Page 1

PRINTED IN JAPAN

TOSHIBA Thermal Printer

B-SA4T SERIES

Document No. EO10-33016A

Original Jul., 2005

(Revised Sep., 2005)

Product Description

Page 2

EO10-33016A

(Revision Date: Feb. 14, 2008)

TABLE OF CONTENTS

Page

1. OUTLINE -------------------------------------------------------------------------------------------------1- 1

1.1 Printer Specifications--------------------------------------------------------------------------------------1- 1

1.2 Description of Model Number---------------------------------------------------------------------------1- 1

1.3 Appearance and Dimensions (Approximate) -------------------------------------------------------1- 2

1.3.1 Front View/Rear View ---------------------------------------------------------------------------1- 2

1.3.2 Operation Panel-----------------------------------------------------------------------------------1- 2

1.3.3 Dimensions (Approximate)---------------------------------------------------------------------1- 2

1.3.4 Weight-----------------------------------------------------------------------------------------------1- 2

1.4 Basic Specifications ---------------------------------------------------------------------------------------1- 3

1.5 Electronics Specifications--------------------------------------------------------------------------------1- 7

2. SUPPLY SPECIFICATIONS-------------------------------------------------------------------------2- 1

2.1 Media --------------------------------------------------------------------------------------------------------2- 1

2.2 Ribbon --------------------------------------------------------------------------------------------------------2- 5

2.3 Care and Handling of the Media and Ribbon -------------------------------------------------------2- 6

2.4 Specification of RFID Tag --------------------------------------------------------------------------------2- 7

3. OPTIONAL KIT -----------------------------------------------------------------------------------------3- 1

3.1 Cutter Module: B-SA204-QM/B-SA204-QM-R------------------------------------------------------3- 1

3.2 Strip Module: B-SA904-H-QM-R -----------------------------------------------------------------------3- 2

3.3 Serial Interface Board: B-SA704-RS-QM-R---------------------------------------------------------3- 3

3.4 Wireless LAN Board: B-SA704-WLAN-QM----------------------------------------------------------3- 4

3.5 300-Dpi Print Head: B-SA704-TPH3-QM-R---------------------------------------------------------3- 8

3.6 Expansion I/O Board: B-SA704-IO-QM-R -----------------------------------------------------------3- 8

3.7 Real Time Clock: B-SA704-RTC-QM-R--------------------------------------------------------------3- 9

3.8 RFID Module: B-SA704-RFID-U2-EU-R ------------------------------------------------------------ 3-10

CAUTION!

1. This manual may not be copied in whole or in part without prior written permission of TOSHIBA

TEC.

2. The contents of this manual may be changed without notification.

3. Please refer to your local Authorised Service representative with regard to any queries you

may have in this manual.

Copyright © 2005

by TOSHIBA TEC CORPORATION

A

ll Rights Reserved

570 Ohito, Izunokuni-shi, Shizuoka-ken, JAPAN

NOTE:

Though the pictures used in this document are mostly those of the B-SA4TM (Metal cover model), the

replacement procedures are in common with the B-SA4TP (Plastic cover model).

[B-SA4TM] [B-SA4TP]

Page 3

1. OUTLINE EO10-33016A

1.1 Printer Specifications

1- 1

1. OUTLINE

1.1 Printer Specifications

1) Various bar codes, characters and graphic data can be printed using both thermal transfer and thermal

direct methods. This printer can also print writable characters and logos at designated coordinates by

using a graphic command.

2) Centronics, LAN, and USB are provided as standard interfaces for communicating with a PC.

Additionally, serial interface and wireless LAN interface are optionally available.

3) A 32-bit CPU and a Field Programmable Gate Array (FPGA) equipped with several peripheral LSIs

realizes high system performance.

4) An area required to place a printer is about A4 size, in spite of both media and ribbon being loaded

inside it. Also, the Top Cover is opened upward, which saves the installation space.

5) Clear print is realized by an 8 dots/mm (203 dpi) (GS12 model) or 11.8 dots/mm (300 dpi) (TS12 model)

print head, at a printing speed of 50.8 mm/sec. (2 inches/sec.), 101.6 mm/sec. (4 inches/sec.), or 152.4

mm/sec. (6 inches/sec.)

6) As the enclosure is made of metal, the printer can be used in an industrial environment such as a factory.

7) Design of the printer is simple. Especially, attachment and removal of the print head and platen are very

simple, which makes maintenance easy.

8) Optional cutter module or optional strip module will expand the application of the printer .

NOTE: Every size is written in millimeter (mm) in this manual. To obtain the size in inch, divide by 25.4.

1.2 Description of Model Number

B – S A 4 T M – G S 1 2 – Q M - R

RoHS compliant

Destination Code

QM: Standard for Worldwide

CN: China

Machine Type

Machine Version

Issue mode

S: Batch

Resolution

G: 8 dots/mm (203 dpi)

T: 11.8 dots/mm (300 dpi)

Material of enclosure

M: Metal

P: Plastic

Printing method:

T: Thermal direct or Thermal transfer

Printing width

4: 4 inches

Page 4

1. OUTLINE EO10-33016A

1.3 Appearance and Dimensions (Approximate)

1- 2

1.3 Appearance and Dimensions (Approximate)

1.3.1 Front View/Rear View

Front View Rear View

1.3.2 Operation Panel

LCD Message Display: When the power is turned on and it is ready to print, ON LINE is displayed.

ON LINE LED (Green): 1) Flashes when communicating with a host PC.

2) Lights while printing.

ERROR LED (Red): Lights when the printer is in an erroneous state.

FEED key: Feeds media.

RESTART key: Resets the printer when paused or when an error occurs.

Used to set a threshold. (Refer to the Owner’s Manual.)

PAUSE key: Pauses printing.

Message display shows PAUSE and a remaining count.

Used to set a threshold (Refer to the Owner’s Manual.)

1.3.3 Dimensions (Approximate)

B-SA4TM (Metal cover type): 238 mm (W) x 402 mm (D) x 332 mm (H)

B-SA4TP (Plastic cover type): 238 mm (W) x 339 mm (D) x 332 mm (H)

1.3.4 Weight

B-SA4TM (Metal cover type): 15Kg

B-SA4TP (Plastic cover type): 12Kg

L

CD Message

Display

Operation

Panel

Media Outlet

Top Cover

Supply Window

Power Switch

{: OFF

|: ON

LAN Connector

Ribbon Cover

Parallel Interface

Connector (Centronics)

Serial Interface

(Option),

Wireless LAN

interface (Option)

AC Power Inlet

USB Connector

LCD Message Display

ON LINE LED (Green)

ERROR LED (Red)

[PAUSE] key

[FEED] key

[RESTART] key

Page 5

1. OUTLINE EO10-33016A

1.4 Basic Specifications

1- 3

1.4 Basic Specifications

1) Printing method: Thermal direct printing or thermal transfer printing

2) Print head

GS12 model TS12 model

Total number of dots 832 dots 1248 dots

Dot density 8 dots/mm 11.8 dots/mm

Effective print width 104 mm 105.7 mm

Thermal pitch 0.125 mm 0.0847 mm

3) Print speed: 6”/sec., 4”/sec., 2”/sec.

NOTE: These print speeds are available when printing ratio is less than 30% of the entire label or tag paper.

4) Format size (W) x (L)

GS12 model: Max. 104.0 mm x 997.0 mm

TS12 model: Max. 105.7 mm x 997.0 mm

5) Issue mode

• Batch

• Auto cut (Auto cut mode is available only when the optional cutter is attached.)

• Strip (Strip mode is available only when the optional strip module is attached.)

6) Type of bar code/two dimensional code

(1) JAN8, EAN8, J AN13, EAN13, UPC-A, UPC-E

(15) Industrial 2 of 5

(2) EAN8, EAN13, UPC-A, UPC-E + 2digit (16)

Customer Bar Code

(3) EAN8, EAN13, UPC-A, UPC-E + 5digit Postal code for Japan)

(4)

NW-7

(17)

POSTNET (Postal code for USA)

(5)

CODE39 (STANDARD)

(18)

RM4SCC (Postal code for UK)

(6)

CODE39 (FULL ASCII)

(Royal Mail 4 State Customer Code)

(7)

ITF

(19)

KIX CODE (Postal code for Belgium)

(8)

MSI

(20)

Maxi Code

(9) CODE93 (21)

Micro PDF417

(10)

CODE128 (Automatic code change) (22) CP CODE

(11)

EAN128

(23)

RSS14

(12)

Data Matrix (24) High priority customer bar code

(13)

PDF417 (25) GTIN (Global Trade Item Number)

(14)

QR Code

7) Bar code rotation: 0

°, 90°, 180°, 270°

Page 6

1. OUTLINE EO10-33016A

1.4 Basic Specifications

1- 4

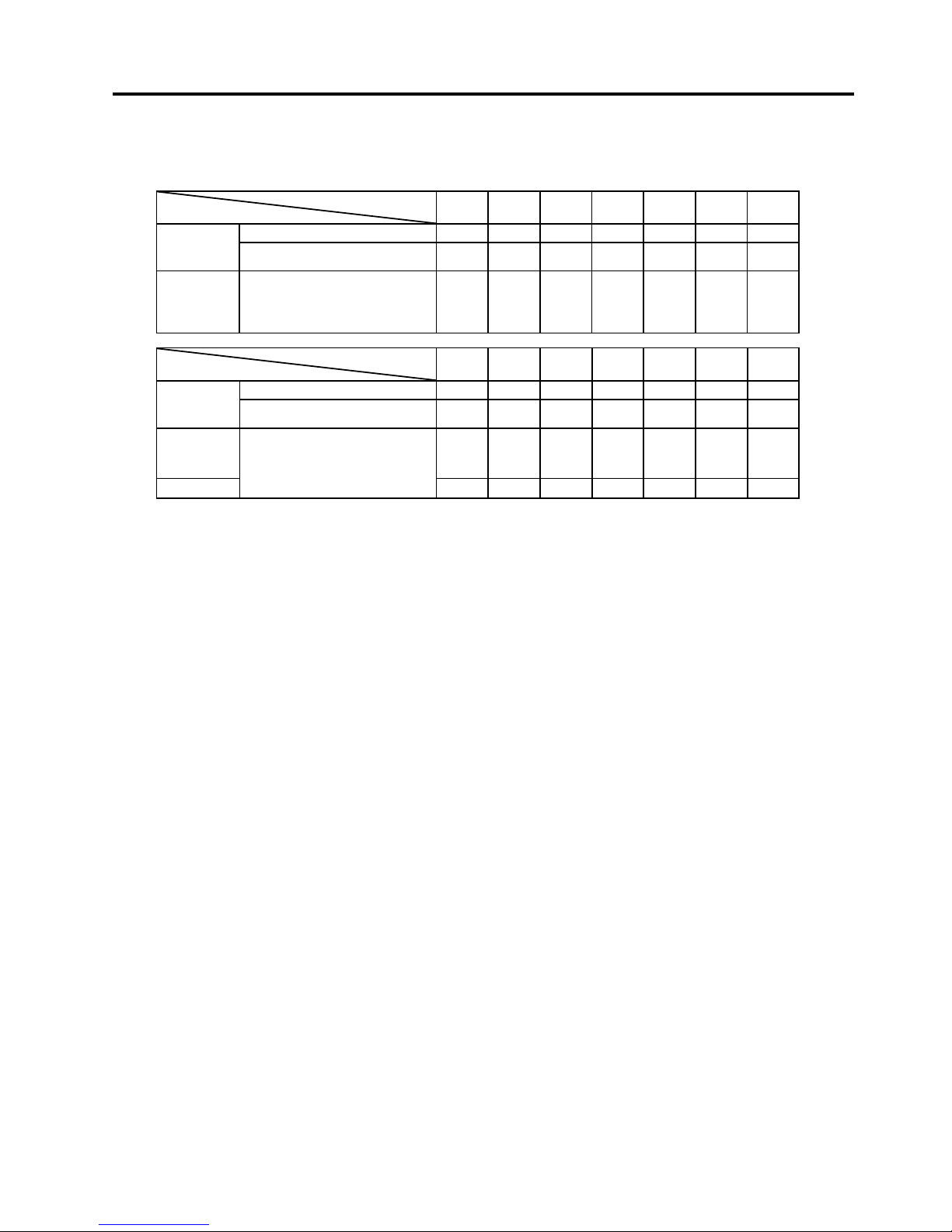

8) Magnification of bar code

UPC/EAN/JAN/CODE93/128/PDF417............Up to 6 modules can be automatically calculated using

1-module width designation (1 to 15 dots).

