Page 1

TOSHIBA Barcode Printer

B-FV4D SERIES

Owner’s Manual

Page 2

CE Compliance (for EU only)

)

This product complies with the requirements of EMC and Low Voltage Directives including their amendments.

CE marking is the responsibility of TOSHIBA TEC GERMANY IMAGING SYSTEMS GmbH, Carl-Schurz-Str. 7,

41460 Neuss, Germany.

For a copy of the related CE Declaration of Conformity, please contact your dealer or TOSHIBA TEC.

This is a Class A product. In a domestic environment this product may cause radio interference in which case

the user may be required to take adequate measures.

FCC Notice

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to

Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates, uses,

and can radiate radio frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operations of this equipment in a

residential area is likely to cause harmful interference in which case the user will be required to correct the

interference at his own expense.

WARNING

Changes or modifications not expressly approved by the party responsible for compliance could void the user's

authority to operate the equipment.

CAN ICES-3 (A) / NMB-3 (A)

This Class A digital apparatus complies with Canadian ICES-003.

(for USA only)

(for CANADA only)

The EA1050B-240 AC adapter should be exclusively used for the B-FV4D-xxxx-QM-R Series printer.

The B-FV4D-xxxx-QM-R Series printer must be powered by the EA1050B-240 AC adapter.

The EA10681P-240 AC adapter should be exclusively used for the B-FV4D-xxxx-QQ-R Series printer.

The B-FV4D-xxxx-QQ-R Series printer must be powered by the EA10681P-240 AC adapter.

California Proposition 65 Warning: USA-California only

This Product contains chemicals known to the State of California to cause cancer, birth defects, or other

reproductive harm.

The following information is for EU-member states only:

Disposal of products

(based on EU-Directive 2002/96/EC,

Directive on Waste electrical and electronic equipment –WEEE

The use of the symbol indicates that this product may not be disposed as unsorted municipal waste and

has to be collected separately. Integrated batteries and accumulators can be disposed of with the

product. They will be separated at the recycling centers.

The black bar indicates that the product was placed on the market after August 13, 2005.

By ensuring this product is disposed of correctly, you will help prevent potential negative consequences

for the environmental and human health, which could otherwise be caused by inappropriate waste

handling of this product.

For more detailed information about the take-back and recycling of this product, please contact your

supplier where you purchased this product.

Notification (for Turkey)

AEEE Yönetmeliğine Uygundur

Following information is only for India:

The use of the symbol indicates that this product may not be treated as household waste. By ensuring this

product is disposed of correctly, you will help prevent potential negative consequences for the environment

and human health, which could otherwise be caused by inappropriate waste handling of this product.

For more detailed information about the take-back and recycling of this product, please contact your

supplier where you purchased the product.

This product complies with the “India E-waste Rule 2011” and prohibits use of lead, mercury, hexavalent

chromium, polybrominated biphenyls or polybrominated diphenyl ethers in concentrations exceeding 0.1%

by weight and 0.01% by weight for cadmium, except for the exemption set in Schedule II of the Rule.

This product is designed for commercial usage and is not consumer product.

Page 3

Precautions for the handling of Wireless Communication Devices

This product is classified as “wireless equipment for stations of low-power data transmissions systems” under the

Wireless Telegraphy Act, and does not require a radio transmission license. The law prohibits modification of the

interior of this product.

Regulatory Information

This product must be installed and used in strict accordance with the manufacturer’s instructions as described in

the user documentation that comes with the product. This device complies with the following radio frequency and

safety standards.

Standards below are certified under the operation with the provided antenna. Do not use this product with other

antennas.

Europe - EU Declaration of Conformity

Hereby, TOSHIBA TEC, declares that B-FV4D / B-FV4T series are in compliance with the essential requirements

and other relevant provisions of Directive 2014/53/EU.

USA-Federal Communications Commission (FCC)

NOTE: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates, uses, and

can radiate radio frequency energy and, if not installed and used in accordance with the instruction manual, may

cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to

cause harmful interference in which case the user will be required to correct the interference at his own expense.

CAUTION:

This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions:

(1) this device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that may cause undesired operation.

Any changes or modifications not expressly approved by the grantee of this device could void the user's authority

to operate the equipment.

RF EXPOSURE WARNING:

This equipment must be installed and operated in accordance with provided instructions and the antenna(s) used

for this transmitter must be installed to provide a separation distance of at least 20 cm from all persons and must

not be co-located or operating in conjunction with any other antenna or transmitter. End-users and installers must

be provide with antenna installation instructions and transmitter operating conditions for satisfying RF exposure

compliance.

Canada - Industry Canada (IC)

This device complies with Canada licence-exempt RSS standard(s).

Operation is subject to the following two conditions:

(1) this device may not cause interference, and

(2) this device must accept any interference, including interference that may cause undesired operation of the

device.

Cet appareil est conforme avec Industrie Canada exemptes de licence RSS standard(s).

Son fonctionnement est soumis aux deux conditions suivantes:

(1) cet appareil ne doit pas causer d'interférence et

(2) cet appareil doit accepter toute interférence, notamment les interférences qui peuvent affecter son

fonctionnement.

Radio Frequency (RF) Exposure Information

The radiated output power of the Wireless Device is below the Industry Canada (IC) radio frequency exposure

limits. The Wireless Device should be used in such a manner such that the potential for human contact during

normal operation is minimized.

This device has also been evaluated and shown compliant with the IC RF Exposure limits under mobile exposure

conditions. (antennas are greater than 20cm from a person's body).

Page 4

Informations concernant l'exposition aux fréquences radio (RF)

La puissance de sortie émise par l’appareil de sans fil est inférieure à la limite d'exposition aux fréquences radio

d'Industry Canada (IC). Utilisez l’appareil de sans fil de façon à minimiser les contacts humains lors du

fonctionnement normal.

Ce périphérique a également été évalué et démontré conforme aux limites d'exposition aux RF d'IC dans des

conditions d'exposition à des appareils mobiles (antennes sont supérieures à 20 cm à partir du corps d'une

personne).

Approved Countries/Regions for use for the devices

This equipment is approved to the radio standard by the specific countries/regions. Please ask TOSHIBA TEC

authorized dealer or service engineer.

Precaution for Use

This product communicates with other devices by radio. Depending on the installation location, orientation,

environment, etc., its communication performance may deteriorate or devices installed near by may be affected.

Bluetooth® and Wireless LAN devices operate within the same radio frequency range and may interfere with one

another. If you use Bluetooth® and Wireless LAN devices simultaneously, you may occasionally experience a

less than optimal network performance or even lose your network connection.

If you should experience any such problem, immediately turn off your Bluetooth® or Wireless LAN device.

Keep away from a microwave.

Communication performance may deteriorate or a communication error may occur due to the radio emitted from

a microwave.

Do not use the product on a metal table or near a metal object. Communication performance may be deteriorated.

* Bluetooth® is a registered trademark owned by Bluetooth SIG, Inc.

Page 5

Safety Precautions ENGLISH VERSION

W

W

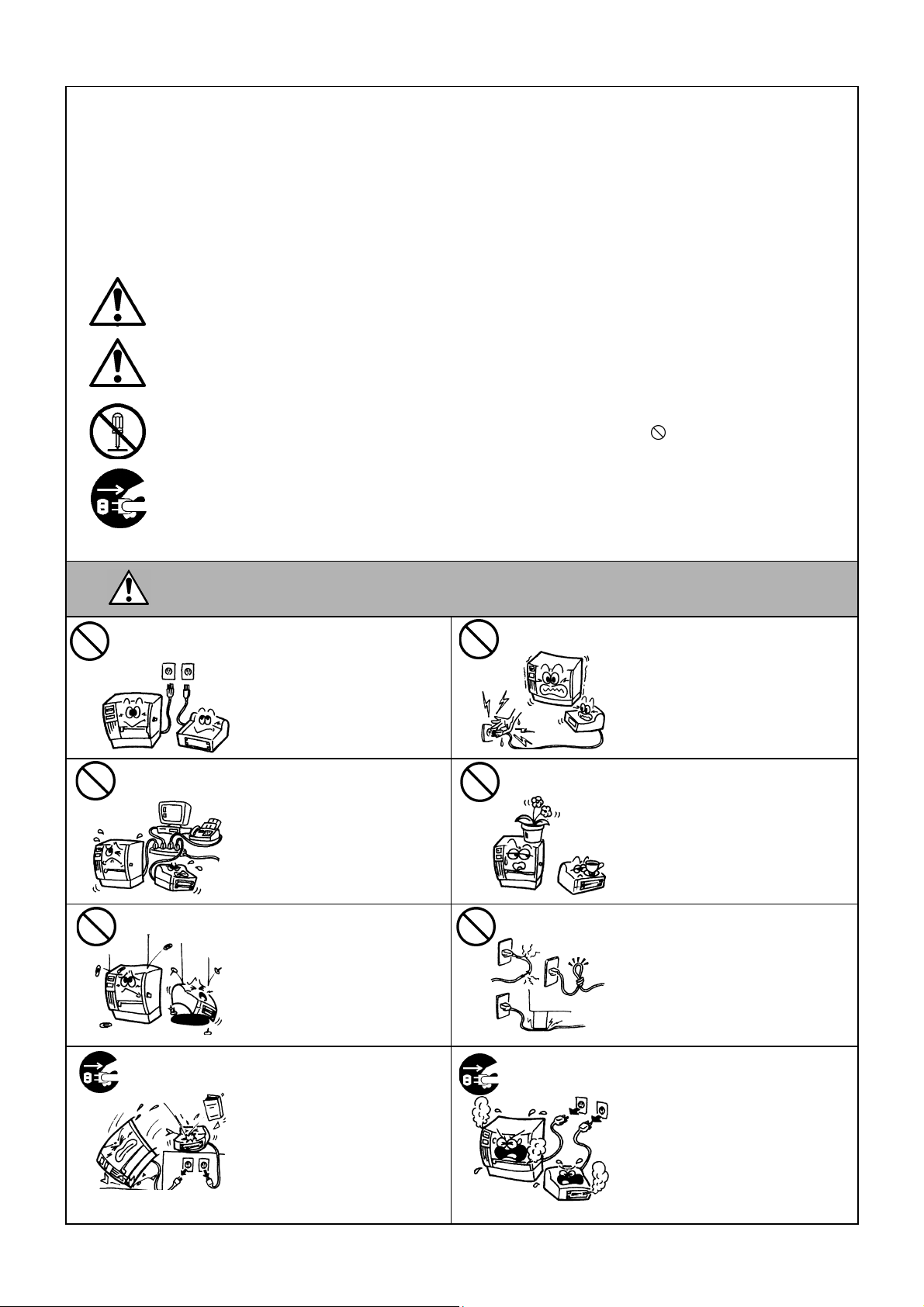

Safety Summary

Personal safety in handling or maintaining the equipment is extremely important. Warnings and Cautions necessary for safe

handling are included in this manual. All warnings and cautions contained in this manual should be read and understood

before handling or maintaining the equipment.

Do not attempt to effect repairs or modifications to this equipment. If a fault occurs that cannot be rectified using the

procedures described in this manual, turn off the power, unplug the machine, and then contact your authorised TOSHIBA

TEC CORPORATION representative for assistance.

Meanings of Each Symbol

This symbol indicates a potentially hazardous situation which, if not avoided, could

result in death, serious injury, or serious damage, or fire in the equipment or surrounding

objects.

This symbol indicates a potentially hazardous situation which, if not avoided, may result

in minor or moderate injury, partial damage to the equipment or surrounding objects, or

loss of data.

This symbol indicates prohibited actions (prohibited items).

Specific prohibited contents are drawn inside or near the

(The symbol on the left indicates “no disassembling”.)

symbol.

This symbol indicates actions which must be performed.

Specific instructions are drawn inside or near the symbol.

(The symbol on the left indicates “disconnect the power cord plug from the outlet”.)

ARNING

CAUTION

PROHIBITED

MUST be

Performed

NOTE: Indicates information to which you should pay attention when operating the manual.

Any other than the

specified AC voltage

is prohibited.

Prohibited

Prohibited

ARNING

Do not use voltages other than the

AC voltage specified on the rating

plate, as this may cause fire or

electric shock.

If the machine share the same

electrical outlet with any other

appliance that consumes a large

amount of power, the voltage will

fluctuate widely each time these

appliances operate. Be sure to

provide an exclusive outlet for the

machine as this may cause fire or

electric shock.

Do not insert or drop metal,

flammable or other foreign objects

into the machine through the

ventilation slits, as this may cause

fire or electric shock.

This indicates that there is the risk of death or serious injury if the

machine is improperly handled contrary to this indication.

Prohibited

Prohibited

Prohibited

Do not plug in or unplug the power

cord with wet hands as this may cause

electric shock.

