

cut mode)

rea to be detected.

Label

Gap

Label

Min. 8 mm

Centre of media

Sensor position

Print side

Media feed direction

6 mm

A1.3.3 Detection Area of the Reflective Sensor

The Reflective Sensor is movable within the full range of the media width.

The reflection factor of the Black Mark must be 10% or lower with a waveform length of 950 nm.

The Reflective Sensor should be aligned with the centre of the Black Mark.

Sensor should be positioned at the

centre of the black mark.

Min. 2 mm

(Min. 6 mm:

Cut mode)

Min. 8 mm

Media feed direction

Sensor is movable within the full range.

Detecting the black marks on

the back.

EA1- 3

Page 29

APPENDIX 1 SPECIFICATIONS ENGLISH VERSION EO1-33061

±

N

A1.3.4 Effective Print Area

The figure below illustrates the relation between the head effective print width and media width.

Out of print range

Print head element

Out of print range

2 mm

108.0 mm

(Head Effective Print Range)

112.0 mm (Max. media width)

0.2mm

2 mm

The figure below shows the effective print area on the media.

1.5mm from the left edge of media

Start line

1mm

1.5mm from the right edge of media

Guaranteed print area

1mm

Media feed direction

(Backing paper width is not included.)

Media width

OTES:

1. Be sure not to print on the 1.5-mm wide area from the media edges (shaded area in the above figure).

2. The centre of media should be positioned at the centre of the print head.

3. Print quality is not guaranteed within 3 mm from the print head stop position (including 1-mm slow-up.)

4. Average print (black) rate should be 15% or less. For bar code print area, the print rate should be 30% or

less.

5. Line weight should be 3 to 12 dots.

A1.3 Media

EA1- 4

Page 30

APPENDIX 2 INTERFACE ENGLISH VERSION EO1-33061

N

APPENDIX 2 INTERFACE

APPENDIX 2 INTERFACE

Interface Cables

To prevent radiation and reception of electrical noise, the interface cables must meet the following

requirements:

• Fully shielded and fitted with metal or metallized connector housings.

• Keep as short as possible.

• Should not be bundled tightly with power cords.

• Should not be tied to power line conduits.

RS-232C Cable description

The serial data cable used to connect the printer to a host computer should be one of the following two

types (9-pin or 25-pin connector):

Connector to the Host Computer

Function 9 pin 25 pin

RXD 2 3

TXD 3 2

DTR 4 20

GND 5 7

DSR 6 6

RTS 7 4

CTS 8 5

Connector to Printer

Pin No. Function

1 +5V

2 TXD

3 RXD

4 RTS

5 GND

6 CTS

7 RTS

8 CTS

9 +5V

OTE:

Use an RS-232C cable with a connector with inch type securing screws.

EA2- 1

Page 31

GLOSSARIES ENGLISH VERSION EO1-33061

GLOSSARIES

Bar code

A code which represents alphanumeric characters

by using a series of black and white stripes in

different widths. Bar codes are used in various

industrial fields: Manufacturing, Hospitals,

Libraries, Retail, Transportation, Warehousing, etc.

Reading bar codes is a fast and accurate means of

capturing data while keyboard entry tends to be

slow and inaccurate.

Batch mode

Issue mode that continuously prints media until the

required number has been printed.

Black mark

A mark printed on the media enabling the printer to

detect the correct start position of the media,

helping to maintain constant print position.

Black mark sensor

A reflective sensor that detects the difference

between a black mark and the print area to find the

print start position.

Cut mode

Printer mode of operation where an (optional)

cutter module is installed to automatically cut

media from the supply roll after they are printed.

The print command can specify to cut every media

or to cut after a set number of media have been

printed.

DPI

Dots Per Inch

A unit used to express print density or resolution.

Feed gap sensor

A transmissive sensor that detects the difference

between the gap between labels and the label itself,

to find the print start position of the label.

Font

A complete set of alphanumeric characters in one

style of type. E.g. Helvetica, Courier, Times

Gap

Distance from the bottom of one label to the top of

the next label.

IPS

Inch per second

A unit used to express print speed.

GLOSSARIES

Label

A type of media with adhesive backing supplied on

a backing paper.

Media

Material on which images are printed by the printer.

Label, tag paper, fanfold paper, perforated paper,

etc.

Printer driver

A software program that will convert the

application program’s printing request into the

language that the printer understands.

Print head element

The thermal print head consists of a single line of

tiny resistive elements which when current is

allowed to flow through them it heats up causing a

small dot to be burned onto thermal paper or a

small dot of ink to be transferred from a thermal

ribbon to ordinary paper.

Printing speed

The speed at which printing occurs. This speed is

expressed in units of IPS (inches per second).

Resolution

The degree of detail to which an image can be

duplicated. The minimum unit of divided image is

called a pixel. As the resolution becomes higher,

the number of pixels increases, resulting in a more

detailed image.

Supply

Media

Tag

A type of media having no adhesive backing but

black marks to indicate the print area. Usually tags

are made of cardboard or other durable material.

Thermal print head

A print head using thermal transfer or thermal

direct printing method.

Page 32

INDEX ENGLISH VERSION EO1-33061

INDEX

INDEX

B

Backing paper A1-3

Bar code A1-1

Batch mode 2-6

Black mark A1-2

Black mark length A1-3

Black mark sensor 2-6, 2-9

C

Centronics 1-4, 2-2, 2-3, A1-1

Cover open sensor 1-4, 3-2

Cut mode 2-7

Cutter module A1-2

D

Dimensions 1-3, A1-1

E

Effective print range A1-4

External media roll hanger 2-8

F

Feed gap sensor 2-6

FEED/PAUSE button 1-3, 1-4

G

Gap between labels A1-3

Gap length A1-3

Guaranteed print area A1-4

I

Indicator lamp 1-3, 1-4

Interface A1-1, A2-1

Issue mode 2-6, A1-1

J

Jammed media 4-1

K

Keyboard display unit A1-2

L

Label A1-2

Label length A1-3

Label pitch A1-3

Label width A1-3

LAN 1-1, 1-3, 2-3, A1-1

LAN adapter A1-2

M

Media 3-3, A1-2

Media guide 1-4, 2-6

Media guide adjustment knob 1-4, 2-6

Media holder 1-4, 2-5

Media sensor 1-4, 2-6, 2-9, 3-2

Media shaft 1-4, 2-5

P

Parallel interface 1-3, 2-3, A1-1

Parallel port 2-3

Platen 1-4, 3-2

Power adapter 1-1, 2-4

Power consumption A1-1

Power cord 1-3, 2-4

Power jack 1-3, 2-3, 2-4

Power switch 1-3, 2-2, 2-3

Printer driver 2-2

Print head 1-4, 3-1

Print head cleaner 3-1

Print head element 3-1

Printing method A1-1

Printing speed A1-1

R

Rear media guide 1-3, 2-8

Resolution A1-1

Rotations A1-1

RS-232C 2-2, 2-3, A1-1, A2-1

Page 33

INDEX ENGLISH VERSION EO1-33061

INDEX

S

Serial interface 1-3, 2-3, A1-1, A2-1

Strip mode 2-7

Supply voltage A1-1

T

Tag paper A1-2

Thermal direct A1-1

3”-diameter media shaft 2-8

Two-dimensional code A1-1

U

USB interface 2-3, A1-1

W

Weight A1-1

Page 34

EO1-33061A

E

Loading...

Loading...