Dots/Module

Bar code

2 3 4 5 6 7 8

Min. Module Width (mm)

0.25 0.38 0.50 0.63

– – –

UPC-A/E

EAN8/13

JAN8/13

Magnification (times)

0.76 1.14 1.51 1.91

– – –

CODE93

EAN128

CODE128

PDF417

Min. Module Width (mm)

0.25 0.38 0.50 0.63 0.75 0.88 1.00

Dots/Module

Bar code

9 10 11 12 13 14 15

Min. Module Width (mm)

– – – – – – –

UPC-A/E

EAN8/13

JAN8/13

Magnification (times)

– – – – – – –

CODE93

EAN128

CODE128

1.13 1.25 1.38 1.50 1.63 1.75 1.88

PDF417

Min. Module Width (mm)

1.13 1.25

– – – – –

NW-7/CODE39/ITF/MSI/Industrial 2 of 5 .......The width of narrow bars, wide bars and spaces can be

optionally changed in a range of 1 to 99 dots.

Data Matrix.......................................................The width of one cell can be changed in a range of 1 to

99 dots.

9) Type of characters

(1) Times Roman medium (12, 15 point) (9) Prestige Elite medium (10.5 point)

(2)

Times Roman bold (15, 18, 21 point) (10) Prestige Elite bold (15 point)

(3)

Times Roman Italic (18 point) (11) Courier medium (15 point)

(4)

Helvetica medium (9, 15, 18 point) (12) Courier bold (18 point)

(5)

Helvetica bold (18, 21 point) (13) OCR-A, B (12 point)

(6)

Helvetica Italic (18 point) (14) Outline font (Helvetica bold, Helvetica bold proportional,

(7) Presentation bold (27 point) Price Font (1,2,3), Times roman proportional, Pop

(8)

Letter Gothic medium (14.3 point) Proportional, Proportional)

(15)

Writable characters (2-byte character is available.)

10) Character code

(1) PC-850 (2) PC-8 (3) PC-852 (4) PC-857 (5) Arabic (6) LATIN 9 (7) PC-1257 (8) PC-1254

(9) PC-1253 (10) PC-1252 (11) PC-1251 (12) PC-1250 (13) PC-855 (14) PC-851 (15) PC-866

11) Character magnification

(1) Regular font: 0.5 to 9. 5 t imes (magnified by 0.5 times in each direction)

(2) Outline font: 2.0 to 85.0 mm (magnified 0.1 mm in each direction)

NOTE: When the outline font size is large, the ribbon may wrinkle according to the quality of the ribbon or

print tone.

Page 7

1. OUTLINE EO10-33016A

1.4 Basic Specifications

1- 5

12) White or black background all types of characters are available.

13) Character rotation: 0

°, 90°, 180°, 270°

14) Character strings rotation: 0

°, 90°, 180°, 270°

15) Type of line

(1) Horizontal line (2) Vertical line (3) Slant line (4) Square (5) Rounded Rectangle (6) Circle

16) Line Width: 0.1 to 9.9 mm can be specified (in units of 0.1 mm)

17) Mechanism

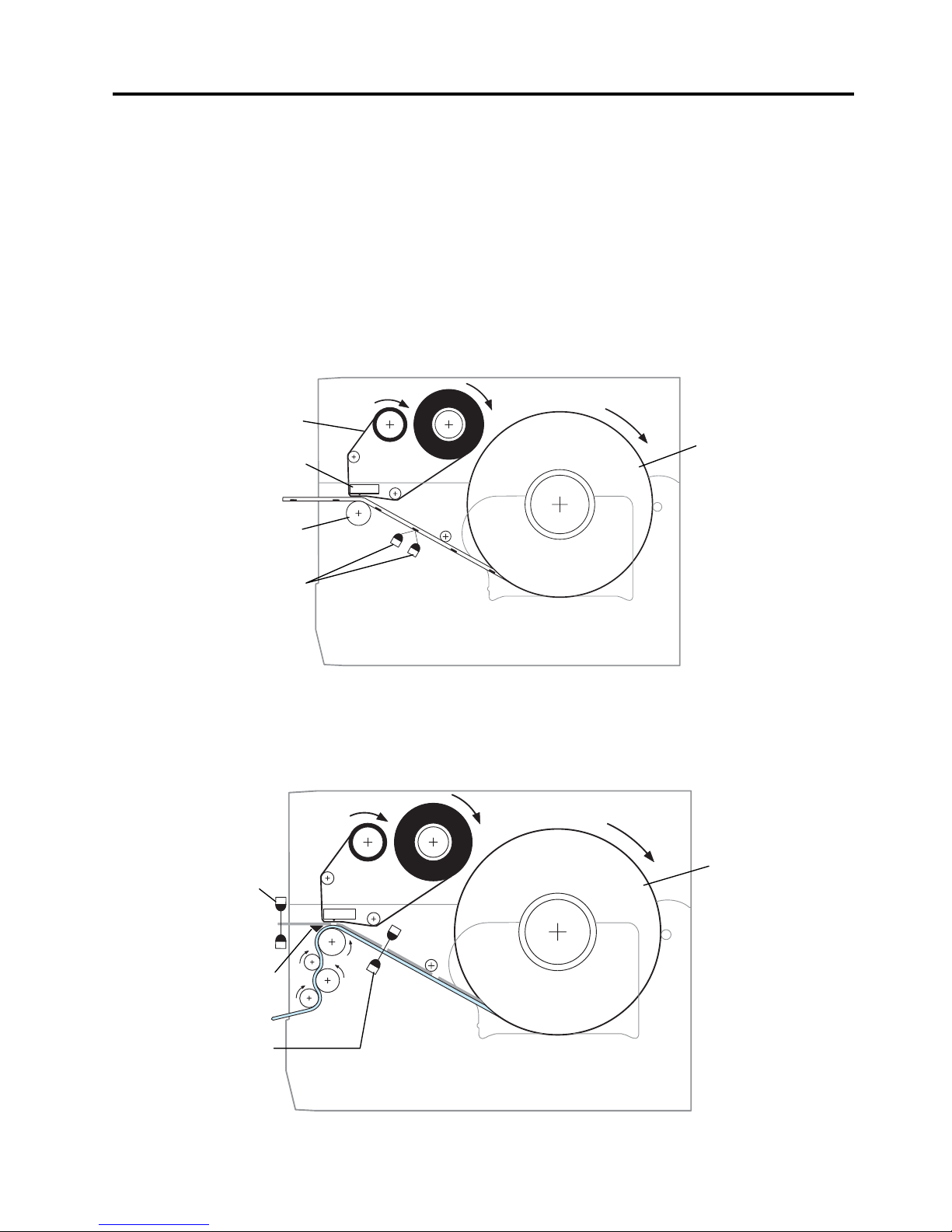

(1) Batch mechanism

This is the standard mechanism which lets the printer print continuously until the number of media

specified in the label issue command has been printed.

(2) Strip mechanism (Option)

When an optional strip module is attached, a label is stripped from the backing paper by the strip

shaft, and the backing paper is drawn into the strip module. The next label will not be printed until

the preceding label is removed, as a presence of the label at the strip shaft is monitored by the strip

sensor.

Ribbon

Print Head

Platen

Black Mark Sensor

Tag Stock

Strip Sensor

Strip Shaft

Feed Gap Sensor

Label Stock

Page 8

1. OUTLINE EO10-33016A

1.4 Basic Specifications

1- 6

(3) Auto cut mechanism (Option)

When an optional cutter module is attached, printed media is fed to the cutter unit and cut off from

the media roll.

18) Power supply

Universal power supply: AC100 to 240 V ±10%, 50/60Hz

Harmonics: Class A

19) Power consumption

During a print job: 2.1A (100V) to 1.1A (240V), 155W rating

During standby: 0.19A (100V) to 0.15A (240V), 13W (100V) to 22W (240V)

20) Rush current

100V input: 10A

240V input: 22A

NOTE: Be sure to use an exclusive power outlet for the printer.

21) Operating temperature range

Thermal direct:: 0°C to 40°C

Thermal transfer: 5°C to 40°C

22) Relative humidity

25% to 85%RH (no condensation)

Cutter

Black Mark Sensor

Tag Stock

Page 9

1. OUTLINE EO10-33016A

1.5 Electronics Spec i fications

1- 7

1.5 Electronics Specifications

1) CPU: HD6417705F133BV

2) Memory

(1) Program: 16-MB Flash ROM

(2) Backup: 512-byte EE-PROM

(3) Image buffer + Work: 16-MB SD-RAM

3) Interface

(1) Parallel interface (Standard interface)

c Centronics interface conforming to IEEE1284, supporting SPP mode (compatibility mode) and

nibble mode.

d Data input method: 8-bit parallel (DATA 1 to 8)

e Control signals

Compatibility mode

nStrobe, nAck, Busy, PError, Select, nAutoFd, nInit, nFault, nSelectIn

Nibble mode HostClk, PtrClk, PtrBusy, AckDataReq, Xflag, HostBusy, nInit, nDataAvail,

IEEE1284Active

f Data input code: ASCII, JIS 8-bit code for European characters, 8-bit code for graphic

g Receiving buffer: 1MB (shared with other interfaces)

h Input/Output circuit configuration and Input/Output conditions

Type

Signal Name

Configuration

Input/

Output

Data 1 to 8

SN74LVX161284 or equivalent

1K

+5V

Input

nStrobe/HostClk

nInit/nReverseRequest

nAutoFd/HostBusy/HostAck

nSelectIn/IEEE1284Active

SN74LVX161284 or equivalent

1K

+5V

100P

Output

Busy/PtrBusy/PeriphAck

nFault/nDataAvail/nPeriphRequest

nAck/PtrClk/PeriphClk

Select/XFlag

PError/AckDataReq/nAckReverse

SN74LVX161284

or equivalent

+5V

1K

100P

Logical level

(input)

"1" = 2~5V

"0" = 0~0.4V

Logical level

(output)

"1" = 2.4~5V

"

