Page 1

TOSHIBA Barcode Printer

B-FV4 SERIES

Printer Manual

Original Jul., 2014

(Revised: Nov., 2016)

Document No. EO18-33030I

This manual includes the contents of the Product Description, and Maintenance Manual.

R140621P0308-TTEC

PRINTED IN JAPAN

Page 2

Trademarks

• Data MatrixTM is a trademark of International Data Matrix Inc., U.S.

• PDF417TM is a trademark of Symbol Technologies Inc., US.

• QR Code is a trademark of DENSO CORPORATION.

• Maxi Code is a trademark of United Parcel Service of America, Inc., U.S.

• Centronics is a trademark of Centronics Data Computer Corp.

• Windows is a registered trademark of Microsoft Corporation in the United States and/or other

countries.

•

Other company names and product names in this manual are the trademarks of their

respective companies.

Copyright© 2014 - 2016 TOSHIBA TEC CORPORATION All rights reserved

Under the copyright laws, this manual cannot be reproduced in any form without prior

written permission of TOSHIBA TEC CORPORATION.

Page 3

GENERAL PRECAUTIONS REGARDING THE SERVICE FOR THIS

EQUIPMENT

The installation and service shall be done by a qualified service technician.

1. Installation

- Select a suitable place for installation. Avoid excessive heat, high humidity, dust, vibration and direct

sunlight.

- The equipment shall be installed near the socket outlet and shall be accessible.

- Be sure to fix and plug in the power cable securely after the installation so that no one trips over it.

- When the equipment is used after the option is removed, be sure to install the parts or the covers

which have been taken off so that the inside of the equipment is not exposed.

2. General Precautions at Service

- Be sure to turn the power OFF and unplug the power cable during service.

- Unplug the power cable and clean the area around the prongs of the plug and socket outlet once a

year or more. A fire may occur when dust lies on this area.

- When the parts are disassembled, reassembly is the reverse of disassembly unless otherwise noted

in this manual or other related documents. Be careful not to install small parts such as screws,

washers, pins, E-rings, star washers in the wrong places.

- Basically, the equipment should not be operated with any parts removed or disassembled.

- The PC board must be stored in an anti-electrostatic bag and handled carefully using a wristband

since the ICs on it may be damaged due to static electricity.

Caution:

Before using the wristband, unplug the power cable of the equipment and make sure that

there are no charged objects which are not insulated in the vicinity.

- Be sure not to touch high-temperature sections such as the print head.

- Make sure that the equipment will not operate before touching potentially dangerous places (e.g.

rotating/operating sections such as gears).

- Be careful when removing the covers since there might be the parts with very sharp edges

underneath.

- Use recommended measuring instruments or equivalents.

- Return the equipment to the original state and check the operation when the service is finished.

3. General operations

- Check the procedures and perform them as described in this Manual.

- Avoid exposure to your skin and wear protective gloves as needed.

Page 4

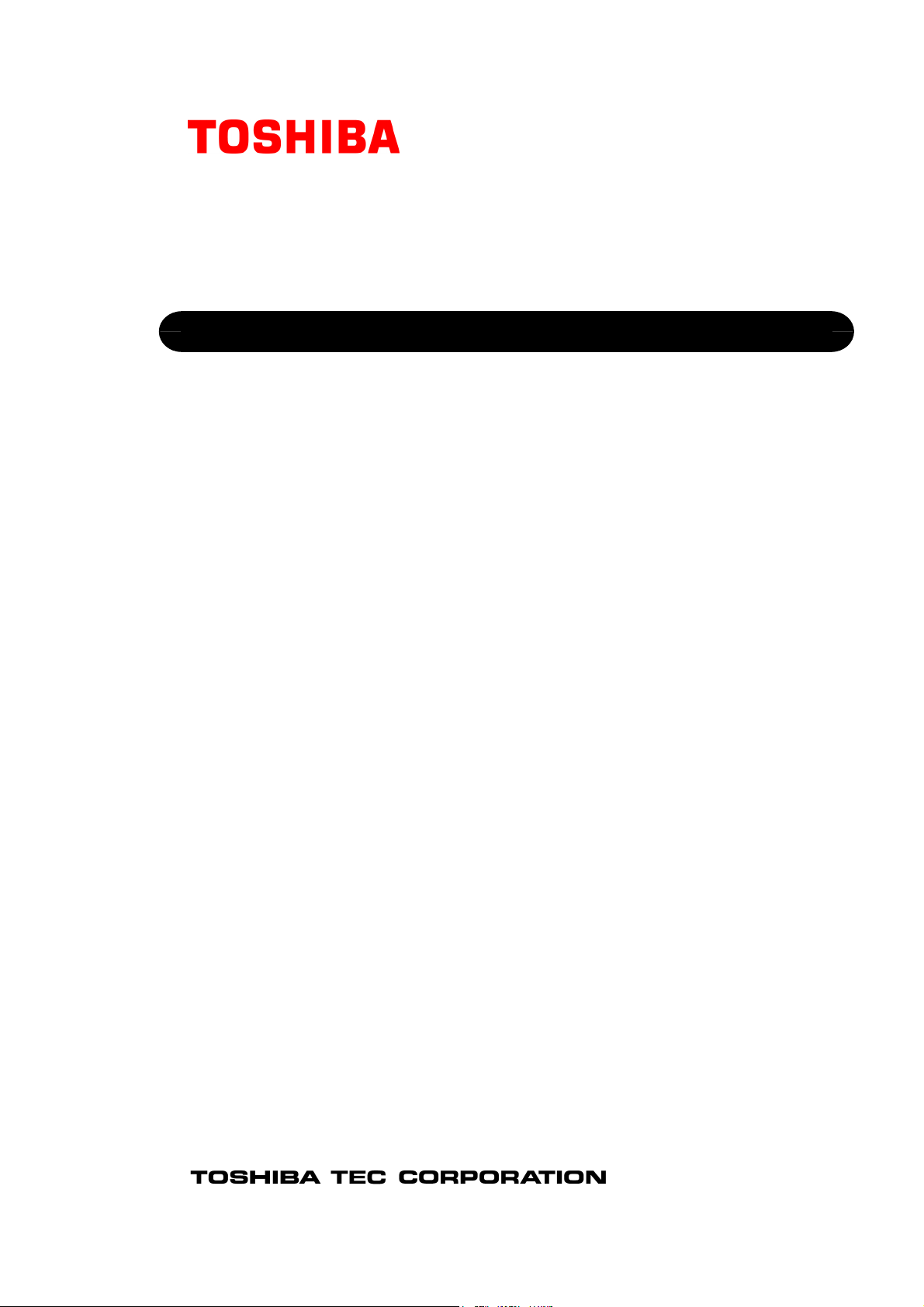

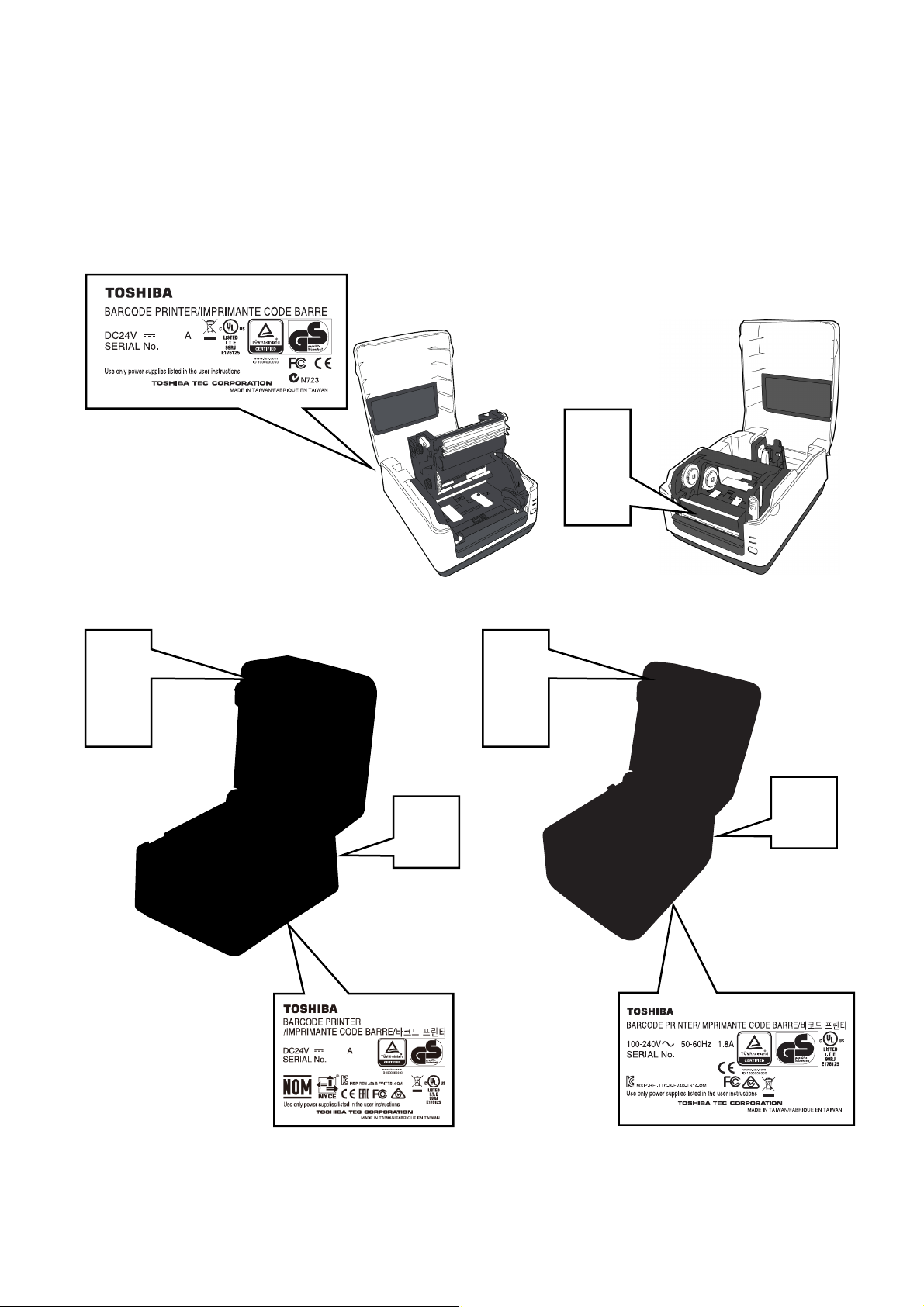

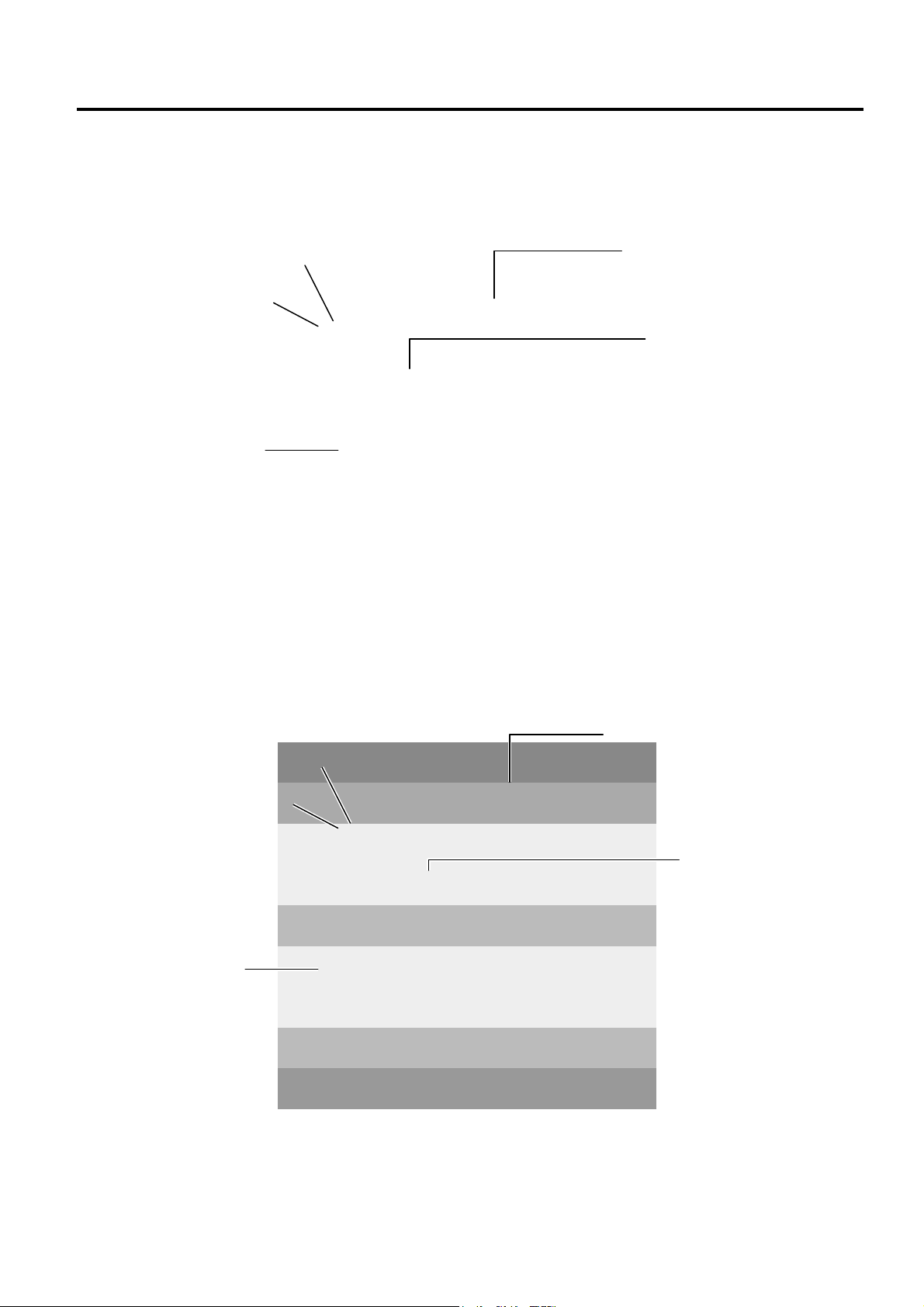

4. Cautionary Labels

- During servicing, be sure to check the rating plate and cautionary labels to see if there is any dirt on

their surface and if they are properly stuck to the equipment.

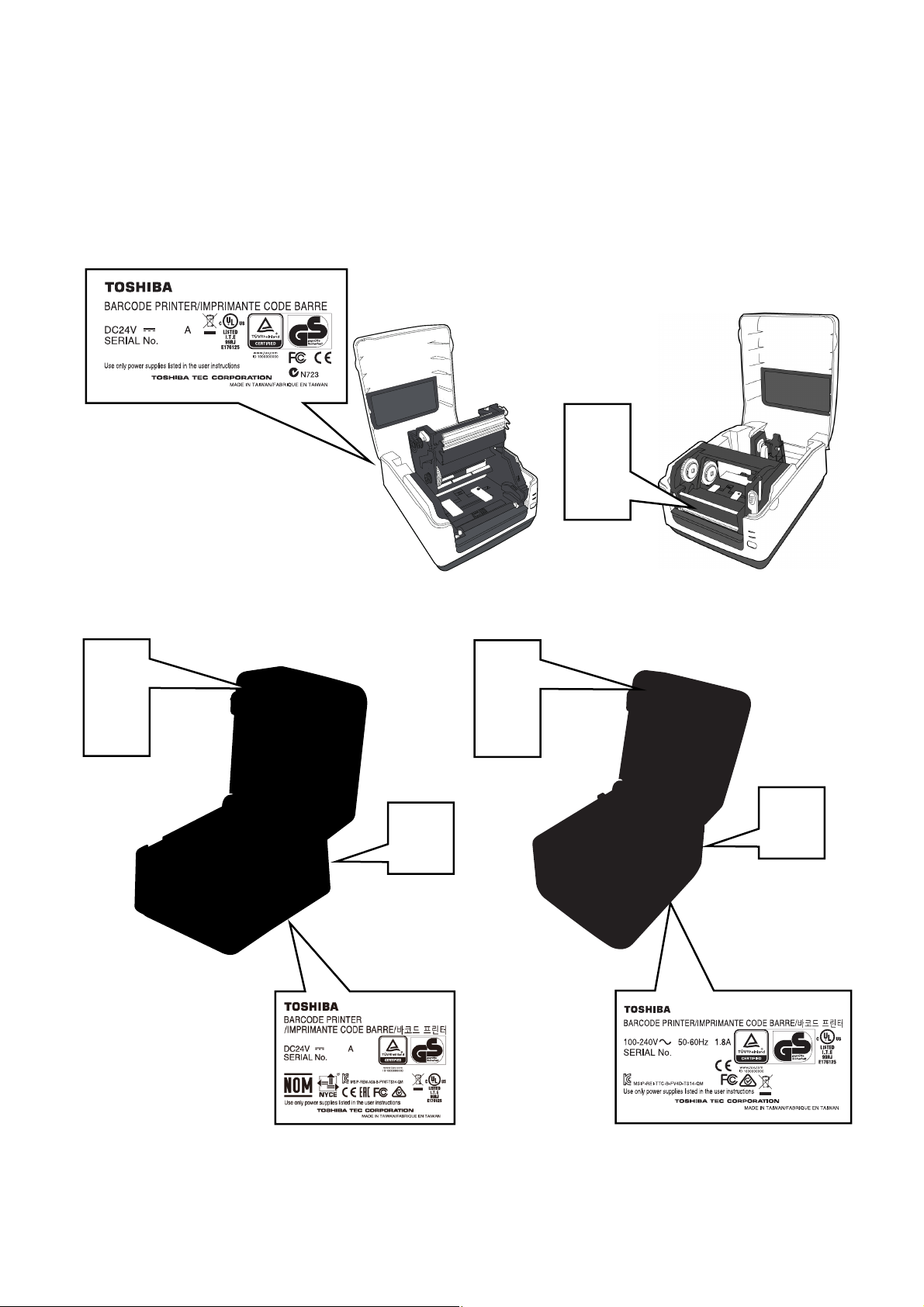

B-FV4T-GS/TS

B-FV4T-GS12-QM-R

3.75

23xxxxxxx

B-FV4D-GS/TS B-FV4D-GH

B-FV4D-GH14-QM-R

XXXXXXXXX

Page 5

B-FV4D-GL

5. Disposal of the Equipment, Supplies and Packing Materials

- Regarding the recovery and disposal of the equipment, supplies and packing materials, follow the

relevant local regulations or rules.