Do not place metal objects or waterfilled containers such as flower vases,

flower pots or mugs, etc. on top of the

machine. If metal objects or spilled

liquid enter the machine, this may

cause fire or electric shock.

Do not scratch, damage or modify the

power cords. Also, do not place heavy

objects on, pull on, or excessively bend

the power cords, as this may cause fire

or electrical shock.

Disconnect

the plug.

If the machine is dropped or their

cabinet damaged, first turn off the

power switch and disconnect the

power cord plug from the outlet,

and then contact your authorised

TOSHIBA TEC CORPORATION

representative for assistance.

Continued use of the machine in

that condition may cause fire or

electric shock.

Disconnect

the plug.

Continued use of the machine in an

abnormal condition such as when the

machine is producing smoke or strange

smells may cause fire or electric

shock. In these cases, immediately

turn off the power switches and

disconnect the power cord plug from

the outlet. Then, contact your

authorised TOSHIBA TEC

CORPORATION representative for

assistance.

( i )

Page 6

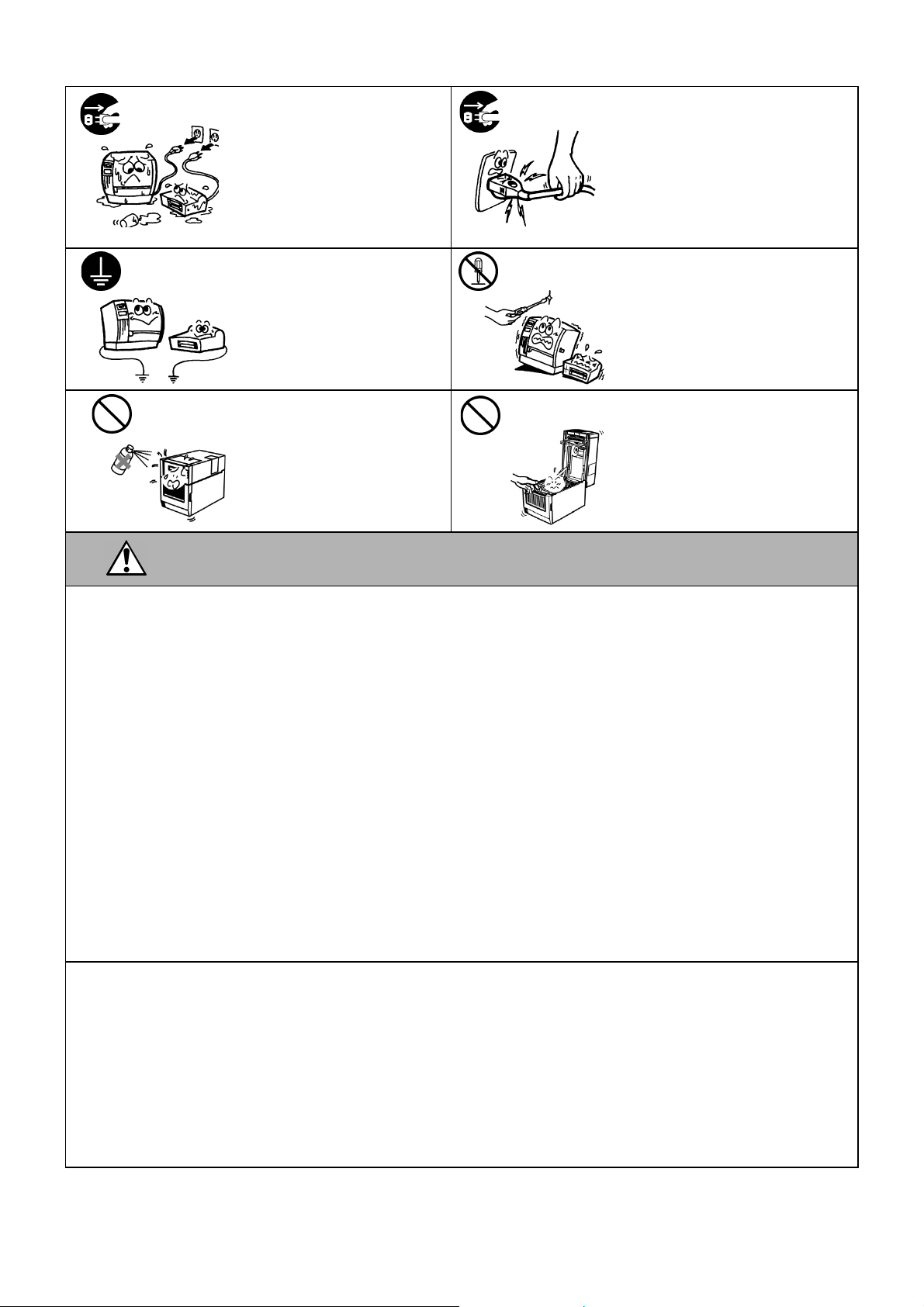

Safety Precautions ENGLISH VERSION

Disconnect

the plug.

Connect a

grounding wire.

If foreign objects (metal fragments,

water, liquids) enter the machine,

turn off the power switch and

disconnect the power cord plug

from the outlet, and then contact

your authorised TOSHIBA TEC

CORPORATION representative

for assistance. Continued use of

the machine in that condition may

cause fire or electric shock.

Ensure that the equipment is

properly grounded. Extension

cables should also be grounded.

Fire or electric shock could occur

on improperly grounded

equipment.

Disconnect

the plug.

No

disassembling.

When unplugging the power cords, be

sure to hold and pull on the plug.

Pulling on the cord may cut or expose

the internal wires and cause fire or

electric shock.

Do not remove covers, repair or

modify the machine by yourself.

Contact your authorised TOSHIBA

TEC CORPORATION representative

for assistance. You may be injured by

high voltage, very hot parts or sharp

edges inside the machine.

Prohibited

Do not use a spray cleaner

containing flammable gas for

cleaning this product, as this may

cause a fire.

Prohibited

Care must be taken not to injure

yourself with the printer paper cutter.

This indicates that there is the risk of personal Injury or damage to objects if the

CAUTION

machine is improperly handled contrary to this indication.

Precautions

The following precautions will help to ensure that this machine will continue to function correctly.

Try to avoid locations that have the following adverse conditions:

* Temperatures out of the specification * Direct sunlight * High humidity

* Shared power source * Excessive vibration * Dust/Gas

The cover should be cleaned by wiping with a dry cloth or a cloth slightly dampened with a mild detergent solution. NEVER USE

THINNER OR ANY OTHER VOLATILE SOLVENT on the plastic covers.

USE ONLY TOSHIBA TEC CORPORATION SPECIFIED paper and ribbons.

DO NOT STORE the paper or ribbons where they might be exposed to direct sunlight, high temperatures, high humidity, dust, or

gas.

Ensure the printer is operated on a level surface.

Any data stored in the memory of the printer could be lost during a printer fault.

Try to avoid using this equipment on the same power supply as high voltage equipment or equipment likely to cause mains

interference.

Unplug the machine whenever you are working inside it or cleaning it.

Keep your work environment static free.

Do not place heavy objects on top of the machine, as these items may become unbalanced and fall causing injury.

Do not block the ventilation slits of the machine, as this will cause heat to build up inside the machine and may cause fire.

Do not lean against the machine. It may fall on you and could cause injury.

Unplug the machine when it is not used for a long period of time.

Place the machine on a stable and level surface.

RISK OF EXPLOSION IF BATTERY IS REPLACED BY AN INCORRECT TYPE. DISPOSE OF USED BATTERIES

ACCORDING TO THE INSTRUCTIONS.

Request Regarding Maintenance

Utilize our maintenance services.

After purchasing the machine, contact your authorised TOSHIBA TEC CORPORATION representative for assistance once a year

to have the inside of the machine cleaned. Dust will build up inside the machine and may cause a fire or a malfunction. Cleaning is

particularly effective before humid rainy seasons.

Our preventive maintenance service performs periodic checks and other work required to maintain the quality and performance of

the machine, preventing accidents beforehand.

For details, please consult your authorised TOSHIBA TEC CORPORATION representative.

Using insecticides and other chemicals

Do not expose the machine to insecticides or other volatile solvents. This will cause the cabinet or other parts to deteriorate and

may cause the paint to peel.

( ii )

Page 7

ENGLISH VERSION EO1-33097

TABLE OF CONTENTS

Page

1. PRODUCT OVERVIEW .......................................................................................................... E1-1

1.1 Introduction .................................................................................................................... E1-1

1.2 Features ........................................................................................................................ E1-1

1.3 Unpacking ...................................................................................................................... E1-1

1.4 Accessories .................................................................................................................. E1-1

1.5 Appearance ................................................................................................................... E1-3

1.5.1 Dimensions ................................................................................................................. E1-3

1.5.2 Front View .................................................................................................................. E1-3

1.5.3 Rear View ................................................................................................................... E1-4

1.5.4 Interior ........................................................................................................................ E1-4

1.5.5 Button and Indicator Lamp ......................................................................................... E1-5

2. PRINTER SETUP ................................................................................................................... E2-1

2.1 Precautions .................................................................................................................... E2-1

2.2 Procedure before Operation .......................................................................................... E2-2

2.3 Turning the Printer ON/OFF .......................................................................................... E2-2

2.3.1 Turning ON the Printer ............................................................................................... E2-2

2.3.2 Turning OFF the Printer .............................................................................................. E2-3

2.4 Connecting Cables to the Printer ................................................................................... E2-4

2.5 Connecting the Power Adapter and the Power Cord ..................................................... E2-5

2.6 Opening/Closing the Top Cover .................................................................................... E2-6

2.7 Loading the Media ......................................................................................................... E2-7

2.8 Media Sensor Calibration, Self Print Test, and Dump Mode Utilities ........................... E2-15

2.8.1 Media Sensor Calibration ......................................................................................... E2-15

2.8.2 Self Print Test and Dump Mode ................................................................................ E2-16

3. MAINTENANCE ..................................................................................................................... E3-1

3.1 Cleaning ........................................................................................................................ E3-1

3.1.1 Print Head .................................................................................................................. E3-1

3.1.2 Sensors ...................................................................................................................... E3-2

3.1.3 Platen Roller ............................................................................................................... E3-2

3.1.4 Media Housing ............................................................................................................ E3-3

3.2 Care/Handling of the Media ........................................................................................... E3-4

4. TROUBLESHOOTING ........................................................................................................... E4-1

4.1 Troubleshooting Guide .................................................................................................. E4-1

4.2 Status Lamp .................................................................................................................. E4-2

4.3 Removing Jammed Media ............................................................................................. E4-3

APPENDIX 1 SPECIFICATIONS ................................................................................................ EA1-1

A1.1 Printer .......................................................................................................................... EA1-1

A1.2 Options ........................................................................................................................ EA1-3

A1.3 Media ........................................................................................................................... EA1-3

A1.3.1 Media Type ........................................................................................................... EA1-3

A1.3.2 Detection Area of the Feed Gap (Transmissive) Sensor ....................................... EA1-5

A1.3.3 Detection Area of the Black Mark (Reflective) Sensor .......................................... EA1-5

A1.3.4 Effective Print Area ............................................................................................... EA1-5

APPENDIX 2 INTERFACE .......................................................................................................... EA2-1

GLOSSARIES

Page 8

ENGLISH VERSION EO1-33097

NOTES:

• This manual may not be copied in whole or in part without prior written permission of TOSHIBA TEC

CORPORATION.

• The contents of this manual may be changed without notification.

• Please refer to your local Authorized Service representative with regard to any queries you may have in this

manual.

• Centronics is a registered trademark of Centronics Data Computer Corp.

• Windows is a registered trademark of Microsoft Corporation.

Page 9

1. PRODUCT OVERVIEW ENGLISH VERSION EO1-33097

1. PRODUCT OVERVIEW

1.1 Introduction

1.2 Features

1.3 Unpacking

1.4 Accessories

Thank you for choosing the TOSHIBA B-FV4D series barcode printer.

This Owner’s Manual contains valuable information from general set-up

to confirming the printer's operation using test prints. You should read it

carefully to help you gain maximum performance and life from your

printer. This manual should be kept close at hand for everyday reference.

Please contact your TOSHIBA TEC CORPORATION representative for

further information concerning this manual.

This printer has the following features:

Interfaces

The printer comes fitted with a USB port and Ethernet port interfaces as

standard. Moreover, it contains either a Serial (RS-232C) or a Centronics

interface

Bluetooth can be installed.

*1The Centronics interface provided for this printer does not support bi-

directional communications.

Easy to use

The printer mechanism is designed to allow very easy operation and easy

access for maintenance.

Flexible hardware

Sharp clear print can be produced by an 8 dots/mm (203 dpi) (in the BFV4D-GS) print head at speeds up to 152.4 mm/sec. (6 inches/sec.) or an

11.8 dots/mm (300 dpi) (in the B-FV4D-TS) print head at speeds up to

101.6 mm/sec. (4 inches/sec.)