0" = 0~0.4V

Page 10

1. OUTLINE EO10-33016A

1.5 Electronics Spec i fications

1-8

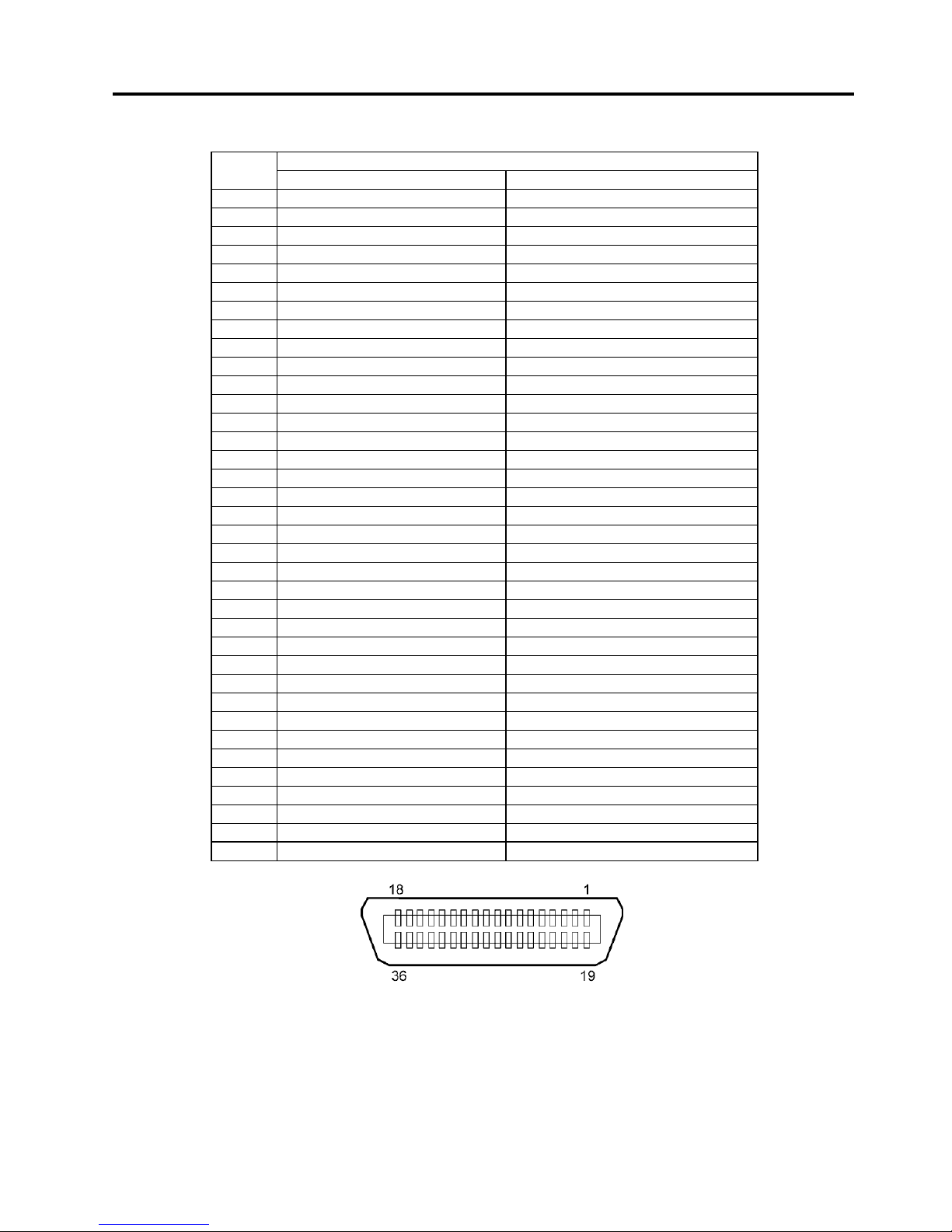

i Pin Layout (IEEE1284-B Connector)

Signal PIN

No.

SPP Mode Nibble Mode

1 nStrobe HostClk

2 Data 1 Data 1

3 Data 2 Data 2

4 Data 3 Data 3

5 Data 4 Data 4

6 Data 5 Data 5

7 Data 6 Data 6

8 Data 7 Data 7

9 Data 8 Data 8

10 nAck PtrClk

11 Busy PtrBusy

12 PError AckDataReq

13 Select Xflag

14 nAutoFd HostBusy

15 NC NC

16 0V 0V

17 CHASSIS GND CHASSIS GND

18 +5V (For detection) +5V (For detection)

19 TWISTED PAIR GND(PIN1) TWISTED PAIR GND(PIN1)

20 TWISTED PAIR GND(PIN2) TWISTED PAIR GND(PIN2)

21 TWISTED PAIR GND(PIN3) TWISTED PAIR GND(PIN3)

22 TWISTED PAIR GND(PIN4) TWISTED PAIR GND(PIN4)

23 TWISTED PAIR GND(PIN5) TWISTED PAIR GND(PIN5)

24 TWISTED PAIR GND(PIN6) TWISTED PAIR GND(PIN6)

25 TWISTED PAIR GND(PIN7) TWISTED PAIR GND(PIN7)

26 TWISTED PAIR GND(PIN8) TWISTED PAIR GND(PIN8)

27 TWISTED PAIR GND(PIN9) TWISTED PAIR GND(PIN9)

28 TWISTED PAIR GND(PIN10) TWISTED PAIR GND(PIN10)

29 TWISTED PAIR GND(PIN11) TWISTED PAIR GND(PIN11)

30 TWISTED PAIR GND(PIN31) TWISTED PAIR GND(PIN31)

31 nInit nInit

32 nFault NDataAvail

33 0V 0V

34 NC NC

35 NC NC

36 nSelectIn IEEE1284Active

IEEE1284-B Connector

Page 11

1. OUTLINE EO10-33016A

1.5 Electronics Spec i fications

1-9

j Input/Output Signals

Signal I/O Description

Data1 to 8 Input z Input data signals for the 1st to 8th bits.

z Logic 1 is “High” level.

z Min. data pulse width of 2.5 µsec.

nStrobe Input z Synchronizing signal for reading the above data.

z Normally at “High” level. The data is read at the rise of the Low level pulse.

z Minimum data pulse width of 0.5 µsec.

Busy Output

z This signal indicates that the printer is in a Busy state.

z When initialized after the power is turned on

, the printer becomes ready to

receive data and turns the signal to “Low” level.

z

The signal turns to “Hig h” level (in a Busy state) when data is set fr om the

host (at the fall of the nStrobe signal).

z The signal turns to “Low” level when the printer reads the data.

z When the free space of the receive buffer becomes

512 bytes or less, the

printer keeps the sign al at “High” level ( in a Bus y state) for 10 seconds when

data is set from the host, to extend the data read interval.

z When the receive buffer has become full

, the printer stops reading data.

When data is set from the host, t

hen, it keeps the si gnal at “High” leve l (in a

Busy state) until the receive buffer has a free space.

z T he signal is kept at “High ” level (in a Busy sta te) until one of the f

ollowing

states is cleared.

• PAUSE state caused by the [PAUSE] key

• Paper end state

• Ribbon end state

• Head open state

• Printer error state

z Initialization in progress upon receipt of the nInit signal

nAck Output

z This s ignal indicates that t he p

rinter has read the data set by the host and is

ready to receive the next data.

z

The signal is normally at “High”. It is at “Low” for about 5 µsec. after the fall of

the BUSY signal. The ho st should usually set data after the ACK s ignal is

turned from “Low” to “High”.

z

If the nAck signal is ignored and th e next data is s et while the nAck signal is

Low, the “LOW ” level continues about f urther 5 µsec at the fall of the BUSY

signal. However, the data can be received properly.

nInit Input z Reset request signal from the host.

z Normally at “High” level. An input of this signal at “Low” level

causes the

printer to be initialized in the same manner as when the power is turned on.

*

When “Reset process when the nInit signal is ON” is set to “OFF” in the

pa

rameter setting in the sys tem mode, the printer is not initialized even if it

receives this signal at low level.

z

When the nInit signa l is input during pr inting, the printer completes print ing

one tag/label which is being printed, cancels the next process

ing, then is

initialized in the same manner as when the power is turned on.

*

When “Reset process when the nInit signal is ON” is set to “OFF” in the

parameter setting in the s ystem mode, the next pr ocess proceeds without

being canceled.

z Minimum pulse width of 0.5 µsec.

SPP mode

Page 12

1. OUTLINE EO10-33016A

1.5 Electronics Spec i fications

1-10

Select Output

z This is an output sign al which indicat es whether the p rinter is in Pa use state

or placed online. The printer can receive data while placed online.

z The signal is at “Low” level while the printer is in a Pause state.

z

The signal is k ept at “Low” level ( in a Pause stat e) until one of the following

states is cleared.

• Pause state caused by the [PAUSE] key

• Paper end state

• Ribbon end state

• Head open state

• Printer error state

• Initialization in progress upon power on or receipt of the nInit signal

nFault Output

z Output signal indicating that the printer is in a Fault state.

z At “Low” level while the printer is in a Fault state.

z T he signal is kept at “Low” level (in a Fault s tate) until one of the followi

ng

states is cleared.

• Pause state caused by the [PAUSE] key

• Paper end state

• Ribbon end state

• Head open state

• Printer error state

• Initialization in progress upon power on or receipt of the nInit signal

Perror Output

z Output signal indicating a label end or ribbon end state.

z At “High” level when the printer is in a label end or ribbon end state.

z Turns to “Low” level when the label end or ribbon end state is cleared.

+5V ---- z This is not a signal but a +5 V power supply voltage.

z The maximum current of 500 mA can be taken out.

nSelectIn Input Not used

nAutoFd Input Not used

Signal I/O Description

PtrClk Output

z Reverse data transfer phase:

It is used for evaluating data sent to the

host.

z Reverse idle phase: When the printer changes the signal from

Low to High, an interrupt i nforming the host

that the data is available, occurs

PtrBusy Output

z Reverse data transfer phase:

Data bit 3 is used f or the fi rst transfer. Data

bit 7 is used for the second transfer.

Indicates

the forward channel is in a Busy

state.

AckDataReq Output

z Reverse data transfer phase:

Data bit 2 is used f or the fi rst transfer. Data

bit 6 is used for the second transfer.

z Reverse idle phase:

This signal is set to high until the data

transfer is

requested by the h ost. Then, the

process is performed according to the

nDataAvail signal.

Xflag Input z Reverse data transfer phase:

Data bit 1 is used f or the fi rst transfer. Data

bit 5 is used for the second transfer.

Nibble mode

Page 13

1. OUTLINE EO10-33016A

1.5 Electronics Spec i fications

1-11

HostBusy Input

z Reverse data transfer phase:

It indicates that the host can receive data

from the printer by setting the signal to low.

Then, the host sets the signa l to high, and

sends the Ack indicating th at the nibb le data

is received. When the signal is set to low

after one reve

rse channel data transfer is

performed, the interface phase changes to

the idle phase. At that time, there is no

available data on the printer.

z Reverse idle phase:

When this signal is set to high according to

the low pulse of t he PtrClk signal, the host

enters the reverse data transfer phase

again. If this signal is se t to high when the

IEEE1284 Active signal is low, the

IEEE1284 idle phase stops, and the

interface enters the Compatibility mode.

nDataAvail Output

z Reverse data transfer phase: When the signal is low, it indicates the

printer has data to be sent to the host. And

it is used for sending data bits 0 and 4.

z Reverse idle phase: It is used for indicating that the data is

available.