Page 6

ALLGEMEINE SICHERHEITSMASSNAHMEN FÜR DIESES GERÄT

Die Installation und die Wartung sind von einem qualifizierten Service-Techniker durchzuführen.

1. Installation

- Einen geeigneten Standort für die Installation wählen. Standorte mit zuviel Hitze, hoher

Luftfeuchtigkeit, Staub, Vibrieren und direkter Sonneneinstrahlung sind zu vermeiden.

- Das Gerät ist in der Nähe der Steckdose zu installieren; diese muss leicht zu erreichen sein.

- Nach der Installation muss das Netzkabel richtig hineingesteckt und befestigt werden, damit niemand

darüber stolpern kann.

- Falls der Auspackungsstandort und der Installationsstandort des Geräts verschieden sind, die

Bildqualitätsjustierung (automatische Gammajustierung) je nach der Temperatur und

Luftfeuchtigkeit des Installationsstandorts und der Papiersorte, die verwendet wird, durchführen.

2. Allgemeine Sicherheitsmassnahmen in bezug auf die Wartung

- Während der Wartung das Gerät ausschalten und das Netzkabel herausziehen.

- Das Netzkabel herausziehen und den Bereich um die Steckerpole und die Steckdose die Umgebung

in der Nähe von den Steckerzacken und der Steckdose wenigstens einmal im Jahr reinigen. Wenn

Staub sich in dieser Gegend ansammelt, kann dies ein Feuer verursachen.

- Wenn die Teile auseinandergenommen werden, wenn nicht anders in diesem Handbuch usw erklärt,

ist das Zusammenbauen in umgekehrter Reihenfolge durchzuführen. Aufpassen, dass kleine Teile

wie Schrauben, Dichtungsringe, Bolzen, E-Ringe, Stern-Dichtungsringe, Kabelbäume nicht an den

verkehrten Stellen eingebaut werden.

- Grundsätzlich darf das Gerät mit enfernten oder auseinandergenommenen Teilen nicht in Betrieb

genommen werden.

- Das PC-Board muss in einer Anti-elektrostatischen Hülle gelagert werden. Nur Mit einer Manschette

bei Betätigung eines Armbandes anfassen, sonst könnte es sein, dass die integrierten Schaltkreise

durch statische Elektrizität beschädigt werden.

Vorsicht:

Vor Benutzung der Manschette der Betätigung des Armbandes, das Netzkabel des Gerätes

herausziehen und prüfen, dass es in der Nähe keine geladenen Gegenstände, die nicht

isoliert sind, gibt.

- Auf keinen Fall Hochtemperaturbereiche, wie der Druckkopf, berühren.

- Vor dem Berühren potenziell gefährlicher Bereiche (z. B. drehbare oder betriebsrelevante Bereiche,

wie das Getriebe) sicherstellen, dass das Gerät sich nicht bedienen lässt.

- Beim Entfernen von Abdeckungen vorsichtig vorgehen, da sich darunter scharfkantige Komponenten

befinden können.

- Empfohlene oder gleichwertige Messgeräte verwenden.

- Nach Abschluss der Wartungsarbeiten das Gerät in den ursprünglichen Zustand zurück versetzen

und den einwandfreien Betrieb überprüfen.

3. Allgemeine Sicherheïtsmassnahmen

- Die Verfahren sind zu überprüfen und wie im diesem Handbuch beschrieben durchzuführen.

- Um Aussetzung zur Haut zur vermeiden, tragen Sie wenn nötig Schutzhandschuhe.

Page 7

4. Warnetiketten

- Im Rahmen der Wartung unbedingt das Leistungsschild und die Etiketten mit Warnhinweisen

überprüfen, um sicherzustellen, dass sie nicht verschmutzt sind und korrekt am Gerät angebracht

sind.

B-FV4T-GS/TS

B-FV4T-GS12-QM-R

3.75

23xxxxxxx

B-FV4D-GS/TS B-FV4D-GH

B-FV4D-GH14-QM-R

XXXXXXXXX

Page 8

B-FV4D-GL

5. Entsorgung des Geräts, der Verbrauchs- und Verpackungsmaterialien

- In Bezug auf die Entsorgung und Wiederverwertung des Geräts, der Verbrauchs- und

Verpackungsmaterialien sind die einschlägigen nationalen oder regionalen Vorschriften zu befolgen.

Page 9

EO18-33030

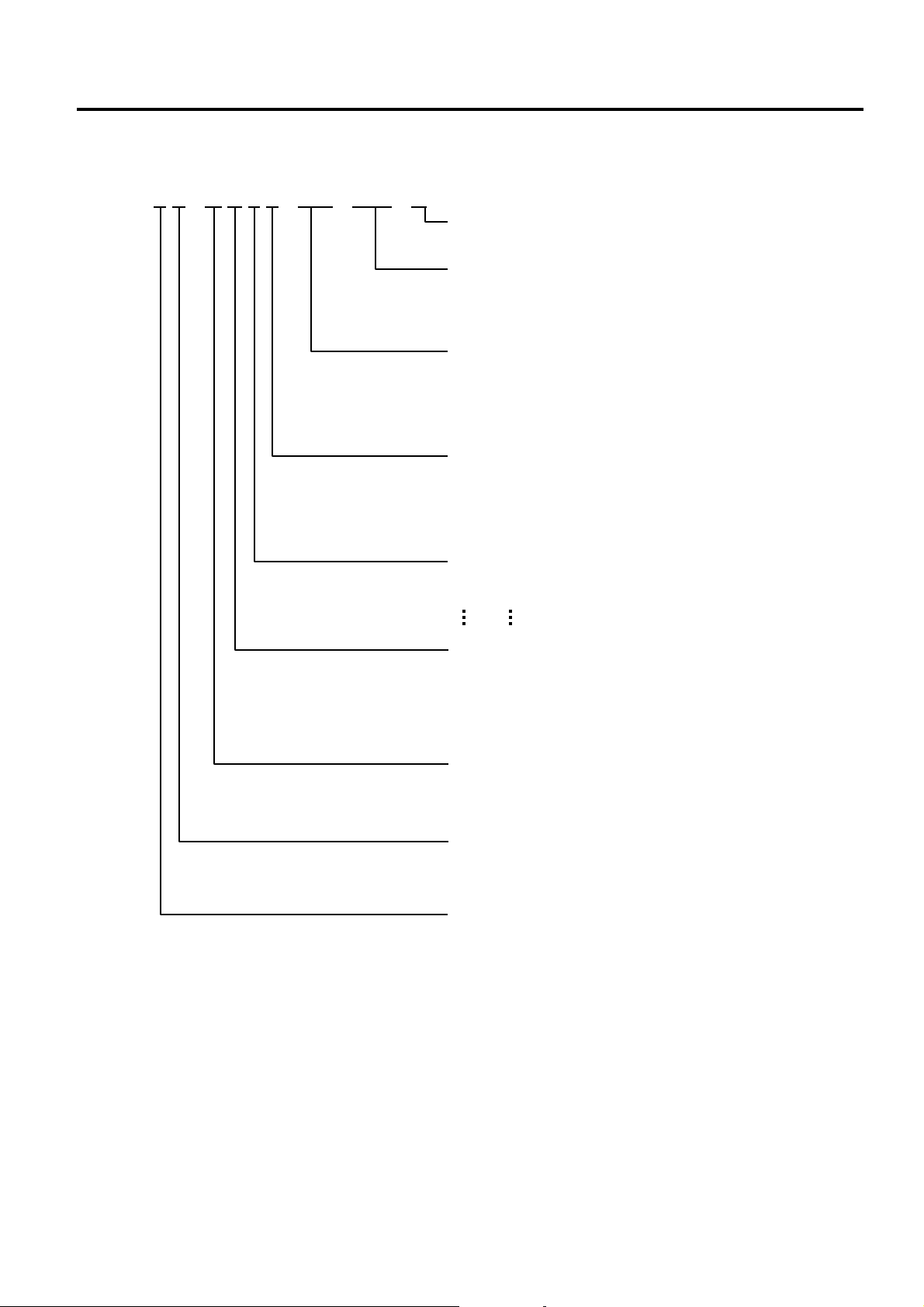

TABLE OF CONTENTS

Page

1. OUTLINE ------------------------------------------------------------------------------------------------------------- 1- 1

1.1 Features of the B-FV4T series -------------------------------------------------------------------------- 1- 1

1.1.1 Front View ------------------------------------------------------------------------------------------ 1- 1

1.1.2 Rear View ------------------------------------------------------------------------------------------ 1- 3

1.1.3 Interior ----------------------------------------------------------------------------------------------- 1- 5

1.2 Indication of the Model Name --------------------------------------------------------------------------- 1- 8

1.3 Specifications ----------------------------------------------------------------------------------------------- 1- 9

1.3.1 Basic Specifications (for B-FV4T) ------------------------------------------------------------ 1- 9

1.3.2 Basic Specifications (for B-FV4D) ----------------------------------------------------------- 1-11

1.3.3 Basic Specifications (for B-FV4D-GL) ----------------------------------------------------- 1-13

1.3.4 Wireless LAN ------------------------------------------------------------------------------------- 1-15

1.3.5 Bluetooth ------------------------------------------------------------------------------------------- 1-16

1.3.6 Ethernet -------------------------------------------------------------------------------------------- 1-16

1.4 Interface I/O Port ------------------------------------------------------------------------------------------ 1-17

1.4.1 USB ------------------------------------------------------------------------------------------------- 1-17

1.4.2 Ethernet -------------------------------------------------------------------------------------------- 1-17

1.4.3 RS-232C ------------------------------------------------------------------------------------------- 1-18

1.4.4 Centronics ----------------------------------------------------------------------------------------- 1-19

1.5 Key and LED ----------------------------------------------------------------------------------------------- 1-20

1.6 Supply Specifications ------------------------------------------------------------------------------------ 1-21

1.6.1 Media Type ---------------------------------------------------------------------------------------- 1-21

1.6.2 Media Type (B-FV4D-GL) --------------------------------------------------------------------- 1-23

1.6.3 Detection Area of the Feed Gap (Transmissive) Sensor ------------------------------ 1-23

1.6.4 Detection Area of the Black Mark (Reflective) Sensor --------------------------------- 1-24

1.6.5 Effective Print Area ------------------------------------------------------------------------------ 1-24

1.6.6 Ribbon (B-FV4T only) -------------------------------------------------------------------------- 1-25

2. ELECTRONIC SPECIFICATIONS ---------------------------------------------------------------------------- 2- 1

2.1 Main PC Board Diagram --------------------------------------------------------------------------------- 2- 1

2.2 Main PC Board Layout ------------------------------------------------------------------------------------ 2- 3

2.2.1 Type 1 (USB + Ethernet), Type 2 (USB + Ethernet + RS-232C) -------------------- 2- 3

2.2.2 Type 3 (USB + Centronics) ------------------------------------------------------------------- 2- 5

2.3 Main PC Board Connector Pin Assignment --------------------------------------------------------- 2- 6

2.3.1 Pin Assignment for B-FV4T-GS/TS ---------------------------------------------------------- 2- 6

2.3.2 Pin Assignment for B-FV4D-GS/TS --------------------------------------------------------- 2-11

2.3.3 Pin Assignment for B-FV4D-GH ------------------------------------------------------------- 2-15

2.3.4 Pin Assignment for B-FV4D-GL -------------------------------------------------------------- 2-18

2.4 DIP Switch -------------------------------------------------------------------------------------------------- 2-21

3. REPLACING THE IMPORTANT PARTS ------------------------------------------------------------------- 3- 1

3.1 Replacing the Parts for B-FV4T-GS/TS -------------------------------------------------------------- 3- 2

3.1.1 Replacing the Top Cover and the Mid Cover ---------------------------------------------- 3- 2

3.1.2 Replacing the Main PC Board ----------------------------------------------------------------- 3- 5

3.1.3 Replacing the Stepping Motor ----------------------------------------------------------------- 3- 8

3.1.4 Replacing the Feed Gap Sensor / Black Mark Sensor ---------------------------------- 3- 9

3.1.5 Replacing the Ribbon Sensor ---------------------------------------------------------------- 3-12

Page 10

EO18-33030

3.1.6 Replacing the Platen Roller ------------------------------------------------------------------- 3-13

3.1.7 Replacing the Print Head Assembly -------------------------------------------------------- 3-14

3.2 Replacing the Parts for B-FV4D-GS/TS ------------------------------------------------------------- 3-16

3.2.1 Replacing the Top Cover ---------------------------------------------------------------------- 3-16

3.2.2 Replacing the Platen Roller and the Front Cover --------------------------------------- 3-17

3.2.3 Replacing the Bottom Cover and the Main PC Board ---------------------------------- 3-18

3.2.4 Replacing the Mid Cover ---------------------------------------------------------------------- 3-19

3.2.5 Replacing the Stepping Motor ---------------------------------------------------------------- 3-20

3.2.6 Replacing the Media Sensor [Feed Gap Senor (Lower) / Black Mark Sensor] -- 3-21

3.2.7 Replacing the Feed Gap Sensor (Upper) ------------------------------------------------- 3-22

3.2.8 Replacing the Micro Switch ------------------------------------------------------------------- 3-24

3.2.9 Replacing the Print Head Assembly -------------------------------------------------------- 3-25

3.2.10 Replacing the Media Holder ------------------------------------------------------------------ 3-26

3.3 Replacing the Parts for B-FV4D-GH/GL ------------------------------------------------------------- 3-28

3.3.1 Replacing the Top Cover ---------------------------------------------------------------------- 3-28

3.3.2 Replacing the Platen Roller ------------------------------------------------------------------- 3-29

3.3.3 Replacing the Power Adapter Cover and the Power Adapter ------------------------ 3-30

3.3.4 Replacing the Bottom Cover and the Main PC Board ---------------------------------- 3-32

3.3.5 Replacing the Mid Cover ---------------------------------------------------------------------- 3-34

3.3.6 Replacing the Stepping Motor ---------------------------------------------------------------- 3-35

3.3.7 Replacing the Feed Gap Sensor (Lower) [Media Sensor] ---------------------------- 3-36

3.3.8 Replacing the Feed Gap Sensor (Upper) [Media Sensor] ---------------------------- 3-37

3.3.9 Replacing the Micro Switch ------------------------------------------------------------------- 3-39

3.3.10 Replacing the Print Head Assembly -------------------------------------------------------- 3-40

3.3.11 Replacing the Media Holder Lever ---------------------------------------------------------- 3-41

3.3.12 Replacing the Peel-off unit and the Peel-off sensor (B-FV4D-GH only) ----------- 3-42

3.3.13 Replacing the Cutter Unit (B-FV4D-GL only) --------------------------------------------- 3-44

4. TROUBLESHOOTING ------------------------------------------------------------------------------------------- 4- 1

4.1 LED Status --------------------------------------------------------------------------------------------------- 4- 1

4.2 Print Quality -------------------------------------------------------------------------------------------------- 4- 2

5. MAINTENANCE ---------------------------------------------------------------------------------------------------- 5- 1

5.1 Cleaning of the Printer ------------------------------------------------------------------------------------ 5- 1

5.2 Cleaning of the Optional Cutter Module -------------------------------------------------------------- 5- 2

5.3 Cleaning of the Cutter Module (B-FV4D-GL Series) ---------------------------------------------- 5- 6

6. SYSTEM MODE ---------------------------------------------------------------------------------------------------- 6- 1

6.1 Feed Gap Sensor / Black Mark Sensor Adjustments --------------------------------------------- 6- 2

6.2 Parameter Clear -------------------------------------------------------------------------------------------- 6- 3

6.3 TPCL Auto Call Cancellation ---------------------------------------------------------------------------- 6- 5

6.4 BASIC Interpreter Disable ------------------------------------------------------------------------------- 6- 5

6.5 Self-Test Printing / Dump Mode ------------------------------------------------------------------------ 6- 6

6.5.1 Self-Test -------------------------------------------------------------------------------------------- 6- 6

6.5.2 Dump Mode --------------------------------------------------------------------------------------- 6-21

7. B-FV SETTING TOOL -------------------------------------------------------------------------------------------- 7- 1

7.1 Installing B-FV Setting Tool (V1.0.21) ---------------------------------------------------------------- 7- 1

7.2 Working with B-FV Setting Tool (V1.0.21) ----------------------------------------------------------- 7- 4

7.2.1 Menu bar -------------------------------------------------------------------------------------------- 7- 4

7.2.2 Toolbar ---------------------------------------------------------------------------------------------- 7- 6

7.2.3 Navigation Pane --------------------------------------------------------------------------------- 7-10

7.3 Installing B-FV Setting Tool (V1.0.27) --------------------------------------------------------------- 7-35

Page 11

EO18-33030

7.4 Working with B-FV Setting Tool (V1.0.27) ---------------------------------------------------------- 7-38

7.4.1 Menu bar ------------------------------------------------------------------------------------------- 7-38

7.4.2 Toolbar --------------------------------------------------------------------------------------------- 7-40

7.4.3 Navigation Pane --------------------------------------------------------------------------------- 7-44

7.5 Installing B-FV Setting Tool (V1.0.34) --------------------------------------------------------------- 7-80

7.6 Working with B-FV Setting Tool (V1.0.34) ---------------------------------------------------------- 7-83

7.6.1 Menu bar ------------------------------------------------------------------------------------------- 7-83

7.6.2 Toolbar --------------------------------------------------------------------------------------------- 7-85

7.6.3 Navigation Pane --------------------------------------------------------------------------------- 7-89

8. UPDATING FIRMWARE ----------------------------------------------------------------------------------------- 8- 1

8.1 Updating Firmware in B-FV Setting Tool (V1.0.27 or earlier) ----------------------------------- 8- 1

8.1.1 Updating via USB or COM Port --------------------------------------------------------------- 8- 1

8.1.2 Updating via LAN or Multi-LAN Port --------------------------------------------------------- 8- 6

8.2 Updating Firmware via USB Host (V1.0.27 or earlier) ------------------------------------------- 8-11

8.3 Updating Firmware in Atmel Mode -------------------------------------------------------------------- 8-12

8.4 Updating Firmware in B-FV Setting Tool (V1.0.34 or later)------------------------------------- 8-16

8.4.1 Updating via USB or COM Port -------------------------------------------------------------- 8-16

8.4.2 Updating via LAN or Multi-LAN Port -------------------------------------------------------- 8-22

8.5 Updating Firmware via USB Host (V1.0.34 or later) ---------------------------------------------- 8-28

9. NETWORK ---------------------------------------------------------------------------------------------------------- 9- 1

9.1 Network Architecture -------------------------------------------------------------------------------------- 9- 1

9.2 SNMP Trap -------------------------------------------------------------------------------------------------- 9- 3

9.3 MIB List ------------------------------------------------------------------------------------------------------- 9- 4

9.4 Ethernet Status Indicators ------------------------------------------------------------------------------- 9- 4

APPENDIX --------------------------------------------------------------------------------------------------------------- A- 1

Establishing a Bluetooth connection with B-FV4D and B-FV4T --------------------------------------- A- 1

Page 12

EO18-33030

CAUTION!