Full range of options

The printer can also be fitted with the following optional devices:

•Cutter Module •External Media Stand

•Peel-off Module •Wireless LAN Interface

•Bluetooth Interface

1. Unpack the printer.

2. Check for damage or scratches on the printer. However, please note

that TOSHIBA TEC CORPORATION shall have no liability for any

damage of any kind sustained during transportation of the product.

3. Keep the carton and internal packaging for future transportation of the

printer.

When unpacking the printer, please check that the following accessories

are supplied with the printer.

CD-ROM (1 copy)

Power Adapter (1 pc.)

Quick Installation Manual (1 copy)

Safety Precautions (1 copy)

USB Cable (1 pc.)

1.1 Introduction

1

*

depending on the model, and thus either Wireless LAN or

E1- 1

Page 10

1. PRODUCT OVERVIEW ENGLISH VERSION EO1-33097

gdom

1.4 Accessories

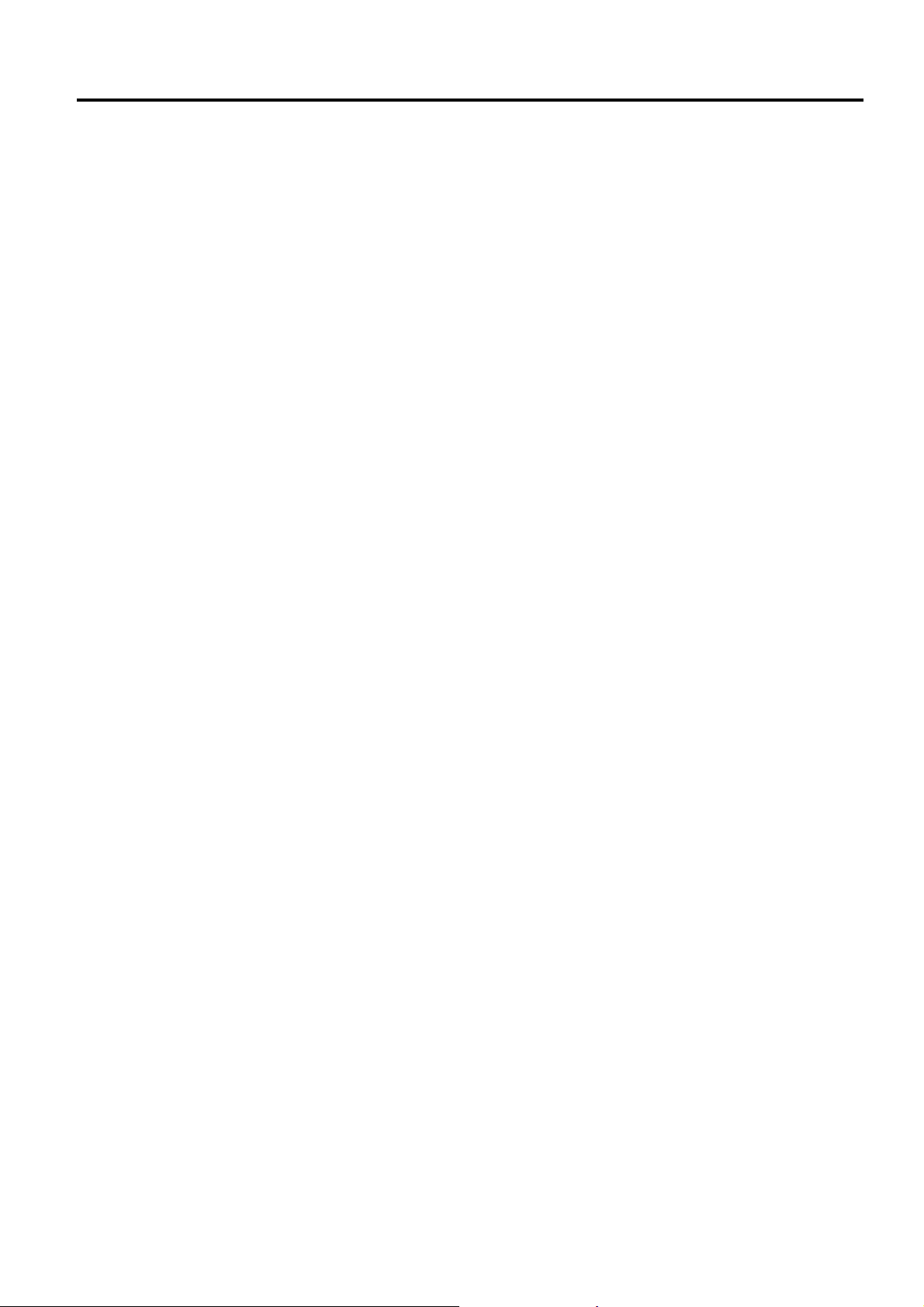

When you need to purchase a power cord

In some countries the power cord is not provided with this unit, if this is the case then please purchase an

approved one that meets the following standards or contact your authorised TOSHIBA TEC CORPORATION

representative.

(As of Oct. 2014)

Country Agency

Australia SAA Germany VDE Sweden SEMKKO

Austria OVE

Belgium CEBEC

Canada CSA

Certification

mark

Country Agency Certification mark Country Agency

Ireland NSAI

Italy IMQ

Japan METI

Switzerland SEV

UK ASTA

UK BSI

Certification

mark

Denmark DEMKO

Finland FEI

France UTE

Netherlands KEMA

Norway NEMKO

Spain AEE

U.S.A. UL

Europe HAR

China CCC

Power Cord Instruction

1. For use with 100 – 125 Vac mains power supply, please select a power cord rated Min. 125V, 10A.

2. For use with 200 – 240 Vac mains power supply, please select a power cord rated Min. 250V.

3. Please select a power cord with the length of 2m or less.

4. The power cord plug connected to the AC adapter must be able to be inserted into an ICE-320-C14 inlet. Refer to the

following figure for the shape.

Country/Region North America Europe

Power Cord

Rated (Min.)

Type

Conductor size

125V, 10A

SVT

No. 3/18AWG

250V

H05VV-F

3 x 0.75 mm

(Min.)

Plug Configuration

(locally approved

type)

Rated (Min.)

125V, 10A

250V, 10A

*1: At least, 125% of the rated current of the product.

2

United

Kin

250V

H05VV-F

3 x 0.75 mm

250V, *1

250V

AS3191 approved,

Light or Ordinary Duty type

2

3 x 0.75 mm2

250V, *1

Australia China

250V

GB5023

3 x 0.75 mm

250V, *1

2

E1- 2

Page 11

1. PRODUCT OVERVIEW ENGLISH VERSION EO1-33097

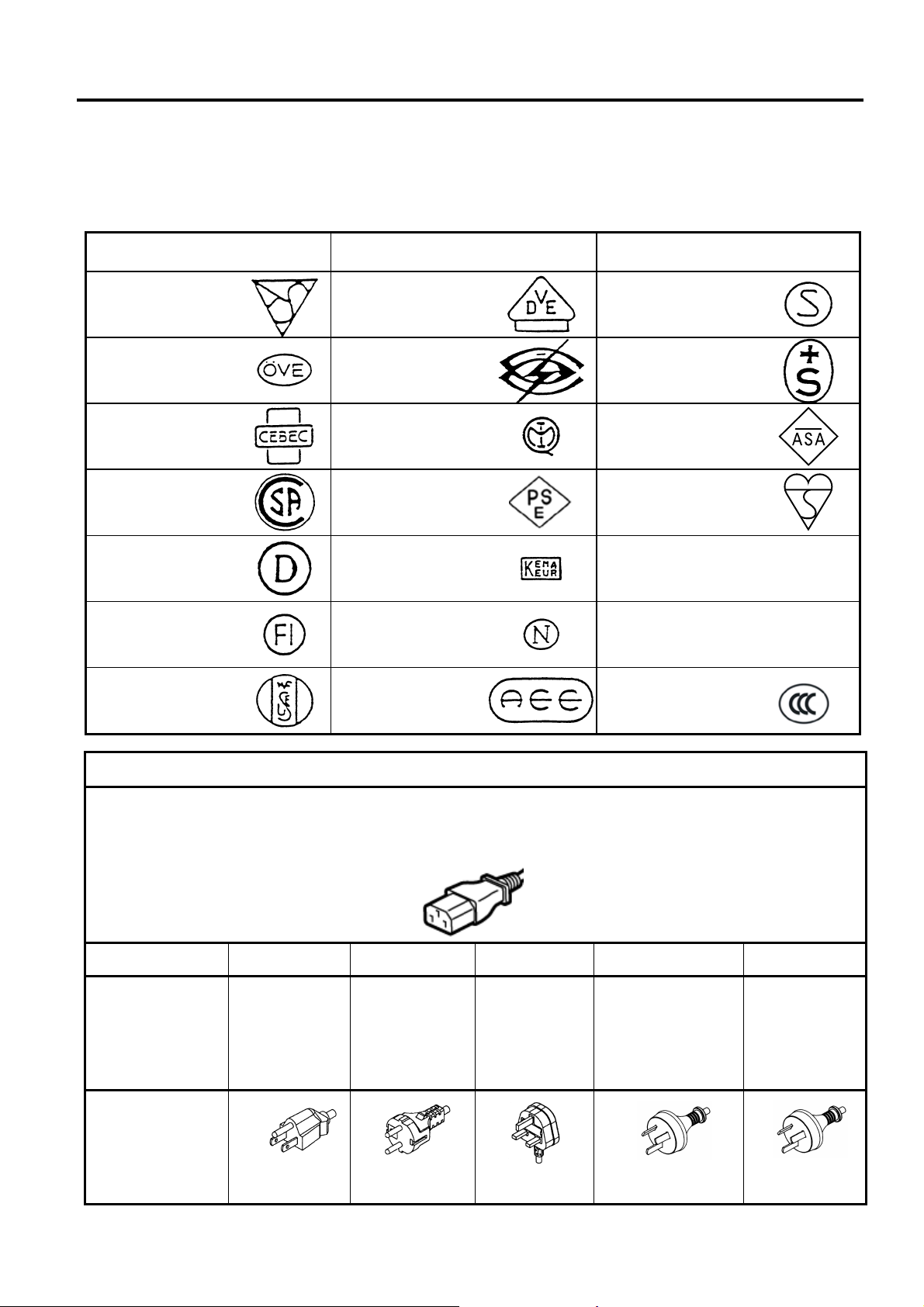

1.5 Appearance

1.5.1 Dimensions

1.5.2 Front View

1.5 Appearance

The parts and units shown and named in this section are used for

descriptions in the following chapters.

W: 183.8 (7.2”) x D: 226.2 (8.9”) x H: 166.0 (6.5”)

Dimensions in mm (inches)