Page 14

1. OUTLINE EO10-33016A

1.5 Electronics Spec i fications

1-12

(2) USB (Standard interface)

c Standard: Conforming to Rev. 2.0

d Transfer type: Control transfer, Bulk transfer

e Transfer rate: Full speed (12M bps)

f Transfer control method: Data transfer is controlled by sending/receiving a status with the receive

buffer free space information.

g Receiving buffer: 1MB (shared with other interface)

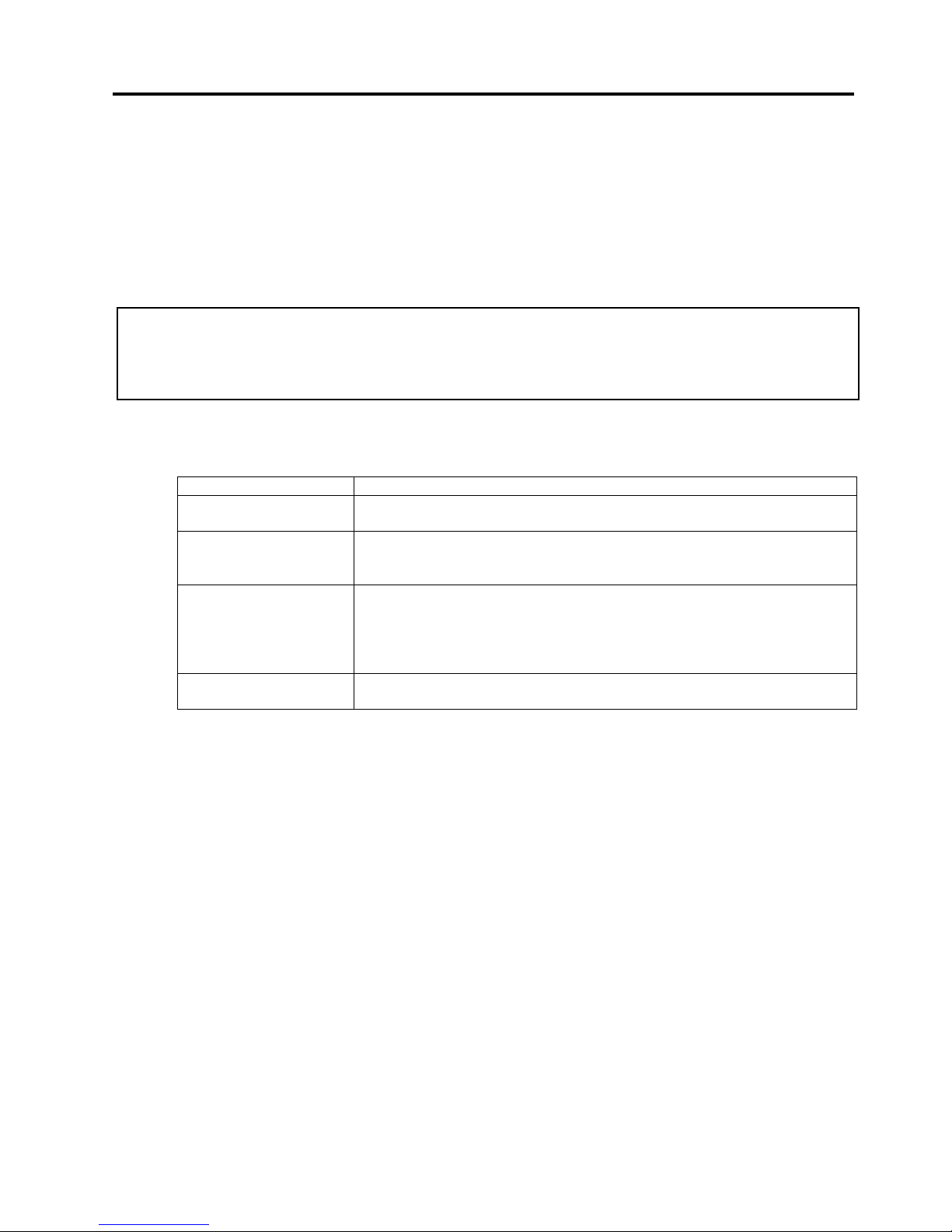

(3) LAN interface (Standard interface)

c Constitution: 10 Base-T or 100 Base-TX LAN controller

d Protocol: TCP/IP

e Network specifications:

Function Description

LPR Server Function Supporting LPR protocol (Line Printer Daemon Protocol) which enables

printing via TCP/IP network.

WEB printer f unction When the printer is connected to a PC via TCP/IP network, browsin g the

printer status, issuin g media, checking or changing t he printer settings, or

downloading the firmware are enabled.

Socket communication

protocol

Socket is an end point of a connection to other host computer via TCP/I P

network, which is used to send/receive data between the PC and the

printer.

Use of Socket Communication protocol allows a communication only by

reading/writing data to/from the socket.

E-mail function Commands are sent to the printer by an e-mail. This function allows

remote control of the printer.

f Receiving buffer: 1MB (shared with other interface)

(4) Serial interface (Optional interface)

A serial interface conforming to RS-232C is available when an optional serial interface board, B-

SA704-RS-QM-R, is installed in the printer.

c Communication mode: Full-duplex

d Transmission speed: 2400,4800,9600,19200, 38400, 115200 bps (selectable)

e Synchronization: start- st op synchronization

f Transmission parameter

Parity: None, EVEN, ODD

Start bit: 1-bit

Stop bit: 1-bit or 2-bit

Word length: 7-bit or 8-bit

g Error detection

Parity check: VRC (Vertical Redundancy Checking)

Framing error: This error occurs when no stop bit is found in the frame specified starting with

the start bit.

h Data entry code: ASCII, 8-bit code for European characters, 8-bit code for graphic

i Receiving buffer: 1MB (shared with other interface)

j Protocol: No-procedure method

CAUTION!

Do not directly connect the LAN cable wired

outside of a building to the LAN port provided on this product, as the LAN port on

this product is intended for indoor connection.

To connect such LAN cable to the product, be sure to use any communication equipment, like a router, a hub, or a modem

which

is located within the same building as the product.

Page 15

1. OUTLINE EO10-33016A

1.5 Electronics Spec i fications

1-13

k Flow control

XON/XOFF (DC1/DC3) pr otocol

This is a software flow control using XON (DC1)/XOFF (DC3) code.

• When initialized after power on, this printer becomes ready to receive data and sends an

XON code (11H). (Transmission or non-transmission of XON code is selectable by means of

the parameter setting.)

• The printer sends an XOFF code (13H) when the free area in the receive buffer becomes

10K Bytes or less.

• The printer sends an XON code (11H) when the free area in the receive buffer are 512KB or

more.

• When there is no free area in the receive buffer, the printer discards received data which

exceeds the receive buffer capacity without storing it in the buffer. (After detect ing the XOFF

code, the host computer must stop transmission before the printer receive buffer becomes

full.)

• The printer sends an XOFF code (13H) at power off time. (Transmission or non-transmission

of XOFF code is selectable with the parameter setting.)

• The DTR signal is always “High” level (Ready).

• The RTS signal is always “High” level (Ready).

READY/BUSY (DTR) protocol

This is a hardware flow control using DTR signal as a control code.

• When initialized after power on, this printer becomes ready to receive data and conv ert s t he

DTR signal to "High" level (READY).

• The printer converts the DTR signal to "Low" level (BUSY) when the free area in the receive

buffer amount to 10K bytes or less.

• The printer converts the DTR signal to "High" level (READY) when the free area in the

receive buffer amount to 512KB or more.

• When there is no free area in the receive buffer, the printer discards received data which

exceeds the receive buffer capacity without storing it in the buffer. (After detect ing a BUSY

signal, the host computer must stop transmission before the printer receive buffer becomes

full.)

• The RTS signal is always “High” level.

XON/XOFF (DC1/DC3) pr otocol + READY/BUSY (DTR) protocol

This is a software and hardware flow control using XON/XOFF code and DTR signal.

• When initialized after power on, this printer becomes ready to receive data and conv ert s t he

DTR signal to "High" level (READY). The printer sends an X O N code (11H).

• When the free area in the receive buffer are 10K bytes or less, the printer converts the DTR

signal to "Low" level (BUSY) and sends an XOFF code (13H).

• When the free area in the receive buffer are 512KB or more, the printer converts the DTR

signal to "High" level (READY) and sends an XON code (11H).

• When there is no free area in the receive buffer, the printer discards received data which

exceeds the receive buffer capacity without storing it in the buffer. (After detect ing the XOFF

code or BUSY signal, the host computer must stop transmission before the printer receive

buffer becomes full.)

• The printer sends an XOFF code (13H) at power off time.

• The RTS signal is always “High” level.

Page 16

1. OUTLINE EO10-33016A

1.5 Electronics Spec i fications

1-14

READY/BUSY (RTS) Protocol

This is a hardware flow control using RTS signal as a control code.

• When initialized after power on, this printer becomes ready to receive data and converts the RTS

signal to "High" level (READY).

• The printer converts the RTS signal to “Low” level (BUSY) when the free area in the receive

buffer amount to 10K bytes or less.

• The printer converts the RTS signal to “High” level (READY) when the free area in the receive

buffer amount to 512KB or more.

• When there is no free area in the receive buffer, the printer discards received data which exceed

the receive buffer capacity without storing it in the buffer. (After detecting a BUSY signal, the host

computer must stop transmission before the printer receive buffer becomes full.)

• The DTR signal is always “High” level (READY).

• The host should keep the DSR signal “High” level.

NOTE: Be sure to select the READY/BUSY (RTS) protocol when controlling the flow between the

Windows. Also, be sure to select “Hardware” for the flow control in the Windows

communication port setting.

l Pin description

Pin No.

Signal I/O Description

1 FG (Frame Ground) --- Ground line for circuit protection.

2 RD (Received Data) Input

Data line from which the printer receives data from the host

(receive data line).

Logic “1” is “Low”, and “0” is “High”. It is LOW (MARK) while no

data is being sent.

3 TD (Transmit Data) Output

Data line from which the printer sends data to the host (send data

line).

Logic “1” is “low”, and “0” is “High”. It is LOW (MARK) while no

data is being sent.

4 CTS (Clear to Send) Input Input signal from the host. This printer ignores this signal.

5 RTS (Request to Send) Output

Output signal to the host.

When READ/BUSY (RTS) protocol is selected,

this signal means READY to receive data.

When the receive buffer is nearly full, the signal turns to “Low”,

and “High” when nearly empty.

In case of other protocol is selected, this signal is always “High”

level after the power is turned on.

6 DTR (Data Terminal Ready) Output

Output signal from the printer.

When READY/BUSY (DTR) or XON/XOFF

(DC1/DC3)+READY/BUSY (DTR) is selected, this signal means

READY to receive data.

When the receive buffer is nearly full, the signal turns to “Low”,

and “High” when nearly empty.

In case of XON/XOFF (DC1/DC3) or READY/BUSY (RTS), this

signal is always “High” level after the power is turned on.