1. This manual may not be copied in whole or in part without prior written permission of TOSHIBA TEC.

2. The contents of this manual may be changed without notification.

Copyright© 2014 - 2016 TOSHIBA TEC CORPORATION All rights reserved

1-11-1, Osaki, Shinagawa-ku, Tokyo 141-8562, JAPAN

Page 13

1. OUTLINE EO18-33030

t

1.1 Feature of the B-FV4 series

1. OUTLINE

1.1 Feature of the B-FV4 series

1.1.1 Front View

B-FV4T-GS/TS

Media Outle

B-FV4D-GS/TS

Media Outlet

LED 2

LED 1

Media View Window

LED 2

LED 1

FEED Button

Media View Window

FEED Button

1-1

Page 14

1. OUTLINE EO18-33030

1.1 Feature of the B-FV4 series

B-FV4D-GH

LED 2

Media View Window

LED 1

FEED Button

Media Outlet

B-FV4D-GL

LED 2

LED 1

Media View Window

Media Outlet

FEED Button

1-2

Page 15

1. OUTLINE EO18-33030

1.1 Feature of the B-FV4 series

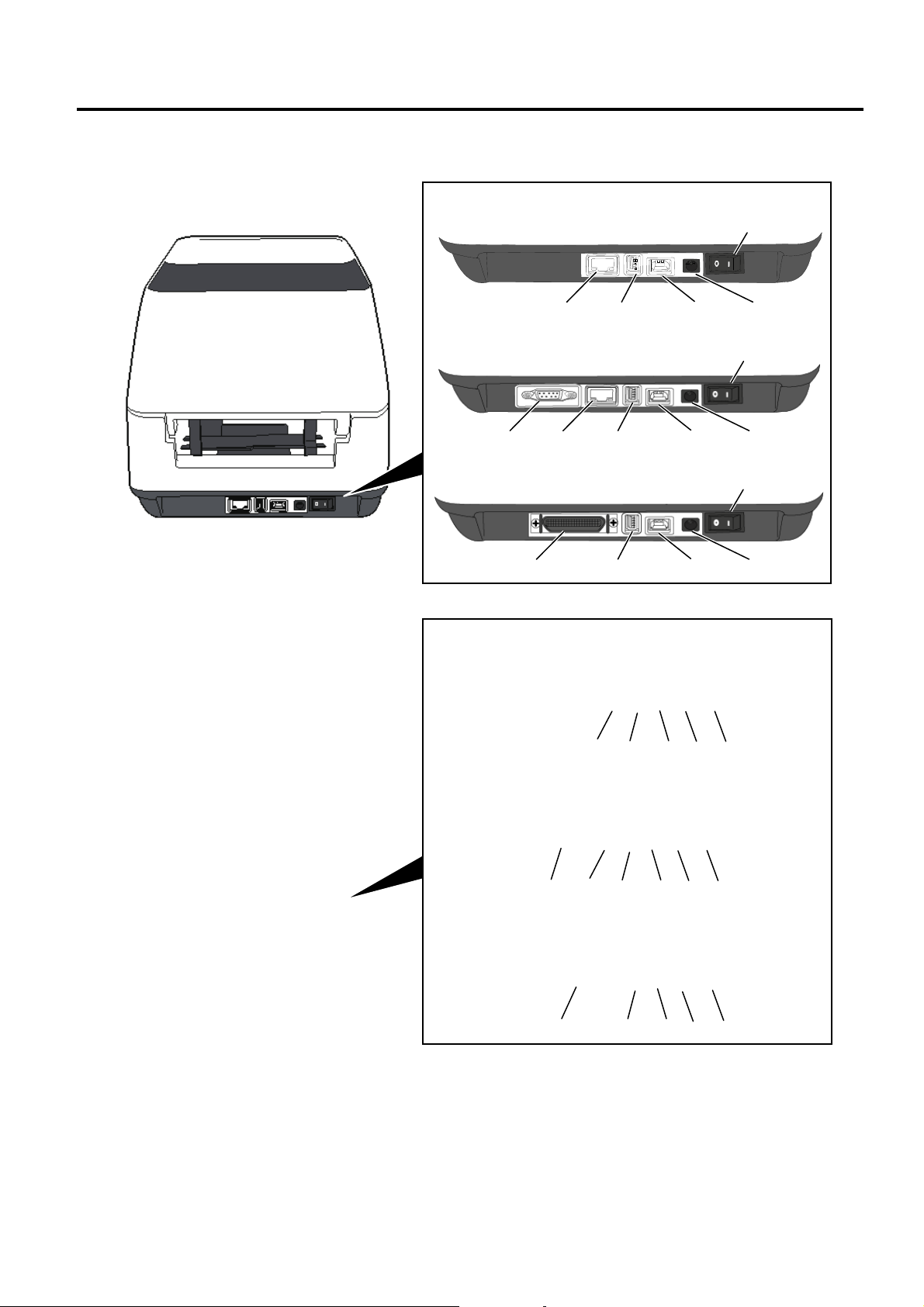

1.1.2 Rear View

B-FV4T-GS/TS

B-FV4D-GS/TS

Printer having the USB and Ethernet Interfaces

Printer having the Serial Interface (RS-232C)

Printer having the Parallel Interface (Centronics)

Printer having the USB and Ethernet Interfaces

Printer having the Serial Interface (RS-232C)

Printer having the Parallel Interface (Centronics)

Power Switch

Power Jack

USB Interface for connecting to a host computer

USB Host Interface for connecting a USB memory device.

Ethernet Interface

Serial Interface (RS-232C)*

* Some models have no serial interface (RS-232C).

Parallel Interface (Centronics)

1-3

Page 16

1. OUTLINE EO18-33030

1.1 Feature of the B-FV4 series

B-FV4D-GH / B-FV4D-GL

Printer having the USB, Ethernet and Serial Interfaces

Power Switch

Power Jack

Remark:

Make sure that the Power Jack is connected to the printer as shown above.

USB Interface for connecting a host computer

USB Interface for connecting a USB memory

Ethernet Interface

Serial Interface (RS-232C)

AC Power Inlet

1-4

Page 17

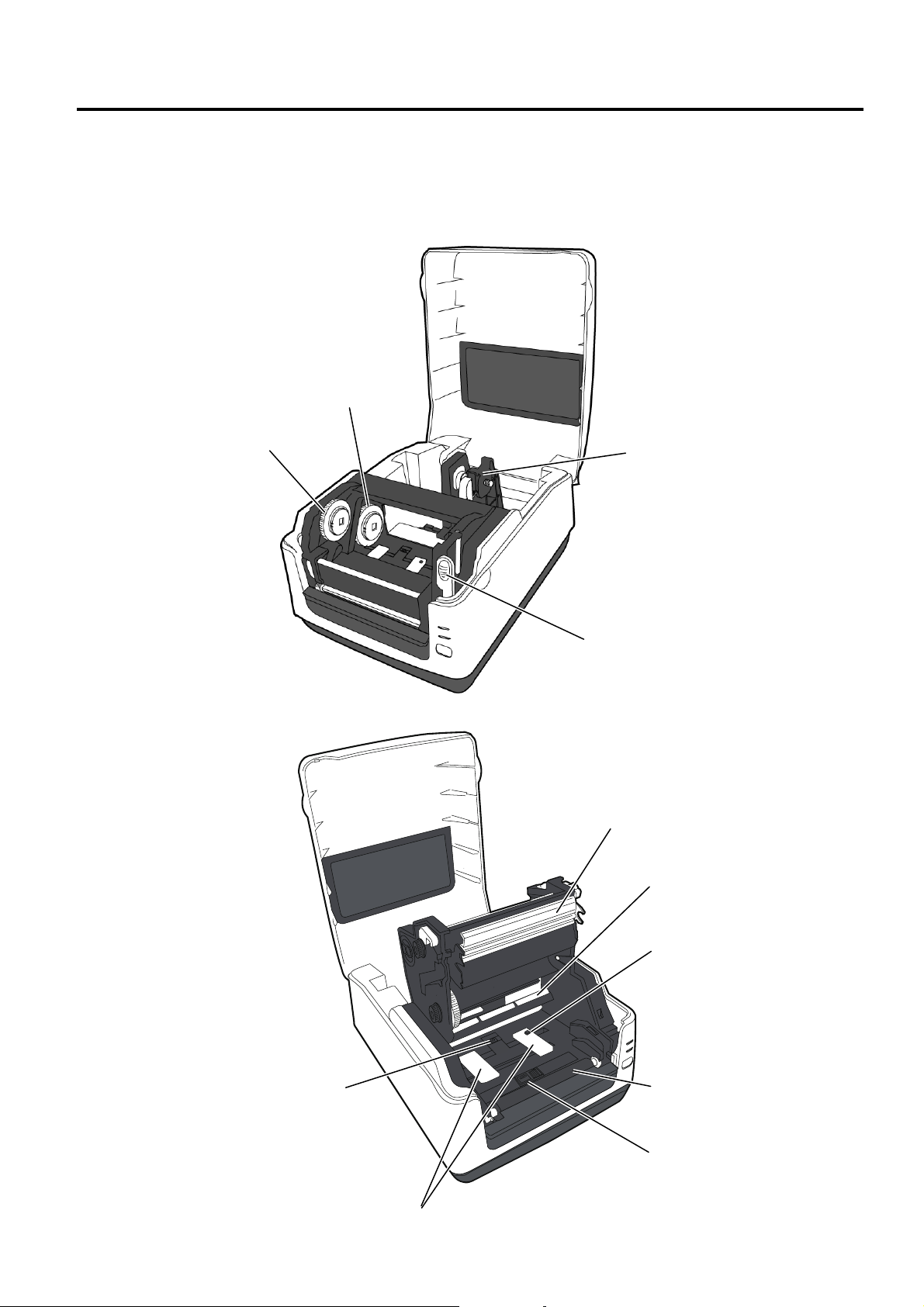

1. OUTLINE EO18-33030

1.1 Feature of the B-FV4 series

1.1.3 Interior

B-FV4T -GS/TS

View 1

Take-Up Gear

View 2

Feed Gap Sensor

Supply Gear

Media Roll Holders

Print Head Release Latch

Print Head

Media Guide Roller

Lock Button

Platen Roller

Black Mark Sensor

Media Guides

1-5

Page 18

1. OUTLINE EO18-33030

1.1 Feature of the B-FV4 series

B-FV4D-GS/TS

Print Head

Feed Gap Sensor

Core Holders

Media Roll Holders

Thumbscrew

Holder Lock Lever

Media Guides

Black Mark Sensor

Platen Roller

B-FV4D-GH

Print Head

Media Roll Holder Lever

Media Roll Holders

Media Sensor

Lock Release Portions

Media Guide

Platen Roller

Peel-off Unit

Thumbscrew

Peel-off Sensor

Media Guide

1-6

Page 19

1. OUTLINE EO18-33030

1.1 Feature of the B-FV4 series

B-FV4D-GL

Print Head

Media Roll Holder Lever

Lock Release Portions

Transmissive Senso r

Cutter Sensor

Cutter Tray

Media Roll Holders

Cutter Unit

1-7

Page 20

1. OUTLINE EO18-33030

1.2 Indication of the Model Name

1.2 Indication of the Model Name

B - F V 4 T - G S 1 2 - QM - Cxx - R

RoHS Compliance

R : RoHS compliant model

Custom code

(blank) : Standard model

Cxx : Custom model

(x : 0 to 9, A to Z or blank)

Destination country/region code

QM : Standard for World Wide (Except China)

CN : China

QP : Europe

QQ : North America

Interface

0 : USB + RS-232C

2 : USB + Ethernet (Standard type for Worldwide)

4 : USB + Ethernet + RS-232C

6 : USB + Centronics

H/W version

1 : Version 1

2 : Version 2

Printing style

S : Standard

H : Peel-off

C : Cutter

L : Cutter for label without liner

Print resolution

G : 8 dots/mm (203 dpi)

T : 11.8 dots/mm (300 dpi)