Media Outlet

LED 2

LED 1

Media View Window

FEED Button

E1- 3

Page 12

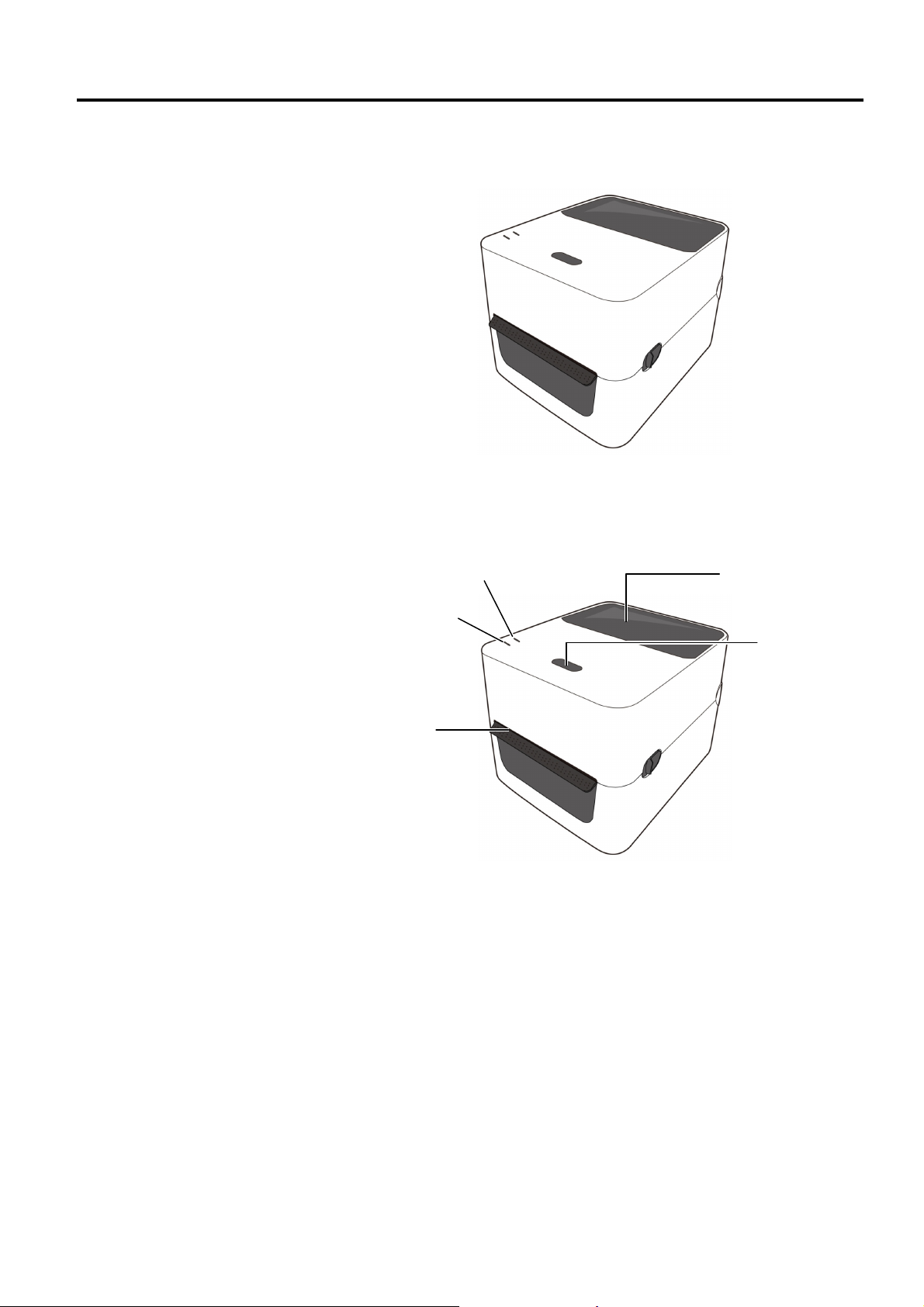

1. PRODUCT OVERVIEW ENGLISH VERSION EO1-33097

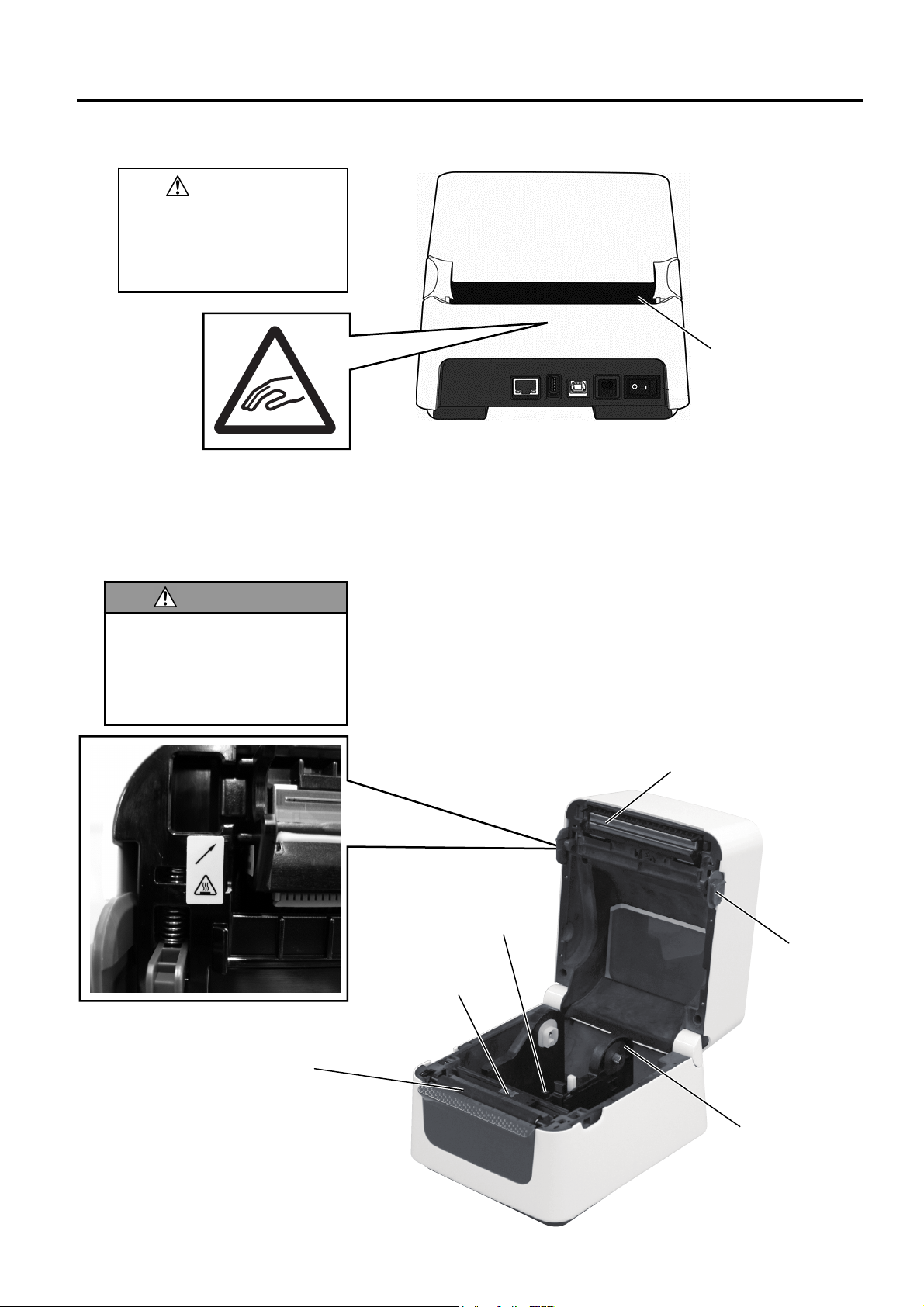

1.5.3 Rear View

To avoid injury, be careful

not to trap your fingers in the

Paper Slot while opening or

closing the Top Cover.

CAUTION!

1.5.4 Interior

The print head becomes very

hot during printing. Do not

touch the print head or touch

around it directly after printing.

By doing so you may get burnt.

WARNING!

Platen Roller

1.5 Appearance

For details of the rear view, refer to Section 2.4 Connecting the Cables

to the Printer.

Media Guides

Media Sensor

Paper Slot

Print Head

Lock Release

Portions

E1- 4

Media Roll Holders

Page 13

1. PRODUCT OVERVIEW ENGLISH VERSION EO1-33097

b

t

t

1.5.5 Button and Indicator Lamp

The [FEED] button has three functions. It can operate as a FEED,

RESTART or PAUSE button depending on current the printer state.

As a FEED

utton

As a RESTART

button

As a PAUSE

button

Pressing this button when the printer is online will cause

the media to feed forwards.

Pressing this button after removing the cause of an error

returns the printer to an online state.

Pressing this button with the printer is paused will resume

printing.

Pressing this button while the printer is printing will stop

the printing after completing the current label. The printer

is then paused.

The indicator lamps (LED1 and LED 2) light up or flash in different

colors and sequences depending on the printer status. A quick guide to

lamp statuses and their meaning is shown inside the top cover.

LED 1 LED 2 Printer Status

Unlit Unlit

Green Unli

Green S Unlit

F

Green

Green Green

Green Green

Orange Green A paper jam occurred.

Orange Red The media has ended.

Orange Red

Red Red

Red Orange

Red Green

Red Green

Red Green

Red Green

Red Orange

F: Flashes fast (0.5 sec)

M: Flashes at medium speed (1.0 sec)

S: Flashes slowly (2.0 sec)

Unli

M

F

M

F

S

M

F

M

1.5 Appearance

The power is off.

The print head block is open if the

printer power is on.

Stand-by

Printing is temporarily stopped

(paused).

Communicating with a host

Writing data to the flash or USB

memory

The Flash ROM on the CPU board or

USB memory is being initialized.

The media has ended while the print

data is being sent to the printer.

Thermal Head open error. The thermal

head has been opened during an

operation.

The print head temperature exceeded

the upper limit.

A communication error occurred.

(Only when the RS-232C is used.)

Command error

Flash ROM on the CPU board error,

or USB memory error

An erase error while formatting the

Flash ROM on the CPU board or

USB memory

Unable to save files due to

insufficient storage space on the

Flash ROM on the CPU board or

USB memory.

A paper jam occurred in the cutter unit.

(Only when the cutter unit is fitted.)

The print head is broken.

E1- 5

Page 14

2. PRINTER SETUP ENGLISH VERSION EO1-33097

2. PRINTER SETUP

2.1 Precautions

Avoid using the printer in

the locations where it is

subjected to intense light

(e.g. direct sunlight, desk

light). Such light may affect

the sensors of the printer,

causing malfunctions.

CAUTION!

This section outlines the steps necessary to setup your printer prior to its

operation. The section includes precautions, connecting cables,

assembling accessories, loading media, and performing a test print.

To insure the best operating environment, and to assure the safety of the

operator and the equipment, please observe the following precautions.

Operate the printer on a stable, level, operating surface in a location

Keep your work environment static free. Static discharges can cause

Make sure that the printer is connected to a clean source of AC Power

Ensure that the printer is connected only to AC mains that has a

Do not operate the printer with the cover open. Be careful not to

2.1 Precautions

free from excessive humidity, high temperature, dust, vibration or

direct sunlight.

damage to delicate internal components.

and that no other high voltage devices that may cause line noise

interference are connected to the same mains.

proper ground (earth) connection.

allow fingers or articles of clothing to get caught into any of the

moving parts of the printer.

Make sure to turn off the printer power and to remove the power

adapter connector from the printer whenever working on the inside of

the printer or when cleaning the printer.

For best results, and longer printer life, use only TOSHIBA TEC

CORPORATION recommended media. (Refer to the Supply Manual.)

Store the media in accordance with the specifications.

This printer mechanism contains high voltage components; therefore

you should never remove any of the covers of the machine as you may

receive an electrical shock. Additionally, the printer contains many

delicate components that may be damaged if accessed by unauthorised

personnel.

Clean the outside of the printer with a clean dry cloth or a clean cloth

slightly dampened with a mild detergent solution.

Use caution when cleaning the thermal print head as it may become

very hot while printing. Wait until it has had time to cool before

cleaning.

Use only the TOSHIBA TEC CORPORATION recommended print

head cleaner to clean the print head.

Do not turn off the printer power or remove the power plug while the

printer is printing or while the Indicator Lamp is flashing.

The socket-outlet needs to be installed near the equipment and must

be easily accessible.

Pull out the plug from the outlet more than once a year to clean around

the prongs. Accumulating dust and dirt could cause a fire due to the

heat released by electric leakage.

E2-1

Page 15

2. PRINTER SETUP ENGLISH VERSION EO1-33097

f

2.2 Procedure before

Operation

1. To be able to communicate with

a host computer, an RS-232C,

Centronics, Ethernet, or USB

cable connection is required.

(1) RS-232C cable: 9 pins

(do not use a null modem

cable)

(2) Centronics cable: 36 pins

(3) Ethernet cable: 10/100 Base

(4) USB cable: V2.0 (Full Speed)

2. Use of the Windows Driver will

enable printing from Windows

applications.

The printer can also be controlled

with its own programming

commands. For details, please

contact your TOSHIBA TEC

CORPORATION representative.

NOTES:

2.3 Turning the Printer ON/OFF

2.3.1 Turning ON the Printer

Use the power switch to

turn the printer on/off.

Plugging or unplugging the

power cord to turn the

printer on/off may cause

fire, an electric shock, or

damage to the printer.

CAUTION!

2.2 Procedure before Operation

This section describes the steps needed to setup the printer correctly.

1. Unpack the printer and its accessories from the box.

2. Place the printer where it is to be used referring to Safety

Precautions supplied with the printer for tips on the correct use and

placement.

3. Make sure that the Power Switch is off. (Refer to Section 2.3.)

4. Connect the printer to a host computer or network using an RS-232C,

Centronics, Ethernet or USB cable. (Refer to Section 2.4.)

5. Connect the Power Adapter to the printer, and then plug the Power

Cord into a properly grounded power outlet. (Refer to Section 2.5)

6. Load the media. (Refer to Section 2.7.)

7. Adjust the position of the Feed Gap Sensor or Black Mark Sensor to

match the media being used. (Refer to Section 2.7.)

8. Install the Printer Driver on the host computer. (Refer to the Printer

Driver on the CD-ROM.)

9. Turn the Power ON. (Refer to Section 2.3.)

When the printer is connected to a host computer it is good practice to

turn the printer ON before turning on the host computer and to turn OFF

the host computer before turning off the printer.

1. To turn ON the printer power, press the power switch as shown in the

diagram below. Note that ( | ) is the power ON side of the switch.