7 SG (Signal Ground) --- Ground line for all data and control signals.

20 DSR (Data Set Ready) Input

Input signal from the host. It must be “High” for the printer to

receive data.

l Interface circuit

Input circuit Output circuit

Signal level

Input voltage: "H" .. +3V~ + 15V Output voltage: "H" .. +6V ~ +13V

"L" ... –3V~ – 15V "L" ... –6V ~ –13V

R

D

C

TS

D

SR

SN75189 or equivalent

TD

RTS

DTR

SN75188 or equivale

nt

Page 17

1. OUTLINE EO10-33016A

1.5 Electronics Spec i fications

1-15

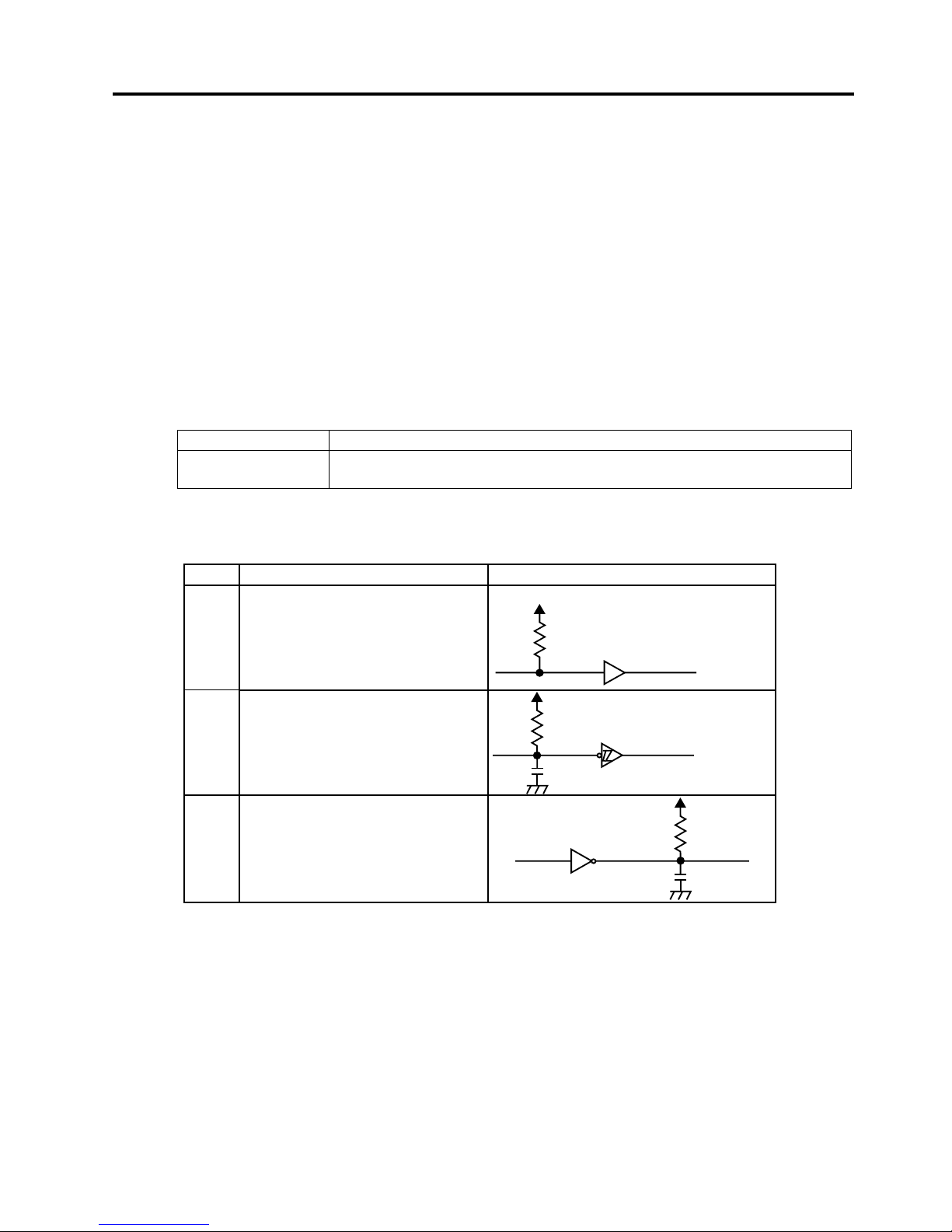

(5) Expansion I/O interface (Optional interface)

Interface circuit

Input circuit

There are six input circuits, and each input is a current loop using a photo-coupler.

The anode of the photo-coupler is connected to common pin COM1 in each of the six circuits. Each

cathode is independent. The voltage of Vcc is 24 V (max.) while the diode operating current is 16 mA.

Output circuit

There are seven output circuits, and each output is an open collector. The voltage of Vcc is 24V (max.)

while the operating current is 150 mA.

For other details, please refer to the Expansion I/O specifications stored in the enclosed CD-ROM or

posted on the web site with the URL, http://barcode.toshibatec.co.jp.

External controller, etc.

Vcc

R

R

Photo-coupler

TPL521 (TOSHIBA)

COM1

IN0

IN5

~

Printer

TLP521 (TOSHIBA)

External controller, etc.

(In the case of photo-coupler)

~

~

Printer

OUT0

OUT6

Vcc

COM2

Page 18

1. OUTLINE EO10-33016A

1.5 Electronics Spec i fications

1-16

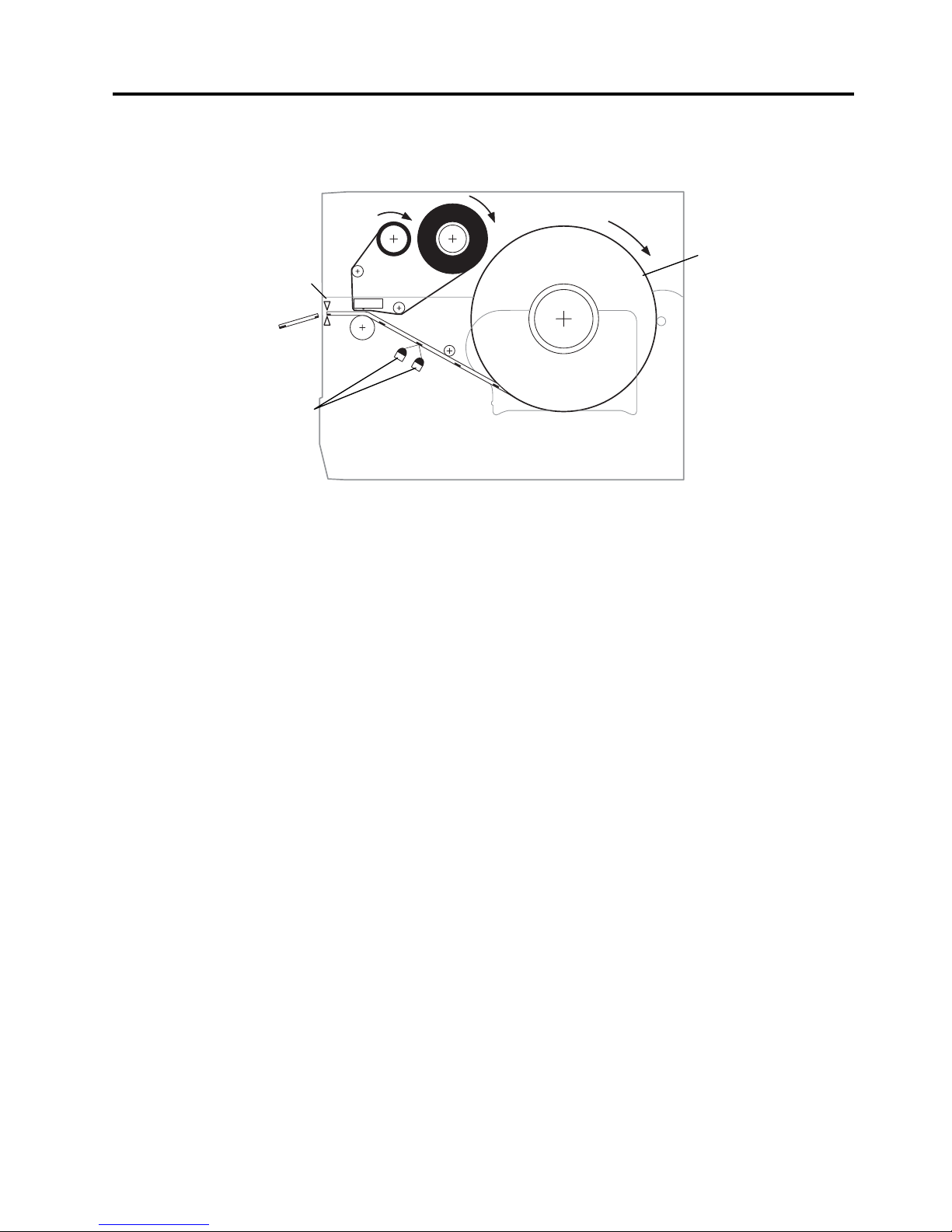

4) Sensor/switch

(1) Media sensor

This sensor is comprised of the black mark sensor and feed gap sensor. It is positioned 92.1 mm

from the platen.

The sensor position is adjustable according to the black mark position. It can be manually moved

from the center to the left edge of media.

Black mark sensor (Reflective sensor)

This sensor detects the difference of potential between a black mark and a print area to find a

print start position of the tag paper.

Side detection (max.)

Center detection

Feed g ap sensor (Transmissive sensor)

This sensor detects the difference in potential between the backing paper and the label to

find the print position of the label. The feed gap sensor is located at 10 mm to the right of

the black mark sensor.

Side detection (max.)

Center detection

Black Mark Sensor

Black Mark

Media Center

Tag Paper

Black Mark Sensor

Black Mark

Media Center

Tag Paper

Feed Gap Sensor

Media Center

Label

Backing Paper

Feed Gap Sensor

Media Center

Home position of the

Feed Gap Sensor

Label

Backing Paper

Page 19

1. OUTLINE EO10-33016A

1.5 Electronics Spec i fications

1-17

(2) Slit sensor (Transmissive sensor)

The ribbon motor block has three same slit sensors: Two of them are attached to the ribbon

feed motor side, and the other one is t o t he ribbon take-up side.

A slit sensor is a photo-coupler, consisting of an LED and a transistor.

This sensor detects the amount of taken ribbon, ribbon feed amount, the rotation count of the

ribbon shaft and the ribbon motors, and t he dir ection of rotation.

The slit sensor on the ribbon take-up side detects the amount of taken ribbon by monitoring the

time of detecting slits of the ribbon slit gear.

The two slit sensors on the ribbon feed side detects a ribbon end when the motor rotates in the

reverse direction at a ribbon break or ribbon end.

(3) Top cover open sensor

On each side of the printer, same top cover open sensor is provided. This sensor is a photo-

coupler, consisting of an LED and a transistor. A top cover open status is detected depending

on the two hook plates linked with the top cover release button intercept the photo-coupler or

not.

W hen a top cover open status is detected, “HEAD OPEN” is displayed on the LCD, the error

LED illuminates, and printing is stopped.

Slit Sensor (Take-up)

Slit

Slit Sensor (Feed)

Ribbon Slit Gear

(Take-up)

Ribbon Slit Gear

(Feed)

Hook Plate

Top Cover Open Sensor

Page 20

1. OUTLINE

EO10-33016A

1.5 Electronics Specifications

1-18

(4) Front cover open sensor

On the right side of the printer front, a front cover open sensor is provided. This sensor is a

photo-coupler, consisting of an LED and a transistor. A front cover open status is detected

depending on the tab of the front cover intercepts the photo-coupler or not.

When a front cover open status is detected, “COVER OPEN”.

(5) Strip sensor (transmissive sensor) for optional strip module

This sensor detects whether or not the label has been taken away from the media outlet and

controls the label feed.

Front Cover Open

Sensor

Front Cover

Tab

Strip Sensor

Page 21

1. OUTLINE EO10-33016A

1.5 Electronics Spec i fications

1-19

(6) Cutter home position sensor for optional cutter module

This sensor is positioned inside of the cutter unit. This is a photo-coupler, consisting of an LED

and a transistor. When the arm linked with the cutter blade intercepts the photo-coupler, it is

considered as a cutter home position.

(7) Cutter front cover sensor (micro switch)

The cutter front cover sensor is a micro switch, which is provided on the lower left of the cutter

unit. When the cutter front cover is closed, the arm of the cover turns the micro switch. A cutter

front cover status is detected depending on t he m icr o switch is tur ned on or off.