Print method

D : Direct thermal

T : Thermal transfer & Direct thermal

Print width

4 : 4inch

1-8

Page 21

1. OUTLINE EO18-33030

1.3 Specifications

1.3 Specifications

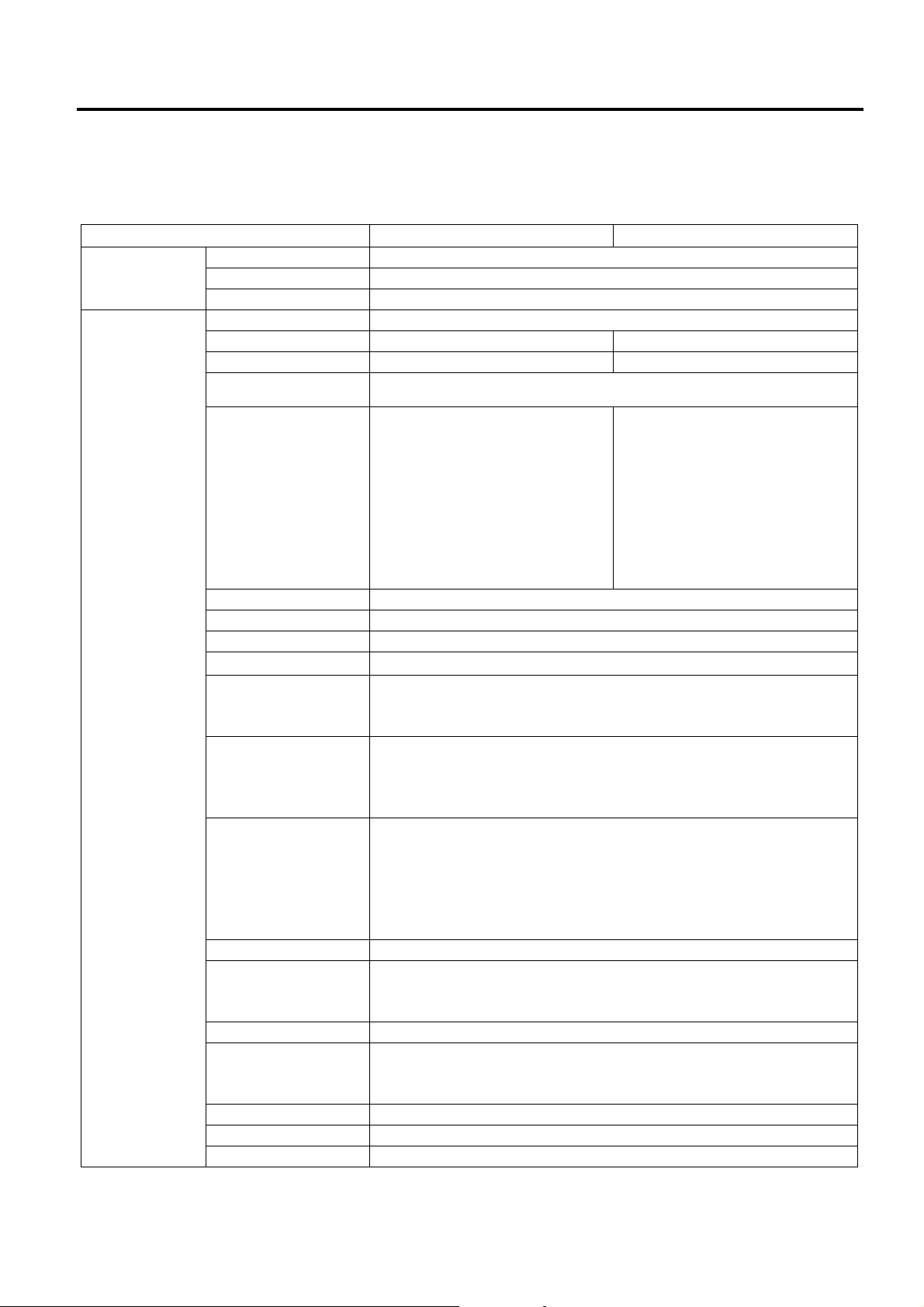

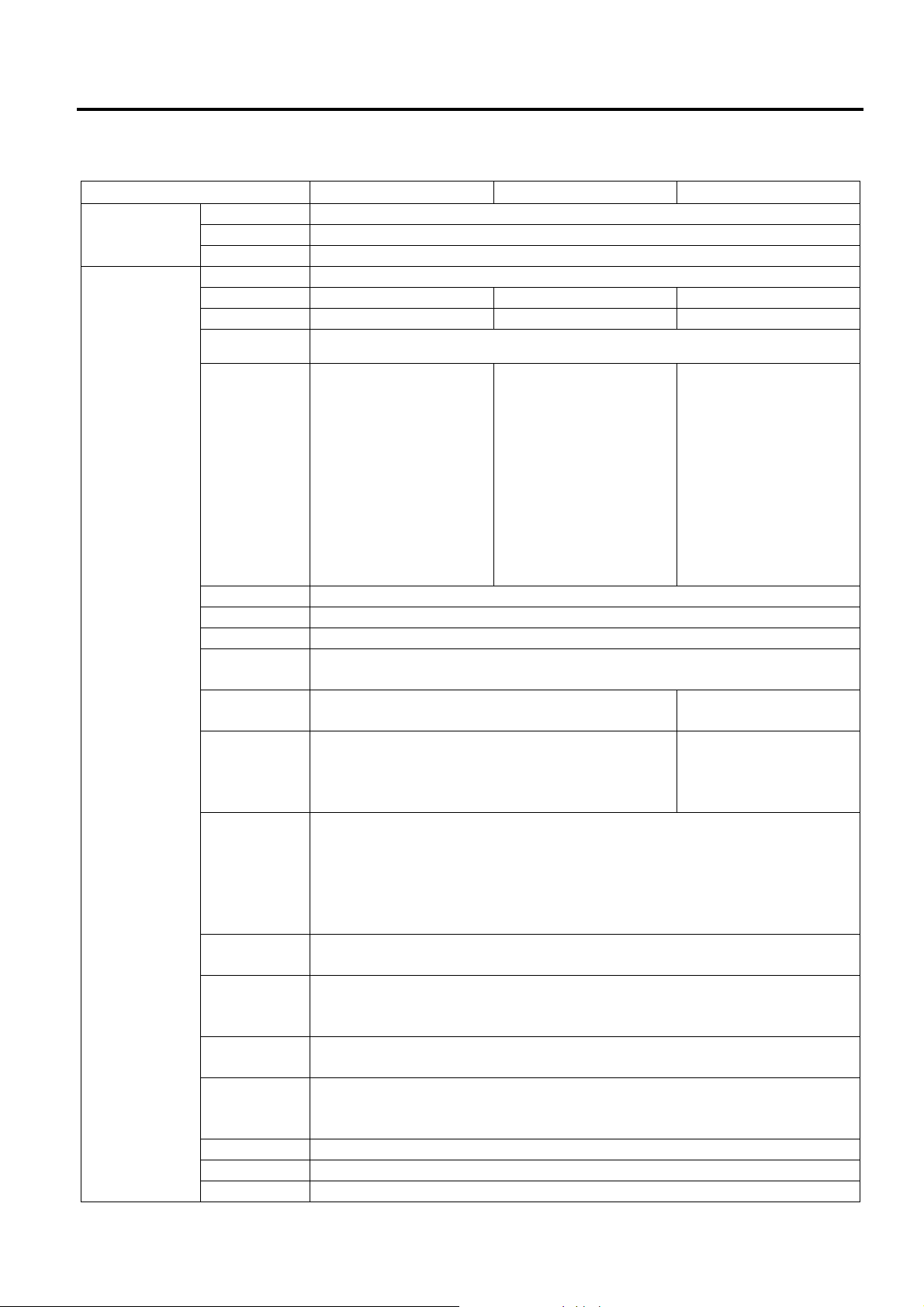

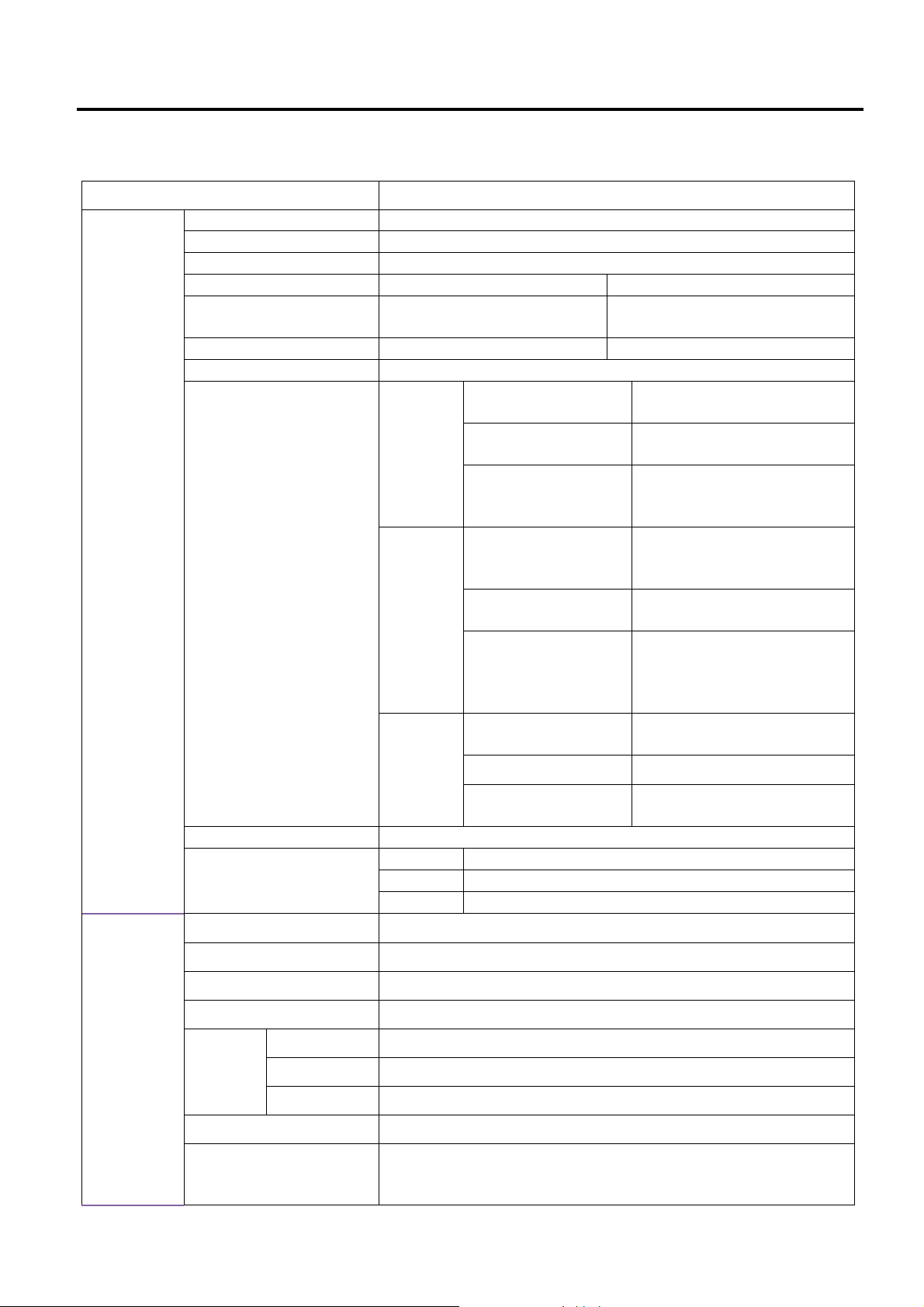

1.3.1 Basic Specifications (for B-FV4T)

Model B-FV4T-GS Series B-FV4T-TS Series

General

Characteristics

Printer

characteristics

Construction Double walled casing & Clam shell design

Maintenance No tool required to repair thermal head and platen

Paper holder No roll spindle & No paper holder spring

Print method Direct thermal & thermal transfer

Resolution 203 dpi (8 dots/mm) 300 dpi (11.8 dots/mm)

Print width Max. 108 mm (4.25”) Max. 105.7 mm (4.16”)

Print length Max. 999 mm (39”)

Batch/Cut mode:

50.8 mm/sec. (2”/sec.),

76.2 mm/sec. (3”/sec.),

101.6 mm/sec. (4”/sec.),

Print Speed

RAM 32 MB SDRAM

Flash ROM 16 MB

User area 3 MB

Optional memory Max. 16 GB USB

Media sensors

I/F (User installable)

Barcode Linear

Printer Language TPCL (Refer to External Equipment I/F manual)

2D Barcode Data Matrix, PDF417,

Composite symbol GS1-128 Composite (CC-A/CC-B/CC-C)

Fonts Times Roman (6 size s), Helvetica (6 sizes), Presentation (1 size),

LED Two LEDs w/ 3 colors (w/ silk screen print of “STATUS”, “1”, and “2”)

Key Feed key (w/ silk screen print of “FEED”)

Switch Power S/W

127 mm/sec. (5”/sec.),

152.4 mm/sec. (6”/sec.)

Strip mode:

50.8 mm/sec. (2”/sec.),

76.2 mm/sec. (3”/sec.)

Feed gap sensor (Transmissive)

Black mark sensor (Reflective)

Ribbon sensor (Reflective encoder sensor)

Serial interface RS-232C

Parallel interface (Centronics)

USB 2.0 full Speed

Ethernet interface (10/100 Base)

UPC-A, UPC-E, EAN8/13,

UPC-A add on 2&5, UPC-E add on 2&5,

EAN-8/13 add on 2&5,

CODE39, CODE93, CODE128, GSI-128(UCC/EAN128),

NW7, MSI, Industrial 2 of 5, ITF, POSTNET, RM4SCC, KIX-Code,

USPS Intelligent mail barcode, GS1 DataBar

QR Code, Maxi Code,

Micro PDF417

Letter Gothic (1 size), Courier (2 sizes), Prestige Elite (2 sizes),

OCR-A (1 type), OCR-B (1 type), Simplified Chinese (1 size)

Batch/Cut mode:

50.8 mm/sec. (2”/sec.),

76.2 mm/sec. (3”/sec.),

101.6 mm/sec. (4”/sec.)

Strip mode:

50.8 mm/sec. (2”/sec.),

76.2 mm/sec. (3”/sec.)

1-9

Page 22

1. OUTLINE EO18-33030

Model B-FV4T-GS Series B-FV4T-TS Series

Operating

characteristics

Physical

characteristics

Related products Options Full cutter module (B-FV204T-F-QM-R)

Operating temperature

Storage temperature -20C to 60C (-4F to 140F)

Operating humidity 25 to 85 % (Non-condensing R.H) (*1)

Storage humidity 10 to 90 % (Non-condensing R.H)

Electrical

Agency approvals FCC Class A

Environmental

complaint

Width 220.6 mm (8.7”)

Height 182.0 mm (7.2”)

Depth 278.5 mm (11.0”)

Weight 2.4Kg (5.29 lb) (Excluding media and ribbon)

Accessories CD-ROM (1 copy)

5C to 40C (41F to 104F) (*1)

AC Adapter

100 to 240 VAC ± 10%, 47 to 63 Hz

Power consumption (100 to 120 V)

During standby: 0.07 A, 3.4 W maximum

During a print job: 0.90 A, 49.0 W maximum

Power consumption (200 to 240 V)

During standby: 0.05 A, 3.5 W maximum

During a print job: 0.47 A, 48.1 W maximum

Inrush Current

115 to 230 VAC: 90 A

C-Tick

CE

TUV-GS

UL, cUL

RoHS

WEEE

Partial cutter module (B-FV204T-P-QM -R)

Peel-off module (B-FV904T-H-QM-R)

External media stand (B-FV904-PH-QM-R)

Bluetooth interface (B-FV704T-BLTH-QM-R)

TPH kit (B-FV704-TPH2-QM-R) TPH kit (B-FV704-TPH3-QM-R)

Power Adapt er (1 pc.)

Quick Installation Manual (1 copy)

Safety Precautions (1 copy)

USB cable (1pc.)

1-inch Ribbon S pindle (2 pcs.)

0.5-inch Ribbon S pindle (2 pcs.)

Paper Support Roller for Outside-wound Media (1 pc.)

1.3 Specifications

NOTES:

*1 Since the adhesive strength of labels becomes higher in hot and humid conditions, the possibility of

label jam increases.