Power Switch

NOTE:

the LED 1 or 2 is illuminated in

I

red, go to Section 4.1,

Troubleshooting Guide.

2. As the printer powers on LED 1 and 2 will lite first in orange then off

and finally LED 1 should stay illuminated in green.

E2-2

Page 16

2. PRINTER SETUP ENGLISH VERSION EO1-33097

2.3.2 Turning OFF the Printer

1. Do not turn off the printer

power while the printer is

printing as this may cause

a paper jam or damage to

the printer.

2. Do not turn off the printer

power while LED 1 is

flashing as this may lead to

loss or corruption of the

data being downloaded.

CAUTION!

2.3 Turning the Printer ON/OFF

1. Before turning off the printer power switch, verify that: LED 1 is

illuminated in green (not flashing) and LED 2 is extinguished.

2. To turn OFF the printer power, press the power switch as shown in the

diagram below. Note that ( ) is the power OFF side of the switch.

Power Switch

E2-3

Page 17

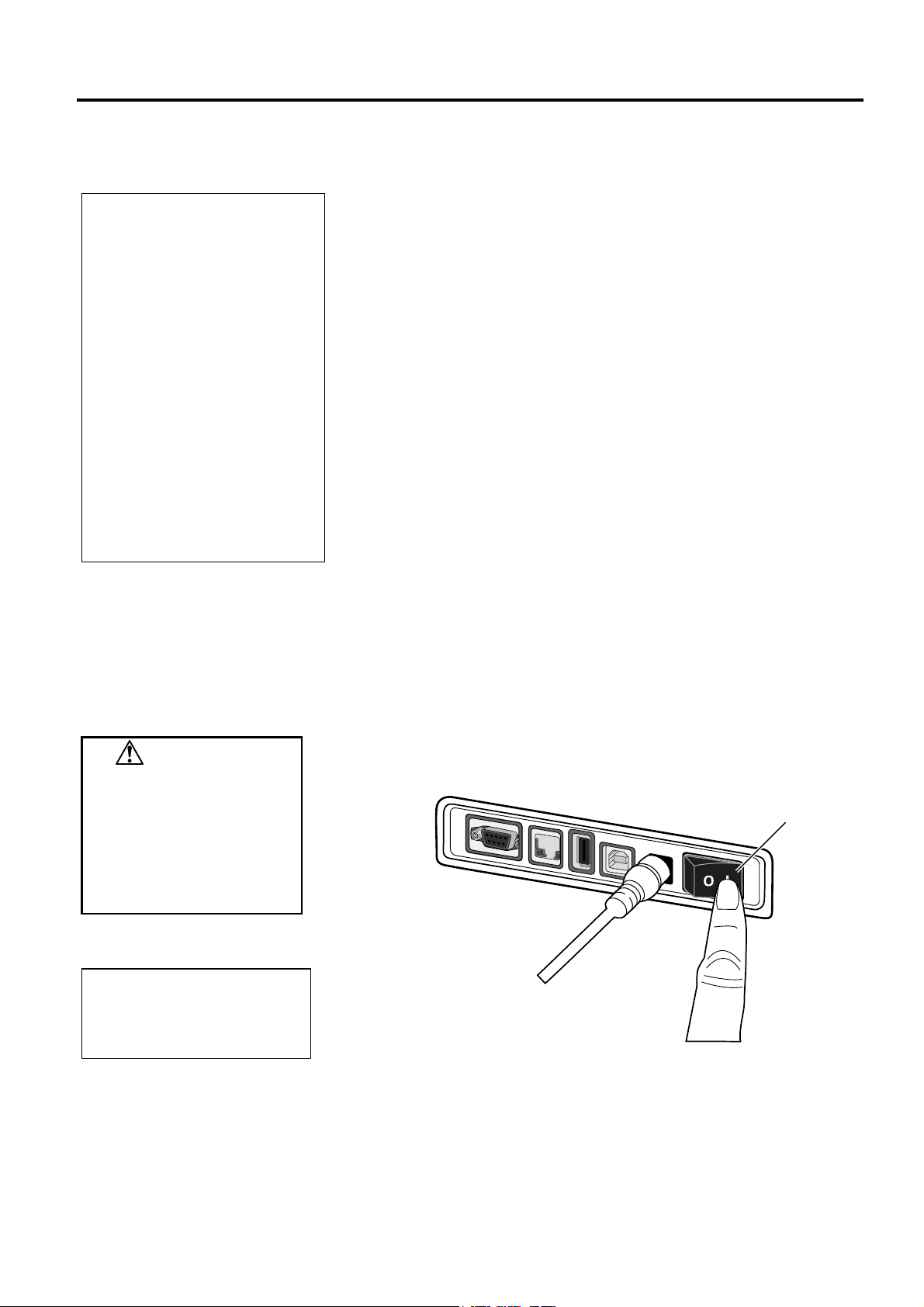

2. PRINTER SETUP ENGLISH VERSION EO1-33097

2.4 Connecting Cables to the Printer

Be sure to connect the serial

or parallel cable while the

printer and the host computer

are in a powered-off state.

Failure to do this may cause

electric shocks, short-circuits,

or damage to the printer or

Host computer.

For the specifications of the

serial interface cable, refer to

APPENDIX 2, INTERFACE.

Power Switch

Power Jack

USB Interface for connecting a host

USB Interface for connecting a USB

Ethernet Interface

Serial Interface (RS-232C)*

Parallel Interface (Centronics)

CAUTION!

NOTE:

computer

memory

* Some models have no serial

interface (RS-232C).

2.4 Connecting the Cables to the Printer

This section details how to connect communication cables to the printer

from your host computer or other devices. There are four different means

of connection that can be used on the printer. These are:

An Ethernet cable connection can be used to connect to a network

or directly to your host computer’s Ethernet port.

NOTE:

▪ Use an Ethernet cable conforming to the standard.

10BASE-T: Category 3 or greater

100BASE-TX: Category 5 or greater

Cable length: Up to 100 m segment length

▪ In some environments communication errors may be caused by

electromagnetic interference on the cable. If this occurs you

may need to use a shielded cable (STP).

A USB cable connection between the printer’s USB interface port

and one of your host computer’s USB ports.

NOTE:

▪ When disconnecting the USB cable from the host computer,

follow the “Safely remove hardware” procedure on the host

computer.

▪ Use a USB cable conforming to V2.0 or greater and with a Type

B plug on one end.

A serial cable connection between the printer’s RS-232C serial

port and one of your host computer’s COM ports.

A parallel cable connection between the printer’s standard parallel

port and your host computer’s parallel port (LPT).

The diagrams below show all the possible cable connections to the

current versions of the printer.

Printer having the USB and Ethernet Interfaces

Printer having the Serial Interface (RS-232C)

Printer having the Parallel Interface (Centronics)

E2-4

Page 18

2. PRINTER SETUP ENGLISH VERSION EO1-33097

2.5 Connecting the Power Adapter and the Power Cord

1. If a power cord is not provided

with this printer, please

purchase the correct one

referring to page 1-2.

2. The EA1050B-240 AC adapter

should be exclusively used for

the B-FV4D-xxxx-QM-R

Series printer. The B-FV4Dxxxx-QM-R Series printer

must be powered by the

EA1050B-240 AC adapter.

3. The EA10681P-240 AC

adapter should be exclusively

used for the B-FV4D-xxxxQQ-R Series printer. The BFV4D-xxxx-QQ-R Series

printer must be powered by

the EA10681P-240 AC

adapter.

NOTES:

2.5 Connecting the Power Adapter and the Power Cord

1. Make sure that the printer power switch is in the OFF (O) position.

2. Insert the Power Cord into the inlet of the Power Adapter.

Power Cord

Power Adapter

3. Insert the Power Adapter connector into the Power Jack on the rear of

the printer.

Power Jack

Power Adapter Connector

WARNING!

The areas indicated by the ellipse have sharp edges.

To avoid injury, be careful not to touch them when handling the

printer.

E2-5

Page 19

2. PRINTER SETUP ENGLISH VERSION EO1-33097

2.6 Opening/Closing the Top Cover

WARNING!

To avoid injury, be careful

not to trap your fingers while

opening or closing the cover.

CAUTION!

1. Be careful not to touch the

Print Head Element when

opening the Top Cover.

Failure to do this may

cause missing dots by

static electricity or other

print quality problems.

2. Do not cover the Cover

Open Sensor with your

finger, hand, etc. Doing so

may cause the sensor to

wrongly detect a cover

close state.

NOTE:

Be sure to close the Top Cover

completely. Failure to do this

may affect the print quality.

Top Cover

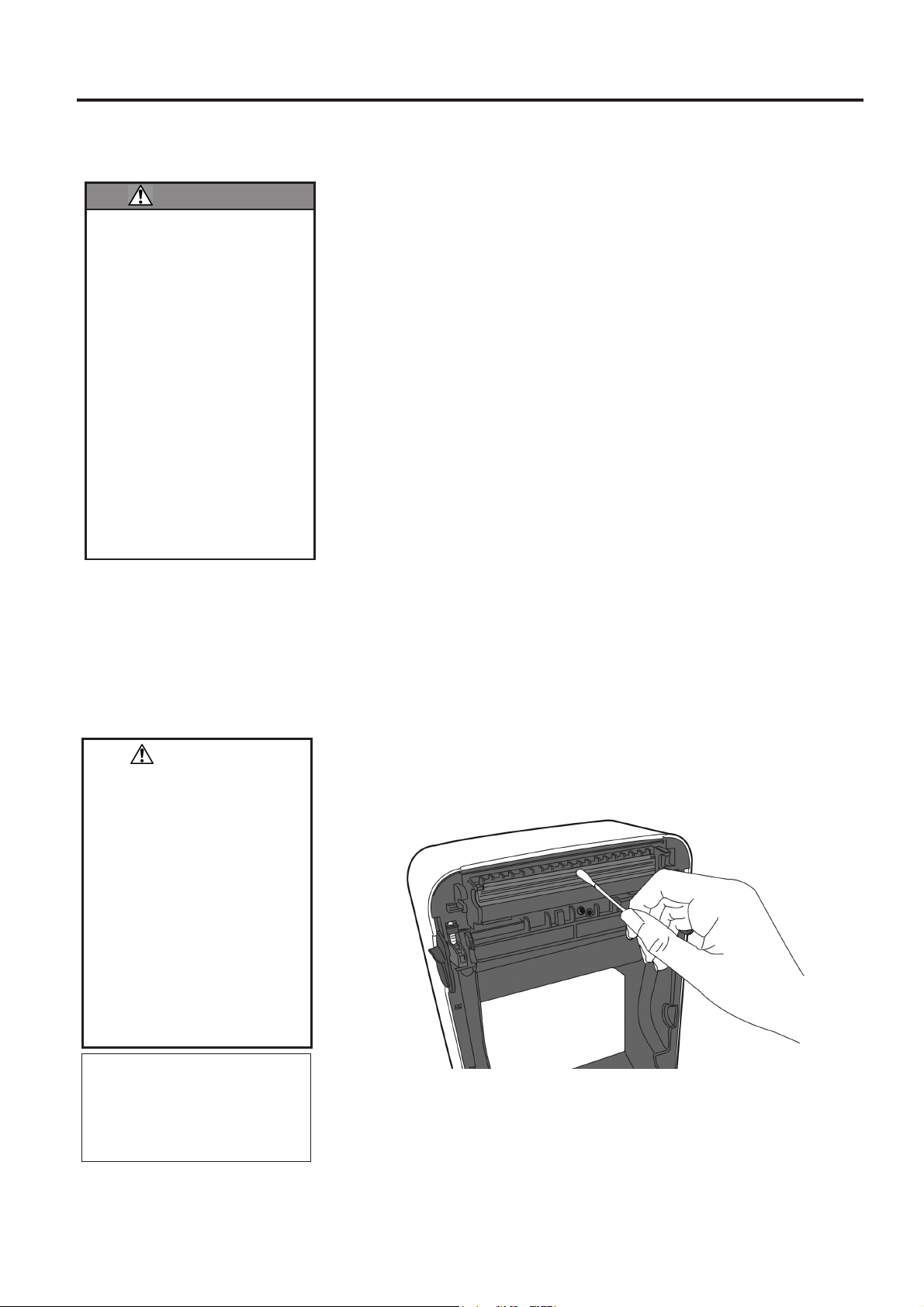

2.6 Opening/Closing the Top Cover

When opening or closing the Top Cover, please be sure to follow the

instructions below.

To open the Top Cover:

1. Open the Top Cover while pulling the Lock Release Portions as

indicated by the arrows.

Lock Release Portion

To close the Top Cover:

1. Close the Top Cover.

E2-6

Page 20

2. PRINTER SETUP ENGLISH VERSION EO1-33097

2.7 Loading the Media

1. Do not touch any moving

parts. To reduce the risk

of fingers, jewellery,

clothing, etc. being drawn

into the mechanism, be

sure to load the media

only once the printer has

completely stopped

moving.