Cutter Home

Position Sensor

Cutter Front Cover Sensor

Arm

Cutter Unit

Arm

Page 22

2. SUPPLY SPECIFICATIONS EO10-33016A

2.1 Media

2- 1

2. SUPPLY SPECIFICATIONS

Information regarding the supply specifications contained in Product Description is essential to service

engineers. Detail specifications and other information on the media and ribbon are described in Supply

Manual by model. It is issued by and sent from TOSHIBA TEC H.Q (Sales Division) upon release of new

model or manual's revision. When purchasing the supplies locally, be sure to refer to the Supply Manual for

details. Use of non-specified media may shorten the print head life and result in problems with bar code

readability or print quality. Be sur e t o r ead car efully and understand the Supply Manual since it also

includes the details about notes, precision of the print start position, limitations on printing, etc. When

selling the products to VARs, instruct them to buy media and ribbons that the substances described in the

following precautions are not included

2.1 Media

(1) Media Size and Appearance

(Unit: mm)

Label dispensing mode

Item

Batch mode Strip mode Cut mode

Thermal direct 10.0 – 999.0

c Media pitch

Thermal transfer 15.0 – 999.0

19.0 – 999.0

19.0 - 999.0

Thermal direct 8.0 – 997.0

d Label length

Thermal transfer 13.0 – 997.0

17.0 – 997.0

16.0 – 997.0

Thermal direct 25.0 – 118.0

e Media width/backing paper width

Thermal transfer 25.0 – 114.0

Thermal direct 22.0 – 115.0

f Label width

Thermal transfer 22.0 – 111.0

g Gap length 2.0 – 20.0 2.0 – 5.0 3.0 – 20.0

h Black mark length (Tag paper) 2.0 – 10.0

i Maximum effective print width 104.0 (200-dpi type), 105.7 (300-dpi type)

Thermal direct 6.0 – 995.0

Label

Thermal transfer 11.0 – 995.0

15.0 – 995.0

14.0 - 995.0

Thermal direct 8.0 – 997.0

j Effective print length

Tag paper

Thermal transfer 13.0 – 997.0

---- 17.0 – 997.0

k Print speed up/slow down area 1.0

Thermal direct 0.08 – 0.17 (Note 4) 0.13 – 0.17 0.08 – 0.17 (Note 4)

Thickness

Thermal transfer 0.1 – 0.17 (Note 4) 0.13 – 0.17 0.1 – 0.17 (Note 4)

Maximum outer roll diameter Ø200 (B-SA4TM) / Ø152.4 (B-SA4TP)

Roll direction Inside/Outside

Inner core diameter Ø38, 40, 42, 76.2±0.3

Label

Tag paper

Cut position

Cut position

Stop

position

Stop

position

Feed Direction

Black Mark

(on reverse side)

Black Mark

(on reverse side)

h

e

c

e

g

h

c

d

i

i

k

k

f

j

Page 23

2. SUPPLY SPECIFICATIONS EO10-33016A

2.1 Media

2- 2

NOTES:

1. To ensure print quality and print head life use only TOSHIBA

TEC specified media.

2. The ratio of a label length to a gap length must be a minimum of

3 to 1 (3:1).

3. Backing paper must be wider than a label; the distance between

the edge of the backing paper and that of a label should be at

least 1.5 mm.

4. For the backing paper Glassine paper 7K or 8K white or

equivalent should be used. Also, the light transmission rate of

the backing paper should be 22% or above.

5. When cutting media, fine adjust a cut position properly. (See System Mode Manual, Section 2.3.)

6. If a printing stop position (strip position) is improper, use a procedure for the strip position fine adjustment to

correct the position. (See System Mode Manual, Section 2.3.)

7. When a gap length is 5 mm or mover, first set a label length to the maximum (= label pitch – 2mm), then,

fine adjust a strip position using a Strip position fine adjustment procedure. (See System Mode Manual,

Section 2.3.)

8. If the top edge of media is curled onto the platen during the cut issue, set the Forward Wait parameter in the

system mode to ON. (See System Mode Manual, Section 2.2.)

9. When using a label stock, or tag paper with a thickness of 150

µ

m

(0.15mm) or less, move the Head Position Levers toward the

printer front (c

LABEL ). If clear print cannot be obtained, move

the levers opposite.

When using tag paper with a thickness of exceeding 150

µ

m

(0.15mm), move the Head Position Levers toward the printer

back (d

TAG ). If clear print cannot be obtained, move the levers

opposite.

10. Thermal paper used for the direct thermal printing must not have

the specifications which exceed Ca

2+

, K +, Na+ 800 ppm, K + 250

ppm, and Cl

–

500 ppm.

11. Avoid using media containing SiO

2

or talc which wears the print

head protection layer.

12. Ink used for pre-printing the media should not contain hard substances such as carbonic calcium (CaCO3)

and Kaolin (Al

2O3

, 2SiO2, 2H2O).

13. Use of the tag paper of 25 mm to 50 mm in width and 171

µ

m to 263 µm in thickness may shorten the platen

life.

14. When using a label stock in cut mode, be sure to cut the gaps. Cutting labels will cause the glue to stick to

the cutter, which may affect the cutter performance and shorten the cutter life.

15. To make tearing off a label easier, set the Auto Forward Wait function (Forward Wait parameter) to ON in

the system mode (See System Mode Manual, Section 2.2). Doing so will cause the last label printed to be

fed and stopped past the strip shaft. However, if a next label is issued without tearing off the label on the

strip shaft, the label may peel while it is fed backward, causing a printer failure.

1.5 mm or more

1.5 mm or more

Label

Backing Paper

c

d c d

Head Position Lever

Head Position Lever

Page 24

2. SUPPLY SPECIFICATIONS EO10-33016A

2.1 Media

2- 3

(2) Specification of a Gap or a Black M ark

• Feed Gap Sensor and a Gap

<Tag paper> A hole is used for detection.

• Black Mark Sensor and a Black Mark

<Tag paper> A black mark is used for detection.

Sensor is movable within thi s

range. (45 mm: in units of 2.5 mm)

Sensor should be positioned at

the centre of the black mark.

Centre of media

Min. 12 mm

Media feed direction

Min. 2.0 mm

Sensor is movable within this range.

(55 mm: in units of 2.5 mm)

Detecting the black

marks on the back.

Sensor position

Centre of media

Min. 12 mm

Media feed direction

Min. 2.0 mm

Rectangle holes

Print side

Sensor position

Area to be detected

Centre of media

Print side

Min. 12 mm

Label

Gap

Label

Min. 2.0 mm

Sensor is movable

within this range.

Media feed direction

Round hole

Min.

Ø2.5 mm

Page 25

2. SUPPLY SPECIFICATIONS EO10-33016A

2.1 Media

2- 4

(3) Effective Printing Area

• Relationship between the head effective print width and paper

•

Effective printing area of a label/tag paper

NOTES:

1. Be sure not to print on the 1-mm wide area from the media edges (shaded area in the above figure).

Printing this area may cause ribbon wrinkles, resulting in a poor print quality of the guaranteed print area.

2. The center of media is positioned at the center of the Print Head.

3. Print quality in the 3-mm area from the print head stop position (including 1-mm non-printable area for

print speed slow down) is not guaranteed.

7.0

mm

118 mm (Max. media width)

104.0 mm (GS model)

105.7 mm (TS model)

Out of print range

Out of print range

7.0

mm

Start line

Area to be detecte

d.

Area to be detected.

Media feed direction

1 mm from the

left edge of media

Media width

(backing paper width is not included.)

Media height

10 –99.9 mm

1 mm from the ri ght

edge of media

1mm

1mm

Guaranteed print area

Head Effective Print Range

Page 26

2. SUPPLY SPECIFICATIONS EO10-33016A

2.2 Ribbon

2- 5

2.2 Ribbon

(1) Specification of Ribbon

No.

Item Specification

1 Shape Spool type

2 Width 60 to 110 mm (Recommended width is 60, 90, and 110 mm)

3 Max. length 450 m (within ø 75 mm)

4 Max. outer diameter ø 75 mm

5 Back treatment Coated

Material Cardboard 6 Core

Shape See the following figures.

7 Leader tape Polyester film (Opaq ue) , 260 ± 5 mm long

8 End tape None

9 Winding m ethod The ink side faces outside of ribbon winding

NOTES: 1. To ensure print quality and print head life use only TOSHIBA TEC specified ribbons.

2. Too much difference in width between media and ribbon may cause ribbon wrinkles. To avoid

ribbon wrinkles use a ribbon for proper media width shown in the above table. Do not use a

ribbon that is narrower than media.

.

Ribbon width 60 mm 90 mm 110 mm

Proper media width 25 to 55 mm 55 to 85 mm 85 to 105mm

(2) Ribbon Core Shape

NOTE: When purchasing ribbon locally, they must meet the above size. There may be TOSHIBA TEC-

approved ribbons which do not fall within the above size, however, they have no functional problem.

25.8 ±0.2 mm

Max. 118 –0, -0.5mm

Page 27

2. SUPPLY SPECIFICATIONS EO10-33016A

2.3 Care and Handling of the Media and Ribbon

2- 6

(3) Appearance of Ribbon

2.3 Care and Handling of the Media and Ribbon

• Do not store the media and ribbon for longer than the manufactures recommended shelf life.

• Store media rolls on the flat end, do not store them on the curved sides as this might flatten that side

causing erratic media advance and poor print quality.

• Store the media in plastic bags and always reseal after opening. Unprotected media can get dirty and

the extra abrasion from the dust and dirt part icles will shor ten the print head life.

• Store the media and ribbon in a cool, dry place. Avoid areas where they would be exposed to direct

sunlight, high temperature, high humidity, dust or gas.

For further information please contact your local distributor or your media and ribbon manufacturer.

CAUTION!

Be sure to read carefully and understand the Supply Manual. Use only media and ribbon which meet

specified requirements. Use of non-specified media and ribbon may shorten the head life and result in

problems with bar code readability or print quality. All media and ribbon should be handled with care to

avoid any damage to the media, ribbon or printer. Read the following guideline carefully.

Adhesive tape

Adhesive tape

Leader tape

Ink ribb

on

Adhesive tape

Ink outside

Core

Core

Base

Treated back side

End tape

(Non transmissive)

This inked surfac

e

faces the outside

This ribbon should be wound at center of the core.

Page 28

2. SUPPLY SPECIFICATIONS EO10-33016A

(Revision Date: Feb. 14, 2008)

2.4 Specification of RFID Tag

2- 7

2.4 Specification of RFID Tag

2.4.1 General Description

The RFID supplies are RFID tag (wireless IC tag) inlays designed to be converted into tag and label

applications. Printers, which are equipped with an RFID kit, can print data on the surface of RFID tags

as well as write data on them.

The B-SA4T series optional RFID kit, B-SA704-RFID-U2-EU-R, is destined for Europe and operates in

the UHF band 869.7MHz to 870.0MHz (

Center Frequency: 869.85MHz).

NOTE: Regarding the specification of RFID supplies and the ribbon used for printing on them, refer to

Section 2.1 MEDIA and Section 2.2 RIBBON.

2.4.2 Available RFID Tag

The B-9704-RFID-U2-EU-R supports EPC C1 Gen2 tags.

2.4.3 Location of RFID Tag

The location of an RFID tag in a label influences on the accuracy of writing data on the RFID tag. It is

impossible to define the one best location for every RFID tag in labels because the best location depends

on the type of RFID tag and RFID tag antenna.

The RFID Analyze Tool (7FM001113) can evaluate the accuracy of writing data on the RFID tag. For the

usage of this tool, refer to the RFID Analyze Tool Operation Specification (TAA-2195).

As a guideline, the best location for some common RFID tags is given below.

It is recommended to use the RFID Analyze Tool to evaluate the accuracy of writing data on an RFID tag to

be used, then determine a specific location of the RFID tag.

If the RFID tag cannot be placed on the best location specified, perform a forward/reverse feed before a

data write using the RFID Tag Position Adjustment Command ([ESC]@003).

However, the label bottom edge may be stuck on the print head edge during a reverse feed from the print

start position, resulting in a feed jam. Therefore, a location where no reverse feed is required is the ideal

location.