1-10

Page 23

1. OUTLINE EO18-33030

1.3 Specifications

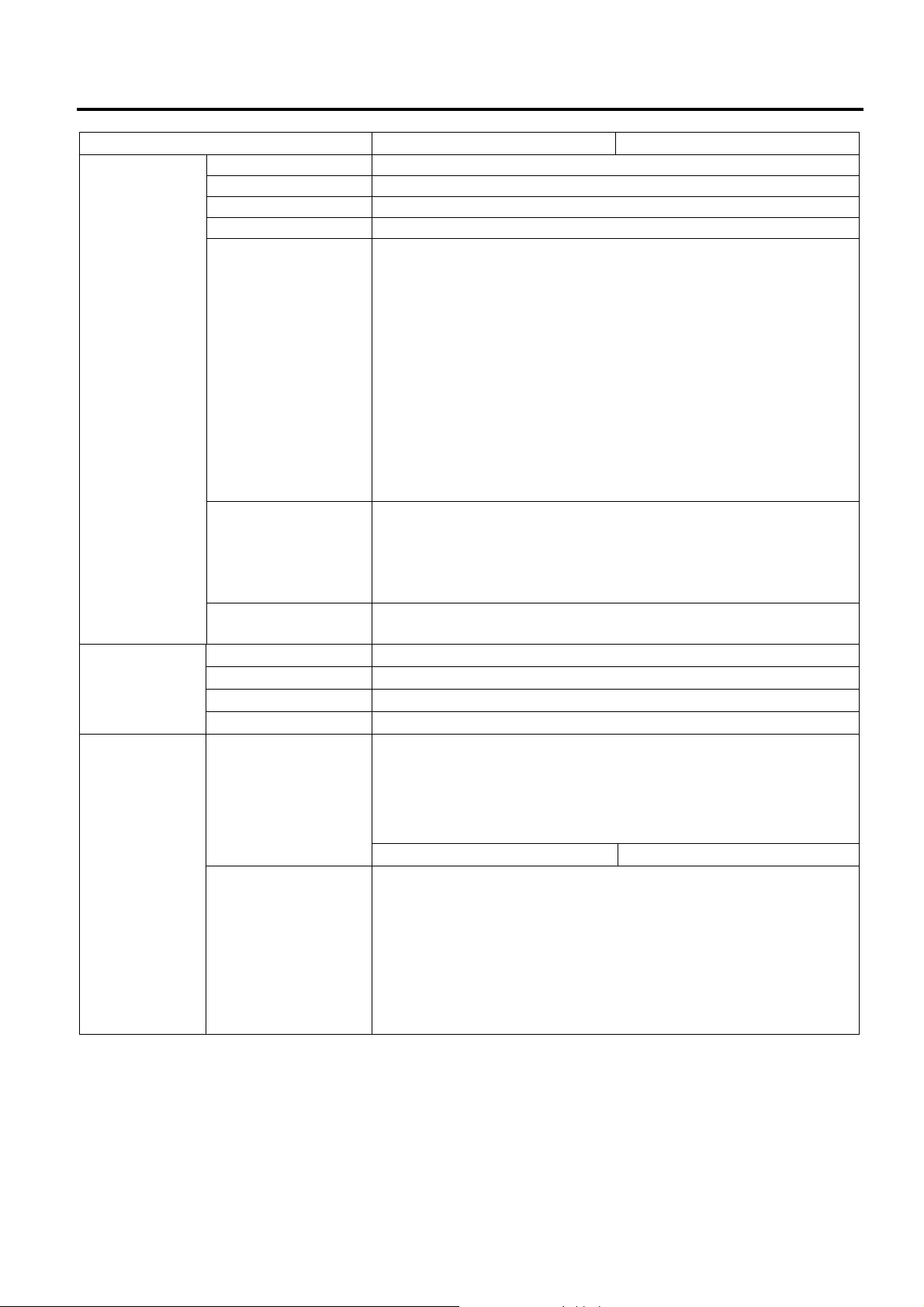

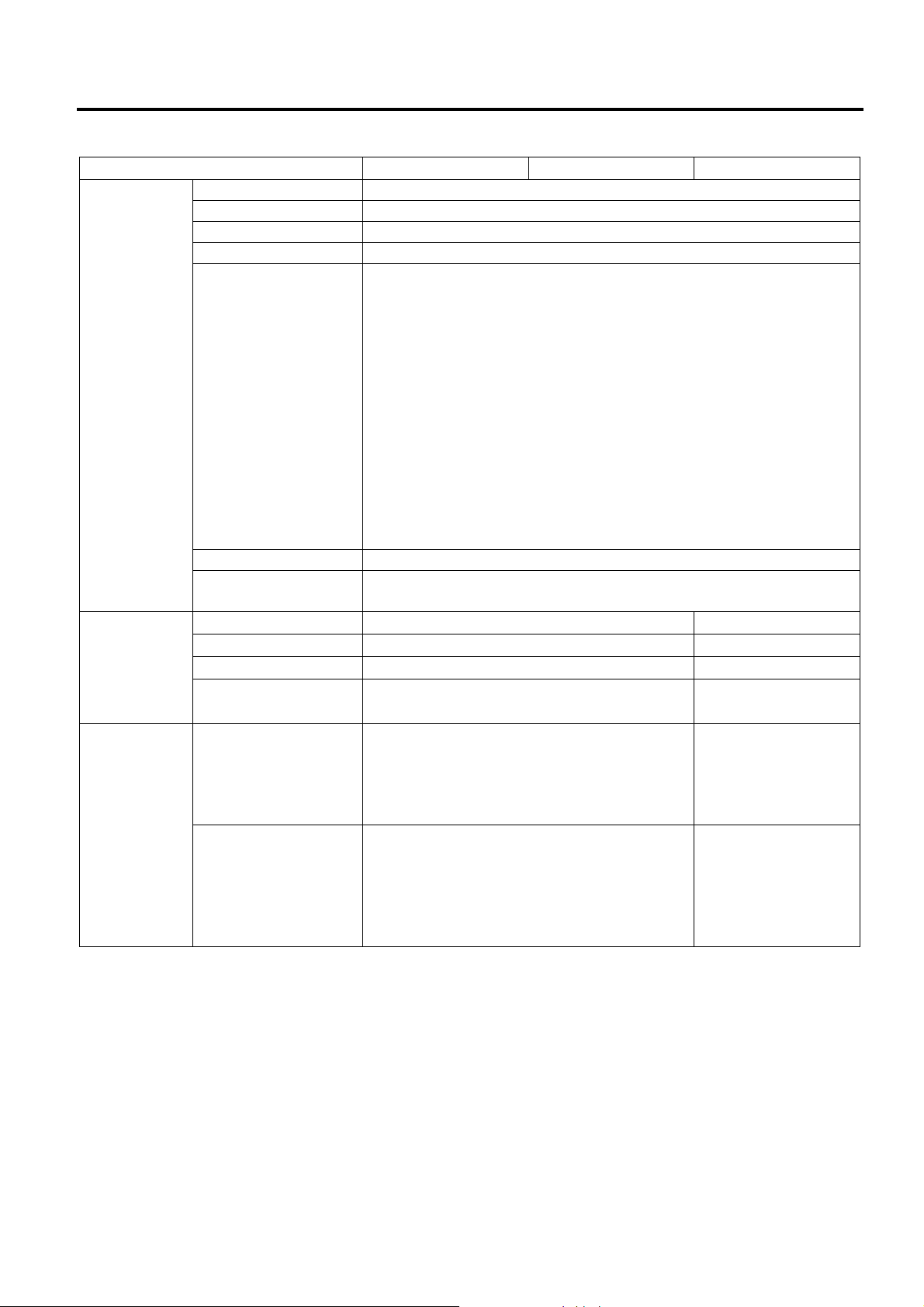

1.3.2 Basic Specifications (for B-FV4D)

Model B-FV4D-GS Series B-FV4D-TS Series B-FV4D-GH Series

General

Characteristics

Printer

characteristics

Construction Double walled casing & Clam shell design

Maintenance No tool required to repair thermal head and platen

Paper holder No roll spindle & No p aper holder spring

Print method Direct thermal

Resolution 203 dpi (8 dots/mm) 300 dpi (11.8 dot s/mm) 203 dpi (8 dots/mm)

Print width Max. 108 mm (4.25”) Max. 105.7 mm (4.16”) Max. 99.0 mm (3.89”)

Print length Max. 999 mm (39”)

Batch/Cut mode:

50.8 mm/sec. (2”/sec.),

76.2 mm/sec. (3”/sec.),

101.6 mm/sec.

(4”/sec.),

Print Speed

RAM 32 MB SDRAM

Flash ROM 16 MB

User area 3 MB

Optional

memory

Media sensors

I/F (User

installable)

Barcode Linear

Printer

Language

2D Barcode Data Matrix, PDF417,

Composite

symbol

Fonts Times Roman (6 sizes), Helvetica (6 sizes), Presentat ion (1 size),

LED Two LEDs w/ 3 colors (w/ silk screen print of “STATUS”, “1”, and “2”)

Key Feed key (w/ silk screen print of “FEED”)

Switch Power S/W

127 mm/sec. (5”/sec.),

152.4 mm/sec.

(6”/sec.)

Strip mode:

50.8 mm/sec. (2”/sec.),

76.2 mm/sec. (3”/sec.)

Max. 16 GB USB

Feed gap sensor (Transmissive)

Black mark sensor (Reflective)

Serial interface RS-232C

Parallel interface (Centronics)

USB 2.0 full Speed

Ethernet interface (10/100 Base)

UPC-A, UPC-E, EAN8/13,

UPC-A add on 2&5, UPC-E add on 2&5,

EAN-8/13 add on 2&5,

CODE39, CODE93, CODE128, GSI-128(UCC/EAN128),

NW7, MSI, Industrial 2 of 5, ITF, POSTNET, RM4SCC, KIX-Code,

USPS Intelligent mail barcode, GS1 DataBar

TPCL (Refer to External Equipment I/F manual)

QR Code, Maxi Code,

Micro PDF417

GS1-128 Composite (CC-A/CC-B/CC-C)

Letter Gothic (1 size), Courier (2 sizes), Prestige Elite (2 sizes),

OCR-A (1 type), OCR-B (1 type), Simplified Chinese (1 size)

Batch/Cut mode:

50.8 mm/sec. (2”/sec.),

76.2 mm/sec. (3”/sec.),

101.6 mm/sec. (4”/sec.)

Strip mode:

50.8 mm/sec. (2”/sec.),

76.2 mm/sec. (3”/sec.)

Batch mode:

50.8 mm/sec. (2”/sec.),

76.2 mm/sec. (3”/sec.),

101.6 mm/sec.

(4”/sec.),

127 mm/sec. (5”/sec.),

152.4 mm/sec.

(6”/sec.)

Strip mode:

50.8 mm/sec. (2”/sec.),

76.2 mm/sec. (3”/sec.)

Feed gap sensor

(Transmissive)

Serial interface RS-232C

USB 2.0 full Speed

Ethernet interface (10/100

Base)

1-11

Page 24

1. OUTLINE EO18-33030

1.3 Specifications

Model B-FV4D-GS Series B-FV4D-TS Series B-FV4D-GH Series

Operating

characteristics

Physical

characteristics

Related

products

Operating temperature 5C to 40C (41F to 104F) (*1)

Storage temperature -20C to 60C (-4F to 140F)

Operating humidity 25 to 85 % (Non-condensing R.H) (*1)

Storage humidity 10 to 90 % (Non-condensing R.H)

AC Adapter

B-FV4D- GS/TS Series

100 to 240 VAC ± 10%, 47 to 63 Hz

B-FV4D-GH Series

100 to 240 VAC ± 10%, 50 to 60 Hz

Power consumption (100 to 120 V)

Electrical

Agency approvals FCC Class A, C-Tick, CE, TUV-GS, UL, cUL

Environmental

complaint

Width 183.8 mm (7.2”) 183.8 mm (7.2”)

Height 166.9 mm (6.5”) 198.7 mm (7.8”)

Depth 226.2 mm (8.9”) 244.5 mm (9.6”)

Weight 1.76Kg (3.8 lb) (Excluding media)

Options

Accessories

During standby: 0.12 A, 3.7 W maximum

During a print job: 1.0 A, 60 W maximum

Power consumption (200 to 240 V)

During standby: 0.07 A, 3.8 W maximum

During a print job: 0.6 A, 59 W maximum

Inrush Current

100 VAC: 40 A, 240 VAC: 80 A At cold start, maximum load

RoHS,

WEEE

2.2Kg (4.9 lb)

(Excluding media)

Full cutter module (B-FV204D-F-QM-R)

Partial cutter module (B-FV204D-P-QM-R)

Peel-off module (B-FV904D-H-QM-R)

External media stand (B-FV904-PH-QM-R)

Bluetooth interface (B-FV704D-BLTH-QM-R)

CD-ROM (1 copy)

Power Adapt er (1 pc.)

Quick Installation Manual (1 copy)

Safety Precautions (1 copy)

USB cable (1pc.)

CD-ROM (1 copy)

Quick Installation

Manual (1 copy)

Safety Precautions

(1 copy)

USB cable (1pc.)

N/A

NOTES:

*1 Since the adhesive strength of labels becomes higher in hot and humid conditions, the possibility of

label jam increases.

1-12

Page 25

1. OUTLINE EO18-33030

1.3 Specifications

1.3.3 Basic Specifications (for B-FV4D-GL)

Model B-FV4D-GL Series

General

Characteristics

Printer

characteristics

Construction Double walled casing & Clam shell design

Maintenance No tool required to repair thermal head and platen

Paper holder No roll spindle & No p aper holder spring

Print method Direct thermal

Resolution 203 dpi (8 dots/mm)

Print width Max. 99.0 mm (3.89”)

Print length Max. 152.4 mm (6.0”)

Cut mode:

50.8 mm/sec. (2”/sec.),

Print Speed

RAM 32 MB SDRAM

Flash ROM 16 MB

User area 3 MB

Optional

memory

Media sensor Paper End Sensor (Transmissive)

I/F (User

installable)

Barcode Linear

Printer

Language

2D Barcode Data Matrix, PDF417,

Composite

symbol

Fonts Times Roman (6 sizes), Helvetica (6 sizes), Presentat ion (1 size),

LED Two LEDs w/ 3 colors (w/ silk screen print of “STATUS”, “1”, and “2”)

Key Feed key (w/ silk screen print of “FEED”)

Switch Power S/W

76.2 mm/sec. (3”/sec.),

101.6 mm/sec. (4”/sec.),

127 mm/sec. (5”/sec.),

152.4 mm/sec. (6”/sec.)

Max. 16 GB USB

Serial interface RS-232C

USB 2.0 full Speed

Ethernet interface (10/100 Base)

UPC-A, UPC-E, EAN8/13,

UPC-A add on 2&5, UPC-E add on 2&5,

EAN-8/13 add on 2&5,

CODE39, CODE93, CODE128, GSI-128(UCC/EAN128),

NW7, MSI, Industrial 2 of 5, ITF, POSTNET, RM4SCC, KIX-Code,

USPS Intelligent mail barcode, GS1 DataBar

TPCL (Refer to External Equipment I/F manual)

QR Code, Maxi Code,

Micro PDF417

GS1-128 Composite (CC-A/CC-B/CC-C)

Letter Gothic (1 size), Courier (2 sizes), Prestige Elite (2 sizes),

OCR-A (1 type), OCR-B (1 type), Simplified Chinese (1 size)

1-13

Page 26

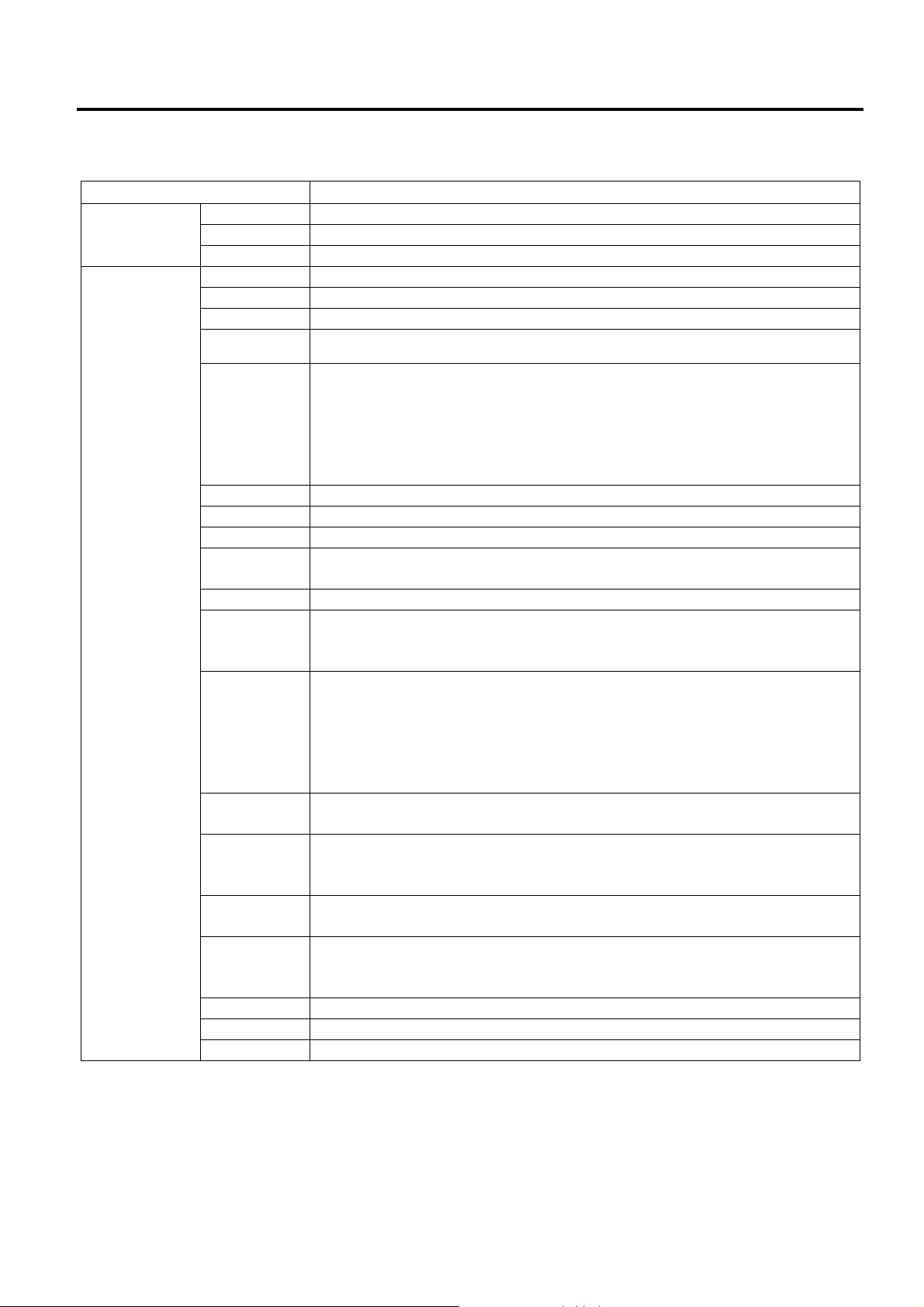

1. OUTLINE EO18-33030

Operating

characteristics

Physical

characteristics

Related

products

Model B-FV4D-GL Series

Operating temperature 5C to 35C (41F to 95F) (*1)

Storage temperature -20C to 60C (-4F to 140F)

Operating humidity 30 to 75 % (Non-condensing R.H) (*1)

Storage humidity 10 to 90 % (Non-condensing R.H)

AC Adapter

100 to 240 VAC ± 10%, 50 to 60 Hz

Power consumption (100 to 120 V)

During standby: 0.12 A, 3.7 W maximum

During a print job: 1.0 A, 60 W maximum

Electrical

Agency approvals RCM, CE, TUV-GS

Environmental

complaint

Width 184.0 mm (7.2”)

Height 198.8 mm (7.8”)

Depth 271.2 mm (10.7”)

Weight 2.8Kg (6.2 lb) (Excluding media)

Options

Accessories

Power consumption (200 to 240 V)

During standby: 0.07 A, 3.8 W maximum

During a print job: 0.6 A, 59 W maximum

Inrush Current

100 VAC: 40 A, 240 VAC: 80 A At cold start, maximum load

RoHS,

WEEE

N/A

CD-ROM (1 copy)

Quick Installation Manual (1 copy)

Safety Precautions (1 copy)

USB Cable (1pc.)

Scraper (1 pc.)

Cleaner Pen (1 pc.)

Cutter Tray (1 pc.)

1.3 Specifications

NOTES:

*1 Since the adhesive strength of labels becomes higher in hot and humid conditions, the possibility of

label jam increases.