2. To avoid injury, be careful

not to trap your fingers

while opening or closing

the Top Cover.

Be careful not to touch the

Print Head Elements when

opening the Top Cover. Doing

this may cause damage to

some of the dots through

static discharge or other print

quality problems.

WARNING!

CAUTION!

2.7 Loading the Media

This section describes how to load the media in the printer. This printer

accepts label rolls, tag rolls, and fanfold paper stocks. Please use

TOSHIBA TEC CORPORATION approved media.

NOTES:

1. Please perform a media sensor calibration whenever you change the

media type.

2. The size of the media which can be loaded inside the printer is as

follows:

Outer roll diameter: Max. 127mm (5”)

Inner core diameter: 25.4 (1”) mm or 38.1 mm (1.5”)

When the outer roll diameter exceeds 127 mm or the inner core

diameter exceeds 38.1 mm, an optional External Media Stand is

required. For details, refer to the

FV904-PH-QM-R External Media Stand

At factory shipment, the core holder size is set for 1.5” on the Media

Roll Holders. If you want to use 1” core media, detach the core

holders by loosening the thumb screws, reverse the core holders then

re-attach them with the thumb screws to the Media Roll Holders as

shown below.

Installation Manual for the B-

.

Core Holder

3. Media rolls can be wound inside or wound outside. (See the diagram

below.) Both types of media roll should be loaded so that the print

side faces up.

Outside wound Inside wound

E2-7

Page 21

2. PRINTER SETUP ENGLISH VERSION EO1-33097

r

2.7 Loading the Media

(Cont.)

1. Make sure that the print side

2. Cut the leading edge of the

NOTE: Media path

For the outside- wound media

Feed Gap Sensor

Platen

For the inside- wound media

Feed Gap Sensor

Platen

faces up.

media straight with scissors.

Black mark sensor

Black mark sensor

NOTES:

2.7 Loading the Media

1. Open the Top Cover while pulling the Lock Release Portions as

indicated by the arrows.

Top Cover

Lock Release Portion

2. Open the Media Roll Holders by pressing the Holder Lock Lever and

slide them outward. Place the media roll between the holders ensuring

that print side is facing up, then using Holder Lock Lever slide the

Media Roll Holders to clamp the media roll tightly.

Holder Lock Leve

E2-8

Page 22

2. PRINTER SETUP ENGLISH VERSION EO1-33097

2.7 Loading the Media

(Cont.)

2.7 Loading the Media

3.

Pass the media through the Media Guides. Pull the media until it reaches

the front of the printer.

Media Guide

Media Guide

E2-9

Page 23

2. PRINTER SETUP ENGLISH VERSION EO1-33097

f

2.7 Loading the Media

(Cont.)

1. The sensor type used in the last

print job is selected by default.

To change the sensor type, refer

to Section 2.8.1 Media Sensor

Calibration.

2. The Feed Gap Sensor is

positioned 6.35 mm right from

the media centre.

3. The Black Mark Sensor is

movable over the range of the

media width.

Black Mark Sensor is movable

in the full range.

Be careful not to squeeze the

media with the Media Guides.

Doing so bends the media,

which can cause a paper jam or

eed failure.

NOTES:

Feed Gap Sensor

6.35mm

NOTE:

2.7 Loading the Media

4. Check and adjust the media sensor position and select the sensor type

to be used. (Refer to Section 2.8.1.)

This printer has a Black Mark Sensor which can detect black marks

printed on the reverse side of the media, and a Feed Gap Sensor which

detects inter-label gaps. As the Feed Gap Sensor position is fixed, it is not

necessary to adjust it. When using the Black Mark Sensor, align it with

the centre of the black mark on the media. Failure to do this will disable

the detection of printed black marks, resulting in an error.

Black Mark Sensor

E2-10

Page 24

2. PRINTER SETUP ENGLISH VERSION EO1-33097

2.7 Loading the Media

(Cont.)

2.7 Loading the Media

5. Close the Top Cover, then press the [FEED] button to check the media

feeds correctly.

FEED Button

CAUTION!

To separate the printed

media from the printer in

batch mode, be sure to tear

the media off at the Media

Outlet or cut the media past

the Strip Plate. If you tear

the media off at the Print

Head by mistake, be sure to

feed one label (10 mm or

more) with the FEED Button

prior to the next issue.

Failure to do this may cause

a paper jam.

There are three issue modes available for this printer.

Batch mode:

In the batch mode, the media is continuously printed and fed until the

number of prints specified in the issue command has been printed.

E2-11

Page 25

2. PRINTER SETUP ENGLISH VERSION EO1-33097

2.7 Loading the Media

(Cont.)

1. When printing labels without

removing them from the backing

paper, it is not necessary to pass

the media through the Strip Block.

2. When the media is correctly set,

the backing paper should be

pinched between the Platen and

the Strip Feed Roller as shown

below.

Strip Plate

Label

Strip Feed Roller

Backing Paper

When opening the Peel-off Unit

for loading the media, be

careful not to drop metal or

other foreign objects, such as a

paper clip into the module, as

this may cause a malfunction of

the printer.

NOTES:

Platen

CAUTION!

2.7 Loading the Media

Strip mode (Option):

When printing in strip mode, labels are automatically removed from the

backing paper as each label is printed.

How to set the media

When issuing labels in the strip mode, set the label in the following

procedure:

1. Load the media as described on the previous pages.

2. Open the Peel-off Unit by pulling it out.

Peel-off Unit

3. Remove enough labels from the leading edge of the media to leave 20

cm of backing paper free, and insert the top edge of the backing paper

into the media slot in the Peel-off Unit as shown below.

4. Close the Peel-off Unit and Top Cover.

E2-12

Page 26

2. PRINTER SETUP ENGLISH VERSION EO1-33097

2.7 Loading the Media

(Cont.)

HAZARDOUS MOVING PARTS

KEEP FINGERS AND OTHER

BODY PARTS AWAY

The cutter is sharp, so care must

be taken not to injure yourself

when handling the cutter.

WARNING!

1. Be sure to cut only the backing

paper of the label. Cutting

labels will cause glue to stick to

the cutter blades which may

affect the cutter quality and

shorten the cutter life.

2. Use of tag paper which

thickness exceeds the

maximum specified value may

affect the cutter life.

When placing fanfold paper

stock at the rear of the printer,

care should be taken of the

following points.

1. Face the print surface up.

2. The fanfold paper stock is

parallel to the fanfold paper

slot.

3. The interface and power

cables do not interfere with

the feeding of the fanfold

paper.

CAUTION!

NOTE:

2.7 Loading the Media

Cut mode (Option):

When a Cutter is fitted, the media can be automatically cut. When

loading the media as described on the previous pages, insert the leading

edge of the media through the Media Outlet of the Cutter Cover while

pulling the media through the printer.

Cutter Cover

Media Outlet

How to Load Fanfold Paper Stock

1. Place the fanfold paper stock at the rear of the printer, insert the

leading edge of the paper into the Fanfold Paper Slot.

Fanfold Paper Stock

Fanfold Paper Slot

2. Refer to the previous pages to feed the fanfold paper through the

printer until it extends past the media outlet.

E2-13

Page 27

2. PRINTER SETUP ENGLISH VERSION EO1-33097

2.7 Loading the Media

(Cont.)

External Media

Stand (Option)

Fanfold Paper Slot

2.7 Loading the Media

When the media roll has an outside diameter exceeding 127 mm (5”) or

the inner core diameter is 76.2 mm (3”), the optional External Media

Stand is needed.

Remark:

Pictures below is the thermal transfer printing model of the B-FV4 series.

1. Fit the feet on the bottom of the printer as shown below.

2. Insert the Media Shaft into the core of the media roll.

3. Place it into the slots on the External Media Stand.

4. Pull the media forward and insert the leading edge into the Fanfold

Paper Slot.

Media Shaft (Option)

5. Refer to the previous pages to complete the media loading.

E2-14

Page 28

2. PRINTER SETUP ENGLISH VERSION EO1-33097

2.8 Media Sensor Calibration, Self Print Test, and Dump Mode Utilities

2.8.1 Media Sensor

Calibration

The selected sensor used in the last

print job is remembered and always

used. The factory default sensor is

the Feed Gap Sensor.

NOTE:

2.8 Media Sensor Calibration, Self Print Test, and Dump Mode Utilities

These utilities are used to calibrate the sensitivity of the Feed Gap/Black

Mark Sensor, Print out a test with details of the printer settings and set

the printer into Dump mode.

When changing from one type of media to another, it is necessary to

calibrate the media sensors.

1. Turn off the printer, make sure the media is correctly loaded, and

close the Top Cover.

Note: Do not place a pre-printed area above the media sensor, as

doing so disables correct sensor calibration.

2. Press and hold the [FEED] Button while turning on the printer.

3. Both status lights (LED 1 and LED 2) will light up in the following

order:

Orange Green Other colour sequences

4. Release the [FEED] button when LED 1 and LED 2 light to match the

sensor you want to calibrate.

Feed Gap (Transmissive) Sensor: LED 1 green, LED 2 in red.

Black Mark (Reflective) Sensor: LED 1 green, LED 2 orange.

5. Press the [FEED] button.

The printer will feed the media and perform the sensor calibration.

6. To return to Online operation, turn the printer off, then on again.

E2-15

Page 29

2. PRINTER SETUP ENGLISH VERSION EO1-33097

-

FV4D-G P

2.8.2 Self Print Test and

Dump Mode

The following commands will

have no effect the test print. D,

AX, XS, Z2;1, Z2;2 (only the AY

command will)

NOTE:

2.8 Media Sensor Calibration, Self Print Test, and Dump Mode Utilities

1. Turn off the printer power and install a full width media roll

(104mm/4inch) in the printer.

Press and hold the [FEED] Button while turning on the printer. The

2.

status lamps (LED 1 and LED 2) will light up in the following order:

Orange Green Other colour sequences

3. Release the [FEED] Button when LED 1 lights in orange and LED 2

lights in green.

4. Press the [FEED] button.

5. The printer prints the self print test, and then enters Dump Mode.

6. To return to Online operation, turn the printer off, then on again.

Print test label sample

B

PROGRAM VERSION 05MAY2014B-FV4 V1.1J

TPCL VERSION 28APR2014 V1.0K

CG VERSION 27FEB2014 V1.0

CHINESE VERSION 27FEB2014 V1.0

CODEPAGE VERSION 27FEB2014 V1.0

BOOT VERSION V1.1C

KERNEL FONT VERSION 1.0.03

WLAN MODULE [Installed]

BLUETOOTH MODULE [Installed]

[PARAMETERS]

HW DETECT [0000000000000000]

TONE ADJUST(T) [---]

TONE ADJUST(D) [+00]

FEED ADJUST [+0.0mm]

CUT ADJUST [+0.0mm]

BACKFEED ADJUST [+0.0mm]

X-COORD. ADJUST [+0.0mm]

CODEPAGE [PC-850]

ZERO SLASH [0]

FEED KEY [FEED]

EURO CODE [B0]

CONTROL CODE [AUTO]

MAXI CODE SPEC. [TYPE 1]

SENSOR SELECT [Transmissive]

PRINT SPEED [5ips]

FORWARD WAIT [ON]

AUTO CALIB. [OFF]

MULTI LABEL [OFF]

AUTO THP CHK [OFF]

BASIC [OFF]

Reserved item1

Reserved item2

FLASH ROM [16MB]

SDRAM [32MB]

USB SERIAL NUM. [000000000001]

[INFORMATION]

INFORMATION [B-FV4D-GS12-QM-R]

[2303A000006]

TOTAL FEED1 [0.00km]

TOTAL FEED2 [00000cm]

[0000.0inch]

TOTAL PRINT [0.00km]

TOTAL CUT [0]

[RS-232C]

BAUD RATE [9600]

BIT [8]

STOP BIT [1]

PARITY [None]

FLOW [XON/XOFF]

RINTER INFO.

E2-16

Page 30

2. PRINTER SETUP ENGLISH VERSION EO1-33097

2.8.2 Self Print Test and

Dump Mode (Cont.)

Printed when the Wireless LAN

interface option is installed.

Printed when the Bluetooth

interface option is installed.