Note that the best location described in this specification may not be applicable depending on the type or

paper or glue even if the same RFID tags are used. This guideline applies to RFID labels for thermal

transfer issue. When using the media made of PET or thermal paper, the best location needs to be found

again.

Page 29

2. SUPPLY SPECIFICATIONS EO10-33016A

(Revision Date: Feb. 14, 2008)

2.4 Specification of RFID Tag

2- 8

(1) UPM Raflatac’s Rafsec Short Dipole 2 Tag

It is recommended to locate the vertical center of an RFID tag at 27 mm ± 3 mm from a leading edge of a

label and align the horizontal center with the horizontal center of the label.

27mm±3mm

Media feed direction

Page 30

2. SUPPLY SPECIFICATIONS EO10-33016A

(Revision Date: Feb. 14, 2008)

2.4 Specification of RFID Tag

2- 9

(2) UPM Raflatac’s Rafsec WEB Tag

It is recommended to locate the vertical center of an RFID tag at 58 mm ± 6 mm from a leading edge of a

label and align the horizontal center with the horizontal center of the label.

As this tag intersects vertically to the antenna of the RFID kit, the radio receiving area becomes narrower,

which may cause the sensitivity to be low. In this case, an AGC threshold for data write is required to be set

again. The factory default of the AGC threshold for data write is 11, however, it is recommended to change

this value to 10.

Especially, when the operating temperature is low (5°C to 10°C), the sensitivity tends to become low.

Variation of the sensitivity of tags may also lower the read rate. Operation at normal temperature (15°C to

30°C) is desired.

58mm±6mm

Media feed direction

Page 31

2. SUPPLY SPECIFICATIONS EO10-33016A

(Revision Date: Feb. 14, 2008)

2.4 Specification of RFID Tag

2- 10

2.4.4 Short-pitch tag (Rafsec Short Dipole2)

A Shield Sheet is supplied with the B-SA704-RFID-U2-EU-R to enable the RFID kit to encode short-pitch

tags properly. When the Shield Sheet is attached to the printer, the write field will be narrower.

The RFID kit is designed so that the second label is positioned just above the antenna while the first label is

at the print start position, when using the following short-pitch label.

After printing a label, a reverse feed for a distance equivalent to one label pitch is required to write data onto

its tag. During this reverse feed, the bottom edge of the printed label may be stuck on the print head edge,

causing a feed jam. This is because the labels become thicker due to embedded tags.

When several labels are issued in a batch, set the offset printing parameter to 1 (Offset printing is

performed without a reverse feed of the first label.) in order to make the printer issue labels without

performing a reverse feed. In this case, however, the printer does not print or write data on the first label,

so it is wasteful. This mode is not suitable for applications where a small number of labels are issued on an

as-needed basis.

For details of the offset printing feature, refer to the B-SA4T External Equipment Interface Specification

(EAA-2165).

20mm

5mm

Page 32

2. SUPPLY SPECIFICATIONS EO10-33016A

(Revision Date: Feb. 14, 2008)

2.4 Specification of RFID Tag

2- 11

2.4.5 Cautions for using RFID Tags

(1) Damage to Thermal Head by RFID Chip

The thermal head may be damaged when it passes over an RFID tag chip.

Our endurance test using TOPPAN’s Class 1 Generation 2 labels proved that issuing 1,200,000 labels

did not damage the thermal head. However, the thermal head may be damaged depending on RFID

tag types or embedded conditions of tags.

(2) Storage of RFID Supplies

Do not store RFID tags close to printers, or their communication performance may not be as specified

when they are used.

(3) Roll-type RFID Supplies

When RFID supplies are to be rolled, roll hardness must be concerned.

Although it depends on the type of glue, tag, and backing paper, RFID-tag embedded labels tend to

stay rolled. Especially, when they are wound outside, a media jam error may occur. Unless otherwise

specified, it is recommended that the RFID-tag embedded labels be wound inside.

(4) Sensor

When the transmissive sensor or reflective sensor is enabled, transmissivity or reflectivity of a label or

tag may vary at an RFID-tag embedded area depending on the pattern of an antenna or other factors.

In such cases, a manual threshold setting is required in Online mode. For details, refer to the B-SA4T

Key Operation Specifications (

EAA-2166).

(5) Cutter

When an RFID label or tag is used in cut issue mode, care must be taken not to cut an antenna of the

RFID tag or an IC chip in order not to damage the cutter.

(6) Static Electricity

When printing is performed in a place where humidity is low or under some specific conditions, writing

data on an RFID tag may fail due to static electricity generated by a label or a ribbon.

Page 33

2. SUPPLY SPECIFICATIONS EO10-33016A

(Revision Date: Feb. 14, 2008)

2.4 Specification of RFID Tag

2- 12

2.4.6 Printing on Bump (Chip/Antenna) Area

Embedding RFID tags in labels creates bumps in a chip/antenna area in the labels, causing incomplete

printing.

Especially, in the areas 5 mm from and left and right sides of the RFID-tag embedded area shown in the

figure below, uneven printing or incomplete printing can occur easily.

NOTE: The degree of poor printing quality differs depending on height of a chip/antenna used.

Media

feed

direction

RFID tag

embedded

area

Prin t qu al ity on t he

sides of RFID tag

is not guaranteed.

Prin t qu al ity on

bumps is not

guaranteed.

Prin t qu al ity on

bumps is not

guaranteed.

Print qual ity on

the IC chip is not

guaranteed.

5mm

2.4.7 Ambient Temperature

Low temperature deteriorates wireless performance, under which conditions writing data on an RFID tag

may fail.

2.4.8 Strip Issue

Stripping performance in strip issue mode depends on the type of glue, tag, and backing paper. For some

RFID supplies used, an issue may not be performed properly in strip issue mode.

5mm

Page 34

2. SUPPLY SPECIFICATIONS EO10-33016A

(Revision Date: Feb. 14, 2008)

2.4 Specification of RFID Tag

2- 13

2.4.9 Caution for Minimum Label Pitch Length

When media, of which label pitch length is short, is used, data may be written on an RFID tag next to the

target RFID tag.

As the location, where data is to be written, differs among RFID tag types, a check must be performed to

make sure that the data is written on the target RFID tags.

The B-SA RFID Analyze Tool (7FM001113) can be used for this purpose.

2.4.10 Defective RFID Tag

Defective tags could be embedded while they are converted into labels, and the error rate differs depending

on the tag types or the conversion methods.

Label manufacturers should mark such defective labels with something to indicate the tag is defective, or

should prevent defective tags from being used.

Also, how to identify defective tags and good tags should be properly notified to end users.

2.4.11 Print Position Accuracy

When using RFID tag embedded media, the print position accuracy may exceed the guaranteed tolerance

of ±1 mm in all issue modes.

It is required to check the print position accuracy for each media type.

2.4.12 Paper Jam Error

Depending on the type of glue or the flexibility of labels, a label may come unstuck in front of the sensor unit,

which cause a paper jam. Particularly, the frequency of paper jam could become higher on the condition of

low operating temperature or use of short-pitch labels.

It is required to check the media feed using the media to be used under the actual operating environment.

2.4.13 Improvement of Writing Accuracy

As RFID tags use wireless technologies, writing data on the RFID tag may fail depending on environment

and characteristics of the RFID tags.

In order to improve the accuracy of writing data on the RFID tags, the following method can be used:

(1) Change of the maximum number of write retries

The maximum number of write retries is variable and can be changed in the system mode. Setting the

greater value can improve the writing accuracy. However, overall printing throughput may become

worse because a retry is also performed for tags on which data cannot be written.

For details of settings, refer to the B-SA4T Key Operation Specification (EAA-2166).

(2) Enabling of RFID adjustment for retry

The printer has the RFID adjustment for retry feature. If writing data on the RFID tag fails, the printer

automatically feeds the RFID tag forward or backward for a specified length in order to retry a data

write.

Enabling this feature can improve the writing accuracy. However, overall printing throughput may

become worse because a retry is performed even for defective tags.

For details of settings, refer to the B-SA4T Key Operation Specification (EAA-2166).

Page 35

2. SUPPLY SPECIFICATIONS EO10-33016A

(Revision Date: Feb. 14, 2008)

2.4 Specification of RFID Tag

2- 14

(3) Adjustment of location of antenna

When writing data on tags, especially on short-pitch tags, the antenna may communicate with nontarget tags, and this lowers the write rate.

The B-SA4T has a feature to pinpoint a target tag by evaluating the output power (AGC) of tags.

Setting an AGC threshold for data write enables choosing a tag of which AGC is higher than the

threshold, determining this tag to be a target tag positioned just above the antenna, and writing data on

it. This feature can prevent writing data to non-target tags (= off the antenna).

For details of settings, refer to the B-SA4T Key Operation Specification (EAA-2166).

Page 36

3. OPTIONAL KIT EO10-33016A

(Revision Date: Feb. 14, 2008)

3. OPTIONAL KIT

3- 1

3. OPTIONAL KIT

Option Name Type Usage

300-dpi Print

Head

B-SA704-TPH3-QM-R This print head enables a conversion of a 203-dpi print

head of the B-SA4TM-GS12 model into a 300-dpi print

head. This option is intended for use when you desire to

print Kanji (Chinese characters) or to obtain clearer print.

Cutter module B-SA204-QM-R

B-SA204P-QM-R

B-SA204-QM

A cutter which cuts the media one by one. This module is

slim and compact enough to be fitted in the Front Cover.

NOTE: The B-SA204-QM and the B-SA204-QM-R are

exclusively for the B-SA4TM series.

The SA-204P-QM-R is exclusively for the B-SA4P

series.

Strip module B-SA904-H-QM-R

B-SA904P-H-QM-R

This module peels off a printed label from the backing

paper at the media outlet. It is slim and compact enough to

be fitted in the Front Cover.

NOTE: The B-SA904-H-QM-R is exclusively for the B-

SA4TM series. The B-SA904P-H-QM is

exclusively for the B-SA4TMP series.

Serial Interface

Board

B-SA704-RS-QM-R

Installing this PC board provides an RS232C interface port.

Wireless LAN

Board

B-SA704-WLAN-QM

B-SA704-WLAN-QM-R

Installing this PC board allows a communication by wireless

LAN.

RFID module B-SA704-RFID-U2-EU-R Installing this module enables read and write of RFID tags.

Frequency range: 869.7-870.0MHz (Center frequency:

869.85MHz).

Available RFID tag type: EPC C1 Gen2.

Expansion I/O

Board

B-SA704-IO-R-QM Installing this board in the printer allows a connection with

an external device with the exclusive interface.

Real Time Clock B-SA704-RTC-QM-R This module holds the current time: year, month, day, hour,

minute, second

NOTE: To purchase the optional kits, please contact the TOSHIBA TEC Head Quarters.

Page 37

3. OPTIONAL KIT EO10-33016A

3.2 Strip Module: B-SA904-H-QM-R

3- 2

3.1 Cutter Module: B-SA204-QM/B-SA204-QM-R/B-SA204P-QM-R

Item Specification

Cutting method Guillotine cutter

Media to be cut Thermal paper, normal paper, label stock

Media thickness 80 to 290µm

Rated voltage DC24V ±5%

Cutter life 80 to 160mm-thick paper: 1000000 cuts

160 to 290mm-thick paper: 500000 cuts

Operating environment

Temperature

Humidity

0 to 40°C

25 to 85% RH (No condensation)

Storage environment

Temperature

Humidity

-10 to 50°C

5 to 90% RH (No condensation)

Media feed speed 2”/sec., 4”/sec., 6”/sec.