1-14

Page 27

1. OUTLINE EO18-33030

1.3 Specifications

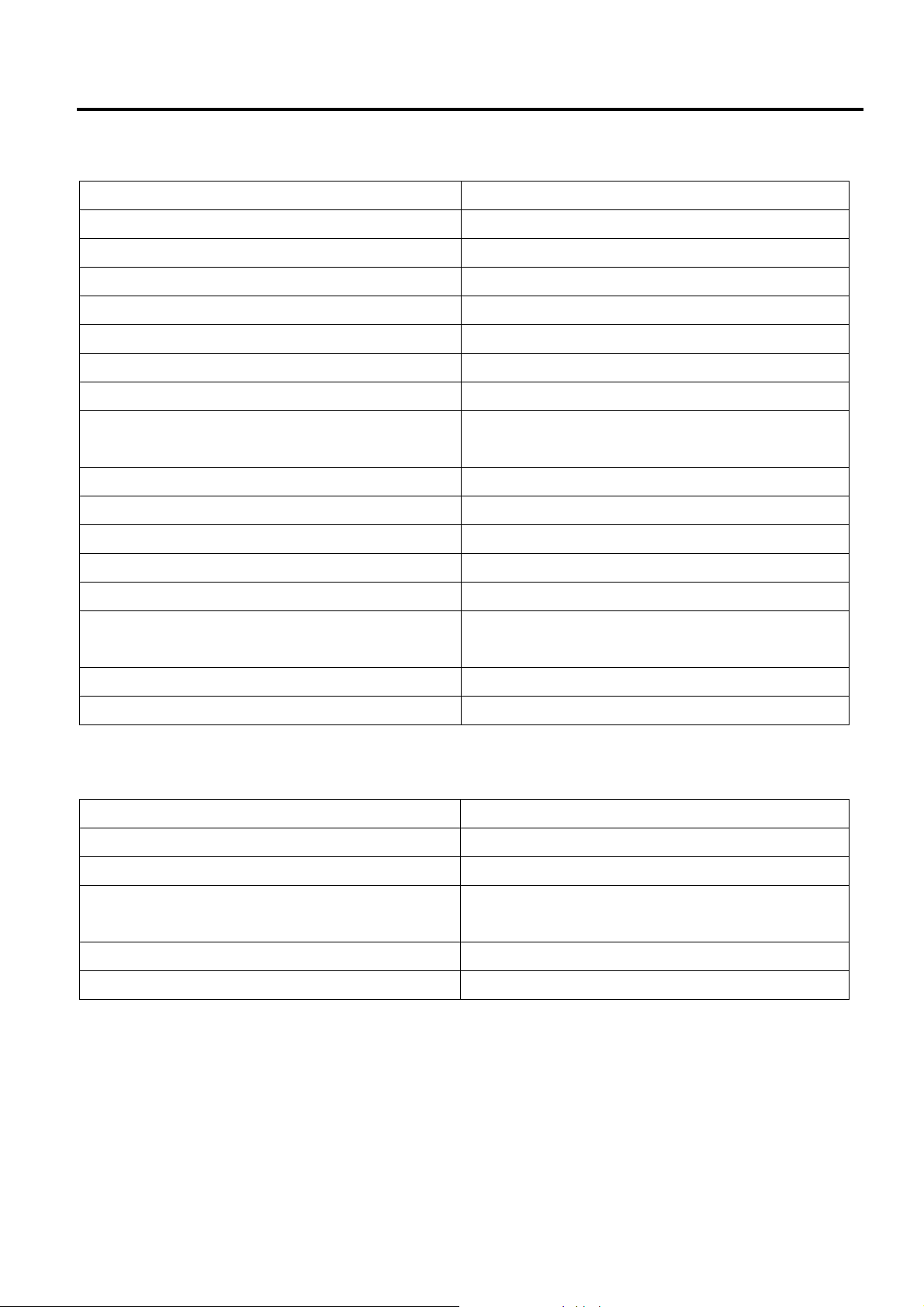

1.3.4 Wireless LAN

Properties Wireless LAN I/F

Hardware

Software Connection mode Infrastructure, Adhoc

Protocol IEEE 802.11 b/g

Enabled Device B-FV4 Series

Operating Temperature +5°C ~ +40°C

Destination USA Europe

Frequency

(Center Channel)

Channel 1 ~ 11 ch 1 ~ 13 ch

Spacing 5 MHz

Transmission Speed/

Modulation

Antenna External antenna

Aerial power 802.11b 10 dBm Max

2412 ~ 2462 MHz 2412 ~ 2472 MHz

IEEE

802.11b

IEEE

802.11g

IEEE

802.11n

802.11g 10 dBm Max

802.11n N/A

Transmission

Method

Channel

Data Transmission

Speed/Modulation

Transmission

Method

Channel Depending on the

Data Transmission

Speed/Modulation

Transmission

Method

Channel

Data Transmission

Speed/Modulation

Conforming to IEEE 802.11b

DSSS method

Depending on the

country/region

11/5.5 Mbps: CCK

2 Mbps: DQPSK

1 Mbps: DBPSK

Conforming to IEEE 802.11g

OFDM method

DSSS method

country/region

54/48 Mbps: 64 QAM

36/24 Mbps: 16 QAM

18/12 Mbps: QPSK

9/6 Mbps: BPSK

N/A

N/A

N/A

Default IP Address 192.168.xxx.yyy Set the printer ID for xxx.yyy.

Default Subnet Mask

Default ESSID

Security

Protocol

Wireless LAN Parameter

Setting and Status

Monitor

Cryptography

Authorization

255.255.0.0

TOSHIBATEC

IEEE 802.11i

WEP 128 bit, TKIP (WPA), AES (WPA2)

Open Key (for WEP), PSK

TCP/IP, Socket, DHCP

Parameter Setting: Command (PC Setting Tool)

1-15

Page 28

1. OUTLINE EO18-33030

1.3 Specifications

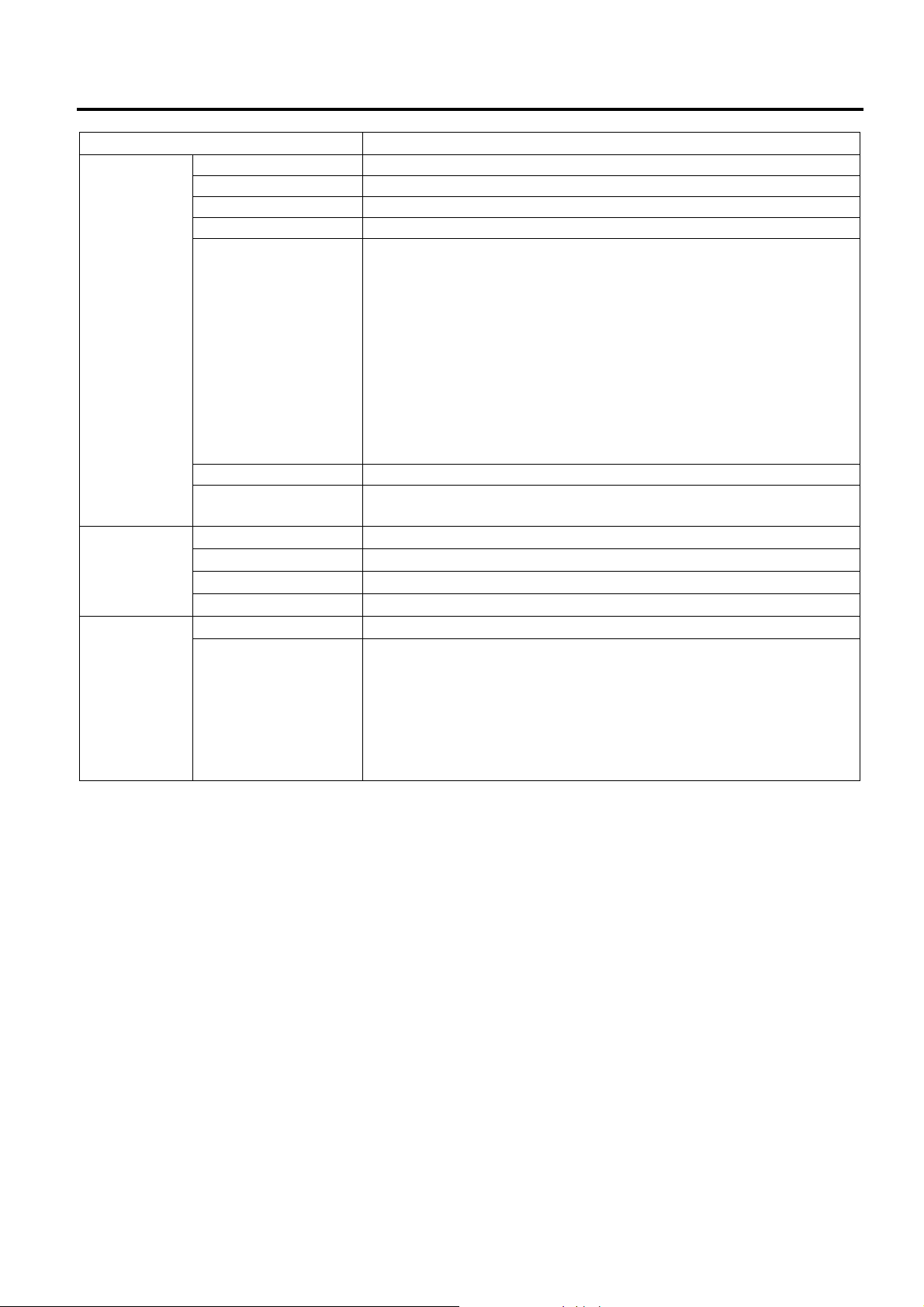

1.3.5 Bluetooth

Properties Bluetooth I/F

Standard Bluetooth 2.1 + EDR or later

Enable Device B-FV4 Series

Operating Temperature 41°F (5°C) ~ 104°F (40°C)

Storage Temperature -4°F (-20°C) ~ 140°F (60°C)

Operating Humidity 25 ~ 85 % Non-condensing R.H

Storage Humidity 10 ~ 90 % Non-condensing R.H

Connection Form Only one-to-one connection is supported.

Support Profile Serial Port Profile (SPP)

PIN code is supported.

Class of Radio Transmission CLASS 2

Transmission Method Bi-direction al (Half-duplex)

Flow Control Credit based flow control

Operating Mode Slave Mode

Transmission Distance 3 m (360 degrees)

SR Mode in Page/Inquiry Scanning R1 Scan Interval 1.28 sec.

Scan Window 22.5 msec.

RF Frequency Range 2402 ~ 2480 MHz

Nominal Output Power +4 dBm (2.51 mW) MAX

1.3.6 Ethernet

Properties Description

Port RJ-45

Speed 10Base-T/100Base-T (Auto Detecting)

Protocol ARP, IP, ICMP, UDP, TCP, HTTP, DHCP, Socket, LPR,

IPv4, SNMPv2

Mode TCP Server/Client, UDP Client

T echnology HP Auto-MDIX, Auto-Negotiation

1-16

Page 29

1. OUTLINE EO18-33030

1.4 Interface I/O Port

1.4 Interface I/O Port

This section provides information about IO port specifications for your printer.

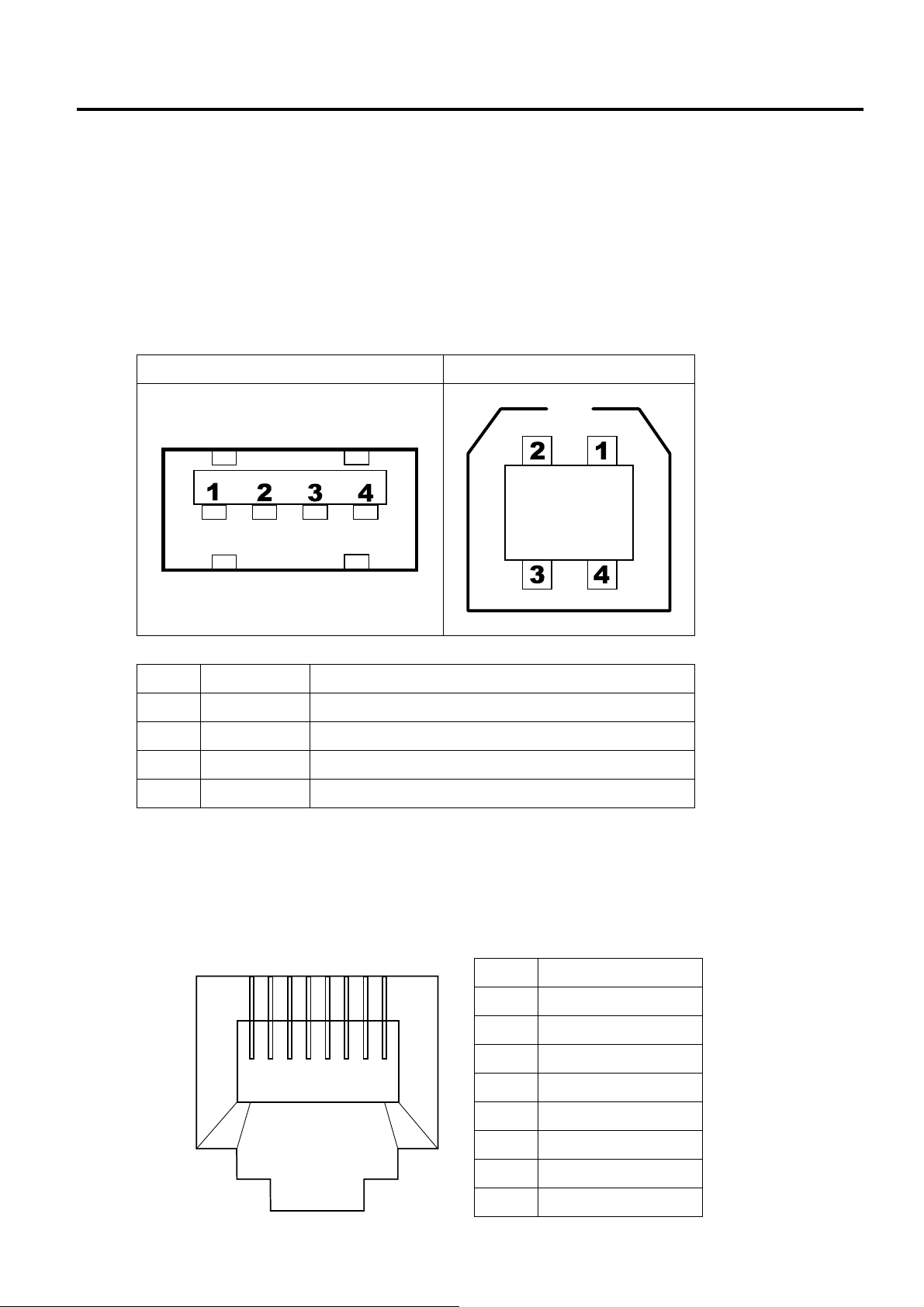

1.4.1 USB

Your printer has two USB ports: type A and type B. Typically, type A is found on computers and hubs;

type B is found on devices and hubs. The figure below shows their pinouts.

Type A Type B

Pin Signal Description

1 VBUS +5V

2 D- Differential data signaling pair 3 D+ Differential data signaling pair +

4 Ground Ground

1.4.2 Ethernet

The Ethernet uses RJ-45 cable, which is 8P8C (8-Position 8-Contact). The figure below shows its

pinout.

2

1

3456

8

7

Pin Signal

1 Transmit+

2 Transmit3 Receive+

4 Reserved

5 Reserved

6 Receive7 Reserved

8 Reserved

1-17

Page 30

1. OUTLINE EO18-33030

1.4 Interface I/O Port

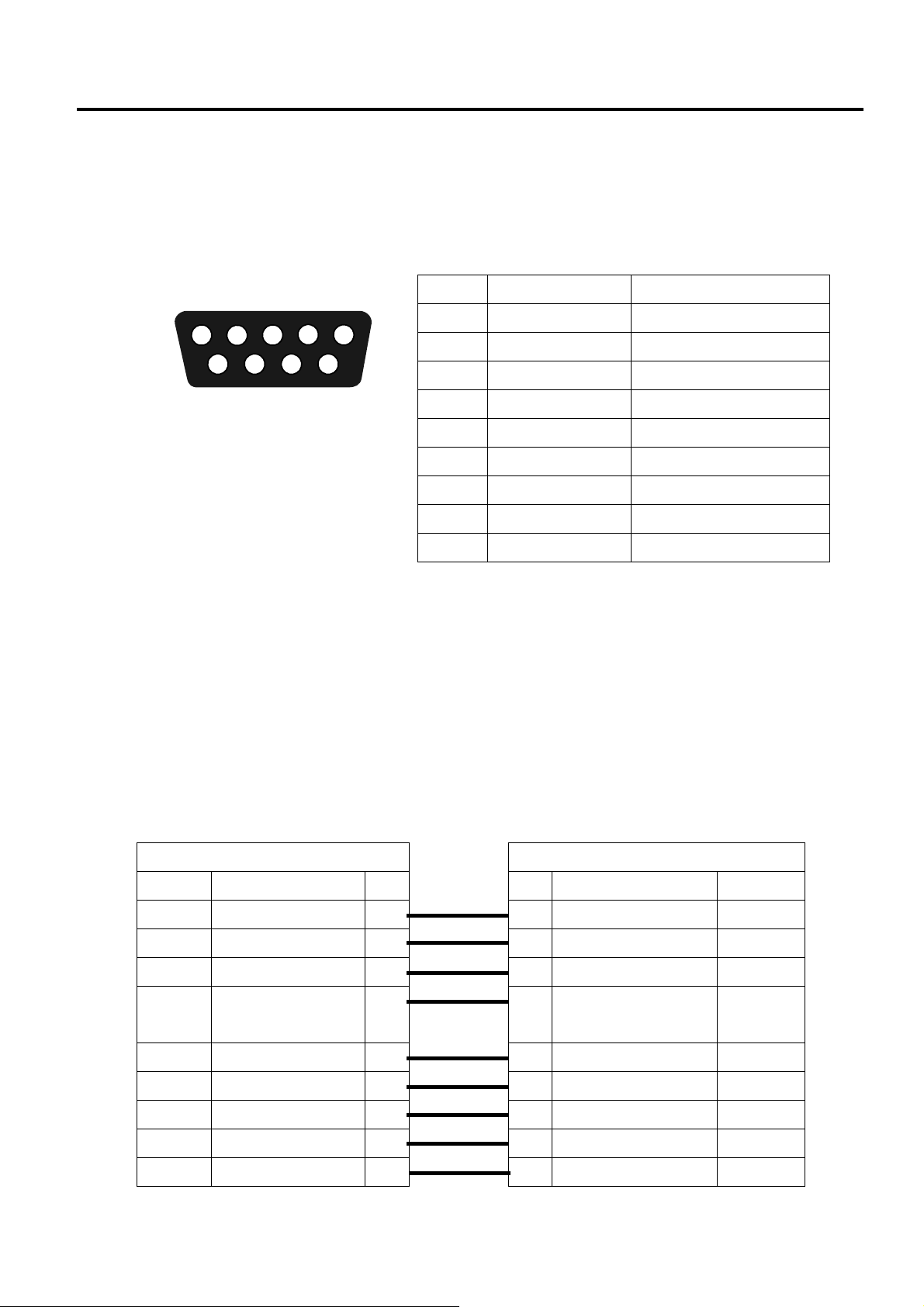

1.4.3 RS-232C

The RS-232C on your printer is DB9 female. It transmits data bit by bit in asynchronous start-stop

mode. The figure below shows its pinout.