2.8 Media Sensor Calibration, Self Print Test, and Dump Mode Utilities

[LAN]

IP ADDRESS [192.168.010.020]

SUBNET MASK [255.255.255.000]

GATEWAY [000.000.000.000]

MAC ADDRESS [ab-cd-ef-01-23-45]

DHCP [OFF]

DHCP CLIENT ID [FFFFFFFFFFFFFFFF]

[FFFFFFFFFFFFFFFF]

DHCP HOST NAME [ ]

[ ]

SOCKET COMM. [ON]

SOCKET PORT [8000]

[WLAN]

WLAN IP ADDRESS [192.168.10.200]

WLAN SUBNET MASK [255.255.255.000]

WLAN GATEWAY [0.0.0.0]

WLAN MAC ADRESS [00-80-92-4F-44-B]

WLAN DHCP [OFF]

WLAN DHCP HOSTNAME [00-80-92-4F-44-B]

[ E]

WLAN SOKET PORT [9100]

ESS ID [TOSHIBA_B-FV4]

[ ]

WLAN MODE [Infrastructure]

NETWORK AUTH. [OPEN]

WEP [OFF]

WEP DEFAULT KEY [1]

WPA ENCRYPTION [DISABLE]

EAP METHOD [DISABLE]

REGION CODE [USA]

CHANNEL [AUTO]

[BLUETOOTH]

DEVICE NICKNAME [B-FV4]

INQUIRY [EVERY]

ADDRESS

* The barcode printed here displays a

Bluetooth address.

Barcode

The test print content are different based on the emulation mode. The list

below is for TPCL mode.

PROGRAM VERSION ------------------------

TPCL VERSION --------------------------------

CG VERSION -----------------------------------

CHINESE VERSION--------------------------- Firmware version

CODEPAGE VERSION -----------------------

BOOT VERSION -------------------------------

KERNEL FONT VERSION -------------------

WLAN MODULE ------------------------------ WLAN module installation flag

BLUETOOTH MODULE --------------------- Bluetooth module installation flag

HW DETECT ------------------------------------ Hardware detection flag

TONE ADJUST(T) ----------------------------- Reserved parameter

TONE ADJUST(D) ----------------------------- Print tone fine adjustment value

FEED ADJUST---------------------------------- Print position fine adjustment value

CUT ADJUST ----------------------------------- Cut position fine adjustment value

E2-17

Page 31

2. PRINTER SETUP ENGLISH VERSION EO1-33097

2.8 Media Sensor Calibration, Self Print Test, and Dump Mode Utilities

BACKFEED ADJUST ------------------------- Back feed amount fine adjustment value

X-COORD. ADJUST --------------------------- X-coordinate fine adjustment value

CODEPAGE ------------------------------------- Character code selection

ZERO SLASH ----------------------------------- Font “0” selection

FEED KEY--------------------------------------- [FEED] key function setting

EURO CODE ------------------------------------ Euro code setting

CONTROL CODE ------------------------------ Control code type

MAXI CODE SPEC. --------------------------- Maxicode specification setting

SENSOR SELECT ------------------------------ Sensor type

PRINT SPEED ---------------------------------- Print Speed

FORWARD WAIT ----------------------------- Forward feed standby after issue

AUTO CALIB. ---------------------------------- Automatic calibration setting

MULTI LABEL --------------------------------- Multi label setting

AUTO TPH CHECK --------------------------- Automatic print head check for broken dots

setting

BASIC -------------------------------------------- Basic interpreter setting

Reserved item1 ---------------------------------- Reserved parameter

Reserved item2 ----------------------------------

FLASH ROM ------------------------------------ Flash ROM Capacity

SDRAM ------------------------------------------ SDRAM Capacity

USB SERIAL NUM. --------------------------- USB serial number

INFORMATION -------------------------------- Printer model name and serial number.

TOTAL FEED1 --------------------------------- Total feed distance (condition1)

TOTAL FEED2 --------------------------------- Total feed distance (condition2)

TOTAL PRINT ---------------------------------- Total Print distance

TOTAL CUT ------------------------------------ Total Cut Count

[RS-232C] ---------------------------------------- RS-232C setting value

(BAUD RATE, BIT, STOP BIT, PARITY, FLOW)

[LAN] --------------------------------------------- Network setting values

(IP ADDRESS, SUBNET MASK, GATEWAY, MAC ADDRESS, DHCP, DHCP

CLIENT ID, SOCKET COMM., SOCKET PORT)

[WLAN] ------------------------------------------ Network setting values

(WLAN IP ADDRESS, WLAN SUBNET MASK, WLAN GATEWAY, WLAN MAC

ADRESS, WLAN DHCP, WLAN DHCP HOSTNAME, WLAN SOKET PORT, ESS

ID, WLAN MODE, NETWORK AUTH., WEP, WEP DEFAULT KEY, WPA

ENCRYPTION, EAP METHOD, REGION CODE, CHANNEL)

[BLUETOOTH] --------------------------------- Network setting values

(DEVICE NICKNAME, INQUIRY, ADDRESS

*

ADDRESS (Bluetooth address) is displayed with a barcode.

*

)

E2-18

Page 32

3. MAINTENANCE ENGLISH VERSION EO1-33097

3. MAINTENANCE

1. Be sure to turn OFF the

2. To avoid injury, be careful

3. Be careful when handling

4. Do not pour water directly

3.1 Cleaning

3.1.1 Print Head

1. Do not allow any hard

objects to touch the print

head or platen, as this may

cause damage to them.

2. Do not use any volatile

solvents including thinner

and benzene, as this may

cause discoloration of the

cover, print failure, or

breakdown of the printer.

3. Do not touch the print head

element with bare hands,

as static may damage the

print head.

WARNING!

power before performing

any maintenance. Failure

to do this may cause an

electric shock.

not to trap your fingers

while opening or closing

the cover.

the print head as it

becomes very hot during

printing. Allow it to cool

before performing any

maintenance.

onto the printer.

CAUTION!

3.1 Cleaning

This chapter details the routine maintenance procedures.

To ensure the continuous high quality operation of your printer, you

should regularly perform these maintenance routines. Where the printer is

intensively used (high throughput) it should be done on a daily basis.

Where the printer is not intensively used (low throughput) it should be

done on a weekly basis.

To maintain the printer performance and print quality, please clean the

printer regularly, or whenever the media is replaced.

1. Turn the power off.

2. Open the Top Cover.

3. Clean the Print Head Element with a Print Head Cleaner, cotton swab

or soft cloth slightly moistened with ethyl alcohol.

NOTE:

Print Head Cleaners can be

purchased from your authorised

TOSHIBA TEC CORPORATION

service representative.

E3- 1

Page 33

3. MAINTENANCE ENGLISH VERSION EO1-33097

3.1.2 Sensors

3.1.3 Platen Roller

3.1 Cleaning

1. Wipe the media sensors with a soft cloth or a cotton swab lightly

moistened with absolute (pure) ethyl alcohol.

2. To remove dust or paper particles wipe the media sensors with a dry

soft cloth.

Wipe the platen roller with a soft cloth moistened with absolute (pure) ethyl

alcohol.

E3- 2

Page 34

3. MAINTENANCE ENGLISH VERSION EO1-33097

3.1.4 Media Housing

3.1 Cleaning

Wipe the media housing with a dry soft cloth. Wipe off dirt with a soft cloth

slightly moistened with mild detergent solution.

E3- 3

Page 35

3. MAINTENANCE ENGLISH VERSION EO1-33097

3.2 Care/Handling of the Media

CAUTION!

Be sure to carefully review and

understand the Supply

Manual. Use only media

which meet specified

requirements. Use of nonspecified media may shorten

the head life and result in

problems with barcode

readability or print quality. All

media should be handled with

care to avoid any damage to

the media, or printer. Read

the guideline in this section

carefully.

3.2 Care/Handling of the Media and Ribbon

Do not store media for longer than the manufacturer’s recommended

shelf life

Store media rolls on the flat end. Do not store them on the curved

sides as this might flatten that side causing erratic media advance and

poor print quality.

Store the media in plastic bags and always reseal after opening.

Unprotected media can get dirty and the extra abrasion from the dust

and dirt particles will shorten the print head life.

Store the media in a cool, dry place. Avoid areas where they would be

exposed to direct sunlight, high temperature, high humidity, dust or

gas.

The thermal paper used for direct thermal printing must not have

specifications which exceed Na

ppm.

Some ink used on pre-printed media may contain ingredients which

shorten the print head’s product life. Do not use labels pre-printed

with ink which contain hard substances such as carbonic calcium

(CaCO

For further information, please contact your local distributor or your

media manufacturer.

) and kaolin (Al2O3, 2SiO2, 2H2O).

3

+

800 ppm, K+ 250 ppm and Cl- 500

E3- 4

Page 36

4. TROUBLESHOOTING ENGLISH VERSION EO1-33097

4.1 Troubleshooting Guide

4. TROUBLESHOOTING

If a problem cannot be solved by taking actions described in this chapter, do not attempt to repair the

printer. Turn off and unplug the printer. Then contact an authorised TOSHIBA TEC

CORPORATION service representative for assistance.

4.1 Troubleshooting Guide

Symptom Cause Solutions

The power lamp of the

Power Adapter does not

light up though the power

cord is plugged in an AC

outlet.

LED 1 does not light up in

green when the power

switch is turned on though

the power lamp of the

Power Adapter is lit.

Media is not issued. The media is not loaded correctly. Reload the media correctly.

Nothing is printed. The media loaded is not direct

Poor print TOSHIBA TEC

Missing dots The print head is dirty.

The power cord is not connected

to the Power Adapter.

There is a power failure or the

power is not being supplied to the

AC outlet.

The fuse of the building has

blown or the circuit breaker has

tripped.

The Power Adapter Connector is

disconnected from the Power

Jack.

The interface cable is not

connected correctly.

The media sensor is dirty. Clean the media sensor.

thermal media though direct

thermal mode is selected.

The media is not correctly loaded.

Print data is not sent from the host

computer.

CORPORATION approved media

is not used.

The print head is dirty.

Some of the print head elements

are broken.

WARNING!

Disconnect the power cord from the AC outlet,

connect the power cord to the Power Adapter,

then connect it to the AC outlet.

( Section 2.5)

Test the AC outlet with a power cord from

another electric appliance.

If power is not being supplied, consult an

electrician or your Electricity supplier.

Check the fuse or circuit breaker.

Disconnect the power cord from the AC outlet,

insert the Power Adapter Connector into the

Power Jack, then connect the power cord to the

AC outlet. ( Section 2.5)

( Section 2.7)

Connect the interface cable again.

( Section 2.4)

( Section 3.1.2)

Load a thermal paper roll.

( Section 2.7)

Reload the media correctly.

( Section 2.7)

Send the print data.

Replace the media with an approved one.

Clean the print head. ( Section 3.1.1)

Clean the print head. ( Section 3.1.1)

When missing dots affect the printout, turn off

the printer and contact the nearest TOSHIBA

TEC CORPORATION representative to ask for

the replacement of the print head.

E4-1

Page 37

4. TROUBLESHOOTING ENGLISH VERSION EO1-33097

4.2 Status Lamp

Symptom Cause Solutions

Labels are not correctly

separated from the backing

paper. (When the optional

Peel-off unit is fitted.)

TOSHIBA TEC

CORPORATION approved media

is not used.

The labels have been loaded

Replace the media with an approved one.

Load the label correctly. ( Section 2.7)

incorrectly.

The media is not cut

cleanly. (When the optional

cutter unit is fitted.)

The cuter blade has reached the

end of its useful life.

Turn off the printer and contact the nearest

TOSHIBA TEC CORPORATION

representative to ask for the replacement of the

cutter unit.

The Wireless LAN

communication error

occurs immediately after

turning on the printer.

It takes approx. 10 seconds to

enable the Wireless LAN

communication after the Status

Lamp shows a stand-by state.

Turn on the printer, and wait more than 10

seconds after the Status Lamp shows a stand-by

state, then start the communication.

4.2 Status Lamp

LED 1 LED 2 Cause Solutions

Green Unlit Stand-by Normal

Green F

Green S

Red

Red

Orange

Orange

Red

Red

Red

Unlit

Flashing speed of the LED

Symbol Status Flashing interval

S

M

F

Flashing slowly 2.0 sec.

Flashing at medium speed 1.0 sec.

Flashing fast 0.5 sec.

Unlit

Unlit

Orange F

Green A communication error

Red

Green

Red M

Green

Orange M

Unlit

Communicating with a host Normal

Printing is temporarily stopped

Press the [FEED] Button. Printing is resumed.

(paused.)

The print head temperature

exceeded the upper limit.

Stop printing and allow the print head to cool

until LED 1 lights in green. If LED 1 does not

light in green or this problem occurs frequently,

contact the nearest TOSHIBA TEC

CORPORATION representative.

Press the [FEED] Button to restart the printer or

occurred. (Only when the RS232C is used.)

Turn off the power and then back on. If this

problem frequently occurs, turn off the printer

and contact the nearest TOSHIBA TEC

CORPORATION representative.

The media has ended. Load a new media roll, then press the [FEED]

Button. ( Section 2.7)

A paper jam occurred. Remove the jammed media, then reload the

media correctly and press the [FEED] Button.