Cutting time 0.5 sec. or less/cut

Cut cycle 2 sec. or more/cycle

Dimension 184mm (W) x 212mm (H) x 87mm (D)

Weight Approximate1500 g

Safety device Power supply is stopped when the interlock switch detects an open of

the cutter front cover.

Removal of jammed

media

In case of a cutter error due to a media jam, rotate the cutter motor shaft

by hand to remove the jammed media.

3.2 Strip Module: B-SA904-H-QM-R/B-SA904P-H-QM-R

Item Specification

Peel off method Backing paper feed rollers draw the backing paper.

Media to be stripped Thermal label, normal label

Backing paper width 25.4mm to 114 mm

Label width 21.4 to 110 mm

Label length 13 to 997 mm

Label pitch 15 to 999 mm

Gap length 2 to 5 mm

Effective print length 11 to 995 mm

Media thickness 130 to 170µm

Operating environment

Temperature

Humidity

0 to 40°C

25 to 85% RH (No condensation)

Storage environment

Temperature

Humidity

-40 to 60°C

10 to 90% RH (No condensation)

Strip speed 2 ips, 4 ips, 6 ips

Dimension 146mm (W) x 201 mm (H) x 50mm (D) (Front cover is not included.)

Weight Approximate 1000 g

NOTE: Labels of which length exceeds 76.2 mm may stick to the media outlet after it is stripped from the

backing paper.

Page 38

3. OPTIONAL KIT EO10-33016A

3.2 Strip Module: B-SA904-H-QM-R

3- 3

3.3 Serial Interface Board: B-SA704-RS-QM-R

Item Specification

Type RS-232C

Communication mode Full duplex

Transmission speed 2400 bps, 4800 bps, 9600 bps, 19200 bps, 38400 bps, 115200 bps

Synchronization Start-stop synchronization

Start bit 1 bit

Stop bit 1 bit, 2 bit

Data length 7 bit, 8 bit

Parity None, Even, O dd

Error detection Parity error, Framing error, Overrun error

Protocol Unprocedure communication

Data input code ASCII code, European character 8 bit code, Graphic 8 bit code, JIS 8

code, Shift JIS Kanji code, JIS Kanji code

Receive buffer 1M byte (shared with other interface)

Pin No.

Signal

1 N.C

2 TD (Transmit Data)

3 RD (Received Data)

4 DSR (Data Set Ready)

5 SG (Signal Ground)

6 DTR (Data Terminal Ready)

7 CTS (Clear to Send)

8 RTS (Request to Send)

Connector

9 N.C

1

5

6

9

Page 39

3. OPTIONAL KIT EO10-33016A

3.4 Wireless LA N Board: B-SA704-WLAN-QM

3- 4

3.4 Wireless LAN Board: B-SA704-WLAN-QM

Hardware Specifi cat i on

Item Specification

Wired LAN part Connected to a wired LAN port of the printer.

Transfer mode Conforming to IEEE802.11a

Orthogonal Frequency-Division

Multiplexing (OFDM)

Channel Depending on countries

Transmission speed 54, 48, 36, 24, 18, 12, 9, 6 (Mbps)

(Fix/automatic)

Access method CSMA/CA+ACK (RTS/CTS)

Wireless category Small power data communication

system (5.150 to 5.250GHz)

IEEE802.11a

Radio wave power 10mW/MHz or less

Transfer mode Conforming to IEEE802.11b

DSSS

Channel Depending on countries

Transmission speed 11, 5.5, 2, 1 (Mbps)

(Fix/automatic)

Access method CSMA/CA+ACK (RTS/CTS)

Wireless category Small power data communication

system (2.4 to 2.497GHz)

IEEE802.11b

Radio wave power 10mW/MHz or less

Transfer mode Conforming to IEEE802.11g

OFDM, DSSS

Channel Depending on countries

Transmission speed 54, 48, 36, 24, 18, 12, 9, 6, 11, 5.5, 2,

1 (Mbps) (Fix/automatic)

Access method CSMA/CA+ACK (RTS/CTS)

Wireless category Small power data communication

system (2.4 to 2.4835GHz)

IEEE802.11g

Radio wave power 10mW/MHz or less

Wireless LAN part

Antenna Chip type, diversity antenna

Software Specif ication

Item Specification

Unit type Access point [Station]

Operating mode Standard, [Compatible], Advanced

Default country code US

Default IP address 192.168.10.21

Default subnet mask 255.255.255.0

Default password Described separately.

Encryption WEP (64.128.152 bit) or AES, AES-OCB (128 bit)

TKIP (only when using WPA, WPA-PSK)

TWSL (Unique encryption) only when a POS is connected.

Parameter setting Browser or telnet (For telnet, internal use only)

Browser Microsoft IE5.01 or greater

Protocol IP (RFC791), ICMP (RFC792), UDP (RFC768)

TCP (RFC793, 896), ARP (RFC826), HTTPD (RFC1866), TELNET

FTPD (RFC959), DHCP (RFC2131), SNMP

Page 40

3. OPTIONAL KIT EO10-33016A

3.4 Wireless LA N Board: B-SA704-WLAN-QM

3- 5

Country code

As available frequency bands are different from country to country, be sure t o set a country code

before installing a wireless LAN module in a user’s printer. Also, ask an end user to confirm a country

code. Use of a wireless LAN module with a wrong country code could violate each country ’s Law s

and Regulations for Radio Equipment, and violators could be subject to penalties.

The country code cannot be changed through the Web browser, but TELNET.

<How to set a country code using TELNET>

(1) Disconnect the LAN cable connected to the printer, connect the printer to a host PC with a

straight LAN cable via a relay connector.

When using a hub in place of a relay connector, use a cross cable or

(2) Open the MS-DOS prompt, type in “telnet 192.168.10.21” (default IP address).

(3) Enter a password, “tecbcp”, to log in.

(4) From the top menu, change a country code using the following command.

=>ctryXX (XX=new country code. See Country Code Table.)

(5) The new country code will become effective by turning the printer off and on again.

(6) A country code can be checked by typing “=>ctry ” on t he t elnet console.

Country Code Table

Country

code

Country name

Country

code

Country name

Country

code

Country name

US U.S.A./Canada GR Greece IE Ireland

FR France SE Sweden GB U.K.

PT Portugal HU Hungary AU Australia

NO Norway BE Belgium FI Finland

DE Germany IT Italy LU Luxembourg

ES Spain NL Netherlands CH Switzerland

IS Iceland LI Liechtenstein NZ New Zealand

AT Austria DK Denmark

MAC address

MAC address of the Wireless LAN module will be necessary when setting the MAC address filtering

function of an access point. As it is printed on the top of the wired LAN connector on the Wireless

LAN Board, write down it on Installation Manual before mounting the covers so that an end user can

know the MAC address.

MAC Address

12-digit code printed on the right side of

“W” is MAC address.

CAUTION! The following information must not be disclosed to users. (I nt ernal use only)

Page 41

3. OPTIONAL KIT EO10-33016A

3.4 Wireless LA N Board: B-SA704-WLAN-QM

3- 6

NOTE: MAC address can be checked by using “arp -a” command on MS-DOS Prompt.

<Example>

The following screen shows an example of executing an arp –a command on MS-DOS Prompt.

After wireless LAN board (default IP address: 192.168.10.21) is pinged, IP address and MAC address

are displayed.

NOTE: As obtained IP address and MAC address are stored in the cache of the host for a certain period of

time, other device’s address may be displayed.

LED

<Operation>

LED Status LAN status

ON Communicating LED1 (Red)

Blink Starting

ON Wired LAN is connected.

Blink Communicating with the printer

LED 2

(Orange)

OFF Disconnected from the printer.

ON In case of station mode:

Log in the access point.

In case of access point mode:

User unit is log in.

Blink Communicating with a device connected

via wireless LAN.

LED 3

(Orange)

OFF In case of station mode:

Log out from the access point.

In case of access point mode:

User unit is log out.

ARP –a command

IP address of p

rinter

MAC address of printer

Address of other

(Refer to Note)

IP Address of Host PC

Page 42

3. OPTIONAL KIT EO10-33016A

3.4 Wireless LA N Board: B-SA704-WLAN-QM

3- 7

<Downloading the firmware>

LED Status LAN status

LED1

LED2

LED3

Blink at the same time Firmware is being overwritten.

<Error>

LED Status LAN status

LED2 Blink Wired LAN error

LED3 Blink Wireless LAN error

Certification

The wireless LAN module complies with the following standards.

FCC: Part 15B/Part 15C/Part 15E

CE: R&TTE (Certification for wireless LAN module)

IC: Canada EMC standard (To be certified in August 2005)

Precautions

• When using this product, please follow the Laws and Regulations for Radio Equipment.

• IEEE802.11g and IEEE802.11b uses 2.4GHz band. As a microwave uses the same frequency

band, interference may take place depending on the location where this product is installed.

• Also, this frequency band is IMS band. Do not use this product in locations where use may be

forbidden, for example, in an airport or hospital.

• This product communicates with other devices by radio. Depending on the installation location,

orientation, environment, etc., its communication performance may deteriorate or dev ices inst alled

near by may be affected.

• Before installing this product, conduct a site survey.

Handling Precautions for B-SA704-WLAN-QM

• Even in a country where the printer is shipped, this wireless LAN module cannot be used unless

the country code is matched.

• Use of this module in Japan is prohibited.

• Regarding the shipment to Canada:

This module is under application for certification as of June 2005, and to be certified in August

2005. Until then, a shipment or use of this module to/in Canada is forbidden by the Radio Waves

Law of Canada. As soon as certified, we will announce to you separ ately.

The country code is “US”.

• IEEE802.11a standard

IEEE802.11a-compliant devices are only for indoor use. Outdoor use is prohibited by Radio Law .

(As of June 2005)

• How to connect to telnet and set a country code must be secret to end users.

Use of a wireless LAN module with a wrong country code could violate each country’s Law s and

Regulations for Radio Equipment, and violators could be subject to penalties.

• Take security measures to prevent illegal access.

Page 43

3. OPTIONAL KIT EO10-33016A

(Revision Date: Jan. 19, 2006)

3.5 300-Dpi Print Head: B-SA704-TPH3-QM-R

3- 8

3.5 300-Dpi Print Head: B-SA704-TPH3-QM-R

Item Specification

Print head type KPG-106-12TAO4-TE

Effective print width 105.7±0.2mm

Number of dots 1248 dots

Resolution 11.8 dots/mm

Thermal element pitch 0.0847 mm

Average resistance 1000 ohm±3%

STROBE 2 strobe

Data input method 4 data input

Glazing

Width

Height

700µm

25µm

Operating environment

Temperature

Humidity

0 to 40°C

20 to 90% RH (No condensation)

Storage environment

Temperature

Humidity

-5 to 50°C

5 to 90% RH (No condensation)

Applied voltage 24 V

NOTES:

1. Do not touch the print head by bare hands.

2. Use TOSHIBA TEC approved media only.

3. Do not perform printing when the printer built up dew condensation.

4. Use a print head cleaner or a cotton swab or soft cloth slightly moistened with absolute ethyl alcohol to

clean the print head element.

5. Care must be taken not to damage the print head by hitting a hard or sharp object against it.

3.6 Real Time Clock: B-SA704-RTC-QM-R

Item Specification

Clock function Time counter (second/minute/hour) and calendar counter (day/day of

the week/month/year)

Automatic adjustment of leap years

Battery-powered time keeping

Accuracy RRT daily variance ±4 sec. (25°C)

Functions Time and calendar data printing

Low battery voltage detection

Clock adjustment function

Battery CR2032 (Standardized product s can be used.)

Battery life Approximately 2 y ears or more when t he bat t ery is fully charged.

The battery power is burned as long as the battery is inst alled, as t he