4

3

2

1

5

7

89

6

Pin Signal Description

1 +5V Provide 5V Power

2 TxD Transmit

3 RxD Receive

4 CTS Clear to Send

5 GND Ground

6 RTS Request to Send

7 NC No Connection

8 RTS Request to Send

9 NC No Connection

Speed: 2400, 4800, 9600, 19200, 38400, 57600, 115200 Bauds

Parity: Odd, Even or None

Data Bits: 7 or 8 Bits

Stop Bits: 1 or 2 Bits

Flow Control: XON/XOFF or RTS

Default Parameters: 9600 Bauds, No Parity, 8 Data Bits, 1 Stop Bit, XON/XOFF

Host (DB9)

Signal Description Pin

CD Carrier Detect 1

RxD Receive 2 2 Transmit TxD

TxD Transmit 3 3 Receive RxD

DTR Data Terminal

Ready

GND Ground 5 5 Ground GND

DSR Data Set Ready 6 6 Request to Send RTS

RTS Request to Send 7 7 No Connection NC

CTS Clear to Send 8 8 Request to Send RTS

CI 9

4 4 Clear to Send CTS

Pin Description Signal

1 Provide 5V Power +5V

9 No Connection NC

Printer (DB9)

1-18

Page 31

1. OUTLINE EO18-33030

1.4 Interface I/O Port

1.4.4 Centronics

The 36-pin Centronics on your printer uses parallel communication, and complies with IEEE 1284

compatibility mode (also called SPP, Standard Parallel Port). The figure below shows its pinout.

36

Pin Signal Direction Signal Pin Signal Direction Signal

1 To Printer /STB 19 Ground GND

2 To Printer Data 1 20 Ground GND

3 To Printer Data 2 21 Ground GND

4 To Printer Data 3 22 Ground GND

5 To Printer Data 4 23 Ground GND

6 To Printer Data 5 24 Ground GND

7 To Printer Data 6 25 Ground GND

8 To Printer Data 7 26 Ground GND

9 To Printer Data 8 27 Ground GND

10 From Printer /ACK 28 Ground GND

11 From Printer BUSY 29 Ground GND

118

19

12 From Printer PE 30 Ground GND

13 From Printer SELECT 31 - NC

14-15 - NC 32 From Printer /FAULT

16-17 Ground GND 33 Ground GND

18 - +5V 34-36 - NC

1-19

Page 32

1. OUTLINE EO18-33030

S

F

M

F

S

F

M

F

1.5 Key and LED

1.5 Key and LED

B-FV4T-GS/TS B-FV4D-GS/TS

LED 2

LED 1

FEED Button

LED 1

B-FV4D-GH

FEED Button

LED 2

LED 1

LED 2

LED 1

FEED Button

The [FEED] button as has three functions. It can operate as a FEED, RESTART or PAUSE button depending

on current the printer state.

As a FEED button

Pressing this button when the printer is online will cause the media to feed

forwards.

Pressing this button after removing the cause of an error returns the printer to an

As a RESTART button

online state.

Pressing this button with the printer is paused will resume printing.

As a PAUSE button

Pressing this button while the printer is printing will stop the printing after

completing the current label. The printer is then paused.

The indicator lamps (LED1 and LED 2) light up or flash in different colors and sequences depending on the

printer status.

LED 1 LED 2 Printer Status

Unlit Unlit The power is off. The print head block is open if the printer power is on.

Green Unlit Stand-by

Green

Green

Unlit Printing is temporarily stopped (paused).

Unlit Communicating with a host

Green Green Writing data to the flash or USB memory

Green Green

The Flash ROM on the CPU board or USB memory is being initialized.

Orange Green A paper jam occurred.

Orange Red The media has ended.

Red Red

Red Orange

M

The print head temperature exceeded the upper limit.

Thermal Head open error.

The thermal head has been opened during an operation.

Orange Orange The ribbon has ended. (For thermal transfer mode)

Red Green A communication error occurred. (Only when the RS-232C is used.)

Red Green

Command error

- Flash ROM on the CPU board error or USB memory error

Red Green

M

- An erase error while formatting the Flash ROM on the CPU board or USB

memory

- Unable to save files due to insufficient storage space on the Flash ROM on

the CPU board or USB memory

Red Green

Red Orange

Orange Red

A paper jam occurred in the cutter unit. (Only when the cutter unit is fitted.)

The print head is broken.

The media has ended while the print data is being sent to the printer.

F : Flash fast (0.5 sec)

M : Flashes at medium speed (1.0 sec)

S : Flashes slowly (2.0 sec)

LED 2

B-FV4D-GL

FEED Button

1-20

Page 33

1. OUTLINE EO18-33030

1.6 Supply Specifications

1.6 Supply Specifications

1.6.1 Media Type

The table below shows the size and shape of the media that can be used on this printer.

Label

B-FV4T-GS/TS Unit: mm (inch)

Issue mode

Item

Media width

(Including backing paper)

Label width 22.4 to 115.0 (0.88 to 4.53)

Label

Media pitch

Tag

Label length

Gap/black mark length

Black mark width Min. 8.0 (0.31)

Thickness 0.06 to 0.19 (0.0024 to 0.0075)

Max. outer roll diameter

Roll direction Outside (standard), Inside

Inner core diameter 25.4, 38.1, or 76.2 (1.0, 1.5, or 3.0)

NOTES:

1. To ensure print quality and print head life use only TOSHIBA TEC approved media.

2. When using a media roll of 76.2-mm (3”) inner core diameter, the 3”-Diameter Media Shaft included in the

optional External Media Roll Hanger is required.

Black Mark

(on reverse side)

Thermal

Transfer

Direct

Transfer

Thermal

Transfer

Direct

Transfer

Thermal

Transfer

Direct

Transfer

Tag paper

Black Mark

(on reverse side)

Cut position

Feed Direction

Batch mode

10 to 999

(0.39 to 39.3)

10 to 999

(0.39 to 39.3)

10 to 999

(0.39 to 39.3)

10 to 999

(0.39 to 39.3)

8 to 997

(0.31 to 39.2)

8 to 997

(0.31 to 39.2)

Ø203.2 (8.0): When the optional External Media Roll Hanger is used.

Batch mode

(Tear-off)

25.4 to 118.0 (1.00 to 4.65)

32 to 999

(1.26 to 39.3)

30 to 997

(1.18 to 39.2)

2.0 to 10.0 (0.08 to 0.39)

2.0 to 3.0 (0.08 to 0.12)

Ø127 (5.0)

Strip mode Cut mode

25.4 to 152.4

(1.0 to 6.0)

37 to 152.4

(1.46 to 6.0)

-----

-----

23.4 to 150.4

(0.92 to 5.92)

35 to 150.4

(1.38 to 5.92)

(See NOTE 2)

25.4 to 999

(1.0 to 39.3)

41 to 999

(1.61 to 39.3)

25.4 to 999

(1.0 to 39.3)

25.4 to 999

(1.0 to 39.3)

19.4 to 993

(0.76 to 39.1)

35 to 993

(1.38 to 39.1)

6.0 to 10.0

(0.24 to 0.39)

6.0

(0.24)

1-21

Page 34

1. OUTLINE EO18-33030

1.6 Supply Specifications

B-FV4D-GS/TS Unit: mm (inch)

Item

Media width

(Including backing paper)

Issue mode

Batch mode

Batch mode

(Tear-off)

Strip mode Cut mode

25.4 to 118.0 (1.00 to 4.65)

Label width 22.4 to 115.0 (0.88 to 4.53)

Label

10 to 999

(0.39 to 39.3)

Media pitch

Tag

Label length

10 to 999

(0.39 to 39.3)

8 to 997

(0.31 to 39.2)

Gap/black mark length 2.0 to 10.0 (0.08 to 0.39)

25.4 to 152.4

(1.0 to 6.0)

(See NOTE4)

-----

23.4 to 150.4

(0.92 to 5.92)

(See NOTE4)

25.4 to 999

(1.0 to 39.3)

(See NOTE2)

25.4 to 999

(1.0 to 39.3)

(See NOTE2)

19.4 to 993

(0.76 to 39.1)

(See NOTE2)

6.0 to 10.0

(0.24 to 0.39)

Black mark width Min. 8.0 (0.31)

Thickness 0.06 to 0.19 (0.0024 to 0.0075)

Max. outer roll diameter

Ø203.2 (8.0): When the optional External Media Stand is used.

Roll direction Outside (standard), Inside

Inner core diameter 25.4, 38.1, or 76.2 (1.0, 1.5, or 3.0)

Ø127 (5.0)

(See NOTE 2)

(See NOTE 2)

NOTES:

1. To ensure print quality and print head life use only TOSHIBA TEC CORPORATION approved media.

2. When you use inside wound media in cut mode, the specifications are restricted as follows:

- Media pitch (Label): 25.4 mm to 84.2 mm (1.0” to 3.31”)

- Media pitch (Tag): 25.4 mm to 84.2 mm (1.0” to 3.31”)

- Label length: 23.4 mm to 76.2 mm (0.92” to 3.0”)

- Inner core diameter: 76.2 mm (3.0”)

3. When using a media roll of 76.2-mm (3”) inner core diameter, the 3”-Diameter Media Shaft included in the

optional External Media Stand is required.

4. When you use inside wound media in strip mode, the specifications are restricted as follows:

- Media pitch (Label): 25.4 mm to 84.2 mm (1.0” to 3.31”)

- Label length: 23.4 mm to 76.2 mm (0.92” to 3.0”)

B-FV4D-GH Unit: mm (inch)

Issue mode

Item

Media width

(Including backing paper)

Batch mode /

Batch mode (Tear-off)

105 (4.1) +1.0/-1.5

Strip mode

Label width 102 (4.0)

Media pitch 10 to 999 (0.39 to 39.3)

Label length 8 to 997 (0.31 to 39.2)

See NOTE 2.

See NOTE 2.

25.4 to 152.4 (1.0 to 6.0)

23.4 to 150.4 (0.92 to 5.92)

See NOTE 2.

See NOTE 2.

Gap length 2.0 to 10.0 (0.08 to 0.39)

Thickness 0.06 to 0.19 (0.0024 to 0.0075)

Max. outer roll diameter Ø127 (5.0)

Roll direction Outside (standard), Inside

Inner core diameter 25.4, 38.1

(See NOTE 2.)

(See NOTE.2)

NOTES:

1. To ensure print quality and print head life use only TOSHIBA TEC CORPORATION approved media.

2. When you use inside wound media, the specifications are restricted as follows:

Issue mode Batch mode / Batch mode (Tear-off) Strip mode

Media pitch 10 to 999 (0.39 to 39.3) 25.4 to 86.2 (1.0 to 3.39)

Label length 8 to 997 (0.31 to 39.2) 23.4 to 76.2 (0.92 to 3.0)

Inner core diameter 38.1 (1.5) 38.1 (1.5)

1-22

Page 35

1. OUTLINE EO18-33030

A

1.6 Supply Specifications

1.6.2 Media Type (B-FV4D-GL)

The table below shows the size and shape of the media that can be used on this printer.

Cut position

B-FV4D-GL Unit: mm (inch)

Item

Label width 102.0 (4.0)

Cut length 25.4 to 152.4 (1.0 to 6.0)

Thickness 0.06 to 0.19 (0.0024 to 0.0075)

Max. outer roll diameter

Roll direction

Inner core diameter 40.0 (1.57)

NOTES:

1. To ensure print quality and print head life use only TOSHIBA TEC approved media.

2. A label jam is more likely to occur with the approach of label end because labels around the paper core

curl intensely.

Label without liner

Issue mode

Feed Direction

Cut mode

Ø127 (5.0)

Outside wound

1.6.3 Detection Area of the Feed Gap (Transmissive) Sensor

The Transmissive sensor is fixed and positioned at 6.35 mm (for GS/TS Type) or 6.27 mm (for GH Type)

right of the centre of the media path.

The Transmissive Sensor detects a gap between labels, as illustrated below.

Sensor position

Min. 2 mm

(Min. 6 mm:

cut mode)

Min. 8 mm

rea to be detected

Label

Gap

Label

6.35 mm (for GS/TS Type)

6.27 mm (for GH Type)

1-23

Sensor position

Print side

Media feed direction

Page 36

1. OUTLINE EO18-33030

1.6 Supply Specifications

1.6.4 Detection Area of the Black Mark (Reflective) Sensor

The Reflective Sensor is movable within the full range of the media width.

The reflection factor of the Black Mark must be 10% or lower with a waveform length of 950 nm.

The Reflective Sensor should be aligned with the centre of the Black Mark.

Sensor should be positioned at the

centre of the black mark.

Min. 2 mm

Min. 8 mm

Detecting the black marks on the

back

Media feed direction

Sensor is movable within the full range.

1.6.5 Effective Print Area

The figure below illustrates the relation between the head effective print width and media width.

(for GS Type)

(for TS Type)

Out of print range

Out of print range

Print head element

5.0 mm

(Head Effective Print Range)

118.0 mm (Max. media width)

6.15 mm

(Head Effective Print Range)

118.0 mm (Max. media width)

108.0 mm

Print head element

105.7 mm

5.0 mm

6.15 mm

Out of print range

Out of print range

(for GH/GL Type)

Out of print range 1.5mm

Print head element

99.0 mm

(Head Effective Print Range)

102.0 mm (Max. label width)

1-24

Out of print range 1.5mm

Page 37

1. OUTLINE EO18-33030

1.6 Supply Specifications

The figure below shows the effective print area on the media.

1.5mm from the left edge of media

Start line

1mm

1.5mm from the right edge of media

Guaranteed print area

1mm

Media feed direction

(Backing paper width is not included.)

Media width

NOTES:

1. Be sure not to print on the 1.5-mm wide area from the media edges (shaded area in the above figure).

2. The centre of media should be positioned at the centre of the print head.

3. Print quality is not guaranteed within 3 mm from the print head stop position (including 1-mm slow-up.)

4. Average print (black) rate should be 15% or less. For bar code print area, the print rate should be 30%

or less.

5. Line weight should be 3 to 12 dots.

1.6.6 Ribbon (B-FV4T only)

Type

Width

Spool type

40 mm to 110 mm (1.57” to 4.33”)

Max. Length

Max. outside diameter

Inside diameter of core

Roll direction

300 m (984 feet)

(Depends on its thickness and outside diameter of core.)

65 mm (2.56”)

12.7 mm or 25.4 mm (0.5” or 1.0”)

Outside

NOTES:

1. To ensure print quality and print head life use only TOSHIBA TEC specified ribbons.

2. Too much diff erence in width between media and ribbon may cause ribbon wrinkles. To avoid ribbon

wrinkles use a ribbon for proper media width shown in the above table. Do not use a ribbon that is

narrower than media.

3. When discarding ribbons, please follow the local rule.

1-25

Page 38

2. ELECTRONICS SPECIFICATIONS EO18-33030

2.1 Main PC Board Diagram

2. ELECTRONIC SPECIFICATIONS

2.1 Main PC Board Diagram

Main Board

A printed circuit board assembly (PCBA) consists of a microcontroller, flash memory, SDRAM and

more.

Panel

A two-layer PCBA consists of one button and two LEDs.

Media Sensor

A two-layer PCBA consists of a reflective and two see-through sensors, which is designed for media

detection.

Ribbon Sensor (B-FV4T only)

A two-layer PCBA consists of a reflective sensor, which is designed for ribbon detection.

2-1

Page 39

2. ELECTRONICS SPECIFICATIONS EO18-33030

2.1 Main PC Board Diagram

Thermal Printhead (TPH)

It consists of a line of tiny resistors that is electronically controlled to produce heat for printing. For

direct thermal printing, a TPH directly heats up an area of the thermal paper to produce an image.

Stepping Motor

A stepping motor rotates certain degrees in each step in response to an electronic pulse.

RTC (Optional)

A real-time clock tracks the current date and time.

Cutter or Peeler * (Optional)

A cutter is a guillotine cutter which automatically cuts the printed label. There are two cutting types:

full and partial. A peeler automatically removes the liner from a printed label. The sensor on the

peeler detects if the peeled label is taken away.

* For B-FV4D-GH, the peeler is installed as standard.

* For B-FV4D-GL, the full-cut type cutter is installed as standard.

2-2

Page 40

2. ELECTRONICS SPECIFICATIONS EO18-33030

2.2 Main PC Board Layout

2.2 Main PC Board Layout

2.2.1 Type 1 (USB + Ethernet), Type 2 (USB + Ethernet + RS-232C)

B-FV4T-GS/TS

B-FV4D-GS/TS

2-3

Page 41

2. ELECTRONICS SPECIFICATIONS EO18-33030

2.2 Main PC Board Layout

B-FV4D-GH

B-FV4D-GL

2-4

Page 42

2. ELECTRONICS SPECIFICATIONS EO18-33030

2.2 Main PC Board Layout

2.2.2 Type 3 (USB + Centronics)*

* This board will be available in the near future.

B-FV4T-GS/TS

B-FV4D-GS/TS

2-5

Page 43

2. ELECTRONICS SPECIFICATIONS EO18-33030

2.3 Main PC Board Connector Pin Assignment

2.3 Main PC Board Connector Pin Assignment

2.3.1 Pin Assignment for B-FV4T-GS/TS

J1 (Print Head): This connector is connected to the print head.

The voltages and signals for controlling the print head are input/output

Signal

GND 1

GND 2

+24V 3

+24V 4

+24V 5

+24V 6

+24V 7

+24V 8

DI 9

DO 10

nLAT 11

+5V 12

GND 13

GND 14

STB1 15

TM 16

+24V 17

+24V 18

GND 19

GND 20

CLK 21

STB2 22

GND 23

GND 24

GND 25

GND 26

J4 (Stepping Motor): This connector is connected to the Stepping Motor.