( Section 4.3)

An issue or feed was

attempted with the print block

Close the print block correctly, then press the

[FEED] button. Printing will resume.

opened.

A paper jam occurred in the

F

cutter unit. (Only when the

cutter unit is fitted.)

Remove the jammed media, then reload the

media correctly and press the [FEED] Button.

( Section 4.3)

The print head is broken. Turn off the power switch and contact the

nearest TOSHIBA TEC CORPORATION

representative.

The power is off.

The print head block is open if

Turn the power on.

Close the print block correctly.

the printer power is on.

E4-2

Page 38

4. TROUBLESHOOTING ENGLISH VERSION EO1-33097

4.3 Removing Jammed Media

4.3 Removing Jammed Media

This section describes in detail how to remove jammed media from the printer.

CAUTION!

Do not use any tool that may damage the print head.

1. Turn the power off.

2. Open the Top Cover and open the print head block.

3. Remove the media roll.

4. Remove the jammed media from the printer. DO NOT USE any sharp implements or tools as these could

damage the printer.

If a paper jam has occurred inside the Cutter Unit, follow the steps below to remove the paper.

1) Turn the power off.

2) Tilt the printer to the left.

3) Remove the jammed paper by forcibly rotating the cutter motor using a cross/philips screwdriver.

Remark:

The picture above is the thermal transfer printing model of the B-FV4 series.

5. Clean the Print Head and Platen, then remove any further dust or foreign substances.

6. Load the media again, and close the Top Cover.

Cutter Motor

E4-3

Page 39

APPENDIX 1 SPECIFICATIONS ENGLISH VERSION EO1-33097

APPENDIX 1 SPECIFICATIONS

Appendix 1 describes the printer specifications and supplies for use on the B-FV4D printer.

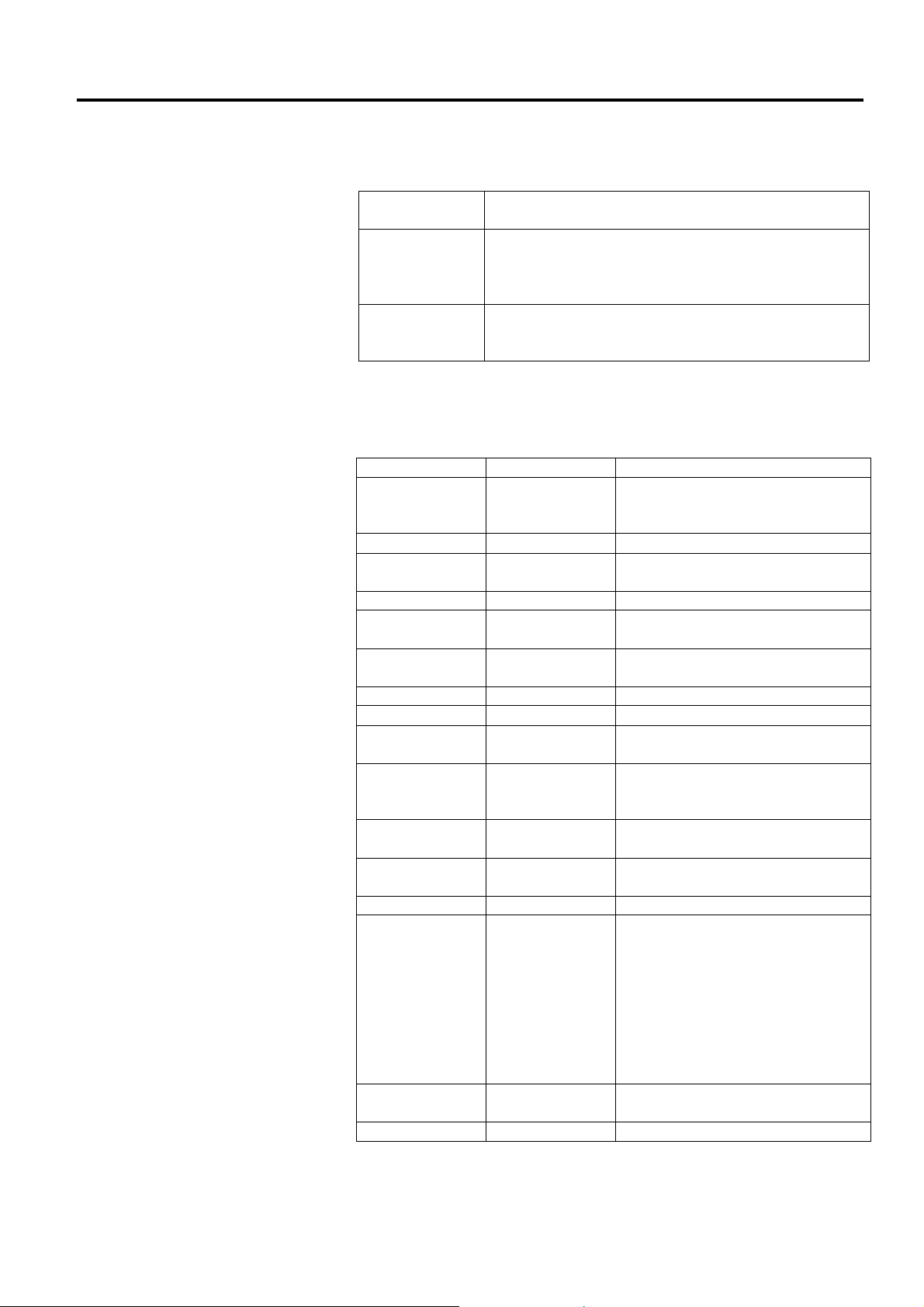

A1.1 Printer

The following are the printer specifications.

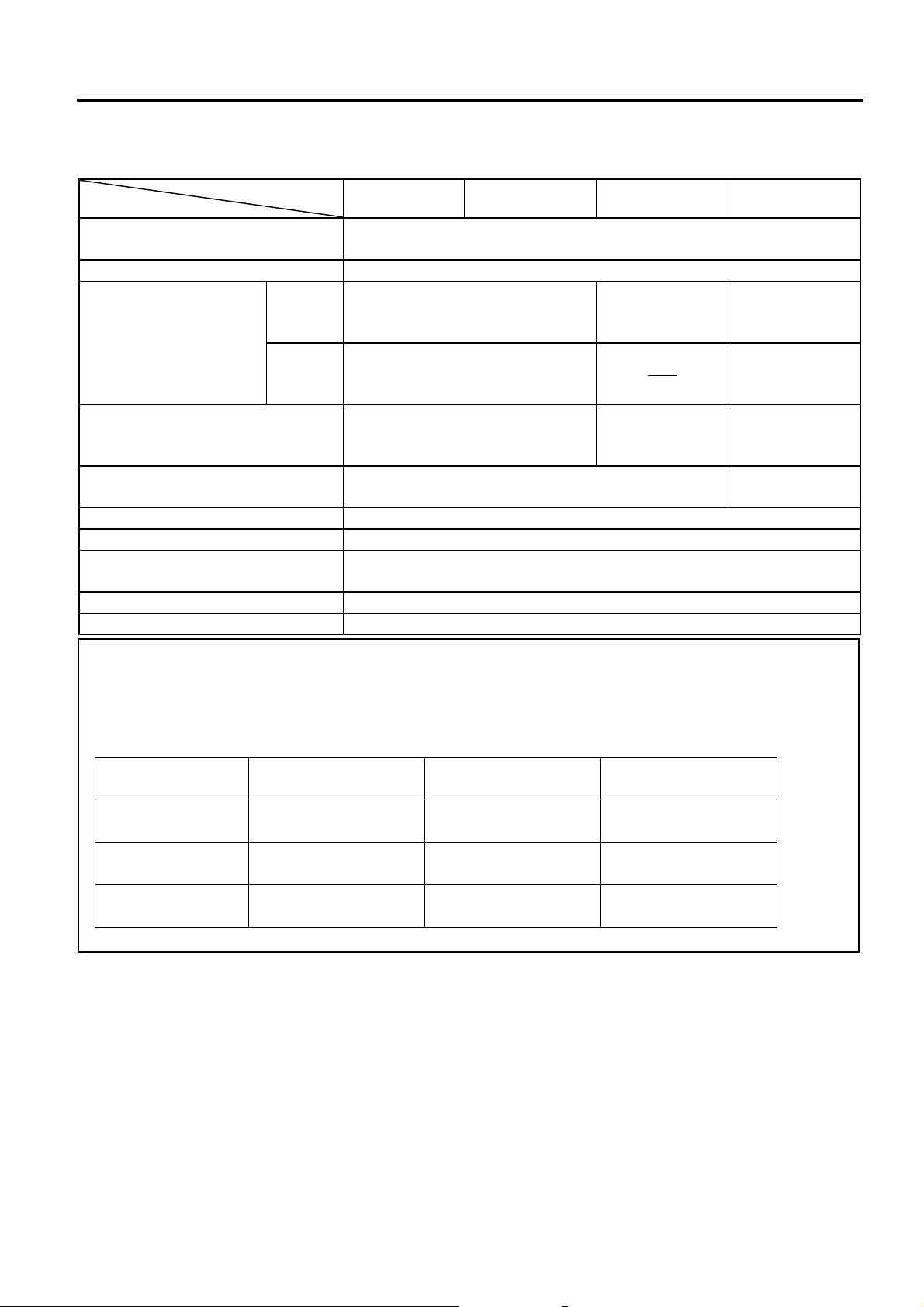

Item B-FV4D-GS Series

Supply voltage

Power consumption

During a print job

During standby

Operating temperature range

Storage temperature range

Relative humidity

Humidity for storage

Resolution

Printing method

Issue mode

Printing speed

In the batch/cut mode

In the strip mode

Available media width

(including backing paper)

Effective print width (max.)

Max. print ratio

Dimension (W D H)

Weight

Available barcode types

Available two-dimensional code

Available composite symbol

Available font

Rotations

Standard interface

Option interface

NOTES:

Data Matrix

PDF417

QR Code is a trademark of DENSO CORPORATION.

Maxi Code is a trademark of United Parcel Service of America, Inc., U.S.

TM

is a trademark of International Data Matrix Inc., U.S.

TM

is a trademark of Symbol Technologies Inc., US.

Bluetooth® is a registered trademark owned by Bluetooth SIG, Inc.

AC100 to 240V, 50/60 Hz (External Power Adapter)

100 to 120V: 1.0 A, 60 W maximum, 200 to 240V: 0.6 A, 59 W maximum

100 to 120V: 0.12A, 3.7 W maximum, 200 to 240V: 0.07 A, 3.8 W maximum

5C to 40C (41F to 104F)

-20C to 60C(-4F to 140F)

25% to 85% RH (no condensation)

10% to 90% RH (no condensation)

203 dpi (8 dots/mm)

Direct thermal

Batch, Strip (option), Cut (option)

50.8 mm/sec. (2”/sec.), 76.2 mm/sec. (3”/sec.), 101.6 mm/sec. (4”/sec.),

127 mm/sec. (5”/sec.), 152.4 mm/sec. (6”/sec.)

50.8 mm/sec. (2”/sec.), 76.2 mm/sec. (3”/sec.)

25.4 mm (1.0”) to 118 mm (4.6”)

108.0 mm (4.25”)

Average 15%

183.8 mm x 226.2 mm x 166.0 mm (7.2” x 8.9” x 6.5”)

1.76 kg (3.8 lb) (Excluding media)

EAN8/13, EAN8/13 add on 2&5, UPC-A, UPC-E, UPC-A add on 2&5, UPC-E

add on 2&5, CODE39, CODE93, CODE128, GS1-128 (UCC/EAN128), NW7,

MSI, Industrial 2 of 5, ITF, RM4SCC, KIX-Code, POSTNET, USPS Intelligent

mail barcode, GS1 DataBar

Data matrix, PDF417, QR Code, Maxi Code, Micro PDF417

GS1-128 Composite (CC-A/CC-B/CC-C)

Times Roman (6 sizes), Helvetica (6 sizes), Presentation (1 size), Letter Gothic

(1 size), Courier (2 sizes), Prestige Elite (2 sizes), OCR-A (1 type), OCR-B (1

type), Simplified Chinese (1 size)

0, 90, 180, 270

USB 2.0 full speed

Ethernet interface (10/100 Base)

Serial interface (RS-232C) (factory option)

Parallel interface (Centronics) (factory option)

Wireless LAN interface (IEEE802.11b/g/n)

Bluetooth interface (Ver.2.1)

A1.1 Printer

EA1-1

Page 40

APPENDIX 1 SPECIFICATIONS ENGLISH VERSION EO1-33097

Item B-FV4D-TS Series

Supply voltage

Power consumption

During a print job

During standby

Operating temperature range

Storage temperature range

Relative humidity

Humidity for storage

Resolution

Printing method

Issue mode

Printing speed

In the batch/cut mode

In the strip mode

Available media width