Signal

A 1

nA 2

B 3

nB 4

J5 (Feed Gap Sensor (Upper)): This connector is connected to the Feed Gap Sensor (Upper).

Signal

Control 1

5V 2

Pin

No.

Pin

No.

Pin

No.

into/from the connector.

2-6

Page 44

2. ELECTRONICS SPECIFICATIONS EO18-33030

2.3 Main PC Board Connector Pin Assignment

J6 (Feed Gap Sensor (Lower)): This connector is connected to the Feed Gap Sensor (Lower).

Signal

+3.3V 1

ST MEDIA 2

N/C 3

Pin

No.

J8 (Cutter Module): This connector is connected to the Cutter Module.

Signal

+24V 1

GND 2

+3V3 3

GND 4

CUT ON 5

CUT DIR 6

CUT SW 7

+3V3 8

+24V 9

CTYPE 10

GND 11

+24V 12

Pin

No.

J9 (Panel board): This connector is connected to the Panel board.

Signal

KEY1 1

N/C 2

LED 1 3

LED 2 4

+3V3 5

GND 6

LED 4 7

LED 3 8

GND 9

Pin

No.

J11 (Head Open Sensor): This connector is connected to the Head Open Sensor.

Signal

GND 1

COVER SW 2

Pin

No.

2-7

Page 45

2. ELECTRONICS SPECIFICATIONS EO18-33030

2.3 Main PC Board Connector Pin Assignment

J12 (Ribbon Sensor): This connector is connected to the Ribbon Sensor.

Signal

+5V 1

GND 2

+3V3 3

RIBBON 4

Pin

No.

J13 (Black Mark Sensor): This connector is connected to the Black Mark Sensor.

Signal

+5V 1

REF I 2

+3V3 3

REF MEDIA 4

Pin

No.

J14 (Peeler Sensor): This connector is connected to the Peel-off Module.

Signal

+5V 1

GND 2

+3V3 3

PEELR 4

Pin

No.

J15 (RF Module): This connector is connected to the RF Module.

Signal

+3V3 1

GND 2

PB nCTS 3

PB nRTS 4

PB RXD 5

PB TXD 6

BT DISCON 7

BT CON IND 8

GND 9

+3V3 10

Pin

No.

P1 (DC Jack): This DC jack is connected to the DC plug of the AC adaptor.

Signal

Power 1

GND 2

GND 3

Pin

No.

2-8

Page 46

2. ELECTRONICS SPECIFICATIONS EO18-33030

2.3 Main PC Board Connector Pin Assignment

P2 (USB Device port): This connector is used for the USB device port.

Signal

+5 V 1

D- 2

D+ 3

N/C 4

GND 5

Pin

No.

P3 (USB Host port): This connector is used for the USB host port.

Signal

+5 V 1

HDMA 2

HDPA 3

GND 4

Pin

No.

P4 (Ethernet port): This connector is used for the Ethernet port (10/100 Base).

Signal

TD+ 1

TD- 2

RD+ 3

TCT 4

N/C 5

RD- 6

RCT 7

N/C 8

Pin

No.

P5 (Serial Interface port): This connector is used for the Serial interface (RS-232C).

+5V is output from the pin 1.

The TXD signal is a serial signal and output from the pin 2.

The RXD signal is a serial signal and input into the pin 3.

Signal

+5 V 1

TXD 2

RXD 3

CTS 4

GND 5

RTS 6

N/C 7

RTS 8

N/C 9

Pin

No.

2-9

Page 47

2. ELECTRONICS SPECIFICATIONS EO18-33030

2.3 Main PC Board Connector Pin Assignment

JP2 (Parallel Interface port): This connector is used for the Parallel interface (Centronics).

Signal

n/STROBE 1

Data 1-8 2-9

nACK 10

BUSY 11

PE 12

5V 13

NC 14

NC 15

Ground 16

Ground 17

NC 18

Ground 19-30

NC 31

nFAULT 32

NC 33-35

NC 36

Pin

No.

2-10

Page 48

2. ELECTRONICS SPECIFICATIONS EO18-33030

2.3 Main PC Board Connector Pin Assignment

2.3.2 Pin Assignment for B-FV4D-GS/TS

J1 (Print Head): This connector is connected to the print head.

The voltages and signals for controlling the print head are input/output

Signal

GND 1

GND 2

+24V 3

+24V 4

+24V 5

+24V 6

+24V 7

+24V 8

DI 9

DO 10

nLAT 11

+5V 12

GND 13

GND 14

STB1 15

TM 16

+24V 17

+24V 18

GND 19

GND 20

CLK 21

STB2 22

GND 23

GND 24

GND 25

GND 26

J4 (Stepping Motor): This connector is connected to the Stepping Motor.

Signal

A 1

nA 2

B 3

nB 4

J5 (Feed Gap Sensor (Upper)): This connector is connected to the Feed Gap Sensor (Upper).

Signal

Control 1

5V 2

Pin

No.

Pin

No.

Pin

No.

into/from the connector.

2-11

Page 49

2. ELECTRONICS SPECIFICATIONS EO18-33030

2.3 Main PC Board Connector Pin Assignment

J6 (Feed Gap Sensor (Lower)): This connector is connected to the Feed Gap Sensor (Lower).

Signal

+3.3V 1

ST MEDIA 2

N/C 3

Pin

No.

J8 (Cutter Module): This connector is connected to the Cutter Module.

Signal

+24V 1

GND 2

+3V3 3

GND 4

CUT ON 5

CUT DIR 6

CUT SW 7

+3V3 8

+24V 9

CTYPE 10

GND 11

+24V 12

Pin

No.

J9 (Panel board): This connector is connected to the Panel board.

Signal

KEY1 1

N/C 2

LED 1 3

LED 2 4

+3V3 5

GND 6

LED 4 7

LED 3 8

GND 9

Pin

No.

J11 (Micro Switch): This connector is connected to the Micro Switch.

Signal

GND 1

COVER SW 2

Pin

No.

J13 (Media Sensor): This connector is connected to the Media Sensor.

Signal

+5V 1

REF I 2

+3V3 3

REF MEDIA 4

Pin

No.

2-12

Page 50

2. ELECTRONICS SPECIFICATIONS EO18-33030

2.3 Main PC Board Connector Pin Assignment

J14 (Peeler Sensor): This connector is connected to the Peel-off Module.

Signal

+5V 1

GND 2

+3V3 3

PEELR 4

Pin

No.

J15 (RF Module): This connector is connected to the RF Module.

Signal

+3V3 1

GND 2

PB nCTS 3

PB nRTS 4

PB RXD 5

PB TXD 6

BT DISCON 7

BT CON IND 8

GND 9

+3V3 10

Pin

No.

P1 (DC Jack): This DC jack is connected to the DC plug of the AC adaptor.

Signal

Power 1

GND 2

GND 3

Pin

No.

P2 (USB Device port): This connector is used for the USB device port.

Signal

+5 V 1

D- 2

D+ 3

N/C 4

GND 5

Pin

No.

P3 (USB Host port): This connector is used for the USB host port.

Signal

+5 V 1

HDMA 2

HDPA 3

GND 4

Pin

No.

2-13

Page 51

2. ELECTRONICS SPECIFICATIONS EO18-33030

2.3 Main PC Board Connector Pin Assignment

P4 (Ethernet port): This connector is used for the Ethernet port (10/100 Base).

Signal

TD+ 1

TD- 2

RD+ 3

TCT 4

N/C 5

RD- 6

RCT 7

N/C 8

Pin

No.

P5 (Serial Interface port): This connector is used for the Serial interface (RS-232C).

+5V is output from the pin 1.

The TXD signal is a serial signal and output from the pin 2.

The RXD signal is a serial signal and input into the pin 3.

Signal

+5 V 1

TXD 2

RXD 3

CTS 4

GND 5

RTS 6

N/C 7

RTS 8

N/C 9

Pin

No.

JP2 (Parallel Interface port): This connector is used for the Parallel interface (Centronics).

Signal

n/STROBE 1

Data 1-8 2-9

nACK 10

BUSY 11

PE 12

5V 13

NC 14

NC 15

Ground 16

Ground 17

NC 18

Ground 19-30

NC 31

nFAULT 32

NC 33-35

NC 36

Pin

No.

2-14

Page 52

2. ELECTRONICS SPECIFICATIONS EO18-33030

2.3 Main PC Board Connector Pin Assignment

2.3.3 Pin Assignment for B-FV4D-GH

J1 (Print Head): This connector is connected to the print head.

The voltages and signals for controlling the print head are input/output

Signal

GND 1

GND 2

+24V 3

+24V 4

+24V 5

+24V 6

+24V 7

+24V 8

DI 9

DO 10

nLAT 11

+5V 12

GND 13

GND 14

STB1 15

TM 16

+24V 17

+24V 18

GND 19

GND 20

CLK 21

STB2 22

GND 23

GND 24

GND 25

GND 26

J4 (Stepping Motor): This connector is connected to the Stepping Motor.

Signal

A 1

nA 2

B 3

nB 4

J5 (Feed Gap Sensor (Upper)): This connector is connected to the Feed Gap Sensor (Upper).

Signal

Control 1

5V 2

Pin

No.

Pin

No.

Pin

No.

into/from the connector.

2-15

Page 53

2. ELECTRONICS SPECIFICATIONS EO18-33030

2.3 Main PC Board Connector Pin Assignment

J6 (Feed Gap Sensor (Lower)): This connector is connected to the Feed Gap Sensor (Lower).

Signal

+3.3V 1

ST MEDIA 2

N/C 3

Pin

No.

J9 (Panel board): This connector is connected to the Panel board.

Signal

KEY1 1

N/C 2

LED 1 3

LED 2 4

+3V3 5

GND 6

LED 4 7

LED 3 8

GND 9

Pin

No.

J11 (Micro Switch): This connector is connected to the Micro Switch.

Signal

GND 1

COVER SW 2

Pin

No.

J14 (Peeler Sensor): This connector is connected to the Peel-off Module.

Signal

+5V 1

GND 2

+3V3 3

PEELR 4

Pin

No.

P1 (DC Jack): This DC jack is connected to the DC plug of the AC adaptor.

Signal

Power 1

GND 2

GND 3

Pin

No.

2-16

Page 54

2. ELECTRONICS SPECIFICATIONS EO18-33030

2.3 Main PC Board Connector Pin Assignment

P2 (USB Device port): This connector is used for the USB device port.

Signal

+5 V 1

D- 2

D+ 3

N/C 4

GND 5

Pin

No.

P3 (USB Host port): This connector is used for the USB host port.

Signal

+5 V 1

HDMA 2

HDPA 3

GND 4

Pin

No.

P4 (Ethernet port): This connector is used for the Ethernet port (10/100 Base).

Signal

TD+ 1

TD- 2

RD+ 3

TCT 4

N/C 5

RD- 6

RCT 7

N/C 8

Pin

No.

P5 (Serial Interface port): This connector is used for the Serial interface (RS-232C).

+5V is output from the pin 1.

The TXD signal is a serial signal and output from the pin 2.

The RXD signal is a serial signal and input into the pin 3.

Signal

+5 V 1

TXD 2

RXD 3

CTS 4

GND 5

RTS 6

N/C 7

RTS 8

N/C 9

Pin

No.

2-17

Page 55

2. ELECTRONICS SPECIFICATIONS EO18-33030

2.3 Main PC Board Connector Pin Assignment

2.3.4 Pin Assignment for B-FV4D-GL

J1 (Print Head): This connector is connected to the print head.

The voltages and signals for controlling the print head are input/output

Signal

GND 1

GND 2

+24V 3

+24V 4

+24V 5

+24V 6

+24V 7

+24V 8

DI 9

DO 10

nLAT 11

+5V 12

GND 13

GND 14

STB1 15

TM 16

+24V 17

+24V 18

GND 19

GND 20

CLK 21

STB2 22

GND 23

GND 24

GND 25

GND 26

J4 (Stepping Motor): This connector is connected to the Stepping Motor.

Signal

A 1

nA 2

B 3

nB 4

J5 (Transmissive Sensor (Upper)): This connector is connected to the Feed Gap Sensor (Upper).

Signal

Control 1

5V 2

Pin

No.

Pin

No.

Pin

No.

into/from the connector.

2-18

Page 56

2. ELECTRONICS SPECIFICATIONS EO18-33030

2.3 Main PC Board Connector Pin Assignment

J6 (Transmissive Sensor (Lower)): This connector is connected to the Feed Gap Sensor (Lower).

Signal

+3.3V 1

ST MEDIA 2

N/C 3

Pin

No.

J8 (Cutter Module): This connector is connected to the Cutter Module.

Signal

+24V 1

GND 2

+3V3 3

GND 4

CUT ON 5

CUT DIR 6

CUT SW 7

+3V3 8

+24V 9

CTYPE 10

GND 11

+24V 12

Pin

No.

J9 (Panel board): This connector is connected to the Panel board.

Signal

KEY1 1

N/C 2

LED 1 3

LED 2 4

+3V3 5

GND 6

LED 4 7

LED 3 8

GND 9

Pin

No.

J11 (Micro Switch): This connector is connected to the Micro Switch.

Signal

GND 1

COVER SW 2

Pin

No.

J14 (Cutter Come-off Sensor): This connector is connected to the Cutter Unit.

Signal

+5V 1

GND 2

+3V3 3

PEELR 4

Pin

No.

2-19

Page 57

2. ELECTRONICS SPECIFICATIONS EO18-33030

2.3 Main PC Board Connector Pin Assignment

P1 (DC Jack): This DC jack is connected to the DC plug of the AC adaptor.

Signal

Power 1

GND 2

GND 3

Pin

No.

P2 (USB Device port): This connector is used for the USB device port.

Signal

+5 V 1

D- 2

D+ 3

N/C 4

GND 5

Pin

No.

P3 (USB Host port): This connector is used for the USB host port.

Signal

+5 V 1

HDMA 2

HDPA 3

GND 4

Pin

No.

P4 (Ethernet port): This connector is used for the Ethernet port (10/100 Base).

Signal

TD+ 1

TD- 2

RD+ 3

TCT 4

N/C 5

RD- 6

RCT 7

N/C 8

Pin

No.

P5 (Serial Interface port): This connector is used for the Serial interface (RS-232C).

+5V is output from the pin 1.

The TXD signal is a serial signal and output from the pin 2.

The RXD signal is a serial signal and input into the pin 3.

Signal

+5 V 1

TXD 2

RXD 3

CTS 4

GND 5

RTS 6

N/C 7

RTS 8

N/C 9

Pin

No.

2-20

Page 58

2. ELECTRONICS SPECIFICATIONS EO18-33030

2.4 DIP Switch

2.4 DIP Switch

DIP Switch Description Default

1

2

Switch between the

firmware mode and

Atmel mode.

Enable or disable

the watchdog.

ON: Firmware mode.

It boots your printer from the flash memory.

OFF: Atmel mode. It boots your printer from CPU

ROM.

Important

In Atmel mode, DIP 2 (watchdog) must be set to

OFF.

ON: Enable watchdog

OFF: Disable watchdog

ON

ON

3 Reserved N/A OFF

4 Reserved N/A OFF

5 Reserved N/A OFF

6 Reserved N/A OFF

7

8

Select your printer

type. It needs to be

used with DIP 8.

Select your printer

type. It needs to be

used with DIP 7.

DIP 7 DIP 8 Printer Type

ON ON B-FV4D-GL Series

ON OFF B-FV4D-GH Series

OFF ON B-FV4D-GS/TS Series

OFF OFF B-FV4T-GS/TS Series

Depending on

your printer type

2-21

Page 59

3. REPLACING THE IMPORTANT PARTS EO18-33030

!

3.1 Replacing the Parts for B-FV4T-GS/TS

3. REPLACING THE IMPORTANT PARTS

1. Turn off the power switch and disconnect the DC plug of the AC Adapter and the

RS-232C cable before replacing any parts. (For B-FV4T-GS/TS and B-FV4D-GS/TS)

2. Turn off the power switch and disconnect the power cord and the RS-232C cable before

replacing any parts. (For B-FV4D-GH and B-FV4D-GL)

3. Follow all manual instructions. Failure to do so could create safety hazards such as fire

or electrocution.

CAUTION!

1. To protect the connector pins or component from static discharge, do not touch them

with bare hands.

2. Use electrostatic free form and the original carton for transportation.

3. Keep your work environment static free to avoid damage to the printer.

4. Do not remove any connectors from the printer within 10 sec. after unplugging the

power cord.

5. Be sure to insert the connector in the appropriate direction. If it is inserted in the wrong

way up, this will be a cause of a malfunction in the main PC board.

NOTES:

1. Manual instructions must be followed when installing option kits or adding cables to

avoid system failures and to insure proper performance and operation.

2. Failure to follow manual instructions or any unauthorized modifications, substitution or

change to this product will void the limited product warranty.

NOTE: Before replacing the important parts, store the printer parameter data on a PC with the B-FV4 Setting

tool. Uploading the data from the PC to the printer after replacement restores the printer parameter

setting to the status prior to replacement. Regarding the details of B-FV4 Setting Tool, refer to “7.

B-FV Setting Tool”.

WARNING

3-1

Page 60

3. REPLACING THE IMPORTANT PARTS EO18-33030

r

3.1 Replacing the Parts for B-FV4T-GS/TS

3.1 Replacing the Parts for B-FV4T-GS/TS

3.1.1 Replacing the Top Cover and the Mid Cover

1. Holding th e tabs on both sides of the top cover, lift the cover in the direction indicated by the arrow to

fully open it.

Top Cove

2. Push the print head release latch to open the print head block.

Tab

Print Head Block